Page 1

Model 760 Golf Club Cleaning Tool

Owner’s Manual

Safety

•

• Assembly

Operation

•

Accessory Information

•

Warranty

•

Parlez-vous français?

Voir page 16

¿Habla español?

Vea página 33

• Service Parts

P.O. Box 1468

Racine, Wisconsin 53401

1-800-437-3635

http://www.dremel.com

Dremel brand products are manufactured and sold by the

Dremel Division of Robert Bosch Tool Corporation

2 610 925 736 02/05 PRINTED IN U.S.A.

Page 2

General Safety Rules

WARNING

!

below refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

Read all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

The term “power tool” in all of the warnings listed

SAVE THESE INSTRUCTIONS

Work area safety

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigera-

There is an increased risk of electric shock if your

tors.

body is earthed or grounded.

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suit-

able for outdoor use reduces the risk of electric shock.

Do not use AC only rated tools with a DC power supply. While the tool may appear to work, the electrical

components of the AC rated tool are likely to fail and

create a hazard to the operator.

If operating the power tool in damp locations is

unavoidable a Ground Fault Circuit Interrupter (GFCI)

must be used to supply the power to your tool. GFCI

and personal protection devices like electrician’s rubber gloves and footwear will further enhance your personal safety.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use

a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in

serious personal injury.

Use safety equipment. Always wear eye protection.

Safety equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

Avoid accidental starting. Ensure the switch is in the

off-position before plugging in. Carrying power tools

with your finger on the switch or plugging in power

tools that have the switch on invites accidents.

Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool

in unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from

moving parts. Loose clothes, jewelry or long hair can

be caught in moving parts.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

Page 2

Page 3

connected and properly used. Use of these devices

can reduce dust-related hazards.

Keep handles dry, clean and free from oil and

grease. Slippery hands cannot safely control the

power tool.

Power tool use and care

Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or the

battery pack from the power tool before making any

adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk

of starting the power tool accidentally.

Store idle power tools out of the reach of children and

do not allow persons unfamiliar with the power tool or

these instructions to operate the power tool. Power

tools are dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tools operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc., in

accordance with these instructions and in the manner

intended for the particular type of power tool, taking

into account the working conditions and the work to

be performed. Use of the power tool for operations dif-

ferent from those intended could result in a hazardous

situation.

Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may

lead to loss of control.

Battery tool use and care

Recharge only with the charger specified by the manufacturer.A charger that is suitable for one type of bat-

tery pack may create a risk of fire when used with

another battery pack.

Use battery tools only with specifically designated

battery packs. Use of any other battery packs may cre-

ate a risk of injury and fire.

When battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys,

nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause

burns or a fire.

Under abusive conditions, liquid may be ejected

from the battery, avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes,

additionally seek medical help.

the battery may cause irritation or burns.

Ensure the switch is in the off position before inserting battery pack. Inserting the battery pack into power

tools that have the switch on invites accidents.

Liquid ejected from

Service

Have your power tool serviced by a qualified repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

Develop a periodic maintenance schedule for your

tool. When cleaning a tool be careful not to disassemble any portion of the tool since internal wires

may be misplaced or pinched or safety guard return

springs may be improperly mounted. Certain cleaning

agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

SAVE THESE INSTRUCTIONS

Page 3

Page 4

Safety Rules for Cordless Rotary Tools

Hold tool by insulated gripping surfaces when performing an operation where the cutting tool may

contact hidden wiring. Contact with a "live" wire will

make exposed metal parts of the tool "live" and shock

the operator.

Use clamps or other practical way to secure and support the workpiece to a stable platform. Holding the

work by hand or against your body is unstable and may

lead to loss of control.

Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels

and other accessories running over rated speed can

fly apart and cause injury.

If cutting into existing walls or other blind areas

where electrical wiring may exist is unavoidable,

disconnect all fuses or circuit breakers feeding this

worksite.

Before changing accessories remove battery pack.

Accidental starting may occur because battery tools

with a battery inserted are in the operative condition.

Be aware of the switch location, when placing the

tool down or when picking the tool up. You may acci-

dentally activate the switch.

Always hold the tool with two hands during astartup.

The reaction torque of the motor can cause the tool to

twist.

Always wear safety goggles and dust mask. Use

only in well ventilated area. Using personal safety

devices and working in safe environment reduces risk

of injury.

After changing the bits or making any adjustments,

make sure the collet nut and any other adjustment

devices are securely tightened. Loose adjustment

device can unexpectedly shift, causing loss of control,

loose rotating components will be violently thrown.

Do not reach in the area of the spinning bit. The

proximity of the spinning bit to your hand may not

always be obvious.

Allow brushes to run at operating speed for at least

one minute before using wheel. During this time no

one is to stand in front or in line with the brush.

Loose bristles or wires will be discharged during the

run-in time.

Wire and bristle brushes must never be operated at

speeds greater than 15,000/min. Direct the discharge of the spinning wire brush away from you.

Small particles and tiny wire fragments may be discharged at high velocity during the “cleaning” action

with these brushes and may become imbedded in

your skin. Bristles or wires will be discharged from

the brush at high speeds.

"Wear protective gloves and face shield with wire or

bristle brushes. Apply wire or bristle brushes lightly to the work as only the tips of the wire/bristles do

the work. “Heavy” pressure on bristles will cause the

wire or bristle to become overstressed, resulting in a

wiping action and will cause the bristles/wire to be

discharged."

Carefully handle both the tool and individual grinding wheels to avoid chipping or cracking. Install a

new wheel if tool is dropped while grinding. Do not

use a wheel that may be damaged. Fragments from

a wheel that bursts during operation will fly away at

great velocity possibly striking you or bystanders.

Never use dull or damaged bits. Sharp bits must be

handled with care. Damaged bits can snap during

use. Dull bits require more force to push the tool,

possibly causing the bit to break.

Use clamps to support workpiece whenever practical. Never hold a small workpiece in one hand and

the tool in the other hand while in use. Allow for

sufficient space, at least 6", between your hand and

the spinning bit. Round material such as dowel rods,

pipes or tubing have a tendency to roll while being

cut, and may cause the bit to “bite” or jump toward

you. Clamping a small workpiece allows you to use

both hands to control the tool.

Page 4

Page 5

Inspect your workpiece before cutting. When cutting

irregularly shaped workpieces, plan your work so it

will not slip and pinch the bit and be torn from your

hand. For example, if carving wood, make sure there

are no nails or foreign objects in the workpiece. Nails

or foreign objects can cause the bit to jump.

Never start the tool when the bit is engaged in the

material. The bit cutting edge may grab the material

causing loss of control of the cutter.

Avoid bouncing and snagging the wheel, especially

when working corners, sharp edges etc. This can

cause loss of control and kick-back.

The direction of feed with the bit into the material

when carving, routing or cutting is very important.

Always feed the bit into the material in the same

direction as the cutting edge is exiting from the

material (which is the same direction as the chips

are thrown). Feeding the tool in the wrong direction,

causes the cutting edge of the bit to climb out of the

work and pull the tool in the direction of this feed.

If the workpiece or bit becomes jammed or bogged

down, turn the tool “OFF” by the switch. Wait for

all moving parts to stop and unplug the tool, then

work to free the jammed material. If the switch to

the tool is left “ON” the tool could restart unexpectedly causing serious personal injury.

Do not leave a running tool unattended, turn power

off. Only when tool comes to a complete stop it is

safe to put it down.

Do not grind or sand near flammable materials.

Sparks from the wheel could ignite these materials.

Do not touch the bit or collet after use. After use the

bit and collet are too hot to be touched by bare hands.

Regularly clean the tool's air vents by compressed

air. Excessive accumulation of powdered metal inside

the motor housing may cause electrical failures.

Do not allow familiarity gained from frequent use of

your rotary tool to become commonplace. Always

remember that a careless fraction of a second is sufficient to inflict severe injury.

Do not alter or misuse tool. Any alteration or modification is a misuse and may result in serious personal

injury.

This product is not intended for use as a dental drill,

in human or veterinary medical applications.

Serious injury may result.

When using the steel saws, cutoff wheels, high

speed cutters or tungsten carbide cutters, always

have the work securely clamped. Never attempt to

hold the work with one hand while using any of

these accessories. The reason is that these wheels

will grab if they become slightly canted in the groove,

and can kickback causing loss of control resulting in

serious injury. Your second hand should be used to

steady and guide the hand holding the tool. When a

cutoff wheel grabs, the wheel itself usually breaks.

When the steel saw, high speed cutters or tungsten

carbide cutter grab, it may jump from the groove and

you could lose control of the tool.

WARNING

!

drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other

masonry products, and

• Arsenic and chromium from chemicallytreated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

Some dust created by power

sanding, sawing, grinding,

Page 5

Page 6

Battery Disposal

Nickel-Cadmium Batteries

If equipped with a nickel-cadmium battery, the battery must be collected, recycled or disposed of in an

environmentally sound manner.

“The EPA certified RBRC Battery

Recycling Seal on the nickel-cadmium (Ni-Cd) battery indicates

Robert Bosch Tool Corporation is

voluntarily participating in an

industry program to collect and

recycle these batteries at the end of their useful

life, when taken out of service in the United States

or Canada. The RBRC program provides a convenient alterative to placing used Ni-Cd batteries into

the trash or the municipal waste stream, which

may be illegal in your area.

Please call 1-800-8-BATTERY for information on NiCd battery recycling and disposal bans/restrictions

in your area, or return your batteries to a

Skil/Bosch/Dremel Service Center for recycling.

Robert Bosch Tool Corporation’s involvement in

this program is part of our commitment to preserving our environment and conserving our natural resources.”

