Duke SWFM Installation Manual

WATER

WASH

VENTILATOR

OWNER’S

MANUAL

BY

Please read this manual completely before attempting to install,

operate or service this equipment.

This manual is Copyright © 2010 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Co.

Southern Engineering

A Division of Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 0058619

Water Wash Ventilator Owner’s Manual

IMPORTANT WARNING AND SAFETY INFORMATION

POST IN A PROMINENT LOCATION instructions to be followed in

the event the user smells gas. This information shall be obtained by

consulting the local gas supplier.

FOR YOUR SAFETY:

Do not store or use gasoline or other ammable vapors or liquids in the

vicinity of this or any other appliance.

WARNING: Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death. Read the

installation, operating and maintenance instructions thoroughly before

installing or servicing this equipment.

INSTALLATION INSTRUCTIONS

• Units shall be installed by qualied personnel in accordance with all

local and municipal codes.

• Wiring Diagrams are provided with equipment as supplied.

• Exhaust and supply air ow rates shall be in accordance with

NFPA96-UL requirements.

• Exhaust and supply (if provided) air ow rates were established

under controlled laboratory conditions, and greater and/or lesser air

supply may be required for complete vapor and smoke removal in

specic installations.

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE

2

Water Wash Ventilator Owner’s Manual

TABLE OF CONTENTS

LIMITED WARRANTY .........................................................................................................................5

OWNER’S REGISTRATION REFERENCE SHEET ............................................................................6

INSTALLER: FILL OUT THIS FORM, DETACH AND PUT WITH THE

START-UP REPORT TO BE SENT TO SOUTHERN ENGINEERING ................................................7

GENERAL INFORMATION ..................................................................................................................9

PRINCIPLES OF OPERATION ...........................................................................................................9

CONTAMINANT CAPTURE ........................................................................................................9

GREASE EXTRACTION .............................................................................................................9

AUTOMATIC CLEANING ..........................................................................................................10

FIRE PROTECTION CYCLE .....................................................................................................11

Standard Push Button Control ........................................................................................... 11

SEQUENCE OF OPERATION ..........................................................................................................12

STANDARD CONTROL PANEL ................................................................................................12

Wash Cycle Procedure ......................................................................................................12

Fan Cycle ...........................................................................................................................12

MODE COMMANDER ...............................................................................................................13

FIRE SUPPRESSION SYSTEMS .....................................................................................................13

APPLIANCE PROTECTION ......................................................................................................13

DRY AND WET CHEMICAL SYSTEMS ....................................................................................13

WATER FOG SYSTEM .............................................................................................................14

WATER WASH FIRE SUPPRESSION ......................................................................................14

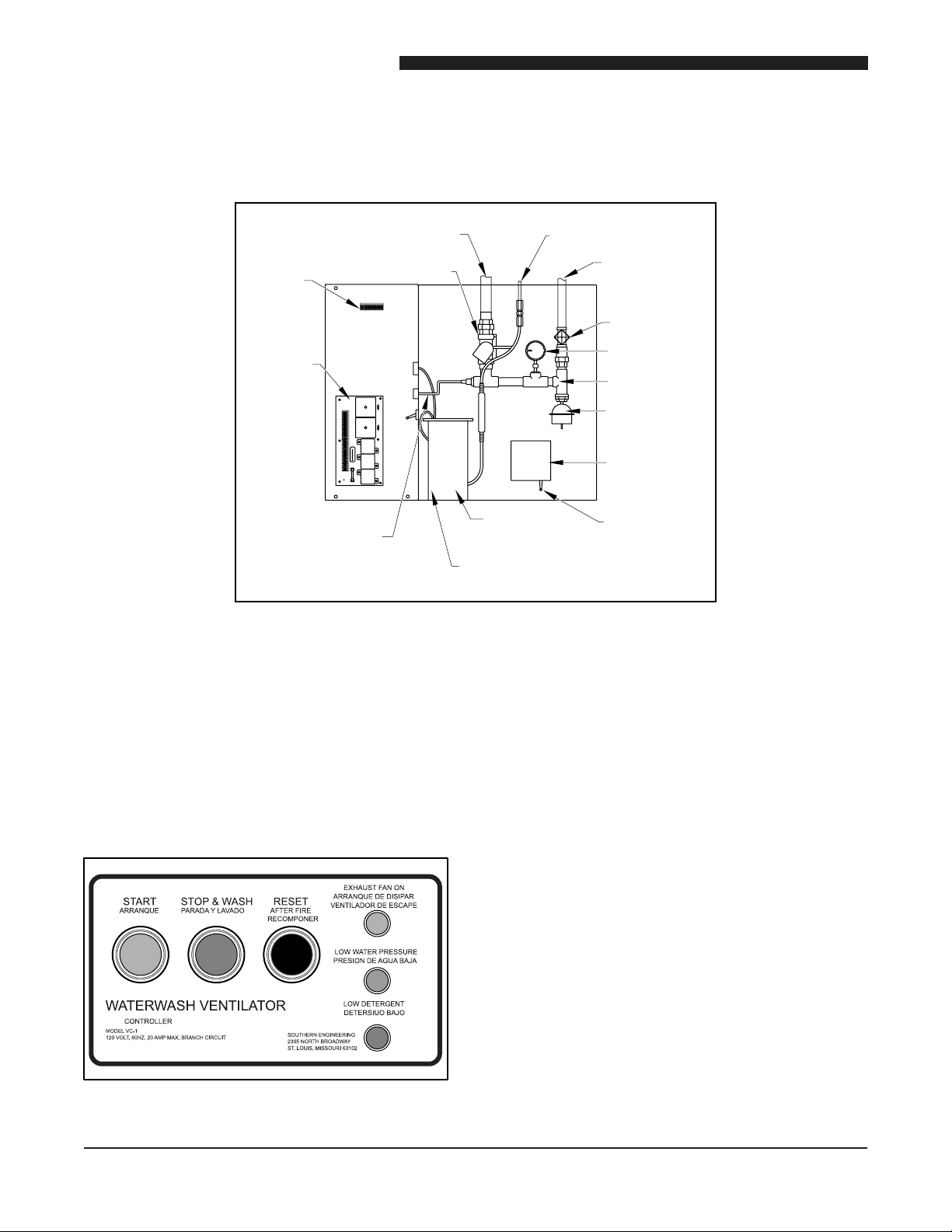

COMPONENT IDENTIFICATION AND ACCESS ..............................................................................16

STANDARD CONTROL CABINET ...........................................................................................16

Push Button Control ...........................................................................................................16

