Page 1

G90 Sub-Micro

8-11mm

90º

Heading Lock Gyro

Instruction Manual

Introduction

The G90 Sub-Micro Heading Lock Gyro’s small size

(20 x 20 x 15mm) and low weight (9.0 grams, including leads

and connectors) make it an ideal choice for a wide variety of

micro and mini class electric helicopter models. With features

like analog and digital servo support, optional dual remote

gain adjustment and Heading Lock or Standard Rate Mode

selection capabilities, it offers locked-in tail performance

and adjustability perfect for the sport and 3D pilot alike.

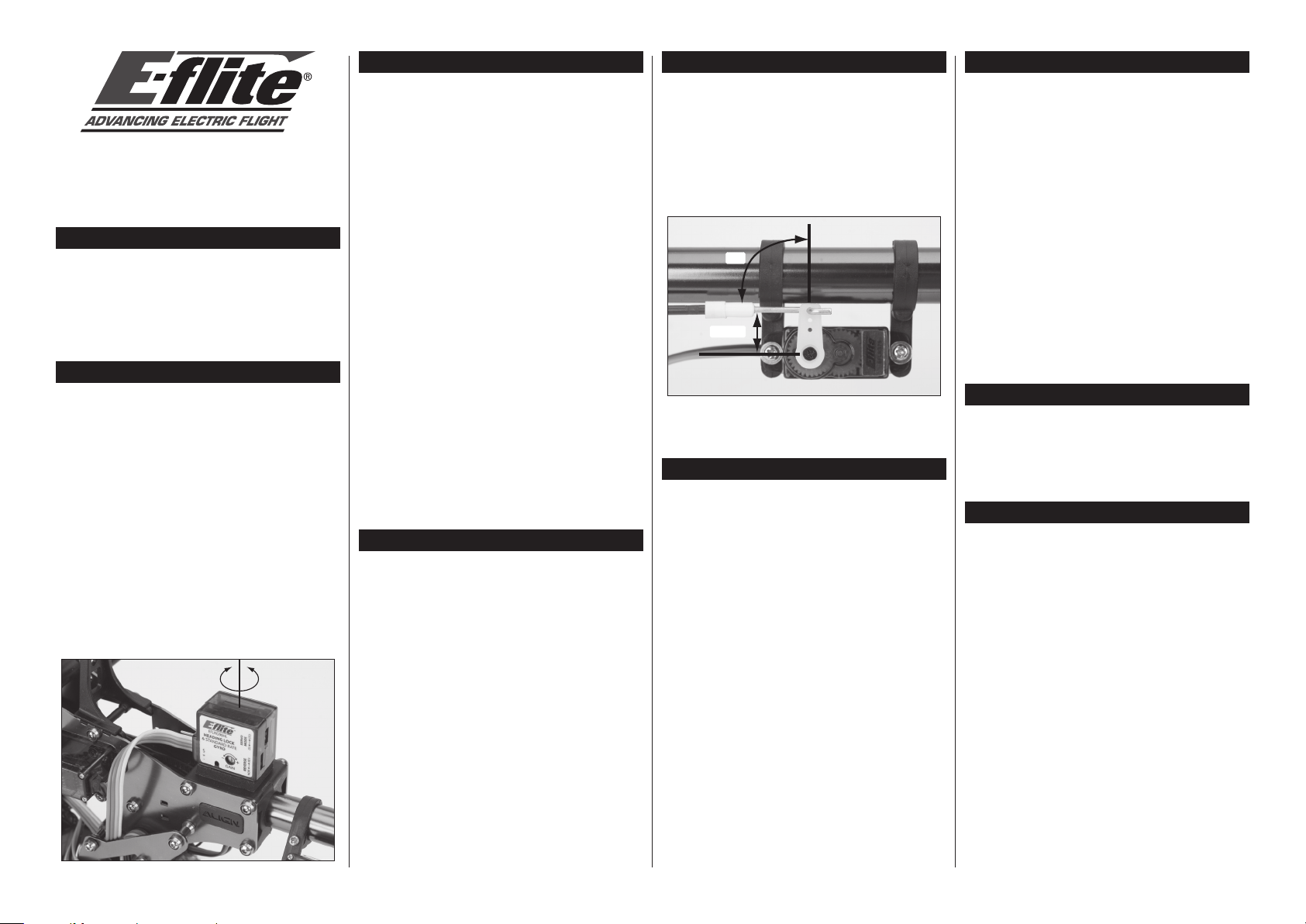

Gyro Installation

When installing the G90, it is typically best to first refer

to your helicopter’s instruction manual for suggestions of

the location in which it should be mounted on the model.

