Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

BEDIENUNGSANLEITUNG

MANUALE D’ISTRUZIONI

MODEL

HCAA-2400A

HCAA-2401A

HCAA-2403A

HCAA-2404A

ENGLISH

FRANÇAIS

DEUTSCH

ITALIANO

WARNING, SEE OPERATOR’S MANUAL

LIRE SOIGNEUSEMENT CE MANUEL AVANT TOUTE UTILISATION

ACHTUNG: BEDIENUNGSANLEITUNG LESEN!

A TTENZIONE, LEGGETE IL MANUALE D’ISTRUZIONI

Page 2

2

MODEL

HCAA-2400A

HCAA-2401A

HCAA-2403A

HCAA-2404A

OPERATOR’S MANUAL

MANUEL D’UTILISATION

BEDIENUNGSANLEITUNG

MANUALE D’ISTRUZIONI

WARNING, SEE OPERATOR’S MANUAL

LIRE SOIGNEUSEMENT CE MANUEL AVANT TOUTE UTILISATION

ACHTUNG: BEDIENUNGSANLEITUNG LESEN!

ATTENZIONE, LEGGETE IL MANUALE D’ISTRUZIONI

ENGLISH

ITALIANO

DEUTSCH

FRANÇAIS

INTRODUCTION

Welcome to the ECHO family. This ECHO product was designed and manufactured to provide long life and onthe-job-dependability. Read and understand this manual you found in the package. You will find it easy to use

and full of helpful operating tips and SAFETY messages.

W ARNING

Read rules for safe operation and instructions carefully. ECHO provides an Operator’s Manual that must be

read and understood for proper and safe operation.

THE OPERATOR’S MANUAL --

contains specifications and information for operation,

maintenance and assembly specific to this product.

TABLE OF CONTENTS

Introduction.....................................................................2

- The Operator’s Manual............................................2

Manual Safety Symbols & Important Information .........3

Safety ..............................................................................3

- Decals.......................................................................3

- International Symbols ..............................................3

- Equipment ................................................................4

- Fuel ..........................................................................4

- Personal Condition & Safety Equipment ................... 4

- Safe Operation..........................................................6

- Extended Operation/Extreme Conditions ..................7

Specifications, descriptions and illustrative material in this literature are as accurate as known at the

time of publication, but are subject to change without notice. Illustrations may include optional

equipment and accessories, and may not include all standard equipment.

Description....................................................................... 8

Specifications ...................................................................9

Assembly ......................................................................... 9

- Gear Box / Drive Shaft............................................. 9

Pre-Operation ................................................................ 10

- Fuel......................................................................... 10

- Equipment Check....................................................11

Operation ....................................................................... 12

- Adjusting Cutting Angle .......................................... 12

- Hedge Trimming ..................................................... 13

Maintenance .................................................................. 14

- Clean & Lubrication ............................................... 14

- Sharpening Blades .................................................. 15

Page 3

HEDGE CLIPPER

OPERATOR’S MANUAL

MANUAL SAFETY SYMBOLS & IMPORTANT INFORMA TION

Throughout this manual and on the product itself, you will find safety alerts and helpful, information messages

preceded by symbols or key words. The following is an explanation of those symbols and key words and what they

mean to you.

DANGER

The safety alert symbol accompanied by the word

“DANGER” calls attention to an act or condition

which WILL lead to serious personal injury or

death if not avoided.

WARNING

The safety alert symbol accompanied by the word

“WARNING” calls attention to an act or

condition which CAN lead to serious personal

injury or death if not avoided.

CAUTION

The safety alert symbol accompanied by the word

“CAUTION” calls attention to an act or condition

which may lead to minor or moderate personal

injury if not avoided.

NOTE

This enclosed message provides tips for use, care and

maintenance of the unit.

IMPORTANT

The enclosed message provides information

necessary for the protection of the unit.

CIRCLE AND SLASH

SYMBOL

This symbol means the specific action

shown is prohibited. Ignoring these

prohibitions can result in serious or fatal

injury.

