Page 1

PC1616/PC1832/PC1864 STANDARD INSTALLATION GUIDE

This Installation Guide provides the basic installation, wiring and programming information required to program the PowerSeries PC1616,

PC1832 and PC1864 control panels. This guide shall be used in conjunction with the PowerSeries PC1616/1832/1864 Reference Manual

which can be obtained from your local dealer or downloaded from the DSC web site at www.dsc.com.

NOTE: All necessary information required to meet UL Listing requirements is contained in this document.

Read the complete guide, then work through each step as indicated.

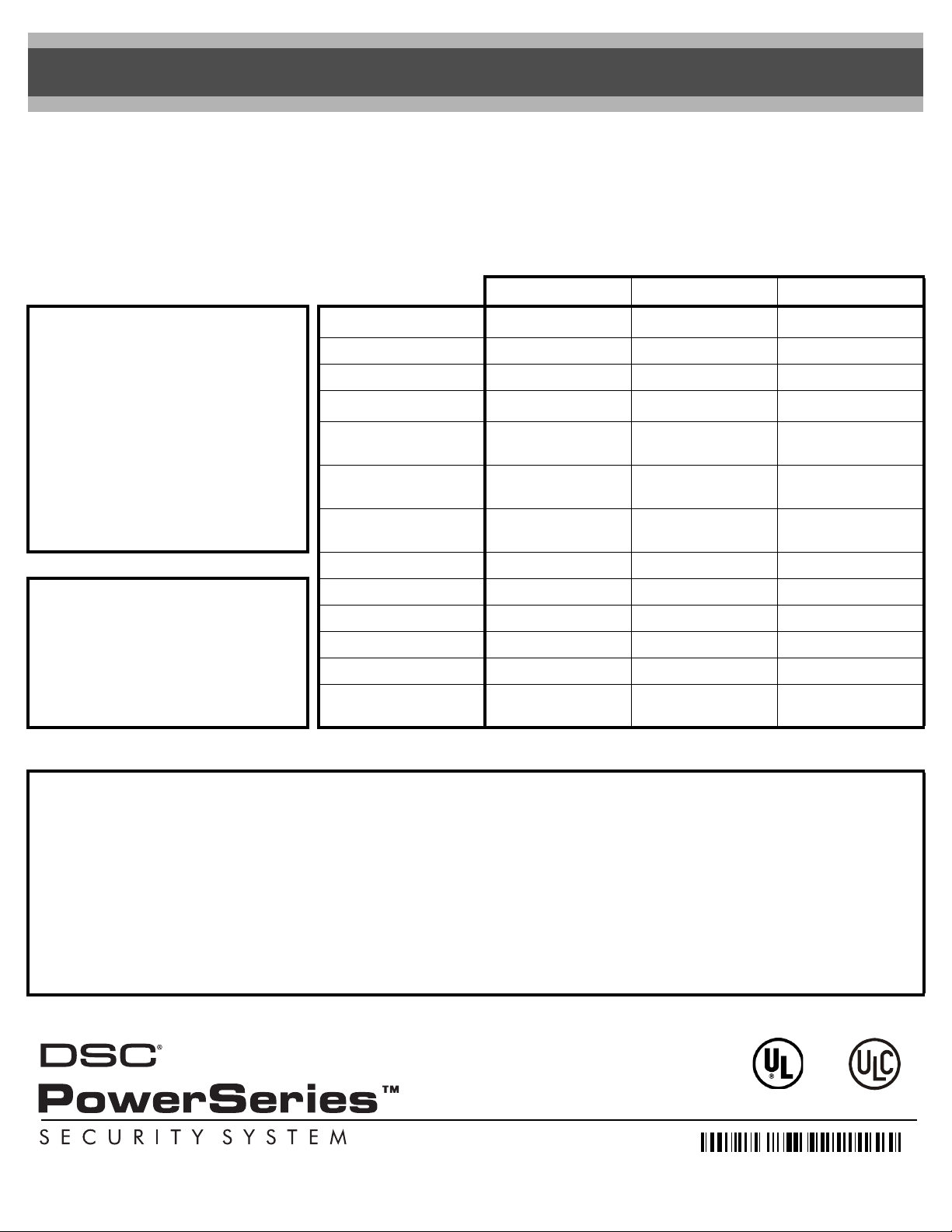

OUT Of THE BOX

Qty 1

Qty 1

Qty 1

Qty 1

Qty 2

Qty 1

Qty 4

Qty 16

Qty 1

Qty 1

Qty 1

Qty 1

Cabinet

PC Module

Installation guide

User manual

Cabinet Label

Cabinet Door Plug

Standoffs

5.6KΩ Resistors

2.2KΩ Resistors

1.0KΩ Resistors

10Ω Resistors

Grounding Kit

SPECIFICATIONS

Temp Range ....... 0°C-49°C (32°F-120°F)

Humidity (Max)...........................93%R.H.

Power Supply........ 16.5VAC/40VA @60Hz

Current Draw (Panel)......... 110mA (nom.)

Aux+ Output............11.1-12.6V

Bell Output..............11.1-12.6VDC/700mA

DC/700mA

FEATURES

On-board Zones 6 8 8

Hardwired Zones 16 (1xPC5108) 32(3xPC5108) 64 (7xPC5108)

Wireless Zones 16 32 32

Keypad Zone Support

On-board PGM Outputs PGM 1 - 50mA

PGM Expansion 8x50mA (PC5208)

Keypads 8 8 8

Par titions 2 4 8

User Codes 32 + Master Codes 32 + Master Codes 32 + Master Codes

Event Buffer 500 Events 500 Events 500 Events

Transformer Required 16.5V

Battery Required 4Ah / 7Ah/14AHr 4Ah / 7Ah/14AHr 4Ah / 7Ah/14AHr

Bell Output 12V/700 mA (cont) 12V/700 mA (cont) 12V/700 mA (cont)

PC1616 PC1832 PC1864

PGM 1 - 50mA

PGM 2 - 300mA

4x500 mA (PC5204)

AC/40VA 16.5VAC/40VA 16.5VAC/40VA

PGM 2 - 300mA

8x50mA (PC5208)

4x500 mA (PC5204)

PGM 1, 3, 4 - 50mA

PGM 2 - 300mA

8x50mA (PC5208)

4x500 mA (PC5204)

COMPATIBLE DEVICES

Keypads (

PK5500 Keypad...........................................................125mA (max.)

PK5501 Keypad...........................................................125mA (max.)

PK5508 LED Keypad................................................... 125mA (max.)

PK5516 LED Keypad................................................... 125mA (max.)

PC5532Z LED Keypad ................................................125mA (max.)

LCD5511 Fixed Message LCD Keypad........................ 85mA (max.)

LED5511Z 8-zone LED Keypad .................................100mA (max.)

Backward compatible with all PowerSeries keypads) Modules

Cabinets

PC5003C ..................................... 222x298x78mm (11.3x11.7x3.0in)

PC500C ......................................... 213x235x78mm (8.4x9.25x3.0in)

Refer to the Reference Manual for alternate control cabinets

Classified in Accordance with ANSI/SIA CP-01-2000 (SIA-FAR)

T-Link TL-250/TL300 .......................................................275/350mA

PC5100 2-wire Interface ............ 40mA plus devices to 170mA max.

PC5132-433 Wireless Receiver .............................................125mA

RF5108-433 Wireless Receiver .............................................125mA

PC5108 Zone Expander ..........................................................30mA

PC5204 Power Supply with 4 Programmable Outputs ............30mA

PC5208 Low Current Programmable Output Module ..............50mA

PC5400 Printer/DVAC Module .................................................65mA

PC5401 Bi-Directional RS232 Module (Not UL Listed) ............65mA

Escort5580 Telephone Interface Module ...............................130mA

Refer to the Reference Manual for additional devices.

29007109R003

Page 2

Hardware Installation

Begin the installation by mounting the cabinet in a dry protected area with access to unswitched AC power.

Install Hardware in the sequence indicated below. Do NOT apply power until installation is complete.

NOTE: All wiring entry points are designated by arrows. All circuits are classified UL power limited except for the battery leads.

Minimum 1/4” (6.4mm) separation must be maintained at all points between power limited and non-power limited wiring and

connections.