If no suggestions are available, choose a solid location

free from vibration, in-line with the yaw axis of the model.

Also, be sure to keep the gyro away from heat generating

sources (like the motor and ESC) and other electronics.

When mounting the G90, be sure the side of the gyro with

the label is mounted vertically on the model (parallel to

the main shaft). The sides of the gyro without the leads

and switches are the top and bottom respectively. Also,

be sure to position the gyro so you can easily access the

gain setting adjustment pot (if not using the remote gain

adjustment option), reversing and servo mode switches.

Once you have found a suitable location, use a small amount

of isopropyl alcohol to clean the mounting area and gyro

where the foam mounting tape will be attached. Then,

use the included foam mounting tape to mount the gyro

securely on the model. It is important to use foam mounting

tape only as it helps to prevent vibration from adversely

affecting the performance and operating life of the gyro.

Gyro Connection(s) to Receiver

Single Mode Connection (Heading Lock Mode Only)

If you will not be utilizing the dual remote gain adjustment

and mode selection option to control gain values and mode

type from an auxiliary channel on the transmitter, it will only

be necessary to connect the Rudder Channel Lead of the gyro

(the connector with three wire leads) to the rudder channel

on the receiver. You will not need to connect the Auxiliary

Channel Lead of the gyro (the connector with one wire lead)

to the receiver, however, to be certain to secure it so it cannot

come into contact with any moving parts on the helicopter.

With just the rudder channel lead of the gyro connected

to the receiver, the gyro will operate in Heading Lock

Mode only. The gain value will then be adjusted using

the Gain Setting Adjustment Pot located on the gyro.

Dual Mode Connections

(Heading Lock and Standard Rate Mode)

If you have chosen to utilize the dual remote gain adjustment

and mode selection option to control gain values and mode type

from an auxiliary channel on the transmitter, it will be necessary

to connect the Rudder Channel Lead of the gyro (the connector

with three wire leads) to the rudder channel on the receiver,

and the Auxiliary Channel Lead of the gyro (the connector with

one wire lead) to the channel on the receiver that will be used

for controlling the gyro from the transmitter. For most radio

systems, it will be best to connect the Auxiliary Channel Lead

of the gyro to Channel 5 (also known as the Gear Channel) on

the receiver, ensuring the yellow wire lead is oriented properly

so it is plugged into the “signal” side of the receiver’s pins.

With both the rudder channel and auxiliary channel leads of

the gyro connected to the receiver, the gyro can be operated

in either the Heading Lock or Standard Rate Mode. Mode

selection and gyro gain settings will then be adjusted using

an auxiliary channel on the transmitter, and the Gain Setting

Adjustment Pot located on the gyro will be disabled.

Tail Servo Selection

Selection of a suitable tail servo is critical for obtaining

maximum performance from the gyro. A servo with

quick transit times (.15 sec/60° or faster) is preferred,

and will allow the G90 to perform to its full potential.

We suggest using the following servos in

their recommended applications:

®

• E-flite

• E-flite S75 Sub-Micro Servo (EFLRS75)

• JR 3400G Mini Digital Heli Gyro Servo (JRPS3400G)

S60 Super Sub-Micro Servo (EFLRS60)