WARNING

!

ponent projecting from the battery terminals.

or injury may result. Prior to disposal, protect

exposed terminals with heavy insulating tape to prevent shorting.

Do not attempt to disassemble

the battery or remove any com-

Fire

Alkaline Batteries

Commercially available alkaline cells can be disposed of in a municipal solid waste stream.

Page 6

Page 7

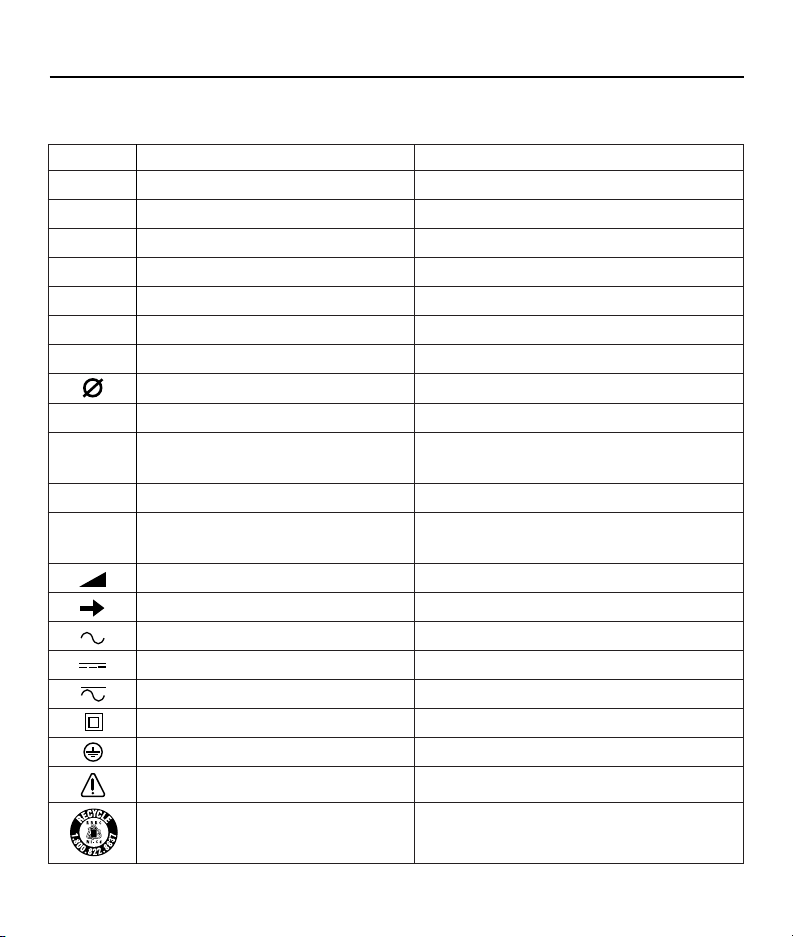

Symbols

0

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

.../min Revolutions or reciprocation per minute Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

No load speed Rotational speed, at no load

orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling program

Page 7

Page 8

Symbols

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates that

this tool is listed by the

Canadian Standards

Association.

This symbol designates that this

tool is listed to Canadian

Standards by Underwriters

Laboratories.

This symbol designates that this

tool is listed by Underwriters

Laboratories, and listed to

Canadian Standards by

Underwriters Laboratories.

This symbol

designates that

this tool

complies

to NOM

Mexican

Standards.

Page 8

Page 9

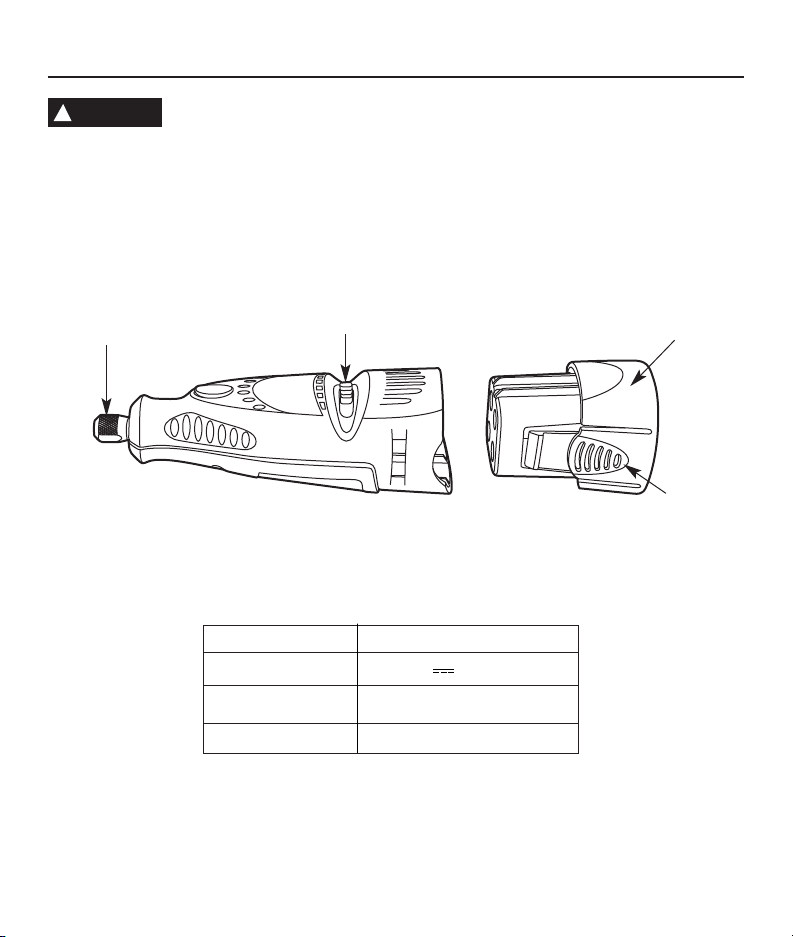

Functional Description & Specifications

WARNING

!

tive safety measures reduce the risk of starting the tool accidentally.

Disconnect battery pack from tool or place the switch in the locked or off position

before making any assembly, adjustments or changing accessories

Golf Club Cleaning Tool

COLLET NUT

Model number 760

Voltage rating 6.0 V

No load speed no7,000-14,000/min

Collet Capacities 1/32”, 1/16”, 3/32”, 1/8”

SWITCH

. Such preven-

BATTERY

PACK

RELEASE TAB

Page 9

Page 10

Assembly

!

WARNING

ALWAYS BE SURE THE TOOL IS

IN THE “OFF” POSITION

BEFORE CHANGING ACCESSORIES, CHANGING

COLLETS OR SERVICING YOUR CORDLESS

ROTARY TOOL.

SHAFT

LOCK

BUTTON

COLLET

NUT

TO LOOSEN

COLLET

(1/8" Collet is included with your tool)

TO TIGHTEN

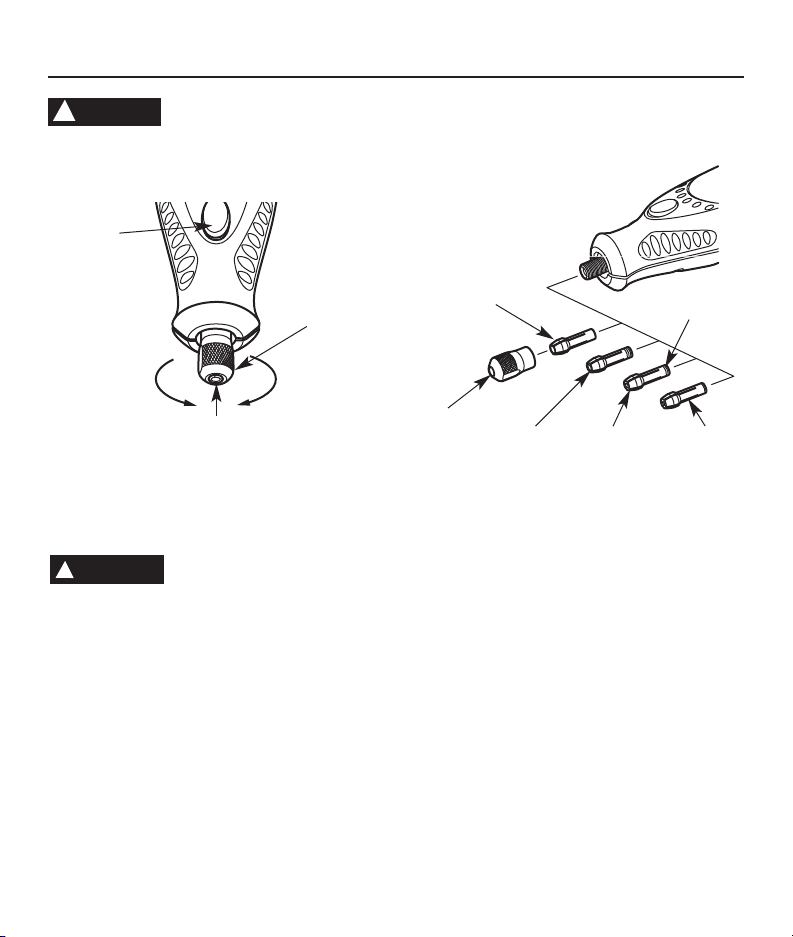

COLLET NUT— To loosen, first press shaft lock but-

ton and rotate the collet nut by hand until the lock

engages the shaft preventing further rotation.

CAUTION

!

Do not engage lock while the

Tool is running.

With the shaft lock engaged, loosen the collet nut by

hand. Change accessories by inserting the new one

into the collet as far as possible to minimize runout

and unbalance. With the shaft lock engaged, finger

tighten the collet nut until the accessory shank is

gripped by the collet.

