Page 1

Instruction Manual

nEXT Turbomolecular Pumps

nEXT240, nEXT300 and nEXT400

B800-00-880

Issue A Original

Description Item Number

nEXT240D B812XXXXX

nEXT240T B813XXXXX

nEXT300D B822XXXXX

nEXT300T B823XXXXX

nEXT400D B832XXXXX

nEXT400T B833XXXXX

Page 2

Page 3

B800-00-880 Issue A

Contents

Section Page

1 Introduction ....................................................................................... 1

1.1 Scope and definitions ................................................................................................... 1

1.2 General description ..................................................................................................... 2

1.3 Pump controller .......................................................................................................... 3

1.4 Operational features .................................................................................................... 3

1.4.1 Power limit setting ...................................................................................................... 3

1.4.2 Standby speed ............................................................................................................ 3

1.4.3 Timer ...................................................................................................................... 4

1.4.4 Analogue output ......................................................................................................... 4

1.4.5 Automatic vent options ................................................................................................. 4

1.4.6 Normal speed setting .................................................................................................... 5

1.5 Logic interface ........................................................................................................... 5

1.5.1 Parallel control and monitoring ....................................................................................... 5

1.5.2 Serial control and monitoring .......................................................................................... 5

1.5.3 Serial control with parallel monitoring ............................................................................... 6

1.5.4 Parallel control with serial monitoring or serial configuration ................................................... 6

1.5.5 Controller configuration (serial set-up) .............................................................................. 6

Contents

2 Technical data .................................................................................... 7

2.1 General ................................................................................................................... 7

2.2 Pumping media ........................................................................................................... 7

2.3 Vent gas specification and vent control data ...................................................................... 17

2.4 Purge gas specification ................................................................................................ 18

2.5 Cooling water ............................................................................................................18

2.6 Materials exposed to gases pumped .................................................................................18

2.7 Electrical data ........................................................................................................... 19

2.8 Logic interface connector .............................................................................................19

2.9 Controller connector socket .......................................................................................... 20

2.10 Indicator LEDs ...........................................................................................................23

2.11 Operating and storage environment .................................................................................23

3 Installation ....................................................................................... 25

3.1 Unpack and inspect ..................................................................................................... 25

3.2 Typical installation .....................................................................................................25

3.3 Connection to the vacuum system ...................................................................................26

3.3.1 Inlet-screen (supplied fitted on CF only) ............................................................................27

3.3.2 Mechanical fixing .......................................................................................................27

3.3.3 Inlet-connection and orientation .....................................................................................27

3.3.4 Base mounting ........................................................................................................... 28

3.3.5 Backing connection ..................................................................................................... 28

3.3.6 Interstage connection (variants only) ............................................................................... 29

3.4 Purge gas connection ...................................................................................................29

3.4.1 Connect the purge gas .................................................................................................29

3.4.2 Recommended purge gas flow ........................................................................................29

3.5 Electrical installation ..................................................................................................29

3.5.1 Introduction .............................................................................................................29

3.5.2 Earth (ground) connections ...........................................................................................29

3.5.3 Connect the logic interface to the TIC ..............................................................................29

3.5.4 Connect the logic interface to your control equipment ..........................................................30

3.5.5 Connect the electrical supply .........................................................................................30

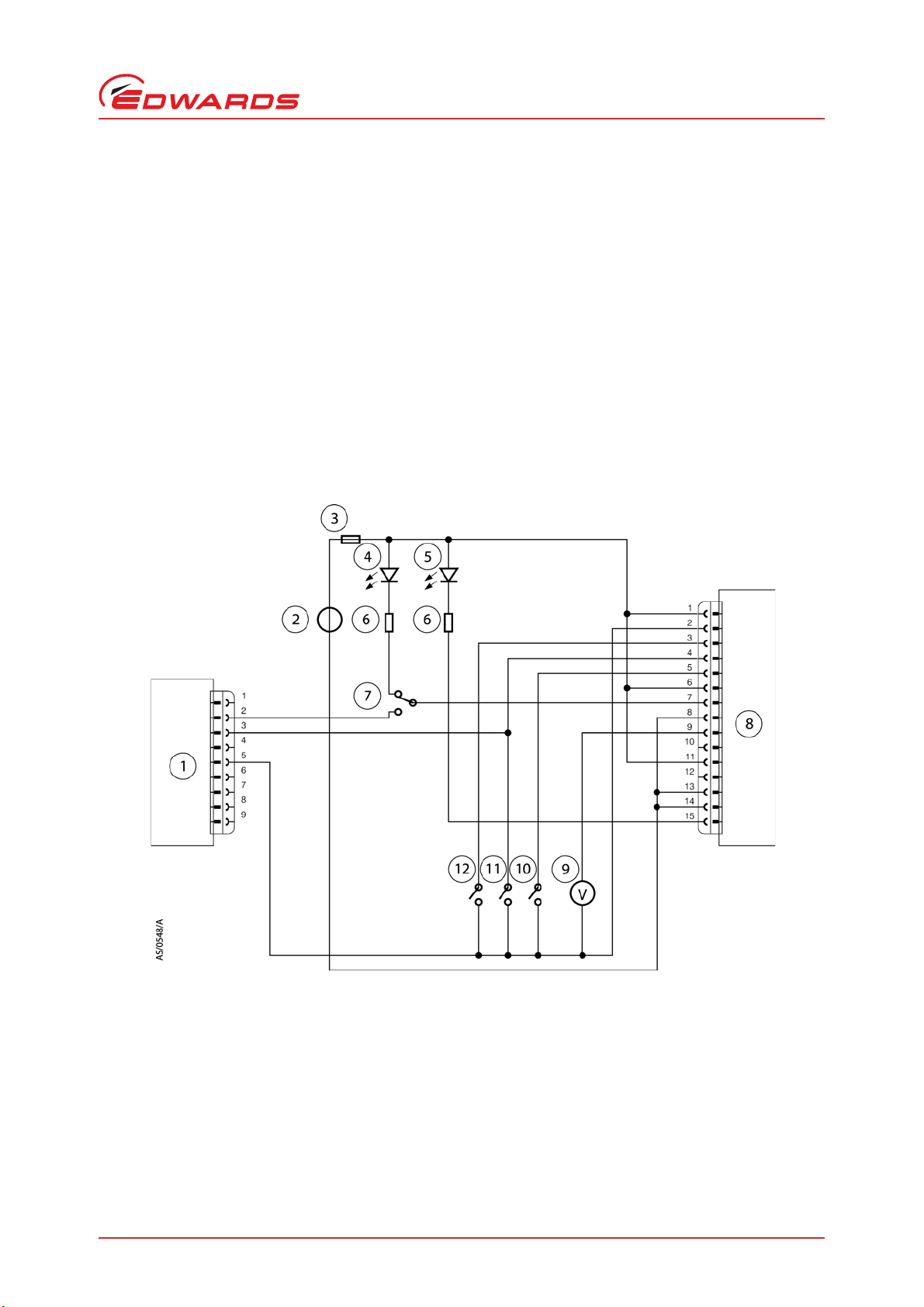

3.6 Connection for parallel control and monitoring ................................................................... 31

