Page 1

Owner’s Manual

ADVANTAGE

™

High Speed Rotary Saw

Model 9000

™

• Safety

• Descriptions

• Assembly

• Operation

• Maintenance and Service

• Warranty

P.O. Box 1468

Racine, Wisconsin 53401

Parlez-vous français?

Voir page 13

¿Habla español?

Vea página 25

1-800-437-3635

www.dremel.com

2610913622 3/02 PRINTED IN U.S.A.

Page 2

Power Tool Safety Rules

WARNING

!

Read and understand all instructions. Failure to follow all instructions

listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

C l u t t e red benches and dark areas invite

a c c i d e n t s .

Do not operate power tools in ex p l o s i v e

atmospheres, such as in the presence of

f l a m m a ble liquids, gases, or dust. P o w e r

tools create sparks which may ignite the dust

or fumes.

Keep by - s t a n d e rs, children, and visitors

aw ay while operating a power tool.

Distractions can cause you to lose contro l .

Electrical Safe t y

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified

electrician to install a polarized outlet. Do

not ch a n ge the plug in any way. D o u b l e

Insulation eliminates the need for the

t h r ee wire ground ed power cord an d

g rounded power su pply sys tem. B e fo r e

plugging in the tool, be certain the outlet

voltage supplied is within the voltage marked

on the nameplate. Do not use “AC only” rated

tools with a DC power supply.

Avoid body contact with grounded surfaces

s u ch as pipes, radiators, ranges and

r e f r i ge r a t o rs . T h e re is an increased risk of

electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your

tool. Electrician’s rubber gloves and footwear

will further enhance your personal safety.

Don't expose power tools to rain or wet

c o n d i t i o n s . Water entering a power tool will

i n c rease the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord aw ay from heat, oil, sharp

e d ges or moving parts. Replace damage d

c o rds immediately. Damaged cords incre a s e

the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked "W- A "

or "W." These cords are rated for outdoor use

and reduce the risk of electric shock. Refer to

“Recommended sizes of Extension Cords” in

the Accessory section of this manual.

Pe rsonal Safe t y

S t ay alert, watch what you are doing and

use common sense when operating a

p ower tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

m e d i c a t i o n . A moment of inattention while

operating power tools may result in serious

personal injury.

Dress pro p e r ly. Do not wear loose cl o t h i n g

or jew e l ry. Contain long hair. Keep yo u r

h a i r, clothing, and gloves aw ay fro m

m oving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts. Keep

handles dry, cl ean and free from oil and

g re a s e .

Avoid accidental starting. Be sure sw i t ch is

“OFF” before plugging in. Carrying tools

with your finger on the switch or plugging in

tools that have the switch “ ON ” invite s

a c c i d e n t s .

R e m ove adjusting keys or wrenches befo r e

turning the tool “ON”. A wrench or a key that

is left attached to a rotating part of the tool

may result in personal injury.

Do not ov e r r e a ch. Keep proper footing and

balance at all times. P roper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Alw ays wear eye

p ro t e c t i o n . Dust mask, non-skid safety shoes,

h a rd hat, or hearing protection must be used

for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

s t a ble platfo r m . Holding the work by hand or

against your body is unstable and may lead to

loss of contro l .

Do not fo rce tool. Use the correct tool fo r

your application. The correct tool will do the

job better and safer at the rate for which it is

d e s i g n e d .

Page 2

Do not use tool if sw i t ch does not turn it

“ON” or “OFF”. Any tool that cannot be

c o n t rolled with the switch is dangerous and

must be re p a i re d .

Disconnect the plug from the power sourc e

b e fore making any adjustments, ch a n g i n g

accessories, or storing the tool. S u c h

p reventive safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of reach of children and

other untrained pers o n s . Tools are

d a n g e rous in the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and cl e a n . P roperly maintained tools,

with sharp cutting edges are less likely to bind

and are easier to control. Any alteration or

modification is a misuse and may result in a

d a n g e rous condition.

C h e ck for misalignment or binding of

m oving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

s e rviced before using. Many accidents are

Rotary Saw Safety Rules

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord. Contact with a "live" wire will

make exposed metal parts of the tool "live"

an d shock the op erato r. If cutting into

existing walls or other blind areas where

e l e c t rical wiring may exist is unavo i d a bl e,

disconnect all fuses or circuit breake r s

feeding this worksite.

A lw ays make sure the work surface is

free from nails and other foreign objects.

Cutting into a nail can cause the bit and the

tool to jump and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

N ever place hands near or below cutting

surface. Clamping the material and guiding

the tool with both hands is safer.