Avoid excessive tightening

of the collet nut when there is no bit inserted.

COLLETS —

Four different size collets (see illustration), to accommodate different shank sizes, are

available for your Cordless Rotary Tool. To install a

different collet, remove the collet nut and remove

the old collet. Insert the unslotted end of the collet

in the hole in the end of the tool shaft. Replace col-

COLLET IDENTIFICATION CHART — Collet sizes

can be identified by the rings on the back end of

collet.

1/32" Collet has one (1) ring.

1/16" Collet has two (2) rings.

3/32" Collet has three (3) rings.

1/8" Collet has no rings.

480 1/8"

COLLET

COLLET

NUT

481 3/32"

COLLET

let nut on the shaft.

482 1/16"

COLLET

Always use the collet which

IDENTIFICATION

RINGS

483 1/32"

COLLET

matches the shank size of the accessory you plan

to use.

Never force a larger diameter shank into a

collet.

BALANCING ACCESSORIES — For precision work,

it is important that all accessories be in good balance (much the same as the tires on your automobile). To true up or balance an accessory, slightly

loosen collet nut and give the accessory or collet a

1/4 turn. Retighten collet nut and run the Tool. You

should be able to tell by the sound and feel if your

accessory is running in balance. Continue adjusting

in this fashion until best balance is achieved. To

maintain balance on abrasive wheel points, before

each use, with the wheel point secured in the collet,

turn on the Cordless Rotary Tool and run the 415

Dressing Stone lightly against the revolving wheel

point. This removes high spots and trues up the

wheel point for good balance.

Page 10

Page 11

Remember, your new Dremel Cordless Rotary Tool

is the finest power tool of its kind. But its performance is only as good as the accessories with

which it is used. We recommend only Dremel

accessories be used. Use of any other accessories

may create a hazard. We hope you’ll enjoy many

years of trouble free pleasure from your Dremel

Cordless Rotary Tool.

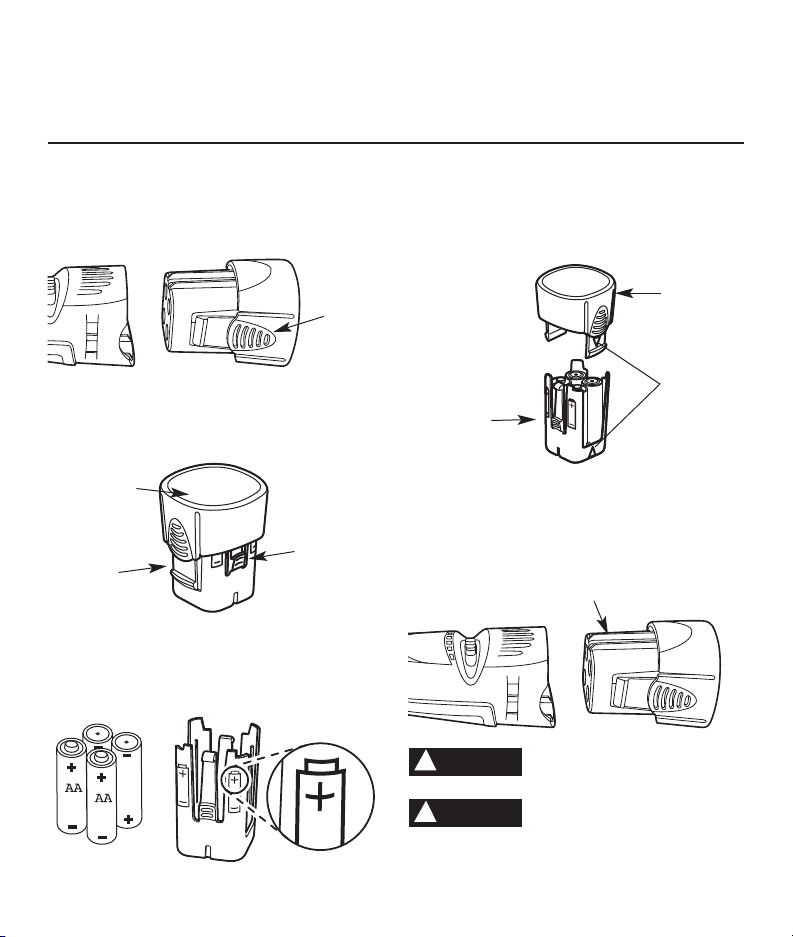

Inserting batteries

1. Remove the battery pack from the tool by squeezing the two tabs on the battery pack together and

slide the battery pack out of the tool.

BATTERY

PACK

RELEASE

TAB

2. Remove battery pack cover from the battery

holder by squeezing the two tabs and remove the

battery cover from the battery holder.

BATTERY PACK

COVER

BATTERY

PACK

BATTERY

HOLDER

3. Paying special attention to the orientation of the

batteries, insert four AA batteries into the battery

holder. Note diagram on the battery holder showing correct battery direction.

COVER

RELEASE

TABS

4. Align arrow in battery pack cover with arrow in

the battery holder and press together. The two

parts will only fit together when the arrows are

aligned. The two parts will join together with a

click.

BATTERY

PACK

COVER

ALIGN

ARROWS

BATTERY

HOLDER

5. Insert the battery pack into the tool by aligning

the guide ribs on the battery with the guide track

on the tool. The two parts will only fit together

when the two arrows align. The two parts will join

together with a click.

GUIDE TRACK

!

WARNING

!

WARNING

may explode or leak.

Page 11

RISK OF FIRE USE ONLY 1.5V

ALKALINE BATTERIES ONLY.

Do not install backwards,

charge or put in fire.

Batteries

Page 12

Operation Instructions

Applications

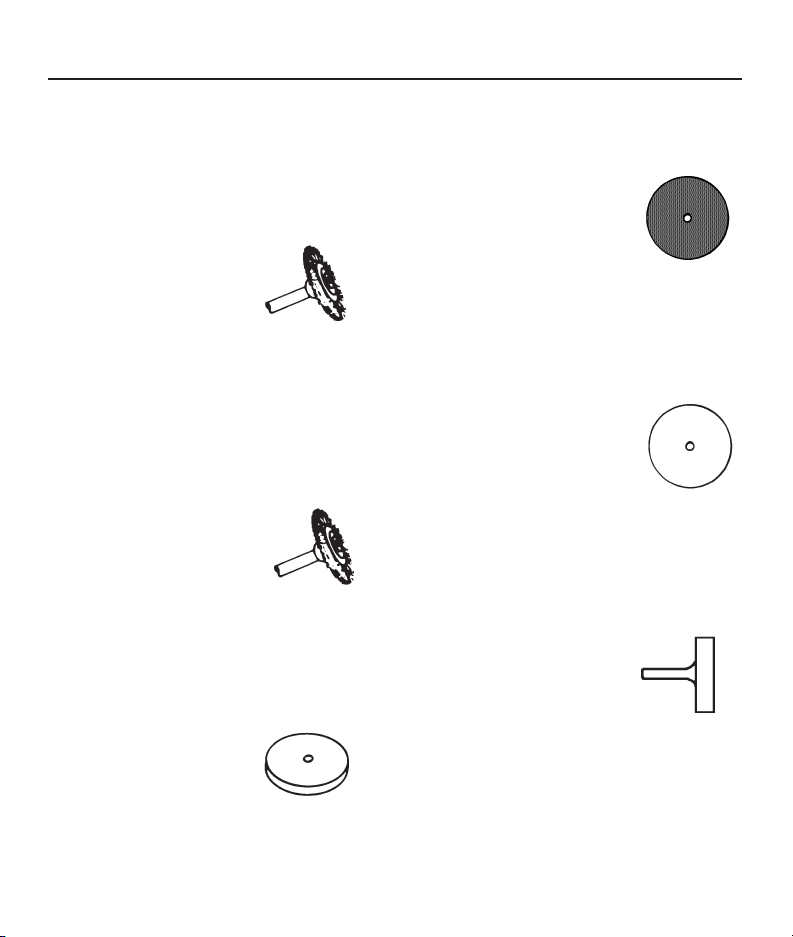

The 760 Golf Club Cleaning Tool can be outfitted

with different Dremel accessories to perform a variety of golf-related tasks. Included below are

descriptions of popular Dremel accessories used

with the 760 tool. Be sure to visit www.Dremel.com

for more information on how to replace golf grips

and size golf clubs.

Brass Brush (included)

Brass brushes are softer than steel, so you’ll be

able to clean away dirt and oxidation without

harming your club heads.

Tip: Use the brass brush at HI speed. The #535

Dremel brass brush is especially effective for

cleaning the grooved surface on a club’s face.

Note: Do not use the brass brush on the varnished surface of wooden golf club heads or on

the painted surfaces of metal or graphite clubs.

Bristle Brush (included)

Bristle brushes are softer than plastic, so you’ll be

able to clean away dirt and grass from graphite

clubs, wood clubs, soles of golf shoes, and bags.

Tip: Use the bristle brush at HI speed. The #403

Dremel bristle brush is especially effective for

cleaning between the cleats on most golf shoes.

Other Accessories (not included)

Cloth Polishing Wheel

Restore a like-new shine to metal club heads and

shafts using the #423 Dremel cloth polishing

wheel and 421 polishing compound.

Tip: Use the polishing wheel at HI speed.

Fiberglass Reinforced Cut-off Wheel

Use the #426 Dremel fiberglass reinforced cut-off

wheel with a #402 mandrel to cut golf club shafts

to the proper length.

Tip: Smooth the shaft tip with a 407 sanding drum.

Cut-off Wheel

When replacing golf club grips use the #409

Dremel cut-off wheel with a #402 mandrel to cut

off the old grips.

Tip: Be careful not to cut into the actual shaft.

