Eaton SC-UN-FT Installation Manual

Installation Instructions

Model # SC-UN-FT

Universal Source Controller - Feed Through

INS #

Contents

Contents

Description Page

Introduction ...................................................................3

Welcome ...................................................................3

Range Overview ..............................................................3

Cabinet Dimensions .........................................................3

Specifications ................................................................5

Safety .......................................................................5

Please Read this First. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Important Points for Consideration ...............................................5

Ambient Atmosphere Requirements ............................................6

Mounting ..................................................................... 6

Location and Spacing ..........................................................6

Mounting Holes ..............................................................7

Standard Weights ........................................................... 7

Accessing the Mounting Holes .................................................8

Supply Wiring ................................................................. 8

Wiring Flow ................................................................. 8

Single Phase Supply ...........................................................9

Connecting the Supply ....................................................... 9

Max. Wire Gauge for Input Lugs (1 Phase) .......................................9

Three Phase Supply ...........................................................9

Connecting the Supply ....................................................... 9

Max. Wire Gauge for Input Lugs (3 Phase) .......................................9

Phase Distribution to Circuits ................................................. 10

Supply to Internal Circuitry ................................................... 10

Load Wiring .................................................................. 10

High Voltage Load Wiring ......................................................10

Total Load Per Channel ...................................................... 11

Load Wire Gauges ......................................................... 11

Earth Connections .......................................................... 11

High Voltage Load Wiring Flows ................................................. 11

Typical Load Connections .................................................... 11

Low Voltage Load Wiring ...................................................... 12

Low Voltage Load Wiring Flows ............................................... 12

Indicators ................................................................. 12

Control Wiring ................................................................ 13

Multiple Control Protocols ..................................................... 13

Termination ............................................................... 13

Control Panel Operation ........................................................ 14

Using The Control Panel ....................................................... 14

Accessing the Operation Menu ............................................... 15

Menu Navigation ........................................................... 15

Overriding Channels ........................................................ 15

Setting the Time and Date ...................................................15

Viewing Power Data Readings ................................................ 16

2

Universal Source Controller - Feed Through

Introduction

Introduction

Welcome

The iLumin Universal Source Controller range from Eaton’s

Cooper Controls Business has been designed to provide

maximum flexibility in both installation and operation.

Every model in the range can accept a variety of industry

standard control options, from iCANbus to DMX, from

ethernet to RS-485. Similarly, every model can drive a wide

range of lighting loads, from incandescents to dimmable

fluorescents, from non-dim apparatus to DALI digital

modules.

Much care and attention has been applied to the installation

and maintenance of the Universal Source Controllers.

Each model provides clear, logical cable routing and every

high voltage channel is controlled by an individual, easy to

replace dimmer card.

Range Overview

Each model is specified using a part number in the following

format:

