Page 1

EFIS-D10A

Installation Guide

This product is not approved for installation in type certificated aircraft

P/N 100341-000, Revision J

For use with firmware version 5.4

August, 2010

Copyright © 2003-2010 by Dynon Avionics, Inc.

Page 2

Page 3

Contact Information

Dynon Avionics, Inc.

19825 141

st

Place NE

Woodinville, WA 98072

Phone: (425) 402-0433 - 7:00 AM – 5:00 PM (Pacific Time) Monday - Friday

Fax: (425) 984-1751

Dynon Avionics offers online sales, extensive support, and continually-updated information on its products via its

Internet sites:

www.dynonavionics.com/support

docs.dynonavionics.com

– Current and archival documentation.

downloads.dynonavionics.com

support.dynonavionics.com

store.dynonavionics.com

wiki.dynonavionics.com

– Dynon’s secure online store for purchasing all Dynon products 24 hours a day.

– Dynon Avionics’ Documentation Wiki provides enhanced, extended,

–Dynon Avionics primary web site; including:

– Software downloads.

– Support resources.

continuously-updated online documentation contributed by Dynon employees and customers.

forum.dynonavionics.com

– Dynon Avionics’ Internet forum where Dynon customers can interact and

receive Dynon technical support outside of telephone support hours. A key feature of the forum is that it

allows the exchange of diagrams, photos, and other types of files.

newsletter.dynonavionics.com

blog.dynonavionics.com

– Dynon’s email newsletter.

– Dynon’s blog where you can find new and interesting Dynon-related content.

Copyright

2003-2010 Dynon Avionics, Inc. All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated or stored in

any storage medium, for any purpose without the express written permission of Dynon Avionics. Dynon Avionics hereby grants permission to

download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed for

personal use, provided that such electronic or printed copy of this manual or revision must contain the complete text of this copyright notice and

provided further that any unauthorized commercial distribution of this manual or any revision hereto is strictly prohibited.

Information in this document is subject to change without notice. Dynon Avionics reserves the right to change or improve its products and to

make changes in the content without obligation to notify any person or organization of such changes. Visit the Dynon Avionics website

(www.dynonavionics.com

products.

) for current updates and supplemental information concerning the use and operation of this and other Dynon Avionics

Limited Warranty

Dynon Avionics warrants this product to be free from defects in materials and workmanship for three years from date of shipment. Dynon

Avionics will, at its sole option, repair or replace any components that fail in normal use. Such repairs or replacement will be made at no charge

to the customer for parts or labor. The customer is, however, responsible for any transportation cost. This warranty does not cover failures due to

abuse, misuse, accident, improper installation or unauthorized alteration or repairs.

THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE, AND IN LIEU OF ALL OTHER WARRANTIES

EXPRES

SED OR IMPLIED, INCLUDING ANY LIABILITY ARISING UNDER WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, STATUTORY OR OTHERWISE. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, WHICH

MAY VARY FROM STATE TO STATE.

IN NO EVENT SHALL DYNON AVIONICS BE LIABLE FOR ANY INCIDENTAL, SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMA

GES, WHETHER RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THIS PRODUCT OR FROM DEFECTS IN

THE PRODUCT. SOME STATES DO NOT ALLOW THE EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

Dynon Avionics retains the exclusive right to repair or replace the instrument or firmware or offer a full refund of the purchase price at its sole

discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

T

hese instruments are not intended for use in type certificated aircraft at this time. Dynon Avionics makes no claim as to the suitability of its

products in connection with FAR 91.205.

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for replacing the optional internal backup battery in

EFIS-based products per the installation guide, our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon Avionics unit is opened up, it will require calibration

and verification at our Woodinville, WA offices before it can be considered airworthy.

Page 4

Page 5

Table of Contents

Contact Information......................................................................................................................................................iii

Copyright......................................................................................................................................................................iii

Limited Warranty .........................................................................................................................................................iii

1. 1-1 Introduction

OEM Installations...................................................................................................................................................... 1-1

Warning ..................................................................................................................................................................... 1-1

About this Guide........................................................................................................................................................ 1-2

Menu Descriptions..................................................................................................................................................... 1-2

2. 2-1 Wiring Overview

Recommended Wiring Practices................................................................................................................................2-1

Power Requirements.................................................................................................................................................. 2-1

25-Pin Female EFIS Harness..................................................................................................................................... 2-2

3. 3-1 Instrument Installation

Selecting a Remote Compass Module Location ........................................................................................................ 3-1

EDC-D10A Communication Cable ........................................................................................................................... 3-2

Power Inputs.............................................................................................................................................................. 3-3

Serial Communication Cable..................................................................................................................................... 3-4

SL30 and/or GPS connection..................................................................................................................................... 3-5

Altitude Encoder Wiring ........................................................................................................................................... 3-8

Audio Alert Output...................................................................................................................................................3-10

Dynon Smart Avionics Bus (DSAB) Wiring............................................................................................................3-11

Panel Location and Mounting...................................................................................................................................3-12

Connecting Static & Pitot Lines ...............................................................................................................................3-14

4. 4-1 EFIS Calibration and Configuration

Ensuring Proper Installation ...................................................................................................................................... 4-1

Setting Zero Pitch (In flight)...................................................................................................................................... 4-1

Compass Heading Calibration ................................................................................................................................... 4-1

Configure Airspeed Color Thresholds....................................................................................................................... 4-7

5. 5-1 DSAB Configuration

Network Concepts ..................................................................................................................................................... 5-1

Example Networks .................................................................................................................................................... 5-2

Initial Setup ............................................................................................................................................................... 5-4

Network Status .......................................................................................................................................................... 5-5

6. 6-1 Autopilot Installation and Configuration

Additional Information and Updates ......................................................................................................................... 6-1

DSAB Firmware Compatibility................................................................................................................................. 6-2

Compass Calibration Critical For Certain AP Modes................................................................................................ 6-2

Autopilot System Electrical Installation .................................................................................................................... 6-3

Servo Mechanical Installation ................................................................................................................................... 6-6

AP74 Mechanical Installation...................................................................................................................................6-11

Firmware Upgrades Required For AP Functionality ................................................................................................6-13

AP Servo Configuration ...........................................................................................................................................6-14

AP74 Configuration..................................................................................................................................................6-30

7. 7-1 Appendix

Appendix A: Ongoing Maintenance and Troubleshooting........................................................................................ 7-1

Appendix B: Dynon OAT Probe Installation and Usage........................................................................................... 7-7

EFIS-D10A Installation Guide v

Page 6

Table of Contents

Appendix C: HS34 Installation and Configuration...................................................................................................7-10

Appendix D: Dynon AOA/Pitot Installation and Calibration ...................................................................................7-24

Appendix E: Encoder Serial-to-Gray Code Converter Installation...........................................................................7-32

Appendix F: Replacing the EFIS-D10A battery pack ..............................................................................................7-35

Appendix G: Weights...............................................................................................................................................7-36

Appendix H: EFIS-D10A Specifications..................................................................................................................7-36

vi EFIS-D10A Installation Guide

Page 7

1. INTRODUCTION

This manual provides information about the physical, electrical, and plumbing installation of the

EFIS-D10A, EDC-D10A and optional AOA pitot probe purchased from Dynon Avionics.

Additionally, this guide deals with setting up the installation-dependant firmware options.

Because you may not have purchased all the components, you need only read through the

relevant sections of this guide. Information about the operation of this instrument can be found

in the EFIS-D10A Pilot’s User Guide.

The EFIS-D10A uses solid-state sensor technology to give an accurate and easy-to-understand

display. To ensure accuracy in its readings, it is very important that you install the instrument

correctly and perform the specified calibration steps. This installation guide will help you

through that process.

OEM Installations

If your EFIS-D10A is installed by an OEM distributor, you may find that you are unable to

access some menus and settings. Some Dynon distributors customize various areas of the EFISD10A firmware to maintain a consistent pilot experience and minimize integration issues across

a large number of installations. Currently, OEMs can customize access levels to the following

settings on Dynon systems: EMS GLOBAL setup menu, EMS SENSOR setup menu, fuel

calibration, trim calibration, flaps calibration, GPS/NAV setup menu, screen configurations, data

logging, and checklists/data panels. OEM distributors have the option of customizing some or all

of these areas. Please contact your aircraft’s manufacturer if you have any questions about how

your unit has been customized.

Warning

Dynon Avionics’ products incorporate a variety of precise, calibrated electronics. Except for

replacing the optional internal backup battery in EFIS-based products per the installation guide,

our products do not contain any field/user-serviceable parts. Units that have been found to have

been taken apart may not be eligible for repair under warranty. Additionally, once a Dynon

Avionics unit is opened up, it will require calibration and verification at our Woodinville, WA

offices before it can be considered airworthy.

EFIS-D10A Installation Guide 1-1

Page 8

Introduction

About this Guide

In the electronic (.PDF) version of this manual, page and section references in the Table of

Contents and elsewhere act as hyperlinks taking you to the relevant location in the manual. The

latest version of this manual is available on the Dynon Avionics website at

docs.dynonavionics.com.

The following icons are used in this guide:

Any text following this icon describes functionality available only with the HS34 HSI

Expansion Module connected to your system.

Any text following this icon describes functionality available only with the AP74

Autopilot Interface Module connected to your system.

Any text following this icon describes functionality that is possible when multiple Dynon

Avionics products are networked together via the Dynon Smart Avionics Bus (DSAB).

Any text following this icon refers to a setting or situation which merits particularly close

attention.

Menu Descriptions

Throughout this guide, the “>“ character is used to indicate entering a deeper level of the menu

system. For example, “EFIS > SETUP > VRSION” indicates entering the EFIS menu, pressing

MORE, then pressing SETUP, and then pressing VRSION to enter the firmware version menu.

Note that the MORE button is not shown in the sequence, since pressing MORE reveals more

options in the same level of the menu system.

1-2 EFIS-D10A Installation Guide

Page 9

2. WIRING OVERVIEW

Please follow these instructions explicitly as improper wiring can result in permanent damage to

your instrument and/or the accompanying sensors.

All electrical power and EFIS-specific lines interface with the EFIS-D10A via the female 25-pin

D-sub connector on the back of the instrument. Ensure that the unit powers on and that all

indicators display expected values before completing the final physical assembly.

Recommended Wiring Practices

For all electrical connections, use correct wiring techniques, taking care to properly

insulate any exposed wire. A short circuit between any of the wires may cause damage to

the EFIS-D10A and/or your aircraft. Make all connections to your harness before

plugging it into any of the components of the system. Do not make connections while

power is applied at any point in the system.

Dynon Avionics sells a wiring harness for all connections to the EFIS-D10A. The harness is

made up of 22 AWG wire and meet Mil Standard MIL-W-22759/16 (Tefzel insulation). If you

have opted not to purchase this harness, please refer to the provided wiring diagrams for

construction information. We recommend that all wire you use also meets Mil Standard MIL-W22759/16; all wire supplied by Dynon Avionics (with the exception of thermocouple wire, which

uses FEP insulation) meets this specification.

When using any pre-manufactured harness, verify that each pin has continuity with the expected

wire on the wiring diagram. This test can be easily done with a multimeter. When verifying

harnesses, use the wiring charts and diagrams in this guide as your ultimate authority on pin

function (for any harness) and wire color (for harnesses purchased from Dynon Avionics).

Route all wiring such that there are no spots where it could chafe or break. Use appropriate strain

relief at all junctions between wires and connectors. We recommend that you secure all wires at

regular intervals along wiring runs to accommodate vibration effects.

All connections on the EFIS female 25-pin harness are described in the Instrument Installation

section on page 3-1.

Power Requirements

22 AWG wire is normally sufficient for the power supply and ground lines, but we recommend

that you consult a wire sizing chart and determine the size required for the wire routing in your

particular aircraft. Ensure that the power lines include a circuit breaker or an appropriately sized

fuse for the wire you select. Power is fed to the EFIS-D10A via pins in the female D-25

connector as shown on the 25-Pin Female EFIS Harness diagram on page 2-2.

The EFIS-D10A system-wide power requirement is 8 watts typical and 13 watts maximum. On

a 12-volt system, this translates to about 1 amp of maximum current draw. On a 24-volt system,

this translates to about 0.5 amp maximum current draw. Normally, a 2-amp circuit breaker or

fuse is sufficient.

EFIS-D10A Installation Guide 2-1

Page 10

Wiring Overview

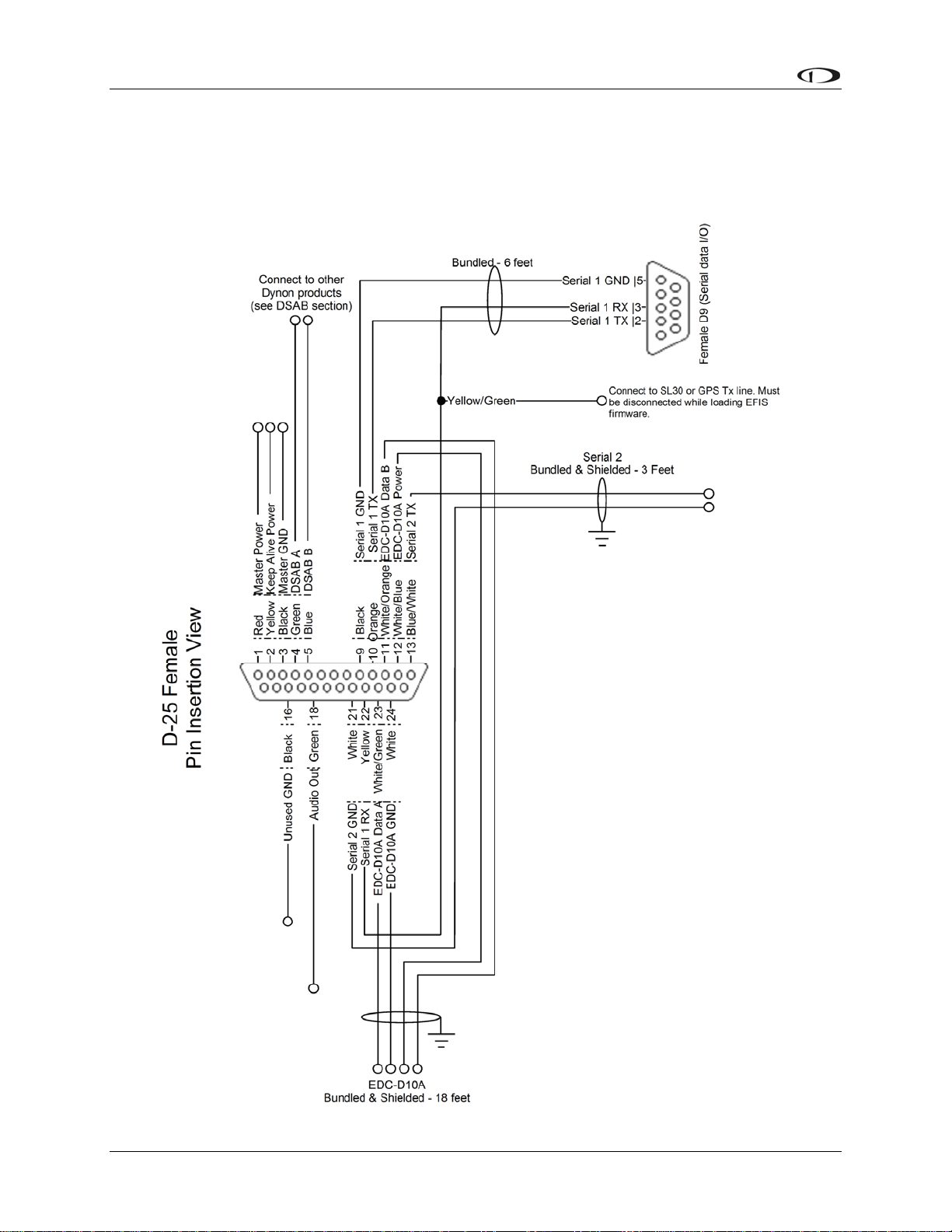

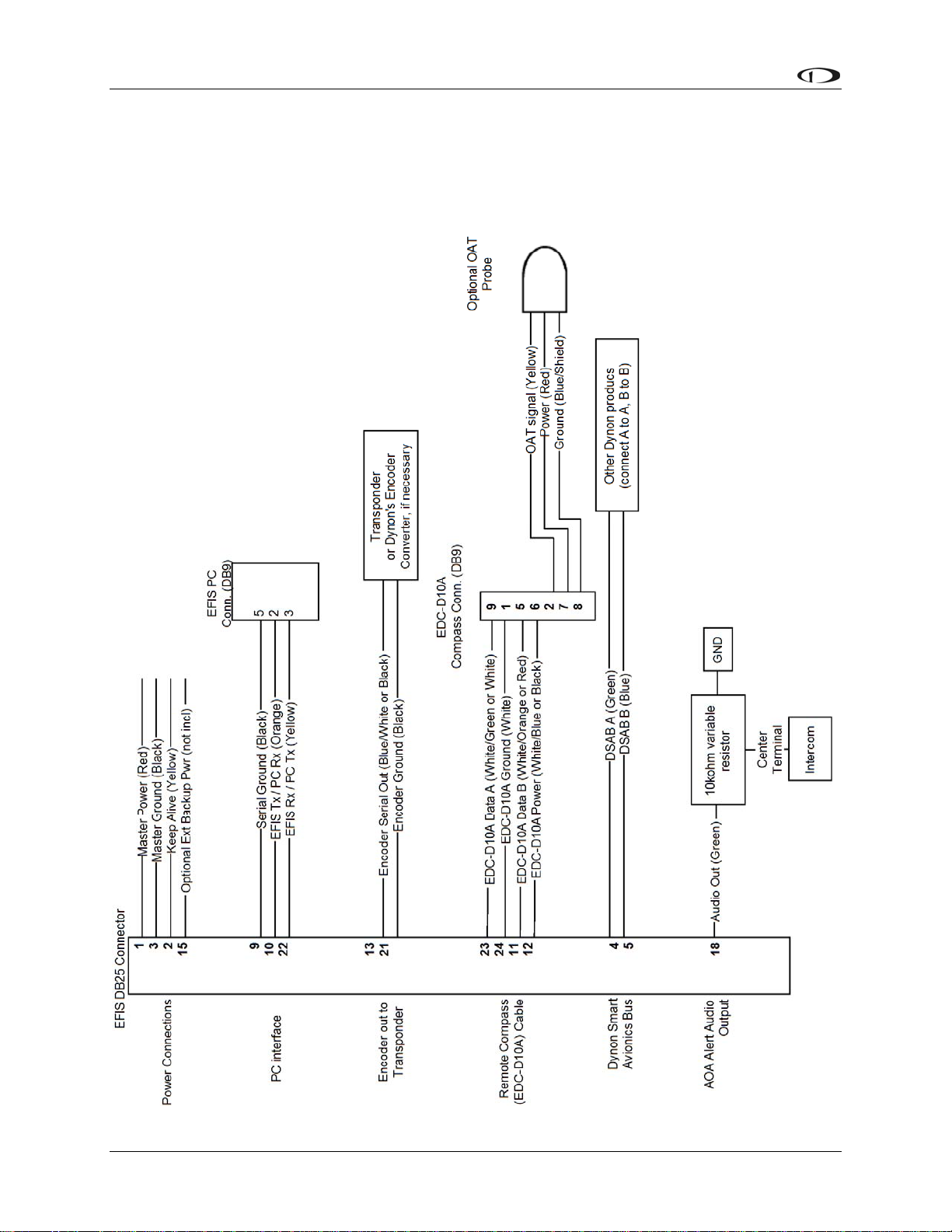

25-Pin Female EFIS Harness

Below is the wiring diagram of the EFIS 25-pin female harness. If you purchased your harness

from Dynon Avionics, it is color coded according to the chart on the following page. Unless

noted otherwise, all wires are 3 feet long on the Dynon-provided harness.

