Page 1

ASSEMBLY INSTRUCTIONS

DX-WD1202

Corner TV Stand

Safety information and specifications ............2

Tools needed............................................................3

Package contents ...................................................3

Assembly instructions...........................................6

Page 2

2 DX-WD1202

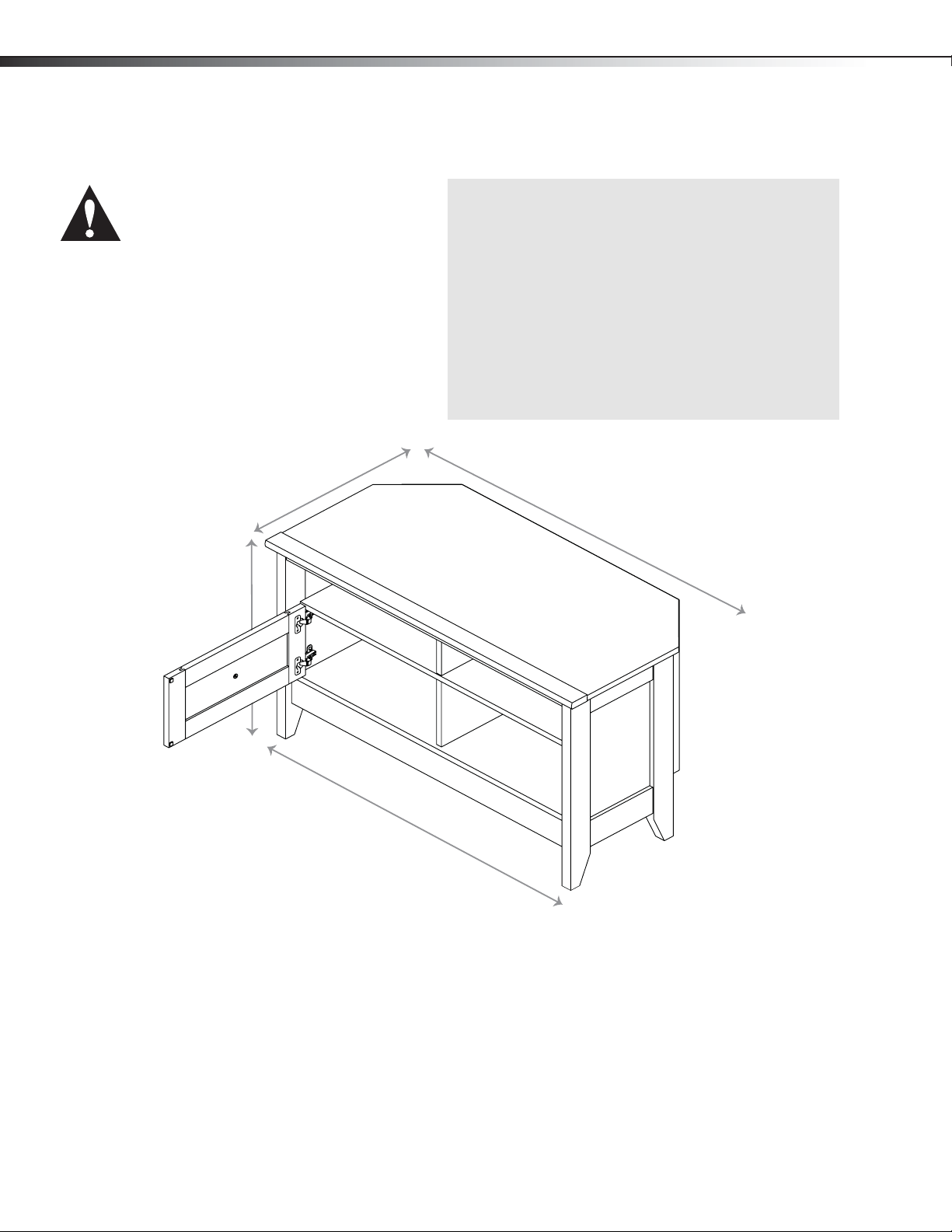

Safety information and specifications

CAUTION:

This stand’s work surface is intended only for use

with a product not weighing more than 95 lbs.

(43.09 kg) and accommodates most 37" and

some 42" flat-panel TV’s or 27" CRT TV’s with dimensions

that will permit the TV to sit evenly on the stand. Using with

other products, including products that weigh more than

the maximum weight allowed, may result in instability,

which may cause possible injury.