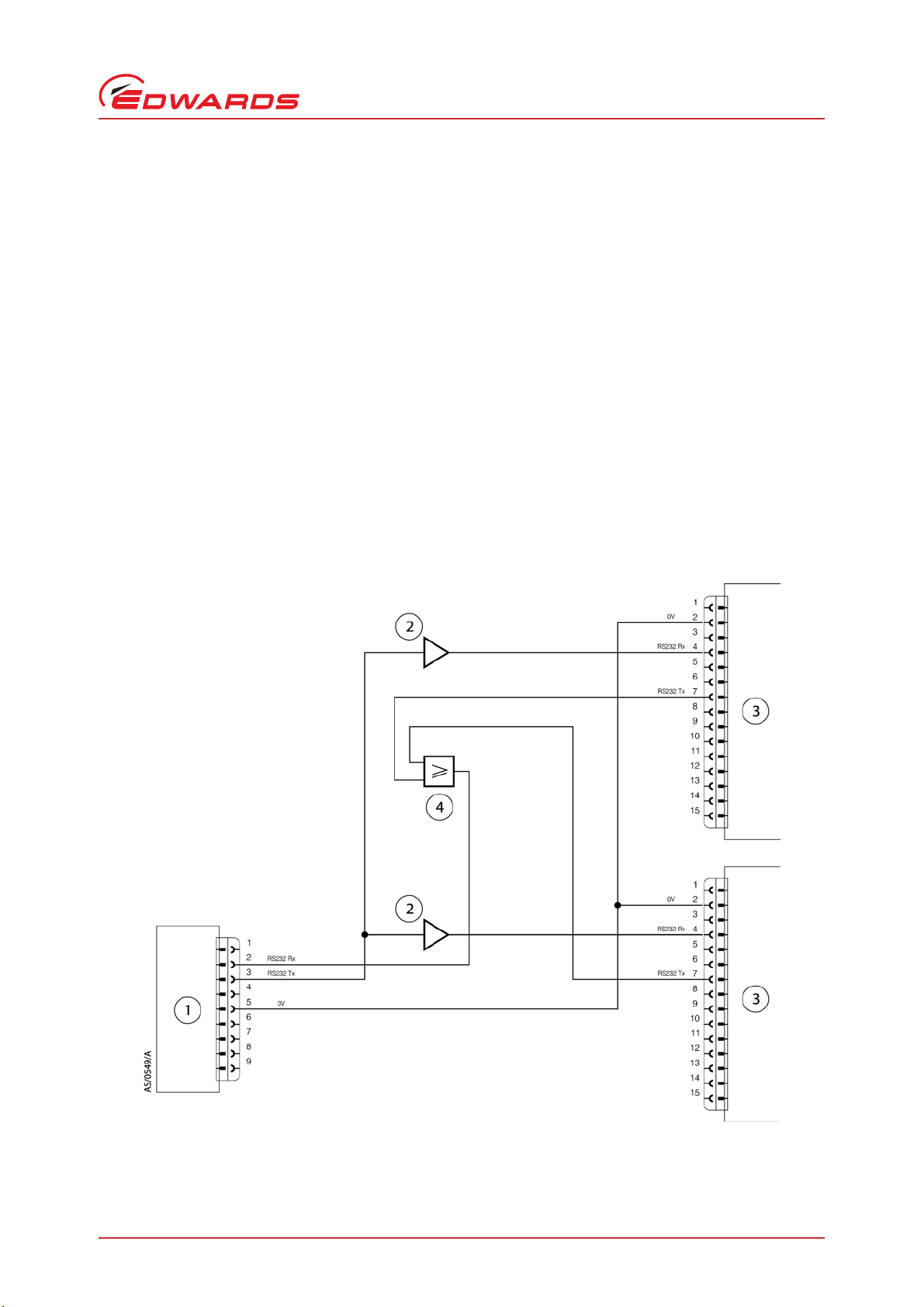

3.7 Connection for serial control and monitoring ......................................................................32

IA/030/03/09

© Edwards Limited 2009. All rights reserved. Page i

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 4

B800-00-880 Issue A

Contents

3.7.1 Connect the serial interface to your control equipment .........................................................32

3.7.2 Serial enable .............................................................................................................34

3.7.3 Serial protocol ...........................................................................................................35

3.7.4 Message structure .......................................................................................................36

3.7.5 Command set ............................................................................................................ 37

3.7.6 Simultaneous parallel and serial operation ......................................................................... 39

3.7.7 Multi-drop operation ...................................................................................................40

3.8 Vent options, vent valve connection and control .................................................................. 40

3.8.1 Manual vent valve ...................................................................................................... 40

3.8.2 TAV5 or TAV6 solenoid vent valve ....................................................................................40

3.8.3 Controlled venting ...................................................................................................... 41

3.8.4 Alternative valve connected to the vacuum system ..............................................................42

3.9 Cooling ...................................................................................................................42

3.9.1 Introduction .............................................................................................................42

3.9.2 Forced air cooling ....................................................................................................... 42

3.9.3 Water-cooling ...........................................................................................................43

4 Operation ........................................................................................ 45

4.1 Configuring the nEXT pump using serial commands ...............................................................45

4.1.1 Power limit setting .....................................................................................................45

4.1.2 Powering a fan from the Controller .................................................................................. 46

4.1.3 Controlled venting options ............................................................................................46

4.1.4 Standby speed setting .................................................................................................. 47

4.1.5 Normal speed setting ...................................................................................................47

4.1.6 Timer setting and options .............................................................................................48

4.1.7 Analogue signal options ................................................................................................ 49

4.1.8 Factory settings .........................................................................................................49

4.1.9 Assigning a multi-drop address .......................................................................................49

4.2 Configuring the nEXT pump using a TIC .............................................................................50

4.3 Start-up ..................................................................................................................51

4.3.1 Close the vent valve .................................................................................................... 51

4.3.2 Pre-start checks ......................................................................................................... 51

4.4 Operation with parallel control and monitoring ...................................................................52

4.4.1 Start the pump ..........................................................................................................52

4.4.2 Running at standby speed .............................................................................................52

4.4.3 Stop the pump ........................................................................................................... 52

4.4.4 Parallel monitoring .....................................................................................................52

4.5 Operation with serial control and monitoring ...................................................................... 52

4.5.1 Delayed start ............................................................................................................ 52

4.5.2 Start the pump ..........................................................................................................53

4.5.3 Standby speed ........................................................................................................... 53

4.5.4 Stop the pump ........................................................................................................... 53

4.5.5 Temperature readings ................................................................................................. 53

4.5.6 Link parameter readings ...............................................................................................54

4.5.7 Measured motor speed ................................................................................................. 54

4.6 Simultaneous parallel and serial operation ......................................................................... 54

4.7 Operation with a TIC ...................................................................................................54

4.8 Decelerating and venting .............................................................................................. 54

4.9 Operation at extreme conditions ..................................................................................... 55

4.9.1 Operation with high inlet pressure ................................................................................... 55

4.9.2 Operation at high temperatures ......................................................................................55

4.9.3 Operation at over-speed ...............................................................................................55

4.9.4 Electrical supply failure ............................................................................................... 55

4.10 Bakeout ...................................................................................................................56

5 Maintenance ..................................................................................... 59

5.1 Introduction .............................................................................................................59

5.2 Bearing and oil cartidge maintenance ............................................................................... 59

5.3 Rotor life ................................................................................................................. 59

Page ii © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 5

B800-00-880 Issue A

5.4 Clean the external surfaces of the pump ...........................................................................60

5.5 Fault finding .............................................................................................................60

5.5.1 Flashing Service Codes ................................................................................................. 63

5.5.2 Flashing error codes .................................................................................................... 63

5.5.3 Decoding system status words ........................................................................................64

5.5.4 Useful service information ............................................................................................66

6 Storage and disposal ........................................................................... 67

6.1 Storage ...................................................................................................................67

6.2 Disposal ...................................................................................................................67

7 Service, spares and accessories .............................................................. 69

7.1 Introduction .............................................................................................................69

7.2 Service ....................................................................................................................69

7.2.1 Returning a pump for service .........................................................................................69

7.2.2 Bearing and oil cartridge on-site maintenance .................................................................... 69

7.3 Spares .....................................................................................................................70

7.3.1 ISX inlet-screen ......................................................................................................... 70

7.3.2 Inlet-strainer ............................................................................................................70

7.3.3 Inlet-flange seals and integrated inlet screens ....................................................................70

7.4 Accessories ...............................................................................................................70

7.4.1 Installation ...............................................................................................................70

7.4.2 ACX air-cooler ...........................................................................................................70

7.4.3 WCX water-cooler ...................................................................................................... 71

7.4.4 BX bakeout band ........................................................................................................71

7.4.5 TAV vent-valve and vent-port adaptor ..............................................................................71

7.4.6 VRX vent-restrictor .....................................................................................................71

7.4.7 Vent-port adaptor ......................................................................................................72

7.4.8 PRX purge-restrictor ....................................................................................................72

Contents

Index .............................................................................................. 75

For return of equipment, complete the HS Forms at the end of this manual.

Illustrations

Figure Page

1 nEXT240 Performance Curve .......................................................................................... 12

2 nEXT300 Performacne Curve .......................................................................................... 12

3 nEXT 240D dimensions (mm) ..........................................................................................14

4 nEXT 300D dimensions (mm) ..........................................................................................15

5 nEXT 400D dimensions (mm) .........................................................................................16

6 Maximum allowed rate of pressure rise during venting: pressure against time (with pump initially at full

rotational speed) 17

7 Controller Connector showing pin numbers ........................................................................ 21

8 Interface circuits for nEXT turbo pump controllers ...............................................................22

9 Typical pumping system with a nEXT pump ........................................................................26

10 Logic interface connections - parallel mode .......................................................................31

11 Controller status information ......................................................................................... 33

16 Schematic diagram of the logic interface connections ...........................................................39

17 Maximum relative humidity to avoid condensation with water cooling ........................................ 43

18 nEXT exploded accessories view ..................................................................................... 73

19 nEXT exploded accessories view ..................................................................................... 74

© Edwards Limited 2009. All rights reserved. Page iii

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 6

B800-00-880 Issue A

Contents

Tables

Table Page

1 Power limits .............................................................................................................. 3

2 General data .............................................................................................................. 7

3 nEXT 240 pumps technical data ....................................................................................... 8

4 nEXT 300 pumps technical data ....................................................................................... 9

5 nEXT 400 pumps technical data ....................................................................................... 9

6 nEXT pumps technical data ...........................................................................................11

7 nEXT400 Performance Curve .......................................................................................... 13

8 Vent gas specification and vent control ............................................................................. 17

9 Purge gas specification ................................................................................................ 18

10 Cooling water specification ...........................................................................................18

11 Logic interface technical data ........................................................................................ 19

12 Logic interface connector pins .......................................................................................20

13 Controller technical data ..............................................................................................21

14 Indicator LEDs ...........................................................................................................23

15 Operating and storage environment .................................................................................23

16 Checklist of components ...............................................................................................25

17 Summary of commands that can be sent to the nEXT pump ..................................................... 37

18 Command abbreviations ...............................................................................................38

19 Error codes ............................................................................................................... 38

20 Vent options .............................................................................................................41

21 Vent-restrictor orifice diameter (with atmospheric pressure at the inlet of the vent-valve) ..............42

22 Power limit setting .....................................................................................................45

23 Analogue signal options ................................................................................................ 49

24 Behaviour of a pump when the power is re-instated after an electrical supply failure .....................57

25 Fault finding .............................................................................................................60

26 Flashing service codes ................................................................................................. 63

27 Flashing error codes .................................................................................................... 63

28 Hexadecimal conversion table ........................................................................................ 64

29 Status flags .............................................................................................................. 65

30 Example decoding of system status words .......................................................................... 65

31 Inlet-flange seals and intergrated inlet screens ...................................................................70

32 Vent restrictors .........................................................................................................71

Trademark credits

Windows™ is trademark of Microsoft Corporation.

