Page 1

x7722271404 / x772000164

GT-225SF

GRASS TRIMMER

Operator’s Manual

ENGLISH

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects,

or other reproductive harm.

Read and understand operator’s manual (and safety

manual if included) before use. Failure to read the

manuals could result in serious injury.

Specifications, descriptions and illustrative material in this literature are

as accurate as known at the time of publication, but are subject to

change without notice. Illustrations may include optional equipment and

accessories, and may not include all standard equipment.

X7732274700

© 12/2017 ECHO Inc.

Page 2

TABLE OF CONTENTS GT-225SF

TABLE OF CONTENTS

Table of Contents ........................................................................................ 2

Introduction ................................................................................................. 3

Servicing Information .................................................................................. 3

Parts/Serial Number ............................................................................ 3

Service................................................................................................. 4

Echo Consumer Product Support ........................................................ 4

Product Registration ............................................................................ 4

Additional or Replacement Manuals .................................................... 4

Safety.......................................................................................................... 4

Manual Safety Symbols and Important Information............................. 4

International Symbols .......................................................................... 5

Personal Condition and Safety Equipment .......................................... 7

Equipment.......................................................................................... 12

Emission Control (Exhaust & Evaporative) .............................................. 13

CARB And EPA Emissions Control Information................................. 13

Description ................................................................................................ 14

Contents.................................................................................................... 16

Assembly................................................................................................... 17

Shield Installation............................................................................... 17

Support Handle.................................................................................. 17

Operation .................................................................................................. 18

Fuel.................................................................................................... 19

Starting Cold Engine.......................................................................... 21

Starting Warm Engine........................................................................ 22

Stopping Engine ................................................................................ 23

Maintenance ............................................................................................. 24

Skill Levels......................................................................................... 24

Skill Levels......................................................................................... 25

Maintenance Intervals........................................................................ 25

Air Filter ............................................................................................. 26

Fuel Filter........................................................................................... 27

Spark Plug ......................................................................................... 28

Cooling System.................................................................................. 28

Exhaust System................................................................................. 30

Carburetor Adjustment....................................................................... 31

Lubrication ......................................................................................... 33

Nylon Line Replacement.................................................................... 33

Nylon Line Head Disassembly Instructions........................................ 34

Troubleshooting ......................................................................................... 35

Storage...................................................................................................... 37

Long Term Storage (Over 30 Days) ................................................... 37

Specifications............................................................................................ 38

2 X7732274700

© 12/2017 ECHO Inc.

Page 3

GT-225SF INTRODUCTION

Product Registration ................................................................................. 40

Notes ........................................................................................................ 42

INTRODUCTION

This product was designed and manufactured to provide long life and onthe-job dependability. Read and understand this manual (and safety manual

if included). Keep the manuals in a safe place for future reference.

The operators manual contains specifications and information for safety,

operation, maintenance, storage and assembly specific to this product.

Scan the QR codes throughout the operator’s manual for more information.

The safety manual explains possible hazards and the measures you should

take to insure safe operation.

For questions regarding terms used in this manual, visit:

https://www.echo-usa.com/Support-Help/TechnicalDocuments?gt=true

OR

https://www.shindaiwa-usa.com/Tech-Support/TechnicalDocuments.aspx?gt=true

SERVICING INFORMATION

Parts/Serial Number

ENGLISH

Genuine ECHO Parts and

Assemblies for your ECHO products

are available only from an

Authorized ECHO Dealer. When you

do need to buy parts always have

the Model Number and Serial

Number of the unit with you. For

future reference write them in the

space provided below.

Model No. _________________

Serial No. _________________

X7732274700 3

© 12/2017 ECHO Inc.

Page 4

SAFETY GT-225SF

Service

Service of this product during the warranty period must be performed by an

Authorized ECHO Service Dealer. For the name and address of the

Authorized ECHO Service Dealer nearest you, ask your retailer or call:

1-800-432-ECHO (3246). Dealer information is also available on our Web

Site www.echo-usa.com. When presenting your unit for Warranty service/

repairs, proof of purchase is required.

Echo Consumer Product Support

If you require assistance or have questions concerning the application,

operation, or maintenance of this product, call the ECHO Consumer

Product Support Department at 1-800-673-1558 from 8:00 am to 5:00 pm

(Central Standard Time) Monday through Friday. Before calling, please

know the model and serial number of your unit.

Product Registration

Register your ECHO equipment on-line at www.echo-usa.com or by filling

out the product registration sheet included in this manual. Registering your

product confirms warranty coverage and provides a direct link to ECHO if

we find it necessary to contact you.

Additional or Replacement Manuals

Replacement Operator or Safety Manuals, and Parts

Catalogs

Service Dealer, or at www.echo-usa.com, or by contacting

ECHO Inc., 400 Oakwood Road, Lake Zurich, IL 60047

(800-673-1558). Always check www.echo-usa.com for

updated information.

Safety Videos are available from your Authorized ECHO Service Dealer. A

$5.00 shipping charge is required for each video.

, are available from your Authorized ECHO

SAFETY

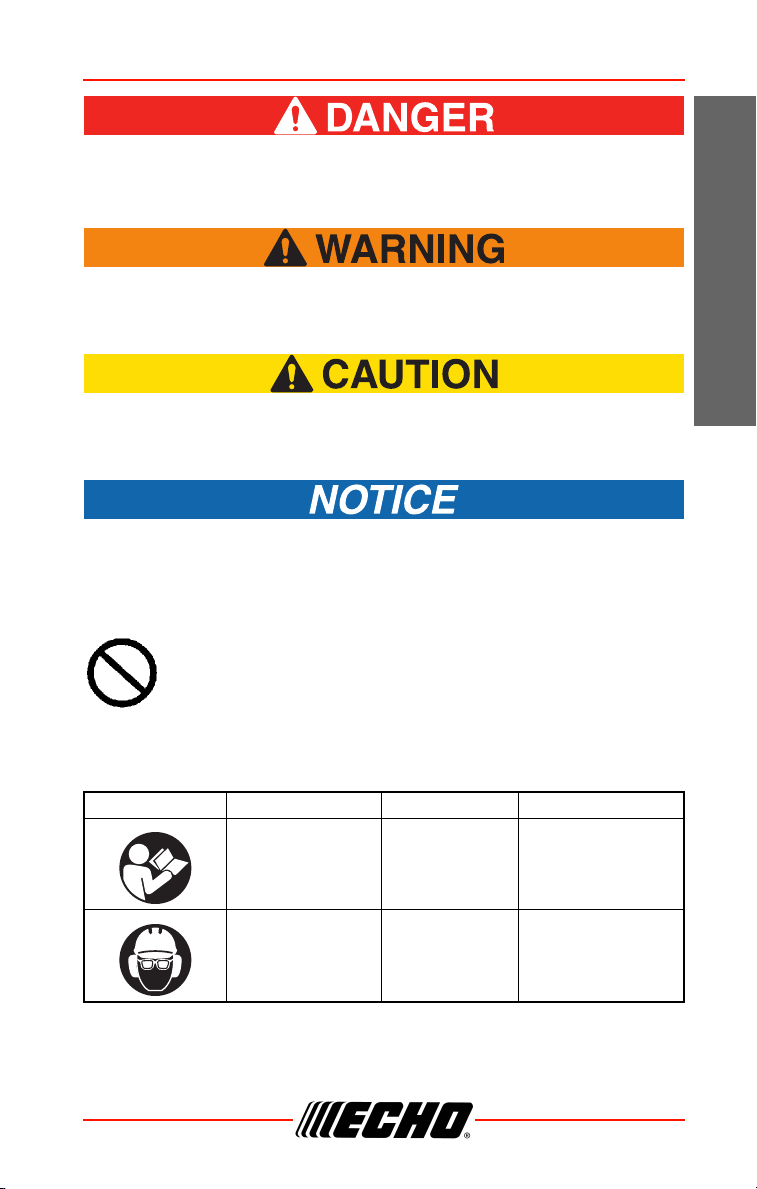

Manual Safety Symbols and Important Information

Throughout this manual and on the product itself, you will find safety alerts

and helpful, informational messages preceded by symbols or key words.