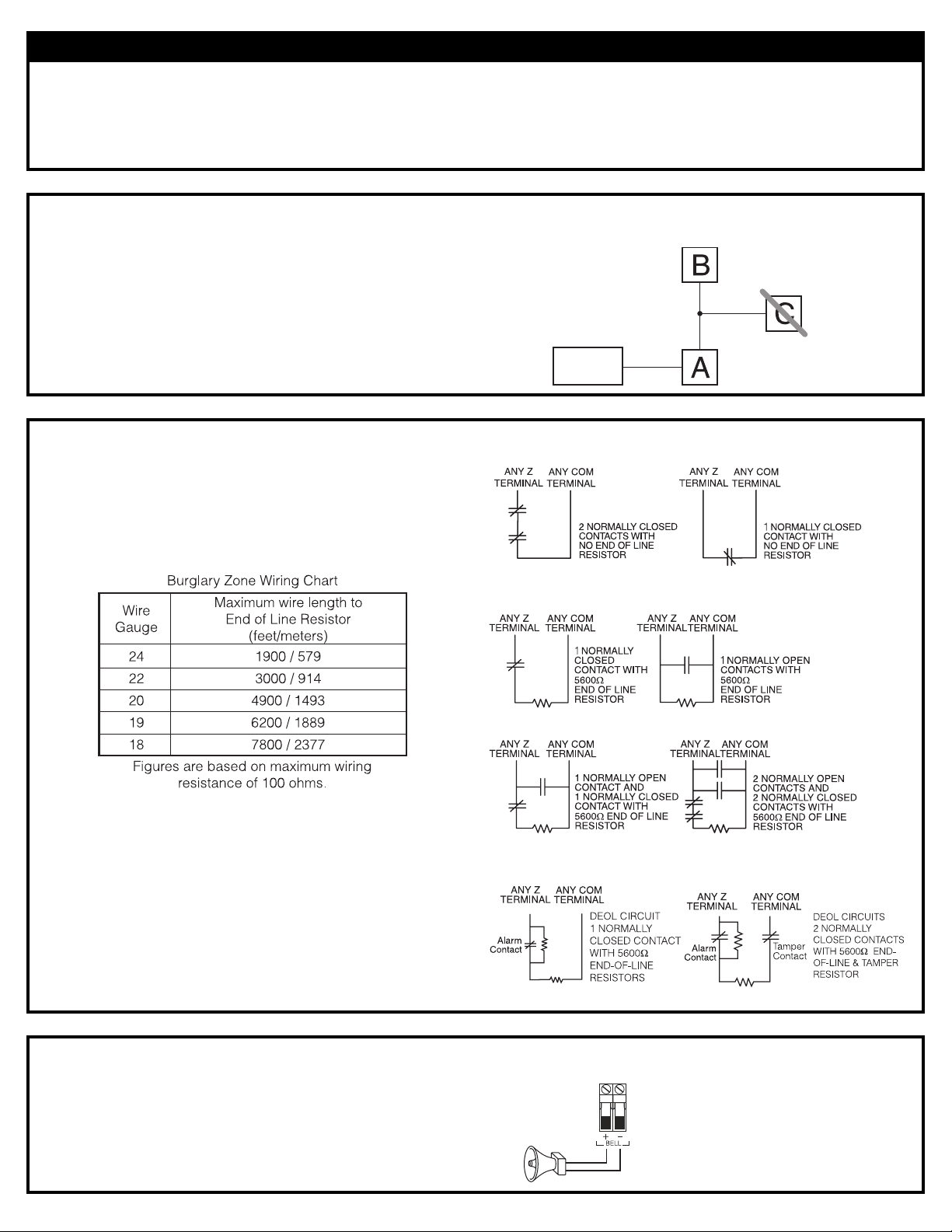

1. Keybus Wiring

The 4-wire KEYBUS (red, black, yellow and green) is the communication connection between the control panel and all modules. The 4 KEYBUS terminals of all modules must be connected to the 4 KEYBUS terminals of the main control panel.

The following rules must be followed when wiring the Keybus:

• Minimum 22 AWG wire, maximum 18 AWG (2-wire twisted preferred

•Do NOT use shielded wire

• Modules can be home run, connected in series or can be Ttapped provided that the maximum wire distance from the control

panel to any module does not exceed 1,000 feet (305m)

• No more than 3,000 feet (915m) of wire can be used in total

2. Zone Wiring

Zones can be wired for Normally Open, Normally Closed Contacts

with Single-end-of-line (SEOL) resistors or Double End-of-Line

(DEOL) resistors. Observe the following guidelines

• For UL Listed Installations use SEOL or DEOL only.

• Minimum 22 AWG wire, maximum 18 AWG

•Do NOT use shielded wire

• Wire run resistance shall not exceed 100

below.

Ω. Refer to the chart

150’ (46m)

500’ (152m)

CONTROL

PANEL

150’ (46m)

500’ (152m)

Normally Closed Loops - Do NOT use for UL Installations

Single End-of-Line Resistor Wiring

• Section [001-004] Selects Zone Definition

• Section [013] Opt [1] Selects Normally Closed or EOL resistors

• Section [013] Opt [2] Selects Single EOL or Double EOL resistors.

Zone Status

Loop Resistance

- 0Ω (shorted wire/loop)

- 5600Ω (contact closed)

- infinite (broken wire, open)

- 11,200Ω (contact open)

Loop Status

Fault

Secure

Ta m pe r

Violated

3. Bell Wiring

These terminals supply 700mA of current at 12VDC for commercial

installations and 11.1-12.6 V

SD-15 WULF). To comply with NFPA 72 Temporal Three Pattern

requirements:

Program Section [013] Opt [8] ON.

The Bell output is supervised and power limited. If unused, connect a

1000Ω resistor across Bell+ and Bell- to prevent the panel from displaying a trouble. See [][2].

DC for residential installations (e.g.DSC

Double End-of-Line Resistor Wiring

BELL/SIREN

700mA (max.)

OBSERVE

POLARITY

NOTE: Bell output is current limited by 2A PTC

NOTE: Steady, Pulsed and Temporal Three Pattern alarms are

supported.

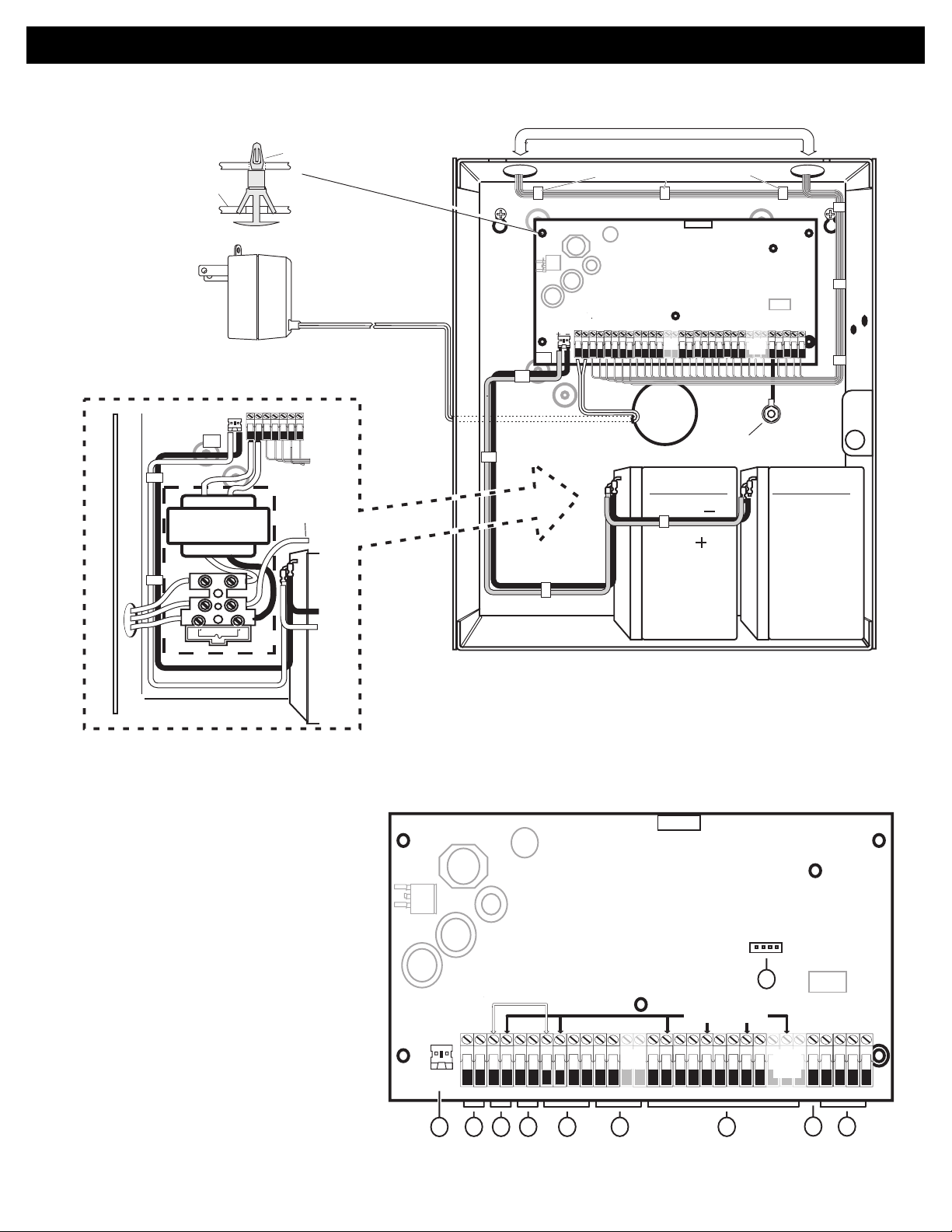

Page 3

1. Insert Stand off into cabinet

220

220

mounting hole in the

desired location. Snap-inplace.

2. Position circuit board

mounting holes over

standoffs. Press firmly

on board to snap-in-place.

230 V /50 Hz InternationalAC

PC Board

Cabinet

CON1

BAT+BAT-

16.5V /40VA

AC

Hardware Installation (Cont.)

North America Only

POWER LIMITED

Stand Off

Cable Tie (not supplied) recommended

Primary:120VAC/60Hz.

Secondary: 16.5VDC 40VA

DSCPTD 1640U

Class II Transformer

NOTE: Do not connect

transformer to receptacle

controlled by a switch

AC AC

PC1616/1832/1864

220

High Voltage. Disconnect AC Power

and telephone lines before servicing

CON1

BAT+BAT-

AUX+ BELL+

AC AC RED BLKYEL GRN Z1 COM Z2 Z3 COM Z4 Z5 COM Z6 Z7 COM Z8

AUX- BELL-

UA503

WAR NIN G:

PC1864

Only

PGM1 PGM3

PGM2 PGM4

PC1864

PC1832

See Section 9

for ground wiring details

12V / 7 AHr 12V / 7 AHr

To EGND

Terminal

BLACK

RED

DSC

Only

TB-2

RING R-1

EGND

TIP T-1

FUSE

IMPORTANT:

a)This equipment, Alarm Controller PC1616/1832/1864 shall

be installed and used within an environment that provides the

pollution degree max 2 and overvoltages category II

NON-HAZARDOUS LOCATIONS, indoor only. The equipment is

FIXED and PERMANENTLY connected and is designed to be

installed by service persons only; [service person is defined as a

person having the appropriate technical training and experience

necessary to be aware of hazards to which that person may be

exposed in performing a task and of measures to minimize the risks

to that person or other persons.]

b)The connection to the mains supply must be made as per the local

authorities rules and regulations.

An appropriate disconnect device must be provided as part of the

building installation. Where it is not possible to rely on identification of

the neutral in the AC Mains supply the disconnecting device must

disconnect both poles simultaneously (line and neutral). The device

shall disconnect the supply during servicing.

c)The equipment enclosure must be secured to the building structure

before operation.

e)Internal wiring must be routed in a manner that prevents:

- Excessive strain on wire and on terminal connections;

- Loosening of terminal; connections;

- Damage of conductor insulation

f) Disposal of the used batteries shall be made according to the waste

recovery and recycling regulations applicable to the intended market.

g) Before servicing, DISCONNECT the telephone connection.