19.5" (49.53 cm)

11.38" (28.9 cm)

Maximum weight: 95 lbs. (43.09 kg)

Maximum screen size: Most 37" and some 42" flat-panel TV’s or

27" CRT TV’s

Weight capacity (top of stand): 95 lbs. (43 kg)

Weight capacity (middle shelf): 25 lbs. (11 kg) per side

Weight capacity (total lower shelf): 40 lbs (18 kg)

Overall dimensions: W × H × D

39.25" x 11.38" × 19.5" (99.69 × 28.9 × 49.53 cm)

Top of st and : W × H

39.25" × 19.5" (99.69 × 49.53 cm)

Usable middle shelf: W × H × D

17.38" × 5.75" × 17" (44.15 × 14.6 × 43.18 cm) per side

Usable lower shelf: W × H × D

16.5" × 8" × 16.75" (4.9 × 20.3 × 42.55 cm)

39.25" (99.69 cm)

Warnings

• Do not let children climb on your stand or play near it. The stand may tip over causing the TV or stand to

injure someone.

• When placing items on the shelves or the top of the stand, load the bottom shelf first and work up to the top

of your stand.

• Do not overload the shelves. They may break.

• Do not move your stand with items on the top or shelves. Your stand may tip over and injure someone. Before

you move your stand, unload starting with the top of your stand and working to the bottom shelf.

• Do not push your stand to move it. With the help of a second person, lift your stand to move it.

37.5" (95.88 cm)

Need help? Call 800-305-2204

Page 3

DX-WD1202

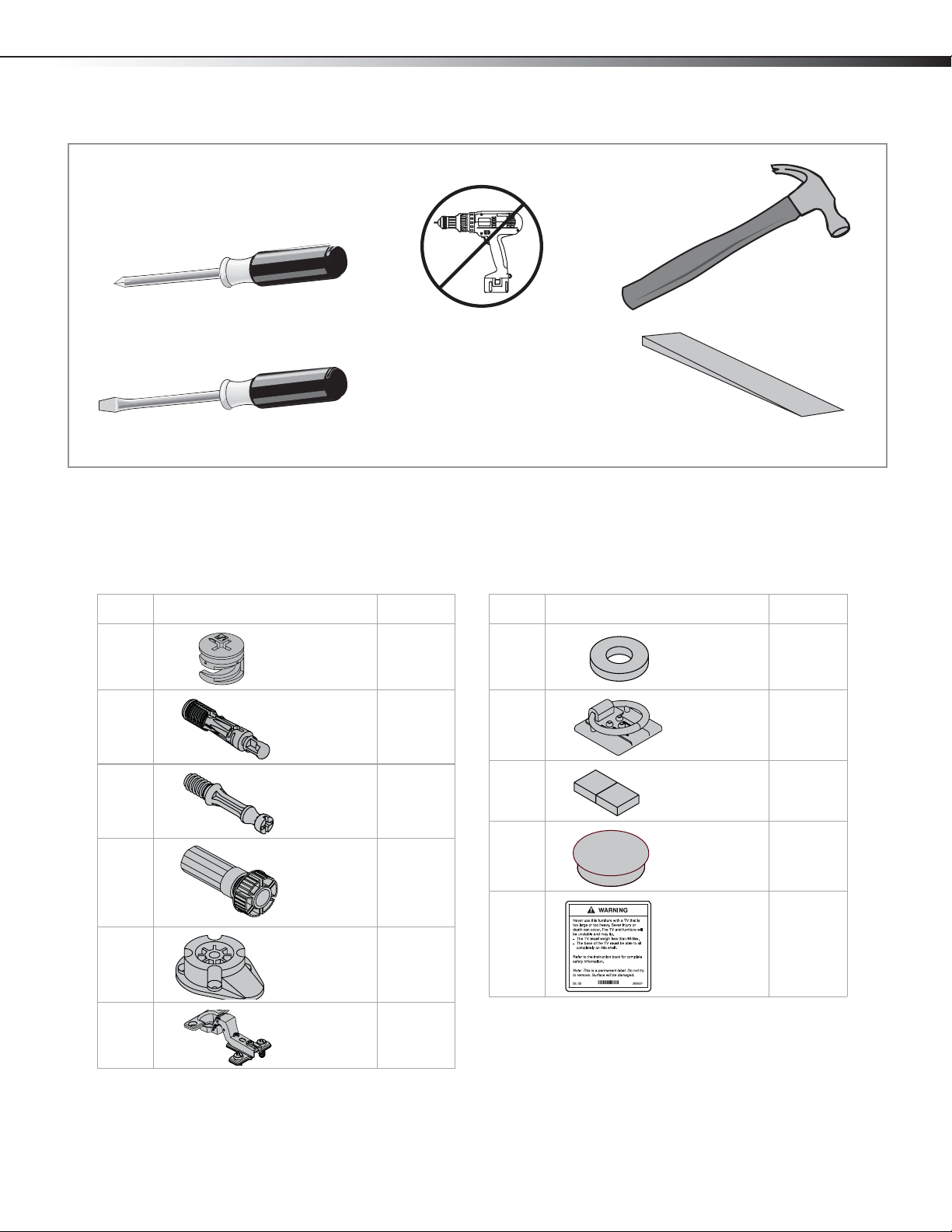

Tools needed

3

No. 2 Phillips screwdriver

Caution: Do not

use an electric drill

or screwdriver

Flatblade screwdriver

Package contents

Package contents: hardware

Note: You may receive extra hardware with your new TV stand.