2-2 EFIS-D10A Installation Guide

Page 11

Wiring Overview

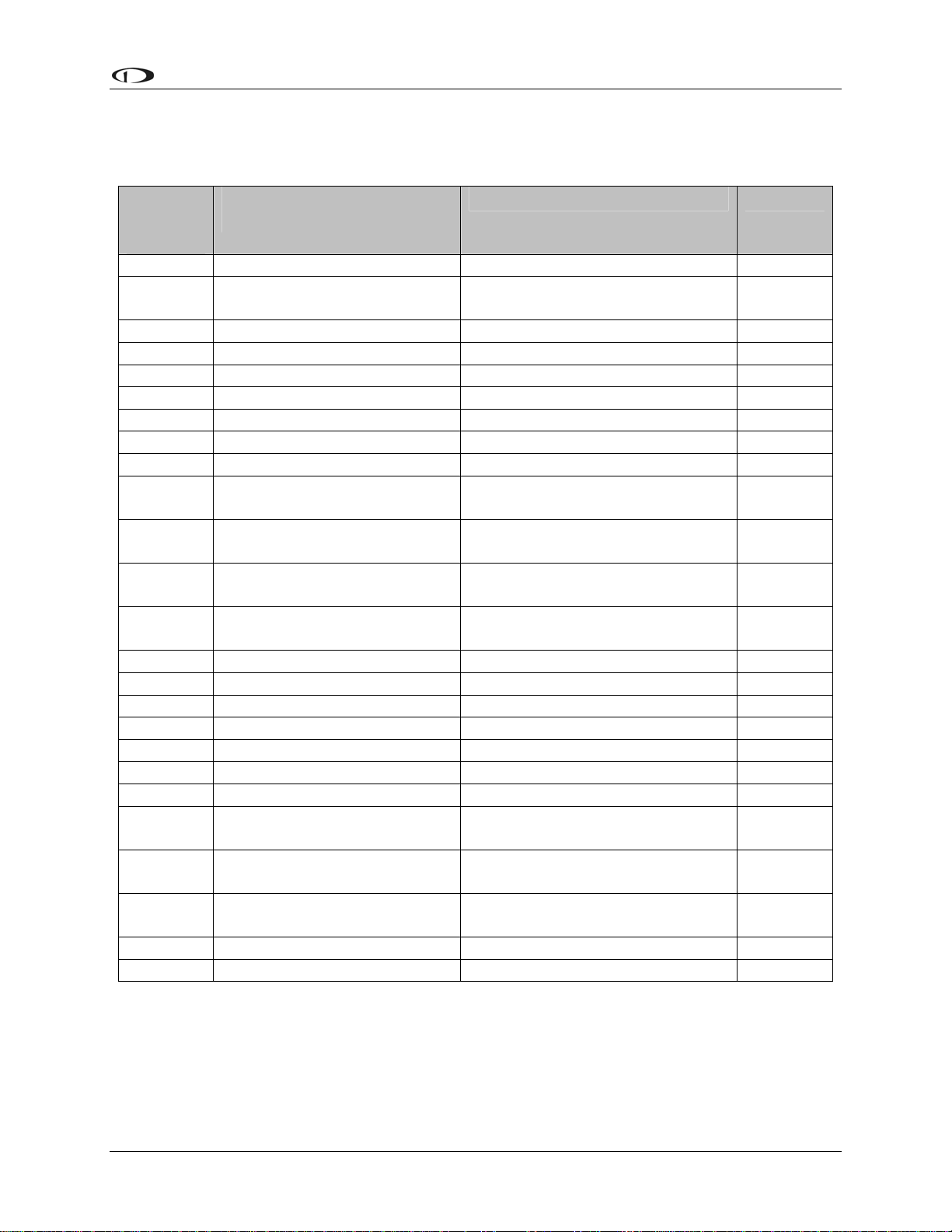

The pin assignments for the female 25-pin harness are repeated below. Note that the pin numbers

are labeled on the face of both the female and male connector. Each connection on the harness

supplied by Dynon is color-coded. These colors are listed in the following chart.

Female

DB25

Pin #

1 Red Master Power (10-30 volts) Page 3-3

2 Yellow

3 Black Master Ground Page 3-3

4 Green DSAB-A Page 3-11

5 Blue DSAB-B Page 3-11

6 N/A No Connect

7 N/A No Connect

8 N/A No Connect

9 Black (bundled) PC Serial Ground Page 3-4

10 Orange (bundled)

11

12

13

14 N/A No Connect

15 N/A External Backup Power Page 3-3

16 Black Ground

17 N/A No Connect

18 Green Audio out Page 3-10

19 N/A No Connect

20 N/A No Connect

21

22 Yellow (Bundled)

23

24 White EDC-D10A GND Page 3-1

25 N/A No Connect

Dynon Harness Wire

Color

White/Orange (Red on some

harnesses)

White/Blue (Black on some

harnesses)

Blue/White (black on some

harnesses)

White (Bundled in Encoder

cable)

White/Green (Green on some

harnesses)

Function Details

Keep Alive Power (10-30 volts,

always on)

EFIS-D10A Transmit / PC Serial

Receive (RS-232)

EDC-D10A Data B

EDC-D10A Power (12V)

Serial Encoder Transmit (RS-232)

Serial Encoder Ground

EFIS-D10A Receive / PC Serial

Transmit (RS-232)

EDC-D10A Data A

Page 3-3

Page 3-4

Page 3-1

Page 3-1

Page 7-32

Page 7-32

Page 3-4

Page 3-1

EFIS-D10A Installation Guide 2-3

Page 12

Wiring Overview

WIRING SYSTEM OVERVIEW

The following block diagram depicts the basic layout of the EFIS DB25 electrical connections

and is for reference only. Read the specific instructions for each connection prior to installation.

The colors shown refer to the Dynon-supplied EFIS harness.

2-4 EFIS-D10A Installation Guide

Page 13

3. INSTRUMENT INSTALLATION

This section provides you with the information needed to physically and electrically install the

EFIS-D10A.

Selecting a Remote Compass Module Location

Finding a good location for the EDC-D10A

remote compass module is critical to an

accurate EFIS-D10A heading display. Keep

in mind that calibration can compensate for

small static magnetic fields superimposed

upon the earth’s field; it cannot take

into account dynamic effects like

AC currents, non-constant DC

currents and non-stationary ferrous

material (e.g., an electric turn

coordinator). Use the following

suggestions to help you find a good

location for your EDC-D10A.

Keep the EDC-D10A away

from any source of magnetic fields (such

as electrical equipment and currentcarrying wires) and ferrous material.

Move a handheld compass throughout the

space surrounding your location to get a

rough idea of the suitability of your

chosen location. If the needle deviates

significantly from magnetic north in any

given area, that location would not be

ideal for the EDC-D10A.

The EDC-D10A can be mo unted

anywhere in the aircraft (away from

magnetic interference) such that its pitch

is as close to that of the EFIS-D10A as

possible. It does not need to be

directly along any axis of the EFISD10A. It should be mounted with the

long axis parallel to the wings, the

electrical connector facing toward the

front of the plane, and the mounting

tabs on the bottom. The bracket used

to hold the EDC-D10A must hold th

EDC-D10A at the same pitch, roll,

and yaw as the EFIS-D10A with

EFIS-D10A Installation Guide 3-1

e

Side view of EDC-D10A, tabs mounted

down and aligned within 1 degree of pitch

Connector forward and

tabs mounted down

with EFIS-D10A

Connector toward

direction of flight

Page 14

Instrument Installation

respect to the airframe. We recommend that you use an electronic level, if available, t

make sure the EDC-D10A is alignedo with the EFIS-D10A to better than 1 degree.

All mounting hardware needs to be made from non-ferrous material such as aluminum,

plastic, or brass. Many stainless steel screws are magnetic. If the item is attracted to a

magnet, it should not be used in the installation. The EDC-D10A needs to be mounted in

a location as free from magnetic interference as possible. This means keeping the EDCD10A away from any ferrous nuts, bolts, and screws, aircraft tubing, as well as from

wires or devices carrying any appreciable current such as strobe light wiring, autopilot

servos, or other electronics.

EDC-D10A Communication Cable

DO NOT ATTEMPT TO POWER UP THE EFIS-D10A WITH THE EDC CABLE

LEADS EXPOSED (UNSHEATHED) AND NOT INSTALLED IN THE DB9

CONNECTOR. SHORTING THESE CONNECTIONS WILL CAUSE DAMAGE TO

THE UNIT.

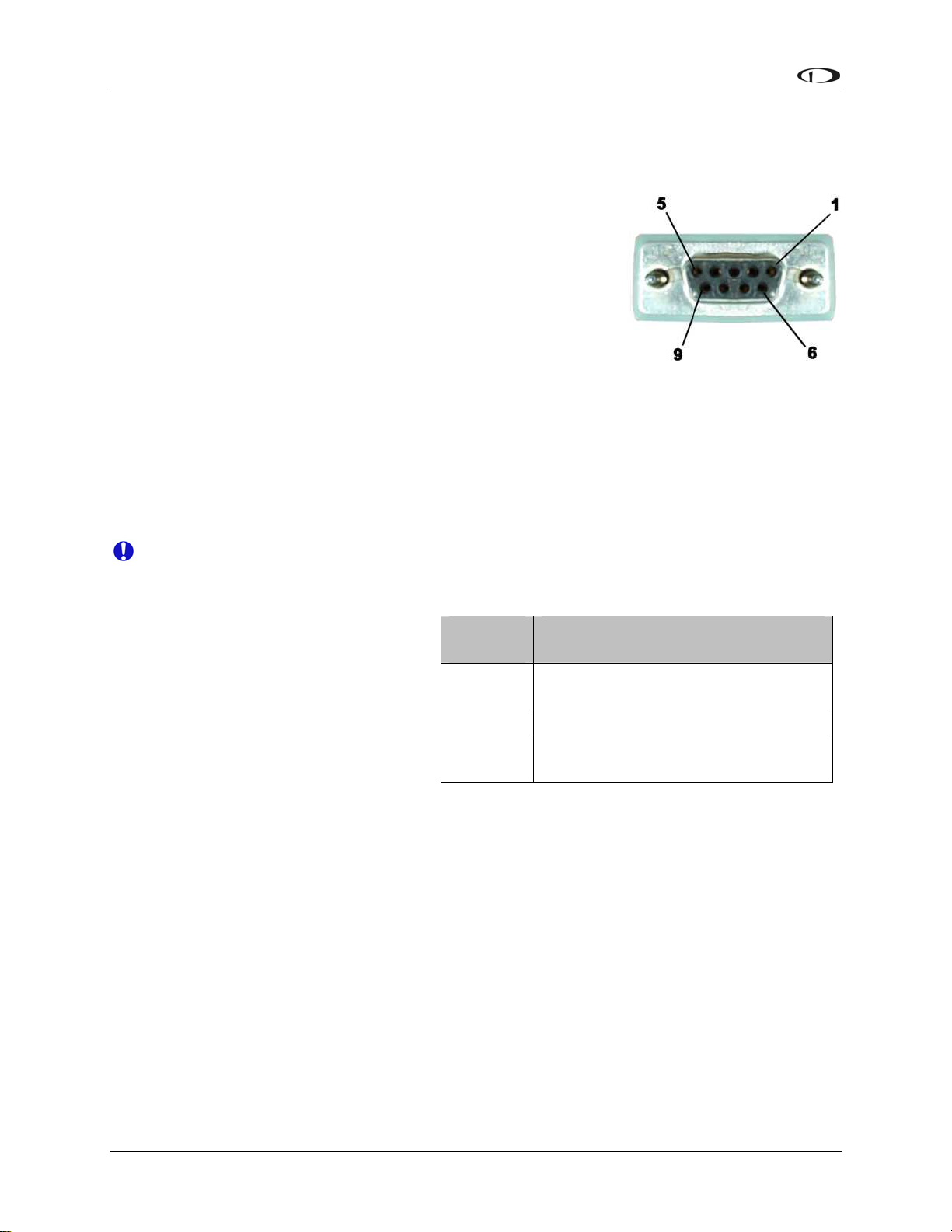

Like the RS-232 PC Communication cable, the EDC-D10A communications cable terminates in

a standard female DB9 connector. While they look similar, do not plug the EDC cable into a PC

or vice versa. The following table outlines the four connections that must be made to ensure

proper communication between the EFIS-D10A and the EDC-D10A remote compass module.

The Dynon-supplied harness colors are listed, as well.

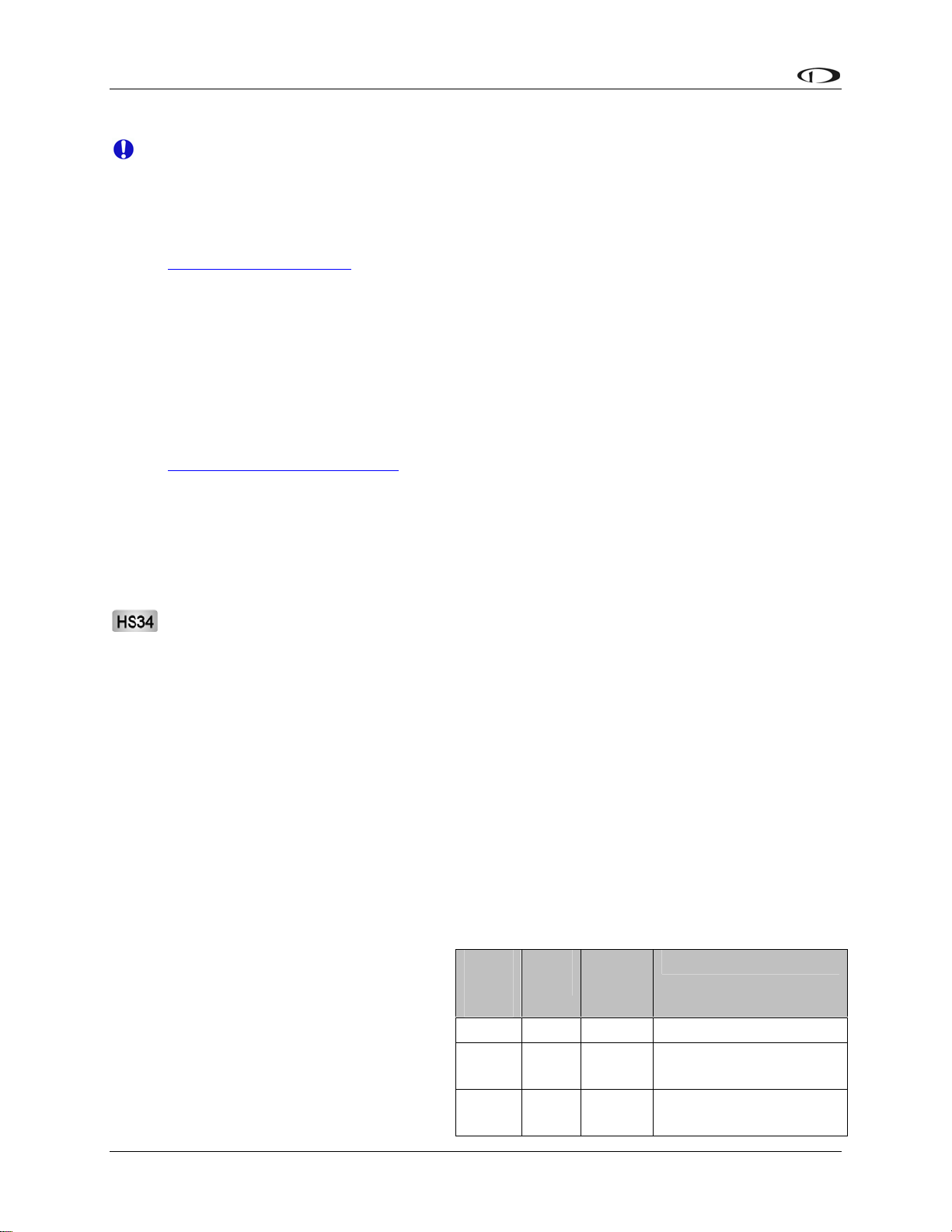

EFIS

DB25 pin#

11 5 EDC Data B White/Orange (or Red)

12 6 EDC Power White/Blue (or Black)

23 9 EDC Data A White/Green (or Green)

24 1 EDC Ground White

The EDC cable in the harness supplied by Dynon consists of 4 conductors, surrounded by a

metal shield and white insulation. These 4 wires are terminated with crimped female D-sub pins

wrapped in plastic tubing. If you are building your own cable, we recommend that you use

shielded cable as well.

