Duke 59-EV Service Manual

5/9 THE OVEN

ELECTRIC HALF – SIZE

CONVECTION OVEN

Installation, Operation, Parts

& Maintenance Manual

DUKE MANUFACTURING CO.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 314.231.1130 • 314.231.5074 Fax

www.dukemfg.com

155131P

INDEX

PAGE

5/9 Electric Specifications 3

Installation Instructions

A. Qualified Personnel

B. Delivery & Inspection 4

C. Location of Oven 4

D. Electrical Connections 4-5

E. Oven Assembly 5

F. Adjustments Associated with Installation 5

Operating Instructions

A. Oven Controls

B. General Guidelines for Operation 26

C. Suggested Times & Temperatures 27

D. Cook & Hold – Roast & Hold 28

4

6-25

Maintenance Instructions

A. Adjustments 29

B. Door Adjustment 29

C. Door Switch Adjustment 29

D. Thermostat Calibration 29-30

E. Cleaning the Oven 30

Repair Parts List 31

Door Assembly 32

“V” Controller Assembly 33

“X” Controller Assembly 34

“Z” Controller Assembly 35

“XX” Controller Assembly 36

“ZX” Controller Assembly 37

“ZZ” Controller Assembly 38

Contactor Identification 39

Flue Guard 40

Double Stack Ovens 40

Wiring Diagrams 42 - 51

Please supply the ID Number and the Serial Number when

ordering replacement parts or requesting service.

2 of 52

We recommend service by Duke Authorized Service

Agencies during and after the warranty period.

FOR YOUR SAFETY:

Do not store gasoline or other flammable vapors or liquids in the vicinity of this or

any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

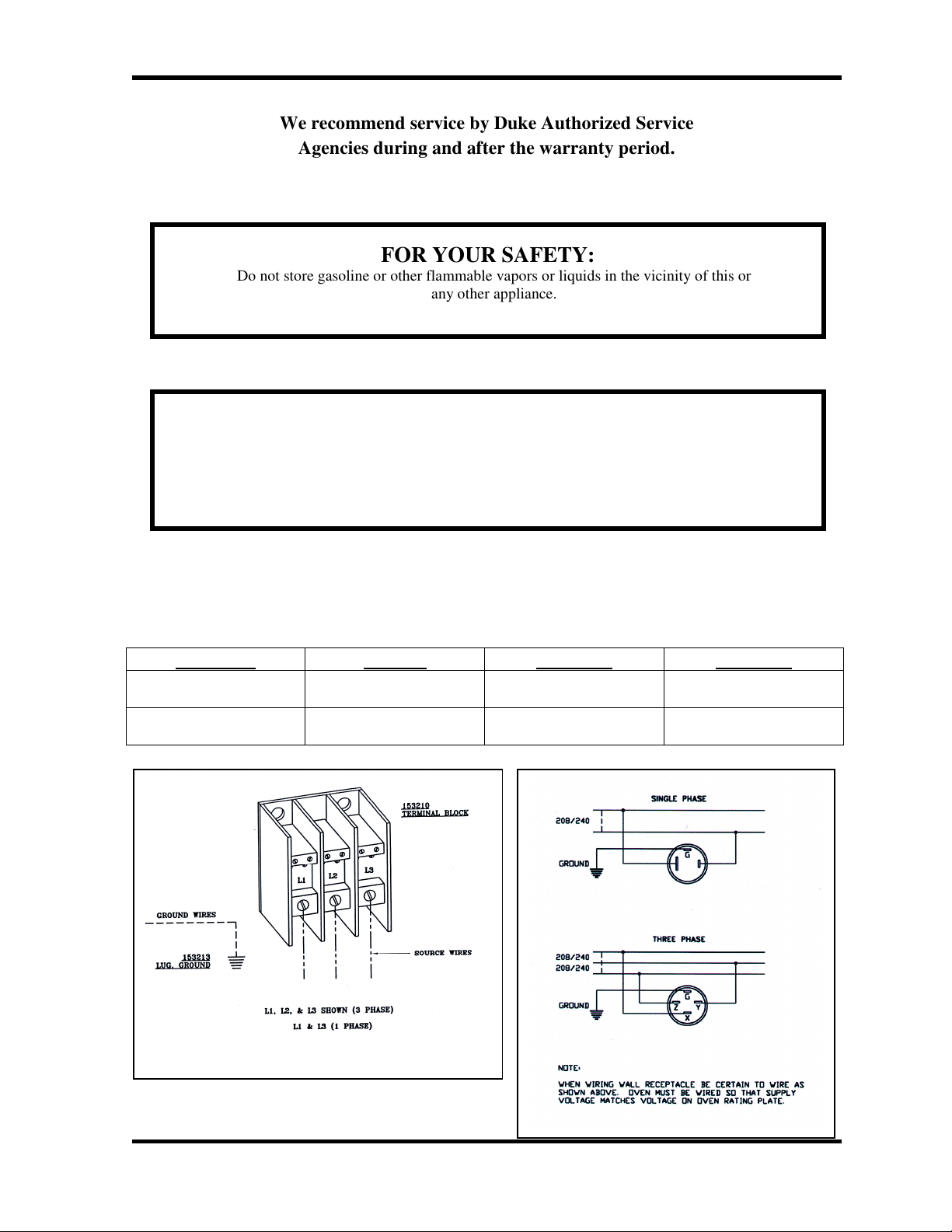

ELECTRICAL SPECIFICATIONS

Total KW VOLTS 1 PHASE 3 PHASE

8.0 208 41.0 24.0 amps/pl

8.0 240 36.0 21.0 amps/pl

Power Supply Connections

3 of 52

INSTALLATION INSTRUCTIONS:

A. Qualified Personnel

These installation instructions are for the use of

qualified installation and service personnel only.

Installation or service by other than qualified personnel

may result in damage to the oven and/or injury to the

operator.