N ever lay workpiece on top of hard

surfaces, like concrete, stone, etc...

P rotruding cutting bit may cause tool to

jump.

caused by poorly maintained tools. Develop a

periodic maintenance schedule for your tool.

Use only accessories that are recommended by the manufacturer for yo u r

model. Accessories that may be suitable for

one tool, may become hazardous when used

on another tool.

S e rv i c e

Tool service must be performed only by

qualified repair pers o n n e l . Servic e or

main te nance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard re t u rn springs may be

i m p roperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manu a l .

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning

agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

A lw ays wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working

in safe environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

a ny other adjustment devices are

s e c u r e ly tightened. Lo ose adjustment

device can unexpectedly shift, causing loss

of control, loose rotating components will be

violently thrown.

N ever start the tool when the bit is

e n g aged in the material. The bit cutting

edge may grab the material causing loss of

control of the cutter.

A lw ays hold the tool with two hands

during start-up. The reaction torque of the

motor can cause the tool to twist.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. Most materials

should be cut in a clockwise direction. An

exception is when cutting around an outlet

Page 3

Page 3

box in drywall, which should be cut counterclockwise. Steering the tool in the wro n g

direction, causes the cutting edge of the bit

to climb out of the work and pull the tool in

the direction of the feed.

N ever use dull or damaged bits. Sharp

bits must be handled with care. Damaged

bits can snap during use. Dull bits re q u i re

m o re force to push th e tool, possibly

causing the bit to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to

be touched by bare hands.

N ever lay the tool down until the motor

has come to a complete standstill. T h e

spinning bit can grab the surface and pull

the tool out of your control.

N ever use bits that have a cutting

diameter greater than the opening in the

base.

Do not use the tool for drilling purposes.

This tool is not intended to be used with drill

bits.

S y m b o l s

!

WARNING

Some dust created by

p ower sanding, saw i n g ,

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects or other

r e p roductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically-

treated lumber.

Your risk fro m t he se exposu re s var ie s,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated are a ,

and work with approved safety equipment,

such as those dust masks that are specially

designed to filter out microscopic particles.

Always use the tool with the depth guide

s e c u r e ly attached and positioned flat

against material being cut. The guide

securely positioned on the material improves

the stability and control of your tool.

A l t e rnating curre n t Type or a characteristic of curre n t

D i rect curre n t Type or a characteristic of curre n t

A l t e rnating or direct curre n t Type or a characteristic of curre n t

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal G rounding terminal

Wa rning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery re c y c l i n g

p ro g r a m

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters Laboratories.

This symbol designates

This symbol designates

that this tool is listed by

the Canadian Standard s

A s s o c i a t i o n .

that this tool is listed by

Underwriters Laboratories,

and listed to Canadian

S t a n d a rds by Underwriters

L a b o r a t o r i e s .

This symbol

d e s i g n a t e s

t h a t

this tool

c o m p l i e s

to NOM

M e x i c a n

S t a n d a rd s .

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

S y m b o l N a m e D e s i g n a t i o n / E x p l a n a t i o n

V Vo l t s Voltage (potential)

A A m p e re s C u r re n t

H z H e r t z F requency (cycles per second)

W Wa t t P o w e r

k g K i l o g r a m s We i g h t

m i n M i n u t e s T i m e

s S e c o n d s T i m e

D i a m e t e r Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

. . . / m i n Revolutions or re c i p rocation per minute Revolutions, strokes, surface speed,

