Page 1

ELECTRONIC SPEED CONTROL

OPERATING INSTRUCTIONS

• Do not run the car near water! Never allow water, moisture, or any

foreign material onto the ESC’s PC board.

• Never use more than 7 cells (8.4 volts total) in the main

battery pack.

• Do not mix instructions. If you are building a vehicle that has a

mechanical speed control, do not use the wiring diagram included

with the vehicle.

• Never cut or splice the ESC input harness wires. The receiver does

not need to have anything plugged into the “battery” slot, it receives

power through the ESC input harness which plugs into the

CHANNEL 2 slot.

• Three 0.1μF (50V) ceramic capacitors must be properly installed on

every motor. (See step 2)

• Always disconnect the battery pack from the ESC when not

in use.

• Never turn on the ESC before plugging it into the receiver and

switching on the transmitter.

• Be careful not to touch the heat sink when it is hot.

PLEASE FOLLOW ALL INSTRUCTIONS CAREFULLY!

IMPORTANT PRECAUTIONS

(ESC=ELECTRONIC SPEED CONTROL)

STEP 1

MOUNTING THE SPEED CONTROL

The following mounting information will assure that your speed

control performs at maximum efficiency and minimizes the chances

of overheating and radio interference problems.

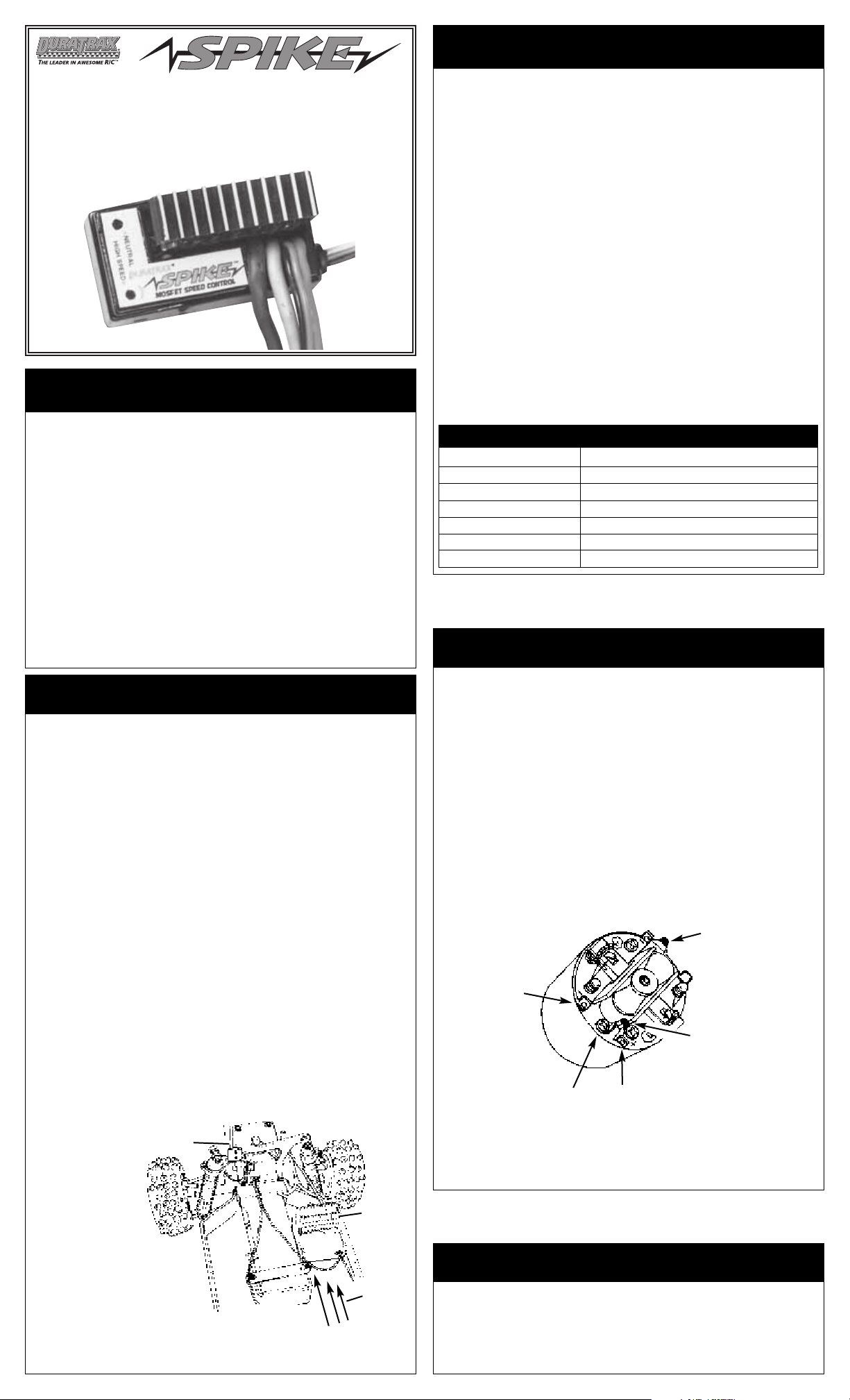

MOUNTING THE SPEED CONTROL (Figure 1)

1. Mount the ESC to the chassis using mounting tape. Mounting the

ESC to achieve good airflow through the heat sinks is very

important for maximum performance. For off-road cars, the ESC

