Dynon Avionics SkyView SE, SkyView HDX, SkyView Classic, SkyView Touch System Installation Manual

Page 1

SkyView SE

SkyView Classic

SkyView Touch

SkyView HDX

System Installation Guide

Document 101320-026, Revision AA

For use with Software version v15

December, 2016

Copyright © 2009-2016 by Dynon Avionics, Inc.

Permission to print this manual is granted to third parties.

Page 2

Page 3

Contact Information

Dynon Avionics, Inc.

19825 141st Place NE

Woodinville, WA 98072

Phone: 425-402-0433 - 8:00 AM – 5:00 PM (Pacific Time) Monday – Friday

Dynon Avionics Technical Support available 7:00 AM–4:00 PM (Pacific Time) Monday – Friday

Email: mailto://support@dynonavionics.com

Fax: 425-984-1751

Dynon Avionics offers a number of Internet sites for support:

http://www.dynonavionics.com – Dynon Avionics primary web site; including:

http://docs.dynonavionics.com – Current and archival documentation.

http://downloads.dynonavionics.com – Software downloads.

http://license.dynonavionics.com – Redeem SV-MAP-270, SV-SYNVIS-280, and SV-VPX-290 licenses.

http://store.dynonavionics.com – Dynon Avionics’ secure online store for purchasing all Dynon Avionics products.

http://register.dynonavionics.com – Register your Dynon Avionics product.

http://support.dynonavionics.com – Support resources.

Stay in touch with Dynon Avionics:

http://blog.dynonavionics.com – Dynon Avionics’ blog.

https://www.facebook.com/dynonavionics - Dynon Avionics is on Facebook. Please “friend” us!

http://forum.dynonavionics.com – Dynon Avionics’ Internet forum for SkyView pilots.

http://newsletter.dynonavionics.com – Dynon Avionics’ email newsletter.

https://twitter.com/dynon - Dynon Avionics is on Twitter!

Training

http://www.dynonavionics.com/videos – Video training, including short vignettes on specific operations.

http://www.dynonavionics.com/training – Hands-on training at various events.

Copyright

2009-2016 Dynon Avionics, Inc. All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated or stored in

any storage medium, for any purpose without the express written permission of Dynon Avionics. Dynon Avionics hereby grants permission to

download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed for

personal use, provided that such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice

and provided further that any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Information in this document is subject to change without notice. Dynon Avionics reserves the right to change or improve its products and to

make changes in the content without obligation to notify any person or organization of such changes. Visit the Dynon Avionics website

(www.dynonavionics.com) for current updates and supplemental information concerning the use and operation of this and other Dynon

Avionics products.

Page 4

iv SkyView System Installation Guide - Revision AA

Limited Warranty

Dynon Avionics warrants this product to be free from defects in materials and workmanship for three years from date of shipment. Dynon

Avionics will, at its sole option, repair or replace any components that fail in normal use. Such repairs or replacement will be made at no charge

to the customer for parts or labor performed by Dynon Avionics. The customer is, however, responsible for any transportation cost and any

costs that are incurred while removing, reinstalling, or troubleshooting the product. This warranty does not cover failures due to abuse, misuse,

accident, improper installation or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE, AND IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED,

INCLUDING ANY LIABILITY ARISING UNDER WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, STATUTORY OR

OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH MAY VARY FROM STATE TO STATE AND IN COUNTRIES OTHER THAN

THE USA.

IN NO EVENT SHALL DYNON AVIONICS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES, WHETHER

RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT. SOME STATES AND COUNTRIES

DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Dynon Avionics retains the exclusive right to repair or replace the instrument or Software or offer a full refund of the purchase price at its sole

discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

These instruments are not intended for use in type certificated aircraft at this time. Dynon Avionics makes no claim as to the suitability of its

products in connection with FAR 91.205.

Dynon Avionics’ products incorporate a variety of precise, sensitive electronics. SkyView products do not contain any field/user-serviceable

parts. Units found to have been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon Avionics unit is opened

up, it is not considered airworthy and must be serviced at the factory.

Dynon Avionics Returns and Warranty web page can be found at http://support.dynonavionics.com.