3

SAFETY

DECALS

WARNING / INFORMATIONAL

Locate this safety decal on your unit. Make sure the decal is legible and that you understand and follow the

instructions on them. If a decal cannot be read, a new one can be ordered from your ECHO dealer.

INTERNATIONAL SYMBOLS

Symbol

form/shape

Symbol

description/

application

Read and

understand

Operator’s

Manual

Wear eyes,

ears and

head

protection

Hot

Surface

Safety/Alert

Avoid all power

lines. This unit is

not insulated

against electrical

current.

Keep

bystanders

at least 15 m

away

Symbol

form/shape

Symbol

description/

application

Fuel and oil

mixture

Finger

Severing

Wear hand

protection.

Use

two handed.

DO NOT

smoke

near fuel

Do not operate

closer than 15 m

from electrical

hazards

Plan retreat

path from

falling

objects

Symbol

form/shape

Symbol

description/

application

DO NOT

allow flames

or sparks

near fuel

Engine

choke

control

Emergency

stop

Carburettor

adjustment

- Low speed

mixture

Carburettor

adjustment

- High speed

mixture

Carburettor

adjustment

- Idle speed

Symbol

form/shape

Symbol

description/

application

Wear slip

resistant

foot wear

Ignition

ON/OFF

Primer bulb

Bystanders

keep clear

Keep clear

of electrical

eources

Page 4

4

EQUIPMENT

Before operation a complete check of the unit must be performed;

- Check unit for loose/missing nuts, bolts and screws. Tighten and/

or replace as needed.

- Inspect fuel lines, tank and area around carburettor for fuel leaks.

DO NOT operate unit if leaks are found.

- Check that the blade assembly is firmly attached and in safe

operating condition. Dull, loose or damaged blades should not be

used.

FUEL

DANGER

Fuel is VERY flammable. Use extreme care when mixing, storing

or handling, or serious personal injury may result.

- Use an approved fuel container.

- DO NOT smoke near fuel.

- DO NOT allow flames or sparks near fuel.

- Fuel tanks/cans may be under pressure.

Always loosen fuel caps slowly allowing pressure to equalize.

- NEVER refuel a unit when the engine is HOT!

- NEVER refuel a unit with the engine running.

- DO NOT fill fuel tanks indoors.

ALWAYS fill fuel tanks outdoors over bare ground.

- Securely tighten fuel cap after refuelling.

- Inspect for fuel leakage.

If fuel leakage is found, do not start or operate unit until leakage

is repaired.

After Refuelling;

3 m

- Wipe any spilled fuel from the unit.

- Move at least 3 m from refuelling location before starting.

After Use;

- DO NOT store a unit with fuel in its tank.

Leaks can occur.

Return unused fuel to an approved fuel storage container.

PERSONAL CONDITION & SAFETY EQUIPMENT

W ARNING

Hedge Clipper users risk injury to themselves and others if the shaft hedge clipper is used improperly and or

safety precautions are not followed. Proper clothing and safety gear must be worn when operating a shaft

hedge clipper.

Page 5

HEDGE CLIPPER

Physical Condition --

Your judgment and physical dexterity may not be good:

- if you are tired or sick,

- if you are taking medication,

- if you have taken alcohol or drugs.

Operate unit only if you are physically and mentally well.

Eye Protection --

Eye protection goggles that meet CE requirements were included

with your trimmer. Wear these goggles whenever you operate the

shaft hedge clipper.

Face & Head Protection --

When trimming overhead, wear head protection meeting CE with a

full face shield.

OPERATOR’S MANUAL

5

Hand Protection --

Wear no-slip, heavy duty work gloves to improve your grip on the

Shaft Hedge Clipper handles. Gloves also reduce the transmission of

machine vibration to your hands. Special vibration reducing gloves

such as ECHO’s Pro-Comfort are designed to provide additional

comfort.

Hearing Protection --

ECHO recommends wearing hearing protection whenever unit is

used.

Proper Clothing --

Wear snug fitting, durable clothing;

- Pants should have long legs, shirts with long sleeves.

