Page 1

F-4 Phantom 32 DF

Assembly Manual

* Pilot figures shown are not included

Page 2

Notice

All instructions, warranties and other collateral

documents are subject to change at the sole

discretion of Horizon Hobby, Inc. For up-to-date

product literature, visit http://www.horizonhobby.

com and click on the support tab for this product.

Meaning of Special Language

The following terms are used throughout the product

literature to indicate various levels of potential harm

when operating this product:

NOTICE: Procedures, which if not properly followed,

create a possibility of physical property damage

AND a little or no possibility of injury.

CAUTION: Procedures, which if not properly followed,

create the probability of physical property damage

AND a possibility of serious injury.

WARNING: Procedures, which if not properly followed,

create the probability of property damage, collateral

damage, and serious injury OR create a high

probability of superficial injury.

This is a sophisticated hobby product and NOT a

toy. It must be operated with caution and common

sense and requires some basic mechanical

ability. Failure to operate this Product in a safe

and responsible manner could result in injury or

damage to the product or other property. This

product is not intended for use by children without

direct adult supervision. Do not attempt disassembly,

use with incompatible components or augment

product in any way without the approval of Horizon

Hobby, Inc. This manual contains instructions for

safety, operation and maintenance. It is essential to

read and follow all the instructions and warnings

in the manual, prior to assembly, setup or use, in

order to operate correctly and avoid damage or

serious injury.

Warnings

Read and follow all instructions and safety precautions

before use. Improper use can result in fire, serious

injury and damage to property.

Age Recommendation:

For advanced fliers ages 14 and above.

This is not a toy.

COMPONENTS

INTAKE/FAN

Keep loose items that can get entangled in the

fan away from the intake and exhaust, including

loose clothing or other objects such as pencils and

screwdrivers. Especially keep your hands away from

the intake and exhaust, as injury can occur.

BATTERIES

Notes on Lithium Polymer Batteries

When misused, lithium polymer batteries are

significantly more volatile than alkaline or Ni-Cd/

Ni-MH batteries used in RC applications. Always

follow the manufacturer’s instructions when using and

disposing of any batteries. Mishandling of Li-Po batteries

can result in fire causing serious injury and damage.

SMALL PARTS

This kit includes small parts and should not be left

unattended near children as choking and serious injury

could result.

SAFETY PRECAUTIONS

• Checkallcontrolsurfacespriortoeachtakeoff.

• Donotflyyourmodelnearspectators,parking

areas or any other area that could result in injury to

people or damage of property.

WARNING: Read the ENTIRE instruction

manual to become familiar with the features of the

product before operating. Failure to operate the

product correctly can result in damage to the

product, personal property and cause serious injury.

2 E-flite F-4 Phantom 32 DF Assembly Manual

Use only with compatible components. Should any

compatibility questions exist, please refer to the

product instructions, the component instructions or

contact Horizon Hobby, Inc.

FLIGHT

Fly only in open areas to ensure safety. It is

recommended flying be done at AMA (Academy of

Model Aeronautics) approved flying sites. Consult local

laws and ordinances before choosing a location to fly

your aircraft.

• Donotflyduringadverseweatherconditions.

Poor visibility and/or strong winds can cause

disorientation and loss of control of your aircraft.

• Donottakechances.Ifatanytimeduringflightyou

observe any erratic or abnormal operation, land

immediately and do not resume flight until the cause

of the problem has been ascertained and corrected.

Safety can never be taken lightly.

• Donotflynearpowerlines.

Page 3

Table of Contents

Introduction

Using the Manual

Introduction ........................................................... 3

Important Information Regarding

Warranty Information ..................................... 3

Specifications ......................................................... 3

Using the Manual ................................................... 3

Contents of Kit/Parts Layout .................................... 3

Recommended Radio Equipment ............................. 4

Motor Setup ........................................................... 4

Optional Accessories .............................................. 4

Optional Retracts ................................................... 4

Optional Batteries .................................................. 4

UltraCote® Covering Colors .................................... 4

Hardware/Accessory Sizes ..................................... 4

Required Tools and Adhesives ................................. 4

Wing Tip Installation .............................................. 5

Hinging the Ailerons and Flaps ............................... 6

Aileron and Flap Servo Installation .......................... 7

Control Horn Installation ....................................... 10

Flap and Aileron Linkage Installation ..................... 11

Wing Spar Installation .......................................... 13

Main Landing Gear Installation ............................. 15

Optional Main Landing Gear Doors ...................... 18

Rudder and Elevator Servo Installation ................... 21

Rudder Installation ............................................... 22

Elevator Installation .............................................. 24

Fan Installation..................................................... 26

Nose Gear Installation .......................................... 28

Receiver and Speed Control Installation ................. 32

Motor Battery Installation ...................................... 33

Canopy Assembly ................................................ 34

Decal Placement ................................................... 35

Center of Gravity ................................................. 36

Control Throws..................................................... 37

Preflight ............................................................... 37

Range Test Your Radio .......................................... 38

Flying Your Model ................................................ 38

Daily Flight Checks ............................................... 39

Limited Warranty ................................................. 39

Warranty Services ................................................ 40

Compliance Information for the European Union .... 41

Academy of Model Aeronautics

National Model Aircraft Safety Code ............ 41

E-flite takes scale ARF ducted fan performance and

engineering to new heights with the F-4 Phantom

32 DF. Designed around the E-flite® Delta-V® 32

80mm fan unit and 2150Kv DF32 brushless motor, its

bifurcated intake and exhaust, which are engineered

for best performance, allow this potent combo to

produce large amounts of thrust when powered with

an E-flite 6S 5000mAh 30C Li-Po pack. And it does

so without resorting to drag-inducing cheater holes.

The result is a sport EDF with exhilarating speed that

will give even experienced jet jockeys goose bumps.

The Platinum Series E-flite

32 also boasts a level of fit and finish that is every bit

as impressive as its performance. Its sleek fiberglass

fuselage comes pre-painted and integrates the vertical

stabilizer. The fully-sheeted wings are mounted with

carbon blade spars and the full flying stabilator is

preassembled from the factory to ensure accuracy.

And it’s covered with genuine UltraCote® covering for

the best look and finish. Just add the optional E-flite

electric retracts (sold separately), and you’ve got a

scale jet that truly stands out from the crowd.

®

ducted fan F-4 Phantom DF

Important Information

Regarding Warranty Information

Please read our Warranty and Liability Limitations in

the back of this manual before building this product.

If you as the Purchaser or user are not prepared

to accept the liability associated with the use of

this Product, you are advised to return this Product

immediately in new and unused condition to the place

of purchase.

Specifications

Wingspan: 34.8 in (885mm)

Wing Area: 406 sq in (26.2 sq dm)

Length: 47.2 in (1200mm)

Weight w/o Battery: 5.15–5.45 lb (2.35–2.50 kg)

Weight with Battery: 7.05–7.40 lb (3.20–3.35 kg)

This manual is divided into sections to help make

assembly easier to understand and to provide breaks

between each major section. In addition, check boxes

have been placed next to each step to keep track

of its completion. Steps with a single circle () are

performed once, while steps with two or more circles

() indicate the step will require repeating, such as

for a right or left wing panel, two servos, etc.

Remember to take your time and follow the directions.

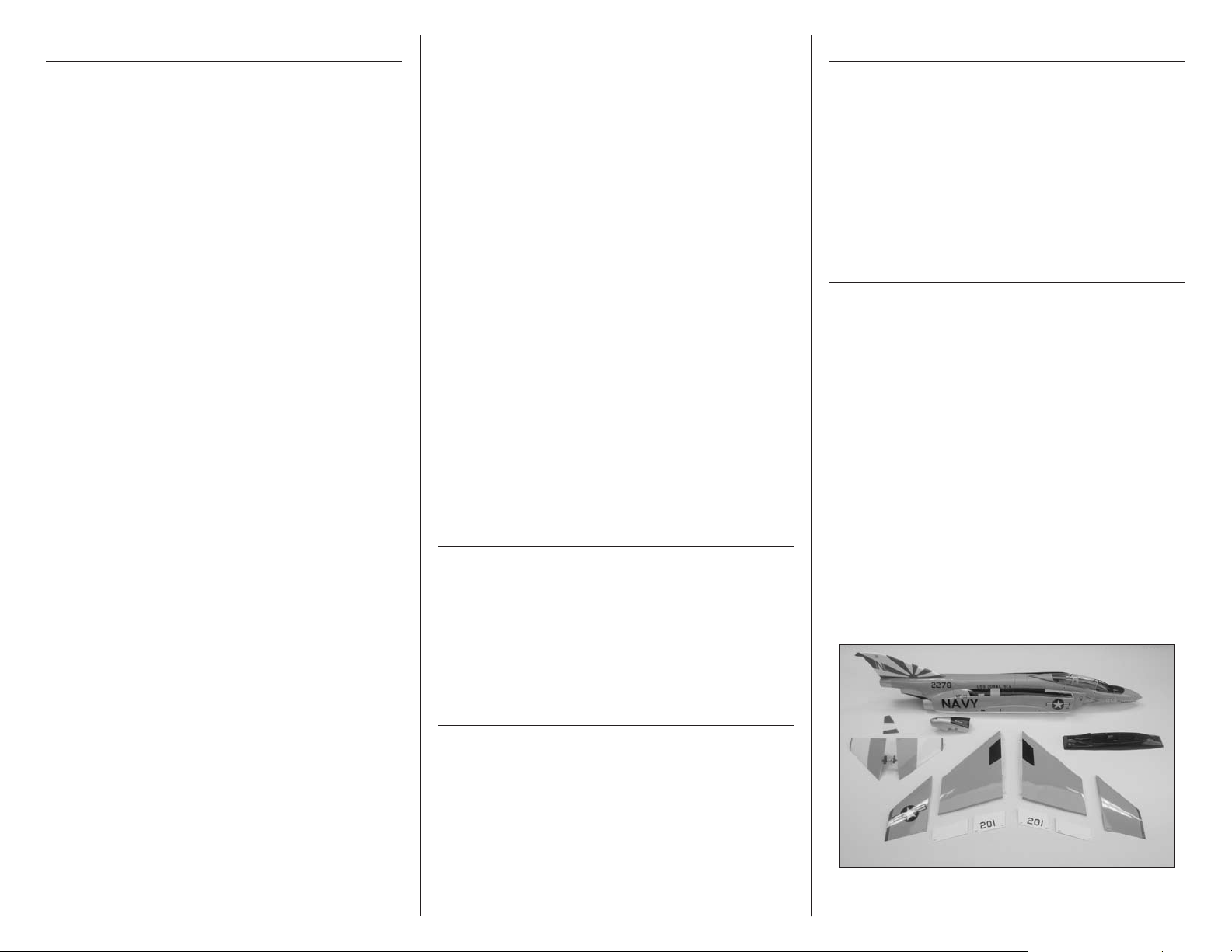

Contents of Kit/Parts Layout

Replacement Parts

EFL812501 Fuselage with Hatches

EFL812502 Main Wing Left

EFL812503 Main Wing Right

EFL812504 Horizontal Stabilizer Assembly

EFL812505 Canopy and Engine Hatches

EFL812506 Plastic Accessories

EFL812507 Rudder

EFL812508 Hardware

EFL812509 Pushrods

EFL812510 Decal Sheet

EFL812511 Landing Gear Struts

EFL812512 Tail Cone

EFL812513 Fixed Nose Gear

EFL812514 Foam Main Wheels, 48mm dia

EFL812515 Foam Nose Wheels, 33mm dia

3E-flite F-4 Phantom 32 DF Assembly Manual

Page 4

Recommended Radio Equipment

Motor Setup

Required Tools and Adhesives

You will need a minimum 5-channel transmitter,

receiver and seven servos.

Complete Radio System

SPM8800 DX8 DSM2™ 8CH system

8-channel receiver installation:

SPMAR8000 AR8000 DSMX 8-Channel Full-

Range Receiver

JSP20030 MC35 Servo (6)

JRPSDS3421 DS3421 Premium Digital Servo,

elevator

SPMA3058 Y-harness

SPMA3052 9-inch (228mm) servo extension

The extensions listed for the 8-channel

operation (separate ailerons and nose gear)

will require the use of mixing at the transmitter.

6-channel receiver installation:

SPMAR6210 AR6210 DSMX 6-Channel Full-

Range Receiver

JSP20030 MC35 Servo (6)

JRPSDS3421 DS3421 Premium Digital Servo,

elevator

SPMA3058 Y-harness (3)

SPMA3052 9-inch (228mm) servo extension

lightweight

The extensions listed for the 6-channel

operation will require surfaces (flaps, ailerons

and steering-to-rudder) using a Y-harness.

