Page 1

Strata 128Strata 128

Strata 128

Strata 128Strata 128

Strata 128 PlusStrata 128 Plus

Strata 128 Plus

Strata 128 PlusStrata 128 Plus

Strata 128 PorStrata 128 Por

Strata 128 Por

Strata 128 PorStrata 128 Por

INSTINST

INST

INSTINST

StrataVStrataV

StrataV

StrataVStrataV

ALLAALLA

ALLA

ALLAALLA

TION AND OPERATION AND OPERA

TION AND OPERA

TION AND OPERATION AND OPERA

INSTRINSTR

INSTR

INSTRINSTR

UCTIONSUCTIONS

UCTIONS

UCTIONSUCTIONS

1

iewiew

iew

iewiew

tabletable

table

tabletable

TIONTION

TION

TIONTION

®

Page 2

TABLE OF CONTENTSTABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

INTRODUCTION..............................................................................................3

SPECIFICATIONS ...........................................................................................3

INSTALLATION -Transducer ........................................................................... 5

POWER CONNECTIONS ...............................................................................13

BRACKET INSTALLATION ............................................................................14

PORTABLE ASSEMBLY ................................................................................15

SPEED/TEMP SENSORS ..............................................................................16

KEYBOARD BASICS ......................................................................................20

DISPLAY .........................................................................................................2 0

OPERATION ................................................................................................... 2 1

MENUS ...........................................................................................................21

AUTOMATIC ................................................................................................... 2 1

RANGE ...........................................................................................................2 1

ZOOM .............................................................................................................2 2

SENSITIVITY ..................................................................................................24

GRAYLINE® ...................................................................................................24

FISH ID ...........................................................................................................25

FISH TRACK™ ...............................................................................................26

TARGET TRACK ............................................................................................26

CHART SPEED ..............................................................................................27

DISPLAY MODE .............................................................................................28

ALARMS .........................................................................................................3 2

BACK LIGHT...................................................................................................33

FEET/METER .................................................................................................33

DISPLAY CONTRAST ....................................................................................33

ASP (Advanced Signal Processing) ...............................................................34

SIMULATOR ...................................................................................................34

TROUBLESHOOTING .................................................................................... 35

WARRANTY ...................................................................................................38

Copyright © 1998, Eagle ElectronicsCopyright © 1998, Eagle Electronics

Copyright © 1998, Eagle Electronics

Copyright © 1998, Eagle ElectronicsCopyright © 1998, Eagle Electronics

All features and specifications in this manual are subject to change

without notice.

All screens in this manual are simulated.

Eagle Electronics

PO Box 669

Catoosa, OK 74015

2

Page 3

INTRODUCTION

Thank you for purchasing an Eagle sonar. Your sonar unit is a high quality

sonar designed for both professional and novice fishermen. All of our

sonars have an automatic feature that finds and displays the bottom, fish,

structure, and more! All you have to do is press the on key. However, if

you wish to fine tune the unit, all you have to do is press the menu key. The

Strata series has powerful features available through easy-to-use menus.

To get started with your Eagle unit, first read the installation section. This

is where it all begins. Improper installation can cause problems down the

road. After you’ve read the instructions, install the unit, then read the rest

of the manual. The more you know about your unit, the better it will perform

for you. Take this manual for reference when you head for the water.

SPECIFICATIONS

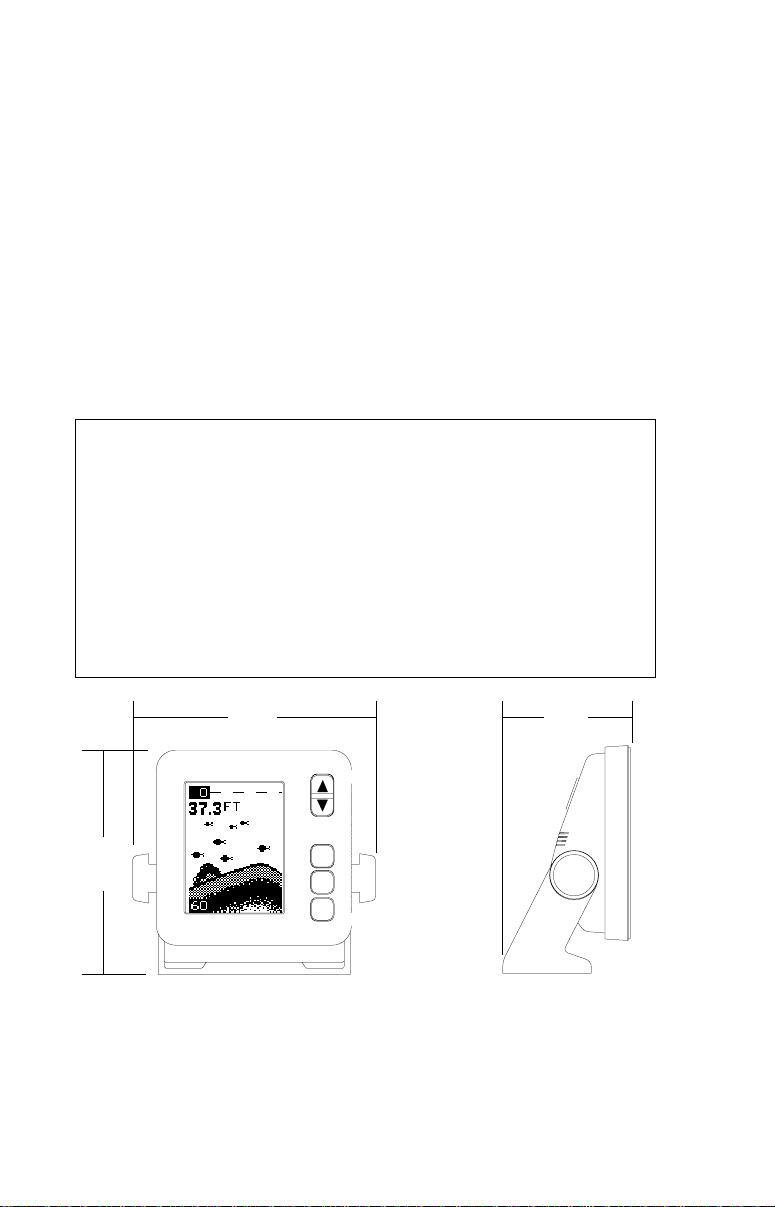

Dimensions ...................... 5.9" W x 5.35" H x 3.4" D

Input Voltage .................... 10 - 15 vDC

Current Drain ................... 350 ma (lights off)

........................... 500 ma (lights on)

Transmitter

Frequency.......... 192 kHz

Output Power..... 275 watts (peak-to-peak) (typical)

........................... 34.4 watts (RMS)

Display ........................... 128 pixels (H) x 65 pixels (W)

........................... Supertwist Liquid Crystal Display

5.9" 3.4"

5.35"

NOTICE!

The storage temperature for your unit is from -4 degrees to +167 degrees

Fahrenheit (-20 degrees to +75 degrees Celcius). Extended storage in temperatures higher or lower than specified will damage the liquid crystal display in your

unit. This type of damage is not covered by the warranty. For more information,

contact the factory customer service department or your local service center.

3

Page 4

Transducer Installation

The transducer included with your sonar is a transom mount transducer

The “kick-up” mounting bracket helps prevent damage if the transducer

strikes an object while the boat is moving. If the transducer does “kickup”, the bracket can easily be pushed back in place without tools.

Read this manual carefully before attempting the installation. Determine

which of the mounting positions is right for your boat. Use extreme care

if mounting the transducer inside the hull, since once it is epoxied into

position, the transducer usually cannot be removed. Remember, the

transducer location is the most critical part of a sonar installation.

Location - General

1. The transducer must be placed in a location that has a smooth flow of

water at all times. If the transducer is to be mounted inside the hull,

then the chosen location must be in the water at all times. If the

transducer is not placed in a smooth flow of water, interference will

show on the sonar’s display in the form of random lines or dots

whenever the boat is moving.

2. The transducer should be installed with it’s face pointing straight

down, if possible.

3. If the transducer is mounted on the transom, make certain it doesn’t

interfere with the trailer or hauling of the boat. Also, don’t mount it

closer than approximately one foot from the engine’s lower unit. This

will prevent cavitation interference with the propeller. Typically, the

transducer should be mounted as deep in the water as possible. This

increases the chance that it will be in the water in high speed and

reduces the possiblity of air bubble interference.

4. If possible, route the transducer cable away from other wiring on the

boat. Electrical noise from engine wiring, bilge pumps, and areators

can be displayed on the sonar’s screen. Use caution when routing

the transducer cable around these wires.

4

Page 5

Shoot-thru-hull v.s. Transom Mounting

(Strata 128 and Strata 128 Plus Only)

Typically, shoot-thru-hull installations give excellent high speed operation and good to excellent depth capability. There is no possibility of

damage from floating objects. It can't be knocked off when docking or

loading on the trailer.

However, the shoot-thru-hull installation does have its drawbacks. One,

some loss of sensitivity does occur, even on the best hulls. This varies

from hull to hull, even from different installations on the same hull. This

is caused by differences in hull layup and construction. Two, the angle

of the transducer cannot be adjusted for the best fish arches. This can

be a problem on some hulls that sit with the bow high when at rest or at

slow trolling speeds. Follow the procedure listed in the shoot-thru-hull

installation section in this manual to determine if you can satisfactorily

shoot through the hull.