orbits etc. per minute

0 O ff position Z e ro speed, zero torq u e . . .

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

A r ro w Action in the direction of arro w

Page 4

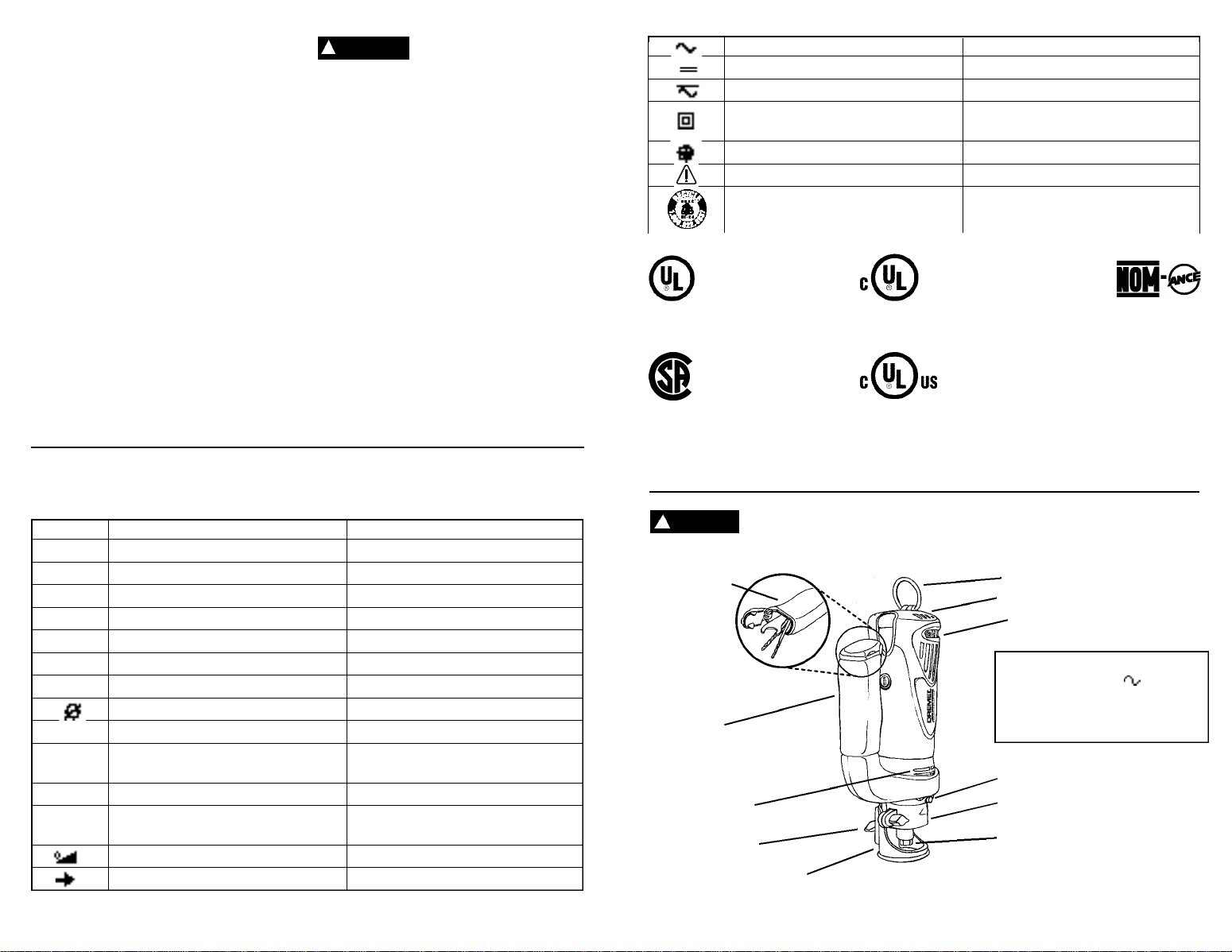

Functional Description and Specifications

WARNING

!

measures reduce the risk of starting the tool accidentally.

TO O L

S TO R AG E

AU X I L I A RY

H A N D L E

E X H AUST

AIR VENTS

DEPTH GUIDE

LOCKING WINGNUT

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive safety

DEPTH GUIDE

Page 5

HANG BA I L

I N TAKE AIR VENTS

SPEED DIAL

Model number 9000

Voltage rating 120V 50 - 60Hz

Amperage rating 4.5 A

No load speed n0 1 0 , 0 0 0 - 3 5 , 0 0 0 /m i n

Collet capacities 1 / 8", 1 / 4"

SHAFT LOCK

DEPTH GUIDE BRAC K E T

COLLET NUT

Page 4

Page 5

WARNING

!

Do not attempt to use this

tool to make cut-outs

a round any fixture or opening which has

live electrical wires, or on any wall which

m ay have live electrical wiring behind it,

as the bit could conduct current to the

tool, creating an electrocution hazard fo r

the operator. Shut off breakers or re m o v e

fuses to disconnect the circuit. Always hold

the tool by its thermoplastic housing, and

always wear eye protection when operating

this device.

• Step 1: Be certain that the box or fixture

which re q u i res a cut-out is firmly mounted

and all wires or other obstructions aro u n d

the opening are pushed back out of the way.

The drywall cut-out bit uses the outer edge

of the box or fixture as a guide, so it is

important that there is nothing in the way

which can prevent it from guiding completely

around the opening. For the purposes of this

instruction manual, the procedure discussed

will be to make a cut-out around a standard

2 1/8" x 3 3/4" electrical box.

• Step 2: Before fastening the drywall sheet,

make a mark close to the center of the

opening in the box on the side of the drywall

facing you. You may then begin to screw or

nail the sheet to the wall, but do not install

fasteners closer then about 15" to the box,

or the sheet will likely bulge and crack before

you cut the opening.

