Ducati 250 GT 1965, 250 Monza 1965, 250 Mach 1 1965, 250 Mark 3 1965, 250 Scrambler 1965 Instructions For Use And Maintenance Manual

~n~_~'l~.~l~.f.~~.~,,~__

- ~¡~~~~~~l.~

~-~-

.~

j-,

;~ . '~I

.¡'¡.tj. J~

!,.r"

:~t~\:~

!rj~

,l,~

"';,1

'''.~

. :;~t)':

"~'.~

.. ',"'t;

',-"IJ.!;)"

. ':,,:';,'

,c;lr' \~

::: ,~L'i;~

.~.' '-~~~

':~l~

~:L.

j

'.

:,1:

'-,,",

:~(I\

" .,' ~

"-,~.

'. y'

~\

:tl'

..

'"

,

;'J~

.~:'

\

~

\

, . 9 .' ;,~:t~'t~~itŽ~~

~/påad!l-' -";:T:t~;ç:.t:~V~~~:i!t~.

.,... ";'. . 1 t d ',....., ..', / :',. '-',t:...;;~~...f..t;¿.~~.. ~;~

~lleqS':u.,e3p,alf~ahO; .~~?DsZ¿~d~

.' . :.;.....~. ....,...".,..:. ..1; ..,(:;f; 'r';:, '.~," ~,.;-ti'; ....:.,':ö

...... . ,,..... . . . '. d '. . . . .' '. ......'. '''''''ò "r '~"', ,,~"''' ~ii

s'sài'åÁ5äòlol .

~~.":'''~:''\~'~;~' ~ ':l";'"~~';;,~~,'r'~-I,,,.,,,'~~, :.... - '~r"'...l' .

~~ .. '.. I'''f~,,~j--!~ ",." ~. \;f l 1!,~;, ~~~\'.:: '. ~:). ,1:::: ~"~'

,.':;: 7¡'Ô~'iiâ:!l;JoisiQt"'L~ ;¡~~'~:l"~;~\'.~,'~:,:'~~'''';. ....

~~èlOlOV\.,.ll .lH38 :y..../;:~¡

....~:i

. ..

,,;..

~ ..,

't.

.. . i ..

i "::.:

.....

~./¡;(~.,~ ..:

'" .r. ,

" . , ~¡,.', c.

, .

~,,~~.

,

. ~'d;;~1~(r~~~r~rf¡~~iIJ~11

. ',-rl

~

.~~

-~

':1

-;

'.

.:.

. "....

'. .

~

. ,~~.;, ~~;

~ ,., '. ~..:'-i

..

i .

t~

......-...,

v

.

. ~..".;'~ ..

-j,i: .'..~~~:tt~~.~~;~

,

r":4"

'0' ."'..,.'1....

,..

,~ t.i~.UN.,I~;riN.iHd

.j

, ~_,-,__ _~41

ç' ':_.9 d s- -9/V 1/1 h,L 1J)l Wi

~ j

d.. b t "': " 9 0 G. : ~'. ~ ..""-A~'CJ? ;?A / b /11

.'~

~

~

:'il

,:~

.. -~'.'

...t

, '~

. ".:~

· ~ n , t '1). ',::,;,'

.;~.: l7-f tl.iJ

-; .,,, l7/1 t II .~

, ,

? "7b7~ ø ~-' -CI 1-t

? ~' l ." ~ ~ l"l? , 8 I

" $' ", · '1 ox"' I. -t , G .i~

J-,, _-r I .)

.... C1!." )

(~'- -he-f.-) "'t;.6--t1tP. t7M!~l

. 1M .tI:l t: nnf, (j J g. 7-. r ç; J lJ- n I: í

d_d_--l~':_.)¡,_f2P · J,. ~(.. /' ...,U(J(

o

"_,.1-"

'.'..,

:ileys-we:J peey .Ieiio pøøds _ 9

~ JL wd) ll CQ

96L S37::A::lJO.LOW

l~ OSZ

ezuow OSZ

L Lf:iew OSZ

~/

'-l,\

;.-..

III lIJew OSZ

SSOJ:l°lOW OSZ

3~N\fN31NI\fl' - 3Sn - SNOI1\f~I:lI~3dS

1 st. ISSUE - PRINTED DM - Mod. 751/E December 1964 - 10.000

Every Motorcycle receives one copy of the present booklet.

GUARANTEE CARD

Every D U CAT I MOT 0 R C Y C LEis supplied with

a (( Guarantee Card )) which will be found in the sealed

tool box.

The seal may be broken only by the purchaser.

4

(

The contents of this booklet are not binding and though the maIn specIfi-

cations of the motorcycle described and Illustrated in this booklet remain

unchanged. the DUCATI MECCANICA S,p,A, will be free to Introduce

modifications of some details. or of some accessories, If these modifi-

cations will be judged necessary, or if they can Improve the motorcycle,

or finally for some technical-economical exigencies. but without being

obliged to bring this booklet up-to-date.

~

~

\

~

I

~...-~~...-.. -:..:. 7...._ _~~..:.::"'~,':':_"',~.~ _'':_":_,,~ ,,:'~~ -:... ": .-"__"'~"":-:",-_,..._..........:~..__", :.

\(l

Dear Sir;

We are very glad to welcome you among our clients, and feel sure

that you will not fail to appreciate the magnificent performance

of the DUCATI Motorcycles.

I~,';,'

\~

The magnificent performance and reliability of our machines reo

fleet the experience gained throughout many years of successful

racing both on track and road.

In order to obtain the fine service that the Ducati machine is

capable of giving, it is essential that the instructions contained

in ' this book be religiously adhered to.

If ,these instructions are followed closely, particularly during the

running-in period of the machine then you will be assured 0f-

many years trouble-free enjoyable riding.

We thank your for your patronage and congratulate you on your

wise choice of such a fine machine with its unequalled perfor-

mance.

DUCATI MECCANICA S.p.A.

#'

~

-

LÐ osi IL v~na 3:'1~Å~1I0LOW

_ì

lf\

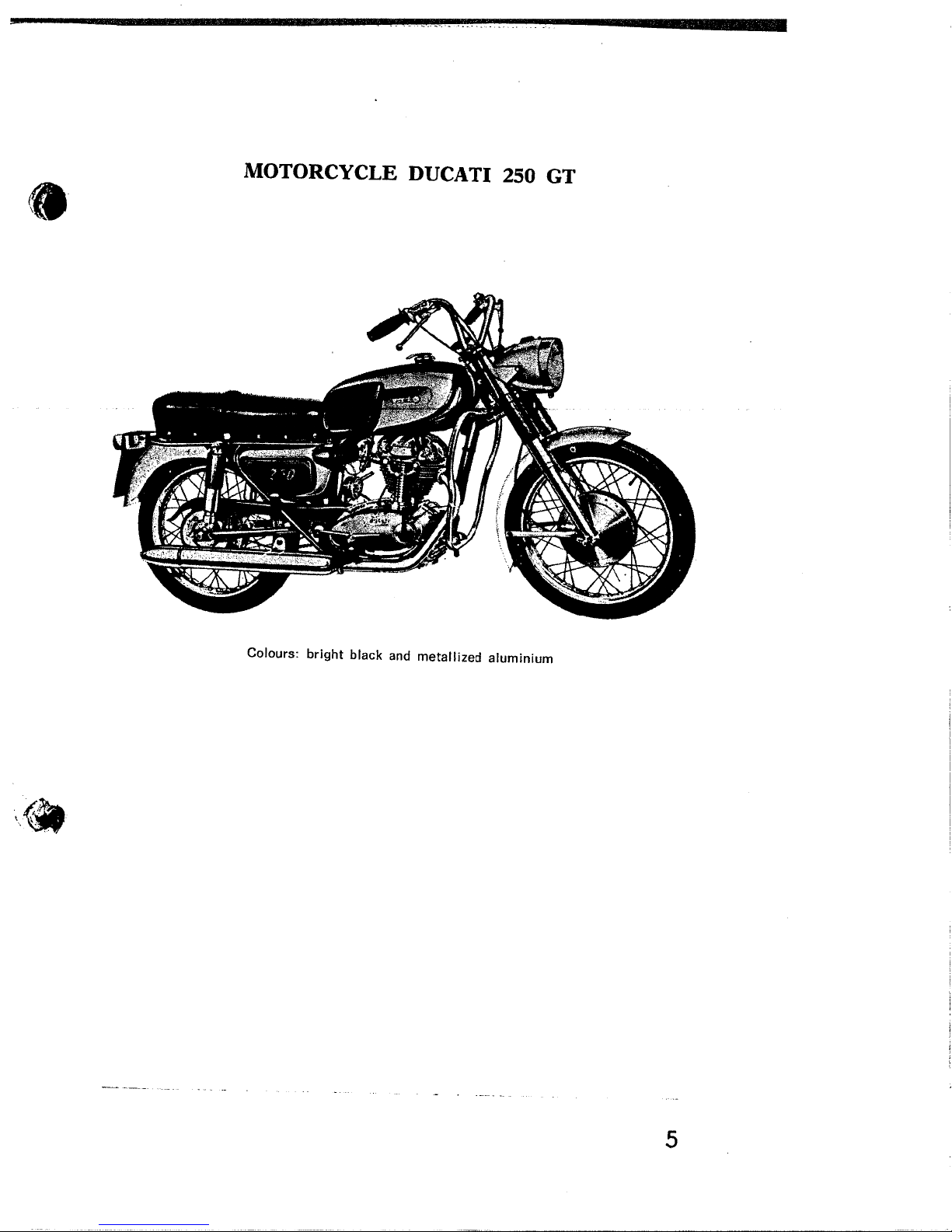

wn!u!wnie paz!iielaw pue )j3e1Q l4BpQ :s~noio::

ç

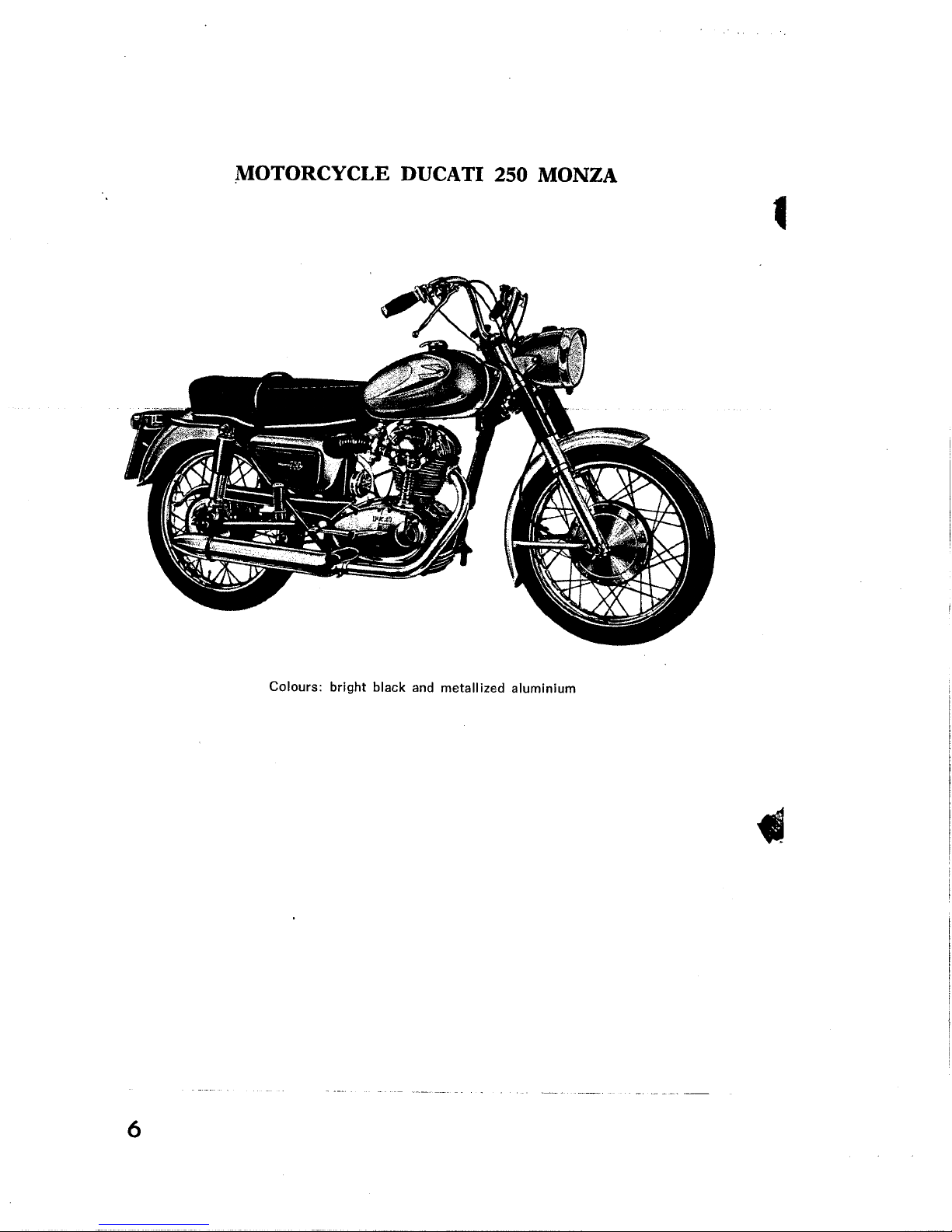

VZNOW osi iiV~na 3'1~Å~1I0iOW

l

9

WnlU!wnle paz!liel3W pue )f:miq l4filJq :sJn0I0:J

.

....-.~-----,_.:.._....~:".;....:~:, ~_

r;

.,'11

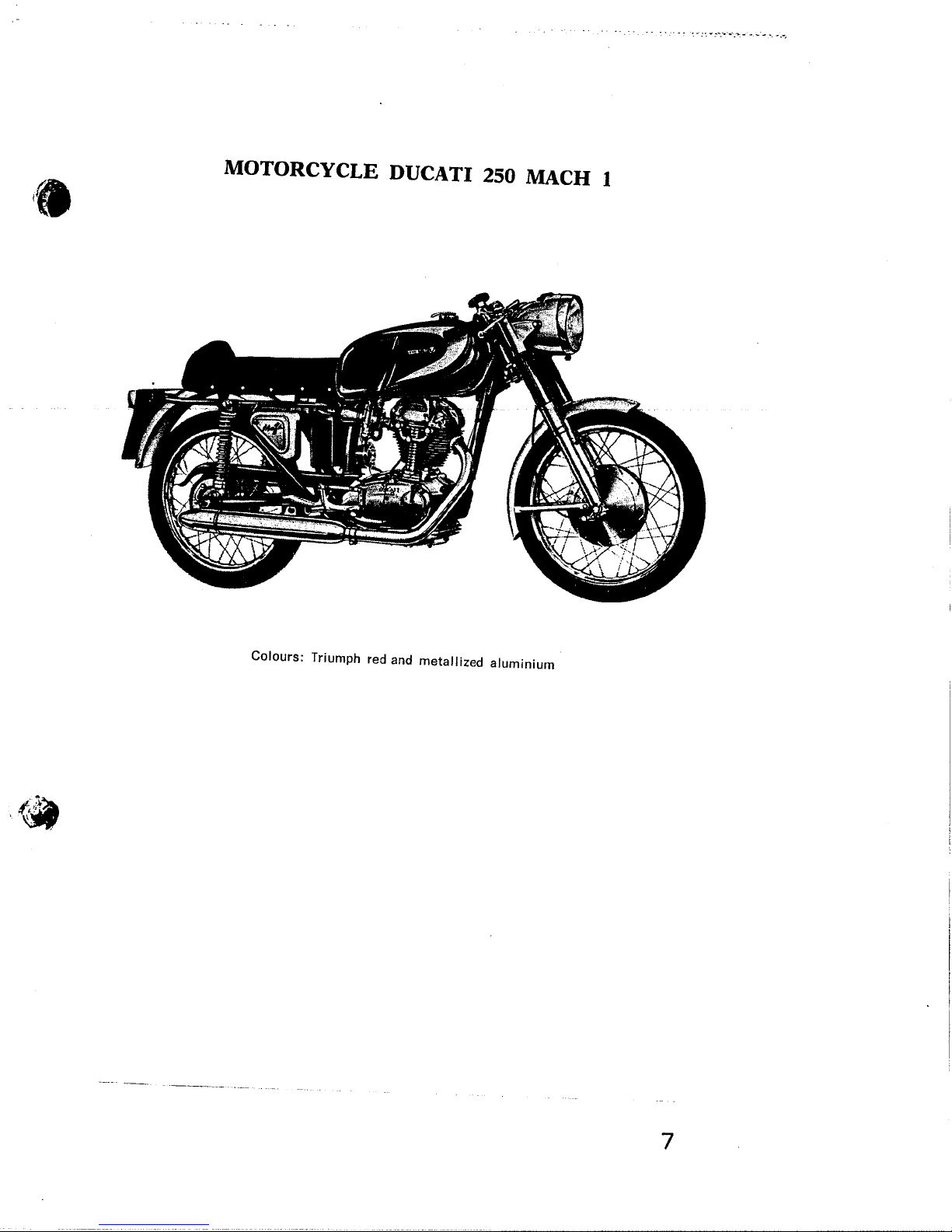

I H3\iW OSZ ii \i3na 31:3Á3HOiOW

~lr:i

ii"