ELECTRICAL COMPARTMENT ................................................................................................17

PLUMBING COMPARTMENT ...................................................................................................19

EXTERNALLY MOUNTED COMPONENTS .....................................................................................22

VENTILATOR MOUNTED COMPONENTS AND ACCESS PANELS ...............................................23

WATER WASH MAINTENANCE PROCEDURES .............................................................................26

DETERGENT SYSTEM .............................................................................................................26

Water Wash Detergent Pump Replacement ......................................................................26

Start-up of the Detergent Pump Assembly ........................................................................28

Care and Adjustments .......................................................................................................28

Gaskets and Check Valves ................................................................................................29

Detergent Reservoir ...........................................................................................................29

3

Water Wash Ventilator Owner’s Manual

Service and Repairs ..........................................................................................................30

Pump Head Assembly or Diaphragm .................................................................................30

Ball Check and Valve Seat Replacement ..........................................................................31

Approved Detergents .........................................................................................................31

Water Wash Hood Detergent/Water Consumption Chart ..................................................32

EXTERNALLY MOUNTED COMPONENTS .....................................................................................33

REMOTE FIRE PULL ................................................................................................................33

VACUUM BREAKER .................................................................................................................33

WASH SOLENOID VALVES ......................................................................................................34

DAMPER MOTOR .....................................................................................................................35

WASH NOZZLES ......................................................................................................................35

TROUBLESHOOTING ......................................................................................................................36

WIRING SCHEMATICS .....................................................................................................................41

MODE COMMANDER FOR ONE VENTILATOR ......................................................................41

MODE COMMANDER FOR TWO VENTILATORS ...................................................................42

MODE COMMANDER FOR THREE VENTILATORS ...............................................................43

MODE COMMANDER FOR FOUR VENTILATORS .................................................................44

STANDARD WIRING DIAGRAM FOR VENTILATOR (OLD STYLE) ........................................46

PREVENTIVE MAINTENANCE CHART ...........................................................................................47

SERVICE AND ORDERING INFORMATION ....................................................................................48

WATER WASH VENTILATOR REPLACEMENT PARTS LIST ..........................................................49

CUSTOMER ASSISTANCE ...............................................................................................................51

4

Water Wash Ventilator Owner’s Manual

LIMITED WARRANTY

Southern Engineering Systems products are warranted to be free from defects in material or workmanship for a period of one year

from the date of start-up or 18 months from the date of shipment (whichever comes rst) when installed, operated and serviced

in accordance with the Southern Engineering Systems recommendations, when used under normal conditions for their intended

purposes; and when evidence of such installations, proper and acceptable to Southern Engineering Systems, are recorded at the

factory. Southern Engineering Systems reserves the right to void this warranty for operations of its product outside of these terms.

Southern Engineering shall further warrant motorized conveyor drive components (consisting of motor, gear reduction unit, track

glide wear surfaces, speed controller, bearings, shaft(s)) for an additional 48 months after the expiration of the above described

one-year warranty. This additional warranty does not apply to renewable parts such as drive chains or gears, or the belting; and

is for parts replacement only if these motorized conventional conveyor drive components become inoperative due to a defect

in factory workmanship or a failure in material utilized in its original operation and maintenance instructions, labor not included.

Any request for repair or replacement must be made to the Service Department of Duke Manufacturing Co., 2305 N. Broadway,

St. Louis, MO 63102. Southern Engineering Systems’ warranty shall be limited to repair or replacement (at Duke Manufacturing

Co's. option) of any part of said equipment that proves to be defective after an examination by its Service Department or designate.

The labor required to make repairs or replacement under this warranty shall be furnished by Duke Manufacturing Co. or its

authorized representative between the hours of 8:00 AM and 400 PM Monday through Friday, and is limited to the actual repairs

or replacements of the warranty item. Labor and cost of such labor to inspect and/or determine the origin of the problem involving

the examination of equipment or systems not furnished or manufactured by Southern Engineering Systems is specically excluded.

This warranty is only for applications which the equipment was originally installed, and only covers original equipment components.

This warranty does not cover routine maintenance (such as but not limited to tightening belts, adjustment of linkage or controls,

cleaning, etc.) or replacement of renewable items such as belts, chains, detergent, lters, etc. Malfunctions caused by improper

water pressure, electrical power variances, exhaust fan performance (ventilators only), or restricted drainage systems are also

excluded from warranty protection. Warranty claims will not be honored unless the manufacturer is advised in advance of the

work being performed by an authorized and approved representative of Duke Manufacturing Co.

This warranty does not cover loss of food, other products, or other consequential damage resulting from any equipment failure.

THIS WARRANTY IS THE ONLY WARRANTY; THERE BEING NO OTHER WARRANTY EITHER EXPRESSED OR IMPLIED.

5

Water Wash Ventilator Owner’s Manual

OWNER’S REGISTRATION REFERENCE SHEET

FOR SOUTHERN ENGINEERING SYSTEMS BY DUKE WATER WASH VENTILATORS

(ll out at time of installation)

DO NOT REMOVE FROM THIS MANUAL

Model No. ______________________________ Serial No. _______________________________

Customer’s Name: _________________________________________________________________

_________________________________________________________________________________

Address: _________________________________________________________________________

Installer’s Name: __________________________________________________________________

Address: _________________________________________________________________________

Installed At: ______________________________________________________________________

Installation Date: __________________________________________________________________

Remarks: ________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

6

Water Wash Ventilator Owner’s Manual

INSTALLER: FILL OUT THIS FORM, DETACH AND

PUT WITH THE START-UP REPORT TO BE SENT TO

SOUTHERN ENGINEERING

WARRANTY REGISTRATION

for

SOUTHERN ENGINEERING SYSTEMS BY DUKE WATER WASH VENTILATORS

Model No. ______________________________ Serial No. _______________________________

Customer’s Name: _________________________________________________________________

_________________________________________________________________________________

Address: _________________________________________________________________________

Installer’s Name: __________________________________________________________________

Address: _________________________________________________________________________

Installed At: ______________________________________________________________________

Installation Date: __________________________________________________________________

Remarks: ________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

For Factory Use Only S/O# __________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

7

Water Wash Ventilator Owner’s Manual

8

Water Wash Ventilator Owner’s Manual

GENERAL INFORMATION

TO E N SUR E P R OPE R O P ERATI ON AN D

MAINTENANCE OF THE SOUTHERN ENGINEERING

BY DUKE WATER WASH VENTILATION SYSTEM,

PLEASE READ AND UNDERSTAND THIS MANUAL

THOROUGHLY.

