Page 1

D

Pac® 5000 CO, H2S, O

Instructions for Use

2

ϝΎϤόΘγϻ ΔϘϳήσ

ʹʥʮʩʹ ʺʥʠʸʥʤ

Page 2

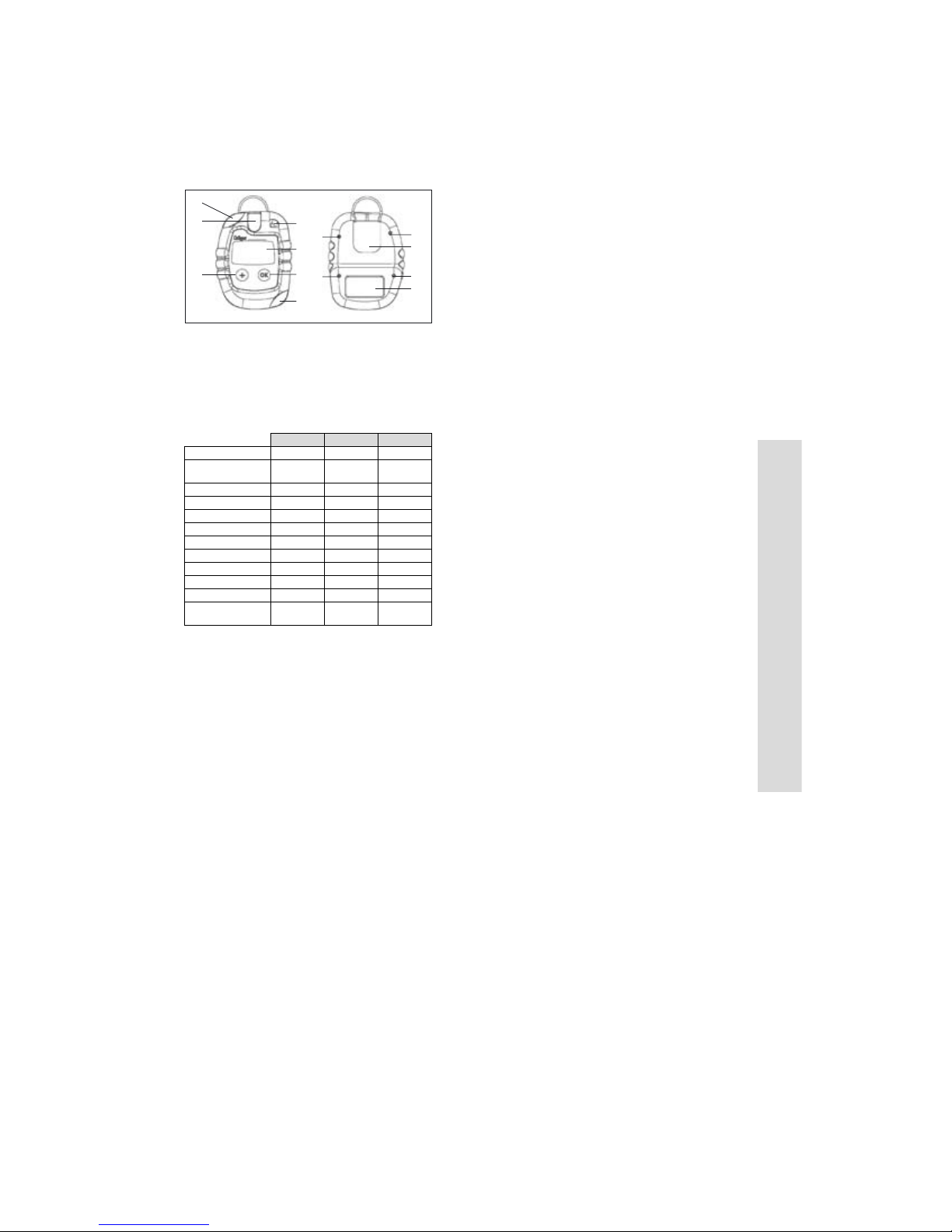

1 What is what

1

6

5

1 Alarm LED 6 Gas Opening

2 Horn 7 Screw

3 Concentration Display 8 Clip

4 OK Key On/Off/Alarm Acknowledge 9 Label

5 + Key Off/Bump Test

2 Standard configuration

Order No.