Make sure you have all the hardware necessary to assemble your new TV stand:

Label Hardware Qty.

Q30

R22

Hidden cam

Cam dowel

Label Hardware Qty.

W2

X2

Hammer

Shim

Washer

Pull

S8

T1

U1

V4

Cam screw

Foot

Foot base

Hinge

Y2

AA 2

BB 1

Bumper card

Hole cover

Warning

label

Need help? Call 800-305-2204

Page 4

4 DX-WD1202

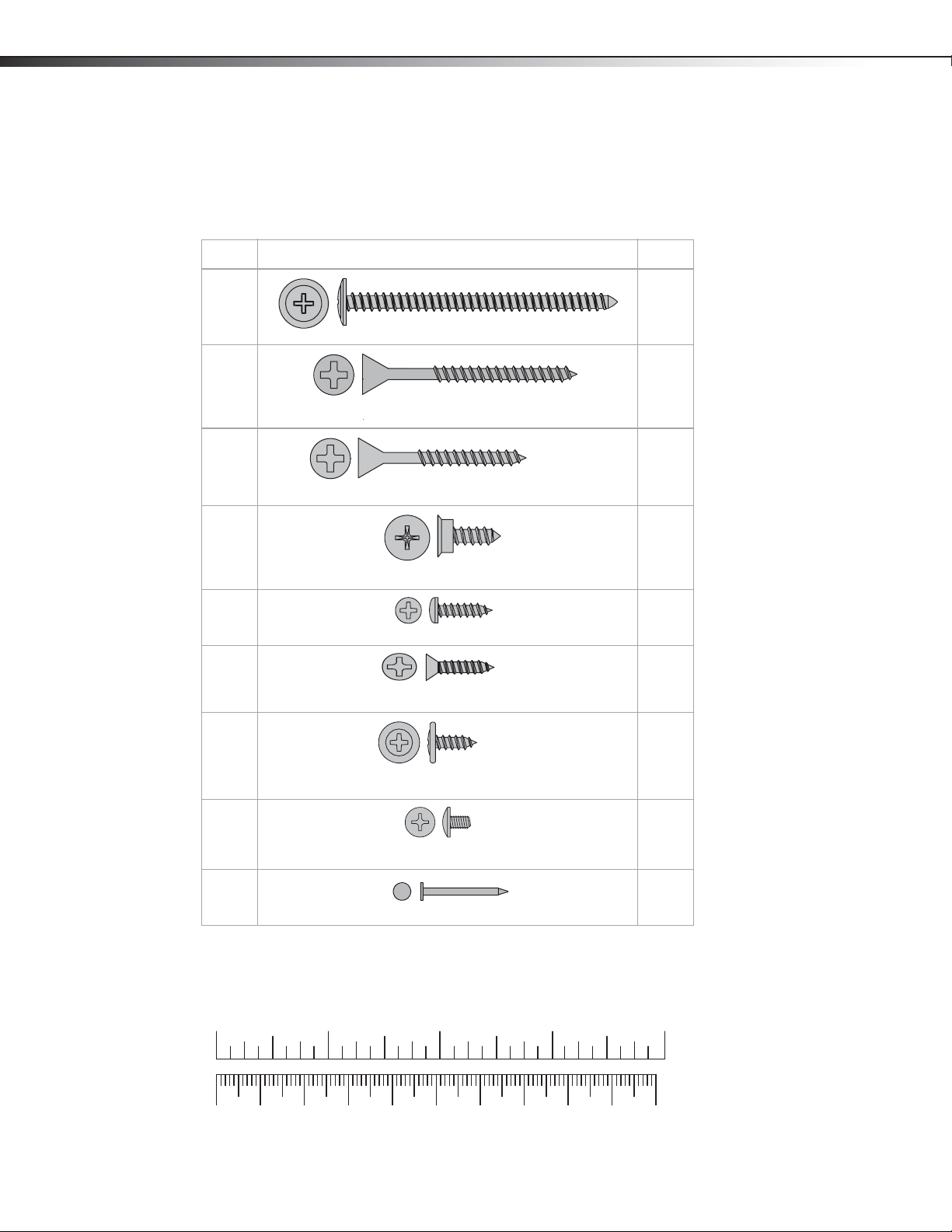

Package contents: hardware (continued)

Using a screw that is too long will cause damage to your stand. Before beginning assembly, separate

each type of screw. Carefully study the screw table below. You can use the ruler at the bottom of the

screw table to measure screws. Pay close attention to the color of each screw.

Letter Description Qty.