Qualified installation personnel are those individuals,

firms, companies or corporations which either in person

or through an agent is engaged in and responsible for:

• The installation of electrical wiring from the

electric meter, main control box or service outlet

to the electrical appliance. Qualified installation

personnel must be familiar with all precautions

required and have complied with all

requirements of state and local authorities having

jurisdiction. See: National Electrical Code,

ANSI/NFPA70.

B. Delivery and Inspection

Duke Manufacturing Co. does everything within its

power to insure you received your oven in good

condition. They are strapped down on heavy wooden

skids and surrounded by heavy "tri-wall" cartons to

prevent shipping damage. They have all been carefully

inspected before they were packaged and consigned to

the carrier.

Upon delivery of your Duke oven:

• Look over the shipping container, carefully noting

any exterior damage on the delivery receipt,

which must also be signed by the driver/ delivery

person.

• Uncrate and check for any damage, which was not

evident on the outside of the shipping container.

This is called concealed damage. The carrier must

be notified within fifteen (15) days of the delivery

of the oven and the carton, skid and all packaging

materials must be retained for inspection.

Duke Manufacturing Co. cannot assume liability for

loss or damage suffered in transit. The carrier assumes

full responsibility for delivery in good order when the

shipment was accepted. However, we are prepared to

assist you in filing your claim.

C. Location of the Oven

Proper planning and placement of the oven will give

you the best results in terms of long-term user

convenience and satisfactory performance. We urge you

to give adequate thought in the placement of your oven

prior to its arrival.

• The oven should be placed in an area that is free

from drafts and accessible for proper operation

and servicing.

• The area around the oven must be kept clear of

combustible materials. A minimum clearance

of:

Combustible Non-

Combustible

RIGHT SIDE

LEFT SIDE

REAR

FLOOR

1" 0”

1" 0”

3" 3”

8" 8”

Must be maintained between the oven and any

combustible or non-combustible surface.

It is also important not to obstruct the natural flow

of ventilation air if the oven is to operate properly.

This oven should not be installed on a curb base or

sealed to the wall. Either condition can restrict the

flow of air to or prevent proper ventilation of the

blower motor. The blower motor has a thermal

protection device, which will trip, because of

excessive ambient temperatures at the back of the

oven. This condition should be corrected

immediately to avoid damaging the oven

permanently.

The flue located near the top at the rear of the oven

must not be obstructed. Proper ventilation is

important to avoid high temperatures at the rear of

the oven. High temperatures can cause premature

blower motor failure.

Before making any connections to the oven, check

the rating plates to be sure the oven specifications

concur with the voltage and phase to be supplied to

the oven.

The rating plate is located behind the lower front

panel. To access, loosen the four screws below the

doors, and pull the panel outward.

The plate bearing the oven’s serial number is

attached to the underside of the upper ledge above

the control panel.

D. Electrical Connections

Your oven is supplied for connection to a 208, 240,

440 or 480 volt grounded circuit. The electric

motor, oven lights, indicator lights and control

circuits are connected internally and require no

secondary power supply.

Before making any connections to these units, check

the rating plate to assure that the voltage and phase

4 of 52

of the oven is compatible with the electrical supply.

When installing, all ovens must be electrically grounded

in accordance with local codes or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA

70 (in Canada – CSA Std. C22.1). Wiring diagrams are

located in the control compartment area. Standard

wiring schematics are also included at the back of this

manual.

The proper method of connecting the power source to

the terminal block is shown in the Exploded Views

Section.

Note to Electrical Inspector:

Inspection of electrical connection should be

accomplished by the removal of the Control Panel.

E. Oven Assembly

Before assembling and installing the oven, please check

to make sure that all necessary parts are present. In

addition to the oven itself, there will also be legs, feet or

casters, the vent guard, (for double sections, retaining

clips, vent riser) and miscellaneous hardware. Please

check the interior of all oven sections for the parts

needed to assemble and install your oven(s).

Leg Attachment

• Once the oven has been removed from the

carton, lay it on its lift side (the side without

the controls).

• Position one of the legs against the bottom of

the oven, aligning the center hole on the leg

plate with the center threaded hold on the

bottom of the oven.

• While supporting the leg, carefully start the

bolt in the center hole and finger tighten.

(Avoid cross threading.)

• Align the other two leg plate holes with those

in the bottom of the oven.

• Carefully start the bolts in the remaining holes

and finger tighten. (Avoid cross threading.)

• Secure each of the bolts using a wrench.

• Repeat this process for all legs.

• Addt the two (2) storage shelves between the

four (4) legs and secure with the bolts

provided.

• Raise the oven up on the legs.

Caster Installation

Casters are available as an option for double oven

sections. They are packed inside the oven for shipment.

• Place the tip of a large screwdriver against the

lip of the adjustable foot on the bottom of the

leg.

• Using a hammer, drive the foot out of the leg.

• Insert the caster fully into the opening where

the foot came out.

• Using a wrench, tighten the locking nut on the

bottom of the caster to expand the

compression sleeve until secure.

• Repeat this process for the remaining legs.

NOTE: The casters with locking brakes are best

mounted on the front side of the oven for easier

access.

NOTE: If you plan to use casters, a fixed restraint of

the proper length is recommended to eliminate

strain on the connecting wire. If the oven is removed

from its normal position, the restraint must then be

reattached when returned.

F. Adjustments Associated with Installation

Each oven section and all its component parts have

been tested thoroughly and inspected before your oven

was shipped from the factory. However, it is sometimes

necessary to further test or adjust the oven once it has

been installed. Such adjustments are the responsibility

of the Dealer or Installer. These types of adjustments

are not considered defects, rather a normal and routine

part of the proper installation of the equipment.

These adjustments include but are not limited to:

• Adjustments and recalibration of the thermostat

• Adjustment to the doors.