– For sub-micro and micro helicopters

– For micro and mini helicopters

– For mini helicopters

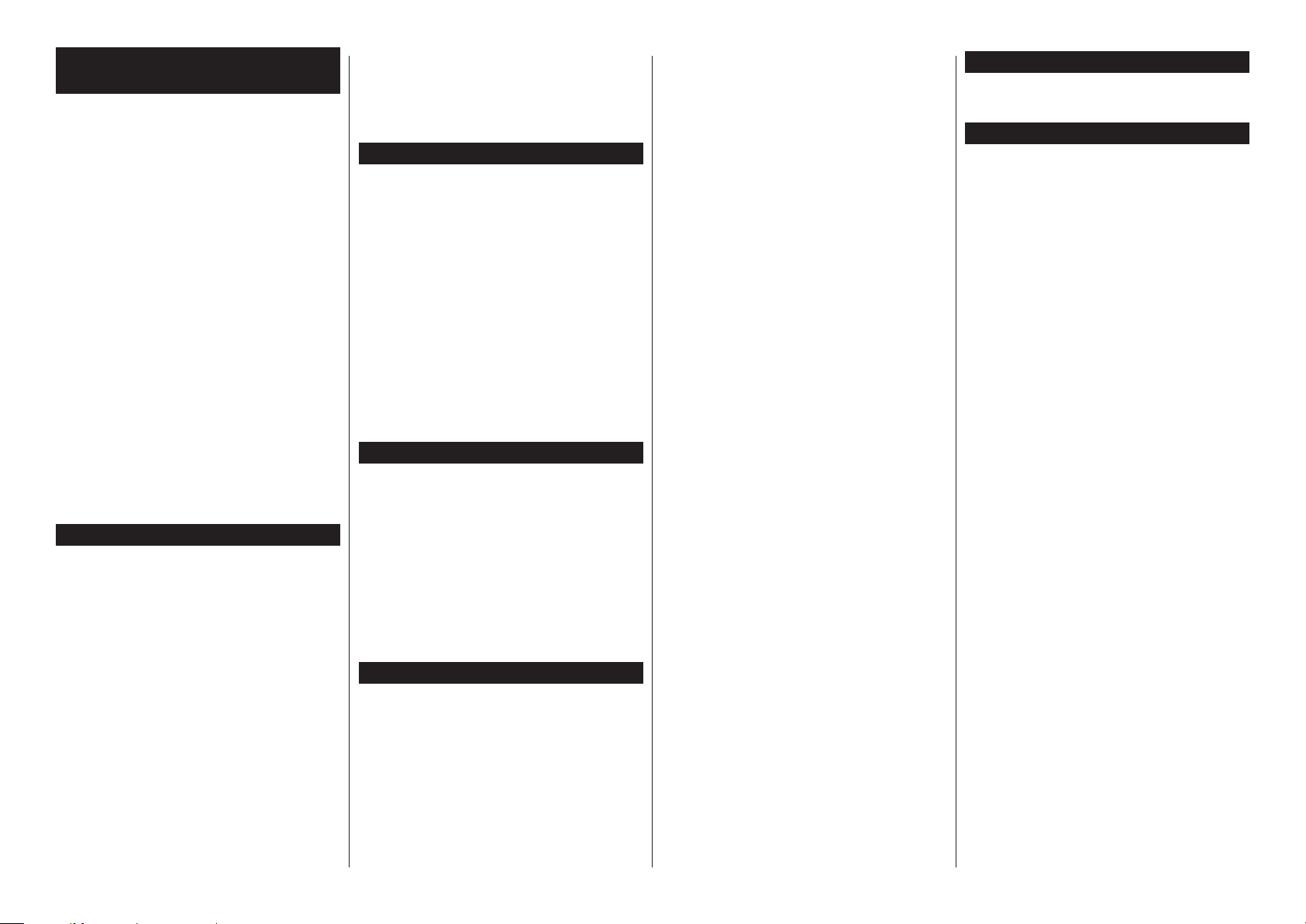

Servo Arm and Pushrod Setup

After installing your chosen servo on the model, it will be best

to center the servo electronically using an open channel before

installing the servo arm and connecting the servo to the G90.

Once you have centered the servo electronically, choose a

servo arm that allows the tail rotor pushrod linkage or linkage

ball to be positioned approximately 8–11mm (typical for T-REX

and similar models) from the center of the servo’s output

gear/shaft. Then, install the servo arm on the servo, ensuring

it is perpendicular to the tail rotor pushrod linkage when in the

centered/neutral position. Also, be sure to remove any unused

portions of the servo arm to prevent any binding or obstruction.

After installing the tail rotor pushrod linkage on the tail servo

arm, and ensuring the tail servo is still centered electronically,

adjust the length of the pushrod so the tail pitch slider is centered

on the tail rotor shaft, between the tail case and tail hub.

Servo Connection to Gyro

Once the tail servo, servo arm and linkage have been installed

on the model, it will be necessary to connect the servo to

the G90. Connect the servo lead to the servo connection

on the gyro (the three pins exiting the gyro case), ensuring

proper orientation and polarity direction of the wire leads

by following the markings on the label of the gyro:

S = Signal wire lead connection location

+ = Positive wire lead connection location

– = Negative wire lead connection location

Servo Mode Setting

Standard (STD) Servo Mode

If you are using an analog servo (like the E-flite S60 or

S75), be sure the Servo Mode switch located on the side of

the gyro is set to the Standard (STD) position for the best

possible performance. If it is set to the Digital Servo (DS)

position, the analog servo may not operate correctly and/or

will be damaged due to the high frame rate output of the gyro

when it is in the Digital Servo Mode. Do not use analog

servos with the gyro set for Digital Servo Mode.

