Page 1

This user guide also contains tips on effective

washing and important safety notes.

Please read this handbook carefully before use.

User guide

TM

Helpline 08706 002 701

Dyson Ltd Tetbury Hill Malmesbury

Wiltshire SN16 ORP

Page 2

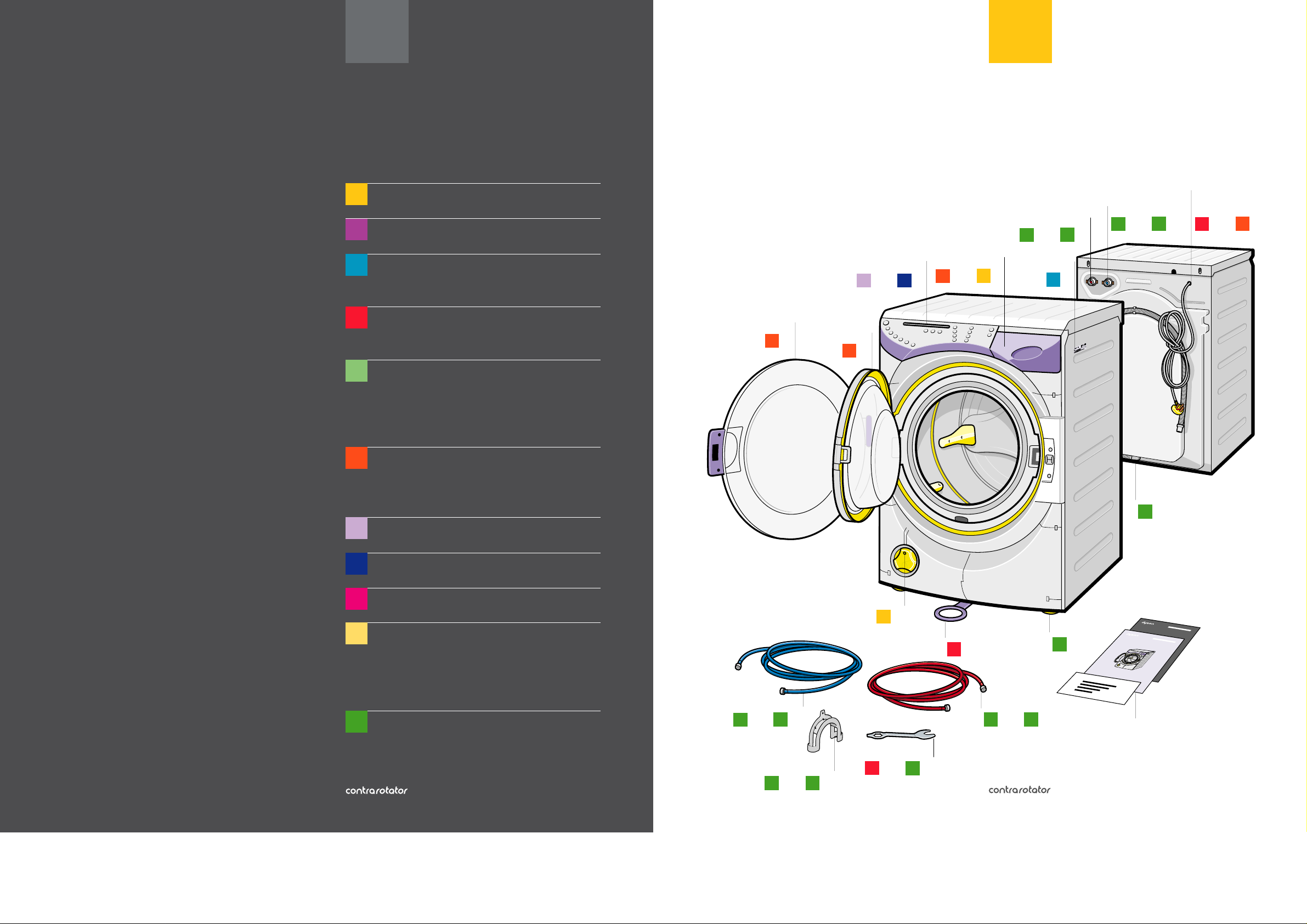

Overview of your Dyson Contrarotator

TM

1 01Overview

Outer door

Control panel

Soap tray

Hot water inlet

Cold water inlet

Hot inlet pipe

Cold inlet pipe

Drainage hose hook

Power cable

with plug

&

Inner door

Rating Plate

Adjustable feet

Dyson guarantee form

Reply envelope

Fabric care leaflet

Drainage hose

& adjustable clip

Rollerjack

TM

Coin trap

Dyson spanner

4 01

6 02

&

5 01

5 02

&

5 01

5 02

5 02

5 03

4 01

10 02

6 02

6 02

6 02

3 01

&

10 01

7 01&8 01

4 01&5 01

5 01&5 02

5 01&5 02

5 01&5 02

Contents

Overview of your Dyson Contrarotator

TM

The only 2-drum wash action

Registration

Important safety notes

Inner transit packaging removal

Moving

Location

Drainage

Water supply

Electrical installation

First wash cycle

Sorting your clothes

Loading your Contrarotator

TM

Using default settings

Personalising the wash programme

Programme wash table

Cleaning

Coin trap maintenance

Water filter maintenance

Emergency door release

Problem solving

01

01

01

01

01

02

03

01

02

01

01

01

01

02

03

01

Overview

Your Contrarotator

TM

User instructions

Before installation

Installation

Operation

Starting your wash

Optional settings

Programme table

Maintenance

Troubleshooting

1

2

3

4

5

6

7

8

9

10

11

Page 3

Do not:

stack tumble dryers or other appliances on top of the machine.

alter the machine or modify it in any way, as this will invalidate

your guarantee and could be dangerous.

carry out any maintenance work on the machine other than

that outlined in this handbook.

use the washing machine if any part appears to be faulty,

missing or damaged.

overload the washing machine; the maximum loads are

indicated in the programme table section

use adapters or extension cables.

use the washing machine for commercial or industrial

purposes, as this will invalidate your guarantee. The machine

is designed for domestic use.

Always:

use the Rollerjack

TM

for moving the machine as it is very heavy.

Care must be taken when moving it.