• Leveling.

• Tightening of fasteners.

No installation should be considered complete

without proper inspection and, if necessary, any

adjustments by qualified service or installation

personnel.

Level the oven by turning the adjustable feet in or out as

needed.

5 of 52

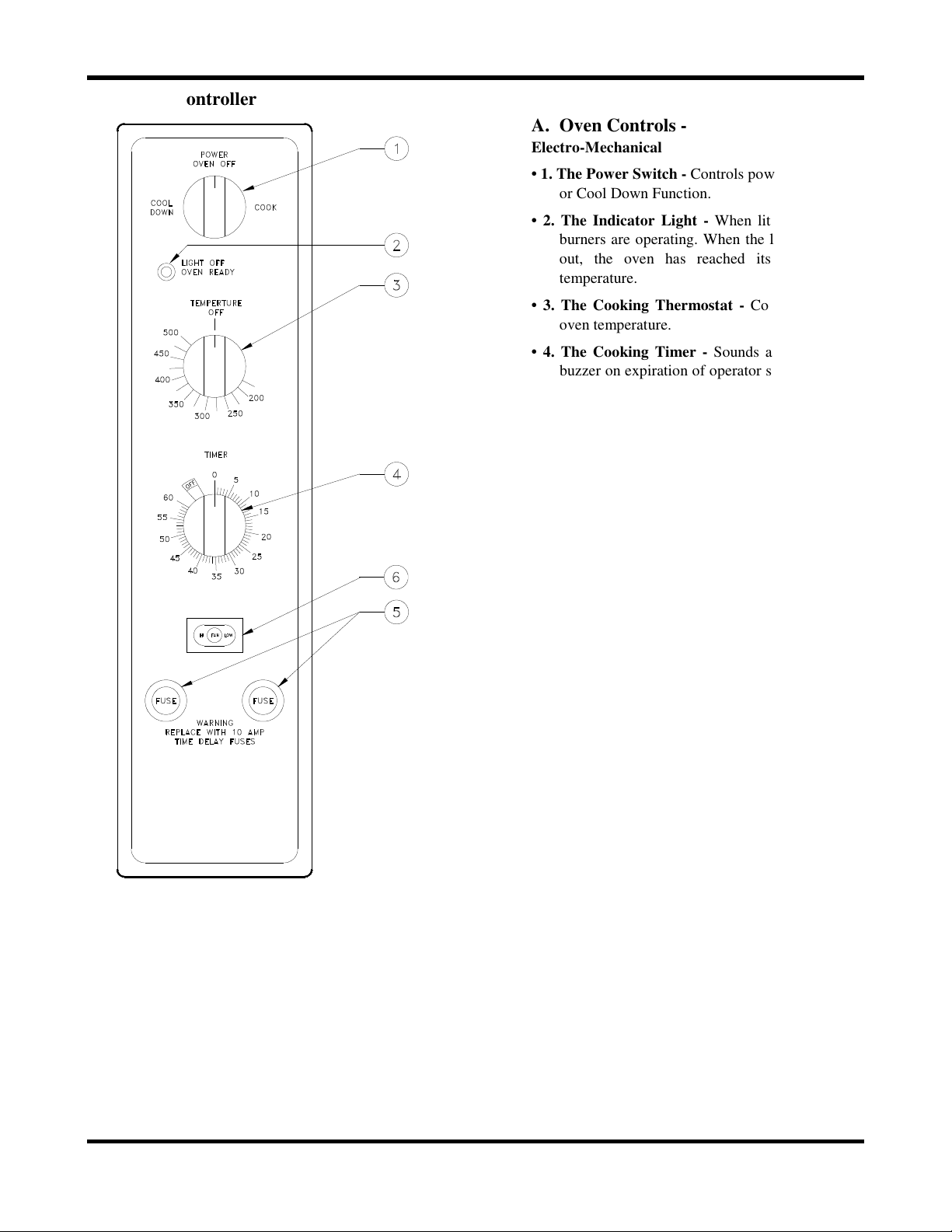

V” Controller

A. Oven Controls -

Electro-Mechanical

• 1. The Power Switch - Controls power to ON

or Cool Down Function.

• 2. The Indicator Light - When lit indicates

burners are operating. When the light goes

out, the oven has reached its cooking

temperature.

• 3. The Cooking Thermostat - Controls the

oven temperature.

• 4. The Cooking Timer - Sounds an electric

buzzer on expiration of operator set time as

a reminder to remove product at end of

cooking cycle.

• 5. The Fuse Holders – Contain circuit

protecting fuses.

• 6. The Fan Speed Switch (Optional) - Sets

fan speed to high or low.

6 of 52

Operating Instructions - “V” Controller

Timer Resolution

The Timer displays time from 0 to 60 minutes, in one-

minute increments.

Temperature Scale

The Temperature Control displays the temperature in

°F. The temperature range is from 150°F - 500°F, in

25°F increments.

Cool Down

This feature enables the oven to be cooled rapidly by

allowing the fan to operate with the heating elements

turned off. To activate, turn the Power Switch to the

COOL position and open the oven door. When the

door is opened enough to disengage the door switch,

the fan will turn on. Closing the door will turn the fan

off.

Fan Speed Switch

The fan speed can be set to high or low speed by

placing the FAN HI/LOW button to the desired setting.

Cooking

A cooking cycle can be initiated as follows:

• Turn the Power Switch to COOK position.

• Set the Cooking Temperature by turning the

TEMPERATURE dial to the desired

temperature. The OVEN READY indicator

light will turn on.

• When the OVEN READY indicator light turns

off, place the product to be cooked in the

oven.

• Set the cooking Time by turning the COOK

TIMER dial to the desired time.

During the Cook Cycle, The OVEN READY Indicator

light will cycle on and off with the heating elements.