When necessary, the following information will be

indented and paraphrased.

NO T E: Infor m ation pert aining to special

instructions regarding the care and use of the

Mode Commander.

CAUTION: Information intended to indicate

situations which may cause immediate or

future damage to the Mode Commander.

WARNING: Advice against improper use or

procedures which may result in bodily injury

for which Southern Engineering will accept

no responsibility.

All information, illustrations and specications contained

in this manual are based on the latest product information

available at the time of printing. Southern Engineering

by Duke reserves the right to make changes at any

time, without notice, in specications, and models, also

to discontinue models. Southern Engineering by Duke

also reserves the right to change any specications or

parts at any time without incurring obligation to equip

the same on models manufactured prior to the date

of such change.

The continuing accuracy of this manual cannot be

guaranteed.

All illustrations used in this manual may not depict

models or equipment and are intended as representative

views for reference only.

Future supplement sheets will be added or deleted

as necessary.

Prints or system details located in this manual are for

instructional purposes only and do not represent actual

or scale drawings.

PRINCIPLES OF OPERATION

CONTAMINANT CAPTURE

The primary purpose of any kitchen ventilator system

is to take objectionable odors, grease, steam and dust

particles from the cooking surface and transfer them

to an un-objectionable area.

The two most important considerations in achieving

contaminant capture are air velocity and volume.

Because one directly affects the other, each will determine

how well the ventilator captures contaminants and will

be fully explained in a following section of this manual.

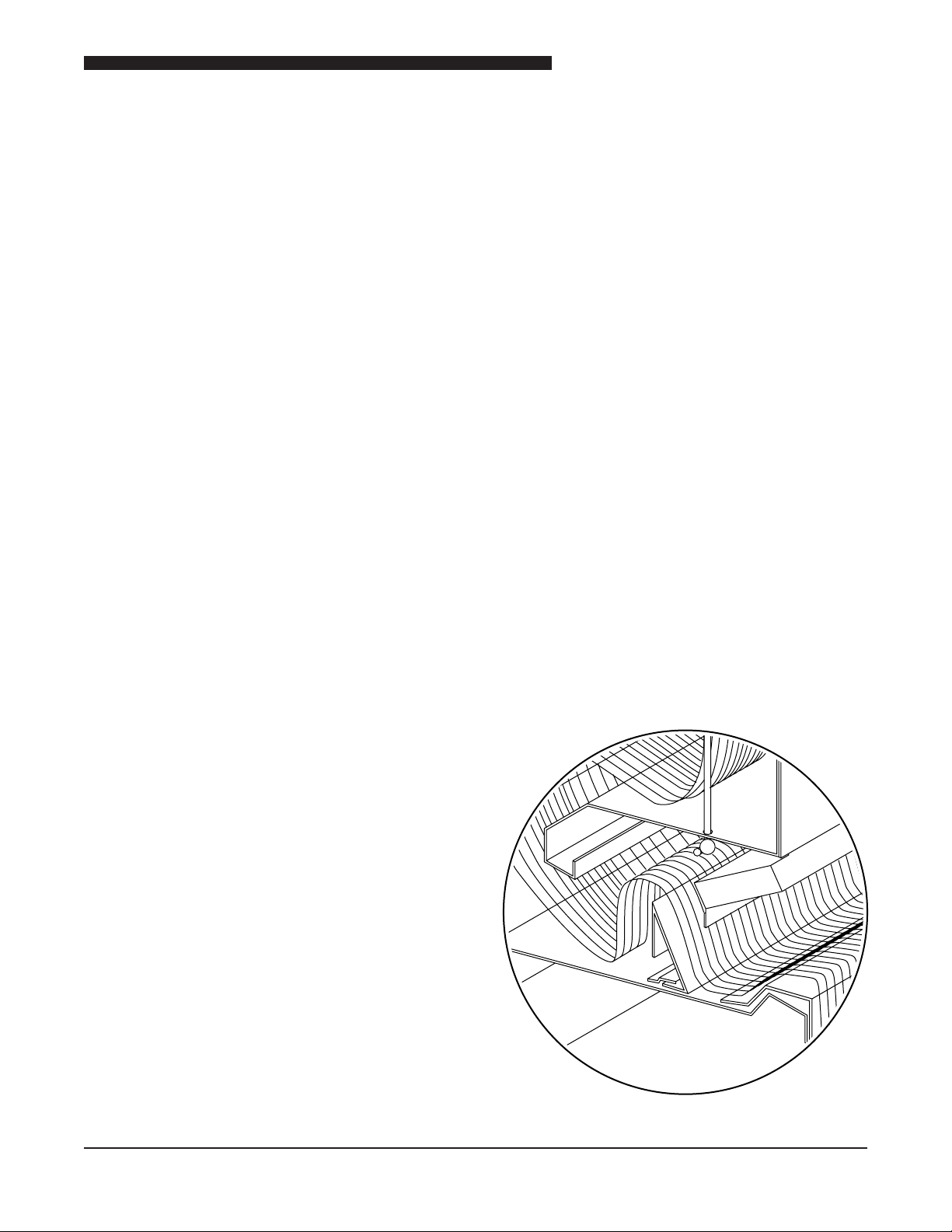

GREASE EXTRACTION

Because of environmental concerns and regulations, it

is more important than ever before to remove as much

grease and unwanted contaminants as possible from

the air stream being expelled from the system. The

Water Wash Ventilator is one of the most effective in

grease removal on the market.

This is accomplished by centrifugal force as the air is

drawn through a series of bafes and forced to make

turns during which the grease particles impinge upon the

bafe plates. The grease will remain inside the ventilator

through the duration of the normal cooking cycle.

Centrifugal Grease Extraction

9

Water Wash Ventilator Owner’s Manual

Centrifugal grease extraction is the removal of grease

and dust from the air stream by means of centrifugal

action without any removable parts, moving parts, or

continuous, wasteful water spray.

At the termination of this cycle, the equipment is shut

down, and the ventilator will automatically clean the

grease from the system. This extraction is accomplished

without the use of lter media or moving parts to clog

with grease.

Because of this type of extraction, the Water Wash

Ventilator is well suited for commercial and industrial

applications and removes grease much more efciently

than bafe or mesh lter systems.

