Page 1

EFIS-D60

Installation Guide

This product is not approved for installation in type certificated aircraft.

P/N 101207-000, Revision A

For use with firmware version 1.0

May, 2009

Copyright © 2003-2009 by Dynon Avionics, Inc.

Page 2

Page 3

Contact Information

Dynon Avionics, Inc.

19825 141

Woodinville, WA 98072

Phone: (425) 402-0433 - 7:00 AM – 5:00 PM (Pacific Time) Monday - Friday

Fax: (425) 984-1751

Dynon Avionics offers online sales, extensive support, and continually-updated information on its products via its Internet sites:

st

Place NE

• www.dynonavionics.com

• docs.dynonavionics.com

• downloads.dynonavionics.com

• support.dynonavionics.com

• store.dynonavionics.com

• wiki.dynonavionics.com

documentation contributed by Dynon employees and customers.

• forum.dynonavionics.com

outside of telephone support hours. A key feature of the forum is that it allows the exchange of diagrams, photos, and other types of

files.

• newsletter.dynonavionics.com

• blog.dynonavionics.com

–Dynon Avionics primary web site; including:

– Current and archival documentation.

– Software downloads.

– Support resources.

– Dynon’s secure online store for purchasing all Dynon products 24 hours a day.

– Dynon Avionics’ Documentation Wiki provides enhanced, extended, continuously-updated online

– Dynon Avionics’ Internet forum where Dynon customers can interact and receive Dynon technical support

– Dynon’s email newsletter.

– Dynon’s blog where you can find new and interesting Dynon-related content.

Copyright

© 2003-2009 Dynon Avionics, Inc. All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated or stored in

any storage medium, for any purpose without the express written permission of Dynon Avionics. Dynon Avionics hereby grants permission to

download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed for

personal use, provided that such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice and

provided further that any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Information in this document is subject to change without notice. Dynon Avionics reserves the right to change or improve its products and to

make changes in the content without obligation to notify any person or organization of such changes. Visit the Dynon Avionics website

(http://www.dynonavionics.com

Avionics products.

) for current updates and supplemental information concerning the use and operation of this and other Dynon

Limited Warranty

Dynon Avionics warrants this product to be free from defects in materials and workmanship for three years from date of shipment. Dynon

Avionics will, at its sole option, repair or replace any components that fail in normal use. Such repairs or replacement will be made at no charge

to the customer for parts or labor. The customer is, however, responsible for any transportation cost. This warranty does not cover failures due to

abuse, misuse, accident, improper installation or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE, AND IN LIEU OF ALL OTHER WARRANTIES

EXPRESSED OR IMPLIED, INCLUDING ANY LIABILITY ARISING UNDER WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH

MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL DYNON AVIONICS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES, WHETHER RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN

THE PRODUCT. SOME STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Dynon Avionics retains the exclusive right to repair or replace the instrument or firmware or offer a full refund of the purchase price at its sole

discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

These instruments are not intended for use in type certificated aircraft at this time. Dynon Avionics makes no claim as to the suitability of its

products in connection with FAR 91.205.

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for replacing the optional Internal Backup Battery in

EFIS-based products per the installation guide, our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon Avionics unit is opened up, it will require calibration

and verification at our Woodinville, WA offices before it can be considered airworthy.

Page 4

Page 5

Table of Contents

Contact Information......................................................................................................................................................iii

Copyright......................................................................................................................................................................iii

Limited Warranty .........................................................................................................................................................iii

1. Introduction 1-1

Warning ..................................................................................................................................................................... 1-1

About this Guide........................................................................................................................................................ 1-2

Menu Descriptions..................................................................................................................................................... 1-2

2. Wiring Overview 2-1

Recommended Wiring Practices................................................................................................................................2-1

Power Requirements.................................................................................................................................................. 2-1

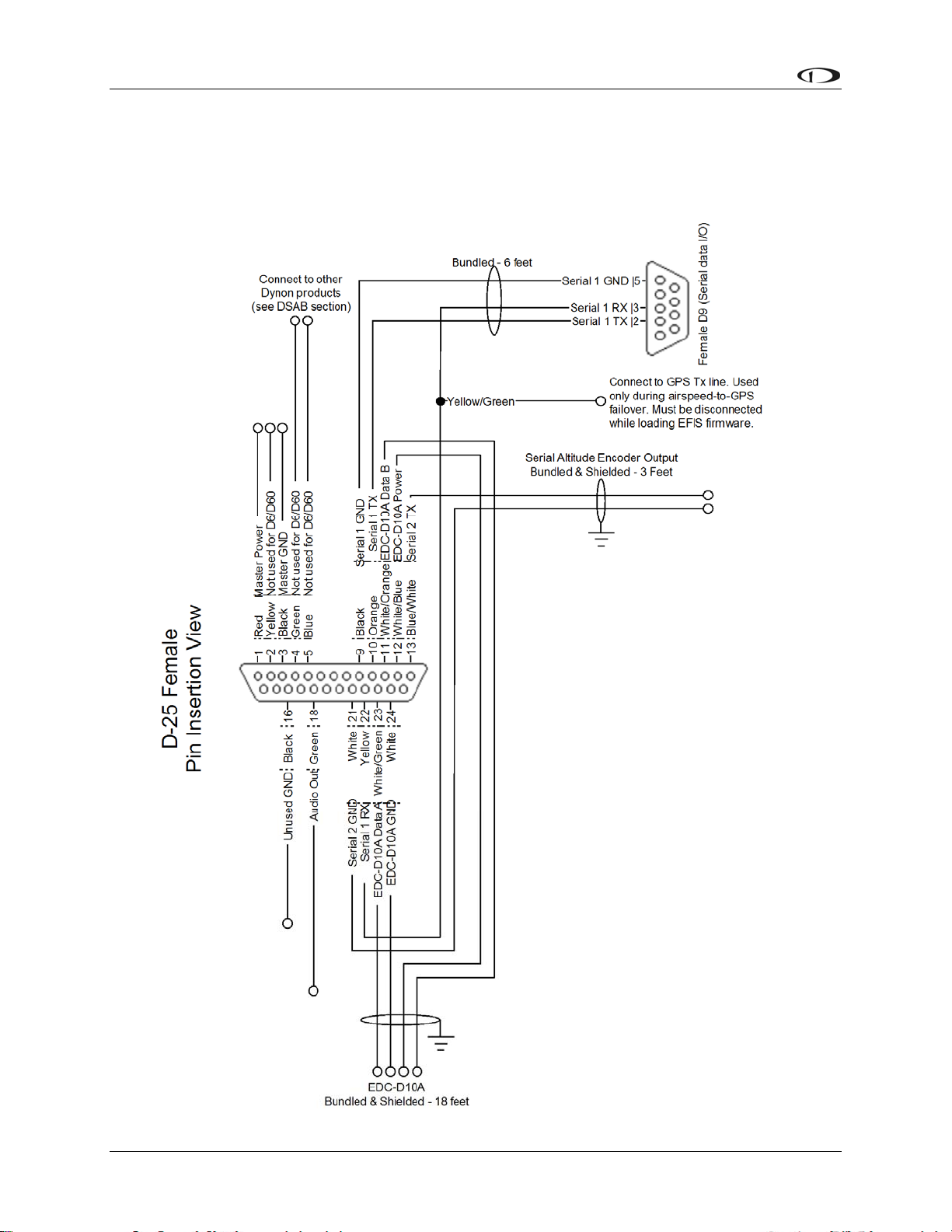

25-Pin Female EFIS Harness..................................................................................................................................... 2-2

3. Instrument Installation 3-1

Selecting a Remote Compass Module Location ........................................................................................................ 3-1

EDC-D10A Communication Cable ........................................................................................................................... 3-2

Power Inputs.............................................................................................................................................................. 3-3

EFIS Serial Harness................................................................................................................................................... 3-3

Altitude Encoder Wiring ........................................................................................................................................... 3-5

Audio Alert Output.................................................................................................................................................... 3-7

Panel Location and Mounting.................................................................................................................................... 3-8

Connecting Static & Pitot Lines ................................................................................................................................3-9

4. EFIS Calibration and Configuration 4-1

Ensuring Proper Installation ...................................................................................................................................... 4-1

Setting Zero Pitch (In flight)...................................................................................................................................... 4-1

Compass Heading Calibration ................................................................................................................................... 4-1

Configure Airspeed Color Thresholds....................................................................................................................... 4-4

5. Appendix 5-1

Appendix A: Instructions for Continued Airworthiness............................................................................................ 5-1

Appendix B: Dynon AOA/Pitot Installation and Calibration .................................................................................... 5-7

Appendix C: Encoder Serial-to-Gray Code Converter Installation ..........................................................................5-15

Appendix D: Replacing the EFIS-D60 Internal Backup Battery ..............................................................................5-18

Appendix E: Upgrading EFIS-D60 to EFIS-D100...................................................................................................5-18

Appendix F: Weights................................................................................................................................................5-19

Appendix G: EFIS-D60 Specifications.....................................................................................................................5-19

EFIS-D60 Installation Guide v

Page 6

Page 7

1. INTRODUCTION

This manual provides information about the physical, electrical, and plumbing installation of the

EFIS-D60, EDC-D10A and optional AOA pitot probe purchased from Dynon Avionics.

Additionally, this guide deals with setting up the installation-dependant firmware options.

Because you may not have purchased all the components, you need only read through the

relevant sections of this guide. Information about the operation of this instrument can be found

in the EFIS-D60 Pilot’s User Guide.