turn off the machine using the ‘Mains on/off’ button when not

in use and switch off at the socket.

turn off the water supply to the machine when it is not in use

for long periods.

close both the inner and the outer doors when not in use.

close soap tray before starting the machine.

Child safety

Never allow children to play with or use the washing machine.

If children are present, always use the child lock when running

the machine; see section

Always engage the child lock when the machine is not in use.

To do this, close both doors, press and hold ‘minimum iron’

button, switch the machine off at ‘Mains on/off’ button.

Always check drums are empty before loading the machine.

Keep all packaging out of the reach of children.

Registering your Dyson Contrarotator

TM

Every Dyson washing machine comes with a 2 year guarantee,

with an option to extend the guarantee for a further 1 to 3

years. For more details on these options, please refer to the

enclosed guarantee form.

It is important to register your Dyson washing machine. This

will ensure that you receive prompt and efficient service if your

machine requires attention during the 2 year guarantee

period. Registration will also entitle you to software upgrades

as they become available.

How to register

To register your Dyson washing machine, please:

complete the enclosed guarantee card and return it in the

freepost envelope to: Dyson Registration Department,

P.O. Box 26, Bedworth, Warwickshire, CV12 8ZZ.

alternatively you can register the machine at www.dyson.com.

Helpline 08706 002 701

If a problem arises with your Dyson washing machine, or if it is

displaying a fault code, please refer to the troubleshooting

guide section

If you still cannot solve the problem, please:

contact the helpline 08706 002701 8am-8pm, 7 days a week,

visit our website at www.dyson.com,

or you can email us at service@dyson.com.

Serial number

For future reference, fill in your machine's details in the space

provided. The serial number can be located on the rating

plate, position shown in section

Serial Number

Date of purchase

Place of purchase

Important safety notes

Registration

User instructions

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

3 01

•

•

•

•

•

•

•

☎

1 01.

8 01.

9 01.

11 01 to

11 03.