High Voltage. Disconnect AC Power

and telephone lines before servicing

WARNING:

NON-POWER LIMITED

WARNING:

Incorrect connections may result in PTC failure or improper operation.

DSC Model BD7-12

or equivalent

Battery

StandbyTime:

24Hrs min.

Inspect wiring and ensure connections are correct before applying power.

Incorrect connection of batteries may result in battery rupture or Fire Hazard.

Do NOT allow metal objects to connect the Positive and Negative Terminals.

Ensure that batteries are connected with correct polarity (Red to (+), Black to (-)).

Failure to comply with this may result in battery rupture and/or Fire Hazard.

All circuits are classified for UL Installations as Power Limited/Class II Power Limited

except for battery leads which are not power limited.

Do NOT route any wiring over circuit boards. Maintain at least 1"(25.4mm) separation.

A minimum of 1/4" (6.4mm) separation must be maintained at all points between

power limited wiring and all other non-power limited wiring.

UA503

220

PC1616/1832/1864

AUX+ and Keybus (Red) are Internally Connected

Total current draw from Keypads, PGM Outputs and

Aux circuits must not exceed 550ma

PC1864

CON1

BAT+BAT-

AUX+ BELL+

AC AC RED BLK YEL GRN Z1 COM Z2 Z3 COM Z4 Z5 COM Z6 Z7 COM Z8

AUX- BELL-

98431

Only

PGM1 PGM3

PGM2 PGM4

5

REV XX

PC-LINK

Internally Connected

2

10

PC1864

PC1832

Only

See corresponding Section NumberText for wiring details.

EGND

7

RING R-1

TIP T-1

6

DSC

TB-2

Page 4

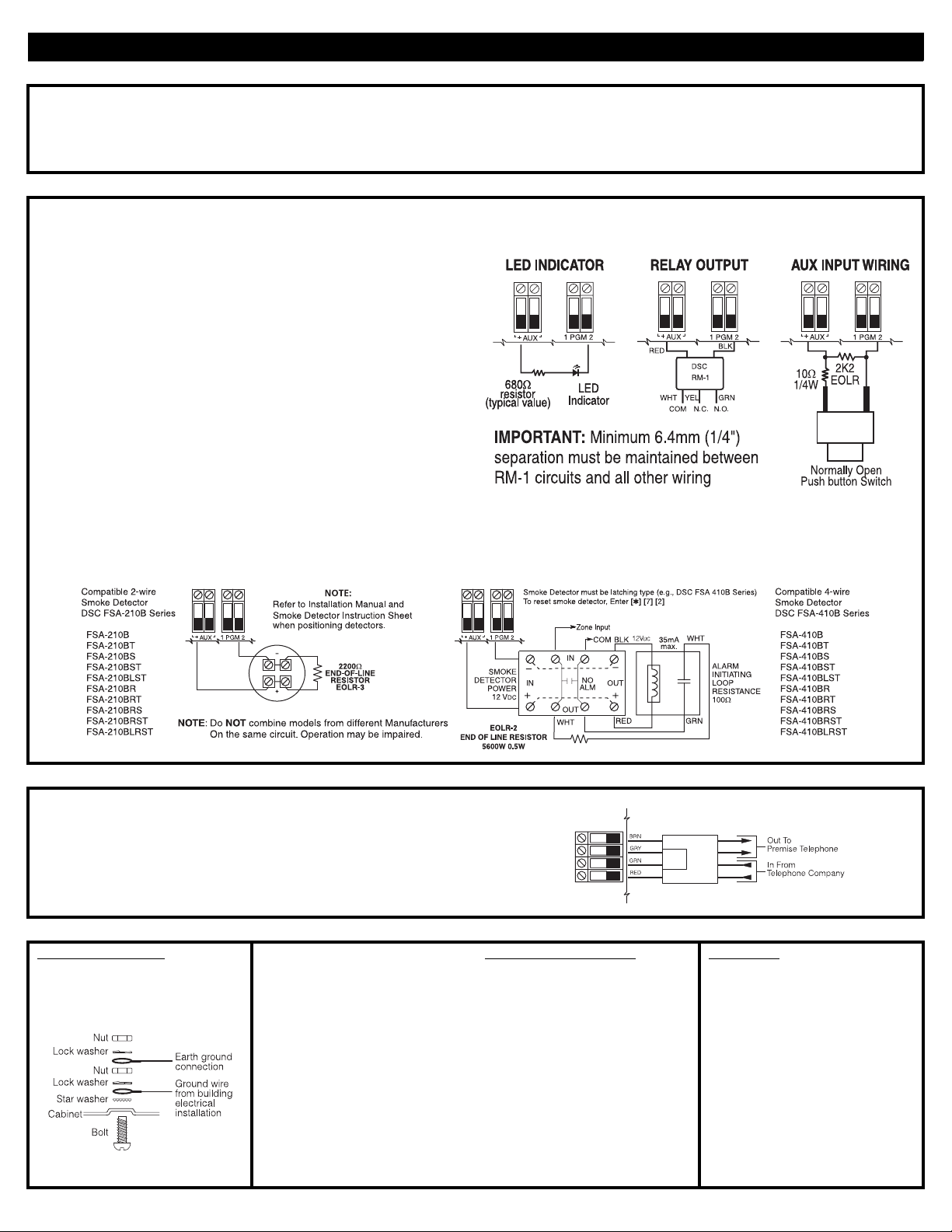

Hardware Installation (Cont.)

4. AUX Power Wiring

The control panel can provide a maximum of 700mA of current for modules, powered detectors, relays, LED’s etc.… If the total current

required exceeds 700mA an additional power supply is required (e.g.,PC5200, PC5204). See list below.

NOTE: Min/max operating voltages for devices, sensors and modules is 9.5V

Refer to the list of Compatible Devices on the first page for the current draw of individual devices

5. PGM Wiring

PGMs switch to ground when activated by control panel.

Connect the positive side of the device to be activated to the AUX+

Terminal. Connect the negative terminal to the PGM.

current output is as follows

• PGM 1, 3, 4 .................... 50mA

• PGM 2 .......................... 300mA

For currents levels greater than 300mA a relay is required.

PGM2 can also be used for 2-wire smoke detectors.

NOTE: Use SEOL resistors on Fire Zones ONLY.

2-wire Smoke Detectors Initiating Circuit

• Style B (Class B), Supervised, Power Limited

• Compatibility Identifier ........................................................ PC18-1

• DC Output Voltage..................................................... 9.8-13.8 VDC

• Detector Load ............................................................. 2 mA (MAX)

• Single-end-of-line (SEOL) Resistor ..................................... 2200Ω

• Loop Resistance ............................................................24Ω (MAX)

• Standby Impedance.................................................. 1020Ω (ΝΟΜ)

• Alarm Impedance ........................................................ 570Ω (MAX)

• Alarm Current ............................................................ 89 mA (MAX)

PGM 1, LED Output with current limiting resistor and Optional Relay

driver output

DC - 14VDC

Compatibility ID For FSA-210B Series is: FS200 4-wire Smoke Detectors

RM-1/RM-2 POWER LOOP

SUPERVISORY RELAY

6. Telephone Line Wiring

Wire the telephone connection terminals (TIP, Ring, T-1, R-1) to an

RJ-31x Connector as indicated.

T-1

For connection of multiple devices to the telephone line, wire in the

sequence indicated.

Telephone format is programmed in section [350].

R-1

RING

TIP

RJ-31X

Telephone Call Directions are programmed in section [351]-[376].

7 . G r o u n d 8 . B a t t e r y 9 . A C W i r i n g

Ground Installation A sealed, rechargeable, lead

acid battery or gel type battery is

Tighten nut to break paint and make

good connection to the cabinet

required to meet UL requirements for power standby times.

NOTE: UL Residential/Commercial Burglary installations require

4Hrs Power Standby time.

NOTE: UL/ULC Residential Fire

& Home Care installations

require 24 Hr power standby.

ULC Commercial Burglary

and Fire monitoring installations

require 24 Hr power standby.

Standby Battery Guide

Battery Charging Current: 400 mA

Batt Standby

Size 4Hr 24Hr

-------------------------------------------------

4Ahr 700mA --- 7Ahr 700mA 180mA

14Ahr 700mA 470mA

NOTE:

Replace batteries every 3-5 years.

Battery capacity will deteriorate with

age and number of charge/discharge

cycles

AC Wiring

UL Listed Installations

Primary: 120VAC/60Hz./0.33A

Secondary: 16.5VAC/40VA

DSCPTD 1640 Plug-in, Class 2

Transformer.

NOTE: Do not connect trans-

former to a receptacle controlled

by a switch. (UL Listed Installations

Only)

Page 5

TESTING & TROUBLESHOOTING

Testing:

• Power up system

• Program options as required (See Programming Section on reverse side)

Note: For advanced programming refer to the PC1616/1832/1864 Reference manual

• Violate, then restore zones

• Verify correct Reporting Codes are sent to the Central Station

Troubleshooting:

LCD5500 LCD Programmable-Message Keypad

•Press [✱][2] to view a trouble condition.

• The trouble light will flash and the LCD will display the first trouble condition present.

• Use the arrow keys to scroll through all trouble conditions present.

NOTE: When additional information is available for a specific trouble condition a [✱] will appear on the display.

Press the [✱] key to view the additional information

LED Keypads, LCD Fixed Message Keypads

•Press [✱][2] to view a trouble condition.

• The trouble light will flash.

• Refer to the Trouble Summary chart below to determine the trouble condition(s) present.

Trouble Summary:

Light [1]✱ Service Required - Press [1] for more information

[1] Low Battery

[2] Bell Circuit

[3] General System Trouble

[4] General system Tamper

[5] Module Supervision

[6] RF Jam Detected

[7] PC5204 Low Battery

[8] PC5204 AC Failure

Light [2] AC Trouble

Light [3] Telephone Line Trouble

Light [4] Failure to Communicate

Light [5]✱ Zone Fault -Press [5] for more information

Light [6]✱ Zone Tamper - Press [6] for more information

Light [7]✱ Wireless Device Low Battery - Press [7] for more information

Light [8] Loss of Time or Date

Page 6

Trou ble Cause Troubleshooting

Trouble [1] Service Required Press [1] to determine specific trouble

[1] Low Battery Main panel battery less than 11 VDC

NOTE: If battery is new allow 1 Hr. for battery to charge.