The EFIS-D60 uses solid-state sensor technology to give an accurate and easy-to-understand

display. To ensure accuracy in its readings, it is very important that you install the instrument

correctly and perform the specified calibration steps. This installation guide will help you

through that process.

Warning

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for

replacing the optional internal backup battery in EFIS-based products per the installation guide,

our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon

Avionics unit is opened up, it will require calibration and verification at our Woodinville, WA

offices before it can be considered airworthy.

EFIS-D60 Installation Guide 1-1

Page 8

Introduction

About this Guide

In the electronic (.PDF) version of this manual, page and section references in the Table of

Contents and elsewhere act as hyperlinks taking you to the relevant location in the manual. The

latest version of this manual may be downloaded from our website at

downloads.dynonavionics.com.

Any text following this icon refers to a setting or situation which merits particularly close

attention.

Menu Descriptions

Throughout this guide, the “>“ character is used to indicate entering a deeper level of the menu

system. For example, “SETUP > VRSION” indicates entering the EFIS menu, pressing MORE,

then pressing SETUP, and then pressing VRSION to display the firmware version menu. Note

that the MORE button is not shown in the sequence, since pressing MORE reveals more options

in the same level of the menu system.

1-2 EFIS-D60 Installation Guide

Page 9

2. WIRING OVERVIEW

Please follow these instructions explicitly as improper wiring can result in permanent damage to

your instrument and/or the accompanying sensors.

All electrical power and EFIS-specific lines interface with the EFIS-D60 via the female 25-pin

D-sub connector on the back of the instrument. Ensure that the unit powers on and that all

indicators display expected values before completing the final physical assembly.

Recommended Wiring Practices

For all electrical connections, use correct wiring techniques, taking care to properly

insulate any exposed wire. A short circuit between any of the wires may cause damage to

the EFIS-D60 and/or your aircraft. Make all connections to your harness before plugging

it into any of the components of the system. Do not make connections while power is

applied at any point in the system.

Dynon Avionics sells a wiring harness for all connections to the EFIS-D60. The harness is made

up of 22 AWG wire and meets Mil Standard MIL-W-22759/16 (Tefzel insulation). If you have

opted not to purchase this harness, please refer to the provided wiring diagrams for construction

information. We recommend that all wire you use also meets Mil Standard MIL-W-22759/16; all

wire supplied by Dynon Avionics (with the exception of thermocouple wire, which uses FEP

insulation) meets this specification.

When using any pre-manufactured harness, verify that each pin has continuity with the expected

wire on the wiring diagram. This test can be easily done with a multimeter. When verifying

harnesses, use the wiring charts and diagrams in this guide as your ultimate authority on pin

function (for any harness) and wire color (for harnesses purchased from Dynon Avionics).

Route all wiring such that there are no spots where it could chafe or break. Use appropriate strain

relief at all junctions between wires and connectors. We recommend that you secure all wires at

regular intervals along wiring runs to accommodate vibration effects.

All connections on the EFIS female 25-pin harness are described in the Instrument Installation

section on page 3-1.

Power Requirements

22 AWG wire is normally sufficient for the power supply and ground lines, but we recommend

that you consult a wire sizing chart and determine the size required for the wire routing in your

particular aircraft. Ensure that the power lines include a circuit breaker or an appropriately sized

fuse for the wire you select. Power is fed to the EFIS-D60 via pins in the female D-25 connector

as shown on the 25-Pin Female EFIS Harness diagram on page 2-2.

The EFIS-D60 system-wide power requirement is 12 watts typical and 17 watts maximum. On a

12-volt system, this translates to about 1.5 amps of maximum current draw. On a 24-volt system,

this translates to about 0.75 amps maximum current draw. Normally, a 3-amp circuit breaker or

fuse is sufficient.

EFIS-D60 Installation Guide 2-1

Page 10

Wiring Overview

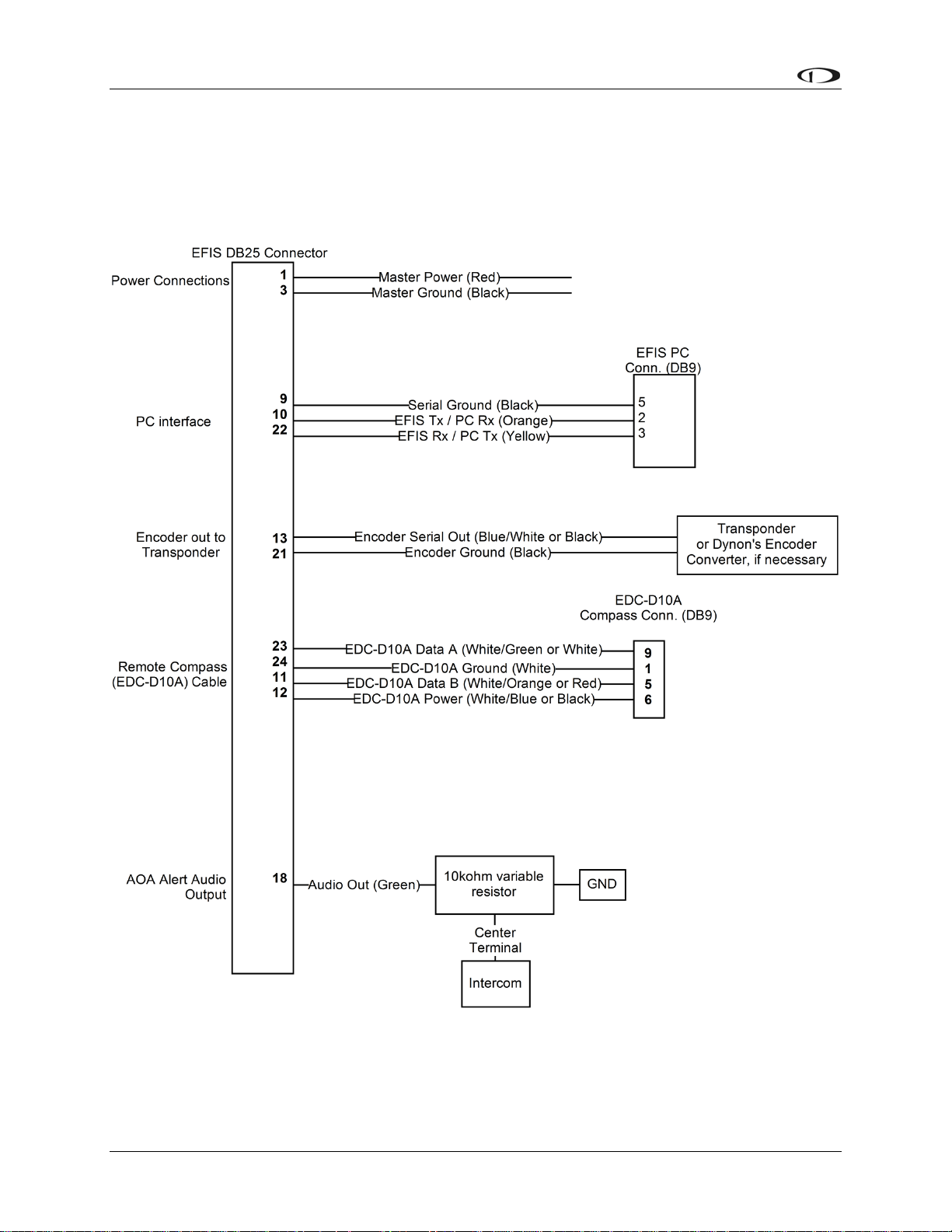

25-Pin Female EFIS Harness

Below is the wiring diagram of the EFIS 25-pin female harness. If you purchased your harness

from Dynon Avionics, it is color coded according to the chart on the following page. Unless

noted otherwise, all wires are 3 feet long on the Dynon-provided harness.

