INSTALLATION

MANUAL

PC3OOO

Version 7.51

DOC NOTICE

DOC NOTICE

NOTICE: The Canadian Department of Communications label identifies certified equipment. This certification means that the equipment meets certain telecommunications network

NOTICE: The Canadian Department of Communications label identifies certified equipment. This certification means that the equipment meets certain telecommunications network

protective, operational and safety requirements. The Department does not guarantee the equipment will operate to the user's satisfaction.

protective, operational and safety requirements. The Department does not guarantee the equipment will operate to the user's satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local telecommunications company. The equipment must also be

Before installing this equipment, users should ensure that it is permissible to be connected to the facilities of the local telecommunications company. The equipment must also be

installed using an acceptable method of connection. In some cases, the company's inside wiring associated with a single line individual service may be extended by means of certified

installed using an acceptable method of connection. In some cases, the company's inside wiring associated with a single line individual service may be extended by means of certified

connector assembly (telephone extension cord). The customer should be aware that compliance with the above conditions may not prevent degradation of service in some situations.

connector assembly (telephone extension cord). The customer should be aware that compliance with the above conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier. Any repairs or alterations made by the user to this

Repairs to certified equipment should be made by an authorized Canadian maintenance facility designated by the supplier. Any repairs or alterations made by the user to this

equipment, or equipment malfunctions, may give the telecommunications company cause to request the user to disconnect the equipment.

equipment, or equipment malfunctions, may give the telecommunications company cause to request the user to disconnect the equipment.

User should ensure for their own protection that the electrical ground connections of the power utility, telephone lines and internal metallic water pipe system, if present, are

User should ensure for their own protection that the electrical ground connections of the power utility, telephone lines and internal metallic water pipe system, if present, are

connected together. This precaution may be particularly important in rural areas.

connected together. This precaution may be particularly important in rural areas.

CAUTION:

CAUTION:

Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection authority, or electrician, as appropriate.

Users should not attempt to make such connections themselves, but should contact the appropriate electric inspection authority, or electrician, as appropriate.

The Load Number

The Load Number

overloading. The termination on a loop may consist of any combination of devices subject only to the requirement that the total of the Load Numbers of all the devices does not

overloading. The termination on a loop may consist of any combination of devices subject only to the requirement that the total of the Load Numbers of all the devices does not

exceed 100.

exceed 100.

The Load Number of this device is 42.

The Load Number of this device is 42.

AVIS:

AVIS:

L'étiquette du ministère des Communications du Canada identifie le matériel homologué. Cette étiquette certifie que le matériel est conforme à certaines normes de

L'étiquette du ministère des Communications du Canada identifie le matériel homologué. Cette étiquette certifie que le matériel est conforme à certaines normes de

protection, d'exploitation et de sécurité des réseaux de télécommunications. Le Ministère n'assure toutefois pas que le matétiel fonctionnera à la satisfaction de l'utilisateur.

protection, d'exploitation et de sécurité des réseaux de télécommunications. Le Ministère n'assure toutefois pas que le matétiel fonctionnera à la satisfaction de l'utilisateur.

Avant d'installer ce matériel, l'utilisateur doit s'assurer qu'il est permis de le raccorder aux installations de l'entreprise locale de télécommunication. Le matériel doit également être

Avant d'installer ce matériel, l'utilisateur doit s'assurer qu'il est permis de le raccorder aux installations de l'entreprise locale de télécommunication. Le matériel doit également être

installé en suivant une méthod acceptée de raccordement. Dans certains cas, les fils intérieurs de l'entreprise utilisés pour un service individuel a ligne unique peuvent être prolongés

installé en suivant une méthod acceptée de raccordement. Dans certains cas, les fils intérieurs de l'entreprise utilisés pour un service individuel a ligne unique peuvent être prolongés

au moyen d'un dispositif homologué de rassordement (cordon prolongateur tèlèphonique interne). L'abonné ne doit pas oublier qu'il est possible que la conformité aux conditions

au moyen d'un dispositif homologué de rassordement (cordon prolongateur tèlèphonique interne). L'abonné ne doit pas oublier qu'il est possible que la conformité aux conditions

énoncées ci-dessus n'empechent pas la dégradation du service dans certaines situations. Actuellement, les entreprises de télécommunication ne permettent pas que l'on raccorde leur

énoncées ci-dessus n'empechent pas la dégradation du service dans certaines situations. Actuellement, les entreprises de télécommunication ne permettent pas que l'on raccorde leur

matériel a des jacks d'abonné, sauf dans les cas précis prévus par les tarrifs particuliers de ces entreprises.

matériel a des jacks d'abonné, sauf dans les cas précis prévus par les tarrifs particuliers de ces entreprises.

Les réparations de matériel homologué doivent etre effectuées par un centre d'entretien canadien autorisé désigné par le fournisseur. La compagnie de télécommunications peut

Les réparations de matériel homologué doivent etre effectuées par un centre d'entretien canadien autorisé désigné par le fournisseur. La compagnie de télécommunications peut

demander à l'utilisateur de débrancher un appareil à la suite de réparations ou de modifications effectuées par l'utilisateur ou à cause de mauvais fonctionnement.

demander à l'utilisateur de débrancher un appareil à la suite de réparations ou de modifications effectuées par l'utilisateur ou à cause de mauvais fonctionnement.

Pour sa propre protection, l'utilisateur doit s'assurer que tous les fils de mise à la terre de la source d'énergie électrique, des lignes téléphoniques et des canalisations d'eau métalliques,

Pour sa propre protection, l'utilisateur doit s'assurer que tous les fils de mise à la terre de la source d'énergie électrique, des lignes téléphoniques et des canalisations d'eau métalliques,

s'il y en a, sont raccordés ensemble. Cette précaution est particulièrement importante dans les régions rurales.

s'il y en a, sont raccordés ensemble. Cette précaution est particulièrement importante dans les régions rurales.

AVERTISSEMENT:

AVERTISSEMENT:

selon le cas.

selon le cas.

L'indice de charge

L'indice de charge

bouclé utilisé par ce dispositif. La terminaison du circuit bouclé peut etre constituée de n'import quelle combinaison de dispositifs, pourvu que la somme des indices de charge de

bouclé utilisé par ce dispositif. La terminaison du circuit bouclé peut etre constituée de n'import quelle combinaison de dispositifs, pourvu que la somme des indices de charge de

l'ensemble des dispositifs ne dépasse pas 100.

l'ensemble des dispositifs ne dépasse pas 100.

L'indice de charge de cet dispositif est 42.

L'indice de charge de cet dispositif est 42.

(LN) assigned to each terminal device denotes the percentage of the total load to be connected to a telephone loop which is used by the device, to prevent

(LN) assigned to each terminal device denotes the percentage of the total load to be connected to a telephone loop which is used by the device, to prevent

L'utilisateur ne doit pas tenter de faire ces raccordements lui-meme; il doit avoir recours a un service d'inspection des installations électriques, ou a electricien,

L'utilisateur ne doit pas tenter de faire ces raccordements lui-meme; il doit avoir recours a un service d'inspection des installations électriques, ou a electricien,

(IC) assigné a chaque dispositif terminal indique, pour éviter toute surcharge, le pourcentage de la charge totale qui peut etre raccordée a un circuit téléphonique

(IC) assigné a chaque dispositif terminal indique, pour éviter toute surcharge, le pourcentage de la charge totale qui peut etre raccordée a un circuit téléphonique