should be mounted in the chassis, and as far away from the

receiver as possible to prevent radio interference.

2. Mount the ON/OFF switch in a convenient place using mounting

tape or screws provided.

MOUNTING THE RECEIVER

To prevent radio interference, mount the receiver and antenna at

least two inches away from the motor, batteries, power wires, servo,

or any large piece of metal — such as a metal chassis.

For off-road cars, the receiver and antenna should always be

mounted on the rear shock tower. Mounting the receiver in the tub of

the chassis greatly reduces the range of your radio and increases the

chance of radio interference. For the best performance, we

recommend using an FM receiver.

If your car has a graphite chassis, and you want to mount the

receiver on the chassis, mounting the receiver on edge with the

crystal and antenna as far away from the chassis as possible to

reduce the chance of radio interference.

Figure 1

Mount the speed control

to obtain maximum parallel

airflow THROUGH the

transistors. For off-road cars,

or cars with a metal or

graphite chassis, mount the ESC on the chassis, and the receiver

and antenna on the rear shock tower to reduce radio interference.

Speed

Control

Airflow

Antenna

Adjusting your transmitter is critical for proper speed control operation.

The transmitter (TX) throttle adjustments are described below:

• ATV, EPA, or ATL — set all to maximum.

• Throttle Trims and Sub Trims — set all at neutral or zero.

• Set the throttle reversing switch to reverse.