EFLM3032DFA DF32 Brushless Motor, 2150Kv

EFLDF32 Delta-V® 32 80mm EDF

EFLA1080B 80-Amp Pro SB

Brushless ESC v2

EFLB50006S30 5000mAh 6S 22.2V 30C Li-Po,

10AWG EC5

Optional Accessories

EFLC3025 Celectra™ 80W AC/DC Multi-

Chemistry Battery Charger

EFLA110 Power Meter

EFLAEC512 EC5™ Device Charge Lead with

6-inch Wire and Jacks, 12AWG

PKZ7003 Pilot (2)

Optional Retracts

EFLG230 15–25 Tricycle Electric Retracts

SPMA3000 3-inch (76mm) Servo

Extension (2)

SPMA3004 18-inch (457mm) servo

extension

Optional Batteries

EFLB50006S50 5000mAh 6S 22.2V 50C Li-Po,

10AWG EC5

THP50006SPP65 5000mAh 6-Cell/6S 22.2V

G64 Pro Power 65C Li-Po

UltraCote® Covering Colors

Light Gray HANU882

True Red HANU866

Silver HANU881

White HANU870

Tools & Equipment

Balancing stand Ball driver: 9/64-inch

Flexible tape Clear tape

Drill Coarse grit sandpaper

Epoxy brush Felt-tipped pen

Hobby scissors Low-tack tape

Mixing cup Mixing stick

Needle-nose pliers Paper towels

Pencil Petroleum jelly

Pin vise Razor saw

Rotary tool Rubbing alcohol

Ruler Sanding block

Sanding drum Scissors

Side cutter String

Tie-wraps Toothpick

Trim seal tool Two-sided tape

Flat file

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Hex wrench: 1.5mm, 2.5mm

Hobby knife with #11 blade

Medium grit sandpaper

Phillips screwdriver: #0, #1

Adhesives

5-minute epoxy PAAPT38

15-minute epoxy MEUEPX15MIN

CA accelerator PAAPT715

Canopy glue PAAPT56

Thin CA PAAPT08

Threadlock PAAPT42

Silicone adhesive DEVS250

Hardware/Accessory Sizes

Main wheel diameter 17/8-inch (48mm)

Nose wheel diameter 15/16-inch (33mm)

Wing bolt 8-32 x 1/4-inch

4 E-flite F-4 Phantom 32 DF Assembly Manual

Page 5

During the course of building your model, we

suggest you use a soft base for the building surface.

Such things as a foam stand, large piece of

bedding foam or a thick bath towel will work well

and help protect the model from damage during

assembly. This is not shown in the instructions

to provide the greatest detail in the photos.

When referencing directions (up, down, left,

right top and bottom), these directions are in

relationship to the pilot sitting in the cockpit

of the aircraft unless noted otherwise.

Before starting the assembly of your model, we

recommend preparing your radio system for

installation. This includes charging the transmitter and

receiver batteries, as well as centering the trims and

sticks on your transmitter. If using a computer radio,

make sure to reset a model memory and name it for

this particular model. We also recommend binding

the transmitter and receiver at this time following

the instructions provided with your radio system.

Wing Tip Installation

Required Parts

Main wing panel (right and left)

Wing tip (right and left)

3mm x 40mm hardwood dowel (4)

Required Tools and Adhesives

Felt-tipped pen 5-minute epoxy

Mixing stick Mixing cup

Low-tack tape Rubbing alcohol

Paper towels Hobby knife with #11 blade

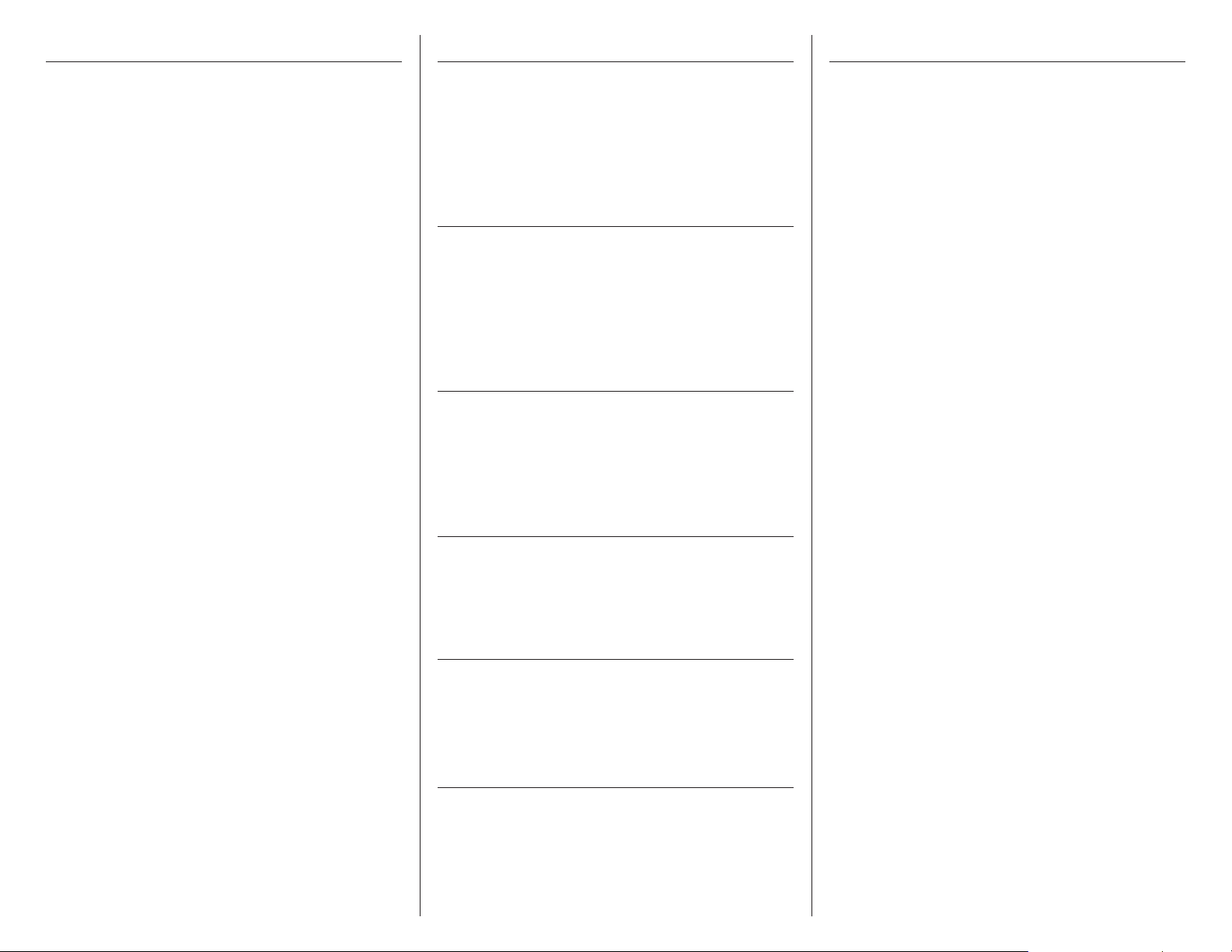

1. Insert the two 3mm x 40mm hardwood dowels

into the wing tip panel.

2. Fit the tip panel to the main panel. Use a felt-

tipped pen to trace the outline of the main wing

panel on the tip panel.

3. Remove the tip panel and dowels. Use a hobby

knife and #11 blade to remove the covering 1/32inch (1mm) inside the line drawn. Use a paper

towel and rubbing alcohol to remove the pen lines.

4. Use 5-minute epoxy to glue the two 3mm x

40mm hardwood dowels into the wing tip panel.

Use a paper towel and rubbing alcohol to remove

any excess epoxy. Allow the epoxy to fully cure

before proceeding.

5. Apply a thin coat of 5-minute epoxy to the

exposed wood of the main wing panel and the

wing tip panel, as well as to the wood dowels.

Fit them together and use low-tack tape to hold

them together until the epoxy fully cures. Remove

any excess epoxy using a paper towel and

rubbing alcohol.

We highly recommend re-binding the radio

system once all the control throws are set. This will

keep the servos from moving to their endpoints

until the transmitter and receiver connect.

6. Repeat steps 1 through 5 to install the remaining

wing tip panel to the main wing panel.

5E-flite F-4 Phantom 32 DF Assembly Manual

Page 6

Hinging the Ailerons and Flaps

Required Parts

Wing panel (left and right)

Aileron (left and right)

Flap (left and right) CA hinge (8)

Required Tools and Adhesives

Thin CA T-pins

Pin vise Drill bit: 1/16-inch (1.5mm)

Please follow the procedure for hinging

the ailerons and flaps as described in this

manual. Failure to correctly hinge these surfaces

could result in the surface becoming loose in

flight, resulting in the loss of your aircraft.

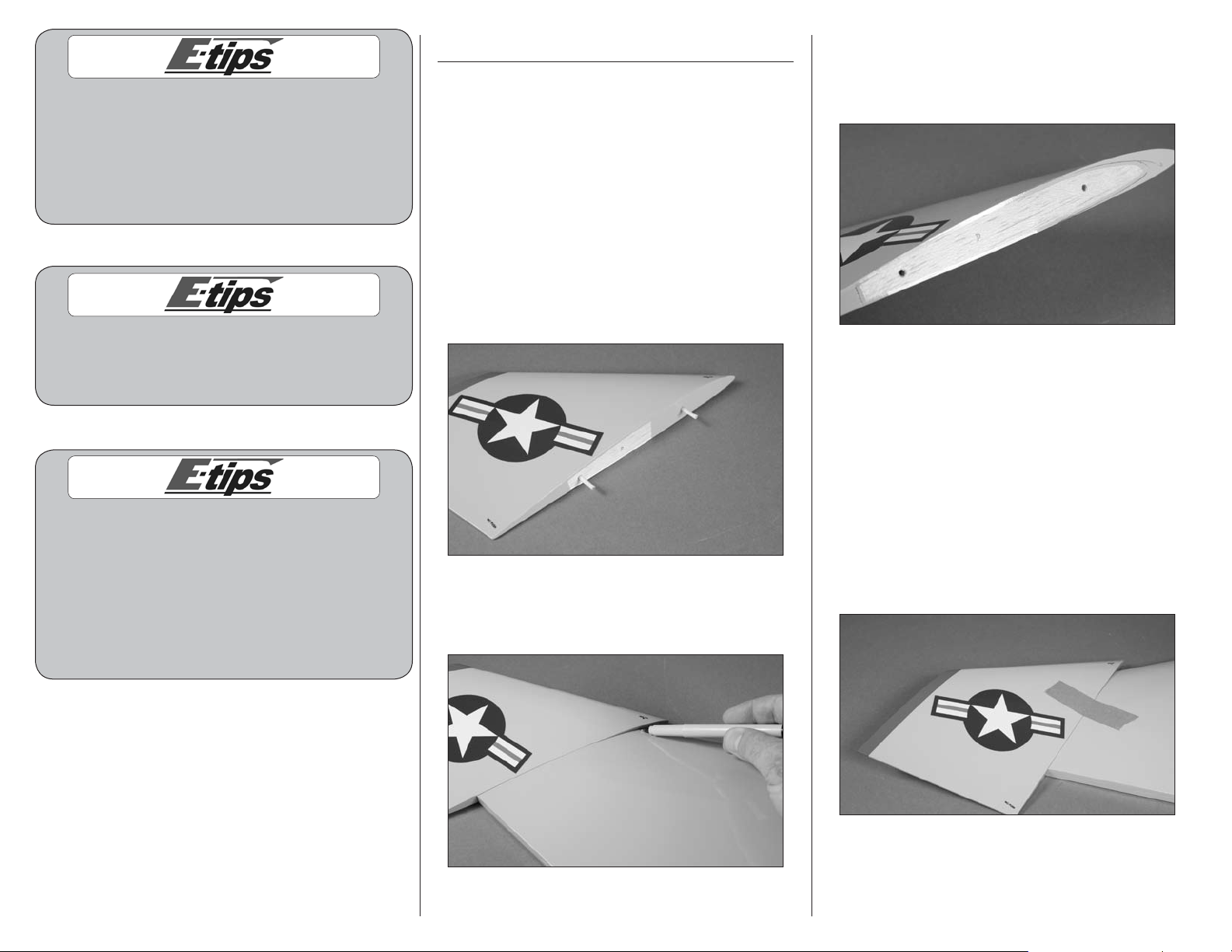

2. Slide the hinges into the aileron and flap. Insert

the hinges so the holes in the hinge are at the

hinge line. Insert a T-pin through one of the holes to

keep the hinge centered while the aileron and flap

are installed on the wing panel.

1. Use a pin vise and 1/16-inch (1.5mm) drill bit

to drill a hole in the center of each hinge slot in the

ailerons, flaps and wing panels. This will provide

a tunnel for the CA to wick into, making the bond

between the hinge and wood stronger.

3. Slide the hinges in the aileron into the slots on

the wing. Note the orientation of the ailerons and

flaps. They will only fit correctly one way with all

decals showing on the top. Leave a small gap

at the wing tip. Installl the flap making sure the

aileron and flap can move without interference.

Also make sure the flap is set in an equal distance

from a line projected from the root of the wing to

prevent it from rubbing against the fuselage. The

gap between each surface, and the line projected

from the wing root, should be equal.

When gluing the hinges, do not use a CA

accelerator. The CA must be allowed time to

soak into the hinges to provide the best bond

between the hinge and surrounding wood.

4. Remove the T-pins from the hinges. Make sure

the aileron and flap are tight against the wing.

Wick thin CA into each hinge, both top and

bottom, until the hinge is saturated with CA. Allow

the CA to fully cure before proceeding.

