Duke FBBT-PC-120 Installation Manual

BURGER KING

FLEXIBLE

BATCH BROILER

WITH TOUCH

SCREEN CONTROL

Installation and

Operation Manual

Please read this manual completely before attempting

to install, operate or service this equipment

This manual is Copyright © 2017 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Co.

Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 176747B

03/06/2017

Installation and Operation of Flexible Batch Broiler

With Touch Screen Control

2

Installation and Operation of Flexible Batch Broiler

With Touch Screen Control

TABLE OF CONTENTS

IMPORTANT WARNING AND SAFETY INFORMATION ..................................................4

I. GENERAL INFORMATION ..........................................................................................5

A. BATCH BROILER SPECIFICATIONS ...............................................................5

II. INSTALLATION INSTRUCTIONS ..............................................................................7

A. VENTILATION .....................................................................................................7

B. INSTALLATION SPECIFICATIONS ................................................................... 8

C. DELIVERY AND INSPECTION .......................................................................... 8

D. BROILER ASSEMBLY ......................................................................................10

E. ADJUSTMENTS AT INSTALLATION ............................................................... 11

F. LOCATION OF THE BROILER ......................................................................... 12

G. GAS PIPING ....................................................................................................... 12

H. ELECTRICAL CONNECTIONS ........................................................................ 12

III. OPERATION INSTRUCTIONS ................................................................................14

A. DAILY BROILER START-UP .............................................................................15

B. COOKING PRODUCT........................................................................................16

C. SPECIAL FUNCTION SCREENS ..................................................................... 18

D. CLEANING .........................................................................................................23

IV. SERVICE AND REPAIR ...........................................................................................31

V. REPLACEMENT PARTS LIST ................................................................................. 33

VI. ELECTRICAL SCHEMATIC ....................................................................................35

3

Installation and Operation of Flexible Batch Broiler

WARNING

CAUTION

With Touch Screen Control

IMPORTANT WARNING AND SAFETY INFORMATION

HAZARD WHICH COULD RESULT IN DEATH OR SERIOUS

INJURY

HAZARD WHICH COULD RESULT IN MINOR OR MODERATE

INJURY

ELECTRICAL SHOCK HAZARD WHICH COULD RESULT IN DEATH OR SERIOUS

INJURY AND/OR EQUIPMENT DAMAGE

HOT SURFACE WHICH COULD RESULT IN MINOR OR MODERATE INJURY.

TASKS MUST BE PERFORMED ONLY FOLLOWING PROPER TRAINING

• Read all instructions before using equipment

• Do not attempt to defeat the grounded connector

• Install or locate the equipment, only for its intended use, as described in this manual.

• Do not use corrosive chemicals, water jet equipment, or other pressurized liquid spraying equipment to clean

this unit.

• Do not block any openings on the unit.

• Unit may start operating with inadvertent contact with the touch screen display or from other extraneous

sources. Turn off external mains supply disconnect and/or unplug the unit from the mains supply, should

abnormal or unwanted operations occur.

• This appliance is not intended for use by children or persons with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety. Children shall not play with the

appliance.

• Turnoff the external mains supply disconnect or disconnect the appliance line supply cord and allow the unit

to cool down before servicing or performing maintenance.

• The procedures in this manual may include the use of chemical products. You must read the Material Safety

Data Sheets (MSDS) before using any of these products.

• Properly rated all poles mains protection and earthing compliance with local codes are required for safe

operation of this unit.

• Disposal of this unit must be in accordance with local environmental codes and/or other applicable codes.

• Consult the local gas supplier for instructions to be followed in the event user smells gas.

• Do not store or use gasoline or other ammable vapors or liquids in the vicinity of this or any other appliance.