Aluminum Oxide Abrasive Wheel

Use the #500 Dremel aluminum oxide abrasive

wheel to remove rust from your irons.

Tip: Use the abrasive wheel at LO speed.

Page 12

Page 13

WARNING

Wear Eye Protection

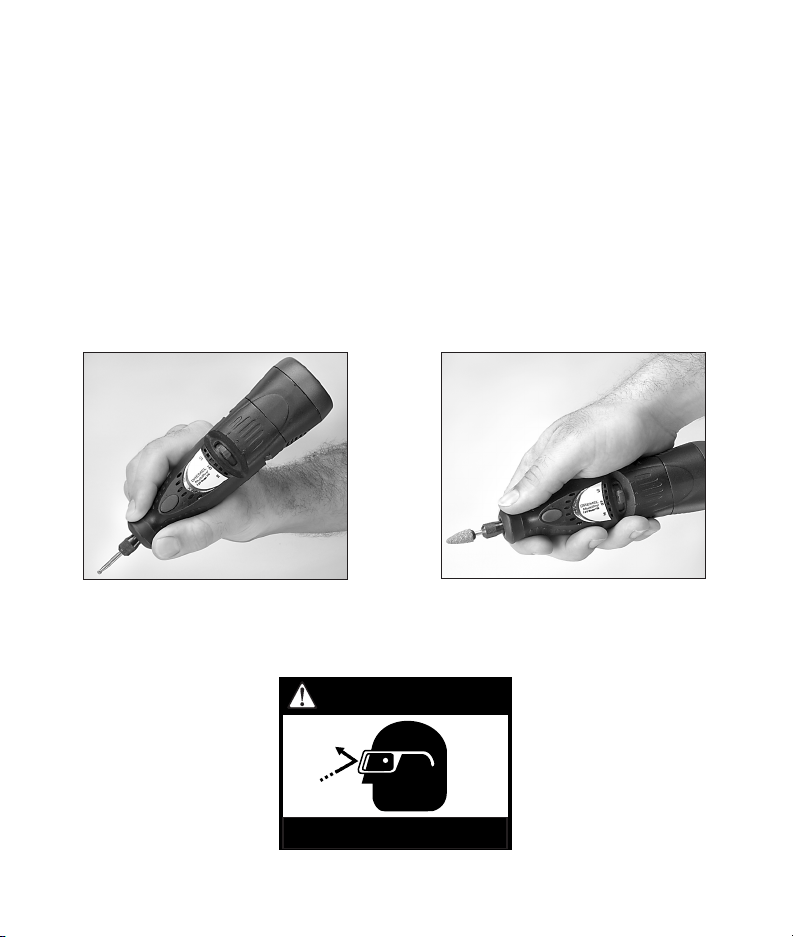

Using the Cordless Rotary Tool

The first step in learning to use the Cordless Rotary

Tool is to get the “feel” of it. Hold it in your hand and

feel its weight and balance. Feel the taper of the

housing. This taper permits the tool to be grasped

much like a pen or pencil.

When you turn on the tool for the first time, hold it

away from your face. Accessories can be damaged

during handling, and can fly apart as they come up

to speed. This is not common, but it does happen.

Practice on scrap materials first to see how the

Cordless Rotary Tool works. Keep in mind that the

work is done by the speed of the tool and by the

accessory in the collet. You should not lean on or

push the tool into the work.

Instead, lower the spinning accessory lightly to the

work and allow it to touch the point at which you

want to begin. Concentrate on guiding the tool over

the work using very little pressure from your hand.

Allow the accessory to do the work.

Usually, it is best to make a series of passes with the

tool rather than attempt to do all the work in one

pass. Pass the tool back and forth over the work,

much as you would a small paint brush. For most

work, the deft, gentle touch is best. With it, you have

the best control, are less likely to make errors, and

will get the most efficient work out of the accessory.

For best control in close work, grip the Rotary Tool

like a pencil between your thumb and forefinger.

The “handgrip” method of holding the tool is used

for operations such as cleaning a flat surface.

Page 13

Page 14

Operating Speeds For Accessories

Set the speed indicator to fit the job to achieve the

best job results when working with different

materials.

To select the right speed for each job, use a practice piece of material. Vary speed to find the best

speed for the accessory you are using and the job

to be done.

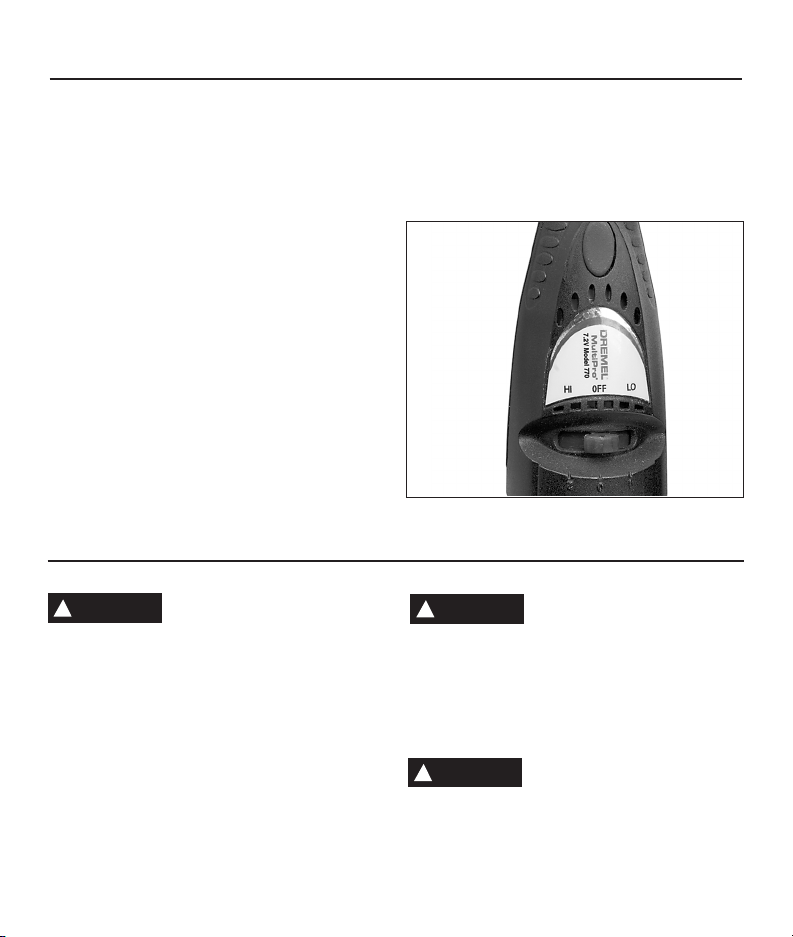

On the Model 760, there is a LO and HI switch.

When the switch indicator is in position 1 or LO, the

tool runs at about 7,000 RPM. When the switch

indicator is in position 2 or HI, the tool runs at about

14,000 RPM.

NOTE: Speed is affected by voltage changes.

Weaker batteries with reduced voltage will slow the

RPM of the tool, especially at the lowest setting. If

your tool appears to be running more slowly than

normal, replace the batteries with fresh ones to

increase tool speed.

Most applications using the 760 Golf Club Cleaning

Tool can be accomplished using the HI speed setting (position 2). The HI speed setting (position 2)

Maintenance

Service

WARNING

!

nance performed by unauthorized personnel may

result in misplacing of internal wires and components which could cause serious hazard.

recommend that all tool service be performed by a

Dremel Service Facility.

D.C. motors

The motor in your tool has been engineered for

many hours of dependable service. To maintain peak

efficiency of the motor, we recommend it be examined every six months. Only a genuine Dremel

replacement motor specially designed for your tool

should be used.

NO USER SERVICEABLE PARTS

INSIDE. Preventive mainte-

We

is recommended when using the 403 bristle and

535 wire brush accessories included with the tool.

LO speed is needed only for certain tasks when

more control in needed.

The speed of Model 760 is controlled by

setting this indicator on the housing.

Cleaning

WARNING

!

cleaning.

with compressed dry air.

gles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept

clean and free of foreign matter. Do not attempt to

clean by inserting pointed objects through opening.

CAUTION

!

Some of these are: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

Page 14

To avoid accidents, always disconnect battery pack before

The tool may be cleaned most effectively

Always wear safety gog-

Certain cleaning agents and solvents damage plastic parts.

Page 15

Dremel Limited Warranty

Your Dremel product is warranted against defective material or workmanship for a period of two years from date of

purchase. In the event of a failure of a product to conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid, along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center Dremel Service Center

4915 Twenty-First Street OR 4631 E. Sunny Dunes

Racine, Wisconsin 53406 Palm Springs, CA 92264

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write

Scarborough, Ont. to Dremel, 4915 Twenty-First St.

Canada M1C 4A7 Racine, Wisconsin 53406

1-888-285-3476

We recommend that the package be insured against loss or in transit damage for which we cannot be responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT RESULTING FROM

TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR ALTERATIONS, UNAPPROVED

ATTACHMENTS OR OTHER CAUSES UNRELATED TO PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT

COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel. If Dremel

inspection shows that the problem was caused by problems with material or workmanship within the limitations of

the warranty, Dremel will repair or replace the product free of charge and return product prepaid. Repairs made necessary by normal wear or abuse, or repair for product outside the warranty period, if they can be made, will be

charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, AND ALL IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE ABOVE

MENTIONED OBLIGATION ARE HEREBY DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state. The

obligation of the warrantor is solely to repair or replace the product. The warrantor is not liable for any incidental or

consequential damages due to any such alleged defect. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado en México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405, Zona Industrial,

Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

Page 15

Page 16

Outil de nettoyage de bâtons de

golf modèle 760 Mode d’emploi

• Sécurité

• Assemblage

• Fonctionnement

• Informations sur les accessoires

• Garantie

• Pièces de service

P.O. Box 1468

Racine, Wisconsin 53401

1-800-437-3635

http://www.dremel.com

Les produits de marque Dremel sont fabriqués et commercialisés par la

Division Dremel de Robert Bosch Tool Corporation

Page 16

Page 17

Consignes générales de sécurité

!