Page 5

SkyView System Installation Guide - Revision AA v

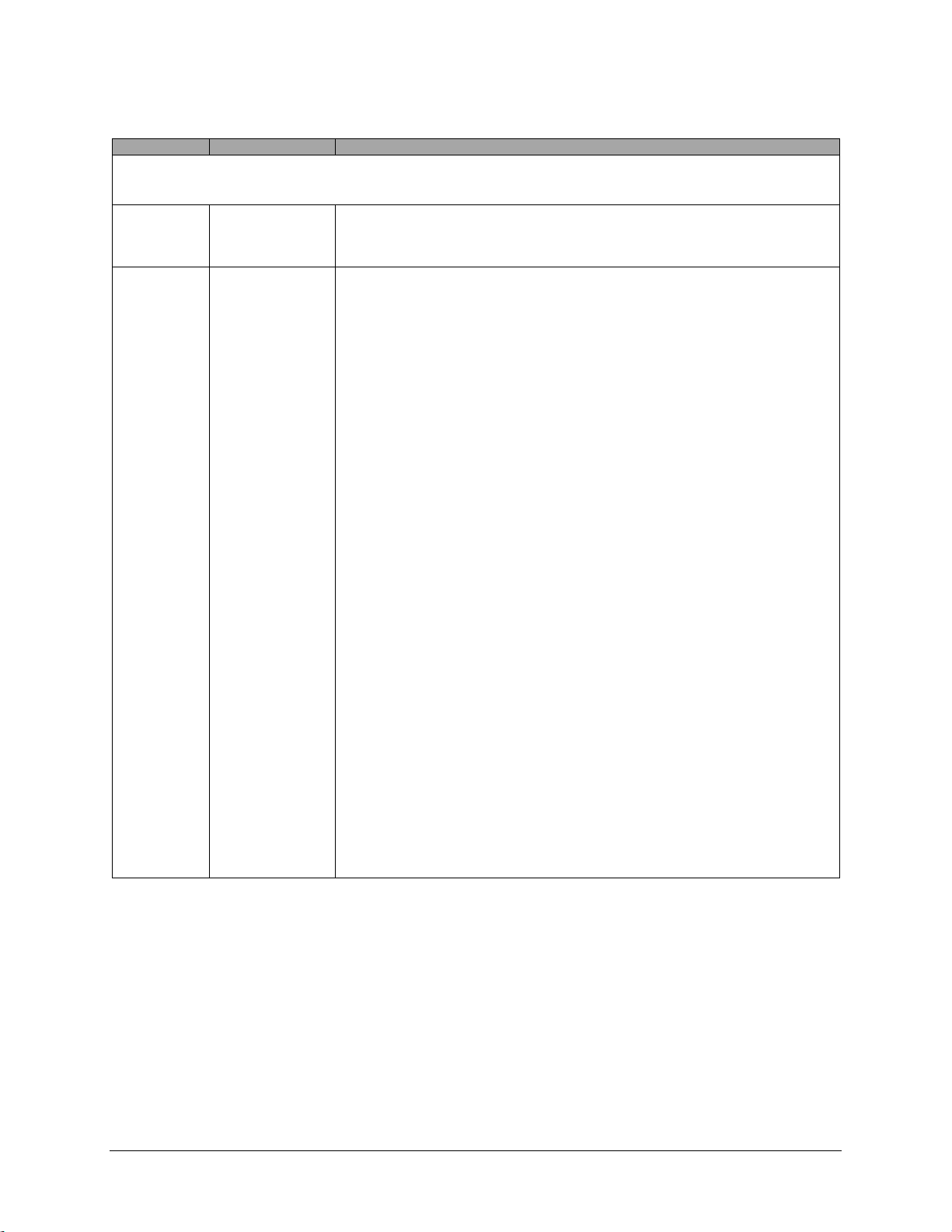

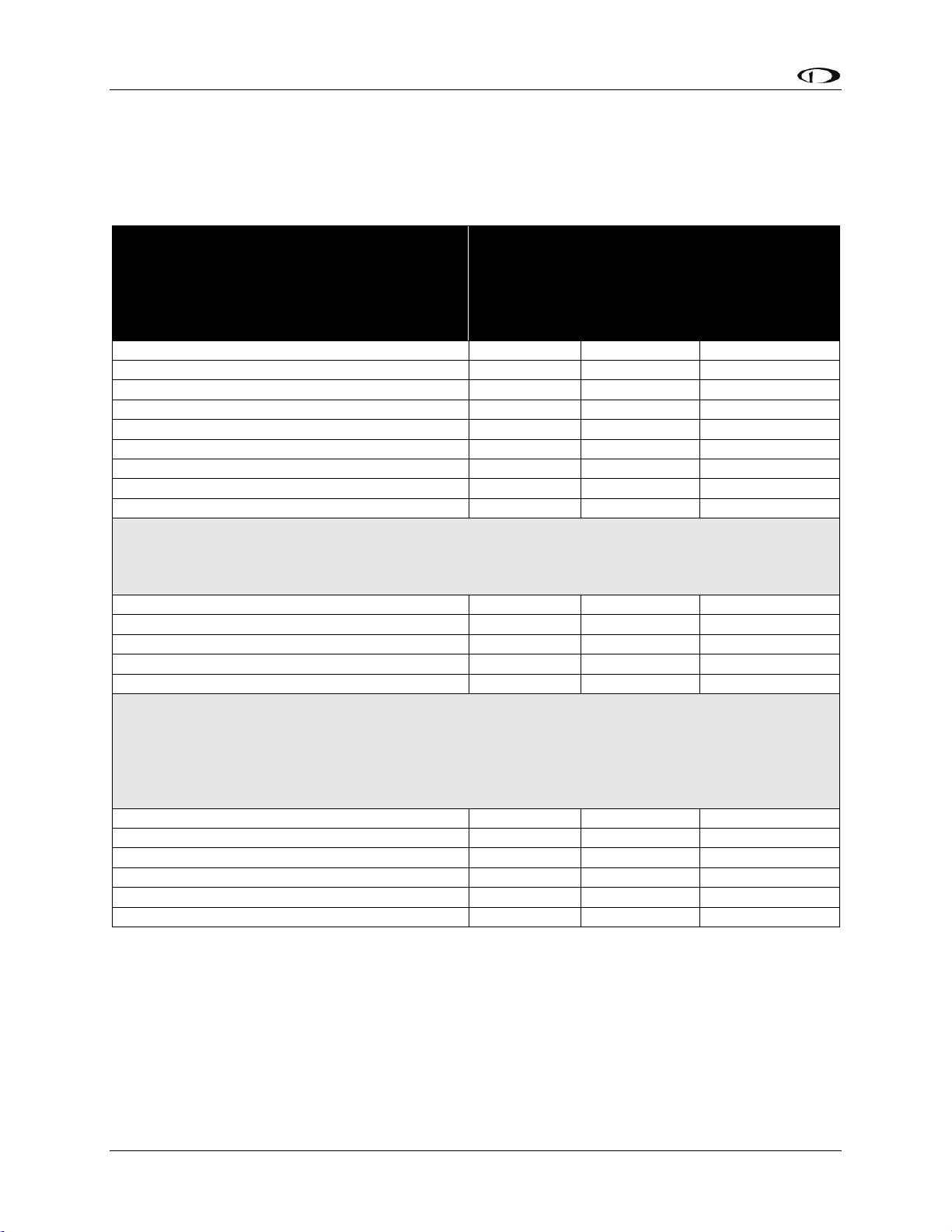

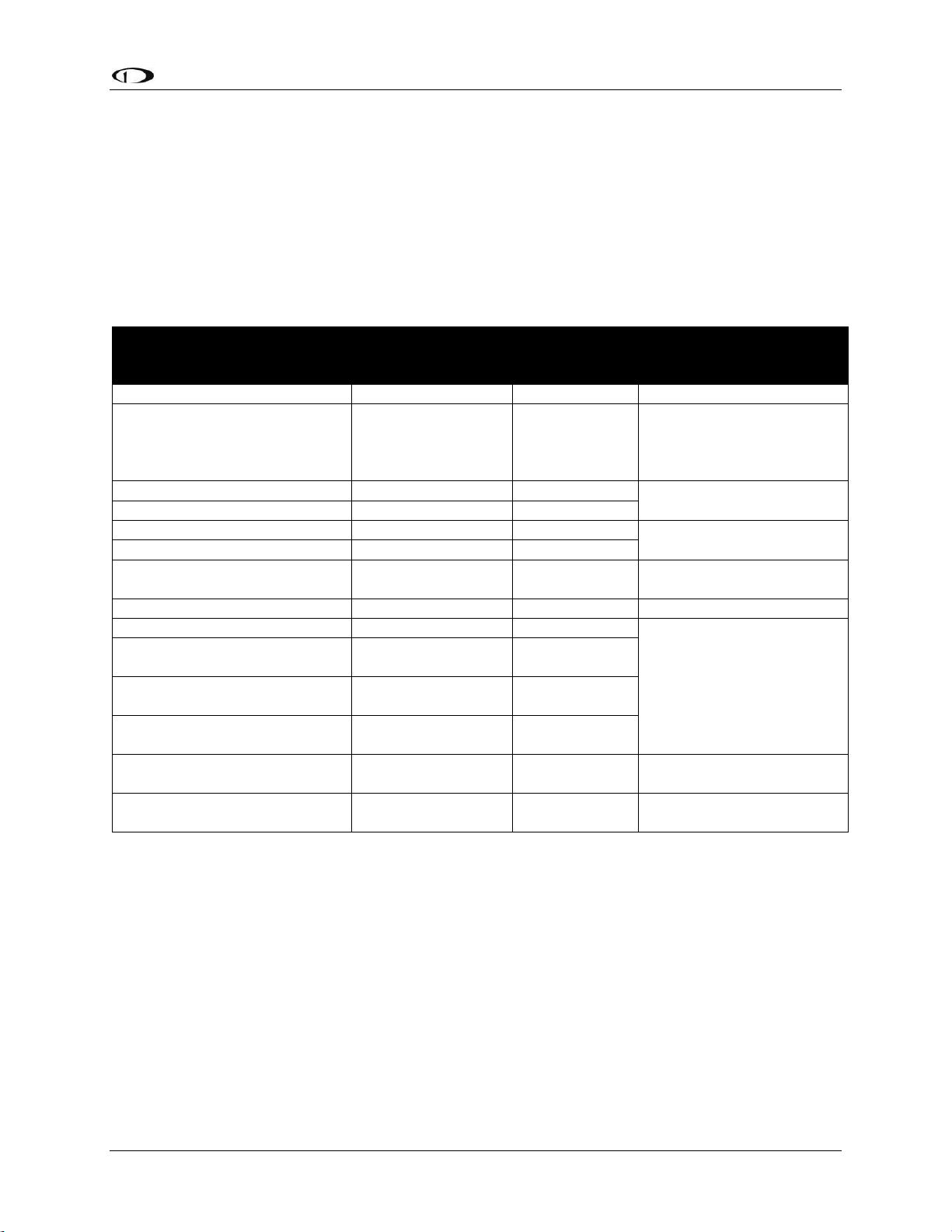

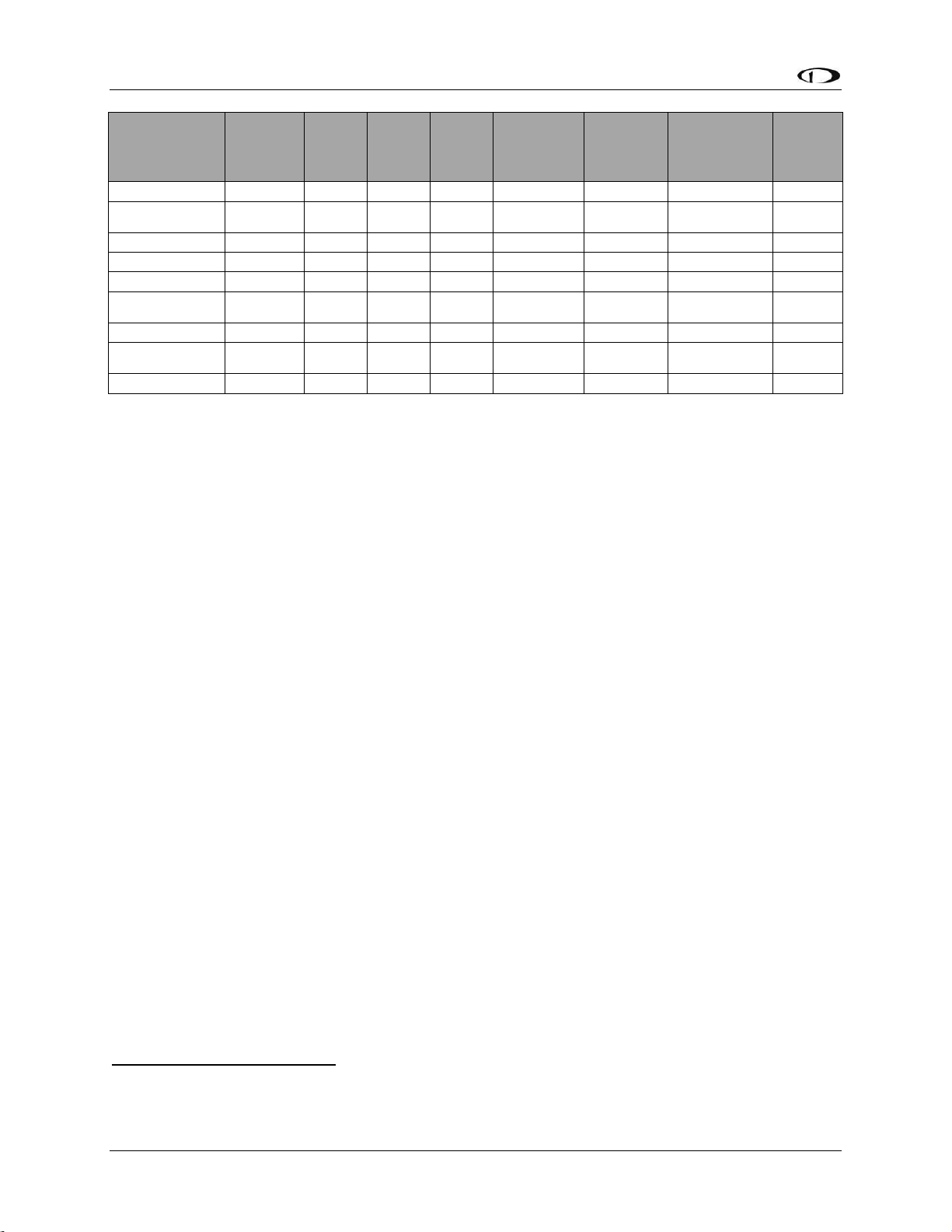

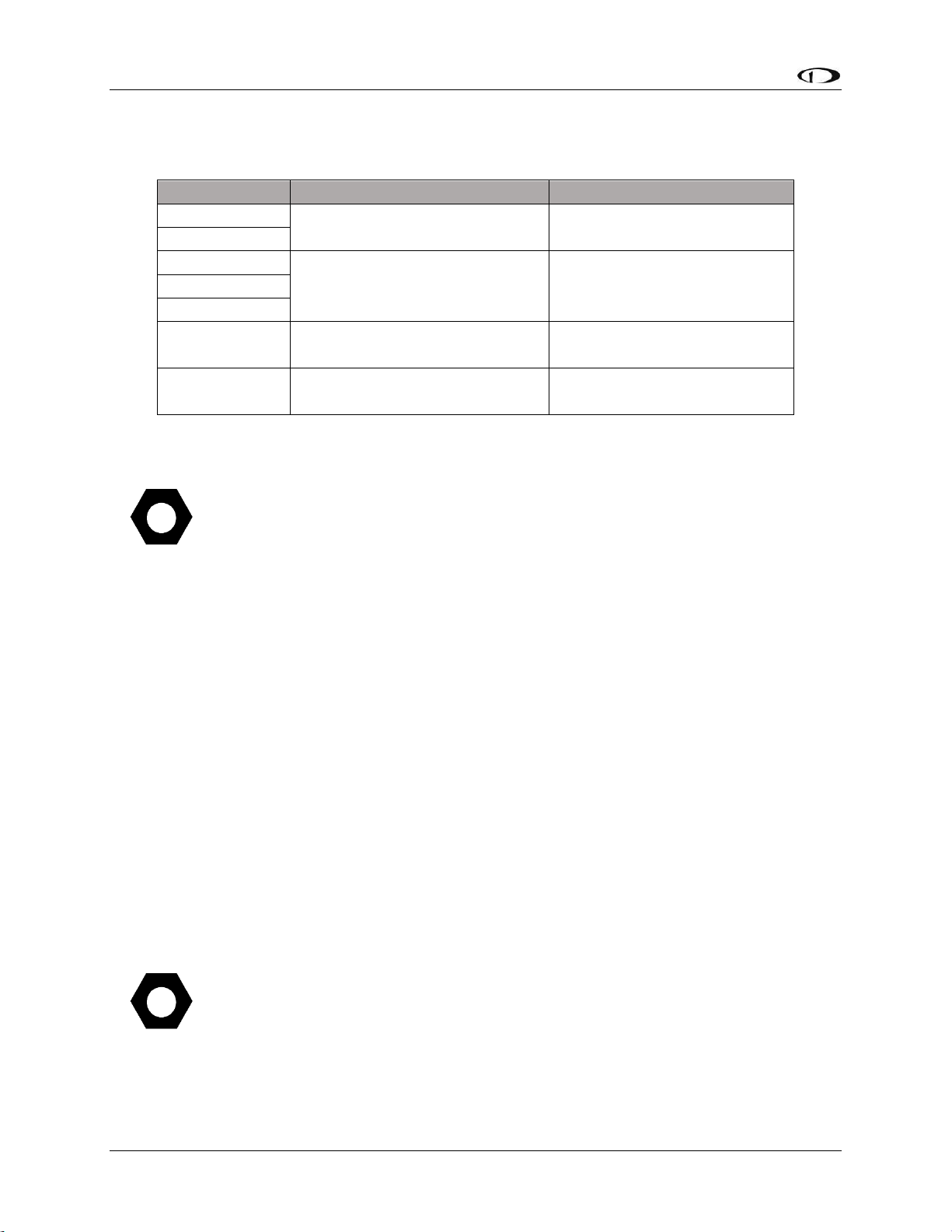

Changes in this Revision

Revision

Revision Date

Description

Revision History for previous revisions is located in

Appendix I: SkyView System Installation Guide Revision History.

AA

December, 2016

Improvements:

o Corrected table of contents missing links

o Corrected misc. formatting issues

o Updated Table 75 adding missing transponder harness wire colors

Z

October, 2016

Document number changed to 101320-025, Revision Z

New products:

o SkyView SV-HDX800 display

o SkyView SV-HDX1100 display

o ADS-B (UAT) Antenna – Rod type (978 MHz)

o Transponder antenna – Rod type (1090 MHz)

o SV-MAP-270 included with new SkyView displays and SkyView HDX

(Section 6)

New features:

o Weight and Balance (Setup)

o Maintenance Log (Setup)

o Ability to change label “CHT” to “CLNT”

o Ability to change aural message “Cylinder Head Temperature” to

“Coolant Temperature”.

Software changes in SkyView Software v15.0.0, released 2016-10-18.

o SkyView SV-HDX800 display (new product)

o SkyView SV-HDX1100 display (new product)

o SV-BAT-320 charging algorithm improved to be able to charge units

that are in protection mode.

Documentation improved in this revision:

o Section 4 – Added connection and configuration instructions for GNC

255 COM/NAV radio.

o Section 5 – Corrected incorrect references to Figures on different

AOA/Pitot Probes

o Section 7 – Updated references to use of dual SV-EMS-220/221

modules to monitor large engines or dual engines is only supported in

SkyView Classic (not SkyView SE or SkyView HDX [as of Software

v15.0])

o Section 7 – Added mention of SV-NET-SPL for use with dual SV-EMS-

220/221 installations.

o Section 7 – Added lists of all available and recommended Dynon

Avionics engine sensor kits.

o Section 11 – Added detail about the permissible use of SV-XPNDR-262

after 2020 (outside Class B and Class C airspaces)

o Section 13 – Explanation that to monitor operation of VPX, one

display must include an SV-BAT-320 or be powered independently of

the VP-X.

o Section 16 – Added alternate method for adjusting Microphone Gain

of SV-COM-C25.

o 579 pages

Table 1 – Changes in this Revision of SkyView Classic / SkyView SE / SkyView HDX System Installation Guide

Page 6

Page 7

SkyView System Installation Guide - Revision AA vii

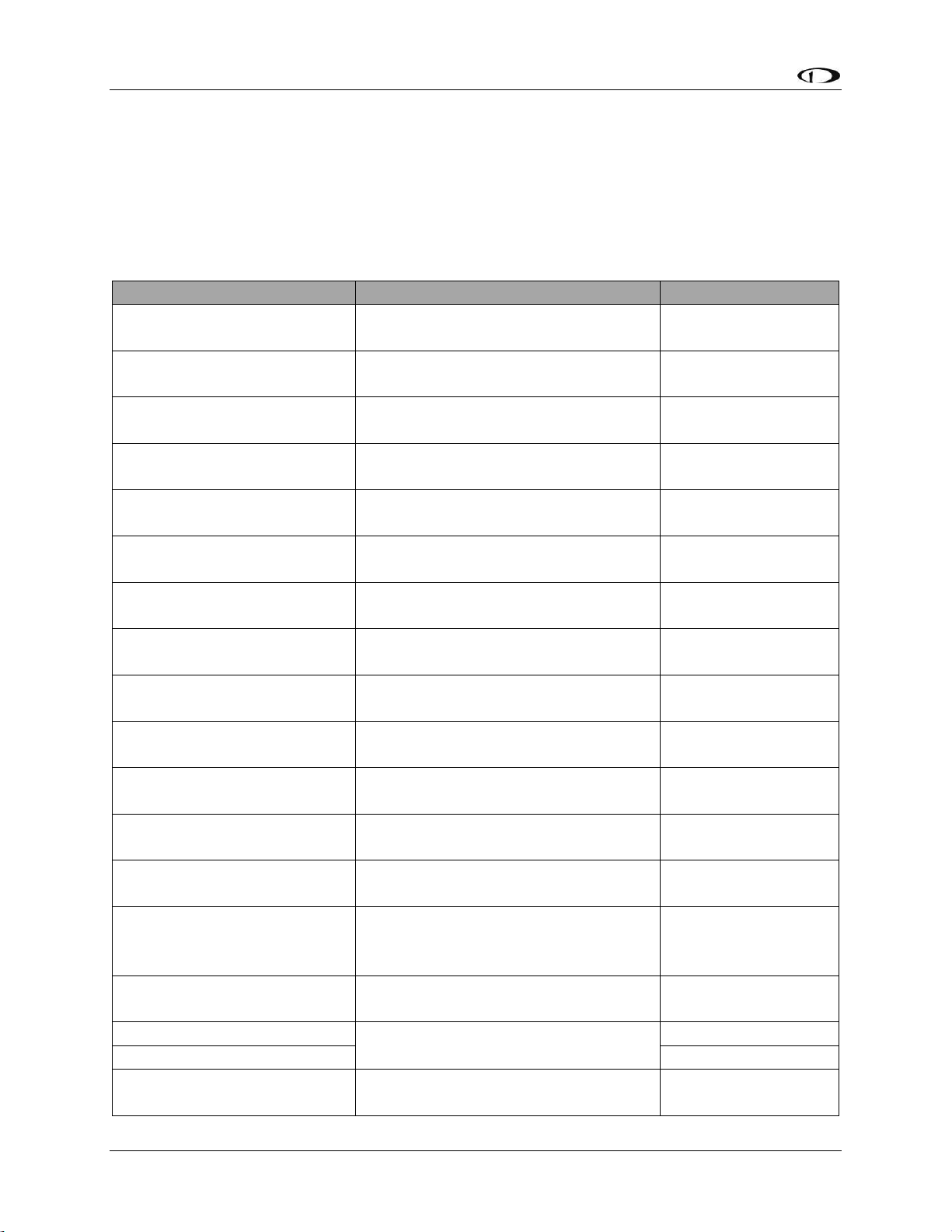

Table of Contents

Contact Information ..................................................................................................................................................... iii