• SAVE THESE INSTRUCTIONS

4

Installation and Operation of Flexible Batch Broiler

With Touch Screen Control

I. GENERAL INFORMATION

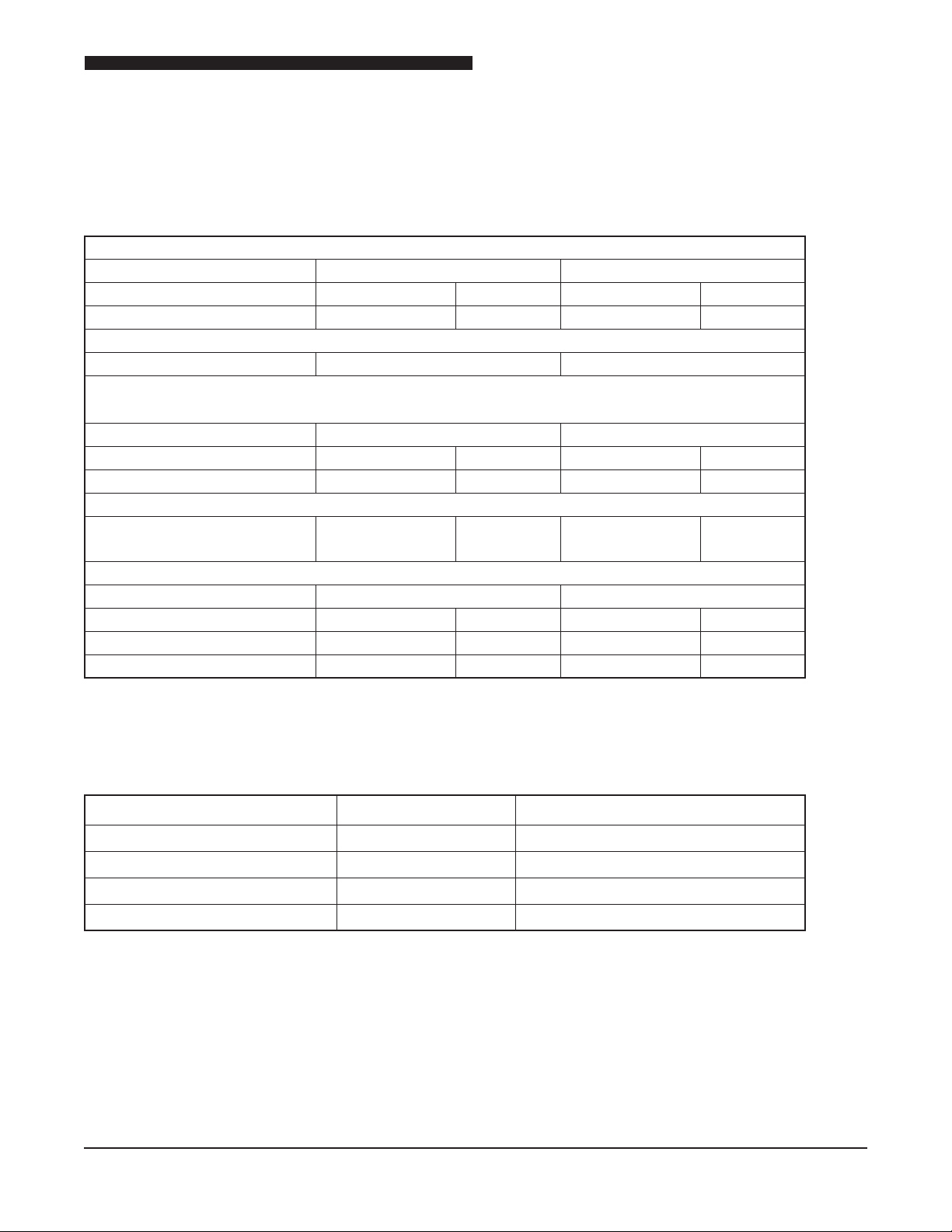

A. Batch Broiler Specications

FLEXIBLE BATCH BROILER SPECIFICATIONS

NATURAL GAS PROPANE

ALTITUDE (MAXIMUM) 2000 FT 607 m 2000 FT 607 m

GAS PIPE CONNECTION 3/4" F-NPT 3/4" F-NPT

INLET PRESSURE RANGE 7" – 12" W.C. 10" – 12” W.C.

NOTE: High Pressure Kit is required if supply pressures are greater than 12.0” W.C. (3.0 kPa)

Reference Duke P.N. 175689

MANIFOLD PRESSURE MANIFOLD PRESSURE

INFRARED BURNERS (TOP) 3.75" W.C. 0.93 kPa 8.0" W.C. 2.0kPa

LOWER BURNER 3.75" W.C. 0.93 kPa 8.0" W.C. 2.0kPa

TOTAL ENERGY RATE

FRONT INFRARED BURNER #40 2.49mm #52 1.61mm

BACK INFRARED BURNER #36 2.70mm #51 1.70mm

LOWER BURNER #31 3.05mm #49 1.85mm

SHIPPING WEIGHT: 482 lbs (219 Kg)

SHIPPING DIMENSIONS: 47” x 34” x 68” (119.4 x 86.4 x 172.7 cm)