AVERTISSEMENT

de blessures corporelles graves. Dans toutes les mises en garde ci-dessous, le terme « outil électroportatif

» se rapporte à des outils branchés sur le secteur (avec fil) ou à des outils alimentés par piles (sans fil).

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé.

Les risques d’accident sont plus élevés quand on travaille dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des atmosphères explosives, comme par exemple en présence

de gaz, de poussières ou de liquides inflammables.

Les outils électroportatifs produisent des étincelles qui

risquent d’enflammer les poussières ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une

perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent correspondre à la prise. Il ne faut absolument jamais modifier la fiche. N’utilisez pas d’adaptateur de prise

avec des outils électroportatifs munis d’une fiche de

terre. Le risque de choc électrique est moindre si on

utilise une fiche non modifiée sur une prise qui lui correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente

si votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à la pluie ou

à l’humidité. Si de l’eau pénètre dans un outil électro-

portatif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif, pour le

tirer ou pour le débrancher. Éloignez le cordon de la

chaleur, des huiles, des arêtes coupantes ou des

pièces mobiles. Les cordons abîmés ou emmêlés aug-

mentent les risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

Veuillez lire et comprendre toutes les consignes. Si on n'observe pas toutes les

consignes décrites ci-dessous, il y a risque de choc électrique, d’incendie et/ou

CONSERVEZ CES CONSIGNES

employez une rallonge conçue pour l’extérieur.

rallonges sont faites pour l’extérieur et réduisent le

risque de choc électrique.

N’utilisez pas un outil conçu uniquement pour le C.A.

sur une alimentation en C.C. Même si l’outil semble

fonctionner, les composants électriques d’un outil prévu

pour le C.A. tomberont probablement en panne et

risquent de créer un danger pour l’utilisateur.

S’il est nécessaire d’utiliser l’outil dans un lieu

humide, il faut l’alimenter par l’intermédiaire d’un

disjoncteur différentiel de fuite à la terre (DDFT).

L’emploi d’un DDFT et de dispositifs de protection personnelle tels que gants et chaussures d’électricien en

caoutchouc améliorent votre sécurité personnelle.

Ces

Sécurité personnelle

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque vous

utilisez un outil électroportatif. N'employez pas

d’outils électroportatifs quand vous êtes fatigué ou

sous l’emprise de drogues, d’alcool ou de médicaments. Quand on utilise des outils électroportatifs, il

suffit d’un moment d’inattention pour causer des

blessures corporelles graves.

Utilisez des équipements de sécurité. Portez toujours

une protection oculaire. Si les conditions le deman-

dent, il faut porter un masque à poussière, des chaussures de sécurité antidérapantes, un casque de chantier

ou une protection auditive pour réduire le risque de

blessure corporelle.

Évitez les démarrages intempestifs. Assurez-vous

que l’interrupteur est en position arrêt (OFF) avant de

brancher l’outil. Transporter un outil électroportatif

avec le doigt sur la gâchette ou le brancher quand l’interrupteur est en position “marche” (ON) présente des

risques d’accident.

Page 17

Page 18

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé

sur une pièce tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations inattendues.

Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ou de bijoux. Attachez les

cheveux longs. N’approchez pas les cheveux, les

vêtements ou les gants des pièces en mouvement.

Les vêtements amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le raccordement d’un système d’aspiration et de collecte

des poussières, assurez-vous que ces dispositifs sont

raccordés et utilisés correctement. L’utilisation de ces

dispositifs peut permettre de réduire les dangers liés à

la poussière.

Maintenez les poignées sèches et exemptes d’huile

et de graisse. On ne pas maîtriser un outil électropor-

tatif en toute sécurité quand on a les mains glissantes.

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et

est plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son

interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter.Tout outil électroportatif qui ne peut pas être

commandé par son interrupteur est dangereux et doit

être réparé.

Débranchez la fiche de la prise ou enlevez le bloc-pile

de l’outil électroportatif avant tout réglage, changement d’accessoires ou avant de ranger l’outil électroportatif. De telles mesures de sécurité préventive

réduisent le risque de démarrage intempestif de l’outil

électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans

les mains d’utilisateurs inexpérimentés.

Entretenez les outils électroportatifs. Vérifiez que les

pièces mobiles sont alignées correctement et ne

coincent pas. Vérifiez qu’il n’y a pas de pièces

cassées ou d’autre circonstance qui risquent d’affecter le fonctionnement de l’outil électroportatif. Si

l’outil est abîmé, faites-le réparer avant de l’utiliser.

De nombreux accidents sont causés par des outils électroportatifs mal entretenus.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de

coincer et sont plus faciles à maîtriser.

Utilisez l’outil électroportatif, les accessoires, les

embouts etc. selon ces consignes et de la manière

prévue pour chaque type particulier d’outil électroportatif en tenant compte des conditions de travail et

de la tâche à accomplir. L'emploi d’outils électropor-

tatifs pour des tâches différentes de celles pour

lesquelles ils ont été prévus peut résulter en une situation dangereuse.

Utilisez des brides ou d’autres moyens pratiques de

brider ou de supporter la pièce sur une plate-forme

stable. Tenir la pièce à la main ou contre le corps est

instable et risque de résulter en une perte de contrôle.

Utilisation et entretien des outils à piles

Rechargez les piles uniquement avec le chargeur

spécifié par le fabriquant. Un chargeur qui convient à

un type de bloc-piles peut entraîner un risque d’incendie

quand il est utilisé avec un autre bloc-piles.

Utilisez des outils alimentés par piles uniquement

avec les blocs-piles spécifiquement désignés pour

eux. L’utilisation de tout autre bloc-piles peut créer un

risque de blessures et d’incendie.

Lorsque le bloc-piles n’est pas utilisé, gardez-le à

distances d’autres objets métalliques tels que des

trombones, des pièces de monnaie, des clés, des

clous, des vis ou de tout autre objet métallique pouvant faire une connexion entre une borne et une

Page 18

Page 19

autre. Court-circuiter les bornes des piles peut causer

des brûlures ou un incendie.

Dans des conditions abusives, du liquide peut être

éjecté de la pile ; dans un tel cas, évitez tout contact

avec ce liquide. Si un contact se produit accidentellement, rincez avec de l’eau. Si le liquide entre en contact avec les yeux, consultez un médecin. Du liquide

éjecté de la pile peut causer des irritations ou des

brûlures.

Veillez à ce que l’interrupteur soit dans la position de

fermeture avant d’insérer le bloc-piles. L’insertion

d’un bloc-piles dans un outil électroportatif dont l’interrupteur est dans la position de marche est une invite aux

accidents.

CONSERVEZ CES INSTRUCTIONS

Consignes de sécurité pour outil rotatif sans cordon

Tenez l'outil par les surfaces isolées de prise en

exécutant une opération lorsque l'outil de coupe

peut venir en contact avec des fils cachés. Le con-

tact avec un fil sous tension rendra les parties

métalliques exposées de l'outil sous tension et

causera des secousses électriques à l'opérateur.

Utilisez des brides ou d’autres moyens pratiques de

brider ou de supporter la pièce sur une plate-forme

stable. Tenir la pièce à la main ou contre le corps est

instable et risque de résulter en une perte de contrôle.

Les accessoires doivent être prévus pour au moins

la vitesse recommandée sur l'étiquette d'avertissement de l'outil. Les meules et les autres accessoires

utilisés à une vitesse supérieure à la vitesse nominale

peuvent se détacher et provoquer des blessures.

Pour couper dans des murs existants ou autres

endroits aveugles pouvant dissimuler des fils électriques, débranchez tous les fusibles ou les disjoncteurs alimentant ce lieu de travail.

Avant de changer les accessoires, retirez le bloc-pile.

Il peut y avoir mise en marche accidentelle parce que les

outils à pile avec pile insérée sont en état de marche.

Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de

rechange identiques. Ceci assure que la sécurité de

l’outil électroportatif est préservée.

Créez un agenda d’entretien périodique pour votre

outil. Quand vous nettoyez un outil, faites attention de

n’en démonter aucune pièce car il est toujours possible de mal remonter ou de pincer les fils internes ou

de remonter incorrectement les ressorts de rappel

des capots de protection. Certains agents de nettoyage

tels que l’essence, le tétrachlorure de carbone, l’ammoniaque, etc. risquent d’abîmer les plastiques.

Connaissez l'emplacement de l'interrupteur lorsque

vous déposez l'outil ou lorsque vous le reprenez.

Vous pouvez actionner l'interrupteur par mégarde.

Tenez toujours le couteau des deux mains durant la

mise en marche. Le couple de réaction du moteur peut

faire tordre l'outil.

Portez toujours des lunettes de sécurité et un masque

anti-poussières. N'utilisez l'outil qu'à un endroit bien

aéré. L'utilisation de dispositifs de sécurité personnelle

et le travail dans un environnement sûr réduisent les

risques de blessures.

Après avoir changé les lames ou effectué quelque

réglage que ce soit, assurez-vous que l'écrou de la

douille et tout autre dispositif de réglage sont bien

serrés. Un dispositif de réglage lâche peut bouger

soudainement et causer ainsi une perte de contrôle avec

projection violente des composants en rotation.