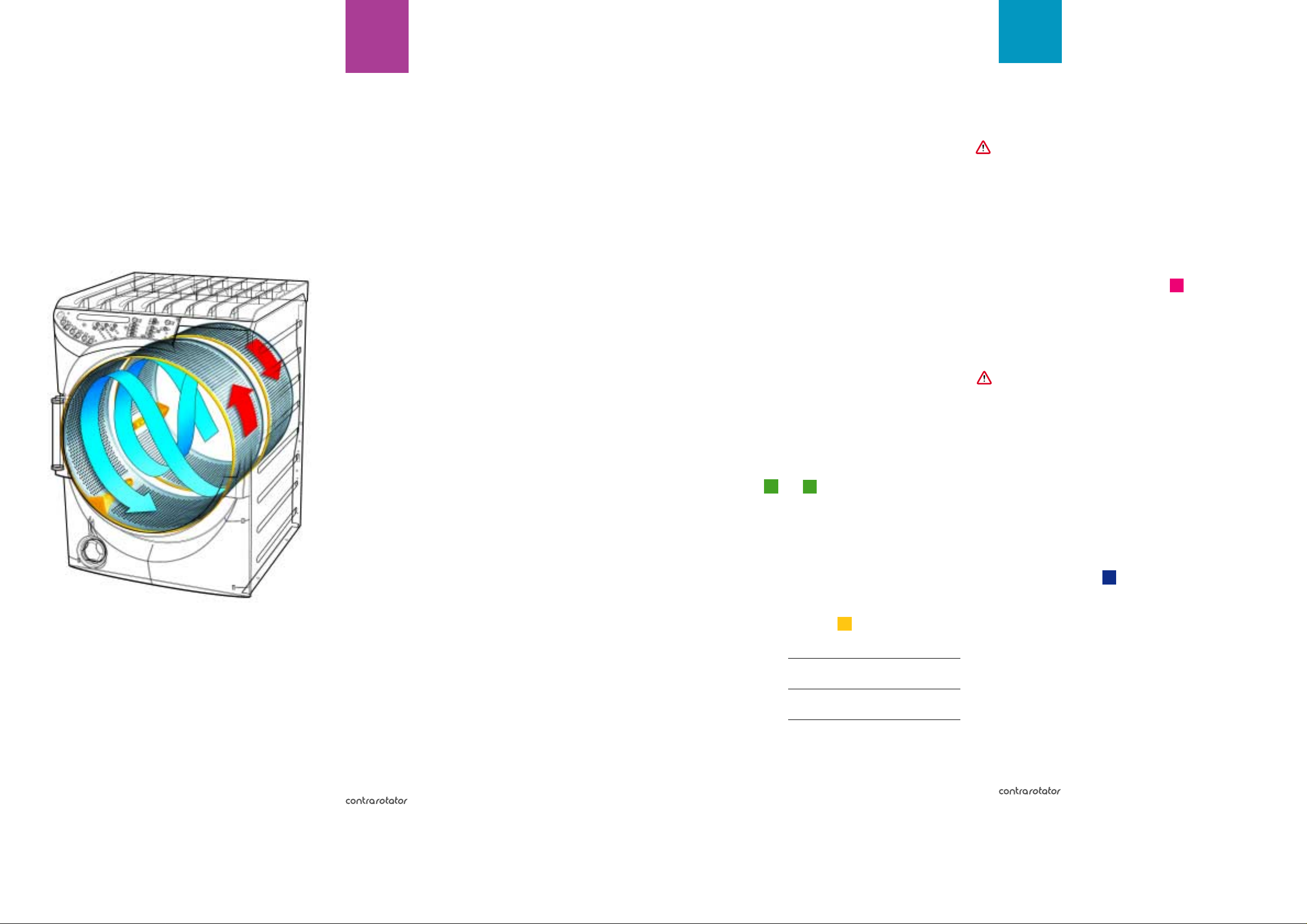

The only 2-drum wash action

2 01Your Contrarotator

TM

Conventional washing machines may seem convenient, but

their poor performance lets you down. So James Dyson asked

his engineers to experiment with every imaginable way of

washing to design a better washing machine.

Along the way, Dyson’s engineers made a surprising

discovery: washing by hand gave better wash results than

single drum machines. Because the clothes are constantly on

the move, they are manipulated and flexed – every centimetre

of the fabric is exposed to the detergent. It opens the weave

of the fabric and agitates the dirt more, to release it easily

and quickly. It’s an active, efficient process.

To replicate the movement of hand washing Dyson’s

engineers designed two aligned drums and engineered them

to rotate in opposite directions at the same time. The effect of

this revolutionary action on the clothes is dramatic. Instead of

revolving in the old single pattern of ‘drop and flop’, the

clothes are much more active, moving in an infinitely variable

dance, to flex the fabric and open the weave to the detergent.

Because the Contrarotator

TM

releases dirt more effectively, it

can wash clothes cleaner.

