M

Installation

Instructions

S E C U R I T Y S Y S T E M

Please refer to the System Installation Manual for information

on limitations regarding product use and function and information on the limitations as to liability of the manufacturer.

TM

T

PC51OO

Version 1.O

Limited Warranty

Digital Security Controls Ltd. warrants that for a period of twelve months from the date of purchase, the

product shall be free of defects in materials and workmanship under normal use and that in fulfilment of

any breach of such warranty, Digital Security Controls Ltd. shall, at its option, repair or replace the

defective equipment upon return of the equipment to its factory. This warranty applies only to defects in

parts and workmanship and not to damage incurred in shipping or handling, or damage due to causes

beyond the control of Digital Security Controls Ltd. such as lightning, excessive voltage, mechanical

shock, water damage, or damage arising out of abuse, alteration or improper application of the equipment.

The foregoing warranty shall apply only to the original buyer, and is and shall be in lieu of any and all

other warranties, whether expressed or implied and of all other obligations or liabilities on the part of

Digital Security Controls Ltd. This warranty contains the entire warranty. Digital Security Controls Ltd.

neither assumes, nor authorizes any other person purporting to act on its behalf to modify or to change

this warranty, nor to assume for it any other warranty or liability concerning this product.

In no event shall Digital Security Controls Ltd. be liable for any direct or indirect or consequential

damages, loss of anticipated profits, loss of time or any other losses incurred by the buyer in connection

with the purchase, installation or operation or failure of this product.

WARNING: Digital Security Controls Ltd. recommends that the entire system be completely tested on

a regular basis. However, despite frequent testing, and due to, but not limited to, criminal tampering or

electrical disruption, it is possible for this product to fail to perform as expected.

FCC COMPLIANCE STATEMENT

CAUTION: Changes or modifications not expressly approved by Digital Security Controls Ltd. could void your

authority to use this equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

■

Re-orient the receiving antenna.

■

Increase the separation between the equipment and receiver.

■

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

■

Consult the dealer or an experienced radio/television technician for help.

The user may find the following booklet prepared by the FCC useful: “How to Identify and Resolve Radio/

Television Interference Problems”. This booklet is available from the U.S. Government Printing Office, Washington D.C. 20402, Stock # 004-000-00345-4.

Digital Security Controls Ltd. 160 Washburn St., Lockport, NY 14094

This Class [B] digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe [B] est conforme à la norme NMB-003 du Canada.

S E C T I O N 1

1.1 Specifications

PC5100 2-Wire Addressable Device Interface Module

• The PC5100 is an interface module for the PC5010 and PC5015

alarm control panels. The module is used to connect 2-wire

addressable devices to the Power832 Security System.

• Current draw: 40mA

• Addressable loop maximum current draw: 170mA

• Up to 32 2-wire addressable devices can be added to the system

• Compatiblilty PC5010 v2.x or higher; PC5015 v2.x or higher.

Addressable Multiplex Loop (AML) Devices

All addressable series devices use a 2-wire connection for power and

to communicate with the control panel. This simplifies wiring and

permits fast and efficient installations.

WARNING: Connect only DSC Addressable Series devices to the

addressable loop connections. Connection of ANY other type of

device will impair operation. Any devices other than Addressable

Series devices which require power to operate must be powered

separately.