Extraction Chamber

Model SWFM Hi-Velocity Wall Style Water

Wash Ventilator With “Lazy Air” Make-up

Chamber

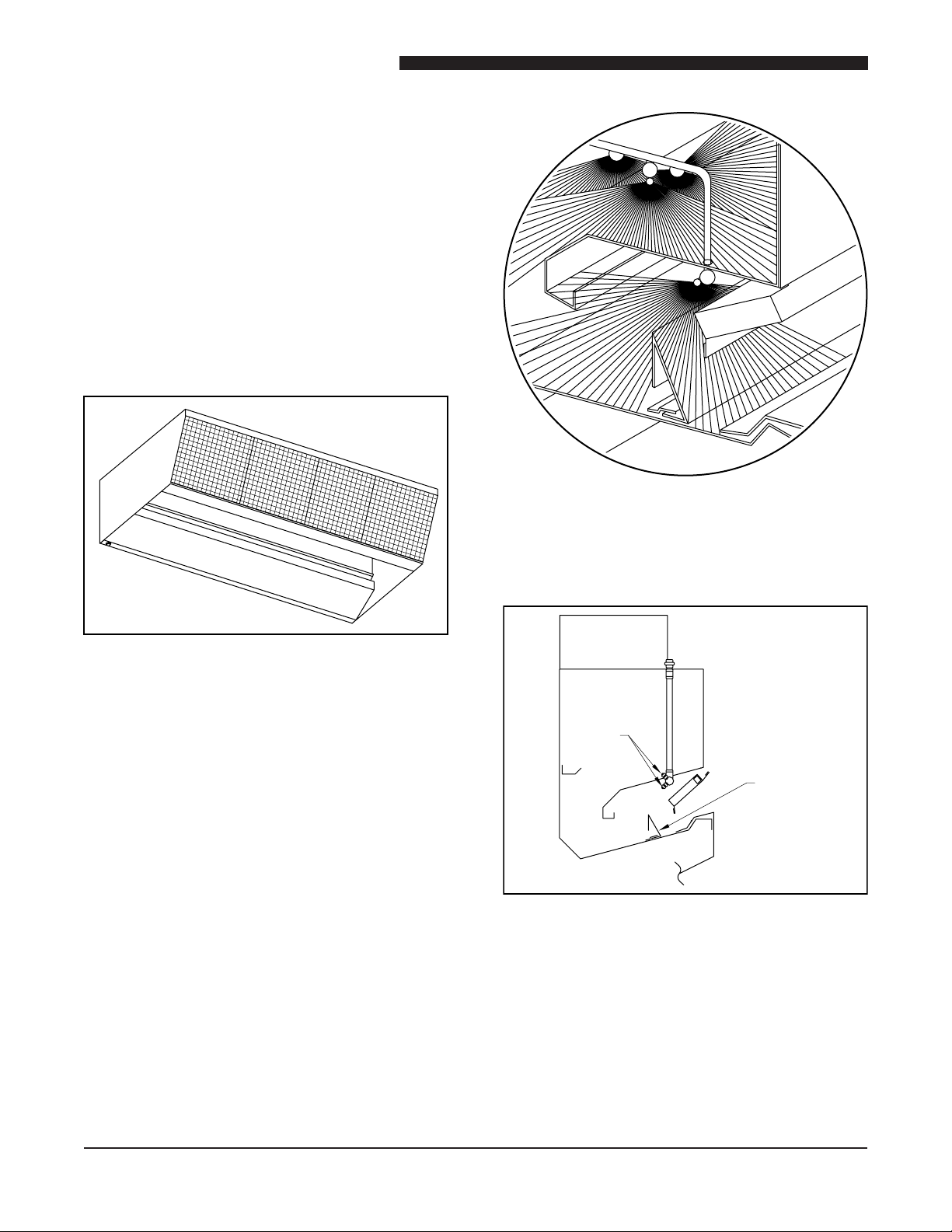

AUTOMATIC CLEANING

The grease and dust that accumulate within the

extraction chamber during operation of the ventilator

must be removed regularly. If allowed to accumulate

for long periods of time, the grease will “bake on” to

the interior of the ventilator forming a combustible

and difcult to remove coating. To prevent this build

up, the Water Wash Ventilator features an automatic

cleaning cycle this is initiated each time the exhaust

fan is turned off, or at the preset time during which

the Water Wash Mode Commander calls for a wash

cycle. When either of this situations occur, the exhaust

fan will stop. The ventilator damper will close and the

ventilator will be sprayed with a pressurized hot water

and detergent combination. The waste water will ow

from the system into an approved plumbing drain. This

will be explained in detail in the Sequence of Operations

section of the manual.

Thorough cleaning of the extraction chamber interior

is achieved by means of a pressurized hot detergent

water spray.