6 E-flite F-4 Phantom 32 DF Assembly Manual

Page 7

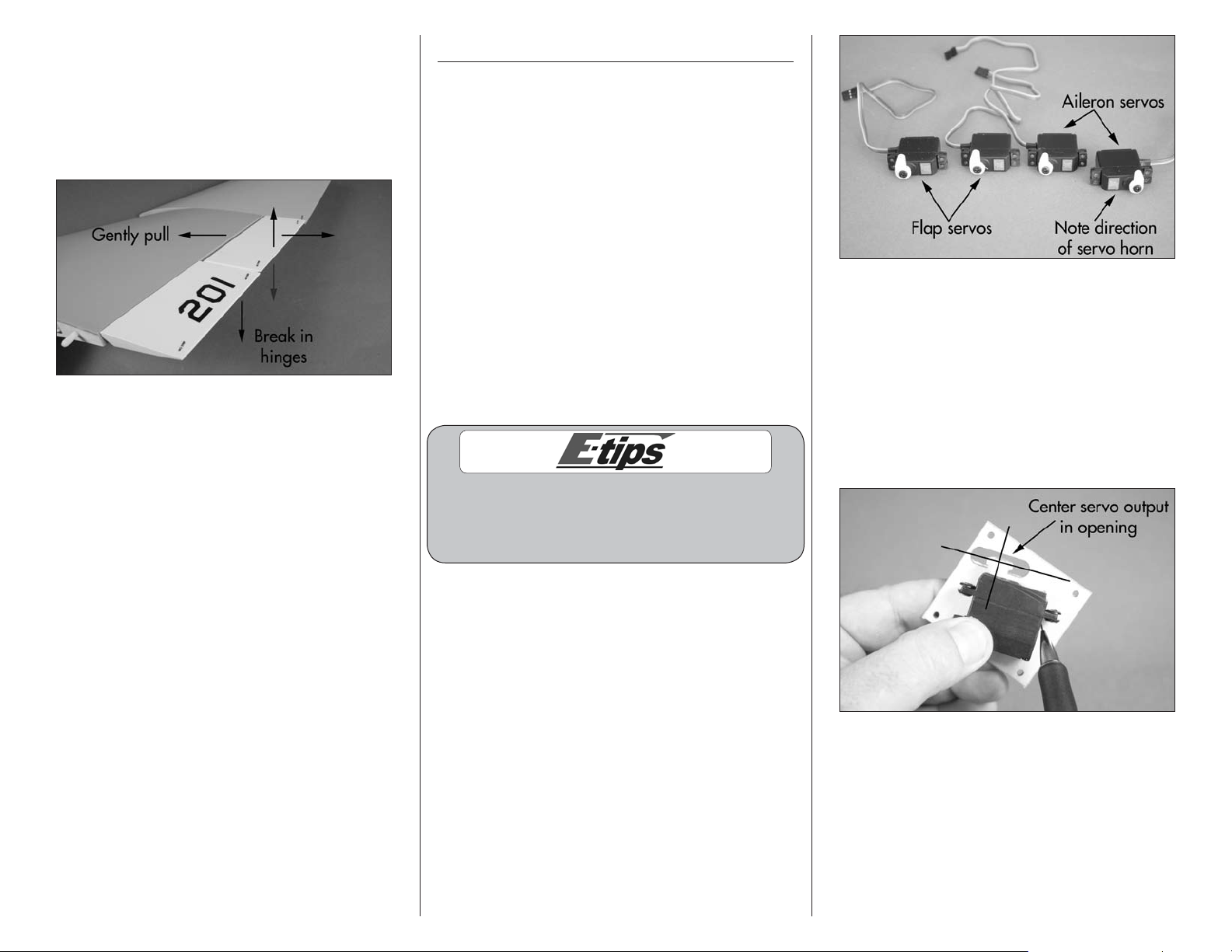

5. Once the CA has fully cured, gently pull on

the wing and aileron (and flap) to make sure the

hinges are glued securely. If not, reapply thin CA

to any hinges that are not secure. Flex the aileron

and flap through their range of motion a number

of times to break in the hinges. This will reduce the

initial load on the servo for your first flights.

6. Repeat Steps 1 through 5 to install the remaining

aileron and flap hinges.

Aileron and Flap Servo Installation

Required Parts

Wing panel (right and left)

Transmitter Receiver

Receiver battery

Servo with hardware (4)

Hardwood block, 15mm x 13mm x 6mm (8)

2mm x 8mm self-tapping screw (16)

Required Tools and Adhesives

Phillips screwdriver: #1

Hobby knife with #11 blade

Pencil Razor saw

Thin CA 5-minute epoxy

Mixing cup Mixing stick

Drill Drill bit: 5/64-inch (2mm)

Side cutter Pin vise

Felt-tipped pen Medium grit sandpaper

When centering the flap servo, begin by setting

the throws at the transmitter to 0% for both the

up and down flap positions. This should be done

for both 2- and 3-position flap switches.

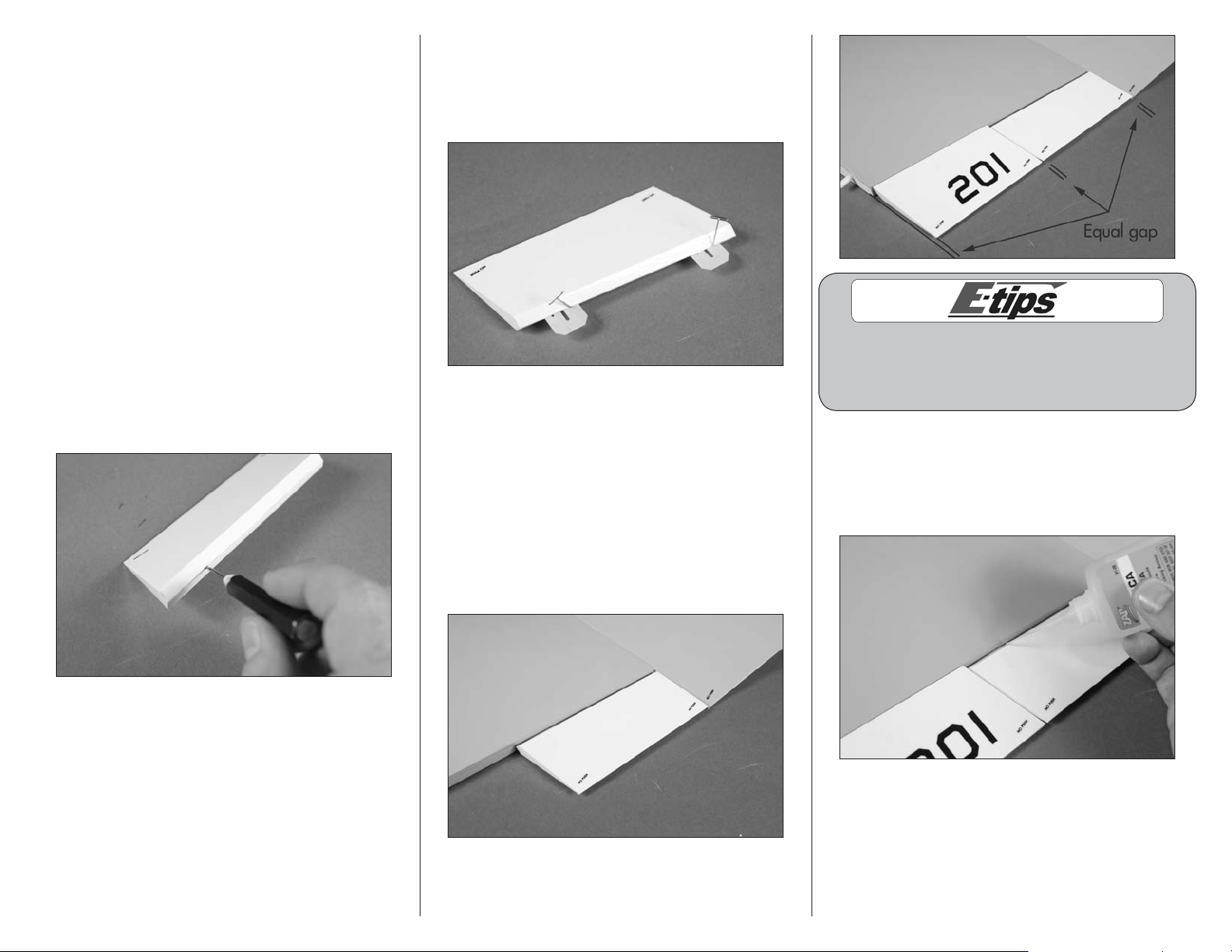

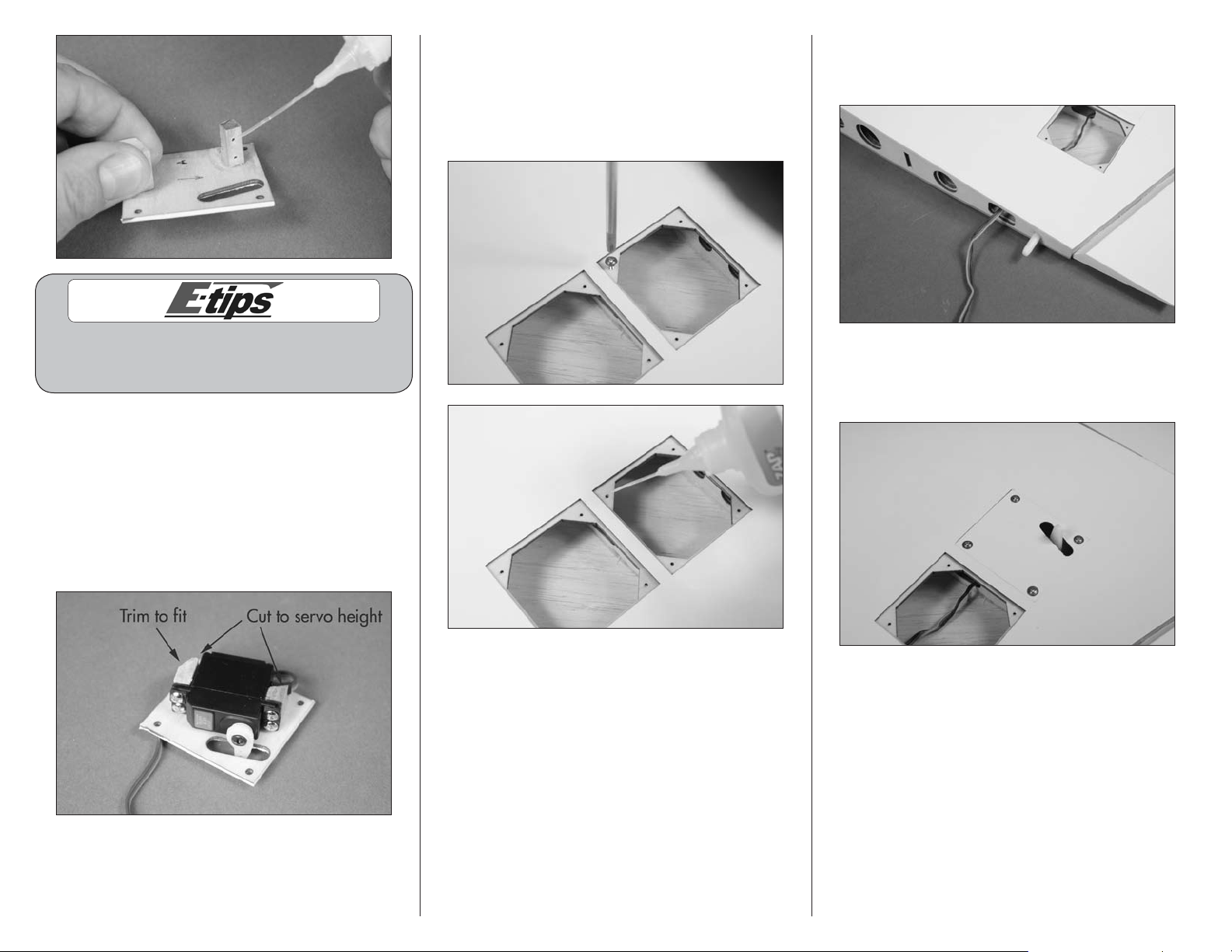

2. Use a felt-tipped pen to mark the flap and

aileron servo covers so they can be returned to

their correct locations, then remove the covers from

the wing. Set the flap cover aside. Use a pencil

to mark the centerlines for the servo output on the

cover. Position the servo on the cover so the center

of the servo horn is centered in the opening using

the lines drawn on the cover. Use a pencil to mark

the locations for the servo mounting blocks on the

servo cover.

