Duke 59-E3P Parts List

DUKE MANUFACTURING CO. 155409E

POPEYE’S

Duke 59-E3P

ELECTRIC HALF-SIZE

CONVECTION OVEN

Installation, Operation, Parts

& Maintenance Manual

1111

2305 N. Broadway, St. Louis, MO 63102 155433P

800-735-3853 •••• 314-231-1130 •••• 314-231-5074 FAX:

www.dukemfg.com

We recommend service by Duke A

uthorized Service

INDEX

59-E3P Electrical Specifications 4

Installation Instructions

A. Qualified Personnel 5

B. Delivery & Inspection 5

C. Location of Oven 5

D. Electrical Connections 5-6

E. Ventilation 6

F. Electric Oven Assembly 6

G. Adjustments Associated with Installation 6

Control Panel 7

A. Program Parameters 8

B. Programming Instructions 8-9

C. Operation of Oven 9

D. Cool Down Operation 9

E. Emergency Back-Up System 10

F. Troubleshooting 10

G. Control Failure Diagnostics 11

Cleaning the Oven 12

Maintenance Instructions 13

A. Adjustments 13

B. Door Adjustments 13

C. Lubrication 13

D. Calibration Check 13

Repair Parts List and Corresponding Drawings 14-19

Wiring Diagram 20-22

Please supply the Model Number and the Serial Number when

ordering replacement parts or requesting service.

Agencies during and after the warranty period.

3 of 24

Model 59

-

E3P

TOTAL KW

VOLTS

1 PHASE

3 PHASE

FOR YOUR SAFETY

Do not store gasoline or other flammable liquids in the vicinity of this appliance.

WARNING

Improper installation, adjustment, service or maintenance can cause property

damage, injury or death. Read all installation, operating and maintenance

instructions thoroughly before installing or servicing this appliance.

8.0 208 41.0 AMPS 24.0 AMPS/PH

8.0 240 36.0 AMPS 21.0 AMPS/PH

Power Supply Connection

ELECTRICAL SPECIFICATIONS

4 of 24

INSTALLATION INSTRUCTIONS

A. Qualified Personnel

These installation instructions are for the use of

qualified installation and service personnel only.

Installation or service by other than qualified

personnel may result in damage to the oven

and/or injury to the operator.

Qualified installation personnel are those individuals, firms,

companies or corporations which either in person or

through an agent are engaged in and responsible for:

• The installation of electrical wiring from the

electric meter, main control box or service

outlet to the electrical appliance. Qualified

installation personnel must be familiar with all

precautions required and have complied with all

requirements of state and local authorities

having jurisdiction. See: National Electrical

code, ANSI/NFPA 70-1990.

B. Delivery and Inspection

Duke Manufacturing Co., does everything within its power

to insure you receive your oven in good condition. They

are strapped down on heavy wooden skids and surrounded

by heavy "tri-wall" cartons to prevent shipping damage.

They have all been carefully inspected before they were

packaged and consigned to the carrier.

Upon Delivery of your Duke oven:

C. Location of the Oven

Proper planning and placement of the oven will give you

the best results in terms of long term user convenience and

satisfactory performance. We urge you to give adequate

thought in the placement of your oven prior to its arrival.

• The oven should be placed in an area which is

free from drafts and accessible for proper

operation and servicing.

• The area around the oven must be kept clear of

combustible materials. A minimum of one (1)

inch from the left or right side, three (3) inches

from the rear and eight (8) inches from the floor

must be maintained between the oven and any

combustible or non-combustible surface.

It is also important not to obstruct the natural flow of

ventilation air if the oven is to operate properly. Do

not place any objects on top of the oven. This oven

should not be installed on a curb base or sealed to the

wall. Either condition can prevent proper ventilation

of the blower motor. The blower motor has a thermal

protection device which will trip because of excessive

ambient temperatures at the side of the oven. If the

device trips continually, this condition should be

corrected immediately to avoid damaging the oven

permanently.

Before making any connections to the over, check the rating

plate to be sure the oven specifications concur with the

voltage and phase to be supplied to the oven.

• Look over the shipping container carefully

noting any exterior damage on the delivery

receipt which must also be signed by the

driver/delivery person.

• Uncrate and check for any damage which was

not evident on the outside of the shipping

container. This is called concealed damage.

The carrier must be notified within fifteen (15)

days of the delivery of the oven and the carton,

skid and all packaging materials must be

retained for inspection.