Page 4

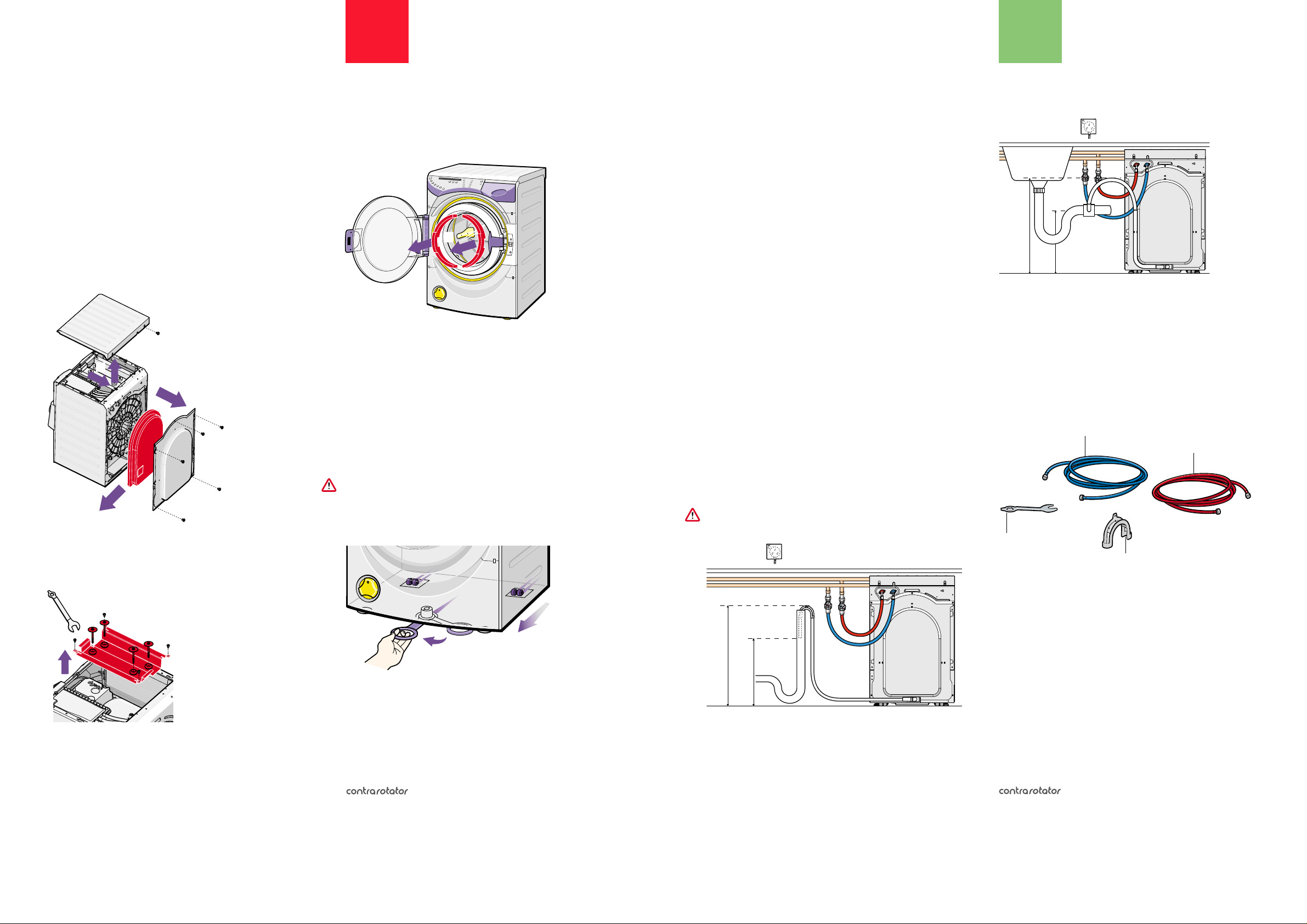

Every Dyson machine is tested before it is dispatched. As a

result, there may be some dampness or water in the machine.

The machine should not be installed in a location where the

temperature may drop below freezing.

The machine should not be installed in a bathroom.

The machine must be installed on a secure and flat surface.

Soft floors, such as carpet or carpet tiles, are not suitable

surfaces.

If the machine is to be installed on floorboards, the unit must

be placed on a water-resistant wooden board at least 30mm

thick with at least 50mm spare on each side of the machine.

This board must be screwed securely to at least two joists.

If possible, the machine should also be positioned in the

corner of the room.

The maximum distance and suggested layout of the drain,

taps and power socket from the machine are illustrated below.

The inlet water pipes, drain hose and the electrical mains

lead must be positioned carefully to avoid damage or kinking

when the machine is fully installed. The machine can be

connected to a standpipe, under sink pipe connection or

other drainage system, but the critical dimensions must be

followed.

Important

Stand pipe connection

5 01Installation

Sink pipe connection

Water supply, drainage and electricity

The washing machine comes with:

2 inlet pipes (one blue, one red).

1 drainage hose hook.

1 Dyson spanner.

1 drainage hose located at the rear of the machine.

All of the above items can be found in the drums.

NB: the model ‘CRO1 Memory’ has leak protection hoses with

a small rectangular block at the end of the cold inlet pipe

which are different from those illustrated.

Hot inlet pipe

Cold inlet pipe

Drainage hose hook

Dyson spanner

600 mm

MAX.

450 mm

MIN.

600 mm

MAX.

450 mm

MIN.

•

•

•

•

•

Location

Refit the lid and two screws.

Open the outer door and carefully lift out the two foam inserts

from the front of the inner door.

Please retain the transit packaging for future use, as it should

be used whenever the machine is moved.

To replace the packaging, reverse the above procedure.

Moving

To move the machine, pull out the RollerjackTMhandle from

under the front of the machine which enables you to

manoeuvre the machine easily into your desired position.

Replace the Rollerjack

TM

slowly because the handle may return

with force. The Rollerjack

TM

is not designed for moving the

machine over long distances.

Inner transit packaging removal

Before installation, check the washing machine for damage.

A qualified person should always carry out installation.

All packaging must be removed before the machine is

connected to power or water supplies.

Remove the rear panel by removing the five screws.