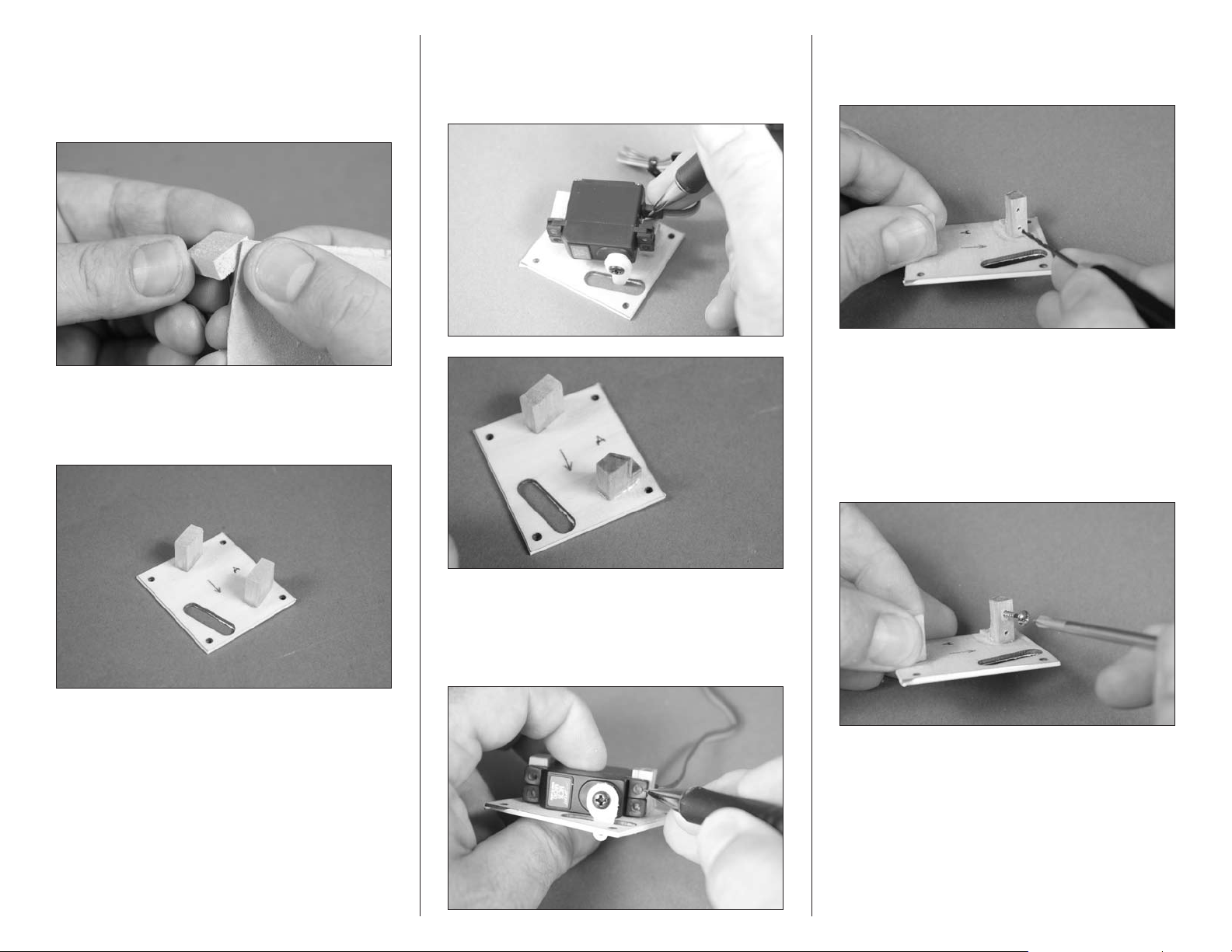

1. Prepare the aileron and flap servos by installing

the rubber grommets and brass eyelets as shown in

the radio or servo instructions. Use the shorter side

of a JR standard horn for the two aileron servos

and the longer side for the flap servos. Center the

aileron and flap servos using the radio system. Use

side cutters to remove any arms from the horn that

may interfere with the operation of the servo. Note

that one servo is set in the opposite orientation as

shown in the photo in the following column.

7E-flite F-4 Phantom 32 DF Assembly Manual

Page 8

3. Sand the 6mm x 13mm end of the four

hardwood blocks using medium grit sandpaper to

provide a surface for the glue to adhere to. This

will be the end glued to the plate in the following

step.

4. Use 5-minute epoxy to glue the blocks to the

cover in alignment with the marks you made. Allow

the epoxy to fully cure before proceeding.

5. Position the servo on the blocks. Use a

pencil to mark the block for the servo lead. Use a

razor saw to trim the block to provide clearance for

the servo lead.

7. Use a drill and 5/64-inch (2mm) drill bit to

drill the holes for the mounting screws. Use care not

to enlarge the holes any larger than the drill bit.

8. Use a #1 Phillips screwdriver to thread

a servo mounting screw into each of the holes.

Remove the screw then apply 2–3 drops of thin

CA in each hole and saturate the front and rear of

the block to harden the hardwood block. This will

help keep the blocks from splitting when the servo

mounting screws are installed.

6. Position the servo between the two blocks.

With the servo resting against the servo cover, use

a pencil to mark the locations for the four servo

mounting screws on the blocks.

8 E-flite F-4 Phantom 32 DF Assembly Manual

Page 9

Do not use a CA accelerator. Using an accelerator

will not allow the CA to soak into the fibers of

the wood, hardening the hardwood block.

9. Sand the top of the blocks so they are flush

with the top of the servo. Also trim or sand the

edge of the block so that it does not interfere with

the mounting rim of the wing hole. The blocks may

be a very close fit, and may just hit the mounting

rim on the cover. This is dependant on the exact

location of the servo. Use the screws provided with

the servo and a #1 Phillips screwdriver to attach

the servo to the mounting blocks.

10. Use a #1 Phillips screwdriver to thread a

2mm x 8mm self-tapping screw into each of the

servo cover mounting holes. This will cut threads

in the surrounding wood. Remove the screw then

apply 2–3 drops of thin CA in each hole to harden

the wood.

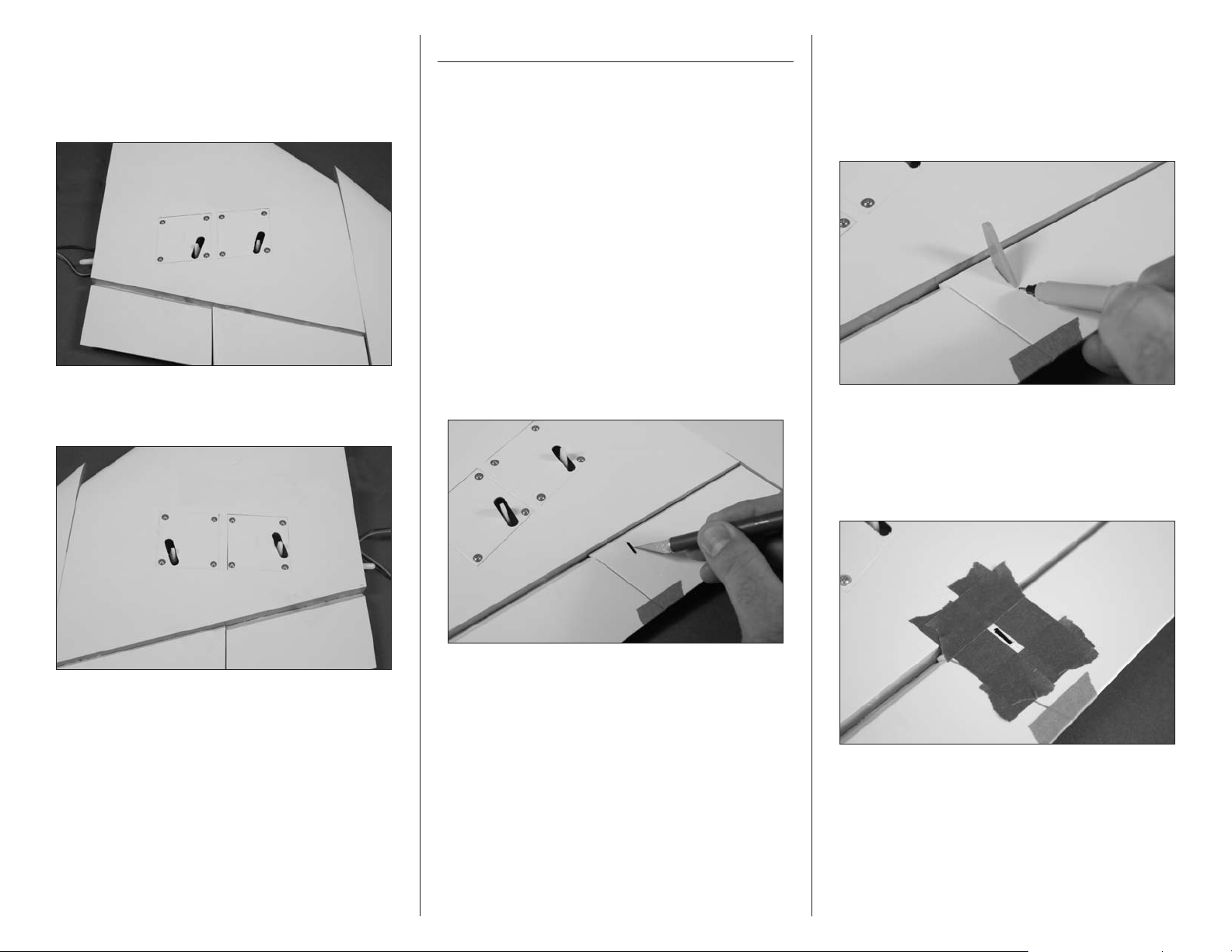

11. Tie the end of the string around the end of the

aileron servo lead. Use the string to pull the leads

through the wing and out at the root rib as shown.

12. Use four 2mm x 8mm self-tapping screws

and a #1 Phillips screwdriver to secure the aileron

servo cover to the wing.

9E-flite F-4 Phantom 32 DF Assembly Manual

Page 10

13. Pass the flap servo lead through the same

hole in the wing root as the aileron servo. Use

four 2mm x 8mm self-tapping screws and a #1

Phillips screwdriver to secure the flap servo cover

to the wing.

14. Repeat steps 2 through 13 for the remaining

wing panel.

Control Horn Installation

Required Parts

Wing panel (right and left)

Fiberglass control horn (4)

Required Tools and Adhesives

Felt-tipped pen 5-minute epoxy

Mixing stick Mixing cup

Low-tack tape Coarse grit sandpaper

Hobby knife with #11 blade

1. Use low-tack tape to tape the aileron at the tip

and tape the flap to the aileron so they don’t move

during the control horn installation.

1. Use a hobby knife and #11 blade to

remove the covering from the slot for the

aileron control horn.

2. Check the fit of the fiberglass control horn

in the slot in the aileron. The hole in the control

horn will align with the hinge line. The horn

should fit flush in the hole. Use a felt-tipped pen to

mark the front and rear edge of the control horn

on the aileron.

3. Apply low-tack tape around the opening

for the aileron control horn. Position the tape so

it is 1/32-inch (1mm) away from the sides of

the hole, as well as from the marks made in the

previous step.

10 E-flite F-4 Phantom 32 DF Assembly Manual

Page 11

4. Use coarse grit sandpaper to lightly sand

the control horns where they fit into the openings in

the flap and aileron.

7. After around 3 minutes, before the epoxy

cures, carefully remove the tape from around the

control horns. Pull the tape away from the horn,

being careful not to disturb the position of the

control horn. This will allow the epoxy to flow out

slightly, leaving a fillet between the control horn

and control surface.

Flap and Aileron Linkage Installation

Required Parts

Wing panel (right and left)

Transmitter Receiver

Receiver battery Silicone tubing

Metal clevis (8) 2mm nut (6)

Threaded rod, 2mm x 25mm (2)

Threaded rod, 2mm x 40mm (2)

Required Tools and Adhesives

Ruler Threadlock

Needle-nose pliers

5. Repeat Steps 1 through 4 to prepare the

remaining aileron and flap control horns.

6. Use 5-minute epoxy to glue the control horn

into the holes for the aileron. Use a square to make

sure the control horn is perpendicular to the control

surface. Double-check the hole in the control horn

to ensure it is directly over the hinge line.