The following is an explanation of those symbols and key words and what

they mean to you.

4 X7732274700

© 12/2017 ECHO Inc.

Page 5

GT-225SF SAFETY

H

T

The safety alert symbol accompanied by the word “DANGER”

calls attention to an act or condition which WILL lead to serious

personal injury or death if not avoided.

The safety alert symbol accompanied by the word “WARNING”

calls attention to an act or condition which CAN lead to serious

personal injury or death if not avoided.

The safety alert symbol accompanied by the word “CAUTION”

calls attention to an act or condition which may lead to minor or

moderate personal injury if not avoided.

The enclosed message provides information necessary for the

protection of the unit.

Note: This enclosed message provides tips for use, care and

maintenance of the unit.

CIRCLE AND SLASH SYMBOL

This symbol means the specific action shown is prohibited.

Ignoring these prohibitions can result in serious or fatal injury.

ENGLISH

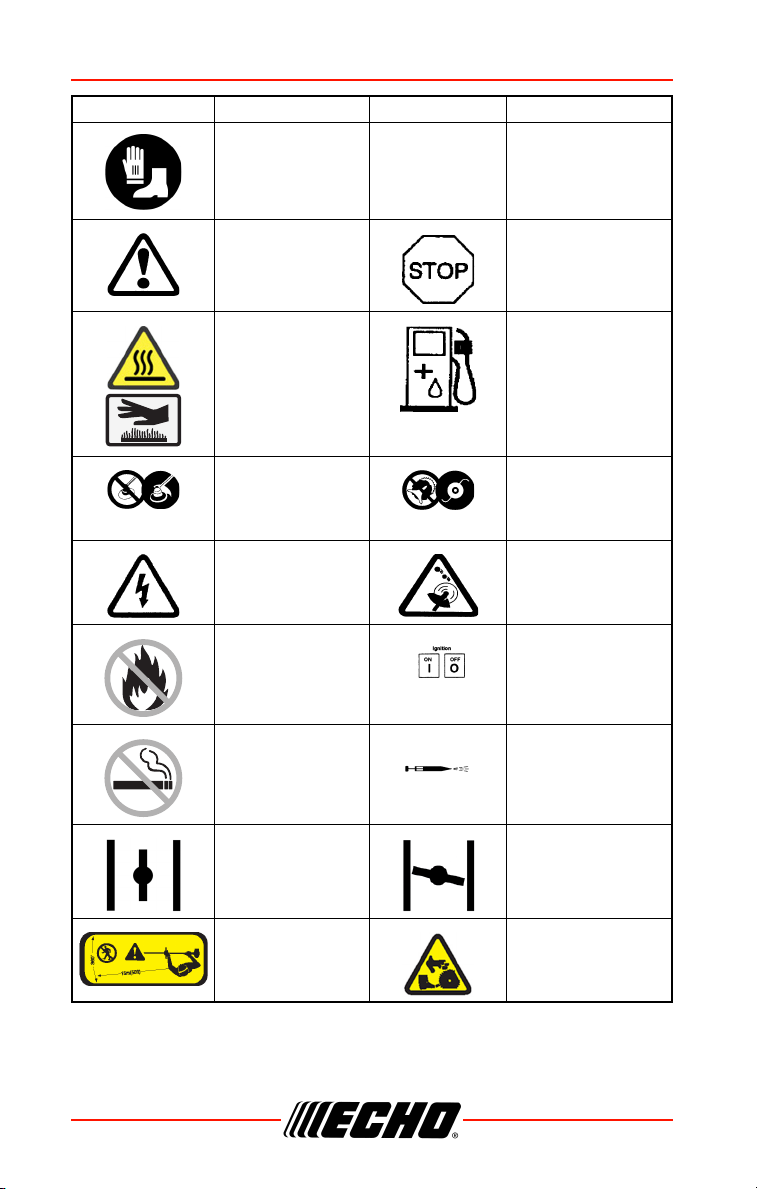

International Symbols

Symbol Description Symbol Description

Warning, See

Operator’s Manual

Wear Eye, Ear and

Head Protection

X7732274700 5

© 12/2017 ECHO Inc.

Carburetor Adjustment -

High Speed Mixture

Carburetor Adjustment -

Idle Speed

Page 6

SAFETY GT-225SF

L

Symbol Description Symbol Description

Wear Hand

and Foot Protection

Safety/Alert Emergency Stop

Hot Surface Fuel and Oil Mixture

Do not operate without

guards and shields in

place.

Avoid all power lines.

This unit is not

insulated against

electrical current.

DO NOT Allow Flames

or Sparks Near Fuel

Carburetor Adjustment -

Low Speed Mixture

Do not use blades.

String line only.

Plan retreat path from

falling objects

Ignition

ON / OFF

DO NOT Smoke Near

Fuel

Choke Control “RUN”

Position (Choke

Open)

Keep Bystanders and

Helpers

Away 15 m (50 ft.).

Primer Bulb

Choke Control “COLD

START” Position

(Choke Closed)

Rotating Cutting

Attachment

6 X7732274700

© 12/2017 ECHO Inc.

Page 7

GT-225SF SAFETY

Symbol Description Symbol Description

Do not exceed

10,000 RPM

Wear slip resistant

footwear

Personal Condition and Safety Equipment

ENGLISH

Burn Hazard

The muffler or catalytic muffler and surrounding cover

may become extremely hot. Always keep clear of

exhaust and muffler area, otherwise serious personal

injury may occur.

Users of this product risk injury to themselves and others if the

unit is used improperly and/or safety precautions are not

followed. Proper clothing and safety gear must be worn when

operating unit.

Physical Condition

Your judgment and physical dexterity may not be good:

X7732274700 7

© 12/2017 ECHO Inc.

Page 8

SAFETY GT-225SF

• If you are tired or sick

• If you are taking medication

• If you have taken alcohol or drugs

Operate unit only if you are physically and mentally well.

Eye Protection

◆ Eye protection that meets ANSI Z87.1 or CE requirements

must be worn whenever you operate the unit.

◆ For additional safety, a full-face shield may be worn over

safety glasses or goggles to provide protection from sharp

branches or flying debris.

Hand Protection

Wear sturdy, no-slip, rubber work gloves to improve your grip on the

handles. Gloves also provide protection against cuts and scratches, cold

environments, and reduce the transmission of machine vibration to your

hands.

Hearing/Ear Protection

ECHO recommends wearing hearing protection whenever unit is used.