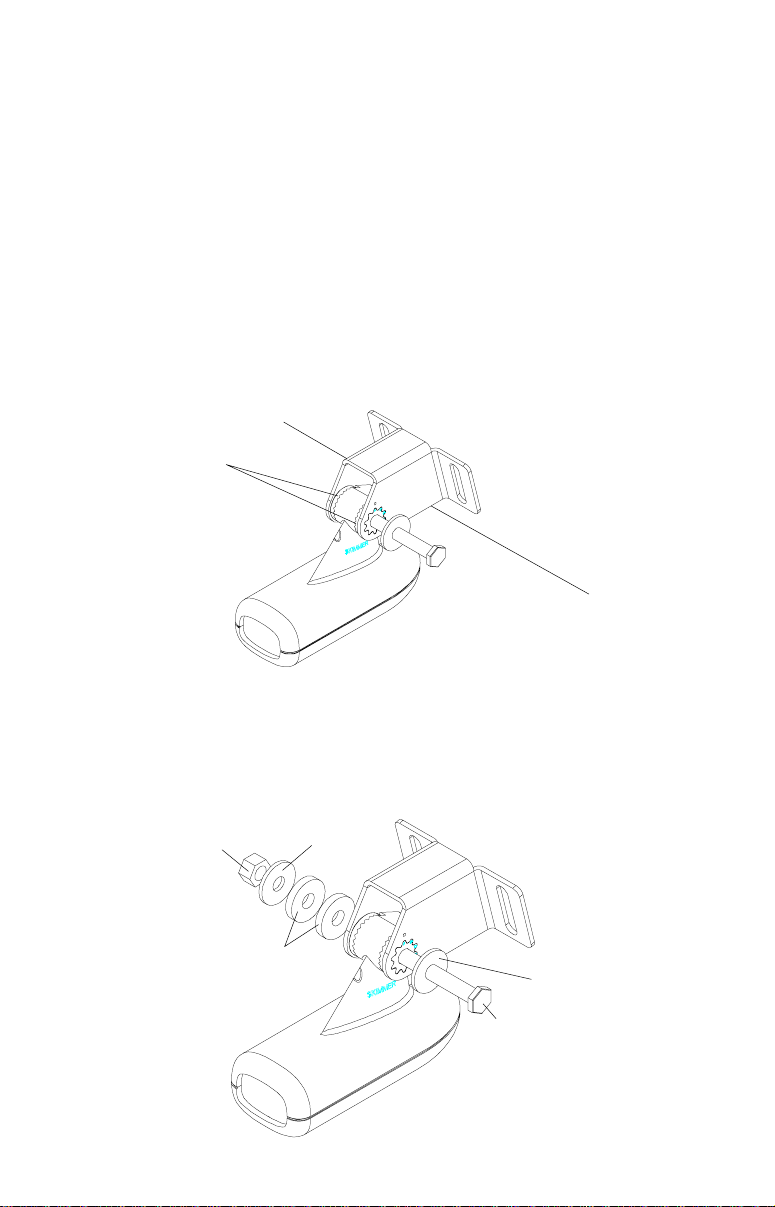

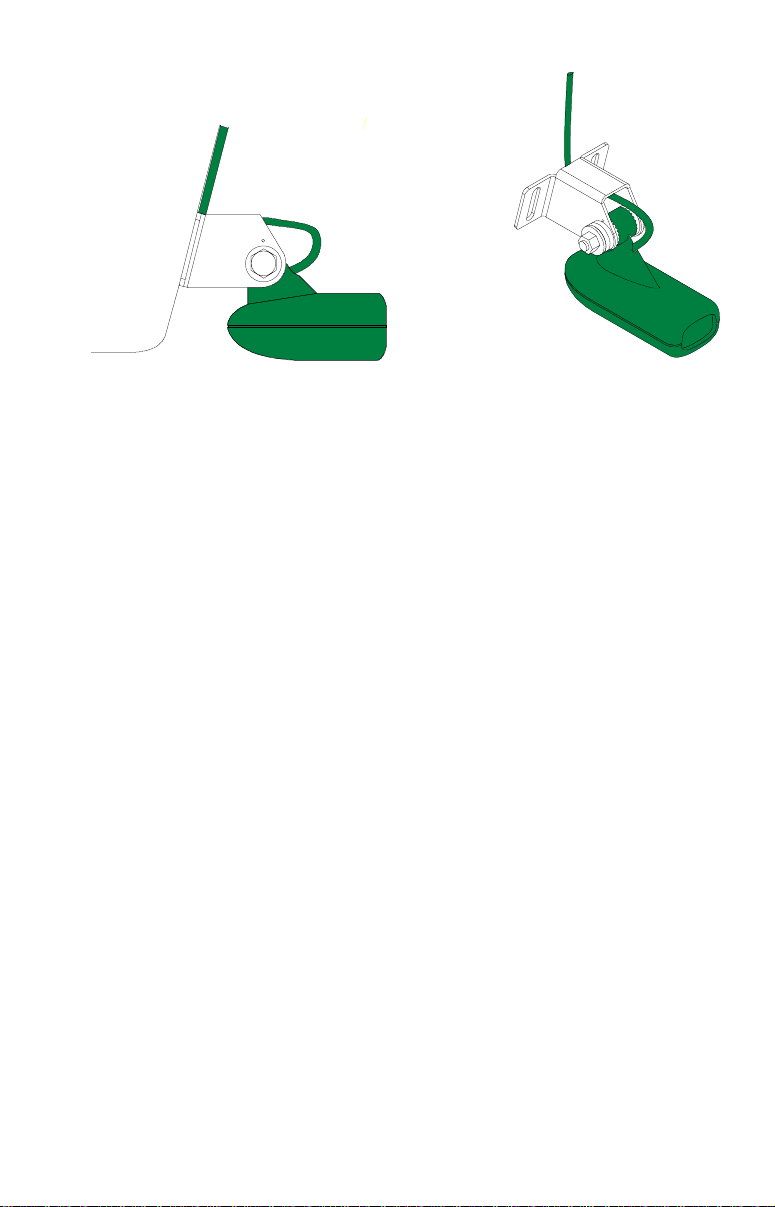

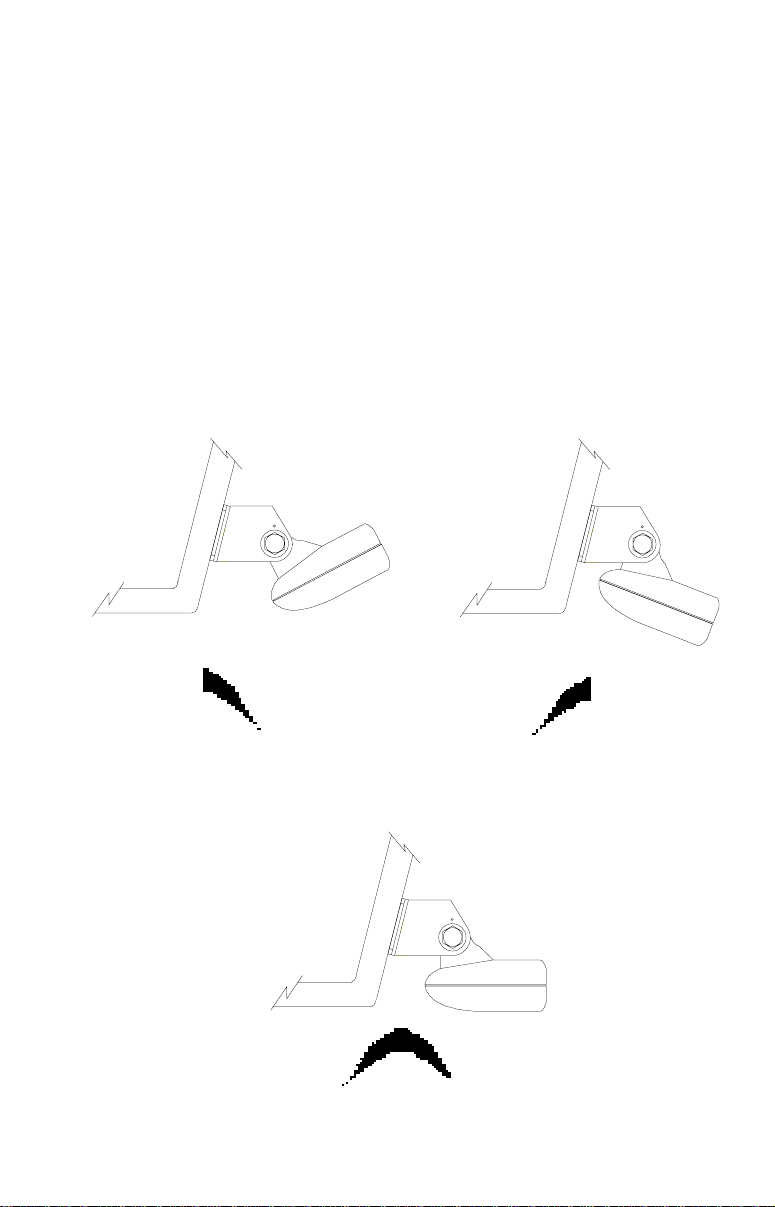

T ransducer Assemb l y and Mounting - All Units

The best way to install this transducer is to loosely assemble all of the

parts first, place the transducer’s bracket against the tr ansom and see if

you can move the tr ansducer so that it’s parallel with the ground.

1. Press the two small plastic ratchets into the sides of the metal brac ket

as shown below. Notice there are letters molded into each ratchet.

Place each ratchet into the bracket with the letter “A” aligned with the

dot stamped into the metal bracket. This position sets the transducer’ s

coarse angle adjustment for a fourteen (14) degree transom. Most

outboard and stern-drive transoms have a fourteen degree angle.