Spray

Nozzles

Primary

Diverter

Baffle

Southern Wash Extraction Chamber

10

Spray Manifold

Water Wash Ventilator Owner’s Manual

Cover ÊPlate

Thermostat

Mounting

Plate

J-Box

Duct

Collar

Spray Manifold

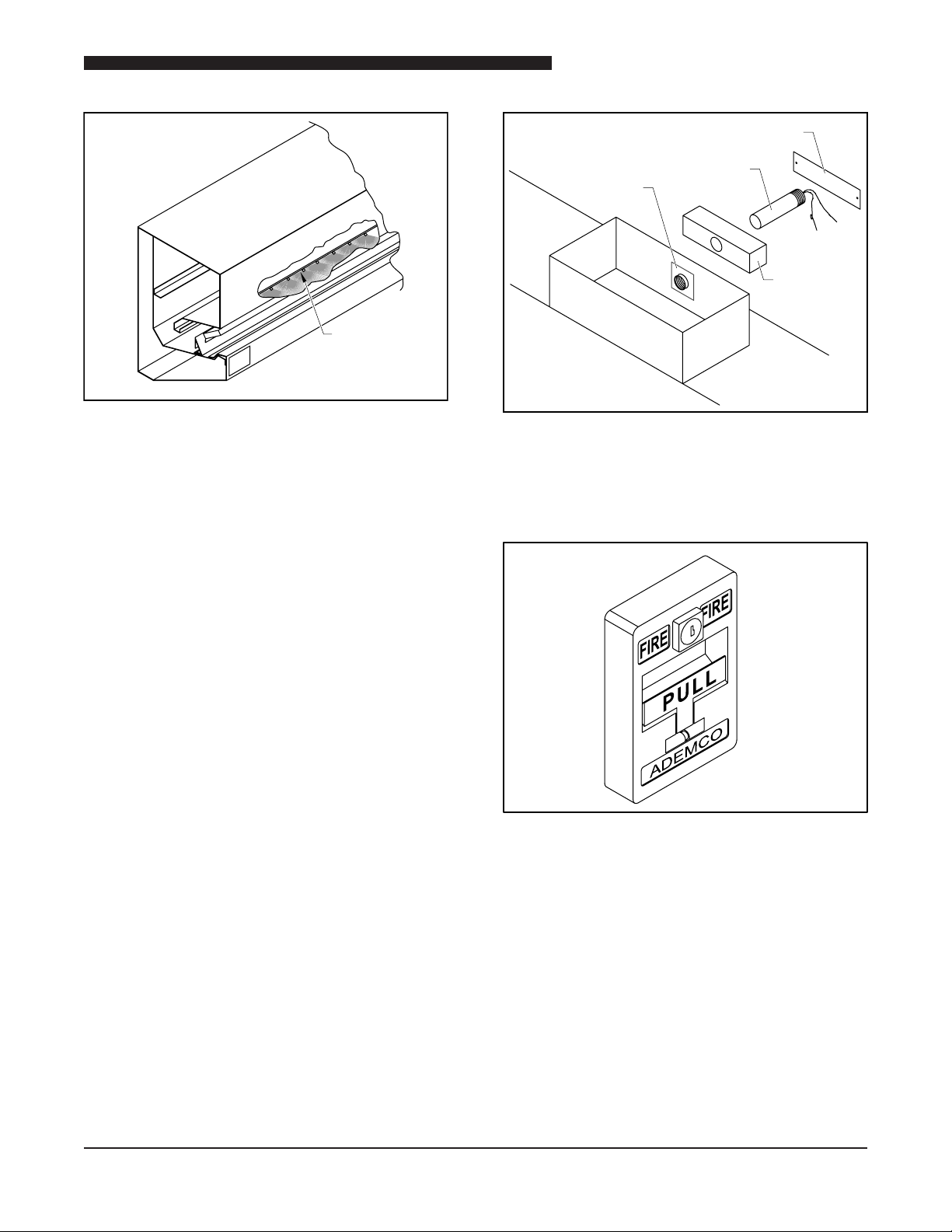

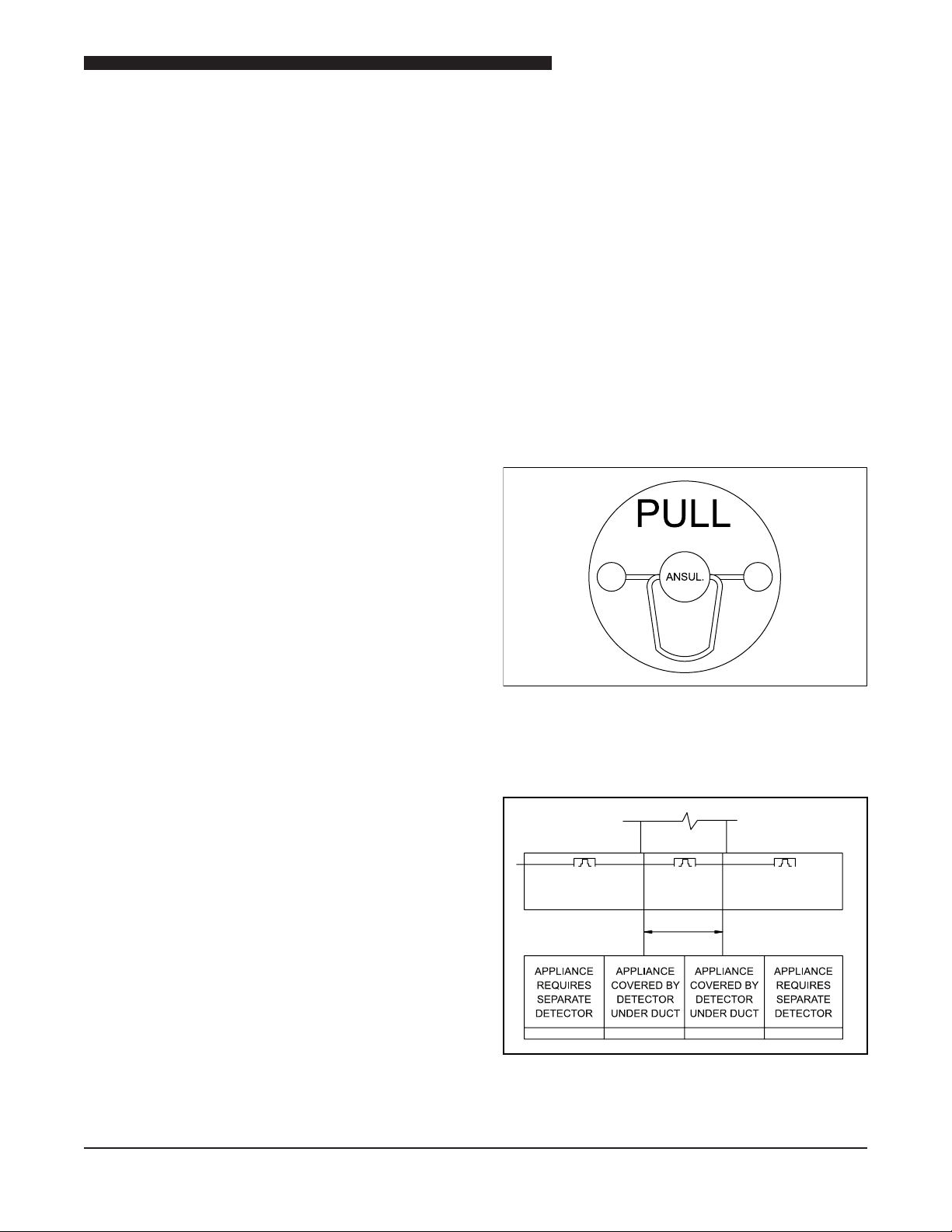

FIRE PROTECTION CYCLE

STANDARD PUSH BUTTON CONTROL

In the event of a re in the cooking area under the

ventilator, the exhaust ductwork should be protected

to prevent the exhaust fan from spreading the re to

the ductwork and the building roof. The Water Wash

Ventilator features an automatic re protection cycle to

contain res under the canopy to prevent their spread.

The re protection cycle is automatically initiated by

thermostats located in the exhaust air path at the duct

collars of the ventilator.

Location of Fire Detection Thermostats

As a back up, there is a remote re pull furnished near

a door. When pulled, this device will provide the same

results as the automatic re cycle.

Remote Fire Pull

In case of re, pull for the instant activation of the

Ventilator Fire Cycle.

