Page 1

This user guide also contains tips on effective

washing and important safety notes.

Please read this user guide carefully before use.

User guide

TM

www.dyson.com

Page 2

Page 3

Contents

Overview of your Dyson Contrarotator

TM

The only 2-drum wash action

Free registration

Important safety notes

Inner transit packaging removal

Moving the Contrarotator

TM

Specification

Location

Drainage, water supply and electricity

Drainage

Water supply

Electrical installation

After installation

Loading the Contrarotator

TM

Detergent use

To start your wash, using default settings

To personalise the default wash programmes

Fabric care

Programme table

Cleaning

Coin trap

Water filter

Emergency door release

Troubleshooting

01

01

01

01

01

02

03

01

01

01

01

02

01

02

03

01

02

03

Overview

Dyson Contrarotator

TM

User Instructions

Before installation

Installation

Operation

Starting your wash

Optional settings

Fabric care and Programme table

Maintenance

Troubleshooting

1

2

3

4

5

6

7

8

9

10

11

Page 4

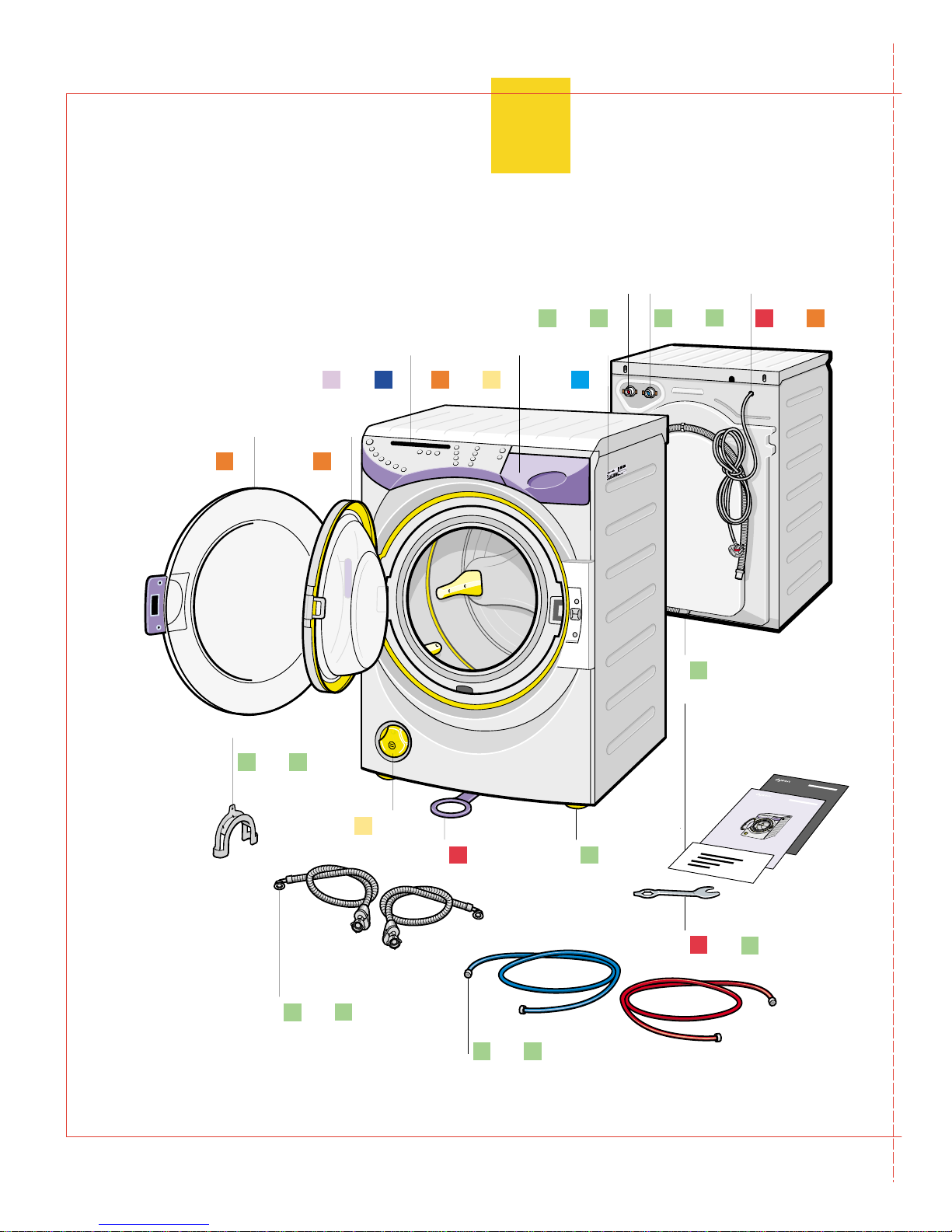

Overview of your Dyson Contrarotator

TM

1 01Overview

Outer door

Control panel

Soap tray

Hot water inlet

Cold water inlet

Drainage hose hook

Power cable & plug

&

Inner door

Rating plate

Adjustable feet

Drainage hose & adjustable clip

Rollerjack

TM

Coin trap

4 01

6 01

&

5 01

5 02

&

5 01

5 02

5 02

5 03

4 01

10 02

6 01

6 01

6 01

3 01

&

10 017 01&8 01

Hot & cold leak protection

inlet hoses

CRO1 Flowcheck and Memory only

5 01&5 02

5 01&5 02

Dyson guarantee form

Reply envelope

Fabric care leaflet & letter

Dyson spanner

4 01&5 01

Hot & cold inlet hoses

5 01

&

5 02

Page 5

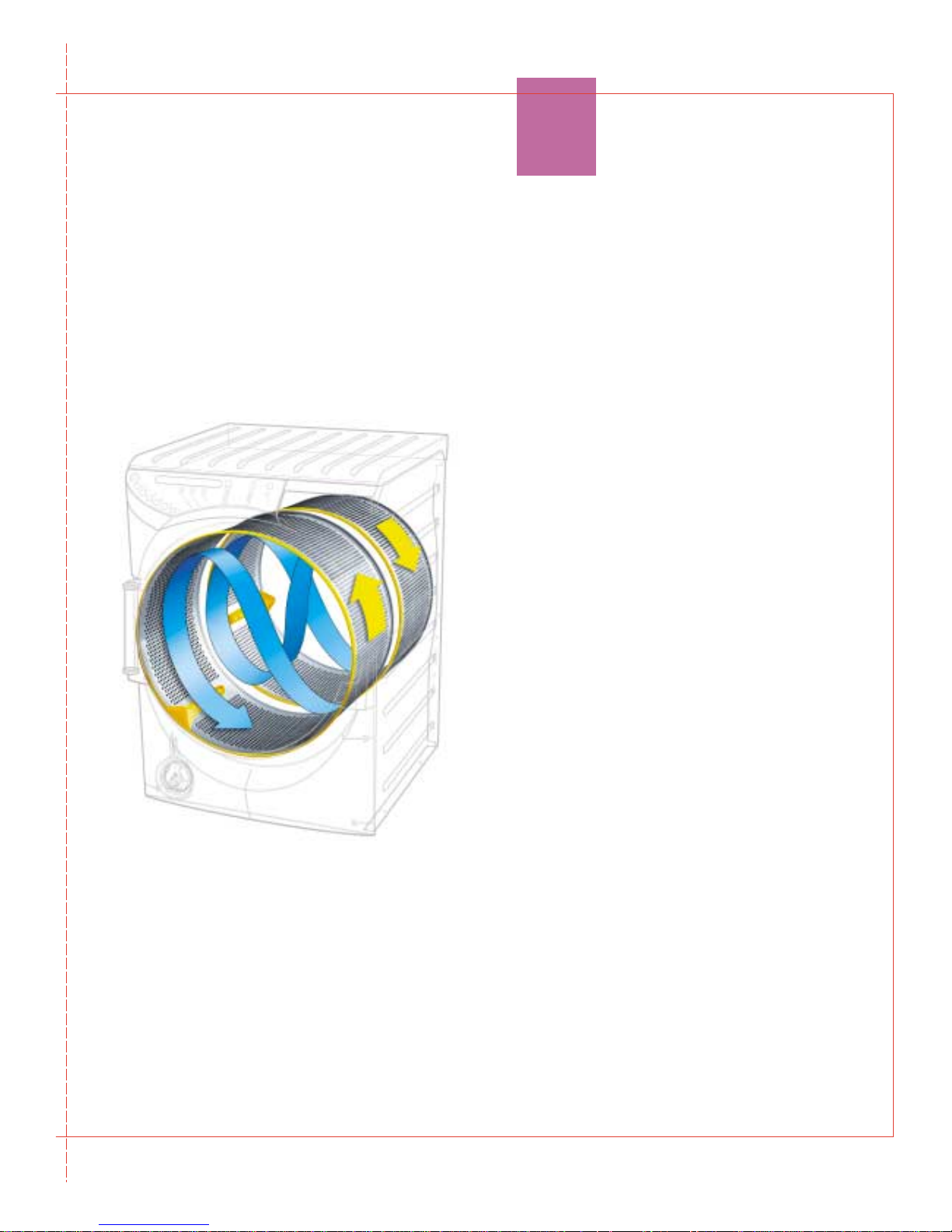

The only 2-drum wash action.

Dyson Contrarotator

TM

Conventional washing machines may seem convenient,

but their poor performance lets you down. So James Dyson

asked his engineers to experiment with every imaginable way

of washing to design a better washing machine.

Along the way, Dyson engineers made a surprising discovery:

washing by hand gave better wash results than single drum

machines. Because the laundry is constantly on the move,

it is manipulated and flexed. This opens the fabric to the