Copyright ...................................................................................................................................................................... iii

Limited Warranty .......................................................................................................................................................... iv

Changes in this Revision ................................................................................................................................................ v

1. Introduction 1-1

Warning ...................................................................................................................................................................... 1-2

Dynon Avionics Product Registration ......................................................................................................................... 1-2

About this Guide ......................................................................................................................................................... 1-3

Semantics of “Software” vs “Software” ...................................................................................................................... 1-4

SkyView Classic, SkyView Touch, SkyView SE, and SkyView HDX ............................................................................... 1-4

Special Light Sport Aircraft (S-LSA) Considerations with SkyView .............................................................................. 1-4

Getting Started ........................................................................................................................................................... 1-5

2. System Planning 2-1

SkyView units cannot / should not be mixed ............................................................................................................. 2-1

9-pin D9F and D9M Connectors are SkyView Network (not RS-232 Serial) ............................................................... 2-2

SkyView Network is a “Party Line” ............................................................................................................................. 2-2

External Switches and Indicators ................................................................................................................................ 2-3

SkyView Display Resolution ........................................................................................................................................ 2-3

SkyView System Maximum Number of Displays ........................................................................................................ 2-3

Power Specifications ................................................................................................................................................... 2-4

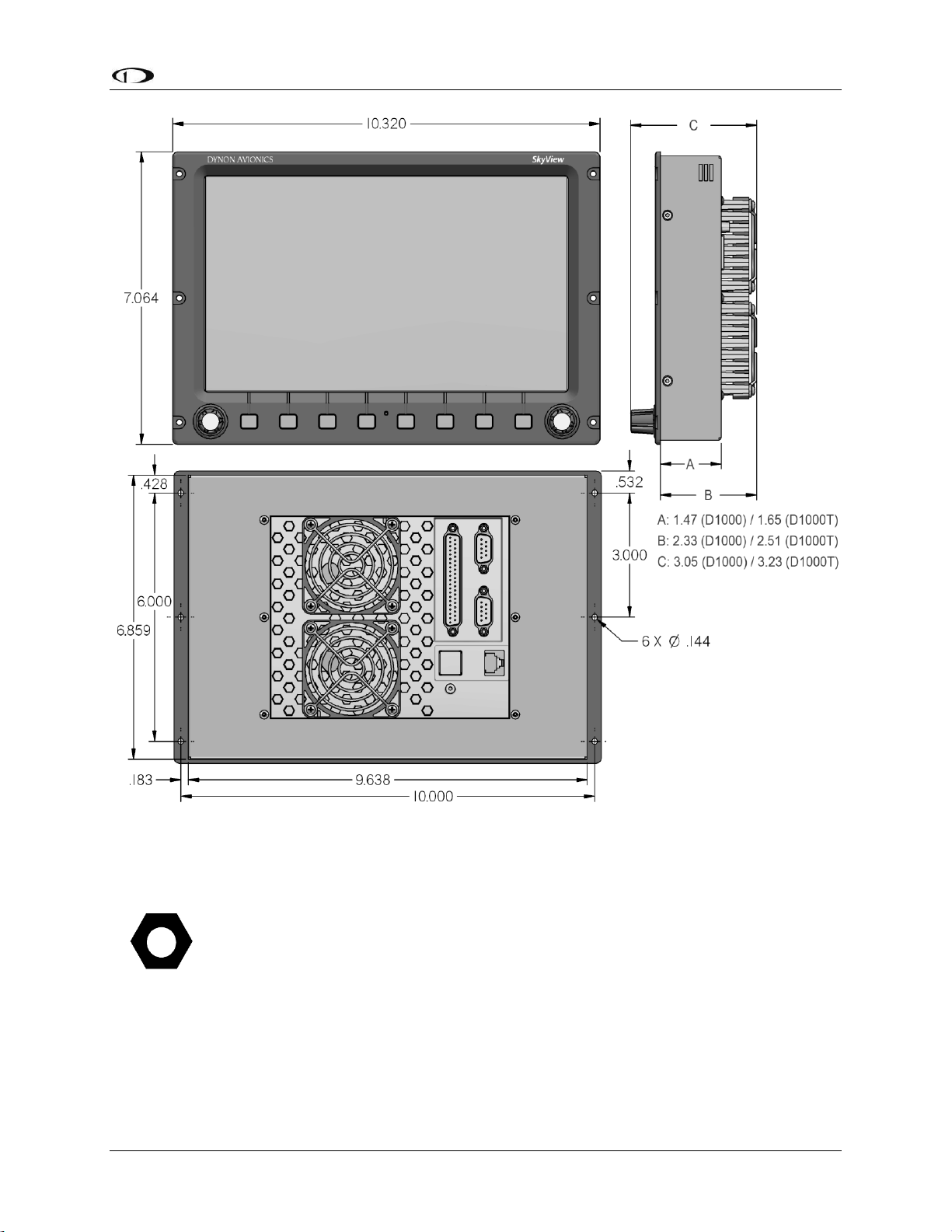

Major Unit Physical Specifications .............................................................................................................................. 2-6

Temperature Specifications ........................................................................................................................................ 2-7

General System Installation Tips ................................................................................................................................ 2-8

SkyView System Can Be On During Engine Start ........................................................................................................ 2-8

Installing SkyView in an IFR-Equipped Aircraft ........................................................................................................... 2-8

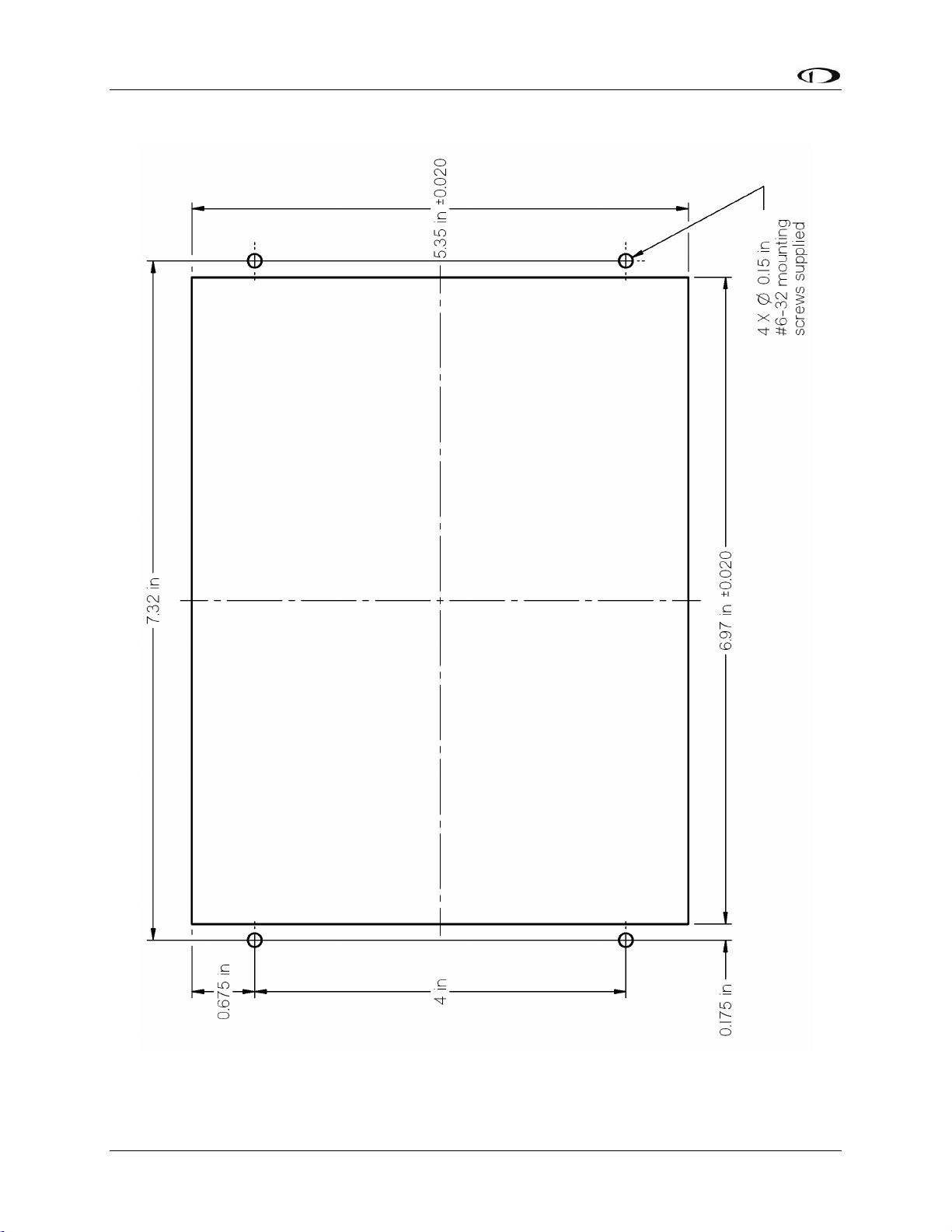

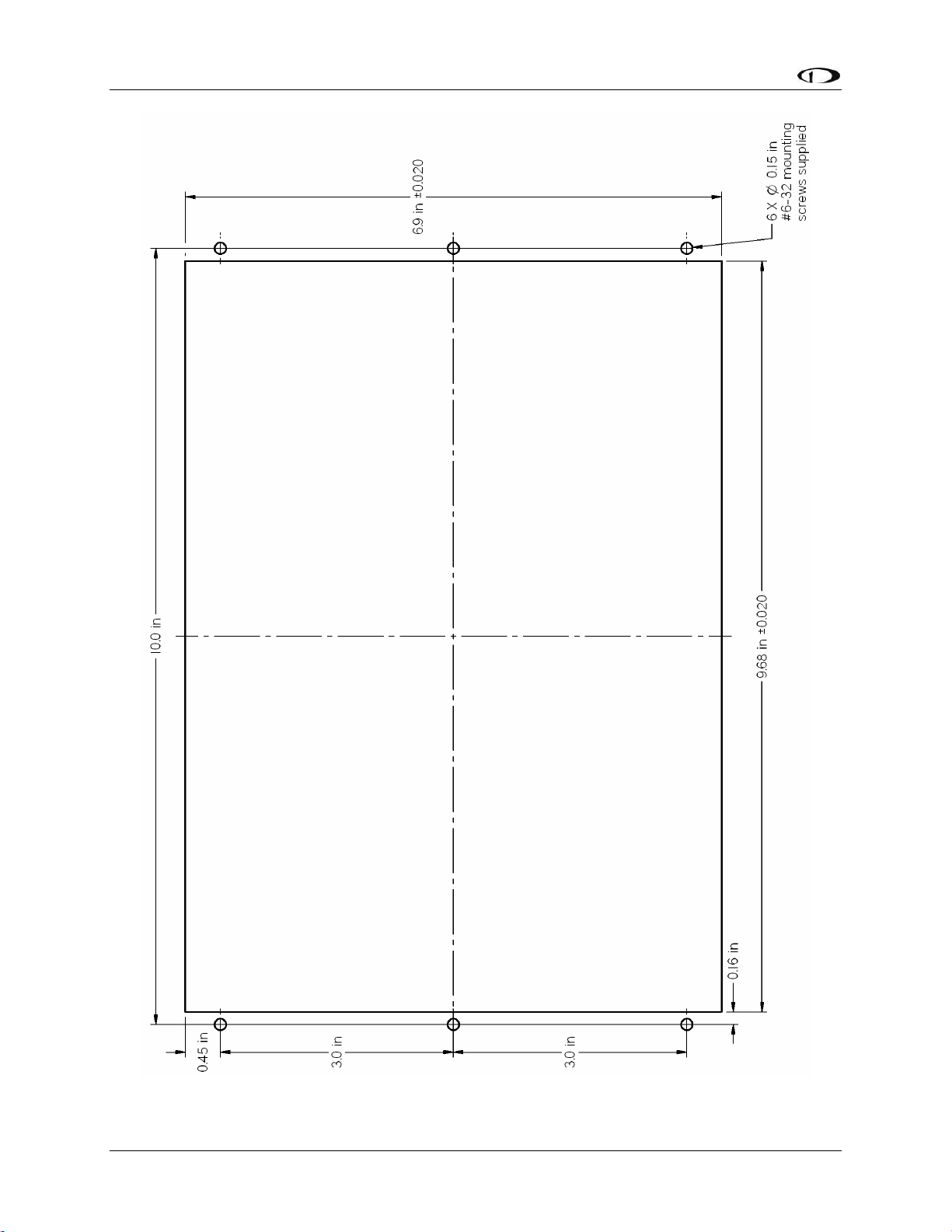

Mounting Requirements............................................................................................................................................. 2-9