TABLE OF CONTENTS

Specifications ____________________________________________________________1

Features ___________________________________________________________________ 2

Installation ________________________________________________________________ 3

Bench Testing ______________________________________________________________ 3

Mounting Panel _____________________________________________________________ 3

Hook-up Procedure __________________________________________________________ 3

Terminal Connections _______________________________________________________ 4

Guidelines for Smoke Detector Location ___________________________ 6

Keypad Functions _______________________________________________________ 7

Introduction ________________________________________________________________ 7

Master Code ________________________________________________________________ 7

Installer’s Programming Code ________________________________________________ 7

Arming _____________________________________________________________________7

Disarming __________________________________________________________________ 7

Auto-Bypass/Home-Away Arming _____________________________________________ 7

Zone Bypassing __________________ [Q]+[1] _________________________________ 7

Trouble Display ___________________ [Q]+[2] _________________________________ 8

Alarm Memory Display _____________ [Q]+[3] _________________________________ 8

Switched Auxiliary Supply Control ___ [Q]+[Hold Down 4] _______________________9

User’s Programming Commands ____ [Q]+[5]+[Master Code] ___________________ 9

User’s Functions Command ________ [Q]+[6]+[Master Code] ___________________ 9

Installer’s Test ____________________ [Q]+[6]+[Master Code]+[0] _____________ 10

Setting the Clock __________________ [Q]+[6]+[Master Code]+[1] _____________ 10

Auto-arm Time of Day _____________ [Q]+[6]+[Master Code]+[2] _____________ 10

Quick Arm ________________________ [Q]+[6]+[Master Code]+[4] _____________ 10

Auto-arm Enable __________________ [Q]+[6]+[Master Code]+[5] _____________ 10

Door Chime ______________________ [Q]+[6]+[Master Code]+[6] _____________ 10

System Test ______________________ [Q]+[6]+[Master Code]+[8] _____________ 10

User Callup _______________________ [Q]+[6]+[Master Code]+[9] _____________ 10

Utility Output Command ___________ [Q]+[7] or [Q]+[7]+[Access Code] _______ 11

Installer’s Programming Commands _ [Q]+[8]+[Installer’s Code] _______________ 11

“At Home” Arming _________________ [Q]+[9]+[Access Code] ________________ 11

“Quick Arm” Command ____________ [Q]+[0] _______________________________ 11

Quick Exit ________________________ [Q]+[0] when armed ____________________ 11

Keypad Zones ____________________________________________________________ 11

Printer Setup ___________________________________________________________ 12

Configuring the Printer _____________________________________________________ 12

Programming the Panel for Use with a Printer _________________________________ 12

Downloading ____________________________________________________________ 13

Programming Guide ___________________________________________________ 14

Introduction ______________________________________________________________ 14

Reviewing Programmed Data _______________________________________________ 14

[00] Binary Programming ___________________________________________________ 14

[01] 1st Phone Number ____________________________________________________ 14

[02] 1st Account Code _____________________________________________________ 15

[03] 2nd Phone Number ___________________________________________________ 15

[04] 2nd Account Code ____________________________________________________ 15

[05]...[15] Reporting Code Explanation ______________________________________ 15

[05] Alarm Reporting Codes Zones 1 to 8 ____________________________________ 15

[06] Alarm Reporting Codes Zones 9 to 16 ___________________________________ 15

[07] Restoral Reporting Codes Zones 1 to 8 __________________________________ 15

[08] Restoral Reporting Codes Zones 9 to 16 _________________________________ 16

[09] Utility Alarm Reporting Codes __________________________________________ 16

[10] Utility Restoral Reporting Codes ________________________________________ 16

[11] Reporting Codes for Closing (Arming) with Access Codes 1 to 8 ___________ 16

[12] Reporting Codes for Closing (Arming) with Access Codes 9 to 16 __________ 16

[13] Reporting Codes for Opening (Disarming) with Access Codes 1 to 8 _______ 16

[14] Reporting Codes for Opening (Disarming) with Access Codes 9 to 16 ______ 16

[15] Reporting Codes for Miscellaneous Functions ____________________________ 17

[16] Zone Definitions for Zones 1 to 8 ________________________________________ 17

[17] Zone Definitions for Zones 9 to 16 ______________________________________ 17

[18] 1st System Option Code _______________________________________________ 18

[19] 2nd System Option Code ______________________________________________ 18

[20] Zones 1 to 8 Bypass Mask _____________________________________________ 18

[21] Zones 9 to 16 Bypass Mask ____________________________________________ 18

[22] System Times ________________________________________________________ 18

[23] System Clock Times ___________________________________________________ 19

[24] New Installer’s Code __________________________________________________ 19

[25] New Master Code (Access Code Number 1) _____________________________ 19

[26] Downloading Access Code ____________________________________________ 19

[27] Communicator Format Options _________________________________________ 19

[28] Programmable Input and Output Options ________________________________ 20

[29] [30] [31] [32] Split Arming ______________________________________________ 21

[33] Communicator Call Direction Options ___________________________________ 21

[34] Software Reset EEPROM Memory to Factory Defaults _____________________ 22

[35] Through [42] - For Future Use __________________________________________ 22

[43] Access Bypass Mask (Codes 1 to 8) ____________________________________ 22

[44] Access Bypass Mask (Codes 9 to 16) ___________________________________ 22

[45] TLM Restoral Reporting Code __________________________________________ 22

[46] Downloading Computer Telephone Number ______________________________ 22

[47] Modem Configuration __________________________________________________ 22

[48] Panel Identification Code ______________________________________________ 22

[49] Printer Configuration ___________________________________________________ 22

[50] After Alarm Reporting Code ____________________________________________ 23

[51] 3rd System Option Code _______________________________________________ 23

[52] Delay Before Transmission _____________________________________________ 23

[53] Auto-arm Abort Reporting Code ________________________________________ 23

[54] System Test Reporting Code ___________________________________________ 23

[90] Installer’s Lockout Enable ______________________________________________ 23

[91] Installer’s Lockout Disable _____________________________________________ 23

Programming Work Sheets ___________________________________ 24

Just for the Record ____________________________________________________ 35

Hookup Diagrams ______________________________________________________ 36

Limited Warranty ______________________________________________________ 38

SPECIFICATIONS

Control Panel Specifications

21 zones including:

• 16 fully programmable supervised zones (EOL resistors)

• Supervised fire zone

• 1 auxiliary normally open zone

• 3 keypad activated zones

Audible alarm output:

• Bell output

700 mA, fused at 5 Amps, 12 V

• Steady or pulsed output

EEPROM memory:

• Does not lose codes or system status on complete AC

and battery failure

Programmable output:

• Transistor switch sinks 50 mA to ground

• Operation controllable through program options

Powerful 1.5 amp regulated power supply:

• 400 mA auxiliary supply, 12 V

• Separately fused for battery, keypad/auxiliary supply and

bell output

• Supervision for loss of AC power, low battery

• Internal clock locked to AC power frequency

Switched Smoke Detector Supply Output:

• Controlled from keypad [Q][4] command

Battery required:

• 12 volt 4 Ah minimum rechargeable gel-cell or sealed

lead-acid battery

DC unregulated

DC unregulated

Remote Keypad Specifications

(PC3000RK)

• Four wire (QUAD) hook-up and up to 3 keypads per

system

• Built-in piezoelectric buzzer

• Full annunciation of zones and system status

• Nominal current draw 60 mA

• Dimensions 5.5” x 4.5” x 1” deep (140 x 114 x 25 mm)

Output Voltage Specification

Typically, with normal AC in and a fully charged battery, the

output voltage will be 13.8 V

discharged battery, the voltage will go to 10 volts. Devices

that require power from the control panel should be capable

of normal operation over the voltage range of 10 to 14 V

DC. With AC off and a

DC.

Digital Communicator Specifications

• 94 reporting codes

• Transmits all 10BPS and 20BPS single line and extended

formats

• Radionics Rounds and Radionics Parity formats

• Sescoa Superfast format

• 3/1, 4/2 and hexadecimal numbers

• DTMF and Pulse dialing

• DPDT line seizure

• True dial tone detection

• Anti-jam feature

• Two telephone numbers and two account codes

• Split reporting of selected transmissions to each

telephone number

Transformer required:

• 16.5 VAC, 40VA

Dimensions:

• 11” x 11.8” x 3.3” deep (279 x 300 x 84 mm)

Weight:

• 6.5 lbs (3 kg)

1

FEATURES

Keypad Programming

The PC3000 comes with a default program so it is

operational with a minimum of programming. It is completely

programmable from the keypad. The panel uses EEPROM

memory so that all information is retained even if the panel

loses both AC and battery power.

Multiple Level Static/Lightning

Protection

The PC3000 has been carefully designed and tested to

provide reliable service. It is built to take static and lightning

induced surges and keep on working. Multiple level surge

filters are on all zone inputs, the power supply, the keypad

connections, the bell output, the auxiliary power supply and

the telephone interface. A special “ZAP-TRAC” circuit

board configuration catches high voltage impulses right at

the wiring terminals. Protective ground planes surround

sensitive areas preventing the spread of damaging voltage

surges. Metal Oxide Varistors (MOV’s) are placed in all the

critical areas to further reduce impulses to safe levels.