CC 4

Black 2 1/2" (63.5 mm) large head screw

DD 4

Black 1 7/8" (47.75 mm) flat head screw

EE 3

Brown 1 1/2" (38.1 mm) flat head screw

FF 8

Black 9/16" (14.22 mm) flat head

GG 4

HH 8

II 8

JJ 2

KK 33

Black 9/16" (14.22 mm) pan head screw

Black 1/2" (12.7 mm) flat head screw

Brown 7/16" (11.17 mm) large head screw

Silver 1/4" (6.35 mm) machine screw

Nails

1234in

10 20 30 40 50 60 70 80 90 1 00mm

Need help? Call 800-305-2204

Page 5

DX-WD1202

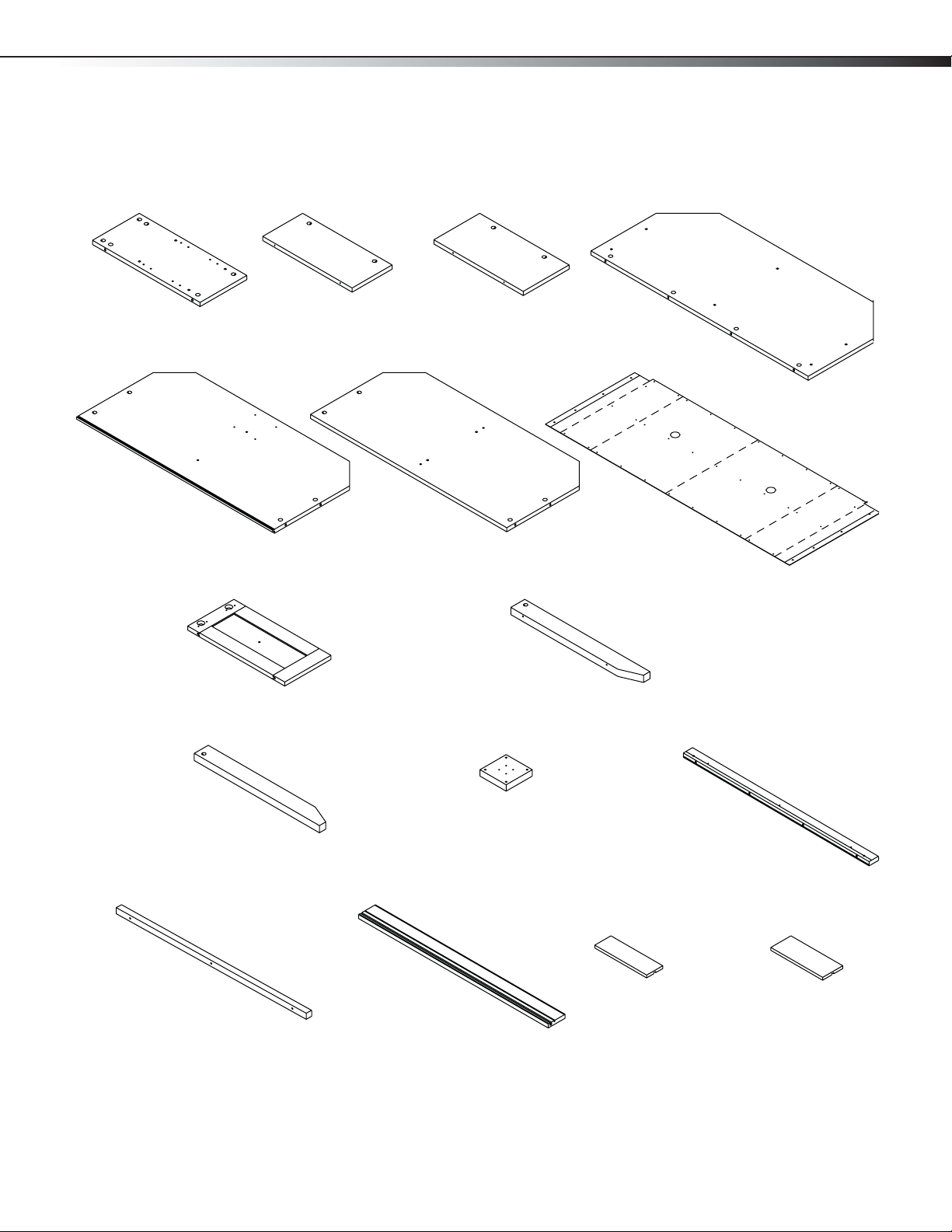

Package contents: parts

5

A End (2)

E Bottom (1) F Shelf (1)

H Door (2) I Right front and left rear leg (2)

B Upright (1) C Lower upright (1) D Top (1 )

G Back (1)

J Left front and right rear leg (2) K Extension (2) L Stop molding (1)

M Top m o lding ( 1 ) N Base (1) O Top ra il (2) P Bottom rail (2)