Measuring Range 0 to 500

Vibrating alarm Yes Yes Yes

Alarm Threshold A1 30 ppm 10 ppm 19 vol.-%

acknowledgeable Yes Yes No

latching No No Yes

Alarm Threshold A2 60 ppm 20 ppm 23 vol.-%

acknowledgeable No No No

latching Yes Yes Yes

Display numeric numeric numeric

Life Signal on on on

Turning the

instrument off

2

7

3

4

7

1

1)

CO H2S O

0 to 100

ppm

always

allowed

ppm

always

allowed

2

0 to 25

vol.-%

always

allowed

7

8

7

9

3 Safety advisory

— The use of the Dräger Pac 5000 instruments assumes a

complete knowledge and adherence to the users manual.

— The Pac 5000 may only be used in areas subject to

explosion hazards which are explicitly covered under the

Ex Approvals which have been given to the Pac 5000.

— Pac 5000 is not for use in oxygen-enriched atmospheres.

— Please check calibration before safety relevant use.

— The performing of calibration and bump testing shall be

conducted according to local regulations.

— Dräger Safety AG & Co. KGaA is not responsible for

damages incurred when the above guidelines are not

explicitly adhered to.

4 Intended Use

— Personal gas alarm in the workplace.

5 Operation

5.1 Remaining life of the instrument

— Once activated check the remaining life by pressing [+]

while instrument is turned off. The gas to be measured will

be shown. After another press “d” will be shown.

After another press the remaining time in days will be

shown, e. g. “CO”, “d”, “750”.

_____________

1) Please be aware of special settings by customer requirements.

2) For O

A1 is the lower alarm threshold, used to indicate oxygen deficiency

2

5.2 Activating a new instrument

— Press and hold [+] for approximately 3 seconds while

“3, 2, 1“ appears in the display. The instrument’s usable

life is now started. The number of days remaining is

shown in alternation with “d” until the + key is released.

e.g. “750”, ”d”, “750”, “d”, ...

5.3 Turning the instrument on

— Press and hold [OK]. The display counts down until

startup: “3, 2, 1”.

— All display segments are lit. Next, the LED, Alarm and

Vibrating alarm are activated in sequence. Please check

these before each use.

— The instrument will perform a self test.

00123806_1.eps

— The software version and the gas name are displayed.

— The number of days of remaining operation are shown,

e. g. “750”, “d”.

— The A1 and A2 alarm limits are displayed.

— When the instrument is first activated, a sensor warm up

time of up to approx. 5 minutes is needed. The gas name

flashes until the warm up time has passed.

5.4 Before entering a working place

— After turning the instrument on, the gas name to be

measured will normally be shown in the display.

— Check for the notice icon [!]. When lit, it is recommended

that you perform a bump test as described in section 5.5.

— Clip the instrument to clothing before working in or near

potential gas hazards.

— Insure that the gas opening is not covered and that the

instrument is also near to your breathing area.

2)

5.5 Performing a “bump test” with gas

— Prepare a Dräger test gas cylinder with 0.5 l/min and a

gas concentration higher than the alarm threshold to be

tested.

— Connect Pac 5000 and the test gas cylinder to the

calibration adapter or to the Dräger Bump Test Station.

— To achieve the bump test mode press and hold [+] for

3 seconds. The instrument beeps twice, quickly. The

Display begins to flash slowly. Release [+].

— Open the regulator valve to let test gas flow over the

sensor.

— If gas concentration exceeds the alarm thresholds A 1 or

A 2 the corresponding alarm will occur.