2-2 EFIS-D60 Installation Guide

Page 11

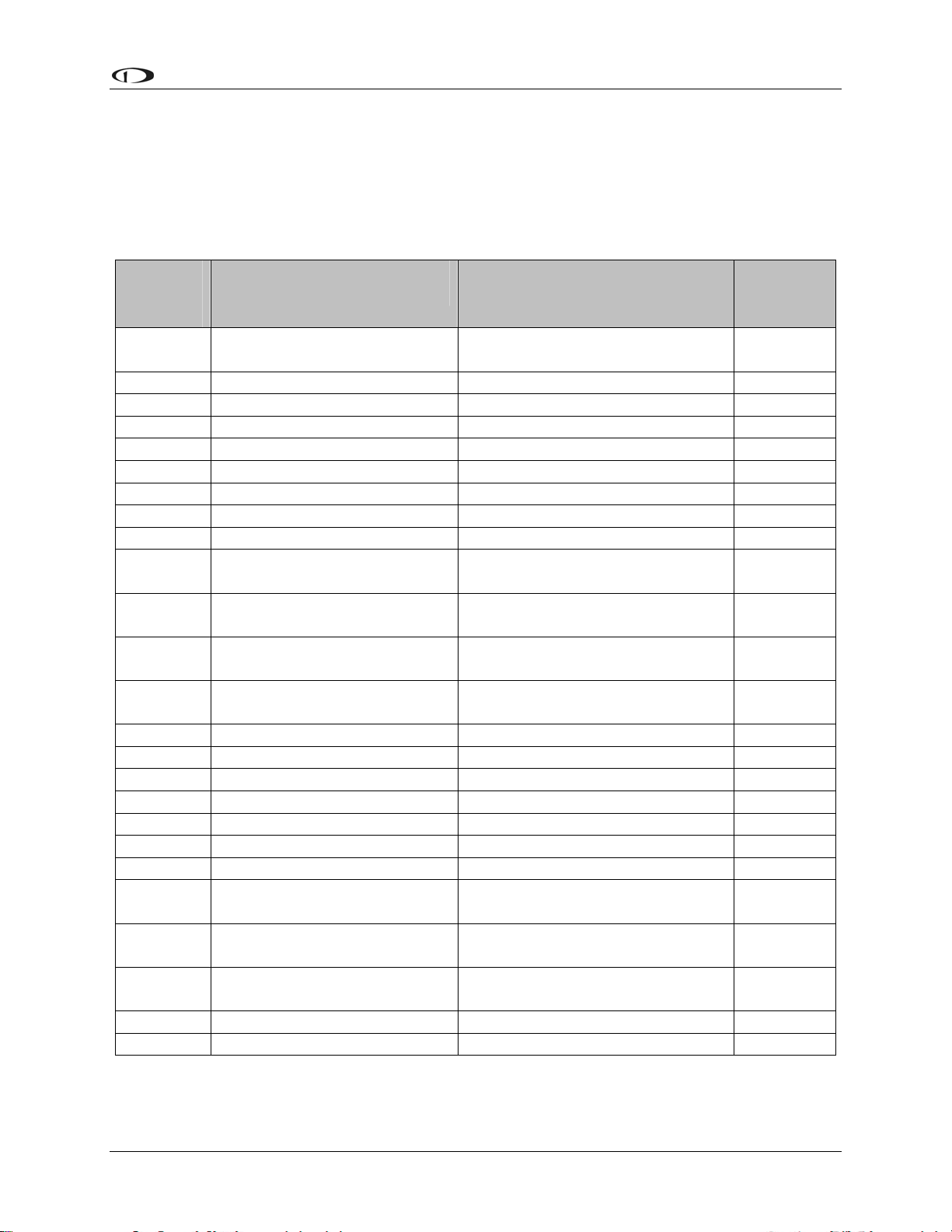

Wiring Overview

The pin assignments for the female 25-pin harness are repeated below. Note that the pin numbers

are labeled on the face of both the female and male connector. Each connection on the harness

supplied by Dynon is color-coded. These colors are listed in the following chart.

For wires that are marked “(Unused in EFIS-D60)”, terminate these wires in an appropriate

manner (insure that they do not short). Dynon recommends not cutting or removing these wires

to preserve the option of upgrading the EFIS-D60 to a EFIS-D100

Female

DB25

Dynon Harness Wire

Color

Function Details

Pin #

1 Red

Master Switch Power

(10-30 volts)

Page 3-3

2 Yellow (Unused in EFIS-D60)

3 Black Primary Ground Page 3-3

4 Green (Unused in EFIS-D60)

5 Blue (Unused in EFIS-D60)

6 N/A No Connect

7 N/A No Connect

8 N/A No Connect

9 Black (bundled) PC Serial Ground Page 3-4

10 Orange (bundled)

11

12

13

White/Orange

(Red on some harnesses)

White/Blue

(Black on some harnesses)

Blue/White

(Black on some harnesses)

EFIS-D60 Transmit / PC Serial

Serial Encoder Transmit (RS-232)

Receive (RS-232)

EDC-D10A Data B

EDC-D10A Power (12V)

Page 3-4

Page 3-2

Page 3-2

Page 5-15

14 N/A No Connect

15 N/A Emergency Backup Power Page 3-3

16 Black Ground

17 N/A No Connect

18 Green Audio out Page 3-7

19 N/A No Connect

20 N/A No Connect

21

22 Yellow (Bundled)

23

White (Bundled in Encoder

cable)

EFIS-D60 Receive / PC Serial

White/Green

(Green on some harnesses)

Serial Encoder Ground

Transmit (RS-232)

EDC-D10A Data A

Page 5-15

Page 3-4

Page 3-2

24 White EDC-D10A GND Page 3-2

25 N/A No Connect

EFIS-D60 Installation Guide 2-3

Page 12

Wiring Overview

WIRING SYSTEM OVERVIEW

The following block diagram depicts the basic layout of the EFIS DB25 electrical connections

and is for reference only. Read the specific instructions for each connection prior to installation.

The colors shown refer to the Dynon-supplied EFIS harness

2-4 EFIS-D60 Installation Guide

Page 13

3. INSTRUMENT INSTALLATION

This section provides you with the information needed to physically and electrically install the

EFIS-D60.

Selecting a Remote Compass Module Location

Finding a good location for the EDC-D10A

remote compass module is critical to an

accurate EFIS-D60 heading display. Keep in

mind that calibration can compensate for

small static magnetic fields superimposed

upon the earth’s field; it cannot take

into account dynamic effects like

AC currents, non-constant DC

currents and non-stationary ferrous

material (e.g., an electric turn

coordinator). Use the following

suggestions to help you find a goo

location for yod ur EDC-D10A.

• Keep the EDC-D10A away from

any source of magnetic fields

(such as electrical equipment and currentcarrying wires) and ferrous material.

• Move a handheld compass throughout the

space surrounding your location to get a r

idea of the suitability of your chosen location

If the needle deviates significantly from

magnetic north in any given area, that locatio

would not be ideal for the EDC-D10A.

• The ED

the aircraft (away from magnetic interference)

such that its pitch is as close to that of the

EFIS-D60 as possible. It does not need to b

directly along any axis of the EFIS-D60. It

should be mounted with the long axis

parallel to the wings, the electrical

connector facing toward the front of the

plane, and the mounting tabs on the bottom.

The bracket used to hold the EDC-D10A

must hold the EDC-D10A at the same pitc

roll, and yaw as the EFIS-D60 with respect

to the airframe. We recommend that you use

an electronic level, if available, to make

sure the EDC-D10A is aligned with the

EFIS-D60 to better than 1 degree.

C-D10A can be mounted anywhere in

ough

.

n

e

h,

Connector toward

direction of flight

Connector forward and

tabs mounted down

Side view of EDC-D10A, tabs mounted

down and aligned within 1 degree of pitch

with EFIS-D60

EFIS-D60 Installation Guide 3-1

Page 14

Instrument Installation

• All mounting hardware needs to be made from non-ferrous material such as aluminum,

plastic, or brass. Many stainless steel screws are magnetic. If the item is attracted to a

magnet, it should not be used in the installation. The EDC-D10A needs to be mounted

location as free from magnetic interference as possible. This means keeping the EDC-D10A

away from any ferrous nuts, bolts, and screws, aircraft tubing, as well as from wires or

devices carrying any appreciable current such as strobe light wiring, autopilot servos, or

other electronics.

in a

EDC-D10A Communication Cable

DO NOT ATTEMPT TO POWER UP THE EFIS-D60 WITH THE EDC CABLE

LEADS EXPOSED (UNSHEATHED) AND NOT INSTALLED IN THE DB9

CONNECTOR. SHORTING THESE CONNECTIONS WILL CAUSE DAMAG

THE UNIT.

E TO

Like the RS-232 PC Communicatio

a standard female DB9 connector. While they look similar, do not plug the EDC cable into a PC

or vice versa. The following table outlines the four connections that must be made to ensure

proper communication between the EFIS-D60 and the EDC-D10A remote compass module. T

Dynon-supplied harness colors are listed, as well.

EFIS

DB25 pin#

11 5 EDC Data B White/Orange (or Red)

12 6 EDC Power White/Blue (or Black)

23 9 EDC Data A White/Green (or Green)

24 1 EDC Ground White

The EDC cable i e harness s lied b ts of 4 condu urrounded by a

metal shield and white insulation. These 4 wires are terminated with crimped female D-sub p

wrapped in plastic tubing. If you are building your own cable, we recommend that you use

shielded cable as well.

• With the 25-pin EFI

tubing off the 4 D-sub pins.

• Route the cable to the EDC-D

above.

• Install t

chart above.

• Install the bac

n th upp y Dynon consis ctors, s

he female pins in the correct holes on the included DB9 connector, according to the

k shell around the DB9 connector.

DB9 pin# Function Wire color

S harness disconnected from the EFIS-D60, carefully cut or pull the

n cable, the EDC-D10A communications cable terminates in

he

EDC

ins

10A mounting location chosen according to the instructions

Correct wiring installation can be easily verified once

the EDC-D10A connected to it. If you have correctly wired your EDC-D10A wiring harness you

will see the heading properly displayed at the top of the screen (provided you have turned on the

heading display in the CLUTTR menu). If wiring is not correct, or the EDC-D10A is not

communicating properly with the EFIS-D60, you will see the message REMOTE COMPA

NOT DETECTED in place of the heading onscreen.

3-2 EFIS-D60 Installation Guide

completed. Power on the EFIS-D60 with

SS

Page 15

Instrument Installation

The metal shield around the EDC communication cable is connected to the short black/white

wire from the DB25. Connect this wire to ground.

Power Inputs

The EFIS-D60 has two separate power inputs, located on the DB25 EFIS connector. Only Master

Switch Power is required to operate the instrument. The other input provides redundancy. Below

is a table that explains both power inputs and their purposes. Both inputs share a common ground

signal, wired to pin 3 on the connector.

EFIS

DB25

pin#

1 Master

3 Primary

15 Emergency

Function EFIS DB25 wire

Switch

Power

Ground

Backup

Power

Description

color

Red Provides primary power to the instrument.

The EFIS-D60 will switch on upon

application of power. Connect to a switched

power source. Will not be adversely affected

by engine cranking.

Black Connect to ground. Must carry as much as 3

amps.