detergent, releasing dirt quickly and effectively.

To replicate the movement of washing by hand, Dyson

engineers designed two aligned drums and engineered them

to rotate in opposite directions at the same time: laundry is

constantly on the move, manipulated and flexed.

Because the Contrarotator

TM

releases dirt more effectively,

it can wash laundry cleaner, faster and in larger loads.

This product is protected by the following:

Patents and Patent Applications:

Registered Designs:

GB 2090907 DE 40008214.4 FR 004914 AU 143433

CH 127265 IT MI 2000 O 000588 JP 1114510 US 29/128,794

Trade Marks:

DYSON

TM

CONTRAROTATOR

TM

DYSON CONTRAROTATORTMCRO1TMROLLERJACK

TM

Equivalent rights exist in other territories.

For patent information please see www.dyson.com

2 01

GB 00 01848.1

GB 01 21535.9

US 09/853,689

WO 01/71086

WO 01/88256

WO 01/71084

WO 01/71085

PCT/GB 01/03730

US 09/956,248

WO 01/71087

WO 01/73939

WO 01/71083

PCT/GB01/03716

PCT/GB01/04324

US 09/956,163

GB 2 337 274

US 6,311,527

EP 1078119

JP 2000-548539

US 09/853,689

WO 00/68490

PCT/GB01/02974

WO 99/58753

CA 2,332,024

AU 39393/99

Page 6

Always:

• use the Rollerjack

TM

to move the machine. Care should be

taken when moving it, as it is very heavy.

• turn off the machine with the ‘Mains on/off’ button and

switch off at the socket when not in use.

• turn off the water supply to the machine and close both the

inner and outer doors when not in use.

• close the soap tray before starting the machine.

• remove all items from pockets.

Do not:

• stack tumble dryers or other appliances on top of the

washing machine.

• alter the machine or modify it in any way, as this will

invalidate your guarantee and could be dangerous.

• carry out any maintenance work on the machine other than

that outlined in this guide.

• use the washing machine if any part appears to be faulty,

missing or damaged.

• overload the washing machine; the maximum loads are

indicated in the programme table in section 9 02.

• use adapters or extension cables.

• use the washing machine for commercial or industrial

purposes, as this will invalidate your guarantee. The machine

is designed for domestic use.

Child safety

The Dyson Contrarotator

TM

has a child lock option.