87000 – 111,000

BTU/HR

BURNER ORIFICE SIZE BURNER ORIFICE SIZE

25.5 – 32.5 kW79,000 – 105,000

BTU/HR

23.2 – 30.7

kW

MODEL NUMBER ELECTRIC NATURAL & LP GAS

FBBT-NO-120 120VAC, 2A, 60Hz 87,000 – 111,000 BTU/HR

FBBT-NC-120 120VAC, 2A, 60Hz 87,000 – 111,000 BTU/HR

FBBT-PO-120 120VAC, 2A, 60Hz 79,000 – 105,000 BTU/HR

FBBT-PC-120 120VAC, 2A, 60Hz 79,000 – 105,000 BTU/HR

A-1.0 Model Number Key

FBBT-XY-120

X = N (NATURAL GAS) OR P (PROPANE / LP GAS)

Y = O (NO CATALYST) OR C (CATALYST)

120 = 120 VOLTS

5

Installation and Operation of Flexible Batch Broiler

(100.3 cm)

With Touch Screen Control

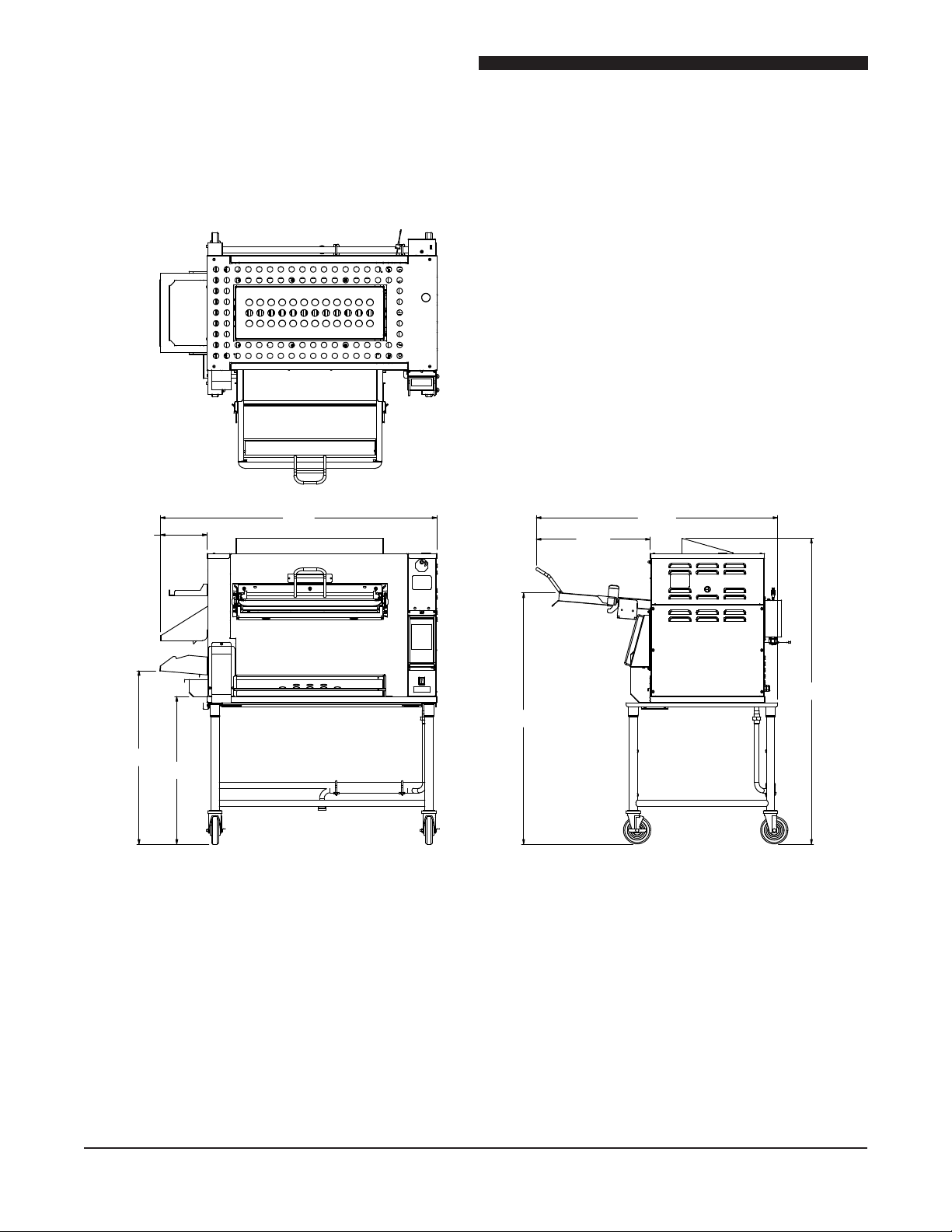

A-2.0 Broiler Dimensions

8 1/2"