SC 120 06 UN 1P FT

Product

SC = Source Controller

Panel Feed

FT = Feed Through

Cabinet Dimensions

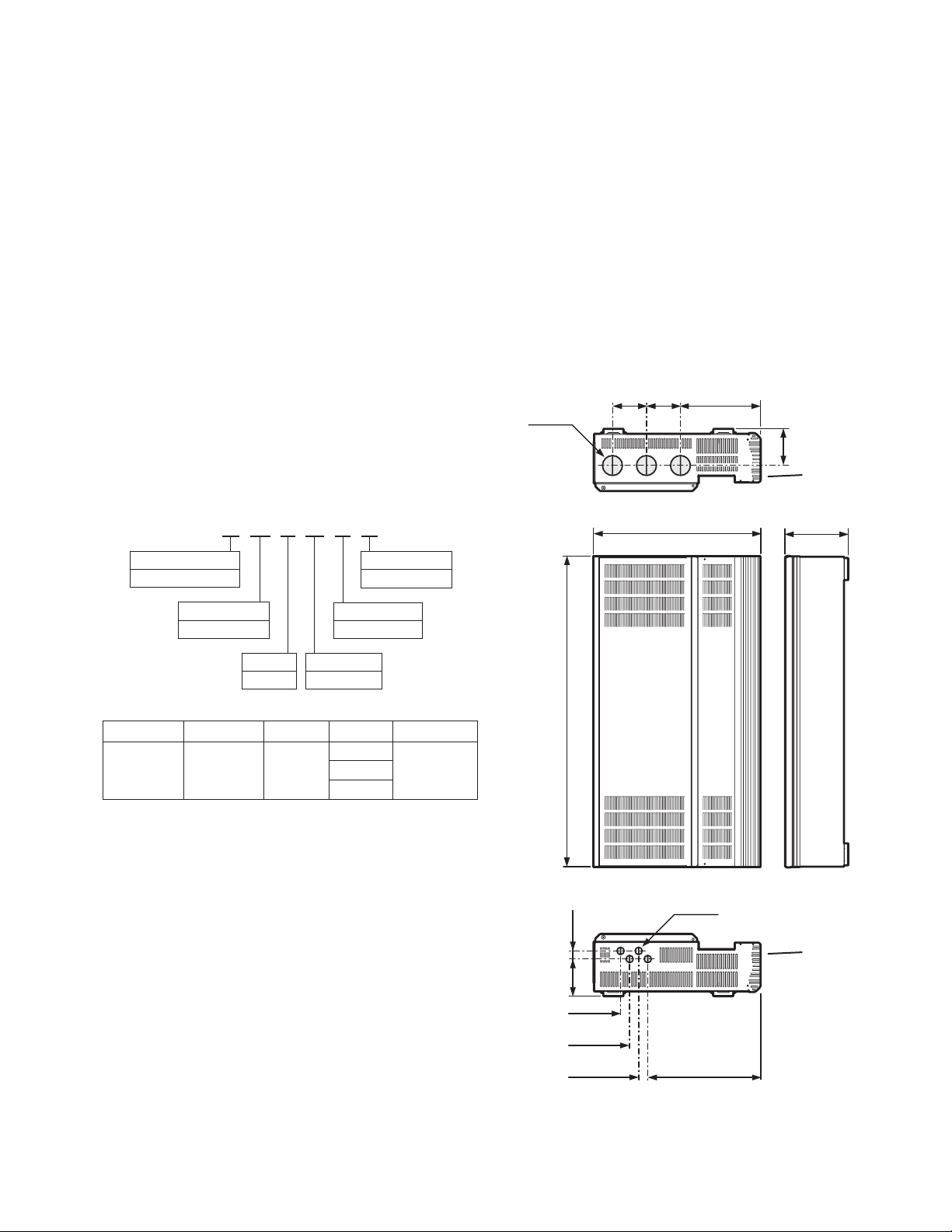

Three overall cabinet sizes are available as shown on this

and the following pages.

6 Circuit Cabinet

Weight

Packed: 100 lbs (45 Kg)

Unpacked: 88 lbs (40 Kg)

9.78 in.

(248.5 mm)

4.13 in.

(105 mm)

20.3 in.

(517 mm)

(105 mm)

4.45 in.

(113 mm)

Knockouts for

Supply and Load

Wiring Only

7.6 in.

(193 mm)

4.13 in.

Ø 2.42 in.

61.5 mm

Supply Voltage

277-120 to 277 VAC

Channels

06, 12, 24

Model Number Supply Voltage Supply Type Circuits Maximum Load

SC277-06-UN-1P-FT

SC277-12-UN-1P-FT

SC277-24-UN-3P-FT

120 to 277 VAC 1 Phase

Supply Type

1P = Single Phase

Type

UN = Universal

6

16A per Channel12

24

0.98 in.

(25 mm)

4.53 in.

(115 mm)

37.2 in.

(945 mm)

1.1 in.

(28 mm)

1.1 in.

(28 mm)

1.1 in.

(28 mm)

Ø 0.89 in.

(22.5 mm)

Knockouts for

Low Voltage

Control Wiring

Only

13.76 in.

(349.5 mm)