STEP 3

TRANSMITTER ADJUSTMENTS

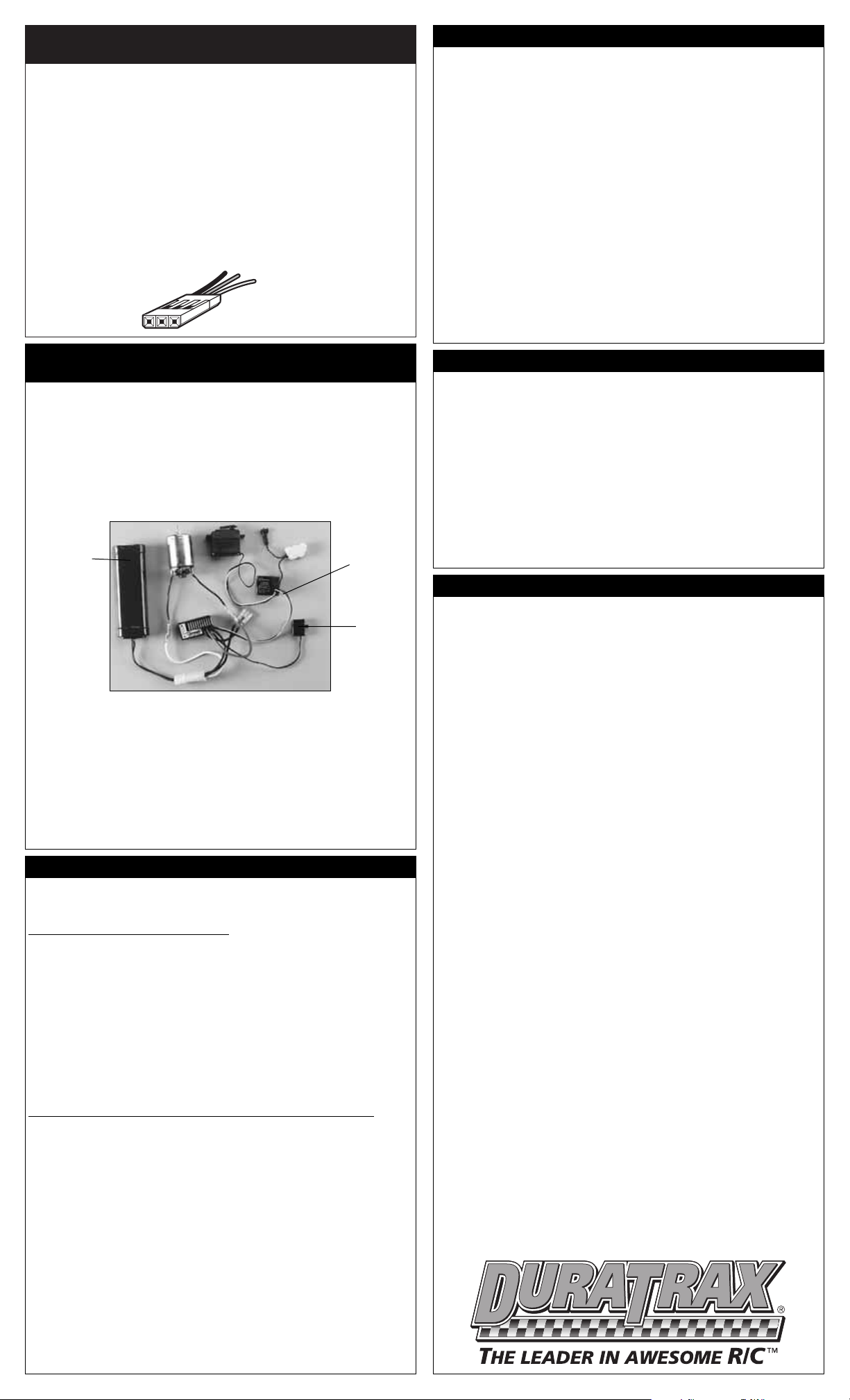

INSTALLING MOTOR CAPACITORS (Figure 2)

Motors generate radio noise which can interfere with your receiver

and cause problems. Your speed control package includes two 0.1μF,

50V, non-polarized, ceramic capacitors. These capacitors must be

used at all times on every motor to help reduce the radio noise

generated by the motor and prevent possible damage to the speed

control. Solder the capacitors between:

• POSITIVE (+) motor brush tab & GROUND motor tab†.

• NEGATIVE (-) motor brush tab & GROUND motor tab†.

STEP 2

HOOK-UP INSTRUCTIONS

INTRODUCTION TO

SPIKE ESC INSTRUCTIONS

The following instructions will help you get trouble-free speed control

operation. These simple steps will allow your speed control to achieve

maximum performance and minimize the chance of problems due to

incorrect installation.

Consult the specifications printed on the speed control header card

for limitations on the number of cells that the speed control can be

used with. You should always ask your hobby dealer or call our

service department before using the speed control for an application

other than what is listed in these instructions.

The Spike is equipped with a 20 amp reverse protection fuse, which

protects the speed control if the battery pack is hooked-up

backwards. Replacement fuses can be purchased at a local

electronics or automotive supply shop.

• An external diode can be used and may provide slight benefits in

brake smoothness and resistance to brake fade.

• The Spike is designed to be used with any stock motor and run on

5 to 7 cells only (1.2 volts/cell connected in series). Using more

than 7 cells may damage the speed control.

• When using an external receiver battery pack, the red wire in the

speed control input plug should be removed from its plastic

housing. Be sure to insulate the exposed metal pin.

