Page 1

Autopilot Servo Installation Guide

RV10 Pitch

This product is not approved for installation in type certificated aircraft

Document 101046-006, Revision F

January, 2013

Copyright © 2009-2013 by Dynon Avionics, Inc.

Permission to print this this manual is granted to third parties

Page 2

DYNON AVIONICS

Contact Information

Dynon Avionics, Inc.

19825 141st Place NE

Woodinville, WA 98072

Phone: (425) 402-0433 - 8:00 AM – 5:00 PM (Pacific Time) Monday – Friday

Dynon Technical Support available 7:00 AM–4:00 PM (Pacific Time) Monday – Friday

Email: support@dynonavionics.com

Fax: (425) 984-1751

Dynon Avionics offers online sales, extensive support, and frequently updated information on its products via its

Internet sites:

www.dynonavionics.com –Dynon Avionics primary web site; including:

docs.dynonavionics.com – Current and archival documentation including Installation Guides.

downloads.dynonavionics.com – Software downloads.

support.dynonavionics.com – Support resources.

store.dynonavionics.com – Dynon’s secure online store for purchasing all Dynon products 24 hours a day.

wiki.dynonavionics.com – Dynon’s Documentation Wiki provides enhanced, extended, frequently updated online

documentation contributed by Dynon employees and customers.

forum.dynonavionics.com – Dynon’s Internet forum where Dynon customers can interact with each other and

Dynon Avionics. A key feature of the forum is that it allows the exchange of diagrams, photos, and other types of

files.

newsletter.dynonavionics.com – Dynon’s email newsletter.

blog.dynonavionics.com – Dynon’s blog where you can find new and interesting Dynon-related content.

register.dynonavionics.com – Register your Dynon Avionics product.

license.dynonavionics.com – Redeem certificates for navigation mapping software, synthetic vision, and other

features for license codes that add new functionality to your SkyView system.

Copyright

2008-2012 Dynon Avionics, Inc. All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated or stored in

any storage medium, for any purpose without the express written permission of Dynon Avionics. Dynon Avionics hereby grants permission to

download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed for

personal use, provided that such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice

and provided further that any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Information in this document is subject to change without notice. Dynon Avionics reserves the right to change or improve its products and to

make changes in the content without obligation to notify any person or organization of such changes. Visit the Dynon Avionics website

(www.dynonavionics.com) for current updates and supplemental information concerning the use and operation of this and other Dynon

Avionics products.