DOT

5

Page 6

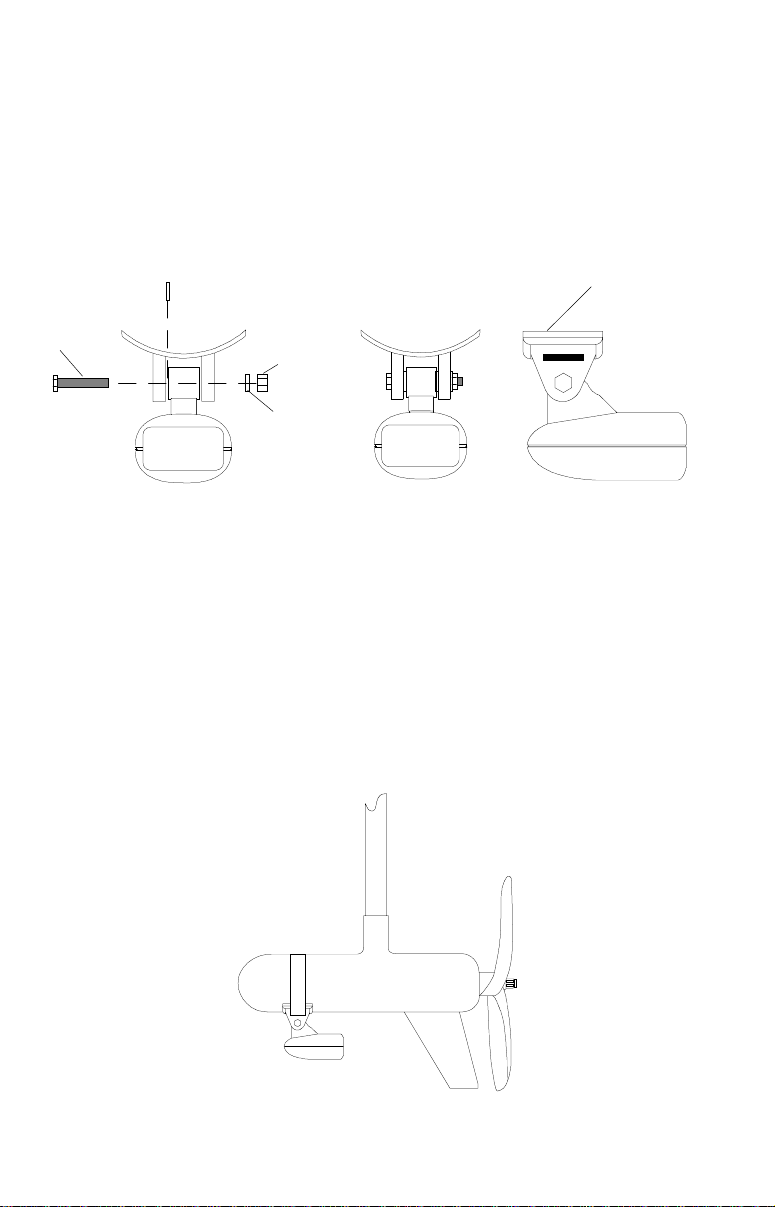

2. Slide the transducer between the two ratchets. Temporally slide the

bolt though the transducer assembly and hold it against the transom.

Looking at the transducer from the side, check to see if it will adjust so

that its face is parallel to the ground. If it does, then the “A” position is

correct for your hull. If the transducer’ s face isn’t parallel with the ground,

remove the transducer and r atchets from the bracket. Place the ratchets into the holes in the bracket with the letter “B” aligned with the dot

stamped in the bracket. Reassemble the transducer and brac ket and

place them against the transom. Again, chec k to see if y ou can mo ve

the transducer so it’s parallel with the ground. If you can, then go to

step 3. If it doesn’t, repeat step 2, b ut use a different letter until you can

place the transducer on the transom correctly.

RATCHETS

3. Once you determine the correct position for the ratchets, assemble

the transducer as shown at left. Don't tighten the loc k nut at this time.

METAL

NUT

WASHER

RUBBER

WASHERS

METAL

WASHER

BOLT

6

Page 7

CAUTION!CAUTION!

CAUTION!

CLAMP THE TRANSDUCER CABLE TOCLAMP THE TRANSDUCER CABLE TO

CLAMP THE TRANSDUCER CABLE TO

CLAMP THE TRANSDUCER CABLE TOCLAMP THE TRANSDUCER CABLE TO

TRANSOM NEAR THE TRANSDUCER. THISTRANSOM NEAR THE TRANSDUCER. THIS

TRANSOM NEAR THE TRANSDUCER. THIS

TRANSOM NEAR THE TRANSDUCER. THISTRANSOM NEAR THE TRANSDUCER. THIS

WILL HELP PREVENT THE TRANSDUCERWILL HELP PREVENT THE TRANSDUCER

WILL HELP PREVENT THE TRANSDUCER

WILL HELP PREVENT THE TRANSDUCERWILL HELP PREVENT THE TRANSDUCER

FROM ENTERING THE BOAT IF IT ISFROM ENTERING THE BOAT IF IT IS

FROM ENTERING THE BOAT IF IT IS

FROM ENTERING THE BOAT IF IT ISFROM ENTERING THE BOAT IF IT IS

KNOCKED OFF AT HIGH SPEED.KNOCKED OFF AT HIGH SPEED.

KNOCKED OFF AT HIGH SPEED.

KNOCKED OFF AT HIGH SPEED.KNOCKED OFF AT HIGH SPEED.

POOR ANGLEPOOR ANGLE

POOR ANGLE

POOR ANGLEPOOR ANGLE

CAUTION!CAUTION!

POOR LOCATIONPOOR LOCATION

POOR LOCATION

POOR LOCATIONPOOR LOCATION

GOOD LOCATIONGOOD LOCATION

GOOD LOCATION

GOOD LOCATIONGOOD LOCATION

GOOD LOCATIONGOOD LOCATION

GOOD LOCATION

GOOD LOCATIONGOOD LOCATION

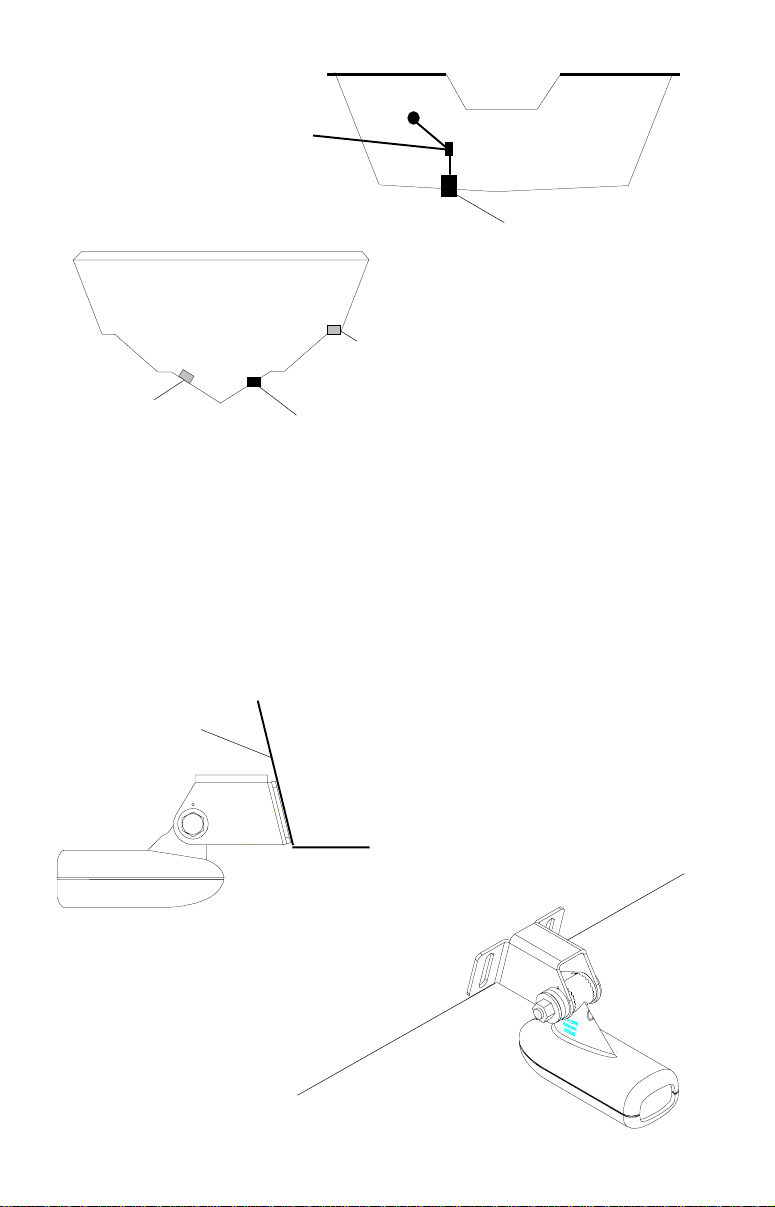

4. Hold the transducer and bracket assembly against the transom. The

transducer should be roughly parallel to the ground. The bottom of the

transducer bracket should be in line with the bottom of the hull.

let the bracket extend below the hull!

Mark the center of the slots for

Don't

the mounting holes. Drill two 5/32" holes in the marked locations for

the #10 screws supplied with the transducer .

TRANSOM

SIDE VIEW

7

Page 8

5. Remove the transducer from the bracket and re-assemble it with the

cable passing through the bracket over the bolt as shown above. Attach the transducer to the transom. Slide the transducer up or down

until it’s aligned properly on the transom as shown abov e. Tighten the

bracket’ s mounting screws. Adjust the transducer so that it’ s parallel to

the ground and tighten the lock nut until it touches the flat washer , then

add 1/4 turn.

Don’t over tighten the lock n ut!

If you do, the tr ansducer

won’t “kic k-up” if it strikes an object in the water .

6. Route the transducer cable to the sonar unit. Make certain to leave

some slack inthe cable at the transducer as shown abo ve . If possib le,

route the transducer cable aw ay from other wiring on the boat. Electrical noise from the engine’s wiring, bilge pumps, VHF radio wires and

cables, and aerators can be pic ked up by the sonar . Use caution when

routing the transducer cable around these wires.

IMPORTANT!

Clamp the transducer cable to the transom close to the transducer. This

can prevent the transducer from entering the boat if it is knocked off at

high speed.