(Not wired in

Dynon harness)

Will operate the EFIS-D60 only if Master

Switch Power is not present. The transition

from Master Switch Power to Emergency

Backup Power will display a warning,

requiring you to press ACK within 30

seconds to keep the unit operating. This

warning will also display when transitioning

from either Master Switch Power or

Emergency Backup Power to Internal Backup

Battery power.

EFIS Serial Harness

The EFIS-D60 has one RS-232 serial port that can be used for two purposes. The EFIS Serial

port (DB9) is used for:

Connecting to a PC to use the Dynon Support Program to perform firmware upgrades,

configure checklists, and download internal logs. The Help Files of the Support Program

provide detailed instructions on these functions. The latest version of the Dynon Support

Program can be downloaded at downloads.dynonavionics.com.

• Connecting a compatible GPS receiver to serve as a backup to airspeed in the event of a

blocked pitot.

EFIS-D60 Installation Guide 3-3

Page 16

Instrument Installation

PC CONNECTION FOR FIRMWARE UPDATES

On the EFIS 25-pin wiring harness

available from Dynon, there are three

wires bundled together, terminating in a

standard DB9-pin female connector. This

cable is 6’ long and pre-assembled for

connection to a PC-based laptop. Route

this cable to a convenient location that can

be accessed whenever you need to update

your product’s firmware or checklists.

If you did not purchase a harness from

EFIS

DB25

DB9

Pin#

Wire

Color

RS-232 Function

Pin#

9 5 Black Signal ground

10 2 Orange EFIS-D60 transmit /

device receive

22 3 Yellow EFIS-D60 receive /

device transmit

Dynon, obtain a 9-pin D-sub connector

and make the three connections shown in the table.

To verify proper communication between the EFIS-D60 and the PC, use the Dynon Support

Program’s “Detect Firmware Version” function. Download the latest version of the Support

Program at downloads.dynonavionics.com.

GPS CONNECTION FOR AIRSPEED FAILOVER

A yellow/green wire is spliced into the EFIS serial receive

line. In the event of loss of airspeed data (e.g., via pitot

icing), the EFIS-D60 uses GPS groundspeed. This allows the

EFIS-D60’s attitude to operate properly despite

compromised airspeed accuracy. Connect this yellow/green

wire to your GPS’s serial transmit line. See the table at right

for GPSs known to work.

To use the GPS-failover feature on your EFIS-D60, your

GPS must output either “aviation format” or the $GPRMC

and $GPGGA NMEA sentences in its serial stream. You

must also have a supported cable that exposes your GPS’s

serial transmit line. If you own a Garmin 430 or 530, in the

UNITS/MAGVAR option, set the MAGVAR to AUTO.

To verify your GPS connection, plug your pitot tube and taxi

at a speed greater than 25 knots. If the GPS is properly

connected, the alert GPS ASSIST is displayed on the attitude

indicator. This verifies that, in the event of airspeed loss in

flight, your GPS will be properly utilized for attitude

calculation.

PC USB CONNECTION

GPS units known to work

AvMap EKP-IV (v2.06.116R,

NMEA set to “processed”)

Bendix/King Skymap (set to

AR NAV 9600 output)

Garmin

96, 96c, 150XL, 195, 196, 295,

296, 396, 400, 420, 430,

430W, 496, 500, 520, 530,

530W, GX60, GX65

Lowrance handhelds

A frequently updated list of

compatible GPS units and

settings is available at our

Documentation Wiki at

wiki.dynonavionics.com

.

If you do not have a serial port on your PC, use the included USB-to-Serial adapter to connect

the EFIS-D60 to your PC’s USB port. If you are using Windows 2000 or XP, ensure that the

adapter driver CD is inserted in your PC before plugging the adapter into the USB port for the

first time. If you are using Windows Vista or Windows 7, ensure that you are connected to the

Internet and do not use the driver CD; the operating system will download the correct driver.

3-4 EFIS-D60 Installation Guide

Page 17

Instrument Installation

Also, do not have your EFIS-D60 plugged into the USB-to-Serial adapter while installing the

driver.

Altitude Encoder Wiring

The EFIS-D60 outputs its altitude

measurements in one of four standard serial

outputs and is readable by many modern

transponders. The EFIS-D60 will function

properly whether or not this altitude encoder

functionality is used. To use the EFIS-D60‘s

altitude encoder functionality, simply wire

the 2 encoder connections (GND and

Encoder Transmit) from the DB25 connector to their

respective connections on your transponder.

Per ATC/FAA requirements, the serial encoder output

of the EFIS-D60 reports pressure altitude, which, by

definition, is indicated altitude when the baro is set to

29.92. So, when you set your EFIS-D60‘s baro

adjustment to 29.92, its indicated altitude will match

the altitude that is being reported to your transponder.

There are four different serial formats used by

transponders. The EFIS-D60 can output any of these

formats. To select which format the EFIS-D60 sends out its serial encoder output port, you must

choose the appropriate format via the menu system. When the menu system is displayed, push

the following sequence of buttons: SETUP > ALTENC. When in the Altitude Encoder Setup

menu, you can toggle the resolution of the output between 10 and 100 feet; this accommodates

some transponders which can input and display altitude in 10 foot increments. In this menu, you

can also select between the four different output formats, which are described below.

If your transponder requires parallel Gray

code input, and you wish to use the EFIS-D60

as your altitude encoder, you will need to

purchase Dynon Avionics’ Encoder Serial-toParallel Converter. Please refer to page 5-13

for more information on the installation of

this option.

EFIS

DB25

pin# Function Wire color

Encoder

13

21 Ground White

serial

transmit

Blue/White

(or black)

Dynon’s supplied EFIS harness has a serial altitude encoder cable which consists of 2

conductors, surrounded by a metal shield and white insulation. Dynon has shipped harnesses

with different colors for Encoder serial transmit line. Determine your connections using the table

above. Connect the Encoder serial transmit to your transponder’s serial input or to Dynon’s

Serial-to-Parallel Converter as described in the Encoder Serial-to-Gray Code Converter

Installation section on page 5-15 in the Appendix.

EFIS-D60 Installation Guide 3-5

Page 18

Instrument Installation

SERIAL ALTITUDE FORMATS

There are four formats used by serial transponders. Choose the correct format for your

transponder in the ALTENC menu, using the FRMAT button.

Format 1

Used By

Baud rate

Format

Example message

Format 2

Used By

Baud rate

Format

Example message

Format 3

Used By

Baud rate

Format

Example message

Dynon Encoder Serial-to-Gray Code Converter, Garmin

AT (formerly UPS Aviation Technologies)

1200

#AL, space, +/-sign, five altitude bytes, T+25, checksum,

carriage return

#AL +05200T+25D7[CR]

Magellan

1200

$MGL, +/- sign, five altitude digits, T+25, checksum, carriage

return

$MGL+05200T+25E3[CR]

Northstar, Garmin

2400

ALT, space, five altitude bytes, carriage return

ALT 05200[CR]

Format 4

Used By

Baud rate

Format

Example message

Garmin GTX327, GTX328, and GTX330 (set on Icarus

input), Icarus, Trimble

9600

ALT, space, five altitude bytes, carriage return

ALT 05200[CR]

3-6 EFIS-D60 Installation Guide

Page 19

Instrument Installation

Audio Alert Output

The EFIS-D60 has an audio alert output for

sounding AOA and altitude alarms through

an intercom or audio panel. You must have

DB25

pin#

18 Green EFIS Audio Alert Output

Color Function

the optional AOA Pitot Probe to use this

functionality.

Connect the alarm output from the EFIS-D60 to the outside terminal of a 10 kΩ variable resistor

(not included). Ensure that audio outputs are connected similar to the following diagram. The 10

kΩ variable resistor can be obtained from Radio Shack (P/N 271-1715) or other electronics

suppliers.

Outside terminal

To EFIS-D60 Audio

Alert Out

Center terminal

To intercom/audio

panel auxiliary input.

Outside terminal

To ground

To set the volume of the AOA alarm, you will need your EFIS-D60 powered on and the alarm

output wired as described above. Enter the EFIS menu by pressing any button (except the

leftmost or rightmost) beneath an EFIS page. Press SETUP > AOAALM. In that menu, press the

TEST button. While the button is held down, the AOA alarm will sound. Adjust the variable

resistor until the volume in the intercom or audio panel is at an acceptable level.