• When the COOK TIMER reaches “zero”, the

alarm will sound.

• To cancel the alarm, turn the COOK TIMER

dial to the OFF position.

7 of 52

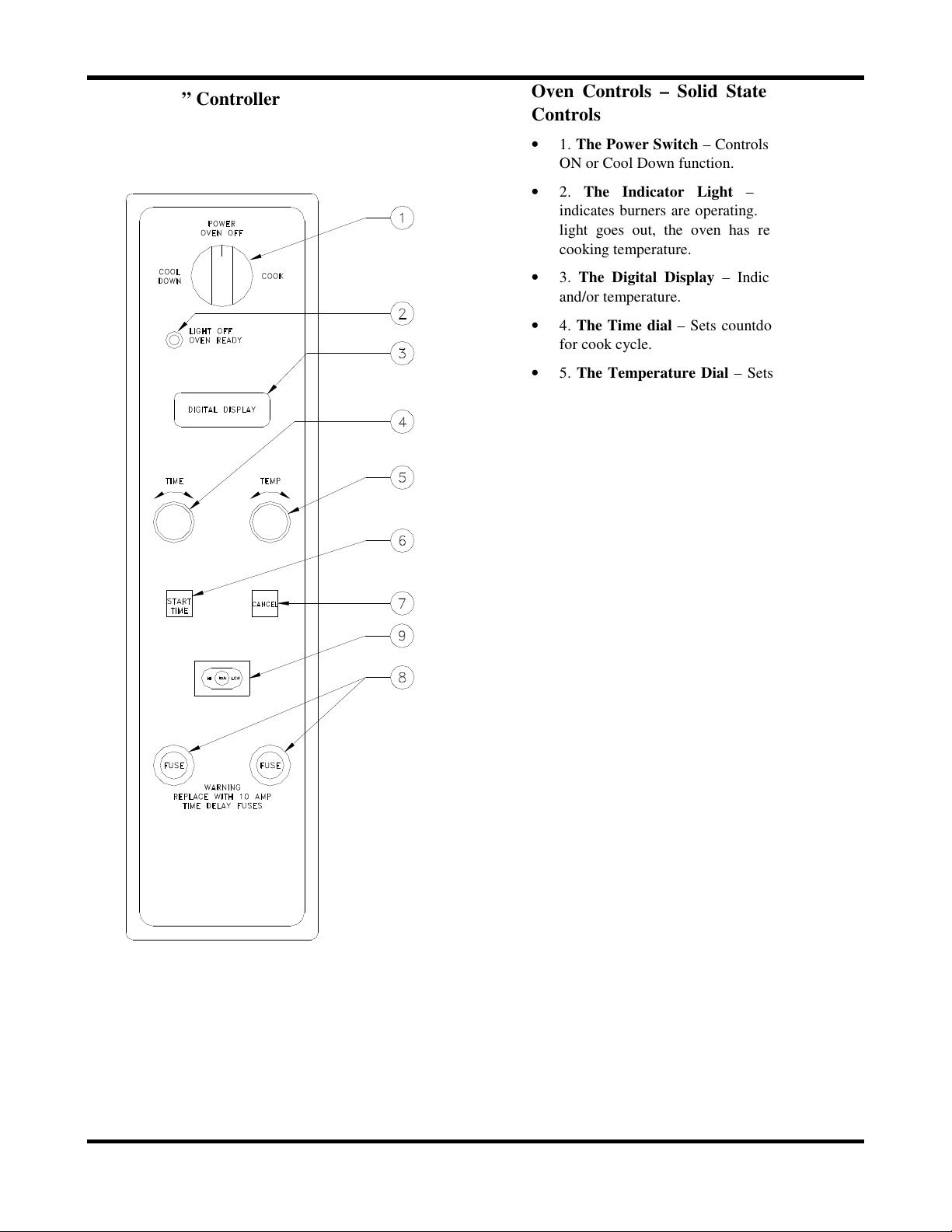

“X” Controller

Oven Controls – Solid State Digital

Controls

• 1. The Power Switch – Controls power to

ON or Cool Down function.

• 2. The Indicator Light – When lit

indicates burners are operating. When the

light goes out, the oven has reached its

cooking temperature.

• 3. The Digital Display – Indicates time

and/or temperature.

• 4. The Time dial – Sets countdown timer

for cook cycle.

• 5. The Temperature Dial – Sets cooking

temperature.

• 6. The Start Time Button – Initiates

timing cycle.

• 7. The Cancel Button – Cancels preset

time and/or temperature.

• 8. The Fuse Holders – Contain circuit

protecting fuses.

• 9. The Fan Speed Switch (Optional) –

Sets fan speed to high or low.

8 of 52

PROGRAMMING & OPERATION

INSTRUCTIONS FOR “X” CONTROLLER

Timer Resolution

The Timer displays time in two (2) different scales. From

0 to 60 minutes, the timer is displayed in Minutes/Seconds

(“MN” Mode). From 1 to 12 hours, the time is displayed in

Hours/Minutes (“HR” Mode). The mode indicators are

located in the first number digit to the left of the colon.

Temperature Scale

The controller can be set to display toe temperature in °F or

°C as follows:

• Turn Power Switch to COOK position.

• Set TIME to 00:00 and TEMP so “20” is

displayed in the right two temperature digits.

• Press and hold both the START TIME and

CANCEL buttons for 5 seconds. The control will

display “CCC” and “FFF” in the temperature

digits to indicate it has entered the mode.

• Turn the TIME or TEMP dial to toggle

between “CCC” and “FFF”.

• Press CANCEL to exit.

Power Input Frequency

The controller can be set to operate on 50Hz or 60Hz as

follows:

• Turn Power Switch to COOK position.

• Set TIME to 00:00 and TEMP so “40” is

displayed in the right two temperature digits.