7. Make a test run to determine the results. If the bottom is lost at high

speed, or if noise appears on the display, try sliding the transducer

bracket down. This puts the transducer deeper into the water, hopefully below the turbulence causing the noise. Don't allow the transducer bracket to go belo w the bottom of the hull!

8

Page 9

TROLLING MOTOR BRACKET INSTALLATION

(StrataView Only)

1. Attach the TMB-S bracket to the transducer as shown below using the

hardware supplied with the transducer. (Note: The internal tooth washer

is supplied with the TMB-S.)

INTERNAL TOOTH

WASHER

BOLT

NUT

FLAT WASHER

TMB-S

BRACKET

2. Slide the adjustable strap supplied with the TMB-S through the slot in

the transducer bracket and wrap it around the trolling motor. Position

the transducer to aim straight down when the motor is in the water.

Tighten the strap securely. Route the transducer cable alongside the

trolling motor shaft. Use plastic ties (not included) to attach the

transducer cable to the trolling motor shaft. Make certain there is

enough slack in the cable for the motor to turn freely. Route the cable

to the sonar unit and the transducer is ready for use.

9

Page 10

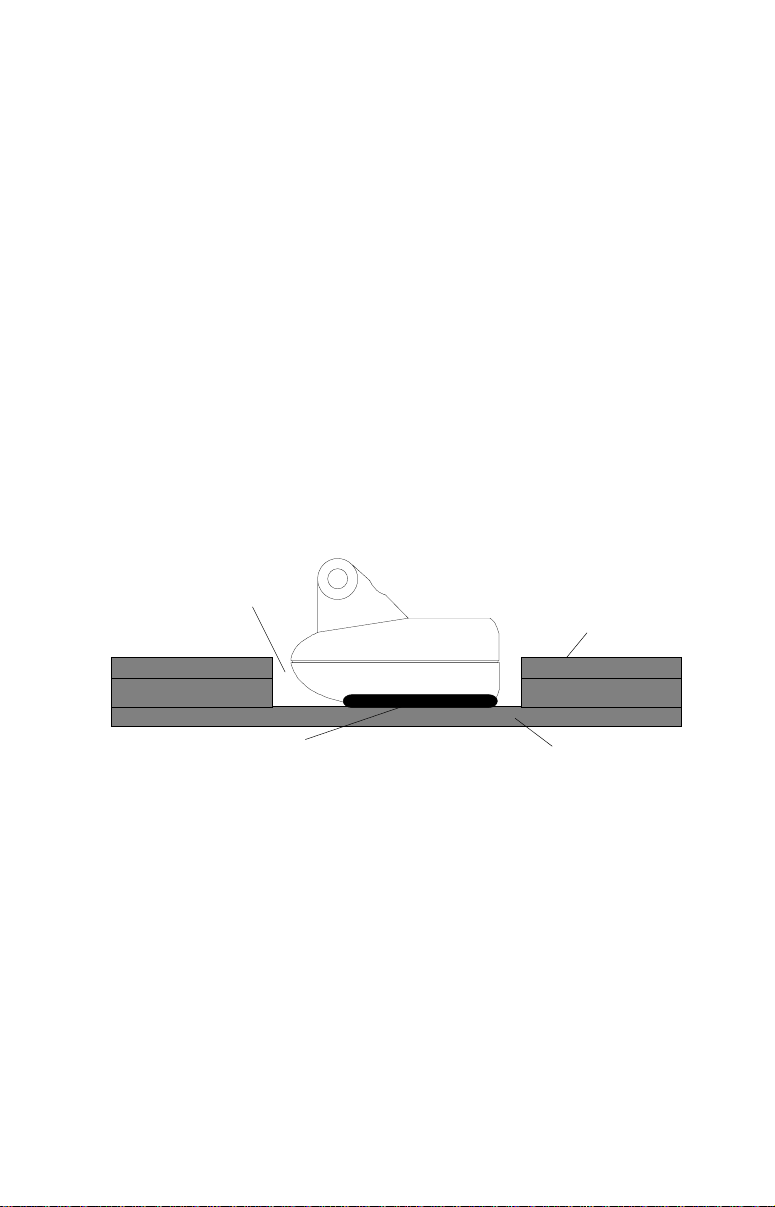

SHOOT-THRU-HULL

(Strata 128 and Strata 128 Plus Only)

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass

layers. The sonar signal must pass through solid fiberglass. A successful transducer installation can be made on hulls with flotation materials

(such as plywood, balsa wood, or foam) between layers of fiberglass if

the material is removed from the chosen area. For example, some

manufacturers use a layer of fiberglass, then a core of balsa wood,

finishing with an outer layer of fiberglass. Removing the inner layer of

fiberglass and the balsa wood core exposes the outer layer of fiberglass.

The transducer can then be epoxied directly to the outer layer of fiberglass. After the epoxy cures, the hull is watertight and structurally sound.

Remember, the sonar signal must pass through solid fiberglass. Any air

bubbles in the fiberglass or the epoxy will reduce or eliminate the sonar

signals.

To choose the proper location for thru-hull mounting, anchor the boat in

60 feet of water. Add a little water to the sump of the boat. Plug the

FILL WITH EPOXY

INNER HULL

EPOXY TO HULL FIRST

OUTER HULL

transducer into the sonar unit, turn it on, then hold the transducer over

the side of the boat. Adjust the sensitivity and range controls until a

second bottom echo is seen on the display. (you will need to turn both

automatic and ASP off.) Don’t touch the controls once they’ve been set.

Next, take the transducer out of the water and place it in the water in the

sump of the boat. Observe the sonar signal to see if there is a noticeable decrease in sensitivity. The second bottom signal may disappear

and the bottom signal may decrease in intensity. Move the transducer

around to find the best location. If the sensitivity control has to be

increased greatly to compensate, then the transducer should be

mounted on the outside of the hull. If not, then mark the location that

shot through the hull the best and follow the instructions on the next

pages for a shoot-thru-hull mounting.

10

Page 11

TRANSDUCER LOCATION

(HIGH SPEED)

TRANSDUCER LOCATION

(TROLLING SPEED)

Shoot-thru-hull Installation

(Strata 128 and Strata 128 Plus Only)

1. Make certain the area is clean, dry, and free of oil or grease, then

sand both the inside surface of the hull and the face of the transducer

with 100 grit sandpaper. The surface of the hull must be flat so the entire

transducer face is in contact with the hull prior to bonding.

SPREAD EPOXY HERE

SAND THIS SURFACE

2. Follow the instructions on the epoxy package and mix it thoroughly.

Do not mix it too fast, as it will cause bubbles to form in the epoxy.

(NOTE! Use only the epoxies specified on the inside front cover of this

manual! Failure to use one of these epoxies may result in poor sonar

performance!) Apply a small amount on the face of the transducer as

shown above, then spread a small amount onto the sanded area on the

11

Page 12

hull. Place the transducer into the epoxy, twisting and turning it to force

any air bubbles out from under the transducer face. The face of the

transducer should be parallel with the hull, with a minimum amount of

epoxy between the hull and transducer. After the epoxy dries, route the

cable to the sonar unit.

Fish Arches

If you do not get good fish arches on your display, it could be the

transducer is not parallel with the ground when the boat is at rest in the

water, or at slow trolling speeds. If the arch slopes up, but not back

down, then the front of the transducer is too high and needs to be

lowered. If only the back half the the arch is printed, then the nose of the

transducer is angled too far down and needs to be raised.

TRANSDUCER AIMED TOO FARTRANSDUCER AIMED TOO FAR

TRANSDUCER AIMED TOO FAR

TRANSDUCER AIMED TOO FARTRANSDUCER AIMED TOO FAR

BACKBACK

BACK

BACKBACK

PROPER TRANSDUCER ANGLEPROPER TRANSDUCER ANGLE

PROPER TRANSDUCER ANGLE

PROPER TRANSDUCER ANGLEPROPER TRANSDUCER ANGLE

12

TRANSDUCER AIMED TOOTRANSDUCER AIMED TOO

TRANSDUCER AIMED TOO

TRANSDUCER AIMED TOOTRANSDUCER AIMED TOO

FAR FORWARDFAR FORWARD

FAR FORWARD

FAR FORWARDFAR FORWARD

Page 13

POWER CONNECTIONS - Permanent mount units only

This unit works from a 12 volt DC system only. For the best results, run the

power cable directly to the boat’s battery. Keep the power cable away from

other boat wiring, especially the engine’s wires. This will give the best

isolation from electrical noise. If the supplied cable is not long enough to

reach the battery, splice #18 gauge insulated wire to it. You can attach the

power cable to an accessory or power buss, however, you may have

problems with electrical interference. Make certain to attach the in-line fuse

holder to the positive lead as close to the battery or terminal strip as

possible. This will protect both the unit and the power cable in the event of

a short. Use a 3-amp fuse.

WARNING!

Do not use this product without a 3-amp fuse wired into the power cable!

Failure to use a 3-amp fuse will void your warranty!

This unit has reverse polarity protection. No damage will occur if the power

wires are reversed. However, the unit will not work until the wires are

attached correctly.

TO SONAR UNIT

TO SPEED/TEMP

SENSOR

(STRATA 128 PLUS &

STRATAVIEW ONLY)

BLACK

WIRE

12 VOLT

BATTERY

13

RED

WIRE

3 amp

FUSE

Page 14

Bracket Installation - Permanent mount units only

You can install the sonar unit on the top of a dash or from an overhead with

the supplied bracket. It can also be installed in the dash with an optional

IDA-3 mounting kit. If you use the supplied bracket, you may be interested

in the optional GBSA-1 swivel bracket kit. This converts the unit's gimbal

bracket to a swivel mount which can be used on the dash or overhead

mounting positions. Installation instructions for the in-dash and swivel

mounting kits are supplied with the adapter kits.