SkyView System Construction .................................................................................................................................... 2-9

Example SkyView Systems ........................................................................................................................................ 2-13

HSI Requirements ..................................................................................................................................................... 2-17

3. Basic SkyView Display Operation 3-1

Screen Synchronization .............................................................................................................................................. 3-1

Display Bezel Layout ................................................................................................................................................... 3-2

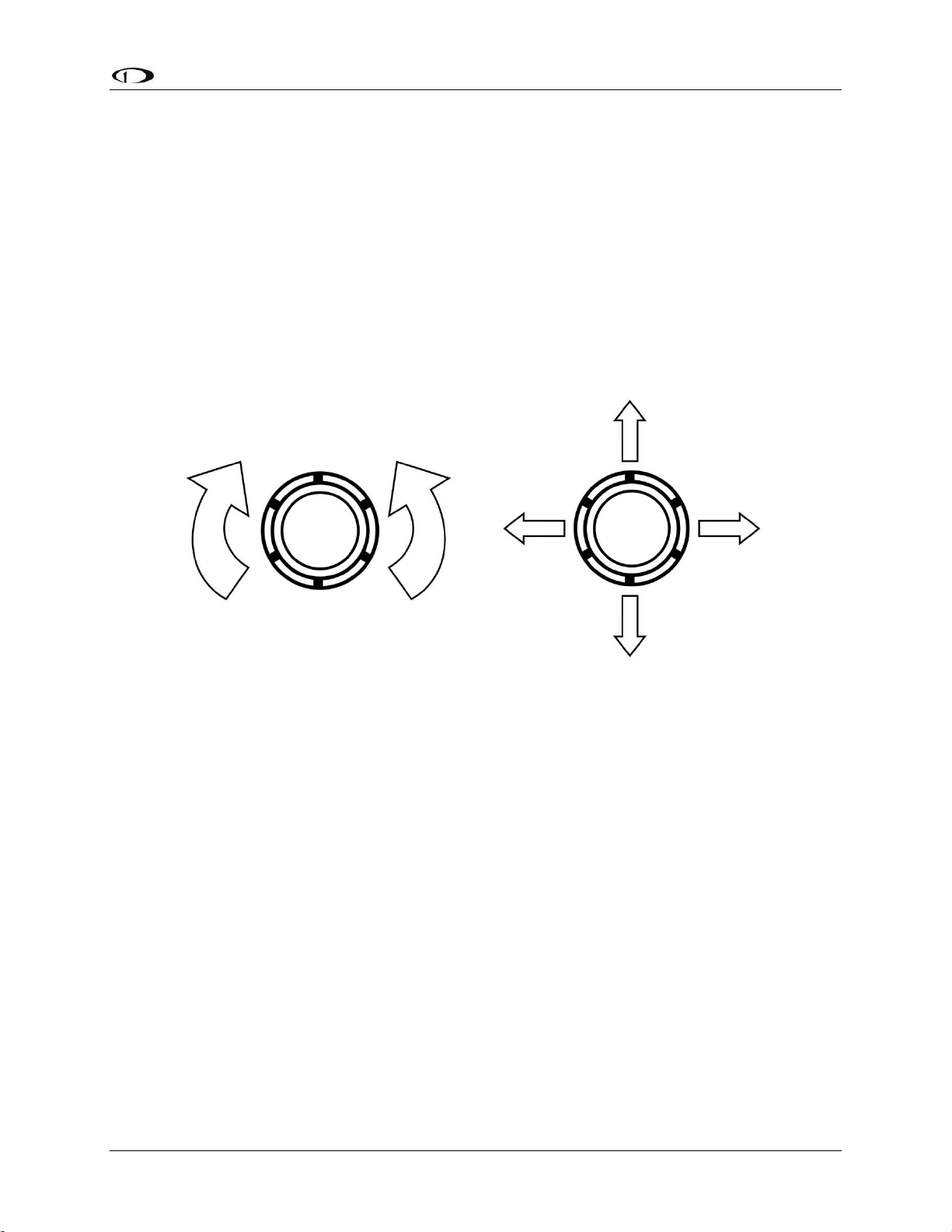

Joystick and Button Operation ................................................................................................................................... 3-3

SkyView Touch – Touch Interface Features Not Used in Setup Menus ...................................................................... 3-5

Menu Navigation ........................................................................................................................................................ 3-6

Basic Display Operation Procedures ........................................................................................................................... 3-7

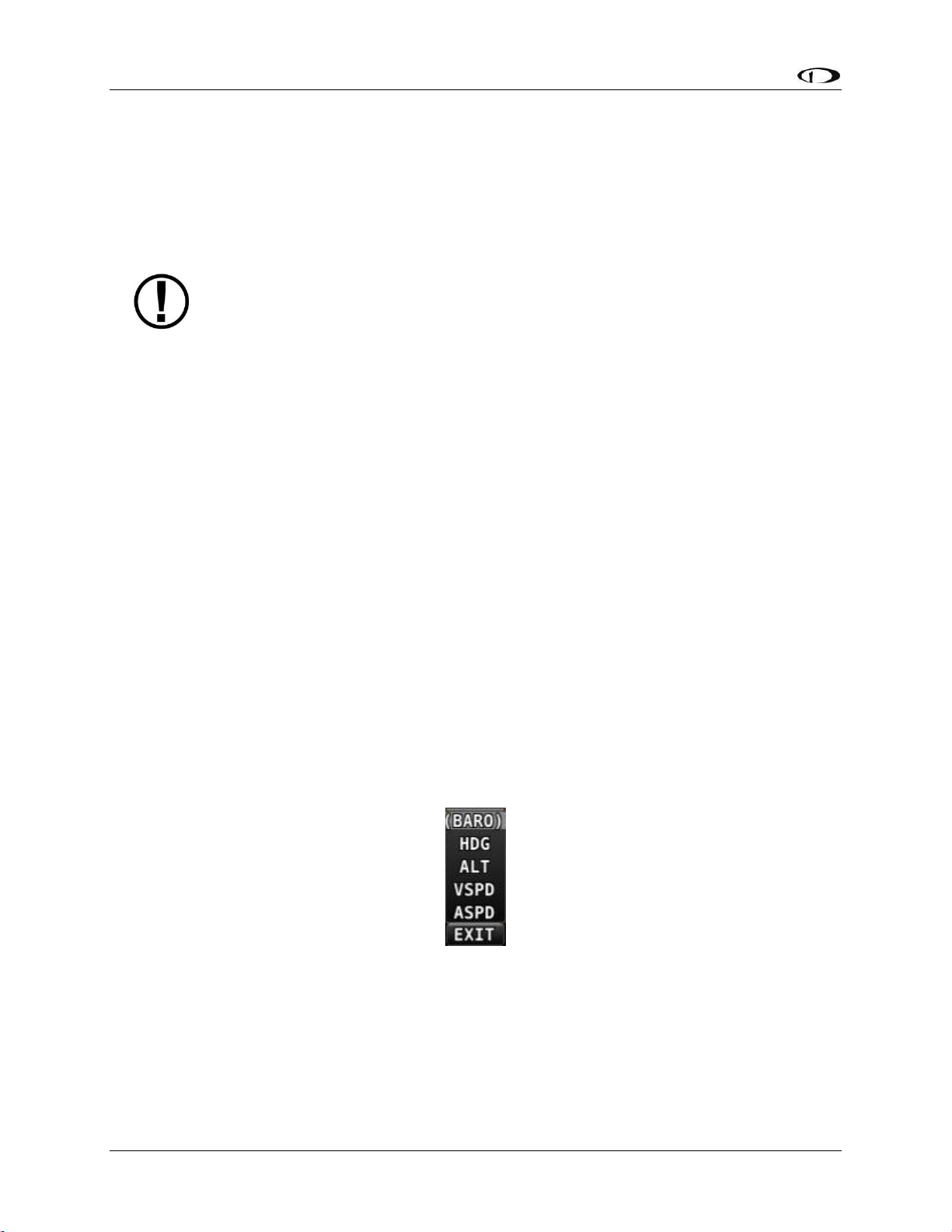

In Flight Setup Menu .......................................................................................................................................... 3-9

SETUP MENU .................................................................................................................................................... 3-10

SYSTEM EVENT Menu ....................................................................................................................................... 3-10

SYSTEM SOFTWARE Menu ................................................................................................................................ 3-11

SYSTEM SETUP Menu ....................................................................................................................................... 3-12

LOCAL DISPLAY SETUP Menu ............................................................................................................................ 3-13

PFD SETUP Menu .............................................................................................................................................. 3-14

EMS SETUP Menu ............................................................................................................................................. 3-15

MAP SETUP Menu ............................................................................................................................................. 3-15

AUTOPILOT SETUP Menu .................................................................................................................................. 3-16

TRANSPONDER SETUP Menu ............................................................................................................................ 3-16

Page 8

Table of Contents

viii SkyView System Installation Guide - Revision AA

HARDWARE CALIBRATION Menu...................................................................................................................... 3-16

Software Updates and File Operations ..................................................................................................................... 3-17

How to Update Software .................................................................................................................................. 3-18

How to Export System Settings ........................................................................................................................ 3-19

How to Load and Delete Files ........................................................................................................................... 3-19

How to Export Data Logs and Waypoints ......................................................................................................... 3-19