• Press and hold both the START TIME and

CANCEL buttons for 5 seconds. The control

will display “50” and “60” to indicate it has

entered the mode.

• Turn the TIME or TEMP dial to toggle

between “50” and “60”.

• Press CANCEL to exit.

Actual Temperature Button

The actual temperature can be viewed by pressing and

holding the START TIME button for approximately 2

seconds. The temperature will be displayed in the

temperature digits. This can be viewed anytime the

oven is in operation, except when the oven is in the

HOLD mode.

• Press and hold both the START TIME and

CANCEL buttons for 5 seconds. The

control will display “Con” or “CYC” to

indicate it has entered the mode.

• Turn the TIME and TEMP dial to toggle

between “Con:” and “CYC”.

• Press CANCEL to exit.

The fan cannot be set to cycle if the HOLD mode is

to be used.

Fan Speed Switch

The fan speed can be set to high or low speed by

placing FAN HI/LOW switch to the desired setting.

The display does not indicate which mode the fan is

operating.

Cool Down

This feature enables the oven to be cooled rapidly

by allowing the fan to operate with the burners

turned off. To activate, turn the Power Switch to the

COOL position and open the oven door. When the

door is opened enough to disengage the door switch,

the fan will turn on. Closing the door will turn the

fan off.

Cooking

A cooking cycle can be initiated as follows:

• Turn Power Switch to COOK position.

• Set the cooking time by turning the TIME

dial until the desired time is shown on the

display.

• Set the desired cooking temperature by

turning the TEMP dial until the desired

temperature is shown on the display. The

indicator light will turn on and the display

will flash when a minimum temperature of

150°F is entered. The flashing display

indicates that the oven is in its Preheating

Mode. It will no longer flash once the

oven reaches the temperature set point.

The indicator light will cycle on and off

with the burners.

• Press the START TIME button to begin the

timed cooking cycle. Pressing the

CANCEL button will “zero” the timer at

any time.

Pulse

The controller can be set to operate the fan

continuously, or cycle on and off every 30 seconds

during the COOK cycle as follows:

• Turn Power Switch to COOK position.

• Set TIME to 00:00 and TEMP to 000.

Cook & Hold

The controller can be set to hold the oven at a set

temperature at the end of the cooking cycle as

follows:

• Turn Power Switch to COOK position.

• Set TIME to 00:00 and TEMP so “50” is

displayed in the right two temperature

9 of 52

digits.

• Press and hold both the START TIME and

CANCEL buttons for 5 seconds. The control

will display “HOLD” in the time digits, and

the current Hold Set Temperature in the

temperature digits to indicate it has entered the

mode.

• Turn the TIME or TEMP dial to set the desired

temperature. Setting it to “000” will turn the

Hold mode off.

• Press CANCEL to exit.

When the timer counts down to zero, the alarm will

sound for 5 seconds and “HOLD” will appear in the

display with the current hold temperature. The timer

will not count up. Manual timing is required.

Offset

To compensate for the difference in temperature from

the sensing element to the center of the oven the control

can be programmed with an offset. The offset is

adjustable in 1ºF increments up to a maximum of

±49ºF.

Note: a negative offset will have the effect of raising

the cavity temperature, (Example: an oven set at 375ºF

is determined to run at a 350ºF internal oven

temperature. By programming in a -25ºF offset the

oven will run at a 375ºF internal oven temperature.).

The offset is programmed as follows:

• Turn Power Switch to COOK position.

• Set TIME to 00:00 and TEMP so “10” is

displayed in the right two temperature digits.

• Press and hold both the START TIME and

CANCEL buttons for 5 seconds. The control

will display “UPO” in the time digits, and the

current Offset in the temperature digits to

indicate it has entered the mode.

• Turn the TIME or TEMP dial to raise or lower

the offset.

• Press CANCEL to exit.