See section 8 01 for usage instructions.

Always:

• use the ‘child lock’ when the machine is not in use.

• check the drums are empty before loading the machine.

• use the ‘child lock’ when running the machine, if children

are present.

• keep all packaging out of the reach of children.

Do not:

• allow children to play with or use the machine.

Important safety notes

Free registration

User Instructions

3 01

Registering your Dyson Contrarotator

TM

Every Dyson washing machine comes with a complimentary

2 year guarantee, with an option to extend the guarantee for

a further 1 to 3 years. For more details on these options,

please refer to the enclosed guarantee form.

How to register

Please ensure that you register your guarantee as soon as

possible. This can be done by:

• registering your machine at www.dyson.com

• or completing the enclosed guarantee card and returning it

in the envelope provided.

(Please keep your proof of purchase in a safe place to ensure that you

have this information available as it may be required in order for a service

engineer to carry out a repair).

Dyson service

If a problem arises with your Dyson washing machine, or if it

is displaying a fault code, please refer to the troubleshooting

guide section 01 to 11 03.

If the problem is still not resolved, please:

• visit our website at www.dyson.com for on-line help

• or contact the helpline:

UK 0870 600 2701, 7 days a week (8am-8pm)

email service@dyson.com

ROI (01) 475 7109

email irelandservice@dyson.com

Serial number

For future reference, fill in your machine’s details in the space

provided. The serial number is on the rating plate

(see section 01 for location).

Serial number

Date of purchase

Place of purchase

1

11

Page 7

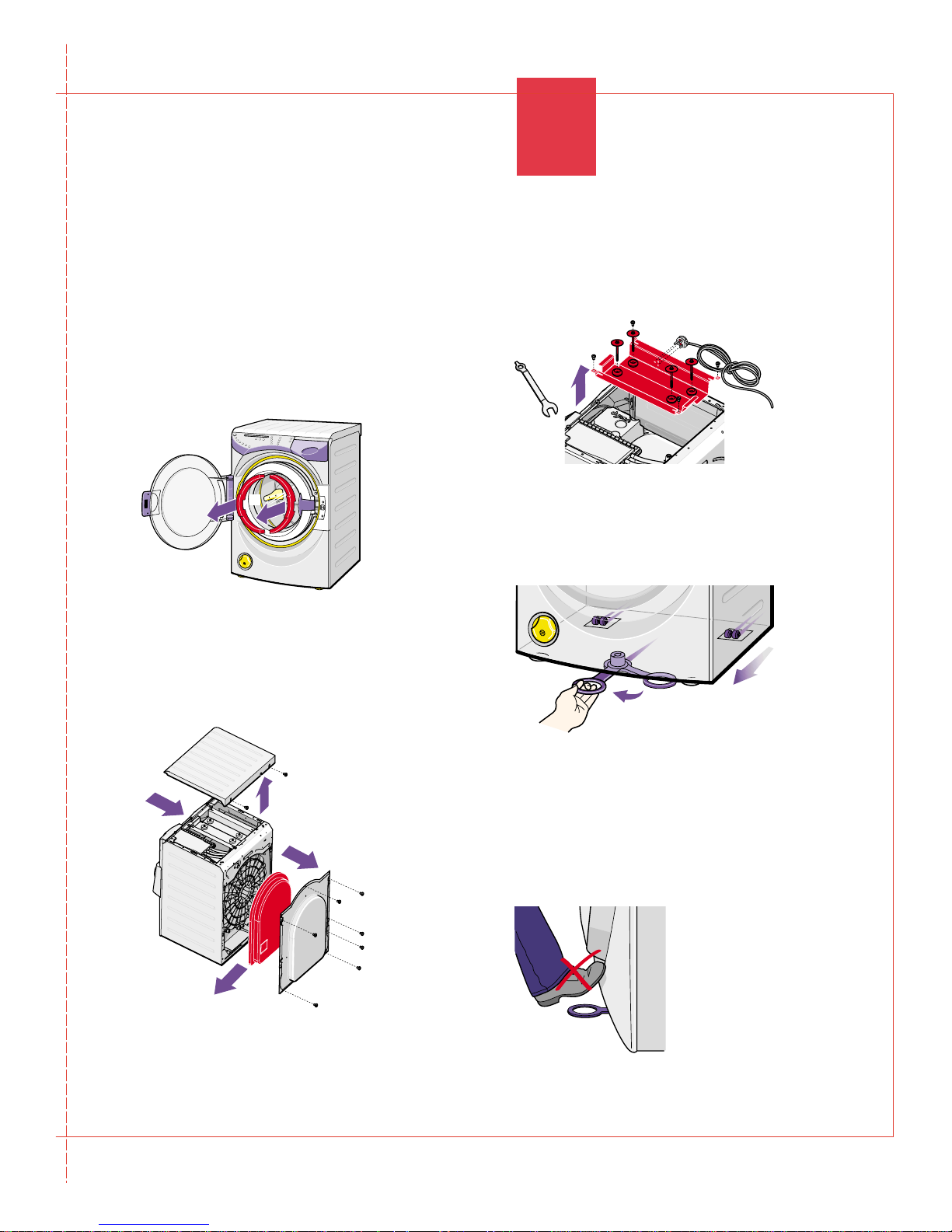

Inner transit packaging removal

Before installation

8 Remove the four screws securing the bracket to the machine

casing and lift out the transit bracket.

• Refit the lid and two screws.

To replace the packaging (eg: for moving house), reverse the

procedure described above.

Please retain the transit packaging for future use, as it

should be used whenever the machine is relocated.

Moving the Contrarotator

TM

• To move the machine, pull out the RollerjackTMhandle from

underneath the machine, which will enable you to manoeuvre

the machine easily into your desired position.

• Replace the Rollerjack

TM

slowly because the handle may return

with force.

NB: The Rollerjack

TM

is designed for final positioning only and

not suitable over long distances. Do not push with your foot.

4 01

Before installation, check the machine for damage.

A qualified person should always carry out installation.