EFIS-D60 Installation Guide 3-7

Page 20

Instrument Installation

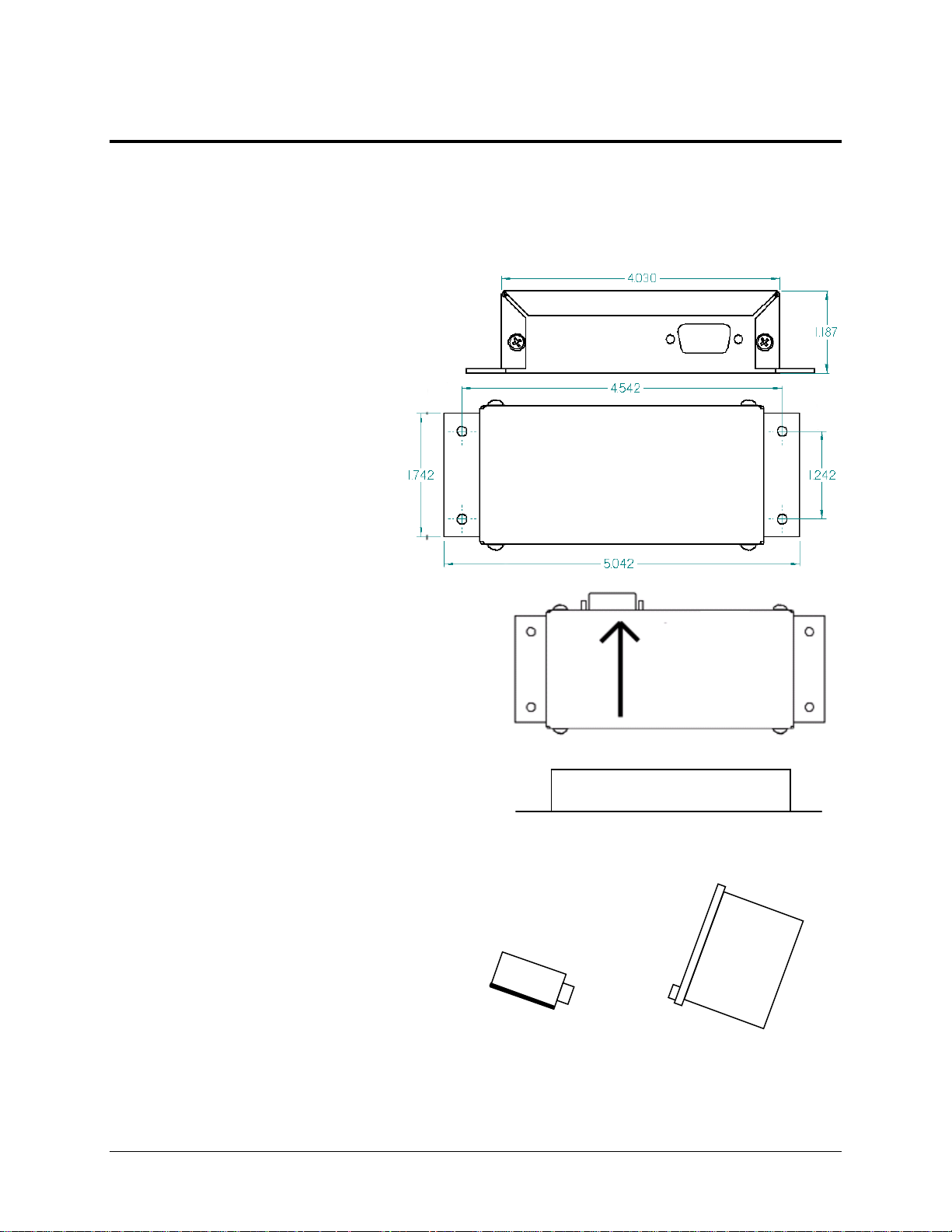

Panel Location and Mounting

The diagram below shows the outside dimensions of the front bezel of the EFIS-D60. Note that

the instrument and tray extend about 4.5” behind the panel, and the supplied harness extends

three inches more. Use the dimensions (in inches) found on the diagram to plan for the space

required by the instrument. Take the following considerations into account when selecting a

mounting location for the EFIS-D60.

Avoid placing the instrument near heater vents or any source of extremely hot or cold air. Keep

in mind that the air surrounding the EFIS-D60 during operation may be no warmer than 50 °C.

Plan a panel location that allows convenient viewing of the instrument with no obstruction.

When flying straight and level, the panel angle from vertical may not be greater than +/- 30

degrees. The unit must be aligned as close as possible with the longitudinal and lateral axes of

the aircraft. The firmware supports an adjustment for panel tilt, but not for mounting errors in

yaw or roll. Correct attitude performance depends on mounting the EFIS-D60 square with the

direction of flight.

To mount the EFIS-D60, you must make a rectangular cutout in your panel. Ensure that the

dimensions of the cutout are: 6.780” wide and 4.750” tall. Place the D100-series mounting tray

behind the cutout. Secure it to your panel in whatever way you desire. Riveting it to the panel is

ideal, but drilling holes for mounting screws and nuts will work as well. You may cut off 2

horizontal or vertical tabs from the mounting tray to minimize the space taken up behind the

panel. Upon securing the mounting rack to the back of your panel, slide the EFIS-D60 into it.

Use the included 7/64” Allen wrench to secure the mounting screw (at the bottom left of the

front bezel) into mounting rack. At your discretion, you can also screw a #6-32 screw into the

back of the mounting rack on the opposite side. This screw should penetrate into the instrument

no further than ¼”.

3-8 EFIS-D60 Installation Guide

Page 21

Instrument Installation

Connecting Static & Pitot Lines

The AOA, pitot, and static ports on the back of the

EFIS-D60 are equipped with 1/8” NPT Female

fittings. To attach your pitot and static lines to the

back of the EFIS-D60, you must use standard 1/8”

NPT Male fittings at the end of each of the lines.

To install, simply connect your static and pitot

sources to the EFIS-D60. T’ing off of existing lines

is acceptable if performing a retrofit or connecting

in parallel with other instruments. View the

following back view diagram the placement of your pressure lines.

Use a wrench to secure the mating pressure line fittings to the corresponding locations on the

back of the EFIS-D60. Do not over-tighten.

If you purchased Dynon’s AOA pitot tube, note that it has pitot and AOA ports on it, but not

static. You will need to provide your own source of static pressure for the EFIS-D60 and any

other instrument in your panel which requires it.

The EFIS-D60’s attitude calculation

requires either airspeed (from pitot

and static) or GPS data. To ensure

proper operation, at least one of these

data sources must be available. We

recommend the EFIS-D60 be

connected to pitot and static systems

in all installations.

EFIS-D60 Installation Guide 3-9

Page 22

Page 23

4. EFIS CALIBRATION AND CONFIGURATION

During manufacture, your EFIS-D60 underwent a comprehensive calibration, verification, and

burn-in routine that minimizes setup time and ensures that your EFIS-D60 meets Dynon’s

stringent performance specifications. To account for your individual preferences and your

aircraft’s particular setup, there are a few simple calibration and configuration steps that you

must complete before using your EFIS-D60. This section takes you through these steps to make

sure that you have properly installed and configured your EFIS-D60.

CAUTION: It is your responsibility to fly your plane safely while performing any

configuration or calibration in flight. The best scenario would include a second person to

perform any necessary steps on the unit.

Ensuring Proper Installation

Turn your unit on by energizing the aircraft power to which it is connected. Ensure that the

screen is bright and readable and that all instrument displays appear. If a desired display item is

not present, refer to the User’s Guide to use the CLUTTR feature to display the missing item.

Setting Zero Pitch (In flight)

For the purposes of this setting, level is defined as the attitude at which the aircraft’s

longitudinal axis is parallel to the ground. For most aircraft, the attitude the aircraft

assumes at normal cruise speeds will be acceptable. Additionally, this feature should not

be used to “zero out” pitch when the aircraft is at an attitude other than level. Do not

think of this adjustment as you would the parallax adjustment on a normal attitude

indicator. Instead, think of it as a calibration step which is not changed often.

With your aircraft flying straight and level, enter the SETUP > PITCH menu. Press INC or DEC

until the horizon line intersects the center of the crosshairs. It is important that this be done while

the aircraft is level to ensure proper pitch and roll display throughout all maneuvers.

Compass Heading Calibration

This section guides you through the calibration and configuration of your magnetic heading

indication. Prior to calibrating your EDC-D10A, you must configure the local magnetic

inclination and magnetic intensity as described in the sections below.

SETTING MAGNETIC INCLINATION ANGLE AND INTENSITY (REQUIRED)

To calibrate your EFIS-D60 heading, you must input your location’s current magnetic

inclination angle and intensity. Before doing this, you must obtain these two values for

the geographic location where you will be performing the calibration. Note that this

procedure only needs to be done once, prior to magnetic calibration. Moving the aircraft

to another location does not require repeating this procedure.

EFIS-D60 Installation Guide 4-1

Page 24

EFIS Calibration and Configuration

Obtaining Magnetic Inclination and Intensity

1. Browse to web page: www.dynonavionics.com/docs/maginfo.html. (Looking up this

information does not have to be done on a computer at the plane, with live Internet

access.)

2. The Dynon Avionics “Magnetic Inclination and Intensity” web page is updated as

needed; it contains a link to a NOAA web pages and instructions for easily finding your

local magnetic inclination and intensity by inputting your ZIP code (in the US) or your

latitude and longitude and inputting the resulting data into your Dynon EFIS.

3. Follow the instructions listed on the web page, especially clicking the “Compute

Magnetic Field Values” button at the bottom of the linked page – the values required by

your Dynon EFIS will be displayed only after clicking that button.

Entering inclination and intensity into the EFIS-D60

1. Enter the inclination setup menu by pressing any button beneath an EFIS page (except the

far left or far right hotkeys), then SETUP > MAGINC

2. Press INC or DEC to increment or decrement the displayed inclination angle. Press and

hold to change values more rapidly.

3. When the display shows the magnetic inclination angle for your location, press BACK to

leave the menu.

4. Enter the magnetic intensity setup menu by pressing any button beneath an EFIS page

(except the far left or far right hotkeys), then SETUP > MAGINT

5. Press SEL to change the digit being incremented or decremented. Press INC or DEC to

increment or decrement the selected digit. Press and hold to change values more rapidly.

6. When the display shows the magnetic intensity for your location, press BACK to leave

the menu.

4-2 EFIS-D60 Installation Guide

Page 25

EFIS Calibration and Configuration

EDC-D10A HEADING CALIBRATION (ON GROUND ONLY)

The procedure for in-plane calibration of the EDC-D10A involves pointing the aircraft in four

directions and taking data at each direction using the EFIS-D60. The EFIS-D60 will then

perform some calculations to ensure an accurate calibration.