(21.6 cm)

39 1/2"

34 3/4"

(88.4 cm)

50 3/8"

(128 cm)

53 5/8"

(136.1 cm)

20 3/4"

(52.9 cm)

44"

(111.9 cm)

63 5/8"

(161.7 cm)

6

Installation and Operation of Flexible Batch Broiler

WARNING

With Touch Screen Control

II. INSTALLATION INSTRUCTIONS

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

that complies with ANSI Z21.69 / CSA 6.16

Connectors for Moveable Gas Appliances

and a quick-disconnect device that complies

IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATION,

SERVICE, OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE,

INJURY, OR DEATH. READ THE

INSTALLATION, OPERATING, AND

MAINTENANCE INSTRUCTIONS

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT.

Installation and/or service repair of gas

appliances requires Skilled or Qualied

Personnel. Skilled or Qualied Personnel are

individuals, rms, companies or corporations

which are directly authorized by Duke

Manufacturing (Assignee) or meet the

requirements of governmental authority having

jurisdiction for the task.

with ANSI Z21.4 / CSA 6.9 Quick –Disconnect

Devices for Use with Gas Fuel.

When installing a broiler mounted on casters

with quick-disconnect hose, adequate means

must be provided to limit the movement of the

broiler without depending on the connector,

hose, or system piping to limit movement. A

restraining device may be attached to the rear

vertical portion of the broiler’s base frame.

A. VENTILATION:

This appliance requires a ventilation system

to prevent unacceptable concentrations of

substances harmful to health in the room where

the appliance is installed.

Ventilation System Specications:

Electrical wiring tasks must be in conformance

with National Electrical Code ANSI/NFPA70

Gas supply interconnection must be in

conformance with National Fuel Gas Code

ANSI Z223.1/NFPA54 and Natural Gas and

Propane Installation Code CSAB149 including

the following:

• The appliance must have an individual manual

shutoff valve at the connection to the gas supply

piping system during any pressure testing of

that system at test pressures in excess of ½ psi

(3.5kPa).

• The appliance must be isolated from the gas

supply piping system by closing its individual

manual shut off valve during any pressure

testing of the gas supply systems at test

pressures equal to or less than ½ psi (3.5kPa).

For a broiler mounted on casters, the

installation must be made with a connector

Must be a Mechanically Driven Exhaust Hood

System

Minimum Capacity: 1,700 m3/hr (1,000 cfm)

Minimum Opening: 39.4” x 51.2” (100cm x

130cm)

The Ventilation System must be inspected,

maintained, and annually serviced by

Qualied Personnel as part of or in addition to

governmental requirements

NOTE: Ventilation Systems for multiple or

additional appliances must have capacity

in addition to the specications for this

appliance.

7

Installation and Operation of Flexible Batch Broiler

WARNING

With Touch Screen Control

Maintenance of Ventilation System

The ventilation system must be maintained and annually

inspected by Qualied Personnel concurrent as part of

or in addition to governmental requirements.

This inspection/maintenance should consist of, but

not be limited to:

• Inspection for blockages or build up which might

interfere with the venting of the broiler.

• Repair of such blockages.

• Inspection of the venting canopy, its drive

motors and bells, etc.

: Do not place any objects such as sheet

pans, food containers or aluminum foil on the top of

the broiler. This will obstruct the venting of cooking

vapors and airow through the unit—resulting in

poor cooking performance.

B. INSTALLATION SPECIFICATIONS:

The broiler has been fully tested before

shipping with adjustments to optimize operation

of the gas system IR (top) burners and bottom

burner. The Skilled or Qualied Personnel

installing the broiler must verify gas systems

adjustments to verify adjustments were not

impacted during transit shipping. Please

contact Duke Manufacturing Co. for adjustment

procedures.

This broiler must not be installed on a curb

base or sealed to a wall. The area around the

broiler must be clear of combustible materials.