Servo Mounting Instructions – RV-10 Pitch Kit 1

101046-006 Rev F

Page 3

DYNON AVIONICS

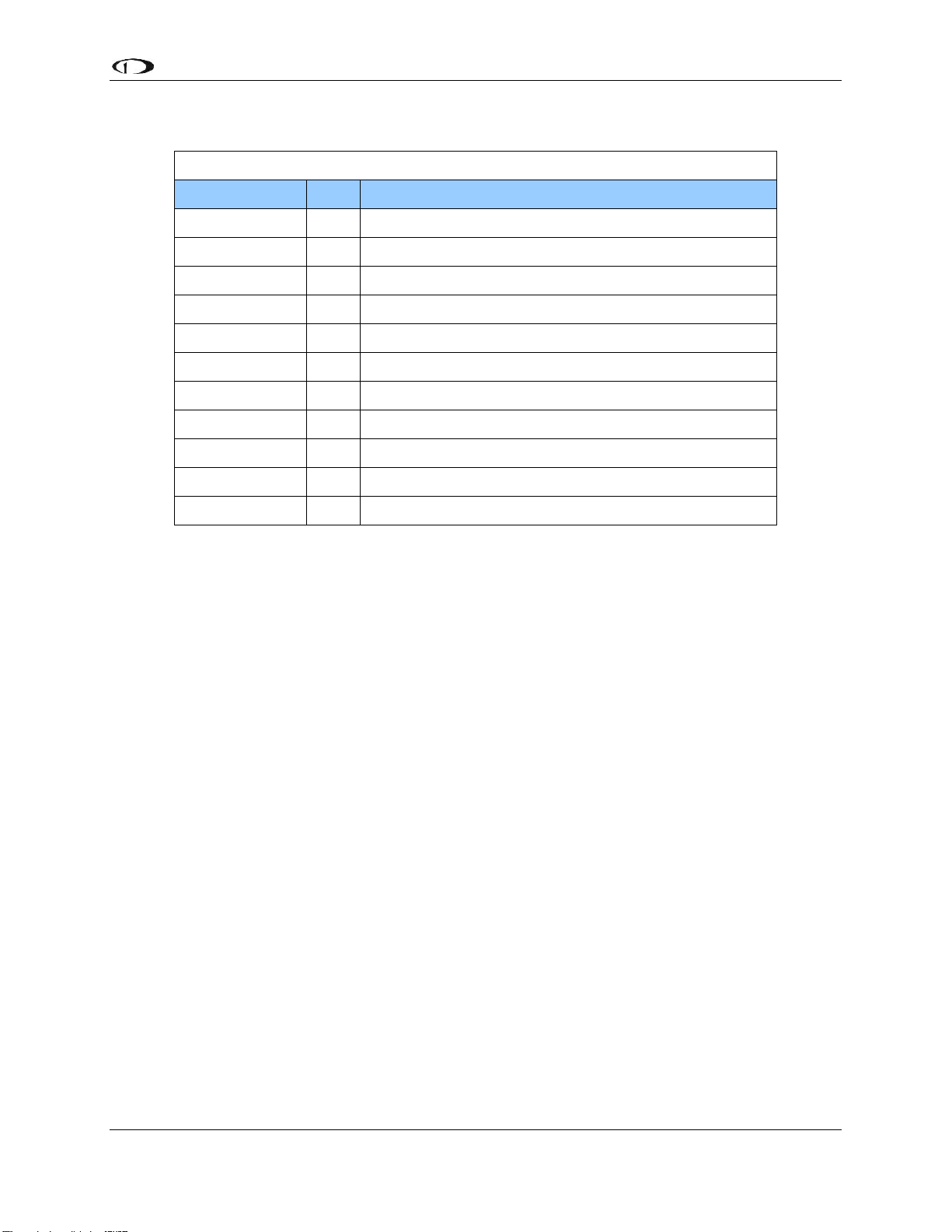

Kit Contents

Dynon Part #

QTY

Part Description

100836-000

2

Large Male Rod End

100966-008

1

Aluminum Pushrod Tube – 3.0”

100973-000

1

RV10 Pitch Bracket

100975-002

2

AN315-4R Jam Nut

100976-011

2

AN365-1032A Nylon Insert Locknut

100977-000

2

AN970-3 Large Flat Washer

100978-003

10

AN960-10 Small Flat Washer

100979-002

4

MS35333-39 #10 Internal Star Washer

100981-000

4

AN3H-3A Bolt - 3/8"

100981-005

1

AN3H-10A Bolt - 1"

100981-006

1

AN3H-11A Bolt – 1 1/8"

SERVO MOUNTING INSTRUCTIONS – RV-10 PITCH KIT

The RV-10 pitch servo mounting kit includes a mounting bracket, pushrod linkage, and most of the

required fasteners to mount the servo and properly link it to the aircraft control system. All Dynonsupplied parts are illustrated in dark grey to distinguish them from existing aircraft hardware. Refer

to the drawing to locate the servo mounting bracket in the aircraft.

Fasteners along the mounting plate surface must be removed and can be re-used to secure the

bracket in place. The Dynon mounting bracket must be drilled to match the existing hole pattern of

the aircraft plate. Once the bracket has been drilled, fasten it to the aircraft. It is up to the installer

to verify the hardware used is tightened back to aircraft specification.