If you attempt a magnetic caibration without having performed the preceding section

(Setting Magnetic Inclination Angle and Intensity), a warning message will be displayed:

WARNING: MAGNETIC INCLINATION NOT SET.

During magnetic calibration, do not turn the power off on the EFIS-D60. This will cause

any recorded compass calibration data to be lost; the calibration will need to be restarted.

To perform the calibration, you will need the following:

1. EFIS-D60 and EDC-D10A installed in aircraft.

2. Magnetic inclination angle and intensity properly entered into the EFIS-D60 per the

section above.

3. An accurate method of aligning the aircraft with magnetic North, East, South, and West,

such as an airport’s compass rose.

Once you have the installation completed, have verified that your EDC-D10A communicates

with the EFIS-D60 (i.e., you see the heading tape displayed on the EFIS main page), and have

located a suitable place to perform the calibration, perform the following steps:

1. Turn on the EFIS-D60 and allow it to warm up for at least 15 minutes before performing

the calibration.

2. Align the aircraft pointing magnetic North as closely as possible.

3. On the EFIS-D60, enter the menu system by pressing any button beneath an EFIS page

(except the far left or far right hotkeys) and press SETUP > MAGCAL. You should see a

menu that reads NORTH, EAST, SOUTH, and WEST. If you do not, then the EDCD10A is not properly communicating with your EFIS-D60.

4. Press the NORTH button; you will see the message, COLLECTING DATA FOR

NORTH along with a 15 second timer. Let the time run out before proceeding.

5. Align the aircraft pointing magnetic East as closely as possible.

6. Press the EAST button; you will see the message, COLLECTING DATA FOR EAST

along with a 15 second timer. Let the time run out before proceeding.

7. Align the aircraft pointing magnetic South as closely as possible.

8. Press the SOUTH button; you will see the message, COLLECTING DATA FOR

SOUTH along with a 15 second timer. Let the time run out before proceeding.

9. Align the aircraft pointing magnetic West as closely as possible.

10. Press the WEST button; you will see the message, COLLECTING DATA FOR WEST

along with a 15 second timer. Let the time run out before proceeding.

11. Press the END button. This will cause the EFIS-D60 to pause as it calculates. This pause

should last between 1-20 seconds. However, if the collected data is poor, this can take as

EFIS-D60 Installation Guide 4-3

Page 26

EFIS Calibration and Configuration

long as 5 minutes. A message will be displayed onscreen: CALCULATING MAGNETIC

CALIBRATION VALUES.

12. Wait for the message CALIBRATION COMPLETE before attempting to use the EFIS-

D60 or remove power. Press BACK to leave the menu.

This completes the EDC-D10A calibration process. The process can be repeated as often as

desired. The overall accuracy of the compass depends on the installation location (away from

any ferrous materials or current carrying wires or devices), the installation alignment (aligned

with the EFIS-D60 in pitch, roll, and yaw), and the calibration procedure (accurately aligning the

aircraft with North, East, West, and South and having the correct magnetic inclination angle

loaded into the EFIS-D60). If the compass performance is not adequate for your usage, we

suggest that you investigate each of these factors and try to optimize your installation for each

factor.

If the heading shown onscreen is off by a small, but constant amount, you can change a heading

offset in the EFIS-D60 which will correct this. Orient your plane in a known direction,

preferably on a compass rose at the airport. Navigate to the Heading Adjustment menu by

pressing SETUP > MAGADJ. Increment or decrement the value of the heading offset until the

EFIS-D60 heading corresponds to the direction in which your plane is pointed.

Configure Airspeed Color Thresholds

To configure the airspeed bar color thresholds for your unit enter the SETUP > IASCLR menu.

This displays the Airpseed Color Threshold menu. In this menu, enter the values for five

airspeed constants (Vso, Vs1, Vfe, Vno, and Vne), each of which has its own button. Enter these

values in units of knots, mph, or km/h depending on what airspeed units you are currently using

(you may change the displayed airspeed units via SETUP > UNITS > IAS).

Perform the following steps for each airspeed constant:

1. Press SEL to select the digit you wish to increment or decrement.

2. Press DEC- or INC+ to decrement or increment the selected digit.

3. Press BACK to return to the previous menu.

You will not be able to see some of the colors until the aircraft has achieved airspeeds in

the range of each threshold

4-4 EFIS-D60 Installation Guide

Page 27

5. APPENDIX

The appendices contain additional information pertaining to the installation and maintenance of

the EFIS-D60. You will find here a table of weights, specifications, a configuration table, the

maintenance manual, the AOA Pitot Installation Guide, and the Encoder Serial To Gray Code

Converter Installation Guide.

Appendix A: Instructions for Continued Airworthiness

INTRODUCTION

This section gives the installer or mechanic information pertaining to maintenance of the EFISD60. Additionally, it provides the steps necessary to ensure continued airworthiness for the unit.

CAUTION

With the exception of replacing the Internal Backup Battery, the EFIS-D60 contains no userserviceable parts. Refer all servicing to Dynon Avionics.

INSTRUCTIONS FOR CONTINUED AIRWORTHINESS

Other than for regulatory periodic checks and an annual Internal Backup Battery capacity test (if

optional Internal Backup Battery is installed), maintenance of the EFIS-D60 is “on-condition”

only. With the exception of the Internal Backup Battery, periodic maintenance of the EFIS-D60

is not required.

ALTIMETER CHECK

The following test can be performed on an as-needed basis. If the altimeter is found to be out of

specification, the following single-point adjustment can be performed by navigating the menus to

SETUP > ALTADJ. In the Altimeter Adjustment menu, you can change the displayed altitude by

up to 500 feet up or down. After making this adjustment, ensure that the altimeter on the EFISD60 meets the tolerances allowed between 0 and 30,000 feet. If this adjustment does not bring

the altimeter on the EFIS-D60 to within specification at all attitudes, please contact Dynon

Avionics to return for service.

INTERNAL BACKUP BATTERY CHECK

If your EFIS-D60 has a rechargeable Internal Backup Battery, it is necessary to ensure that the

battery capacity is such that it will last at least 2 hours on a full charge. At least once per year,

perform the following test.

1. With the EFIS-D60 drawing power from an external source, allow it to charge its Internal

Backup Battery above 16.0 volts. Observe the voltmeter (to display, use SETUP >

CLUTTR > VMETER). The battery may charge to as high as 16.8 volts, but it is only

necessary to charge it to 16.0 volts for this test.

2. Remove all sources of external power from the EFIS-D60, ensuring that it is operating

off its Internal Backup Battery.

EFIS-D60 Installation Guide 5-1

Page 28

Appendix

3. Ensure that the screen is at its full brightness level. To do this, enter the menu system by

pressing any button and press DIM and increase the brightness until it will not increase

anymore.

4. Let the unit remain on for 2 hours.

5. If, after these 2 hours, your EFIS-D60 has not turned off and does not display the

INTERNAL BATTERY LOW warning, the Internal Backup Battery passes the capacity

test.

6. Make sure you recharge your battery; a full charge is reached when the voltmeter shows

at least 16.0 volts on the Internal Backup Battery.

If your Internal Backup Battery does not pass the above test, please contact Dynon Avionics and

refer to Appendix E for instructions on how to replace the Internal Backup Battery.

FIRMWARE UPGRADE

Dynon Avionics provides free firmware updates for all its products, and continues to add new

features periodically. We suggest that you regularly ensure that your EFIS-D60 has the latest

firmware by visiting our website at downloads.dynonavionics.com and downloading the latest

Dynon Product Support Program. This software contains the latest firmware updates for all

Dynon products.

The EFIS-D60 is upgraded by connecting a PC to the EFIS-D60’s serial port and starting the

Dynon Support Program on the PC.

DISPLAYED ALERT MESSAGES

The following table describes the alert messages that the EFIS-D60 can display.

Alert Message Description End condition

INTERNAL

ERROR

SERVICE UNIT

This error can occur for a few

reasons, including an aborted upload.

It signifies that the EFIS-D60 has

detected internal problems in its

firmware or calibration tables.

When this error appears, it may be

possible to recover your unit in the

field. The best way of ensuring this

is to call Dynon Avionics

immediately. However, there is a

good possibility that the unit will

have to be returned for service.

5-2 EFIS-D60 Installation Guide

Page 29

Appendix

Alert Message Description End condition

ATTITUDE

RECOVERING…

TEMPERATURE

UNSTABLE

TEMPERATURE

OUT OF SPEC

This alert is displayed anytime the

unit is rotated at a rate faster than

150 degrees/second or the unit is

powered on with airspeed applied.

Rotating the unit faster than this

threshold will saturate the gyros,

leading to potentially erroneous

display. The blue/brown horizon

indication will turn grey and black to

indicate that the artificial horizon is

not currently a trusted source. Note

that this alert only appears when

airspeed is non-zero; using the EFISD60 on the bench will not trigger this

alert.

When the unit is turned on after

having been off for a long period, its

internal temperature will rise above

ambient at a fast rate. This fast

change in temperature can sometimes

reduce the reliability of the output of

the sensors. Therefore, this alert is

displayed and the horizon indication

is changed from blue/brown to

grey/black.

The temperature inside the unit is

outside of -30ºC to 50ºC.

The grey/black horizon indication

and onscreen message will remain

until the unit has resumed normal

operation. In the case of rotation

rate greater than 150

degrees/second, the unit enters a fast

recovery mode and usually recovers

within 5 seconds of coordinated

flight.

The screen remains normal color,

but the message is displayed until

the temperature within the unit has

stabilized. This temperature

instability should last no longer than

2 minutes. For this reason, it is a

good idea to turn the unit on before

you run through any of the preflight

procedures, so that it will be ready

by the time you are ready to fly.