8. Repeat Steps 6 and 7 to install the remaining

aileron and flap control horn.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

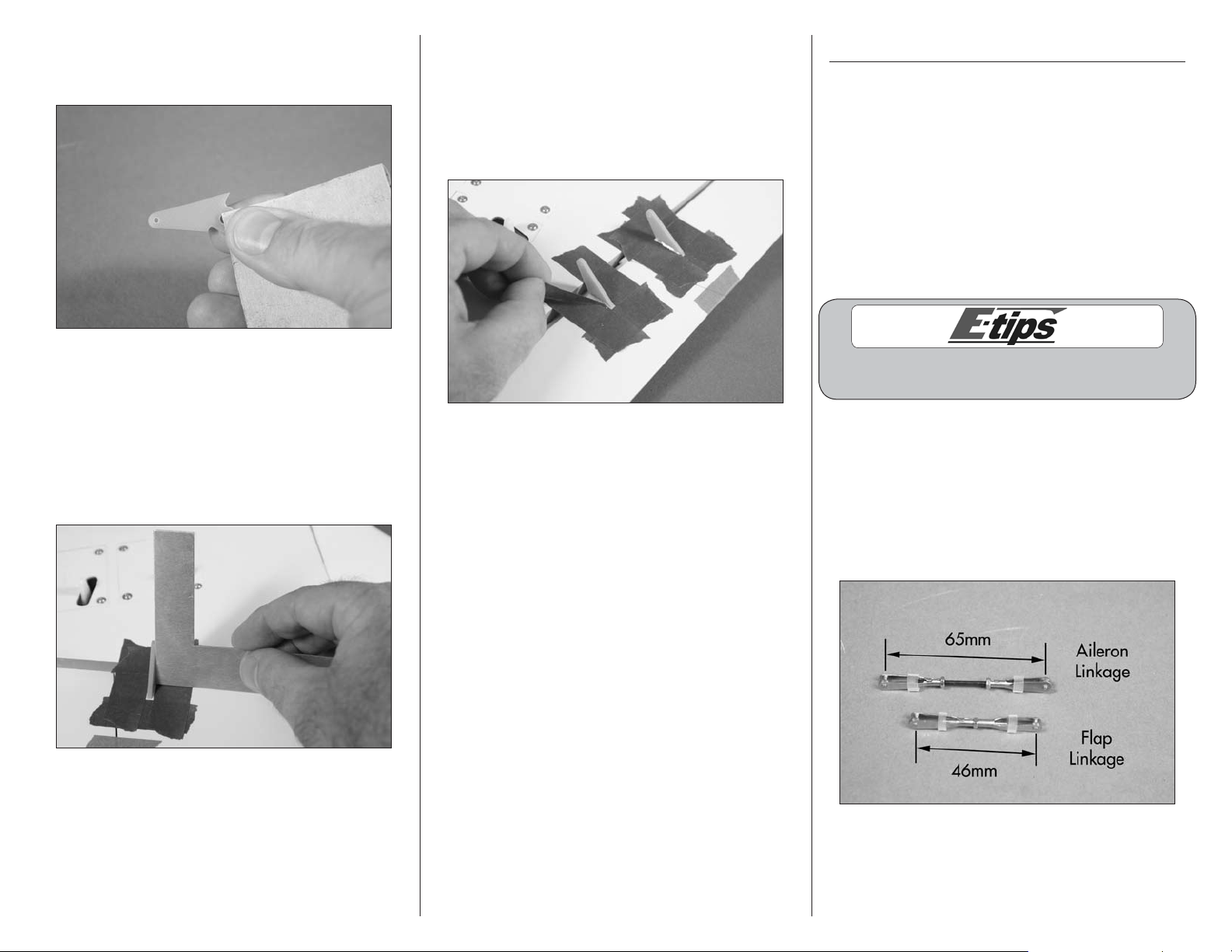

1. Use a hobby knife to cut four 1/4-inch (6mm)

pieces of silicone tubing. Assemble the aileron

linkage using the silicone tubing, two 2mm nuts,

two metal clevises, and a 2mm x 25mm threaded

rod. Assemble the flap linkage using the silicone

tubing, one 2mm nut, two metal clevises, and a

2mm x 25mm threaded rod. Use the length in the

photo as a starting point for the length of the rod.

11E-flite F-4 Phantom 32 DF Assembly Manual

Page 12

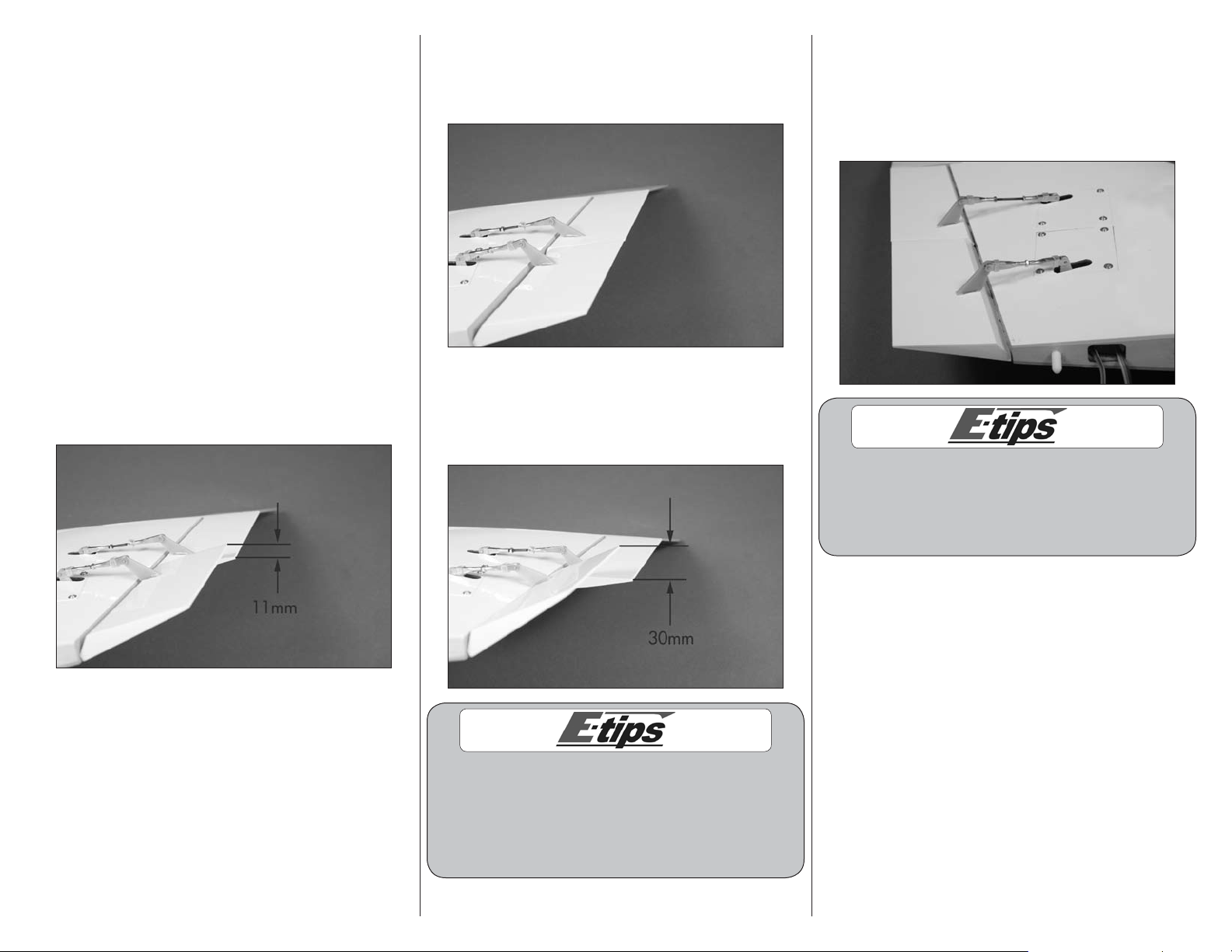

2. Connect the aileron linkage to the hole in the

servo horn 7/16-inch (11mm) from the center of

the servo arm, and connect the flap linkage to the

hole in the servo horn 1/2-inch (13mm) from the

center of the arm.

3. Remove the tape holding the flap and aileron in

position. Connect one clevis of the longer pushrod

to the outer hole of the aileron servo horn. The

remaining clevis connects to the aileron control

horn. Adjust the length of the linkage so the aileron

is centered when the servo is centered. Connect

one clevis of the shorter pushrod to the outer hole

of the flap servo arm and the other end to the

flap control horn. Adjust the length of the flap

linkage so when the flap servo is centered, the

flap is positioned as shown. Once the length of

the linkages has been adjusted, slide the tubing

over the forks of the clevises to keep them from

accidentally opening in flight. Use needle nose

pliers to tighten the nuts against the metal clevises.

4. Set the switch at the transmitter to the UP flap

position. Adjust the flap system values of the

transmitter for the up position until the flap is aligned

with the aileron. This will be the UP flap position.

5. Set the switch at the transmitter to the DOWN

flap position. Adjust the ATV at the transmitter for

the down position until the flap is 30mm below the

aileron. This will be the DOWN flap position.

6. Repeat steps 2 through 5 to prepare and install

the remaining flap and aileron linkages. Before

connecting the flap linkage, set the flap switch to

the UP flap position. Connect the linkage to the flap

servo and adjust its length until the flap is aligned

with the aileron. This will be the UP flap position.

You may have to fine-tune both flap linkages up

or down so they align at all three positions: up,

middle, and down. It is very important to use servo

arms positioned at the same angle on the splines of

the servo so the travel will match in all positions.

Because there can be minor differences in control

horn and servo positions, do not connect the

linkage as described in steps 2 to the opposite

flap until you have checked the throws. Doing so

may cause the servo to bind in the UP position,

which could cause damage to the flap servo.

12 E-flite F-4 Phantom 32 DF Assembly Manual

Page 13

Wing Spar Installation

Required Parts

Fuselage Carbon wing spar (2)

8-32 x 1/4-inch socket head screw (4)

Wing panel assembly (right and left)

Required Tools and Adhesives

Low-tack tape

15-minute epoxy Mixing cup

Paper towels Mixing stick

Epoxy brush Rubbing alcohol

Ruler Medium grit sandpaper

Petroleum jelly Felt-tipped pen

Ball driver: 9/64-inch

1. Remove the radio cover and canopy from the

fuselage by lifting them up from the base, rather

than from the sides, as the magnets are strong to

hold them down during high-speed maneuvers. The

radio cover is held in place with magnets at the

front and a pin in the rear. Set the cover aside so it

doesn’t get damaged.

2. Use a 9/64-inch ball driver to start the four

8-32 x 1/4-inch socket head bolts in the aluminum

wing sockets inside the fuselage. Only thread the

screws in a few turns at this time. Use care not to

cross-thread the screws and damage the threads in

the aluminum sockets.

3. Locate the carbon wing spar. The spar is

symmetrical and has no top or bottom. Slide the

carbon wing spar in the spar pocket of the wing,

narrow end first. The spar will slide in easily, so

don’t force it in any further than it will slide. Use a

felt-tipped pen to mark the spar at the wing root.

4. Remove the spar from the spar pocket. Use

medium grit sandpaper to lightly sand the spar

where it fits into the wing. Sand both the front and

back of the spar.

5. Slide the spar into the spar pocket in the fuselage.

It will easily slide into the pocket up to the line made

in step 3. If not, the screws installed in step 2 may

be in the way and require loosening.

13E-flite F-4 Phantom 32 DF Assembly Manual

Page 14

6. Check the fit of the wing on the fuselage. It must

rest tightly against the fuselage. If the spar fits into

the wing and fuselage spar pockets without any

problems, the fit should be perfect. Make sure to

guide the leads for the aileron and flap into the

fuselage so they don’t interfere with the fit.

Before mixing any epoxy, make sure to read through

and understand the following steps. It is important

to perform these steps before the epoxy fully cures.

8. Mix 1/2 ounce (15mL) of 15-minute epoxy.

Apply the epoxy to the spar pocket of the wing

using a mixing stick.

10. Slide the spar into the spar pocket of the wing,

making sure it is oriented correctly. Use a paper

towel and rubbing alcohol to remove any excess

epoxy from the wing and spar.

7. Remove the wing and spar from the fuselage.

Apply a thin coat of petroleum jelly to the fuselage

around the wing socket. This will keep you from

accidentally gluing the wing to the fuselage during

the following procedure.

9. Use an epoxy brush to apply epoxy to the front,

back, top and bottom of the spar where it fits into

the wing.

Epoxy will ooze out from the spar pocket of the

wing. If epoxy does not ooze out, not enough

epoxy was used to glue the spar into the wing.

11. Before the epoxy cures, slide the wing into

position against the fuselage. Keep the wing tight

against the fuselage until the epoxy fully cures. You

can use a 9/64-inch ball driver to lightly tighten

the screws to secure the wing joiner in the fuselage,

and low-tack tape to hold the wing in position until

the epoxy has cured.

14 E-flite F-4 Phantom 32 DF Assembly Manual

Page 15

12. Once the epoxy has cured, remove the wing

panel from the fuselage. Repeat steps 3 through 11

to install the remaining wing panel to the fuselage.

13. Once the epoxy has fully cured and both wing

panels have spars, remove any petroleum jelly

residue from the fuselage and wing using rubbing

alcohol and a paper towel.

Main Landing Gear Installation

Required Parts

Wing panel assembly (right and left)

Aluminum wheel collar with setscrew, 3.5mm (2)

Aluminum wheel spacer, 3.5mm (2)

Wheel, 17/8-inch (48mm) (2)

Main landing gear strut (right and left)

3mm x 14mm countersunk self-tapping screw (8)

Required Parts (Fixed Gear Specific)

Main fixed landing gear unit (2)

Required Parts (Retract Specific)

Transmitter Receiver

Receiver battery

Servo extension, 3-inch (76mm) (2)

Main landing gear retract (2)

Required Tools and Adhesives

Drill Drill bit: 5/64-inch (2mm)

Threadlock Hex wrench: 1.5mm

Thin CA Phillips screwdriver: #1

Trim seal tool Hobby knife with #11 blade

Low-tack tape

The installation of the retracts and fixed

gear follow the same procedure. The only

difference is the cutting of the covering and

the routing of the retract lead, which has been

highlighted in gray.