• Verify voltage measured across AC terminals is

NOTE: This trouble condition will not

clear until the battery voltage is

12.5VDC min., under load.

16-18 V

• Disconnect battery wire leads

• Verify battery charging voltage measured across bat-

AC. Replace transformer if required.

tery leads = 13.70 - 13.80 V

DC.

• Connect battery, remove AC power

• Verify measured voltage across battery terminals is

DC min.

12.5V

[2] Bell Circuit Bell+, Bell-...Open Circuit • Disconnect Bell-/Bell+ wire leads, measure resistance

of wire leads.

• Open circuit indicates break in wiring or defective

siren/bell

• Jumper Bell+, Bell- with 1K resistor (Brown, Black, Red)

• Verify trouble clears

[3] General System Trouble PC5204 Output#1 Open Circuit • If Output#1 is unused: Ensure that terminals O1, AUX

are jumpered with 1K resistor (Brown, Black, Red)

• If Output #1 is used: Disconnect wire leads from O1,

AUX terminals, measure the resistance of the wire leads

• Open circuit indicates a break in the wiring

PC5204 AUX • Verify voltage measured across AC input terminals is

16-18VAC.

• Disconnect all connections to PC5204 AUX terminal.

• Verify AUX voltage is 13.70 - 13.80 V

DC.

Printer connected to PC5400 offline Verify printer operation (out of paper, paper jam etc.)

T-Link Network Fault present

T-Link Receiver Trouble present

T-Link Interface Trouble present

[4] General System Tamper Tamper input on module(s) open

circuit

Wireless Receiver - excessive noise

detected

[5] Module Supervision Panel does not communicate with

module(s) on KEYBUS

Keypad assigned to incorrect slot.

[6] RF Jam Detected Wireless Receiver - excessive noise

detected.

Refer to the T-Link TL250/350 Installation Manual for details.

Short tamper terminal to COM terminal on unused modules

connected to KEYBUS (PC5100, PC5108, PC5200,

PC5204, PC5208, PC5320, PC5400, PC5700).

Check for external 433MHZ signal sources

To disable RF Jam: enable Option [7] in program section

[804] subsection [90].

Modules are immediately enrolled and supervised when

detected on the KEYBUS. If a module has been removed, or

if the slot assignment of a keypad has been changed, module supervision must be reset.

• View the event buffer (via DLS or LCD5500 keypad) to

identify the specific module(s) in trouble

• To reset module supervision:

• Enter Program Section [902].

• Press [#] (wait 1 minute for panel to scan KEYBUS).

• Enter Program Section [903] to identify modules

connected to KEYBUS.

Check for external 433MHZ signal sources

To disable RF Jam: enable Option [7] in program section

[804] subsection [90].

[7] PC5204 Low Battery PC5204 battery less than 11.5VDC

See [1] Low Battery above

NOTE: This trouble condition will not

clear until the battery voltage is

12.5V

DC min., under load.

[8] PC5204 AC Failure No AC at PC5204 AC inputs Verify voltage measured across AC terminals is 16-18VAC.

Replace transformer if required.

Page 7

Trou ble Cause Troubleshooting

Trouble [2] AC Failure

Trouble [3] Telephone Line Trouble

Trouble [4] Failure to Communicate

No AC at panel AC input

terminals

Phone Line Voltage at TIP, RING on

main panel less than 3V

Panel fails to communicate one or

more events to central station

DC

Verify voltage measured across AC terminals is 16-18VAC.

Replace transformer if required.

• Measure the voltage across TIP and RING on the panel:

• No phone off-hook – 50V

• Any phone off-hook – 5VDC (approx)

• Wire incoming line directly to TIP and RING.

• If trouble clears, check wiring or the RJ-31 phone

jack.

Connect a headset to TIP and RING of the control panel.

Monitor for the following conditions:

• Continuous dial tone

• Reverse TIP and RING

• Recorded operator message comes on

• Verify correct phone number is programmed

• Dial the number programmed using a regular

telephone to determine if a [9] must be dialed or if

800 service is blocked.

• Panel does not respond to handshakes.

• Verify the format programmed is supported by the

central station.

• Panel transmits data multiple times without

receiving a handshake

• Verify that the account number and reporting codes

are correctly programmed.

NOTE:

Contact ID and Pulse formats

• Program a HEX [A] to transmit a digit [0]

SIA format

• Program a digit [0] to transmit a digit [0]

DC (approx)

Trouble [5] Zone Fault Press [5] to determine specific zones with a fault trouble

Open circuit is present on one or

more fire zones on the main panel or

zone expander

An open circuit is present on PGM2

being used as a 2-wire smoke

detector input

• Ensure fire zones have a 5.6K resistor (Green, Blue,

Red) connected.

• Remove the wire leads from Z and COM terminals and

measure the resistance of the wire leads.

• An open circuit indicates a break in the wiring or

resistor not connected.

• Connect a 5.6K resistor (Green, Blue, Red) across the Z

and COM terminals. Verify the trouble condition clears.

• Ensure the correct 2.2K end-of-line resistor is connected (Red, Red, Red).

• Remove the wire leads from PGM2 and AUX+ terminals

and measure the resistance of the wire leads.

• An open circuit indicates a break in the wiring or no

resistor connected.

• Connect a 2.2K resistor (Red, Red, Red) across the

PGM2 and AUX+ terminals. Verify the trouble condition

clears.

Page 8

Trou ble Cause Troubleshooting

Trouble [5] Zone Fault (Cont.)

One or more wireless devices have

not checked in within the

programmed time

A short circuit is present on one or

more zones with double end-of-line

resistors enabled

• If the trouble occurs immediately, a conflict with a hard

wired zone exists:

• The zone being used is already assigned to a

PC5108 zone expander

• The zone being used is assigned as a keypad zone

• Perform a Module Placement Test – Program Section

[904] and verify the wireless device is in a good location.

• If bad test results occur, test the wireless device in

another location

• If the wireless device now tests good, the original

mounting location is bad

• If the wireless device continues to give bad test

results replace the wireless device

• Remove the wire leads from Z and COM terminals and

measure the resistance of the wire leads.

• A short circuit indicates a short in the wiring.

• Connect a 5.6K resistor (Green, Blue, Red) across the Z

and COM terminals.

• Verify the trouble condition clears.

Trouble [6] Zone Tamper Press [6] to determine specific zones with a tamper trouble

A tamper condition is present on one

or more wireless devices

An open circuit is present on one or

more zones with double end-of-line

resistors enabled

• Perform a Module Placement Test –Section [904]

• Violate, then restore the tamper:

• If no test result then replace wireless device

• Remove the wire leads from Z and COM terminals.

• Measure the resistance of the wire leads.

• Open circuit indicates a break in the wiring.

• Connect a 5.6K resistor (Green, Blue, Red) across the Z

and COM terminals.

• Verify the trouble condition clears.

Trouble [7] Wireless Device Low Battery Press [7] to toggle through specific devices with low battery trouble

1st press – Wireless Zones

2nd press – Handheld Keypads

3rd press – Wireless Keys

One or more wireless devices has a

low battery

NOTE: The event will not be logged

to the event buffer until the wireless

device low battery delay time expires

• Program Section [377] Opt 9

Replace battery

NOTE: Replacing batteries will cause a tamper. Replacing

cover will restore the tamper causing the associated reporting codes to be sent to the Central Station.

Trouble [8] Loss of Clock/Date

The main panel internal clock is not

set

To program the time and date:

•Enter [✱][6][Master Code] then Press [1]

or Press function key programmed with definition #26

• Enter the time and date (in military) using the following

format: HH:MM MM/DD/YY

Example.

For 6:00 pm, June 29, 2005

Enter: [18] [00] [06] [29] [05]

IMPORTANT!

Ensure you have the following information available before contacting Customer Support

- Control Panel Type and Version, (e.g., PC1864 v4.1)

NOTE: Version number can be accessed by entering [

✱][Installer Code][900] on any system keypad. This information is

also located on a sticker on the Printed Circuit Board.

- List of modules connected to Control Panel, (e.g., PC5400, PC5204 etc.)

Page 9

PROGRAMMING

How to Program:

DSC recommends filling in the Programming Worksheet with the required

programming information before programming the system. This will reduce the

time required to program and will help eliminate errors.

To enter Installer Programming press [*][8][5555].

The Program light will FLASH (or in the case of the programmable LCD keypad

the display will change to ‘Enter Section’).

An error tone indicates the installer code entered is not correct.

Press [#] to clear any key presses and try again

The Armed and Ready lights indicate programming status:

Armed Light ON Panel waiting for 3-digit section number

Ready Light ON Panel waiting for data to be entered

Ready Light FLASHING Panel waiting for HEX data to be entered

NOTE: You cannot enter installer programming while the system is armed or

in alarm.

Programming Toggle Options:

.

the required data. The Ready light will turn OFF and the Armed light

will turn ON.

At any time the [#] can be pressed to exit any program section. All

changes made up to that point will be saved.

HEX (or hexadecimal) digits are sometimes required. To enter a HEX

digit, press the [*] key to begin HEX programming. The Ready light will

FLASH. Refer to the chart below and press the number corresponding

to the HEX digit required. The Ready light will continue to FLASH.

Press [*] again to return to normal decimal programming. The Ready

light will turn ON.

HEX [A] [*] [1] [*]

HEX [B] [*] [2] [*]

HEX [C] [*] [3] [*]

HEX [D] [*] [4] [*]

HEX [E] [*] [5] [*]

HEX [F] [*] [6] [*]

How to Exit Installer Programming:

To exit installer programming, press the [#] key when the panel is

waiting for a 3-digit section number (the Armed light is ON).

Enter the 3-digit programming section number.

• The Armed light will turn OFF and

• The Ready light will turn ON.

• The keypad will display which toggle options are ON or OFF according to

the chart below:

Keypad Type

LED

Fixed-Message LCD

Programmable-Message LCD

• To toggle an option ON or OFF, press the corresponding number on the

keypad. The display will change accordingly.

• When all the toggle options are configured correctly, press the [#] key to

exit the program section.

• The Ready light will turn OFF and the Armed light will turn ON.