All packaging must be removed before the machine is

connected to power or water supplies.

1 Open the outer door and carefully lift out the foam inserts

from the front of the inner door.

2 Take off the rear panel by removing the seven screws, using

a cross-head screwdriver.

3 Carefully withdraw the foam block and then refit the rear

panel and screws.

4 Remove the two screws from the rear of the lid.

5 Remove the lid by sliding it backwards and upwards.

6 Remove the plug inserted into the transit bracket from inside

the machine.

7 Using the Dyson spanner remove the four bolts securing the

top transit bracket.

2

3

5

4

1

7

8

6

Page 8

600 mm

MAX.

450 mm

MIN.

848 mm

595mm

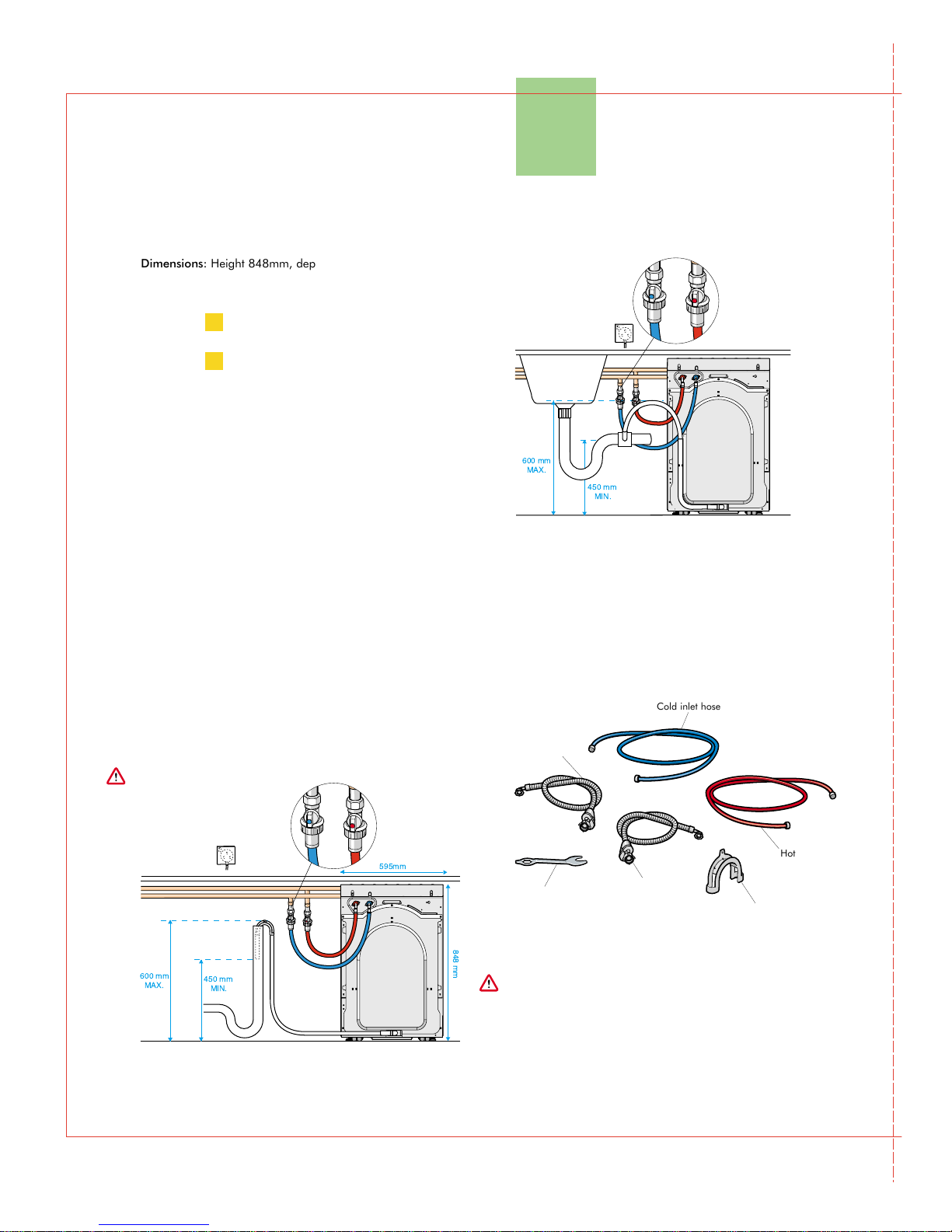

Dimensions: Height 848mm, depth 575mm, width 595mm

Weight: 103kg.

Voltage: 220-240V, 50Hz. Please refer to rating plate

(see section 1 01 for location).

Power: 2750W (230V). Please refer to rating plate

(see section 1 01 for location).

Water pressure: 0.4-5 bar.

Capacity: 7kg dry laundry (maximum).

Location

Every Dyson washing machine is tested before it leaves the

factory. As a result, there may be some dampness or water in

the machine.

• The machine should not be installed in a location where the

temperature may drop below freezing.

• The machine should not be installed in a bathroom.

• The machine must be installed on a secure and flat surface.

Soft floors, such as carpet or carpet tiles, are not suitable.

The layout of the drainage taps and power socket and their

distance from the machine are illustrated below. The water

inlet hoses, drainage hose and electrical mains lead must be

positioned carefully to avoid damage or kinks when the

machine is in use. The machine can be connected to a

standpipe, under-sink pipe connection or other drainage

system, but the critical dimensions must be adhered to.

Important

Specification

Installation

Drainage using a sink pipe*

Drainage, water supply and electricity

The washing machine comes with:

2 inlet hoses or

2 leak protection inlet hoses

CRO1 Flowcheck and Memory only

1 drainage hose hook

1 Dyson spanner

1 drainage hose at the back of the machine

The above items are found in the drum unless stated otherwise.

NB: The leak protection hoses can be fitted to either

supply, ensuring that the valve end is attached directly

to the water mains. Take care not to cross the hoses

eg: hot outlet to cold inlet.

5 01

600 mm

MAX.

450 mm

MIN.