11

Water Wash Ventilator Owner’s Manual

SEQUENCE OF OPERATION

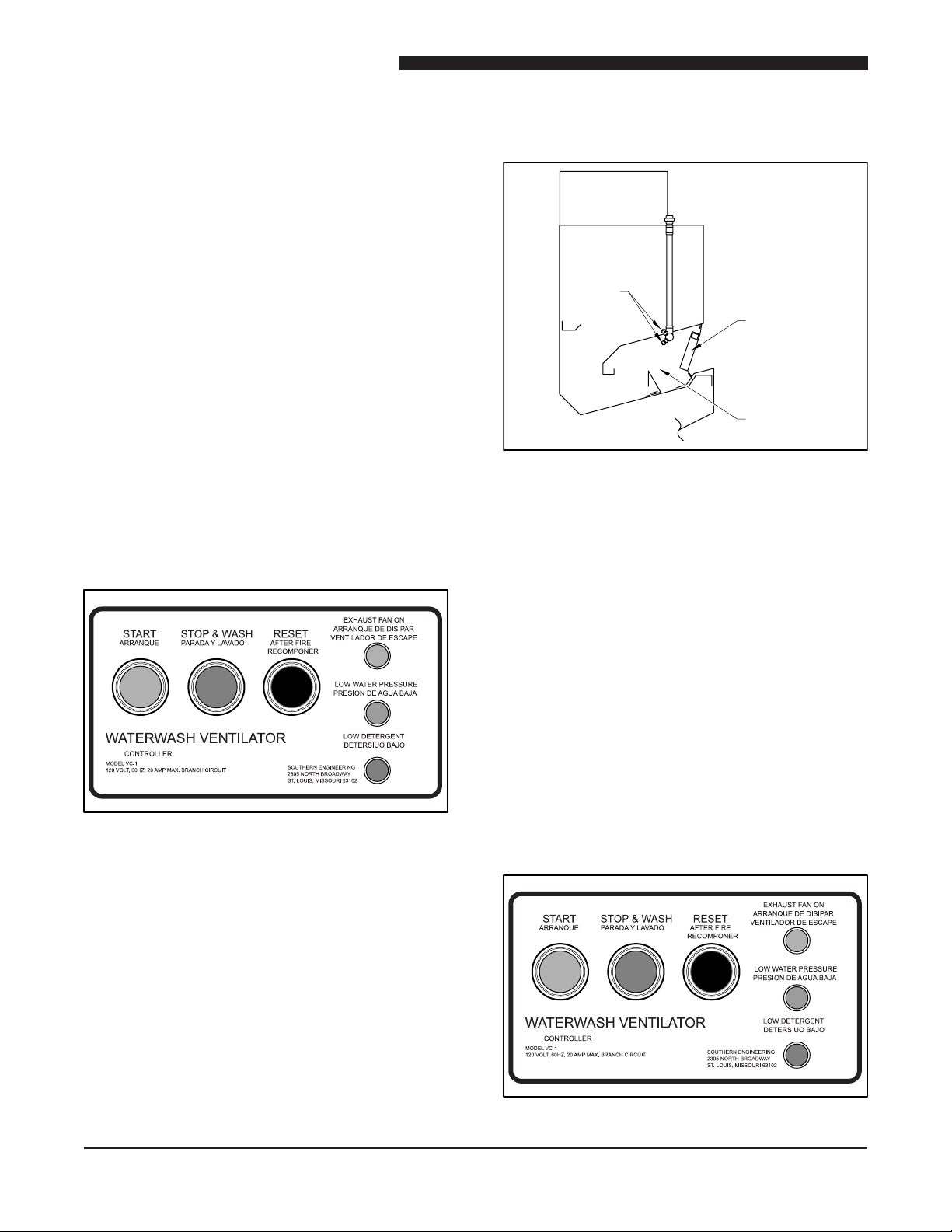

STANDARD CONTROL PANEL

Contaminants accumulated during the normal cooking

cycles are washed from the system at the end of each

operating cycle. This can be achieved automatically

(through the used of the Mode Commander) or manually

by turning OFF the exhausts fans using the Standard

Control Panel.

CAUTION: Always turn cooking equipment

off 15 minutes prior to shutting down the

exhaust system.

This will prevent accidental tripping of the appliance

re suppression system due to heat build-up when the

exhaust system is terminated.

Spray

Nozzles

Damper Door

Extraction

Chamber

WASH CYCLE PROCEDURE

1. Turn off all cooking appliances and allow to cool

for minimum of 15 minutes.

2. Press the STOP & WASH button.

Water Wash Ventilator Controller

• The exhaust fan will coast to a stop

• The supply fan (if required) will stop.

Inlet Damper Location

• The wash solenoid valve will open and the detergent

pump will start.

• Hot detergent water (120°F @40 psi) will be injected

through the spray nozzles for a predetermined

period of time.

• When the wash cycle ends, the wash solenoid

closes terminating water ow, and the detergent

pump stops. The inlet damper will remain closed

awaiting the next fan cycle.

• When the Mode Commander is furnished, up to

four wash sequences may be run consecutively.

FAN CYCLE

Push the START button on the Control Panel.

• The inlet damper will close.

12

Water Wash Ventilator Controller

Water Wash Ventilator Owner’s Manual

• The Inlet damper will open.

• The Exhaust fan will start.

• Ventilator make-up air supply will start (if required).

• Turn on cooking appliances as needed.

CAUTION: Do not turn on cooking appliances if

inlet damper is closed or exhaust fan is not running.

Failure to comply my result in an accidental re

suppression discharge.