wn!u!wnie paz!iielaw pue paJ 4dwn!Jl :sJnofO~

---_..._---.._-_. '_. -----

L

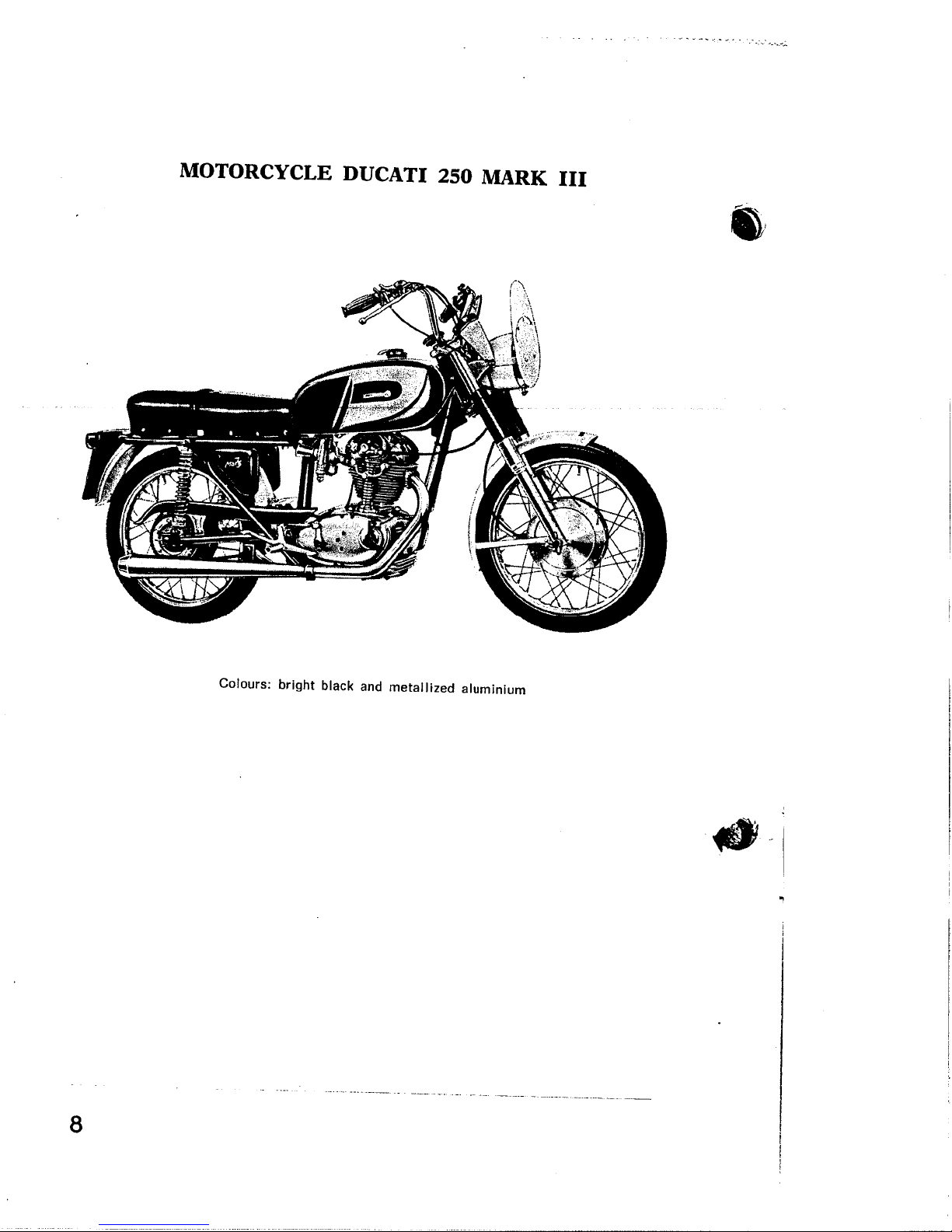

III )UIVW osi iiV~na 3'13A3HOiOW

I.

WnlU!wnle paz!lielaw pue )j::eiq l451Jq :sJnolo:)

'*

~

----------_..._--.._-----_._--- ---------- '-.- -- --_. .._-...._---- -- --~--_.~._- --.

e

.

_' _. ~_'~.'. -~ .~_-_ ~~~:"'-;-':~"":'~~""~;;'';'ø..~;:....~;:..;.-';::':-~.'

"7.-'''~-~-.''~-';~:''_-'~'.'7.~--~'--:;~.---.-: ~---:-':r::-:-:~:- ;~7 ... ~ ":.-: ~.- ~':':".:.:- .....:._..~:-..._.. _.... "', "_.'"

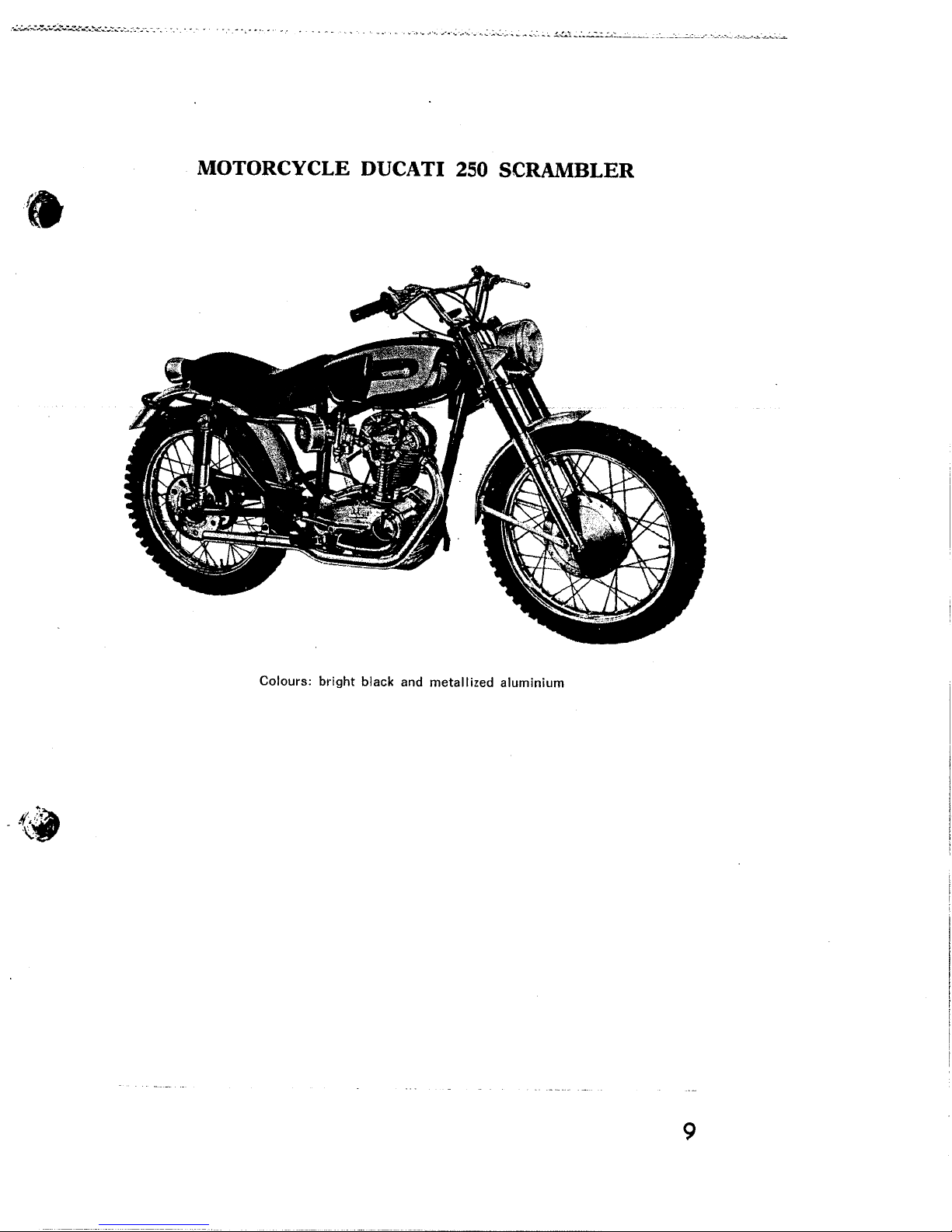

ll3:'1gWVll~S osi IL V3ILO 3:'13X3l10LOW

i;il1T

" ,., J;' -

wniu!wnie paz!lielaw pue lI:ielq l46l.q :smol0:J

e~'

6

..'~ . ..'~.-:- :'':_~:'.'':=-~-'~. - .-- ...-...

A FOREWORD

The main goal of the present instruction booklet is to enable the

owner of an over head earn-shaft DUCATI Motorcycle to use his

vehicle in the best possible way.

The lollöwìng notices are tñerêtore only simple recommendations,

suggestions, advices, and terms of reference, sufficient to enable

anyone, having no experience or ignoring any special technical

knowledge, to use his vechicle and to maintain it for a long time

in perfect working condition.

i

(I

-l

10

.

.:.......:~:-..~~.¿...::Y.-~~-;.:;...-.. -... .', . ,'.. .. , ..'...~ ..-., ..:............. .......;.. _'L...~-_.. -~~_: _...~~.:....~.._..~..,;.~ -"--A',:.O ~'~"";'."._~'_'-"_ _:....~. ~. .. _ _:. _" ,_ .~.:.7"):.,:.. ~ ..' .. ..'''''' ,... ..~.. _:. :...~...:.~:: :':'''''~''::''.'..____''.....-_'..

'.

DUCATI SERVICING GARAGE

It is advisable when taking the machine to a garage for

repairs to ensure that the garage is a Ducati agent as the

staff will have been specially trained and the garage will

have been equipped with the necessary tools to carry out

any repair required. They will also carry a full stock of

genuine Ducati spares.

SPARE PARTS

It is absolutely necessary that each order for spare parts

clearly states the following data:

1) The catalogue code of the spare part (obtained from

the Spare Parts Catalogue of the model wanted).

2) Serial number of the engine (when ordering spare

parts of the engine).

3) Serial number of the frame (when ordering spare

parts of the frame).

~-t;"" .

l,

~"-

11

- ~ ~ ~ ~ 4 '_'~ :.'~ ~ "_'_~:_'#;.'~."

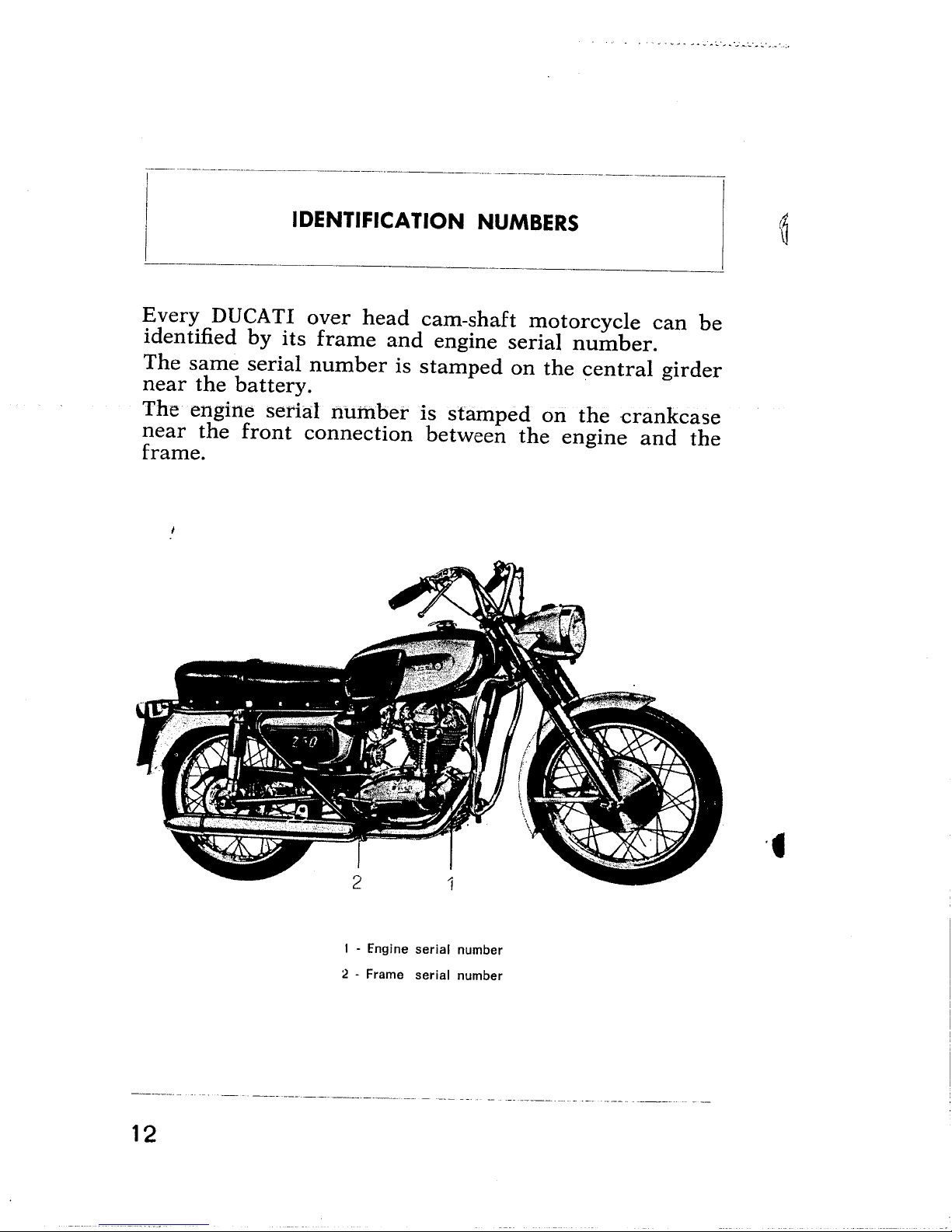

IDENTIFICATION NUMBERS

Every DUCATI over head earn-shaft motorcycle can be

identified by its frame and engine serial number.

The same serial number is stamped on the central girder

near the battery.

The engine serial I1ürtbet is stamped on the crankcase

near the front connection between the engine and the

frame.

/!

(0

-- -. ---_.-------_._----- -'--- - ._-- --

12

.t

I - Engine serial number

2 - Frame serial number

._- ------_._-. - - _... -- . -- -----_.-

~.~.~ -"'.":.'::'_.. .., ,=..-=~::.,:_';~::;.. ;.'_; ':.' ':' :....:,__.

.'".. .,'-". ..... '...~..'''' .... '.' ~.~ ,,~-.._., '-~ .~- '~'~-' -., ..... '~-,'~'.'4"':;"-~-":"""':';-'..": ..... ..-_.........." ..,. _"'_'~":':''~ _' ~ .'.

.

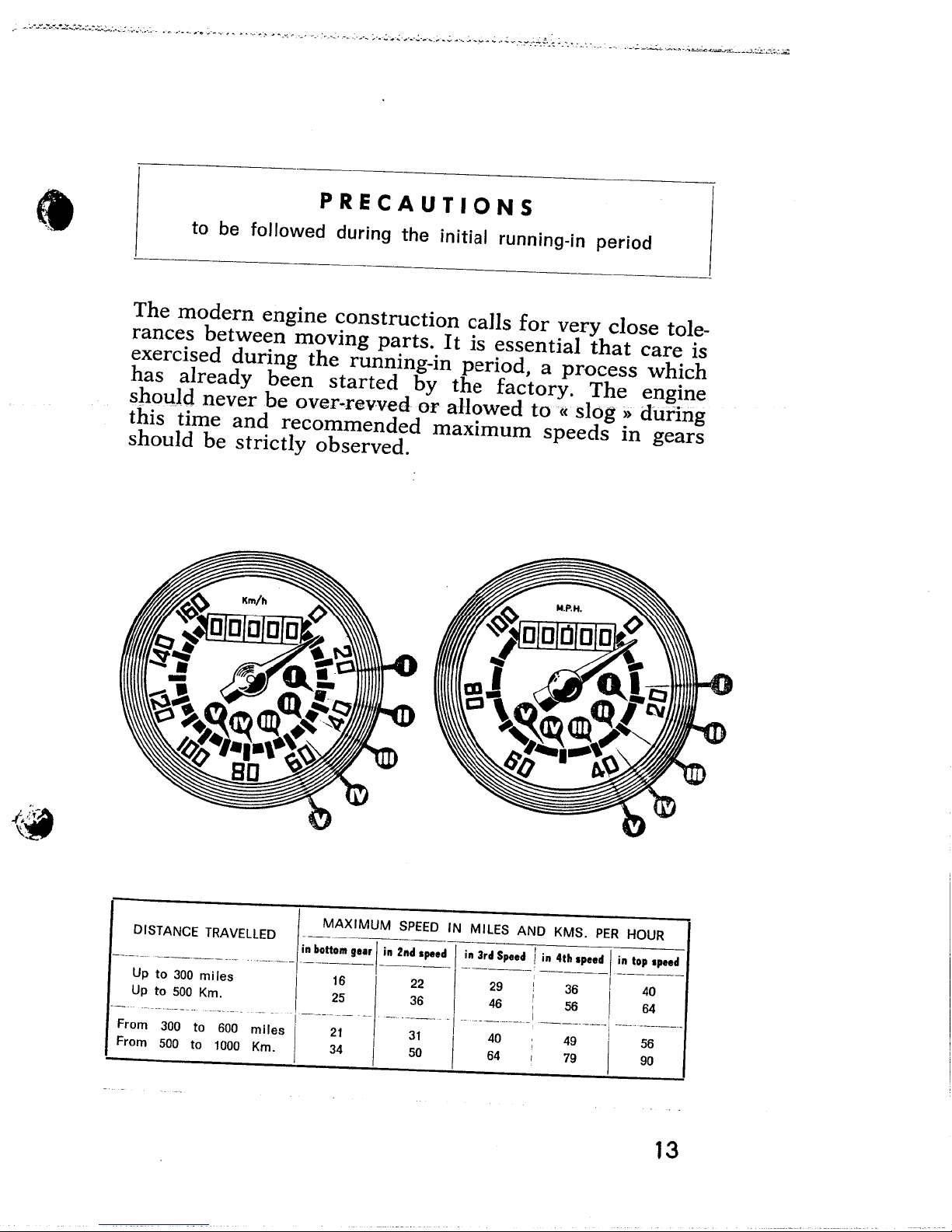

The modern engine construction calls for very close tole-

rances between moving parts. It is essential that care is

exercised during the running-in period, a process which

has already been started by the factory. The engine

sliolJJd never he over-revved or allowed to(( slög )) dtifing

this time and recommended maximum speeds in gears

should be strictly observed.

. " . .. _. .. ~ -. '.'

"-,:,,-~....~~, .~~~--~-""...:;:..:i,,:',.:

PRECAUTIONS

to be followed during the initial running-in period

t.