NOTE: If the panel is a local system, press [#] to skip this step.

NOTE: In addition to the standard digits 0-9, HEX digits can also be

programmed if required.

HEX [A]

HEX [B]

HEX [C]

HEX [D]

HEX [E]

Not Supported

Simulated [*] key

Simulated [#] key

Dial tone search

Two second pause

Option ON Option OFF

Zone Light ON

Indicator # ON

# Displayed

Zone Light OFF

Indicator # OFF

Dash [-] Displayed

Press [*][2][*]

Press [*][3][*]

Press [*][4][*]

Press [*][5][*]

Programming Decimal and Hexadecimal (HEX) Data:

• Enter the 3-digit programming section number.

• The Armed light will turn OFF and The Ready light will turn ON.

• Enter the data written in the boxes.

For sections that require multiple 2 or 3 digit numbers, the keypad will

double-beep after each 2 or 3 digit entry and move to the next item in

the list. After the last digit in the section is entered, the keypad will

beep rapidly 5 times and exit the program section. The Ready light will

turn OFF and the Armed light will turn ON.

For sections that do not require data for every box (such as phone

numbers) press the [#] key to exit the program section after entering all

Viewing Programming

LED and LCD5501Z Keypads

Any programming section can be viewed from an LED or LCD5501Z keypad. When a programming section is entered, the keypad will immediately

display the first digit of information programmed in that section.

The keypad displays the information using a binary format, according to

the following chart:

See Hex data

entry instructions

Press any of the Emergency keys (Fire, Auxiliary or Panic) to advance to

the next digit.

When all the digits in a section have been viewed, the panel will exit the

section: the Ready light will turn OFF, and the Armed light will turn ON,

waiting for the next 3-digit programming section number to be entered.

Press the [#] key to exit the section

LCD Keypad

When a programming section is entered, the keypad will immediately display all the information programmed in that section. Use the arrow keys (<

>) to scroll through the data being displayed. To exit the section, scroll

past the end of the data displayed, or press the [#] key.

DLS Programming

Hardware Setup - Local (PC-Link)

Connect a RS-232 to PC-Link Cable between the Computer with DLS

Software installed and the alarm panel to be programmed.

[401] First Downloading Option Code

The 1st toggle option in this section is used to enabled/disable Downloading.

Configure the options as required and press [#] to exit

Opt Default Description

2 I__I ON User can enable DLS Window

OFF User can NOT enable DLS Window

.

Page 10

[402] Downloading Computer Phone Number (32-digits)

IDII___II___II___II___II___II___II___II___II___II___II___II___II___II___II___I

I___II___II___II___II___II___II___II___II___II___II___II___II___II___II___II___I

[403] Downloading Access Code

Enter 4 or 6-digit code

This code identifies the downloading computer to the panel.

The downloading access code prevents unauthorized access to the panel.

This code must match the code programmed in the downloading file before the

panel will allow remote or local DLS connection. Enter a new downloading

access code to disable downloading.

Default

XXXX

XX I___II___II___II___II___ II___I

[404] Panel Identification Code

This code identifies the panel to the downloading computer.

See section [403]

Enter 6 decimal places

Default

XXXXXX

I___II___II___II__ _II___II___I

[499][Installer Code][499] Initiate PC-Link

Enter [499][Installer Code][499]

Special Installer Functions

Enter section# for the following features

[900]

[902]

[903]

[904]

[990] INSTALLER CODE [990]

[991] INSTALLER CODE [991]

[993] INSTALLER CODE [993]

[995] INSTALLER CODE [995]

[996] INSTALLER CODE [996]

[997] INSTALLER CODE [997]

[999] INSTALLER CODE [999]

Panel Version ([][8][Installer Code][900])

Module Supervision Reset ([][8][Installer Code][902])

Module Supervision Field ([][8][Installer Code][903])

Wireless Module Placement Test ([][8][Installer Code][904])

Enter section#, Installer Code section# for the following features

Installer Lockout Enable

Installer Lockout Disable

Restore Alt.Comm. Factory Defaults

Restore Escort 5580 Factory Defaults

Restore PC5132 Factory Defaults

Restore PC5400 Factory Defaults

Restore Panel Factory Defaults

[000] Keypad Programming

Note: This programming must be done at each keypad

[0]

Slot Address (0-8) for partition, 1-8 for slot

[1]

Function key Assignment (00-32)

[2]

Function key Assignment (00-32)

[3]

Function key Assignment (00-32)

[4]

Function key Assignment (00-32)

[5]

Function key Assignment (00-32)

Key 1Key 2Key 3Key 4Key

Slot Address

ICON

LED

Defaults

Full Message

Defaults

Keypad 1

Keypad 2

Keypad 3

Keypad 4

Keypad 5

Keypad 6

Keypad 7

Keypad 8

11 03 04 06 14 16

18 03 04 06 14 16

5

KEYPAD FUNCTION KEY DEFINITIONS

00 Null Key (Key not used)

01 Partition 1 Select

02 Partition 2 Select

03 Stay Arm

04 Away Arm

05 [][9] No entry arm

06 [][4] Chime On/Off

07 [][6][----][4]System Test

08 [][1] Bypass Mode

09 [][2] Trouble display

10 [][3] Alarm memory

11 [][5] User programming

12 [][6] User functions

13 Command output 1 [71]

14 Command output 1 [72] Sensor

Reset

15 General voice prompted help

16 [][0] Quick Exit

17 [][0] Activate Stay/Away

18 Identified voice prompted

help

19 Command output 3 [73]

20 Not used

21 Command output 4 [74]

22 Active camera monitor

selection

23 Bypass Recall

24 Bypass Group Recall

25 Not Used

26 Time Programming

27 Partition 3 Select

28 Partition 4 Select

29 Partition 5 Select

30 Partition 6 Select

31 Partition 7 Select

32 Partition 8 Select

[001]-[004] Zone Definitions

Enter the number corresponding to the zone definitions required.The keypad

will beep rapidly 3 times and move to the next step. If an invalid number is

entered the keypad will revert to the default setting (option [1]).

Press [#] to exit the section.

[001] Zone 1-16 Definitions

Def

01

I__II__I Zone 1

03

I__II__I Zone 2

03

I__II__I Zone 3

03

I__II__I Zone 4

04

I__II__I Zone 5

04

I__II__I Zone 6

04

I__II__I Zone 7

04

I__II__I Zone 8

[002] Zone 17-32 Definitions

Def

00

I__II__I Zone 17

00

I__II__I Zone 18

00

I__II__I Zone 19

00

I__II__I Zone 20

00

I__II__I Zone 21

00

I__II__I Zone 22

00

I__II__I Zone 23

00

I__II__I Zone 24

[003] Zone 33-48 Definitions

Def

00

I__II__I Zone 33

00

I__II__I Zone 34

00

I__II__I Zone 35

00

I__II__I Zone 36

00

I__II__I Zone 37

00

I__II__I Zone 38

00

I__II__I Zone 39

00

I__II__I Zone 40

[004] Zone 49-64 Definitions

Def

00

I__II__I Zone 49

00

I__II__I Zone 50

00

I__II__I Zone 51

00

I__II__I Zone 52

00

I__II__I Zone 53

00

I__II__I Zone 54

00

I__II__I Zone 55

00

I__II__I Zone 56

ALL Models

Def

00

I__II__I Zone 9

00

I__II__I Zone 10

00

I__II__I Zone 11

00

I__II__I Zone 12

00

I__II__I Zone 13

00

I__II__I Zone 14

00

I__II__I Zone 15

00

I__II__I Zone 16

PC1864 & PC1832

Def

00

I__II__I Zone 25

00

I__II__I Zone 26

00

I__II__I Zone 27

00

I__II__I Zone 28

00

I__II__I Zone 29

00

I__II__I Zone 30

00

I__II__I Zone 31

00

I__II__I Zone 32

PC1864

Only

Def

00

I__II__I Zone 41

00

I__II__I Zone 42

00

I__II__I Zone 43

00

I__II__I Zone 44

00

I__II__I Zone 45

00

I__II__I Zone 46

00

I__II__I Zone 47

00

I__II__I Zone 48

PC1864

Only

Def

00

I__II__I Zone 57

00

I__II__I Zone 58

00

I__II__I Zone 59

00

I__II__I Zone 60

00

I__II__I Zone 61

00

I__II__I Zone 62

00

I__II__I Zone 63

00

I__II__I Zone 64

00 Null Zone (not used)

01 Delay 1

02 Delay 2

03 Instant

04 Interior

05 Interior, Stay/Away

06 Delay, Stay/Away

07 Delayed 24-hr Fire

(Hard-wired)

08 Standard 24-hr Fire

(Hard-wired)

09 24-hr Supervisory

10 24-hr Supervisory Bu

11 24-hr Burglary

12 24-hr Holdup

13 24-hr Gas

14 24-hr Heat

15 24-hr Medical

16 24-hr Panic

17 24-hr Emergency

18 24-hr Sprinkler

19 24-hr Water

20 24-hr Freeze

21 24-hr Latching

Tamper

22 Momentary Keyswitch

arm

23 Maintained Key-

switch Arm

24 Future Use

25 Interior Delay

26 25-hr non-alarm

27 Delayed 24-hr Water

Flow

28 Instant 24-hr Water

Flow

29 Auto-verified Fire

30 Fire Supervisory

31 Day zone

32 24-hr Bell/Buzzer

33 Push to set

34 Final Door set

35 Instant Stay, Away

36 24-hr Non latching

Tamper

37 Night Zone

87 Delayed 24-hr Fire

(Wireless)

88 24-hr Fire (Wireless)

Page 11

[005] System Times

This section programs the entry and exit delays for the control panel.

After entering section [005] press [1] to select partition 1.

Enter the 3-digit delay time for Delay 1 type zones, Delay 2 type zones

followed by the exit delay time. Press [#] to exit the sub-menu and

return to regular programming.

NOTE: For SIA FAR Installations, the Exit Delay must be within the

range of 045-255 seconds (Default 60 seconds). If the Exit Delay is

silent (Section 14, Option 6 or Stay Function Key Arming) the exit

delay must be twice the programmed value but must not exceed 255

seconds (i.e., 090-255 seconds).

NOTE: For UL Installations, the Entry Delay plus the Communications

Delay must not exceed 60 seconds.