Page iv © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 7

B800-00-880 Issue A

This page has been intentionally left blank.

Page v © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 8

B800-00-880 Issue A

CAUTION

WARNING

1Introduction

1.1 Scope and definitions

This manual provides installation, operation, maintenance and storage instructions for the Edwards nEXT

Turbomolecular Pumps. You must use the nEXT pumps as specified in this manual. If you do not, the protection

provided by the nEXT pumps may be impaired.

Read this manual before you install and operate the nEXT pump. Important safety information is highlighted as

WARNING and CAUTION instructions; you must obey these instructions. The use of WARNINGS and CAUTIONS is defined

below.

Warnings are given where failure to observe the instruction could result in injury or death to

people.

Cautions are given where failure to observe the instruction could result in damage to the equipment, associated

equipment and process

Introduction

The units used throughout this manual conform to the SI international system of units of measurement; where

appropriate US equivalent units of measurement are also given. When flow rates are specified, the abbreviation

‘sccm’ is used to mean standard cubic centimetres per minute. This is a flow of 1 cm

of 0 ºC and a pressure of 1013 mbar (1.013 x 10

In accordance with standard EN61010, the following warning label appears on the nEXT pump:

Warning - refer to accompanying documentation.

5

Pa).

3

-1

min

at an ambient temperature

© Edwards Limited 2009. All rights reserved. Page 1

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 9

B800-00-880 Issue A

CAUTION

WARNING

WARNING

Introduction

1.2 General description

Improper use of the equipment could cause damage to it or injury to people. The user is

responsible for the safe operation, installation and monitoring of the system.

The Drive contains electrolytic capacitors and, under certain fault conditions, may emit dangerous

fumes. Ensure that the Drive is operated in a well-ventilated area.

Do not attempt to separate the Controller from the pump since this will cause damage to the electrical

connections.

The nEXT pumps consist of the turbomolecular pump with a permanently attached controller containing drive

electronics.

The controller controls the electrical supply to the pump with the exception of standby speed control. It has no

manual controls and can only be operated through the logic interface. To operate the nEXT pump you must connect

it to your own control equipment and power supply or alternatively use the Edwards TIC Turbo Instrument Controller

or TIC Turbo Controller.

The controller drives the brush-less d.c. motor in the pump.

There are three main variants of the nEXT pump,

The “S” or “Simplex” variant contains only turbomolecular blades.

The “D” or “Duplex” variant contains turbomolecular blades and a Siegbahn drag mechanism allowing

operation at higher backing pressures than pure turbomolecular pumps.

The “T” or “Triplex” variant contains turbomolecular blades, a Siegbahn drag mechanism and a regenerative

mechanism. The regenerative stage offers the option to utilise “boost” mode.

Also available is an “iD” or “iT” interstage variant, which provides an interstage port between the turbomolecular

blades and Siegbahn drag mechanism.

nEXT pumps are supplied with an inlet-screen fitted into the centering O-ring for ISO version pumps and into envelope

for CF version pumps. nEXT pumps with an NW25 interstage port are supplied with an inlet-strainer that fits into the

interstage-port. The inletscreen and inlet-strainer protect the pump against damage that would be caused by debris

entering the pump.

The nEXT pumps have a vent-port for venting the pump and vacuum system to atmospheric pressure. The pump is

supplied with a manual vent-valve fitted; this can be replaced with a TAV5 or TAV6 solenoid-operated vent-valve

(available as accessories – see Section 7). The TAV valve can be directly controlled by the on-board controller.

The nEXT pumps have a purge-port: an inert purge gas can be introduced to protect the bearing and motor from

corrosion. An optional vent-port adapter and purge restrictor can be fitted to the purge-port to control the flow rate

of the purge gas and to filter the gas supply. (Refer to Section 7).

Air-coolers and a water-cooling block are available as optional accessories to cool the nEXTpumps. (Refer to

Section 7).

Page 2 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 10

B800-00-880 Issue A

1.3 Pump controller

The pump controller contains the drive electronics that control the pump operation and the TAV vent valve. There

is a connector socket on the side of the controller where the TAV vent valve can be plugged-in. (Refer to Section 2.9)

The controller has three indicator LEDs that signal the general status, operation and service status of the pump, that

can also be used for fault finding if a problem should occur. (Refer to Section 2.10)

The drive electronics system has a number of built-in safety features to protect the nEXT pumps from damage in the

event of sustained high pressure or temperature:

The electronics constantly monitors the temperature inside the controller and the temperature of the motor

within the pump. If either part becomes too hot, the controller reduces the power supplied to the pump

motor and the pump speed will drop. If the pump rotational speed falls below 50% full speed, the electronics

may trip into a Fail condition, depending on how you have configured the system. (Refer to Section 1.4.3).

If the nEXT pump's inlet pressure increases, the power supplied to the pump-motor increases to counteract

the gas frictional load. However, when the built-in maximum power limit is reached, the speed of the pump

will start to drop. If the pump rotational speed falls below 50% full speed, the electronics may trip into Fail

condition, depending on how the system has been configured. (Refer to Section 1.4.3).

In the event of an electrical supply failure, the drive electronics uses the motor within the pump as a

generator. This means the nEXT pumps have their own regenerative supply and do not require a separate

battery for emergency power back-up. The regenerated energy is used to maintain the electrical supply to

the vent valve until the pump speed falls to below 50% of full rotational speed: this will ensure that the vent

valve remains shut until below 50% of full rotational speed and will prevent the pump from venting at full

speed.

Introduction

1.4 Operational features

In addition to the basic start and stop commands, the nEXT pumps have several other features which allow you to

tailor the pump operation to your particular application. Refer to Table 14 for factory default settings of the

parameters discussed in the following Sections.

1.4.1 Power limit setting

You can select the maximum power that will be drawn by the pump (refer to Section 4.1.1). The more power you

supply, the quicker the pump will accelerate to reach full speed. Therefore if your application requires fast cycling,

you should set the power limit to the maximum value. If ramp time is not important in your application, you can use

a lower power limit, down to a minimum value, refer to Table 1.

Tab l e 1 - Pow er li mi ts

Pump Standard default setting

nEXT240, nEXT300 & nEXT400 160 W 200 W 50 W

You must make sure that the power supply you use is capable of delivering sufficient power to the nEXT pump. By

choosing a lower power limit setting, you could use a smaller power supply. For more information, refer to

Section 2.7.

1.4.2 Standby speed

Maximum value

setting

Minimum value setting

In Standby mode the pump rotational speed is lower than the full rotational speed. The default setting for standby

speed is 70% of full speed. Note that in order for standby speed to be selected, the pump must also be in the start

condition.

© Edwards Limited 2009. All rights reserved. Page 3

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 11

B800-00-880 Issue A

Introduction

If your application does not require the pump to be running at maximum speed at all times, you can use the Standby

speed feature rather than switching the pump off. This feature can be used for vacuum system tuning or as a system

power saving option.

The Standby speed is a user-selectable value (refer to Section 4.1.4).

1.4.3 Timer

When the pump is started, an internal timer is automatically started within the drive electronics. The default timer

setting is 8 minutes. If the pump fails to reach 50% of full rotational speed within the timeout period, the controller

will signal a Fail and will decelerate the pump to rest. This feature prevents the controller from driving the pump at

maximum power for a long time. The pump may fail to reach 50% speed if the gas load is too high (for example if

there is a leak in the system), if the backing pump fails, or if the pump is too hot.

The timeout period is a user-selectable feature (refer to Section 4.1.6), so if your application requires the pump to

ramp up slowly, you can extend the timeout period. The Timer is permanently enabled for ramp-up.