• Step 3: Holding the tool firmly switch the

tool to th e "ON " pos ition as described

earlier.

• Step 4: Holding the tool firmly with both

hands, push the bit through the drywall at

the mark you made in step 2. Guide the bit

to the right until you feel it make contact with

the inside edge of the box. Then retract the

bit slightly, (do not pull entirely out) to allow it

to penetrate through the drywall and contact

the outside edge of the box by continuing to

move the tool slightly to the right as you cut.

• Step 5: Keeping the bit in contact with the

outside of the box, move the tool counterclockwise to crea te the opening. When

ro unding a co rn e r, keep app lying li gh t

pressure towards the center of the box while

moving the bit steadily and smoothly around

the whole box until the entire cut has been

completed. Slide the switch to the "OFF"

position, and pull the bit free of the drywall.

You may then remove the piece you have

cut, and you will have a smooth opening.

The rest of the screws or nails may now be

put in place on the drywall sheet, and the

task is completed.

CAUTION

!

The motor may stall if

i m p ro pe rly used or overloaded. Reduce the pre s s u re or feed rate to

p revent possible damage to the tool. Do not

attempt to start the tool when the bit is

engaged in the workpiece. Always be sure the

collet nut is tightened securely before use.

Page 8

MAKING CUT-OUTS IN MATERIALS

OTHER THAN DRYWALL

Your tool is capable of cutting many types of

building materials in addition to drywall.

T h e re are several diff e rent bits available for

use on these materials. Most materials can

be cut with the "multipurpose" bit, however

the "carbide" burr bits must be used for

h a rd, abrasive materials such as ceramic

wall tile (will not work on ceramic floor grade

tile), cement board, plaster etc.

To ma ke cut-outs, insert and adjust the

proper bit according to previous instructions.

Hold the tool firmly and turn it on. Place the

depth guide at about a 45º angle against the

work surface and tilt the tool to an upright

po sition with the bit entering the scrap

portion of the area being cut. Move the bit to

the line you wish to follow and cut in a

clockwise direction. Cutting at a slow even

rate will make following a line easier and will

put less stress on the bit.

N OT E : When cutting on a vertical surface,

avoid ending your cut at the bottom of the

hole. If possible, start and end your cut at

the top so the scrap part will not drop onto

the rotating bit. Turn the tool off and remove

it from the cut out hole.

Maintenance Information

C L E A N I N G

To avoid accidents alw ays disconnect the

tool from the power supply before cl e a n i n g

or performing any maintenance. The tool

may be cleaned most effectively with

c o m p ressed dry air. A lw ays wear safety gog-

gles when cleaning tools with compressed

a i r. Ventilation openings and switch levers

must be kept clean and free of foreign matter.

Do not attempt to clean by inserting pointed

objects through openings.

!

CAUTION

p a rt s . Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents,

ammonia and household detergents that

contain ammonia.

C e rtain cleaning agents and

solvents damage plastic

P r eventive maintenance performed by

SERVICE

u n a u t h o r i zed personnel may result in

misplacing of internal wires and

components which could cause serious

h a z a rd. We recommend that all tool service be

performed by a Dremel Service Facility.

FIG. 11

BRUSH & SPRING

ASSEMBLY

B RUSH CA P

CURVED END OF BRU S H

MUST MATCH CURVAT U R E

OF HOUSING

CARBON BRU S H E S

The brushes and commutator in your tool have

been engineered for many hours of dependable

service. To maintain peak efficiency of the

m o t o r, we recommend every two to six months

the brushes be examined. Only genuine Dre m e l

replacement brushes specially designed for

your tool should be used.

MAINTENANCE OF REPLAC E A B L E

B RUSHES Model 9000

The brushes should be inspected fre q u e n t l y

when tools are used continuously. If your tool

runs sporadically, loses power, makes unusual

noises or runs at a reduced speed, check the

brushes. To continue using the tool in this

condition will permanently damage your tool.

With the cord unplugged, remove the brush

caps one at a time with a small screwdriver by

rotating cap counter-clockwise and check each

b r u s h .

If the brush is less than 1/4" long and the end

surface of the brush that contacts the

commutator is rough and/or pitted, they should

be replaced. Check both brushes. Usually the

brushes will not wear out simultaneously. If one

brush is worn out, replace both brushes. Make

s u re the brushes are installed as illustrated. The

curved surface of the brush must match the

c u r v a t u re of the commutator.

After replacing brushes the tool should be run

at no-load; place it on a clean surface and run it

f reely for 5 minutes before loading (or using) the

tool. This will allow the brushes to “seat”

p roperly and will give you more hours of life

f rom each set of brushes. This will also extend

the total life of your tool since the commutator

surface will “wear” longer.