Drainage using a stand pipe*

Cold inlet hose

Hot inlet hose

Drainage hose hook

Note: CRO1 Flowcheck and Memory have grey leak protection inlet hoses

*All hoses can be supplied in 2.5m lengths if required. Please contact the helpline to order.

Inlet valve

Dyson spanner

Leak protection

inlet hoses

Page 9

Water supply

Drainage

Installation

Always:

• connect your machine to the water supply by hand, using the

hoses supplied. Do not tighten the plastic hose connections

with a spanner. Do not use old hoses.

* Note: CRO1 Flowcheck and Memory have grey leak protection inlet hoses

• ensure the water pressure is between 0.4 and 5 bar.

Do not:

• connect the machine to a mixer tap.

*Note: CRO1 Flowcheck and Memory have grey leak protection inlet hoses

Hot and cold water supply

• Attach the blue inlet hose/grey leak protection hose to the

cold inlet tap and the red hose/other grey leak protection

hose to the hot inlet tap, and turn on water supply.

5 02

You can alter the direction of the drainage hose to the left

or right.

• To change the direction of the machine’s drainage hose,

squeeze open the retaining clip using a pair of pliers and

hold it open while you rotate the hose.

• Ensure the hose is inserted properly before releasing the clip.

• Thread the drainage hose through the hose hook and adjust

the protruding end to a distance of 30mm. The hose hook

has a small retention hole that can be used to secure the

hose in position.

Do not use the hose hook for under-sink connections.

When installed with a standpipe or under-sink connection,

ensure that the water outlet end of the drainage hose is no

lower than 450mm above ground level. Position the hose so

that none of it lies higher than 600mm above ground level

(refer to section 5 01 for position).

NB: Failure to comply with these dimensions could cause

the machine to malfunction.

*Note: CRO1 Flowcheck and Memory have grey leak protection inlet hoses

Drainage hose hook

Drainage hose

30mm

Stand pipe

Page 10

When all the instructions on the previous pages have been

completed, the machine can be installed into its operating

position using the Rollerjack

TM

handle (see section 4 01).

• Using the Dyson spanner, adjust the two front feet so that the

machine is perfectly stable and will not rock on three of its

four contact points.

• Do not use wood, carpet or other material to stabilise the

washing machine.

After installation

• Run an empty 60ºC cotton cycle with a half measure of

detergent. For the correct dosage, please follow the

manufacturer’s instructions on the detergent packaging.

See sections 7 01 and 8 01 on how to start the machine.

• This will clean any test water out of the machine, and ensure

the machine is installed and levelled correctly.

• Observe it regularly during the first wash and check

connections afterwards and during the first week, to ensure

that they have been fitted correctly.

Cold water only supply

• If there is no hot water supply, attach the cold and hot hoses

to the machine as normal. Then, attach both hoses to a

Y-piece (which can be ordered from the helpline) and finally

connect the Y-piece to the cold inlet tap.

*Note: CRO1 Flowcheck and Memory have grey leak protection inlet hoses

• Once all connections have been made, turn on the tap(s) to

check that there are no leaks.

Electrical installation

Warning: This machine must be earthed

• Any electrical work required to install the washing machine

should be carried out by a qualified electrician.

• Before using your machine, check that the plug and sockets

match, and check that the voltage in your home corresponds

to the machine’s voltage.

This information is on the rating plate (see section 1 01).

• The machine should be plugged into an earthed socket

which can be switched on & off, and that is easily accessible

after installation.

• Do not use an extension cord or plug adapter.

• If the supply cord or plug are damaged disconnect the

machine from the socket outlet immediately. The supply cord

must only be replaced by Dyson or its appointed agents, as

special purpose tools and service techniques are required.

• If the plug supplied needs to be removed it should be cut off

and safely disposed of. Under no circumstances should the

severed plug be inserted into a socket outlet as this will

present an electric shock hazard.

European conformity information

This Contrarotator

TM

has been tested and conforms to the

following European Directives:

73/23/EEC Low Voltage Directive.

93/68/EEC CE Marking Directive.

89/336/EEC EMC Directive.

Installation

5 03

Page 11

Operation

6 01

• Plug the machine into the mains and switch on at the socket.

• Turn on the water supply at the mains.

• Open the outer and inner doors.

• Check the drums are empty before placing the sorted laundry

into the washing machine.

• Close both doors, making sure that both have ‘clicked’ shut.

It is important not to overload the machine. Maximum loads

for each programme are shown in the table section 9 02.

Tests have shown that overloading can reduce the wash

performance and may cause damage to your machine.

Detergent use

• To open the soap tray, press the hand on the soap tray.

Do not try to pull out the soap tray without first pressing it.

• Add detergent to the compartment marked 2 for all the main

wash programmes.

• For a pre-wash option, add detergent to the compartment

marked 1.

• Fabric conditioner can be added to the compartment marked

to the level indicated.

• Push the soap tray to close, ensuring it ‘clicks’.

Loading the Contrarotator

TM

Detergent use

Type of laundry Type of detergent

Brightly coloured/multi coloured Colour care

Whites Conventional biological or non-biological

Wool, silk Non biological wool/silk

Detergent format

Place wash balls and nets directly into the drums of the

washing machine.

Do not:

• place wash balls or tablets in drums when using the start

delay option (CRO1 Memory). This could fade coloured

laundry if the detergent touches the fabric before the water

soaks the laundry.

• place wash balls or tablets in drums when using a pre-wash.

All the detergent will be used in the pre-wash, leaving none

for the main wash. Use the soap tray instead.

• cover wash balls or tablets with laundry, as this can inhibit the

dispersal of detergent.

• stop the wash for long periods of time once it has started.

The detergent may not have had time to disperse and

concentrations may damage the laundry.

Detergent quantity

• CRO1’s drum capacity is 60% larger than other leading ‘AAA’

washing machines.

• This larger load will require a slight increase in detergent, as

there will be more dirt circulating in the wash.