Additional Specifications

Voltage Input 5 to 7 Cells

Case Size (w/o heat sinks) 1.65"x.82"x.67" (41mm x 21mm x 17mm)

Weight (w/o heat sinks) 1.27 oz (36g)

On-Resistance .01

Max. Constant Current 150 amps

Fuse Rating 30A

BEC 5.6 volts

Figure 2

Proper installation of motor capacitors.

Solder a 0.1μF

between the

negative brush

tab and the

ground tab†.

Solder a 0.1μF

between the

positive brush

tab and the

ground tab†.

Positive (+)

Brush Tab

Ground

Tab†

† Solder to the can of the motor if your motor doesn’t

have a ground tab.

Negative (-)

Brush Tab

Page 2

The radio connector on this ESC is universal. It can be directly

connected to any Futaba®J, Airtronics “Z”, Hitec “S”, or JR receiver

without modification. For proper connection refer to your radio’s

manual. The yellow “signal wire” on this ESC should be in the same

position in the receiver slot as the white wire on Futaba, the blue

wire on the new Airtronics “Z” connector, the yellow wire on the Hitec

“S” connector, and the orange wire on JR. WARNING: This connector

is NOT directly compatible with the old Airtronics connector style. For

old Airtronics radios, it is highly recommended to use an Airtronics

Servo Adapter to connect this ESC to the older style Airtronics radios.

NEVER ALLOW THE RED (+) AND BLACK (-) WIRES TO CROSS ON

ANY RECEIVER OR ESC AS PERMANENT DAMAGE WILL RESULT

TO BOTH ITEMS.

STEP 4

RADIO CONNECTOR POLARITIES

Radio interference can cause the speed control to rapidly switch

between forward and full brakes, causing overheating of the brake

transistors and possible damage to the ESC. Here are a few of the

most common causes of radio problems:

• CAPACITORS NOT INSTALLED ON MOTOR. Electric motors

generate radio noise that can interfere with the receiver. To prevent

radio problems, every motor should have two 0.1μF (50V) ceramic

capacitors installed (See step 2).

• RECEIVER MOUNTED ON GRAPHITE OR METAL CHASSIS.

Graphite and metal chassis transmit radio noise generated by the

motor. To prevent radio problems, mount the receiver on the rear

shock tower or away from the chassis. If the receiver is mounted on

the chassis, stand it on its side with the crystal as far away from

the chassis as possible.

• RECEIVER ANTENNA CUT OR MOUNTED WRONG. If the

receiver’s antenna is cut, the range will be reduced. The antenna

should be mounted away from the motor and power wires. Coiling

the antenna wire, or keeping the entire antenna inside the body will

reduce the range and increase the risk of radio problems.

Before you begin this step, your speed control should be plugged into

the receiver and your transmitter should have already been adjusted.

Before you connect the main battery pack to the speed control, make

sure that the ESC switch is turned off. Connect the battery pack to

the speed control, turn on the transmitter and ESC, and begin setting

the adjustment pots.

CAUTION! Forcing the adjustment pots past their stops can cause

internal speed control damage.

SETTING THE ADJUSTMENT POTS

1. Rotate the NEUTRAL pot until the motor stops running.

2. Hold the transmitter at 90% throttle and rotate the HIGH SPEED

pot until the motor is at maximum R.P.M.

3. Use the coast brake adjustment on the transmitter to dial in more

or less brakes. If there is no coast brake adjustment, rotate the

speed control’s NEUTRAL pot a few degrees counterclockwise for

desired coast brakes and re-adjust the HIGH SPEED pot.

Remember to seal the adjustment pots with tape to keep debris out of

the electronic speed control.

STEP 5

SPEED CONTROL SET-UP

Note: The Trouble Shooting Guide is separated into two sections. Please

review applicable sections and refer to all instructions.

SPEED CONTROL DOES NOT WORK

Problem: Motor and/or Steering Servo are dead.

1) Re-charge dead batteries.

2) Bad power plugs.

3)

Damaged connection between ESC and receiver. Check plug prongs.

4) Internal damage†.