NOTE: Exit Time Restart shall be disabled when the panel is used in

combination with T-Link TL250/TL300.

[005]

[01] Partition 1 Entry/Exit Times

Def Enter 3 digits

030 I___II___II___I

*045 I___II___II___I

**120 I___II___II___I

*Entry Delay 2 Default is 030 for SIA CP-01 Installations

**Exit Delay 1 Default is 060 for SIA CP-01 Installations

Entry Delay 1

Entry Delay 2

Exit Delay 1

[[001]-[255]

Valid entries: [030] to [255]

Valid entries: [030] to [255]

Valid entries: [060] to [255]

[006] Installer Code

Enter a new 6-digit Installer Code

Default

555555

I___II___II___II___II___II___I

[007] Master Code

Enter a new 6-digit Master Code

123456

Default

I___II___II___II___II___II___I

[008] Maintenance Code

Enter a new 6-digit Maintenance Code

Default

AAAAAA

I___II___II___II___II___II___I

[009-010] PGM Programming

PGMs 3&4 apply to PC1864 only

[009]

Main Board PGM Output Programming

Def Enter 2 digits

I___II___I

19

I___II___I

10

I___II___I

01

I___II___I

01

01 Fire & Burglary Output

02 Not Used

03 Sensor Reset (72

04 2-Wire Smoke (PGM2 Only)

05 Armed Status)

06 Ready to Arm

07 Keypad buzzer follow mode

08 Courtesy Pulse

09 System Trouble output (with Trouble

Options)

10 System Event (with Event Options)

11 System Tamper (All Sources)

12 TLM and Alarm

13 Kiss-off Output

14 Ground Start Pulse

15 Remote Operation

16 Future Use

PGM 1

PGM 2

PGM 3

PGM 4

)

[[01]-[32]

Section [009]

Section [009]

Section [010] ...... PC1864 Only

Section [010] ...... PC1864 Only

17 Away Armed Status

18 Stay Armed Status

19 Command Output#1 (

20 Command Output#1 (

21 Command Output#1 (

22 Command Output#1 (

23 24-hr Silent Input

24 24-hr Audible Alarm

25 Delayed Fire & Burglary Output

26 Battery Test Output

27 Police Code Output

28 Holdup Output

29 Zone Follower Inverted Output

30Partition Status Alarm Memory

Output

31 Alternate Communications

32 Open After Alarm (Abort Code)

71)

72)

73)

74)

[013] – First System Option Code

The first two toggle options in this section are used to determine what

type of EOL resistors are being used, toggle option [1] to determine if

normally-closed or EOL resistors are being used and option [2] to

determine if single or double EOL resistors are being used. Configure

the options as required and press [#] to exit

Opt Default Description

1 I__I ON Normally Closed loops

OFF End-of-line Resistors

2 I__I ON Double End-of-Line Resistors

OFF Single End-of-Line Resistors

8 I__I ON Temporal Three Fire Signal

OFF Standard Pulsed Fire Signal.

.

[015] – Third System Option Code

This section is used to determine if the Panic keys on the keypads will

be audible or silent (toggle option [2]) and if phone line supervision is

enabled or disabled (toggle option [7]). Configure the options as

required and press [#] to exit.

Opt Default Description

2 I__I ON [P] Key Audible (Bell/Beeps) loops

OFF [P] Key Silent

7 I__I ON TLM Enabled

OFF TLM Disabled

[018] Cross Zone/Police Code

NOTE: The panel uses the cross zoning attribute for Burglary Verification. This feature requires two or more trips on a zone(s) specified as

‘cross zones’ within a specified time before starting an alarm sequence

(See Section[101] Option 3, page 33 of the Reference Manual).

Opt Default Description

6 I__I ON Cross Zoning Enabled

OFF Police Code is Enabled

[165] Maximum Dialing Attempts to each Phone Number

This section programs the number of Dialing Attempts. Enter a

3-digit. For UL Listed Installations 5-10 Dialing attempts are

required.

[165]

Maximum Dialing Attempts to each Phone

Def Enter 3 digits

005 I___II___II___I

Valid entries: [001] to [005]

[[001]-[005]

[301] First Telephone Number (32-digits)

Program the central station phone number or CAA for T-LINK.

In addition to the standard digits [0] - [9], Hex digits may also be

required (Refer to the “Programming Decimal and Hexadecimal (HEX)

Data” at the beginning of this section).

IDII___II___II___II___II___II___II___II___II___II___II___II___II___II___II___I

I___II___II___II___II___II___II___II___II___II___II___II___II___II___II___II___

[304] Call Waiting Cancel String (6 Digits)

Program Unused digits with Hex F

Default

DB70EF

[Hex] I___II___II___II___II___II___I

Page 12

[310]-[311] Partition Identifier Codes

Enter a 6 digit Maintenance Code

[310 System Acct. Code I___II___II___II___II___II___I

[311] Partition 1 Acct. Code I___II___II___II___I

[350] – Communicator Format Options

This section determines the communication format used for central

station reporting. From the chart listed below program the 2-digit number for the desired format for the first and second telephone number

Def Enter 2 digits

0404I___II___I

I___II___I

01 20BPS, 1400 Hz Handshake

02 20BPS, 2300 Hz Handshake

03 DTMF Contact ID

04 SIA FSK

05 Pager

06 Residential Dial

NOTE:

From Chart Below

3rd Phone Number follows the format of the

1st Phone Number

07 10BPS, 1400 Hz Handshake

08 10BPS, 2300 Hz Handshake

09 Private Line

10 Scantronics 4-8-1 Fast Slo

12 Robofon

13 CESA 200

[367] – Opening/Closing Call Direction Options

The first toggle option in this section is used to enable/disable opening/

closing reporting for partition 1. To enable opening/closing reporting

turn option [1] ON. Configure the options as required and press [#] to

.

exit

Opt Default Description

1 I__I ON 1st Telephone Number

OFF Disabled

2 I__I ON 2nd Telephone Number

OFF Disabled

5 I__I ON Alternate Communicator

OFF Disabled

[380] – First Communicator Option Codes

Opt Default Description

1 I__I ON Communications Enabled

OFF Communications Disabled

2 I__I ON Restorals on Bell Time-out

OFF Restorals Follow Zones

3 I__I ON Pulse Dialing

OFF DTMF Dialing

5 I__I ON 3rd Telephone Number Enabled

OFF 3rd Telephone Number Disabled

8 I__I ON Delinquency Follows Zone Activity (Hours)

OFF Delinquency Follows Arming (Days)

[381] – Second Communicator Option Codes

The 3rd toggle option in this section is used to enable/disable automatic SIA reporting. The 5th toggle option is used to enable/disable

automatic Contact ID reporting. Configure the options as required and

press [#] to exit.

NOTE:If the automatic SIA or automatic Contact ID reporting formats

are not used, reporting codes must be programmed. To program

reporting codes refer to the PowerSeries PC1616/1832/1864 Reference Manual which can be downloaded from the DSC web site at

www.dsc.com

Opt Default Description

3 I__I ON SIA Sends Programmed Reporting Codes

OFF SIA Sends Automatic Reporting Codes

5 I__I ON Contact ID Uses Programmed Reporting

Codes

[377] Communication Variables

NOTE: For UL Installations, the Entry Delay plus the Communications

Delay must not exceed 60 seconds.

Def Enter 3 digits

003 I___II___II___I

003 I___II___II___I

003 I___II___II___I

000 I___II___II___I

030 I___II___II___I

010 I___II___II___I

030 I___II___II___I

030 I___II___II___I

007 I___II___II___I

030 I___II___II___I

000 I___II___II___I

NOTE:

Option 1 is defaulted to

Option 4 is defaulted to

Option 11 is defaulted to

Swinger Shutdown

(Alarms and Rest.

Swinger Shutdown

(Tamper and Rest.

Swinger Shutdown

(Maint. and Rest.

Communication Delay

AC Failure Comm Delay

TLM Trouble Delay

Test Transmission Cycle

(land line)

Not Used

Zone low Battery

Transmission Delay

Delinquency Transmission Cycle

Communications

Cancelled Window

as indicated below

001

for CP-01 Installations

030

for CP-01 Installations

005

for CP-01 Installations

(001-014 Transmissions)

(001-014 Transmissions,

000=disabled)

(001-014 Transmissions,

000=disabled)

(000-255 seconds)

(001-255 minutes)

No. of checks req’d (003-

255)

(001-255 days/minutes)

(000-255 days)

(000-255 days/hours)

(000-255 minutes)

OFF Contact ID Uses Automatic Reporting Codes

[382] – Third Communicator Option Codes

The 4th toggle option in this section is used to enable/disable Call

Waiting Cancel. Configure the options as required and press [#] to exit.

NOTE:A Call Waiting Cancel on a Non Call Waiting line will prevent

successful connection to the central station.

Opt Default Description

4 I__I ON Call Waiting Cancel Enabled

OFF Call Waiting Cancel Disabled

5 I__I ON T-Link Interface Enabled

OFF T-Link Interface Disabled

[701] – First International Options Codes

Option 7 in this section Selects Battery Charge Options.

Select ON for 7 Ahr and 14 Ahr batteries (700 mA charge rate)

Select OFF for Standard 4 Ahr batteries (400 mA charge rate)

Opt Default Description

7 I__I ON High Current Battery Charge (700mA)

OFF Standard Battery Charge Rate (400mA)

Page 13

LISTING REQUIREMENTS

UL Listed Commercial and Residential Installations

The installation requirements listed below must be met for the following

grades of service.

Grade AA Central Station and Police Connect (Standard or Encrypted Line

Security Service)

The installation must use T-Link module which communicates over LAN/WAN to

the Sur-Gard MLR-IP receiver or the TL200/250 which communicates over LAN/

WAN/Internet to the SG System III receiver. Polling time must be 90 seconds. Compromise detection time must be 6 minutes.

Grade A Local

•The installation must have a bell which is UL Listed for mercantile local alarms

(AMSECO MBL10B with model AB-12 bell housing).

•The digital communicator must be enabled.

•The control panel must be in the attack-resistant enclosure (DSC Model CMC-1

or PC4050CAR).

Grade B Central Station and Police Connect

•The installation must have a bell which is UL Listed for mercantile local alarms

(AMSECO MBL10B with model AB-12 bell housing).