1. Use a hobby knife with a new #11 blade to

remove the covering to access the landing gear

mounts and wheel well if using the retracts. Leave

1/32-inch (1mm) of covering around the inside

edges. Use a trim seal tool to iron down the

covering around the edges to finish the opening.

2. Place a main landing gear block or retract

mechanism in the wing. The landing gear block

may distort the covering slightly during its

installation when installing the fixed gear. Make

sure it is resting flat on the landing gear rails.

15E-flite F-4 Phantom 32 DF Assembly Manual

Page 16

3. Prepare a 5/64-inch (2mm) drill bit by wrapping

a piece of low-tack tape around the drill bit 5/8inch (16mm) from the end of the bit. This will act as

a marker so you don’t accidentally drill through the

top of the wing. Place the drill bit in a drill.

4. Use the drill and drill bit prepared in the

previous step to drill the four holes for the landing

gear block or retract mechanism mounting screws.

5. Remove the landing gear block or retract

mechanism from the wing. Use a #1 Phillips

screwdriver to thread a 3mm x 14mm countersunk

self-tapping screw in each hole to cut threads into

the landing gear rails. Remove the screws after

threading the holes.

16 E-flite F-4 Phantom 32 DF Assembly Manual

Page 17

6. Place 2–3 drops of thin CA in each of the holes.

This will harden the threads made by the screws,

making them more secure when the landing gear

block or retract mechanism is installed.

A. Secure a 3-inch (76mm) servo extension to

the retract lead using string or dental floss.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

7. Slide a main gear strut into the main landing

gear block or retract mechanism. Use the setscrews

and a 1.5mm hex wrench to secure the main

gear wire in the block. The setscrews will tighten

down on each of the flat areas at the top of the

strut to prevent the strut from rotating in the block.

Assemble the right and left main gear assemblies at

this time.

B. Tie the string to the extension. Use the string

to pull the lead through the wing and out

along-side of the aileron and flap leads. Mark

the retract lead so it can be easily identified.

We have designed the main gear struts to work

with both the fixed gear and the suggested

retracts. These struts are designed for the weight

and speeds of the F-4 Phantom. Use the struts

supplied with the kit for the retract assembly.

17E-flite F-4 Phantom 32 DF Assembly Manual

Page 18

8. Place the correct main gear assembly in position.

The axle will face to the root of the wing, and the

spring will face to the trailing edge of the wing. Use

four 3mm x 14mm countersunk self-tapping screws

and a #1 Phillips screwdriver to tighten the screws.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

9. Slide a 3.5mm aluminum wheel spacer on the

axle, then the wheel. A 3.5mm wheel collar is used

to secure the wheel in position by tightening the

setscrews onto the axle using a 1.5mm hex wrench.

Optional Main Landing Gear Doors

Required Parts

Wing assembly (right and left)

Transmitter Receiver

Receiver battery Landing gear door (2)

2mm x 8mm self-tapping screw (8)

Landing gear door block (4)

Required Tools and Adhesives

Rotary tool Sanding drum

Sanding block Medium grit sandpaper

Ruler Pencil

Pin vise Drill

Canopy glue Drill bit: 1/16-inch (1.5mm)

Thin CA Side cutter

Phillips screwdriver: #0

The installation of the landing gear doors

are optional, and they can be installed at any

time during the life of your model.

1. Use a hobby knife with a #11 blade to separate

the two landing gear doors.

The end of the axles may have a slight bur

on them from the factory. If the wheel is hard

to install, use a file to remove this bur.

18 E-flite F-4 Phantom 32 DF Assembly Manual

10. Repeat steps 2 through 9 to install the

remaining main landing gear and wheel.

Page 19

2. Use a pencil to draw a centerline on the

unpainted side of the landing gear door. Draw two

lines on the door that are 1-inch (24mm) and 13/4inch (44mm) from the top edge of the landing gear

door as the center lines for the mounting blocks.

4. Use a straight edge or ruler to lightly bend the

landing gear door along the center line so it will

rest tightly against the wing when the gear are

retracted. Work slowly to avoid cracking the paint

on the outside of the landing gear door.

6. Rest the landing gear door block on the gear

door, centering it on the lines previously drawn.

Use a pencil to transfer the mounting holes from the

landing gear door onto the block.

3. Use a pin vise and 1/16-inch (1.5mm) drill bit

to drill four holes in the landing gear door that are

5/32-inch (4mm) from the centerline along the

lines drawn in the previous step.

5. Locate the landing gear door blocks. Use a

sanding block and medium grit sandpaper to sand

an angle on the notched side, so the block will rest

flat against the angle of the landing gear door.

Prepare both blocks at this time.

7. Use a drill and 1/16-inch (1.5mm) drill bit

to drill the two mounting holes in the landing gear

door block.

19E-flite F-4 Phantom 32 DF Assembly Manual

Page 20

8. Use a sanding block and medium grit

sandpaper to round the back of the landing

gear door block. This will allow the gear to

retract into the wing and help center the gear

while it is retracting.

9. Use a #0 Phillips screwdriver to install a

2mm x 8mm self-tapping screw in each of the

mounting holes in the landing gear door block.

Remove the screws after cutting the threads in the

blocks. Be careful not to split the blocks as you

install the screws for the first time.

10. Place 2–3 drops of thin CA in each of the

mounting holes. This will harden the threads made

by the screws, making them more secure when the

landing gear door is installed.

11. Repeat steps 7 through 10 to prepare the

second landing gear door mounting block.

12. Attach the landing gear door to the strut using

four 2mm x 8mm self-tapping screws and a #0

Phillips screwdriver.

13. Use side cutters and a rotary tool with a

sanding drum to smooth the ends of the screws

against the inside of the blocks. If this is not done,

the screws could catch on the edges of the retract

opening and cause the gear to not retract correctly.

14. Slide the landing gear door so the top block

is resting against the coil of the landing gear strut.

Apply a thin bead of canopy glue along the front

and back of the strut against the landing gear

door. Rotate the door a few times to work the glue

behind the strut.

Work slowly when using a sanding drum on the

screws. The screws will heat up while sanding,

which could melt the landing gear door.

20 E-flite F-4 Phantom 32 DF Assembly Manual

Page 21

15. Retract the landing gear using the radio

system. This will set the correct angle for the

landing gear door against the wing. Allow the glue

to cure overnight before moving the gear back to

the down position.

16. Repeat steps 2 through 15 to install the second

landing gear door.

Rudder and Elevator Servo Installation

Required Parts

Fuselage assembly Transmitter

Receiver Receiver battery

Hardwood block, 15mm x 13mm x 6mm (4)

Servo with hardware (rudder and elevator)

Required Tools and Adhesives

Phillips screwdriver: #1

Pencil Razor saw

Thin CA 5-minute epoxy

Mixing cup Mixing stick

Drill Drill bit: 5/64-inch (2mm)

Medium grit sandpaper

1. Use a pencil to mark the servo mounting plate in

the fuselage for the servo locations.

2. Prepare the elevator servo using the grommets

and eyelets included with the servo. Position the

servo so the bottom of the mounting tabs are

aligned with the line drawn on the plate. The servo

output will align with the line that is 13/8-inch

(36mm) from the rear of the plate. Use a pencil to

mark the plate for the sides of the servo.

3. Prepare and epoxy the servo mounting

blocks as shown in the section “Aileron and

Flap Servo Installation.” Allow the epoxy to

fully cure before proceeding.

21E-flite F-4 Phantom 32 DF Assembly Manual

Page 22

4. Mount the elevator servo as shown in the section

“Aileron and Flap Servo Installation.” Make sure

to center the elevator servo and prepare the servo

horn before installing the servo. The elevator and

rudder servo will use a short side of a standard JR

4-way horn. Make sure to trim the servo mounting

block to allow fitting of the servo lead as shown in

the aileron and flap servo mounting section.

Rudder Installation

Required Parts

Fuselage assembly Transmitter

Receiver Receiver battery

Pin hinge (2) Rudder

Rudder torque rod Torque rod end

Metal clevis (2) Silicone tubing

2mm nut (2)

2mm x 360mm pushrod with 295mm carbon tubing

Required Tools and Adhesives

Side cutters Petroleum jelly

5-minute epoxy Toothpick

Mixing cup Mixing stick

Rubbing alcohol Paper towel

Low-tack tape Thin CA

Needle nose pliers Threadlock

Hobby knife with #11 blade

Medium grit sandpaper

2. Apply a small amount of petroleum jelly to the

knuckle of the hinge to prevent epoxy from entering

the hinge.

3. Check the fit of the hinge. The pin will align with

the hinge line of the rudder. Position the hinge so it

will move perpendicular to the rudder.

5. Repeat steps 2 through 4 to install the rudder

servo. Make sure the output of the rudder servo is

aligned with the mark that is 15/32-inch (12mm)

from the front of the plate when marking for the

servo mounting blocks.

1. Use side cutters to trim one end of each of

the hinges to the length shown. The 11/16-inch

(17mm) hinge is used at the top of the rudder.

Dipping the hinge knuckles in heated petroleum

jelly (in a liquid state) is easier than trying to

apply it with a toothpick in the gel state.

22 E-flite F-4 Phantom 32 DF Assembly Manual

Page 23

4. Check the fit of the torque rod. It must fit flush

with the leading edge of the rudder. Make sure that

the threaded end of the torque rod is on the outside

of the rudder.

5. Remove the torque rod and use medium grit

sandpaper to lightly sand the torque rod where it

comes in contact with the rudder.

6. Mix a small amount of 5-minute epoxy. Apply

the epoxy in the holes for the hinges and torque

rod. Fit the hinges and torque rod to the rudder.

Use a paper towel and rubbing alcohol to remove

any excess epoxy before it can cure.

7. Once the epoxy has fully cured, thread the

torque rod end on the rudder torque rod so it is

flush with the end of the rod.

8. Center the carbon tube on the pushrod and

apply thin CA to the pushrod and carbon tube

to glue them together. Allow the CA to wick in

between the two for a secure bond.

9. Cut a piece of silicone tubing and slide it onto the

clevis. Thread a 2mm nut on the pushrod, then the

clevis to the pushrod. Prepare both ends of the pushrod

at this time. Make sure to use threadlock on the clevis

and nut to prevent them from vibrating loose.

10. Attach the clevis to the torque rod. Slide the

silicone tubing over the clevis.

23E-flite F-4 Phantom 32 DF Assembly Manual

Page 24

11. Fit the rudder to the fin while guiding the

pushrod into the fuselage. With the rudder tight

against the fin, check the length of the pushrod.

Adjust the pushrod length so it is close to aligning

with the rudder servo horn. Once adjusted, remove

the rudder and use needle nose pliers to tighten the

nut against the clevis at the rudder. Adjusting the

clevis at the rudder will be difficult once the rudder

has been hinged to the fin.

12. With the rudder removed, mix a small amount

of 5-minute epoxy. Apply the epoxy to the hinges

and in the holes in the fin. Position the rudder and

use low-tack tape to hold it while the epoxy cures.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

13. Once the epoxy has cured, remove the tape

from the rudder. Use the radio to center the

rudder servo. Attach the clevis to the servo horn

on the inner hole and adjust the length of the

pushrod so the rudder is centered. Tighten the

2mm nut against the clevis, then slide the silicone

tubing over the clevis.

Elevator Installation

Required Parts

Fuselage assembly Transmitter

Receiver Receiver battery

Metal clevis (2) 2mm nut (2)

Silicone tubing 3mm x 6mm socket head screw

Tail cone Clear tape

3mm x 12mm socket head screw (4)

2mm x 290mm pushrod with 225mm carbon tube

Required Tools and Adhesives

Thin CA Ruler

Threadlock Hex wrench: 2.5mm

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

1. Secure the elevator control arm to the joiner

wire using a 3mm x 6mm socket head screw and a

2.5mm hex wrench. Make sure the arm is centered

between the collars and the screw is tightened on

the flat area of the elevator torque rod.

24 E-flite F-4 Phantom 32 DF Assembly Manual

Page 25

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

2. Secure the elevator mounting brackets to the

fuselage using four 3mm x 12mm socket head

screws and a 2.5mm hex wrench.

3. Center the carbon tube on the pushrod and

apply thin CA to the pushrod and carbon tube

to glue them together. Allow the CA to wick in

between the two for a secure bond.

4. Cut a piece of silicone tubing and slide it onto the

clevis. Thread a 2mm nut on the pushrod, then the

clevis to the pushrod. Prepare both ends of the pushrod

at this time. Make sure to use threadlock on the clevis

and nut to prevent them from vibrating loose.

5. Attach the clevis to the outer hole of the elevator

control arm.

6. Connect the clevis to the outer hole of the

elevator servo horn. Make sure to use threadlock

on the clevis and nut to prevent them from

vibrating loose.

7. With the radio on and the elevator servo

centered, adjust the length of the pushrod so the

distance from the tip of the elevator and the line

projected from the fuselage shown in the photo

below measures 9/16-inch (14mm). Use the hatch

line for a reference to project the reference line to

measure from.

8. Once the elevator position has been set, slide

the silicone keepers onto both clevises to keep the

clevises from opening accidentally.