DISTANCE TRAVELLED

--~------ '_.__.~- ~,-- . .. -------

Up to 300 mi les

Up to 500 Km,

"-", '-""'-""-" '" -'-", ,..,..

From

300

to

600

From

500 to 1000

miles

Km.

¡, ..;.. ,.w I ;. -z;¡ .... ;. .'dO... i ;, .., .,"'! ;, h, _

. ---- _.._---'--- -----

----..,,-, ---" '-'--,-.. - ,..-,--,----! '--'-'---i --, -----,-

MAXIMUM SPEED IN MILES AND KMS, PER HOUR

16 22 29 j 36 I 40

~ æ ~! æ M

21

34

31

50

40

64

I

i

49

79

i

56

90

I

13

-'-". -- -_. -_...

-. - .'~.. ......;......-.. ....ø.....wo;"'..:'. ..~..'

. . - -., -'.

It is advisable to change the oil first at 300 miles and

then at 600 miles (with the engine warm). Re-adjust

the tappets, regulating the adjusting screw in the 250 _

GT and MONZA, fitting the rocker appropriate shim

in the other 3 models; tighten cylinder head and holding

nuts, crankcase nuts and screws. Do not overtighten

as damage may result in thread stripping or bolts brea-

king. Readjust contact breaker.

In order to ensure careful running-in the carburetor has

been fitted with a distance piece which restricts the full

use of the accelerator. After

moved by your Ducati dealer.

Failure to comply with the above recommendations

absolves the manufacturer from all

and any damage that may result.

600 miles this should be re;.

liability of guarantee

14

._~..- --_. --~_._- ---

l

--... ...- -~ ....__.._~_._--

~~"'X""'''':''::~~''''''.;;'..:__-__ _ _.. ~ _

,. C'_" ,. . '~::'. . .-,~. _,',. ..... .,..... '.' ..... ......_.. .,_'-_.~_-:..,,'~ _ _:. .~._

-. ..' .'. .. ~__ ~ _ ..a._ .'~

.

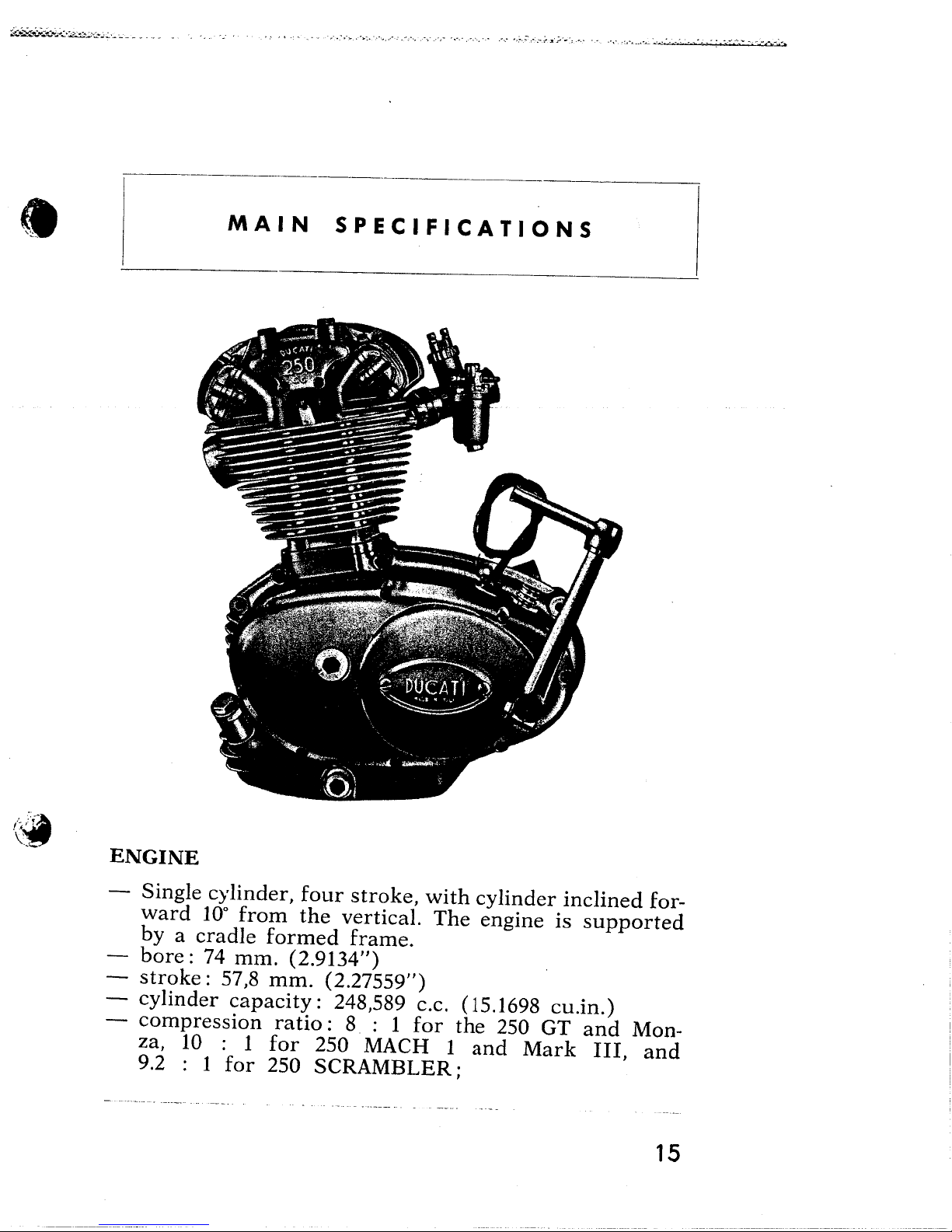

MAIN SPECIFICATIONS

',/~!(ir

ENGINE

- Single cylinderl four strokel with cylinder inclined for-

ward 10° from the verticaL. The engine is supported

by a cradle formed frame.

- bore: 74 mm. (2.9134l')

- stroke: 57,8 mm. (2.27559")

- cylinder capacity: 248l589 C.c. (15.1698 cu.in.)

- compression ratio: 8 : 1 for the 250 GT and Mon-

zal 10 : 1 for 250 MACH 1 and Mark III, and

9.2 : 1 for 250 SCRAMBLER;

15

- . , ~ , ~. -.' ~. ''; -','-:' .J..,. ~ '.........;._:'..":.~~..~~~:.;.....~......:./..:.;~-i"!.i..":

- combustion chamber with hemispherical ceiling;

- cylinder barrel of light alloy, deeply finned and with

inserted special cast-iron liner;

- connecting rod of special steel with big-end assembled

on a cage roller' bearing and little-end bushed to take

the gudgeon pin;

- pistons of light alloy, convex topped and in one piece,

with four piston rings, two of which are slotted oils

scrapers;

- cylinder head cast in light alloy and closely finned

with inserted valve seats.

TIMING

The .¡timing system is provided with overhead valves, in-

clined at 80° timed by an overhead camshaft. The valves

are made of special steel.

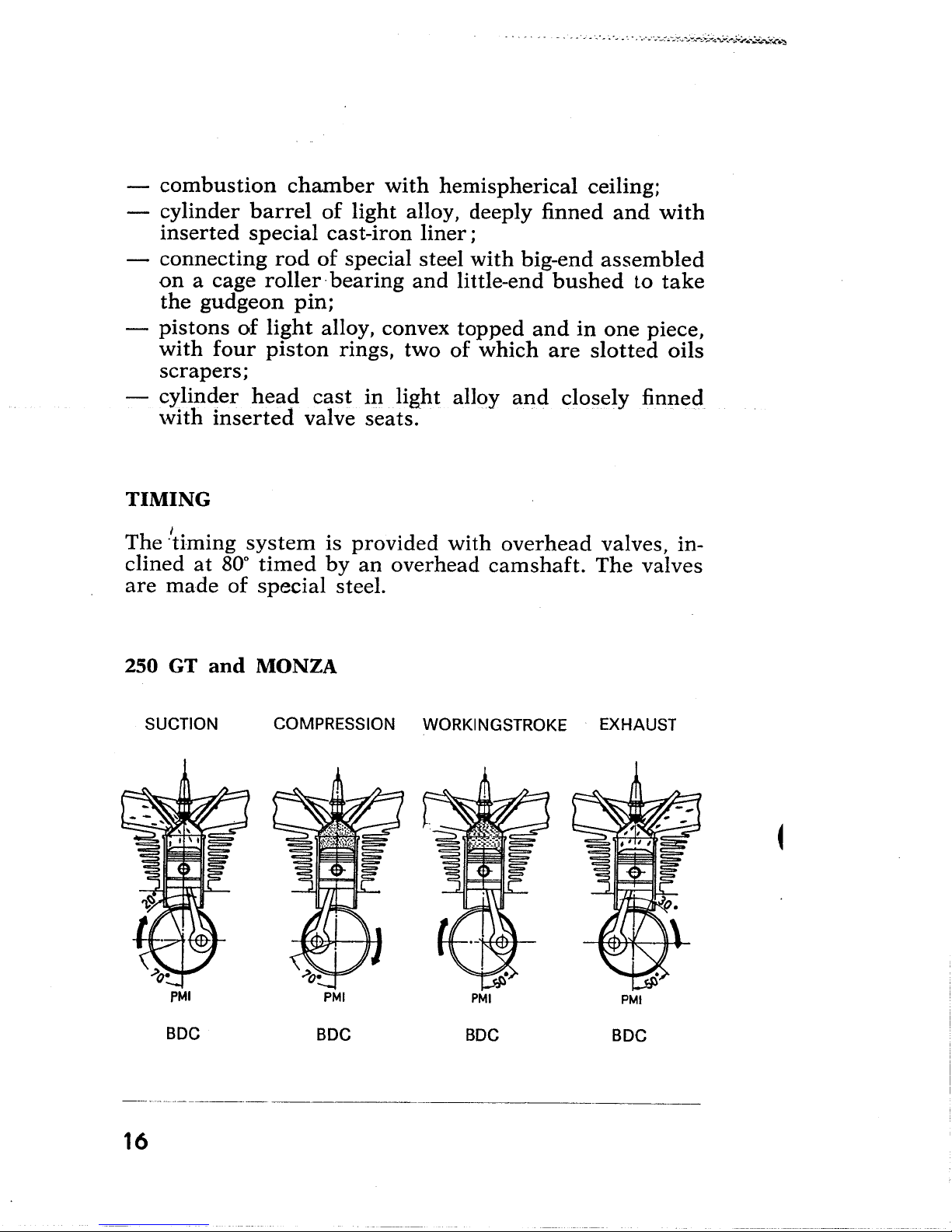

250 GT and MONZA

SUCTION

COMPRESSION WORKINGSTROKE EXHAUST

~

PMI

BOC

BOC

16

PMI

PMI

BOC

PMI

BOC

~:Y:'~'-'';"'' , . -

.

~ r R.. ..". _.,_~ .. '...,;..~..........~_:.4'u.:~.....:"'~...:..:...~~.~~..~.....~~~.;..~~..,;.,:;.~~..:..-.j..,~..--.."._:-...._~~~_;.......,. "'_"-'-,:- "".."',~:"::-":~...~'-.-;.._#'

.. R. "'r .-'~''''",.:z"":~,,:-=..:;'._::~_._.,_..,

Specifications

The timing values, with a clearance of 0.20 mm. (0.0079")

between the valve and the rocker are the following:

Opening :t 5"

200 before TOC

500 before BOC

*

BDC

** TDC

Valve

Suction

Exhaust

i

Bottom dead center.

Top dead center.

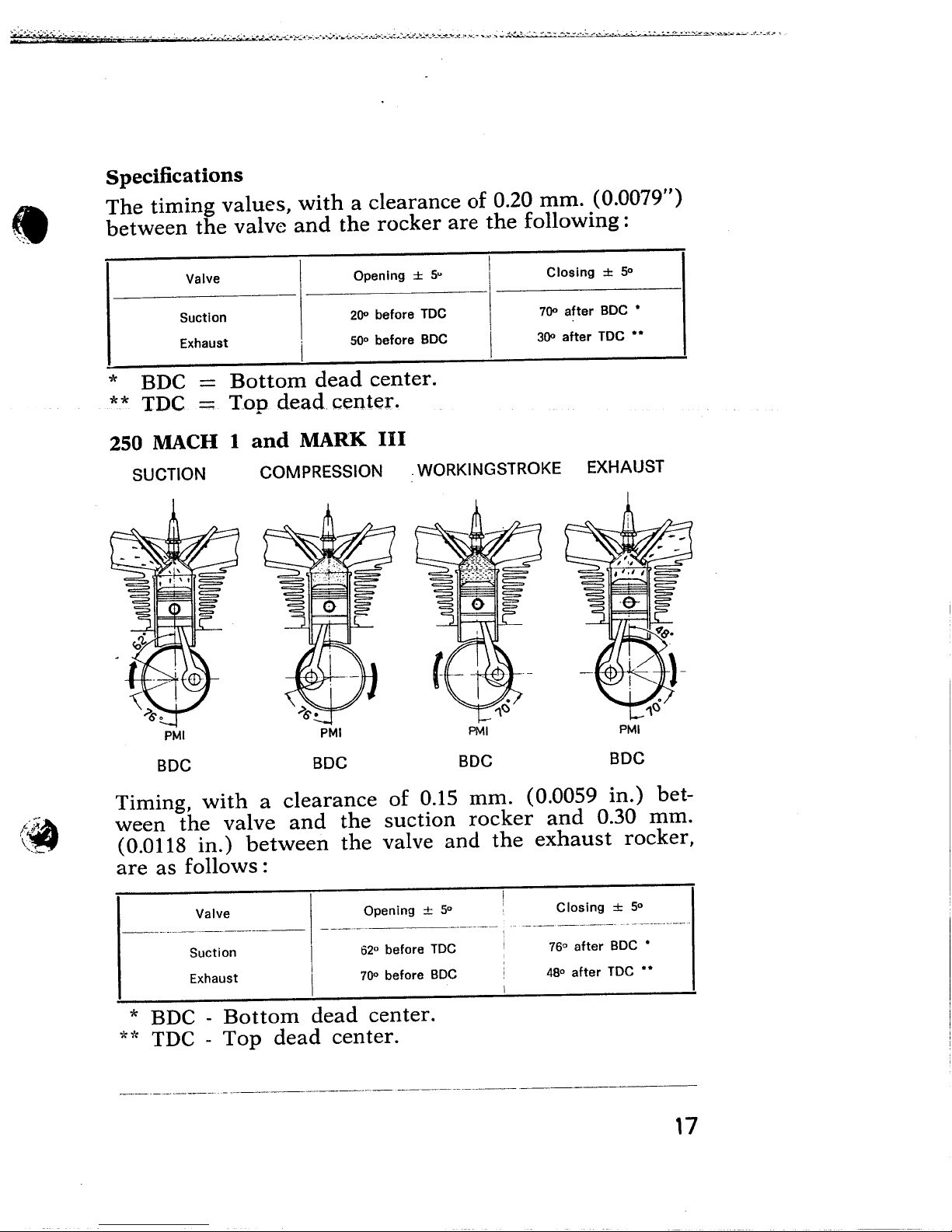

250 MACH i and MARK III

SUCTION

COMPRESSION ,WORKINGSTROKE EXHAUST

I

I

Closing :t 50

700 after BOC .

300 after TOC ..

/:!~

\~~

PMI

BOC

BOC

BOC

BOC

Timing, with a clearance of 0.15 mm. (0.0059 in.) bet-

ween the valve and the suction rocker and 0.30 mm.

(0.0118 in.) between the valve and the exhaust rocker,

are as follows:

--_.._..~- ~--------' ---_.._-'---

Valve i Opening :! 5°

Suction 62° before TOC

Exhaust 700 before BOC

Closing :t 5°

76° after BOC .

48° after TOC ..

* BDC - Bottom dead center.

** TDC - Top dead center.

---,._~----- - -----.~_._----- _.,--------~

17

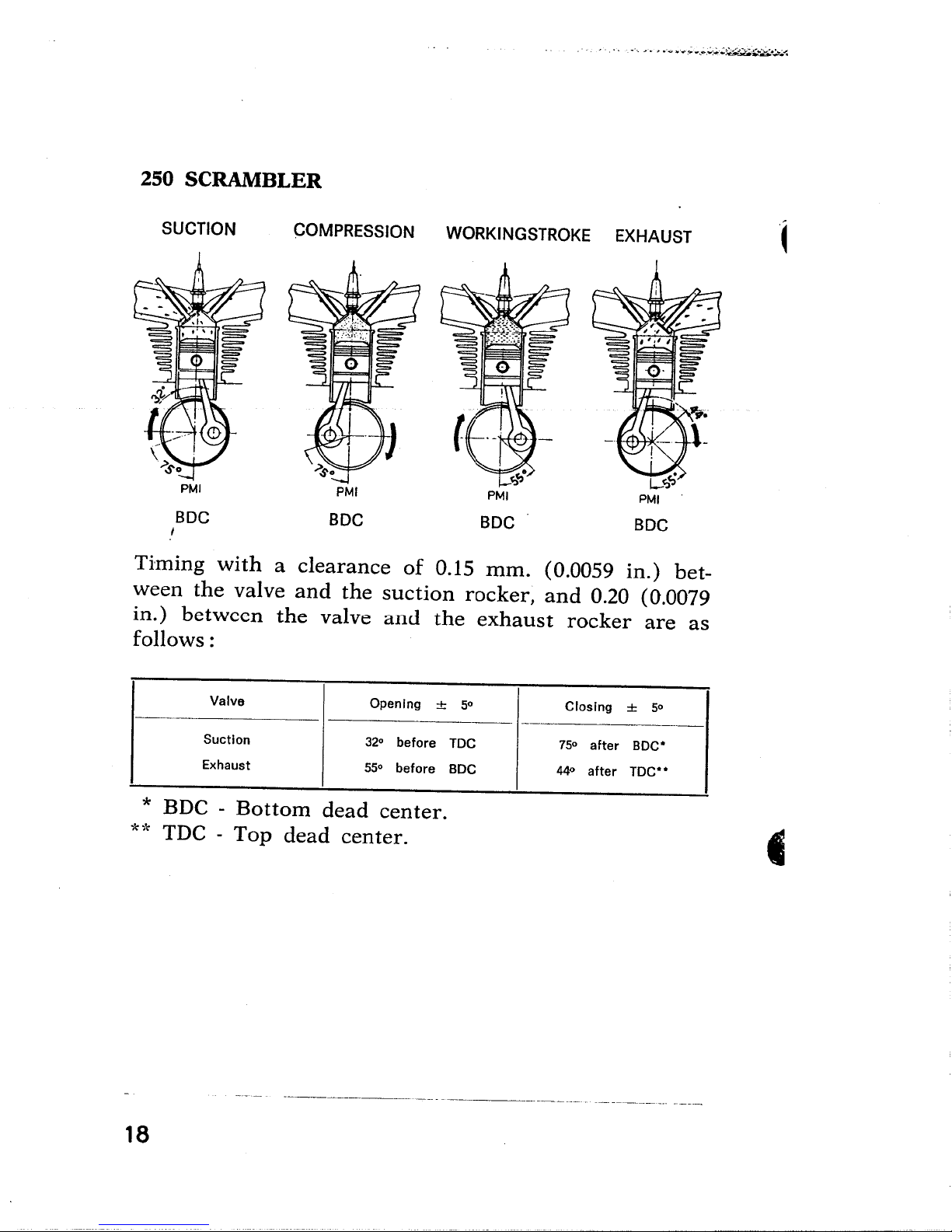

250 SCRABLER

'''/0. ..-.."...."'...;..;....:.:..:.;~~;;~..~.-

SUCTION

BOC

i

COMPRESSION WORKINGSTROKE EXHAUST

PMI

BOC

BOC

BOC

Timing with a clearance of 0.15 mm. (0.0059 in.) bet-

ween the valve and the suction rocker, and 0.20 (0.0079

in.) between the valve and the exhaust rocker are as

follows:

'~

-,

Valve

Suction

Exhaust

Opening

32°

before

55°

before

* BDC - Bottom dead center.