• When using your Dyson washing machine we recommend the

following doses:

CRO1 with a half load CRO1 with a full load

Powder Powder

1 scoop 1

1

/

2

scoops

Liquid Liquid

1 dose 1

1

/

2

doses

Tablets Tablets

2 tablets 3 tablets

*For maximum dosage based on very heavy soil and hard water please refer to

manufacturer’s instructions on detergent pack.

• Use only powder suitable for automatic washing machines.

Page 12

1

2

Switch on the machine

Select the programme

Select Cotton/Synthetics/Wool/

Delicate/Handwash items or Duvet.

Temperature, spin and soil type

settings will automatically adjust to

the default settings to give the best

options for the selected wash.

Please see section 8 01 for

details of how to change the

default settings.

To start your wash cycle using the default settings

7 01

Starting your wash

Page 13

End of wash cycle

The display will show ‘Programme finished’ once the

cycle is complete. Remove the washing and turn off

the machine by pressing the ‘Mains on/off ’ button.

3

Start your wash cycle

Press to start your chosen

programme.

Pause your wash cycle

To pause the wash, press the ‘Start’

button (for example to add a

forgotten item to the wash).

Press ‘Start’ once more to resume

the wash. When a programme is

paused, the door may remain

locked for safety reasons (see

section 8 01 for the door lock).

Cancel your wash cycle

To cancel the wash, press and hold

down the ‘Cancel’ button. The outer

door will unlock once the water has

drained away, and if the inner

door is cool enough (see section

8 01 for the door lock).

Page 14

8 01

Optional settings

To personalise the default wash programmes

Adjust your programme

After selecting the fabric type, press the temperature, spin and soil

type buttons to scroll through the options and select your preferred

settings. Note: on certain programmes some options are not

available (see section 9 02).

Page 15

Start delay

only available on CRO1 Memory

This allows you to programme

the wash to finish when you want

it to. Use the < and > arrows to

adjust the settings (eg: if you want

the wash to start in 10 hours time,

press the > arrow 10 times) and

press ‘Start’ to activate it.

The display will countdown the

delay time to start. Press the

‘Cancel’ button at any time to

cancel the wash.

Memory

Only available on CRO1 Memory

This allows you to store the three

programmes you use the most.

Select the programme with any

additional options, then press

and hold one of the memory

buttons for one second. A beep

will confirm the programme has

been stored.

To select a stored programme,

press the relevant ‘Memory ’

button and then press ‘Start’.

To re-programme a stored cycle,

follow the steps for programming

a memory cycle.

Door lock

The door lock light indicates

that the outer door is locked.

Child lock

This option locks the settings on

the control panel and locks the

outer door. Once a programme

is running, use this option to

prevent it from being altered,

paused or cancelled. You can

also use the Child lock when the

machine is not in use to keep the

outer door locked.

Press and hold the ‘Minimum

iron’ button to activate and cancel

the Child lock, before starting

the cycle.

Additional options

To activate any of the additional

options below after you have

selected your programme,

press your desired option button

once; press it again to cancel

the option.

Minimum iron

This holds your laundry in water

after the final rinse to minimise

creasing. To spin the laundry and

finish the programme, press the

‘Start’ button. Minimum iron is

not suitable on all programmes

but is particularly good for

synthetics and delicates.

(Please refer to section 9 02).

Pre-wash

This removes excess dirt before

the main wash cycle.

Extra rinse

This adds one extra rinse for

people with sensitive skin.

Rinse & spin/Spin only

Press once for ‘Rinse & spin’

option, press twice for ‘Spin’

only option and press a third

time to cancel.

Soil type selection

Soil type can be adjusted on

the Cotton and Synthetic

programmes only, cleaning from

everyday washing to heavily

stained football kits.

Dirt

For lightly soiled laundry.

Dirt & stains

For typical everyday soiling.

Heavy stains

For heavily stained items.

(see section 9 02).

Page 16

Fabric care and advice

9 01

Wash tips

Always:

Care label

• check the wash care label on laundry

to select the most appropriate

programme. If you are unsure of the

care label, use a gentle programme

such as Wool.

Mixed fabric load

• wash a mixed load according to the

most delicate item in it.

• sort laundry according to care label.

Sort laundry according to colours

• wash dark colours separately.

• wash new items separately for their first

few washes as excess dye may run.

Wash bag

• place small items in a wash bag e.g.

bras, stockings etc…

Prepare your laundry

• empty all pockets before loading the

laundry into the machine, fasten zips,

draw strings, tie belts and press studs

before washing. Turn sleeping bags,

duvet covers, jeans, knitted fabrics and

coloured items inside out before

washing, checking the wash care label.

Duvets

• check your duvet is machine washable.

• wash duvets on the Duvet cycle.

• refer to care label for wash temperature

and drying recommendations.

• If the duvet is over 10.5 tog, we do not

recommend spinning. If it is 10.5 tog

or below, we recommend a maximum

spin speed of 500 rpm.

• To load the duvet into the machine,

feed the corner into the rear of the

drum and continue to feed the duvet

along its outer seam.

• CRO1 will wash most machine

washable king size duvets up to 13.5 tog.

Different manufacturers’ duvet sizes can

vary under the same tog rating.

Do not:

wash frayed or torn fabrics.

Care symbol

Washing process

Cotton

A wash tub with no bar underneath

indicates the item is suitable for a

high agitation wash. The maximum

temperature is normally specified in

the wash tub.

Suggested Dyson wash programme - Cotton

Synthetics

A wash tub with one bar underneath

indicates the item is suitable for a

medium agitation wash. The maximum

temperature is normally specified in

the wash tub.

Suggested Dyson wash programme - Synthetics

Wool/Delicate

A wash tub with two bars underneath

indicates the item is suitable for a gentle

agitation wash. The maximum temperature

is normally specified in the wash tub.

Suggested Dyson wash programme Wool/Delicates. Note: Machine washable

wool and wool mixes should only be washed

on the Wool cycle.

Handwash

Wash gently by hand or in a washing

machine with a gentle handwash

programme.

Suggested Dyson wash programme - Handwash

items. Not all handwash items are suitable for a

machine handwash programme. Check care

label or contact garment manufacturer.