Ne placez pas la main à proximité de la mèche qui

tourne. Vous ne vous rendrez pas toujours compte de

cette proximité.

Laissez les brosses tourner à la vitesse de fonctionnement pendant au moins une minute avant d’utiliser

Page 19

Page 20

la meule. Durant cette période, personne ne doit se

tenir devant la meule ou en ligne avec celle-ci.

Pendant la période de rodage, les poils ou fils de fer

seront éjectés de la brosse.

Les brosses (à poils standards ou métalliques) ne

doivent jamais être utilisées au-dessus de 15 000

tr/min. Dirigez la décharge de la brosse métallique en

rotation en sens opposé à vous. Des petites particules

et des petits fragments de fil peuvent être déchargés à

grande vitesse durant l'action de « nettoyage » de ces

brosses et peuvent se loger dans votre peau. À haute

vitesse, les poils ou fils de fer mal attachés seront éjectés.

Portez des gants et un écran de protection quand vous

utilisez une brosse à poils standard ou une brosse

métallique. N’appuyez que légèrement la brosse à

poils standard ou la brosse métallique sur la pièce

car seuls les extrémités des brins sont actives. Si on

appuie trop fort, les brins subissent des contraintes

exagérées résultant en un mécanisme d’essuyage suivi

de l’éjection de brins.

Maniez soigneusement l'outil aussi bien que les

meules individuelles pour éviter les éclats ou les fissurations. Posez une nouvelle meule si l'outil tombe

pendant la rectification. N'utilisez pas une meule qui

peut être endommagée. Les fragments d'une meule

qui éclate durant le fonctionnement seront projetés à

grande vitesse et pourraient frapper des personnes

présentes ou vous-même.

N'utilisez jamais de lames émoussées ou abîmées.

Les lames affilées doivent être maniées soigneusement.

Les mèches abîmées peuvent se rompre brusquement

durant l'usage. Les lames émoussées nécessitent plus

de force pour pousser l'outil, causant éventuellement un

bris de la lame.

Utilisez des pinces pour supporter l'ouvrage autant

que possible. Ne tenez jamais un petit ouvrage d'une

main et l'outil de l'autre main pendant que celui-ci

est en usage. Prévoyez un espace suffisant, d'au

moins 150 mm, entre votre main et la mèche qui

tourne. Les pièces rondes, telles que tiges cylindriques,

tuyaux ou tubes, ont tendance à rouler pendant qu'on

les coupe et, de ce fait, la mèche peut « mordre » ou

sauter vers vous. En fixant un petit ouvrage, vous pourrez utiliser vos deux mains pour contrôler l'outil.

Inspectez l'ouvrage avant de le couper. Avant de

couper un ouvrage de forme irrégulière, planifiez

votre travail de manière à ce que l'ouvrage ne glisse

pas et ne vienne pas pincer la mèche qui sera

arrachée de votre main. Ainsi, si vous taillez du bois,

assurez-vous de l'absence de clous ou de corps

étrangers dans l'ouvrage. Sous l'effet du contact avec

des clous ou corps étrangers, la mèche peut sauter.

Ne mettez jamais l'outil en marche alors que la lame

est enfoncée dans le matériau. Le tranchant de la lame

peut se coincer dans le matériau et vous faire perdre le

contrôle du couteau.

Évitez de faire rebondir et de heurter la meule, surtout

en travaillant des coins, des arêtes vives, etc. Ceci

peut causer une perte de contrôle et un rebond.

Le sens d'avance de la mèche dans l'ouvrage lorsque

vous taillez, détourez ou coupez est très important.

Avancez toujours la mèche dans l'ouvrage dans le

sens dans lequel le tranchant sort de l'ouvrage (ce qui

correspond au sens d'éjection des copeaux). L'avance

de l'outil dans le mauvais sens fait sortir le tranchant de

la mèche de l'ouvrage et tire l'outil dans le sens de cette

avance.

Si le matériau ou la mèche se grippe ou se bloque,

mettez l'outil hors tension « OFF » par l'interrupteur.

Attendez que toutes les pièces mobiles s'immobilisent et débranchez l'outil, procédez ensuite à

débloquer l'ouvrage bloqué.

Si l'interrupteur de l'outil

est laissé en position de marche « ON », l'outil pourrait

se remettre en marche par mégarde et causer ainsi des

blessures graves.

Ne laissez pas un outil en marche sans surveillance,

mettez hors tension. L'outil peut être déposé en toute

sécurité uniquement lorsqu'il s'est arrêté complètement.

Ne rectifiez et ne poncez pas à proximité de matières

inflammables. Les étincelles provenant de la meule

pourraient enflammer ces matières.

Ne touchez pas la mèche ou la douille après usage.

Après usage, la mèche et la douille sont trop chaudes

pour être touchées à mains nues.

Nettoyez régulièrement les prises d'air de l'outil à

l'aide d'air comprimé. Une accumulation excessive de

métal en poudre à l'intérieur du carter du moteur peut

Page 20

Page 21

causer des défaillances électriques.

Ne soyez pas dupé par la familiarité acquise par un

usage fréquent de votre outil rotatif. N'oubliez pas

qu'une fraction de seconde d'insouciance suffit à

infliger des blessures graves.

Ne modifiez pas l'outil et n'en faites pas un usage

erroné. Toute altération ou modification constitue un

usage erroné et peut provoquer des blessures graves.

Ce produit n’a pas été conçu pour être utilisé comme

fraise de dentiste ou pour des applications médicales sur des personnes ou des animaux. Il y a risque

de blessure grave.

Lorsque vous utilisez les scies en acier, les disques

de découpage, les couteaux à grande vitesse ou les

couteaux au carbure de tungstène, assurez-vous que

la pièce est toujours bien assujettie. Ne tentez jamais

de tenir la pièce d’une seule main tout en utilisant

l’un de ces accessoires. La raison en est que ces roues

grippent lorsqu’elles sont le moindrement inclinées

dans la rainure, et elles peuvent alors rebondir, vous

faisant ainsi perdre le contrôle et causant des blessures

graves. Votre autre main doit servir à stabiliser et guider

la main qui tient l’outil. Lorsqu’un disque de découpage

grippe, on peut généralement s’attendre à ce qu’il se

brise. Lorsque la scie en acier, les couteaux à grande

vitesse ou le couteau au carbure de tungstène grippent,

ils peuvent sauter hors de la rainure et vous pouvez perdre le contrôle de l’outil.

!

AVERTISSEMENT

meulage, perçage et autres travaux du bâtiment peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire l’exposition à ces produits chimiques, il faut travailler dans un

lieu bien ventilé et porter un équipement de sécurité

approprié tel que certains masques à poussière conçus

spécialement pour filtrer les particules microscopiques.

Les travaux à la machine

tel que ponçage, sciage,

Page 21

Page 22

Mise au rebut des piles

Piles nickel-cadmium

Si le produit est équipé d'une pile nickel-cadmium, la

pile doit être ramassée, recyclée ou mise au rebut d'une

manière qui ne soit pas nocive pour l'environnement.

“Le sceau RBRC de recyclage des

piles, homologué par l’EPA

(Agence pour la protection de l’environnement des États-Unis), qui

se trouve sur les piles au nickel-

cadmium (Ni-Cd) indique que

Robert Bosch Tool Corporation participe volontairement à un programme industriel de ramassage et de

recyclage de ces piles au terme de leur vie utile,

pourvu qu’elles soient mises hors service aux ÉtatsUnis ou au Canada. Le programme du RBRC offre une

alternative pratique à la mise des piles au Ni-Cd usées

au rebut ou au ramassage d’ordures municipal, ce qui

pourrait être interdit dans votre région.

Veuillez appeler le 1-800-8-BATTERY pour obtenir de

plus amples renseignements sur le recyclage des piles

au Ni-Cd et sur les restrictions ou interdictions de

mise au rebut qui s’appliquent à votre région ou

renvoyez vos piles à un Centre de Service

Skil/Bosch/Dremel pour recyclage. La participation de

Robert Bosch Tool Corporation à ce programme s'insère dans le contexte de notre engagement à préserver notre environnement et à conserver nos ressources

naturelles.”

!

AVERTISSEMENT

ou d’enlever tout composant faisant saillie des

bornes de piles, ce qui peut provoquer un incendie ou

des blessures. Avant la mise au rebut, protégez les

bornes exposées à l’aide d’un ruban isolant épais pour

prévenir le court-circuitage.

Ne tentez pas de

désassembler le bloc-piles

Pile alcalines

Les piles alcalines du commerce peuvent être mises

au rebut normalement avec les autres déchets solides

municipaux.

Page 22

Page 23

Symboles

0

Important : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon

plus efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules, etc.

n

0

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de position.

l, ll, lll, ... Un nombre plus élevé signifie une vitesse plus grande.

Vitesse à vide Vitesse de rotation, à vide

minute etc., par minute,

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif ou continu Type ou caractéristique du courant

Construction classe II isolation Désigne des outils construits avec double

Borne de terre borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages d'avertissement.

Sceau Ni-Cad RBRCmc Désigne le programme de recyclage des piles Ni-Cad.

Page 23

Page 24

Symboles

Important : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et appren-

dre leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon

plus efficace et plus sûre.

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories.

Ce symbole signifie que cet

outil est approuvé par

l'Association canadienne de

normalisation.

Ce symbole signifie que

cet outil est approuvé

conformément aux normes

canadiennes par Underwriters

Laboratories.

Ce symbole signifie que cet

outil est approuvé par

Underwriters Laboratories

et qu’il a été homologué selon

les normes canadiennes par

Underwriters Laboratories.