Overview

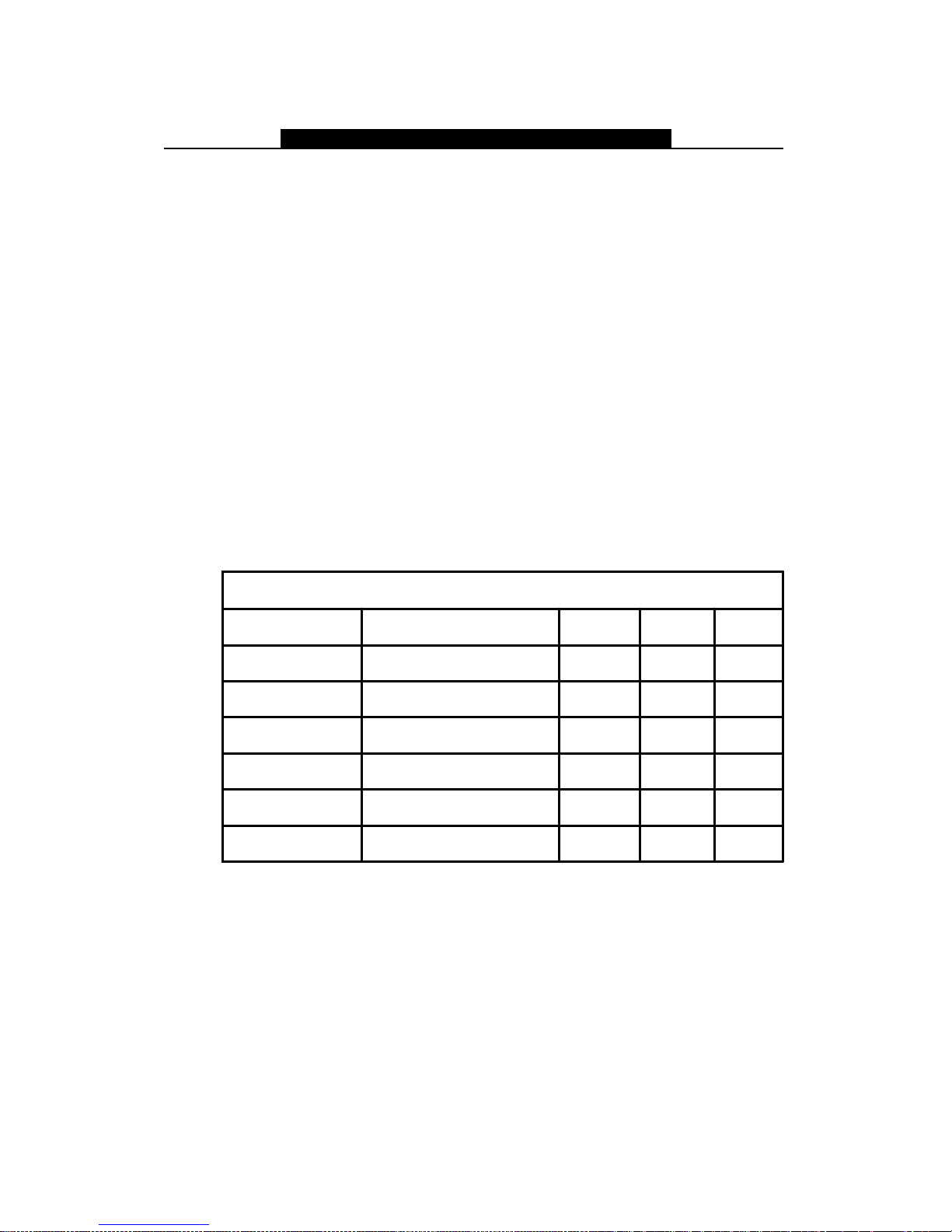

ADDRESSABLE DEVICE CURRENT LOADING

Device Description Standb y* Alarm T est

AMS-220/AMS-2 20T Smoke Detector 0.8 mA 1.5 mA 1.5 mA

AMB-300 Motion Dete ct or 2.5 mA 2.5 mA 5.0 mA

AMB-500 Ceiling Mount Motion Detector 2.5 mA 2.5 mA 5.0 mA

AMB-600 Pet Immune Motion Dete ctor 3.5 mA 3.5 mA 6.5 mA

AMA-100 Glassbreak De t ecto r 3.5 mA 3.5 mA 5.5 mA

AMP-700/AMP-7 01 Contact 0.8 mA 0.8 mA 0.8 mA

*Always use the Standby Current Draw when calculating maximum

wire run lengths.

1

Getting Started

S E C T I O N 2

2.1 Connecting the PC5100 Interface Module

Remove all power from the control panel before connecting

any module to the system.

Connect the PC5100 to the PC5010/5015 Keybus by inserting the red,

black, yellow and green Keybus wires into their corresponding terminals.

If the PC5100 is not located within the main cabinet, a PC5204

power supply must be used to power the module, as in the

diagram below.

After wiring is complete, add power back to the PC5010/PC5015.

The system will detect the new module and it will be supervised.

2.2 Calculating Current Draw

Up to 32 addressable devices can be connected to the PC5100.