”WATCHDOG MONITOR” Circuit

Even when all precautions are taken so that voltage surges

do not cause damage to the control panel, it is possible to

cause temporary disruption to the operation of the

microprocessor causing it to lose track of the program

sequence. The PC3000 is equipped with an external

“Watchdog Monitor” circuit which continually checks the

microprocessor program execution.

Advanced Features

The PC3000 has many advanced features. Features which

provide the security system design flexibility and selling

advantage necessary to win those demanding jobs and

make them profitable.

Some of these features include:

• EEPROM memory retains all data even on complete AC

and battery failure. Panel powers up in last armed or

disarmed state before power loss.

• All programmable zones may be selected as one of 10

different types including; delay, double delay, quadruple

delay, instant, follower, follower with home-away, delay

with home-away, and 4 types of 24 hour emergency and

supervisory circuits.

• Keypad programming of up to sixteen security codes.

• Zone bypassing from the keypad.

• Individual zone and system function indicators on keypad.

• A keypad activated utility output function for operating

lights, door openers, cameras or other devices.

Although the PC3000 has many features, it is not difficult to

use. All keypad commands are similar and are assisted by

audible and visual cues.

System Supervision Features

The PC3000 continuously monitors a number of possible

trouble conditions including:

• An active battery supervision circuit that periodically tests

the battery under load.

• A loss of the AC power supply.

• A supervised circuit trouble condition.

• A telephone line monitoring circuit.

• A bell circuit failure indicates open circuit or fuse failure.

• A test code feature which transmits a communicator test

code to the monitoring station at a selected time

everyday. The test code can be sent at intervals from 1 to

99 days.

• A bell/siren/communicator test feature which can be

activated from the keypad.

• TLM (Telephone Line Monitoring) restoral transmission.

2

INSTALLATION

Bench Testing

The PC3000 contains a factory default program. Any

additional programming required can be done through the

keypad. For many applications all that will be required is to

enter the telephone number and alarm codes with keypad

entries that are as straight forward as dialing a telephone

number. If you need help talk to your DSC equipment

distributor.

Connect 1K ohm 1/2 watt end of line resistors from each

zone (Z1 to Z16) input to the closest common “COM”

terminal. Connect an end of line resistor between the “Fire”

input terminal and the “COM” terminal between “Z1” and

“Z2”. Unless all zone are properly terminated with end of

line resistors the “Ready” light will not be on and the panel

will not arm unless the “Ready” light is on.

Connect the four keypad wires to the control panel as

shown in the connection drawing.

To completely test the PC3000 including the communicator

data, it is necessary to connect the panel to a digital

receiver through a telephone line connection or by

connecting the telephone terminals on the PC3000 to a

digital communicator test set such as the DSC DTS-1. The

DSC DTS-1 digital communicator test set is an inexpensive

unit which can simulate the telephone system dial tone and

the receiver hand shake and kiss-off tones as well as

display the data sent out by a digital communicator. Also,

the DTS-1 has a “listen-in” feature which makes it ideal for

monitoring the transmission between communicator and

receiver when the PC3000 is connected to the telephone

line.

If you are using a DTS-1, connect the green and red

telephone clips to the “TIP” and “RING” terminals and

connect the red and black power clips to the “AUX [+]” and

“AUX [-]” terminals on the PC3000. When power is applied

to the panel press the red local-line button on the DTS-1

and observe the display window area. The “local-line”

indicator should be in the local position.

For testing purposes, so that the sound level is not too loud,

connect a small buzzer to the “BELL [+]” and “BELL [-]”

terminals to indicate when the panel is in alarm.

Connect a 16.5 VAC, 40 VA transformer to the “AC”

terminals. Before plugging in the transformer be sure the

circuit board is not resting on anything metallic which may

cause a short.

Note: The PC3000 will not start up is “AC” is off and

the battery is low. The panel will display trouble #1

under these conditions.

When the transformer is plugged in there should be lights

on the keypad and the buzzer connected to the bell

terminals may go on for a few seconds. The “Armed” light

may be on or off the first time the panel is powered. The

last armed/disarmed condition is stored in the EEPROM

memory so the panel will always power up in the last

armed/disarmed state. If the “Armed” light is on, enter the

default master code [1234] to disarm the panel. If the

keypad is not active, check for the presence of AC power

at the “AC” terminals, check the keypad connections and

check the panel fuses.

If all the zones are properly connected with end of line

resistors all of the zone lights will be off. Note that the panel

will arm only if all zones are properly connected with end of

line resistors (including FIRE zone) so that the “Ready” light

is on. The keypad should beep several times to indicate

acceptance of the master code. Enter the master code to

arm or disarm the panel.

Read the “Keypad Commands” section of this manual or the

Instruction Manual and enter commands on the keypad to

become familiar with the different commands.

Turn to the “Programming Guide” in this manual and enter a

sample program into the panel through the keypad to

become familiar with the programming commands.

Mounting Panel

Select a dry location close to an unswitched AC source, a

ground connection and the telephone connection.

Remove printed circuit board, mounting hardware and

keypad from cardboard retainer inside panel. Before

attaching cabinet to wall, press the five white nylon printed

circuit board mounting studs and the ground connection

screw into cabinet from the back.

Pull all cables into cabinet and prepare them for connection

before mounting the circuit board to the back of the cabinet.

Press circuit board down onto mounting studs.

Hook-up Procedure

DO NOT connect transformer or battery until all other wiring

has been connected. See power-up procedure.

Connect a ground cable from the cabinet ground

connection by the shortest and most direct route to a

grounding rod.

Connect zone cables to zone inputs and put end of line

resistors on any unused zones. Connect wires supplying

power to motion detectors to auxiliary supply.

Install keypads and connect wires to keypad terminals on

panel. Connect RJ31-X cord to telephone terminals. Do not

insert plug into RJ31-X jack.

Warning: Do not use this equipment on a telephone

line equipped with “call holding” feature because the

tone generated may interfere with the communicator

operation.

Connect bell or siren to “BELL [+]” and “BELL [-]” terminals.

Observe correct polarity for sirens and polarized bells.

Connect 1K ohm 1/2 watt resistor across terminals to

eliminate trouble condition if bell circuit is not being used.

3

Terminal Connections

“AC” Power Terminals

Use a 16.5 VAC transformer with a minimum 40 VA rating to

supply AC power to the PC3000. The transformer should not

be connected to an outlet that is controlled by a switch. If

AC failure occurs it is displayed as a trouble on the keypad

(see “Keypad Functions [Q][2] Trouble Conditions”). It can

also be transmitted to the monitoring station as a trouble

condition (see “Programming Guide [Q][8]” sections [09]

and [10] for alarm and restore codes and section [20] for

AC transmission delay).

switch to ground. A 100 ohm current limiting resistor is

connected in series. A small relay, a buzzer or other DC

operated device may be connected between the 12 V

“AUX” (positive) terminal and the “PGM OUT” (switched

negative) terminal on the main board.

DC

Auxiliary Power Terminals “AUX” and “GND”

The auxiliary power supply can be used to power motion

detectors and other devices requiring 12 V

DC is available from the “AUX” (positive) and “GND”

V

DC. 400 mA 12

(negative) terminals when the PC3000 is used with one

keypad. For each additional keypad the auxiliary supply

rating must be reduced by 60 mA. The auxiliary supply is

fused with the keypad supply at 1 amp. Auxiliary fuse failure

transmission can be sent (see [Q][8] sections [09] and

[10]).

Switched Auxiliary Power Terminals

“SW AUX” and “GND”

The switched auxiliary supply can be switched off

momentarily from the keypad (see “Keypad Commands

[Q][4]”). The “SW AUX” terminal is positive and the “GND”

terminal negative. The 400 mA auxiliary supply rating must

be reduced by any current taken from the switched auxiliary

supply. The switched supply shares the same fuse as the

auxiliary supply.

Bell/Siren Terminals “BELL [+]” and “BELL [-]”

These terminals are for powering bells or other devices

requiring a steady output voltage on alarm. The bell output

is fused for 5 amps. When connecting sirens (speakers with

siren driver already built-in), be sure to observe the correct

polarity. Connect the positive lead to the “BELL [+]” terminal

and the negative lead to the “BELL [-]” terminal.

If no siren or bell is used, connect a 1000 ohm resistor

between “BELL [+]” to “BELL [-]”. The bell/siren alarm

output is pulsed (1 second on 1 second off) when an alarm

is created by the [F] keypad zone, by the FIRE zone, or

when the Bell Pulse option is enabled in section [19] light 1.