* ,.. TDC - Top dead center.

~'--'-'- -~------- ----

18

:f

5°

TOC

BOC

Closing

75°

44°

after

after

:f

BOC'

TOC"

50

~

'':..~~~~.i''~~~.:.:~.:~- ...... ~.. . . ~. ... 'w' A';' '... ',_-~,'~~~.'~_.::,~.:...~~..'",,,'':~'';~;'J':';:'T:''::'-:''.;-:-'::''''''::....~ ..-. ".:':-i, ...... -.:~~~e.~,:..:.-......:.:_

" - ."". -... .",-' ~"...-:.-..,-;,--,~.;...-~~.;...::~~::~

.

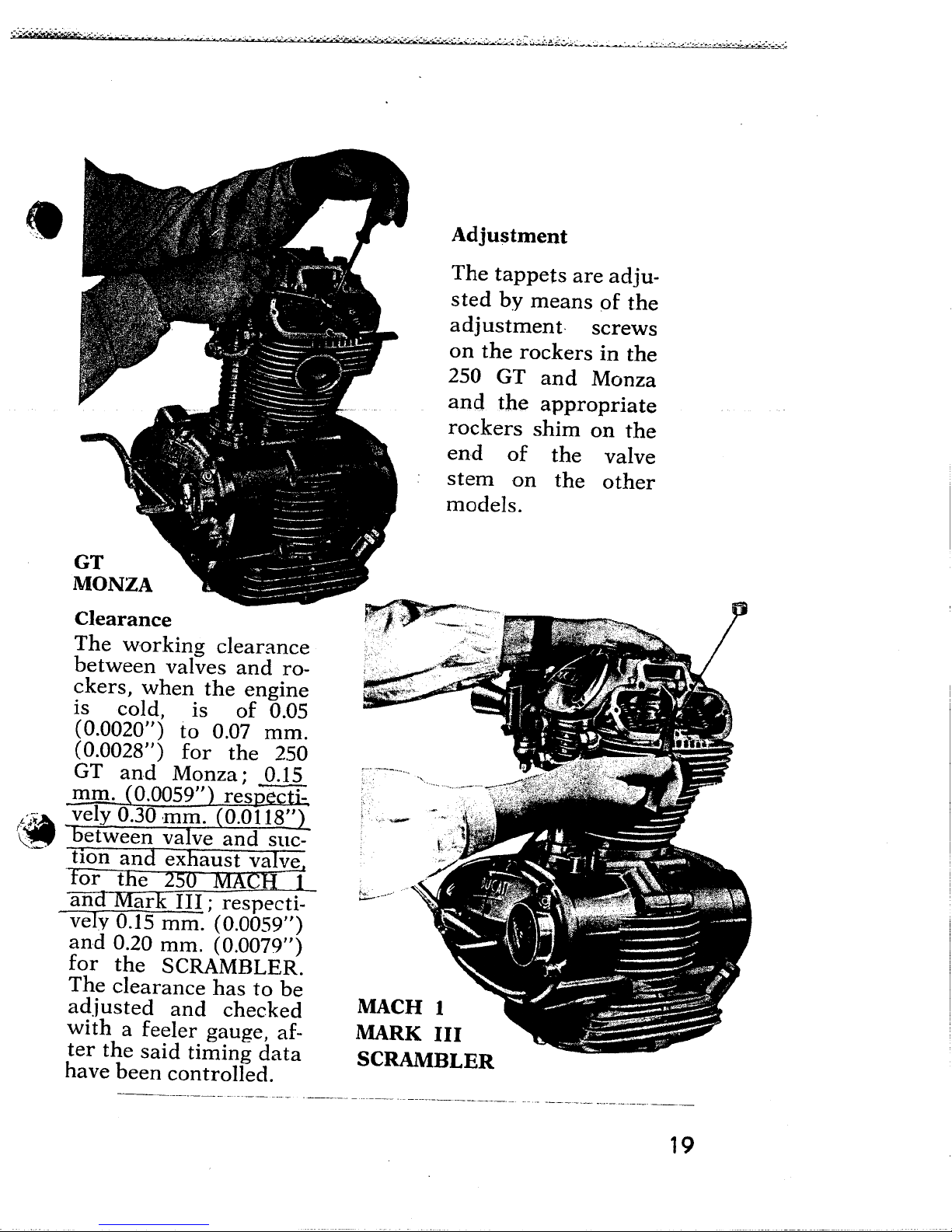

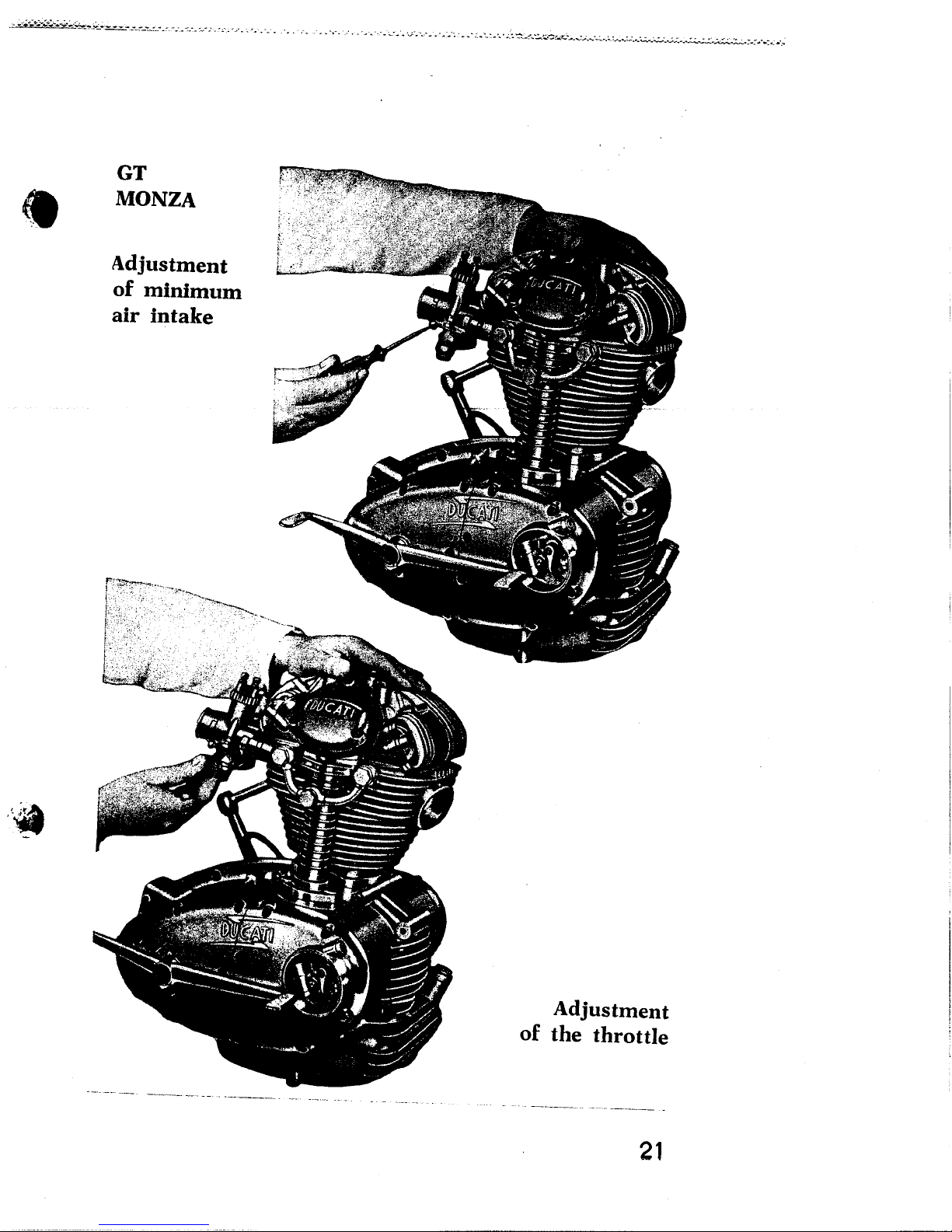

GT

MONZA

Clearance

The working clearance

between valves and ro-

ckers, when the engine

is cold, is of 0.05

(0.0020") to 0.07 mm.

(0.0028") for the 250

GT and Monza; 0.15

mm. (0.0059") respe

Li~ . vely 0.30 ,mm. (0.0118"2

t"' -Detween valve and suc-

-- tion and exhaust valve.

'for ~e 250 MACH -i

and ark III; respecti-

vely 0.15 mm. (0.0059")

and 0.20 mm. (0.0079")

for the SCRAMBLER.

The clearance has to be

adjusted and checked

with a feeler gauge, af-

ter the said timing data

have been controlled.

--~._---~_._------_._- .-__.- - ---._.- _.. ---_..- ._- ---------~._._--- ..- ..- ---_.._---- .".--'-- ---'----

Adjustment

The tappets are adju-

sted by means of the

adjustment screws

on the rockers in the

250 GT and Monza

and the appropriate

rockers shim on the

end of the valve

stem on the other

models.

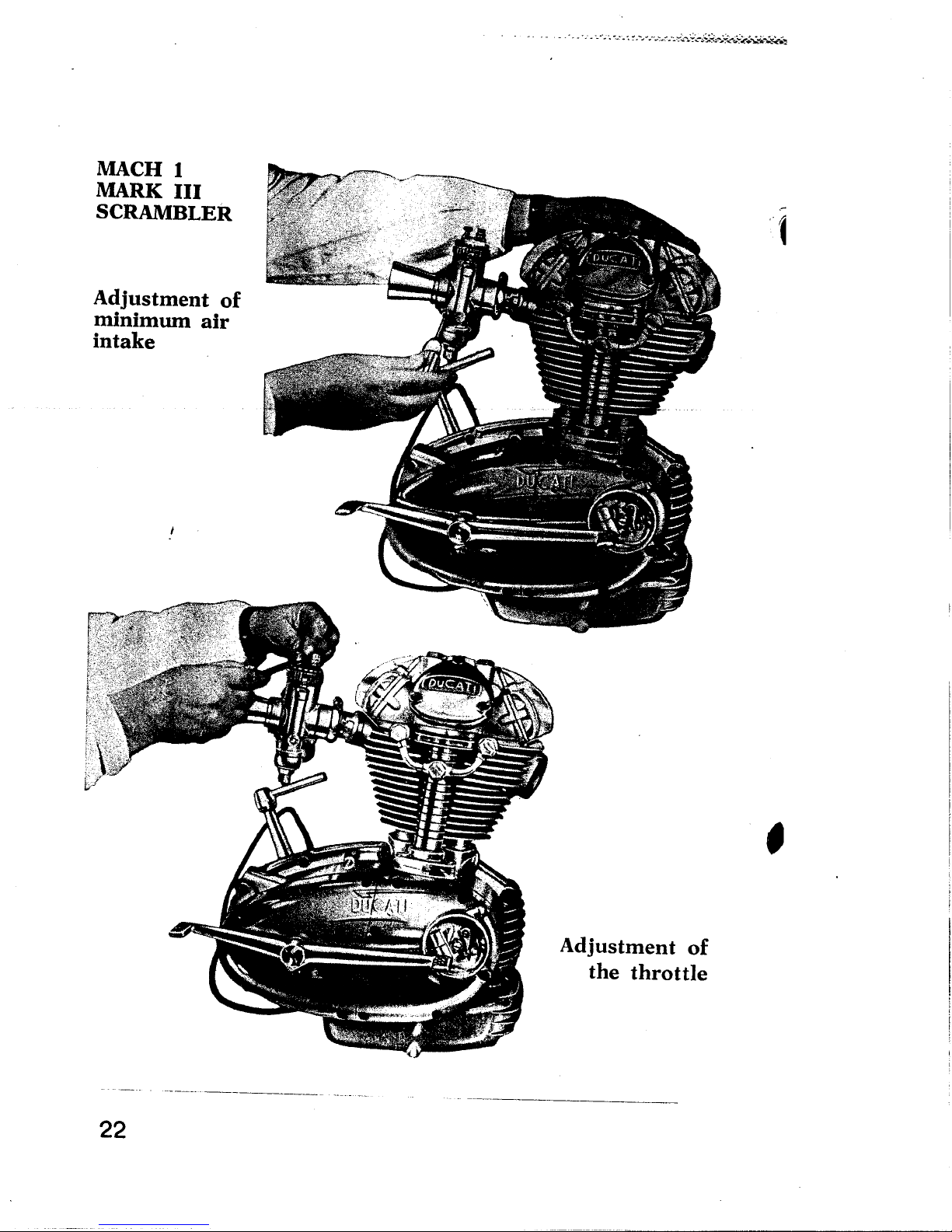

MACH 1

MARK III

SCRAMBLER

19

.... ~ ---.. '_ .'_' _-;. "~':,'.':~_.o-.'~': w.=".O:....:"..O:...4-_...........~:-..

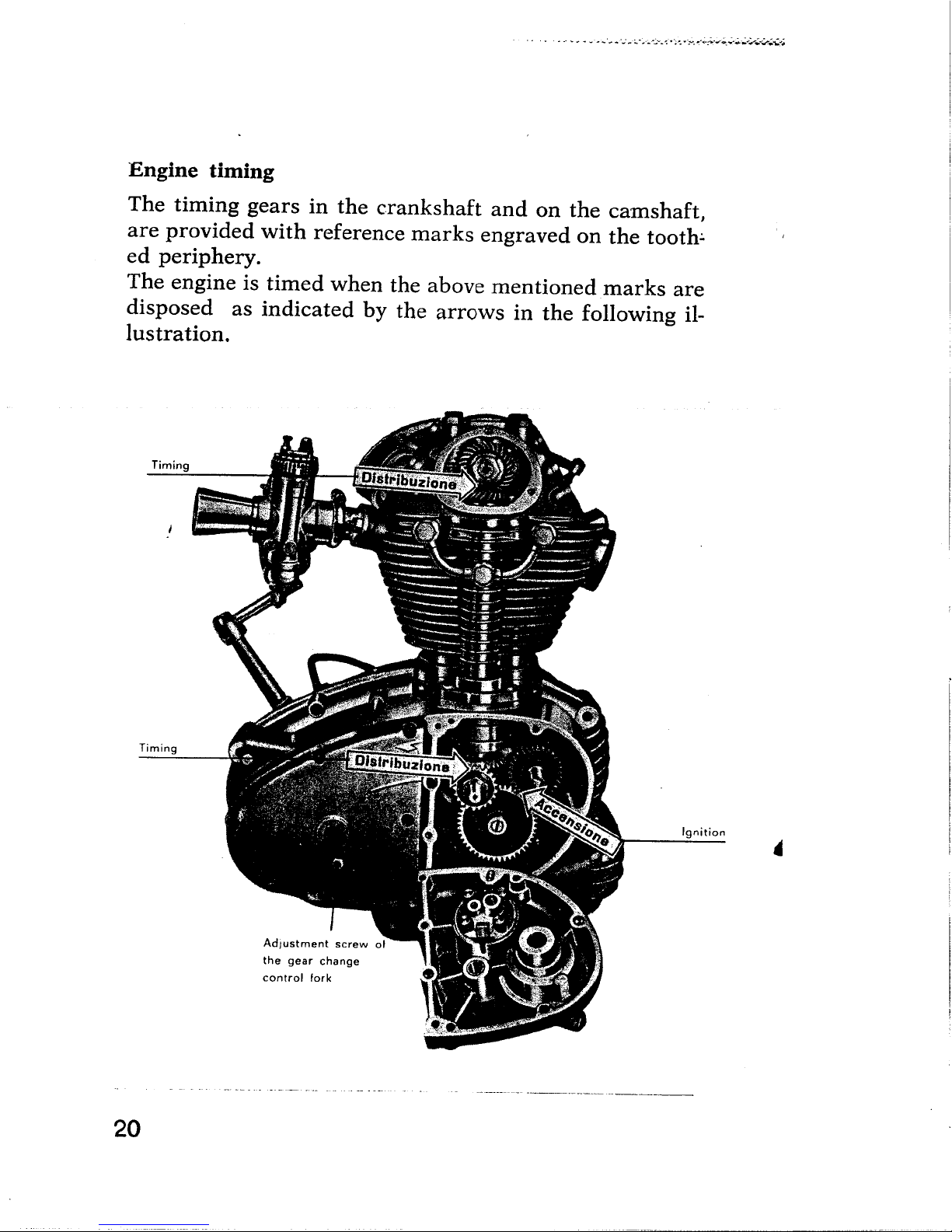

Engine timing

The timing gears in the crankshaft and on the camshaft,

are provided with reference marks engraved on the tooth:.

ed periphery.