However, a maximum of 170mA of current can be used on the addressable loop. Calculate how much current your selection of devices will

require by completing the following table:

2

G E T T I N G S T A R T E D

Model # Description Quantity x

AMS-220 Smoke Detector x 0.8 mA =

AMB-300 PIR Detector x 2.5 mA =

AMB-500 Ceiling Mount PIR x 2.5 mA =

AMB-600 Dual PIR Detector x 3.5 mA =

AMA-100 Glass-break Detector x 3.5 mA =

AMP-700 Magnetic Door/Window Contact x 0.8 mA =

AMP-701 Contact Input Module x 0.8 mA =

Total Current Draw (Maximum 170 mA) =

2.3 Connecting 2-Wire AML Devices

The 2-wire addressable devices are connected to the STR+ and STRterminals on the PC5100. All devices can be home-run, t-tapped or

connected in a daisy chain. Please refer to the diagram below:

Max. Device

Current Draw

(in standby mode)

Total

Current

The wiring length of each addressable loop is restricted to the following

distances, depending on the amount of current required (see Section

2.2 “Calculating Current Draw”). Consult the wiring chart on the next

page.

For longer wire runs, you can split

the addressable devices onto two

or more loops from the STR terminals. For example, 32 AMB-300

detectors (2.5mA each) take 80mA

total. In one 18AWG wire run, this

would allow a maximum length of

720 feet (220 m). If you split the 32

devices into two wire runs of 16

detectors each, using 18AWG wire,

each wire run could be 1736 feet

(529 m) long. See the diagram on

the right.

3

G E T T I N G S T A R T E D

Not more than four

24AWG conductors

should be connected to a

single terminal as wire

bulk may cause improper

operation.

All devices must be enrolled as

individual zones on the system

by entering their serial numbers

(see section 3.2 “Enrolling

Devices”).

Loop Current vs. Wiri ng Di st a nce

To tal loop

current (mA)

10 2880/878 5143/1568

20 1620/494 3645/1111

30 1010/308 2520/768

40 771/235 1736/529

50 600/183 1250/381

60 500/152 980/298

70 400/122 800/244

80 321/98 720/220

90 250/76 500/152

100 200/61 310/95

110 165/50 220/67

120 135/41 155/47

130 115/35 130/39

22 AWG

distance (ft/m)

18 AWG

distance (ft/m)

140 106/32 126/38

150 100/30 124/37

160 98/29 122/36

170 96/28 120/35

If any of the system keypads indicate a PC5100 module tamper,

or if any zones show as open, or show a zone fault, there may

be a short on the AML loop. The PC5100 module and zones will

not be restored until the short is corrected - remove power

from the system and re-check the zone wiring.

2.4 Connecting the PC5100 Tamper

The PC5100 has a built-in tamper switch (SW1). If an external tamper

switch is being used, connect the switch according to the following

diagram.

If neither the built-in tamper nor an external switch is being

used, you must short the TAM and BLK terminals. If you do not

make this connection, a trouble condition will be indicated.

4

Programming the PC5100

S E C T I O N 3

3.1 How to Program

You can program the PC5100 by entering installer’s programming

mode ([

All PC5100 programming is in programming section [805] (see page 8).

3.2 Enrolling Devices

To enroll AML devices:

1. At a system keypad, enter [Q][8][Installer’s code] to go to the

2. Enter programming section [805].

3. Enter the 2-digit number corresponding to the zone the device is to

NOTE: You cannot enroll more than one device to a zone.

Q] [8] [Installer’s code]) at any system keypad.

Ensure that you have double checked each entry for all device

serial number sections. If you have entered data which was not

accepted, the section will not change from the previous

settings and device serial numbers will revert to [00000].

installer’s programming section.

occupy ([01] to [32]).

If you install AML devices on zones programmed as interior

and delay zone types, the delay zones must have a lower zone

number than the interior zones. For example, if zone number

[04] is a delay zone, interior zones that use AML devices can

only be installed on zones [05] or higher. If you program an

AML delay zone with a higher number than AML interior zones,

the system may detect a violation on the interior zone before

the delay zone is triggered, causing a false alarm.

4. Enter the device’s serial number. The entry

5. The device is now enrolled on the system. Record the serial number

and the assigned zone number in the programming worksheets in

the back of this manual.

6. Continue with steps 3 - 5 until you have enrolled all devices.

7. To exit press [#].

Once you have enrolled all the AML devices, you should

program the Panel Key. See section 3.7 for more information.

3.3 Zone Programming

The AML devices will not work properly until you complete the zone and

partition programming. Select a zone definition for each used zone in

programming sections [001] – [004].

You must also enable the wireless/AML zone attribute for each zone

that has been assigned to an AML device. To do this, turn ON option 8

in the appropriate programming section (one or more of sections [101]

– [132]). See your PC5010 or PC5015

information.