Keypad Terminals “RED”, “BLK”, “YEL” and “GRN”

Connect the four coloured wires from the keypads to these

terminals. When connecting more than one keypad, connect

in parallel across the keypad terminals at the control panel

(i.e. all reds wires together, all blacks together, all yellows

together and all greens together). The keypad red and black

power supply terminals are fused through the auxiliary fuse.

Programmable Output Terminal “PGM OUT”

The operation of the Programmable Output depends upon

which option is selected in the programming table. See the

“Programming Guide” section [28] for a list of options for the

“PGM OUT” output. The “PGM OUT” is a 50 mA maximum

Auxiliary Input Terminal “AUX IN” (also KEY ARMING)

The “AUX IN” input terminal is a normally open 24 hour

zone. It can be programmed from the keypad to be silent or

audible. There is no display on the keypad for the “AUX IN”

input. An alarm on this input is created by applying a

positive voltage or by closing a contact between the “AUX

IN” terminal and the positive auxiliary supply. See

“Programming Guide [Q] [8]” sections [09] and [10] for

programming the alarm and restoral codes.

The “AUX IN” terminal can also be used as a momentary

key arming/disarming input. See “Programming Guide”

section [28] for a list of options for the “AUX IN” terminal.

”FIRE” Zone Input

The “FIRE” zone is a supervised (normally open alarm

initiating contact) end-of-line resistor circuit designed to

accept “Latching” four-wire smoke detectors.

(See “Fire Circuit Installation Diagram”.)

On alarm, (fire zone shorted) the bell output will pulse the

signal to indicate that the fire zone has been activated.

Alarm memory and transmission by the digital

communicator is delayed 30 seconds. If the alarm is

acknowledged, by pressing the [#] key before the 30

second delay has expired the signals will silence and the

transmission will be aborted. If the alarm is not

acknowledged and the 30 second delay expires, the fire

memory latches and the transmission cannot be aborted.

If after signal silence, the smoke detector is not restored to

normal, the signals will resound after 90 seconds, and 30

seconds after that, the communicator will transmit. If the

signals resound, they may again be silenced, [#] key, and

the communicator will be aborted if silence occurs within the

30 second delay period.

To restore the smoke detector to normal, clear all products

of combustion from the detector and reset the detector by

pressing [Q] and then holding down [4] for 2 or 3 seconds.

This action will remove power from the smoke detector and

if it is clear of smoke, the detector will return to normal. If the

detector is still in alarm, the signals will sound immediately

and the above sequence will repeat.

For an open on the FIRE zone, the keypad sounder will beep

twice every 10 seconds and the “Trouble” light will show on

the keypad. The communicator will transmit the trouble

condition if programmed for trouble transmission. The

audible “Trouble” signal may be silenced by pressing the [#]

key. To determine the nature of the trouble, press [Q][2].

(see the “Trouble Display” section.)

4

Zone Input Terminals “Z1” to “Z16”

Zone inputs “Z1” to “Z16” are supervised end of line (E.O.L.)

resistor circuits. Each input must be terminated with a 1K

ohm E.O.L. resistor. An alarm condition will be created if a

normally open contact is used to short across the E.O.L.

resistor. An alarm is also created if normally closed

contacts, wired in series with the E.O.L. resistor, are

opened. See the wiring diagram for normally open and

normally closed contact connection. The type of circuit or

zone definition (delay, instant, 24 hour etc.) is programmed

from the keypad using the [Q][8] Installer’s Programming

commands ("Programming Guide" sections [16] and [17]).

Telephone Terminals “TIP”, “RNG”, “T-1” and “R-1”

The wires from the RJ31-X telephone jack are connected to

these terminals in the following way.

TIP Green wire Incoming line from

RNG Red wire telephone company

T-1 Brown wire

Outgoing line to

R-1 Grey wire house telephone(s)

Note: For proper operation there must be no other

telephone equipment connected between the control

panel and the telephone company's facilities.

Battery Connections

Do not connect the battery or the transformer until the wiring

is complete. Connect the red battery lead to the positive

battery terminal and the black lead to the negative battery

terminal. If the connection is made in the reverse the battery

fuse will fail. The battery charging voltage is factory adjusted

and normally needs no adjustment.

Keypad Installation

Mount the keypads near the exit-entry doors. The

PC3000RK keypad has a red, a black, a green and a yellow

wire on the back. Connect these four wires to the four

keypad terminals on the control panel using four conductor

(quad) telephone wire. Up to three keypads may be

connected to one PC3000. Connect all green wires from the

keypads to the “GRN” terminal on the panel. Connect all

yellow wires from the keypads to the “YEL” terminal on the

panel. Connect all red wires from the keypads to the “RED”

terminal. Connect all black wires from the keypads to the

“BLK” terminal.

Power-up Procedure

If the keypads are located a distance from the panel, install

an extra keypad temporarily at the panel during power up

testing. An extra keypad with a short length of cable and

alligator clips attached is helpful for testing and

programming PC3000 systems.

Connect the transformer, wait approx. 5 seconds.

Enter a few keypad commands and open a zone to be sure

that the panel and keypad are responding to signals. If the

keypad does not respond and there are no indicators on,

check for AC voltage at the “AC” terminals. If there is 16

VAC present, check that the keypad wiring is correct and

check the keypad/auxiliary supply fuse. If the keypad/

auxiliary supply fuse is blown check for a short between the

keypad red and black wires before replacing the fuse.

If the keypad is responding normally, connect the battery.

The red battery lead attaches to the positive battery post

and the black battery lead attaches to the negative battery

post.

Note: The PC3000 will not start up is “AC” is off and

the battery is low. The panel will display trouble #1

under these conditions.

Testing The System

See Installer’s test - [Q] [6] [Master Code] [0] (page 9), or

do the following. Contact the monitoring station to request a

transmission test. Plug the telephone cord into the RJ31-X

jack. If a DTS-1 is being used to monitor communicator

transmissions, connect as described in “Bench Testing”

section and place the DTS-1 in the line mode by pressing

the red “LINE/LOCAL” button. Arm the panel, wait for the

exit delay to expire and trip a detector on an instant circuit.

Wait for the communication to complete. Disarm panel and

check with the monitoring station to confirm the

transmission. Perform additional transmissions required by

the monitoring station.

Check the “Trouble” light on the keypad. If it is on, press [Q]

then [2] to determine if there is a system trouble. The

“Trouble Display” section in “Keypad Commands” gives a

description of the different trouble conditions.

Instructing End-User

Fill out the system reference guide in the PC3000 Instruction

Manual. Check off sections in the manual which apply to the

user’s system and make additional notes if necessary.

Describe the system to an authorized user. Describe arming

and disarming procedures. Describe the basic keypad

functions. Assist the user in working through examples of

each type of command.

Provide user with the Instruction Manual and instruct them to

read the manual to become familiar with the system

operation.

Instruct the user to test the system on a regular basis as

described in the Instruction Manual. The Master Code

should be changed from the default setting and recorded in

the Instruction Manual.

5

GUIDELINES FOR SMOKE

DETECTOR LOCATION

Experience has shown that all hostile fires in family living

units generate smoke to a greater or lesser extent.

Experiments using typical fires in family living units indicate

that detectable quantities of smoke precede detectable

levels of heat in most cases. For these reasons, smoke

detectors should be installed outside of each sleeping area

and on each additional story of the family unit.

The following information is for general guidance only and it

is recommended that the smoke detector manufacturer's

literature be used for detailed installation instructions.

It is recommended that additional smoke detectors beyond

those required be installed for increased protection. The

added areas include: basement, bedrooms, dining rooms,

furnace room, utility room and hallways not protected by

the required detectors.

Bedroom Bedroom

Living

Room

Basement

Hall

Dining

Room

Bedroom Bedroom

Bathroom

Kitchen

A smoke detector should be located between

FIG. 1:

Bedroom

Living

Room

the sleeping area and the rest of the family unit.

Living

Room

Dining

Room

Family

Room

Bedroom

FIG. 2:

Bedroom

Bedroom

Kitchen

In the family living units with more than one

sleeping area, a smoke detector should be located to

protect each sleeping area.

FIG. 3:

A smoke detector should be located on each

story of the living unit.

4 in.

Ceiling

Acceptable here

Note:

Measurements shown are to the

closest edge of the detector.