Universal Source Controller - Feed Through

3

Introduction

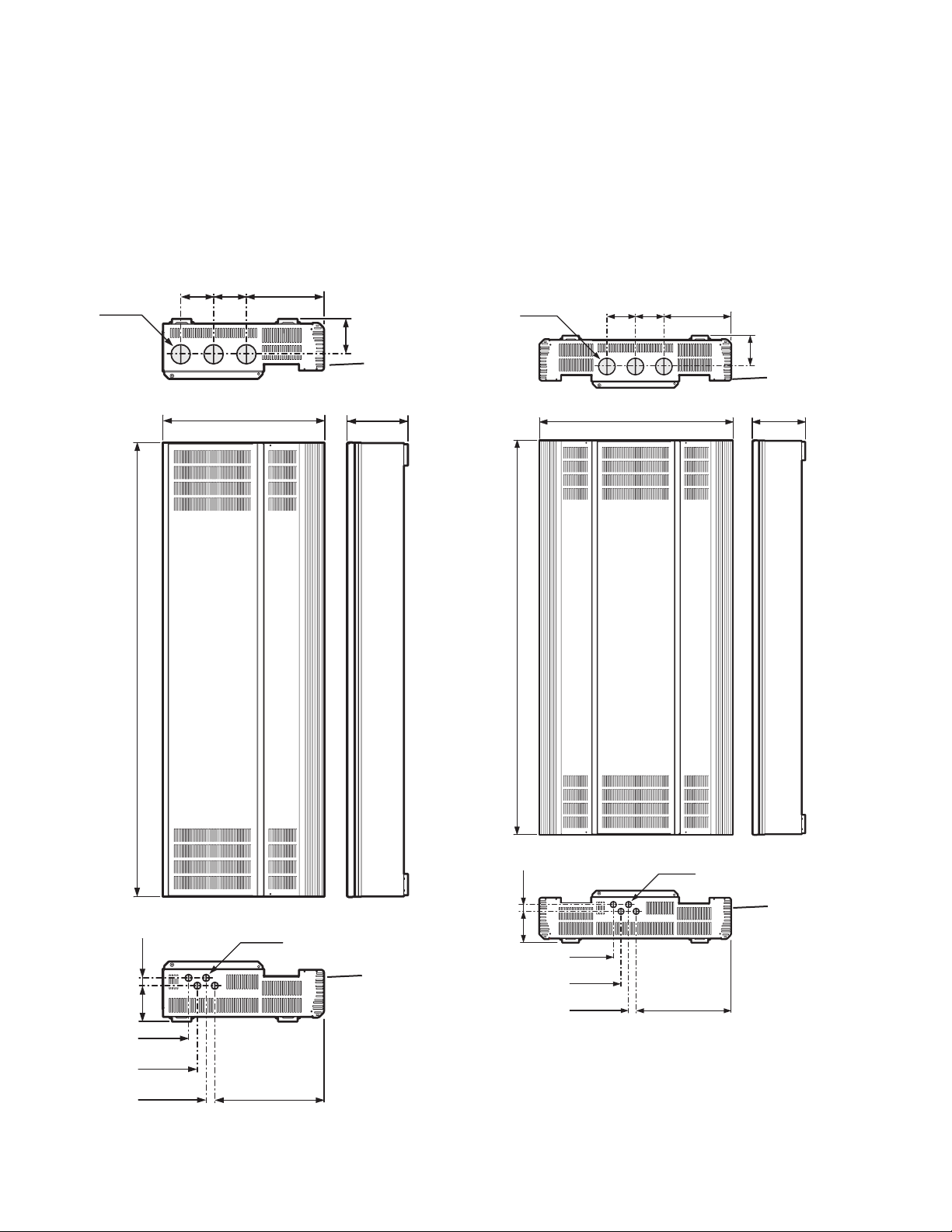

12 Circuit Cabinet

Weight

Packed: 160 lbs (72 Kg)

Unpacked: 132 lbs (60 Kg)

4.13 in.

(105 mm)

Ø 2.42 in.

61.5 mm

(517 mm)

4.13 in.

(105 mm)

20.3 in.

9.78 in.

(248.5 mm)

4.45 in.

(113 mm)

Knockouts for

Supply and Load

Wiring Only

7.6 in.

(193 mm)

24 Circuit Cabinet

Weight

Packed (24): 220 lbs (100 Kg)

Unpacked (24): 200 lbs (90 Kg)

4.13 in.

Ø 2.42 in.

61.5 mm

(105 mm)

4.13 in.

27.8 in.

(707 mm)

9.78 in.

(248.5 mm)

(105 mm)

4.45 in. (113 mm)

Knockouts for

Supply and Load

Wiring Only

7.6 in.

(193 mm)

0.98 in.

(25 mm)

4.53 in.

(115 mm)

56.7 in.

(1440 mm)

1.1 in.

(28 mm)

1.1 in.

(28 mm)

1.1 in.

(28 mm)

Ø 0.89 in.

(22.5 mm)

13.76 in.