With the 25-pin EFIS harness disconnected from the EFIS-D10A, carefully cut or pull the

tubing off the 4 D-sub pins.

Route the cable to the EDC-D10A mounting location chosen according to the instructions

above.

Install the female pins in the correct holes on the included DB9 connector, according to

the chart above. Note that Dynon has shipped harnesses with different colors for the

EDC cable; determine your connections using the two sets of colors in the table above.

Install the back shell around the DB9 connector.

Correct wiring installation can be easily verified once completed. Power on the EFIS-D10A with

the EDC-D10A connected to it. Observe the displayed heading and then hold one of the

earpieces of a headset near the front of the EFIS-D10A. If the EDC-D10A is correctly wired, you

should see no change in the displayed heading when the headset earpiece and its magnetic

EDC

DB9 pin# Function Wire color

3-2 EFIS-D10A Installation Guide

Page 15

Instrument Installation

speaker is near the EFIS-D10A. If you see a substantial change in heading, there is a

communication problem between the EFIS-D10A and the EDC-D10A.

The metal shield around the EDC communication cable is connected to the short black/white

wire emanating from the DB25. Connect this wire to ground close to the EFIS-D10A, ideally the

panel.

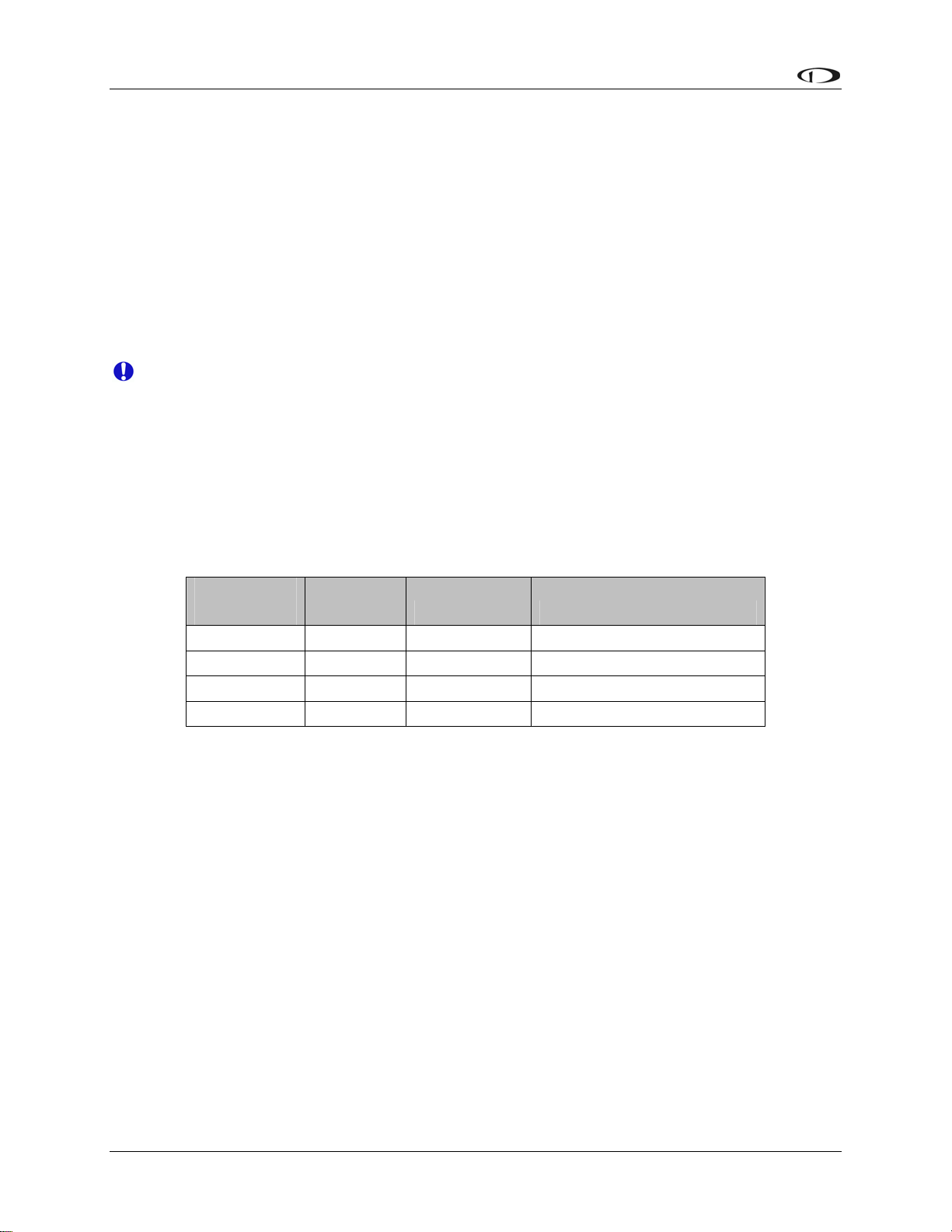

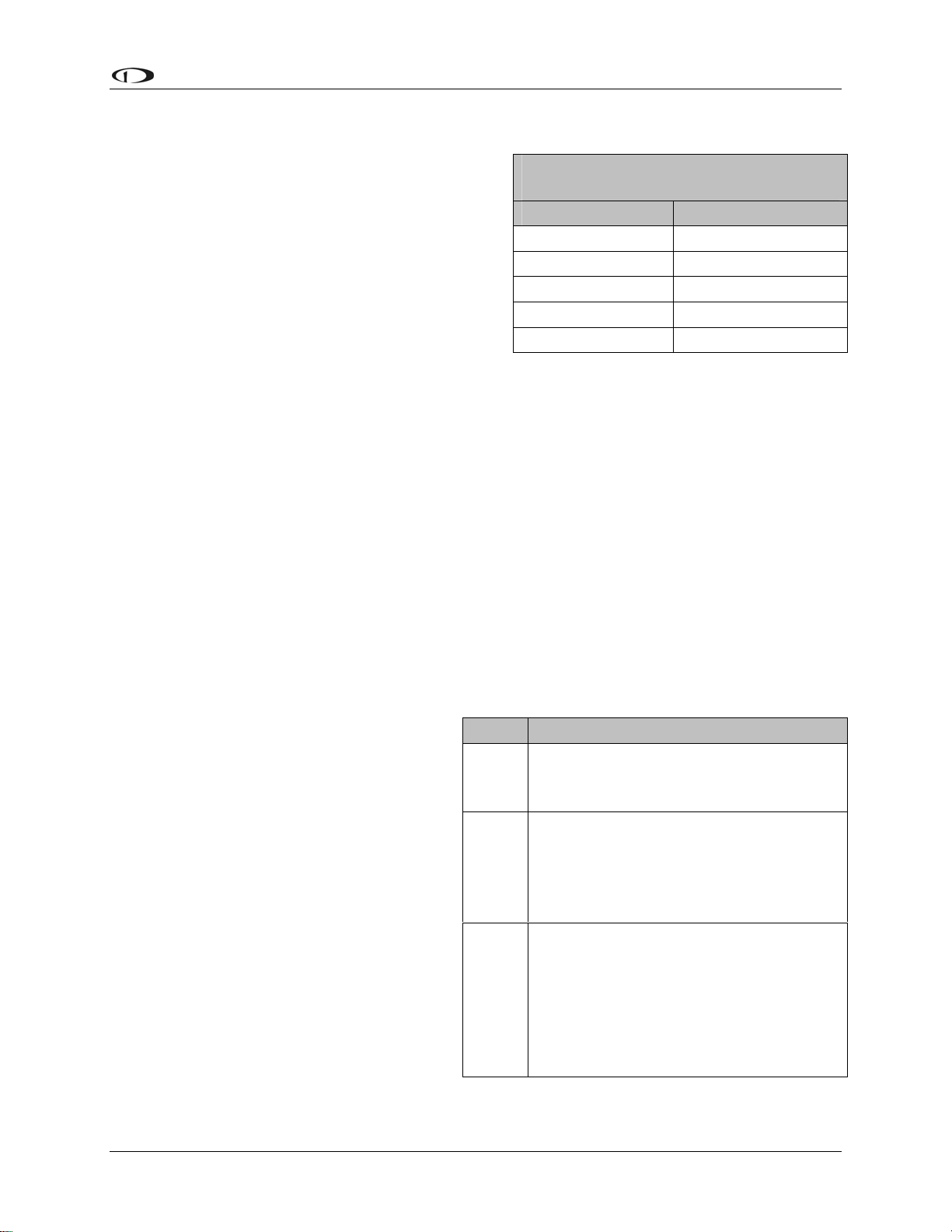

Power Inputs

The EFIS-D10A has three separate power inputs, located on the DB25 EFIS connector. Of the

three, only Master Power is required to operate the instrument. The other two inputs provide

redundancy. Below is a table that explains the three inputs and their purposes. All three of these

inputs share a common ground signal, wired to pin 3 on the EFIS connector.

EFIS

DB25

pin#

1 Master

2 Keep Alive

3 Master

15 External

Function EFIS DB25

Power

Power

Ground

Backup

Power

Description

wire color

Red Provides primary power to the instrument. The

EFIS-D10A will switch on upon application of

power. Connect to a switched power source. Will

not be adversely affected by engine cranking.

Yellow A very low current power input which is only

used if both Master and External Backup Power

are not applied. Keep Alive draws just enough

current to keep the clock running. It draws less

than 1 milliamp of current when not charging the

internal backup battery.

Dynon Avionics recommends not connecting the

Keep Alive wire when the EFIS-D10A has an

internal battery installed or is connected to a GPS.

Keep Alive is only used in installations with no

battery or GPS to keep the clock running when

the unit is powered off.

Black Connect to ground. Must carry as much as 2

amps.

(Not wired in

Dynon

harness)

Will operate the EFIS-D10A only if Master

Power is not present. The transition from Master

Power to External Backup Power will bring up a

warning, requiring you to press ACK within 30

seconds to keep the unit operating. This warning

will also display when transitioning from either

Master or External Backup to Internal Battery

power.

EFIS-D10A Installation Guide 3-3

Page 16

Instrument Installation

Serial Communication Cable

More Information Is Available Online: Serial communication to non-Dynon devices,

and interfacing of other devices in general can be involved and detailed. This Installation

Guide is intended to provide general installation advice for the most common devices and

situations. Dynon’s Documentation Wiki provides enhanced, extended, frequently

updated online documentation contributed by Dynon employees and customers at

wiki.dynonavionics.com.

The EFIS-D10A has one RS-232 serial port that can be used for several purposes. This serial

port can only be configured for one purpose at a time.

The EFIS Serial port (DB25) is used for:

Connecting to a PC, and using the Dynon Avionics Product Support Program to perform

firmware upgrades, configure checklists, and download internal logs. The Help Files of

the Support Program provide detailed instructions on these functions. The latest version

of the Product Support Program is available on the Dynon web site at

downloads.dynonavionics.com.

Connecting serial devices such as a GPS receiver or an SL30.

“Streaming” real-time EFIS flight data to an external serial device for recording. For data

formats and other information, see the Appendix in the EFIS-D10A Pilot’s User Guide.

Note that for the purposes of logging data, version 5.0 of EFIS-D10A firmware added

internal data logging and retrieval via the Dynon Product Support Program.

When an optional HS34 Expansion Module is connected to your Dynon DSAB network,

all GPS and NAV radios must be connected to it. This simplifies the connection and

usage of multiple serial devices. The HS34 also provides interfaces to non-serial devices

such as those with only analog and ARINC-429 interfaces.

PC USB CONNECTION

If you do not have a serial port on your PC, you may use a USB-to-Serial adapter to connect the

EFIS-D10A to your PC’s USB port. You may purchase an adapter from us, Radio Shack, or

many computer stores. If you are using Windows 2000 or XP, ensure that the adapter driver CD

is inserted in your PC before plugging the adapter into the USB port for the first time. If you are

using Windows Vista, ensure that you are connected to the Internet and do not use the driver

CD; the operating system will download the correct driver. Also, do not have your EFIS-D10A

plugged into the USB-to-Serial adapter while installing the driver.

EFIS SERIAL HARNESS

On the EFIS 25-pin wiring harness

available from Dynon, there are three

wires bundled together, terminating in a

standard DB9-pin female connector. This

cable is 6’ long and pre-assembled for

connection to a PC-based laptop. Route

this cable to a convenient location that can

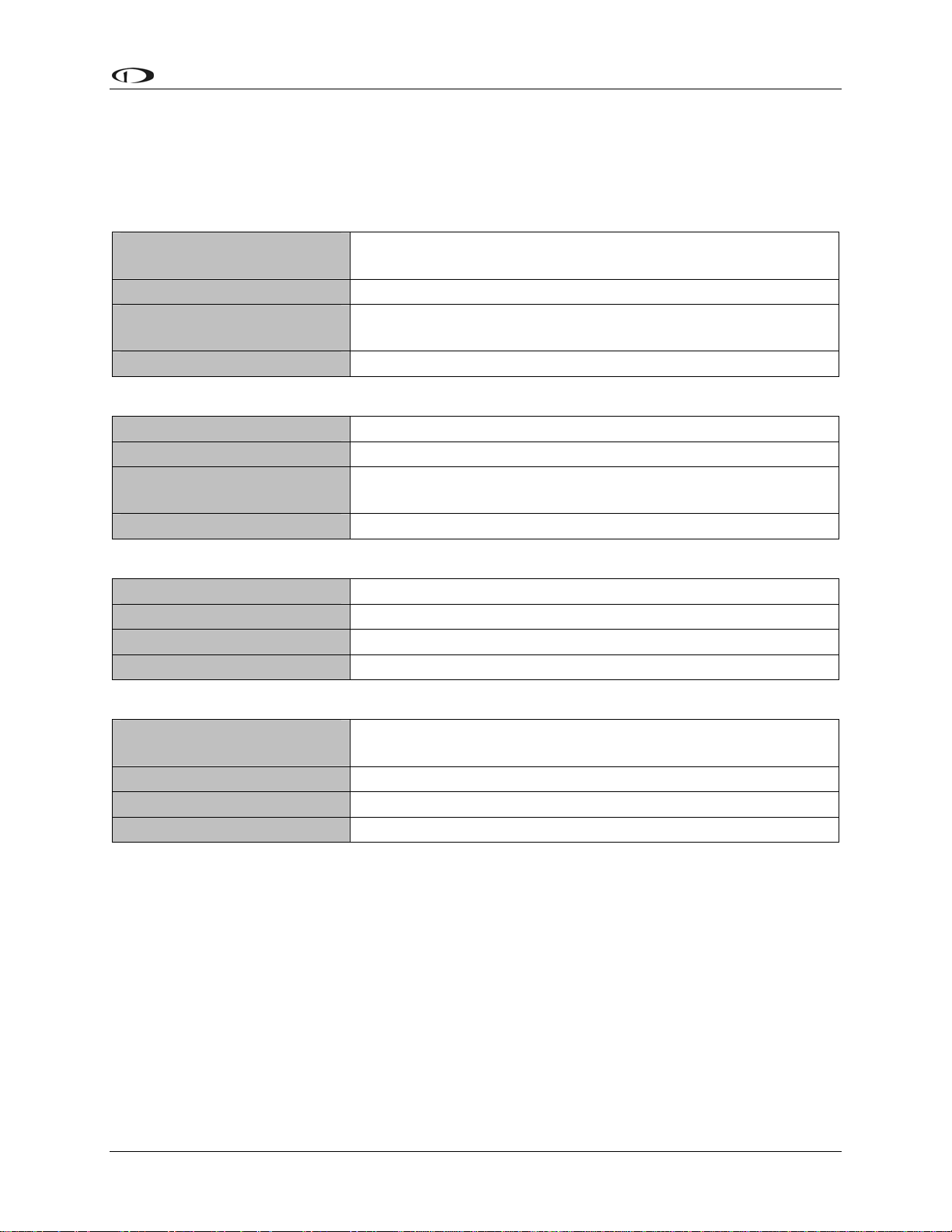

EFIS

DB25

Pin#

9 5 Black Signal ground

10 2 Orange EFIS-D10A transmit /

22 3 Yellow EFIS-D10A receive /

DB9

Pin#

Wire

Color

RS-232 Function

device receive

device transmit

3-4 EFIS-D10A Installation Guide

Page 17

Instrument Installation

be accessed whenever you need to update your product’s firmware or checklists.

If you did not purchase a harness from Dynon, obtain a 9-pin D-sub connector and make the

three connections shown in the table.

To verify proper communication between the EFIS-D10A and the PC, use the Dynon Avionics

Product Support Program’s “Detect Firmware Version” function. Download the latest version of

the Support Program from the Dynon Web Site at download.dynonavionics.com.

SL30 and/or GPS connection

Depending on the number and types of Dynon units you own,

you have several options for connecting a GPS unit and/or

Garmin/Apollo SL30 to your Dynon system. The GPS can be

used as a data source for the EFIS, HSI, and Fuel pages, as

well as Dynon’s EFIS-based Autopilot. The SL30 can be

used as a VOR, localizer, or ILS (localizer + glideslope)

source for the HSI. If you wish to connect a GPS and/or

SL30 to your Dynon system, read the section below which

corresponds to your set of Dynon products.

If your system has an HS34, it is required that all

GPS and NAV devices are connected to the HS34.

The EFIS-D10A does not support directly connected

GPS and NAV devices when an HS34 is installed in

the system. Refer to the HS34 Installation and

Configuration section on page 7-10 for device

connection details.

To use the GPS-related features on your EFIS and/or EMS,

your GPS must output either “aviation format” or the

following NMEA sentences in its serial stream: $GPRMC,

$GPRMB, $GPGGA, and one of $GPBOD or

$GPAPB. You must also have a supported cable

that exposes your GPS’s serial transmit line. If

you own a Garmin 430 or 530, in the

UNITS/MAGVAR option, set the MAGVAR to

AUTO. The EFIS-D10A auto-detects most

GPSs, but may require a manual setting for

some. This is true for communication with at

least the Garmin 480 and maybe others such as

the GX50, and GX60, and Bendix/King Skymap

IIIc. From the EFIS menu, enter SETUP >HSI

>EFIS_SERIAL; from the EMS menu enter

SETUP >GLOBAL >EMS SERIAL. In that

menu select the INPUT to be AVIATION and

the BAUD RATE to be 9600.