Ce symbole

signifie que

cet outil se

conforme aux

normes

mexicaines

NOM.

Page 24

Page 25

Description fonctionnelle et spécifications

!

AVERTISSEMENT

soires. Ces mesures de sécurité préventives réduisent le risque d'une mise en marche accidentelle de l'outil.

Débranchez le bloc-pile de l'outil ou placez l'interrupteur à la position de blocage

ou d'arrêt avant d'effectuer tout assemblage ou réglage ou de changer les acces-

Outil de nettoyage de bâtons de golf

ÉCROU DE

DOUILLE

Numéro de modèle 760

Intensité nominale 6,0 V

Régime à vide no7 000-14 000/min

Capacités de la douille 0,8 mm, 1,6 mm, 2,4 mm, 3,2 mm

INTERRUPTEUR

BLOC-PILE

PATTE DE

DÉTACHEMENT

Page 25

Page 26

Assemblage

!

AVERTISSEMENT

SITION “OFF” AVANT DE CHANGER LES ACCESSOIRES

OU LES DOUILLES, OU DE FAIRE L’ENTRETIEN DE

VOTRE OUTIL ROTATIF SANS CORDON.

BOTON DE

FIJACION

DEL EJE

ASSUREZ-VOUS TOUJOURS

QUE L’OUTIL EST À LA PO-

TUERCA DEL

PORTAHERRAMIENTA

TABLEAU D’IDENTIFICATION DES DOUILLES DE SERRAGE — Les tailles des douilles de serrage peuvent être

identifiées par les anneaux à l’extrémité arrière de la douille.

La douille de 0,8 mm possède un (1) anneau.

La douille de 1,6 mm possède deux (2) anneaux.

La douille de 2,4 mm possède trois (3) anneaux.

La douille de 3,2 mm ne possède aucun anneau.

PORTAHERRAMIENTA

480 DE 3,2 mm

PARA

AFLOJAR

PORTAHERRAMIENTA

(El portaherramienta de 3,2 mm se incluye

con la herramienta)

PARA

APRETAR

ÉCROU DE DOUILLE — Pour desserrer, appuyez

d’abord sur le bouton de blocage de l’arbre et tournez

l’écrou de douille à la main jusqu’à ce que le dispositif

de blocage engage l’arbre, empêchant ainsi toute rotation ultérieure.

!

MISE EN GARDE

N’appuyez pas sur la

bouton de blocage de

l’arbre pendant que l’outil est en marche.

L’arbre étant bloqué, desserrez l’écrou de douille à la

main. Changez les accessoires en insérant le nouveau

le plus loin possible dans la douille de serrage,

réduisant ainsi les possibilités qu’il ne se libère ou ne se

déséquilibre. L’arbre étant bloqué, serrez à la main

l’écrou de douille jusqu’à ce que la tige de l’accessoire

soit retenue solidement par la douille. Évitez de serrer

l'écrou de douille trop fort quand il n'y a pas d'embout.

DOUILLES — Quatre tailles différentes de douilles (re-

portez-vous à l’illustration), adaptées à des tailles différentes de tiges, sont offertes pour votre outil rotatif sans

cordon. Pour poser une autre douille, retirez l’écrou de

la douille ainsi que la douille à remplacer. Insérez l’extrémité non fendue de la douille dans l’ouverture à l’extrémité de l’arbre de l’outil.

TUERCA DEL

PORTAHERRAMIENTA

PORTA-

HERRAMIENTA

481 DE 2,4 mm

PORTA-

HERRAMIENTA

482 DE 1,6 mm

IDENTIFICACION

483 DE 0,8 mm

Replacez l’écrou sur l’arbre. Utilisez toujours la douille

de même grosseur que la tige de l’accessoire que

vous désirez utiliser. Ne forcez jamais une tige trop

grosse pour la douille.

ÉQUILIBRAGE DES ACCESSOIRES — Pour le travail de

précision, il est important que tous les accessoires

soient bien équilibrés (tout comme les pneus de votre

voiture). Pour rectifier ou équilibrer un accessoire,

desserrez légèrement l’écrou de la douille, et tournez

l’accessoire ou la douille d’un quart de tour. Resserrez

l’écrou de la douille et mettez l’outil rotatif sans cordon

en marche. Le son qui se fait entendre et le maniement

de l’outil devraient vous indiquer si l’accessoire est bien

équilibré. Continuez l’ajustement de cette façon jusqu’à

ce que vous obteniez le meilleur équilibre. Pour maintenir l’équilibre des pointes de meule abrasive, avant

chaque usage, alors que la pointe de roue est retenue

fermement dans la douille, mettez l’outil rotatif sans cordon en marche et tenez la pierre à rectifier 415 légèrement appuyée sur la pointe de la meule en rotation. Ceci

a pour effet d’éliminer les points élevés tout en rectifiant

la pointe de meule pour un meilleur équilibre.

Page 26

ANILLAS DE

PORTA-

HERRAMIENTA

Page 27

N’oubliez pas que votre nouvel outil rotatif sans cordon

Dremel constitue le meilleur outil à moteur du genre.

Cependant, son rendement ne peut dépasser celui des

accessoires avec lesquels il est utilisé. Nous vous

recommandons d’utiliser uniquement les accessoires

Installation des piles

1. Enlevez le bloc de piles de l’outil en appuyant sur ses

deux languettes afin de pouvoir le faire glisser hors de

l’outil.

LANGUETTE

DE

RETENUE

DU BLOC DE

PILES

Dremel. L’utilisation de tout autre accessoire peut

présenter un danger. Nous espérons que vous utiliserez

votre outil rotatif sans cordon Dremel avec plaisir pendant de nombreuses années.

4. Alignez la flèche du couvercle du bloc de piles sur

la flèche du boîtier des piles et enfoncez pour assembler. Les deux pièces ne peuvent être assemblées que

si les deux flèches sont alignées. Un déclic se produit

quand on assemble ces deux pièces.

COUVERCLE

DU BLOC

DE PILES

2. Retirez le couvercle du bloc de piles du boîtier des

piles en appuyant sur les deux languettes pour le faire

glisser hors du boîtier des piles.

COUVERCLE

DU

BLOC DE PILES

BOÎTIER DES

PILES

3. Insérez quatre piles de taille AA dans le boîtier des

piles en faisant bien attention à leur sens. Remarque :

le sens correct de montage des piles est indiqué sur

le schéma se trouvant sur le boîtier des piles.

LANGUETTES

DE RETENUE

DU COUVER-

CLE DU

BLOC DE

PILES

Página 27

ALIGNEZ LES

BOÎTIER

DES PILES

5. Insérez le bloc de piles dans l’outil en positionnant

les nervures d’alignement sur la pile en face des rainures d’alignement de l’outil. Les deux pièces ne peuvent être assemblées que si les deux flèches sont

alignées. Un déclic se produit quand on assemble ces

deux pièces.

REPÈRES D’ALIGNEMENT

!

AVERTISSEMENT

DES PILES ALCALINES DE 1,5 V.

!

AVERTISSEMENT

pas, ne les jetez pas au feu. Les piles risquent d’exploser ou de fuir.

RISQUE D’INCENDIE,

UTILISEZ EXCLUSIVEMENT

N’installez pas les piles à

l’envers, ne les rechargez

FLÈCHES

Page 28

Consignes d’utilisation

Applications

L’outil de nettoyage de bâtons de golf No 760 peut

être muni d’accessoires DREMEL divers pour

effectuer une variété de tâches se rapportant au golf.

Ci-dessous se trouvent les descriptions des accessoires Dremel utilisés communément avec l’outil

760. Veuillez consulter le site www.Dremel.com pour

de plus amples renseignements sur le remplacement

des poignées de bâton de golf et la mise à longueur

des bâtons.

Brosse en laiton (comprise)

Les brosses en laiton sont moins dures que celles en

acier. Elles vous permettent d’enlever la boue et l’oxydation sans abîmer les têtes de vos bâtons.

Conseil : Utilisez la brosse en laiton sur la haute

vitesse (HI). La brosse en laiton Dremel No 535 est

particulièrement efficace pour nettoyer les surfaces

rainurées sur la face des bâtons.

Remarque : N’utilisez pas la brosse en laiton sur la

surface vernie des têtes de bâtons en bois ou sur

les surfaces peintes des bâtons en graphite ou en

métal.

Brosse en soies de porc (comprise)

Les soies de porc sont moins dures que le plastique.

Vous pourrez donc utiliser la brosse pour enlever la

boue et l’herbe des semelles de chaussure de golf et

des sacs.

Conseil : Utilisez la brosse en soies de porc sur la

haute vitesse (HI). La brosse en soies de porc Dremel

No 403 est particulièrement efficace pour nettoyer

entre les crampons de la plupart des chaussures de

golf.

Autres accessoires (non compris)

Meule de polissage en tissu

Remise à neuf du brillant des têtes et manches de

bâton en métal à l’aide de la meule de polissage en

tissu Dremel No 423 et du produit de polissage No

421.

Conseil : Utilisez la meule de polissage sur la haute

vitesse (HI).

Meule à tronçonner renforcée par fibres de verre

Utilisez la meule à tronçonner renforcée Dremel No

426 avec un axe No 402 pour tronçonner les manches de bâtons de golf afin de les mettre à la longueur

désirée.

Conseil : Polissez l’extrémité du manche avec un

tambour de ponçage No 407.

Meule à tronçonner

Quand vous remplacez la poignée d’un bâton de golf,

utilisez la meule à tronçonner Dremel No 409 avec un

axe No 402 pour tronçonner la vieille poignée.

Conseil : Faites attention de ne pas entamer le

manche

Meule abrasive en oxyde d’aluminium

Utilisez la meule abrasive en oxyde d’aluminium

Dremel No 500 pour décaper la rouille de vos fers.