— To finish the bump test press [OK] for 1 second, the [!]

icon is removed from the display and the instrument

returns to the measuring mode.

— If during the bump test no alarm occurs within 1 minute,

the instrument beeps three times to indicate failure. The

[X] icon is lit; error code 240 is shown for 10 seconds.

Afterwards, “-- -- --“ is shown instead of the gas name, and

the [X] icon stays lit. In this case the bump test can be

repeated or the instrument can be calibrated.

— The result of the bump test (passed or failed) will be

stored in the event logger (see section 5.8).

— The bump test can also be made by an automatic function.

This function can be activated using the PC software

Pac Vision or CC Vision (see section 5.9).

5.6 During operation

— If the allowable measurement range is exceeded or a

negative drift occurs, the following will appear in the

display: “_ _ _” (too high concentration) or “___” (negative

drift).

— Alarms are indicated as described in section 6.

— Continuous function of the instrument is indicated by the

life signal, which is a beep every 60 seconds, if

configured (see section 2).

5.7 Turning the instrument off

— Simultaneously hold both keys for approximately 2

seconds until “3” appears in the display. Continue to hold

both keys until the countdown is finished. The alarm and

LED will be activated momentarily.

5.8 Event logger

— Pac 5000 is equipped with an event logger. The event

logger stores 60 events. If event No. 61 occurs the logger

overwrites the oldest stored event.

— For download of the stored data connect Pac 5000 to a

PC using the connecting cradle or the E-Cal System. The

stored data can be downloaded with installed software

Pac Vision or Gas Vision.

English

Page 3

English

5.9 Calibration and configuration

— For calibration or individual configuration connect Pac

5000 to a PC using the connecting cradle or the E-Cal

System. Calibration and configuration can be done with

installed software Pac Vision or CC Vision. A calibration

“due date” can be set using the operation timer (in days).

5.10 Adjustable operation timer (in days)

— Pac 5000 is equipped with an adjustable operation timer.

The operation timer can be used to set an individually

operation period e. g. to adjust a “calibration due date”,

an “inspection due date”, an “out of order date” etc.

— To adjust the operation timer connect Pac 5000 to a PC

using the connecting cradle or the E-Cal System. The

adjustment can be done with installed software Pac

Vision or CC Vision.

6 Alarms

6.1 Concentration Pre/Main Alarms

— The alarm will activate whenever the alarm thresholds A1

or A2 are exceeded. The instrument is equipped with a

vibrating alarm. It vibrates in parallel to these alarms.

— During an A1, the LED will blink and the alarm will sound.

— During an A2, the LED and alarm tone will repeat in a

double repeating pattern.

— The display will alternate between the measurement value

and “A1” or “A2”.

— The alarms may, according to the selected configuration,

be acknowledged or turned off. (See section 2.)

“Acknowledgeable”: alarms and LED can be

acknowledged by pressing [OK] for 1 second.

— “Latching”: The alarm will only deactivate when the

concentration falls under the alarm threshold and then

[OK] is pressed for 1 second.

— If the alarm is not latching, the alarm will deactivate as

soon as the concentration falls under the alarm threshold.

6.2 Battery pre/main alarms

— When the battery pre-alarm is activated, the audible alarm

sounds and the LED blinks, and the “low battery” icon

»«

flashes.

— To acknowledge the pre-alarm, push [OK] for 1 second.

— After the first battery pre-alarm, the battery will last for

approx. 1 further week and the “low battery” icon stays lit.

— When the battery main alarm is activated, the audible

alarm sounds in a repeating pattern of 2 repeating tones

and the LED blinks in the same pattern.

— The battery main alarm is not acknowledgeable; the

instrument will automatically turn off after approx. 1

minute.

— In case of a very low battery, the internal voltage monitor

could activate the LED’s.

6.3 Changing the battery

— Do not change the battery in explosion-hazard areas!