FIG. 4:

Smoke Detector mounting - “Dead” Air Space.

(0.1m)

Never here

Top of detector

acceptable here

4 in.

(0.1m)

minimum

Side wall

12 in.

(0.3m)

maximum

The smoke from a fire generally rises to the ceiling,

spreads out across the ceiling surface and begins to

bank down from the ceiling. The corner where the

ceiling and wall meet is an air space into which the

smoke may have difficulty penetrating. In most fires,

this “dead” air space measures about 4 in. (0.1m)

along the ceiling from the corner and about 4 in.

(0.1m) down the wall as shown in Figure 4. Detectors

should not be placed in the dead air space.

6

KEYPAD FUNCTIONS

Introduction

The PC3000RK remote keypad provides complete

information and control of the PC3000 control panel. The

panel can be fully programmed from the keypad. The 16

zone lights and the fire alarm light provide alarm and status

indication for the alarm circuits. The 6 function lights guide

the user in operating the system. The built-in buzzer lets the

user hear correct key entries and other alert signals. The 12

digit keypad is used for code entry and other programming

functions. All keypad entries are made by pressing one key

at a time.

The keypad is normally resting in the arm-disarm mode. In

this condition the zone lights are indicating the opening and

closing of zones. The “Ready” light comes on when all zones

are closed. The system can be directed to perform other

functions such as zone bypassing, displaying trouble

conditions, displaying alarm memory and programming by

entering one of the various [Q] commands described below.

Pressing the [#] key or not making any key entry for 2

minutes always returns the keypad to the arm-disarm mode.

Master Code

A default Master Security Code “1234” is programmed into

the PC3000 at the factory. The Master Security Code is used

for arming and disarming the control panel, for

programming up to fifteen additional security codes using

the [Q][5] command and for entering other user functions

using the [Q][6] command. The Master Code can be

reprogrammed if the installer leaves section [19] light 2 off.

Because the PC3000 uses EEPROM memory the codes and

other data are retained even after complete AC and battery

failure.

Installer’s Programming Code

A default Installer’s Programming Code “3000” is

programmed into the PC3000. This code is used with the

[Q][8] command by the installer to gain access to the

system in order to enter panel or communicator program

information. The Installer’s Programming Code may be

changed by the installer.

Arming

Check to see if the “Trouble” or “Bypass” light is on before

arming the PC3000. Close all protected doors and windows

and stop movement in areas covered by motion detectors.

Check to see that the “Ready” light is on (all zones are

closed). The system cannot be armed unless the “Ready”

light is on. Enter a [4 Digit Security Code]. As each digit is

entered the keypad buzzer will beep. If the security code

was entered incorrectly, the sounder will beep steadily for 2

seconds. If the code was entered correctly but the “Ready”

light was not on, the keypad will beep quickly followed by a

steady tone. When the correct code is entered, the “Armed”

light will come on and the keypad buzzer will beep quickly.

Exit the premises through the designated exit-entry door. At

the end of the allowed exit time all lights on the keypad will

go out except the “Armed” light. See the “Installer’s

Programming [Q][8] Command” section for instructions on

how to change the exit time. Also see, “Quick Arm” and “At

Home Arming”.

Disarming

Enter the premises through the designated exit-entry door.

The keypad buzzer will be on. Go to the keypad and enter

the [4 digit security code]. If an error is made in entering the

code, press the [#] key and enter the code again. The

“Armed” light will go out and the keypad sounder will stop.

The correct security code must be entered before the

allowed entry time expires. To change the entry time see

“Installer’s Programming Command”, [Q][8]. If an alarm

occurred while the panel was armed, the “Memory” light and

the “Zone” light which caused the alarm will start to flash

and stay flashing for 2 minutes when the panel is disarmed.

Pressing the [#] key returns the panel to the normal armdisarm mode.

Auto-bypass/Home-Away Arming

If a correct security code is entered, and you do not exit the

premises, the system will, at the end of the Exit delay time,

arm with interior zones automatically bypassed if those

interior zones have been programmed as “Home-Away”

zones. The “Bypass” light will come on immediately following

the arming code being entered until a delay zone is tripped

or [Q] [1] is entered to reactivate bypassed home-away

zones. (See programming sections [16] and [14], zone

definitions for programming zones as “Home-Away”.)

This is a convenience feature for the user who wishes to

remain at home with the system armed. The user does not

have to manually bypass the home-away zones.

To reactivate the home-away zones that have been

automatically bypassed, press [Q] [1]. The “Bypass” light

will go out. This command is a quick method of fully arming

the system before going to bed.

Zone Bypassing

[Q]+[1]

A bypassed zone will not cause an alarm. If a zone is

bypassed the panel may be armed (“Ready” light will be on)

even if the zone is open. Use zone bypassing when access

is needed to part of the protected area. Also, damaged

wiring or contacts on a zone may be temporarily bypassed

until repairs can be made so that the panel can be armed.

To bypass zones, enter [Q] [1] and the zone number(s) to

be bypassed. Press [#] to return to “Ready” (arm-disarm

mode). When bypassing zones, two digits must be entered

for the zone number(s) to be bypassed (e.g. [Q] [1]

[01]....[16]). To remove all bypasses, enter [Q] [1] [00] [#].

The “Zone” lights which are on, while the “Bypass” light is

flashing, indicate the bypassed zones. Remember that if no

keypad entry is made for more than 2 minutes the keypad

will return to the arm-disarm mode. Then, in order to bypass

a zone the complete command must be re-entered. Once

7

the bypass command is entered, pressing [99] recalls the

last zone or group of zones which was bypassed. If the

same group of zones is bypassed each time, this bypass

recall feature can be used instead of having to bypass

zones individually.

When the PC3000 is programmed, the ability to bypass

certain zones may be eliminated. In this case, the “Zone”

lights for those zones will not come on in response to the

bypass command. See the “Zone Bypass Mask” instruction

in the [Q][8] Installer’s programming section. If the “Bypass”

light is on when arming the panel, the [Q][1] command

should be used to see which zones are bypassed so that

zones are not unintentionally bypassed. Zone bypasses are

automatically cancelled when the panel is disarmed.

If light 8 in section [19] is on then a code must be entered

with [Q]+[1] to bypass zones. Only the zones assigned to

the same side of the system as the user code can be

bypassed. The ability to bypass using certain access codes

can be eliminated. See the “Access Bypass Mask”

instruction in the [Q] [8] Installer’s Programming section.

Note: At no time can any armed zone be bypassed.

Trouble Display

[Q]+[2]

The PC3000 continuously monitors a number of possible

trouble conditions. If one of these conditions occurs, the

keypad “Trouble” indicator will light and the audible

indication will sound (two short beeps every 10 seconds).

When the [#] key is pressed the audible indication will stop

but the “Trouble” indicator light will remain on until the

trouble is cleared. Trouble conditions can also be

transmitted to the monitoring station (see “Programming

Guide” sections [09] and [10] for alarm and restoral trouble

codes). Press the [Q] then [2] keys to display the type of

trouble. The “Zone” lights indicate the type of trouble

condition.

1 Low stand-by battery

2 AC power failure

3 Day zone trouble

4 Telephone line trouble

5 Unsuccessful communication attempt with monitoring

station

6 Bell circuit failure

7 Smoke detector zone trouble

8 Loss of time on internal clock

Press [#] to return to “Ready”.

1 Low Battery...A battery trouble will be displayed and can

be reported if the battery is weak, disconnected or the

battery fuse is blown. Only one low battery alarm or restoral

transmission takes place per arming period. Low battery

trouble display is latching and can only be cleared by

battery restoration, arming and disarming panel then

accessing trouble indication.

2 AC Power Failure...There is no audible annunciation on

AC power failure. The system “Trouble” light will come on but

the audible indication will not sound until there is a low

battery condition. Transmission delay can be programmed

for 1 to 99 minutes. See “Programming Guide” section [22].

3 Day Zone Trouble...This trouble applies only to zones

which have been programmed as day zones.

(“Programming Guide” section 16 & 17). A day zone creates

a trouble signal when the panel is disarmed and an alarm

signal when the panel is armed.

4 Telephone Line Trouble...A telephone line trouble is

generated when the line voltage drops below 3 volts for

more than 30 seconds. It generates a keypad trouble when

the system is disarmed and rings a local alarm when the

panel is armed if section [19] light 5 is off.