Mount the unit in any convenient location, provided there is clearance

when it’s tilted for the best viewing angle. Holes in the bracket’s base allow

wood screw or through bolt mounting. It may be necessary to place a piece

of plywood on the back side of thin panels to reinforce the panel. Make

certain there is enough room behind the unit to attach the power and

transducer cables.

Drill a hole in the dash for the power and transducer cables. The best

location for this hole is immediately under the gimbal bracket. This way, the

bracket covers the hole. The smallest hole the power and transducer cable

connectors can pass through is 5/8". After drilling the hole, pass the power/

transducer connector up through the hole from under the dash. Slide the

bracket over the hole, then route the cables out the slot in the back of the

bracket. Finally, fasten the bracket to the dash.

SONAR UNIT

GIMBAL BRACKET

RUBBER WASHER

PLASTIC WASHER

(PORTABLE UNITS ONLY)

GIMBAL KNOB

Attach the unit to the gimbal bracket using the supplied gimbal knobs and

washers as shown above.

14

Page 15

STRATA 128 PORTABLE ASSEMBLY

INSTALLING THE BATTERIESINSTALLING THE BATTERIES

INSTALLING THE BATTERIES

INSTALLING THE BATTERIESINSTALLING THE BATTERIES

Release the latch on the front of the battery case. Open the compartment

and install four "D" cell batteries into the adapter. For the longest life, we

recommend you use alkaline batteries. This battery case will also hold one

rechargable battery instead of the "D" cells. See the enclosed coupon for

more information on the rechargable battery.

"D" CELL BATTERY

After installing the batteries, close the case and plug the power cable on

the battery case into the Strata 128 Portable. Turn the sonar unit on. If it

doesn't work, make certain the battery terminals are making good contact

against the battery contacts. Also check the wiring connections on the Dcell battery adapter. The red wire on the power cable should be attached

to the red wire on the D-cell battery adapter and the power cable's black

wire should be connected to the black wire on the D-cell battery adapter.

If it still doesn't work, check the battery voltage. Most of the complaints we

15

Page 16

receive about portable units result from stale batteries. Make certain the

ones you buy are fresh. Always remove batteries from the battery

compartment before storing the unit as dead batteries can leak and

corrode the contacts.

In cold weather the efficiency of dry cell batteries drops with the temperature. We find it a good idea to have the sonar unit good and warm along with

the batteries before we leave home. If the batteries do lose a charge, you

can sometimes restore them by placing them in a warm room or car interior.

A better way is to replace them with batteries that have been kept warm.

Don't ever heat the batteries over an open flame or direct hot air onto them.

A fire or explosion could result.

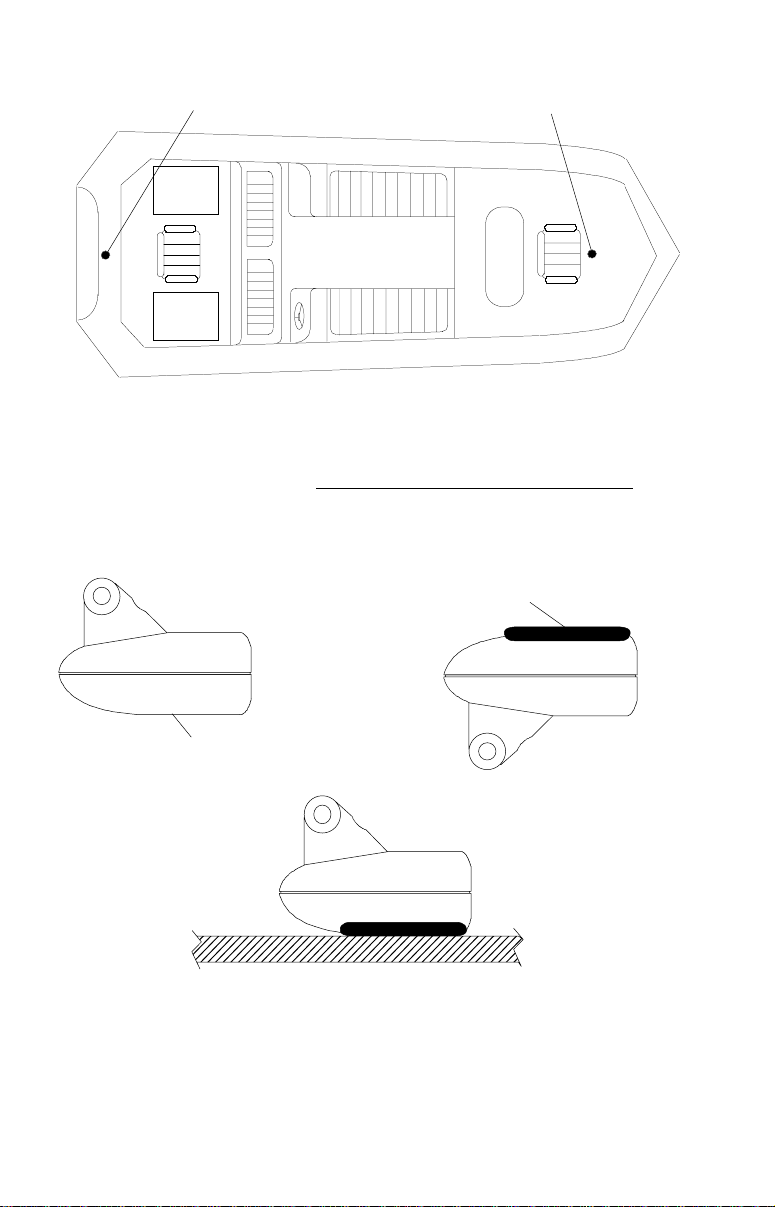

PORTABLE TRANSDUCER ASSEMBLYPORTABLE TRANSDUCER ASSEMBLY

PORTABLE TRANSDUCER ASSEMBLY

PORTABLE TRANSDUCER ASSEMBLYPORTABLE TRANSDUCER ASSEMBLY

Assemble the transducer and bracket as shown below. Attach the

transducer to the bracket with the supplied hardware. Make certain there

is one washer on each side of the transducer, inside the bracket. Slide the

other washer over the end of the bolt and thread the nut onto it. Screw the

suction cup onto the bracket using the supplied screw and flat washer. Tie

the nylon cord through the hole in the top of the bracket. When using this

transducer, tie the other end of the nylon cord to the boat. This will help

prevent the loss of the transducer if it comes off the boat.

BOLT

WASHER

TIE

NYLON

CORD

HERE

SCREW

NUT

WASHER

16

Page 17

Clean the chosen area of the hull before attaching the suction cup. Locate

the transducer on the hull as shown below. Don't allow the bracket to go

below the hull, as water pressure against it can cause the suction cup to

come off at speed. Moisten the cup, then press it onto the hull as firmly as

possible. Tie the nylon cord to the boat and route the transducer cable to

the sonar unit. Plug the transducer connector into the unit and your

portable sonar is now ready for use.

HULL

SPEED/TEMPERATURE SENSORS

The Strata Plus and StrataView can use up to three temperature sensors

which can monitor surface water, live well, air, and virtually any other

temperature. You do need to be careful when purchasing the temperature

sensors, however. Each temperature sensor has its own "address". The

sensors are labeled "Water", "T-2" (or Temp-2), and "T-3" (or Temp-3). If

you want two (or more) temperature readings, you'll need to use the proper

sensors. For example, you can't use two T-3 sensors. The sensors that will

fit these units are:

TS-1BK One sensor for "Water" temperature display.

TS-2BK One sensor for "T-2" temperature display.

TS-3BK One sensor for "T-3" temperature display.

TS-12BK Two sensors for "Water" and "T-2" temperature displays.

ST-TBK One speed sensor and one temperature sensor for

"Speed" and "Water" displays. (comes with Strata Plus)

You can combine these sensors in many combinations. See the list on the

following page for temperature and speed sensor combinations.

17

Page 18

Sensor Chart

(Note: Do not use these sensors in any other combination.)

ST-TBK = 1 speed sensor and 1 temperature display

ST-T BK + TS-2BK = 2 temp sensors and one speed sensor

ST-TBK + TS-2BK + TS-3BK = 3 temp sensors and one speed sensor

TS-1BK = 1 temperature sensor

TS-12BK = 2 temperature sensors

or

TS-1BK + TS-2BK = 2 temperature sensors

TS-12BK + TS-3BK = 3 temperature sensors

or

TS-1BK + TS-2BK +TS-3BK = 3 temperature sensors

Here's some sample wiring diagrams:

Two Temperature Sensors

(Water and T-2)

STRATAVIEW'S POWER CABLE

TS-12 BK

STRATA PLUS'S OR

18

Page 19

TS-12 BK

TS-3 BK

STRATA PLUS OR

STRATAVIEW

POWER CABLE

Sensor Chart

(Note: Do not use these

sensors in any other combina-

tion.)

Three Temperature Sensors

(Water, T-2, and T-3)

ST-TBK

Three Temperature Sensors

plus Speed

(Water, T-2, T-3, and Speed)

TS-2 BK

TS-3 BK

STRATA PLUS OR

STRATAVIEW

POWER CABLE

19

Page 20

KEYBOARD BASICS

The unit sounds a tone when you press

any key. This tells you the unit has accepted a command.

PWR/CLEAR

Use this key to turn the unit on. It also

clears menu selections and the menus

from the screen. This key also turns the

unit off. NOTE: You must hold the OFF key

down for a few seconds in order to turn the

unit OFF.

MENU FWD / MENU REV

These sonar units have many features that are accessed with the menu

keys. The MENU FWD key moves forward through the menus, the MENU

REV key moves backward. To see the first menu, simply press either

MENU key. To see the other menus, press a MENU key repeatedly.

UP and DOWN ARROWS

Use these keys to adjust virtually every feature and function on the unit.

NOTE: The up arrow key also stops the chart when no menus are

displayed. In other words, anytime you wish to stop the chart, first make

certain no menu is on the screen. Now press the up arrow key. The chart

freezes and the word “STOP” appears at the top of the screen. To start the

chart, press the up arrow key again or the PWR/CLEAR key.