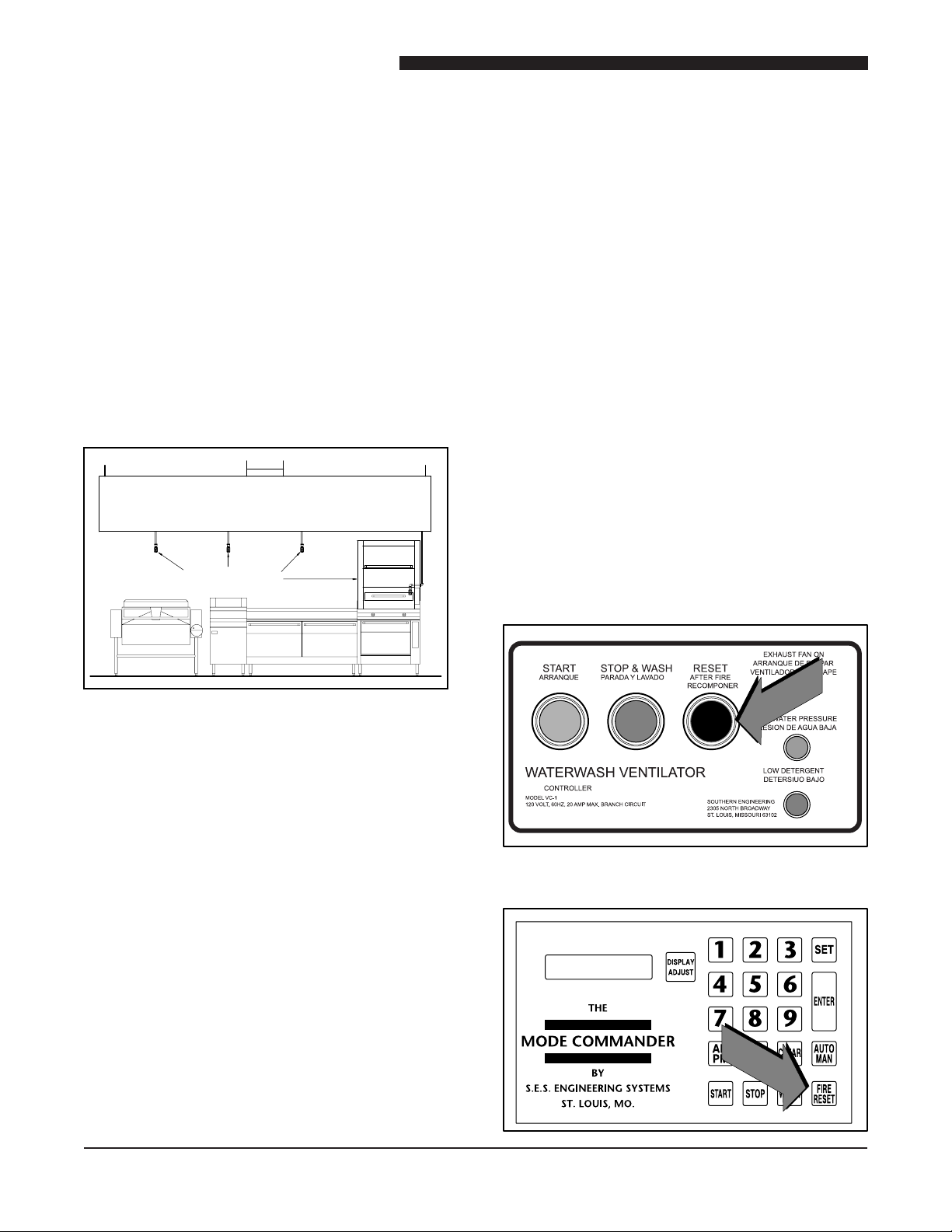

MODE COMMANDER

MANUAL MODE:

VENT #1 ON Damper opens, fan starts

VENT #1 STOP Fan stops, damper closes,

timed wash begins. Wash ends

after elapsed time, fan remains

OFF.

VENT #1 WASH Same sequence as stop

sequence

All Water Wash systems have two separate means of

re suppression built in to protect the ventilator and

duct system should a re occur.

APPLIANCE PROTECTION

This is the rst line of defense in the event of a re.

Basically, there are three types which will be discussed

in detail in separate sections of this manual. They are

water mist, dry chemical and wet chemical. Each type

is designed for one purposes, suppression of out of

control cooking res.

DRY AND WET CHEMICAL SYSTEMS

The dry chemical and wet chemical systems make

use of remote re pulls, usually located near an exit,

which when pulled will activate the chemical solution.

VENT #1 FIRE Upon manual or thermal

activation, fan stops, damper

closes, continuous suppressive

spray initiates. Remains in this

state until manual deactivated

by depressing the FIRE

RESET button.

NOTE: In order to deactivate re suppression,

the temperature in the extraction chamber must

be below 325°F.

NOTE: When multiple ventilators are supplied

with single fan systems, all sequences are

simultaneous with the exception of re status,

which remains individual.

VENT #1: Fan sequence is automatically initiated at

programmed times.

NOTE: May be repeated up to three cycles in a

24-hour timeframe.

FIRE SUPPRESSION SYSTEMS

Typical Remote Fire Pull

They also employ fusible links which are located directly

above the cooking equipment.

Fusible Links above Appliances

When one of these links melt, the re suppression

system activates. When activated, wet or dry powder

13

Water Wash Ventilator Owner’s Manual

will be sprayed directly on the re through strategically

placed nozzles located above the appliances. Once

the chemicals are discharged, the gas valve will be

electrically or mechanically closed and the exhaust and

supply fans can be shut down or remain in operations

dependent upon local jurisdictional authority. Once

these systems are activated, the chemicals must be

replaced along with all fusible links which have been

affected. Once this is accomplished the gas valve can

be reset and normal operation resumed.

WATER FOG SYSTEM

When water fog systems are specied, there are some

basic differences which that should be noted. The

sprinkler nozzles are point of use and do not utilize

remote pulls or fusible links.

WATER FOG

NOZZLES

All Water Wash Ventilators utilize built in methods

of re suppression acting separately of appliance

protection. In the event a re has not been suppressed

and is drawn into the extraction chamber causing

a temperature rise above 325°F (275°F on down

draft models), re-stat contacts will close, sending a

signal to the ventilator control panel. The following

sequences will occur.

1. The exhaust fan shuts off, stopping the induced

draft over the cooking equipment and preventing

re from being pulled into the ductwork.

2. The UL rated damper door at the inlet to the

extraction chamber closes and provides a barrier

to the re, preventing a heat induced draft from

rising up the exhaust shaft.

3. The water-detergent wash system is activated,

releasing its water spray within the ventilator to

quench any re, wash away grease and dust that

could support combustion, and cool the damper

and extraction chamber, protecting the ventilator

from heat damage.

4. The water spay continues until the thermostat(s)

cool below 325°F and the FIRE RESET button on

the ventilator control panel is reset,

Typical Water Fog System

When a nozzle vial is heated to the designated

temperature and breaks, a continuous water spray

begins. Unlike chemical systems, all nozzles do not

open unless each/all are heated. Water continues

to ow until it is manually stopped. As with chemical

systems, the gas or electric appliances will be shut

down along with the exhaust system as required. All

systems may be incorporated with automatic signaling

devices for alarms.