10 of 52

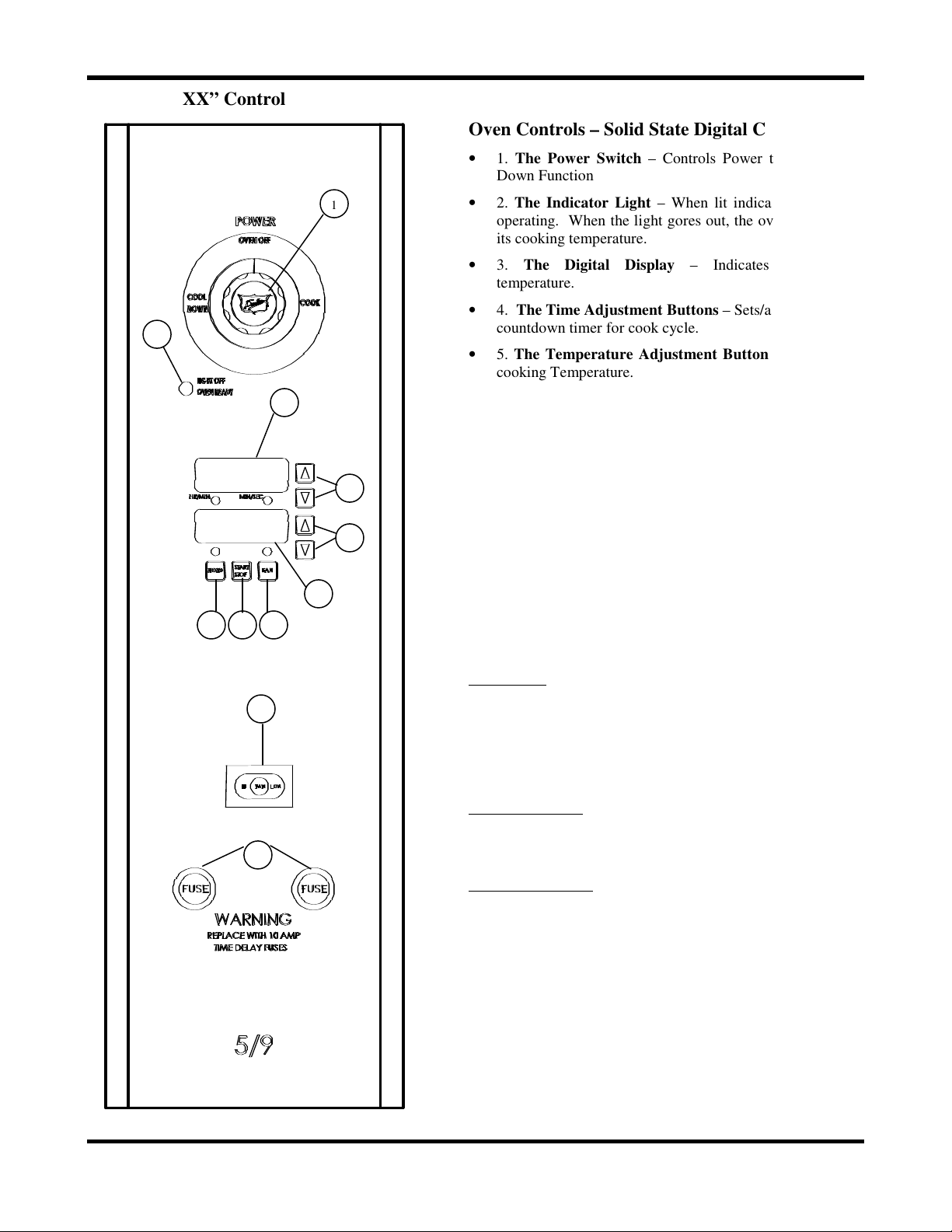

“XX” Control

Oven Controls – Solid State Digital Controls

• 1. The Power Switch – Controls Power to ON or Cool

Down Function

• 2. The Indicator Light – When lit indicates burners are

operating. When the light gores out, the oven has reached

its cooking temperature.

• 3. The Digital Display – Indicates time and/or

temperature.

• 4. The Time Adjustment Buttons – Sets/adjusts

countdown timer for cook cycle.

• 5. The Temperature Adjustment Buttons – Sets/adjusts

cooking Temperature.

• 6. The Temperature Digital Display: Displays the

temperature inside the oven.

• 7. The Pulse Fan Button: Enables/Disables the Pulse Fan

Function.

• 8. The Start/Stop Button: Starts/Stops the cooking cycle.

• 9. The Hold Button: Enables/Disables the Hold Function.

• 10. The Fan Speed Switch: (Optional) – Sets fan speed to

high or low.

• 11. The Fuse Holders: Each holds a 10 AMP Time Delay

Fuse.

Programming and Operating Instructions –

“XX” Controller

Timer Scale: The Timer displays in two (2) different scales.

From 0 to 60 minutes, the timer is displayed in

Minutes/Seconds. This is indicated by the MIN/SEC light on

the controller. From 1 to 2 hours, the time is displayed in

Hours/Minutes, indicated by the HOUR/MIN light on the

controller. When the oven is first turned on, the display will

show the last cook time programmed.

Time Adjustment: To increase the cook time, press the top (▲)

button located next to the Time Display. To decrease the cook

time, press the bottom button (▼) located next to the Time

Display.

Temperature Scale: The controller can be set to display the

temperature in ºF or °C as follows:

1) Remove/move control panel so that you have access to the

back of the control board.

2) Locate the blue jumper at connection J3.

3) For °F operation the jumper is not needed. Place the jumper

on one of the pins for future use.

4) For °C operation place the jumper across the two pins of J3.

When the oven is first turned on, the display will show the last

cook temperature programmed. You can view the actual

temperature of the oven by pressing both of the Temperature

Adjustment buttons at the same time.