(349.5 mm)

Knockouts for

Low Voltage

Control Wiring

Only

0.98 in.

(25 mm)

4.53 in.

(115 mm)

56.7 in.

(1440 mm)

1.1 in.

(28 mm)

1.1 in.

(28 mm)

1.1 in.

(28 mm)

Ø 0.89 in.

(22.5 mm)

Knockouts for

Low Voltage

Control Wiring

Only

13.76 in.

(349.5 mm)

4

Universal Source Controller - Feed Through

Safety

Specifications

The numerous models within the Universal Source

Controller range share the following key specifications.

Information specific to each cabinet model are provided

elsewhere throughout this guide.

All channels provide switched (non-dim) and dimmed high

voltage load control as standard

Leading-edge triac dimmer engines capable of

withstanding repetitive inrush currents of 50 times

operating current without impacting lifetime

All dimming and switching circuitry for every channel

located on individual boards for quick and easy swap-out,

if necessary

Voltage and frequency compensation to maintain light

level during supply fluctuations

Power monitoring for each circuit and the total panel

Bypass jumpering fitted as standard to protect circuits

and allow work lighting during installation

Selectable low voltage load control available per channel

for dimmable ballast control

Low maintenance and quiet operation thanks to fanless,

convection cooled operation

Support for multiple control protocols: iCAN for links

to multiple control sources; DMX512A for links with

entertainment systems; RS-485 for integration with

building management schemes and ethernet for

connection to a variety of systems

Dual volt-free switch inputs, with programmable

responses, for integration with emergency control

devices, building management systems, etc

Compact wall mounted design with easy access to all

internal items and lockable front panel door for added

security

Intuitive control panel provides straightforward

programming and configuration of the system. The control

panel allows a base level installation to be configured

without the use of separate PC programming

Safety

Please Read This First

The Universal Source Controllers are designed, built and

tested to strict safety regulations. By following the steps

listed below and elsewhere within this guide, you can

ensure safe installation and operation of these controller

units.

The Universal Source Controllers must be installed only

by a qualified electrician

The installation must comply with the appropriate

electrical codes and regulations in force in your area

The Universal Source Controllers are designed for indoor

installation and use only. The units can, however, be used

to control appropriately certified exterior lighting fixtures

Ensure that all wiring used conforms fully to local

specifications and is sufficiently rated for the installation

All new wiring must be fully verified before applying power

The high voltage supply should be fed to the Universal

Source Controller via an external isolation breaker with

sufficient capacity for the planned installation

All Universal Source Controllers exceed the weight limit

for one person lifting - always use at least two people

when lifting and mounting the units

Do not mix load types within a single channel (e.g. 120V

tungsten and low voltage ballast control)

Ensure that the supply is fully isolated at an external

breaker before removing the chassis covers. Test that

power has been removed before starting to handle

conductors

Ensure that high voltage and low voltage wiring remains

separate

Each dimmer channel should be protected by its own

dedicated external circuit breaker.

Important Points For Consideration

The Universal Source Controllers must be mounted flush

with the wall, do not recess the controller chassis

Upper and lower raceways must not be located within

8 inches (200 mm) of the upper and lower panels of the

Universal Source Controller. Use suitable conduits and

couplers to link the raceways to the controller chassis

Allow adequate space for future maintenance of the unit.

Do not install in a location that will later be difficult to

access

The Universal Source Controllers are designed to be

mounted vertically

During operation, the Universal Source Controllers

will produce audible noise caused by electrical noise

suppression circuitry and also the circuit relays within

the unit. The noise is a low level buzz that varies with

the level of dimming and also clicks when relays are

energised. Take these matters into consideration when

deciding on a suitable mounting position.

Universal Source Controller - Feed Through

5

Mounting

The hinged cover must be unscrewed and removed from

the front cover when the Universal Source Controller

operates at full load in a high ambient environment

Ambient Atmosphere Requirements

Temperature 320 F to 1040 F (00 C to +400 C)