Minimum clearances to combustible or

noncombustible surfaces are:

ELECTRICAL SPECIFICATIONS:

Electrical Rating: 120V~ 2A 60Hz

Line Connection: NEMA 15

ELECTRICAL SHOCK HAZARD

UNIT MUST BE SAFETY

GROUNDED, EARTHED.

DO NOT MODIFY OR DEFEAT

ELECTRICAL CONNECTIONS

C. DELIVERY AND INSPECTION

• The shipping carrier assumes liability and

responsibility for delivering the appliance

without damage. Duke Manufacturing Co. can

assist with resolution of any shipping related

issues if a problem arises.

• Look over the outer shipping container carefully

when delivered with the person making the

delivery.

• Note any exterior damage on the delivery

receipt before signing.

• The person making the delivery for the shipping

carrier must agree and sign the receipt to

document damage to the outer shipping

container.

• Unpack the broiler and inspect for any damage

not evident on the outer shipping container and

other concealed damage. The shipping carrier

must be notied any damages within fteen (15)

days of receipt.

Discharge end: 12.0” (305mm)

Rear of unit: 4.0” (102mm)

Side Access Panel (Control): 3.0” (76mm)

Floor / Table: 0” (0mm)

8

Installation and Operation of Flexible Batch Broiler

CAUTION

With Touch Screen Control

9. A minimum of three (3) people are required

4

2

to support and balance the broiler while

removing from the palate.

a. Roll the broiler forward until the front

5

caster are clear of the palate

b. Lift the broiler rear caster above the palate

3

and slide out the palate from under the

broiler.

4

5

7

8

The broiler is very heavy!

Use adequate help when lifting.