GPS units with limited functionality

AnywhereMap Does not output all needed

Garmin

(Apollo) GNS

480

A frequently updated list of compatible GPS

units and settings is available at our

GPS units known to work

AvMap EKP-IV (v2.06.116R,

NMEA set to “processed”)

Bendix/King Skymap (set to

AR NAV 9600 output)

Garmin

96, 96c, 150XL, 195, 196, 295,

296, 396, 400*, 420*, 430*,

430W*, 496, 500*, 520*,

530*, 530W*, GX60, GX65

Lowrance handhelds

* Do not output time over

serial; ARINC connection via

HS34 required to receive time.

A frequently updated list of

compatible GPS units and

settings is available at our

Documentation Wiki at

wiki.dynonavionics.com.

sentences. Time output is

wrong.

Possibly works with latest

Dynon product firmware,

but untested. Requires

manual configuration. See

note at left. Fully

compatible via ARINC

into optional HS34.

Documentation Wiki at

wiki.dynonavionics.com.

EFIS-D10A Installation Guide 3-5

Page 18

Instrument Installation

The following connection schemes assume that the external devices share a common ground

with the Dynon product(s). If your GPS is battery powered, and not normally connected to

aircraft ground, you must connect the ground pin on its serial output to a ground common to the

EFIS-D10A.

When a Dynon product is connected to a GPS, it will synchronize its Zulu clock to the time

reported by the GPS. However, some GPSs, such as the Garmin 430 and 530, do not report time

in their serial output stream. Dynon products have no way to synchronize to these GPSs’ clocks.

Read the section below that corresponds to your configuration of Dynon products. All EFISbased product configurations direct you to connect your external device to PC serial receive (pin

22) on your Dynon EFIS product. You may make this connection at any point between pin 22 on

the EFIS DB25 and pin 3 on the connected DB9 EFIS/PC connector. If you purchased your

harness from Dynon Avionics, it may have a yellow/green wire provided for this purpose.

IF YOU OWN ONLY AN EFIS-D10A OR EFIS-D100

Connect the GPS or SL30 transmit line into pin 22 on the DB25 connector. This is the same

Serial Rx line that is used for firmware updates. You will need a way to disconnect this when

you plug your EFIS into a PC for firmware updates and checklists.

If you have both a GPS unit and an SL30, you will need to wire the two transmit lines to a 3-way

switch; connect the output of the switch into pin 22 on the EFIS harness. You will use this switch

to toggle between GPS, SL30 and a disconnected state. The HSI auto-detects the switched

instrument and will change modes automatically.

IF YOU OWN TWO EFIS-ONLY UNITS

When 2 EFIS-only units are connected via DSAB, only the DSAB Bus Master’s serial port is

active.

If you have only one serial device (GPS or SL30), connect its transmit line to pin 22 on the

DB25 connector of the EFIS that you have chosen to be the Bus Master. This is the same Serial

Rx line that is used for firmware updates. You will need a way to disconnect this when you plug

your EFIS into a PC for firmware updates and checklists.

If you have both a GPS unit and an SL30, you have two options:

Wire the 2 devices’ transmit lines to a switch, allowing you to select the serial device active

on the HSI screen.

Do not connect the two EFIS units together via DSAB. You may then wire one device to one

EFIS’ pin 22, and the other device to the other EFIS. Of course, the EFIS devices would be

independent and unable to share GPS or SL30 data.

You will need a way to disconnect both lines when you plug your EFIS into a PC for firmware

updates and checklists.

IF YOU OWN ONLY AN EMS-D10 OR EMS-D120

We recommend that you only connect a GPS to an EMS-only system; without the magnetic

heading from an EFIS, the HSI page will not be functional. Connect the GPS transmit line to pin

19 on the EMS DB37 connector. This connection will give you fuel endurance information

3-6 EFIS-D10A Installation Guide

Page 19

Instrument Installation

(range, MPG, etc) on the fuel page and GPS information only (track, ground-speed, course, etc)

on the HSI page. There is no need to break this connection when doing PC updates.

IF YOU OWN AN EMS AND AN EFIS (NOT FLIGHTDEK-D180)

First, ensure that your EMS and EFIS are connected as described in Dynon Smart Avionics Bus

(DSAB) Wiring on page 3-11.

If you only have either the GPS or SL30 (but not both), connect the GPS or SL30 transm

it line to

pin 19 on the EMS DB37 connector. This is labeled “Aux Serial Receive.” With either a GPS or

an SL30 connected, you are able to display an HSI on either product; with a GPS connected, you

are able to display EMS fuel economy displays.

If you have a GPS and an SL30, connect the GPS to pin 19 on the EMS DB37 connector.

Connect the SL30 to pin 22 on the EFIS DB25 connector. This will allow you to flip between

GPS and SL30 inputs. You can use either the SL30 or GPS as the NAV source on the EFIS

product. You will need to disconnect the SL30 from the EFIS when doing software updates.

IF YOU OWN ONLY A FLIGHTDEK-D180

Connect the SL30 unit to pin 22 on the EFIS DB25 connector, and the GPS to pin 19 on the

EMS DB37 connector. You can display either source on the HSI using the softkeys. You will

need to disconnect the SL30 from the EFIS when doing software updates.

IF YOU OWN A FLIGHTDEK-D180 AND AN EFIS

Connect the SL30 unit to pin 22 on the FlightDEK’s EFIS connector (vertical DB25) and the

GPS to pin 19 on the EMS DB37 connector. You can display either source on the HSI, and you

can display either on the standalone EFIS as well (provided you have connected the DSAB A &

B lines from the FlightDEK-D180 to the standalone EFIS product). You will need to disconnect

the SL30 from the FlightDEK-D180 when doing software updates.

Do not connect any serial devices to the secondary EFIS device. It will only display data from

the serial devices connected to the master FlightDEK-D180.

EFIS-D10A Installation Guide 3-7

Page 20

Instrument Installation

Altitude Encoder Wiring

The EFIS-D10A outputs its altitude

measurements in one of four standard serial

outputs and is readable by many modern

transponders. The EFIS-D10A will function

properly whether or not this altitude encoder

functionality is used. To use the EFISD10A‘s altitude encoder functionality,

simply wire the 2 encoder connections

(GND and Encoder Transmit) from the

DB25 connector to their respective connections on

your transponder.

Per ATC/FAA requirements, the serial encoder output

of the EFIS-D10A reports pressure altitude, which, by

definition, is indicated altitude when the baro is set to

29.92. So, when you set your EFIS-D10A‘s baro

adjustment to 29.92, its indicated altitude will match

the altitude that is being reported to your transponder.

If your transponder requires parallel Gray

code input, and you wish to use the EFISD10A as your altitude encoder, you will need

to purchase Dynon Avionics’ Encoder Serialto-Parallel Converter. Please refer to page 732 for more information on the installation of

this option.

EFIS

DB25

pin# Function Wire color

Encoder

13

21 Ground White

serial

transmit

Blue/White

(or black)

There are four different serial formats used by

transponders. The EFIS-D10A can output any of these formats. To select which format the EFISD10A sends out its serial encoder output port, you must choose the appropriate format via the

menu system. When the menu system is displayed, enter the MORE > SETUP > MORE >

ALTENC. When in the Altitude Encoder Setup menu, you can toggle the resolution of the output

between 10 and 100 feet; this accommodates some transponders which can input and display

altitude in 10 foot increments. In this menu, you can also select between the four different output

formats, which are described below.

Dynon’s supplied EFIS harness has a serial altitude encoder cable which consists of 2

conductors, surrounded by a metal shield and white insulation. Dynon has shipped harnesses

with different colors for Encoder serial transmit line. Determine your connections using the table

at right. Connect the Encoder serial transmit to your transponder’s serial input or to Dynon’s

Serial-to-Parallel Converter as described in the Encoder Serial-to-Gray Code Converter

llation section on page 7-32 in the Appendix.

Insta

3-8 EFIS-D10A Installation Guide

Page 21

Instrument Installation

SERIAL ALTITUDE FORMATS

There are four formats used by serial transponders. Choose the correct format for your

transponder in the ALTENC menu, using the FRMAT button.

Format 1

Used By

Baud rate

Format

Example message

Format 2

Used By

Baud rate

Format

Example message

Format 3

Used By

Baud rate

Format

Example message

Dynon Encoder Serial-to-Parallel Converter, Garmin AT

(formerly UPS Aviation Technologies)

1200

#AL, space, +/-sign, five altitude bytes, T+25, checksum,

carriage return

#AL +05200T+25D7[CR]

Magellan

1200

$MGL, +/- sign, five altitude digits, T+25, checksum, carriage

return

$MGL+05200T+25E3[CR]

Northstar, Garmin

2400

ALT, space, five altitude bytes, carriage return

ALT 05200[CR]

Format 4

Used By

Baud rate

Format

Example message

Garmin GTX330 (set on Icarus input), Garmin GTX327 (set

on Icarus input), Garmin GTX328, Icarus, Trimble

9600

ALT, space, five altitude bytes, carriage return

ALT 05200[CR]

EFIS-D10A Installation Guide 3-9

Page 22

Instrument Installation

Audio Alert Output

The EFIS-D10A has an audio alert output for

sounding AOA and altitude alarms through

an intercom or audio panel.

DB25

pin#

18 Green EFIS Audio Alert Output

Color Function

If you have purchased and installed an HS34 and/or an AP74, we recommend that you

only connect the HS34 audio output or AP74 audio output (but not both) to your audio

panel. The HS34 or AP74 audio output provides voice and tone outputs for both EMSand EFIS-related alerts. When the HS34 or AP74 audio output is connected, it is not

necessary to connect the audio outputs of other Dynon Avionics devices. Connecting the

HS34 audio output and the AP74 audio output in parallel will result in distorted audio.

Refer to the HS34 Wiring section on page 7-10 for more information.

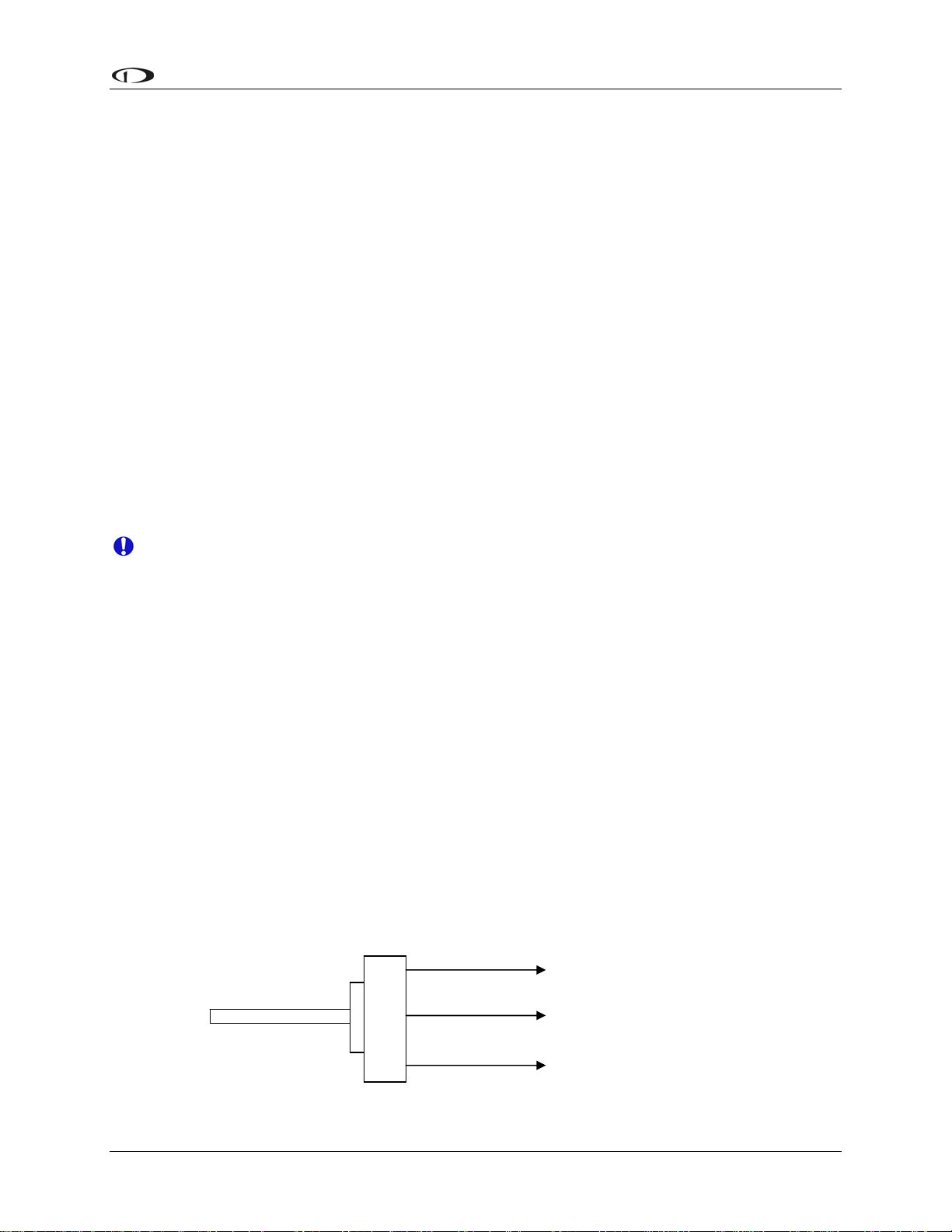

Connect the alarm output from the EFIS-D10A to the outside terminal of a 10 kΩ variable

resistor (not included). Ensure that audio outputs are connected similar to the following diagram.

The 10 kΩ variable resistor can be obtained from Radio Shack (P/N 271-1715) or other

electronics suppliers.

Outside terminal

Center terminal

Outside terminal

To EFIS-D10A Audio

Alert Out

To intercom/audio

panel auxiliary input.

To ground

To set the volume of the AOA alarm, you will need your EFIS-D10A powered on and the alarm

output wired as described above. Enter the EFIS menu by pressing any button (except the

leftmost or rightmost) beneath an EFIS page. Press MORE > SETUP > MORE > MORE >

MORE > AOAALM. In that menu, press the TEST button. While the button is held down, the

AOA alarm will sound. Adjust the variable resistor until the volume in the intercom or audio

panel is at an acceptable level.

3-10 EFIS-D10A Installation Guide

Page 23

Instrument Installation

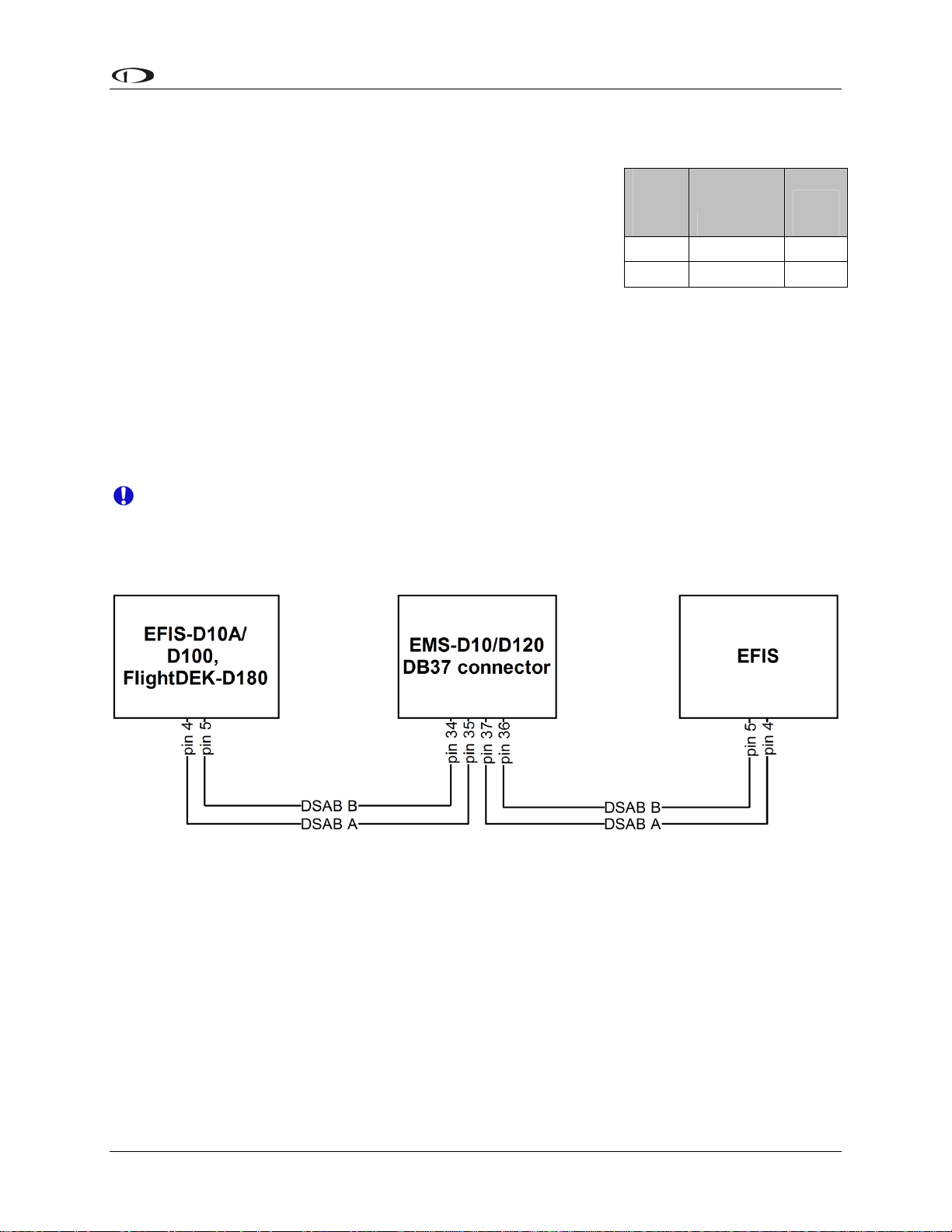

Dynon Smart Avionics Bus (DSAB) Wiring

The Dynon Smart Avionics Bus is the only way Dynon

products can communicate with one another, providing features

such as data sharing and alarm notification. DSAB is a multidrop bus, meaning several devices can be connected to the same

2 wires. If you have an EMS and EFIS product connected via

their serial ports through a null modem, you should disconnect

this legacy interface.