Carefully withdraw the foam block and then refit the rear

panel and screws.

Remove the two screws from the rear of the lid.

Remove the machine lid by sliding it rearwards and then up.

Remove the plug from under the lid by cutting the ties holding

it on to the transit bracket.

Using the Dyson spanner remove the four bolts securing the

top transit bracket.

Remove the four screws securing the bracket to the machine

casing and lift out the transit bracket.

4 01

Before installation

5

6

1

2

3

4

5

6

7

•

7

•

•

•

1

3

2

4

Page 5

European conformity information

This product has been tested and found to be in conformity

with the following European Directives:

73/23/EEC Low Voltage (safety) Directive.

93/68/EEC CE Marking Directive.

89/336/EEC EMC Directive.

When all of the instructions on the previous pages have been

completed, the machine can be installed into its operating

position using the Rollerjack

TM

handle, see section 4 01.

Using the Dyson spanner, adjust the two front feet so that the

machine is perfectly stable and level and will not rock on

three of its four floor contact points.

Do not use wood, carpet or other material to stabilise

the machine.

5 03Installation

•

•

•

•

•

•

•

•

•

•

Cold only water supply

If there is no hot water supply, attach the cold and hot pipes

to the machine as normal. Then, attach both hoses to a Y

piece connector (available as a separate accessory, see rear

page for Helpline telephone number) and finally connect the

Y connector to the cold inlet tap.

Once all connections have been made, turn on the tap(s) to

check that there are no leaks.

Electrical installation

Warning: This appliance must be earthed

Any electrical work required to install the washing machine

should be carried out by a Dyson trained installer or

qualified electrician.

Before using your machine, check that the plug and sockets

match, and check that the voltage in your home corresponds

to that indicated on the rating plate.

For the rating plate's location, see section 101.

The machine should be plugged into a switchable, earthed

socket that is easily accessible after installation.

Do not use an extension cord or plug adapter.

If the supply cord or plug is damaged disconnect the

appliance from the socket outlet immediately. The supply cord

must only be replaced by Dyson or its appointed agent, as

special purpose tools and service techniques are required.

If the plug supplied needs replacing it should be cut off and

safely disposed of. Under no circumstances should the

severed plug be inserted into a socket outlet as this may result

in an electric shock hazard.

Always:

connect your machine to the water supply by hand, using the

hoses supplied. Do not use old hoses.

the water pressure should be between 0.4 and 5 bar.

Do not tighten the plastic hose connections with a spanner.

Do not connect to a mixer tap.

Hot and cold water supply

Attach the blue hose to the cold inlet tap and the red hose to

the hot inlet tap.

Water supply

Drainage

5 02

Installation

•

•

•

•

•

•

•

•

•

Drainage hose hook

Drainage hose

You can alter the direction of the drainage hose to the left or

to the right.

To change the direction of the machine’s drainage hose,

open the retaining clip using a pair of pliers, and hold it open

while you rotate the hose.

Ensure the hose is inserted fully before releasing the clip.

Thread the drainage hose through the hose hook and adjust

the protruding end to a distance of 30mm. The hose hook

has a small retention hole that can be used to secure the

hose assembly in position.

Do not use hose hook for under sink connections.

When installed into a standpipe or under sink connection,

ensure that the water outlet end of the drainage hose is no

lower than 450mm from ground level. Position the hose so

that at no point in its entire length it lies above 600mm from

ground level, refer to image in section 5 01.

Failure to comply with these dimensions could cause the

machine to malfunction.

30mm

Stand pipe

Page 6

Plug machine into the mains and switch on at the socket.

Turn on water supply at the mains.

Open outer and inner doors.

Check drums are empty before placing sorted clothes into the

washing machine.

Close both doors, making sure that both have “clicked” shut.

Do not overload your machine. Maximum loads for each

fabric type are shown in the table in section 9 01.

Tests have proven that overloading can reduce the wash

performance and may cause damage to your machine.

Detergent use

To open the soap tray, press the icon on the soap tray.

Do not try to pull out the soap tray without first pressing it.

Push to close, ensuring it “clicks”.

Add detergent to the compartment marked 2 for all main

wash programmes. To optimise the wash performance of the

machine, we recommend the use of detergent suitable for

automatic washing machines.

If selecting the pre-wash programme, add detergent to the

compartment marked 1.

Fabric conditioner to soften your clothes can be added to the

compartment marked

*

to the level indicated.

Wash tips

Place dosage aids, such as wash balls and nets, directly

inside the drums of the machine.

Do not put detergent or dosage aids directly into the drums if

using start delay (CRO1 Memory only).

Dosage aids must not be used when pre-wash is selected.

Use the correct amount of detergent. Incorrect dosage can

reduce the efficiency of wash performance. For the correct

dosages follow the manufacturer’s instructions on the

detergent packaging.