The Timer has an additional function: if the pump rotational speed drops below 50% full speed for any reason, you

may wish to allow the pump time to recover rather than trigger a Fail condition. The Timer starts as soon as the speed

drops to below 50% full speed. If, during the timeout period, the pump recovers to above 50% full speed then the

Timer will be reset. If the pump rotational speed fails to recover by the end of the timeout period, the controller

will trigger a Fail condition and will decelerate the pump to rest. When you receive the pump, the Timer function

will be enabled, however you can disable it if you wish to. With the Timer disabled, the pump will Fail and decelerate

to rest as soon as pump rotational speed falls below 50%.

1.4.4 Analogue output

The pump controller produces an analogue output that allows you to monitor four different system parameters:

Measured pump rotational speed (default condition)

Measured motor power

Measured motor temperature

Measured controller temperature

The analogue output signal ranges from 0 to 10 V and is directly proportional to the system parameter (refer to

Section 2.8).

Connect the analogue output to a suitable meter or indicator to display the appropriate system parameter or connect

to your control equipment (for example, to operate other components in the pumping system at preset values).

You can only monitor one system parameter at a time using the analogue output. However, it is easy to configure the

controller to monitor a different system parameter (refer to Section 4.1.7).

1.4.5 Automatic vent options

An Edwards TAV vent valve can be connected directly to the nEXT pump’s controller. The controller is capable of

providing a number of different venting options.

The drive electronics can control the rate of venting. Using this feature the pump can be vented from full rotational

speed in a controlled manner that will not damage the pump bearings. Once the pump rotational speed has dropped

to below 50% of maximum speed, it is safe to hard vent (open the vent valve fully.)

There are many venting options available to you, such as:

Hard vent when rotational speed drops below 50%

Controlled vent when above 50% speed and hard vent below 50% speed

Hard vent immediately through a suitable restrictor

Page 4 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 12

B800-00-880 Issue A

A full list of the venting options is given in Section 3.8

In addition there is a feature that allows a delayed start of the nEXT pump. With this feature you can close the vent

valve before you start the nEXT pump. This allows the backing pump to reduce the pressure in the vacuum system

before starting the nEXT pump.

If you do not wish to use the controller to control a TAV vent valve, you could use it to run a fan instead. You can

configure the controller so that the fan is permanently enabled.

1.4.6 Normal speed setting

The Normal Speed is a user-selectable parameter that can be set anywhere from 50% to 100% of full rotational speed.

When the pump reaches Normal Speed, a signal is available on the Normal pin of the logic interface connector. You

can use this signal to control your application since it shows that pump speed, and therefore vacuum performance,

has reached a specific minimum level. The default setting is 80% of full rotational speed. Refer to Section 4.1.5 for

instructions on altering the Normal Speed setting.

1.5 Logic interface

The pump controller can only be operated through the logic interface. The signals on the logic interface are of three

types:

Introduction

Control inputs: these are switch-type signals that are used to control the pump

Status outputs: these outputs identify the status of the system

Analogue output: this provides a 0 – 10 V output for a number of pump parameters.

The logic interface has been designed to support both serial and parallel control and monitoring, operating through

one connector. For serial control either RS232(default) or RS485 can be selected using a slide switch located on the

controller (see Section 3.7).

The logic interface can be plugged directly into the Edwards TIC Turbo Controller or TIC Turbo Instrument Controller

and then use the functionality that they provide. Alternatively, the logic interface can be connected to a customers

own control system. The most useful arrangements are described in the sections below.

For more information about the logic interface, refer to Section 2.8.

1.5.1 Parallel control and monitoring

The simple parallel interface is a quick and easy way to control the pump; this is the same interface used on existing

24V Edwards Turbo Pumps. The controls that are available to use are Start and Standby. You can monitor the system

status using the Normal, Fail and Analogue output signals.

Note: The Serial Enable switch MUST be open (no connection) and the slide switch must be in the RS232 position

(see Section 3.7).

Refer to Section 3.6 for more detailed instructions of how to use the parallel interface.

A system operating with only a parallel connection has no facility to adjust the configuration settings stored in the

controller(for example, power limit setting or controlled venting options). This would place a restriction in that all

these features would be at their factory default settings. It is possible to manually adjust the standby speed if standby

mode is selected. However, the Controller could be configured separately before fitting the nEXT pump to the

system. This is covered in more detail in Section 1.5.5.

1.5.2 Serial control and monitoring

The serial communications link provides complete control and monitoring by using just three signal lines. The Serial

data lines share the same connector pins as the parallel signals Standby and Fail. The serial data lines can be

© Edwards Limited 2009. All rights reserved. Page 5

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 13

B800-00-880 Issue A

Introduction

configured to provide an RS485 compliant or RS232 compatible interface by setting the position of the slide switch

(see Section 3.7)

Th e S erial En a ble signa l M UST be li n k ed to 0 V f o r t he syst e m to accep t c ommands f r o m the ser i a l link. T h i s is a safe t y

feature and acts as an interlock. For pure serial control the parallel start signal will be left unconnected.

The controller will still provide the Normal and Analogue signals on the logic interface connector even when operating

under serial control. The status of the Normal signal and the value of the system parameter on the analogue output

can also be obtained by interrogating the system status via the Serial link.

For more information about the Serial interface, refer to Section 3.7.

1.5.3 Serial control with parallel monitoring

Since Normal and Analogue signals remain available even using Serial control, it is possible to control the pump via

the Serial link whilst monitoring these signals in the parallel interface.

The serial link uses the same connector pins as the parallel signals Standby and Fail respectively so these parallel

control and monitoring signals are not available. The Serial Enable signal MUST be linked to 0 V and the parallel start

signal will be left unconnected.

1.5.4 Parallel control with serial monitoring or serial configuration

This method of control is best for users who normally wish to operate the pump in parallel mode but occasionally

want to adjust the configuration settings stored in the Controller or to monitor operational status of the pump via

the serial link.

Whilst operating under parallel control with the serial link active, the start control signal is available (as described

in Section 1.5.1.) but the standby control line is not since it is used as a serial data line.

The Serial Enable signal must be linked to 0 V for serial communications to take place. We suggest that you make a

special cable for serial communications that includes a link between Serial Enable and 0 V. This way, Serial Enable

is automatically activated when the cable is connected and then deactivated when the cable is removed.

1.5.5 Controller configuration (serial set-up)

All the configuration settings stored within the Controller are retained even when power to the nEXT pump is

removed. This means that it is possible to use a separate system to configure the Controller before fitting the nEXT

pump to your application. This gives the benefit of tailoring the pump functionality to a customer application and

allows the pump to be operated using a simple parallel interface system.

To configure the nEXT pump, either use your own simple serial system or use the Edwards TIC Turbo Controller or

Turbo Instrument Controller. The TICs have a feature which allows storage of a nEXT pump’s configuration. The

configuration can then be downloaded to another nEXT pump. This is useful when configuring a number of nEXT

pumps with the same settings before they are fitted to a system.

Note: The RS485/RS232 slide switch must be in the (default) RS232 position if the TIC is to be used to configure

the nEXT pump. Refer to Section 3.7.1.

TM

The TIC is supplied with a Windows

PC. The program has a simple user interface which means that it is not necessary to use the ASCII message protocol

described in Section 3.7. The TIC PC Program has a facility to save multiple nEXT pump configurations which can then

be downloaded into other nEXT pumps.

based PC program which allows the nEXT pump to be configured from a single

Page 6 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 14

2Technical data

WARNING

WARNING

WARNING

WARNING

2.1 General

Tab l e 2 - G ene r al da ta

General items Reference data

Performance Refer to Table 3, 4 and Figure 1

Dimensions Refer to Figure 3, 4 and 5

Maximum inlet-flange temperature

nEXT240 75°C

nEXT300 80°C

nEXT400 70°C

Maximum permitted external magnetic field 5mT Radial*

B800-00-880 Issue A

Technical data

Pollution degree EN61010 Polution degree 2

Equipment type Fixed equipment, for indoor use only

Enclosure protection (installed) IP40

*Reduce gas load when operating in magnetic field

2.2 Pumping media

Vent dangerous gases and gas mixtures safely, do not expose people to these gases. If pumping

hazardous gases or vapours, observe the safety recommendations of the supplier of the gas/

vapour.

Do not use the nEXT pump to pump pyrophoric or explosive gas mixtures, as it is not suitable for

this purpose. The pump and its connections are not designed to contain an explosion.

In the interstage and booster versions of the nEXT pumps, gas pumped through the interstage port

will mix with gas pumped through the pump inlet. Ensure that the gases will not react or combine

to form dangerous gases and substances.

Do not exceed the maximum continuous operating pressure. Doing so can result in dangerous rotor

temperatures and will shorten the life of the pump.

© Edwards Limited 2009. All rights reserved. Page 7

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 15

B800-00-880 Issue A

CAUTION

WARNING

Technical data

Do not expose any part of the human body to vacuum.