WATER WASH FIRE SUPPRESSION

Fire Reset Button on Standard Control

14

Fire Reset Button on Mode Commander

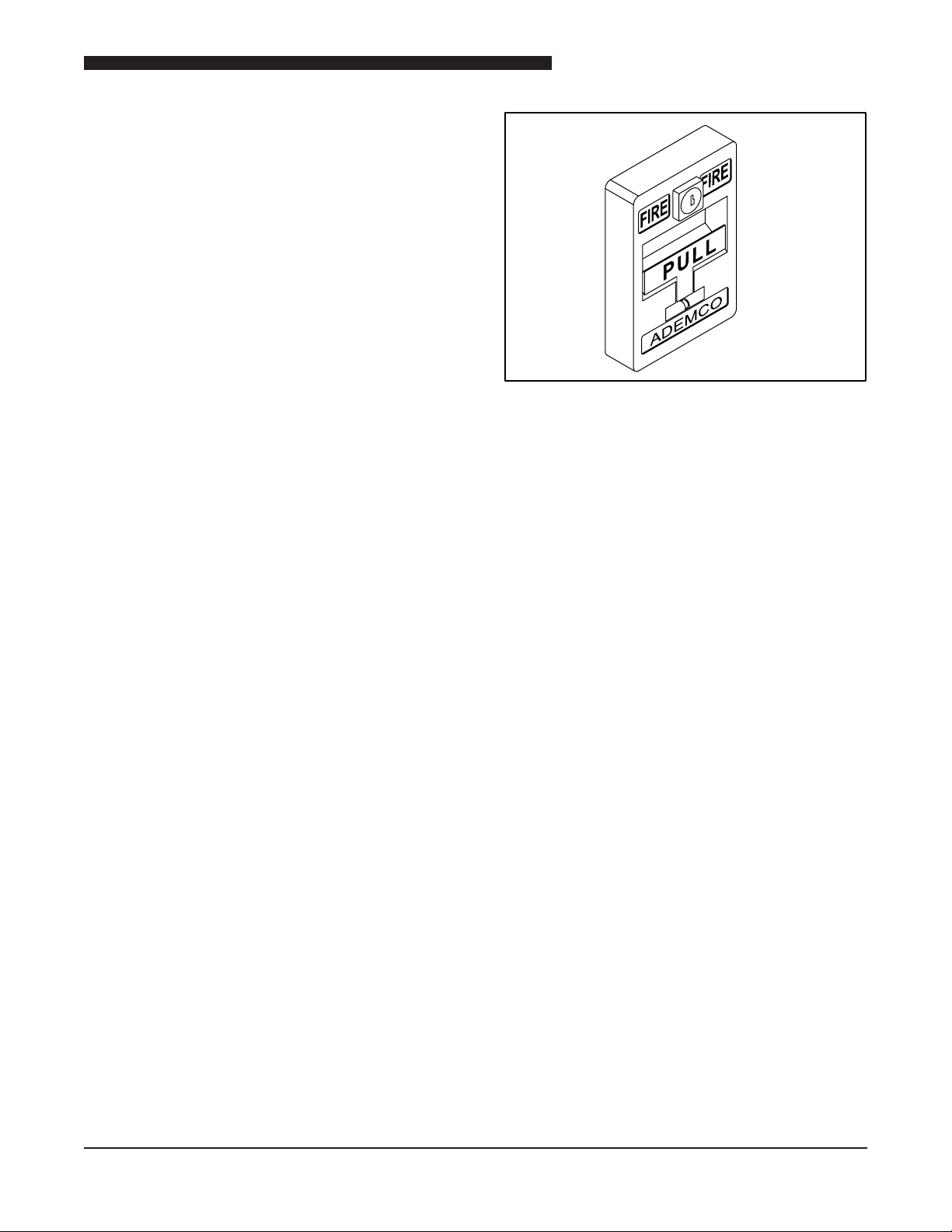

5. A remote manual re pull switch is provided for

mounting in the exit path of the kitchen area. This

switch activates the re protection cycle. The re

switch (ber disc or glass bar) must be replaced

and the FIRE RESET button pushed before the

ventilation system can be restarted. If a remote

manual re switch or other device (such as a re

suppression system) activates the re protection

cycle, this device must also be reset to normal or

supervisory status before the FIRE RESET button

on the control panel will have any effect.

Water Wash Ventilator Owner’s Manual

6. The START button on the Control Panel may then

be pushed to restart the ventilation system.

15

Water Wash Ventilator Owner’s Manual

COMPONENT IDENTIFICATION AND ACCESS

STANDARD CONTROL CABINET

Hot Water Outlet

Terminal

Solenoid Valve

Strip

N H H17 N1 9

Circuit

Board

(See

separate

drawing)

SOUTHERN

WATER WASH

VC1

12

11

10

9

38

8

7

6

5

4

30

20

1

H1

H

G

REPLACE FUSE WITH

THE SAME TYPE AND

RATING ONLY

WST

WSR

WT

WR

TR

02F-SWW-00115A

84-0124 SECO WATER WASH

FR

DIR

MPA-3

Miniature

Pilot

Actuator

This enclosure serves as the xture for the major

electrical and plumbing components utilized by the

ventilator system. Basically the cabinet is divided into

two sections: The electrical compartment on the left side

and the plumbing components on the right. For ease

in identication the components will be discussed in

separate sections: Electrical Compartment, Plumbing

Compartment, Externally Mounted Components, and

Ventilator Mounted Components.

PUSH BUTTON CONTROL

1/4" Detergent Outlet

Hot Water

Supply

Shutoff Valve

Pressure/Temp.

Gauge

Line Strainer

Shock

Arrestor

Detergent

Pump

Detergent

Container

Pump Test

Switch

Detergent Tube Assembly

w/Foot Valve Strainer

START: The green start button is a normally open

switch. Momentary contact close the electrical circuit

to the damper interlock relay energizing the exhaust

fan and blower pilot light.

NOTE: The system must have water pressure

to complete the start sequence.

STOP: The red stop button is a SPDT switch providing

maintained contact with the start button when not

depressed. When depressed, the stop button will stop

the exhaust fans, close the inlet damper and initiate

the wash cycle.

All system functions are controlled by the Push Button

Control.

16

RESET: The black re reset button is normally closed.

When pressed, the re cycle relay is opened terminating

a re cycle.

NOTE: When a re cycle is initiated the STOP

and WASH function will be bypassed

NOTE: All Southern Engineering by Duke re

devices such as the remote re pull and thermostats

must be in normal operating condition before the

termination of a re cycle may be achieved.

EXHAUST FAN PILOT (EFP): Illuminates green when

the exhaust fan is operating, indicating power to the

damper interlock relay.

Loading...

Loading...