Duke Manufacturing Co. cannot assume liability for loss or

damage suffered in transit. The carrier assumes full

responsibility for delivery in good order

when the shipment was accepted. However, we are

prepared to assist you in filing any freight claim.

The rating plate and serial number data are located behind

the motor access cover on the right side panel.

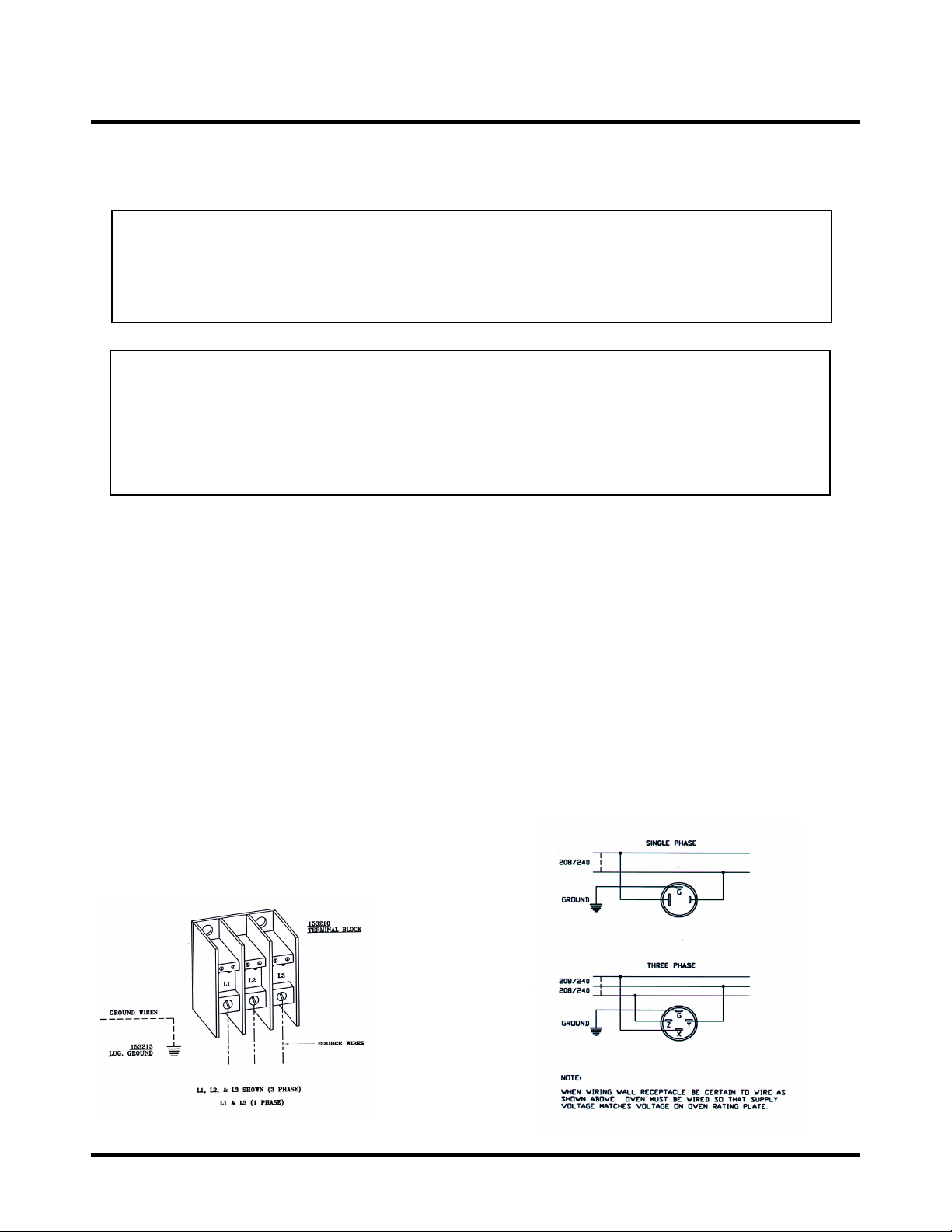

D. Electrical Connections

Each section of the Duke 5/9 Half-Size Convection Ovens

is rated at 8.0 KW.

Your oven is supplied for connection to a 208 or 240 volt,

1-phase or 3-phase grounded circuit. The

electric motor, indicator lights and control circuits are

powered internally and do not have a separate power

supply.