6

4

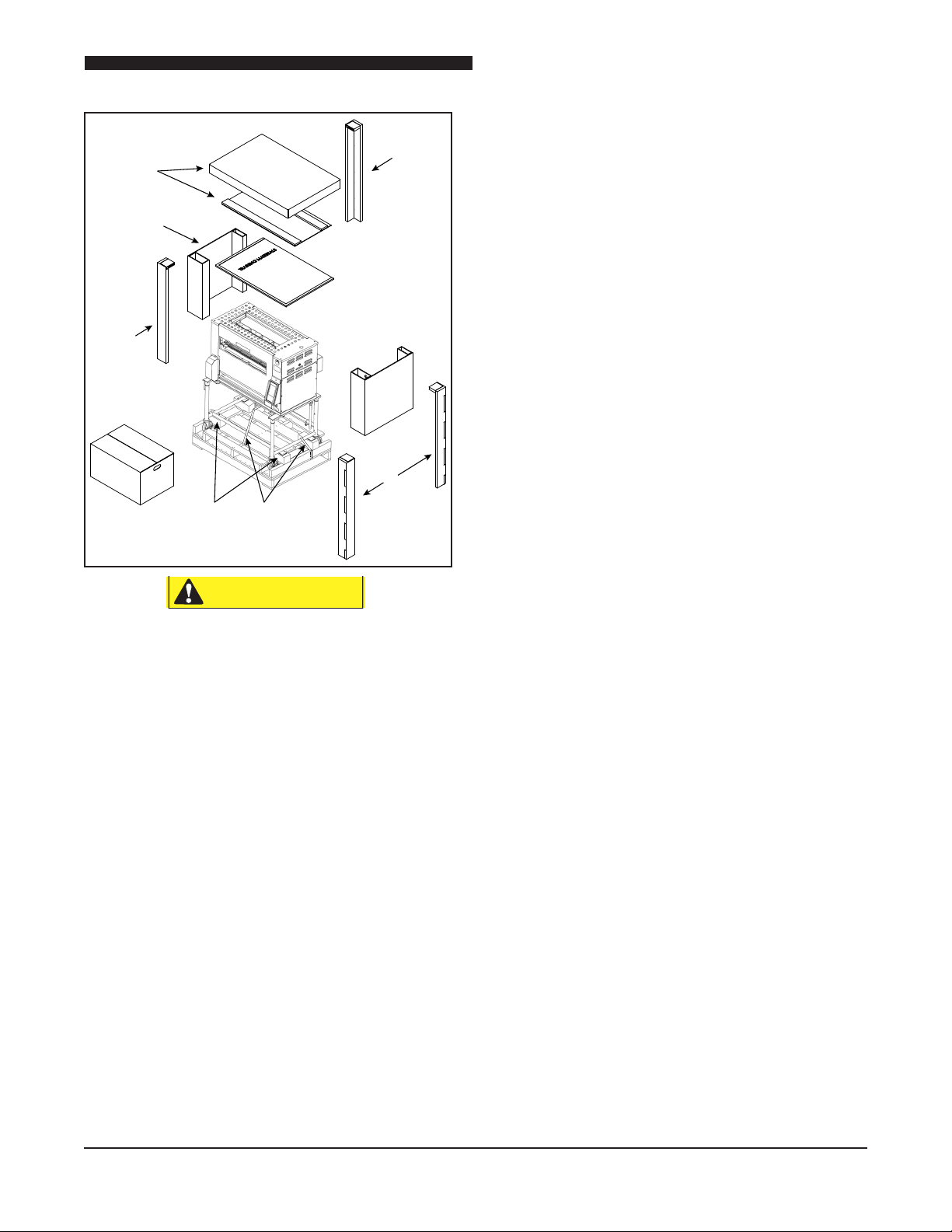

1. Cut away the plastic outer wrap.

2. Remove the top cardboard and inner cap

(Item 2)

c. Gently lower the broiler to the oor to

avoid damage to casters

10. Remove the protective blue tape protecting

the broiler stainless steel panels. Verify all

blue tape is removed before installing and

operating the unit.

3. Remove training material box (Item 7)

4. Remove cardboard corner covers (Item 4)

5. Remove cardboard ends (Item 5)

6. Cut banding straps with a utility knife or

scissors (Items 6)

7. Remove accessories box (Item 8) checking

that no tape remains.

8. Lift one end of the broiler and tap the wood

block toward the center and then sideways

to remove. Repeat for the remaining blocks

allowing the casters to rest on the pallet.

9

Installation and Operation of Flexible Batch Broiler

With Touch Screen Control

D. BROILER ASSEMBLY

Before assembling and installing the broiler, please

check to make sure that all necessary parts are present.