The engine is timed when the above mentioned

marks are

disposed as indicated by the arrows in the following il-

lustration.

Timing

. - ,'-, +,~ ~ . ~ - ~

20

Timing

Ignition

.

AdJustment screw 01

the gear change

control fork

.

.,.,":...,."O"~.~'O-,.-:.n~-;-,--c~,-"~~."""o',~'~;"~,-mo,----;-;:: '" ,.,.:~ -:- ,.., ',':' ,'" ,",',,", .. ,.. C', ", , , .., ',-,' " " . _ _ , ',' ',' ". c ._.' ,'. _ '.. .'" ._. -.-..-.c _", _-i _""~""~.:~.~.~.~ ~ '

i~

VZNOW

lu3U1lsnfpv

uinUlJUlUI )0

3:aelul .lie

~1!;~1

~,'

- _. ...._..- .__. -~----~.- -----.__._----~- ----------._-

lu3U1lsnfpv

3lno.lQl 3Ql JO

_. _.._-~- '-'-- --~------

iZ

I H~VW

ai¡elu!

III )llIVW

lI3:'1HW\~S

)0 lU3wisnfpv

.lie wnwiuiw

~~-;~~-:.J~",-::,.,~f"'~~".,~-:.~~.~:."'''''''''''';:'._~-~.__R..-_-,-,- '.' - -.. ~ -

L

GG

,

)0 luawlsnfpv

a(Ho.lql aql

_..~---_._-- --------.__...._-~-_..

,

"".

.

.,,

"

,

.:

I.:

I::

t;

"

r,

¡\'~

f

I

t:

.

"

t:

~:

~:

",

;

"

r

r

i

.'

(

,

II

"

(

t

c'

\

~. :

(

I.

~'

I-

~,

(c

¥.'

~ '

I'

L

~

f

t

~

.

t

:~

t'

ia'

330

272 071 /

016

'¿ 132

"""-136

I\

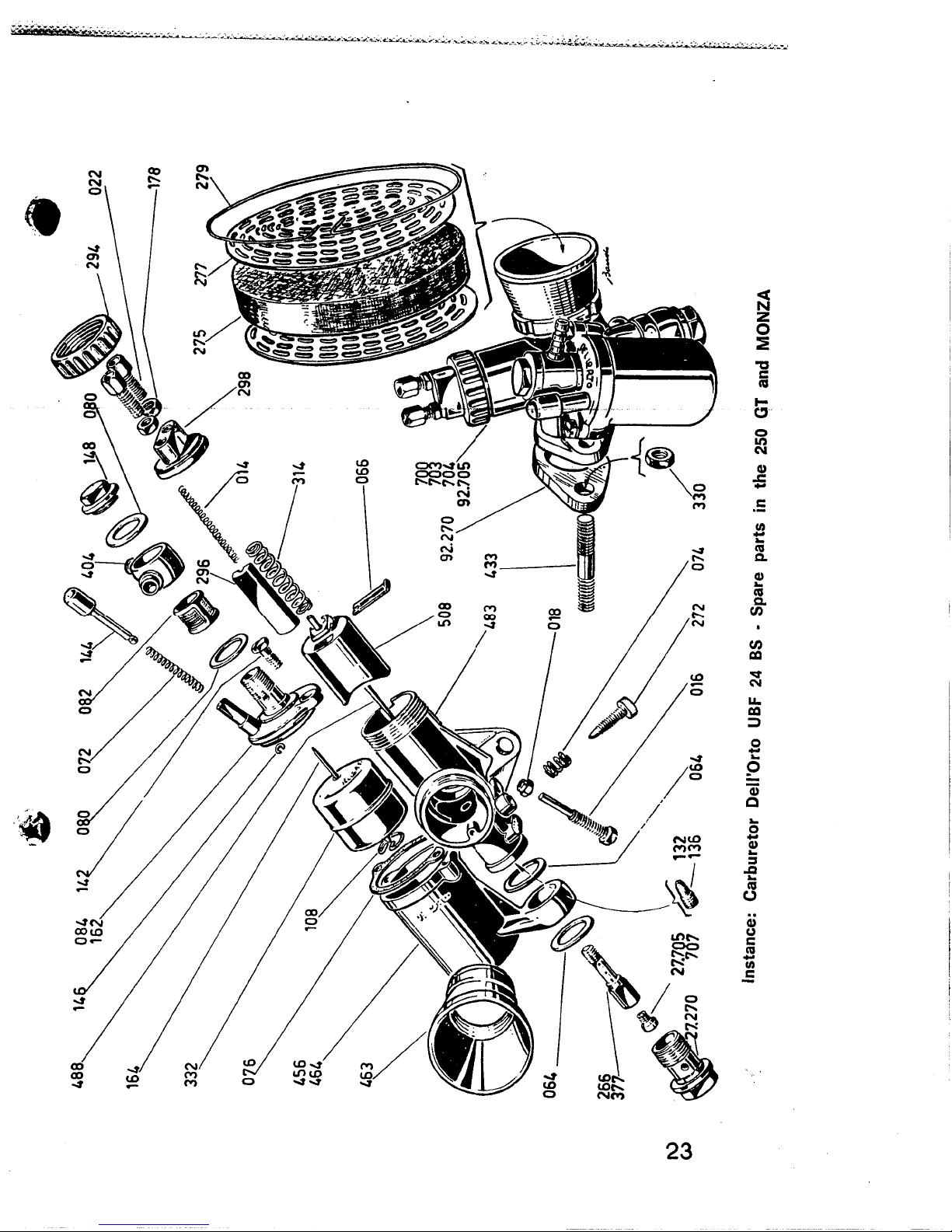

Instance: Carburetor DellOrto UBF 24 BS . Spare parts in the 250 GT and MONZA

úJ

. .." ~."'.. -' _ r _~.."..;:".."":::;~.':--",:"'_..~:.".:,,~'~~:"!- . - ~ ~ ; -~ - - . ~. ~ ~. .

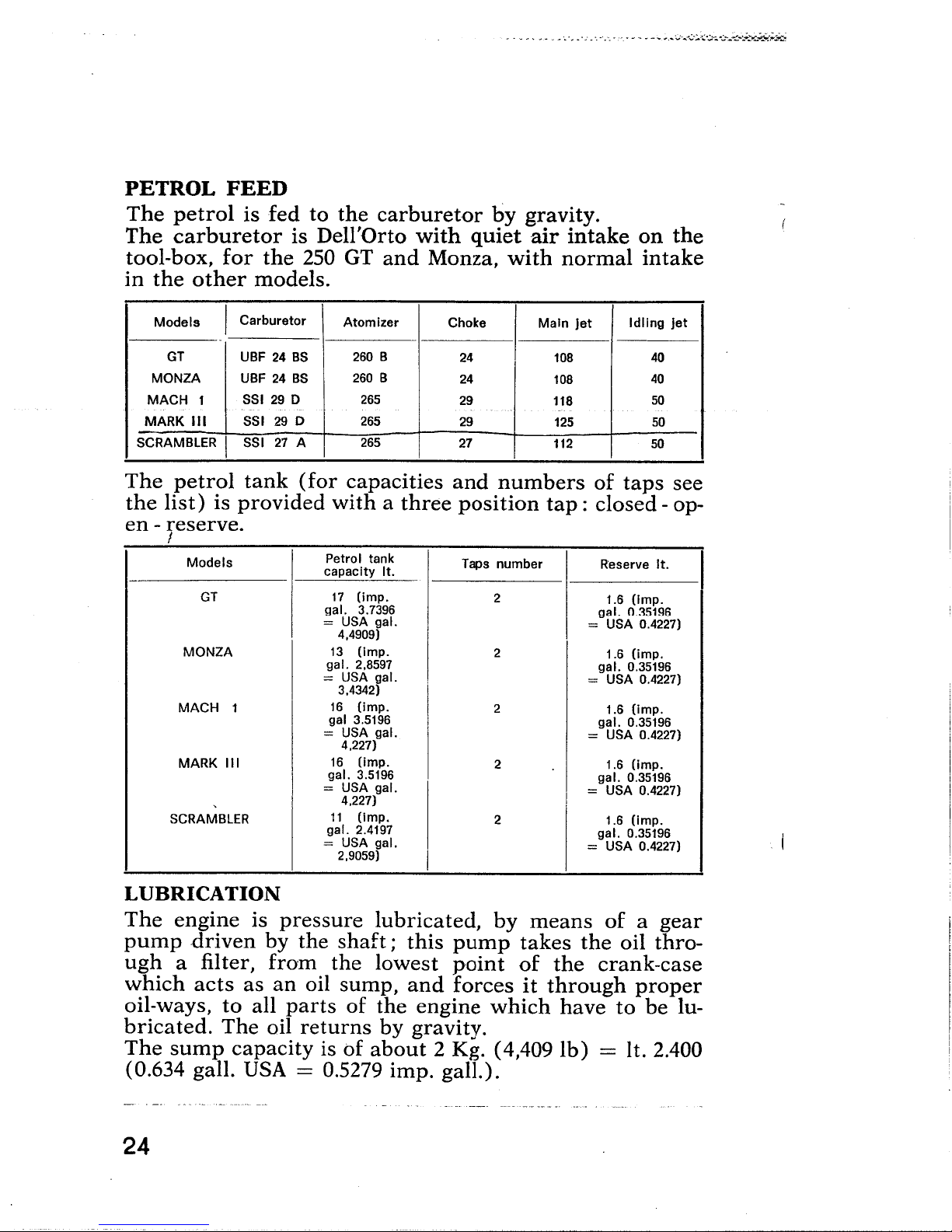

PETROL FEED

The petrol is fed to the carburetor by gravity.

The carburetor is DellOrto with quiet air intake on the

tool-box, for the 250 GT and Monza, with normal intake

in the other models.

.- -. ' ~ ,- , - "

Models

GT UBF 24 BS 260 B

MONZA UBF 24 BS

MACH 1

MARK III

SCRAMBLER I

I Carburetor

SSI 29 0 265

SSI 29 0 265

SSI 27 A

Atomizer

260 B

265

Choke

24 108

24

29

29

27

','

Main Jet

108

118

125

112

Idling jet

40

40

50

50

50

The petrol tank (for capacities and numbers of taps see

the list) is provided with a three position tap: closed - op-

en - reserve.

l

Models

GT

MONZA

MACH 1

MARK III

,

SCRAMBLER

Petrol tank

capacity It,

17

(imp.

gal. 3.7396

= USA gal.

4,4909 )

13

(Imp,

gal. 2.8597

= USA gal.

3.4342)

16

(imp, 2

gal 3,5196

= USA gal.

4.227)

16

(Imp,

gal. 3,5196

= USA gal.

4.227)

11

(imp.

gal. 2,4197

= USA gaL.

2.9059)

Taps number

2

2

2

2

Reserve It,

1,6 (Imp,

gal. 0,35196

= USA 0,4227)

1,6 (imp.

gal. 0.35196

= USA 0.4227)

1,6 (imp,

gaL. 0,35196

= USA 0,4227)

1,6 (Imp.

gal. 0,35196

= USA 0,4227)

I

1,6 (imp.

gaL. 0.35196

= USA 0.4227)

I

LUBRICATION

The engine is pressure lubricated, by means of a gear

pump driven by the shaft; this pump takes the oil thro-

ugh a filter, from the lowest point of the crank-case

which acts as an oil sump, and forces it through proper

oil-ways, to all parts of the engine which have to be lu-

bricated. The oil returns by gravity.

The sump capacity is of about 2 Kg. (4,409 Ib) = it. 2.400

(0.634 galL. USA = 0.5279 imp. gall.).

24

.'

.. --- ......."'~":.,~~~~.;...:...a~~.:~~..1

~_~-,-~..-7'.... p' ..-

~;.-~--.-,_.-..._--

..

. : - -- ~

~~

e'í

P

~

E ;

~ f¡

e

SG

An Oil-filler with stick consisting of:

1) Stick-provided filler plug;

2 ) Sealing gasket;

3) Filler;

4) Sealing gasket;

". .'_"__ ¡'. .._.:,.:~:;-:..~...;...::.:.~.::;~~~~;..:~gi;"'.;~;t

i d

allows the oil

level

measurement.

The filler plug stick is marked by two notches in the spots

where the oil level is respectively at its lowest and at its

highest point.

The oil level is measured by just resting the plug on the

filler.

_ The lubricating system of the DUCATI motorcycles

with single over head earn-shaft engine is of the sim-

plest and requires no special maintenance except the

renewal of the oil level ( 8 ESSO EXTRA MOTOR

OIL 20 W - 30-40 or RACER 40) each 500 Km. (about

310 miles) and the total change of the oil, including

the cleaning of the filter every about 2000 Km. (about

1240 miles).

26

;:it~:;':';~"'':''-''.:...... .~~ -'-_;"':-'_'__:_.:::_--=.~. ~_~ o. __~~;_~ ~ ~ _ ok _ __ ~

CENTRIFUGAL OIL FILTER INSERTED IN THE MAIN-

SHAFT

.

,:Æ.&.

~

D

~

How it works

The oil which is to be filtered, is brought to the filter

through the pipe A; from here, the centrifugal force eli-

minates all the impurities (which are heavier than the

oil), which accumulate all around the threaded plug B of

the main shaft.

The filtered oil, goes through the tube C to lubricate the

big end, and through the duct D, to lubricate the engine-

clutch housing gear.

COOLING

Cooling of the engine is achieved by close finning of both

the cylinder and cylinder head.

27

. - ,.' - _ _ __C'_ _'~'_'_'~-_',C-_~"',"".'''~';';;:ç..;g-,~

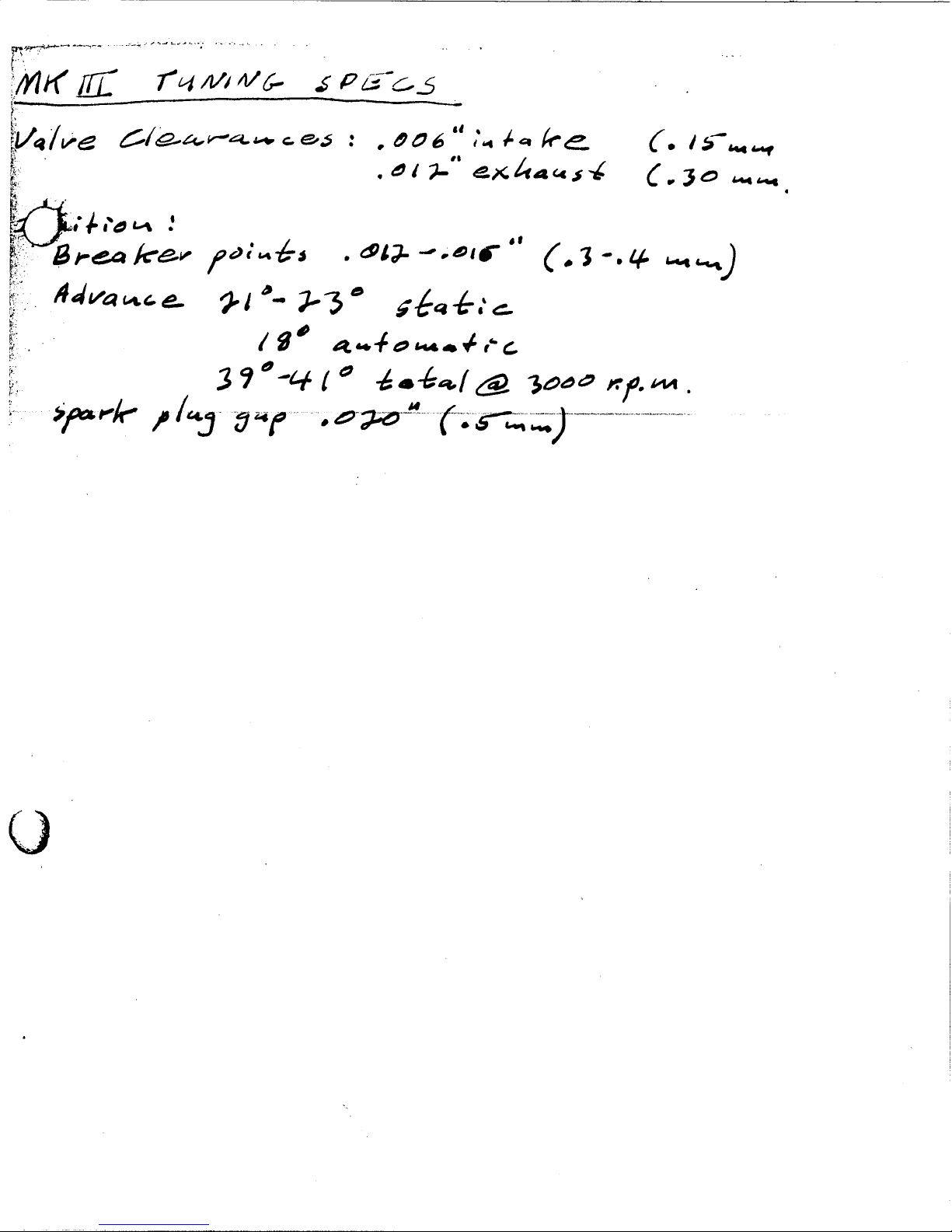

IGNITION

The ignition is battery-coiL.

The partial automatic advance ignition is:

Model

GT

MONZA 5° to 8°

MACH 1

MARK III 21° to 230

SCRAMBLER

Advance with

stopped

I

i

I

5° to 8°

5° to 8°

21° to 23°

engine

Amplitude of

outomatic advance

28° 330 to 36°

28° 33° to 36°

200

18° 3)0 to 41°

180 390 to 41°

Total advance with

engine running at

3,000 r.p.m.