Need help? Call 800-305-2204

Page 6

6 DX-WD1202

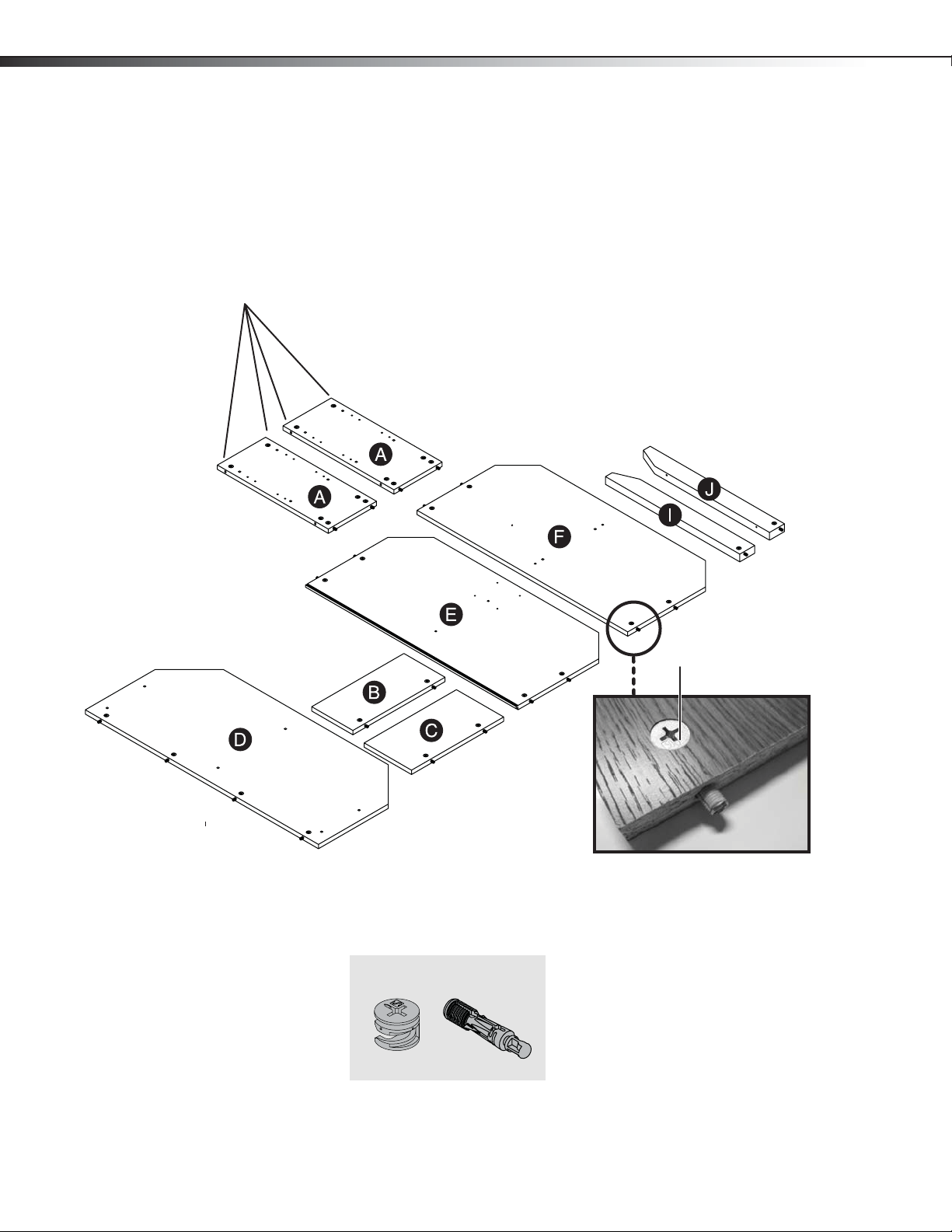

Assembly instructions

Step1:

Assemble your stand on a carpeted floor or on the empty carton to avoid scratching your stand or the floor.

Push thirty hidden cams (Q) into the ends (A), uprights (B and C), top (D), bottom (E), shelf (F), and one set of

legs (I and J). Then, insert twenty-two cam dowels (R) into the hidden cams. Do not insert cam dowels into

the hidden cams on the end of (A) as indicated in the illustration.

Do not insert cam dowels

into these edges.

Do not tighten the hidden cams in this step.