5 Unsuccessful Communication...If the digital

communicator is unsuccessful communicating with the

monitoring station after eight attempts, a trouble is

generated.

If a later attempt to communicate is successful the trouble is

cleared.

6 Bell Circuit Failure...If the bell fuse is blown or the bell

circuit is open, a keypad trouble and a trouble transmission

are generated.

7 Smoke Detector Zone Trouble...If a FIRE zone is open

circuit, a keypad trouble and a trouble transmission are

generated. A trouble on the FIRE zone will unconditionally

initiate an audible indication on the keypad. This means that

even if any other previous trouble has been silenced, a FIRE

zone trouble will restart the keypad buzzer.

8 Loss of Internal Time...When the PC3000 is powered up

or reset, the internal time of day clock needs to be set to the

correct time. This trouble is cleared when the trouble display

is viewed and exited or when an attempt is made to reset

the internal time of day clock. See “[Q][6] User’s Function

Command” for resetting time of day clock.

If the [9] is pressed while in the trouble display mode the

most recent trouble will be displayed on the zone LEDs. This

trouble memory feature is useful as a diagnostic aid when

installing and servicing the PC3000.

Alarm Memory Display

[Q]+[3]

Press [Q] then [3] to enter the alarm memory mode. The

“Memory” light will flash and any alarm caused during the

last armed period will be displayed on the zone lights. In

addition to the last alarm memory there are 2 history levels.

After entering the memory mode (pressing [Q] then [3]),

pressing [9] will cause the keypad to display the two other

levels of alarm history. Each time [9] is pressed the keypad

will beep 1, 2 or 3 times to indicate which level of history is

being viewed. When the panel is armed, the last alarm

memory is cleared and the contents moves to the 1st history

level. The “Memory” light will only be on when there was an

alarm during the last armed period.

Press [#] to return to “Ready”.

Switched Auxiliary Supply Control

[Q]+[Hold Down 4]

To interrupt the switched auxiliary power supply press [Q]

then hold down [4] for the desired interrupt time. When the

[4] is released the system returns to the “Ready” mode and

the switched auxiliary supply is restored.

8

User’s Programming Commands

[Q]+[5]+[MASTER CODE]

The [Q][5] user’s programming command is used to

program additional access codes. Up to 16 user arm-disarm

codes may be programmed. The 1st code is the master

code (factory default [1234]). The 16th code is optionally a

“One Time Use” or maid code. The 16th code may be

changed from a “One Time Use” code to a regular code

using an installer’s programming command (section

[18]...1st system option code). Remember if no keypad entry

is made for more than 2 minutes the keypad will return to the

normal arm-disarm display and the complete command will

have to be re-entered to program a new access code.

Programming Additional Access Codes

1 Press the [Q] and [5] keys then enter the Master Security

Code (default [1234]) to enter the additional code

programming mode. The “Program” light and “Zone 1” light

will be on to show that the first code (the Master Code) is

already programmed with the factory default code [1234].

The Master Code may be changed but do not try to erase

the Master Code. The installer can disable user changing of

the Master Code by turning on light 2 in section [19].

2 15 additional codes may be programmed. The zone lights

are used to indicate which of these codes are already

programmed (zone light on steady) and the one which is

currently being programmed (zone light is flashing).

3 To program the second code, press [02] then enter a 4

digit code. Zone 2 light will flash and sounder will beep three

times and zone light 2 will come on steady after the 4 digit

code is entered.

4 To remove the second code, press [02] - the buzzer will

beep three times and zone light 2 will flash. Enter [Q] [Q] [Q]

[Q], the buzzer will beep three times and zone 2 light will go

out to show that the code has been removed.

5 Follow the instructions in 3 or 4 for programming or

removing any of the other additional codes.

6 Do not try to remove the Master Code (1st code). The

Master Code may be changed but it must not be removed.

When changing the Master Code be sure to enter a valid 4

digit number (use only number keys 0 to 9). Do not enter [#]

or [Q] as one of the digits. If the Master Code is forgotten

and the panel is left disarmed, program a new Master Code

using the [Q][8][Installer’s Code][25] command. If the

Master Code is forgotten and the panel is left armed, the

entire programming can be reset to factory default by using

the “Hardware Reset” method described on page 22.

7 To successfully program or remove additional codes, the

panel must be put into the code program mode by following

step 1 followed by steps 3 or 4. Note that if no key entry is

made for 2 minutes the panel will go back to the normal

arm/disarm mode, after which step 1 must be repeated to

get back into the code program mode.

8 To exit the code program mode press [#].

To review:

programming a new code;

enter [Q] [5] [Master Code] [01 to 16] [4 digit code]

eliminating an existing code;

enter [Q] [5] [Master Code] [02 to 16] [Q Q Q Q].

Note: The access code, numbers must be entered as

two digits. E.g. 02, 03,......, 15, 16.

User’s Functions Command

[Q]+[6]+[MASTER CODE]

This command is used to set the system clock time and to

set the Auto-arm time. It is also used to turn on and off a

number of system functions. The command is used by

entering [Q], [6], [Master Code] then a number from the

following list to select the item to be changed.

[0] Installer’s test

[1] System 24 hour clock (enter HH:MM)

[2] Auto-arming time (enter HH:MM)

[3] DO NOT USE

[4] Quick arm enable/disable

[5] Auto-arm enable/disable

[6] Door chime enable/disable

[7] DO NOT USE

[8] Bell test function

[9] User Initiated Callup

Note: The system clock is a 24 hour clock and times

must be entered as two digit numbers.

e.g.HH - 00, 01,.....10,11,.....22, 23

MM - 00, 01,.....35,36.....58,59

If a printer is attached

Day - 01.....31, Month - 01.....12, Year - XX (two digits)

e.g. HH: MM: DAY: MONTH: YEAR.

Items 1 & 2 are time setting functions. Enter 4 digits

representing the time in hours and minutes (HH:MM) based

on the 24 hour or military clock. Always enter a leading zero

where only one digit is required, 8:05 am would be entered

as 0805, 1:30 pm would be entered as 1330. Items [0], [4],

[5] and [6] turn on and off various features. When the item

key is pressed, the feature is turned on if the keypad beeps

quickly 3 times. The feature is turned off if the keypad

sounds one long beep. Pressing item [8] gives a 2 second

bell and keypad light test. Pressing [9] makes the panel call

the Downloading computer if enabled in section [47].

If a printer is attached to the panel (see section [28]) and is

enabled (see section [49]) the clock data entry will be

automatically extended to include the day (two digits

01.....31), the month (two digits 01.....12) and the year (two

digits...e.g. 91, 92, 93....etc.).

9

Installer’s Test

[Q]+[6]+[MASTER CODE]+[0]

This feature is designed to assist the installer in testing the

system. In this mode, the bell or siren will operate for two

seconds each time a device is tripped and the zone alarm

will be put into the first level memory. The feature is

automatically disabled when the panel is armed and

disarmed. Each time a zone is tripped or restored in this

mode, a signal, if programmed, will be transmitted to the

monitoring station. If this is not desired, it is possible to

disable the communicator during the test (see section [18]

“1st System Option Code”). A printer, if attached, will not

function if the communicator is disabled.

Notes: Do not use the PC16OUT module during the

installer’s test.

Do not use the installer’s test when the panel is

partially armed.

Quick Arm

[Q]+[6]+[MASTER CODE]+[4]

The “Quick Arm” feature is enabled by pressing the [4] key

while in the “User Functions Command” section. When

enabled (enabled 3 beeps....disabled one long beep) the

panel can be armed by entering [Q][0]. The closing code

transmitted for “Quick Arm” is the same as the code which

is programmed for the Master Code.

Auto-arm Enable

[Q]+[6]+[MASTER CODE]+[5]

Entering [Q] [6] [Master Code] [5] will enable/disable the

Auto-arming feature. When the feature is being Enabled, the

keypad buzzer will sound 3 beeps and when being Disabled

the buzzer will sound one long beep.

Setting the Clock

[Q]+[6]+[MASTER CODE]+[1]

Setting the “System 24 Hour Clock” (item [1]) tells the

system the correct time of day. If the system is without

battery and AC power it cannot continue to keep time.

Therefore when the panel is first powered up or when it has

been without AC power long enough to completely

discharge the stand-by battery, the “System 24 Hour Clock”

must be reset. If the time needs to be reset a “Trouble #8”

will be indicated on the keypad (see [Q][2] “System Trouble

Command”). If a printer is attached to the panel, setting the

clock must include the day, month and year. e.g. HH: MM:

DAY: MONTH: YEAR.