With the bracket installed in the aircraft, the bell crank must be drilled. Refer to the drawing for

dimensions, and use a supplied AN960-10 washer as a support between the two halves of the bell

crank to avoid crushing when the linkage is fastened.

Install the 4 AN3H-3A bolts, MS35333-39 star washers, and AN960-10 flat washers to secure the

servo to the bracket per the drawing, noting the orientation of the servo output arm. All AN bolts

supplied by Dynon have drilled heads for use with safety wire. With the servo and bell crank

additions in place, torque all fasteners back to original installation specifications and add safety wire

where needed.

With the servo installed, the linkage needs to be assembled. Refer to the illustration and follow

proper rod end installation techniques. Thread both large rod ends with jam nuts into the supplied

3.0" tube. Mounting of the linkage to the servo arm will include the AN3H-10A bolt, AN970-3 large

diameter flat washer (for capturing the rod end bearing), 2 AN960-10 flat washers, and the AN3651032A lock nut. The other end of the linkage will require the same type of stack-up, using the longer

AN3H-11A bolt and capturing the washer sandwiched between the halves of the bell crank.

To prevent the possibility of the servo arm going over-center, the servo arm must not travel more

than a total of +/-60º from neutral throughout the control system's range of travel. The linkage

Servo Mounting Instructions – RV-10 Pitch Kit 2

101046-006 Rev F

Page 4

DYNON AVIONICS

Neglecting to properly install and/or use Dynon autopilot hardware may

result in failures which could cause loss of aircraft control resulting in

aircraft damage, personal injury or death.

should be installed as close to the Dynon recommendation as possible, as changes will affect

geometry. Dynon suggests installing the linkage at the outer-most hole of the servo arm. Changing

this location will affect servo torque output, servo arm travel, control surface resolution, and the

amount of force required to shear the safety screw, and should only be changed if the installer has

an understanding of these implications. See the diagram on the following page which illustrates the

linear travel and available force for each mount point on standard-arm servos.

The distance between the servo arm and the control system attachment point must allow for the

angle between the servo arm and the push rod to be at approximately 90º when the controls are at

neutral. Use the adjustability in the rod ends to achieve this, and then tighten the jam nuts to lock

the rod ends in place. Installers should always keep in mind the range of motion of the servo. Total

servo arm travel is limited, but verify the arm/linkage do not interfere with anything during the full

motion of the control stick. The built in control stops of the aircraft will limit the servo arm travel

when installed correctly. We recommend the use of the optional Range of Motion Limiting Bracket,

supplied with the servo to eliminate the chance of the servo arm going over-center. This bracket

should not be used as a normal stop; the aircraft's built-in stops should always be the primary range

limit.

Your servo(s) and AP74/76 (if ordered) came with a CD containing the latest documentation for all

Dynon products (also available at dynonavionics.com). Please read through that documentation to

understand the wiring and configuration process for your Autopilot system. We also maintain a

collaborative set of this documentation, which is often updated with new information by both

Dynon and fellow builders. Visit wiki.dynonavionics.com to view and contribute to the latest

version of these documents.

You can also visit forum.dynonavionics.com to discuss and share installation notes, pictures, and

suggestions with other builders.

Servo Mounting Instructions – RV-10 Pitch Kit 3

101046-006 Rev F

Page 5

DYNON AVIONICS

Red

Black

Green

Blue

Yellow

Wht/Grn

Wht/Blu

Servo 1

Wires

Pilot-accessible

Servo Power

Switch/Breaker

Aircraft GND

Red

Black

Green

Blue

Yellow

Wht/Grn

Wht/Blu

Servo 2

Wires

Aircraft GND

Aircraft Power (10-30V)

Pitch and Roll Servos

are wired identically, and can

share wiring for convenience at

any point along the run.