Breathing Protection

Operators who are sensitive to dust or other common airborne allergens

may need to wear a dust mask to prevent inhaling these materials while

operating unit. Dust masks can provide protection against dust, plant debris,

and other plant matter such as pollen. Make sure the mask does not impair

your vision, and replace the mask as needed to prevent air restrictions.

Proper Clothing

Wear snug-fitting, durable clothing:

• Pants should have long legs, shirts should have long sleeves.

• DO NOT WEAR SHORTS.

• DO NOT WEAR TIES, SCARVES, JEWELRY, or clothing with loose or

hanging items that could become entangled in moving parts or

surrounding growth.

• Keep clothing buttoned or zipped, and keep shirt tails tucked in.

8 X7732274700

© 12/2017 ECHO Inc.

Page 9

GT-225SF SAFETY

Wear sturdy work shoes with nonskid rubber soles:

• DO NOT WEAR OPEN TOED SHOES.

• DO NOT OPERATE UNIT BAREFOOTED.

Keep long hair away from engine and air intake. Retain hair with cap or net.

Heavy protective clothing can increase operator fatigue, which may lead to

heat stroke. Schedule heavy work for early morning or late afternoon hours

when temperatures are cooler.

The components of this machine generate an electromagnetic

field during operation, which may interfere with some

pacemakers. To reduce the risk of serious or fatal injury,

persons with pacemakers should consult with their physician

and the pacemaker manufacturer before operating this

machine. In the absence of such information, ECHO

recommend the use of this machine by anyone who has a

pacemaker.

Extended Operation / Extreme Conditions

does not

ENGLISH

Prolonged exposure to cold and/or vibration may result in

injury. Read and follow all safety and operation instructions to

minimize risk of injury. Failure to follow instructions may result

in painful wrist/hand/arm injuries.

It is believed that a condition called Raynaud’s Phenomenon, which affects

the fingers of certain individuals, may be brought about by exposure to

vibration and cold. Exposure to vibration and cold may cause tingling and

burning sensations, followed by loss of color and numbness in the fingers.

The following precautions are strongly recommended, because the

minimum exposure, which might trigger the ailment, is unknown.

X7732274700 9

© 12/2017 ECHO Inc.

Page 10

SAFETY GT-225SF

• Keep your body warm, especially

the head, neck, feet, ankles,

hands, and wrists.

• Maintain good blood circulation by

performing vigorous arm

exercises during frequent work

breaks, and also by not smoking.

• Limit the hours of operation. Try to

fill each day with jobs where

operating the unit or other handheld power equipment is not

required.

• If you experience discomfort, redness, and swelling of the fingers followed

by whitening and loss of feeling, consult your physician before further

exposing yourself to cold and vibration.

Repetitive Stress Injuries

(RSI)

It is believed that overusing the

muscles and tendons of the fingers,

hands, arms, and shoulders may

cause soreness, swelling,

numbness, weakness, and extreme

pain in those areas. Certain

repetitive hand activities may put

you at a high risk for developing a

Repetitive Stress Injury (RSI). An

extreme RSI condition is Carpal

Tunnel Syndrome (CTS), which

could occur when your wrist swells

and squeezes a vital nerve that runs

through the area. Some believe that

prolonged exposure to vibration may contribute to CTS. CTS can cause

severe pain for months or even years.

To reduce the risk of RSI/CTS, do the following:

• Avoid using your wrist in a bent, extended, or twisted position. Instead try

to maintain a straight wrist position. Also, when grasping, use your whole

hand, not just the thumb and index finger.

• Take periodic breaks to minimize repetition and rest your hands.

• Reduce the speed and force with which you do the repetitive movement.

• Do exercises to strengthen the hand and arm muscles.

10 X7732274700

© 12/2017 ECHO Inc.

Page 11

GT-225SF SAFETY

• Immediately stop using all power equipment and consult a doctor if you

feel tingling, numbness, or pain in the fingers, hands, wrists, or arms. The

sooner RSI/CTS is diagnosed, the more likely permanent nerve and

muscle damage can be prevented.

All over head electrical conductors and communications wires

can have electricity flow with high voltages. This unit is not

insulated against electrical current. Never touch wires directly

or indirectly, otherwise serious injury or death may result.

Do not operate this product indoors or in inadequately

ventilated areas. Engine exhaust contains poisonous emissions

and can cause serious injury or death.

Read the Manuals

• Provide all users of this equipment with the Operator’s Manual and Safety

Manual for instructions on Safe Operation.

Clear the Work Area

• Spectators and fellow workers must be warned, and children and animals

prevented from coming nearer than 15 m (50 ft.) while the unit is in use.

ENGLISH

Keep a Firm Grip

• Always hold throttle handle and support handle with thumbs and fingers

tightly encircling the handles.

Keep a Solid Stance

• Maintain footing and balance at all times. Do not stand on slippery,

uneven or unstable surfaces. Do not work in odd positions or on ladders.

Do not over reach.

Avoid Hot Surfaces

• Keep exhaust area clear of flammable debris.

Avoid contact during and immediately after

operation.

X7732274700 11

© 12/2017 ECHO Inc.

Page 12

SAFETY GT-225SF

Equipment

Use only ECHO attachments. Serious injury may result from the

use of a non-approved attachment combination. ECHO, INC. will

not be responsible for the failure of cutting devices,

attachments or accessories which have not been tested and

approved by ECHO. Read and comply with all safety

instructions listed in this manual and safety manual.

◆ Check unit for loose or missing nuts, bolts, and screws.

Tighten or replace as needed.

◆ Inspect shield for damage and ensure that the cut-off knife

is securely in place. Replace if either is damaged or

missing.

◆ Check that the cutting attachment is firmly attached and in

safe operating condition.

◆ Check that handle and harness (if included)

are adjusted for safe, comfortable

operation. See Assembly Section for

proper adjustment.

Moving parts can amputate fingers or cause severe injuries.

Keep hands, clothing and loose objects away from all openings.

◆ ALWAYS stop engine, disconnect spark plug, and make

sure all moving parts have come to a complete stop before

removing obstructions, clearing debris, or servicing unit.

◆ DO NOT start or operate unit unless all guards and

protective covers are properly assembled to unit.

◆ NEVER reach into any opening while the engine is running.

Moving parts may not be visible through openings.

12 X7732274700

© 12/2017 ECHO Inc.

Page 13

GT-225SF EMISSION CONTROL

Periodically Check fuel system (fuel lines, vent, grommet, fuel

tank, and fuel cap) for leaks especially if the unit is dropped. If

damage or leaks are found, do not use unit, otherwise serious

personal injury or property damage may occur. Have unit

repaired by an authorized servicing dealer before using.