•The digital communicator must be enabled.

•The control panel must be in the attack resistant enclosure (DSC Model CMC-1

or PC4050CAR).

Grade C Central Station

•The digital communicator must be enabled.

•The control panel must be in the attack resistant enclosure (DSC Model CMC-1

or PC4050CAR).

All Commercial Installations

•The Entry Delay must not exceed 120 seconds

•The Exit Delay must not exceed 120 seconds.

•The minimum Bell Time-out is 15 minutes.

Residential Fire & Burglary Installations

•The Entry Delay must not exceed 45 seconds

•The Exit Delay must not exceed 60 seconds.

•The minimum Bell Time-out is 4 minutes.

Home Health Care Signaling Equipment

•There must be at least two keypads, one of either the LCD5500Z/LCD5520Z or

LCD5501Z and one of the following models, PC5508Z, PC5516Z or PC5532Z.

•Each system shall be programmed to activate an audible Trouble signal within 90

seconds upon loss of microprocessor memory.

•The minimum Bell Time-out is 5 minutes.

Programming

The notes in the programming sections describing the system configurations for

UL Listed installations must be implemented.

Control of the Protected Premises

In order to have a UL Certificated system the protected area is to be under the

responsibility of one ownership and management (i.e., one business under one

name). This may be a group of buildings attached or unattached with different

addresses but under the responsibility of someone having mutual interest. The

person of mutual interest is not the alarm-installing company.

Bell Location

The alarm sounding device (bell) must be located where it can be heard by the

person or persons responsible for maintaining the security system during the daily

arming cycle.

Protection of the Control Unit

The local control and the local power supply must be protected in one of the following ways:

•The control unit and audible alarm device must be in a protected area which is

armed 24 hours a day.

•Each partition must arm the area protecting the control unit and the audible

alarm device power supply. This may require duplicate protection armed by each

partition. Access to this protected area, without causing an alarm, will require

that all partitions be disarmed.

•In all cases described above, the protected area for the control unit must be programmed as not-bypassable.

Casual Users

The installer should caution the user(s) not to give system information to casual

users (e.g. codes, bypass methods, etc. to baby-sitters or service people). Only the

One-Time Use codes should be given to casual users.

User Information

The installer should advise the users and note in the User’s Manual:

•Service organization name and telephone number

•The programmed exit time

•The programmed entry time

•Test system weekly

Two-Wire Smoke Detector Compatibility (if available)

Maximum loop resistance: 24 Ohms

•Operating Voltage Range: 9.8 - 13.8 V

•Maximum Alarm Current: 89 mA

•Compatibility Identifier: PC18-1

See

Section 5 PGM Wiring

for compatible 2-wire smoke detectors.

DC

SIA FAR Installations

Minimum requirement system for SIA-FAR Installations:

• 1 PC1616/PC1832/PC1864 Control panel

• 2 Local annunciation devices

The local annunciation devices may be any combination of the following keypads,

as long as there is at least one LCD keypad in the installation (Model LCD5500Z or

PK5500).

• LCD5500Z • LCD5501Z • PK5500 • PK5508

• PKP-LCD • PKP-ICN • PK5501 • PK5516

The following optional subassembly modules also bear the SIA FAR classification

and may be used if desired:

PC5108 Zone Expander Module

Compatible initiating devices: Bravo200 series, 300 series, 400 series, 500 series,

600 series, AC-100, Encore300 series, Force200 series, 210 series, MN240.

PC5208 Low Current PGM Output Module

The following optional accessory modules also bear the SIA FAR classification and

may be used if desired.

PC5204 Auxiliary Power Supply with PGM output ports

Escort5580/Escort5580TC, PC5400 Printer Module

Caution

• For SIA FAR installations, only use modules / devices that are listed on this page.

• Fire Alarm Verification feature (Auto Verified Fire zone) is not supported on 2wire smoke detectors zones. This feature may be enabled for 4-wire smoke

detectors only.

• Call Waiting Cancel (Section 382 Option 4) feature on a non-Call Waiting line

will prevent successful communication to the central station.

• All smoke detectors on the system must be tested annually by conducting the

Installer Walk Test prior to exiting the walk test mode, a sensor reset must be

conducted on the system, [,][7][2] to reset all latching 4-wire smoke detectors.

Please refer to the smoke detector installation instructions on how to correctly

test the detectors.

Notes

• Programming at installation may be subordinate to other UL requirements for

the intended application.

• Cross zones have the ability to individually protect the intended area (e.g.,

motion detectors, which overlap).

• Cross zoning is not recommended for line security Installations nor is it to be

implemented on exit / entry zones.

• There is a communication delay of 30 seconds in this control panel. It can be

removed, or it can be increased up to 45 seconds at the option of the end user

by consulting with the Installer.

• Do not duplicate any reporting codes. This applies for all communication formats other than SIA sending automatic programmed reporting codes.

• The control unit must be installed with a local sounding device and an offpremise transmission for SIA communication format.

• For ULC Listed Fire Monitoring Installations & module requirements, please refer

to the ULC Installation Information sheet, part# 29002157.

• Use a CSA/cUL transformer, hardwired.

• All tamper circuits may be connected to the same zone.

• Use ULC-LA for AC Power indication.

Page 14

PC1616/PC1832/PC1864 Installer Programming Quick Reference Chart SIA False Alarm Reduction

SIA Feature

Programming Section

Exit Time

[005], 3rd entry

Progress Annunciation/

Disable - for Silent Exit

[014], Option 6 ON

Exit Time Restart

[018], Option 7 ON

Auto Stay Arm on

Unvacated Premises

[001]-[004] Zone type 05, 06

Exit Time and Progress

Annunciation/Disable

or Remote Arming

[005] and [014] bit 6

Entry delay(s)

[005], 1st and 2nd entry

Abort Window

for Non-Fire zones

[101]-[164] bit 7 ON

Abort Window - for

Non-Fire zones

[377], 4th entry

Abort Annunciation

[382], Option 3 ON

Cancel Annunciation

[328], 8th entry

Duress Feature

[*][5] Master Code

33rd and 34th entries

Cross Zoning

[018] Option 6

[101]-[164] bit 9 OFF

Cross Zone Timer

[176]

Swinger Shutdown for Alarms

[377] 1st entry

Swinger Shutdown Disable

[101] - [164] bit 6 ON

Fire Alarm Verification

Zone type [29]

Call Waiting Cancel Dial String

[304], [382], Option 4 OFF

System Test:

[*][6] Master Code, Option 4

Installer Walk Test Mode:

[901

Alarm Communications

During Walk Test

[382] Option 2:

Walk Test End and Begin

Reporting Codes

st

[348], 1

and 2nd Entries

Comments Range/Default Requirement

Access to Entry and Exit delays for each partition and Bell Time Out for the system For Full or auto arming:

Enables audible exit beeps from the keypad for the duration of exit delay Individual keypads

Enables the exit delay restart feature

Function Key: Stay Arming. All Stay/Away type zones (05, 06) will be automatically

bypassed

System Times and Audible Exit beeps can be disabled when using the Key fob to arm

away the system

Access to Entry and Exit delays for each partition and Bell Time Out for the system

Note:

Combined Entry delay and Communications Delay (Abort Window) shall not

exceed 60s

Access to zone attributes, i.e, swinger shutdown, transmission delay and cross zone.

Individual zones attribute bit 7 (Transmission delay) is by default ON

Access to the programmable delay before communicating alarms

Note:

Combined Entry delay and Communications Delay (Abort Window) shall not

exceed 60s

Enables the “Communication Cancelled" message display on all keypads Annunciate that no

Access to the reporting code for Alarm Cancelled Annunciate that a

Do not derive code from an existing Master/User code (e.g., Master code is 1234, the

duress code should not be 1233 or 1235)

This option enables Cross Zoning for entire system. Individual zones can be enabled for

Cross zoning via Zone attribute bit 9 in sections [101] - [164]

Access to the programmable Cross Zone timer May program

Access to the swinger shutdown limit for zone alarms For all non-fire zones

Access to zone attributes, i.e., swinger shutdown, transmission delay and cross zone.

Individual zones attribute bit 6 (Swinger shutdown enabled) is by default ON

Auto Verified Fire, use only with 4 wire type detectors that can be reset by the panel 4wire smoke detector powered from AUX = and PGM1 - PGM4 (type 03, Sensor reset)

Access to the dialing sequence used to disable call waiting Dependant on user phone line

Range:

45- 255 seconds

Default:

60 sec.

may be disabled

Default:

All Enabled

Default:

Enabled Required

If no exit after full arm

Default:

Enabled

Default:

Enabled Allowed

Range:

30 sec. to 4 min.

Default:

30 sees

May be disabled

by zone or zone type

Default:

Enabled

Range:

15 - 45 sec.

Default:

30 sees

alarm was transmitted

Default:

Enabled

Cancel was transmitted

Default:

Enabled

No 1+ derivative of another

user code. No duplicates with

other user codes

Default:

disabled

Programming required

Default:

Disabled

Range: 001-255 sec./min.

Default:

60 secs

shut down at 1 or 2 trips

Default:

1 Trip

For non-police

response zones

Default:

Enabled

70 seconds reset and

confirmation time

Default:

disabled

Default:

disabled

Testing

The system activates all keypad sounders, bells or sirens for 2 seconds and all keypad lights turn on.

Refer to the User Manual (part no. 29007165).

This mode is used to test each zone on the system for proper functionality.

Enables Communication of zone alarms while installer Walk Test is active.

Access to the reporting codes for Walk Test Begin and Walk Test End.

Required

(programmable)

Allowed

Required

Required

(programmable)

Required

Required

(programmable)

Required

Required

Allowed

Required

Allowed

Required

(programmable)

Allowed

Required

Required

Page 15

Note to Installers

This warning contains vital information. As the only individual in contact with system users, it is your responsibility to bring each item in this warning to the attention of the users of this system.