11 of 52

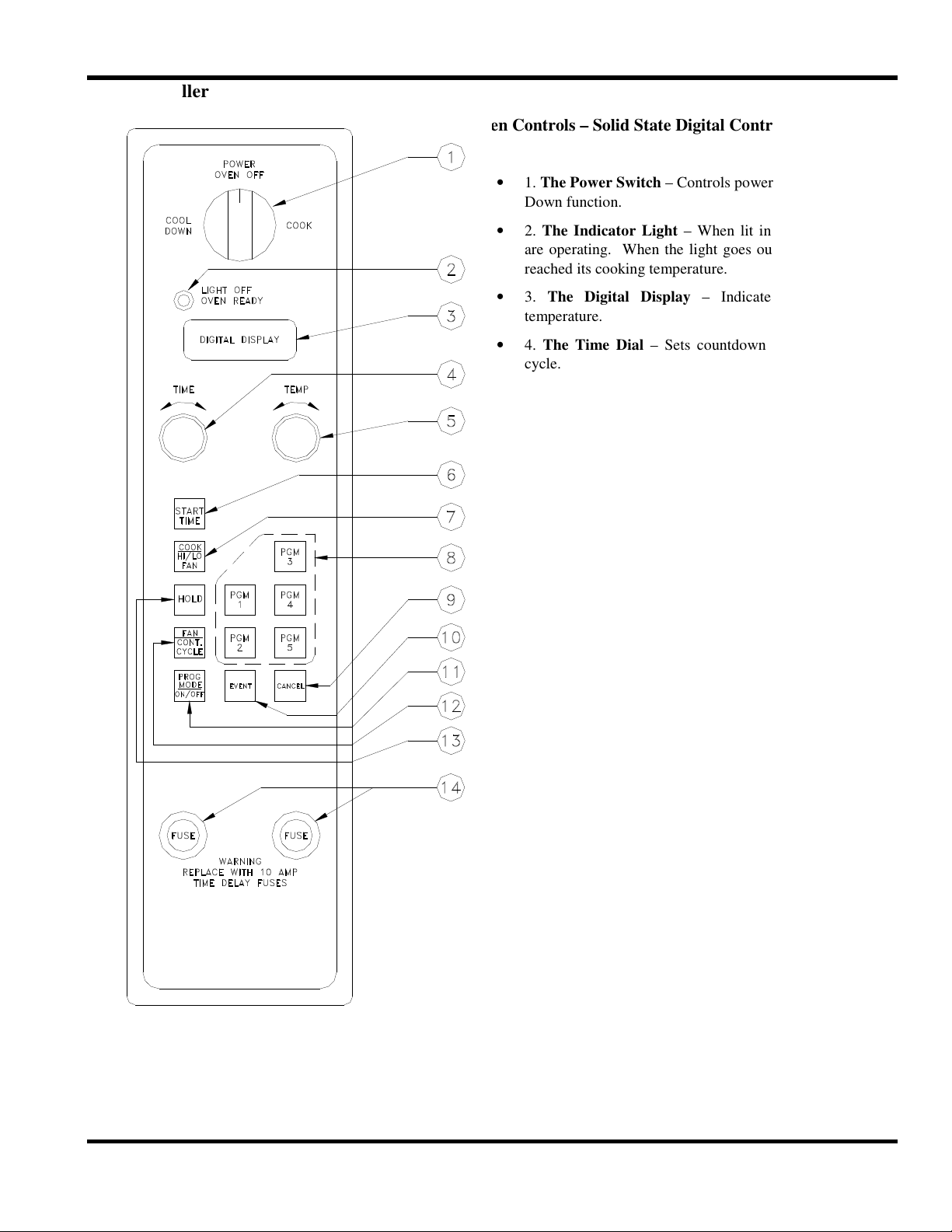

“Z” Controller

Oven Controls – Solid State Digital Controls

• 1. The Power Switch – Controls power to ON or Cool

Down function.

• 2. The Indicator Light – When lit indicates burners

are operating. When the light goes out, the oven has

reached its cooking temperature.

• 3. The Digital Display – Indicates time and/or

temperature.

• 4. The Time Dial – Sets countdown timer for cook

cycle.

• 5. The Temperature Dial – Sets cooking

temperature.

• 6. The Start Time Button – Initiates timing cycle.

• 7. The Cook/HI-LO Button – Sets fan speed to high

or low.

• 8. The Program Button – 5 individual time and

temperature programs. Operator programmed.

• 9. The Cancel Button – Cancels preset time and/or

temperature.

• 10. The Event Button – Used for programming oven

functions that will be chained into one cooking

routine.

• 11. The Program Mode – ON/OFF – Switches from

Operating to Programming Mode and back.

• 12. The Fan Continuous/Cycle Button – Allows

setting of fan to run continuously or turn on and off

with the burners during the cooking cycle.

• 13. The Hold Button – Allows setting of hold time

and temperature.

• 14. The Fuse Holders – Contain circuit protecting

fuses..

12 of 52

PROGRAMMING & OPERATING

INSTRUCTIONS“Z” CONTROLLER -

This controller provides five (5) automatic cooking

chains, which the user can program. It will also a low

non-automatic cooking and cook & hold operations.

The fan motor can be controlled to cycle on and off

with the burners or run continuously. High or low fan

speeds can be selected.

The cooking chains are particularly useful when the

user is producing batches of the same product time

after time, especially if changes to temperature or fan

speed are required during the cooking cycle. The user

can program one of the five program buttons for a

particular product and simply press one button when

it is loaded into the oven. The control will follow the

programmed cooking routine changing temperate

and/or fan speeds or fan cycle/continuous at the

programmed intervals. Thus, once the cooking chain

is programmed, the user would benefit from

consistent results when cooking the same batch.

However, not all usage of the oven requires an

automatic cooking routine. In these cases, the oven

can be used in a normal manner where the times and

temperatures are set using the rotary dials. A manual

Cook & Hold is also available for holding a product

after it has been cooked.

The following instructions will assist you in using this

control with your oven, but if you have any questions

you should contact the Duke Service Department on

our toll free support line: 800.735.3853.

Timer Resolution

The Timer displays time in two different scales.

From 0 to 60 minutes, the time is displayed in

Minutes/Seconds (“MN” Mode). From 1 to 12 hours,

the time is displayed in Hours/Minutes (“HR” Mode).

The mode indicators are located in the firs number

digit to the left of the colon.

Power Input Frequency

The control will display “CCC” or “FFF” in the temperature digits

to indicate it has entered the mode.

Entering will toggle between “CCC” and “FFF”. Pressing and

holding the START TIME button again will also toggle the setting.

Turn Power Switch to OFF position to exit.

Time Dial

The TIME dial sets time intervals for cooking. It is used in either

programmed or manual cooking.

Temp Dial

The TEMP dial sets the temperature. The temperature changes in

5°F or 1°C increments.

Start Time Button

The START TIME button initiates the cooking cycle whether a

programmed chain or manual time set with the TIME dial used.

Cook HI/LO Fan Button

The COOK HI/LOW FAN button puts the control into a cook mode

and enables the heating elements. Each time the button is pressed,

the control switches between the high or low fan speeds. If neither

fan is enabled, the high fan speed is selected automatically. The HI

FAN and LO FAN indicators show, which fan speed, is selected.

Hold Button

The HOLD button is used to set up the Hold Mode. The user

presses the HOLD button and sets the desired temperature and

continuous or cycled fan. During the Hold setup mode, the HOLD

indicator is lit and the CYCLE indicator is lit if the cycled fan is

selected.

During the cook portion hold mode, the timer counts down to zero.

During the hold portion, the timer counts up from zero.

Fan Con/Cyc Button

The FAN CON/CYC button enables the fan to run continuously

during the cooking cycle, or run only when the control is calling for

heat. The display will show FAN CYC when the cycled fan mode

is selected and FAN CON when the continuous mode is selected.