You must connect the DSAB A connection (pin 4) on the EFIS DB25 female harness to the

DSAB A connection for the next device in the chain. Do likewise for the DSAB B connection

(pin 5). Some products – like the EFIS series and the HS34 – have only one pair of DSAB

connections on the back connector; other products – like the EMS series – have two pairs, for

wiring convenience. If you have 3 or more devices in your system, and one of them is an EMSseries product, we recommend that you locate it in the middle of your wiring scheme as shown

below. This eliminates the need to splice two wires together.

EFIS

DB25

pin#

Function

4 DSAB-A Green

5 DSAB-B Blue

Wire

color

Wherever possible, ensure that the two DSAB wires (DSAB A and B) are run as a

twisted pair. This minimizes the system’s susceptibility to electrical noise.

Refer to the DSAB Configuration chapter on page 5-1 for detailed instructions on configuring

your DSAB network.

EFIS-D10A Installation Guide

3-11

Page 24

Instrument Installation

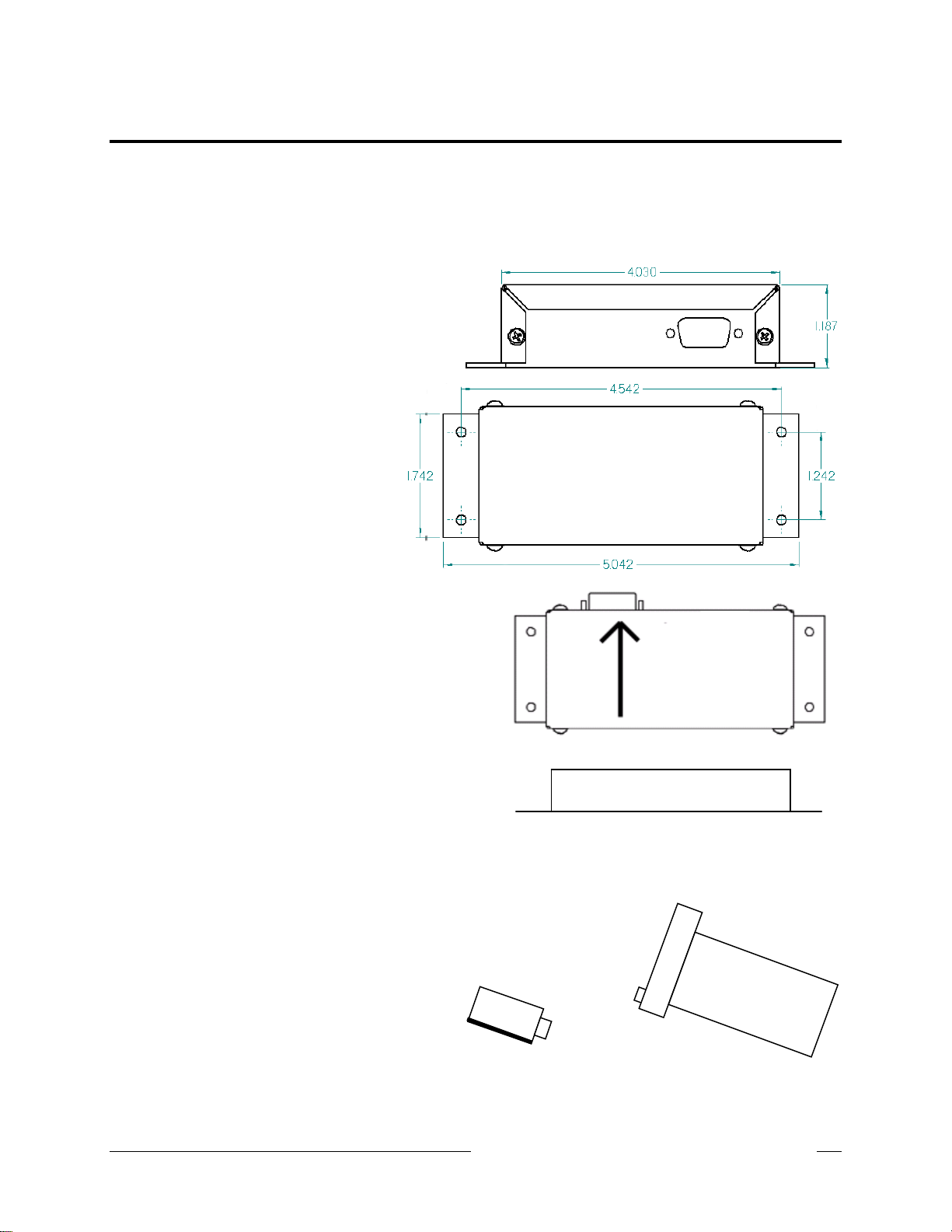

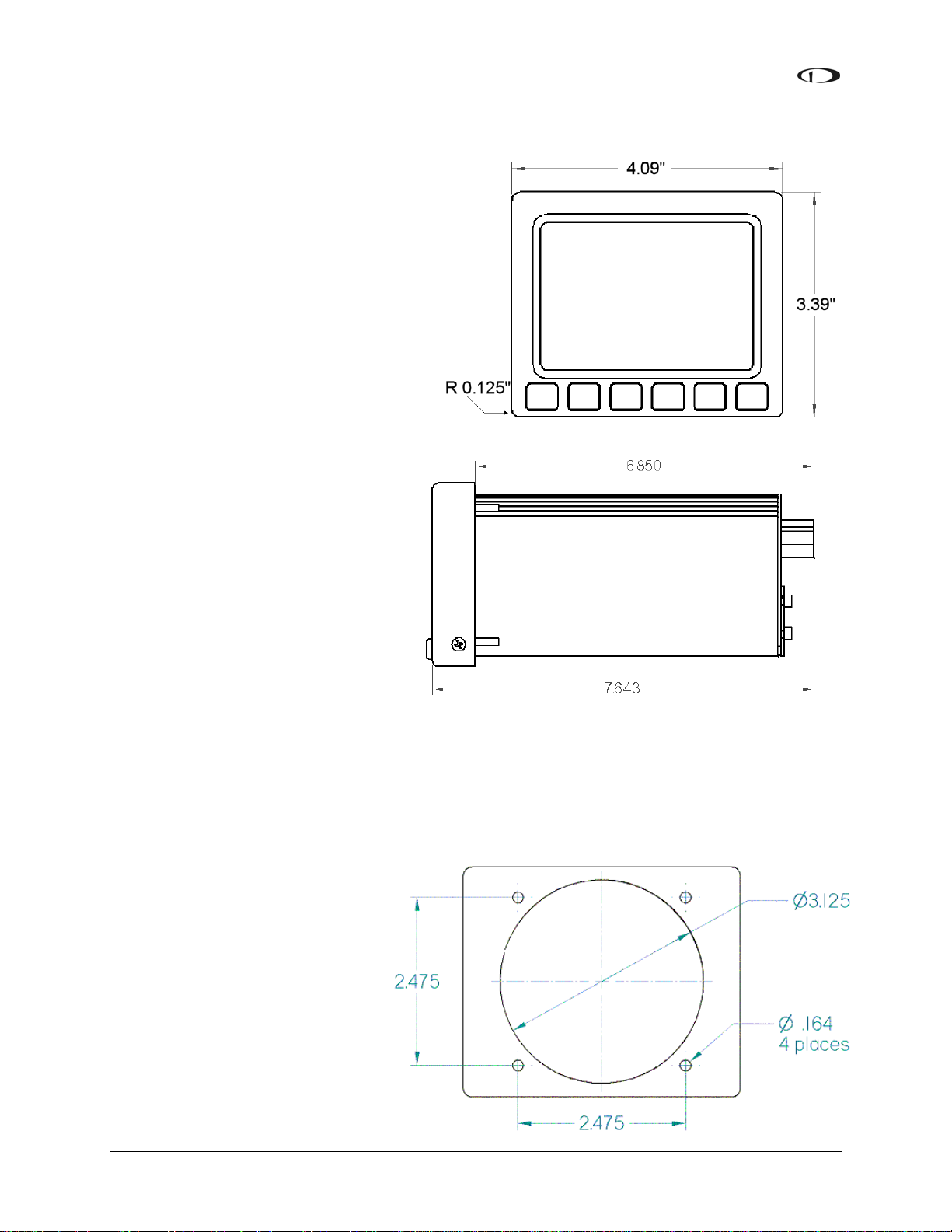

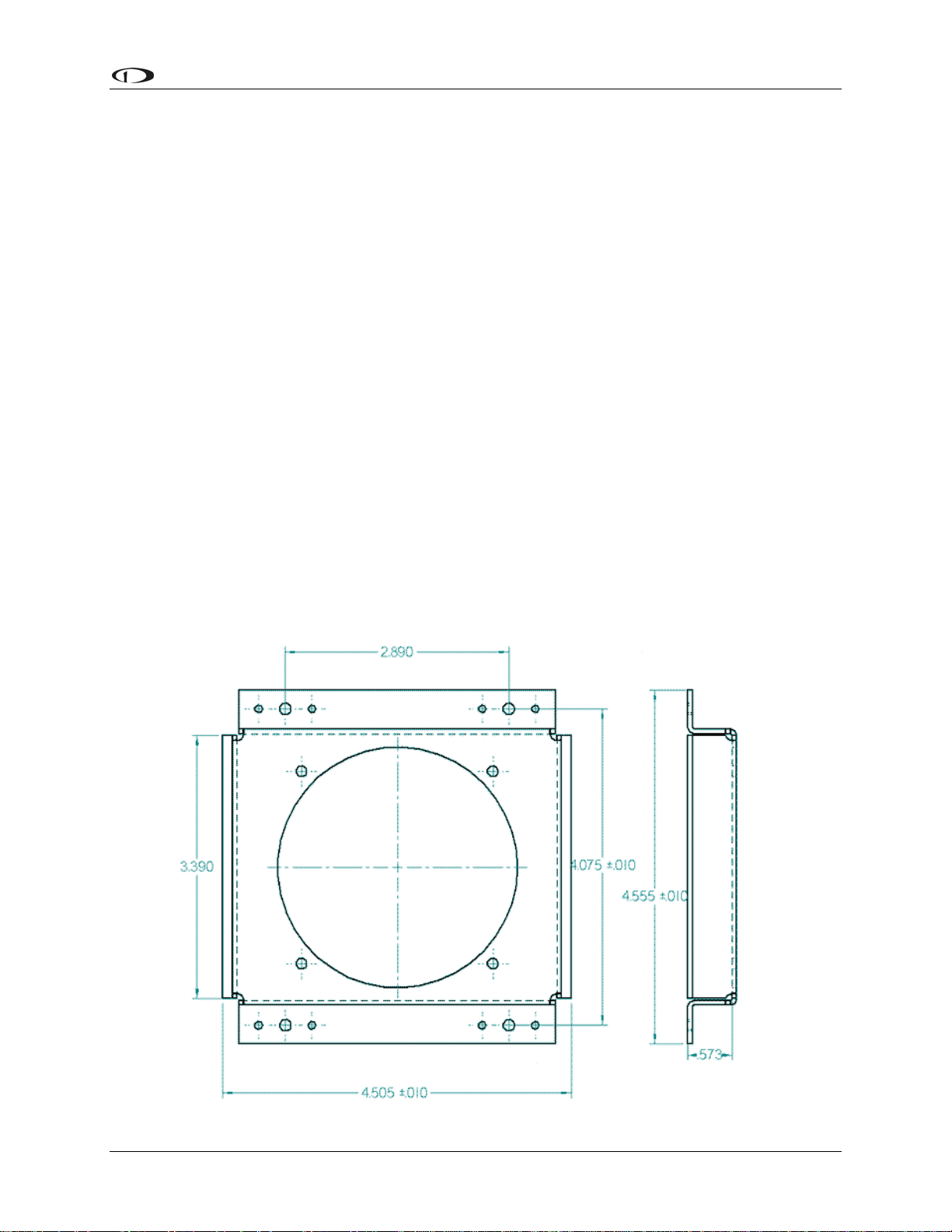

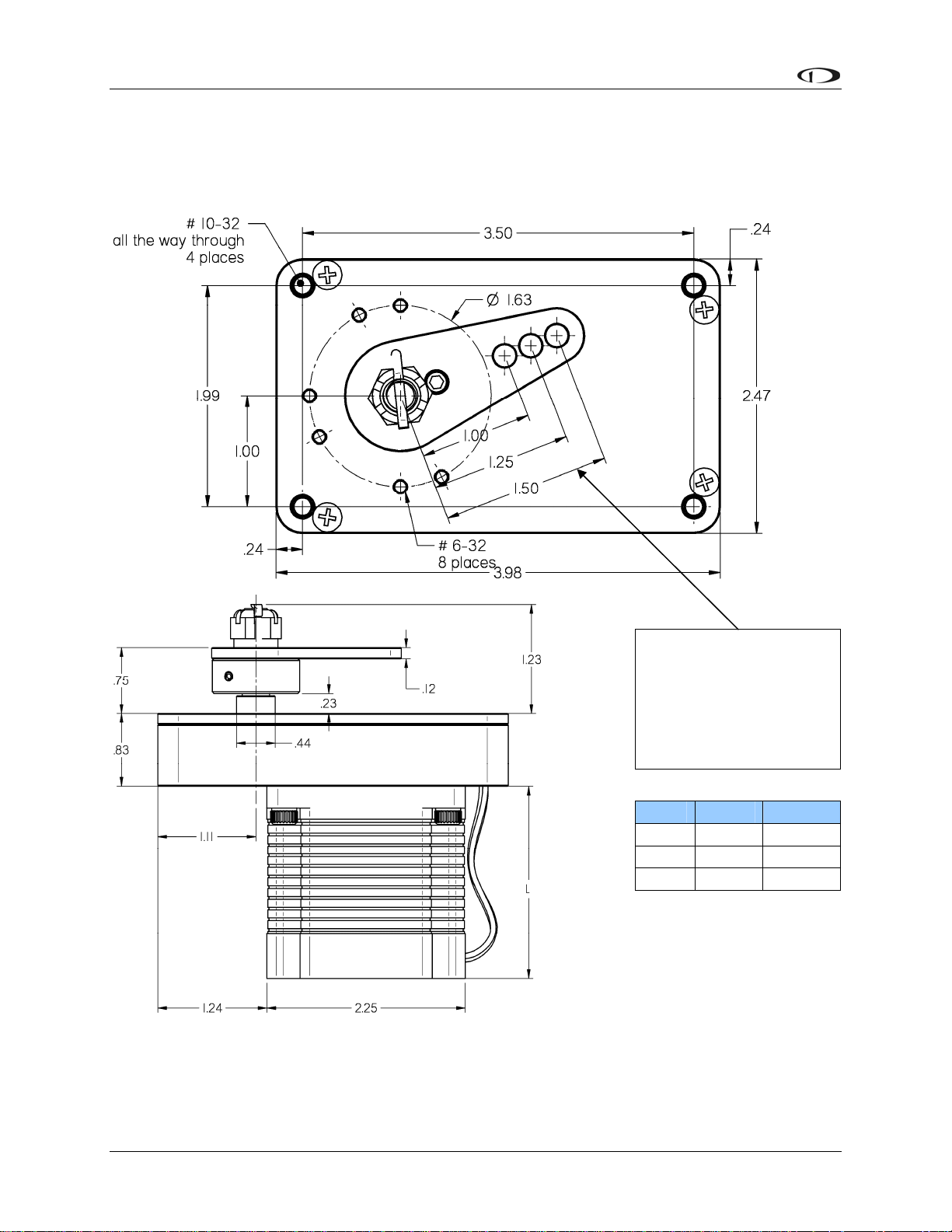

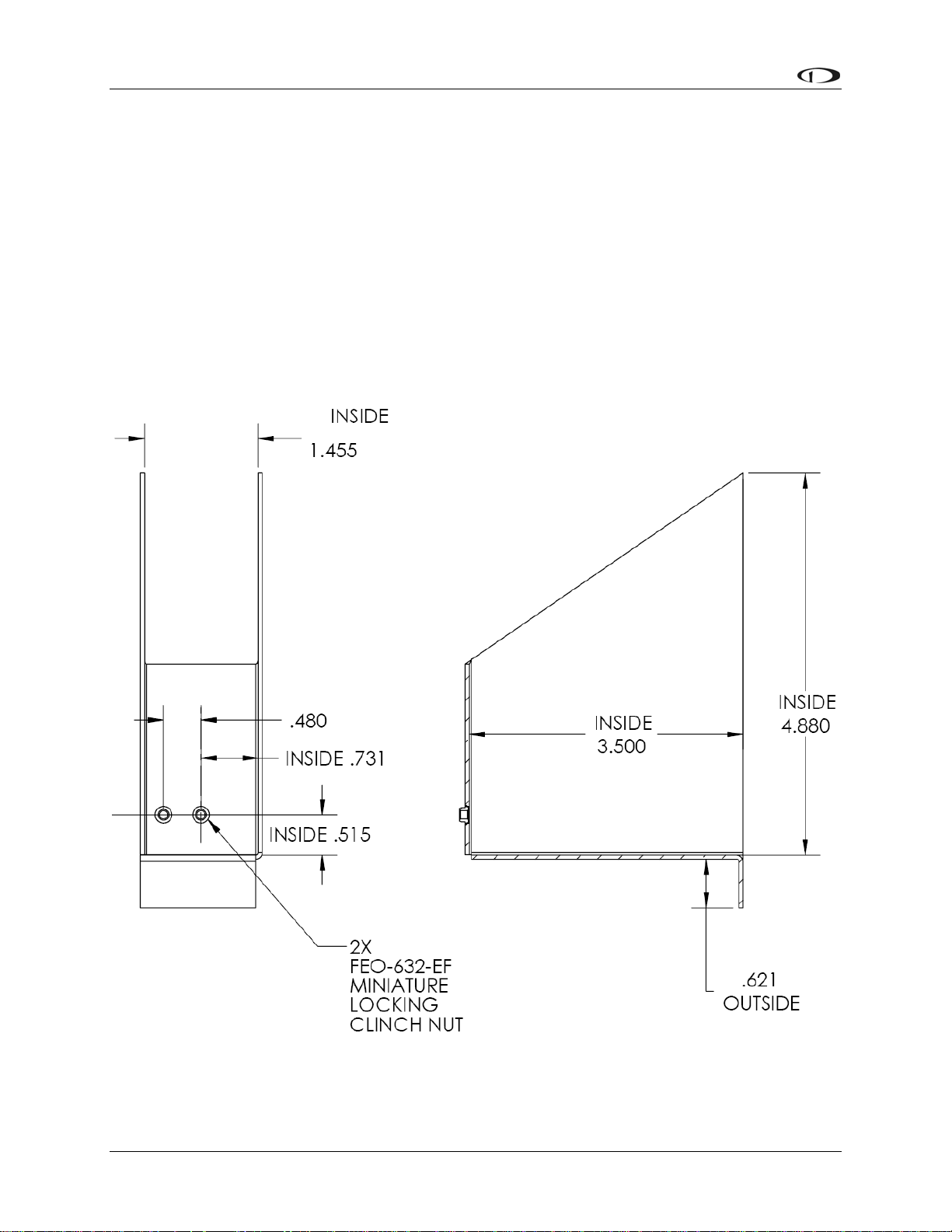

Panel Location and Mounting

The diagram at right shows the outside

dimensions of the front bezel of the EFISD10A. Note that the instrument is about

seven inches deep and the supplied

harness extends three inches more. Use

the dimensions (in inches) found on the

diagram to plan for the space required by

the instrument. Take the following

considerations into account when s

a mounting location for the EFIS-D10

electing

A.