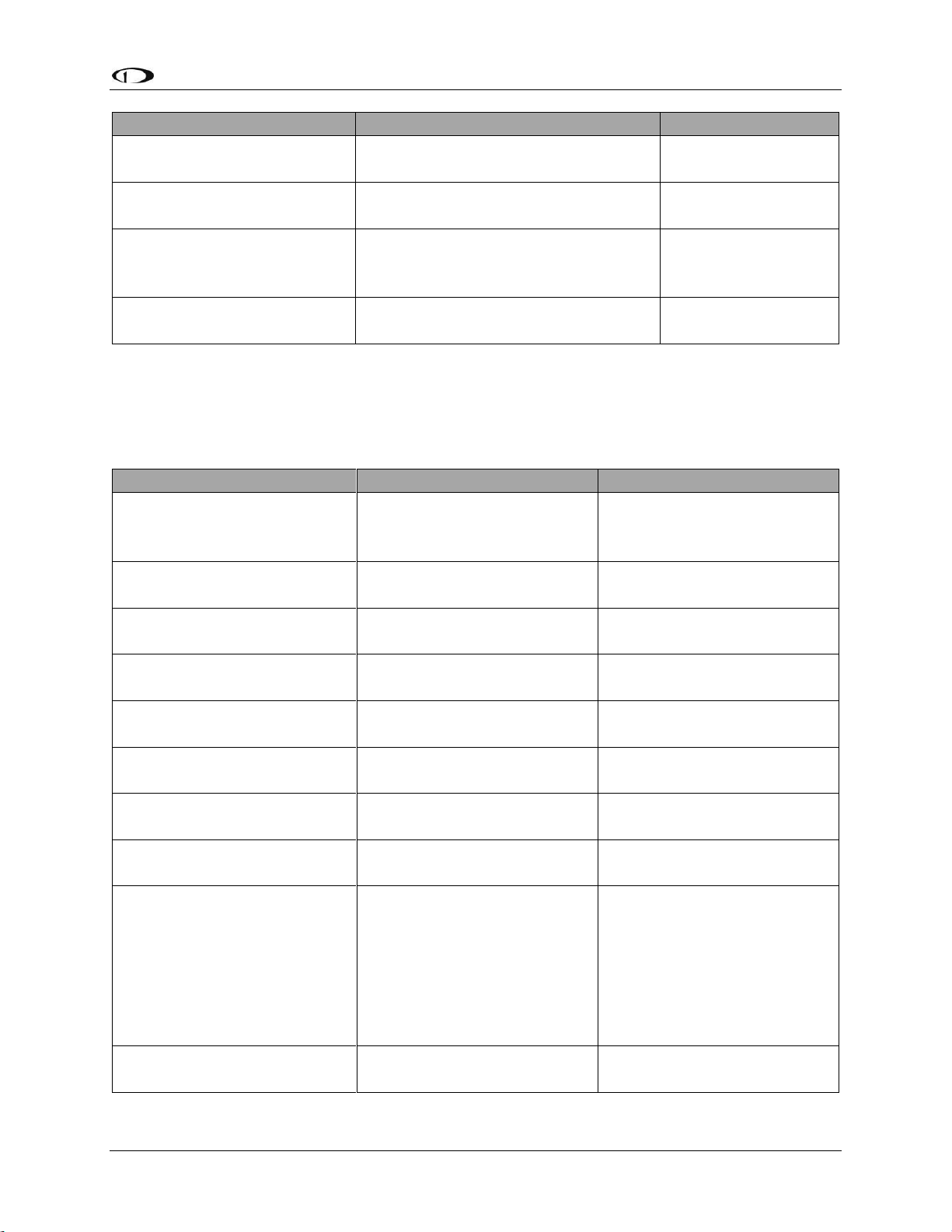

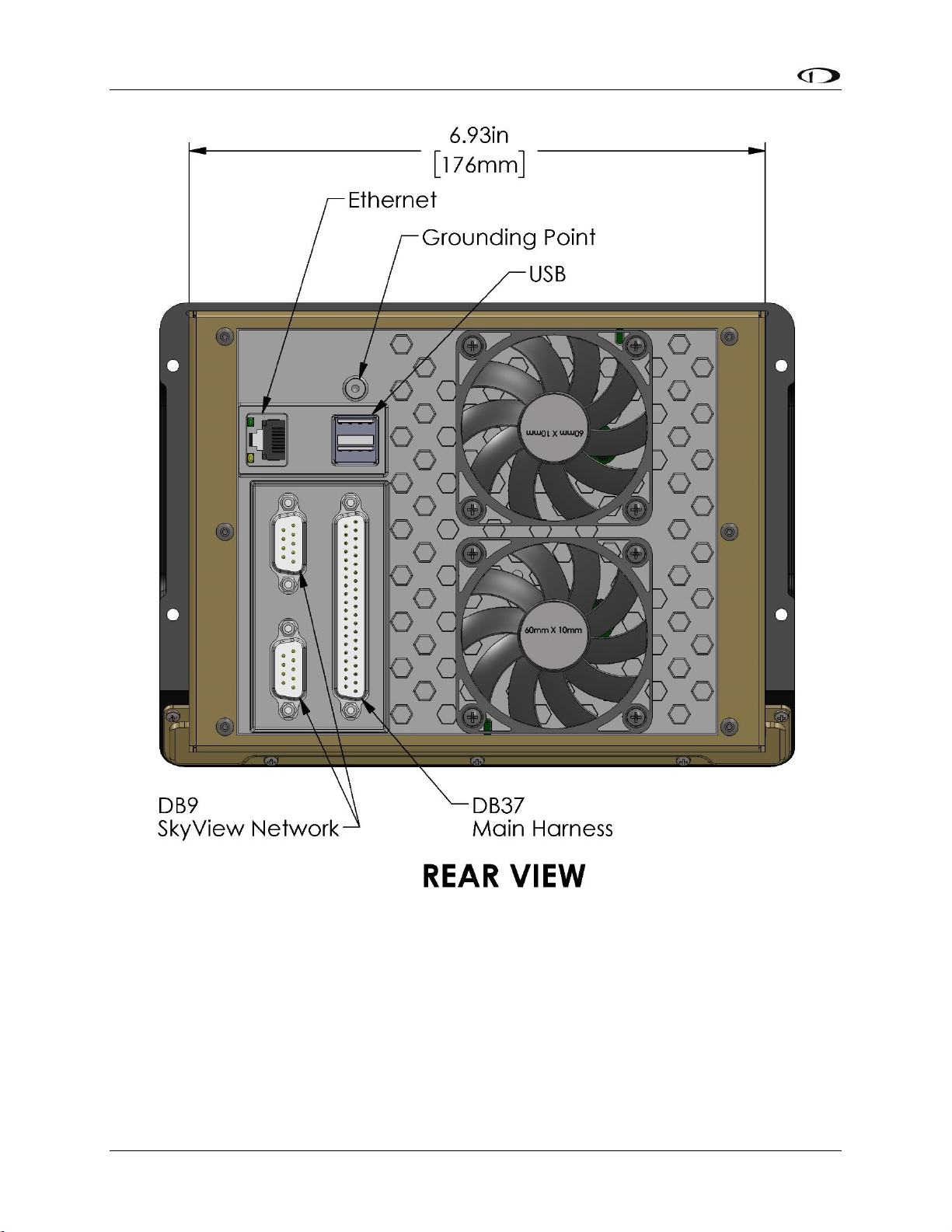

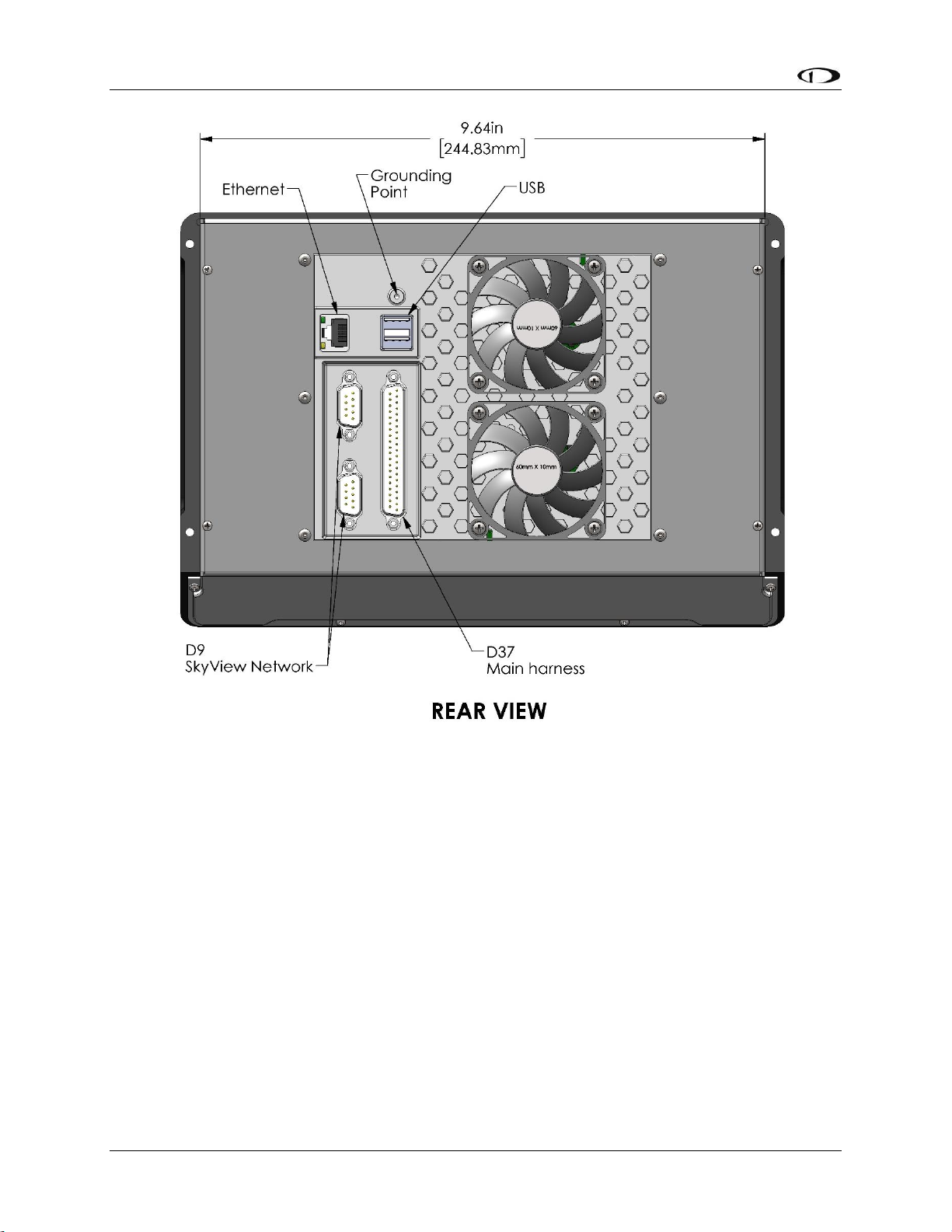

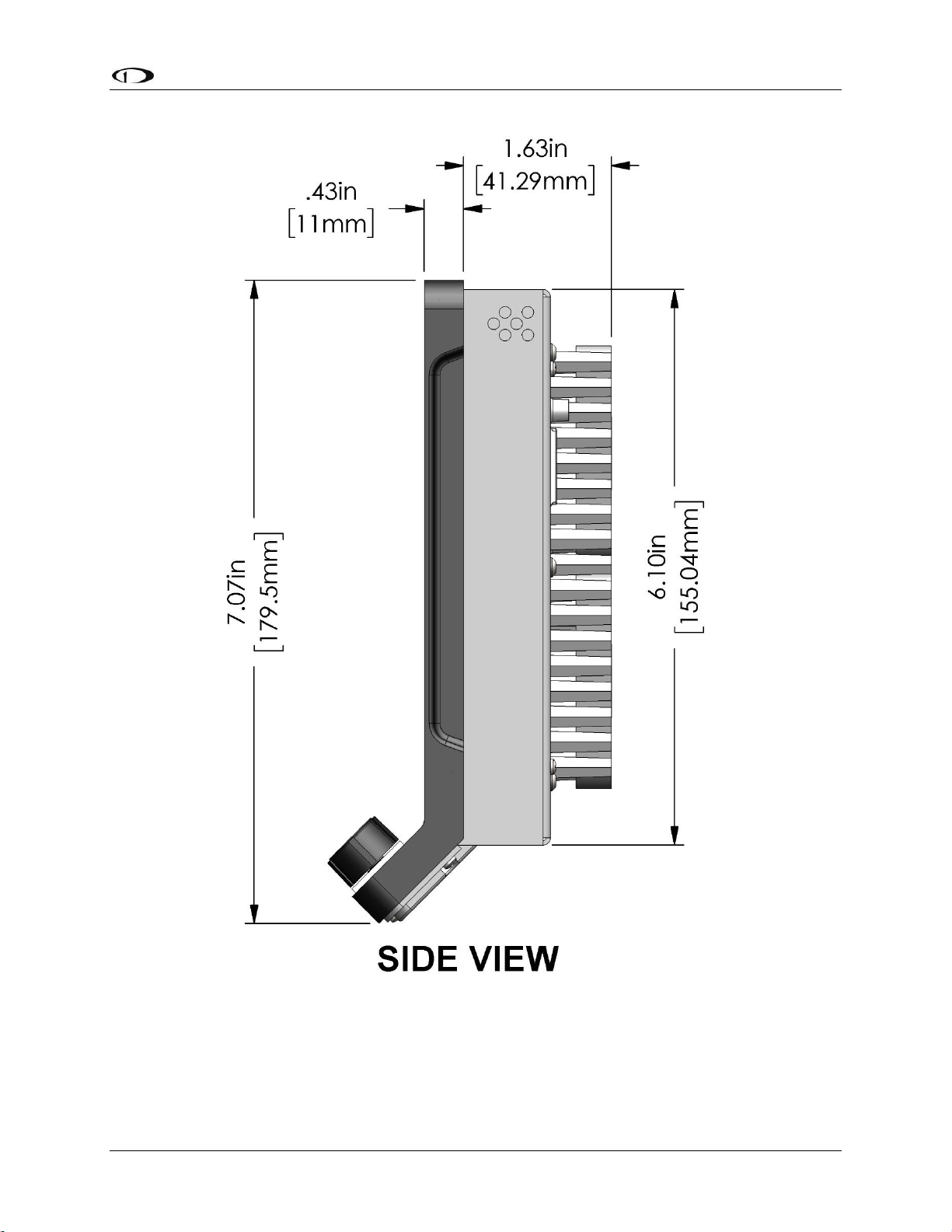

4. SkyView Display Installation and Configuration 4-1

Physical Installation .................................................................................................................................................... 4-2

Location Requirements for SkyView Displays ..................................................................................................... 4-2

Electrical Installation ................................................................................................................................................ 4-17

Power Input ...................................................................................................................................................... 4-17

Grounding ......................................................................................................................................................... 4-17

Airplane Master Contactor / Relay Considerations .......................................................................................... 4-17

SV-BAT-320 Connection and Operation Rules .................................................................................................. 4-17

SkyView Network Connectors .......................................................................................................................... 4-18

Network Setup and Status ................................................................................................................................ 4-18

Ethernet Connection......................................................................................................................................... 4-21

Internal Time Keeping....................................................................................................................................... 4-21

RS-232 Serial Devices ........................................................................................................................................ 4-21

USB Usage and Accessibility ............................................................................................................................. 4-32

External Dim Control (Dimming) Connections .................................................................................................. 4-33

Contact Inputs .................................................................................................................................................. 4-35

Reserved Connections for Future Use .............................................................................................................. 4-35

Display Setup ............................................................................................................................................................ 4-36

How to Access Display Hardware Information ................................................................................................. 4-36

Serial Port Configuration .................................................................................................................................. 4-36

Brightness Setup ............................................................................................................................................... 4-38

Top Bar Setup ................................................................................................................................................... 4-39

Aircraft Information .......................................................................................................................................... 4-39

SkyView Classic, SkyView SE Screen Layout Setup ........................................................................................... 4-40

SkyView HDX Display Setup / Layout ................................................................................................................ 4-41

SkyView Classic and SkyView HDX Touch Setup ............................................................................................... 4-42

Glide Ring Setup ............................................................................................................................................... 4-42

Weight and Balance Setup ................................................................................................................................ 4-42

Maintenance Log Setup .................................................................................................................................... 4-43

5. SV-ADAHRS-200/201 Installation and Configuration 5-1

Optional Components for Easier Installation of your SV-ADAHRS-200/201............................................................... 5-3

Physical Installation .................................................................................................................................................... 5-4

SV-ADAHRS-200/201 Location Requirements ............................................................................................................ 5-4

SkyView Network Connection .................................................................................................................................. 5-12

Pneumatic Ports ....................................................................................................................................................... 5-12

Compass Calibration ................................................................................................................................................. 5-13

On-ground Compass Calibration Procedure: .................................................................................................... 5-14