To ensure proper operation, use zone definitions (87) and (88) for both

delayed and standard fire zones on the addressable loop.

must

be five digits.

Installation Manual

for more

5

P R O G R A M M I N G T H E P C 5 1 0 0

3.4 Module and Device Supervision

To confirm that the panel is supervising the PC5100, enter section

[903]. If the PC5100 is being supervised, on LED keypads light 15 will

be on, and on LCD keypads the message “PC5100” will be displayed.

Devices are supervised as zones. The level of supervision for AML

devices is determined by the type of zone supervision that was selected for the PC5010/5015 (i.e. normally closed, single end of line, or

double end of line supervision).

For more information, please refer to your PC5010 or PC5015

tion Manual

.

Installa-

3.5 Removing Devices

Before removing devices from the system, you must delete their serial

numbers. To remove a 2-wire addressable device from the system,

perform the steps outlined in Section 3.2. Enter [00000] for the serial

number of the device you wish to remove.

You may need to power down the panel to clear troubles which

could be caused by deleted devices.

3.6 Replacing Devices

In order to replace an AML device, you must first remove the old

device, as described in section 3.5, above. Then, enroll the new device

as described in section 3.2.

3.7 Programming Section Descriptions

Sections [01] - [32]: Zone Serial Numbers

These sections are for enrolling the serial numbers of each 2-wire

addressable device on the system. See Section 3.2 for details.

Section [97]: Special Functions

Option 1: Walk test light ON. Turn on this option to enable the walk

test LED on all motion and glassbreak detectors. If a device is working,

its LED will turn on when it is tested.

This option does not turn on the walk test - only the walk test

LEDs. To walk test the system, follow the instructions in the

Walk Test section of the PC5010 or PC5015 Installation Manual.

• To test the motion detectors, create motion in front of each device. If

the LED turns on, the device is working.

• To test the glassbreak detectors, you will also need to turn on option

4 (Glassbreak Test ON). See the

sheet for testing instructions.

Once the walk test has been completed, re-enter Section [97] and turn

option [1] OFF.

Option 2: Smoke test on installer exit. Turn on this option to enable

the smoke test for all AML smoke detectors. The PC5100 will begin the

test after you exit from Installer’s Programming. The PC5100 tests each

smoke detector by:

• turning on the test output of each detector, and then checking for an

alarm state on each detector

AMA-100 Installation Instruction

6

P R O G R A M M I N G T H E P C 5 1 0 0

• turning off the test output and checking for an alarm restore state on

each detector.

If the PC5100 module does not receive an alarm signal from a smoke

detector, there will be a trouble on that zone when the test is over. The

trouble will only be restored when the next smoke test is performed and

the detector passes the test. If the PC5100 module does not receive a

restore signal from a smoke detector, there will be an alarm on that

zone when the smoke test is over. The alarm will be restored once the

zone has been restored.

After you turn on this test, do not enter Installer’s Programming for at

least 60 seconds. The PC5100 will turn off the option once the test is

complete.

See your

AMS-220 Installation Instruction

sheet for more information on

testing AML smoke detectors.

If a smoke alarm occurs during the smoke test, the zone will be

placed into the alarm state once the test has been completed.

Option 3: 24-hour smoke test.

If this option is turned on, the panel will

perform the smoke test as described in option 4, above, every day at

11:00 pm.

Option 4: Glassbreak test ON. Turn this option on to test AMA-100

devices with the AFT-100. After you have turned this option on, follow

the instructions in the Walk Test section of the PC5010 or PC5015

Installation Manual

. See the

AMA-100 Installation Instruction

sheet for

testing instructions.

The AMA-100 will not respnd to the AFT-100 unless this option is turned

on. Turn this option OFF when you are done testing the AMA-100 devices.

Section [98]: Panel Key

IMPORTANT: We strongly recommend that the panel key be

programmed to ensure the security of the system.

The Panel Key is a 2-digit code which acts as a security lock for the

addressable detectors. Once you have enrolled all addressable zones

you must change the panel key from the default “00” to another 2-digit

number (01-FF). When the panel key is changed, the panel will broadcast the new code to each addressable device.

Section [99]: Module Default

To return the module to its factory default settings, enter section [99],

then enter [55].

Before you can continue programming the PC5100 module,

you must exit (press [#] twice), and then re-enter installer’s

programming (enter [*][8][Installer’s Code]).