5 kohm

Optional resistor for

detecting broken

disengage lines

Pilot-accessible

Disengage/CWS button

(Normally open, momentary)

Usually mounted to the stick

Power (10-30V)

Ground

SkyView Network 1 A or DSAB A

SkyView Network 1 B or DSAB B

Disengage

SkyView Network Data 2 A *

SkyView Network Data 2 B *

Power (10-30V)

Ground

SkyView Network 1 A or DSAB A

SkyView Network 1 B or DSAB B

Disengage

SkyView Network Data 2 A *

SkyView Network Data 2 B *

Servo Current Draw at 12V

(halve the current values for 24V systems)

SV32

Powered but disengaged: 0.1 amps

Engaged and holding, 100% torque: 0.80 amps

Engaged and moving, 100% torque: 1.33 amps

SV42

Powered but disengaged: 0.1 amps

Engaged and holding, 100% torque: 1.11 amps

Engaged and moving, 100% torque: 2.03 amps

SV52

Powered but disengaged: 0.1 amps

Engaged and holding, 100% torque: 1.52 amps

Engaged and moving, 100% torque: 2.80 amps

Aircraft GND

Use 22 AWG wire for SkyNet

and Disengage signals.

Use appropriate wire gauge for

servo power based on current

consumption and length of wire run

Green

Blue

Twisted Pair

Twisted Pair

Twisted Pair

D10A/D100/D180

D25

CONNECTOR

SKYVIEW

D9

CONNECTOR

N/A

N/A

5

4

4

8

6

1

WHT/BLU

WHT/GRN

BLU

GRN

Wht/Grn

Wht/Blu

*NOT USED FOR D10A/D100/D180

Wiring Overview

The following diagram provides an overview of the autopilot-specific wiring installation. For the

complete set of wiring and configuration instructions, please see the latest Installation Guide for

your Dynon EFIS product. For a SkyView system please reference the Autopilot Servo

Installation, Configuration, and Calibration chapter of your SkyView System Installation guide.

For EFIS-D10A, EFIS-D100 or FlightDEK-D180 please reference the Autopilot Installation and

Configuration chapter of each respective Installation Guide.

Servo Mounting Instructions – RV-10 Pitch Kit 4

101046-006 Rev F

Page 6

DYNON AVIONICS

Long-arm variants

(as used for RV-6

Roll) have linkage

mount holes at 1.5”,

1.75”, and 2.0”

L Weight

SV32

2.17”

2 lb

SV42

3.10”

3 lb

SV52

4.02”

4 lb

Servo Dimensions

Use the following dimensions (in inches) for reference when planning and implementing your

installation.

Servo Mounting Instructions – RV-10 Pitch Kit 5

101046-006 Rev F

Page 7

DYNON AVIONICS

Long Arm

Max Linear Travel

A: 3.4”, B: 3.0”, C: 2.6”

Max Force @ 100% Torque

SV32L - A: 18lb, B: 20lb, C: 24lb

Linkage mount position force and travel

The diagram below illustrates the maximum travel and force available at each linkage mounting

point. As can be seen, the closer you mount the linkage to the shaft, the more force the servo can

deliver. However, this also means the travel of the arm is shorter. Again, ensure that the servo arm is

nowhere near going over-center throughout the entire range of the control system.

Position A should be used in most RV-6 roll installations. Modify mount position with caution and

take all precautions to ensure that a near over center condition cannot occur.

The autopilot safety shear screw should NEVER be removed or adjusted during this

operation. If the shear screw has broken and needs replacement, there is specific

documentation available for this purpose at http://docs.dynonavionics.com.

Mounting Drawings

The following pages provide detailed views of the mounting and assembly of the servo and

this kit.

Servo Mounting Instructions – RV-10 Pitch Kit 6

101046-006 Rev F

Page 8

DYNON AVIONICS

Servo Mounting Instructions – RV-10 Pitch Kit 7

101046-006 Rev F

Page 9

DYNON AVIONICS

Servo Mounting Instructions – RV-10 Pitch Kit 8

101046-006 Rev F

Page 10

DYNON AVIONICS

Servo Mounting Instructions – RV-10 Pitch Kit 9

101046-006 Rev F

Loading...

Loading...