Digital (DS) Servo Mode

If you are using a digital servo (like the JR 3400G), be sure the

Servo Mode switch located on the side of the gyro is set to the

Digital Servo (DS) position for the best possible performance.

In the Digital Servo Mode, the gyro sends inputs to the servo at

a much higher rate than when in the Standard Servo Mode for

added performance and holding power. However, you must be

sure to use a digital servo that is capable of handling an input

pulse rate of 275Hz or higher (like JR and similar digital servos),

or the servo will not operate correctly and/or will be damaged

due to the high frame rate output of the gyro when it is in the

Digital Servo Mode. Do not use digital servos that cannot

handle an input pulse rate of at least 275Hz, or analog

servos, with the gyro set for Digital Servo Mode.

Initial Transmitter Settings

After completing installation and connection of the G90 and

tail servo on the model, please proceed with confirming

the following initial settings in your transmitter:

• Set the rudder channel trim and subtrim (if available) to neutral

• Disable and inhibit any forms of Revolution (Revo) Mixing

Initializing the Gyro

Once you have confirmed the initial settings in the

transmitter, it will be necessary to power up and

initialize the gyro before proceeding with some of

the following setup and adjustment steps:

• Power the transmitter on first.

• Then, power the receiver and gyro on.

• After powering on the receiver and gyro, make

sure you do not move or sway the model and

allow it to remain motionless until the blue LED

on the gyro illuminates solidly, indicating the gyro

has initialized properly and is ready for use.

Note: It is extremely important you do not move or

sway the model after powering on the gyro and before

it initializes. The gyro must be allowed adequate time

to record the neutral position in order to initialize

for proper operation. If you accidentally move the

model after powering the gyro on, and before it has

initialized, power the model off and repeat the process

to power the model on and initialize the gyro properly.

Page 2

Heading Lock and Standard Rate Mode

Selection and Adjustment

If you have chosen to utilize the dual remote gain adjustment

and mode selection option to control gain values and mode

type from an auxiliary channel on the transmitter, it will now

be necessary to confirm how to select and adjust the Heading

Lock or Standard Rate Modes from your transmitter. If you

have chosen not to utilize this option, please skip to the next

section, as the gyro will always be in the Heading Lock mode.

• With the transmitter, receiver and gyro powered on,

enter the transmitter’s Travel Adjustment function

(also known as ATV or EPA). If, however, you are

using a specialized program within your transmitter

for controlling the gyro (like Gyro Sensitivity or

similar), enter into that particular function.

• Scroll to the channel being used to control the gyro. This

will be the same channel into which you have plugged

the auxiliary channel lead of the gyro into the receiver.

• Then, using the selected channel’s switch on the

transmitter, toggle the switch back and forth in order

to identify the switch position for each gyro mode.

When the gyro is in Heading Lock Mode, you will find

the tail servo will not return the neutral position after

a rudder input is given. When the gyro is in Standard

Rate Mode, the tail servo will always return to the

neutral position after a rudder input is given.

• Typically, you will find when the switch is toggled to the

positive position (+), the gyro will be in the Heading Lock

Mode. Then, when the switch is toggled to the negative

position (-), the gyro will be in the Standard Rate Mode.

• Once you have identified the switch position for each

mode, note you will be making gain adjustments to

the selected mode by changing the Travel Adjustment

(ATV/EPA) value for its given switch position.

Initial Gain Settings and Adjustment

Single Mode (Heading Lock Mode Only)

When utilizing the Single Mode option (Heading Lock Mode

only), you will make adjustments to the gyro gain value by

using the Gain Setting Adjustment Pot located on the gyro

itself. Use a small flat blade screwdriver and extreme care (to

prevent damage to the pot) to adjust the position of the pot.

When the pot is in the fully counterclockwise position (-), the

gain value will be approximately 0%. When the pot is in the full

clockwise position (+), the gain value will be approximately 100%.

We suggest a setting of approximately 50% (pot in the middle

position) for the first test flight after installing the gyro.