EMISSION CONTROL (EXHAUST &

EVAPORATIVE)

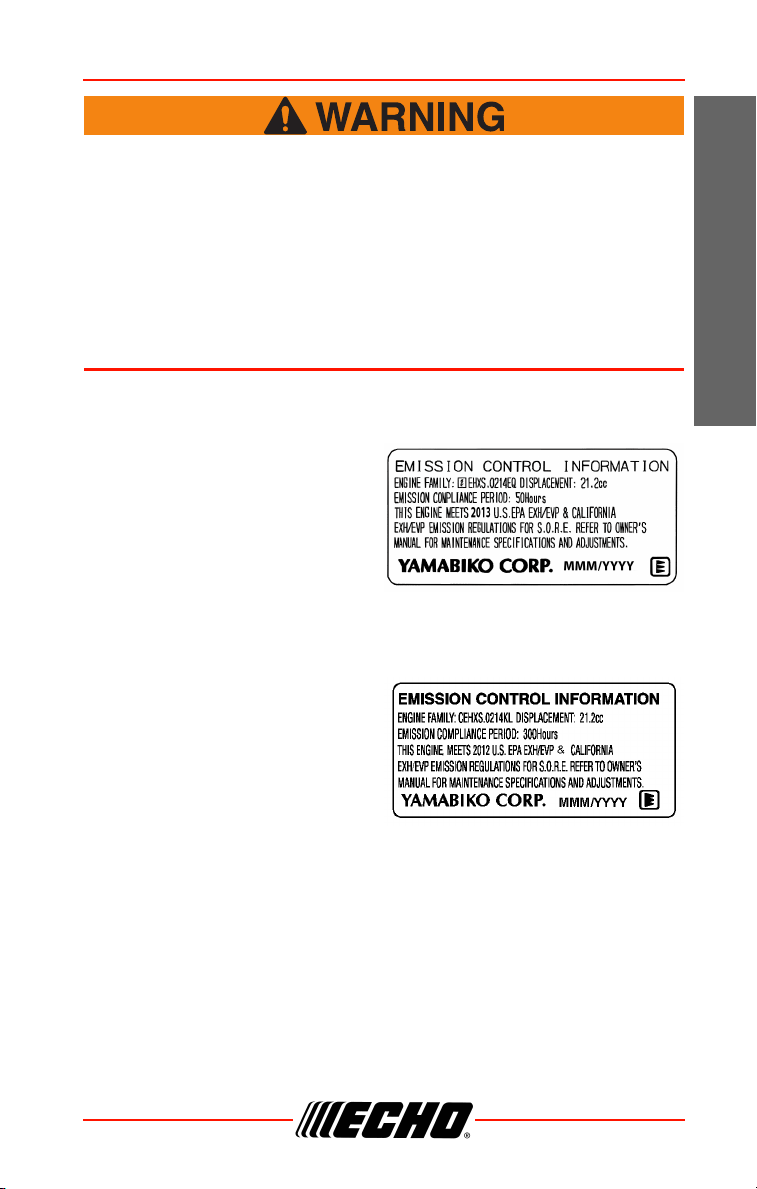

CARB And EPA Emissions Control Information

The emission control system for the

engine is EM (engine modification)

and, if the second to last character

of the Engine Family on the

Emission Control Information label

(sample below) is “B”, “C”, “K”, or

“T”, the emission control system is

EM and TWC (3-way catalyst). The

fuel tank/fuel line emission control

system is EVAP (evaporative emissions). Evaporative emissions for

California models are only applicable to fuel tanks.

ENGLISH

An Emission Control Label is

located on the engine. (This is an

EXAMPLE ONLY, information on

label varies by engine FAMILY).

Product Emission Durability

(Emission Compliance Period)

The 50 or 300 hour emission

compliance period is the time span selected by the manufacturer certifying

the engine emissions output meets applicable emissions regulations,

provided that approved maintenance procedures are followed as listed in

the Maintenance Section of this manual.

X7732274700 13

© 12/2017 ECHO Inc.

Page 14

DESCRIPTION GT-225SF

18

13

11

12

14

15

1

10

16

17

2

3

4

5

6

7

8

9

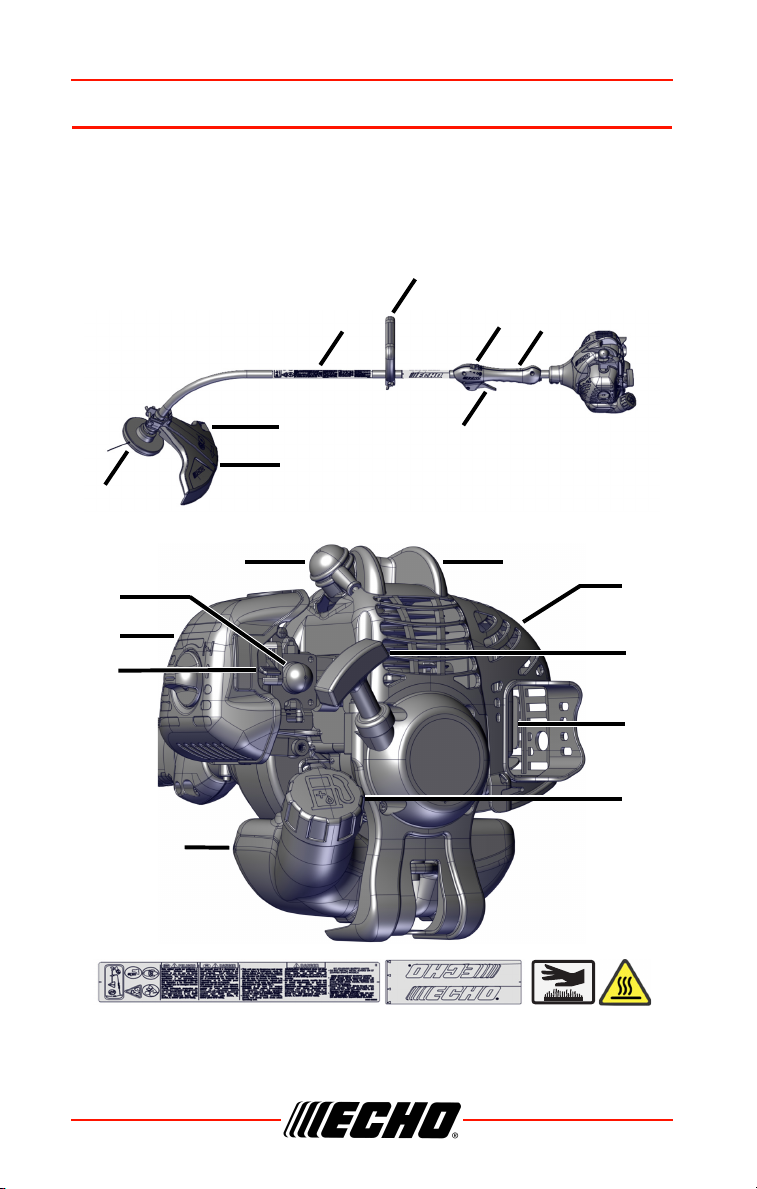

DESCRIPTION

Locate the safety decal(s) on your unit. Make sure the decal(s) is legible and

that you understand and follow the instructions on it. If a decal cannot be

read, a new one can be ordered from your ECHO dealer. The safety decal is

for example only. Your label may appear slightly different.

14 X7732274700

© 12/2017 ECHO Inc.

Page 15

GT-225SF DESCRIPTION

1. Power Head

2. Throttle Handle - For Right Hand

3. Stop Switch

4. Support Handle - For Left Hand

5. Drive Shaft Assembly

6. Nylon Cutter Head

7. Debris Shield with Cut-Off Knife

8. Cut-Off Knife

9. Throttle Trigger

10. Top Guard

11. Spark Arrestor Muffler or Spark Arrestor Muffler with Catalyst

12. Fuel Tank

13. Recoil Starter/Handle

14. Fuel Tank Cap

15. Purge Bulb

16. Choke

17. Air Cleaner

18. Spark Plug

ENGLISH

X7732274700 15

© 12/2017 ECHO Inc.