Avoid placing

the instrument near heater

vents or any source of extremely hot or

cold air. Keep in mind that the air

surrounding the EFIS-D10A during

operation may be no warmer than 50

C to ensure accurate operation. Plan a

panel location that allows convenient

viewing of the instrument with no

obstruction. When flying straight an

d

level, the panel angle from vertical

may not be greater than +/- 30

degrees. The unit must also be p

arallel

to the roll axis of the aircraft (although

not necessarily located along it), and

have no significant roll angle in the

panel. The firmware supports an adju

stm

ent for panel tilt, but not for mounting errors in yaw or

roll. Correct attitude performance depends on mounting the EFIS-D10A square with the

direction of flight.

You have two optio

ns for mounting the EFIS-D10A into your panel: standard or flush. You may

use the optional flush-mount bracket, allowing the face of the EFIS-D10A to be flush with your

panel. If you opted to receive the

flush mount bracket, please skip to

Option 2 below. If you opted not

to receive this bracket and wish to

perform the standard install,

follow the options in Option 1

below.

OPTION 1: NO MOUNTING

BRA

CKET

U e

sing this option, you will b

mounting the EFIS-D10A direc

tly

into your panel. The front bezel of

3-12 EFIS-D10A Installation Guide

Page 25

Instrument Installation

the unit will extend beyond the plane of your panel by 0.8”.

Installation of the EFIS-D10A main unit should only be completed once all other physical and

electrical installations have been performed. This will ensure that last-minute adjustments will

not have to be made with the EFIS-D10A mounted in the panel.

The diagram above shows the dimensions expected for the proper installation of the EFIS-D10A

into your panel using no mounting bracket. All units are in inches. Push the EFIS-D10A through

the main panel hole. The four studs on the back of the EFIS-D10A will fit into the four mounting

holes having dimensions listed in the diagram. Place one of the four supplied washers on each

stud before pushing the EFIS-D10A into place in the panel, putting the washers in between the

EFIS-D10A and the panel. Place one of the 4 supplied mounting nuts on the end of each of the 4

studs protruding from the back of the panel. Secure the nuts tightly against the panel to complete

the installation.

OPTION 2: FLUSH-MOUNT BRACKET

Make a rectangular cutout in your panel, ensuring that it allows the front panel of the EFISD10A to fit. The cutout required should have the dimensions 4.09” wide by 3.39” tall with

corner radii of 0.125”. You also need to drill four 0.164” holes in your panel at the four locations

shown on the diagram below (two above and two below the rectangular cutout). Install #6 plate

nuts on the back side of the bracket. Place one of the supplied washers onto each of the four

mounting studs on the EFIS-D10A and then slide the flush mount bracket over the EFIS-D10A.

The bracket should wrap around the bezel of the EFIS-D10A. Place one of the 4 supplied nuts on

each of the 4 studs and tighten the nuts. The EFIS-D10A/bracket can now be installed from

behind your panel using the #6 screws through the previously drilled holes.

EFIS-D10A Installation Guide 3-13

Page 26

Instrument Installation

Connecting Static & Pitot Lines

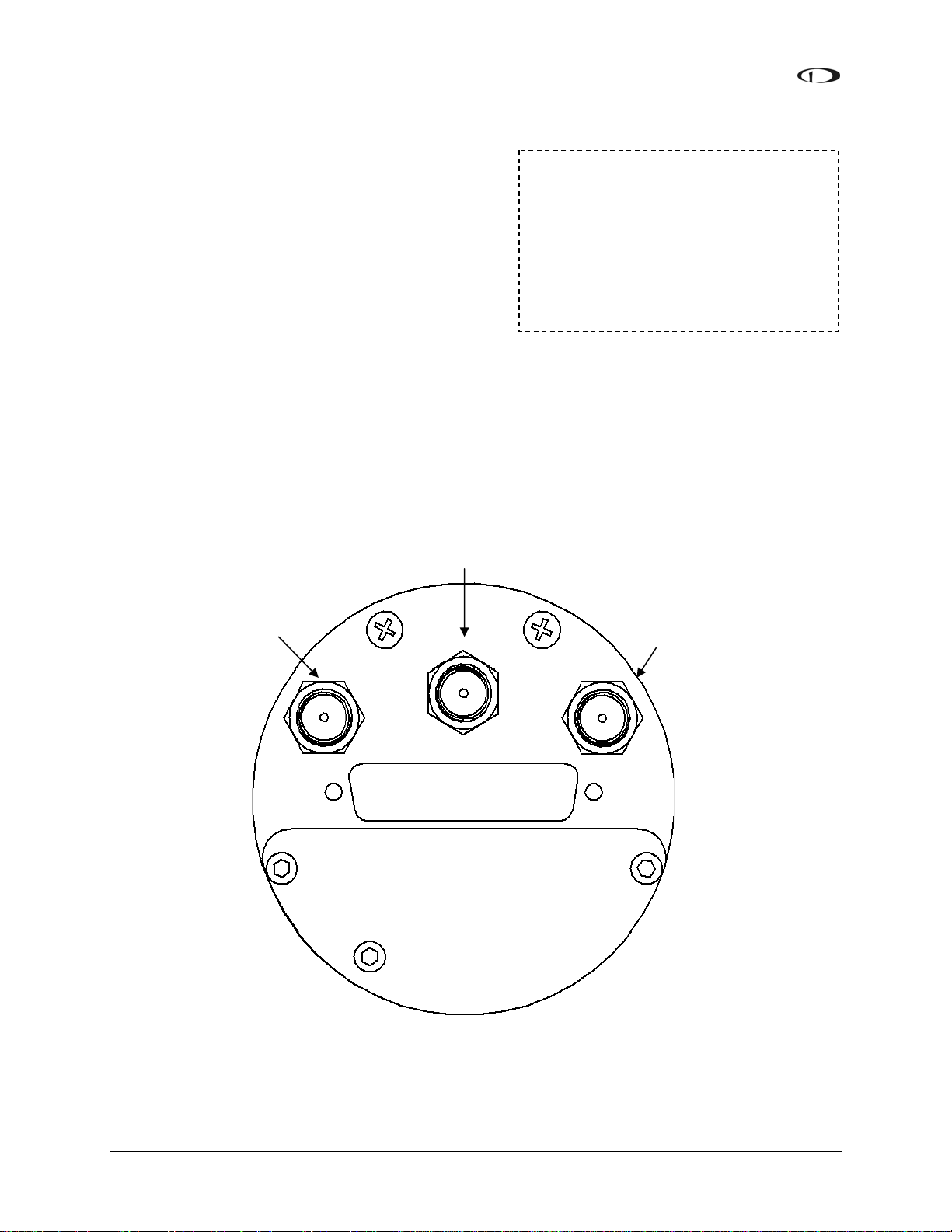

The AOA, pitot, and static ports on the back of the

EFIS-D10A are equipped with 1/8” NPT Female

fittings. To attach your pitot and static lines to the

back of the EFIS-D10A, you must use standard 1/8”

NPT Male fittings at the end of each of the lines.

To install, simply connect your static and pitot

sources to the EFIS-D10A, T’ing off of existing

lines if performing a retrofit. View the following

back view diagram the placement of your pressure

lines.

Use two wrenches to both hold the brass fitting on the EFIS-D10A and secure the mating

pressure line fittings to the corresponding locations on the back of the EFIS-D10A. Do not over-

tighten or allow the brass fittings to rotate.

If you purchased Dynon’s AOA pitot tube, note that it has pitot and AOA ports on it, but not

static. You will need to provide your own source of static pressure for the EFIS-D10A and any

other instrument in your panel which requires it.

The EFIS-D10A’s attitude calculation

requires either airspeed (from pitot

and static) or GPS data. To ensure

proper operation, at least one of these

data sources must be available. We

recommend the EFIS-D10A be

connected to pitot and static systems

in all installations.

Pitot

AOA

Stati

Static

3-14 EFIS-D10A Installation Guide

Page 27

4. EFIS CALIBRATION AND CONFIGURATION

During manufacture, your EFIS-D10A underwent a comprehensive calibration, verification, and

burn-in routine that minimizes setup time and ensures that your EFIS meets Dynon’s stringent

performance specifications. To account for your individual preferences and your aircraft’s

particular setup, there are a few simple calibration and configuration steps that you must

complete before using your EFIS-D10A. This section takes you through these steps to make sure

that you have properly installed and configured your EFIS-D10A.

It is your responsibility to fly your plane safely while performing any configuration or

calibration in flight. The best scenario would include a second person to perform any

necessary steps on the unit.

Ensuring Proper Installation

Turn your unit on by energizing the aircraft power to which it is connected. Ensure that the

screen is bright and readable and that all instrument displays appear. If a desired display item is

not present, refer to the User’s Guide to use the CLUTTR feature to display the missing item.

Setting Zero Pitch (In flight)

For the purposes of this setting, level is defined as the attitude at which the aircraft’s

longitudinal axis is parallel to the ground. For most aircraft, the attitude the aircraft

assumes at normal cruise speeds will be acceptable. Additionally, this feature should not

be used to “zero out” pitch when the aircraft is at an attitude other than level. Do not

think of this adjustment as you would the parallax adjustment on a normal attitude

indicator. Instead, think of it as a calibration step which is not changed often.

With your aircraft flying straight and level, enter the EFIS > SETUP > PITCH menu. Press INC

or DEC until the horizon line intersects the center of the crosshairs. It is important that this be

done while the aircraft is level to ensure proper pitch and roll display throughout all maneuvers.

Compass Heading Calibration

This section guides you through the calibration and configuration of your magnetic heading

indication. Prior to calibrating your EFIS-D10A’s internal sensors or remote EDC-D10A, you

must configure the local magnetic inclination and magnetic intensity as described in the sections

below.

In a DSAB network, the Bus Master’s heading is used as the only heading source for all

connected instruments. However, in the event of a DSAB failure, EFIS instruments revert

to their local heading source. In a system already using a shared heading, you may still

configure and calibrate the local heading source. As soon as you bring up any of the

magnetic calibration menus (MAGINC, MAGCAL, MAGADJ, MAGINT), the heading

and DG displays switch to display the locally-derived heading indication. The display

stays on that source until exiting the magnetic configuration menu. If you do not have an

EDC-D10A connected, REMOTE COMPASS NOT DETECTED is displayed when in

any of these menus.

EFIS-D10A Installation Guide 4-1

Page 28

EFIS Calibration and Configuration

SETTING MAGNETIC INCLINATION ANGLE AND INTENSITY (REQUIRED)

To calibrate your EFIS-D10A heading, you must input your location’s current magnetic

inclination angle and intensity. Before doing this, you must obtain these two values for

the geographic location where you will be performing the calibration. Note that this

procedure only needs to be done once, prior to magnetic calibration. Moving the aircraft

to another location does not require repeating this procedure.

Obtaining Magnetic Inclination and Intensity

1. Browse to web page: www.dynonavionics.com/docs/maginfo.html. (Looking up this

information does not have to be done on a computer at the plane, with live Internet

access.)

2. The Dynon Avionics “Magnetic Inclination and Intensity” web page is updated as

needed; it contains a link to a NOAA web pages and instructions for easily finding your

local magnetic inclination and intensity by inputting your ZIP code (in the US) or your

latitude and longitude and inputting the resulting data into your Dynon EFIS.

3. Follow the instructions listed on the web page, especially clicking the “Compute

Magnetic Field Values” button at the bottom of the linked page – the values required by

your Dynon EFIS will be displayed only after clicking that button. If you are near the

equator or in the southern hemisphere, note that the inclination may be negative number.

Entering inclination and intensity into the EFIS-D10A

1. Enter the inclination setup menu by pressing any button beneath an EFIS page (except the

far left or far right hotkeys), then MORE > SETUP > MORE > MORE > MAGINC

2. Press INC or DEC to increment or decrement the displayed inclination angle. Press and

hold to change values more rapidly.

3. When the display shows the magnetic inclination angle for your location, press BACK to

leave the menu.

4. Enter the magnetic intensity setup menu by pressing any button beneath an EFIS page

(except the far left or far right hotkeys), then MORE > SETUP > MORE > MORE >

MAGINT

5. Press SEL to change the digit being incremented or decremented. Press INC or DEC to

increment or decrement the selected digit. Press and hold to change values more rapidly.

6. When the display shows the magnetic intensity for your location, press BACK to leave

the menu.

4-2 EFIS-D10A Installation Guide

Page 29

EFIS Calibration and Configuration

EFIS-D10A (INTERNAL) HEADING CALIBRATION (ON GROUND AND IN FLIGHT)

NOTE: if you own the EDC-D10A Remote Compass Module, you do not need to perform this

set of steps. Skip to the next section for calibration of the remote compass.

Because our goal is to give the EFIS-D10A a

compass that is accurate in all attitudes, our user

magnetic calibration process is more comprehensive

than that for many other products. The magnetic field

vector in North America is predominantly vertical;

this requires that any complete calibration maneuver

bank the aircraft significantly in order to accurately

map out the unique magnetic signature of your plane

in this three-dimensional field. Therefore, a large

It is crucial that compass heading

calibration be done after the unit is

completely integrated into your

panel. If the unit is calibrated away

from the panel and then inserted at

a later time, it will be improperly

biased by the unique magnetic field

characteristics of your plane.

quantity of data needs to be recorded in a variety of

attitudes. Simpler calibration processes do not perform these steps and suffer by being accurate

only at level attitudes. When properly completed, a magnetic calibration of this complexity will

produce a compass that is accurate during banked maneuvers. Note that the EDC-D10A remote

compass calibration process is not as complex because it is assumed that you have mounted it in

a more magnetically clean environment. Three dimensional calibration has already been done on

the EDC-D10A at the factory.

Before proceeding with the calibration, ensure that you have determined and entered the

magnetic inclination (dip angle) as described above.

Performing the calibration

Perform the first portion of the heading calibration on the ground in an area where you can

accurately determine magnetic North such as on a compass rose. You must also have enough

room to perform a 540 turn on the ground as described below. Turn the EFIS-D10A on and let it

warm up for 10-15 minutes before proceeding. Turn all instruments on that you would normally

be operating during a flight, including the engine.

During magnetic calibration, do not turn the power off on the EFIS-D10A. This will cause any

recorded compass calibration data to be lost; the calibration will need to be restarted.

1. Enter the EFIS calibration menu by pressing any button beneath an EFIS page (except the

far left or far right hotkeys), then MORE > SETUP > MORE > MORE > MAGCAL. You

should see a menu that reads GNDNRT, AIRRGT, and AIRLFT. If it reads NORTH,

EAST, SOUTH, and WEST, you have the EDC-D10A installed and should proceed with

the EDC-D10A heading calibration as described on the following page.

2. With the plane in the normal flight state (engine running, all instruments and avionics

on), align the plane to point as close as possible to magnetic North. Press the GNDNRT

button (the button’s text will toggle to DONE – do not press this until the maneuver is

complete) and hold the plane still for 10 seconds. After the 10 seconds of holding still,

maneuver the plane smoothly to the right through 540 degrees of heading change at a rate

of 20 to 30 seconds per 90 degrees of change; the whole maneuver should take between 2

and 3 minutes. At the end of the maneuver, the aircraft will be pointing magnetic South.

At this point, press DONE. If at any time, you make a mistake, press DONE, align the

EFIS-D10A Installation Guide 4-3

Page 30

EFIS Calibration and Configuration

aircraft to point to magnetic North and repeat the process, starting with pushing the

GNDNRT button.

3. Now proceed to take off for the in-flight part of the calibration. After reaching a safe

altitude, head the plane as close as possible to magnetic North. Press the AIRRGT button

(again, the button’s text will toggle to DONE – wait until completing the maneuver

before pressing this), and continue holding a steady North heading for 10 seconds. Then

make a 30 degree banked turn to the right for 540 degrees. The maneuver ends with the

aircraft pointing South. Fly the maneuver as smooth as possible since this will give you

better results. At the end of the maneuver, while still pointing South, press the DONE

button.

4. Maneuver the aircraft to point to magnetic North again. Press the AIRLFT button

(toggling it to DONE – again, refrain from pressing until the maneuver is complete).

Continue holding a steady heading (North) for 10 seconds, and then make a 30 degree

banked turn to the left for 540 degrees. The maneuver ends with the aircraft pointing

South. Fly the maneuver as smooth as possible since this will give you better results. At

the end of the maneuver, while still pointing South, press the DONE button.

5. At any point in the calibration, you may redo a maneuver by pressing the appropriate

button and repeating that step. The order in which you do the 3 maneuvers is not critical

as long as all three maneuvers are performed completely without cycling the power to the

EFIS-D10A.