DISPLAY - General

The lights flash for about ten seconds when the unit is turned on. Two

menus appear, one after the other. The menus are the lights (BACK

LIGHT) and a feet-meter selection (FEET/METER). To turn the lights on,

press the up arrow key. To switch from feet to meters, press the down

arrow key when the proper menu appears. The menus disappear after a

few seconds. If you don’t want to wait, press the

PWR key to clear the menus from the screen.

When the sonar unit is first turned on, the display

appears similar to the one at right. The unit is in

the automatic mode and the Fish ID feature is

on. The depth range shows on the left side of the

screen. On the screen at right, the range is from

0 to 60 feet and the bottom depth is 48.6 feet.

20

Page 21

OPERATION

MENUS

This unit uses menus to guide you through the

unit’s functions and features. The menu key

accesses these features, allowing you to customize the unit to your particular needs and

water conditions. All you have to do to leave one

menu and enter another is press the menu key

repeatedly. If you ever get lost in the menus,

simply press the PWR key. This clears the

menus from the screen.

Menus change depending on the mode the unit

is in. For example, if the automatic mode is

turned off, the sensitivity menu changes from “AUTO SENS” to “MAN

SENS.” Other messages may appear in menu boxes or new menus can

appear, again depending on previous selections.

AUTOMATIC

When the unit is first turned on, the automatic

feature is enabled. This feature automatically

adjusts the unit’s range and sensitivity according to water conditions. It always keeps

the bottom displayed in the lower portion of

the screen.

To turn the automatic feature off, press the

menu key until the AUTO/MAN menu appears. Now press the down arrow key. This

highlights the letters “MAN.” The unit is now

in the manual mode. Wait a few seconds and

the menu will scroll off the screen’s left side.

Pressing the PWR key also clears it. To turn the automatic feature on

again, repeat the above steps, except this time press the up arrow key.

RANGE

You can’t adjust the range when the unit is in the automatic mode. It is

adjustable when the unit is in the manual mode, however. To do so, first

put the unit in the manual mode. Now press the PWR key to clear the

screen. Then press the menu key until the “RANGE SEL” menu appears

as shown at the top of the next page. The current range shows at the

bottom of the menu. In this case, the range is 60 feet. Now press the up

arrow key to decrease the range, the down arrow key increases the range.

21

Page 22

After you select the desired range, press the

PWR key to clear the display. If you wait a few

seconds, it will automatically clear.

This unit has the following ranges:

10, 20, 40, 60, 120, 240, 480, and 900 feet.

and

5, 10, 20, 40, 60, 100, 200, and 300 meters.

ZOOM

The zoom feature enlarges all echoes on the

screen. If the unit is in the automatic mode, it

tracks the bottom signal, always keeping it

near the bottom of the screen. This lets you

see small detail, at the same time enlarging all

echoes that appear on the screen. The unit

doesn’t track the bottom in the manual mode,

and the adjustments are slightly different.

Zoom - Automatic Operation

To zoom the display, first press the MENU

key until the RANGE/ZOOM menu appears

as shown at right. Now press the down arrow

key. This switches the unit into the zoom

mode. A new menu immediately appears as

shown below.

This is the zoom size menu. Zoom size is the

distance between the upper limit and the

lower limit. The upper limit shows at the top

left corner of the screen. The lower limit is in

the bottom left corner. For example, if the

upper limit is 40 feet and the lower limit is 70

feet, the zoom window size is 30 feet. The

word “TRACK” appears in this menu when

you first activate the zoom as shown at right.

22

Page 23

This means the unit is tracking the bottom in

a zoom window, always keeping it on the

display.

Press the up arrow key to decrease the zoom

size, press the down arrow key to increase

the zoom size.

When the unit is switched into the zoom

mode, the letters “ZM” appear at the top of the

screen. The zoom window size displays in the

top right corner of the screen.

On the screen shown above, the zoom size has been changed to 20 feet.

To turn the zoom feature off, press the menu key until the RANGE/ZOOM

menu appears. Now press the up arrow key. This switches the unit into

the range mode, which turns the zoom feature off.

This unit has the following zoom ranges:

10, 20, 30, 60, 120, 240, and 480 feet

and

5, 10, 20, 30, 50, 100, and 150 meters.

Zoom - Manual Operation

To operate the zoom feature when the unit is in the manual mode, first

press the menu key. Then press the down arrow key in the RANGE/ZOOM

menu to place the unit in the zoom mode. The zoom size menu

automatically appears next. You can change the zoom size by pressing

the up or down arrows. After you select the desired zoom size, press the

menu key until the “MOVE ZOOM” menu appears. This menu lets you

move the zoom window up or down in

one foot

increments by pressing the arrow keys. Thus,

you can move the zoom window up towards

the surface, down to the bottom, or anywhere

in between. The window stays where you put

it. It doesn’t track the bottom signal.

To turn the zoom feature off, press the menu

key until the RANGE/ZOOM menu appears.

Now press the up arrow key. This switches

the unit into the range mode, which turns the

zoom feature off.

23

Page 24

SENSITIVITY

The sensitivity menu lets you control the unit’s ability to pick up echoes. A

low sensitivity level excludes much of the bottom information, fish signals,

and other detail. High sensitivity settings lets you see features, but it can

also clutter the screen with noise and other unwanted signals. Typically,

the best sensitivity level shows a good, solid bottom signal with grayline.

This sonar unit adjusts the sensitivity level to keep a solid bottom signal on

the screen. It adds a little extra when it’s in the automatic mode. This gives

it the capability to show fish and other detail. However, situations occur

where it becomes necessary to increase or decrease the sensitivity level.

Typically, this occurs when you wish to see more detail, so you need to

increase the sensitivity. The procedure to adjust it is the same whether the

unit is in the automatic or manual mode.

To change the sensitivity level, first press the

menu key until the sensitivity menu appears.

If the unit is in automatic, the menu shows

“AUTO SENS.” Otherwise, the menu shows

“MAN SENS.” Now press the up arrow key to

increase the sensitivity, the down arrow to

decrease it. The percentage of sensitivity in

use shows in this menu. Echoes scrolling

onto the screen will also show the effects of

the sensitivity change. If you reach the maximum or minimum sensitivity level, a tone

sounds alerting you to the limits.

After you’ve adjusted the unit to the desired sensitivity level, press the

PWR key to clear the display. If you wait a few seconds, it will automatically

clear.

GRAYLINE

®

Grayline lets you distinguish between strong and weak echoes. It “paints”

gray on targets that are stronger than a preset level. This shows the

difference between a hard or soft bottom, large fish versus smaller ones,

or rocks and brush on the bottom. For example, a soft, muddy, or weedy

bottom returns a weaker signal which shows a narrow or no gray line. A

hard bottom returns a strong signal that causes a wide gray line.

If you have two targets of equal size, one with gray and the other without,

the target with gray is the stronger echo. This helps distinguish fish from

structure, or the larger fish from a smaller one.

24

Page 25

Grayline ® is adjustable. Since it shows the

difference between strong and weak echoes,

changing the level may require a different

sensitivity setting.

To change the Grayline level, first press the

MENU key until the Grayline menu appears.

Now press the up arrow key to increase the

level, the down arrow to decrease it. The

percentage of Grayline now in use shows in

this menu. Echoes scrolling onto the screen

will also show the effects of the Grayline

change. If you reach the maximum or minimum level, a tone sounds

alerting you to the limits.

The level chosen by the unit when it’s first turned on is usually adequate

for most conditions. Experiment with your unit to find the Grayline setting

that’s best.

FISH ID FEATURE

The Fish ID feature identifies targets that meet certain conditions as fish.

The microcomputer analyses all echoes and eliminates surface clutter,

thermoclines, and other undesirable signals. In most instances, remaining

targets are fish. The Fish ID feature displays symbols on the screen in

place of the actual fish echoes. There are three symbol sizes: small,

medium, and large. These show the relative size between targets. In other

words, it displays a small fish symbol when it thinks a target is a small fish,

a medium fish symbol on a larger target, etc.

The microcomputer is sophisticated, but it can be fooled. It can't distinguish between fish and other suspended objects such as turtles, submerged floats, air bubbles, etc. Individual tree limbs extending outwards

from a group of limbs are the hardest objects

for the Fish ID feature to distinguish from fish.

You may see Fish ID symbols on the screen

when, in fact, there are no fish. Practice with

the unit when the Fish ID feature is on and off

to become more familiar with Fish ID. When

the unit is first turned on, the Fish ID feature

is automatically turned on, also. To turn it off,

press the menu key until the Fish ID feature’s

menu appears as shown at right, then press

the down arrow key. To turn it back on, repeat

the above steps, but press the up arrow key

instead.

25

Page 26

The Fish ID feature can’t be used when the unit is in the manual mode. If

you turn the automatic feature off, the Fish ID feature will automatically be

turned off, also.

FISH TRACK™

This unit automatically displays the depth of a target when the Fish ID

feature places a fish symbol on the screen as shown below. This feature

is automatically enabled when the sonar unit is turned on. To turn it off or

on again, press the MENU key repeatedly until the Fish Track menu

appears as shown below. Now press the down arrow key to turn it off.

Remember, Fish ID must be on in order to use the Fish Track feature.

TARGETTRACK™

(StrataView Only)

The StrataView has the unique capability to "see" targets not only straight

down, but also to the right and left, thanks to the BroadView™ transducer.

This transducer has three elements: left, right, and down. The StrataView

uses all three elements to display targets between the surface and the

bottom. Targets are shown as Fish ID symbols. This feature also shows the depth of the

target directly above the fish symbol. In the

screen shown at right, there is one symbol

from the right element at 22 feet, one from the

left element at 29 feet, and one from the center

element at 16 feet. The TargetTrack feature

identifies fish symbols coming from the right

element with a "R" in front of the symbol's

depth. A "L" identifies symbols from the left

element. No letter identifies fish symbols from

the center element. The bottom signal and the

26

Page 27

digital depth display are read from the center

element only.