Page 16

CONTENTS GT-225SF

CONTENTS

The ECHO product you purchased has been factory pre-assembled for your

convenience. Due to packaging restrictions, some assembly may be

necessary.

After opening the carton, check for damage. Immediately notify your retailer

or ECHO Dealer of damaged or missing parts. Use the contents list to check

for missing parts.

1 Power Head / Drive Shaft Assembly

1 Operator’s Manual

1 Safety Manual

1 Warranty Statement

1 Safety Glasses

1 Echo Power Blend X™ 2-Stroke Oil Sample

12 Pieces of pre-cut Nylon Line

1 Shield Assembly

16 X7732274700

© 12/2017 ECHO Inc.

Page 17

GT-225SF ASSEMBLY

A

B

C

C

A

ASSEMBLY

Shield Installation

Parts Required: Shield Assembly.

Cut-off knife on debris shield has sharp edges. Avoid contact

when installing or removing line head.

Wear Gloves or personal injury may result:

◆ Cut-off knife is sharp.

◆ Gear case and surrounding area may be hot.

1. Remove wing nut (A), washer

(B), and bolt (C).

2. Snap the shield over the

bearing housing.

3. Install bolt (C), washer (B), and

wing nut (A).

Support Handle

Note: Label shows minimum

spacing for Support

Handle location.

ENGLISH

Note: Support Handle is pre-

installed. Repositioning and

tightening is all that is required.

X7732274700 17

© 12/2017 ECHO Inc.

Page 18

OPERATION GT-225SF

B

A

1. Position Support Handle (A) in

comfortable operating position

and tighten wing nut (B). The

cutting attachment should be 5

- 7.5 cm (2 - 3 in.) above the

ground and as level as

possible.

OPERATION

Moving parts can amputate fingers or cause severe injuries.

Keep hands, clothing and loose objects away from all openings.

Always stop engine, disconnect spark plug, and make sure all

moving parts have come to a complete stop before removing

obstructions, clearing debris, or servicing unit.

Engine exhaust IS HOT, and contains Carbon Monoxide (CO), a

poison gas. Breathing CO can cause unconsciousness, serious

injury, or death. Exhaust can cause serious burns. ALWAYS

position unit so that exhaust is directed away from your face

and body.

Operation of this equipment may create sparks that can start

fires around dry vegetation. This unit is equipped with a spark

arrestor to prevent discharge of hot particles from the engine.

Metal cutters can also create sparks if the cutter strikes rocks,

metal, or other hard objects. Contact local fire authorities for

laws or regulations regarding fire prevention requirements.

18 X7732274700

© 12/2017 ECHO Inc.

Page 19

GT-225SF OPERATION

Fuel

Diesel fuels and alternative fuels, such as E-15 (15% ethanol),

E-85 (85% ethanol) or any fuels not meeting ECHO requirements

are NOT approved for use in ECHO 2-stroke gasoline engines.

Use of diesel or alternative fuels may cause performance

problems, loss of power, overheating, fuel vapor lock, and

unintended machine operation, including, but not limited to,

improper clutch engagement. Diesel or alternative fuels may

also cause premature deterioration of fuel lines, gaskets,

carburetors and other engine components.

Fuel Requirements

Gasoline - Use 89 Octane [R+M/2] (mid grade or higher) gasoline known to

be good quality. Gasoline may contain up to 10% Ethanol (grain alcohol) or

15% MTBE (methyl tertiary-butyl ether). Gasoline containing methanol

(wood alcohol) is NOT approved. ECHO Red Armor

93 octane, ethanol-free fuel premixed with ECHO Red Armor

50:1 ratio. Use of ECHO Red Armor

to extend engine life in all air-cooled 2-stroke and 2/4-stroke hybrid engines.

Two Stroke Oil - A two-stroke engine oil meeting ISO-L-EGD (ISO/CD

13738) and J.A.S.O.

meet these standards. Engine problems due to inadequate lubrication

caused by failure to use an ISO-L-EGD (ISO/CD 13738) and J.A.S.O.

M345-

FD certified oil, such as Echo brand 2-stroke oils, will void the two-

stroke engine warranty.

FD Standards must be used. Echo brand 2-stroke oils

™

Fuel (Power Fuel™) is recommended

™

Fuel (Power Fuel™) is

™

engine oil at

ENGLISH

ECHO brand 2-stroke oils may be mixed at 50:1 ratio for application

in all ECHO engines sold in the past regardless of ratio specified in

those manuals.

Handling Fuel

Fuel is VERY flammable. Use extreme care when mixing, storing

or handling, or serious personal injury may result.

◆ Use an approved fuel container.

◆ DO NOT smoke near fuel.

X7732274700 19

© 12/2017 ECHO Inc.

Page 20

OPERATION GT-225SF

Fuel to Oil Mix – 50:1 Ratio

US Metric

Gas Oil Gas Oil

gal. fl.oz. L cc

12.65100

2 5.2 10 200

51325500

◆ DO NOT allow flames or sparks near fuel.

◆ Fuel tanks/cans may be under pressure. Always loosen

fuel caps slowly allowing pressure to equalize.

◆ NEVER refuel a unit when the engine is HOT or RUNNING!

◆ DO NOT fill fuel tanks indoors. ALWAYS fill fuel tanks

outdoors over bare ground.

◆ DO NOT overfill fuel tank. Wipe up spills immediately.

◆ Securely tighten fuel tank cap and close fuel container

after refueling.

◆ Inspect for fuel leakage. If fuel leakage is found, do not

start or operate unit until leakage is repaired.

◆ Move at least 3 m (10 ft.) from refueling location before

starting the engine.

Mixing Instructions

1. Fill an approved fuel container

with half of the required

amount of gasoline.

2. Add the proper amount of

2-stroke oil to gasoline.

3. Close container and shake to

mix oil with gasoline.

4. Add remaining gasoline, close

fuel container, and remix.

Spilled fuel is a leading cause of hydrocarbon emissions. Some

states may require the use of automatic fuel shut-off containers to

reduce fuel spillage.

• Empty the fuel tank prior to storing the unit. Return

unused fuel to an approved fuel storage container.

Storage - Fuel storage laws vary by locality. Contact your

local government for the laws affecting your area. As a

precaution, store fuel in an approved, airtight container.

Store in a well-ventilated, unoccupied building, away from

sparks and flames.

Stored fuel ages. Do not mix more fuel than you expect to use in thirty

(30) days, ninety (90) days when a fuel stabilizer is added.

20 X7732274700

© 12/2017 ECHO Inc.

Page 21

GT-225SF OPERATION

A

C

B

Stored two-stroke fuel may separate. ALWAYS shake fuel container

thoroughly before each use.

Used oil and gasoline, and soiled towels are hazardous waste

materials. Disposal laws vary by locality.

Starting Cold Engine

The attachment will operate immediately when the engine

starts, and could result in possible serious injury. Keep

movable parts of the attachment away from objects that could

become entangled or thrown, and surfaces that could cause

loss of control.

1. Stop Switch

Move stop switch (A) away from

the STOP position.

ENGLISH

2. Choke

Move choke (B) to COLD START

(

) (closed) position.

3. Purge Bulb

Pump purge bulb (C) until fuel is

visible and flows freely in the

clear fuel tank return line. Pump

bulb an additional 4 or 5 times.

4. Recoil Starter

X7732274700 21

© 12/2017 ECHO Inc.