330 to 36°

For setting up the ignition, see figure on page 20.

The clearance between the platinum plated contacts is of

0.3 to 0.4 mm. (0.0118" to 0.0157") and has to be checked

bY means ot the feeler gauge (see figure hereupon).

The ignition plug is a Marelli CW 260 N, or a similar

model and is located on the leftside of the top of the

cylinder head.

When replacing the sparking plug make sure the angle of

the plug, relative to the plughole, is correct otherwise the-

re is a risk of stripping the thread in the cylinder head.

Screw the plug lightly at first, then tighten it.

28

ej

- ~:~~_":-~-=:-;:...:;....,.....;:.~;c-__.~.:..::-~.#. ....'---'~-.. .~~..' ....,. ..... ,-.... ...".... -','. .......... .~.... ..~..:--..~~..-~.-'_...-,..O-:----.-,.:'-..:'-7..:'~-.-~'-~'~o:-c..:-.::-~":...;::-.. ....':""~~~~~

'a:J1Jzd lo ¡no JOU f\')

. Cr .grd) JdAOJ din

-. -----_.. -. "-- _.__....._------------

3:;)NVACIV )llIVdS NOI.LIN~I )I;)3H;) O.L MOH

dqi Jdlju) d;)UUAPU )(Juds uorlrugr dq1 ÁnU;)rpOpdd )(;)dqJ

dql iuqi dJnS dq ~ (sdHll OOLI ÁJdAd 'JdijU 'puu 009 lSJg

-U;)pqni IIdM Sr H iuql 'ÁpddOJd S)(JOM d;)rAdP ;)nUll01nu

ad1Jis lo Jno JdqHdU dJU sgupds dqi 1uqi pUU Pdl " ,;tf'

dq isnrn d;)UUAPU JnUllolnu dql jO dpnindllU ÁJUlOJ dq1

-uoW 'in SPPOll dql ur ijuqs gUrAPP dql uo 08L Ol iunbd otr

gUrAPP dq1 uo 081 01 iunbd 06 dq lsnll puu 'i q;)UW 'uz

nOÁ jI 'lI3:'lHWVlIJS puu III )(JUW SIdPOll dql ur ljuqs

'dOqS)(JOM pdZnUpdds U Áq Pd)(;)~q;) H idg 'iqnop ÁUu dAUq

: SJ\\OIIOj SU Pdd;)OJd 'd;)UUAPU )(Juds dql )(;)dq;) 0i

gUrAPP dq1 iu Sr q;)rqM gnid pdpUdJq1 dqi dAOlldlI - 'lsT.

'(r ,grd) lJuq;: gUrlln diquHns B 19 pUU 'IdAdI ijuqs

dJnJdS iuqi MdJJS dqi jO dUO uo JOiU;)rpur UU a~ - 'PUL

ci

", .... ~'~'-_-_-~"_~:~~~:-__"-~--.~""~"'''''_'"-~''''~Â':~;':~~~~

3.rd. - Bring engine to TDC of compression stage and set

the indicator at (( 0 )) of the timing chart.

4th. _ Rotate the driving shaft clockwise for about a quar-

ter of a turri.

clockwise

5th. - To the spring' of the mobile part of the contact

breaker connect a 6V. - 3W. lamp in series with the

+ of the battery (Fig. 2). The lamp should light up.

30

anticlockwisp.

(Fig. 1)

- .- - -- . --~-- _.- -_.---_. ----------.---

------------_.

--_.----- - ~--

f~..~f"".'''"-I0~-:-.._":,... . ".~ .";-:.:.. -'...""./~ ..--:":.__.:. ~ -. .

6th. - Rotate the driving shaft slowly, anticlockwise, till

A

~

the light goes out or its intensity is lowered.

At that very 'moment, the indicator should give on

the goniometer the advance degrees you will find

on page 28.

a

To + of battery

(Q

(Fig. 2)

31

'.:' '-'..,',...'-.,.,-"----'.',"'i_..;;~""*~~.;

\

I

(Fig. 3)

7th. - To be on the safe side, it is advisable to repeat the

test.

8th. - If the reading should not tally with the requested

numbers, then loosen the two screws (A and B)

which secure the plate, and rotate it, advancing or

delaying ignition until the right number found at

page 28 is obtained.

9th. - Bear in mind that if you let go dry the felt which

lubricates the earn, the fibrous slipping block (that

operates the opening of the moving part of the con-

tact breaker arm), will tend to wear out, lowering

thus, the value of the gap.

------.- --_. ---~ --~-- ~------------ -----------

32

~~~~;'~~~;".i~"!;,"~~":i:':..~..J.~:":;~~':;'''''~'.'''::'.''~~'.~'''''''''"'_.._/-.', '_,'", _'

STARTING

._.__-.._.:_:"-':.;",_,,~'. : '" ~-,;'. ;

.

The kick-starter is located on

the left hand side of the en-

gine. In the case the starter

unit is refit, it is indispensable

to carry it out as shown in the

figure aside.

TRASMISSION

The transmission components comprise a clutch and a

gear box. The clutch is òf the multiple plate type with

\~

-----~---._--_....-

_.._--_.. .....- -~---------_._-~-- --_._-- _.._.. -'---------

33

,'. - . - . ..-.. ..-~-~ "'-A"~'_~'~''''':'':'''''~:;;;''_~:~~';*~''JI''~''''Y:'lî

steel and phenol resin disks. It turns in an oil bath and

is mounted on the primary shaft on the gear box.

The clutch housing, made of special wear resisting cast

iron turns on two inner bearings which are set at an ade-

quate distance. It is lubricated together with the engine

sprocket as already explained in the paragraph of the

centrifugal filter. ,

This system ensures smooth movement, solidity and long

wearing; it has been fitted and tested on the 200 cc.

motorcycles, since 1960.

The clutch is operated by a handlever placed on the left

hand side of the handlebar.

the transmission between the engine and the primary

shaft of the gearbox is obtained by means of gears and

the reduction ratio is:

2.500 to 1.

The gearbox is mounted in the crankcase; the gears for

thq 5 speed gearbox are constantly meshed and are ope-

ra fed by a foot pedaL.

The transmission ratios of the gears are the following:

- in bottom gear 1 to 2.53

- in second gear 1 to 1.73

- in third gear 1 to 1.35

- in fourth gear 1 to 1.10

- in top gear 1 to 0.97

The transmission between the gearbox and the rear wheel

is made by means of a chain and the speed ratio is:

/..647 to 1 for the 250 GT and Monza.

2.222 to 1 for the 250 MACH 1 and Mark III,

3.929 to 1 for the 250 SCRAMBLER

FRAME

The frame of the DUCATI motorcycles is of a very smart

and modern design, is manufactured with high tensile

steel and is of the central girder type.

SUSPENSION

The front suspension is composed by the DUCA TI te-

lescopic - hydraulic long-stroke fork, with steering rod.

Each fork leg contains 1 -; 110 cu. cm. (cu. inch 6.1025

to 6.7127) of HYDRAULIC FLUID 542 oiL.

-" --."-- .._--------------------_.-

34

----~---_._-

~"'k'¡I.~"ef:~.';....-,~;;""..-:.;......:;.:..~::.:.~.._;.:'.._~.:.~~.~~_~...__...._..

The rear suspension consists of a robust hinged fork with

double action hydraulic dampers, (shock-absorbers) ,

...

which can be adjusted for three differentt loads: Mini-

mum - Medium - Maximum.

On these machines the fork fulcrum-spindle is fixed to

the frame while the fork with bronze bush rotates on it.

This gives the machines greater solidity and stability.

~:."=.IIÌ.'k.:H,~'~

\

\

~

WHEELS

The wheels are of the spoke type with rims as follows:

Model

250

Material

Wheel Rim

-~--- ._-----~.._-------

Profile

Wheel rim size

Front

Rear

GT

MONZA

MACH 1

MARK III

SCRAMBLER

Steel

Steel

Steel

Steel

Steel

Normal

Normal

Normal

Normal

Normal

18 x 2112

18 x 2112

18 x 21j4

18 x 21/4

19 x 21j2

...__.---- --- ._--------_.- ---.- --_._-------

18 x 2112

10 x 2112

18 x 2'/4

13 x 21/4

19 x 21j2

35

_ . _ ,. ~ ~.~ _._. _ ~.~ ....~.:.,...:..:..:..-Y':..:~;;~~..~~-;,;~~;.;.~;,:.R.:.,~::tt~v..;"..~

The front wheel has a detachable spindle.

The rear wheel has a special cushion drive.

Tyres and pressures are as follows:

Model

250

GT and MONZA

MARK ILL and

MACH 1

SCRAMBLER

"

2.75-18 ribbed

2.50-18 ribbed

"

3,00-19 grooved

for Motocross

Front wheel

Tyre

Pressure

2,25 Kg/cm2

(32.01

Ib/sq. inc.)

2,25 Kg/cm2

(32,01

Ib/sq. rìiê.)

2,25 Kg/cm2

(32,01 for Motocross

Ib/sq, inc.)

3,00-18 grooved

2,75-18 grooved

3.50-19 grooved

Rear wheel

Tyre

Pressure

2,25 Kg/cm2

(32,01

Ib/sq. inc.)

2,25 Kg/cm2

(32,01

Ib/sq. inc.)

2,25 Kg/cm2

(32,01

Ib/sq. inc.)

BRAKES

'Dhe brakes are of the expanding type with two brake-

shoes, - hand operated the front and pedal operated the

rear - with finned brake drums of large diameter width,

and with non fade brake linings.

The diameter of the front brake drum is 180 mm

(7.0866") , the diameter of the rear drum is 160 mm

(6.2992") .

NEW ELECTRICAL SYSTEM

(250 GT - MONZA - MACH i)

The lighting is provided by a storage battery which is re-

charged by the DUCATI flywheel alternator and rectifier.

The head-lamp APRILIA of large diameter carries 3

A mile speedometer VEGLIA with dial of 100 for the

250 GT and Monza, and of 150 for the 250 MACH 1,

lights.

is incorporated in the same headlamp.

The 3-way switch for the light control is situated on the

head lamp. A removable key, placed on the headlamp pro-

vides the contact for the ignition. By removing the key

the engine is stopped.

Alongside the lefthand grip of the handlebar is the switch

for the diplight, the antidazzle light, and the button for

the horn.

- -'--'---._-~ ---._._---- ~-"--~- -------_._~---.~-~

36

'~"'~';~.N;'''.~~"''.,...-.,-:''''''~''':''.;';''..''.!~:.':",'_.:..;_..,:.;'::"_~',.. _~ -.._..._,_...

In the normal position on the rear mudguard are placed

the number-plate carrier, the rear light, the reflector, the

¡,

numberplate lighting and the Stop-light. ,

When the engine is stopped, the electrical current for the

position lights (town light and rear light) is provided by

an acid cell storage battery SAFA, mod. 3L3, of 6 V - 13.5

Ah; the charge is maintained by means of the flywheel al-

ternator and rectifier.

To avoid ruining the effciency of the rectifier, never run

the engine without battery. -Í In cas~ the battery is dischar-

ged, see remedy on page 50.

. - .. -".." . ~. ",-' .," . - _..' ._~ : "~.._,;.;"",-;;:-~. -

-."-_"__~ 'A".~~_~~~ ~_..._._ _"_"___.

ADVANTAGES OF THE NEW ELECTRICAL

EQUIPMENT (250 GT - MONZA - MACH 1)

The electrical system with static regulator of current of-

fers real advantages in comparison with the system em-

ployed till now.

The advantages can be summarised as follows:

1) Regulation of the automatic charge.

2) There are no electrical contacts with the regulator and

therefore there is a grea,ter surety in the working.

3) Simplified commutator system which is limited to the

sole lights section.

~, 4) Possibility of controlling the charge through the red

pilot light.

S) Protection of the electrical system on 3 fuses and then,

possibility to briefly locate the eventual breakdown

and allow the remainding part of the equipment to be

operative: the fuse (7) protects the equipment of the

fr0nt and rear parking lights; the fuse (13) protects

the equipment of the head light (dazzling and anti.

dazzling); the fuse (14), the horn and the stop indica-

tor (see the electrical scheme).

6) Greater simplicity of operation and wiring.

-- - ----- ---- -~---- ~- -,- ~-'--"~--'-

37.

WIRING SYSTEM OPERATION

(250 GT - MONZA - MACH i)

'. ~ .......' ~..". Y," ...:-.::."'..~;,~.,:'.,.:.;~.:....~~~~

1) Key inserted:

the red ignition light lights up when the engine is star-

ted and revs at tick over. The light should go out and

stay out all the time the engine is running faster than

tickover.

commutator:

position 0 - light switched out

position i - switched on the rear and

front parking lights as well

as the green warning light.

position 2 - switched on projector light

l commutable in dazzling and

anti-dazzling lights.

the horn is operating

the battery

charge is well-

balanced in all

conditions.'

the stop indicator is operating

2) Key not-inserted:

4

the machine cannot be run

the red warning light does not lit

commutator:

position 0 - lights switched out

position i - switched on the rear and

front parking lights as well

as the green warning light.

the battery

cannot be

charged.

position 2 - projector light does not lit.

The connection between the static .regulator of current

and rectifier-battery is cut-out.

The horn does not operate.

The stop light indicator does no operate.

38

,~

7 - Fuse protecting the system of the front and

4 . Generator 6V.60W

5 . Plate carrier and Stop Light 6V-3/15W

6 - Stop light switch

2 - Ignition coli In cc, 6 V

3 . Sparking plug

1 . Contact breaker.condenser

the rear parking lights

KEY TO PARTS OF THE ELECTRICAL SCHEME

13 - Fuse protecting the projector light equipment

11 . Three pos iti on commutator

12 . Extractable 4 contact-key

10 - Bulb for the charge warning red light 6V-1.5W

9 - Bulb of the headlamp 6V-25/25W

8 . Bulb for front parking light 6V-3W - warning

(dazzling and anti-dazzling)

green light

!

~

I

ELECTRICAL SCHEME (~~50 GT - MONZA - MACH 1)

19 . Battery SAFA 313 . 13,5 Ah - 6V

lOA

--'---'~-,-.-.-:-,"" .,.... ....-..'

15 . Horn push buton

16 - Terminal block for headlamp

14 . Fuse protecting the horn and the Stop'

indicator

17 . Horn 6V cc,

18 . Static regulator of current and rectifier 6V _

14 13

10) (11

12

..

~

c:

ELECTRICAL SYSTEM (250 MARK III - Scrambler)

The engine of the DUCA TI 250, MARK III and Scrambler

is 'supplied with an alternator-flywheel magnet of the

outer H.T. coil type.

The coil supplies the lighting plant with 40 \V.

The components of this generator are:

1) the rotating flywheel, comprising "the magnets with

their polar expansion, the drum~ustaining the ma-

gnets and the hub. )

2) the stator' plate comprising the 3 . ductors with their

corresponding magnet cores.

NOTE!..- '

When the flywheel is to be fitted on the driving shaft,

in these models and the previous ones, be careful it is

in perfect phase. To carry it out, proceed as follows':

Having the piston at the Top Deal Center (T.D.C.) and

the driving shaft key and flywheel mark in the po-

sition shown in the figure, let the flywheel rotate anti-

clockwise, for the angle ex, till it attains th~ new position.

The headlampcarries 2 lights: the dip light (6 V. - 25 W.)

and the anti-,dazzle (6 V. - 25 W.).

On the handlebar, near the left handgrip, is fitted the

2-way light switch (in-out) with the deviator for the dip

and anti-dazzle lights.

On the rear mudguard, is fitted the taillight with the 6 V.

- 5/20 W. bulb, the catarefractor and the switch. The

latter helps to fastly restore the massbalance of H.T.

coil when the stop bulb turns burnt.

Therefore when the bulb turns burnt,- it is suffcient

to displace the switch lever, to restore the H.T. coil

massabalance.

T,D.C.

I

I

i

250 GT - MONZA -

MACH/i : ex = 0°

250 MARK III -

SCRAMBLER

(J0 = 32° -+ 36°

~

39

I

i

!

¡

¡

i

I

i

¡

I

!

l

I

i

¡

i

i

l

i

ELECTRICAL SCHEME

(250 MARK III and SCRABLER)

Black

'\ Black

Blue

l

i

l

KEY TO PARTS ON 2EELECTRICAL SCHEME

1 - Headlamp Aprlla mod. 13J/ ASN.

2 - ~-Filament bulb 6 V-25/2SW.

3 - Switch and deviator Aprilia 59/N.

4 - Tall light 6V-5/20W.

5 ',Flywheel alternator 6V-40W.

6 - Ignition sparking plug.

7 - Contact breaker-condenser.

8 - Alternated current Ignition coli 6V.

9 . 3-way terminal block.

40

CONTROLS

As mentioned in the foregoing 'paragraph, alongside the

left hand fixed handlebar grip will be found the two swit-

ches for the dip light and the anti

for the horn (this only in the 250 Monza) the hand

dazzle light, the button

operated clutch lever; and above grip is located the

little air-regulating lever. '

The righthand handlebar grip rotates for accelerating and

decelerating the engine. In front of the grip is placed the

operating lever for the front brake and the air control

lever.

Near the left hand footrest is placed the rear wheel brake

lever which also operates the stoplight and the kickstart.

Alongside the right hand footrest is the double lever for

t~e gear change.

1~

\

1 - Front brake control lever

2 . Air regulating' control lever

3 - Rotating throttle control grip

4 - Change double lever

5 - Kickstarter

SADDLE

The motorcycle are provided with a dual-seat, a hand

grip and footrests for pillion rider i,n the 250 and Monza,

and of the racing type in the 250 Mach 1; wide and

comfortable saddles in the 250 Mark III and Scrambler.

/

6 5

LEGEND

6 - Rear brake control lever

7 - 2 way switches for dip light and

antidazzle light, and button for

horn.

8 . Clutch control lever

41

ADJUSTING OF THE CHAIN TENSION

For the correct chain adjustment up and down movement

should be no more than Yí" to ~ ".

I

~--_.

:l..I."

Freccia 15+20 mm.

MOVEMENT: ..to1:

2 4

"

42

,

OVERAL DIMENSIONS AND WEIGHT

o

E

, ~

B

&

---._-

1300101.

5,1181"

1300101.

5,1181"

5.1181"

130 mOl.

5,1181"

C

!J

D E

,_._-

1320 mm.

51.968 "

1350 0101.

53.1495"

1320 mm.

51.968"

1350 mOl.

53.1495"

1350 mOl.

53.1495"

2000 0101.

78.740"

2000 mm.

78.740"

2000 mOl.

78,740"

2000 mm,

78.740"

2020 mOl.

79,5276"

F

,-

800 mOl.

31.4961 "

590 mm.

23,2283"

800 mOl.

31.4961"

800 mOl,

31.4961 "

WeIght

125 Kg.

lb. 275.580

116 Kg.

Ib, 255,735

125 Kg.

lb. 275,580

112 Kg.

lb. 246,918

820 mOl, 1120 Kg.

32,2835" Ib, 264.555

F

Model

250

GT

MACH 1

MONZA

Mark III

SCRAMBLER

A

1070 mOl.

42.1260"

920 mOl.

36,2205"

1070 mm.

42.1260"

1070 mOl.

42,1260"

1050 mOl.

41.3386"

800 0101,

31 ,4961"

760 0101, 130 mm.

29.9213" 5.1181"

800 mm.

31.4961"

800 mm. 130 mm,

31.4961"

750 mOl.

29.5275 "

43

TOOL BOX

A large taal bax af ample capacity is placed under the

saddle at the left side af the rider and cantains the span-

ners and the taals supplied with the matarcycle far the

normal inspectians af the engine, which can be executed

by the rider himself (see fig. page 35), anly far the 250 GT

and Manza madels. In the 250 MACH 1 and Mark III

the toalbax has 2 campartments and is placed under

the saddle.

Far the Scrambler madel the clath taalbag is supplied

separately.

6

~11

1 - Tool bag

2 - Dauble bax spanner 19-22 (0.7480 - 0.8661")

3 - Dauble bax spanner 21' far hexagan 14 (0.8268 _

0.5512")

4 - Tyre lever

5 - Hexagon spanner 14 with tyre puller (=0.5512")

6 - Dauble hexagan spanner 10-11 (=0.3937" _ 0.4331")

7 - Screw driver

8 - Tommy-bar far box spanner 21-22 (=0.8268"

0.8661 ")

9 - Spanner far hallaw hexagan 6 (= 0.2362")

10 - Spanner far hallaw hexagan 5 (= 0.1968")

11 - Tyre inflatar except far the SCRABLER.

44

,Ii:

"

ll~, ,

On the right side of the 250 GT and Monza, is the air

cleaner for the carburetor for the quiet air inlet.

In the inlet duct of the carburetor, is the engine brea-

ther which sends oil vapours to the valves for their

lubrication.

l

¡-

\.

The battery is located between the two boxes in the

said models.

LI.:,,,,)

-...~..j

PERFORMNCE

The maximum speeds allowed for each of the gears,

correspond to the figures recorded in the red circles of

the speedometer reproduced on the next page.

These speeds are obtainable only strictly following the

recommendations for the tuning up, mentioned at pages

13 and 1 and periodically c'arrying out the maintenances

described at pages 52 to 58.