The screen remains normal color,

but the message is displayed until

the temperature within the unit is

within the specified range. This is

most common in unventilated

panels during hot periods. If you

continue to see this alert, provide

more airflow to the space around the

EFIS-D60.

EFIS-D60 Installation Guide 5-3

Page 30

Appendix

Alert Message Description End condition

INTERNAL

BATTERY LOW

You will see this alert only when

operating the unit solely off the

internal backup battery. When its

voltage has dropped below a certain

threshold, you will see this alert.

Additionally, the voltmeter will be

displayed onscreen. When you see

this alert, it is advisable that you turn

the unit off by pressing the POWER

button in Main Menu 1.

The alert will disappear when you

press any button; however, it is

advised that you do not ignore this

alert, as it appears when the unit’s

internal battery has very little life

left. This alert will also go away

upon the application of either the

external backup battery or Master

Power. At that point, the battery will

begin charging off the external

power.

REMOTE

COMPASS NOT

DETECTED

The EFIS-D60 is unable to

communicate with the EDC-D10A.

If you have an OAT connected to

your EDC-D10A, you will lose this

reading, as well.

Ensure that you a) have an EDCD10A installed and b) have verified

that the wiring to the EDC-D10A is

correct. Please see the EFIS-D60

Installation Guide for more

information on verifying the

installation of the EDC-D10A.

This error also can appear if you

have updated the firmware in your

EFIS-D60 while the remote

compass was not connected. If this

is the case, try uploading the new

firmware again with the EDC-D10A

connected. Attempt the connection

within the first few seconds of

operation.

Note that the EFIS-D60 does not

have internal magnetic sensors and

thus requires the EDC-D10A be

connected.

OAT SENSOR

NOT

DETECTED

This alert appears when the EFIS has

an OAT connected and then loses

that connection for some reason.

Double-check your wiring between

the EFIS-D60 and the EDC-D10A

as well as that of the OAT sensor.

Either the EDC-D10A has become

disconnected, or the OAT sensor

itself has become disconnected from

the EDC-D10A.

TROUBLESHOOTING GUIDE

The following table provides a list of potential issues that the EFIS-D60 may experience. The

symptom is given on the left side while the probable solution is listed at the right. You may also

post about your issue at forum.dynonavionics.co

m, where we and other active users may be able

to assist you.

5-4 EFIS-D60 Installation Guide

Page 31

Appendix

Problem Solution

After performing a magnetic

calibration the EFIS-D60‘s

heading is wrong by a constant

amount.

When the barometer on the unit

is set correctly, the displayed

altitude is wrong by a constant

amount at all altitudes.

Airspeed is inaccurate by

between 1 and 10 knots (or

equivalent, in other units) at

takeoff speed.

EFIS-D60 displays continuous or

blinking blue screen

EFIS-D60 screen stays black

when power is applied

EFIS-D60 indicates over

temperature condition

EFIS-D60 indicates incorrect

heading

Orient your plane in a known direction, preferably on a

compass rose at the airport. Navigate to the Heading

Adjustment menu by pressing SETUP > MAGADJ.

Increment or decrement the value of the heading until the

EFIS-D60 heading corresponds to the direction in which

your plane is pointed.

Set the barometer to the correct value for your current

location. Note the difference between the displayed altitude

and the actual altitude for your location. Navigate to the

Altitude Adjustment menu by pressing SETUP > ALTADJ.

Increment or decrement the value of the altitude until the

EFIS-D60 altitude corresponds to that of the current location

of your plane. If you need to adjust by more than 200 ft, or

find that you need to adjust frequently (after setting your

baro), please contact Dynon Technical Support for

assistance.

You may recalibrate your EFIS-D60‘s zero pressure value.

With your plane in as windless an environment as possible

(e.g., a hangar), cover both the pitot and static ports with a

sock or cloth to minimize airflow without putting pressure

on the ports. Next, on the EFIS-D60, enter the EFIS main

menu, press SETUP > SPDCAL. When you are confident

that there is no pressure on the pitot and static ports, press

either button corresponding to SET ZERO PRESSURE.

Press YES to confirm you have zero pressure on the pitot

and static ports. You will see a message indicating that the

unit is calibrating. This should only take a few seconds. On

your next flight, verify that the airspeed is what you expect.

To reset the airspeed calibration to factory defaults, enter the

SPDCAL menu, and press RESET DFLTS.

Ensure that your power supply is capable of supplying at

least 2 amps and that it is at least 10 volts.

If, after verifying that you have met these two conditions the

unit does not operate normally, it is necessary to contact

Dynon Avionics.

Verify Master Switch Power is connected.

Verify Master Switch Power is above 10 volts.

Provide additional cooling to instrument

(Re)calibrate the magnetic heading using the procedure

described above.

EFIS-D60 Installation Guide 5-5

Page 32

Appendix

Problem Solution

Internal Backup Battery life is

too short

Verify Internal Backup Battery is charged to above 16 volts

using EFIS-D60 voltmeter.

Re-run capacity test.

Replace battery if insufficient capacity.

Cannot make connection with PC Verify wiring is correct.

Verify no other programs using the COM port are running

on the PC.

Verify latest version of The Dynon Product Support Program

is being used.

INSTRUCTIONS FOR RETURN

If none of the above sections have helped resolve an ongoing issue with your EFIS-D60, please

contact Dynon Avionics to discuss the issue with Technical Support. If, after troubleshooting

with a Dynon representative, the issue cannot be resolved, we will provide you with a Return

Material Authorization (RMA) number to use when shipping the EFIS-D60 to us. If your unit is

still under warranty, the repairs will be performed and the EFIS-D60 will be returned promptly.

If your warranty has expired, the Dynon representative will make arrangements with you and

make you fully aware of the costs before proceeding with the repair.

We recommend that you also send your EDC-D10A remote compass along with your EFIS-D60.

This ensures that if we upgrade the firmware in your EFIS-D60, the EDC-D10A will have

corresponding firmware.

While Dynon Avionics makes every effort to save and restore your unit’s settings and

calibrations, we cannot guarantee that this will happen. Please note that after you receive your

unit back from Dynon Avionics with a factory calibration, the heading display on the EFIS-D60

may be inaccurate once re-installed in your aircraft. If this is the case, you will have to perform

the magnetic calibration again. When you receive your EFIS-D60, it may have newer firmware

installed on it than it did when you sent it in. Check downloads.dynonavionics.com for

information on what’s new.

5-6 EFIS-D60 Installation Guide

Page 33

Appendix

Appendix B: Dynon AOA/Pitot Installation and Calibration

Thank you for your purchase of Dynon’s AOA/Pitot Probe. This guide walks you through the

steps to install and calibrate both the heated and unheated versions of the AOA/Pitot Probe.

While the probe senses standard pitot pressure, allowing it to work with any standard airspeed

indicator, its AOA functionality is designed specifically to work with Dynon’s EFIS series of

products. Do not expect it to work properly with another AOA system.

To ensure accuracy, it is very important that you install the probe correctly and perform the

specified calibration steps. We recommend that you read the entire guide before proceeding with

the installation.

Dynon’s Heated AOA/Pitot Probe is nickel-plated. Do not polish the probe as this will cause the

finish to come off.

AOA CALCULATION: PRINCIPLES OF OPERATION

Dynon Avionics’ AOA/Pitot probe performs two functions: airspeed sensing and angle of attack

sensing. These functions require two pressure ports on the tip of the probe. The normal pitot

pressure port is on the front face of the probe and is designed to be insensitive to angle of attack.

The second pressure port is located on an angled surface just under the pitot port and is designed

to be very sensitive to AOA. The EFIS-D60 then uses the difference between these two pressures

to calculate the current angle of attack.

HEATING: PRINCIPLES OF OPERATION

The heated version of Dynon’s AOA/Pitot Probe utilizes a heating mechanism unlike any other

heated pitot on the market. The probe is heated by a high-quality nichrome heating element

whose temperature is accurately measured and regulated by the heater controller. This controller

– located in an enclosure which can be mounted in a wing or elsewhere – regulates the heat at the

tip of the probe to a constant temperature. There are several advantages to this, including: lower

power consumption, increased heating element lifespan, and a much cooler pitot on the ground

when de-icing is not necessary. This unique technique ensures that the pitot can be rapidly deiced when required, but does not needlessly waste electricity when not in icing conditions.

While the probe does not operate like a normal heated pitot, it will still get fairly hot in normal

ambient temperatures. When turned on, it will regulate its internal temperature to about 70°C to

80°C. To ensure that the heater is working, briefly touch the end of the pitot farthest from the

snout after 1 minute of operation and verify that it is warm.

FAILURE WARNING

Designed to meet the indication requirements of FAR 23.1326, the heated pitot controller has an

output that can trigger a warning light in the cockpit whenever the probe heater is turned off or is

not functioning properly. While not required for Experimental and LSA category aircraft, this

feature provides peace of mind, giving you instant feedback that your probe’s heater is working

as designed.

TOOLS AND MATERIALS REQUIRED

• Dynon Avionics AOA/Pitot probe.

EFIS-D60 Installation Guide 5-7

Page 34

Appendix

• Two plumbing lines (usually ¼” soft aluminum or plastic tubing) routed from the EFIS-D60

to the probe mounting location.