Page 22

OPERATION GT-225SF

D

A

Lay the unit on a flat area and

keep movable attachment parts

clear of all obstacles. Firmly

grasp throttle handle with left

hand and fully depress throttle

trigger to wide open position.

Rapidly pull recoil starter

handle/rope (D) until engine

fires (or maximum five pulls).

5. Choke

After engine fires (or 5 pulls), move choke (B) to the RUN ( ) (open)

position. Firmly grasp throttle handle with left hand and fully depress

throttle trigger to wide open position. Pull starter handle/rope until engine

starts and runs. Release throttle trigger and allow unit to warm up at idle

for several minutes.

Note: If engine does not start with choke in “RUN” position after 5

pulls, repeat instructions 2 - 5.

6. Throttle Trigger

After engine warm-up, grip throttle handle and support handle. Gradually

depress throttle trigger to increase engine RPM to operating speed.

Starting Warm Engine

The starting procedure is the same as Cold Start except DO NOT close the

choke, and do not depress throttle trigger to wide open position.

The attachment should not move at idle, otherwise serious

personal injury may result.

Note: If attachment moves, readjust carburetor according to

“Carburetor Adjustment” instructions in this manual or see

your ECHO Dealer.

1. Stop Switch

Move stop switch (A) away from

the STOP position.

22 X7732274700

© 12/2017 ECHO Inc.

Page 23

GT-225SF OPERATION

C

D

A

2. Purge Bulb

Pump purge bulb (C) until fuel is

visible and flows freely in the

clear fuel tank return line. Pump

bulb an additional 4 or 5 times.

3. Recoil Starter

Lay the unit on a flat area and

keep movable attachment parts

clear of all obstacles. Firmly grip

throttle handle with left hand.

Rapidly pull recoil starter

handle/rope (D) until engine

fires.

Note: If engine does not start

after 5 pulls, use Cold

Start Procedure.

Stopping Engine

ENGLISH

If engine does not stop when stop switch is moved to STOP

position, close choke - COLD START position - to stall engine.

Have your ECHO dealer repair stop switch before using unit

again.

1. Throttle

Release throttle and allow engine to return to idle before shutting off

engine.

2. Stop Switch

Move stop switch (A) to STOP

position.

X7732274700 23

© 12/2017 ECHO Inc.

Page 24

MAINTENANCE GT-225SF

MAINTENANCE

Moving parts can amputate fingers or cause severe injuries.

Keep hands, clothing and loose objects away from all openings.

Always stop engine, disconnect spark plug, and make sure all

moving parts have come to a complete stop before removing

obstructions, clearing debris, or servicing unit. Allow unit to

cool before performing service. Wear gloves to protect hands

from sharp edges and hot surfaces.

Your ECHO unit is designed to provide many hours of trouble free service.

Regular scheduled maintenance will help your unit achieve that goal. If you

are unsure or are not equipped with the necessary tools, we recommend

that you take your unit to an ECHO Servicing Dealer for maintenance. To

help you decide whether you want to DO-IT-YOURSELF or have the ECHO

Dealer do it, each maintenance task has been graded. If the task is not

listed, see your ECHO Dealer for repairs.

Skill Levels

Level 1 = Easy to do. Common tools may be required.

Level 2 = Moderate difficulty. Some specialized tools may be required.

Level 3 = See your dealer.

Click HERE or go to http://www.echo-usa.com/products/maintenance-kit for

information on Maintenance Kits.

Moving parts can amputate fingers or cause severe injuries.

Keep hands, clothing and loose objects away from all openings.

Always stop engine, disconnect spark plug, and make sure all

moving parts have come to a complete stop before removing

obstructions, clearing debris, or servicing unit. Allow unit to

cool before performing service. Wear gloves to protect hands

from sharp edges and hot surfaces.

24 X7732274700

© 12/2017 ECHO Inc.

Page 25

GT-225SF MAINTENANCE

Your ECHO unit is designed to provide many hours of trouble free service.

Regular scheduled maintenance will help your unit achieve that goal. If you

are unsure or are not equipped with the necessary tools, we recommend

that you take your unit to an ECHO Servicing Dealer for maintenance. To

help you decide whether you want to DO-IT-YOURSELF or have the ECHO

Dealer do it, each maintenance task has been graded. If the task is not

listed, see your ECHO Dealer for repairs.

Skill Levels

Level 1 = Easy to do. Common tools may be required.

Level 2 = Moderate difficulty. Some specialized tools may be required.

Level 3 = See your dealer.

Click HERE or go to http://www.echo-usa.com/products/maintenance-kit for

information on Maintenance Kits.

Maintenance Intervals

ENGLISH

COMPONENT/SYSTEM

Daily or Before Use

Air Filter

Choke Shutter

Fuel System Inspect

Cooling System Inspect/Clean 2

Recoil Starter Rope Inspect/Clean*

Screws/Nuts/Bolts Inspect/Tighten/

Every Refuel

Fuel System Inspect

3 Months

MAINTENANCE

PROCEDURE

Inspect/Clean* 1

(2)

Replace*

(2)

REQURED

SKILL

LEVEL

1

1

1

X7732274700 25

© 12/2017 ECHO Inc.

Page 26

MAINTENANCE GT-225SF

COMPONENT/SYSTEM

Air Filter Replace*

Fuel Filter

Fuel Cap Gasket

Spark Plug

Muffler Spark Arrestor

Cylinder Exhaust Port Inspect/Clean/De-

Drive Shaft (Flex Cable Models) Grease

Gear Housing None –

Yearly

Fuel Filter Inspect/Replace*

Fuel Cap Gasket Replace*

IMPORTANT NOTE - Time intervals shown are maximum. Actual use and

your experience will determine the frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

1Apply lithium based grease every 25 hours of use.

2Low evaporative fuel tanks DO NOT require regular maintenance to

maintain emission integrity.

MAINTENANCE

PROCEDURE

Inspect*

Inspect/Clean/

Replace*

carbon

(1)

REQURED

SKILL

LEVEL

1

2

1

* Replacement is recommended based on the finding of damage or wear

during inspection.

Air Filter

Level 1.

Parts Required: Tune-Up Kit

1. Close choke (COLD START [ ] position). This prevents dirt from

entering the carburetor throat when the air filter is removed. Brush

accumulated dirt from air cleaner area.

26 X7732274700

© 12/2017 ECHO Inc.

Page 27

GT-225SF MAINTENANCE

2. Remove air filter cover. Brush

dirt from inside cover.

3. Replace filter if it is damaged,

fuel soaked, very dirty, or the

rubber sealing edges are

deformed.

• Lightly brush debris from filter.

• Soak heavily soiled filters in

water/detergent solution to

loosen dirt, then brush lightly.

• Rinse with clean water and allow to dry completely before reuse.

4. Install air filter in air filter case.

5. Install air filter cover.

Fuel Filter

Level 1.

Parts Required: Tune-Up Kit

Fuel is VERY flammable. Use extreme care when mixing, storing

or handling, or serious personal injury may result.

1. Use a clean rag to remove

loose dirt from around fuel cap

and empty fuel tank.

2. Pull the fuel filter from the fuel

tank.

ENGLISH

Do not damage fuel line while removing fuel filter from tank.

3. Remove the filter from the line and install the new filter.

X7732274700 27

© 12/2017 ECHO Inc.