To turn the TargetTrack feature off, simply

press the MENU key until its menu appears as

shown at right, then press the down arrow key.

CHART SPEED

The rate echoes scroll across the screen is

called the chart speed. It’s adjustable by

pressing the menu key until the chart speed

menu appears. Chart speed is set to maximum when the unit is first turned on. To

decrease it, press the down arrow key. Press

the up arrow key to increase the speed again.

The percent numbers in the Chart Speed

menu box shows the speed. Echoes scrolling

onto the screen will also show the effects of

the change. If you reach the maximum or

minimum level, an warning tone sounds.

To stop the chart, first clear any menu from the screen by pressing the

PWR key. You can’t stop the chart while a menu is displayed. Now press

the up arrow key. The chart freezes and the word “STOP” appears at the

top right portion of the screen. To start the chart, press the up arrow key

again.

27

Page 28

DISPLAY MODE

The Strata 128 has three different screen modes. The Strata 128 Plus and

Strataview both have eight modes. To change modes, press the MENU

key until the “DISP MODE” (Display Mode) menu appears. Then press the

up or down arrow keys until the desired mode number appears. The modes

are as follows:

STRATA 128 and STRATA 128 Portable

ONLY

CHT 1 (Chart #1)

This is the default mode used when the unit

is first turned on. It has the following

features:

1. Automatic On

2. Fish ID Feature On

3. Digital Depth Display On

CHT 2 (Chart #2)

This is the High Speed Scroll mode. It shifts

the chart speed into high gear, scrolling echoes at a high rate. It has the following features:

1. Automatic Off

2. Fish ID Feature Off

3. Digital Depth Display Off

DIG 1 (Digital #1)

This is the digital only screen. It shows the

digital depth display at the top of the screen in

very large numbers. The shallow and deep

alarm settings are displayed beneath the

digital depth. No chart shows on this screen.

28

Page 29

STRATA 128 PLUS and STRATAVIEW

ONLY

CHT 1 (Chart #1)

This is the default mode used when the unit

is first turned on. It has the following

features:

1. Automatic On

2. Fish ID Feature On

3. Digital Depth Display On

CHT 2 (Chart #2)

Same as Chart-1, but with water temperature added.

CHT 3 (Chart #3)

Same as Chart-1, but with speed added.

29

Page 30

STRATA 128 PLUS and STRATAVIEW

ONLY (cont.)

CHT 4 (Chart #4)

Same as Chart-1, but with water temperature and speed added.

CHT 5 (Chart #5)

This is the High Speed Scroll mode. It shifts

the chart speed into high gear, scrolling echoes at a high rate. It has the following features:

1. Automatic Off

2. Fish ID Feature Off

3. Digital Depth Display Off

DIG 1 (Digital #3)

This is the digital only screen. It shows the

digital depth display at the top of the screen in

very large numbers. The shallow and deep

alarm settings are displayed beneath the digital depth. No chart shows on this screen.

30

Page 31

STRATA 128 PLUS and STRATAVIEW

ONLY (cont.)

DIG 2 (Digital #2)

Digital depth, water temperature, speed,

and distance log (odometer) show on this

page. To reset the log, turn the unit off and

back on again.

DIG 3 (Digital #3)

Digital depth, water temperature, T-2 temperature, and T-3 temperature all show on

this screen.

Temperature Probe Select

You can select the temperature probe's output that shows on Chart 2 and 4, when more

than one temperature probe is connected to a

Strata 128 Plus or a StrataView.

To do this, press a MENU key until the "TEMP

PROBE" menu appears as shown at right.

Now press the up or down arrow keys until the

desired probe appears. Press the PWR key to

erase the menu.

31

Page 32

ALARMS

FISH ALARM

The Fish Alarm sounds a tone when a fish

symbol appears on the screen. To use the

fish alarm, press the menu key until the “FISH

ALARM” menu appears on the screen. Now

press the up arrow key to turn the alarm on.

Repeat the above steps to turn the fish alarm

off.

DEPTH ALARMS

The depth alarms are triggered only by the bottom signal. No other echoes

will activate these alarms. The depth alarms consist of a shallow and deep

alarm. The shallow alarm sounds an alarm tone when the bottom goes

shallower than the alarm’s setting. The deep alarm sounds a tone when

the bottom goes deeper than it’s setting. Both alarms adjust the same,

although through different menus.

Shallow Alarm

To set the shallow alarm, press the menu key

repeatedly until the “SHAL ALARM” menu

appears. Press the down arrow key to increase the shallow alarm's depth setting, the

up arrow key decreases it. The number in the

shallow alarm’s menu box shows the current

shallow alarm setting. When the number

reaches the desired setting, release the arrow key. When the bottom depth goes shallower than the alarm’s setting an alarm tone

sounds. At the same time the alarm sounds,

a message box appears on the screen as

shown at right.

Press the up arrow key to silence the alarm.

This will turn the alarm sound off until the

shallow alarm is triggered again.

To turn the alarm off, press the menu key until

the shallow alarm menu appears. Then press

the up arrow key until the word “OFF” appears.

32

Page 33

Deep Alarm

The deep alarm adjusts the same as the shallow alarm. Use the “DEEP

ALARM” menu to adjust the deep alarm.

When the bottom signal goes deeper than the

setting, an alarm tone sounds.

LIGHTS

The display is backlighted for night use. To

turn the backlights on or off, press the menu

key repeatedly until the BACK LIGHT menu

appears. Now press the up arrow to turn the

lights on or the down arrow to turn them off.

FEET/METER

This unit can show the depth in feet or meters.

When it is in the metric mode, all depth

readings, ranges, zooms, and alarm settings

are in meters. When it's in the feet mode, all

of the above settings are in feet.

To change from feet to meters or vice-versa,

press the menu key until the FEET/METER

menu appears. Press the down arrow key to

switch to metric, the up arrow to switch to feet.

Displays show in feet when the unit is first

turned on. The menu will clear automatically

after a few seconds or you can press the

PWR key to clear the screen.

DISPLAY CONTRAST

The unit’s display contrast is adjustable to suit

different lighting conditions. This will help you

see the screen from different angles, or at

various times of the day.

To adjust the contrast, press the menu key

until the DARK/LIGHT menu appears. To

decrease it, press the down arrow key. Press

the up arrow key to increase the contrast.

The bar graph in the Dark/Light menu box

33

Page 34

shows a graph of the contrast. The screen will also show the effects of the

change. If you reach the maximum or minimum level, a tone sounds

alerting you to the limits. The menu will clear automatically after a few

seconds or you can press the PWR key to clear the screen.

ASP (Advanced Signal Processing)

ASP is a program embedded in the computer

that is specifically designed to eliminate noise.

It continually monitors the signals from the

receiver, determines which echoes are noise

and rejects them. This allows true target

echoes to display on the screen with a minimum of clutter. This feature is especially

useful since it typically lets you operate the

boat at all speeds without adjusting the sensitivity or other controls. When the unit is first

turned on, ASP is enabled. To turn ASP off,

press the menu key repeatedly until the ASP

menu appears. Now press the up arrow to turn it on or the down arrow to

turn it off. The menu will clear automatically after a few seconds or you can

press the PWR key to clear the screen.

SIMULATOR

A simulator is built inside that can show a

simulated bottom signal with fish signals. All

features of the unit work normally when the

simulator is in use. You can change the

range, zoom, and use the alarms as desired.

To use the simulator, press the menu key

repeatedly until the SONAR SIM menu appears. Now press the up arrow to turn it on.

Repeat the above steps to turn it off, or turn

the unit off and back on again.

34

Page 35

TROUBLESHOOTING - IMPORTANT INFORMATION!

If your unit is not working, or if you need technical help, please use the

following troubleshooting section before contacting the factory customer

service department. It may save you the trouble of returning your unit.

Unit won’t turn on:

1. Check the power cable’s connection at the unit. Also check the wiring.

2. Make certain the power cable is wired properly. The red wire connects

to the positive battery terminal, black to negative or ground.

3. Check the fuse.

4. Measure the battery voltage at the unit’s power connector. It should be

at least 11 volts. If it isn’t, the wiring to the unit is defective, the battery

terminals or wiring on the terminals are corroded, or the battery needs

charging.

Unit freezes, locks up, or operates erratically:

1. Electrical noise from the boat’s motor, trolling motor, or an accessory

may be interfering with the sonar unit. Rerouting the power and

transducer cables away from other electrical wiring on the boat may

help. Route the sonar unit’s power cable directly to the battery instead

of through a fuse block or ignition switch

2. Inspect the transducer cable for breaks, cuts, or pinched wires.

3. Check the transducer and power connector. Make certain it's securely

plugged in to the unit.

Weak bottom echo, digital readings erratic, or no fish signals:

1. Make certain transducer is pointing straight down. Clean the face of the

transducer. Oil, dirt, and fuel can cause a film to form on the transducer,

reducing its effectiveness. If the transducer is mounted inside the hull,

be sure it is shooting through only one layer of fiberglass and that it is

securely bonded to the hull. Do NOT use RTV silicone rubber adhesive

or MarinetexTM.

2. Electrical noise from the boat’s motor can interfere with the sonar. This

causes the sonar to automatically increase its Discrimination or noise

rejection feature. This can cause the unit to eliminate weaker signals

such as fish or even structure from the display.

3. The water may be deeper than the sonar’s ability to find the bottom. If

the sonar can’t find the bottom signal while it’s in the automatic mode,

35

Page 36

the digital will flash continuously. It may change the range to limits far

greater than the water you are in. If this happens, place the unit in the

manual mode, then change the range to a realistic one, (for example, 0100 feet) and increase the sensitivity. As you move into shallower water,

a bottom signal should appear.