In-flight Compass Calibration Procedure: ......................................................................................................... 5-15

SV-OAT-340 Location and Installation ...................................................................................................................... 5-17

PFD-Related Settings ................................................................................................................................................ 5-19

Other ADAHRS Calibrations ...................................................................................................................................... 5-21

Performing Pitot/Static Checks ................................................................................................................................. 5-22

6. SV-MAP-270 Navigation Mapping License Purchase and Setup 6-1

License Information .................................................................................................................................................... 6-1

Page 9

Table of Contents

SkyView System Installation Guide - Revision AA ix

Databases ................................................................................................................................................................... 6-3

Viewing Information about Installed Databases ................................................................................................ 6-3

Terrain Database ................................................................................................................................................ 6-6

Aviation/Obstacle Databases.............................................................................................................................. 6-7

US SkyView Pilots – Stadium TFR Database ........................................................................................................ 6-8

Charts and Airport Diagrams .............................................................................................................................. 6-9

Loading Databases ............................................................................................................................................ 6-10

Removing Databases ........................................................................................................................................ 6-10

7. SV-EMS-220/221 Installation and Configuration 7-1

Physical Installation .................................................................................................................................................... 7-3

SkyView Network Connection .................................................................................................................................... 7-5

SkyView EMS Sensor Definition and Configuration Files ............................................................................................ 7-5

Engine Sensor and Transducer Planning..................................................................................................................... 7-5

Example Engine Sensor and Transducer Installations .............................................................................................. 7-20

Lycoming/Continental 4-cylinder Carbureted .................................................................................................. 7-21

Lycoming/Continental 4-cylinder Fuel Injected ................................................................................................ 7-23

Lycoming/Continental 6-cylinder Carbureted .................................................................................................. 7-25

Lycoming/Continental 6-cylinder Fuel Injected ................................................................................................ 7-27

Jabiru 2200 ....................................................................................................................................................... 7-29

Jabiru 3300 ....................................................................................................................................................... 7-31

Rotax 912 ULS Carbureted ................................................................................................................................ 7-33

Rotax 912 iS (Electronic Control Unit) .............................................................................................................. 7-35

Dual Engine Support Using Dual SV-EMS-220/221s and Two SkyView Classic Displays ................................... 7-42

Engine Sensor and Transducer Installation ...................................................................................................... 7-43

Engine Sensor Accuracy and Grounding ........................................................................................................... 7-43

Tools and Equipment Required ........................................................................................................................ 7-44

Voltmeter Inputs............................................................................................................................................... 7-44

Exhaust Gas Temperature (EGT) Sensors ......................................................................................................... 7-44

Cylinder Head Temperature (CHT) Sensors ...................................................................................................... 7-46

Tachometer ...................................................................................................................................................... 7-47

Manifold Pressure Sensor ................................................................................................................................. 7-49

Oil Pressure Sensor ........................................................................................................................................... 7-50

Oil Temperature Sensors .................................................................................................................................. 7-53

Fuel Pressure Sensor ........................................................................................................................................ 7-54

Fuel Flow Transducer ........................................................................................................................................ 7-57

Fuel Level Sensor .............................................................................................................................................. 7-59

Ammeter Shunt ................................................................................................................................................ 7-61

Carburetor Temperature Sensor ...................................................................................................................... 7-65

Rotax CHT Sensors ............................................................................................................................................ 7-65

Trim and Flaps Position Potentiometers .......................................................................................................... 7-66

Coolant Pressure Sensor ................................................................................................................................... 7-67

Coolant Temperature Sensor............................................................................................................................ 7-69

General Purpose Temperature Sensor ............................................................................................................. 7-69

Rotax 914 Air Box Temperature ....................................................................................................................... 7-70

Contacts ............................................................................................................................................................ 7-70

General Purpose Thermocouple ....................................................................................................................... 7-71

External EMS Warning Light ..................................................................................................................................... 7-72

Engine Information ................................................................................................................................................... 7-72

EMS Sensor Definitions, Mapping, and Settings ....................................................................................................... 7-74

EMS Sensor Definitions ..................................................................................................................................... 7-74

EMS Sensor Input Mapping .............................................................................................................................. 7-75

EMS Sensor Settings ......................................................................................................................................... 7-76

Page 10

Table of Contents

x SkyView System Installation Guide - Revision AA

EMS Screen Layout Editor ......................................................................................................................................... 7-85

EMS Sensor Calibration ............................................................................................................................................ 7-87

SkyView HDX ENGINE BOTTOM BAND ..................................................................................................................... 7-88

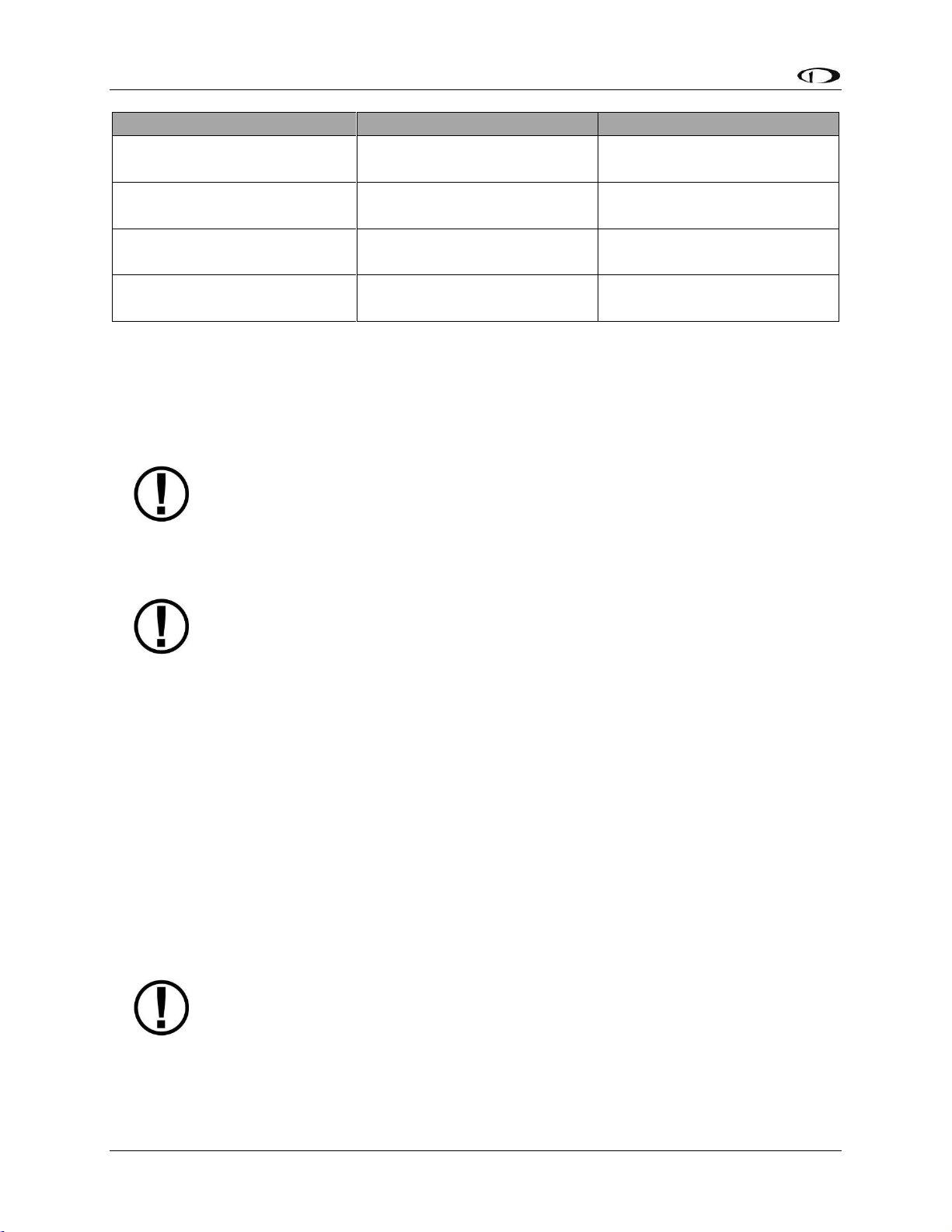

8. SV-GPS-250/2020 GPS Receiver Installation and Configuration 8-1

WAAS Data Reception ................................................................................................................................................ 8-2

Use of the SV-GPS-2020 outside the US ..................................................................................................................... 8-3

Considerations for converting an SV-GPS-250 to an SV-GPS-2020 in Special Light Sport Aircraft (S-LSAs) ............... 8-3

Physical Installation .................................................................................................................................................... 8-4

Considerations for installing an SV-GPS-2020 in an aircraft with an installed SV-GPS-250........................................ 8-6

Serial Data Connection ............................................................................................................................................... 8-7

Configuration – SV-GPS-2020 only, Serial Port 5 ...................................................................................................... 8-10

Configuration – SV-GPS-2020 (Serial Port 5) and SV-GPS-250 (Serial Port 4) ........................................................... 8-10

Testing / troubleshooting installation of the SV-GPS-250 and/or SV-GPS-2020 ...................................................... 8-11

Part 1 – Basic Serial Port Functionality ............................................................................................................. 8-11

Part 2 – GPS Receive Performance ................................................................................................................... 8-12

(US only) Additional configuration required for SDA/SIL=1… ................................................................................... 8-15

Additional Configuration Required for Compliance with FAA 2020 ADS-B Out Mandate ........................................ 8-15

9. SV-BAT-320 Backup Battery Installation 9-1

Physical Installation .................................................................................................................................................... 9-2

SV-BAT-320 Location .......................................................................................................................................... 9-2

Electrical Connection .................................................................................................................................................. 9-3

Charging the SV-BAT-320 ............................................................................................................................................ 9-3

SV-BAT-320 is Automatically Charged in Flight .................................................................................................. 9-4

Charging the SV-BAT-320 on Ground or During Aircraft Construction ............................................................... 9-4

Battery Status Icon ..................................................................................................................................................... 9-5

Detailed Battery Status Check .................................................................................................................................... 9-5

Initial SV-BAT-320 Test ............................................................................................................................................... 9-6

In the Event of Initial SV-BAT-320 Test Failure … ............................................................................................... 9-7

SV-BAT-320 Specifications .......................................................................................................................................... 9-8

Returning an SV-BAT-320 to Dynon Avionics for Exchange (Warranty Replacement) ............................................... 9-8

10. AP Servo Installation, Configuration, and Calibration 10-1

Dynon Avionics Autopilot Servo Models .................................................................................................................. 10-3

Compass Calibration Requirement ........................................................................................................................... 10-3

Additional Resources ................................................................................................................................................ 10-3

Servo Mechanical Installation ................................................................................................................................... 10-4

Autopilot Servo Calibration and Test Procedures .................................................................................................. 10-16

Autopilot Servo Initial Setup ................................................................................................................................... 10-17

Autopilot In-Flight Tuning Procedures .................................................................................................................... 10-23

11. SV-XPNDR-261/262 Installation and Configuration 11-1

Physical Installation .................................................................................................................................................. 11-3

Electrical Connections .............................................................................................................................................. 11-5

Antenna Installation ............................................................................................................................................... 11-12

Transponder-Related SkyView Display Settings ..................................................................................................... 11-16

(US only) Configuration required for SDA/SIL=1 for continued reception of ADS-B Traffic (early 2016) ............... 11-23

SkyView Systems with an SV-GPS-250 as primary GPS… ........................................................................................ 11-24

(US-Only) Equipping for compliance with FAA 2020 ADS-B Out Mandate ............................................................. 11-25

Installation of Dynon Avionics SV-GPS-2020 for compliance with FAA 2020 ADS-B Out mandate ................ 11-27

SV-XPNDR-261/262 Software Updates ................................................................................................................... 11-30

SV-XPNDR-261/262 Software Update SW02.09 ............................................................................................. 11-35

Page 11

Table of Contents

SkyView System Installation Guide - Revision AA xi

SV-XPNDR-261/262 Software Update SW02.09 Quick Decision Points.......................................................... 11-35

Deprecated SV-XPNDR-261/262 Software Update Instructions and notes .................................................... 11-37

SkyView Software v12.2 – v13.0.3 SV-XPNDR-261/262 Software SW02.06 Update ...................................... 11-38

SV-XPNDR-261/262 Software Version (SW) v2.02/v2.04/v2.06 Labeling Requirements (US Registered /

Operated Aircraft Only) .................................................................................................................................. 11-39

SkyView Software v14.0 – v14.1 SV-XPNDR-261/262 Software Update SW02.08 ......................................... 11-40

SV-XPNDR-261/262 Software Update SW02.08 Quick Decision Points.......................................................... 11-40

SV-XPNDR-261/262 Post Installation Checks .......................................................................................................... 11-41

Transponder Warnings (Transponder Self Diagnostics) ......................................................................................... 11-42

Performing Transponder Checks ............................................................................................................................ 11-43

Dynon Avionics SV-GPS-250 and SV-GPS-2020 Compliance Statements ............................................................... 11-44

12. SV-ARINC-429 Installation and Configuration 12-1

Physical Installation .................................................................................................................................................. 12-1

SkyView Network Connection .................................................................................................................................. 12-2

ARINC-429 Device Connection .................................................................................................................................. 12-2

SV-ARINC-429 Related Settings .............................................................................................................................. 12-11

13. Vertical Power VP-X Integration and Configuration 13-1

VP-X Physical, Electrical Installation and Configuration ........................................................................................... 13-1