Do not wash

Laundry with this symbol should not be

put in a washing machine.

Chlorine-based bleach

may be used.

Do not use bleach

Use a colour care detergent for

best results.

Hot iron

Iron 200ºC

Medium iron

Iron 150ºC

Cool iron

Iron 110ºC

Do not iron

Steaming and steam treatments should

not be used.

May be tumble dried

Normal heat setting.

May be tumble dried

Delicate heat setting.

Do not tumble dry

Tumble drying unsuitable laundry

can result in shrinking and melting.

May be dry cleaned

Letters in the circle indicate the type of

solvent suitable.

Do not dry clean

Dry flat

Care symbol Washing process

Note: If in doubt of correct washing guidelines, please contact the garment manufacturer or retailer.

Page 17

9 02

Programme table

Care label Suggested programme Temperature Spin speed Soil type Options

Maximum load

Cotton

Sturdy cottons

Linen

Synthetics

Cotton mixes

Mixed fibre

Polycottons

Fabrics with special finishes

(eg: ‘non-iron’ treated cotton)

Mixed fabric wash loads

Printed cottons

Polyester

Delicates

Micro fibres

Synthetic laundry that

require careful handling

Printed fabrics

Not for wool

Wool

Machine washable

Wool and wool mixes

Handwash items

Machine washable

Handwash items only,

requiring a very gentle action

Washable silks

Duvet

Please also read the duvet

section in the ‘Wash tips’

30 – 60˚C

30 – 85˚C

30 – 50˚C

30 – 40˚C

30 – 40˚C

20 – 30˚C

30 – 40˚C

0 –1400 rpm

0 –1400 rpm

0 – 800 rpm

0 – 1100 rpm

0 – 800 rpm

0 – 500 rpm

0 – 800 rpm

3.5 kg

7 kg

4 kg

3 kg

2 kg

1.5 kg

*Based on 40OC programmes and will vary according to temperature, hot/cold fill and options selected.

‘AAA’ Energy Label declaration is based on a Cotton, 60

O

C Dirt and Stains cycle. On some machines, cycle selections may differ from those shown.

Pre-wash

Extra rinse

Rinse & spin/Spin

Pre-wash

Extra rinse

Minimum iron

Rinse & spin/Spin

Pre-wash

Extra rinse

Minimum iron

Rinse & spin/Spin

Extra rinse

Rinse & spin/Spin

Extra rinse

Rinse & spin/Spin

Pre-wash

Extra rinse

Rinse & spin/Spin

Pre-wash

Extra rinse

Rinse & spin/Spin

Dirt

For lightly soiled laundry

Dirt & stains

For typical everyday soiling

Heavy stains

For heavily stained items

Dirt

For lightly soiled laundry

Dirt & stains

For typical everyday soiling

Heavy stains

For heavily stained items

No option

No option

No option

No option

40 mins*

67 mins*

85 mins*

40 mins*

77 mins*

85 mins*

77 mins*

45 mins*

45 mins*

100 mins*

Cycle time

Page 18

Cleaning

Maintenance

• The soap tray cavity in the machine should be cleaned out

with a small, soft brush, taking care not to dislodge the

rubber seal.

• Replace the soap tray ensuring it ‘clicks’ into place.

Do not:

• wash the soap tray in a dishwasher.

Maintenance wash

To prevent odours and build-up of deposits within the

washing machine, it is recommended that you run an empty

85ºC cotton cycle with a half measure of detergent 2 or 3

times a year.

If the outer door is dislodged from its safety hinge:

1 Locate the top ring of the outer door into the yellow part of

the flexible safety hinge.

2 Lift the door and push it forward until the lower ring of the

door ‘clicks’ into place.

The outer door is designed to ‘pop’ out of its hinge if leant

on, however it is not designed to support a load.

10 01

Always:

• disconnect the machine from the mains before cleaning or

carrying out any maintenance work.

Do not:

• clean the machine with cleaning solutions. Always use a

clean, soft, damp cloth.

Cleaning the soap tray

• Remove the soap tray by pressing the yellow release button at

the back of the tray, and pulling it out.

• Wash it in warm, soapy water with a small, soft brush, taking

care not to scratch the soap tray front.

Page 19

Coin trap

Maintenance

5 Remove any objects from the coin trap.

6 If any more items seem to be blocking the coin trap,

pull out the flow accelerator.

• Remove any items and firmly push the flow accelerator back

into place.

To replace the coin trap cover:

• Ensuring the seal is in place, lubricate with a drop of washing

up liquid.

• Fit the cover with the plug at the top.

• Turn 1

1

/

2

turns clockwise, ensuring the childproof tab ‘clicks’

back into place.

• Make sure the plug is pushed back into the closed position.

10 02

Never remove any objects from the coin trap while the

washing machine is switched on, still running or paused

during a wash. Always allow the water to cool before

opening the coin trap.

• Empty the coin trap when a blockage has occurred.

1 Place a tray or shallow dish underneath the coin trap.

2 Using the Dyson spanner, lever the plug in the middle of the

coin trap. The water will drain from the plug.

3 If the tray or dish is full, push the plug into its original position

by hand, empty the tray or dish and repeat the process.

4 Once the water has been removed (a small quantity of water

will remain below the level of the plug), lift the childproof tab

using the Dyson spanner. Then turn the window anticlockwise

until it is released.

Childproof tab

Coin trap window

Flow accelerator

Plug

Side view: lever hand and spanner 45

o

Page 20

Emergency door release

Water filter

Maintenance

This should be used in the event of a power cut to

remove laundry.

• Switch off and remove the plug from the socket.

• Ensure the drums have stopped moving.

• If the machine has been running on a hot wash, leave it

to cool down.

• Completely drain the washing machine (see section 1002

under ‘coin trap’).

• Remove the soap tray as described in section 1001.

• Using the Dyson spanner or a coin, turn the door release

screw

1

/

4

of a turn anticlockwise to unlock the door,

hold the screw in this position and open the outer door.