Dual Mode (Heading Lock or Standard Rate Mode)

When utilizing the Dual Mode option (Heading Lock or Standard

Rate Mode selectable), you will make adjustments to the gyro

gain value in each mode remotely from the transmitter, using

the auxiliary channel you have selected for gyro control.

Depending on the transmitter and channel used to control the

gyro, you may have the ability to set the Travel Adjustment

(ATV/EPA) value from 0% to approximately 100%, or even up to

150%. This is not a problem, as long as you note the maximum

value you can set for travel adjustment will equal an actual

gain value of 100% for the gyro. In the case of a transmitter

and channel that allows you to set the travel adjustment value

up to 150%, you will achieve approximately 50% gyro gain

value at a travel adjustment value of 75%, and approximately

100% gyro gain value at a travel adjustment value of 150%.

We suggest setting the gyro gain value to approximately

50% in both the Heading Lock and Standard Rate Modes

for the first test flight after installing the gyro.

Confirming Gyro/Servo Operating Direction

It will now be necessary to confirm the tail servo and gyro are

operating in the correct directions for proper control. First, refer

to the instruction manual included with your helicopter model

for information regarding the direction in which the tail servo

should respond to rudder inputs for proper control response.

After confirming the tail servo is responding in the correct

direction to rudder inputs, you will also need to confirm the

gyro is responding properly to movements of the helicopter,

while providing proper inputs to the tail servo in order to

counteract any unwanted changes in yaw. To do this, view the

servo arm (from the top of the servo) and note the direction the

arm moves (clockwise or counterclockwise) when you give a

right rudder input on the transmitter (while the model remains

motionless). Then, yaw the nose of the helicopter quickly to

the left, while again noting the direction the tail servo arm

moves. The arm should move in the same direction as it did for

a right rudder command, helping to counteract the left-hand

yaw movement of the nose. If the arm moves in the opposite

direction, switch the Reverse switch located on the side of the

G90 to its opposite position. Then, repeat the steps above to

confirm the gyro is now operating in the correct direction.

Trimming Neutral with Sub-Trim and Trim

When in Heading Lock Mode, the tail servo arm may “creep” or

move while the model remains motionless, and with no rudder

input from the transmitter. This movement is normal, but can

be minimized by adjusting the sub-trim (preferred, if available)

or trim value of the rudder channel in/on your transmitter. Use

the sub-trim function or trim lever on the transmitter to add a

left or right value to the rudder channel. Then, re-center the tail

servo arm with the control stick and watch for any additional

movement. Add or reduce the sub-trim or trim value as needed

until the tail servo arm moves as little as possible when near

the neutral position. In general, only a small amount of subtrim or trim adjustment will be required in order to minimize

movement of the tail servo arm (and “drifting” of the nose/tail of

the helicopter model in flight), and some very slow movement

that may still remain after making the adjustments is normal.

Adjustments After Test Flights

Once you have completed installation and setup of the

G90, it will be necessary to conduct test flights in order

to identify any settings that must be adjusted so that you

can obtain maximum performance of the gyro. Be careful

when conducting the initial test flight, however, taking your

time to ensure the gyro and tail servo are responding and

performing properly before lifting the model into the air.

Gain Adjustments

During the test flight(s), establish a stable hover and apply some

short and quick rudder inputs while observing the reaction of

the tail when the control stick is returned to its neutral position.

If there is any tendency for the tail to twitch quickly (oscillate)

from side to side, it will be necessary to lower the gyro gain

value. You can do this by adjusting the Gain Setting Adjustment

Pot on the gyro itself counterclockwise a small amount (if using

the Single Mode option), or remotely from the transmitter by

reducing the Travel Adjustment (ATV/EPA) value for the gyro

control channel (if using the Dual Mode option). The goal,

when in Heading Lock Mode, is to find the highest gyro gain

value at which the tail of the helicopter will not oscillate in all

areas of flight, including fast forward flight and descents.

If you are using the Dual Mode option, you will also need to

adjust the gyro gain value for the Standard Rate Mode. In this

mode, the amount of gyro gain value required will typically

depend most on the flying style and preference of the pilot.

Tail Linkage and Pushrod Adjustments

If, after conducting test flights, you find the gyro gain value cannot

be set high enough to cause some oscillation of the tail (even at

the highest setting), it will be necessary to adjust the position of

the tail rotor pushrod linkage on the tail servo arm. In this case,

you will need to move the linkage farther out from the center of

the servo’s output gear/shaft (by approximately 2mm to start).