• Adapters to interface with the 3/16” aluminum tubing from the probe to whatever plumbing

lines are installed in the aircraft (AN919-2D for 3/16 to ¼ , AN819-4D sleeve AN818-4D

nut, AN819-3D sleeve, and AN818-3D nut)

• #36 Drill and 6-32 tap

• AOA Pitot Mounting bracket. Models known to work well include:

o Gretz Aero CBK12 (Chrome) and PBK12 (Paintable), available at

www.gretzaero.com/mountbracket.html or from Aircraft Spruce.

o SafeAir1 also makes a bracket with a joggled lip for the RV series. It is available

from www.safeair1.com.

Please follow these instructions explicitly as improper installation can result in permanent

damage to your device and/or aircraft.

HEATER CONTROLLER WIRING AND MOUNTING

If you have purchased the heated version of the probe, please follow the instructions in this

section. If you have purchased the unheated version of the probe, you may skip to the AOA/Pitot

Probe Mounting section on page 5-11. Please follow these instructions explicitly as improper

installation can result in permanent damage to your device and/or aircraft.

Heater Controller Mounting

The heater controller box should ideally be mounted close to the AOA/Pitot Probe. The box’s

dimensions are found at right, for

reference. When mounting the

controller close to the probe, ensure

that it is close enough for its wires to

mate with the probe’s wires, with

room for strain-relief. If you find it

difficult to mount the controller in

the wing, or simply wish for the

controller to be mounted closer to

the battery, you must extend the

lines using the correct wire gauge as

described in the Wiring section

below.

When the desired location is

selected, secure the heater controller

via the 4 mounting holes. Route the

wiring between the probe, controller, panel, and power source, as described below.

Heated AOA/Pitot Wiring System Overview

The following block diagram depicts the basic layout of the electrical connections between the

probe and heater controller. This diagram should be used in conjunction with detailed

5-8 EFIS-D60 Installation Guide

Page 35

Appendix

instructions on the following pages. Read the specific instructions for each connection prior to

installation.

EFIS-D60 Installation Guide 5-9

Page 36

Appendix

Heater Controller Wiring

Before making the connections to your Heated

AOA/Pitot Probe and controller, refer to the

Recommended Wiring Practices section on page

2-1. The chart at right provides general

recommendations for wire gauge choice, given

wiring run length.

Probe to Controller Wiring

As mentioned above, it is preferable that the

heater controller box be mounted near enough to

the probe that 5 wires between the controller and

Recommended wire gauge for runs,

given 10-amp peak current

Run length Gauge

0’ – 7’ 18 AWG

7’ – 9’ 16 AWG

10’ – 16’ 14 AWG

17’ – 24’ 12 AWG

25’ – 40’ 10 AWG

From FAA AC 43.13-1B, page 11-30

probe can be connected without extension. The

three mating pairs of colored wires – terminated with Fastons – are used to carry the current to

the heating element in the probe. The 2 white wires are for temperature measurement, and can

thus be small. If you have mounted the heater controller near the probe and do not need to extend

the wires between the two, simply plug each wire on the controller into its corresponding likecolored wire from the probe.

If you do need to extend the wires between the probe and the controller, use the recommended

wire size (see chart on page 5-8) for your run length. Since extending the wire runs requires that

you cut the connectors off the 5 wires between the probe and controller, splice the extension

wires between the probe and controller using butt splices or other similarly secure method. The

white wires are not polarity-dependant. Additionally, as the white wires do not carry any

significant current, you may extend them with 26 AWG or larger for any run length.

Controller Power wiring

Three wires – colored red, black, and white

– exit the controller for connection to your

electrical system. Power (between 10 and

15 volts) is fed to the controller via the red

and black wires. The maximum current

draw of the heated pitot controller/probe is

10 amps. You must route your own

appropriately-sized wires to where the

heater controller is mounted. Both power

and ground lines should be able to handle

10 amps with minimal voltage drop, as

recommended in the chart on page 5-8.

The red wire should be connected through

a pilot-accessible switch to the main power

source in the aircraft (limited to 15 volts).

The switch allows you to manually turn the

heater controller on and off, depending on

the situation. Install a 15-amp fuse at any

point along the power line to the heater

Color Notes

Red Connected through a pilot-accessible

switch to 10–15V supply. Must handle

up to 10 amps.

Black Must have a constant connection to

ground. This is required for the warning

light to operate when controller is

powered off or not functioning. Line

must handle up to 10 amps.

White Connected to a light bulb (or resistor &

LED) tied to switched ship’s power.

This line is grounded when the heater

controller is powered off or not

functioning. Connection can handle no

more than 1 amp. Current depends on

light source connected.

5-10 EFIS-D60 Installation Guide

Page 37

Appendix

controller. Remember that even when the controller is powered on, it only heats the probe the

amount necessary to maintain temperature.

The black wire should be permanently connected to ground. Cutting power to the heater

controller should occur via the red power line, not the black ground line.

Heater Status Connection

Note: The probe heater functions properly whether or not you make this connection. It is simply

a status output for your convenience.

The white heater status wire is grounded when the probe heater is turned off or not functioning

properly. This wire should be connected to a light on the panel, whose other terminal is

connected to switched aircraft power. When the heater is on and functioning properly, the white

heater status line is open, leaving the indicator light turned off. When there is no power to the

heater controller – or it is not functioning properly – the white line is grounded, turning the

indicator light on.

Aircraft Spruce P/N 17-410 is an example of a light that will work for this application. An LED

and resistor in series will also suffice. If you use an LED as the indicator, you must choose a

resistor that delivers the appropriate current to the LED, and can accommodate the power

required for its current and voltage drop.

If you own a Dynon EMS-based product, you may also use one of its two contact input to

display an onscreen indication. Connect this heater status output directly to the desired EMS

contact input, with no additional resistors or lights. You must configure the contact display as

described in your EMS-based product’s Installation Guide.

AOA/PITOT PROBE MOUNTING

The Dynon Avionics AOA/Pitot probe has been designed as an under-wing pitot. The following

information applies to this type of installation. If you wish to mount your pitot on nose boom

mount, contact us so we can make the appropriate adjustments to your pitot. The heated version

of Dynon’s AOA/Pitot Probe does not come in a boom-mount configuration.

AOA/Pitot Probe Mount Location

The Dynon Avionics AOA/Pitot probe only functions correctly when mounted in a location

where the airflow over the probe is relatively undisturbed by the aircraft. In general, we

recommend that you mount it at least 6 inches below the wing and with the tip of the probe

between 2 and 12 inches behind the leading edge of the wing. Typically, pitot probes are

mounted about mid-wing span wise to minimize the effects of both the propeller and the wing

tips. Testing during the probe development has shown that the standard mounting locations for

the pitot probe in the RV series of aircraft also works for the Dynon probe.

AOA/Pitot Probe Mounting Instructions

After the mounting location has been determined, mount the pitot mounting kit per the included

instructions or fabricate your own mount. In either case, mount the probe securely to the wing

such that the body of the probe is horizontal during level flight. Drill and tap mounting holes (#6-

32) on the probe to match your mounting bracket. Use caution when drilling the holes, ensuring

that you avoid drilling into the pitot and AOA pressure lines. As long as you do not penetrate

EFIS-D60 Installation Guide 5-11

Page 38

Appendix

these lines, you may drill all the way through the outer metal without affecting the probe’s

waterproofing.

DIMENSIONS

Standard mount

5-12 EFIS-D60 Installation Guide

Page 39

Appendix

Boom mount

PLUMBING

NOTE: Because the pitot and AOA plumbing tubes have not been annealed, they work-harden

rapidly when manipulated. Make gentle bends, and only bend any given section once.

After mounting the probe, route the pitot and AOA lines from the probe to your EFIS-D60. The

tube closest to the snout is the pitot line, while the tube in the rear is the AOA line. There is no

static source on the probe.

After mounting the probe, install adapters to connect the 3/16 plumbing lines from the probe to

whatever plumbing lines run back to the EFIS-D60 in your aircraft (AN 919-2D for 3/16 to ¼).

We strongly recommend using aircraft grade fittings such as standard AN fittings. Make sure the

plumbing lines do not chafe or interfere with any aircraft control systems.

PRESSURE CHECK

Dynon’s pitot design deliberately has a pin-sized leak hole in each of the two tubes to permit

draining any moisture which might accumulate inside. These holes are located in the middle of

the tube at the bottom. Plugging these holes does not guarantee a pneumatic seal (although one is

sometimes present). The leak that may exist does not affect the performance of the probe. You

will, however, need to take it into account when doing pressure/leak tests on your pitot system

CALIBRATION

CAUTION: It is your responsibility to fly your plane safely while performing any

configuration or calibration in flight. The best scenario would include a second person to

perform any necessary steps on the EFIS-D60.

Once you are flying straight and level at a safe altitude for stalls, enter the SETUP > AOACAL

menu. While the AOACAL menu is displayed, oscillate the aircraft between ± 5° pitch 4 times at

fast cruise airspeed. During this maneuver the EFIS-D60 records the lowest angle of attack that

you usually see during flight. You do not need to push any additional buttons before starting this

maneuver.

Refer to the list below of the stalls recommended to complete the user calibration. The general

idea is to record stall data to find the lowest angle of attack stall. The list we have suggested is a

starting point and produces a good calibration under most circumstances. However, if there are

EFIS-D60 Installation Guide 5-13

Page 40

Appendix

flight regimes not listed that you suspect would create stalls at lower angle of attack it would be

good to record those as well.

With full power, no flaps

With no power, no flaps

With full power, full flaps

With no power, full flaps

Push the STALL button before performing each stall. When you push the STALL button, a 45second timer starts. Notice the “T” next to the time that is counting down. During the 45 seconds

that the timer is counting down, you are expected to have completed the stall maneuver. If any