- DO NOT WEAR SHORTS,

- DO NOT WEAR TIES, SCARVES, JEWELRY.

Wear sturdy work shoes with non-skid soles;

- DO NOT WEAR OPEN TOED SHOES,

- DO NOT OPERATE UNIT BAREFOOTED.

Hot Humid Weather --

Heavy protective clothing can increase operator fatigue which may

lead to heat stroke. Schedule heavy work for early morning or late

afternoon hours when temperatures are cooler.

Page 6

6

SAFE OPERATION

DETERMINE OPERATION AREA

- Review the area to be trimmed. Look for hazards that could

contribute to unsafe conditions. DO NOT operate unit if any wires

(power, telephone, cable, etc.) are closer than 5 m to any part of

the operator or unit.

- Spectators and fellow workers must be warned, and children and

animals prevented from coming nearer than 15 m while the Hedge

Clipper is in use.

Operation

Use Proper Clothing & Equipment

- Before starting the unit, equip yourself and any other person

working within the 15 m Safety Zone with the required Protective

Equipment and clothing.

- Check that loop (front) handle and shoulder strap/ or shoulder/

waist harness is adjusted for safe, comfortable operation.

Avoid Hot Surfaces

- During operation, the complete unit, especially the drive shaft

housing, power head, muffler area and gear box may become very

hot, too hot to touch. Avoid contact during and immediately after

operation.

Keep A Firm Grip

- Hold the front and rear handles with both hands with thumbs and

fingers tightly encircling the handles.

Keep A Solid Stance

- Maintain footing and balance at all times. Do not stand on slippery,

uneven or unstable surfaces. Do not work in odd positions or on

ladders. Do not over reach.

15 m

15 m

Adjust Cutting Angle

- Never adjust blade angle while standing.

- Only adjust cutting angle with unit resting flat on the ground, with

the switch in the “STOP” position.

Page 7

HEDGE CLIPPER

OPERATOR’S MANUAL

EXTENDED OPERATION / EXTREME CONDITIONS

Vibration and Cold --

It is believed that a condition called Raynaud’s Phenomenon, which

affects the fingers of certain individuals may be brought about by

exposure to vibration and cold. Exposure to vibration and cold may

cause tingling and burning sensations followed by loss of color and

numbness in the fingers. The following precautions are strongly

recommended because the minimum exposure which might trigger

the ailment is unknown.

• Keep your body warm, especially the head, neck, feet, ankles,

hands and wrists.

• Maintain good blood circulation by performing vigorous arm

exercises during frequent work breaks and also by not smoking.

• Limit the hours of operation. Try to fill each day with jobs where

operating the trimmer or other hand-held power equipment is not

required.

• If you experience discomfort, redness and swelling of the fingers

followed by whitening and loss of feeling, consult your physician

before further exposing yourself to cold and vibration.

7

Repetitive Stress Injuries --

It is believed that overusing the muscles and tendons of the fingers,

hands, arms and shoulders may cause soreness, swelling, numbness,

weakness and extreme pain in those areas. Certain repetitive hand

activities may put you at a high risk for developing a Repetitive

Stress Injury (RSI). An extreme RSI condition is Carpal Tunnel

Syndrome (CTS), which could occur when your wrist swells and

squeezes a vital nerve that runs through the area. Some believe that

prolonged exposure to vibration may contribute to CTS. CTS can

cause severe pain for months or even years.

To reduce the risk of RSI / CTS, do the following:

• Avoid using your wrist in a bent, extended or twisted position.

Instead try to maintain a straight wrist position. Also, when

grasping, use your whole hand, not just the thumb and index finger.

• Take periodic breaks to minimize repetition and rest your hands.

• Reduce the speed and force with which you do the repetitive

movement.

• Do exercises to strengthen the hand and arm muscles.

• See a doctor if you feel tingling, numbness or pain in the fingers,

hands, wrists or arms. The sooner RSI/CTS is diagnosed, the more

likely permanent nerve and muscle damage can be prevented.