6. When you are satisfied with the three maneuvers, press END. This will cause the EFIS-

D10A to calculate the values needed for calibration. This process can take as long as 10

minutes, during which your EFIS-D10A will appear “frozen.” A message will be

displayed onscreen: CALCULATING MAGNETIC CALIBRATION VALUES.

7. Wait for the message CALIBRATION COMPLETE before attempting to use the EFIS-

D10A or remove power. Press BACK to leave the menu.

At this point the calibration is complete. We suggest you evaluate the performance of the EFISD10A heading feature, preferably on a compass rose, and decide if the performance is acceptable

to you. If the resultant compass accuracy is not acceptable, you can either repeat the calibration

process attempting to fly the maneuvers more smoothly, or purchase, install, and calibrate the

Dynon Avionics EDC-D10A Remote Compass.

You will need to repeat this process anytime you move the EFIS-D10A to a new location in your

plane or change the magnetic or electrical characteristics of the nearby environment (i.e. adding

or removing other electrical instruments). Changing geographic location should have no effect

on your heading readings after a user calibration.

Troubleshooting

During the calibration process you may receive one of the following errors. Next to each one is

the corrective action required.

WARNING: MAGNETIC INCLINATION NOT SET. You have not entered the magnetic

inclination into the EFIS-D10A yet. Please see the “Entering the Inclination Angle” section

above.

4-4 EFIS-D10A Installation Guide

Page 31

EFIS Calibration and Configuration

ERR: NOT ENOUGH DATA FOR XXXXXX TURN. One of the 3 maneuvers did not take

enough time for the EFIS-D10A to collect enough data. Please perform just the listed

maneuver again, ensuring that you take at least 2 minutes to perform the turn.

ERR: HOLD N LONGER BEFORE XXXXXX TURN. The EFIS-D10A did not see enough

data for the 10 second north-bound section of the turn. Repeat the listed maneuver, ensuring

that you spend 10 seconds pointed north before beginning the turn.

ERR: XXXXXX 540 DEG TURN NOT COMPLETED. The EFIS-D10A did not see a

complete 540 degree turn. Repeat the listed maneuver, ensuring that you turn through the

entire 540 degrees, ending up pointed south.

EDC-D10A HEADING CALIBRATION (ON GROUND ONLY)

The procedure for in-plane calibration of the EDC-D10A involves pointing the aircraft in four

directions and taking data at each direction using the EFIS-D10A. The EFIS-D10A will then

perform some calculations to ensure an accurate calibration.

During magnetic calibration, do not turn the power off on the EFIS-D10A. This will

cause any recorded compass calibration data to be lost; the calibration will need to be

restarted.

To perform the calibration, you will need the following:

1. EFIS-D10A and EDC-D10A installed in aircraft.

2. Magnetic inclination angle and intensity properly entered into the EFIS-D10A per the

section above.

3. An accurate method of aligning the aircraft with magnetic North, East, South, and West,

such as an airport’s compass rose.

Once you have the installation completed, have verified that your EDC-D10A communicates

with the EFIS-D10A (via the headphone test described in the installation section), and have

located a suitable place to perform the calibration, perform the following steps:

1. Turn on the EFIS-D10A and allow it to warm up for at least 15 minutes before

performing the calibration.

2. Align the aircraft pointing magnetic North as closely as possible.

3. On the EFIS-D10A, enter the menu system by pressing any button beneath an EFIS page

(except the far left or far right hotkeys) and press MORE > SETUP > MORE > MORE >

MAGCAL. You should see a menu that reads NORTH, EAST, SOUTH, and WEST. If

you do not, then the EDC-D10A is not properly communicating with your EFIS-D10A.

4. Press the NORTH button; you will see the message, COLLECTING DATA FOR

NORTH along with a 15 second timer. Let the time run out before proceeding.

5. Align the aircraft pointing magnetic East as closely as possible.

6. Press the EAST button; you will see the message, COLLECTING DATA FOR EAST

along with a 15 second timer. Let the time run out before proceeding.

7. Align the aircraft pointing magnetic South as closely as possible.

EFIS-D10A Installation Guide 4-5

Page 32

EFIS Calibration and Configuration

8. Press the SOUTH button; you will see the message, COLLECTING DATA FOR

SOUTH along with a 15 second timer. Let the time run out before proceeding.

9. Align the aircraft pointing magnetic West as closely as possible.

10. Press the WEST button; you will see the message, COLLECTING DATA FOR WEST

along with a 15 second timer. Let the time run out before proceeding.

11. Press the END button. This will cause the EFIS-D10A to pause as it calculates. This

pause should last between 1-20 seconds. However, if the collected data is poor, this can

take as long as 5 minutes. A message will be displayed onscreen: CALCULATING

MAGNETIC CALIBRATION VALUES.

12. Wait for the message CALIBRATION COMPLETE before attempting to use the EFIS-

D10A or remove power. Press BACK to leave the menu.

This completes the EDC-D10A calibration process. The process can be repeated as often as

desired. The overall accuracy of the compass depends on the installation location (away from

any ferrous materials or current carrying wires or devices), the installation alignment (aligned

with the EFIS-D10A in pitch, roll, and yaw), and the calibration procedure (accurately aligning

the aircraft with North, East, West, and South and having the correct magnetic inclination angle

loaded into the EFIS-D10A). If the compass performance is not adequate for your usage, we

suggest that you investigate each of these factors and try to optimize your installation for each

factor.

If the heading shown onscreen is off by a small, but constant amount, you can change a heading

offset in the EFIS-D10A which will correct this. Orient your plane in a known direction,

preferably on a compass rose at the airport. Navigate to the Heading Adjustment menu by

pressing MORE > SETUP > MORE > MORE > MAGADJ. Increment or decrement the value of

the heading offset until the EFIS-D10A heading corresponds to the direction in which your plane

is pointed.

Troubleshooting

During the calibration process you may receive one of the following errors. Next to each one is

the corrective action required.

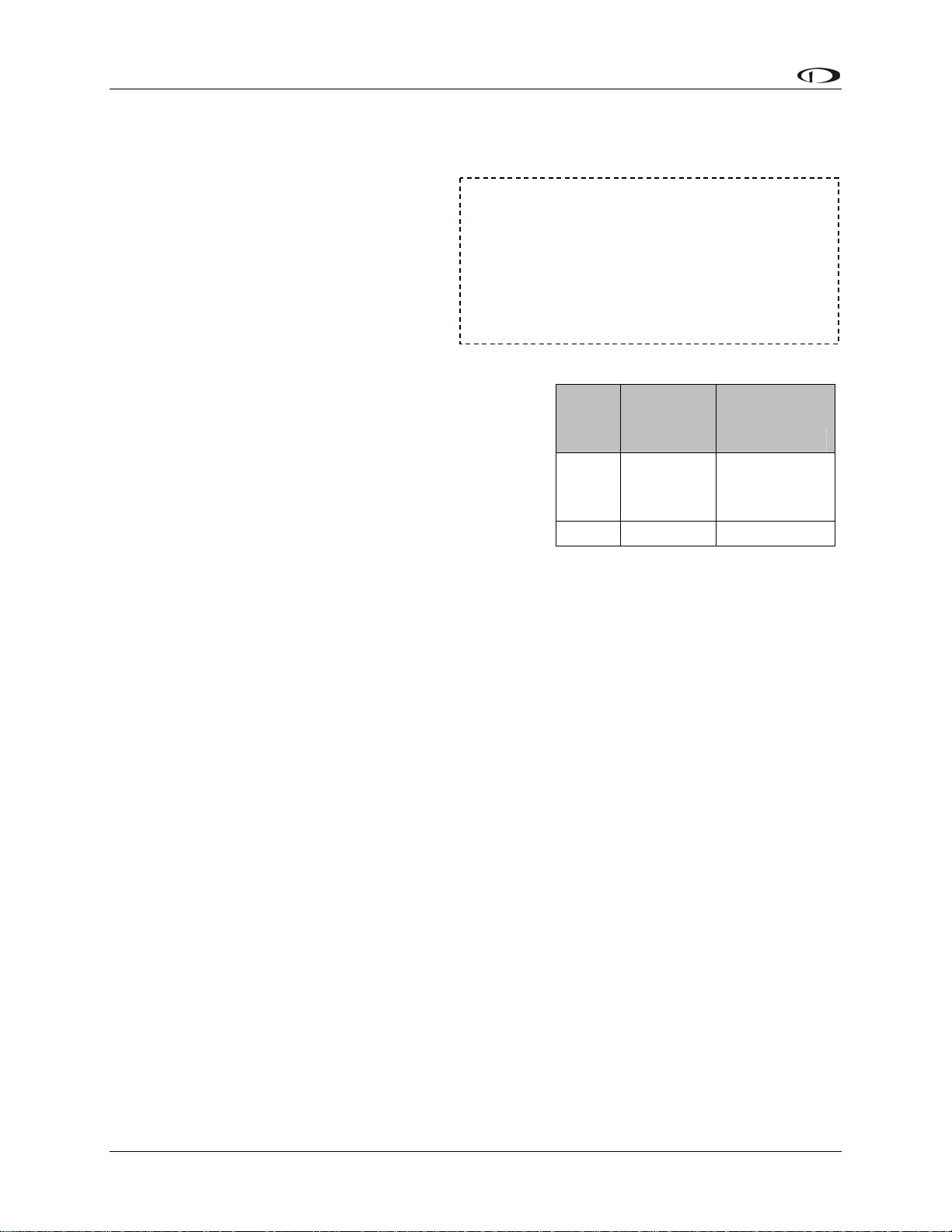

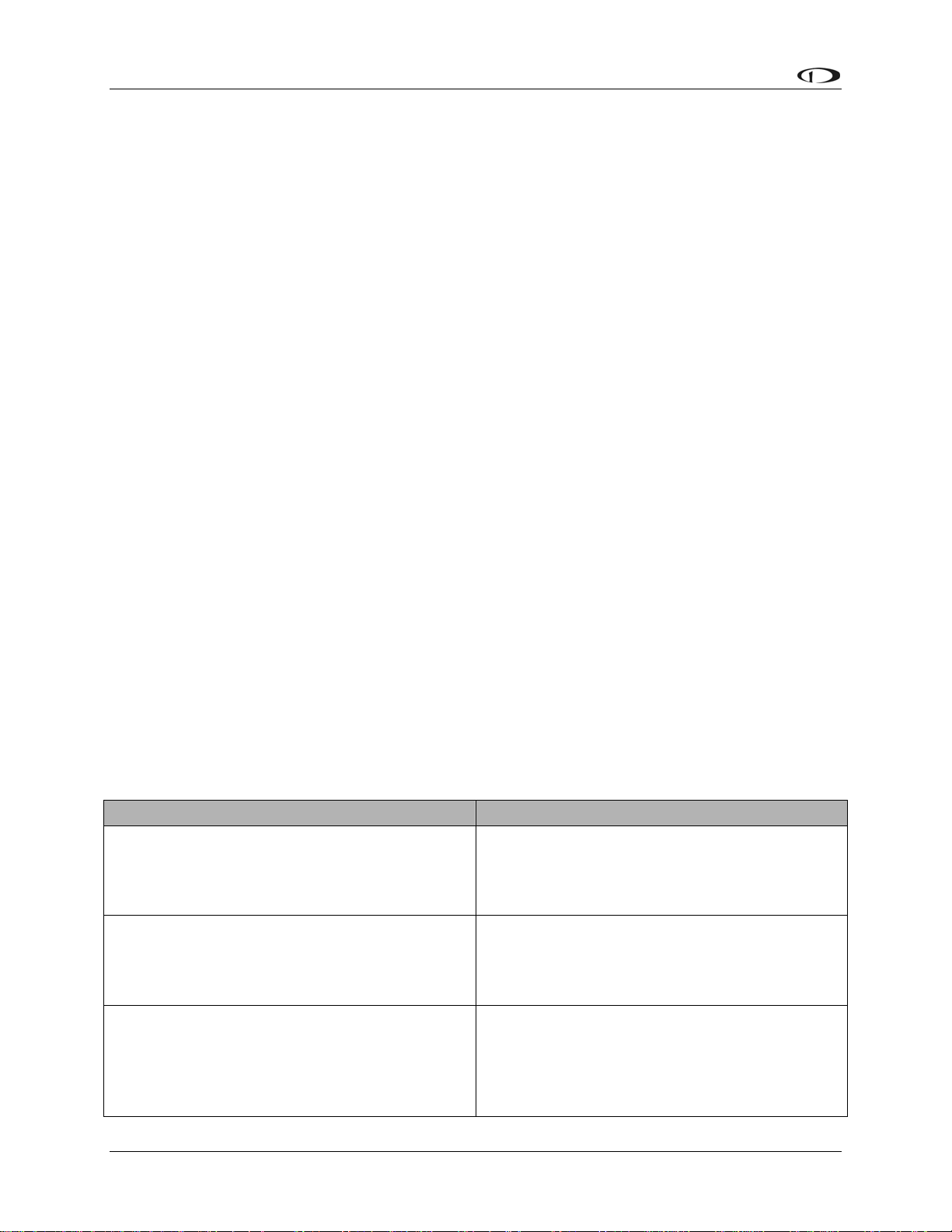

Message Corrective Action

You have not entered the magnetic inclination

WARNING: MAGNETIC INCLINATION

NOT SET.

into the EFIS-D10A yet. Please see the

“Entering Magnetic Intensity and Inclination

Angle” section

You have not entered the magnetic inclination

WARNING: MAGNETIC INTENSITY NOT

SET.

into the EFIS-D10A yet. Please see the

“Entering Magnetic Intensity and Inclination

Angle” section

One of the 3 maneuvers did not take enough

ERR: NOT ENOUGH DATA FOR XXXXXX

TURN

time for the EFIS-D10A to collect enough

data. Please perform just the listed maneuver

again, ensuring that you take at least 2 minutes

to perform the turn.

4-6 EFIS-D10A Installation Guide

Page 33

EFIS Calibration and Configuration

The EFIS-D10A did not see enough data for

ERR: HOLD N LONGER BEFORE

XXXXXX TURN

ERR: XXXXXX 540 DEG TURN NOT

COMPLETED

the 10 second north-bound section of the turn.

Repeat the listed maneuver, ensuring that you

spend 10 seconds pointed north before

beginning the turn.

The EFIS-D10A did not see a complete 540

degree turn. Repeat the listed maneuver,

ensuring that you turn through the entire 540

degrees, ending up pointed south.

Configure Airspeed Color Thresholds

To configure the airspeed bar color thresholds for your unit enter the EFIS > SETUP > IASCLR

menu. This displays the Airpseed Color Threshold menu. In this menu, enter the values for five

airspeed constants (Vso, Vs1, Vfe, Vno, and Vne), each of which has its own button. Enter these

values in units of knots, mph, or km/h depending on what airspeed units you are currently using

(you may change the displayed airspeed units via EFIS > SETUP > UNITS > IAS).

Perform the following steps for each airspeed constant:

1. Press SEL to select the digit you wish to increment or decrement.

2. Press DEC- or INC+ to decrement or increment the selected digit.

3. Press BACK to return to the previous menu.

You will not be able to see some of the colors until the aircraft has achieved airspeeds in

the range of each threshold.

EFIS-D10A Installation Guide 4-7

Page 34

Page 35

5. DSAB CONFIGURATION

This section introduces some concepts that are central to understanding and configuring a

network of DSAB-capable Dynon products. It then takes you through a series of simple steps to

configure your network, enabling data sharing and HS34 functionality. Do not proceed with

DSAB configuration until you perform all installation, calibration, and configuration steps for

each instrument with a display. Display-less instruments – such as the HS34 – cannot be fully

configured until DSAB is active, although their physical and electrical installation should be

complete.

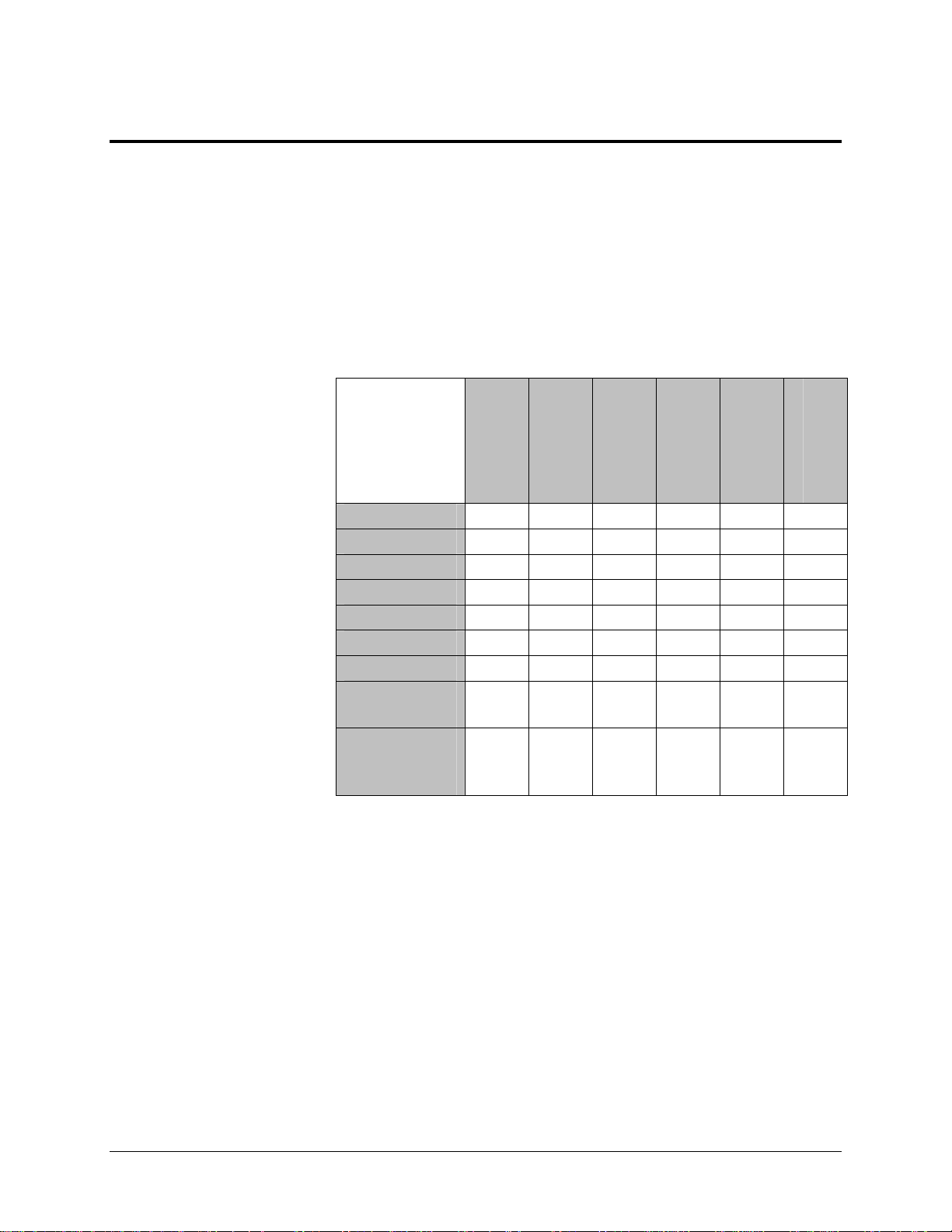

Network Concepts

A few concepts must be

understood before

configuring a DSABconnected system. The

most important is that of

Dynon products as

providers of functions to

the network. These

various functions are

called roles. Some

products, such as the

HS34, only have one role

on the network; other

products can provide

multiple roles at a time.