Page 28

MAINTENANCE GT-225SF

0.65 mm (0.026 in.)

Note: Federal EPA regulations require all model year 2012 and later

gasoline powered engines produced for sale in the United

States to be equipped with a special low permeation fuel

supply hose between the carburetor and fuel tank. When

servicing model year 2012 and later equipment, only fuel

supply hoses certified by EPA can be used to replace the

original equipment supply hose. Fines up to $37,500.00 may

be enforced for using an non-certified replacement part.

Spark Plug

Level 2.

Parts Required: Tune-Up Kit

Use only NGK BPM8Y spark plug (BPMR8Y in Canada) otherwise

severe engine damage may occur.

1. Remove spark plug and check

for fouling, worn and rounded

center electrode.

2. Clean the plug or replace with a

new one. DO NOT sand blast to

clean. Remaining sand will

damage engine.

3. Adjust spark plug gap by

bending outer electrode.

4. Tighten spark plug to 150 - 170 kgf•cm (130 - 150 in•lbf).

Cooling System

Level 2.

To maintain proper engine operating temperatures, cooling air must

pass freely through the cylinder fin area. This flow of air carries

combustion heat away from the engine.

28 X7732274700

© 12/2017 ECHO Inc.

Page 29

GT-225SF MAINTENANCE

B

A

Overheating and engine seizure can

occur when:

• Air intakes are blocked,

preventing cooling air from

reaching the cylinder.

• Dust and grass build up on the

outside of the cylinder. This build

up insulates the engine and

prevents the heat from leaving.

Removal of cooling passage

blockages or cleaning of cooling fins is considered “Normal Maintenance.”

Any failure attributed to lack of maintenance is not warranted.

1. Remove spark plug lead.

2. Remove air cleaner cover (A).

3. Remove engine cover (B).

ENGLISH

DO NOT use a metal scraper to remove dirt from the cylinder fins.

4. Use a brush to remove dirt from

the cylinder fins.

5. Remove ignition wires from clip

for cleaning.

X7732274700 29

© 12/2017 ECHO Inc.

Page 30

MAINTENANCE GT-225SF

C

F

D

E

6. Remove grass and leaves from

the grid between the recoil

starter and fuel tank.

7. Assemble components in

reverse order.

Exhaust System

Spark Arrestor Screen

Level 2.

Parts Required: Spark Arrestor Screen, Gasket

1. Remove spark plug lead and engine cover.

2. Place piston at Top Dead Center (TDC) to prevent carbon/dirt from

entering cylinder.

3. Remove spark arrestor screen

cover (C), gaskets (D), (E), and

screen (F), from muffler body.

4. Clean carbon deposits from

muffler components.

Note: When cleaning carbon

deposit, be careful not to

damage the catalytic

element inside muffler.

5. Replace screen if it is cracked,

plugged, or has holes burned

through.

6. Assemble components in

reverse order.

Exhaust Port Cleaning

Level 2.

Parts Required: As needed: Heat Shield

1. Remove spark plug lead from spark plug, and remove engine cover.

30 X7732274700

© 12/2017 ECHO Inc.

Page 31

GT-225SF MAINTENANCE

B

A

C

C

2. Place piston at top dead center.

Remove muffler (A) and heat

shield (B).

3. Use a wood or plastic scraping

tool to clean deposits from

cylinder exhaust port (C).

ENGLISH

Never use a metal tool to scrape carbon from the exhaust port. Do

not scratch the cylinder or piston when cleaning the exhaust port. Do

not allow carbon particles to enter the cylinder.

4. Inspect heat shield, and replace if damaged.

5. Install heat shield and muffler.

6. Tighten muffler mounting bolts (or nuts) to 90 - 110 kgf•cm (80 - 95

in•lbf).

7. Install engine cover and attach spark plug lead.

8. Start engine, and warm to operating temperature.

9. Stop engine, and re-tighten mounting bolts (or nuts) to specifications.

Carburetor Adjustment

Level 2.

X7732274700 31

© 12/2017 ECHO Inc.

Page 32

MAINTENANCE GT-225SF

A

A

Engine Break-In

New engines must be operated a minimum duration of two tanks of fuel

break-in before carburetor adjustments can be made. During the break-in

period your engine performance will increase and exhaust emissions will

stabilize. Idle speed can be adjusted as required.

High Altitude Operation

This engine has been factory adjusted to maintain satisfactory starting,

emission, and durability performance up to 330 m (1100 ft.) above sea level

(ASL) (96.0 kPa). To maintain proper engine operation and emission

compliance above 330 m (1100 ft.) ASL the carburetor

adjusted by an authorized ECHO service dealer.

If the engine is adjusted for operation above 330 m (1100 ft.) ASL, the

carburetor must be re-adjusted when operating the engine below

330

m (1,100 ft.) ASL, otherwise severe engine damage may result.

Note: Every unit is run at the factory and the carburetor is set in

compliance with emission regulations. Carburetor

adjustments, other than idle speed, must be performed by an

authorized ECHO dealer.

1. Check idle speed and reset if

necessary. If a tachometer is

available, idle speed screw (A)

should be set to the

specifications found on

“Specifications” page of this

manual. Turn idle screw (A)

clockwise to increase idle

speed; counterclockwise to

decrease idle speed.

may need to be

When carburetor adjustment is completed, the cutting

attachment should not move at idle, otherwise serious personal

injury may result.

32 X7732274700

© 12/2017 ECHO Inc.

Page 33

GT-225SF MAINTENANCE

A

B

C

Lubrication

Level 1.

Parts Required: Lithium Based Grease.

1. Remove shield.

2. Loosen bearing housing locating screw (A), at the top of the housing,

loosen mounting screw (B) and remove gear case from drive housing.

3. Pull the flexible drive shaft (C)

from the drive housing, wipe

clean and apply 15 ml (0.5 oz.)

of grease.

4. Slide the flexible drive shaft

back in the drive housing being

careful not to get dirt on the

flexible drive shaft.

5. Install the bearing housing and

shield.

Nylon Line Replacement

Wear gloves or personal injury may result:

◆ Cutoff knife is sharp.

◆ Gearcase and surrounding area may be hot.

ENGLISH

1. Cut one piece of line to

recommended length.

2.0 mm (0.080 in.) diameter

6 m (20 ft.).

2.4 mm (0.095 in.) diameter

6 m (20 ft.).

2. Align arrows on top of knob with

openings in eyelets.

X7732274700 33

© 12/2017 ECHO Inc.

Page 34

MAINTENANCE GT-225SF

3. Insert one end of trimmer line

into an eyelet, and push line

equal distance through trimmer

head.

4. Hold trimmer head while

turning knob clockwise to wind

line onto spool until about 13

cm (5

in.) of each line remains

exposed.

Trimmer head is now fully loaded

and ready for operation.

When the wear indicators

located at the bottom of the

Speed-Feed® head are worn

smooth, or if holes appear,

replacement of the cover or the

entire Speed-Feed® head is

required.

Nylon Line Head Disassembly Instructions

Note: For normal use, Speed Feed® head disassembly is not

necessary. However, if circumstances require disassembly,

follow these instructions.

34 X7732274700

© 12/2017 ECHO Inc.

Page 35

GT-225SF TROUBLESHOOTING

B

A

C

1. Press top of locking tabs (A) on

both sides of Speed Feed®

head to release cover (B) from

eyelet carrier (C).