Page 8

8

DESCRIPTION

HCAA-2400A ; SRM-2306/2306ES

HCAA-2403A ; SRM-220ES

HCAA-2404A ; SRM-265/265ES

4

HCAA-2401A ; PAS-265ES

2

1

2

3

5

6

Safety decal

3

Part Number;

890617-12361

7

4

5

6

1. OPERATOR’S MANUAL - Read and understand this manual before operation. Keep manual in a safe

location for future reference, i.e., operation, maintenance and specifications.

2. BLADES - Double reciprocating blades mounted to a blade support bar. Double-sided blades are capable of

cutting on either side of the blade.

3. BLADE INDEXING RING- Pull ring out and turn 1/4 turn to lockout position when adjusting blade angle.

4. BLADE COVER - Used to cover blade during transport and storage. Remove blade cover before using unit.

5. GEAR HOUSING ASSEMBLY - Gear housing contains drive gears for transmitting power to cutting blades.

Pivoting design permits blades to articulate 180 degrees in 15-degree increments.

6. BLADE ADJUSTMENT HANDLE - Provides secure hand grip for adjusting cutting blade angle.

7. HAND GUARD / BLADE LOCK - Locks blade in place for travel / storage. Always assure blade cover is

installed when locking blade.

8

8. FRONT DRIVE SHAFT GRIP - Cushioned hand grip for gripping drive shaft assembly.

Page 9

HEDGE CLIPPER

OPERATOR’S MANUAL

SPECIFICATIONS

HCAA-2400A

HCAA-2403A HCAA-2401A

HCAA-2404A

Mass

Unit with specified cutting blade kg 2.2 2.7

Cutting device

Type Dual action, double sided

Length mm 510

Pitch mm 35

Height mm 21

Gear ratio 3.95 reduction

External Dimensions

Length mm 810 1015

Width mm 110 130

Height mm 100 95

9

ASSEMBLY

GEAR BOX / DRIVE SHAFT

Tools Required: 4 mm Hexagonal Wrench, Cross Head Screw-

driver.

Parts Required: Power Head/Drive Shaft Assembly and Gear Box/

Blade Assembly.

NOTE

Hedge Clipper Blades are very sharp. Wear gloves to protect hands.

1. Slide the Gear Box/Blade Assembly on the Drive Shaft. Be

certain the Flex Drive Shaft engages the hole in Driver Gear.

2. Align the locating bolt with the locating hole in the Drive Shaft

Housing, tighten screw and clamping bolt.

Clamping bolt

Locating hole

Screw

Page 10

10

PRE-OPERATION

FUEL

Fuel Requirements

Fuel is a mixture of regular grade petrol and an air-cooled 2-stroke

engine oil of reputable brand name. Minimum 89 Octane unleaded

petrol is recommended. Do not use fuel containing methyl alcohol or

more than 10 % of ethyl alcohol.

Recommended mixture ratio; 50 : 1 (2 %) for ISO-L-EGD Standard

(ISO/CD 13738), JASO FC, FD grade and ECHO Premium 50 : 1

oil.

- Do not mix directly in engine fuel tank.

- Avoid spilling petrol or oil. Spilled fuel should always be wiped

up.

- Handle petrol with care, it is highly inflammable.

- Always store fuel in approved container.

Handling Fuel

DANGER

Fuel is VERY flammable. Use extreme care when mixing, storing

or handling, or serious personal injury may result.

- Use an approved fuel container.

- DO NOT smoke near fuel.

- DO NOT allow flames or sparks near fuel.

- Fuel tanks/cans may be under pressure.

Always loosen fuel caps slowly allowing pressure to equalize.

- NEVER refuel a unit when the engine is HOT!

- NEVER refuel a unit with the engine running.

- DO NOT fill fuel tanks indoors.

ALWAYS fill fuel tanks outdoors over bare ground.

- Securely tighten fuel cap after refuelling.

- Inspect for fuel leakage.

If fuel leakage is found, do not start or operate unit until leakage

is repaired.

After Refuelling;

- Wipe any spilled fuel from the unit.

- Move at least 3 m from refuelling location before starting the

engine.