Serial Port Connection .............................................................................................................................................. 13-2

License Information .................................................................................................................................................. 13-3

VP-X SkyView Classic Display Settings ...................................................................................................................... 13-4

Post Installation Checks ............................................................................................................................................ 13-5

14. SV-ADSB-470 Installation and Configuration 14-1

Physical Installation .................................................................................................................................................. 14-2

Electrical Installation ................................................................................................................................................ 14-4

Antenna Selection and Installation ........................................................................................................................... 14-7

SV-ADSB-470-Related SkyView Display Settings ....................................................................................................... 14-9

Post Installation Checks .......................................................................................................................................... 14-10

15. Accessory Installation and Configuration 15-1

SkyView System Angle of Attack Pitot Probe ........................................................................................................... 15-1

Encoder Serial-to-Gray Code Converter ................................................................................................................... 15-5

Capacitance to Voltage Converter for Van’s Capacitive Plates ................................................................................ 15-8

SkyView Video Input Adapter ................................................................................................................................... 15-9

SkyView Wi-Fi Adapter ........................................................................................................................................... 15-13

Advanced Flight Systems (AFS) ADVANCED Control Module (ACM) ...................................................................... 15-16

SV-BUTTON-LEVEL .................................................................................................................................................. 15-17

Pitot/Static/AOA Pneumatic Installation Kit ........................................................................................................... 15-21

Recommended Tools & Installation Accessories ............................................................................................ 15-24

Installation ...................................................................................................................................................... 15-24

Panel Module Faceplate Blank ............................................................................................................................... 15-27

SV-KNOB-DIMMER .................................................................................................................................................. 15-28

16. SV-COM-C25 Installation and Configuration 16-1

Physical Installation: SV-COM-PANEL ....................................................................................................................... 16-2

Electrical Installation ................................................................................................................................................ 16-6

Power Input ...................................................................................................................................................... 16-6

Audio Signal Grounding .................................................................................................................................... 16-6

Audio Shielding ................................................................................................................................................. 16-6

SkyView Network Connectors .......................................................................................................................... 16-6

Page 12

Table of Contents

xii SkyView System Installation Guide - Revision AA

Electrical Connections .............................................................................................................................................. 16-6

Antenna Installation ............................................................................................................................................... 16-15

SkyView System Settings for SV-COM-C25 ............................................................................................................. 16-17

Post Installation Checks .......................................................................................................................................... 16-19

Continued Airworthiness and Maintenance ........................................................................................................... 16-20

17. SV-COM-X83 Installation and Configuration 17-1

Certification Considerations ..................................................................................................................................... 17-2

Physical Installation: SV-COM-PANEL ....................................................................................................................... 17-2

Physical Installation: SV-COM-T8 .............................................................................................................................. 17-4

Electrical Installation ................................................................................................................................................ 17-7

Power Input ...................................................................................................................................................... 17-7

Audio Signal Grounding .................................................................................................................................... 17-7

Audio Shielding ................................................................................................................................................. 17-7

SkyView Network Connectors .......................................................................................................................... 17-7

Electrical Connections .............................................................................................................................................. 17-8

Antenna Installation ............................................................................................................................................... 17-16

SkyView System Settings for SV-COM-X83 ............................................................................................................. 17-19

Post Installation Checks .......................................................................................................................................... 17-20

Continued Airworthiness and Maintenance ........................................................................................................... 17-20

18. SV-AP-PANEL Installation and Configuration 18-1

Physical Installation .................................................................................................................................................. 18-3

Electrical Installation ................................................................................................................................................ 18-4

Autopilot Auto-trim .................................................................................................................................................. 18-9

Post Installation Checks ............................................................................................................................................ 18-9

19. SV-KNOB-PANEL Installation 19-1

Physical Installation .................................................................................................................................................. 19-2

Electrical Installation ................................................................................................................................................ 19-3

Post Installation Checks ............................................................................................................................................ 19-3

20. SV-MAG-236 Installation and Configuration 20-1

Physical Installation .................................................................................................................................................. 20-2

Optional SV-OAT-340 Connected to SV-MAG-236 ................................................................................................... 20-4

SkyView Network Connection .................................................................................................................................. 20-1

Compass Calibration ................................................................................................................................................. 20-1

On-ground Compass Calibration Procedure: .................................................................................................... 20-2

In-flight Compass Calibration Procedure: ......................................................................................................... 20-3

Restoring Use of the SV-ADAHRS-200/201 Internal Magnetometer ........................................................................ 20-5

21. Appendix A: Maintenance and Troubleshooting 21-1

Cleaning a SkyView Display....................................................................................................................................... 21-1

Saving a Screenshot of a Specific Screen .................................................................................................................. 21-2

Savings a Settings File (Configuration of your SkyView system) ............................................................................... 21-2

Saving a Dynon Diagnostic File ................................................................................................................................. 21-2

SkyView Displays Error: SYS EVENT 5: SEE SETUP ..................................................................................................... 21-3

Returning SkyView Components to Service after Repair .......................................................................................... 21-3

In a Multi-display SkyView System, Continuing to Fly with a Missing Display.......................................................... 21-6

Operational Status .................................................................................................................................................... 21-7

Instructions for Continued Airworthiness ................................................................................................................ 21-9

Annual SV-BAT-320 Test ................................................................................................................................. 21-10

Troubleshooting ..................................................................................................................................................... 21-12

Page 13

Table of Contents

SkyView System Installation Guide - Revision AA xiii

22. Appendix B: Specifications 22-1

SkyView / Dynon Avionics Minor Equipment Weights ............................................................................................. 22-1

SkyView Compatible Engine Sensors (sold by Dynon Avionics) ................................................................................ 22-2

SV-BAT-320 Specifications ........................................................................................................................................ 22-3

SV-XPNDR-261 Specifications ................................................................................................................................... 22-4

SV-XPNDR-262 Specifications ................................................................................................................................... 22-5

SV-XPNDR-261/262 ADS-B Information .................................................................................................................... 22-8

SV-COM-C25 Technical Specifications .................................................................................................................... 22-10

SV-COM-X83 (TY91L VHF Radio Unit) Technical Specifications .............................................................................. 22-11

SV-GPS-250 Specifications ...................................................................................................................................... 22-12

SV-GPS-2020 Specifications .................................................................................................................................... 22-13

23. Appendix C: Wiring and Electrical Connections 23-1

Wire Gauge ............................................................................................................................................................... 23-1

Grounding ................................................................................................................................................................. 23-1

DSUB Crimp Contacts and Tools ............................................................................................................................... 23-2

Non-Dynon Avionics Wire Harness Considerations .................................................................................................. 23-2

SkyView Equipment Electrical Connections .............................................................................................................. 23-4

SkyView Equipment Electrical Connector Pinout Tables .......................................................................................... 23-6

Servo Pinout (SV-NET-SERVO) .......................................................................................................................... 23-6

SkyView Display D37 Pinout (SV-HARNESS-D37) .............................................................................................. 23-7

SkyView D37M Block Diagram .......................................................................................................................... 23-8

SV-EMS-220/221 Pinouts (EMS Harnesses) .................................................................................................... 23-11

SV-ARINC-429 Pinout ...................................................................................................................................... 23-14

SV-XPNDR-261/262 Pinout (SV-HARNESS-XPNDR) ......................................................................................... 23-16

SV-AP-PANEL Pinout (D15M connector) ......................................................................................................... 23-18

SV-COM-PANEL Pinout (D15M) ...................................................................................................................... 23-19

SV-COM-425 Pinout ........................................................................................................................................ 23-20

SV-COM-T8 Pinout .......................................................................................................................................... 23-22

24. Appendix D: SV-EMS-220/221 Sensor Input Mapping Worksheet 24-1

25. Appendix E: Serial Data Output 25-1

DYNON ADAHRS Serial Data Format ......................................................................................................................... 25-2

DYNON SYSTEM Serial Data Format ......................................................................................................................... 25-4

DYNON EMS Serial Data Format ............................................................................................................................... 25-7

DYNON ADAHRS / SYSTEM / EMS Serial Data Output Combinations ..................................................................... 25-11

NMEA OUT Serial Data Formats ............................................................................................................................. 25-12

26. Appendix F: User Data Logs 26-1

User Data Log ................................................................................................................................................... 26-1

Recent Flight Data Log ...................................................................................................................................... 26-2

Alert Data Log ................................................................................................................................................... 26-2

History Data Log ............................................................................................................................................... 26-3

Data Logging Recording Options ...................................................................................................................... 26-3

Exporting Data Logs .......................................................................................................................................... 26-3

27. Appendix G: Kavlico Pressure Sensor Part Numbers 27-1

Dynon Avionics Technical Advisory 120214 – Kavlico Pressure Sensors .......................................................... 27-1

28. Appendix H: Sensor Debug Data 28-1

29. Appendix I: SkyView System Installation Guide Revision History 29-1

Page 14

Table of Contents

xiv SkyView System Installation Guide - Revision AA

30. Appendix J: Checklists 30-1

Saving Your Checklist with “UTF-8 Character Encoding” .......................................................................................... 30-2

Example Checklist ..................................................................................................................................................... 30-4

Example Checklist Formatting Notes: ....................................................................................................................... 30-5

Excel Checklist Generation Tool ............................................................................................................................... 30-6

Loading a Checklist ................................................................................................................................................... 30-6

Displaying Your Checklist on your SkyView Display .................................................................................................. 30-9

31. Appendix K: Switches, etc. External to SkyView Units 31-1

Page 15

SkyView System Installation Guide - Revision AA 1-1

1. Introduction

It is the installer’s responsibility to conform to industry standards as applicable.

This guide provides information about the physical (mechanical), electrical, and pneumatic

installation and configuration of the following SkyView major system components:

Advanced Flight Systems (AFS) ADVANCED Control Module (included as part of an

ADVANCED Quick Panel System)*

Angle-of-Attack (AOA) / Pitot Probe (details specific to the SkyView system)

Encoder Serial-to-Gray Code Converter

Capacitance to Voltage Converter

Engine and environmental sensors purchased from Dynon Avionics (and selected

other sensors)

SkyView Video Input Adapter

SkyView Wi-Fi Adapter

SV32 Autopilot servo (all variations, generic installation details)

SV42 Autopilot servo (all variations, generic installation details)

SV52 Autopilot servo (all variations, generic installation details)

SV-AP-PANEL Expert Autopilot Control Panel / Trim Controller**

SV-ADAHRS-200 ADAHRS Module

SV-ADAHRS-201 ADAHRS Module

SV-ADSB-470 ADS-B Receiver Module*

SV-ARINC-429 ARINC 429 Interface Module*

SV-BAT-320 Backup Battery

SV-COM-C25 and SV-COM-X83 COM Radios

SV-D600 SkyView SE Display

SV-D700 SkyView Classic Display

SV-D900 SkyView SE Display

SV-D1000 SkyView Classic Display

SV-D1000T SkyView Classic Display

SV-HDX800 SkyView HDX Display

SV-HDX1100 SkyView HDX Display

SV-EMS-220 Engine Monitoring Module

SV-EMS-221 Engine Monitoring Module

SV-GPS-250 GPS Receiver Module

SV-GPS-2020 GPS Receiver Module

SV-KNOB-PANEL Knob Control Panel

SV-MAG-236 Remote Magnetometer

SV-XPNDR-261 Transponder

SV-XPNDR-262 Transponder

Page 16

Introduction

1-2 SkyView System Installation Guide - Revision AA

* Not applicable to a SkyView SE system

** SV-AP-PANEL buttons not applicable to a SkyView SE system (trim control subsystem does

function in a SkyView SE system.)

The following (optional) units have their own Installation and/or Operating manuals, also

available at http://docs.dynonavionics.com:

Dynon Avionics AOA/Pitot Probes

SV-INTERCOM-2S

SV32, SV42, and SV52 (all variants) installation kits for specific aircraft

This guide deals with setting up installation-dependent Software options. Because you may not

have purchased all of the components mentioned above, you need only read through the

relevant sections of this guide

When a SkyView system is connected to products not manufactured or provided by Dynon

Avionics (such as NAV radios and GPS receivers), it is often necessary to refer to those product’s

technical / installation manuals to configure their settings and their wiring to be compatible

with your SkyView system. While this guide provides some information about some popular

products not manufactured by Dynon Avionics, the information provided in this guide is not

comprehensive. Thus, for any third-party products that you intend to connect to your SkyView

system, we recommend that the installer obtain the full technical / installation manuals

available for reference.

If you are converting to a SkyView or SkyView SE system from an earlier Dynon Avionics

D10/D100 series system, we have written the D10/D100 Series to SkyView Conversion Guide,

which details the changes required to convert between the two product families. It is available

as a downloadable PDF document at http://docs.dynonavionics.com.

Warning

Dynon Avionics’ products incorporate a variety of precise, sensitive electronics. SkyView

products do not contain any field/user-serviceable parts such as fuses. Units found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon

Avionics unit has been opened, it is not considered airworthy and must be serviced at the

factory.

Dynon Avionics Product Registration

Please take a moment to register your Dynon Avionics SkyView Classic / SkyView SE / SkyView

HDX system at http://register.dynonavionics.com. Registering your product with Dynon

Avionics ensures that your contact information is up-to-date. This helps verify product

ownership, can expedite warranty claims, and allows us to notify you in the event a service

bulletin is published for your product. You can also optionally sign up to receive other Dynon

Avionics news and product announcements. Dynon Avionics will not share your contact

information with third parties or send you announcements without your explicit consent.