Do not use a nEXT pump to pump mercury vapour and do not allow mercury (for example, from a McLeod gauge)

to come into contact with the pump. If you do, the pump rotor may corrode and fail.

Note: Concentrations of gases may be modified by the compression of the pump.

The pumps are designed to pump the following residual gases normally used in high-vacuum systems:

Air Carbon dioxide

Methane Neon

Propane Krypton

Butane Helium

Carbon monoxide Ethane

Nitrogen Argon

Hydrogen

You can use the pump to pump oxygen and water vapour, subject to the following conditions:

Oxygen – when the pump is purged by an inert gas, oxygen can be pumped at concentrations above 20% by

volume. Refer to Section 2.4 for Purge gas specification. However, if the pump is not purged, the oxygen

concentration must be less than 20% by volume.

Water vapour - you must ensure that vapour does not condense inside the pump; refer to Section 3.9.3.

If you wish to pump a gas not in the list above, contact your supplier for advice. If you do not contact your supplier,

you may invalidate the warranty on the pump. The pump is not suitable for pumping aggressive or corrosive gases.

Table 3 - nEXT 240 pumps technical data

Parameter

nEXT240D

ISO100

nEXT240D

CF100

nEXT240T

ISO100

nEXT240T

CF100

Mass 5.7kg 8.8kg 6kg 9.1kg

Inlet Flange DN100ISO-K DN100CF DN100ISO-K DN100CF

Outlet Flange DN25NW DN25NW DN25NW DN25NW

Vent Port 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP

Purge Port 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP

Interstage Port DN25NW DN25NW DN25NW DN25NW

Booster Port DN25NW DN25NW DN25NW DN25NW

Inlet Pumping Speed

Inlet Compression Ratio

N

He

H

N

He

H

2

240 l/s

230 l/s

2

2

2

165 l/s

>1 x 10

3 x 10

1 x 10

11

5

4

240 l/s

230 l/s

165 l/s

>1 x 10

3 x 10

1 x 10

240 l/s

230 l/s

165 l/s

11

5

4

>1 x 10

1 x 10

1.5 x 10

11

6

4

240 l/s

230 l/s

165 l/s

>1 x 10

1 x 10

1.5 x 10

11

6

4

Page 8 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 16

B800-00-880 Issue A

Interstage Pumping Speed

N

He

H

2

2

13 l/s

13 l/s

11 l/s

Peak Booster Pumping Speed (Nitrogen)

RV12 b acking pu mp

-

XDS10 backing pump

Ultimate Pressure

*

Ultimate pressure 48 hours after bakeout for CF version and without bakeout for ISO version with 2-stage rotary

*

<6 x 10-8mbar <5 x 10

13 l/s

13 l/s

11 l/s

-

-10

mbar <6 x 10-8mbar <5 x 10

13 l/s

13 l/s

11 l/s

26m3h

24m3h

-1

-1

13 l/s

13 l/s

11 l/s

26m3h

24m3h

-10

-1

-1

mbar

vane backing pump.

Pumping speeds quoted are without an inlet screen

Table 4 - nEXT 300 pumps technical data

Technical data

Parameter

nEXT300D

ISO100

nEXT300D

CF100

nEXT300T

ISO100

nEXT300T

CF100

Mass 5.7kg 8.5kg 6kg 8.8kg

Inlet Flange DN100ISO-K DN100CF DN100ISO-K DN100CF

Outlet Flange DN25NW DN25NW DN25NW DN25NW

Vent Port 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP

Purge Port 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP

Interstage Port DN25NW DN25NW DN25NW DN25NW

Booster Port DN25NW DN25NW DN25NW DN25NW

Inlet Pumping Speed

Inlet Compression Ratio

N

He

H

N

He

H

2

300 l/s

340 l/s

2

2

2

280 l/s

>1 x 10

1 x 10

5 x 10

11

6

4

300 l/s

340 l/s

280 l/s

>1 x 10

1 x 10

5 x 10

300 l/s

340 l/s

280 l/s

11

6

4

>1 x 10

3 x 10

1 x 10

11

6

5

300 l/s

340 l/s

280 l/s

>1 x 10

3 x 10

1 x 10

11

6

5

Interstage Pumping Speed

N

He

H

2

13 l/s

13 l/s

2

11 l/s

13 l/s

13 l/s

11 l/s

13 l/s

13 l/s

11 l/s

13 l/s

13 l/s

11 l/s

Peak Booster

Pumping Speed (Nitrogen)

RV12 b acking pu mp

XDS10 backing pump

--26m

3h-1

24m3h

-1

-1

26m3h

24m3h

-1

Ultimate Pressure

*

Ultimate pressure 48 hours after bakeout for CF version and without bakeout for ISO version with 2-stage rotary

*

<6 x 10-8mbar <5 x 10

-10

mbar <6 x 10-8mbar <5 x 10

-10

mbar

vane backing pump.

Pumping speeds quoted are without an inlet screen

Table 5 - nEXT 400 pumps technical data

Parameter

nEXT400D

ISO160

nEXT400D

CF160

nEXT400T

ISO160

nEXT400T

CF160

Mass 6.5kg 9.5kg 6.8kg 9.8kg

Inlet Flange DN160ISO-K DN160CF DN160ISO-K DN160CF

© Edwards Limited 2009. All rights reserved. Page 9

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 17

B800-00-880 Issue A

Technical data

Outlet Flange DN25NW DN25NW DN25NW DN25NW

Vent Port 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP

Purge Port 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP 1 / 8 inch BSPP

Interstage Port DN25NW DN25NW DN25NW DN25NW

Booster Port DN25NW DN25NW DN25NW DN25NW

Inlet Pumping Speed

Inlet Compression Ratio

Interstage Pumping Speed

Peak Booster

Pumping Speed (Nitrogen)

RV12 b acking pu mp

XDS10 backing pump

N

He

H

N

He

H

N

He

H

2

400 l/s

390 l/s

2

2

2

2

325 l/s

>1 x 10

1 x 10

5 x 10

13 l/s

11

8

5

13 l/s

2

11 l/s

--26m

400 l/s

390 l/s

325 l/s

>1 x 10

1 x 10

5 x 10

13 l/s

13 l/s

11 l/s

400 l/s

390 l/s

325 l/s

11

8

5

>1 x 10

>1 x 10

1 x 10

11

8

6

13 l/s

13 l/s

11 l/s

3h-1

-1

24m3h

400 l/s

390 l/s

325 l/s

>1 x 10

>1 x 10

1 x 10

13 l/s

13 l/s

11 l/s

26m3h

24m3h

11

8

6

-1

-1

Ultimate Pressure

*

Ultimate pressure 48 hours after bakeout for CF version and without bakeout for ISO version with 2-stage

*

<1 x 10-8mbar <1 x 10

-10

mbar <1 x 10-8mbar <2 x 10

rotary vane backing pump.

Note: Pumping speeds quoted are without an inlet screen

-10

mbar

Page 10 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 18

© Edwards Limited 2009. All rights reserved. Page 11

Edwards and the Edwards logo are trademarks of Edwards Limited.

Table 6 - nEXT pumps technical data

Parameter nEXT240D nEXT240T nEXT300D nEXT300T nEXT400D nEXT400T

Critical Backing Pressure N

2

9.5 mbar 20 mbar 9.5 mbar 20 mbar 10 mbar 20 mbar

Critical Backing Pressure He 7 mbar 8.5 mbar 7.5 mbar 8.5 mbar 8.5 mbar 8.5 mbar

Critical Backing Pressure H

2

Maximum Continuous Inlet Flow (at ultimate backing pressure)

*

2.5 mbar 3 mbar 2.9 mbar 3 mbar 3 mbar 3 mbar

Nitrogen:

Water Cooling (40oC Ambient)

Force Air Cooling (35

Natural Convection (30

o

C Ambient) 30 sccm 50 sccm 115 sccm 100 sccm 90 sccm 105 sccm

o

C Ambient) 10 sccm 10 sccm 35 sccm 25 sccm 45 sccm 25 sccm

†

45 sccm 55 sccm 95 sccm 65 sccm 105 sccm 50 sccm

Argon:

Water Cooling (40

Force Air Cooling (35

o

C Ambient) 35 sccm 35 sccm 63 sccm 42 sccm 70 sccm 49 sccm

o

C Ambient) 20 sccm 28 sccm 76 sccm 70 sccm 70 sccm 77 sccm

Natural Convection (30oC Ambient) 7 sccm 7 sccm 20 sccm 20 sccm 28 sccm 20 sccm

Maximum Continuous Backing Pressure (at ultimate inlet pressure)

*

Nitrogen:

Water Cooling (40oC Ambient)

Force Air Cooling (35

o

C Ambient) 4.75 mbar 2.75 mbar 7 mbar 8 mbar 7.5 mbar 9 mbar

Natural Convection (30

†

o

C Ambient) 1 mbar 0.4 mbar 2.75 mbar 1 mbar 4 mbar 1.25 mbar

6 mbar 2.75 mbar 6.75mbar 4.75 mbar 7.5 mbar 4 mbar

Argon:

Water Cooling (40

Force Air Cooling (35

o

C Ambient) 4.75 mbar 2.75 mbar 6 mbar 3.75 mbar 6.5 mbar 4 mbar

o

C Ambient) 3 mbar 1.5 mbar 6.5 mbar 7 mbar 6.5 mbar 8 mbar

Natural Convection (30oC Ambient) 0.5 mbar 0.2 mbar 2 mbar 0.75 mbar 3 mbar 1.2 mbar

Recommended Backing Pump RV12 / XDS10

Operation attitude Vertical and upright to horizontal ±2

o

Normal Rotational Speed 60,000 revolutions per minute

Starting Time to 90% Speed

‡

125 sec 150 sec 160 sec 190 sec 180 sec 210 sec

Sound Pressure Level (1 metre away) < 45 dB(A) ± 3dB(A) Declared dual number noise emission values in accordance with ISO4871

*

Values for maximum continuous inlet pressure obtained using a RV12 backing pump at sea level in negligible magnetic field. Values for maximum

continuous backing pressure obtained under no flow conditions at sea level in negligible magnetic field. Refer to Section 3.9 for cooling conditions.