Humidity 0 to 95% non-condensing

Mounting

Location and Spacing

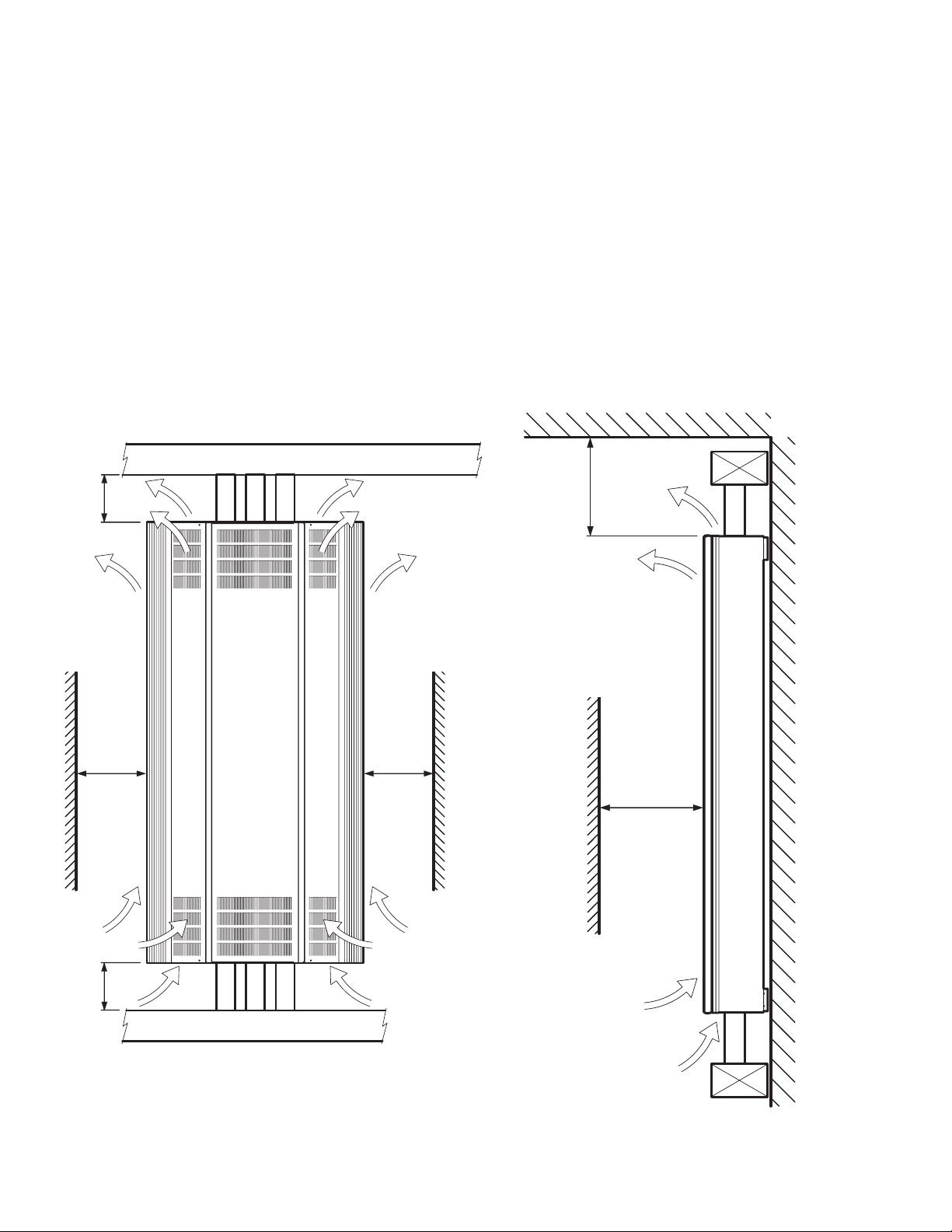

The Universal Source Controller models are all fully

convection cooled, therefore it is vitally important to ensure

that each unit is installed in a ventilated location that

permits sufficient airflow and provides the correct ambient

conditions.

Ensure that the minimum distances to walls and other

equipment shown in the diagrams below are maintained.

Also ensure that the stated ambient atmosphere

requirements are not exceeded.

Refer to ‘Important points for consideration’ when choosing

a mounting location.

8 in.

(200 mm)

Minimum

(130 mm)

Minimum

5 in.

Upper Raceway

Airflow

5 in.

(130 mm)

Minimum

14 in.

(360 mm)

Minimum

Distance

to Ceiling

14 in.

(360 mm)

Minimum

for Door

Access and

Cooling

8 in.

(200 mm)

Minimum

6

Airflow

Lower Raceway

Universal Source Controller - Feed Through

Airflow

Loading...

Loading...