If you find the gyro gain value cannot be set low enough to

prevent oscillation of the tail (when near the lowest setting),

it will be necessary to adjust the position of the tail rotor

pushrod linkage on the tail servo arm. In this case, you will

need to move the linkage closer to the center of the servo’s

output gear/shaft (by approximately 2mm to start).

If you are using the Dual Mode option, and will be switching

between the Heading Lock and Standard Rate Modes during flight,

it is best to mechanically adjust the tail rotor pushrod length so

there is not a significant difference in the rudder trim/sub-trim

values required in each mode for the best performance. This

can be accomplished by flying the model in the Standard Rate

Mode and adjusting the length of the pushrod so the nose/tail of

the model stays as straight as possible, with no rudder input or

rudder trim/sub-trim values that are significantly different than

those set for optimum performance in the Heading Lock Mode.

Rudder Trim Adjustments

During flight, it may be necessary to make some small

adjustments to the rudder trim position/value in order to help

prevent the nose/tail of the model from “drifting” to the left or

right when the rudder stick is in the neutral position. Typically,

only a small amount of adjustment may be necessary.

Rudder Travel Adjustments and Exponential

By increasing or decreasing the left and right Travel Adjustment

(ATV/EPA) values for the rudder channel in your transmitter,

you can adjust the rate at which the model will pirouette when

a full rudder input is given and held, and responds to rudder

inputs in general. You can also further fine-tune response of

the tail around neutral by increasing or decreasing the amount

of Exponential (if available) used for the rudder channel.

Temperature and Environmental Conditions

It is always best to avoid sudden temperature and

environmental condition changes when using a gyro. For

example, it is best to not fly a model on a very hot day

immediately after removing it from an air-conditioned vehicle.

It is also best to keep the gyro out of direct sunlight and

away from any heat generating sources on the model.

To help the gyro better adapt to temperature and environmental

conditions at the flying field, it is best to let the model

stand for approximately 10-15 minutes before flying,

allowing the temperature inside the gyro to stabilize.

Limited Warranty Period

Horizon Hobby, Inc. guarantees this product to be

free from defects in both material and workmanship

for a period of 1 year from the date of purchase.

Limited Warranty & Limits of Liability

Pursuant to this Limited Warranty, Horizon Hobby, Inc. will,

at its option, (i) repair or (ii) replace, any product determined

by Horizon Hobby, Inc. to be defective. In the event of

a defect, these are your exclusive remedies.

This warranty does not cover cosmetic damage or damage due

to acts of God, accident, misuse, abuse, negligence, commercial

use, or modification of, or to any part of the Product. This

warranty does not cover damage due to improper installation,

operation, maintenance, or attempted repair by anyone other than

an authorized Horizon Hobby, Inc. service center. This warranty

is limited to the original purchaser and is not transferable. In

no case shall Horizon Hobby’s liability exceed the original cost

of the purchased product and will not cover consequential,

incidental or collateral damage. Horizon Hobby, Inc. reserves

the right to inspect any and all equipment involved in a warranty

claim. Repair or replacement decisions are at the sole discretion

of Horizon Hobby, Inc. Further, Horizon Hobby reserves the

right to change or modify this warranty without notice.

REPAIR OR REPLACEMENT AS PROVIDED UNDER

THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE

CONSUMER. HORIZON HOBBY, INC. SHALL NOT BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

As Horizon Hobby, Inc. has no control over use, setup, final

assembly, modification or misuse, no liability shall be assumed

nor accepted for any resulting damage or injury. By the act of

use, setup or assembly, the user accepts all resulting liability.

If you as the purchaser or user are not prepared to accept

the liability associated with the use of this product, you

are advised to return this product immediately in new

and unused condition to the place of purchase.

For additional information concerning the Limited Warranty,

Limits of Liability and Safety Precautions, please refer to our web

page for this item or contact your E-flite distributor. You can also

direct emails to productsupport@horizonhobby.com, or in the

U.S., call 877.504.0233 toll free to speak to a service technician.

© 2006 Horizon Hobby, Inc.

www.horizonhobby.com

www.E-fliteRC.com

E-flite® is an exclusive brand of Horizon Hobby, Inc.

#9231

Loading...

Loading...