— The instrument contains a replaceable lithium ion battery.

— The battery is part of the Ex approval.

— Only the following battery types shall be used:

— Duracell DL 123 Lithium Type CR123A, 3 V

— ………

— ………

— Turn the instrument off.

— Unscrew the 4 screws from the back case.

— Open the front case and remove the depleted battery.

— Insert the new battery according to specified polarity

(+/–).

— Place front case back and fasten it by tightening the 4

screws of the back case.

6.4 Handling of exhausted batteries

—Caution:

— Never throw them into a fire!

— Never attempt to charge them!

— Never attempt to open them, danger of explosion!

— Dispose of exhausted batteries only as special waste in

accordance with local regulations.

— Spent batteries may be returned to Dräger for disposal.

6.5 Usable life alarm

— Before the end of the instrument’s usable life, a warning

period begins. During this period the remaining life time

flashes just after turning the instrument on, e. g. “30”/“d”.

— To acknowledge this message [OK] must be pressed for

approx. 1 second. After that, the instrument can be used

further.

— After the usable life has expired the text “0“/“d“ will

alternate in the display and cannot be acknowledged.

Pac 5000 will not longer measure and may be returned to

Dräger for recycling.

6.6 Instrument alarm

— The alarm and LED will be activated three times,

periodically.

— The [X] icon will be lit, with a 3 digit error code shown in

the display.

— If an error appears in the display see section 6.7 and if

necessary please contact DrägerService.

6.7 Trouble shooting errors

Code Cause Remedies

100 Flash / EEprom write

fail

102 AD system defect Contact DrägerService

104 Flash check sum

wrong

107 Self test failed Contact DrägerService

210 Fresh air calibration

failed

220 Span calibration failed Repeat operation

240 Bump test failed Repeat operation or

Contact DrägerService

Contact DrägerService

Repeat operation

calibrate instrument

7 Technical Specifications

Environmental Conditions

During

operation

Conditions

for storage

Ingress

protection

Operating

times

Battery life

(typical at

o

25

C)

Intensity of

alarm

Dimensions 54 x 84 x 34 mm

Weight 120 g

Approvals

(only

approvals

printed on the

instrument

are valid)

o

–30 to 50

700 to 1300 hPa

5 to 95% relative humidity

0 to 40

30 to 80% relative humidity

IP 65

2 years (typical at 25

24 hours of use per day,

2 minutes alarm per day:

CO, H

O2: >3600 hours

typical 90 dBA at 30 cm

CE Sign (89/336/EEC , 94/9/EC)

DMT 98 ATEX E021X

II 2 G EEx ia IIC T4, –40

I M1 EEx ia I, –40

UL Class I, II, III Div I, Group A, B, C, D, F, G,

Temp Code T4, Exia

CSA Class I, Groups A, B, C, D, Exia Temp

Code T4

C

o

C

S: >8000 hours

2

o

C)

o

C ..55 oC

o

C ..55 oC.

8 Sensor Specifications

Reproducibility

Zero point:

Sensitivity:

Temperature Influence

Zero point:≤ ±5 ppm≤ ±2 ppm≤ ±0.2 vol.-%

Sensitivity:

Drift (20

Zero point:

Sensitivity:

Please be aware of possible sensor cross sensitivities (see

Sensor Data Sheet XX XX XXX).

CO H2S O

≤

±5 ppm≤ ±2 ppm≤ ±0.2 vol.-%

≤

±3 % of

measured value

≤

±0.4 % of

measured

value / K

o

C)

≤

±5 ppm/a≤ ±1 ppm/a≤ ±0.5 vol.-%/a

≤

±1 % of

measured

value / month

≤

±5 % of

measured value

≤

±5 % of

measured value

≤

±1 % of

measured

value / month

2

≤

±1 % of

measured value

≤

±1 % of

measured value

≤

±1 % of

measured

value / month

Loading...

Loading...