After use;

- DO NOT store a unit with fuel in its tank.

Leaks can occur.

Return unused fuel to an approved fuel storage container.

3 m

Page 11

HEDGE CLIPPER

Storage;

Fuel storage laws vary by locality. Contact your local government

for the laws affecting your area. As a precaution, store fuel in an

approved, air tight container. Store in a well ventilated, unoccupied

building, away from sparks and flames. Do not store fuel longer than

30 days.

IMPORTANT

Stored fuel ages. Do not mix more fuel than you expect to use in

thirty (30) days.

IMPORTANT

Stored two-stroke fuel may separate. ALWAYS shake fuel

container thoroughly before each use.

OPERATOR’S MANUAL

SM TW T FS

1234567

8 9 10 11 12 13 14

15 16 17 18 19 20 21

22 23 24 25 26 27 28

29 30 31

11

EQUIPMENT CHECK

Before operation a complete check of the unit must be performed;

- Check unit for loose/missing nuts, bolts and screws. Tighten and/or

replace as needed.

- Inspect fuel lines, tank and area around carburettor for fuel leaks.

DO NOT operate unit if leaks are found.

- Check that the blade assembly is firmly attached and in safe

operating condition. Dull, loose or damaged blades should not be

used.

Page 12

12

OPERATION

ADJUSTING

CUTTING ANGLE

WARNING

Never adjust cutting assembly with engine running.

WARNING

Hedge clipper blades are sharp. Always wear gloves when

adjusting cutting assembly.

WARNING

DO NOT stand hedge clipper on end when adjusting cutting

angle, otherwise serious injury may result

1. Place unit on a flat clear area. Assure stop switch is in the

“STOP” position.

Indexing ring

¼ turn

2. Pull out indexing ring, and turn ¼ turn to lockout position.

3. Turn hedge clipper ¼ turn so that indexing ring faces downward.

4. Release hand-guard blade lock with right hand, while holding

blade-adjustment handle with left hand.

5. Rotate blades to desired cutting position.

6. Turn indexing ring ¼ turn to lock blade in place.

WARNING

Gear case assembly becomes HOT during use. Always grip

assembly at blade-adjustment handle when making cutting

angle adjustments, otherwise serious injury may result.

Hand-guard blade lock

Hand-guard

blade lock

Adjustment

handle

Page 13

HEDGE CLIPPER

HEDGE TRIMMING

1. Hold trimmer firmly and squeeze throttle trigger to accelerate

engine.

2. Tilt trimmer so cutting teeth are angled slightly toward the hedge

or shrub and proceed to cut.

WARNING

Never remove hands from unit when blades are moving.

OPERATOR’S MANUAL

13

WARNING

The engine continues running even when the blades have

stopped due to an obstruction. If this occurs, stop the engine,

disconnect ignition cable and remove the obstruction.

Page 14

14

MAINTENANCE

Your ECHO product is designed to provide many hours of trouble free service.

Regular scheduled maintenance will help achieve that goal.

If you are unsure or are not equipped with the necessary tools, you may want to take your unit to an ECHO

Service Dealer for maintenance.