Loading your Contrarotator

TM

6 02

Operation

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Operation

First wash cycle

6 01

Before washing, sort clothes by fabric types and fabric care

label, ensuring that dark colours are not mixed with

light colours.

Fabric care label explanation

The number in the wash tub indicates the maximum wash

temperature. When washing a range of clothing always choose

the lowest temperature from all the wash labels in the load.

A wash tub without a bar underneath it indicates that the

garment is suitable for a cotton wash (maximum agitation)

when washed at the appropriate temperature.

A single bar underneath the wash tub indicates reduced

(medium agitation) wash conditions, at the appropriate

temperature. Wash on delicates or synthetics programme

depending on the garment.

Two bars under the wash tub indicate further reduced

(minimum agitation) wash conditions used specifically for fine

fabrics. Wash on wool programme.

Do not wash

These garments can be washed in the machine by selecting the

handwash items programme.

•

•

•

•

•

•

•

•

•

•

•

•

40

Sorting your clothes

After installation

Run a 60° cotton cycle with half a measure of detergent but

no clothes. For the correct dosage, please follow the

manufacturer’s instructions on the detergent packaging.

See sections 7 01 and 8 01 on how to start the

washing machine.

This will clean any test water out of the machine, ensure the

installation process has been correctly followed and highlight

any problems, for example if the machine has not been

levelled correctly.

To ensure your machine is installed correctly, observe it

regularly during the first wash. Any faults will then either

become apparent or be displayed on the control panel.

Check connections after 1 week to ensure that they have been

fitted correctly.

Machine wash tips

Always:

wash new items separately for their first few washes as they

can contain excessive dye.

consult the wash care label on clothes and select the

appropriate programme accordingly. See programme table in

section 9 01.

empty pockets and fasten buttons and zips before washing.

avoid washing frayed or torn fabrics.

wash duvets and other bulky items on the Duvet programme,

first checking the label to ensure they are machine washable.

NB: wash only synthetic duvets in the machine.

put small items e.g. bras and tights in a pillowcase or wash

bag.

turn double layered textiles, sleeping bags, duvet covers,

knitted fabrics and coloured items inside out before washing.

use detergents suitable for automatic washing machines.

It is not recommended to wash:

large non-clothing items, e.g. trainers, shoes or rucksacks in

the machine, as this may cause damage to the machine.

clothes that have been in contact with flammable materials.

Page 7

Start your wash cycle

Press to start your chosen wash

programme. If at any time you

wish to pause the cycle, press

the ‘start’ button a second

time. When paused, the display

indicates that the programme

may be restarted by pressing

the ‘start’ button.

When a programme is paused,

the door may be locked for

safety reasons, see section

8 01 Door lock.

Cancel your wash cycle

Press and hold down to cancel

a programme at any time.

The machine will stop and

drain all the water and the

doors will then be unlocked if it

is safe to do so.

If, for example, the wash is too

hot after a 85°C cycle, the

doors will stay locked until the

temperature is safe to allow the

doors to be opened.

End of your wash cycle

At the end of the wash programme the display will indicate

‘Programme finished’. Remove the washing and turn off the machine

by pressing the ‘Mains on/off’ button. Switch off the electricity at the

socket and turn off the water supply to the machine.

Mains on/off

Press to turn power on before

selecting a programme.

Select your programme

Press to select your programme

option. Default settings will be set

for temperature, spin and dirt

level which are safe for that

fabric type.

To start your wash cycle using the default settings

7 01Starting your wash

1

2

3

4

Page 8

8 01Optional settings

Adjust your programme

Use these options to adjust the

default settings of the wash

programmes. On certain

programmes some temperature,

spin and soil level settings cannot

be overridden in order to protect

your clothes; see programme table

section 9 01.

To personalise the default wash programmes

1

Start delay

This option allows you to delay

the start of the cycle by up to 24

hours. Use the and arrows

to adjust the settings. The display

will show the delay time to start.

Press the ‘start’ button to initiate

the countdown. Press the ‘cancel’

button at any time to cancel.

The soap tray should be

completely dry before adding the

detergent. Only available on

CRO1 Memory.

Memory buttons

This option allows you to store

three of your favourite

programmes. Once you have

selected your desired

programmes and options, press

and hold one of the memory

buttons for three seconds.

A beep will confirm the

programme has been stored.

To select a stored programme,

press the correct memory button

and then start the cycle.

To override a stored programme,

follow the steps detailed above.

Only available on CRO1 Memory.

Door lock

The door lock light indicates

that the outer door is locked.

When a programme is paused

the door will unlock if it is safe

to do so. If not, the display will

indicate why the door stays

locked. Press the ‘start’ button

to finish the programme.

Child lock

This option locks the settings

on the control panel and locks

the outer door. Before the

programme is started use this

option to prevent the settings

from being altered or the

programme being

inadvertently started. Once a

programme is running use this

option to prevent it being

paused or cancelled.