You’ l l n ee d :

R (22)Q (30)

Arrow

Need help? Call 800-305-2204

Page 7

DX-WD1202

7

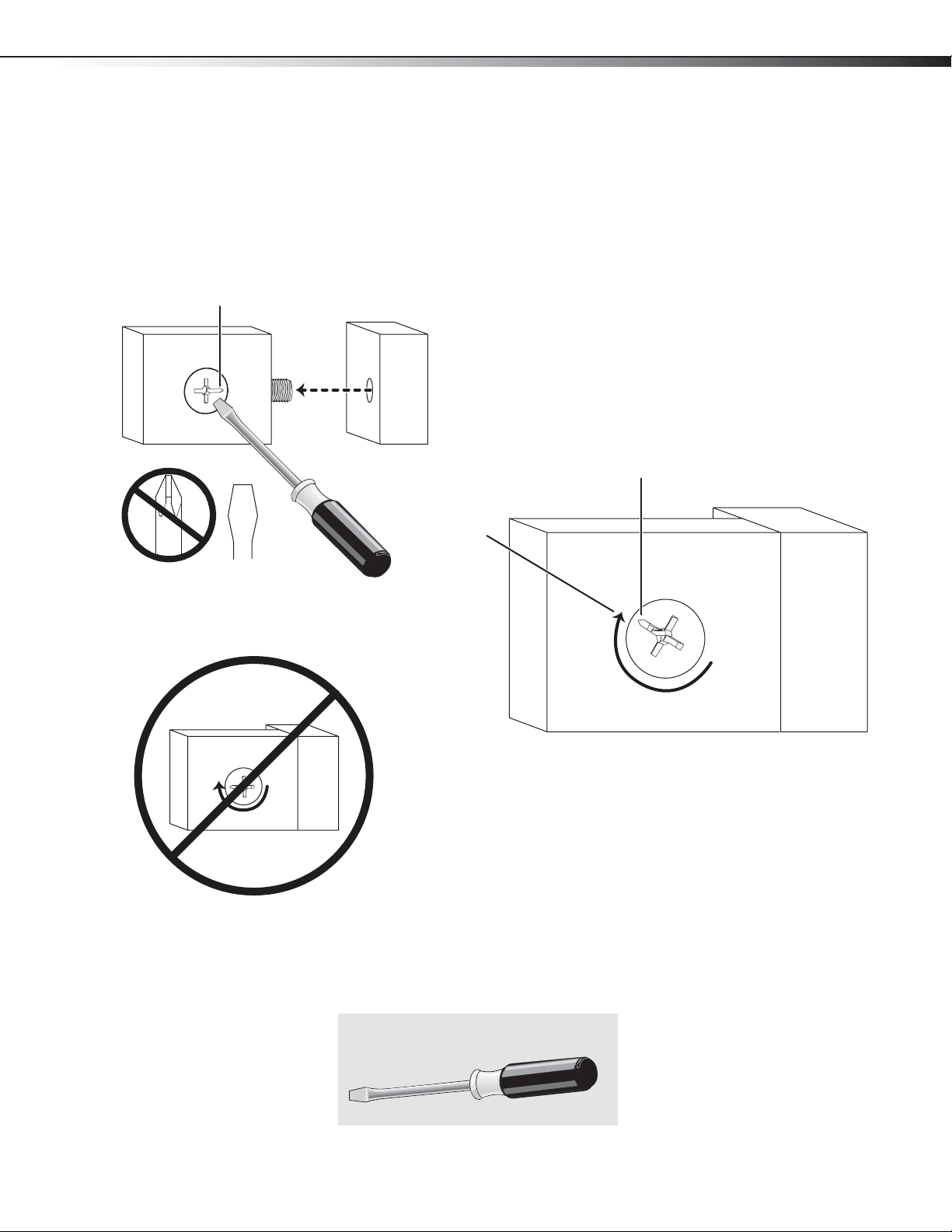

Tightening hidden cams

In the remaining steps, use these illustrations for instructions on tightening hidden cams.

Warning: Risk of damage or injury. Hidden cams must be completely tightened. Hidden cams that are not

completely tightened will loosen, and parts may separate.

A hidden cam (Q) has an arrow. When you insert the hidden cam, make sure that the arrow points toward the

hole in the side of the part you are inserting it into.

Arrow

In the illustration below,

the hidden cam has not

been tightened enough.

Make sure that you turn the

hidden cam 210°. Note the

position of the arrow on the

hidden cam.

Arrow

210°

You’ l l n ee d :

Flatblade screwdriver

Need help? Call 800-305-2204

Page 8

8 DX-WD1202

Step 2:

Screw two cam screws (S) into each of the legs (two I and two J).

Place the ends (A) flat with the side with the hidden cams facing up.

Make sure that the sides of the legs with the hidden cams are toward the ends (A).

Insert the cam screws on one of the legs (I) into one of the ends (A) and cam screws on one of the legs (J) into

the opposite side of the other end (A).

Tighten the four hidden cams. See “Tightening hidden cams” on page 7.

Leg with

hidden cams

Leg with

hidden cams

Surface with

hidden cams

You’ l l n ee d :

Need help? Call 800-305-2204

S (8)Flatblade screwdriver

Page 9

DX-WD1202

9

Step 3:

Carefully turn the ends (A) over so the side without the hidden cams is facing up.

Use a Phillips screwdriver to screw eight black 9/16" flat head screws (FF) (four per end) into the ends (A) until

the shoulders of the screws rest on the surface of the ends. Do not screw the screws in all the way.