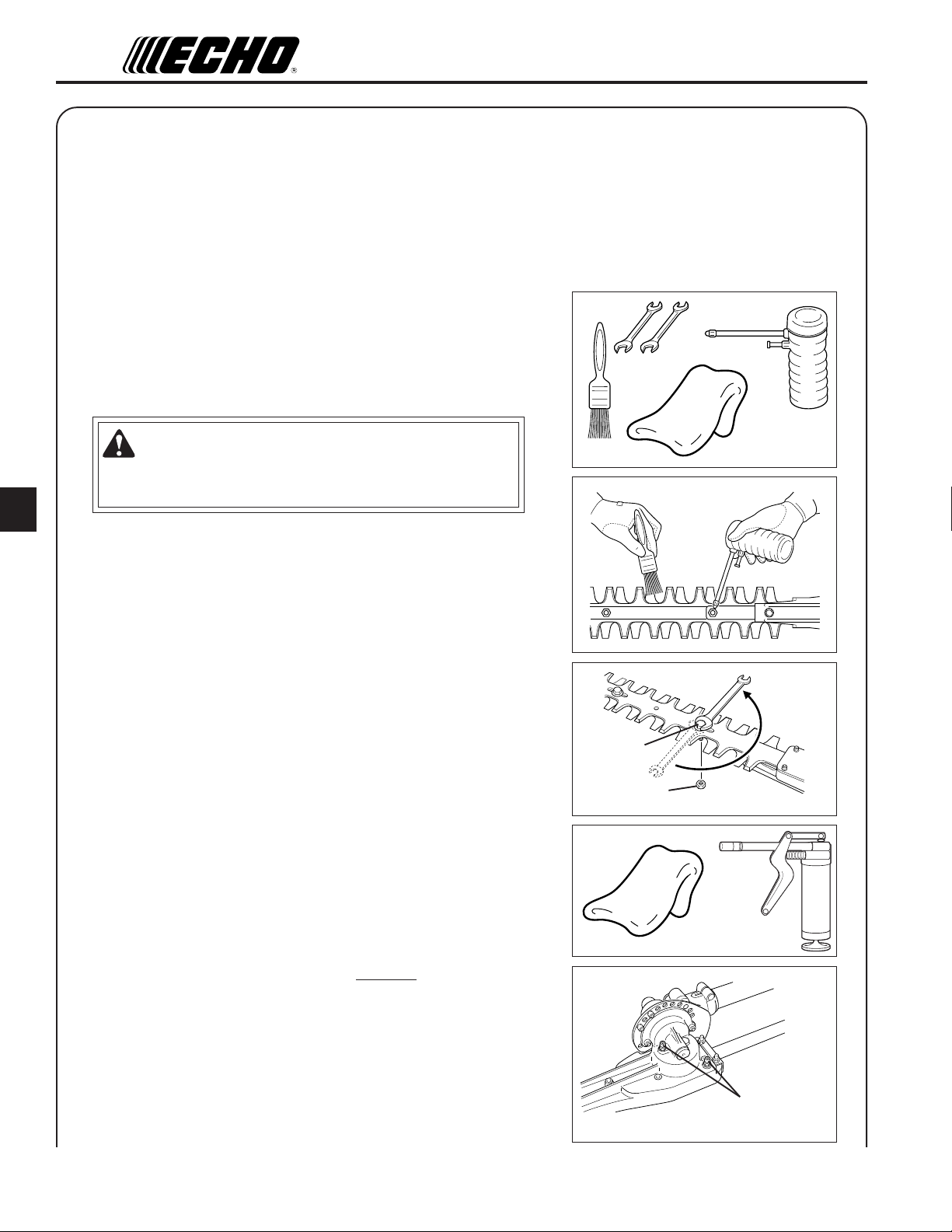

CLEAN & LUBRICATION

Blades

Tools Required: Clean Rag, Brush, Oil Can, (2) 10 mm Wrench.

Parts Required: 20W Engine Oil (lubrication), 50 : 50 mixture of

Kerosene and 20W Oil (cleaning).

W ARNING

Shaft Hedge Clipper Blades are very sharp. Wear gloves to protect

hands, otherwise serious personal injury may result.

1. Brush loose debris from blade and coat both sides of blade with

the 50 : 50 cleaning mixture.

2. Allow cleaning mixture to soften the remaining gummy residue

then wipe it from the blade.

3. Apply clean oil to the entire length of the blade. Be certain the

blade bolts are lubricated.

4. Wipe excess oil from the blade before putting the unit back in

service.

5. Check blade tightness. Tighten blade bolts until snug with 10

mm wrench. Loosen bolts 1/2 turn. Hold bolts from turning and

tighten locknuts with other 10 mm wrench.

Gear housing assembly

Tools required: Grease Gun with Lithium Grease, Rag.

Parts required: Lithium Based Grease.

1. Clean dirt from grease fittings.

2. Carefully pump grease in each fitting. DO NOT force grease.

Too much pressure will force grease past seals and cause damage.