Problem: No brakes.

1) Transmitter adjusted incorrectly.

2) Brake transistor is blown†.

Problem: Case is melted.

Internal damage†.

Problem: ESC runs with switch off.

Drive transistor is blown†.

† – Unit will require service; see “Service Procedures”

SPEED CONTROL WORKS (BUT OTHER PROBLEMS EXIST).

Problem: Receiver glitches or stutters during acceleration.

1) The 2 required motor capacitors are not installed or have broken.

2) Receiver is dropping out due to a large voltage drop during

acceleration. Use either an external battery or a non-BEC receiver

designed to be used with ESCs.

3) Receiver mounted too close to ESC.

4) Bad power plugs or input harness.

5) Receiver mounted flat in chassis.

Problem: Model runs slowly or has no acceleration.

1) Hi-Speed pot not properly adjusted.

2) Bad plug(s), battery, and/or motor.

Problem: Steering Servo works and motor is dead.

Motor brushes are hanging up, are worn out, or motor is bad.

Problem: Overheated motor or hot power plugs.

1) Motor is geared too high.

2) Shorted motor.

3) Defective or loose plug(s).

Problem: Motor runs backwards.

1) Motor wired backwards.

2) Battery pack is wired backwards.

TROUBLE SHOOTING GUIDE

PREVENTING RADIO PROBLEMS

PLEASE NOTE: Speed controls that operate normally when received

will be charged a minimum service fee and return shipping charges.

Before sending your speed control in for service, it is important that

you review the Trouble-Shooting Guide in this instruction set. The

speed control may appear to have failed when other problems exist in

the system — such as a defective transmitter, receiver or servo, or

incorrect adjustments/installation.

• Hobby dealers are not authorized to replace speed controls thought

to be defective.

• Do not cut the input harness, switch harness, or power wires of the

speed control before sending it for service. A fee will be charged for

cut wires which must be replaced for testing.

SERVICE PROCEDURES

DuraTrax warrants this product to be free from defects in materials

and workmanship for a period of 120-days from the date of purchase.

During that period, we will repair or replace, at our option, any

product that does not meet these standards. You will be required to

provide proof of purchase date (receipt or invoice).

If, during the 120-day period, your DuraTrax product shows defects

caused by abuse, misuse, or accident, it will be repaired or replaced

at our option, at a service charge not greater than 50% of the current

retail list price. Be sure to include your daytime telephone number in

case we need to contact you about your repair.

This warranty does not cover components worn by use, application of

reverse voltage, cross connections, poor installation, subjection of

components to foreign materials, any alterations to wires, or tampering.

In no case shall our liability exceed the original cost of the product.

Your warranty is voided if...

A. You apply reverse voltage to the Spike ESC by connecting the

battery pack backwards, or plugging the motor connectors into the

battery pack.

B. You allow any wires to become frayed which could cause a short.

C. You use more than 7 cells (1.2V/cell) in the main battery pack.

D. You tamper with any of the electronic components.

E. You allow water, moisture, or any other foreign material onto the

PC board.

F. You do not remove the red wire in the input harness when using

an external battery pack.

G. You apply too much pressure when installing the heat sink.

H. You force the pots past their stops.

Under no circumstances will the purchaser be entitled to consequential

or incidental damages. This warranty gives you specific legal rights,

and you may also have other rights which vary from state to state. If

you attempt to disassemble or repair this unit yourself it may

void the warranty.

For service to your DuraTrax product, either in or out of warranty,

send it post paid and insured to:

HOBBY SERVICES

1610 Interstate Drive,

Champaign, IL 61822

(217) 398-0007

E-Mail: hobbyservices@hobbico.com

Internet Address: www.duratrax.com

120-DAY LIMITED WARRANTY

Connect the

battery plug

from the ESC

to the battery

plug on a

fully charged

5 to 7 cell

battery pack.

Turn on

the ESC

Plug the

ESC and

servo into

the receiver

© Copyright 1998 V1.1 DTXZ1101 For DTXM1040

b

a

l

(

k

c

red (+)

)

-

(s)

w

llo

ye

Loading...

Loading...