Align the groove on a top rail (O) over the top screw head on one of the ends (A), then slide the rail over the

other screw head. Make sure that the ends of the rail are flush with the edges of the end. Repeat to attach the

other top rail (O) to the other end (A).

Align the groove on a bottom rail (P) over the bottom screw head on one of the ends (A), then slide the rail

over the other screw head. Make sure that the ends of the rail are flush with the edges of the end. Repeat to

attach the other bottom rail (P) to the other end (A).

Apply pressure with your hand as you

guide the rails over the screws on the

ends.

Screw head

You’ ll ne e d:

Need help? Call 800-305-2204

FF (8)Phillips screwdriver

Page 10

10 DX-WD1202

Step 4:

Carefully turn the ends over so the sides with the hidden cams face up.

Attach the unattached leg (I) to the left end (A) and the unattached leg (J) to the right end (A). See Step 2 for

instructions.

Insert a hole plug (AA) into the holes on the legs (I and J) that you just attached.

This end will now be

referred to the left end.

This end will now be

referred to the right end.

You’ l l n ee d :

Flatblade screwdriver

Need help? Call 800-305-2204

AA (2)

Page 11

DX-WD1202

11

Step 5:

Fasten the stop molding (L) to the top (D). Use a flatblade screwdriver to tighten the four hidden cams. See

“Tightening hidden cams” on page 7.

Unfinished

surface

Unfinished surface

You’ l l n ee d :

Rounded edge

Arrow

210°

Flatblade screwdriver

Need help? Call 800-305-2204

Page 12

12 DX-WD1202

Step 6:

Fasten the upright (B) and the left end (A) with the leg (J) to the top (D) and stop molding (L). Use a flatblade

screwdriver to tighten the five hidden cams (two on the upright (B), two on the left end (A), and one on the

leg (J)). See “Tightening hidden cams” on page 7.

Surface without

hidden cams

Finished edge

Arrow

210°

You’ ll ne e d:

Flatblade screwdriver

Need help? Call 800-305-2204

Page 13

DX-WD1202

13

Step 7:

Fasten the shelf (F) to the left end (A). Use a flatblade screwdriver to tighten the two hidden cams. See

“Tightening hidden cams” on page 7.

Fasten the shelf (F) to the upright (B). Use a Phillips screwdriver and two black 1 7/8" flat head screws (DD).

Fasten the lower upright (C) to the shelf (F). Use a flatblade screwdriver to tighten the two hidden cams.

Surface without

hidden cams

fi nie

Unfinished

fi cie sin acabado

surface

Finished

edge

Chant fi ni

Arrow

210°

You’ll need:

Flatblade screwdriver

Phillips screwdriver

DD (2)

Need help? Call 800-305-2204

Page 14

14 DX-WD1202

Step 8:

Fasten the bottom (E) to the left end (A). Use a flatblade screwdriver to tighten the two hidden cams. See

“Tightening hidden cams” on page 7.

Fasten the bottom (E) to the lower upright (C). Use a Phillips screwdriver and two black 1 7/8" flat head

screws (DD).

Slide the base (N) onto the notched edge of the bottom (E) so that the edge of the base is flush with the leg

on left end (A).

Unfinished surface

210°

Notched edge

Arrow

You’ll need:

Flatblade screwdriver Phillips screwdriver

Need help? Call 800-305-2204

DD (2)

Page 15

DX-WD1202

15

Step 9:

Fasten the right end (A) with the leg (I) to the top (D), bottom (E), shelf (F), and stop molding (L). Use a

flatblade screwdriver to tighten the seven hidden cams: A (2), E (2), F(2), and I (1). See “Tightening hidden

cams” on page 7.

Fasten the top molding (M) to the stop molding (L). Use a Phillips screwdriver and three brown 1 1/2" flat

head screws (EE).

Fasten the extension blocks (K) to the bottom (E). Use a Phillips screwdriver and four black 2 1/2" large head

screws (CC).

210°

You’ l l n ee d :

Flatblade screwdriver Phillips screwdriver

EE (3)

Need help? Call 800-305-2204

Arrow

CC (4)

Page 16

16 DX-WD1202

Step 10:

With the top of the unit facing down, fasten the foot base (U) to the extension block (K). Use a Phillips

screwdriver and four black 9/16" pan head screws (GG). Then, push the foot (T) into the foot base (U).

Note: Turn the foot (T ) for adjustments. The foot should not extend beyond the bottom edge of the base (N).

You’ll need:

Phillips screwdriver

Need help? Call 800-305-2204

GG (4)

Page 17

DX-WD1202

17

Step 11:

Carefully turn the unit so the front is facing down, then fasten the back (G) to the legs (I and J). Use a Phillips

screwdriver and eight brown 7/16" large head screws (II).

Fasten the remaining back (G) to your stand using 33 nails (KK).