~~~~"':'""~-:~4~~~,!~-"~..~~....:",,,~ """.~'W'~ ,#'."'. ....

45

Approx.

over

~._ _ _.~ _.'. _ " _ ~ ~ _ _ ~. .:' _'.'~. ..~_........:.r.;.:...,,~:._...:_~.:...~w~~- ......~...z:.~~t...~,;k~

250 GT and MONZA

250 MACH i

(In 19wered position race type and"

exhaust).

with megaphone

over

- --"- -;;'-.' .--,--..~ ...-...--- ----~~~

46

r'i"w;-''" ..~.. ""...:. ~ ._~,:;:~~,;:,,:::::,~""-;."-- :._....~..'...~-=.~_,.."';.r,..._'::'_'._-...-

~.

Approx.

over

250 MARK III

Maximum gradient which can be overcome with rider

only, in the various (gears) speeds (except the 250

Scrambler for which the maximum gradient is practi-,

cally without any limitation). A

ÚÙ

~/

Bottom gear

2nd gear

3rd gear

11th gtldr

Tup gear

\I' lTarcili

IV marcia

V marcla

à

.;

..

..

~

~

A

~

~

~

" ~

.1.,, ~

~~

~ à

- ~

~)) ~

47

CONSUMPTION AND DISTANCE

250 GT and MONZA

The consumption at an economical speed of 85 + 90

Km/h (53 to 56 m.p.h.) about 1 liter = (imp. gal 0,220

+ galL. USA 0.2642) petrol e ESSO EXTRA per 31 Km.

(ml. 19.2624).

Maximum distanc~ of cruising with one tankfuL, 527

Km. (m. 327,267) for 250 GT and 403 Km. (ml. 250,263)

for Monza.

250 MACH i and MARK III.

I

The consumption at an economical speed of 85 + 90

Km/h (53 to 56 m.p.h.) about 1 liter (= galL. USA 0.2642

+ imp. galL. 0.220) petrol 8 ESSO EXTRA for 31

Km. (m!. 19.2624).

Maximum distance of cruising with one tankfuL, 400

Km. (ml. 249).

250 SCRAMBLER

The consumption at an economical speed of 65+ 70

Km/h (40 + 44 m.p.h.) about 1 liter = (imp. gal 0.220

= galL. USA 0.2642) petrol 8 ESSO EXTRA for

28 Km. (17,388 miles).

Maximum distance of cruising with one tankful, 308

Km. (ml. 191.268).

--_.._---_...__._--~--------~-_.-.-.__._---- --------_.__._,-~----~-_..._~ ---_.- ---- ~

,

,

48

.'

HOW TO USE THE SINGLE OVER HE~D CAM-SHAFT

MOTORCYCLES

FILLING UP AND STARTING THE ENGINE

Before starting the engine make sure that there is suff-

cient petrol in the tank, for the distance you wish to

travel. See that the petrol tap is on and that the engine

lubricating oil is at the right leveL.

For the lubrication it is

EXTRA MOTOR OIL 20W - 30-40 or RACER 40.

Having refueled and checked the oil, see that gear lever

is in neutral position and press, down the carburetor

tickler to ensure the correct level of petrol in the float

chamber. Now, after having inserted the contact-key

into its place on the headlamp, turn the righthand hand-

lebar grip (accelerator) for about one-eighth of its travel

advisable to use e ESSO

'~"

",

-_..._._-------~--- -_._--- ----- --- ---. -~---_..-

49

.', .'. _'., ._. ",_,_': ~,:.,;:'_,:.._._:;~_,:..,#:...,:~:,.~~¿.:.~.:,:~~"')o~':4'~..:....:-,.;.~~..

and thrust the kicks

tarter energically downward (in

the models GT, Monza and Mach/1).

If the engine does not start repeat this operation, va-

rying at the same time more or less the opening of the

throttle by means of the handlebar grip. Once the engine

is started, do not race it immediately, especially when

the engine is cold, but before accelerating the engine let

the lubricating oil warm up to facilitate its circulation

throughout the engine, so as to reach all moving parts.

RIDING AWAy AND RUNNING

OF THE MOTORCYCLE

With the engine running, disengage the clutch and using

yopr heeL, push down the rear arm of the gearchange

leveL. When this lever is left to itself it returns to its

original position. With this move the bottom gear is now

engaged. Now turn the righthand grip little by little and

release gradually your hold on the clutch lever; the mo-

torcycle begins slowly to go under way. With the clutch

lever completely released let the motorcycle increase its

speed until about 15/20 Km/h (9-12 m.p.h.). To pass

now from bottom gear in second gear, turn back right-

hand grip fully and quickly; and after having disenga-

ged the clutch follow up at once by pressing down the

front arm of the gearchange lever, with the toe of your

shoe. Now turn forward the righthand grip again, re-

leasing at the same time the clutch lever. Similar opera-

tions are carried out in order to change from second

gear into third gear, from third gear into fourth gear

and from the fourth to the top gear.

To change down from a high gear to a lower one, ope-

rate as follows: close the throttle, disengage the clutch,

accelerate the engine momentarily, thus synchronizing

the gear about to be engaged, engage the lower gear and

then let go off the clutch control.

A good motorcyclist will make use of the controls intelli-

gently and at the right time. When riding uphill and the

engine tends to slow down, change to a lower gear at

50

~.:..~.:-.C'_...~__......___~. Ro .p'___~ .#...... .

once; do not "hang on" to a higher gear when the effort

required from the engine advises to use a lower gear.

.

When the engine turns at a low number of revolutions,

do not accelerate its turning at once: thus you avoid

any oversupply of fuel and too harsh drive to the trans-

mission.

The clutch should not be held long disengaged with a

gear engaged, because the clutch plates will become

overheated, causing rapid wear by friction.

Exèept in case of emergency I- never use the

tally when you are already near behind the obstacle, but

throttle down the engine in right time and then make

brakes bru:-

use of the brakes. ,

Bear in mind that insuffcIently inflated tyres are detri-

mental to the roadholding qualities of the motorcycle,

cause a greater tyre wear and lower effciency.

STOPPING THE MOTORCYCLE

To stop the engine, close the throttle completely (the en-

gine will then act as a gentle brake) disengage the clutch

and put the gear pedal in neutral. A slight use of the

brakes will then stop the motorcycle.

To stop the engine pull out the contact key of the switch

placed on the headlamp (in the models GT, Monza, and

Mach/!).

.

51

'." .. ~ . . - .. ~ _._... ... ..: ...:L."...... -_. - '." 1'"- -_..~_~~~.._,..~.. ..;~~..-.'-~:..,;:~...;.:_....';.~~~..:~,;~

MAINTENANCE

On good maintenance depends the good condition of the

motorcycle.

By following these fundamental rules you can avoid se-

rious trouble and obtain an excellent performance from

your motorcycle.

The operations to be carried but are subdivided ih ac-

cordance with the order on which depends the mileage

run by the motorcycle. The recommendations which fol-

low are, of course, merely indicative, because lubricating,

checking and adjustments depend also on the nature of

the road, the seasonal temperature, the length of the

intérvening period.

EVERY 500 Km (about 310 miles)

- Restore the oil-level in the crankcase;

- Check the tyre pressure with a pressure-gauge;

- Tighten the cylinder head holding down bolts;

- Read just the brakes;

- Check the clearange between valves and rockers. ad-

justing it to 0.002;' to 0.0028" (0.05 to 0.07 mm.) by

means of the screws and nuts placed on the rockers,

(in the models 250 GT and Monza) and for the appro-

priate rocker shim on the valve stem end, Jetting

the clearance be 0.15 mm (0.0059 in.) fo sucti

valve and 0.30 rr-10.011~ in. or t e exhaust valve

in t e 0 H 1 an MARK III); respective y

at 0.15 mm (0.0059 in.) to 0.20 (0.0079") for the

SCRAMBLER.

EVERY 1000 Km (about 620 miles)

- Check and adjust the distance between the sparking

plug electrodes to about O.5mm (0.02") and clean

them with a small wire brush and some petrol;

52

~~,..._,-._..:.~- -

_ Clean the contact breaker platinum plates with a rag

.

damped in petrol and check the distance between the

platinum plates, which opening shoul be 0.3 to 0.4

mm (0.0118" to 0.0157") ;

_ Check the clearance between valves and rockers as

mentioned in the above paragraph.

EVERY 1500 Km (about 930 miles)

_ Lubricate the speedometer drive with S BSSO

MlJL1TPURPOSE GREASE H.

.

EVERY 2000 Km( about 1240 miles)

_ Change the oil in the crankcase draining it while the

engine is hot, make sure that the oil drains off com-

pletely.

_ Remove the carburetor oil filter and wash it in pe-

trol or paraffin oil, in order to remove all impurities

from the gauze.

_ Clean out the carburetor float chamber, the main jet

and the idle jet.

_ Readjust the clutch because the wear on its linings

might otherwise cause slip.

- Lubricate the hinge of the rear fork.

_ Dampen with 2 drops (not more) of thin mineral oil

the lubricating wick of the contact breaker cam.

_ Tighten uniformly the nipples of the spokes and

check whether the screws and the nuts of the wheels

have been firmly tightened.

EVERY 20.000 Km( about 12400 miles)

_ Dismantle the exhaust pipe and the cylinder, in order

to remove the carbon deposits on the cylinder head

and on the piston (this should be done by a Ducati

Servicing Garage).

53

, .'.. ,'. /... ,'.' .'.'". .',; .'. . ~,~,~,~.,;,,;..~,~.~.~.~..:.;.~.~.:~..:~.~..,,-".~-;~-,;

HEADLAMP ALIGNMENT

It is advisable to check periodically the alignment of the

headlight as follows:

- place the motorcycle at a distance of 5 meters (ft.

16.404) from a bright wall;

- make sure that the ground be even and that the optic

axis of the headlamp be perpendicular to the wall;

- the motorcycle with its rider must rest on the wheels,

not on the central stand;

250 GT . MONZA . MACH/1 . MARK III

-

0-

C'

,.

-0

Ñ

..

..

'-

'..

'.., ca

250 SCRABLER

----- -~

, ,

'.. a

'.... E

, ,

ú'1';

.. ~N

.. 0 r-

~ ,.

", E ~

,

,

,

-----

--------

---------

m,5

---------

m.5

'6,10010 ft.

(ft. \ 6.404)

ú'1":

~ ..

CD ,.

~~

E r-

N

54

"'_~""'-~L''' 1'~";_~_,:,'~'" ',_.__ __. __ _~ . ..

-trace a cross in the intersections between the optic

axis and the wall, that is at a height of 0.815 meter

.

(f1. 2.6739) from the ground for 250 GT, Monza,

Machll, Mark III and 0.845 meter (.ft. 2.7723) for

the 250 Scrambler.

_ when the depthlight is ligthed up, the cross must be

in the center of the circular light-beam hitting the

wall.

- to rectify eventually the alignment of the headlamp,

operate by means of the two fixing screws of the

tab nuts of the headlamp on the front fork.

OVERALL CLEANING

The ,motorcycle should be washed and cleaned periodi-

cally, according to the length of time it has been used

and the state of the road. ~

_ Clean the engine with parafin and wipe it dry with a

clean rag;

- wash down the painted parts of the frame with water,

using a sponge for washing and a shammy leather for

drying;

- never use solvents, petrol, spirit or parafin, otherwise

the paint will

- grease the chromium plated parts with vaseline and

polish with shammy leather.

look flat;

~

PROLONGED REST OF THE MOTORCYCLE

If the motorcycle has to be put at rest for several months,

it is advisable to proceed as follows:

- clean the motorcycle thoroughly;

- empty the petrol tank;

- take out the battery and keep it effcient, as per in-

structions hereunder in the models GT, Monza

Machll ;

- squirt through the hole of the sparking plug, several

drops of oil into the cylinder and turn the engine by

hand for several revolutions, distributing a thin oil-

film on the walls;

- put the motorcycle upon two pieces of wood, lifting

the machine from the ground and empty the air out

of the inner tube;

- cover the machine with a canvas, or water-proof

cover.

55

.c....,.. ~_.____~ _ _ _ ........._........ ......-:~_~~:'_~_.......;..;l.........:~-".:..:~~;.h~;~~..~ ..~~......~~d"j'.:_'t.

INSTRUCTIONS FOR THE FIRST CHARGE AND FOR

THE

MAINTENANCE OF THE BATTERY áT,

(250 G.T. - MONZA - MACH/i) '-~)."

Battery SAFA 3L3, with free acid, dry charge.

Type

- tension . . . . . . .

- Capacity at 20 hours.

- Capacity at 10 hours. . .

- Normal charging current .

- Max, recharging current .

- External dimensions .

. 6 V

. 13.5 Ah

. 12 Ah

1.2 Amp

. 2 Amp

. 120 x 90 x 165 mm. =

4.7244 x3 .5433x6 .3960"

Warning

The baitery, must always be preserved in a fresh but

dry place. It is important to check frequently the level

and the density of the electrolyte.

Never let the accumulators completely without charge..

Keep always the plugs well closed and screwed down.

Clean always well the oxyde from the terminals and con-

nections, and protect them with a thin layer of pure va-

seline. Never use grease. The battery must always be pre-

served well cleaned and dry, especially the top part.

Electrolyte

The electrolyte consists of sulphuric acid of regular pu-

rity, diluted with distUled water, so that the density,

referred to a temperature of 15° C (59° F.), corresponds

to the following values: .." Ì'

" '

CONDITIONS PLACE

-'-~.-~---'. -----

Temperate climate

DENSITY OF THE ELECTROLYTE

dry battery

-

1,28+ 1,29

charged battery

- ,-

1 ,27 + 1 ,28

Max. temperat.

of the electrolyte

during charge

500C (122°F)

Tropical climate

1.21 + 1,22

The level of the electrolyte within the elements must be

at the same level of the antisplash gauze.

When all elements have been filled with the electrolyte,

56

1,20+ 1,21

600C (140oF)

t:;~A~~~"~~.r.~...".,,;_-__

let the battery at rest for about 2 hours to allow the

cooling of the plates. '

.

A certain part of the electrolyte will be absorbed by the

separators and by the plates, so that it will be necessary

to add more electrolyte to establish the right leveL.

To check the electrolyte level use only glass sticks or

ebonite.

First charge

Take down the breathers and connect the battery with

a source

1/10 of the normal 10 hours capacity, for a maximum

period of at least 10 consecutive hours.

Take care that during the charge the temperature of the

electrolyte does not overpass 500 C (1220 F).

The charge has to be interrupte,d:

a) when the above mentioned effective number of hours

b) in case of an intense ebullition in all the elements;

c) in case if for at least 3 consecutive readings at inter-

At the end of the charge, the electrolyte should have re-

covered the initial density, and the voltage of each

element should arrive at a minimum of 2.7 Volts under

charge, that is 8.1 Volts for a battery of 3 elements and

of 16.2 Volts for a battery of 6 elements.

At this point the battery is ready to be put in service.