25E-flite F-4 Phantom 32 DF Assembly Manual

Page 26

9. Check the operation of the elevator using the

Fan bottom

Fan centerline

Mounting lug

Label

Mounting lug

radio system. You may need to change the servo

reversing at the transmitter depending on the radio

system and servos used to achieve the correct

direction of throw.

Fan Installation

Required Parts

Fan assembly Fuselage assembly

3mm x 10mm self-tapping screw (4)

Required Tools and Adhesives

Thin CA Phillips screwdriver: #1

Flexible tape Pin vise

Pencil Felt-tipped pen

Ruler Hobby scissors

Drill bit: 5/64-inch (2mm)

The fan used in our instruction model

was a pre-production unit and did not have

a label. The location of the label is called

out as a reference for production units.

1. Locate the fan unit. View the fan unit and use the

drawing provided to determine the top and bottom

of the fan.

3. Fit the fan housing into the fuselage. Slide the

fan forward to make sure it is fully inserted into

the intake.

10. Use the tape included with the model to attach

the tail cone to the fuselage.

2. Follow the instructions included with the fan unit

to prepare it for installation in your model.

26 E-flite F-4 Phantom 32 DF Assembly Manual

Page 27

4. Use a pin vise and 5/64-inch (2mm) drill bit

to drill the four holes for the fan mounting screws.

Make sure to drill the holes against the tabs of the

housing so the fan does not slide forward or aft in

the fuselage.

5. Use a #1 Phillips screwdriver to thread a 3mm

x 10mm self-tapping screw into each of the four

holes for mounting the fan unit.

7. Secure the fan unit to the fuselage using four

3mm x 10mm self-tapping screws. Tighten the

screws using a #1 Phillips screwdriver.

You can also mount the pin vise in a drill

so it can reach down inside the fuselage,

saving some time when drilling the holes.

6. Remove the screws and place 2–3 drops of

thin CA in each hole to harden the surrounding

wood. This hardens the wood, making the screws

more secure.

8. Use hobby scissors to trim the fan cover. Make

sure to make an opening in the top for the fan

fairing as well.

27E-flite F-4 Phantom 32 DF Assembly Manual

Page 28

9. Cut a notch at the front of the cover to fit over the

fan mounting lugs.

10. Fit the cover to the fan, trimming as necessary

to fit the cover tightly over the fan and exhaust tube.

Use flexible tape to secure the cover to the fan and

exhaust tube. Make sure to tape over any areas that

would allow air to pass between the airflow of the

propulsion system and the inside of the fuselage.

Nose Gear Installation

Required Parts

Fuselage assembly Transmitter

Receiver Receiver battery

Silicone tubing Metal clevis (2)

2mm nut (2) Threaded rod, 2mm x 40mm

Servo with hardware

3mm x 8mm socket head screw (4)

Aluminum wheel collar with setscrew, 3.5mm

Aluminum wheel spacer, 3.5mm

Wheel, 1

Dual wheel axle adapter set

Required Parts (Fixed Gear Specific)

Fixed nose gear assembly

Required Parts (Retract Specific)

Nose gear retract assembly

Nose gear strut

Required Tools and Adhesives

Side cutter Hobby knife with #11 blade

Clear tape Threadlock

Pin vise Drill bit: 1/16-inch (1.5mm)

Pencil Hex wrench: 1.5mm, 2.5mm

Flat file Phillips screwdriver: #1

5

/16-inch (33mm)

1. Use a #1 Phillips screwdriver to remove the four

2mm x 8mm self-tapping screws that secure the

nose gear cover to the fuselage. Set the cover and

screws aside until later in the section of the manual.

2. Place the grommets and brass eyelets into the

servo mounting tabs. Note the positioning of the

brass eyelets, as the servo will be mounted to the

top of the plate in the fuselage.

The installation of the retracts and fixed

gear follow the same procedure. The only

difference is the installation of the nose gear

strut, which has been highlighted in gray.

28 E-flite F-4 Phantom 32 DF Assembly Manual

Page 29

3. Place the servo in the opening with the

servo output facing the rear of the fuselage.

Use a pencil to mark the locations for the servo

mounting screws.

5. Use a #1 Phillips screwdriver to thread a servo

mounting screw into the mounting holes for the

steering servo. Remove the screw after cutting the

threads in the plywood.

7. Center the steering servo using the radio system.

The steering servo will use the short side of a

standard JR 4-way horn. Use side cutters to remove

any arms from the horn that may interfere with the

operation of the servo. Secure the horn to the servo

using a #1 Phillips screwdriver and the servo from

the servo.

4. Use a pin vise and 1/16-inch (1.5mm) drill bit

to drill the holes for the servo mounting screws.

6. Place 2–3 drops of thin CA in each of the holes.

This will harden the threads made by the screws

making them more secure when the steering servo

is installed.

8. The steering linkage will be connected to the

hole in the servo that is 7/16-inch (11mm) from the

center of the arm as illustrated in the photo above.

9. Install the steering servo in from the top of the

fuselage using the hardware provided with the

servo and a #1 Phillips screwdriver. The servo

output faces the rear of the fuselage.

29E-flite F-4 Phantom 32 DF Assembly Manual

Page 30

We have designed the nose gear strut to work

with both the fixed gear and the suggested

retracts. These struts are designed for the weight

and speeds of the F-4 Phantom. Use the struts

supplied with the kit for the retract assembly.

B. Use a 1.5mm hex wrench to secure the

steering arm by tightening the setscrew on the

lower flat of the nose gear strut. Make sure

the arm is positioned as shown in the photo.

Install the supplied nose gear strut in the retract

mechanism and tighten the setscrews using a

1.5mm hex wrench. The setscrews should align

with the flat spots on the nose gear leg.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

11. Slide the piece of silicone tubing on one of the

metal clevises. Assemble the steering linkage by

threading a 2mm nut and metal clevis on either

end of the 2mm x 40mm threaded rod as shown.

Thread the clevis without the tubing so the threads

are barely visible between the forks of the clevis.

Adjust the linkage so it is 25/8-inches (67mm) in

length. Use pliers to tighten the nut against the

clevis to keep the clevis from moving.

A. Use the radio system to move the nose gear

retract to the UP position. Use a 1.5mm hex

wrench to loosen the screw on the steering

arm and wheel collar to remove the strut from

the mechanism.

10. Use a hobby knife with a #11 blade to trim a

1/4-inch (6mm) section of the silicone tubing.

12. Connect the clevis without the tubing to the

steering arm of the nose gear assembly.

30 E-flite F-4 Phantom 32 DF Assembly Manual

Page 31

13. Use a flat file to make two flat areas on the

nose gear axle that are 1/4-inch (6mm) wide.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

14. Position the axle on the nose gear so it is

33/16-inches (81mm) from the bottom of the

steering arm to the centerline of the axle. Use

a 1.5mm hex wrench to tighten the setscrews,

securing the axle to the nose gear.

The end of the axles may have a slight bur

on them from the factory. If the wheel is hard

to install use a file to remove this bur.

15. Attach the wheels to the axle using two wheel

collars. Use a 1.5mm hex wrench to tighten the

setscrews securing the wheel collars to the axle.

Cut a 1/2-inch (13mm) piece of silicone

tubing and slide it on a 2.5mm hex wrench.

The 3mm screw can then be placed in the

tubing and against the hex wrench so it can be

easily installed to secure the landing gear.

Always use threadlock on metal-to-metal fasteners

to prevent them from vibrating loose.

16. Secure the nose gear assembly in the fuselage

using four 3mm x 8mm socket head screws.

Connect the linkage to the steering servo horn

and check that the steering is centered when the

steering servo is centered. Once the linkage is set,

tighten the 2mm nut against the clevis using pliers

so the clevis doesn’t vibrate loose. Slide the silicone

over the forks of the clevis and install the screw

to secure the servo horn to the servo using a #1

Phillips screwdriver.

31E-flite F-4 Phantom 32 DF Assembly Manual

Page 32

17. Attach the nose gear cover to the fuselage

using a #1 Phillips screwdriver and the four 2mm x

8mm self-tapping screws removed in step 1.

18. Cycle the retract unit to make sure the nose

gear strut and tires clear the gear door openings.

Some slight trimming may be required.

Add clear tape to both sides of the nose gear

door to help secure it to the fuselage.

Receiver and Speed Control Installation

Required Parts

Fuselage assembly Harness from retract assembly

18-inch (457mm) servo extension (retracts)

9-inch (228mm) servo extension

Steering Y-harness when using the same channel for

both steering and rudder

Hook and loop tape

Y-harness (flaps)

Y-harness (optional for ailerons if not using separate

channels)

Required Tools and Adhesives

Scissors String

Two-sided tape Tie-wraps

8-CHANNEL RECEIVER ASSIGNMENTS FOR DX8 USING

SEPARATE CHANNELS FOR AILERONS AND NOSE

GEAR STEERING:

Throttle Speed Control

Aileron Right Aileron

Elevator Elevator

Rudder Rudder

Gear Flaps (requires Y-harness)

Aux 1 Left Aileron

Aux 2 Nose Gear Steering

Aux 3 Retracts

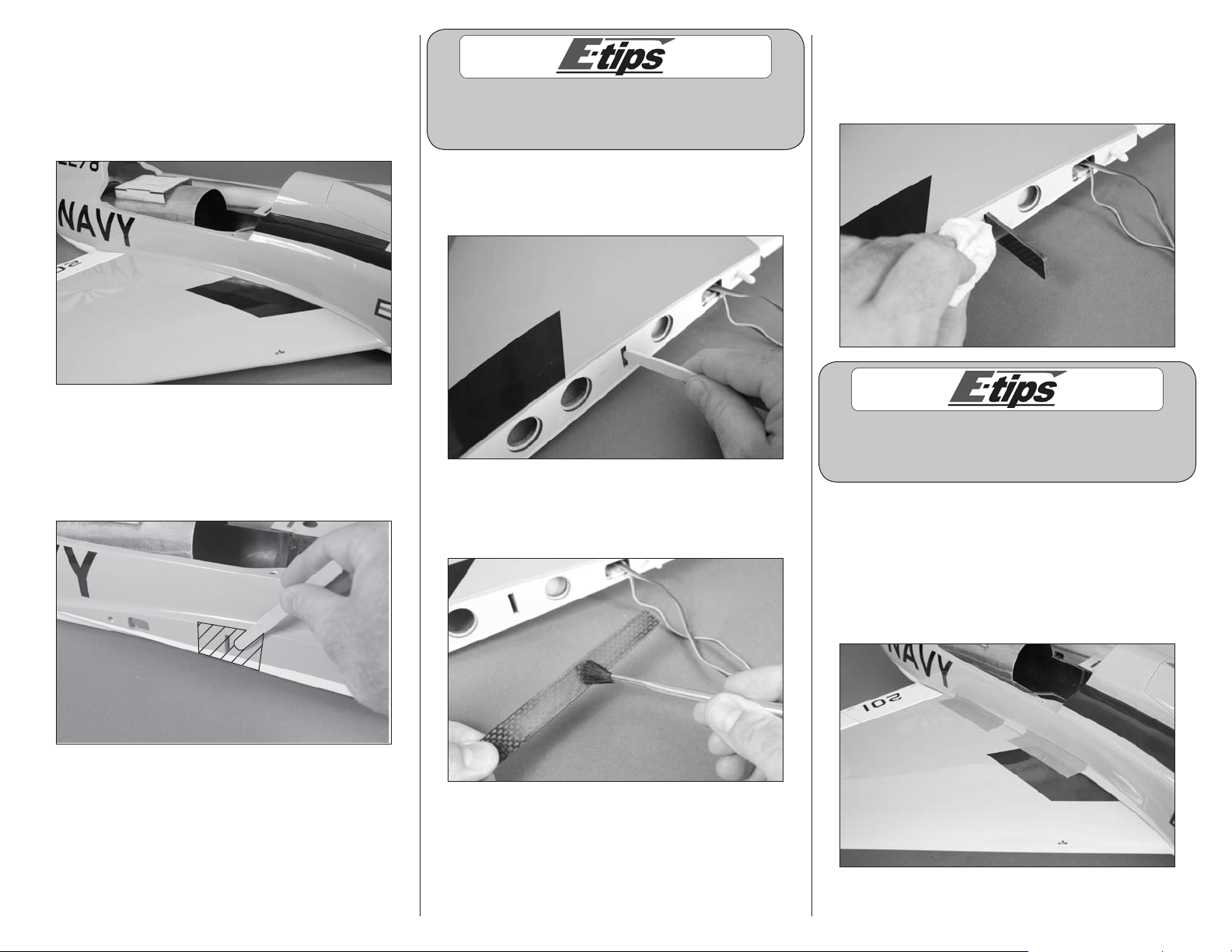

1. Use scissors to cut a piece of hook and loop

tape and apply it to the back of the speed control.

2. Use the hook and loop tape to attach the speed

control to the top of the fan. Route the leads for

the speed control forward in the fuselage. Use

two-sided tape to secure the switch where it can be

accessed when the canopy is removed.

Programs for the F-4 Phantom using the DX8 are

available for download on the Spektum website.

32 E-flite F-4 Phantom 32 DF Assembly Manual

Page 33

3. Connect the leads from the motor and speed

control. Use tie-wraps (not included) to secure

the wiring so it is not moving around inside the

fuselage.