Note: Be sure to tap the nails into the holes that line up over the shelf (F). Perforations have been provided for access through

the back. Carefully cut out the holes needed.

These holes must line

up over shelf (D).

Caution: Do not stand

your stand upright

without the back

fastened. Your stand may

collapse.

You’ll need:

Phillips screwdriver

II (8)KK (33)

Hammer

Need help? Call 800-305-2204

Page 18

18 DX-WD1202

Step 12:

Fasten the hinges (V) to the doors (H). Use a Phillips screwdriver and eight 1/2" flat head screws (HH) (two for

each hinge).

You’ ll ne e d:

Phillips screwdriver HH (8)

Need help? Call 800-305-2204

Page 19

DX-WD1202

19

Step 13:

Carefully turn the unit so the left end is facing down, then fasten one of the doors (H) to the left end (A). Use

a Phillips screwdriver and the screws in the hinges.

Note: You may need to loosen the mounting screw to slide the hinge part way out of the slot. Retighten the screw before you

mount the hinge to the end.

Carefully turn the unit so the right end is facing down, then fasten the other door (H) to the right end (A). Use

a Phillips screwdriver and the screws in the hinges.

Carefully turn the unit so it is right side up.

Align a pull (X) with the screw hole in the middle of the door (H). Place a washer (W) over the screw hole on

the back of the door, then insert a silver 1/4" machine screw (JJ) through the washer and into the pull screw

hole. Tighten the screw. Repeat this step for the other door.

Peel two bumpers from the bumper card (Y) and stick them on the inside of the door where the door comes

in contact with the lower upright (C). Repeat this step for the other door.

Mounting screw

You’ l l n ee d :

Phillips screwdriver W (2)

X (2)

Need help? Call 800-305-2204

Y (4)

JJ (2)

Page 20

20 DX-WD1202

Step 14:

You may need to adjust the doors to make them fit correctly.

To adjust the doors from side to side (horizontal), loosen the mounting screw several turns, then turn the

horizontal adjusting screw in or out. Tighten the mounting screw after making adjustments.

To adjust the doors up and down (vertical), loosen both vertical adjustment screws. Move the doors up or

down to the best location. Tighten the screws after making adjustments. You can use a shim to help hold the

door in place.

To adjust the doors in or out (depth), loosen the mounting screw one turn and move the doors in or out, as

needed. Tighten the mounting screw after making adjustments.

Horizontal

adjusting screw

Vertical

adjusting screws

Mounting

screw (depth)

You’ll need:

Phillips screwdriver

Shim

Shim

Need help? Call 800-305-2204

Page 21

DX-WD1202

21

Step 15:

Apply the warning label (BB) to the top (D). You should be able to read the label when the TV is removed

from your stand. When the TV is in place, it should hide the label. Peel off the backing and apply the label as

shown.

Caution: This is a permanent label intended to last for the life of the product. Once applied, do not try to

remove it. You may damage the finish on the top.

Clean with your favorite furniture polish or a damp cloth. Wipe dry. Your stand is ready to use.

Warning: Never use this furniture with a TV

that is too large or too heavy. Severe injury or

death can occur. The TV and furniture will be

unstable and may tip.

• The TV must weigh less than 95 lbs

(43.09 kg).

• The base of the TV must be able to sit

completely on this shelf.

25 lbs

(11 kg)

Note: One door has been

removed to make the interior

visible.

95 lbs

(43 kg)

25 lbs

(11 kg)

40 lbs.

18 kg

Need help? Call 800-305-2204

Page 22

22 DX-WD1202

Still need help?

For customer service, call: 800-305-2204 (U.S./Canada markets)

Distributed by Best Buy Purchasing, LLC

7601 Penn Avenue South, Richfield, MN USA 55423-3645

© 2011 BBY Solutions, Inc.

All rights reserved. DYNEX is a trademark of BBY Solutions, Inc. Registered in some countries. All other

products and brand names are trademarks of their respective owners.

Need help? Call 800-305-2204

Page 23

Certificate of Conformity

1. This certificate applies to the Sauder

Woodworking Product identified by this

instruction booklet.

2. This certificate applies to the compliance of

this product with the CPSC Ban on

Lead-Containing Paint (16 CFR 1303).

3. This product was manufactured by:

Sauder Woodworking Company

502 Middle Street

Archbold, Ohio 43502

(419) 446-2711

4. Date of Manufacture: ___________

Lot number: 337023

www.dynexproducts.com (800) 305-2204

Distributed by Best Buy Purchasing, LLC

7601 Penn Ave. South, Richfield, MN 55423 U.S.A.

© 2011 BBY Solutions, Inc.

All rights reserved.

DYNEX is a trademark of BBY Solutions, Inc. Registered in some countries. All other products and

brand names are trademarks of their respective owners.

11-0422

ENGLISH

Loading...

Loading...