.

of direct current, having an intensity equal to

is elapsed, reckoning of course also the eventual in-

terruptions ;

vals of one hours each, the density of the electrolyte,

and the voltage of each element remain the same.

SUCCESSIVE CHARGES

The successive charges have to be made preferably with a

current having an intensity in Amp. equal but not greater

than 1/10 of the normal

If during the charge the temperature, checked with a sui-

table thermometer immerged into the electrolyte should

reach 500 C, (1220 F), it will be necessary to reduce or to

interrupt the charge until the temperature falls at least

below 400 C (1040 F).

10 hours capacity.

57

,', ':.'. - .-"'. '.:' ...~, .... ......_-...-~ ~.....'" . ~."" .:...-:~..":~_,,~.w'..''''.''_''''~_'',,''___~;;'-.~~~~~~':~''~J':''':''':..J~

The charge must continue until the density of the elec-

trolyte results to be constant during 3 consecutive read-

ings ,made at intervals of one hour each, and until the

voltage reaches the value of 2. 7 Volts for each element.

Never and for no reason refill the battery with sulphuric

acid of whatever density. The refilling has to be made

only with distilled water, chemically pure, taking care

that the vessel used on this behalf be absolutely clean,

to avoid the spoiling of the electrolyte by noxious sub-

stances and compromise so the effciency of the battery.

In case the accumulators remain temporarily inactive, it

is necëssary to recharge the battery- at

least once each

month, anp each time the batterywtll.bepiit in service.

INSTRUCTIONS FOR THE MAINTEN'ANCE

OF THE ELECTRICAL SYSTEM

(lGT - MONZA. - MACHI i )

In case of inspections or repairs, it is extremely impor-

tant to know the working of the electrical system and

to follow with care the scheme on page 38.

To avoid demagnetizing of the rectifier, be careful never

to send electrical current (direct or alternate current)

in the opposite direction.

Every inspection should be made with a convenient

Ohmmeter.

To avoid ruining the effciency of the rectifier, never

run the engine wi thou t battery.

For no reason, the rectifier and static re~ulator of current

should be opened: if it does not work, send it to the

CONCESSIONAIRES of DUCAT

cement.

I MECCANICA for repla-

58

.

. . '- .'~' ...#"....'-_"r.~."'.#.._~._.~~...~_'-.-..--~..;.-¡.-;;-.--.......~n

~,

Noiivis 3JIAlI3S

z

0

-

-l

:a

-l

Vl

m

n

c:

:i

m

Vl

:i

0

"'

Vl

r-

0

0

-l

r .:.....~:.:__:_.d: .",,',

i' ,"

l, "

¡ "'. ',,"

, I

,

".: ,""

"".."'.,. '

- -

w~_

.¡

w

',', i

--1"".

. '.

~/~

¡ ,., ,

¡

"

I ..

I ..

¡

¡

¡

i

I

i

I

l

to -. ,i

-. ~ 1

0-

..

..

'~~

..~_i~,;.../ci..,." .

1 ~_A-,""""

U)~--

.. /

.. .. ..

(J-

..

.;

"

,.

v

..

"

!:

..

e

LEGEND

TOOL EQUIPMENT

8) Valve seats grinding tool

7) Spanner for nuts with hollow hexagon (ch, 5 (0,1968") or ch. 6 . (0.2362")

6) Gear-holdinç¡ key for tightening the pinion nut

5) Drum-holding key for tightening the drum nut

2) Piston cleaning tool

1) Flywheel puller

4) Housing-holding key for tightening the engine shaft gear

3) Puller for journal bearing bushing

a) with assembled cylinder head b) with dismantled cylinder head

9) Puller for clutch side cover

11) Rocker pin puller

10) Piston position indicator

15) Timing camshaft holding key for tightening of the bevel gear Z == 28

14) Line.up pin for rocker bushing or washer assembly

16-17) Pin for assembling and dismantling of gudgeon pin

19) Spanner for bevel gear Z==28 (see 15)

18) Engine shaft holding tool for tightening of the bevel gear Z == 21

26) Bush for the assembly of the advance ignition cover

25) Plate for removing half-crankcase (on request)

24) Ball bearing puller (3 types)

23) Key for threaded ring of exhaust pipe

22) Grinder for valve seats (one for the inlet and one for the exhaust)

21) Valve assembling and dismantling tool

20) Plug assembly spanner for plugs with hollow hexagon (ch. 12 (0,4724") or ch, 14 (0.5512'i

,: ',)

~~~~,:.. x~ó.~'?.?'. v~:¿..¿,..-.'-~;.~:~~~~~~~~~~~::~~..'ý~7l;,;.~..~~.;....~~.~;-~..'.;::;;~.;..~;~c...'...;:;:.. ~~'-~ :;-'.-. ._" # ... ..',":, .:-;.:~"......:;;--.; --

ElJIAllElS

NOIJ.VJ.S

I

--_._--

LNHWdIIlÙH 'IOOL

HSll HOd SNOIL~HHia

¡

19

ieiind 1884MÁI:I - L

_._--_.._----------------- ----_.. - --~--------- .- -_. ---_._..

,~

~ ~ .' ~. ,', --~ '-,'#.~.:';,"'.~./~' .,"", ...~...:' .".- ;.-=':-~

IOOl 5u!Ue;;l:i UOlS!d - ~

(~

5U!4snq 5u¡Jeaq ieumof JOj Jaiind £

£9

~..~.~~...~ ....~"V..:'~-:..~~.. ~~~J?"'.~~.~~.:i.",:~',",:,'."',""~ :.....~.., '.

I

-,- r-

',;Jii1ml toa 0P.!NOllNllV '

~"'."..'L' . ~t;.1kÌ4i,.!;p

Jea6 Ueqs aui6ua aql 6U!U8l46!l JOJ Áalf fiu!PI04-6ulsnoH . V

v9

fiU!U8l4fi!l JOI Á8lf fiUIPI04-LUnJO . ç

lnu

.

~ ~.~ ~ ~_.~ ~.-~ R _. ..-.-......r':-....;....;-.;;...-:-~

~

lnu uo!u!d 841 BU!U8l4ß!l ~O! Á8)j BU!Plo4.Jl8Ð - 9

100l Bu!pu!~B Sll8S 8/1111¡\ - 8

Ç9

~~~~~:::~~::-~:-_ -.":..:"..~;.~....::--~~":~-:..~-:"7~?''"..:'?..:'..~'f...~..~..?....~..;...~.o- "''',-''.. r.:: ~...' .-. - ~"". ":' _~. -- .. - .. _ . ~ - - -

Jaflo:i apis 4:ilnl' JOl Jaiind . 6

h;'

ì!~c¡ wnJU!WnIV

..

(

;

Î

Jole:ilpU! UOlilsod UOlSld . oi

;,

99

I

~v:-~_.,:,~'.o~

(1

J811nd u!d J911::Olj - LL

Aiqw8sse J94SeM JO 5u!4snq J811:JOJ JOl u!d dn-8U!1 . tL

L9

l)......~~':__.;~~..~~~':~~~~~~~...~~~~....~~..:"~~-:-~..~. --~'~ ~'~ ~ _ ~ ~ ___

UO aq ¡snw ¡OIS a¡ii!! aqi

ôlu¡6aa aliI 10 apts ¡U011 &lj

Jea5 laAaq a4l lO 5u!ua~45!l JOl "alj 5u!P¡04 He4sLUe:i 5u!LU!1 . çl

,

99

u!d uoa5pn5 io 5u!l~ueUJs!p pue 5U!iQLUasse JOl sUlci - 1.-gl

-- _.._---...'-~~~

.'~

..

(.

L(:=z JB8B 18A8q 84l lO BU!U8l40!l JOl IOOl BUlPI04 llB4S 8U!BU3 - BL

IOOl BU!llUBUlS!P pUB BU!lqUl8SSB qAIB¡\ - Ii:

69

~,~~~~~jl,~~~,,"'.~~-A..~";~~~.r-.;"~':';':~:v~r;:::~;i?,-~___..._~_. "'.'4'" _ ~_

sluas aAluA JOl JapuPÐ - 00

OL

Jaiind 6upuaq IIll8 - \70

.' ..,:..:...~__~-w..

.

(.

JaA03 uo!l!uB! a3UeApe a4l lO Áiqwasse G4l JOl iisn8 . 91:

lL

~~~~~'_~~-~~~':O:~~":~~~4-0.'7~.;:-~~"~--"'-"~~:-~~~':':::~?-~X.,:,=-,::'"..:;;~...:~::~:#::~.:-::':... .,"~~.r__&...:... ~-_-.-: ...~... .._~-:_-;._. "' ..,-: _ _~ ,"_-:;.~,_~~.:,,~_;_:_ .,.....

I

,~,,'

,*.

LOCATING AND REMEDYING FAULTS

The following list contains several of the most frequent

faults which may arise and advice on remedying them.

ENGINE DOES NOT START EASILY

First of all"", asçertain, that "there is engugh petrol ,anCl

that the cock is turned on. (A = open; R = reserve). If

these are in order, the fault may be one or more of the

following:

t',

..

CAUSE

Petrol pipe is clogged.

Petrol filter dirty.

Petrol cock filter is dirty.

Carburetor float stuck.

Carburetor float leaking.

Jet is clogged.

The cable of the ignition

coil is broken or spar-

king externally.

Defective sparking plug.

REMEDY

Blow through it until the ob-

stacle is removed.

Dismantle the filter and clean

the gauze by air blast.

Disman tIe the fiter and clean

it by a blast of air through

the gauze.

Remove the float and clean

out the float chamber (this

should be done by a DUCA-

TI Servicing Garage).

Change the float (at a DUCA-

TI Servicing Garage).

Remove the obstacle by a

strong blast of air.

Inspect the cable insulation

for faults and if necessary

change the cable at a DUCA-

TI Servicing Garage.

Change or clean the plug, ma-

king sure that the insula tion

core is not damaged, that

there are no carbon deposits

on the electrodes and that

the spark gap does not ex-

ceed 0.5 mm. (0.0197").

73

. ..,.. ,...... . ~-. ~ . . -. ,-_.. ~. .:.-

. - ~.. 4 ~:.. ~ --. - -.. ._~ ',. ~.-,/~ "':g._~:~~,.. .~:.. -.:.::,t...~;.~~t:Â":."'~~~:;.:Lo~~~..':~.....~~...~.._:~.........~~4.~-:.~~~~..~.;~~~~~

CAUSE

The contact breaker points

do not open.

The contact breaker arm

seized on its pivot.

The contact brëaker poiiits

are dirty.

The capacitor has broken

down or is short cIr4

cuited.

I Compression lacking.

REMEDY

Check the position of the fixed

contact point (at a Ducati

Servicing Garage).

Check movement between ro-

cker arm and pivot and if

necessary lubricate the pi-

vot.

Clean the contact breacker

points with a rag damped in

petrol.

Change the capacitor (at a Du-

cati Servicing Garage).

Check if the sparking plug has

been tightly screwed in,

check the valves for gas-

tightness and the tightness

of the piston rings (at a Du-

ca ti Servicing Garage).

A valve spring is broken.

Valve sticking.

The adjustment screw for

the tappet clearance is

loose (250 GT-Monza).

The rocker adjuster is

worn out (250 MACH 1 -

MARK III - SCRA-

BLER).

The battery is discharged

(250 GT - MONZA -

MACH/1 ).

Change the broken spring (at

a Ducati Servicing Garage).

Dismantle the valve, clean the

valve stem and the bore of

the valve guide, and make

sure that the clearance bet-

ween stem and bore does

not e x c e e d 0.08 mm.

(0.0032") (at a Ducati Servi-

cing Garage).

Readjust the clearance and

tighten the set-nut properly.

Check again the clearance by

fitting the adequate rocker

shim on the valve stem end.

Recharge the battery accor-

ding wi th the instructions

of page 52 (at a Ducati Ser-

vicing Station).

74

-"---' -"- ....~~.__.. ~ ..

()

CAUSE

The battery quickly dischar-

ges for a fault or an in-

terruption in the rechar-

gig circuit. (250 GT -

MONZA MACH i).

REMEDY

Disjoin the wire from the+ter.

miIial block of the battery.

- Insert an amperemeter in

continuous current bet-

ween the terminal block

and the wire.

- Insert the ignition key and

let the engine turn.

The headlamp warning red

light should be cut out

when the engine runs at

1,000 r.p.m.

Checking the Electrical

System.

Make sure that all the bulbs

are effcient.

1) With the lights switched

out (during the day), the

amperemeter should read

o at 1,200 r.p.m. approx.

~

2) With town lights switched

on (during the night) the

amperemeter should read

o at 1,400 r.p.m. approx.

3) With the anti dazzle lights

switched on (during the

night) the amperemeter

should read 0 at 2,200 r.p.m.

approx.

75

.-' - ~:""':- "'"":',~.~ _c~'''~-~~::'::::'?:'~::(~~~~~~f~,,''~~~~..''''~';':''~~;'~i~~~~

INEFFICIENT ENGINE

CAUSE

Irregular feed of petrol

to the carburetor. '

Main jet partly clogged.

Carburetor butterfly valve

does not open comple-

tely.

I The float needle does not

close properly.

Petrol of bad quality.

The spark is not of the

right type.

REMEDY

Clean the carburetor filter,

the petrol cock filter and

the petrol pipe.

Clean the main jet by means

of an air blast.

Readjust the valve travel by

means of the adjustment

screw of the carburetor

Bowden cable (at a Ducati

Service Garage).

Clean out the carburetor

and especially the needle

5eat (at a Ducati Servicing

Garage) .

Empty the petrol tank and re-

fill at a reliable garage.

If the sparking plug over-

heats, you wil have preigni-

tion, knocking, and misses,

especially at high revs. If

the sparking plug remams

too cold, you wil have no

ignition. because the electro-

des wil short-circuit. Use

the right type of sparking

plug; we advise the use of

a plug having a thermal fi-

gure of 260 of the Bosch in-

ternational scale.

The sparking plug cable

sparks externally.

---

-----------

76

Tighten the plug down welL. A

copper washer should al.

ways be placed between the

sparking plug and its sea-

ting in the cylinder head.

Change the cable or repair

the insulation (at a Ducati

Servicing Garage).

------- '-

G'"

"":,,' ":',

~¡ ~ ,

CAUSE

REMEDY

The spark gap between the

electrodes of the spar-

king plug is too wide.

The sparking plug electro-

des are dirty.

The contact breaker ope-

ning is excessive.

The secondary winding of

the coil is short-circuited

or broken.

The silencer is almost

completely clogged-up.

Adjust the gap to the

width of about 0,5 mm.

proper

(0.0197").

Clean the electrodes with a

wire brush.

Readjust the exact opening of

the contact which is 0.3+0.4

mm. = 0.0118" to 0.0157" (at

a Duca ti Servicing Garage).

Change the coil (at a Ducati

Servicing Garage).

Clean the silencer, to ensure

the free discharge of the

spent gases.

~,

77

~-:~:-::--i-:oi~--,;~~..~~":.;,~;:~~~~~.~..?, ~-t.,;""'''';:.''~~''~j'-r~-;~''-"''';"~",,,:-",'''':'' ,,'-r'_ ',,' - -.- ~:. .,' ~:. ---'~..; ~ ..-': - -. ~-""'-:-~-:-_~'- --'"-.:--_""..:-..._,:_._.-:_..._..~.. .'... '-." ..' .

I

ø

X3GNI

.fF~J

~,"

¡

~

t:

t¡

~.'

~..

~,;

~

i;

~,

F

I¥ ' ,

~"','O".",

~'. ,:"',

"

,

~"""',

t.

f

.

;-~.'

~

INDEX

GUARANTEE CARD

FOREWORD . .

Spare Parts . . . .

Ducati Servicing Garage

IDENTIFICATION NUMBERS. . . . . . .

PRECAUTIONS TO BE FOLLOWED DURING THE

INITIAL RUNNING - IN PERIOD

MAIN SP,ECIFICATIONS

Engine

Timing .

Petrol Feed

LubricatioR . . ;

Centrifugal oil filter .

Cooling

Ignition . . . .

How to check advance

Starting .

Transmission

Frame .

Suspension

Wheels

Brakes . . . .

New Electrical System . . . . . . .

Advantages of the new electrical equipment.

Electrical system (250 MARK III - Scrambler)

Con troIs

Saddle . _ . . .

Adjusting of the Chain Tension

Overall dimensions and Weight

Tool box

Performance. . . . . . . . .

HOW TO USE THE O.H.C.-SHAFT MOTORCYCLES:

Filing up and starting of the engine. . .

RidinK away and running of the Motorcycle .

Stoppmg the Motorcycle . . . . . .

MAINTENANCE:

Every 500 Km. ( 310 miles)

Every 1000 Km. ( 620 miles)

Every 1500 Km. ,( 930 miles)

Every 2000 Km. ( 1240 miles)

Every 20000 Km. (12400 miles)

Headlamp alignment . .

Overall cleaning .

Prolonged rest of the Motorcycle. .

Instructions for the first charge and for the mainte-

nance of the Battery . . . . . . . . .

lnstructions for the maintenance of the electrical

system . . . . . . . .

DUCATI SERVICE STATIONS . .

LOCATING AND REMEDYING FAULTS:

Engine does not start easily

Ineffcient Engine

Pag. 2

)) 10

)) 11

)) 11

)) 12

)) 13

)) 15

)) 16

)) 24

)) 24

)) 27

)) 27

)) 28

)) 29

)) 33

)) 33

)) 34

)) 34

)) 35

)) 36

)) 36

)) 37

)) 39

)) 41

)) 41

)) 42

)) 43

)) 44

)) 45

)) 49

)) 50

)) 51

)) 52

)) 52

)) 53

)) 53

)) 53

)) 54

)) 55

)) 55

)) 56

)) 58

)) 59

)) 73

)) 76

VNÐOi08 - \t.d.S VOINV003W u80 au U~

£LE 31ViSOd V113SVO (31VÐINVd 0Ð~OS) n n \t~((líi1

,1NÐOl0B - u03WI1,10nci" IWW'IHÐ3131 (eeu!l o.lnenb) l09l6tr 'N ONO.:3131

Loading...

Loading...