Conseil : utilisez la meule abrasive à faible vitesse

(LO).

Page 28

Page 29

Utilisation de l’outil rotatif sans cordon

Portez Des Lunettes De Protection

AVERTISSEMENT

Apprendre à utiliser l’outil rotatif sans cordon, c’est

d’abord en connaître le maniement. Tenez-le dans votre

main pour en sentir le poids et l’équilibre. Habituez-vous

à la forme conique de son boîtier qui permet d’empoigner l’outil rotatif sans cordon comme s’il s’agissait d’un

stylo ou d’un crayon.

Lorsque vous mettez l’outil en marche pour la première

fois, tenez-le éloigné de votre visage. Certains accessoires peuvent avoir été endommagés durant la manutention et peuvent alors se séparer en morceaux

lorsqu’ils atteignent une certaine vitesse. Ceci ne

survient pas fréquemment, mais il vaut mieux prévenir.

Pratiquez d’abord sur des matériaux de rebut pour voir

comment coupe l’outil rotatif sans cordon. N’oubliez pas

que le travail est accompli par la vitesse de l’outil et par

l’accessoire monté dans la douille de serrage. Vous ne

devez pas vous appuyer sur l’outil ni pousser celui-ci

dans le matériau.

Abaissez plutôt l’accessoire en rotation, légèrement vers

la pièce, en le laissant toucher l’endroit où vous voulez

commencer. Axez vos efforts sur le guidage de l’outil sur

la pièce, en n’exerçant qu’une très faible pression de

votre main. Laissez l’accessoire faire le travail.

Il est habituellement préférable de passer l’outil plusieurs

fois plutôt que de tenter de faire tout le travail d’une seule

fois. Passez l’outil allant-venant sur la pièce, tout

comme vous le feriez avec un petit pinceau. L’approche

douce et adroite est celle qui convient le mieux à la plupart des tâches. Vous exercez ainsi un meilleur contrôle,

êtes moins susceptible de commettre des erreurs, et

obtenez le meilleur rendement de l’accessoire.

Pour obtenir un meilleur contrôle dans le travail de

précision, tenez le Outil Rotatif comme un crayon,

entre le pouce et l’index.

Tenez l’outil dans la « paume de la main » pour le

nettoyant de surfaces planes.

Page 29

Page 30

Vitesses de service et accessoires

Réglez l’indicateur de vitesse selon la tâche à

accomplir pour obtenir les meilleurs résultats en utilisant des matériaux différents.

Utilisez une pièce d’essai afin de sélectionner la

vitesse convenant à chaque tâche. Changez la vitesse

pour trouver celle convenant le mieux à l’accessoire

que vous utilisez et à la tâche à accomplir.

Le modèle 760 possède un interrupteur de BASSE et

HAUTE vélocité. Lorsque l’indicateur est à la position 1

ou BASSE, l’outil tourne à environ 6,000 tours/minute.

Lorsque l’indicateur est à la position 2 ou HAUTE, l’outil

tourne à environ 12,000 tours/minute.

REMARQUE : La vitesse est affectée par un changement dans la tension d’alimentation. Si les piles sont

affaiblies, leur tension réduite ralentit le moteur,

surtout aux vitesses lentes. Si votre outil semble tourner moins vite qu’à l’habitude, remplacez les piles avec

des piles neuves pour augmenter la vitesse de l’outil.

La plupart des tâches effectuées avec l’outil de nettoyage de bâtons de golf No 760 peuvent être accomplies

sur la vitesse élevée HI (position 2). La vitesse élevée

Maintenance

Entretien

!

AVERTISSEMENT

PIÈCE SUSCEPTIBLE D’ÊTRE ENTRETENUE PAR L’UTILISATEUR. L’entretien préventif exécuté par des

personnes non autorisés peut entraîner un positionnement erroné des composants et des fils internes,

ce qui peut présenter de graves dangers.

recommandons de confier toute intervention d’entretien

sur l’outil à un centre de service-usine Dremel.

Moteurs C.C.

Le moteur de votre outil a été conçu pour de nombreuses heures d’utilisation fiable. Pour maintenir l’efficacité maximale du moteur, nous recommandons de

l’examiner tous les six mois. Seul un moteur de remplacement Dremel authentique, conçu spécialement

pour votre outil, doit être utilisé.

IL N’EXISTE À

L’INTÉRIEUR AUCUNE

Nous

HI (position 2) est recommandée avec les brosses en

soies de porc No 403 et en laiton No 535 qui sont comprises avec l’outil. La vitesse lente LO ne s’utilise que

pour certains travaux où il est nécessaire de mieux

maîtriser l’outil.

Pour contrôler la vitesse du modèle 760 il

suffit de régler cet indicateur sur le boîtier.

Nettoyage

!

AVERTISSEMENT

piles avant de nettoyer l’outil. La façon la plus efficace

de nettoyer l’outil est à l’aide d’air sec comprimé. Portez

toujours des lunettes de sécurité en nettoyant les outils à l’air comprimé.

Les prises d’air et les leviers de commutation doivent

être gardés propres et exempts de corps étrangers. Ne

tentez pas de nettoyer en insérant des objets pointus à

travers l’ouverture.

!

MISE EN GARDE

pièces en plastique. Citons notamment l’essence, le

tétrachlorure de carbone, les solvants chlorés de

nettoyage, l’ammoniaque et les détersifs ménagers

qui contiennent de l’ammoniaque.

Page 30

Pour éviter les accidents,

enlevez toujours le bloc de

Certains solvants et agents

nettoyants abîment les

Page 31

Garantie limitée de Dremel

Votre Outil Rotatif Dremel est garanti contre les vices de matériaux ou d’exécution pendant un délai cinq ans depuis la date

d’achat. Dans l’hypothèse où le produit ne se conformerait pas à cette garantie écrite, veuillez procéder de la façon suivante :

1. NE RAPPORTEZ PAS le produit à l’endroit où vous l’avez acheté.

2. Emballez avec soin le produit seul, sans aucun autre article, et renvoyez-le, port payé, accompagné :

A. d’une copie de votre preuve d’achat datée (veuillez en garder une copie pour vous-même)

B. d’une déclaration écrite concernant la nature du problème

C. d’une indication de vos nom, adresse et numéro de téléphone, à l’adresse suivante :

ÉTATS-UNIS

Dremel Service Center Dremel Service Center

4915 Twenty-First Street OU 4631 E. Sunny Dunes

Racine, Wisconsin 53406 Palm Springs, California 92264

1-800-437-3635 1-800-437-3635

CANADA À L’EXTÉRIEUR DU TERRITOIRE

Giles Tool Agency CONTINENTAL DES ÉTATS-UNIS

6520 Lawrence Av. East Consultez votre distributeur local ou écrivez à :

Scarborough, Ontario Dremel

Canada M1C 4A7 4915 Twenty-First St., Racine, Wisconsin 53406

1-888-285-3476

Nous vous recommandons d’assurer le paquet contre la perte ou les dommages en cours de route dont nous ne pouvons

assumer la responsabilité.

Cette garantie n’est offerte qu’à l’acheteur enregistré d’origine. LES DOMMAGES AU PRODUIT RÉSULTANT DE MANIPULATIONS, ACCIDENT, USAGE ABUSIF, NÉGLIGENCE, RÉPARATIONS OU ALTÉRATIONS NON AUTORISÉES, UTILISATION

D’ACCESSOIRES NON APPROUVÉS OU AUTRES CAUSES NON LIÉES À LA DÉFAILLANCE DES MATÉRIAUX OU DE

L’EXÉCUTION NE SONT PAS COUVERTS PAR CETTE GARANTIE.

Aucun employé, mandataire, vendeur ou autre personne n’est autorisé à accorder des garanties au nom de Dremel. Si l’inspection effectuée par Dremel révèle que le problème a été causé par une défaillance des matériaux ou de l’exécution dans

les limites de la garantie, Dremel réparera ou remplacera le produit gratuitement et renverra le produit port payé. Si elles

peuvent être effectuées, les réparations rendues nécessaires par l’usure normale ou un usage abusif, ou les réparations du

produit une fois expirée la période de garantie, seront facturées aux tarifs réguliers de l’usine.

DREMEL N’ACCORDE AUCUNE AUTRE GARANTIE DE QUELQUE NATURE QUE CE SOIT, EXPLICITE OU IMPLICITE, ET

TOUTES LES GARANTIES IMPLICITES DE COMMERCIALISATION ET D’APTITUDE À UN USAGE PARTICULIER EN SUS

DE L’OBLIGATION SUSVISÉE SONT DÉNIÉES PAR LES PRÉSENTES PAR DREMEL ET EXCLUES DE CETTE GARANTIE

LIMITÉE.

Cette garantie vous accorde certains droits précis, et vous pouvez également avoir d’autres droits qui varient d’un endroit

à un autre. L’obligation du garant se limite à réparer ou remplacer le produit. Le garant n’est responsable d’aucun dommage accessoire ou indirect attribuable à cette supposée défaillance. Certaines juridictions ne permettent pas l’exclusion

ou la limitation des dommages accessoires ou indirects ; il se peut donc que les limitations ou l’exclusion qui précède ne

s’appliquent pas à vous.

En ce qui concerne les prix et la façon de vous prévaloir de la garantie sur le territoire continental des États-Unis, mettezvous en contact avec votre distributeur Dremel local.

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado en México por: Robert Bosch, S.A. de C.V., Calle Robert Bosch No. 405, Zona Industrial,

Toluca, Edo. de México, C.P. 50070, Tel. (722) 2792300

Page 31

Page 32

Página 32