Before making any connections to these units, check the

rating plate to assure that the voltage and phase rating of the

oven is compatible with the electrical supply. When

installing, all ovens must be electrically grounded in

accordance with local codes or in the absence of local

codes, with the National Electrical Code, ANSI/NFPA 701990 (in Canada - CSA Std. C22.1).

5 of 24

Wiring diagrams are located on the inside of the motor

access panel, on the right side of the oven.

E. Ventilation

Proper ventilation is very important for the proper function

of your oven. A good ventilation system will allow the oven

to function properly as well as remove unwanted vapors.

Not venting the ovens properly can result in unsatisfactory

baking results as well as the possibility of damaging your

oven.

F. Oven Assembly

Before assembling and installing the oven, please check to

make sure that all necessary parts are present. In addition to

the oven itself, there will also be legs, feet or casters. (For

double sections, retaining clips, and miscellaneous

hardware.) Please check the interior of all oven sections for

the parts needed to assemble and install your oven(s).

Leg Attachment (in lieu of stand)

• Once the oven has been removed from the

carton, lay it on its left side (the side without the

controls).

• Hold the leg and align with the matching holes

in base and leg flange. Carefully start the 5/16

18 bolts, (avoid cross-threading), by turning

clockwise and tighten to the nearest full turn. A

total of (12) 15/16-18 X 3/4 bolts, flat washers

and lock washers are required to secure all legs.

• Once legs are secured, add two (2) storage

shelves between the four (4) legs. Secure these

by using the 1/4-20 X 3/4 self-threading

screws. After completion, carefully lift the oven

to an upright position.

To level the unit, raise or lower the adjustable feet as

required.

G. Adjustments Associated with Installation

Each oven section and all its components parts have been

tested thoroughly and inspected before your oven was

shipped from the factory. However, it is sometimes

necessary to further test or adjust the oven once it has been

installed. Such adjustments are the responsibility of the

Dealer or Installer. These types of adjustments are not

considered defects, rather a normal and routine part of the

proper installation of the equipment.

These adjustments include but are not limited to:

• adjustments and recalibration of the controller

• adjustment to the doors, leveling

• and tightening of fasteners.

No installation should be considered complete without

proper inspection and, if necessary, any adjustments by

qualified service or installation personnel.