System Failures

This system has been carefully designed to be as effective as possible. There are circumstances, however,

involving fire, burglary, or other types of emergencies where it may not provide protection. Any alarm system

of any type may be compromised deliberately or may fail to operate as expected for a variety of reasons. Some

but not all of these reasons may be:

n Inadequate Installation

A security system must be installed properly in order to provide adequate protection. Every installation should

be evaluated by a security professional to ensure that all access points and areas are covered. Locks and latches

on windows and doors must be secure and operate as intended. Windows, doors, walls, ceilings and other

building materials must be of sufficient strength and construction to provide the level of protection expected. A

reevaluation must be done during and after any construction activity. An evaluation by the fire and/or police

department is highly recommended if this service is available.

n Criminal Knowledge

This system contains security features which were known to be effective at the time of manufacture. It is possible for persons with criminal intent to develop techniques which reduce the effectiveness of these features. It is

important that a security system be reviewed periodically to ensure that its features remain effective and that it

be updated or replaced if it is found that it does not provide the protection expected.

n Access by Intruders

Intruders may enter through an unprotected access point, circumvent a sensing device, evade detection by

moving through an area of insufficient coverage, disconnect a warning device, or interfere with or prevent the

proper operation of the system.

n Power Failure

Control units, intrusion detectors, smoke detectors and many other security devices require an adequate power

supply for proper operation. If a device operates from batteries, it is possible for the batteries to fail. Even if the

batteries have not failed, they must be charged, in good condition and installed correctly. If a device operates

only by AC power, any interruption, however brief, will render that device inoperative while it does not have

power. Power interruptions of any length are often accompanied by voltage fluctuations which may damage

electronic equipment such as a security system. After a power interruption has occurred, immediately conduct

a complete system test to ensure that the system operates as intended.

n Failure of Replaceable Batteries

This system’s wireless transmitters have been designed to provide several years of battery life under normal

conditions. The expected battery life is a function of the device environment, usage and type. Ambient conditions such as high humidity, high or low temperatures, or large temperature fluctuations may reduce the

expected battery life. While each transmitting device has a low battery monitor which identifies when the batteries need to be replaced, this monitor may fail to operate as expected. Regular testing and maintenance will

keep the system in good operating condition.

n Compromise of Radio Frequency (Wireless) Devices

Signals may not reach the receiver under all circumstances which could include metal objects placed on or

near the radio path or deliberate jamming or other inadvertent radio signal interference.

n System Users

A user may not be able to operate a panic or emergency switch possibly due to permanent or temporary physical disability, inability to reach the device in time, or unfamiliarity with the correct operation. It is important

that all system users be trained in the correct operation of the alarm system and that they know how to respond

when the system indicates an alarm.

n Smoke Detectors

Smoke detectors that are a part of this system may not properly alert occupants of a fire for a number of reasons, some of which follow. The smoke detectors may have been improperly installed or positioned. Smoke

may not be able to reach the smoke detectors, such as when the fire is in a chimney, walls or roofs, or on the

other side of closed doors. Smoke detectors may not detect smoke from fires on another level of the residence

or building.

Every fire is different in the amount of smoke produced and the rate of burning. Smoke detectors cannot sense

all types of fires equally well. Smoke detectors may not provide timely warning of fires caused by carelessness

or safety hazards such as smoking in bed, violent explosions, escaping gas, improper storage of flammable

materials, overloaded electrical circuits, children playing with matches or arson.

Even if the smoke detector operates as intended, there may be circumstances when there is insufficient warning

to allow all occupants to escape in time to avoid injury or death.

n Motion Detectors

Motion detectors can only detect motion within the designated areas as shown in their respective installation

instructions. They cannot discriminate between intruders and intended occupants. Motion detectors do not provide volumetric area protection. They have multiple beams of detection and motion can only be detected in

unobstructed areas covered by these beams. They cannot detect motion which occurs behind walls, ceilings,

floor, closed doors, glass partitions, glass doors or windows. Any type of tampering whether intentional or

unintentional such as masking, painting, or spraying of any material on the lenses, mirrors, windows or any

other part of the detection system will impair its proper operation.

Passive infrared motion detectors operate by sensing changes in temperature. However their effectiveness can

be reduced when the ambient temperature rises near or above body temperature or if there are intentional or

unintentional sources of heat in or near the detection area. Some of these heat sources could be heaters, radiators, stoves, barbecues, fireplaces, sunlight, steam vents, lighting and so on.

n Warning Devices

Warning devices such as sirens, bells, horns, or strobes may not warn people or waken someone sleeping if

there is an intervening wall or door. If warning devices are located on a different level of the residence or

premise, then it is less likely that the occupants will be alerted or awakened. Audible warning devices may be

interfered with by other noise sources such as stereos, radios, televisions, air conditioners or other appliances,

or passing traffic. Audible warning devices, however loud, may not be heard by a hearing-impaired person.

n Telephone Lines

If telephone lines are used to transmit alarms, they may be out of service or busy for certain periods of time.

Also an intruder may cut the telephone line or defeat its operation by more sophisticated means which may be

difficult to detect.

n Insufficient Time

There may be circumstances when the system will operate as intended, yet the occupants will not be protected

from the emergency due to their inability to respond to the warnings in a timely manner. If the system is monitored, the response may not occur in time to protect the occupants or their belongings.

n Component Failure

Although every effort has been made to make this system as reliable as possible, the system may fail to function as intended due to the failure of a component.

n Inadequate Testing

Most problems that would prevent an alarm system from operating as intended can be found by regular testing

and maintenance. The complete system should be tested weekly and immediately after a break-in, an

attempted break-in, a fire, a storm, an earthquake, an accident, or any kind of construction activity inside or

outside the premises. The testing should include all sensing devices, keypads, consoles, alarm indicating

devices and any other operational devices that are part of the system.

n Security and Insurance

Regardless of its capabilities, an alarm system is not a substitute for property or life insurance. An alarm system also is not a substitute for property owners, renters, or other occupants to act prudently to prevent or minimize the harmful effects of an emergency situation.

Limited Warranty

Digital Security Controls warrants the original purchaser that for a period of twelve months from the date of

purchase, the product shall be free of defects in materials and workmanship under normal use. During the warranty period, Digital Security Controls shall, at its option, repair or replace any defective product upon return

of the product to its factory, at no charge for labour and materials. Any replacement and/or repaired parts are

warranted for the remainder of the original warranty or ninety (90) days, whichever is longer. The original purchaser must promptly notify Digital Security Controls in writing that there is defect in material or workmanship, such written notice to be received in all events prior to expiration of the warranty period. There is

absolutely no warranty on software and all software products are sold as a user license under the terms of the

software license agreement included with the product. The Customer assumes all responsibility for the proper

selection, installation, operation and maintenance of any products purchased from DSC. Custom products are

only warranted to the extent that they do not function upon delivery. In such cases, DSC can replace or credit

at its option.

International Warranty

The warranty for international customers is the same as for any customer within Canada and the United States,

with the exception that Digital Security Controls shall not be responsible for any customs fees, taxes, or VAT

that may be due.

Warranty Procedure

To obtain service under this warranty, please return the item(s) in question to the point of purchase. All authorized distributors and dealers have a warranty program. Anyone returning goods to Digital Security Controls

must first obtain an authorization number. Digital Security Controls will not accept any shipment whatsoever

for which prior authorization has not been obtained.

Conditions to Void Warranty

This warranty applies only to defects in parts and workmanship relating to normal use. It does not cover:

• damage incurred in shipping or handling;

• damage caused by disaster such as fire, flood, wind, earthquake or lightning;

• damage due to causes beyond the control of Digital Security Controls such as excessive voltage, mechanical

shock or water damage;

• damage caused by unauthorized attachment, alterations, modifications or foreign objects;

• damage caused by peripherals (unless such peripherals were supplied by Digital Security Controls Ltd.);

• defects caused by failure to provide a suitable installation environment for the products;

• damage caused by use of the products for purposes other than those for which it was designed;

• damage from improper maintenance;

• damage arising out of any other abuse, mishandling or improper application of the products.

Items Not Covered by Warranty

In addition to the items which void the Warranty, the following items shall not be covered by Warranty: (i)

freight cost to the repair centre; (ii) products which are not identified with DSC's product label and lot number

or serial number; (iii) products disassembled or repaired in such a manner as to adversely affect performance

or prevent adequate inspection or testing to verify any warranty claim. Access cards or tags returned for

replacement under warranty will be credited or replaced at DSC's option. Products not covered by this warranty, or otherwise out of warranty due to age, misuse, or damage shall be evaluated, and a repair estimate shall

be provided. No repair work will be performed until a valid purchase order is received from the Customer and

a Return Merchandise Authorization number (RMA) is issued by DSC's Customer Service.

Digital Security Controls Ltd.’s liability for failure to repair the product under this warranty after a reasonable

number of attempts will be limited to a replacement of the product, as the exclusive remedy for breach of warranty. Under no circumstances shall Digital Security Controls be liable for any special, incidental, or consequential damages based upon breach of warranty, breach of contract, negligence, strict liability, or any other

legal theory. Such damages include, but are not limited to, loss of profits, loss of the product or any associated

equipment, cost of capital, cost of substitute or replacement equipment, facilities or services, down time, purchaser’s time, the claims of third parties, including customers, and injury to property. The laws of some jurisdictions limit or do not allow the disclaimer of consequential damages. If the laws of such a jurisdiction apply

to any claim by or against DSC, the limitations and disclaimers contained here shall be to the greatest extent

permitted by law. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so that the above may not apply to you.

Disclaimer of Warranties

This warranty contains the entire warranty and shall be in lieu of any and all other warranties, whether expressed

or implied (including all implied warranties of merchantability or fitness for a particular purpose) and of all

other obligations or liabilities on the part of Digital Security Controls. Digital Security Controls neither assumes

responsibility for, nor authorizes any other person purporting to act on its behalf to modify or to change this warranty, nor to assume for it any other warranty or liability concerning this product. This disclaimer of warranties

and limited warranty are governed by the laws of the province of Ontario, Canada.

WARNING: Digital Security Controls recommends that the entire system be completely tested on a regular basis. However, despite frequent testing, and due to, but not limited to, criminal tampering or electrical disruption, it is possible for this product to fail to perform as expected.

Out of Warranty Repairs

Digital Security Controls will at its option repair or replace out-of-warranty products which are returned to its

factory according to the following conditions. Anyone returning goods to Digital Security Controls must first

obtain an authorization number. Digital Security Controls will not accept any shipment whatsoever for which

prior authorization has not been obtained.