Above these pressures, rotational speed drops below nominal.

†

Cooling water temperature 15oC at a flow rate of 30l hr-1.

‡

Power limit setting 160W.

B800-00-880 Issue A

Technical data

Page 19

B800-00-880 Issue A

Technical data

Figure 1 - nEXT240 Performance Curve

Figure 2 - nEXT300 Performacne Curve

Page 12 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 20

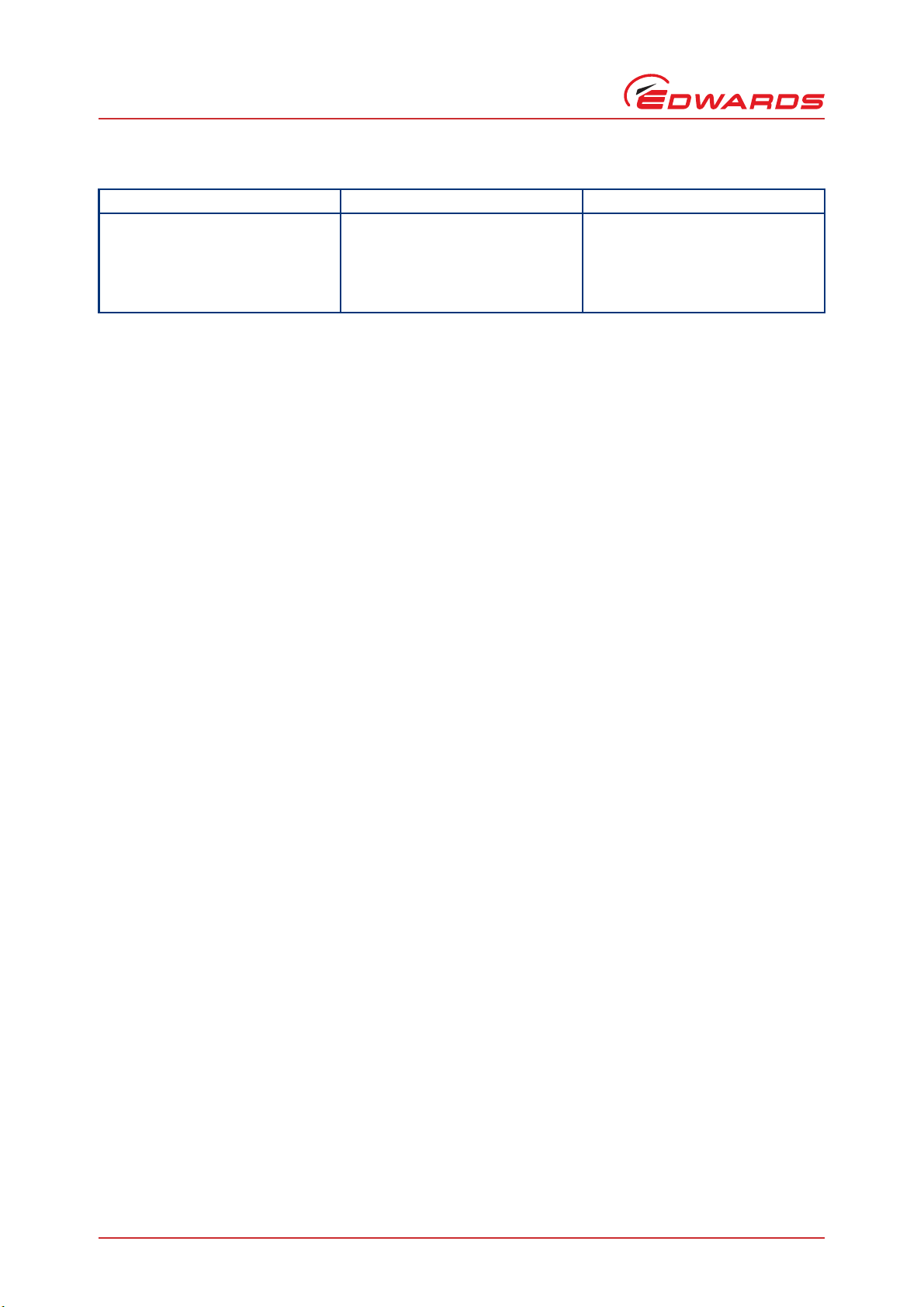

Table 7 - nEXT400 Performance Curve

B800-00-880 Issue A

Technical data

© Edwards Limited 2009. All rights reserved. Page 13

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 21

B800-00-880 Issue A

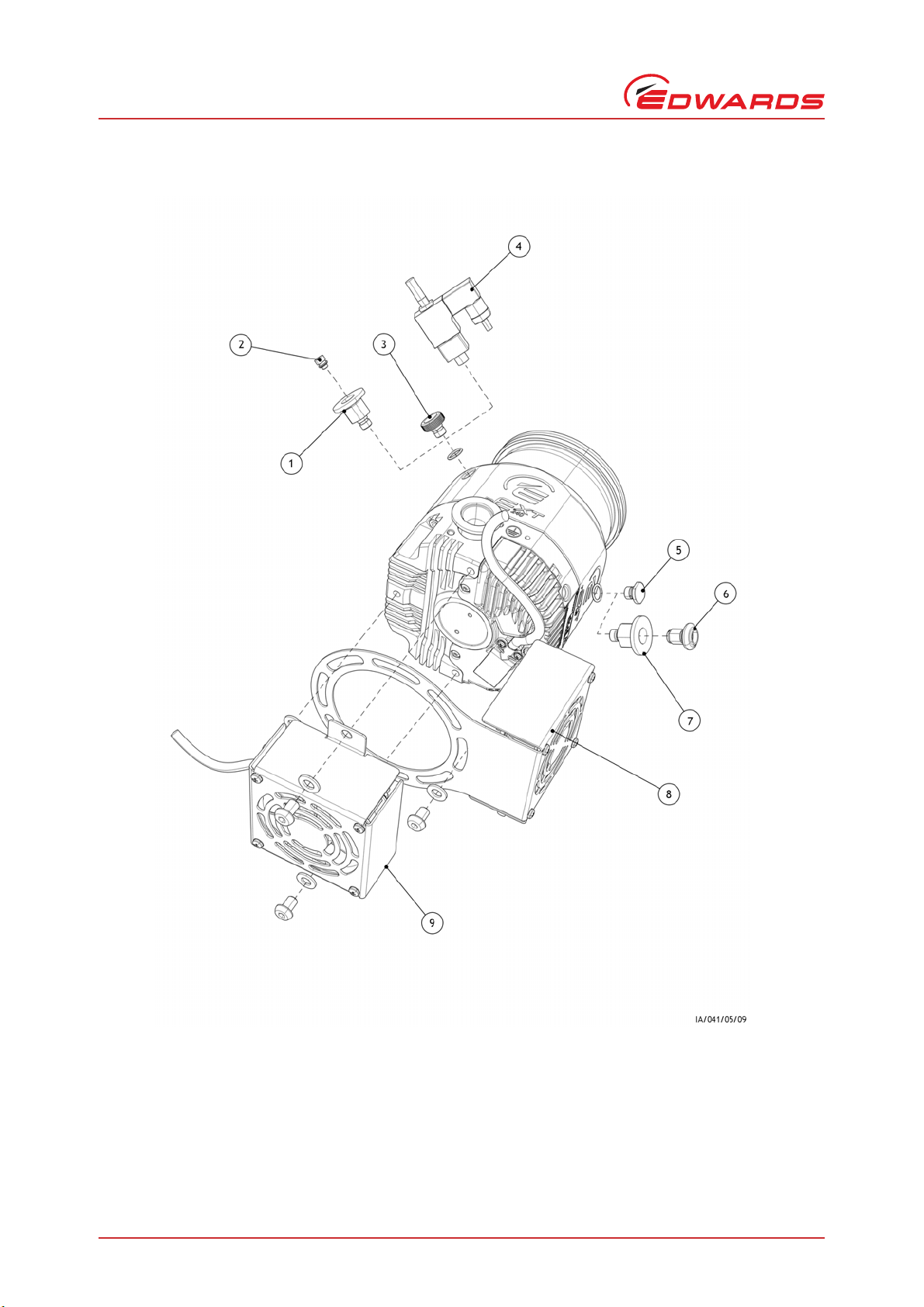

1. Earth point

2. Envelope vent

3. Removable cap RS232/RS485 switch vent valve

socket

4. LED indicators on drive unit

5. Base mounting holes and fan mountings

6. Booster port B

7. Interstage port

8. Booster port A

9. 24/48V Supply

10. Body purge port

11. Electrical drive unit

12. Envelope vent port 1/8” BSP

Technical data

Figure 3 - nEXT 240D dimensions (mm)