2. Remove cover from eyelet

carrier.

TROUBLESHOOTING

Fuel vapors are extremely flammable and may cause fire and/or

explosion. Never test for ignition spark by grounding spark plug

near cylinder plug hole, otherwise serious personal injury may

result.

ENGLISH

ENGINE PROBLEM TROUBLESHOOTING CHART

Problem Check Status Cause Remedy

Engine

starts

hard

or Engine

does not

start

Fuel at

carburetor

No fuel at

carburetor

Fuel strainer or

fuel line

obstructed

Clean or replace

See your Echo

dealer

X7732274700 35

© 12/2017 ECHO Inc.

Page 36

TROUBLESHOOTING GT-225SF

ENGINE PROBLEM TROUBLESHOOTING CHART

Problem Check Status Cause Remedy

No fuel at

cylinder

Carburetor

See your Echo

dealer

OPEN choke

Engine

starts

hard

or

Engine

does not

start

Engine

runs, but

dies

or

Engine

does not

acceler

ate

properly

Engine

does not

crank

Fuel at

cylinder

Spark at

end of plug

wire

Spark at

plug

Air filter Air filter dirty Normal wear Clean or replace

Fuel filter Fuel filter dirty

Fuel vent

Spark plug

Carburetor

Cooling

system

Spark arrestor screen

N/A

Muffler wet

with fuel

No spark

Fuel vent

plugged

Plug dirty or

worn

Improper

adjustment

Cooling

system dirty

or plugged

Spark arrestor screen

plugged

Fuel mixture

too rich

Stop switch

OFF - Electrical

problem - Interlock switch

Incorrect gap Covered with

carbon - Fouled

with fuel - Plug

defective

Contaminants

or residue in

fuel

Contaminated

fuel

Normal wear

Vibration Adjust

Extended operation in dirty or

dusty locations

Normal wear Replace

Internal engine

problem

Clean or replace

air filter

Adjust carburetor

See your Echo

dealer

Turn switch to ON

See your Echo

dealer

Adjust to 0.65mm

(0.026 in.)

Clean or replace

plug

Replace filter or

replace fuel

Clean or replace

Clean and adjust

or replace

Clean

See your Echo

dealer

36 X7732274700

© 12/2017 ECHO Inc.

Page 37

GT-225SF STORAGE

STORAGE

During operation the muffler or catalytic muffler and

surrounding cover become hot. Always keep exhaust area clear

of flammable debris during transportation or when storing,

otherwise serious property damage or personal injury may

result.

Long Term Storage (Over 30 Days)

Do not store your unit for a prolonged period of time (30 days or longer)

without performing protective storage maintenance which includes the

following:

1. Store unit in a dry, dust free place, out of the reach of children.

Do not store in enclosure where fuel fumes may accumulate or

reach an open flame or spark.

2. Place the stop switch in the “OFF” position.

3. Remove accumulation of grease, oil, dirt and debris from exterior of

unit.

4. Perform all periodic lubrication and services that are required.

5. Tighten all the screws and nuts.

6. Drain fuel tank completely. Press purge bulb 6 - 7 times to remove

remaining fuel from carburetor then drain the tank again. Close choke,

start and run the engine until it stops due to lack of fuel.

7. Allow engine to cool. Remove the spark plug lead from the spark plug.

Remove the spark plug. Pour 7 cc (0.25

engine oil into the cylinder through the spark plug hole.

8. Pull the recoil starter handle 2 - 3 times to distribute the oil inside the

engine.

9. Observe the piston location through the spark plug hole. Pull the recoil

handle slowly until the piston reaches the top of its travel and leave it

there.

10. Install the spark plug. Connect the spark plug lead to the spark plug.

oz.) of fresh, clean, two-stroke

ENGLISH

X7732274700 37

© 12/2017 ECHO Inc.

Page 38

SPECIFICATIONS GT-225SF

SPECIFICATIONS

MODEL GT-225SF

Length 1370 mm (53.9 in.)

Width 315 mm (12.4 in.)

Height 540 mm (21.3 in.)

Weight (dry) w/o Cutter

Head

Engine Type

Bore 32.2 mm (1.27 in.)

Stroke 26.0 mm (1.02 in.)

Displacement 21.2 cc (1.29 cu. in.)

Exhaust

Carburetor Diaphragm w/purge pump

Ignition System Flywheel magneto, capacitor discharge ignition type

Spark Plug

Fuel Mixed (Gasoline and Two-stroke Oil)

Fuel/Oil Ratio

Gasoline

Oil

Fuel Tank Capacity 420 mL (14.2 US fl. oz.)

Starter System Automatic Rewind Starter

Clutch Centrifugal Type

Drive Shaft 6 mm (1/4 in.) flexible shaft

Rotating Direction Clockwise; viewed from top

Cutter Head

Handles Support Handle, Throttle Handle

Shoulder Harness Optional P / N 99944200201

4.1 kg (9.04 lb.)

Air cooled, two-stroke, single cylinder gasoline

engine

Spark arrestor muffler or spark arrestor muffler with

catalyst

NGK BPM8Y (BPMR8Y in Canada)(Gap 0.65 mm

[0.026 in.])

50 : 1 Power Blend XTM or ECHO Red Armor® ISOL-EGD (ISO/CD 13738) and J.A.S.O. M345two-stroke, air-cooled engine oil.

Use 89 Octane unleaded. Do not use fuel containing

methyl alcohol, more than 10% ethyl alcohol or 15%

MTBE. Do not use alternative fuels such as E-15 or

E-85.

Power Blend XTM or ECHO Red Armor® Premium

Universal 2-Stroke Oil

Speed Feed® Nylon line head, Line capacity 6.0 m

(20 ft.) .080 or .095 line

FD,

38 X7732274700

© 12/2017 ECHO Inc.

Page 39

GT-225SF SPECIFICATIONS

MODEL GT-225SF

Idle Speed 3,000 RPM

Clutch Engagement Speed 4,300 RPM

Wide Open Throttle Speed

(W.O.T.)

7,800 RPM

ENGLISH

X7732274700 39

© 12/2017 ECHO Inc.

Page 40

PRODUCT REGISTRATION GT-225SF

PRODUCT REGISTRATION

Thank you for choosing ECHO Power Equipment

Please go to http://www.echo-usa.com/Warranty/Register-Your-ECHO to

register your new product on-line. It's FAST and EASY! NOTE: your

information will never be sold or misused by ECHO, Inc. Registering your

purchase enables us to contact you in the unlikely event of a service update

or product recall, and verifies your ownership for warranty consideration.

If you do not have access to the Internet, you can complete the form below

and mail to:

ECHO Inc., Product Registration, PO Box 1139, Lake Zurich IL 60047.

40 X7732274700

© 12/2017 ECHO Inc.

Page 41

GT-225SF PRODUCT REGISTRATION

ENGLISH

X7732274700 41

© 12/2017 ECHO Inc.

Page 42

NOTES GT-225SF

NOTES

42 X7732274700

© 12/2017 ECHO Inc.

Page 43

GT-225SF NOTES

ENGLISH

X7732274700 43

© 12/2017 ECHO Inc.

Page 44

T98514001001 - T98514999999

ECHO, INCORPORATED

400 Oakwood Road

Lake Zurich, IL 60047

www.echo-usa.com

Loading...

Loading...