Apply 1-2 pumps of grease every 15-20 hours of operation.

Loosen

1/2 turn

Bolt

Locknut

Grease

fitting

Page 15

HEDGE CLIPPER

Drive shaft assembly

NOTE

Hedge Clipper drive shaft should be greased every 25-50 hours of

operation.

Tools required: 4 mm Hexagonal Wrench, 8 mm Open End

Wrench, Clean Rag, Small Brush.

Parts required: Lithium Based Grease.

WARNING

Shaft Hedge Clipper Blades are very sharp. Wear gloves to protect

hands, otherwise serious personal injury may result.

1. Loosen gear box locating bolt and clamping bolt. Remove the

gear box from the drive shaft housing.

2. Pull the drive shaft from the housing, wipe clean and recoat with

a thin coating (15 mL) of lithium based grease.

OPERATOR’S MANUAL

Clamping bolt

Locating bolt

15

3. Slide the flexible shaft back into the drive housing being careful

not to get dirt on the flex shaft.

4. Install the gear box assembly.

SHARPENING BLADES

Tools required: Flat file, Small Screwdriver.

Parts required: Gear box gasket, Lithium Based Grease.

NOTE

Blade sharpening requires removal of blades from the unit. Step

by step instruction are included in the Service Manual that apply

to your model.

NOTE

Hedge Clipper Blades are very sharp. Wear gloves to protect

hands.

1. Use screwdriver to separate upper and lower cutters equal

distance apart.

2. File each edge carefully. Follow the original shape of the blade.

43º

Drive shaft

6mm Radius

IMPORTANT

If a power grinder is used DO NOT allow blade to over heat.

3. Lubricate blades. See “Blade Lubrication Instructions”, page 14

this section.

Page 16

16

DECLARA TION “CE” OF CONFORMITY

The undersigned manufacturer:

KIORITZ CORPORATION

7-2 SUEHIROCHO 1-CHOME

OHME ; TOKYO 198-871 1

JAPAN

declares that the hereunder specified new unit:

PORT ABLE HEDGE TRIMMER

Brand: ECHO

T ype : HCAA-2400A,HCAA-2401A

HCAA-2403A,HCAA-2404A

assembled by:

ECHO, INCORPORA TED

400 Oakwood Road

Lake Zurich, Ilinois 60047-1564

U.S.A.

complies with:

*the requirements of Directive 98/37/EC (1998)

(use of harmonized standard ISO 10517 (EN 774))

*the requirements of Directive 2004/108/EC

(use of harmonized standards EN 50081-1, EN 50082-1, EN 55014 & EN

55022)

*the requirements of Directive 2002/88/EC

*the requirements of Directive 2000/14/EC

Conformity assessment procedure followed ANNEX V

SRM-2306/

SRM-2306ES + PAS-265ES+

HCAA-2400A HCAA-2401A

Measured sound power level dB(A) 105 108

Guaranteed sound power level dB(A) 108 111

SRM-265/

SRM-220ES + SRM265ES+

HCAA-2403A HCAA-2404A

Measured sound power level dB(A) 104 108

Guaranteed sound power level dB(A) 107 111

Page 17

HEDGE CLIPPER

OPERATOR’S MANUAL

HCAA-2400A Serial Number S56435001001 and up

HCAA-2401A Serial Number S56535001001 and up

HCAA-2403A Serial Number S56635001001 and up

HCAA-2404A Serial Number S56735001001 and up

Tokyo,

December 1st 2007 Authorized Representative in Europe:

Company: Countax Limited

Address: Countax House, Haseley

Trading Estate,

Great Haseley , Oxfordshire

OX44 7PF, U.K.

Mr . Harry Handkammar

17

GB

Page 18

7-2 SUEHIROCHO 1-CHOME, OHME, TOKYO 198-8711, JAPAN

PHONE: 81-428-32-6118. FAX: 81-428-32-6145.

GB

© 2007

X753-003 43 1

X753 224-790 2

Loading...

Loading...