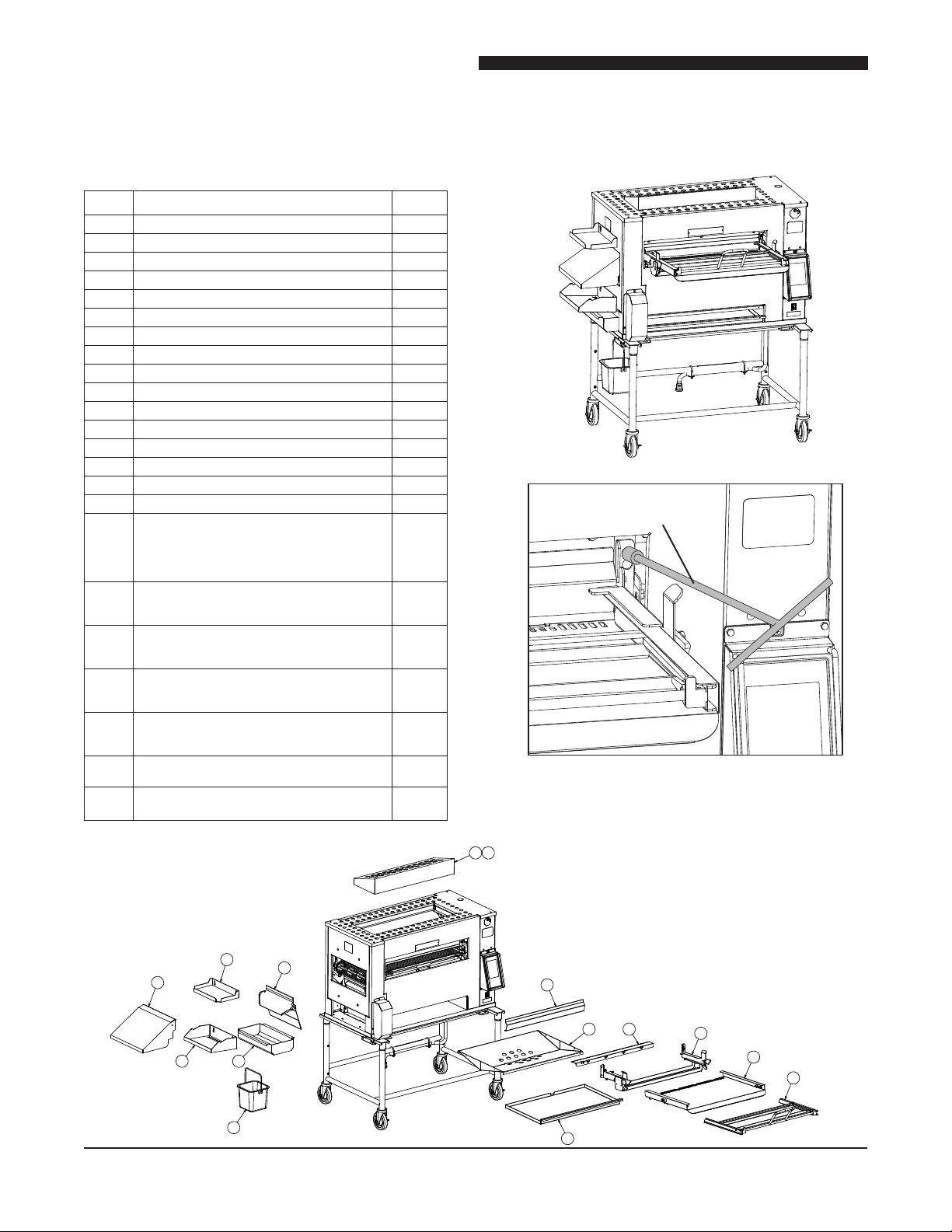

ITEM PART NAME

1 PRODUCT PAN SHELF 175353

2 DISCHARGE CHUTE 175340

3 DISCHARGE HOOD 175778

4 DISCHARGE PAN HOLDER 175358

5 DISCHARGE GREASE PAN 175357

6 “V” GREASE PAN 175325

7 MAIN GREASE PAN 175329

8 LOADER 175444

9 LOADER TRAY 175430

10 LOADER BRACKET 175438

11 DOOR 175429

12 LOADER RAMP 175741

13 IMPEDANCE PAN 175226

14 CATALYST (OPTIONAL) 175480

15 CATALYST GUARD (OPTIONAL) 175482

16 SANITATION PAIL 175842

17 KIT, CLEANING TOOLS/INSTALLATION

TOOL CLEANING – LOWER BURNER

FLAME ROD TUBE CLEANER BRUSH,

TUBE CLEANER TOOL– LOADER

INSTALL WRENCH, ALLEN, 3/16” 175700

18 KIT – BROILER SVC. PARTS,

NAT. GAS W/ CONTROLLER W/COOK

CHAIN (OPTIONAL)

19 KIT – BROILER SVC. PARTS, PROPANE,

W/ CONTROLLER W/COOK CHAIN

(OPTIONAL)

20 KIT – USER REPLACEABLE, BOTTOM

BURNER, FLAME ARRESTOR, LOADER &

BURNER SHIELD (OPTIONAL) 175726

21 KIT – USER REPLACEABLE, BOTTOM

BURNER & FLAME ARRESTOR

(OPTIONAL) 175750

22 KIT – GAS HOSE CONNECTOR

ASSEMBLY (OPTIONAL) 175690

23 KIT – HIGH SUPPLY GAS PRESSURE

REGULATOR (OPTIONAL) 175689

PT.NO.

Setup

Install all items as shown below.

Loader Install Tool

(Included with Broiler

Tools Kit)

Install loader bracket with (4) 1/4-20 nuts.

Use supplied extension tool to remove and reinstall nuts.

(Nuts are shipped installed on loader mounting studs.)

15

13

10

2

3

4

16

1

11

6 12

5

7

10

9

8

Installation and Operation of Flexible Batch Broiler

CAUTION

With Touch Screen Control

E. ADJUSTMENTS AT INSTALLATION

Each broiler section and all its component parts have

been tested thoroughly and inspected before your broiler

was shipped from the factory. However, it is sometimes

necessary to further test or adjust the broiler once it has

been installed. Such adjustments are the responsibility

of the Dealer or Installer. These types of adjustments

are not considered defects, rather a normal and routine

part of the proper installation of the equipment.

These adjustments include but are not limited to:

• Adjustments to the gas pressure regulator

• Broiler height adjustment (if required)

No installation should be considered complete without

proper inspection and, if necessary, any adjustments

by qualied service or installation personnel.

It is also important not to obstruct the natural ow of

combustion and ventilation air if the broiler is to operate

properly. This broiler should not be installed on a

curb base or sealed to the wall. Either condition can

restrict the ow of air to the combustion compartment

or prevent proper ventilation of the unit. Before making

any connections to the broiler, check the ratings plate

to be sure the broiler specications concur with the

type of gas and voltage to be supplied to the broiler.