Press and hold the ‘minimum

iron’ button to activate and

cancel the child lock option.

Add options

To activate any of the options

below after you have selected

your programme, press the

desired option button once; press

again to cancel the option.

Minimum iron

This option holds your clothes in

water after the final rinse to

minimise creasing.

The machine will pause and the

‘start’ button will flash.

Press the ‘start’ button to finish

the cycle. To protect your clothes,

this option is not available on all

programmes.

Pre-wash

This option will remove excess dirt

before the main wash cycle.

Extra rinse

This option adds one extra rinse

(for people with sensitive skin).

Rinse & spin/Spin only

Press once for rinse & spin, press

twice for spin only.

Press again to cancel.

Soil level selection guidelines

Dirt

Select ‘Dirt’ for garments which

are only lightly soiled

(see programme table for

maximum load).

Dirt & stains

Select ‘Dirt & stains’ for typical

everday soiling.

Heavy stains

Select ‘Heavy stains’ for an even

more thorough programme to

remove those rare, heavy stains.

2

3

4

6

5

Page 9

Dirt & stains

Dirt & stains

Dirt & stains

Dirt & stains

Dirt & stains

Dirt & stains

7

40

1100

9 01Programme table

1 king size duvet

or 3 pillows

Maximum load kg

Soil level

Spin rpm

Temperature °C

Programme

Care label

Fabric type

Default settings

2

40

800

40 500

4

Cotton, linen and viscose

without special finishes

Polyester/cotton mixtures,

nylon, acrylics, acetate,

triacetate and viscose with

special finishes

Wool or wool mixed with

other fibres

3

500

40

Delicate fabrics in

man-made fibres e.g. net

curtains, stockings, silk, etc.

Not for wool

1.5

500

30

Synthetic duvets

Synthetic pillows

Items with Handwash only

symbol

800

40

Cotton

Synthetics

Wool

Delicates

Handwash items

Duvet

Heavy

stains

Dirt

Dirt &

stains

1 king size

duvet or

3 pillows

Maximum

load kg

Rinse & spin

Spin only

Extra rinse

Pre wash

Minimum

iron

Spin rpm

Temperature °C

Optional settings

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

7

7

3.5

4

4

2

2

2

Dirt

level

Heavy

stains

Dirt

Dirt &

stains

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

✓

2

✓

0 500 800 1100 1400

0 500 800 1100 1400

0 500 800 1100 1400

0 500 800 1100

0 500

0 500

0 500

0 500 800

0 500

20 30 40 50 60 85

20 30

30 40

30 40

30 40 50 60 85

30 40 50

30 40 50

30 40

30 40

Page 10

Once all the water has been removed, continue to turn the

cap anticlockwise until it is released.

Remove any objects from the coin trap.

If further items appear to be blocking the coin trap, pull out

the flow accelerator.

Remove any item(s) and replace the flow accelerator.

New illustration

To replace the coin trap cover:

lubricate the seal with washing up liquid.

fit the cover with the hole at the bottom ensuring seals are

lined up.

turn 1.5 revolutions in a clockwise direction, ensuring the

childproof tab “clicks” into place.

Never remove any objects from the coin trap whilst the

washing machine is running.

Empty the coin trap when a blockage has occurred.

Place a tray or shallow dish underneath the coin trap.

Using the Dyson spanner, lift the childproof tab and turn the

cap anticlockwise.

The water will flow through the spout.

If the tray becomes full, turn the cap clockwise into its starting

position, empty the tray and repeat the process.

Maintenance

10 02

Coin trap maintenance

Childproof tab

Drainage hole

Flow accelerator

•

•

•

•

•

•

•

•

•

•

•

Always unplug from the mains before carrying out any

maintenance on the washing machine.

The machine should be cleaned regularly with a damp cloth

but not with any cleaning solutions.

Cleaning the soap tray

The soap tray should be cleaned regularly to remove any

detergent residues.

Press the yellow release button at the rear of soap tray to pull

out drawer.

Wash in warm, soapy water.

The cavity for the soap tray should be cleaned out with a

small, soft brush, taking care not to dislodge the rubber seal.

Replace the soap tray ensuring it clicks into place.

Do not wash in a dish washer.

Maintenance wash

To prevent odours and build-up of deposits within the

washing machine, it is recommended that you run a 60°

cotton cycle with half a measure of detergent but no clothes

2 or 3 times a year.

If the outer door is accidently removed

Locate top ring of outer door into the yellow part of

flexible hinge.

Lift the door and push forward until lower ring of door

“clicks” into place.

10 01Maintenance

Cleaning

•

•

•

•

1

2

1

2

Page 11

To access the rear of the machine use the RollerjackTMhandle;

see section

Cleaning the water inlet filters

The water inlet filters should be checked regularly for debris or

limescale build-up, (depending on whether the water in your

area is hard or soft). Contact your local water authority to find

out your water composition.