When a device has been

assigned to provide a role

to the network, no other

device on the network can

provide that role at the

same time.

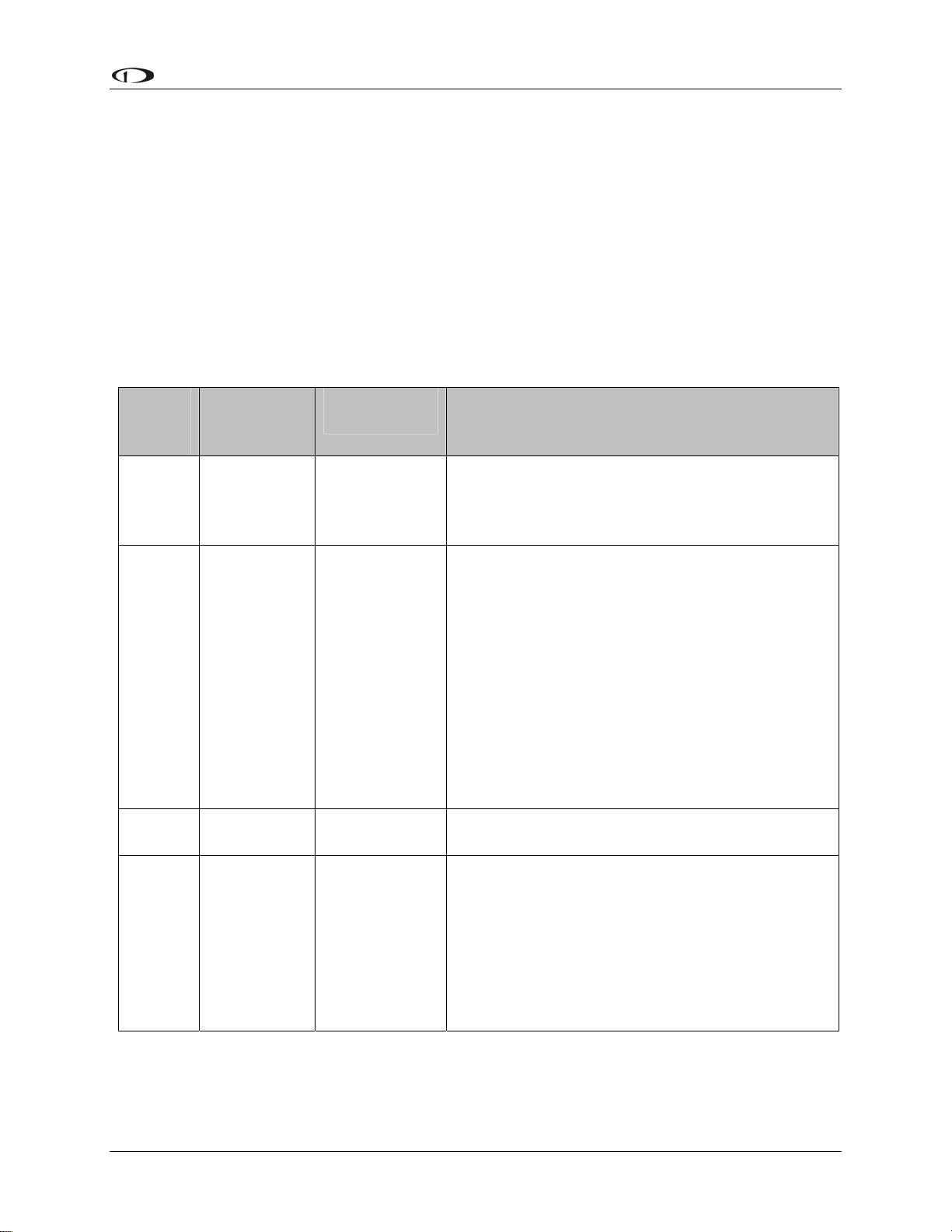

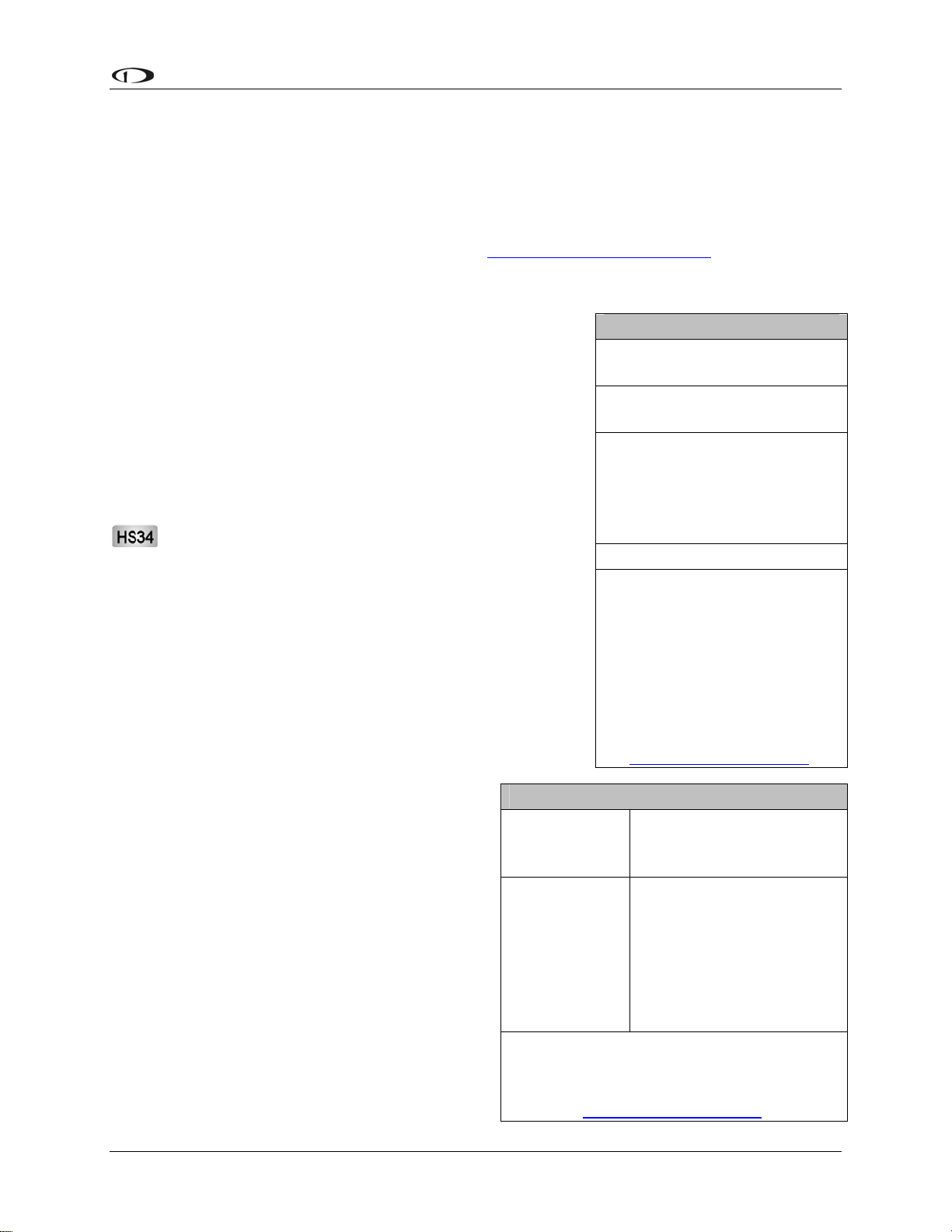

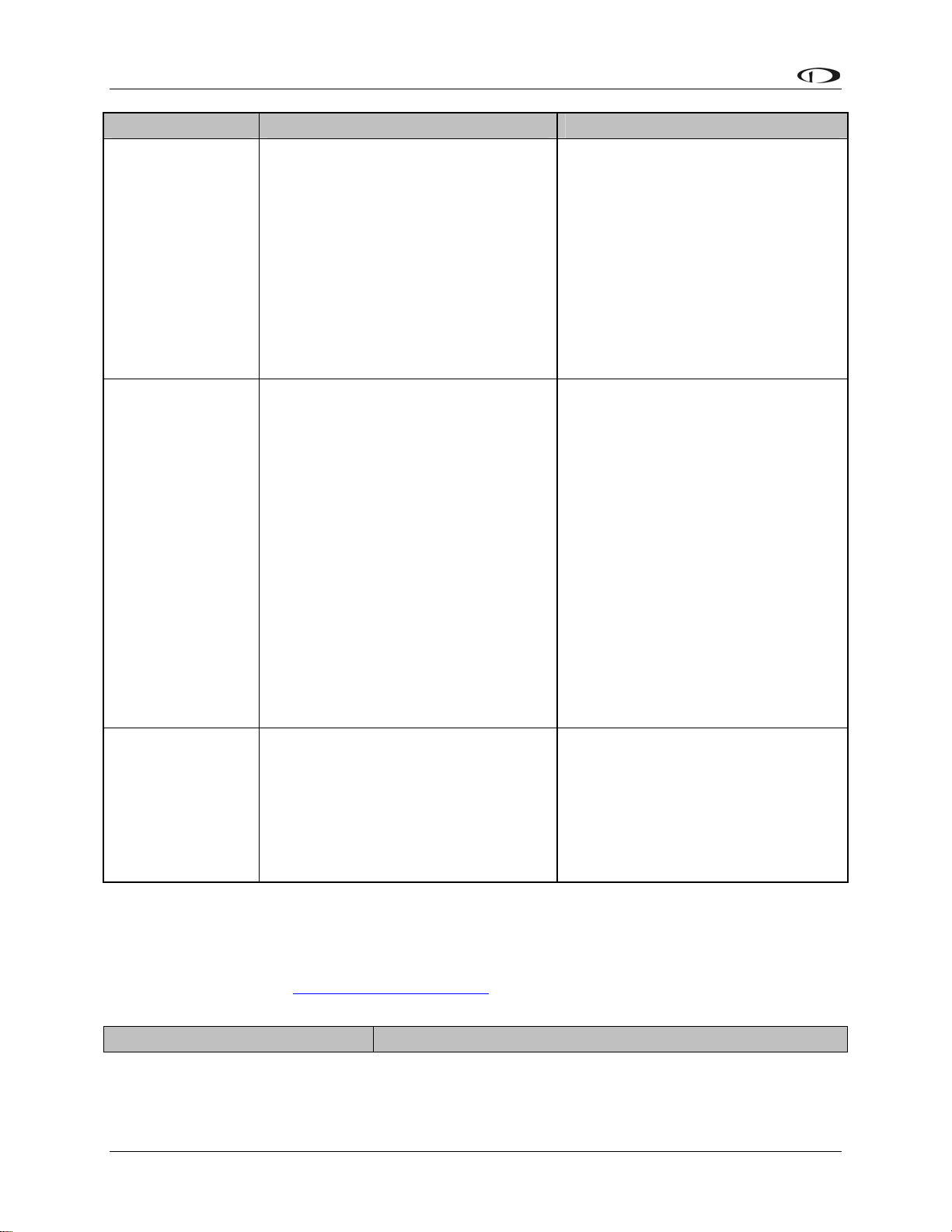

Assignable

roles by

product

Bus Master

EFIS

EMS

OAT

Compass

HS34

Autopilot

AP Control

Panel

AP

Roll/Pitch

Servo

EFIS-D10A/

EFIS-D100

EMS-D10/

EMS-D120

FlightDEK-

D180

X X

X X

X X

X X X

X X

X

X X

X

X

HS34

SV32/42/52

AP74

The table at right lists all available roles and the products which they can be assigned to. Again,

each role can be assigned to no more than one device on the network.

Another important concept is that of the Bus Master. A DSAB-connected network must have at

least one EFIS-based product (EFIS-D10A, EFIS-D100, or FlightDEK-D180), and only an EFISbased product can be assigned the Bus Master role. The Bus Master is the instrument which

manages communication on the network. Additionally, if Autopilot servos are installed, the Bus

Master is the Autopilot. While the Autopilot can be controlled from slave devices, if the Bus

Master is not present, the Autopilot will not function. If the Bus Master is turned off or fails, all

data sharing ceases, causing units to display internally-derived data only. When you first perform

DSAB network configuration on an EFIS-based instrument, that device is automatically assigned

the Bus Master role. Perform DSAB configuration on your primary EFIS-based instrument, as

the Bus Master is also the default provider for both the EFIS and Compass roles.

EFIS-D10A Installation Guide 5-1

Page 36

DSAB Configuration

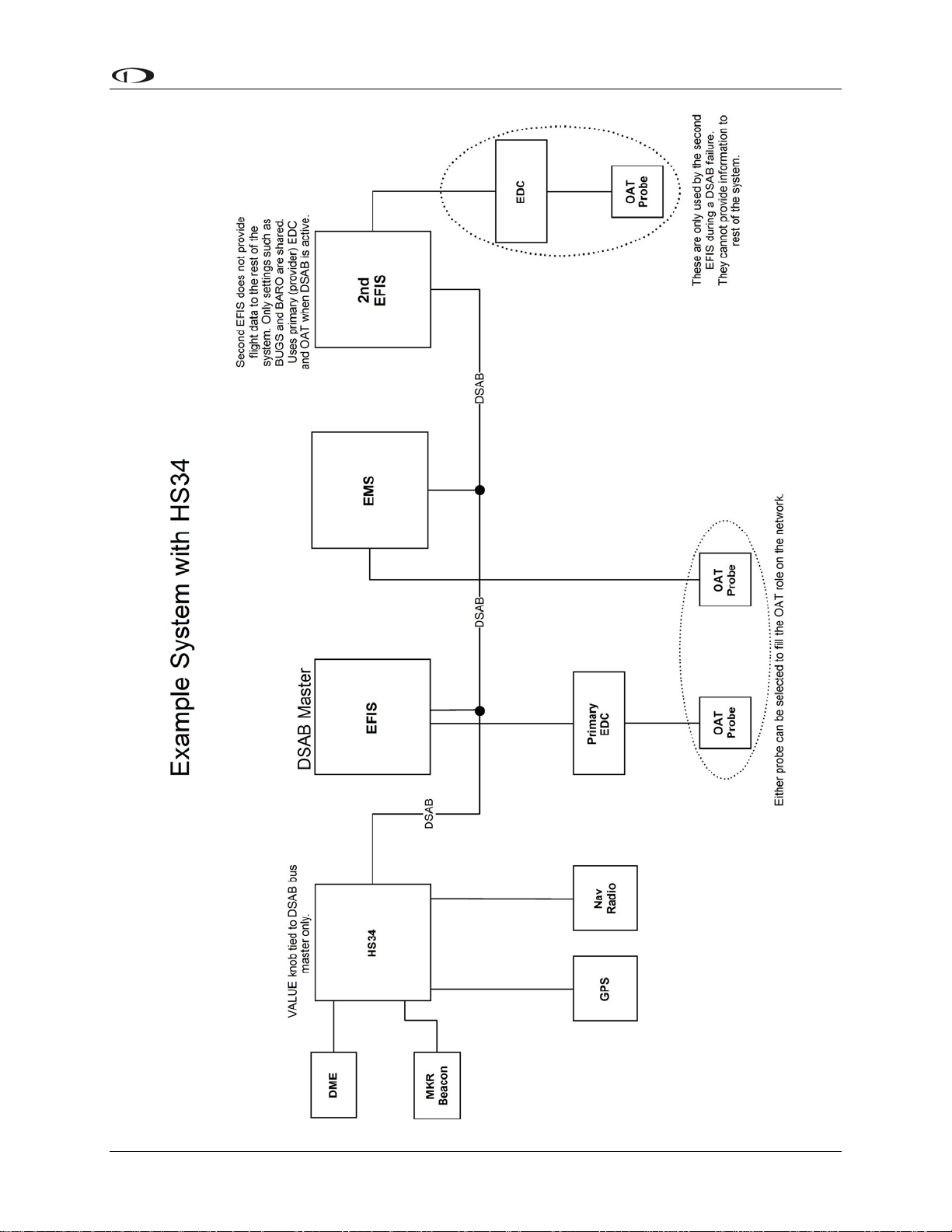

Example Networks

The following two diagrams present example DSAB-connected networks. These examples

illustrate and expand upon some of the concepts discussed above. The first diagram depicts a

system without an HS34 connected, demonstrating where NAV and GPS devices should be

connected. The second diagram depicts a system with an HS34 connected, demonstrating that all

NAV and GPS devices must be connected to the HS34. Both diagrams discuss what devices can

be assigned various roles and what happens when DSAB fails.

5-2 EFIS-D10A Installation Guide

Page 37

DSAB Configuration

EFIS-D10A Installation Guide

5-3

Page 38

DSAB Configuration

Initial Setup