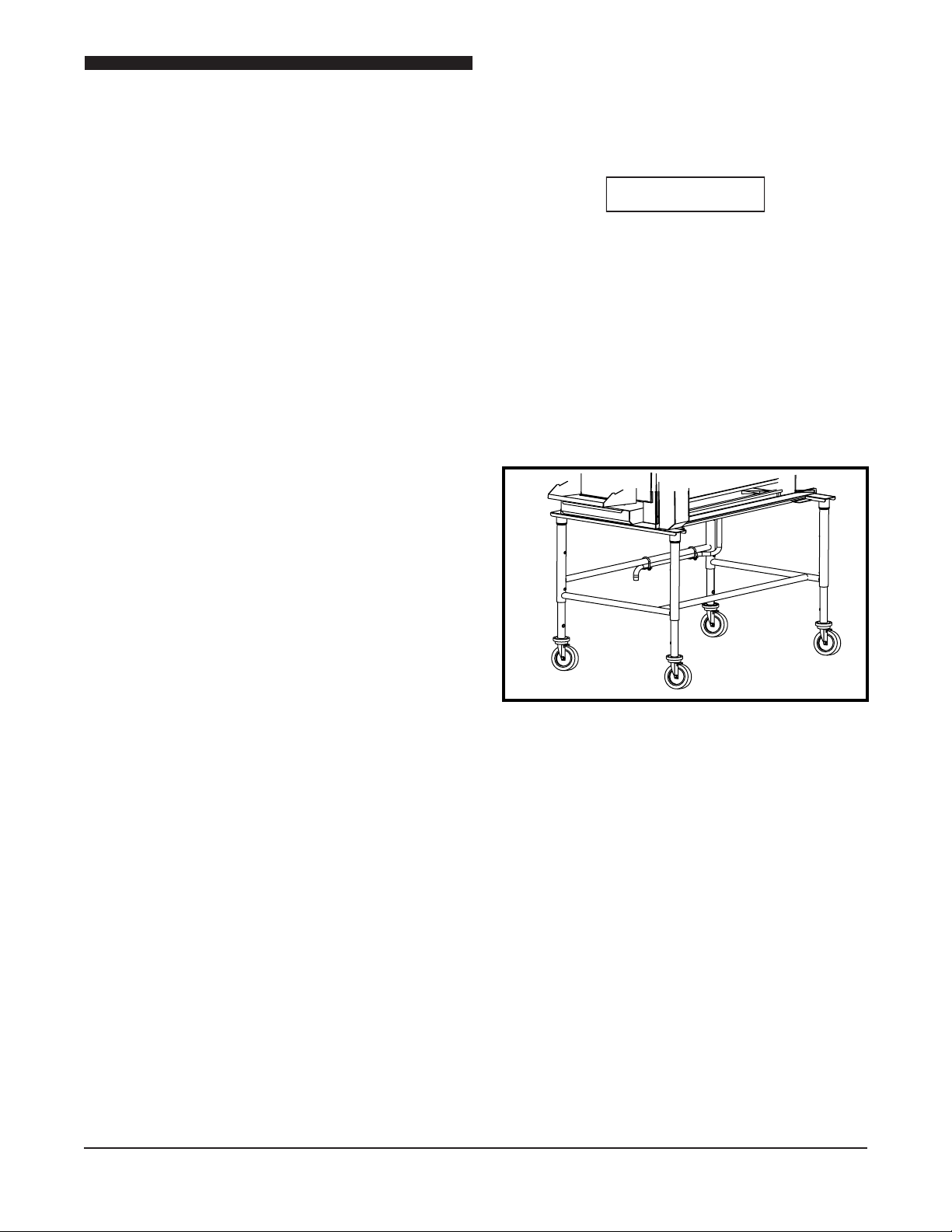

Raise or Lower Broiler

The broiler height can be adjusted via two screws on

each leg.

The Broiler is very heavy! Use adequate

help for lifting.

1. Lift one end of the broiler onto a wide, sturdy stand

(not supplied).

2. Remove (2) screws per leg and raise/lower to

threaded holes. Reinstall screws.

3. Remove stand and safely raise/lower broiler.

4. Place plastic hole plugs (supplied attach to stand)

in any unused holes.

The rating plate is located on the back of the control

compartment cover panel on the right end of the unit.

The plate bearing the broiler’s model number and serial

number is attached to the back side of the unit.

11

Loading...

Loading...