Turn off the water supply to the machine.

Unscrew both water inlet pipes by hand.

Using pliers, pull out the filters and rinse under cold water.

Replace filters and reconnect water inlet pipes.

Water filter maintenance

Emergency door release

10 03

This procedure should be used in the event of a power cut

to remove clothes.

Switch off and remove the plug from the socket.

Ensure the drums have stopped moving.

If the machine has been running a hot wash, leave it to

cool down.

Completely drain the washing machine as described in the

‘Coin trap maintenance’ section, section

Remove the soap tray as described in section

Using the Dyson spanner, turn the door release screw

anticlockwise to unlock the door.

Open the outer and inner doors.

Turn the door release screw clockwise through a quarter of a

turn, to ensure the door will close.

Replace the soap tray.

Maintenance

•

•

•

•

•

•

•

•

•

•

•

•

•

4 01.

10 01.

10 02.

11 01Troubleshooting

LCD display is blank

Machine displays

“Overload reduced

performance”

Machine displays

“Close inner door then

press start”

Certain spin speeds, temperatures,

dirt levels cannot be selected

Cancel button does not

work during a wash

Cannot open door

Washing machine leaks

water

Washing machine shakes

during the cycle

Machine displays

“Close outer door then

press start”

Machine displays

“Not emptying: check hose

and coin trap”

Machine displays

“Not filling: check water supply”

Machine displays

“Uneven load cannot spin”

Before calling the helpline, please read carefully the following pages.

Page 12

In future, refer to programme table

section 9.01 for recommended loads.

Remove some items or reload your

machine and select spin only programme

see section 8 01 then press start.

Close outer door, ensuring nothing is

trapped and press start again.

Close inner door, ensuring nothing is

trapped and press start again.

Refer to 10.02 for removing blockages

and press start.

Check drainage hose is not blocked

or kinked and press start.

Check that water supply is connected,

turned on at the tap, and press start.

Clean filters as detailed in section 10.03

and press start.

Check inlet pipes are not blocked

or kinked and press start.

Check that drainage hose is installed in

accordance with the installation

instructions in sections

and press start.

Contact Dyson Helpline 08706 002 701

or visit our website www.dyson.com with

the following information:

your machine’s serial number.

where you purchased your machine.

when you purchased your machine.

your address.

the fault code that appears on the LCD

display, if applicable.

11 03Troubleshooting

Overload reduced performance

Uneven load cannot spin

Close outer door then press start

Close inner door then press start

Not emptying: check hose and

coin trap

Not filling: check water supply

Fault

The recommended wash load has been

exceeded

The wash load is uneven

Coin trap blocked

Drainage hose not draining

Water supply is not connected

Filter is blocked

Inlet pipes are blocked or kinked

Drainage hose is installed incorrectly

These are technical faults with your

machine.

Most queries can be solved over the

telephone by one of our trained customer

care staff. If they cannot, a qualified

Dyson service engineer will visit you to

repair and test your machine.

LCD display message

Possible causes

Solutions

•

•

•

•

•

8 01,

9 01

10 02

10 03

5 01 &

5 02

Ensure

machine

is plugged in and

switched on. Check fuse and circuit

breaker has not tripped.

See section 9.01 for the programme

options wash table.

Hold down ‘Minimum iron’ button until

‘Child lock off ’ is shown on LCD

display and child lock light is off.

Wait for machine to finish cycle before

opening the door. Cancel wash by

holding down

‘Cancel’

button.

For safety reasons the door stays locked.

Press flashing start button to resume

programme.

Hold down

‘Minimum iron’

button until

‘Child lock off ’ is shown on LCD

display and child lock light is off.

Follow ‘Emergency door release’

instructions in section

Turn off water supply to machine

ensuring that coin trap cover is correctly

fitted, see section

Check discharge hose is draining into a

suitable place (drain, sink or standpipe).

Close soap tray.

Adjust feet until machine is level as

described in section

Return Rollerjack

TM

handle to its position

under machine, see section

LCD display is blank

Certain spin speeds, temperatures, dirt

levels cannot be selected

Cancel button does not work during

the cycle

Cannot open door

Machine leaks water

Machine shakes during the cycle

There is no power to the

machine

To maximise wash performance and

protect the clothes, there are limits on the

temperatures, spin speeds and dirt levels

for each programme

Child lock is active

Washing machine has not finished cycle

Machine is paused

Child lock is active

Power cut or any other cause not listed

Coin trap cover is not in place

Discharge hose is not connected correctly

Soap tray is open

2 adjustable front feet are not level

Rollerjack

TM

handle is still out

11 02Troubleshooting

Symptom

Possible causes

Solutions

9 01

5 03.

4 01.

10 03.

10 02.

Loading...

Loading...