3.8 Testing the System

To verify that each device is working as intended, you should perform a

walk test once all devices have been installed. To perform a walk test,

follow the instructions in section 3.7 (Option 1: Walk Test Light ON),

and in your PC5010 or PC5015

You should also perform a test of the smoke detectors as described in

section 3.7 (Option 2: Smoke test on installer exit).

Installation Manual

7

.

Programming Worksheets

S E C T I O N 4

[805] PC5100 Expansion Programming

Zone Serial Numbers

Default for each section = 00000 (5-digit decimal entry required)

[01] Zone 1

[02] Zone 2

[03] Zone 3

[04] Zone 4

[05] Zone 5

[06] Zone 6

[07] Zone 7

[08] Zone 8

[09] Zone 9

[10] Zone 10

[11] Zone 11

[12] Zone 12

[13] Zone 13

[14] Zone 14

[15] Zone 15

[16] Zone 16

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

[17] Zone 17

[18] Zone 18

[19] Zone 19

[20] Zone 20

[21] Zone 21

[22] Zone 22

[23] Zone 23

[24] Zone 24

[25] Zone 25

[26] Zone 26

[27] Zone 27

[28] Zone 28

[29] Zone 29

[30] Zone 30

[31] Zone 31

[32] Zone 32

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

_____l_____l_____l_____l_____

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

l

[97] Special Functions Options (1-3)

Default = OFF Option ON Option OFF

________

l

________

l

________

l

________

l

________

l

Option 1 Walk test LED ON Walk test LED OFF

l

Option 2 Smoke test on installer exit Smoke test OFF

l

Option 3 24-hour smoke test ON 24-hour smoke test OFF

l

Option 4 Glassbreak test mode ON Glassbreak test mode OFF

l

Option 5-8 Not used

l

[98] Panel Key (2-digit hexidecimal entry)

_____l_____

l

l

[99] PC5100 Module Default

Enter [55] in this location to return the PC5100 to its default settings.

8

Guidelines for Locating Smoke Detectors

NEVER

HERE

Acceptable

here

T op of detector

acceptable here

12"

(0.3m)

Max.

4"

(0.1m)

Max.

4"

(0.1m)

Ceiling

Wall

NOTE: Measurements shown are to

the closest edge of the detector.

A P P E N D I X A

Experience has shown that all hostile fires in family living units generate smoke to a

greater or lesser extent. Experiments using typical fires in family living units indicate that

detectable quantities of smoke precede detectable levels of heat in most cases. In

existing homes, the 1993 edition of NFPA 72 requires that a smoke detector be installed

outside each sleeping area and on each additional story of the family unit.

The following information is for general guidance only and it is recommended that the

1993 edition of NFPA 72 (National Fire Protection Association, One Batterymarch

Park, Quincy,MA 02269) be consulted and that the smoke detector manufacturer’s

literature be used for detailed installation instructions.

It is recommended that additional smoke detectors beyond those required be installed

for increased protection. The added areas include: basement, bedrooms, dining rooms,

furnace room, utility room and hallways not protected by the required detectors.

Bedroom Bedroom

Bedroom

Living RoomKitchen

Figure 1: A smoke detector should be located

between the sleeping area and the rest of the

family unit.

Family Room Bedroom

Dining

Room

Kitchen

Bedroom Bedroom

Living

Room

Figure 2: In family living units with more than one

sleeping area, a smoke detector should be located to protect each sleeping area.

Bedroom Bedroom

Living

Room

Basement

Dining

Room

Figure 3: A smoke detector should be located on

each story of the living unit.

Figure 4: Smoke Detector Mounting - ‘ Dead’

Air Space. The smoke from a fire generally rises

to the ceiling, spreads out across the ceiling

surface and begins to bank down from the ceiling. The corner where the ceiling and wall meet

is an air space into which the smoke may have

difficulty penetrating. In most fires, this “dead”

air space measures about 4 in. (0.1m) along the

ceiling from the corner and about 4 in. (0.1m)

down the wall as shown in Figure 4. Detectors

should not be placed in the ‘dead’ air space.

9

1645 Flint Road, Downsview, Ontario, Canada M3J 2J6

Tel. (416) 665-8460 • Fax (416) 665-7498 • Tech. Line 1-800-387-3630 • www.dscgrp.com

TM

Security Products

© 1999 Digital Security Controls Ltd.

Printed in Canada 29003139 R001

Loading...

Loading...