• Open inner door.

• Turn the door release screw clockwise through

1

/

4

of a turn,

to ensure the door will close. (This is automatic on some models).

• Replace the soap tray.

10 03

To access the rear of the machine use the Rollerjack

TM

handle to pull the machine out (see section 4 01

for details).

Cleaning the water inlet filters

The water inlet filters should be checked regularly for debris

or limescale build-up (particularly in a hard water area).

Contact your local water authority to find out your water

composition.

• Turn off the water supply to the machine.

• Unscrew both water inlet hoses by hand.

• Using pliers, grip the coloured filters, pull them out and rinse

them under cold water.

NB: Some water may remain in the hoses.

Note: CRO1 Flowcheck and Memory have grey leak protection inlet hoses

• Replace the filters, red to the hot fill and blue to the cold fill,

and reconnect the water inlet hoses.

10 01.

10 02

Page 21

11 01Troubleshooting

LCD display is blank

Machine displays

“Overload reduced performance”

Machine displays

“Close inner door then press start”

Certain spin speeds, temperatures,

dirt levels cannot be selected

Cancel button does not

work during a wash

Cannot open door

Machine leaks water

Machine shakes during the cycle

Machine displays

“Close outer door then press start”

Machine displays

“Not emptying: check hose/coin trap”

Machine displays

“Not filling: check water supply”

Machine displays

“Uneven load could not spin”

Before calling the helpline, please carefully read the following pages.

Machine displays

“Child lock on”

Page 22

Ensure the

machine

is plugged in and

switched on. Check the fuse and also

that the circuit breaker has not tripped.

See section 9 02 for the programme

options wash table.

Wait for the machine to finish the cycle

before opening the door. To cancel the

wash hold down the

‘Cancel’

button.

Press ‘Start’ to resume the wash.

Hold down the

‘Minimum iron’

button

until

‘Child lock off ’ is shown on LCD.

Follow the ‘Emergency door release’

instructions in section 10 03.

Turn off the water supply to the machine

and ensure that the coin trap cover is

correctly fitted and that the plug is closed,

see section 10 02.

Adjust the feet until the machine is level,

see section 5 03.

Check the drainage hose is draining

into a suitable place (drain, sink or

standpipe), see section 5 02.

Ensure the hoses are fitted correctly, see

section 5 02 .

Close the soap tray.

Adjust feet until the machine is level, see

section 5 03 .

Return the Rollerjack

TM

handle carefully

to its position under the machine, see

section 4 01 .

Remove top, rear and front packaging,

see section 4 01.

Check orientation of hot and cold pipes.

LCD display is blank

Certain spin speeds, temperatures or

soil types cannot be selected

Cannot open outer door

Machine leaks water

Machine shakes during the cycle

Burning smell

Clothes warm at end of cycle

There is no power to the

machine.

There are limits set on these options for

each programme to prevent unsuitable

options being selected.

Machine has not finished the cycle.

Machine has paused and the water level

is too high or the water is too hot.

Child lock is active.

Power cut or any other cause not listed

above.

Coin trap cover is not in place, or the

plug is not closed.

Machine is not level.

Drainage hose is not connected correctly.

Inlet hoses are not positioned or

correctly fitted.

Soap tray is open.

2 adjustable front feet are not level.

Rollerjack

TM

handle has not been replaced

under the machine.

Transit packaging not removed.

Hot and cold pipes reversed.

11 02Troubleshooting

Symptom

Some solutions may require you to disconnect the electricity and water supply.

Possible causes

Solutions

Page 23

11 03Troubleshooting

Child lock on

Overload reduced performance

Uneven load could not spin

Close outer door then press start

Close inner door then press start

Not emptying: check hose and

coin trap

Not filling: check water supply

Fault

The child lock has not been deactivated.

The recommended wash load has been

exceeded or unusual items have been

washed. The wash load is uneven.

The machine sensed that spinning would

be unsafe. Unusual items eg: trainers

may have been washed.

Outer door not closed properly, manual

release still open.

Inner door not closed properly.

Coin trap blocked.

Machine full of suds.

Drainage hose not draining.

Water supply is not connected.

Filter is blocked.

Inlet hoses are blocked or kinked.

Drainage hose is installed incorrectly.

Flood protection hose (Memory only)

There is a technical fault with your

washing machine.

LCD display message

Possible causes

Solutions

www.dyson.com

Dyson Helpline

UK 0870 600 2701

email service@dyson.com

ROI (01) 475 7109

email irelandservice@dyson.com

NOTE: If an engineer is booked and it is found that the fault could

have been rectified using troubleshooting guide, you may be charged.

Hold down the ’Minimum iron’ button

until ‘Child lock off’ is shown on

the LCD.

In future, refer to the programme table

section 9 02 or cease to wash the

particular unusual item(s).

Remove some items or reload the

machine and select ‘Spin only’ option

(see section 8 01).

Close the outer door, ensuring nothing

is trapped. Turn manual release

clockwise (see section 10 03).

Close the inner door, ensuring nothing

is trapped.

Remove blockages (see section 10 02).

Leave suds to settle. In future, refer to

the manufacturer’s dosage instructions.

Check that the drainage hose is installed

according to the installation instructions

(see sections 5 01 & 5 02).

Check that the water supply is connected

and turned on at the tap.

Clean the filters (see section 10 03).

Unblock or straighten the inlet hoses.

Unblock or straighten the drainage hose.

Fitted back to front.

Contact the Dyson Helpline or visit the

website www.dyson.com with the

following information:

• Your machine’s serial number

(see side of machine).

• Where and when you purchased your

washing machine.

• Your address.

• The fault code that appears on the

LCD display, if applicable.

A Dyson service engineer will visit you to

test your machine and repair if necessary.

Page 24

UK 0870 600 2701

Open 7 days a week, 8am – 8pm

ROI (01)475 7109

Dyson Ltd Tetbury Hill Malmesbury

Wiltshire SN16 ORP

www.dyson.com

JN.6596 30.01.02 PN.50351-01-02

Loading...

Loading...