Page 14 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 22

Figure 4 - nEXT 300D dimensions (mm)

1. Earth point

2. Envelope vent

3. Removable cap RS232/RS485 switch vent valve

socket

4. LED indicators on drive unit

5. Base mounting holes and fan mountings

6. Booster port B

7. Interstage port

8. Booster port A

9. 24/48V Supply

10. Body purge port

11. Electrical drive unit

12. Envelope vent port 1/8” BSP

B800-00-880 Issue A

Technical data

© Edwards Limited 2009. All rights reserved. Page 15

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 23

B800-00-880 Issue A

1. Earth point

2. Envelope vent

3. Removable cap RS232/RS485 switch vent valve

socket

4. LED indicators on drive unit

5. Base mounting holes and fan mountings

6. Booster port B

7. Interstage port

8. Booster port A

9. 24/48V Supply

10. Body purge port

11. Electrical drive unit

12. Envelope vent port 1/8” BSP

Technical data

Figure 5 - nEXT 400D dimensions (mm)

Page 16 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 24

B800-00-880 Issue A

2.3 Vent gas specification and vent control data

Although the pump may be vented to atmosphere, high relative humidity of the air may greatly increase the

subsequent pump-down time. To reduce pump-down times you should vent with dry, clean gases. Refer to Section 3.8

for a description of the vent options and the vent valve connection refer to Section 4.1.3 for configuring the venting

options.

Table 8 - Vent gas specification and vent control

Vent gas specification and control Reference data

Vent gas Dry air, nitrogen, argon or other inert gases

Maximum dew point at atmospheric pressure -22 °C

Maximum size of particulates 1

Maximum concentration of oil 0.1 parts per million

Recommended time for rotational speed to reach 50% > 15 seconds

Maximum allowed rate of pressure rise Refer to Figure 5

Figure 6 - Maximum allowed rate of pressure rise during venting: pressure against time (with pump initially at

full rotational speed)

µm

Technical data

© Edwards Limited 2009. All rights reserved. Page 17

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 25

B800-00-880 Issue A

Technical data

2.4 Purge gas specification

Table 9 - Purge gas specification

Purge gas specification Reference data

Purge gas Dry air, nitrogen, argon or other inert gases

Maximum dew point at atmospheric pressure -22 °C

Maximum size of particulates 1

Maximum concentration of oil 0.1 parts per million

Allowable purge gas flow (when required) 20 to 50 sccm (0.33 to 0.84 mbar l s

Recommended purge gas flow 25 sccm (0.42 mbar l s-1, 42 Pa l s-1)

Maximum allowable purge gas supply pressure 1 bar (gauge); 14.5 psig, 2 x 105 Pa

Table 10 - Cooling water specification

Cooling water specification Reference data

Quality Mechanically clean and optically clear with no deposits

pH value 6.0 to 8.0

Maximum calcium carbonate concentration 75 parts per million

Maximum chloride concentration 100 parts per million

Minimum oxygen concentration 4 parts per million

Minimum cooling water flow rate (at 15 °C) 15 l hr

Water temperature 10 to 20°C

Maximum water pressure 5 bar (gauge), 73.5 psig, 6 x 10

Materials exposed to cooling-water Nickel plated brass

µm

or turbidity

-1

-1

or 33 to 84 Pa l s-1)

5

Pa

2.5 Cooling water

Refer to Table 7 for the cooling water specification corresponds to a typical high-quality drinking water specification.

Check with your water supply authority if you are in doubt about the quality of your supply.

2.6 Materials exposed to gases pumped

The following materials and component types are exposed to the gases pumped:

Aluminium alloys, stainless steels, fluoroelastomer and nitrile O-rings, hydrocarbon lubricant, rare earth

magnets, silicon nitride, carbon-fibre reinforced epoxy resin, fire retardant polypropylene, polyamide, PVC,

Titanium, Silicon, Torlon and Ceramic.

Page 18 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 26

B800-00-880 Issue A

2.7 Electrical data

nEXT p ump s can be d riven ei ther by your own system or by the Edwards TIC Turbo Instrument Controller or TIC Turbo

Controller.

If you wish to use your own system, the size of the power supply required depends on your application. The power

limit setting determines how quickly you can ramp up the pump and dictates the size of power supply you will need.

If you have serial communications capability, or have access to an Edwards TIC, you can select the power limit setting

of the nEXT pump. Refer to Table 11 for the maximum power limit settings for nEXT pumps. If your application

requires rapid cycling of the pump, you can achieve faster ramp times if you use a power supply that delivers higher

current, up to a maximum in accordance with Table 11

If you do not have the facility to adjust the power limit setting, you must use a power supply capable of delivering

enough current to meet the Edwards factory default power limit setting, shown in Table 11.

If you intend to drive the nEXT pump using an Edwards TIC, be aware that there are several variants. Contact Edwards

to determine which is most suitable for your application.

2.8 Logic interface connector

nEXT pumps have a 15-way logic interface connector on the end of the logic interface cable. The logic interface

connector can be plugged directly into the Edwards TIC Turbo Instrument Controller or TIC Turbo Controller. You

must use a suitable connector mating half (not supplied) to connect the nEXT pump to your own equipment. Refer

to Table 11 for the connector mating half type, to Table 12 for Logic Interface connector pins for the electrical

connections and to Figure 7 for the connector interface circuit diagrams.

Technical data

Table 11 - Logic interface technical data

Logic interface item

Connector

nEXT pumps electrical supply:

Start, standby and serial enable control inputs:

Analogue output:

*

Allowable voltage range

(including any ripple)

Maximum voltage ripple 0.5 V r.m.s.

Fuse rating 10A for 24Vdc supply

Factory default setting 160 W

Maximum power limit setting 200 W

Minimum power limit setting

Accuracy of power regulation

Enabled control voltage: low (close) 0 to 0.8 V d.c. (I

Disabled control voltage: high (open) 4 to 26.4 V d.c. (Internal pull up to 6.35 V nominal)

Output voltage 0 to 10 V d.c. (directly proportional to measured

Output current 5 mA

15-way D-type male

24 - 48 V d.c. +5%, -10%

(21.6 to 50.4 V d.c.)

5A to 10A for 28Vdc supply

Type 'T' IEC approved or

Time delay fuse UL/CSA approved

50W

+/- 10W

= 0.55 mA nominal)

out

parameter)

Motor speed: 0 - 1000 Hz (0-100%)

Input power: 0 - 200 W

Motor temperature: 0 - 100 °C

Controller temperature: 0 - 100 °C

© Edwards Limited 2009. All rights reserved. Page 19

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 27

B800-00-880 Issue A

Technical data

Table 11 - Logic interface technical data (continued)

Logic interface item

NORMAL status output:

Typ e Re fer to Figure 8

< Normal speed (default 80%) Off (2.2 k internal pull up to 12 V d.c.)

Normal speed On (<0.8 V d.c. sinking 20 mA)

Current Rating

Voltage Rating

FAI L sta tu s o ut pu t:

Type Open collector transistor

Fail Off (3.3 k pull up to 12 V d.c.)

OK On (<0.1 V d.c. sinking 1.7 mA,

Current Rating

Voltage Rating

*

Mating half of connector not supplied.

20mA to 0V

28.8Vdc maximum external pull up voltage

<0.8 V d.c. sinking 20 mA)

20mA to 0V

28.8Vdc maximum external pull up voltage

Table 12 - Logic interface connector pins

Pin Number Signal Polarity Use

2 0 V Control reference - 0 V reference for all control and status signals below

3 START/STOP control input - Connect to Pin 2 to start pump

4STANDBY control input /

Serial RX/RS485A-

5 Serial enable - Connect to Pin 2 to enable serial interface mode

7 FAIL / Serial TX/RS485 B+ - Logic high when fail condition exists in parallel mode

9 Analogue output Positive 0 - 10 V output proportional to measured output

10 Chassis / Screen - Screen

12 Chassis / Screen - -

15 NORMAL status output - Logic low when pump rotational speed is at normal speed or

8, 13, 14 Electrical supply: 0 V -

1, 6, 11 Electrical supply: 24 V Positive

- Connect to Pin 2 to enable standby speed

above

2.9 Controller connector socket

The nEXT pump has a 3-way Controller Connector Socket in the side of the Controller. When you receive the pump,

this connector will be concealed by a black protective cover. If you intend to use the connector, this cover should

be removed by levering with a small screwdriver. The mating plug for this connector is supplied with the pump.