Page 17

Introduction

SkyView System Installation Guide - Revision AA 1-3

About this Guide

This guide – the SkyView Classic / SkyView SE / SkyView HDX System Installation Guide

(hereafter, “this guide”) contains information for the installation and initial / basic configuration

of the SkyView Classic, SkyView SE, and SkyView HDX Systems. Separate guides – the SkyView

Pilot’s User Guide, SkyView SE Pilot’s User Guide, and SkyView HDX Pilot’s User Guide explain

the use, configuration, and flying the respective SkyView systems that are not considered part

of the installation.

This guide is revised, at a minimum, several times per year, usually coinciding with the release

of a new version of SkyView Software, or introduction of new SkyView-related products from

Dynon Avionics or partner companies.

Printing This Guide

To reduce waste and confusion resulting from outdated information in print, Dynon Avionics no

longer provides this guide in printed form. The latest, most up-to-date, most complete version

of this guide (and all Dynon Avionics documentation, including the various Pilot’s User Guides)

is always available at http://docs.dynonavionics.com. We recommend that you download the

most recent version and print out sections as necessary for your build. If you prefer to print out

the entire guide, rather than printing it out on a home printer (typically, with relatively

expensive inkjet printing) we recommend that you have this take the PDF file of this guide to be

printed at a large office supply retailer that provides printing services. The statement on the

cover of this guide: Permission to print this manual is granted to third parties. should be

sufficient permission to do so.

It is also handy to have the electronic version on your tablet computer as reference as you can

perform keyword searches, and the electronic version includes figures and diagrams that

contain important color information. We have found that the free “iBooks” application that can

be installed on Apple iPad tablet computers can import this guide’s PDF file for easy reference.

In the electronic (.PDF) version of this guide, page and section references in the Table of

Contents and elsewhere act as hyperlinks taking you to the relevant location in the guide.

This icon denotes information that merits special attention.

This icon denotes a helpful installation tip.

If your aircraft was built using components not provided by Dynon Avionics (such as harnesses),

some information provided in this guide may not be applicable. For example, some

manufacturers prefer to build harnesses that do not adhere to the wire color codes of

harnesses manufactured by Dynon Avionics. Some configuration menus described in this guide

may not be accessible as a manufacturer may have restricted access to certain menus.

Page 18

Introduction

1-4 SkyView System Installation Guide - Revision AA

Semantics of “Software” vs “Software”

In a typical personal computer, the “Software” is the (seldom-changed) low-level software that

boots up the computer and then proceeds to loads the “operating system (OS)” (typically

Windows, or Mac OS, or Linux), which then loads the “application software (apps)”. In a

SkyView system, because the “Software”, “OS”, and “apps” functions are embedded into a

single unit with a single function, the “Software”, “OS”, and “software” distinctions aren’t

relevant to the builder or pilot. So, for clarity, in this guide, for clarity, the term “Software” is

used (most of the time) as an encompassing term for “Software”, “OS”, and “app” functions.

SkyView Classic, SkyView Touch, SkyView SE, and SkyView HDX

SkyView SE is a streamlined, simplified edition of SkyView. Although the two editions are within

the same family of products, the two editions cannot interoperate. For example, you cannot

install a SkyView SE display (SV-D600 or SV-D900) into an existing SkyView (non-SE) system and

vice versa. Most notably, SkyView SE does not support the MAP function of SkyView, Synthetic

Vision (SynVis) or the Expert AP mode. The following SkyView features / units are not supported

in SkyView SE:

Alternative languages (US English only)

Charts (not supplied by Dynon Avionics)

SV-ADSB-470

SV-AP-PANEL (buttons; Trim Control Subsystem is supported in SkyView SE)

SV-ARINC-429

SV-D1000T (SkyView Touch)

SV-EMS-220 (a second unit, for supporting dual engines)

Vertical Power VP-X (not supplied by Dynon Avionics)

Video Input Adapter

Wi-Fi Adapter

SkyView HDX, the newest product in the SkyView family, is a successor to SkyView Classic,

including SkyView Touch. Just as many features of SkyView Classic are not supported in SkyView

SE, many features in SkyView HDX are not supported in the older SkyView Classic. The “feature

progression” of the three products are:

SkyView SE → SkyView Classic, Touch → SkyView HDX

The installation details for all three products families are largely the same, thus this manual

(originally written for SkyView [now SkyView Classic and Touch]) has been updated to

incorporate the details of SkyView SE and SkyView HDX installation. The individual sections are

noted if that product is not supported in SkyView SE or SkyView Classic.

Special Light Sport Aircraft (S-LSA) Considerations with SkyView

Modifications / configuration changes to S-SLA aircraft generally require a Letter of

Authorization (LOA) from the aircraft manufacturer or authorized dealer. This includes

modifications as minor as adding a new SkyView component, such as a panel unit, or, in some

Page 19

Introduction

SkyView System Installation Guide - Revision AA 1-5

cases, updating SkyView’s Software. If you have an S-LSA, it is recommended that you consult

your aircraft’s Pilot Operating Handbook and aircraft’s Maintenance Manual. These will guide

you in what modifications, including whether Software updates, are permitted. Please consult

your authorized dealer, or your manufacturer, if you have questions.

Some aircraft manufacturers, notably Van’s Aircraft (the RV-12), and Flight Design, provide

customized versions of SkyView Software in “packages”. Such customized packages provide

Software updates and settings specific to those aircraft, and is available from the aircraft

manufacturer’s website (not Dynon Avionics). Some manufacturers choose to “lock” certain

SkyView settings, including not being able to update a SkyView system using “generic” SkyView

Software. Such restrictions are at the discretion of the aircraft manufacturer, and Dynon

Avionics cannot “override” such restrictions.

SkyView documentation, including this guide, generally does not address specific aircraft types,

options, and specific SkyView configurations.

Generally, we recommend that you update your SkyView system to the latest available

Software as released by Dynon Avionics several times per year, available at

http://downloads.dynonavionics.com. This revision of the SkyView System Installation Guide

includes features, functions, improvements, and new products coinciding with the Software

version stated on the cover page. Updating your system Software ensures that you have access

to the latest features, functions, improvements, and new products to make your SkyView

system…

Go Fly!

Getting Started

This “getting started” section contains a minimal information that can be used to check out

your SkyView system on the bench, or immediately after SkyView has been installed in the

plane. This section is not a substitute for reading this entire guide, which provides instructions

for wiring and configuring SkyView to the unique requirements of your particular airplane.

1. A SkyView display requires 10-30 VDC. You must connect BOTH of the (long) Red wires to

POWER and BOTH of the (long) black wires to Ground. Current for each display can be up to

3.5A @ 12V (add 1.5A if the SV-BAT-320 battery is connected and being charged), so use a

big battery or power supply.

2. To power on or power off a SkyView display manually, push and hold Button #1 (the left-

most button).

3. Any devices connected to SkyView that do not receive their power from the SkyView

Network (such as SV-XPNDR-261/262 and Dynon Avionics Autopilot servos) must also be

powered ON to communicate with SkyView.

4. To finish the installation of the SV-NET-10CP (10 foot) and longer cables, the diagram you

need to insert the pins is SkyView Network in Appendix C: Wiring and Electrical

Connections.

Page 20

Introduction

1-6 SkyView System Installation Guide - Revision AA

5. The EMS 37-pin Main Sensor Harness includes a 9-pin connector that is wired to pins 11

(Orange wire), 12 (Yellow wire), and 30 (Black wire). This connector is used for other Dynon

Avionics products, but is not used in SkyView installations. Thus, the 9-pin connector should

be removed to use these wires for connecting sensors to the SV-EMS-220. Remove the

connector by cutting the three wires close to the 9-pin connector.

6. SkyView SETUP MENU is accessed by pushing and holding Buttons 7+8 together for 2-3

seconds.

7. Setting the Tail Number is required for before you can configure your SkyView Network

(described below): SETUP > AIRCRAFT INFORMATION > TAIL NUMBER. If Tail Number has

not yet been issued for your plane, set TAIL NUMBER to something other than DYNON

AVIONICS. Note that for US planes, the leading N is a required part of the TAIL NUMBER.

TAIL NUMBER should not include dashes (-) or spaces. Examples:

Correct: N12AB

Incorrect: N-12AB or N 12AB

8. SkyView displays and modules communicate over a common set of wires – the SkyView

Network that terminates at the D9 connectors on the back of your SkyView display(s).

Getting all modules and displays “talking” on SkyView Network is done by going to SETUP

MENU > SYSTEM SETUP > SKYVIEW NETWORK SETUP > CONFIGURE > (click right one more

time). If a module is noted as “requires update”, press the UPDATE button. Otherwise, press

the FINISH button. Note that you will not see any flight instruments or engine instruments

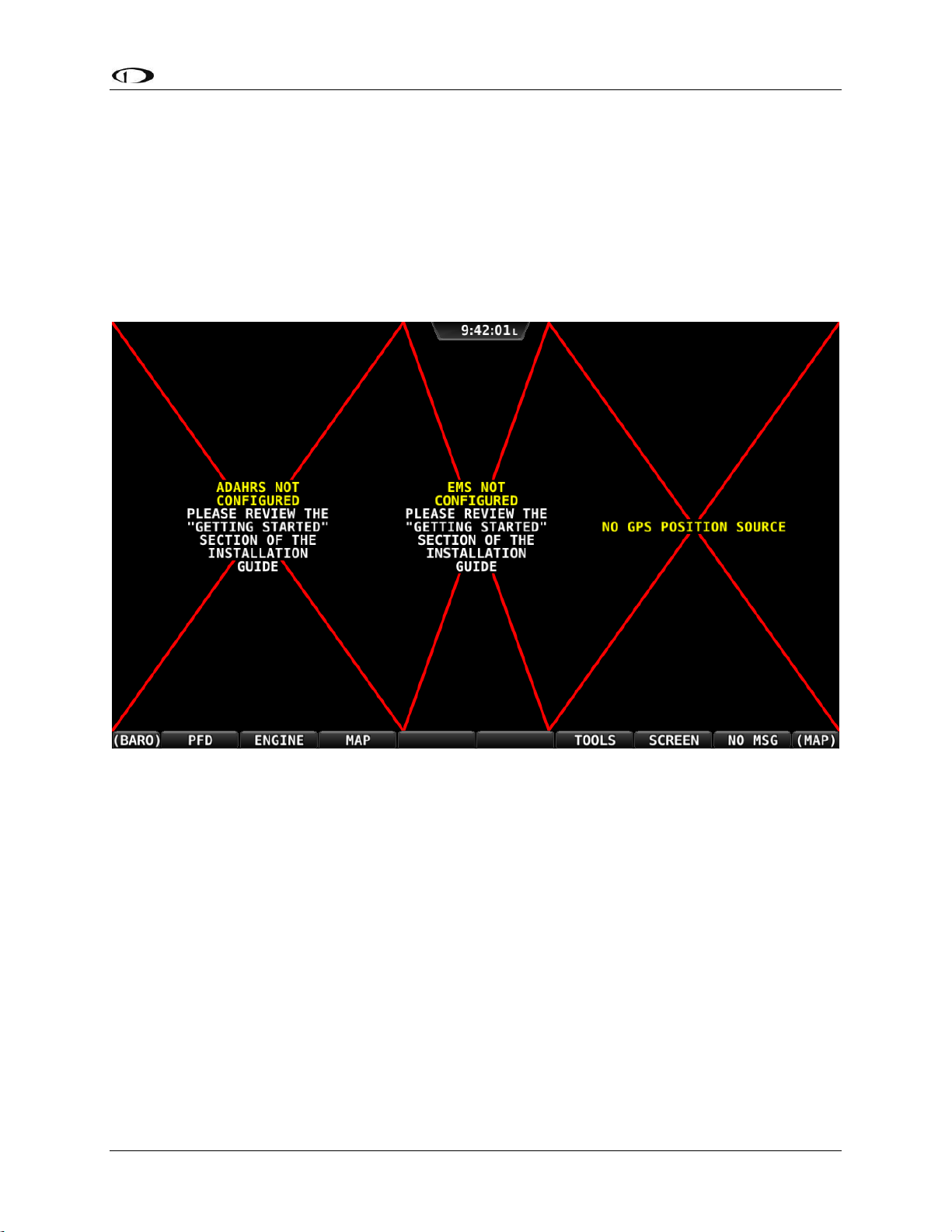

before a network configuration is performed, even if the SV-ADAHRS-200/201 and SV-EMS220/221 have been wired properly and are connected.

9. Devices that do not utilize SkyView Network are connected via RS-232 serial port

connections. Dynon Avionics devices that use RS-232 serial ports include the SV-ADSB-470,

SV-GPS-250/2020, SV-XPNDR-261/262, and various third-party devices. As RS-232 serial

devices are not part of the SkyView Network, they will not be seen on the list of devices

seen as you configure SkyView Network above. Instead, configuring SkyView to

communicate with SV-GPS-250/2020 and SV-XPNDR-261/262 is done via a more manual

process in SETUP MENU > SYSTEM SETUP > SERIAL PORT SETUP.

10. If you have installed an SV-GPS-250/2020, its SERIAL IN FUNCTION must be set to POS 1.

11. After you’ve configured SkyView Network, have properly configured any serial devices, exit

SETUP MENU. Your SkyView display should now display EMS, PFD, and MAP (SkyView SE

does not include MAP as a feature). Map will not display without a GPS fix (the airplane

symbol on the Map page will also flash with “?” if it does not have a GPS fix.

12. Your SkyView System may require various updates such as system Software, databases, and