The CYCLE indicator will light when the cycled fan is enabled.

The controller will automatically set itself to operate

on 50Hz or 60Hz, depending on the power source

used. All timers and internal clocks are automatically

compensated.

Temperature Scale

The controller can be set to display the temperature in

°F or °C. as follows:

• Turn Power Switch to COOK position.

• Set TIME to 00:00 and TEMP so “20” is

displayed in the right two temperature digits.

Press and hold the START TIME button for 5 seconds.

13 of 52

Program Mode On/Off Button

Manual Cooking

This button allows the user to activate the

programming mode. When this mode is selected,

normal oven operation is suspended. The

programming mode allows the user to program the

cook chains. When this button is pressed again, the

program mode is exited and normal oven operation is

resumed. When the programming mode is entered the

PGM indicators flash.

Event # Button

During the programmed chain cooking operation, this

button is used to recall the time remaining in the

current event. In the programming mode, this button

is used to sequence to the next event to be

programmed. During manual operation, this button is

disabled.

Program Buttons (1-5)

The five (5) programming buttons are provided for

chained cooking. Programs 1 and 2 provide the user

with 6 events each, and programs 3, 4 and 5 provide 4

events each. The user sets the value programmed for

each event. The Program buttons are locked out when

the control is running a manual timed cook.

1 Event = time, temp, fan speed, fan mode.

Cancel Button

The CANCEL button is provided to clear the timer

and enable the program buttons and rotary dials. It

also cancels the Programming Mode, the beeper, and

turns off any indicators that are no longer needed.

Power Up

On initial power up, the time digits will always

display zeros with a colon. The temperature digits

will display zeros with the degree (°) indicator lit.

The C will also be lit in the display if the Celsius

option is selected. When the control is turned off, the

temperature/timer setting is stored. When the control

is turned on again, it will automatically return to the

last set time and temperature

A normal, non-programmed cooking cycle can be initiated as

follows:

• Turn Power Switch to COOK position.

• Set the desired time using the TIME dial.

• Set the desired temperature using the TEMP dial.

• Select the desired fan speed using the COOK HI/LO FAN

button.

• Select the fan to be on continuously or cycled using the

FAN/ CON/CYC button.

• Set the HOLD temperature, if desired.

• Press the START TIME button to start the cooking cycle.

• Pressing the CANCEL button will “zero” the Timer at any

time.

Programmed Chain Cooking

With the control in normal operating mode, press the desired chain

(PBM 1-5) button. If the selected chain has been programmed, the

first event will be loaded. The timer will not start until the START

TIME button is pressed. The oven temperature will be controlled to

the temperature programmed to the first event.

Chain Programming

Each of the 5 PGM buttons can be programmed to perform a

different sequence or “chain” of events. Each event, or step,

includes a setting for the time, temperature, fan speed, and fan

mode. PGM 1 and PGM 2 allow the user to set up to 6 events to

be performed during the cooking cycle, while PGM 3,

PGM 4 and PGM 5 allow up to 4 events. The last event for any

of the Programmed Chains can be set to be a Hold mode.

Programming the PGM buttons is performed as follows:

• Turn Power Switch to COOK position.

• Press the PGM MOD ON/OFF button to enter the

programming mode. All PGM indicators will flash and

the balance of the display will be blanked.

• At this time, one of the PGM Button’s (1-5) must be

pressed to select which chain is to be programmed. When

the desired PGM button is pressed, the appropriate PGM

indicator will remain flashing and event 1 time and

temperature will be displayed. The event number (E1-E6)

will be displayed alternately with the temperature digits.

Cool Down

This feature enables the oven to be cooled rapidly by

allowing the fan to operate with the heating elements

turned off. To activate, turn the Power Switch to the

COOL position and open the oven door. Then the

door is opened enough to disengage the door switch,

the fan will turn on. Closing the door will turn the fan

off.

14 of 52

• To change the event time, turn the TIME

dial. The time entered will be displayed in

the time digits.

• To change event temperature, turn the

TEMP dial for the desired set temperature.

The temperature entered will be displayed in

the temperature digits. The event number

display will not be shown while the TEMP

dial is being rotated.

• To change the fan speed, press the COOK

HI/LO FAN button. The display indicators

will show the selected cook mode.

• Press the FAN CON/CYC button to select

continuous or cycled fan. The display will

show FAN CON or FAN CYC to indicate

which mode is selected. The CYCLE

indicator will light if the cycled fan is

enabled.

• To set up a hold mode, press the HOLD

button. The HOLD indicator will be lit

when this mode has been selected.

When an event is programmed as a Hold,

that event will be the last recognized event

of the chain. As an example, if Event 3 is

set up as a Hold and Event 4 was set up as

a Cook, Event 4 would be ignored.

• To exit the Programming mode, press the

PGM ON/OFF or CANCEL button. The

programmed parameters of the previously

programmed chain will be saved at this time.

• To program another event within the same

chain, press the EVENT # button. The

parameters of the previous event are saved at

this time and sequential event will be

displayed. If the previous event was the last

of the chain, the first event will be displayed.

• To program another chain, press the desired

PGM BUTTON (1-5). Event 1 of the

selected chain will be displayed and the

parameters of the previously programmed

chain will be saved at this time.

EXAMPLE: MUFFINS

Event 1

cook time = 4 minutes

Cycled, low fan allows the muffins to rise and skin over

without being distorted by the air movement.

Event 2

continuous fan, cook time = 8 minutes.

Once the product is skinned over, the continuous, highspeed fan will finish the cooking.

TOTAL COOK TIME = 12 MINUTES

(This is an example; your results may vary.)

: Cook temp - 400°F, LOW fan speed, cycled fan,

: Cook temp = 400°F, HIGH fan speed,

15 of 52

Loading...

Loading...