The connector is intended to drive a vent valve or fan connected to the three pins. The connector mating plug is

shown in Figure 7, with the polarity of the pins marked when the vent valve/fan is energised.

Page 20 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 28

B800-00-880 Issue A

Table 13 - Controller technical data

Description Data

Connector plug Phoenix part number FK-MC1881338

Voltage output 24 V d.c. -25%, +10% (18Vdc to 26.4Vdc)

Current output 120 mA

Figure 7 - Controller Connector showing pin numbers

Technical data

Pin Number Signal Polarity

124Vdc Out+

2 Chassis

324Vdc Rtn-

© Edwards Limited 2009. All rights reserved. Page 21

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 29

B800-00-880 Issue A

Technical data

Figure 8 - Interface circuits for nEXT turbo pump controllers

Page 22 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 30

B800-00-880 Issue A

2.10 Indicator LEDs

The nEXT pump has three indicator LEDs, shown in Figure 10.

Table 14 - Indicator LEDs

LED Description

Status LED This yellow LED flashes with a 50% duty cycle at the

rotational frequency of the pump motor. At high speeds

it appears continuously on.

The LED switches off when the rotational speed is very

low or stopped.

If a service is due, this LED flashes in a sequence to

indicate which service operation is required. Refer to

Section 5.5.

Normal LED This green LED remains on all the time that the pump

rotational speed is above the Normal speed setting,

irrespective of whether the pump is accelerating or

decelerating.

Alarm LED This red LED flashes in a sequence to indicate an error

code if a fail condition is preventing pump operation.

The error codes can be used for fault finding as

described in section 5.5.

Technical data

Note: If an external electrical load is connected to the Normal output line, the Normal LED may illuminate.

2.11 Operating and storage environment

Table 15 - Operating and storage environment

Range Data

Ambient operating temperature range 5 °C to 40 °C

Ambient operating humidity range 10 to 90% RH (non-condensing)

Maximum operating altitude 2000 m

Ambient storage temperature range -30 °C to 70 °C

© Edwards Limited 2009. All rights reserved. Page 23

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 31

B800-00-880 Issue A

This page has been intentionally left blank.

Page 24 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 32

3 Installation

WARNING

WARNING

WARNING

The controller cable should not be used as a lifting device. Do not attempt to lift or support the

pump using the cable.

3.1 Unpack and inspect

Take care and use safe lifting practices when manually handling the pump.

The inlet screen is a coarse filter for debris and should not be used as a finger guard

B800-00-880 Issue A

Installation

Take care when you unpack the pump to avoid excessive shocks that could damage the bearings and reduce the life

of the pump. The pump is supplied with the inlet and outlet sealed to prevent entry of dust and vapour. Do not

remove these seals until you are ready to install the pump on your vacuum system.

Remove all packing materials and check the pump. If the pump is damaged, notify your supplier and the carrier in

writing within three days; state the Item Number of the pump together with your order number and your supplier's

invoice number. Retain all packing materials for inspection. Do not use the pump if it is damaged.

Check that your package contains the items listed in Table 16. If any of these items is missing, notify your supplier

in writing within three days.

If the pump is not to be used immediately, store the pump in suitable conditions, following the procedure described

in Section 6.1.

Do not discard the packing materials; retain them to re-package the pump should you need to return it for service.

Table 16 - Checklist of components

Quantity Description Check ()

1 nEXT pump with inlet-screen fitted (fitted to CF pumps only)

1 Inlet seal (either trapped O-ring with integral inlet screen, Co-

seal or copper compression gasket suitable for the inlet-flange

type)

1 Connector (24 V) - for driving accessories from Controller socket

1 Inlet-strainer (fitted in the NW25 interstage and booster port

only)

3.2 Typical installation

A typical pumping system with a nEXT pump is shown in Figure 9.

The accessories available for the nEXT pumps are detailed in Section 7.4; the accessories are shown in Figure 18 and

19.

© Edwards Limited 2009. All rights reserved. Page 25

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 33

B800-00-880 Issue A

WARNING

WARNING

1. Vacuum system

2. High-vacuum gauge

3. Vibration damper

4. Inlet-screen

5. nEXT pump

6. Backing valve

7. Vacuum gauge

8. Flexible bellows

9. Foreline trap

10. Rotary backing

pump

11. Mist filter

12. Vent valve

13. Alternative position for vent valve

14. Air cooler

15. PRX purge restrictor

16. Regulated purge gas supply

17. WCX water-cooler and connections

Installation

3.3 Connection to the vacuum system

Ensure that all wires and piping are routed appropriately to avoid the risk of tripping.

Install the pump in the vacuum system before the logic interface cable is connected to the control

equipment and before the electrical supply is connected. This will ensure that the pump cannot

operate accidentally causing injury.

We recommend that the system is leak tested after installation has been completed.

Figure 9 - Typical pumping system with a nEXT pump

Page 26 © Edwards Limited 2009. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 34

B800-00-880 Issue A

WARNING

WARNING

WARNING

WARNING

3.3.1 Inlet-screen (supplied fitted on CF only)

Removal of the inlet-screen will expose the risk of injury from sharp edges.

Do not remove the inlet-screen unless you can be sure that there is no danger that debris can fall into the pump. If

the inlet-screen is removed, the pumping speed will increase by up to 10% for course and 20% for fine inlet screens.

Do not remove the inlet-screen until you are ready to mount the pump onto your system, since the screen protects

the pump from contamination.

To remove the inlet-screen from a pump with CF inlet-flange, use a bent wire hook or small screwdriver to carefully

lever the inlet-screen out from the inlet-flange.

To replace an inlet-screen, locate it as centrally as possible over the CF inlet-flange and then, with your fingers

spread evenly around the edge of the screen, push it firmly downwards. If they are not already in place, the tangs

must be snapped into the locating groove in the inlet-flange using a suitable tool to press them into position. For ISO

flanged pumps, Edwards supply a combined inlet screen / trapped O-ring.

3.3.2 Mechanical fixing

Installation

Do not operate the pump until it is securely fixed. If the pump seizes, the stored energy of the

rotor can cause rapid movement of the pump, which may cause further damage and injury to

people.

The inlet screen is a coarse filter for debris and should not be used as a finger guard.

Position system viewports and vulnerable components away from the pump inlet to safeguard

against damage from possible ejected parts.

There are two ways in which the nEXT pumps can be securely fixed. The ideal fixing for a nEXT pump is via its inlet

flange to a rigid, firmly fixed vacuum system - refer to Section 3.3.3. If this is not possible because of the nature of

the vacuum system then the base of the pump must be fixed to a firm support, refer to Section 3.3.4 for instructions

on base mounting the pump.

3.3.3 Inlet-connection and orientation

The pump can be securely fixed to the vacuum system via the inlet-flange. The pump can be mounted in any attitude

from the vertical and upright through to horizontal (±2°). If the pump is mounted horizontally, and you are using a

rotary vane pump to back your nEXT pump then the backing port must point vertically downwards (±20°) to reduce

the risk of contamination from the backing pump oil.

Make sure that the pump-inlet and all components fitted to the pump-inlet are clean and dust-free. If the pump-inlet

is not kept clean, the pump-down time may be increased.

The inlet connections for the nEXT pump are CF flange and the ISO flange:

If the pump has a CF flange, use the copper compression gasket supplied with the pump and use a full

complement of bolts to connect the inlet-flange of the pump to the vacuum system.

© Edwards Limited 2009. All rights reserved. Page 27

Edwards and the Edwards logo are trademarks of Edwards Limited.

Page 35

B800-00-880 Issue A

CAUTION

WARNING

WARNING

Installation

If the pump has an ISO flange, use the Edwards combined inlet screen and trapped O-ring supplied with the

pump and use a minimum of four claw clamps (each torqued to 30 Nm) to connect the inlet-flange of the

pump to the vacuum system. Alternatively, use a rotatable collar and the combined inlet screen and trapped

O-ring supplied with the pump to connect the inlet-flange of the pump to the vacuum system; use a full

complement of bolts with the rotatable collar.

All inlet flange bolts must be re-tightened once the system is under vacuum. Ensure that no torques or other forces

are transmitted to the pump from the vacuum system or the associated pipelines. If necessary, fit an inlet vibration

damper between the pump inlet and the vacuum system (refer to Section 7.4). In this case you must fix the base of

your pump to a firm support, as described in Section 3.3.4.

3.3.4 Base mounting