4. Use scissors to cut a small piece of hook and

loop tape. Use the tape to secure the receiver in

the fuselage. Plug the leads for the servos into

the receiver as outlined earlier in this section of

the manual.

5. Use scissors to cut a small piece of hook and

loop tape. Use the tape to secure the remote

receiver in the fuselage.

6. Attach a 18-inch (457mm) servo extension to the

nose gear retract and route it back to the Y-harness

for the retracts. The nose gear steering can either

be connected directly to the receiver using a 9-inch

(228mm) extension, or by a 6-inch Y-harness

plugged into the rudder channel of the receiver

with a 9-inch (228mm) extension. Make sure to use

a string or dental floss on all connections to keep

them from unplugging. Secure the leads inside the

fuselage using clear tape.

Motor Battery Installation

Required Parts

Fuselage assembly Hook and loop tape

Motor battery Hook and loop strap

Required Tools and Adhesives

Scissors

1. Apply the hook and loop tape to the bottom of the

battery. This will keep the battery from sliding in the

fuselage, which could change the center of gravity.

2. Apply the mating hook and loop tape to the

battery tray in the fuselage.

33E-flite F-4 Phantom 32 DF Assembly Manual

Page 34

3. Secure the battery in the fuselage using the hook

and loop strap. Make sure the strap is not pinching

any of the servo leads on the bottom side of the

battery tray.

Canopy Assembly

Required Parts

Canopy Cockpit interior

Pilot (optional) (PKZ4414) (2)

Required Tools and Adhesives

Hobby scissors Clear tape

Silicone adhesive

1. Locate the cockpit interior and use hobby

scissors to trim the interior along the inscribed line.

Trim the interior a little outside the line so it can be

trimmed to fit to the canopy.

3. Use silicone adhesive to glue the pilots to the

cockpit interior.

You can add more detail to the F-4 Phantom

32 cockpit by painting parts of the cockpit with

different colors so it looks more realistic.

4. Place the interior in the canopy. It may be

necessary to bend the interior slightly to fit past the

canopy frame.

2. Use hobby scissors to trim the height of the pilots

so they are 11/4-inches (31mm) in height.

34 E-flite F-4 Phantom 32 DF Assembly Manual

Page 35

5. Use clear tape to secure the interior inside

the canopy.

Decal Placement

Required Parts

Decal sheet Assembled airframe

Required Tools and Adhesives

Hobby scissors Hobby knife with #11 blade

1. Your F-4 already comes with the majority of decals

applied, but also includes an extra set of decal

nomenclature. Apply the decals to your model using

the photos located in this section of the manual, the

box art from your model and on Page 43.

35E-flite F-4 Phantom 32 DF Assembly Manual

Page 36

Center of Gravity

Required Parts

Assembled airframe

Required Tools and Adhesives

Balancing stand Felt-tipped pen

CAUTION: Do not inadvertently skip this step or

property damage and injury could occur.

When balancing your model, adjust the motor battery

as necessary so the model is level or slightly nose

down. This is the correct balance point for your model.

You should find the CG to be very close with the

battery installed as shown in this manual. Mark the

location of the battery on the battery tray using a felttipped pen so it can be returned to this position, if it is

removed from your model.

After the first flights, the CG position can be adjusted

for your personal preference.

3. When balancing your model, support the plane

upright at the marks made on the bottom of the

wing with your fingers or a commercially available

balancing stand. This is the correct balance

point for your model. Make sure your model is

assembled and ready for flight before balancing.

1. Attach the wings to the fuselage following the

procedure outlined earlier in this manual.

2. The recommended Center of Gravity (CG)

location for your model is 511/16 to 61/8-inches

(145 to 155mm) back from the leading edge of the

wing at the root as shown with the battery pack

installed. Mark the location of the CG on the top of

the wing with a felt-tipped pen.

If you have installed retracts, balance

your model with the gear down.

36 E-flite F-4 Phantom 32 DF Assembly Manual

Page 37

Control Throws

1. Turn on the transmitter and receiver of your

model. Check the movement of the rudder using

the transmitter. When the stick is moved right,

the rudder should also move right. Reverse the

direction of the servo at the transmitter if necessary.

2. Check the movement of the elevator with the

radio system. Moving the elevator stick toward

the bottom of the transmitter makes the airplane

elevator move up.

3. Check the movement of the ailerons with the

radio system. Moving the aileron stick right makes

the right aileron move up and the left aileron

move down.

4. Use a ruler to adjust the throw of the elevator,

ailerons and rudder. Adjust the position of

the pushrod at the control horn to achieve the

following measurements when moving the sticks to

their endpoints.

IMPORTANT: Use caution with high rates on

the elevator and ailerons. High rates are only

used for snap and spin aerobatic maneuvers.

Middle rates are suggested for takeoff

and landings. Low rates are suggested for

standard flight maneuvers. If your radio only

has the option for two rates, use the middle

and low rates.

Ailerons

Up

High 11mm Expo 10%

Mid 9mm Expo 8%

Low 7mm Expo 5%

Down

High 9mm Expo 10%

Mid 7mm Expo 8%

Low 6mm Expo 5%

Elevator

Up and down

High 26mm Expo 10% (up/down)

Mid 21mm Expo 5% (up/down)

Low 16mm Expo 0% (up/down)

Rudder

Left and right

High 22mm Expo 10% (left and right)

Mid 18mm Expo 5% (left and right)

Low 15mm Expo 0% (left and right)

Flaps

Mid/Take Off 11mm down

Full/Landing 30mm down

Flap Elev Mix

Mid/Take Off 1 mm up elevator

Full/Landing 2 mm up elevator

Nose Gear Steering

High rate mix 50%

Low rate Mix 30%

The F-4 Phantom does not always require full flaps for

landing. We recommend using full flaps for landings

in no wind or light headwind situations. Use half flaps

for landings in strong headwinds or crosswinds.

Measurements are taken at the inner or

widest point on the control surface.

These are general guidelines measured from our own

flight tests. You can experiment with higher rates to

match your preferred style of flying.

Travel Adjust and Sub-Trims are not listed

and should be adjusted according to each

individual model and preference.

NOTICE: Always re-binding the radio system

once all the control throws are set. This will

keep the servos from moving to their endpoints

until the transmitter and receiver connect.

Preflight

Check Your Radio

Before going to the field, make sure your batteries

are fully charged per the instructions included with

your radio. Charge the transmitter and motor battery

for your airplane. Use the recommended charger

supplied with your particular radio system, following

the instructions provided with the radio. In most

cases, the radio should be charged the night before

going out flying.

Before each flying session, be sure to range check your

radio. See your radio manual for the recommended

range and instructions for your radio system. Each

radio manufacturer specifies different procedures for

their radio systems. Next, run the motor. With the

model securely anchored, check the range again. The

range test should not be significantly affected. If it

is, do not attempt to fly! Have your radio equipment

checked out by the manufacturer.

Double-check that all controls (aileron, elevator, rudder

and throttle) move in the correct direction.

Check the radio installation and make sure all the

control surfaces are moving correctly (i.e., the correct

direction and with the recommended throws).

Check all the control horns, servo horns, and clevises

to make sure they are secure and in good condition.

37E-flite F-4 Phantom 32 DF Assembly Manual

Page 38

Range Test Your Radio

Before each flying session, and especially with a new

model, it is important to perform a range check. It

is helpful to have another person available to assist

during the range check. If you are using a Spektrum™

transmitter, please refer to your transmitter’s manual for

detailed instructions on the range check process.

1. With the model resting on the ground, stand 30

paces (approximately 90 feet) away from the model.

2. Face the model with the transmitter in your

normal flying position. Be sure the throttle is in the

full down position and plug the flight battery into

the speed control.

3. As you move the controls, watch to be sure the

airplane’s motor and controls operate smoothly.

You should have total control of the model at 30

paces (90 feet).

4. If control issues exist, call the appropriate

Horizon Product Support office (see addresses

listed in the Warranty Services section of this

manual) or go to horizonhobby.com to find a local

Spektrum distributor in your country for service

when using a Spektrum radio system.

Flying Your Model

Now that you have finished your F-4 Phantom 32

and it’s ready to go, make one final check on a few

things first. Is the main battery fully charged? Is the

transmitter fully charged? Are the dual rates and travel

adjustments set for the first flight? The F-4 Phantom

32 is very responsive and it is highly recommended

that you take off with high rate, then switch to low

rate right after takeoff. Check that the center of gravity

has been verified and the timer has been set. We

recommend that the timer be set for 3 minutes on the

first flight. 3 minutes of flight will give you a good

safety margin for a few landing approaches. The F-4

Phantom 32 will consistently give you 4+ minutes of

high-speed flight. If you use power management, 6+

minutes is easily achieved.

Only fly this airplane at a sanctioned flying field, as

it is not a parkflyer. Turn on the transmitter, plug in

the flight battery, and turn on the switch for the radio.

Check all control surfaces and basic motor operation.

Check the motor at full throttle. Pick the model up and

cycle the retracts. If everything is working properly, you

are ready for flight.

Taxi the model onto the runway. Make a few taxi tests

and get the nose gear steering adjusted so the model

rolls straight down the runway. For your first flight

leave, the flaps up on takeoff until you are familiar

with its flying characteristics. Set the dual rates to the

high position. If you have set the rudder and steering

separately, you can also set the nose gear for a lower

rate that is not linked to the control surface rates and

can allow for a much smoother takeoff.

Trimming and Flight Characteristics

After takeoff, gain some altitude, retract the landing

gear and switch to low rates. Climb to a safe altitude

and begin to trim the model. Once you have the model

trimmed, you will want to get an idea of the flight

quality with the flaps down and the model slowed

down. Slow the model down to a little below half

power and drop the flaps to the middle position. Check

the trim again and also note if the model needs any

up or down elevator compensation. At this time, you

may also need to come back up on the power a little.

Now try full flaps and note any other trim changes.

The F-4 Phantom 32 will fly very nicely with full flaps

and is very predictable in this configuration. Drop the

landing gear and switch back to high rate to check

the trim once again in landing configuration. Once

you are happy with this, retract the gear, pull the flaps

up, and switch back to low rate and start to enjoy the

performance of the F-4 Phantom 32. You will find the

model tracks very well through all aspects of flight.

From high-speed passes, inverted flight, loops, and

rolls, you will be flying like a true “jet jock” in no time.

Get a feel for all rate settings. High rates are used

mainly for takeoff and landings and low rates are for

normal and precision flight.

Takeoff

While applying power, slowly steer with the rudder to

keep the model straight. The airplane should accelerate

quickly, and as the model gains flight speed, you will

want to rotate when you feel comfortable. Generally,

very slight back pressure on the elevator will allow

the airplane to rotate smoothly at a comfortable, safe

airspeed. The F-4 Phantom 32 will climb out at a nice

angle of attack.

38 E-flite F-4 Phantom 32 DF Assembly Manual

Page 39

Landing

Remember to keep an eye on the radio timer. After

3 minutes on the first flight it’s time to drop the flaps,

retracts, switch to high rates and start shooting a

few approaches with the F-4 Phantom 32. If you are

landing in higher winds or cross winds use half flaps

instead of full flaps as the airplane has a lot of drag.

Adjust power to slow the plane down but keep flying

speed. Don’t be alarmed if you are flying at a much

higher throttle setting than you are used to, ensure

that you give the airplane what it needs to maintain

enough airspeed to fly. As you roll onto final approach

manage the power and begin to pull the nose up. The

F-4 Phantom 32 has a very nice approach and decent

rate. You will find that with the nose slightly high you

can control the final approach descent with power

management. The key to a great landing is to manage

the power and elevator all the way to the ground and

set down lightly on the main landing gear. After a few

flights you will find the F-4 Phantom 32 can be set

down lightly on the mains till it slows and gently settles

the nose. We hope you enjoy flying the E-flite F-4

Phantom 32

Happy Landings!

Daily Flight Checks

1. Check the battery voltage of the transmitter

battery. Do not fly below the manufacturer’s

recommended voltage. To do so may cause your

aircraft to crash.

When you check these batteries, ensure you have the

polarities correct on your expanded scale voltmeter.

2. Check all hardware (linkages, screws, nuts,

and bolts) prior to each day’s flight. Be sure that

binding does not occur and that all parts are

properly secured.

3. Ensure all surfaces are moving in the

proper manner.

4. Perform a ground range check before each

day’s flying session.

5. Prior to starting your aircraft, turn off your

transmitter, then turn it back on. Do this each time

you start your aircraft. If any critical switches are

on without your knowledge, the transmitter alarm

will sound a warning.

Limited Warranty

WHAT THIS WARRANTY COVERS

Horizon Hobby, Inc. (“Horizon”) warrants to the

original purchaser that the product purchased (the

“Product”) will be free from defects in materials and

workmanship at the date of purchase.

WHAT IS NOT COVERED

This warranty is not transferable and does not cover

(i) cosmetic damage, (ii) damage due to acts of God,

accident, misuse, abuse, negligence, commercial use,

or due to improper use, installation, operation or

maintenance, (iii) modification of or to any part of the

Product, (iv) attempted service by anyone other than