Auto-arm Time of Day

[Q]+[6]+[MASTER CODE]+[2]

The PC3000 can be programmed to arm at the same time

each day. Programming item [2] sets this time and the

feature must be enabled as shown in item [5] (see “Autoarm Enable” on this page).

At the selected auto-arm time the keypad beeper begins to

sound and the Bell/Siren will pulse once every 10 seconds to

alert anyone on the premises that the system is about to

arm. The Bell/Siren pulse can be silenced in section [51] by

turning light 1 on.

The keypad beeper will sound for one minute before autoarming unless one of the following two methods is used to

abort the auto-arm.

• Auto-arm abort: Any key can be pressed to abort the

auto-arm sequence and silence the keypad during the

one minute pre-alert (this is the default condition). If

section [51] light 2 is on, then a valid 4 digit access code

is required to abort the auto-arm sequence. The auto-arm

will be attempted at the same time the following day.

• Auto-arm abort with transmission: Any time an auto-

arm is aborted using one of the above methods, the

reporting code programmed in section [53] will be

transmitted to the central station.

Door Chime

[Q]+[6]+[MASTER CODE]+[6]

The “Door Chime” feature is enabled by pressing the [6] key

while in the “User’s Functions Command” section. When

enabled the keypad buzzer will beep quickly 5 times each

time any zone defined as a delay or instant circuit opens or

closes. The “Door Chime” feature does not operate on other

zone definitions. Zone bypass may be used to eliminate

“beeping” on doors where it is not wanted. This feature

operates only while the panel is disarmed.

System Test

[Q]+[6]+[MASTER CODE]+[8]

The system test feature sounds the bell or siren, lights the

keypad indicators and beeps the keypad buzzer for 2

seconds. If a code is programmed in section [54] it will be

transmitted at the same time.

User Callup

[Q]+[6]+[MASTER CODE]+[9]

This function is enabled in section [47]. When activated,

the panel will call the downloading computer. The

downloading computer must be waiting for the panel to

call before downloading can be performed.

Utility Output Command

[Q]+[7] OR [Q]+[7]+[ACCESS CODE]

The programmable output (PGM terminal) on the PC3000

can be made to activate by a command from the keypad.

This output can be used for operating other devices such

as; garage door opener, special lighting or door strikes.

The programmable output must be selected for keypad

utility using the [Q][8][Installer’s Code][28] command and

programming a [2], [3], [4] or [5].

Depending on the option chosen in the programming

section, the programmable output is activated by pressing

the [Q] then [7] keys followed by a Group A access code.

10

Group B access code, any access code, or no code at all.

When the proper keys are pressed the keypad sounder and

the programmable output are activated for 5 seconds.

Installer’s Programming Commands

[Q]+[8]+[INSTALLER’S CODE]

The PC3000 is completely programmed from the keypad by

using commands in the [Q] [8] section. The commands are

described in detail in the programming section of this

manual.

“At Home” Arming

[Q]+[9]+[ACCESS CODE]

Entering [Q], [9] before the arming code, arms the panel

without any entry delay on the delay zones and bypasses

zones that are defined as “Home-Away”. This command is

used for arming the system while at home. When the panel

is armed using [Q], [9], the “Armed” light will be on flashing

and the “Bypass” light will be on to indicate that the “HomeAway” zones are bypassed. Once the panel is armed in this

mode, using [Q], [1] will remove the bypass from those

zones defined as “Home-Away” if they have NOT been

manually bypassed. The [Q], [1] command used here, only

removes the bypass from zones that have been

Automatically bypassed with the [Q], [9] command.”

“Quick Arm” Command

[Q]+[0]

Entering [Q][0] is accepted as a valid arming code when the

“Quick Arm” feature is activated. Quick Arm may be used

as a convenience for regular users or when the sytem is to

be armed by individuals who are not authorized to disarm

the system. See instructions in the “[Q][6] User’s Functions

Command” section for activating the “Quick Arm” feature.

This feature should not be enabled if the One Time Use

Code is enabled. The One Time Use Code must be used for

arming before it is erased.

Keypad Zones

There are three zones which can be activated from the

keypad. The alarm and restoral codes for keypad zones are

programmed using the [Q][8] command.

Pressing the [F] key for 2 seconds activates a Fire alarm.

The fire alarm sounds the siren/bell in a pulsed mode and is

annunciated as a memory condition.

Pressing the [A] key for 2 seconds activates an Auxiliary

keypad zone. If a reporting attempt is made to an alarm

receiver and it is successful the PC3000 will acknowledge

the transmission with a short series of beeps from the

keypad.

Pressing the [P] key for 2 seconds activates the Police (or

Panic) alarm. The panic alarm can be programmed for

audible or silent operation (see section [18] in

“Programming Guide”).

There is no light annunciation from the keypad for the last

two keypad zones, however, the keypad buzzer beeps 3

times to confirm activation on any of the keypad zones. If

the keys are held down the buzzer continues to beep. The

panic alarm can be programmed for silent confirmation in

section [51] light 4.

See section [15] for alarm and restoral codes for all three

keypad zones.

Quick Exit

[Q]+[0] When Armed

Entering [Q] [0] when the system is fully armed will allow the

user 2 minutes to exit the premises through any delay zone

without altering the status of the system if the Quick Exit

feature is enabled. The Quick Exit feature can be enabled

by turning on light 6 in section [51]. After [Q] [0] is entered

into an armed system, one and only one delay zone may be

tripped. Any additional activity on any other active zone will

cause that zone to begin its alarm sequence.

[Q] [0] for Quick Exit on a partially armed system is not

supported.

11

PRINTER SETUP

The PC3000 with version 7.0 or higher software is capable

of sending data to a local printer.

The printer must be capable of serial communication (RS-

232).

The PC3000 should work with most serial printers, however

the printers on the following list are strongly recommended.

Compatible printers:

1. Brother M-1109

2. Brother M-1809

3. Star DP 40

4. Epson EP 40

5. C - Itoh model 8510 B

6. Citizen 120-D with serial card

7. Citizen 180-D with serial card

8. Rolland DG PR 1112 with serial card

9. Panasonic KX P1091 I with serial card

10.Mannesman Tally MT81 with serial card

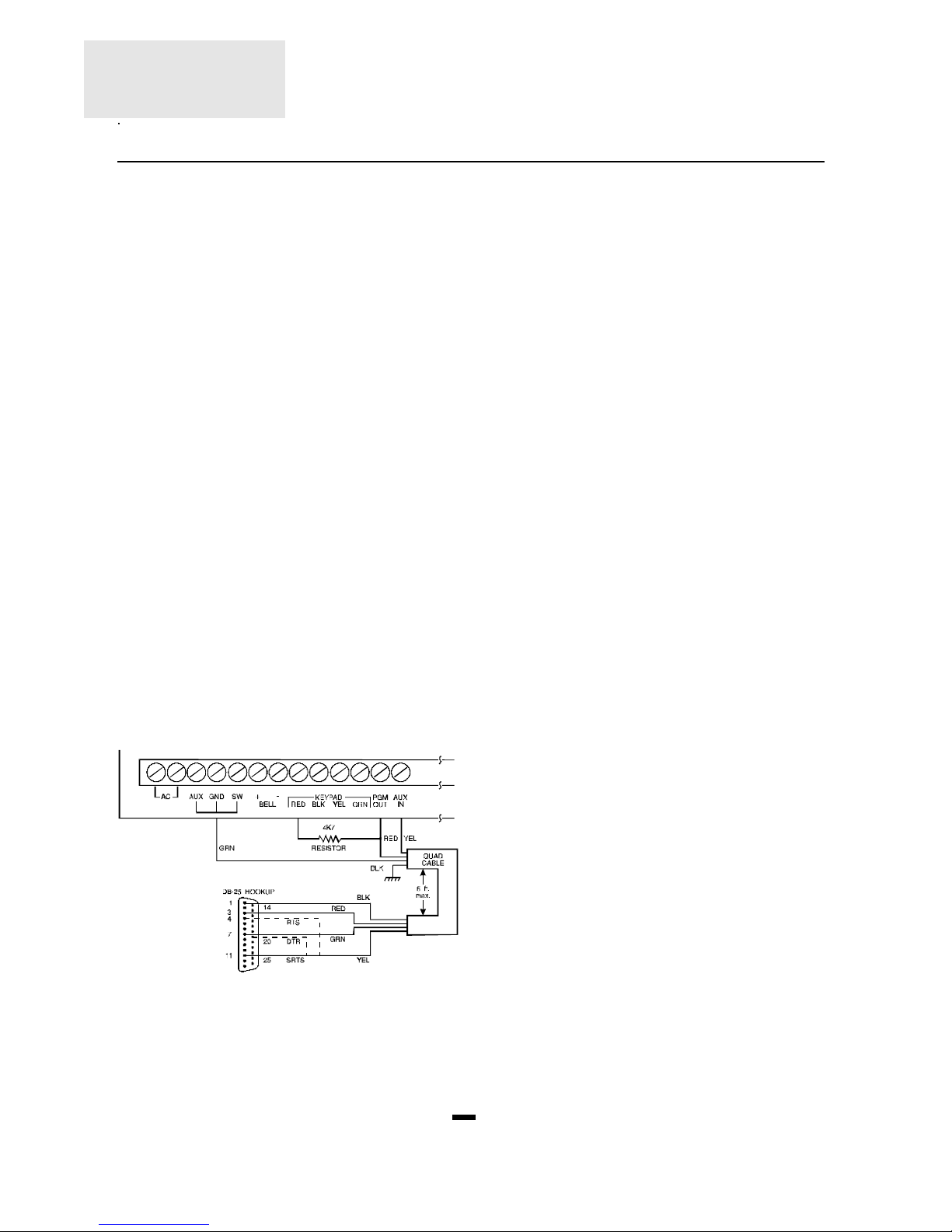

Configuring the Printer

1.Serial interface

2.Baud rate = 2400 (other baud rates may be used but

section [49] must be changed accordingly)

3.Parity = None

4.Character length = 8 bits

5.Auto linefeed = Off

6.American/Canadian character set

To hook up the printer, start by fully powering down the

panel

and the printer. Using A DB-25 connector, connect the

printer

to the panel as shown below. The maximum cable length

should be 6 feet.

Programming the Panel for Use with a

Printer

Section [49] in the panel must be programmed to enable the

printer function. See section [49], page 23. Power up the

panel and program it as described below.

Enter the Installer’s Programming section and edit the

following sections. ([Q]+[8]+[Installer’s Code])

Section Printer Only Monitored and Printer

[01] Do not program Program normally

[02] Program normally Program normally

[03] Do not program Program (see section

[49] zone light 6)

[04] Do not program Program normally

[05] to [15], [45], Program everything

Program everything

[50], [53] and [54] you wish printedyou

wish printed

[16] to [18] Program normally Program normally

[19] Light 4 must be off Light 4 must be off

[20] to [27] Program normally Program normally

[28] Program with “0C” Program with “0C”

[29] to [32] Program normally Program normally

[33] Program all 1's Program normally

[43] to [48] Program normally Program normally

[49] Printer setup Printer setup

[50] to [54] Program normally Program normally

Note: the time of day, day, month and year must be

programmed into the panel using the

[Q]+[6]+[Master Code]+[1] command as described on

page 10.

Plug in the printer, insert paper and turn it on line. Your

serial printer is now ready to use.

Note: If SRTS is not available turn on light 7 in section

[49] and attach yellow to 4 (RTS) or to 20 (DTR).

The following is a sample of a printout from the serial

printer:

07:33 04\01\91 STATION 2 ACC. # 5678

CLOSING ACCESS 1

12:57 04\01\91 STATION 1 ACC. # 1234

ALARM ZONE 2

ALARM ZONE 12

13:01 04\01\91 STATION 1 ACC. # 1234

RESTORE ZONE 2

RESTORE ZONE 12

18:01 04\01\91 STATION 2 ACC. # 5678

OPENING AFTER ALARM

OPENING ACCESS 1

Notes:

Station 0 is for a local only printer.

Station 1 is telephone number 1.

Station 2 is telephone number 2.

12

DOWNLOADING

The PC3000 with version 7.0 or higher software, supports

the DSC “downloading” package. See the downloading

manual for details on specific capabilities.

There are several sections pertaining to the downloading

feature which must be programmed.

Section [23]

The time of day that the periodic download or test

transmission will be done, if selected, is programmed in this

section.

Section [26] - Downloading Access Code

A four digit code must be programmed into this section to

allow access to the control panel by the downloading

computer.

Section [46] - Downloading Computer Telephone Number

If Callback is enabled, section [47] zone light [8], then this

section must be programmed with the telephone number of

the downloading computer.

Section [47] - Modem Configuration

Zone lights [1] to [4] are programmed to set the number of

rings the panel will look for before it answers a call from the

downloading computer.

Zone light [5] is programmed to enable or disable the

control panel for downloading. If downloading is disabled, all

other programming sections relating to downloading need

not be programmed.

Zone light [6] enables or disables user initiated callup to the

downloading computer.

Zone light [7] enables or disables the answering machine

defeat option (Answering Machine Over-ride).

Downloading and Answering Machine

The PC3000 software provides a means to handle

downloading when an answering machine is also connected

to the telephone line. In section [47], if zone light 7 is off, it is

assumed that there is no answering machine connected to

the telephone line and the panel will capture the line after

the set number of rings.

If zone light 7 is off and an answering machine is connected

and it is set to answer before the panel, the panel will be

unable to receive a call from a downloading computer. If the

panel is set to answer before the answering machine, the

answering machine will be unable to receive incoming

messages.

If zone light 7 is on and the panel is called for 1 or 2 rings

only and then called again within a set time of 60 or 120

seconds (set in section 51, light 7), the panel will then

answer the second call on the first ring (Answering Machine

Over-ride Timer).

Once the panel is connected to a downloading computer,

no [Q] functions can be performed. If the [Q] key is pressed

while the panel is connected to a downloading computer,

the keypad buzzer will sound one long tone to indicate an

error.

Zone light [8] is programmed to enable or disable

callback. If callback is disabled, the downloading

computer will have immediate access to the control panel.

The disabled mode is useful if there are multiple

downloading computers (at different telephone numbers).

If callback is enabled the downloading computer will call,

request access then hang up and wait for the control

panel to call. After the control panel has called back and

the downloading computer and the control panel accept

each other as valid, downloading operations are enabled.

Section [48] - Panel Identification Code

A four digit code must be programmed into this section to

allow the downloading computer to identify the panel it is

communicating with.

Section [49] - Printer Configuration

Zone light [8] is programmed to choose between periodic

download (light ON) or test transmission (light OFF).

Section [51] - 3rd System Option Code

Zone light [7] sets the Answering Machine Over-ride Timer

to either 60 or 120 seconds for defeating the answering

machine.

See “Downloading and Answering Machine”.

13

PROGRAMMING

GUIDE

Introduction

The PC3000 is programmed by entering instructions from

the panel keypad. The PC3000 memory is EEPROM and

can be reprogrammed thousands of times. The EEPROM

will not lose memory even on total AC and battery failure. All

essential program information required to define the

operation of the control panel and the communicator is

stored in a section of the EEPROM which can only be

accessed using the Installer’s Programming Code. If the

code is forgotten, the default program code can be reinserted by using the “Hardware Reset” described on page

22, unless Installer’s Lockout is enabled. See sections [90]

and [91].

To begin programming the PC3000, enter [Q], [8], [3000]

while the panel is disarmed. Installer’s Programming can

only be done while the panel is disarmed and not in alarm.

The factory default Installer’s Programming Code is [3000].

This default code can be changed using the Section [24]

command listed below (new Installer’s Code). Once the

basic Installer’s command is entered ([Q] [8] [3000]) the

“Program” light will start to flash. The “Program” light will

continue to flash while programming. Note that while

programming, if no key entry is made for more than 2

minutes, the keypad will return to the arm-disarm mode and

the complete installers command ([Q] [8] [3000]) must be

entered before programming can resume.

The next step is to enter a 2 digit section entry for any of the

commands described in the following pages. Note that while

the keypad is waiting for the section entry the “Armed” light

is on steady. As soon as the 2 digits are entered for the

section the keypad will beep 3 times, the “Armed” light will

go out and the “Ready” light will go on. The keypad is then

ready to accept data entry for the selected section.

A complete description of each programming section will be

given in the remaining pages of this section. A programming

work sheet summarizing all programming commands is