4. Check the battery voltage. If the voltage drops, the unit’s transmitter

power also drops, reducing its ability to find the bottom or targets.

Bottom echo disappears at high speeds or erratic digital reading or

weak bottom echo while boat is moving

1. The transducer may be in turbulent water. It must be mounted in a

smooth flow of water in order for the sonar to work at all boat speeds. Air

bubbles in the water disrupt the sonar signals, interfering with its ability

to find the bottom or other targets. The technical term for this is

‘Cavitation’.

2. Electrical noise from the boat’s motor can interfere with the sonar. This

causes the sonar to automatically increase its Discrimination or noise

rejection feature. This can cause the unit to eliminate weaker signals

such as fish or even structure from the display. Try using resistor spark

plugs or routing the sonar unit’s power and transducer cables away from

other electrical wiring on the boat.

No fish arches when the Fish ID feature is off:

1. Make certain transducer is pointing straight down. This is the most

common problem if a partial arch is displayed. See the Fish Arch section

in your owner's manual for more information.

2. The sensitivity may not be high enough. In order for the unit to display

a fish arch, it has to be able to receive the fish’s echo from the time it

enters the cone until it leaves. If the sensitivity is not high enough, the

unit displays the fish only when it is in the center of the cone.

3. Use the Zoom feature. It is much easier to display fish arches when

zoomed in on a small range of water than a large one. For example, you

will have much better luck seeing fish arches with a 30 to 60 foot range

than a 0 to 60 foot range. This enlarges the targets, allowing the display

to show much more detail.

4. The boat must be moving at a slow trolling speed to see fish arches. If

the boat is motionless, fish stay in the cone, showing on the display as

straight horizontal lines.

36

Page 37

ELECTRICAL NOISE

A major cause of sonar problems is electrical noise. This usually appears

on the sonar’s display as random patterns of dots or lines. In severe cases,

it can completely cover the screen with black dots, or cause the unit

operate erratically, or not at all.

To eliminate or minimize the effects of electrical noise, first try to determine

the cause. With the boat at rest in the water, the first thing you should do

is turn all electrical equipment on the boat off. Make certain the engine is

off, also. Turn your unit on, then turn off ASP (Advanced Signal Processing). There should be a steady bottom signal on the display. Now turn on

each piece of electrical equipment on the boat and view the effect on the

sonar’s display.

For example, turn on the bilge pump and view the sonar display for noise.

If no noise is present, turn the pump off, then turn on the VHF radio and

transmit. Keep doing this until all electrical equipment has been turned on,

their effect on the sonar display noted, then turned off.

If you find noise interference from an electrical instrument, trolling motor,

pump, or radio, try to isolate the problem. You can usually reroute the sonar

unit’s power cable and transducer cable away from the wiring that is

causing the interference. VHF radio antenna cables radiate noise when

transmitting, so be certain to keep the sonar’s wires away from it. You may

need to route the sonar unit’s power cable directly to the battery to isolate

it from other wiring on the boat.

If no noise displays on the sonar unit from electrical equipment, then make

certain everything except the sonar unit is turned off, then start the engine.

Increase the RPM with the gearshift in neutral. If noise appears on the

display, the problem could be one of three things; spark plugs, alternator,

or tachometer wiring. Try using resistor spark plugs, alternator filters, or

routing the sonar unit’s power cable away from engine wiring. Again,

routing the power cable directly to the battery helps eliminate noise

problems. Make certain to use the in-line fuse supplied with the unit

when wiring the power cable to the battery!

When no noise appears on the sonar unit after all of the above tests, then

the noise source is probably cavitation. Many novices or persons with

limited experience make hasty sonar installations which function perfectly

in shallow water, or when the boat is at rest. In nearly all cases, the cause

of the malfunction will be the location and/or angle of the transducer. The

face of the transducer must be placed in a location that has a smooth flow

of water at all boat speeds.

37

Page 38

EAGLE ELECTRONICS

FULL ONE-YEAR WARRANTY

“We", “our”, or “us” refers to EAGLE ELECTRONICS, a division of LEI, the manufacturer of

this product. “You” or “your” refers to the first person who purchases this product as a

consumer item for personal, family, or household use.

We warrant this product against defects or malfunctions in materials and workmanship, and

against failure to conform to this product’s written specifications, all for one year (1) from the

date of original purchase by you. WE MAKE NO OTHER EXPRESS WARRANTY OR

REPRESENTATION OF ANY KIND WHATSOEVER CONCERNING THIS PRODUCT.

Your remedies under this warranty will be available so long as you can show in a reasonable

manner that any defect or malfunction in materials or workmanship, or any non-conformity

with the product’s written specifications, occurred within one year from the date of your

original purchase, which must be substantiated by a dated sales receipt or sales slip. Any

such defect, malfunction, or non-conformity which occurs within one year from your original

purchase date will either be repaired without charge or be replaced with a new product

identical or reasonably equivalent to this product, at our option, within a reasonable time after

our receipt of the product. If such defect, malfunction, or non-conformity remains after a

reasonable number of attempts to repair by us, you may elect to obtain without charge a

replacement of the product or a refund for the product. THIS REPAIR, REPLACEMENT, OR

REFUND (AS JUST DESCRIBED) IS THE EXCLUSIVE REMEDY AVAILABLE TO YOU

AGAINST US FOR ANY DEFECT, MALFUNCTION, OR NON-CONFORMITY CONCERNING THE PRODUCT OR FOR ANY LOSS OR DAMAGE RESULTING FROM ANY OTHER

CAUSE WHATSOEVER. WE WILL NOT UNDER ANY CIRCUMSTANCES BE LIABLE

TO ANYONE FOR ANY SPECIAL, CONSEQUENTIAL, INCIDENTAL, OR OTHER INDIRECT DAMAGE OF ANY KIND.

Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitations or exclusions may not apply to you.

This warranty does NOT apply in the following circumstances: (1) when the product has

been serviced or repaired by anyone other than us, (2) when the product has been

connected, installed, combined, altered, adjusted, or handled in a manner other than

according to the instructions furnished with the product, (3) when any serial number has

been effaced, altered, or removed, or (4) when any defect, problem, loss, or damage has

resulted from any accident, misuse, negligence, or carelessness, or from any failure to

provide reasonable and necessary maintenance in accordance with the instructions of the

owner’s manual for the product.

We reserve the right to make changes or improvements in our products from time to time

without incurring the obligation to install such improvements or changes on equipment or

items previously manufactured.

This warranty gives you specific legal rights and you may also have other rights which may

vary from state to state.

REMINDER: You must retain the sales slip or sales receipt proving the date of your original

purchase in case warranty service is ever required.

38

Page 39

How to Obtain Service

(Canadian Customers Only)

We back your investment in quality products with quick, expert service and genuine Eagle

replacement parts. If you need service or repairs, contact the Eagle Factory Customer

Service Department at the toll-free number listed below. A technician may be able to solve

the problem and save you the inconvenience of returning your unit. You will be asked for your

unit's serial number.

800-324-1354

Canada Only. Monday through Friday 8:00 A.M. - 8:00 P.M. Central Time.

How to Obtain Service

(International Customers Only)

If you need service or repairs, contact the dealer in the country you purchased your unit.

WARRANTY REPAIR WILL BE HONORED ONLY IN THE COUNTRY

Please follow the shipping instructions shown below on this page if you have to mail your

unit to the dealer. For proper testing, repair, and service, send a brief note with the product

describing the problem. Be sure to include your name, return shipping address, and a

daytime telephone number.

UNIT WAS PURCHASED.

Shipping Information

When sending a product for repair, we recommend you do the following:

1. Always use the original shipping container and filler material the product was packed

in when shipping your product.

2 Always insure the parcel against damage or loss during shipment. Eagle does not

assume responsiblity for goods lost or damaged in transit.

3. For proper testing, repair, and service, send a brief note with the product describing the

problem. Be sure to include your name, return shipping address, and a daytime

telephone number.

Accessory Ordering Information

To order accessories such as power cables or transducers, please contact:

1. Your local marine dealer. Most quality dealers that handle marine electronic equipment

should be able to assist you with these items. Consult your local telephone directory for

listings.

2. Canadian customers only can write:

Lowrance/Eagle Canada, 919 Matheson Blvd., E. Mississauga, Ontario L4W2R7

or fax 416-629-3118

39

Page 40

How to Obtain Service (U.S.A. Only)

We back your investment in quality products with quick, expert service and

genuine Eagle™ replacement parts. If you're in the United States and you

have questions, please contact the Factory Customer Service Department

using our toll-free number listed below. You must send the unit to the

factory for warranty service or repair. Please call the factory before sending

the unit. You will be asked for your unit's serial number. Use the following tollfree number:

800-324-1354

U.S.A.only. Monday through Friday 8:00 A.M. - 8:00 P.M. Central time, except holidays.

Your unit is covered by a full one-year warranty. (See inside for complete

warranty details.) If your unit fails and the failure is not covered by the

original warranty, Eagle has a flat-rate repair policy that covers your unit

and accessories packed with the unit at the factory. There is a 180-day

warranty on all non-warranty repairs from the factory, which is similar to the

original warranty, but is for 180 days rather than one year. For further

details, please call us at the above number.

Eagle Electronics may find it necessary to change or end our shipping policies, regulations,

and special offers at any time. We reserve the right to do so without notice.

Accessory Ordering Information

To order accessories such as power cables or transducers, please contact:

1) Your local marine dealer. Most quality dealers that handle marine

electronic equipment should be able to assist you with these items.

Consult your local telephone directory for listings.

2) LEI Extras, Inc. P.O. Box 129 Catoosa, OK 74015-0129

or call

800-324-0045

(USA orders only.)

Remember, non-warranty repairs are subject to Eagle's published flat-rate

charges and 180-day warranty.

EAGLE ELECTRONICS PO BOX 669 CATOOSA OK 74015

LITHO IN U.S.A. 988-0143-34

40

Loading...

Loading...