6 of 24

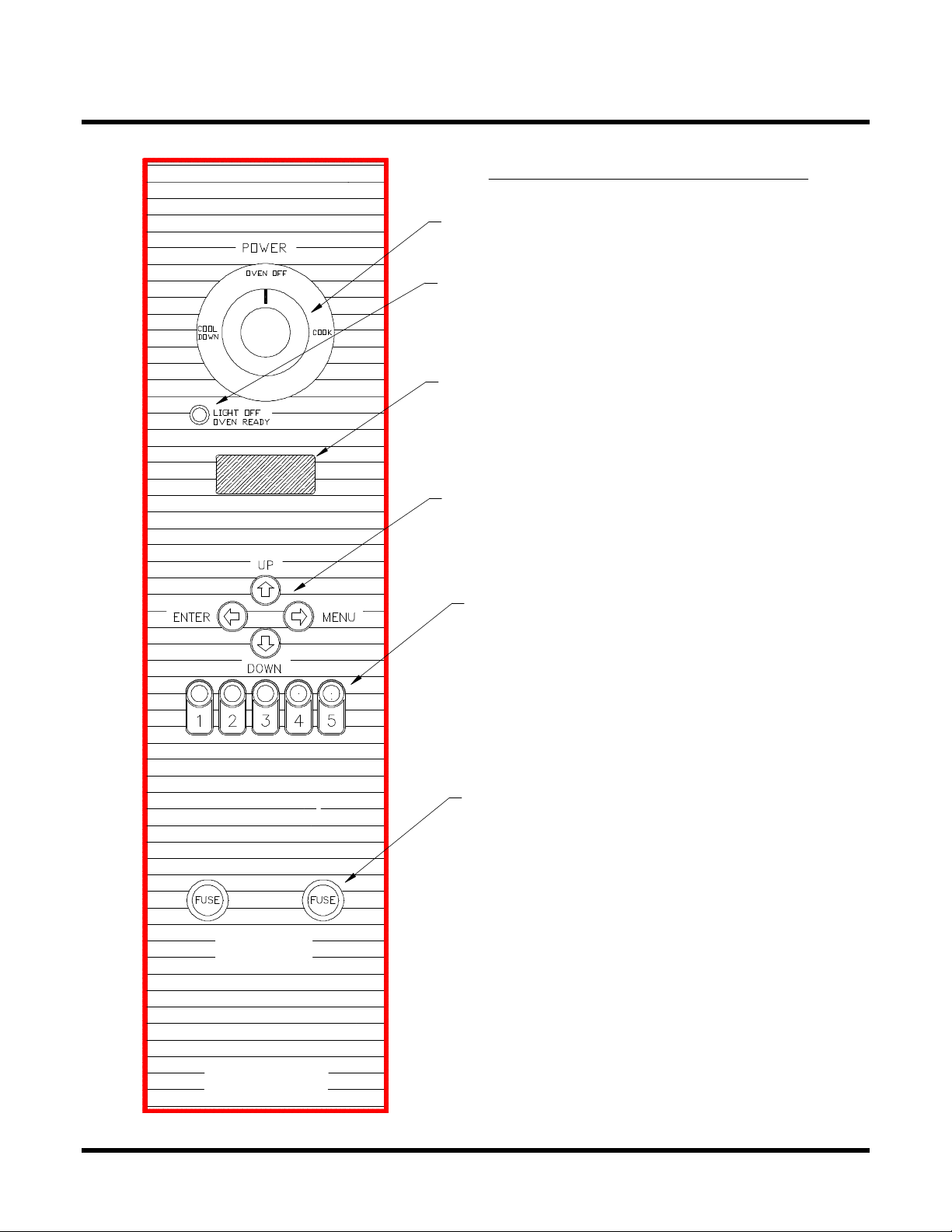

POPEYE'S OVEN CONTROLS

Main Power ON/OFF Switch

Power On Light - Indicates elements are

on. Light will go out when set temperature

has been reached.

Display - Indicates Time and/or Temperature

Programming Buttons

WARNING

REPLAC E WI TH 10 AMP

TIME DELAY FUSES

Preprogrammed Buttons - for

1 through 5 different recipe

settings.

Fuses - 10 Amp Time Delay Protective

FOR TE CHNICAL ASSISTANCE

OR SE RVICE, PLEASE CALL:

1-800-735- 3853

7 of 24

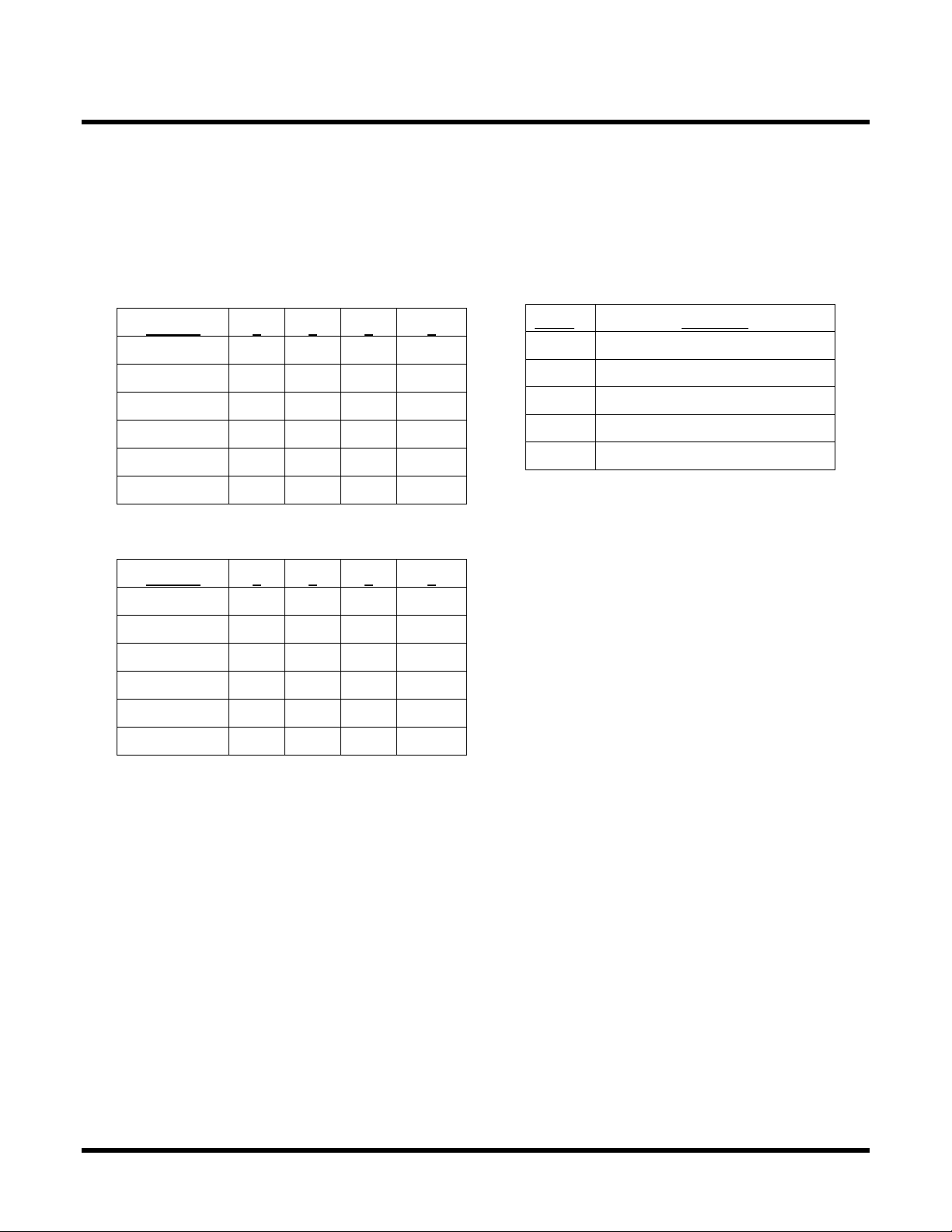

A. Program Parameters

This unit comes preprogrammed from the factory

with the following parameters for Menu items S1

and S2

Menu Item S1 (Use for Par Baked Biscuits)

# Trays 1 2 3 4

Cook Time 6:00 6:00 6:00 6:00

Temperature 375° 375° 375° 375°

On Time 60 80 130 160

Duty Cycle 160 160 160 160

Offset 0 0 0 0

Shelf Position 2 1,3 1,2,3 1,2,3,4

Menu Item S2 (Use for Fresh Biscuits)

# Trays 1 2 3 4

Cook Time 10:00 10:00 10:00 10:00

Temperature 375° 375° 375° 375°

On Time 80 100 130 160

Duty Cycle 160 160 160 160

Offset 0 0 0 0

Shelf Position 2 1,3 1,2,3 1,2,3,4

Shelf position is based on counting from the top rung

downward. (See oven drawing, page 9.)

For proper brownness, position each pan of biscuits in the

following manner.

B. Programming Instructions

Programming the Oven Control is simple. Anytime a

parameter (one of the five cooking times, one of the five

load control settings, duty cycle time-base, setpoint, or

offset) needs to be changed the procedure is:

• Select the desired menu item by holding down the

Gasket Groove

Push each pan all the way in until it hits the back

wall, then pull it forward (toward you) one (1)

inch.

MENU push button and pressing the UP/DOWN

buttons until the menu item is displayed (The Menu

items are numbered S1 through S7)

• Press both the number 1 and number 5

start switches at the same time. This

action tells the control that something is to be

changes; the alarm will sound, and the

number one (1) will appear in the display.

• Press one of the following buttons:

Switch To Change

1 Cooking Time

2 Cooking Temperature (Setpoint)

3 Duty Cycle On-Time

4 Duty Cycle Time Base

5 Offset

Switch 1 Pressed: The display will show the

number “2”. Press the switch that is to have its

baking time changed. The baking time for the

particular switch will be shown in the display. A

baking time must be programmed for selections 1,

2, 3 and 4. Use the UP/DowN buttons to change

the baking time to that desired.

NOTE: To change seconds hold in the start

switch for one tray, then use the UP/DOWN

switches.

Press the "Enter" switch to store the change.

Switch 2 Pressed: The setpoint temperature will

be shown in the display.

Use the Up/Down switch to set the new setpoint.

Press the "ENTER" switch to store the new

setpoint.

Switch 3 Pressed: The display will show the

number "2". Press the switch that is to have its

load control changed. The load control "ON

TIME" for that particular switch will be shown on

the display. An "On Time" must be programmed

for selections 1,2, 3 and 4.

Use the UP/DOWN switches to change the load

control setting.

Press the "ENTER" switch to store the new load

control setting.

Switch 4 Pressed: The Time Base will show in

the display.

8 of 24

Loading...

Loading...