B e a r i n g s - Model 9000 is equipped with ball

bearing construction. Under normal use no

additional lubrication is re q u i re d .

Page 9

C U R VATURE

OF HOUSING

Page 6

If an extension cord is necessary, a cord

Extension Cord s

with adequate size conductors that is

capable of carrying the current necessary

for your tool must be used. This will prevent

excess ive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

N OT E : The smaller the gauge number, the

heavier the cord .

RECOMMENDED SIZES OF EXTENSION

CORDS 120 VOLT ALTERNATING

CURRENT TOOLS

Tool’s

Ampere

Rating

3 - 6

6 - 8

8 - 1 0

1 0 - 1 2

1 2 - 1 6

Cord Size in A.W.G.

Cord Length in Feet Cord Length in Meters

2 5 5 0 1 0 0 1 5 0 1 5 3 0 6 0 1 2 0

1 8 1 6 1 6 1 4 . 7 5 . 7 5 1 . 5 2 . 5

1 8 1 6 1 4 1 2 . 7 5 1 . 0 2 . 5 4 . 0

1 8 1 6 1 4 1 2 . 7 5 1 . 0 2 . 5 4 . 0

1 6 1 6 1 4 1 2 1 . 0 2 . 5 4 . 0 —

1 4 1 2 — — — — — —

Wire Sizes in mm

D r emel Advantage Service

Parts Diagram

Dremel Advantage™

Service Parts List

2

Ref. No. Part Part No.

1 Depth Guide Cutting Base Plate 2610916273

2 Depth Guide Wingnut (pair) 2610914431

3 Depth Guide Nut Plate 2610913184

4 Depth Guide Retainer 2610916274

5 Retainer nut 3603301505

6 Collet nut 2610913319

7 1/8" Collet 2615295093

8 Wrench 2615295097

9 Shaft lock assembly 2610907116

10 Shaft lock retaining ring 2610909201

11 Brush caps (pair) 2610913159

12 Motor brushes and springs (pair) 2610913160

13 Motor brush holder with straight lead 2610915244

14 Motor brush holder with right angle lead 2610915245

15 Cap for on/off switch 2610913156

16 On/off switch 2610996245

17 Power cord 2610913157

18 Speed control assembly 2610913155

19 Motor assembly 2610914664

20 Field assembly 2604220677

21 Rubber isolator ring 2615297373

22 Screws (five) 2610326578

23 Handle assembly 2610913023

24 Housing set with labels 2610907339

25 Tool hanger 2610913164

O rder by part number, not re f e rence number.

Write for current price or call 1-800-4 DREMEL

Page 11Page 10

Page 7

Dremel Limited Wa r r a n t y

Your Dremel product is warranted against defective material or workmanship for a

period of two years from date of purchase. In the event of a failure of a product to

conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight

prepaid, along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center D remel Service Center

4915 Tw e n t y - F i rst Street OR 4631 E. Sunny Dunes

R a c i n e, Wisconsin 53406 Palm Springs, CA 92264

C A N A DA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write

S c a r b o rough, Ont. to Dremel, 4915 Twenty-First St.

Canada M1C 4A7 Racine, Wisconsin 53406

We recommend that the package be insured against loss or in transit damage for

which we cannot be responsible.

This warranty applies only to the original re g i s t e red purc h a s e r. DAMAGE TO THE

PRODUCT RESULTING FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE,

UNAUTHORIZED REPAIRS OR ALT E R ATIONS, UNAPPROVED AT TACHMENTS OR

OTHER CAU SES U NR ELATED T O P ROBLEMS WITH M ATERI AL OR

WORKMANSHIP ARE NOT COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on

behalf of Dremel. If Dremel inspection shows that the problem was caused by

problems with material or workmanship within the limitations of the warranty, Dremel

will repair or replace the product free of charge and return product prepaid. Repairs

made necessary by normal wear or abuse, or repair for product outside the warranty

period, if they can be made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED

OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PA RTIC ULAR PUR POSE WHICH E XCEED THE ABOVE MENTIONED

O B L I G ATION ARE HEREBY DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS

LIMITED WA R R A N T Y.

This warranty gives you specific legal rights and you may also have other rights which

vary from state to state. The obligation of the warrantor is solely to repair or replace the

p roduct. The warrantor is not liable for any incidental or consequential damages due to

any such alleged defect. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitations or exclusion may not

apply to you.

For prices and warranty fulfillment in the continental United States, contact your local

D remel distributor.

Page 12

Loading...

Loading...