Page 1

DYNON AVIONICS

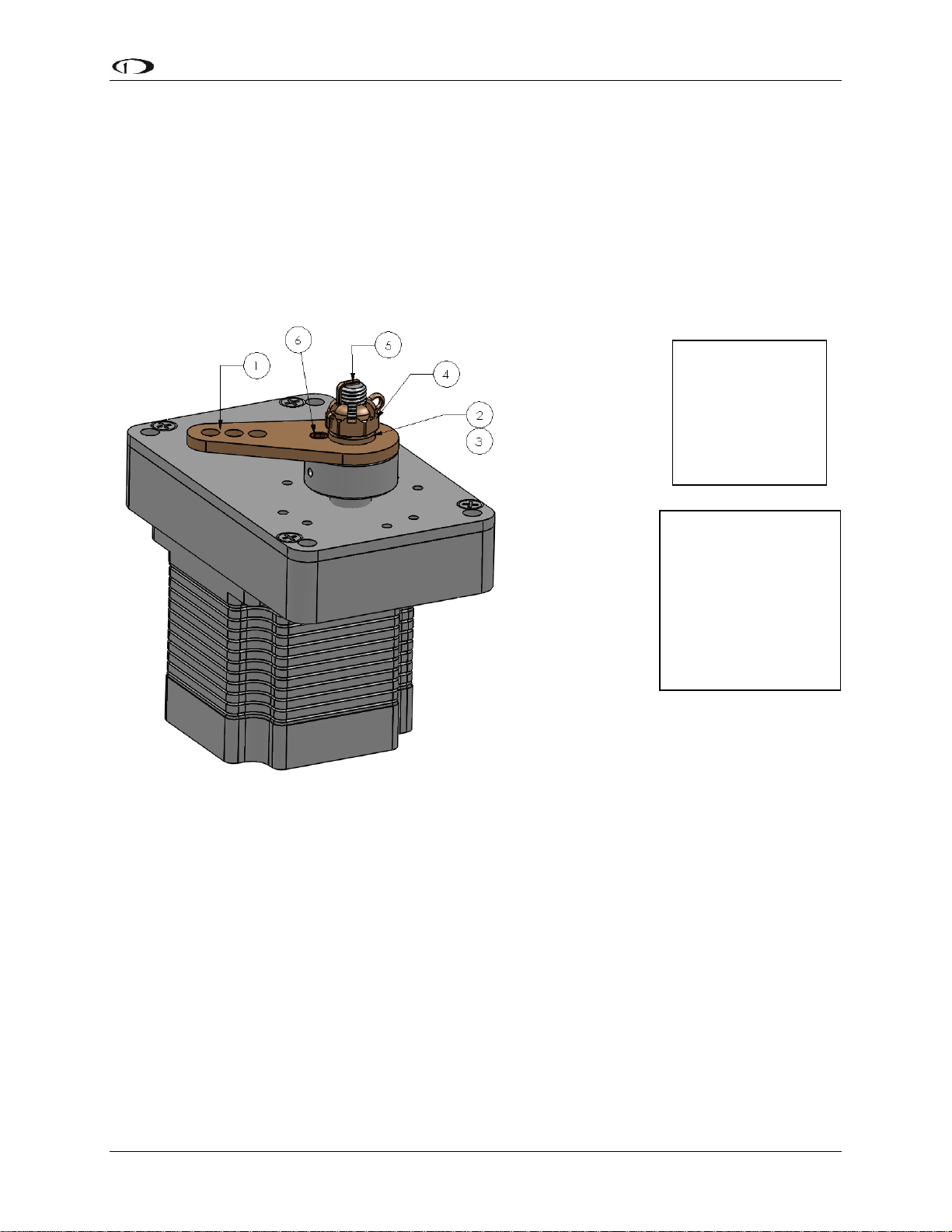

1. Servo Arm

2. Flat washer

3. Wave washer

4. Castle nut

5. Cotter pin

6. Shear screw

Required Tools

1. Needle nose

Pliers

2. Torque Wrench

(must be able to read

4.5 in-lb)

3. 1/2IN SAE

Socket

Dynon Servo Arm/Capstan Removal and Replacement

Instructions

If it is necessary to change the arm or capstan on a Dynon autopilot servo, these instructions,

when followed properly, enable the customer to perform this task in the field. If the

customer does not feel comfortable performing these actions, Dynon will be happy to inspect

and/or repair servos as necessary.

Removing Arm/Capstan

Remove the cotter pin from the castellated nut. Note that cotter pins should never be reused;

replace with a new pin. Unthread the castellated nut, remove wave and nylon washers, and

finally remove the arm or capstan. Put all these pieces aside – they will be reused. DO NOT

REMOVE the socket head safety shear screw.

101156-001 – Rev A 1

Fig 1

Page 2

DYNON AVIONICS

1. Servo Arm

2. Flat washer

3. Wave washer

4. Castle nut

5. Cotter pin

The autopilot safety shear screw should NEVER be removed or adjusted during this

procedure. If the shear screw has broken/damaged and needs replacement, there is

specific documentation available for this purpose at http://docs.dynonavionics.com.

Fig 2

Reassembling the Arm/Capstan Stack

Reverse the disassembly steps to install the remaining hardware. See Figure 2. Assembly order

is:

1. Servo Arm/Capstan

2. Nylon Washer

3. Wave Washer

4. Castle Nut (AN310-5)

5. Cotter Pin (MS24665-210)

Tighten the castellated nut finger tight, and then using a Torque Wrench, tighten until a slot

in the nut lines up with the hole in the shaft for the cotter pin. DO NOT EXCEED 4.5 in-lb (72

in-oz) torque on castle nut. Exceeding this torque specification will affect the yield torque

of the safety shear screw, compromising the safety-enhancing intent of its design.

Install a new cotter pin, MS24665-210, following the standard method of trimming and

bending the pin legs.

Servo arm/capstan rotation should be smooth. No movement should be observed between the

arm/capstan and the attachment disc as described earlier.

101156-001 – Rev A 2

Loading...

Loading...