Page 1

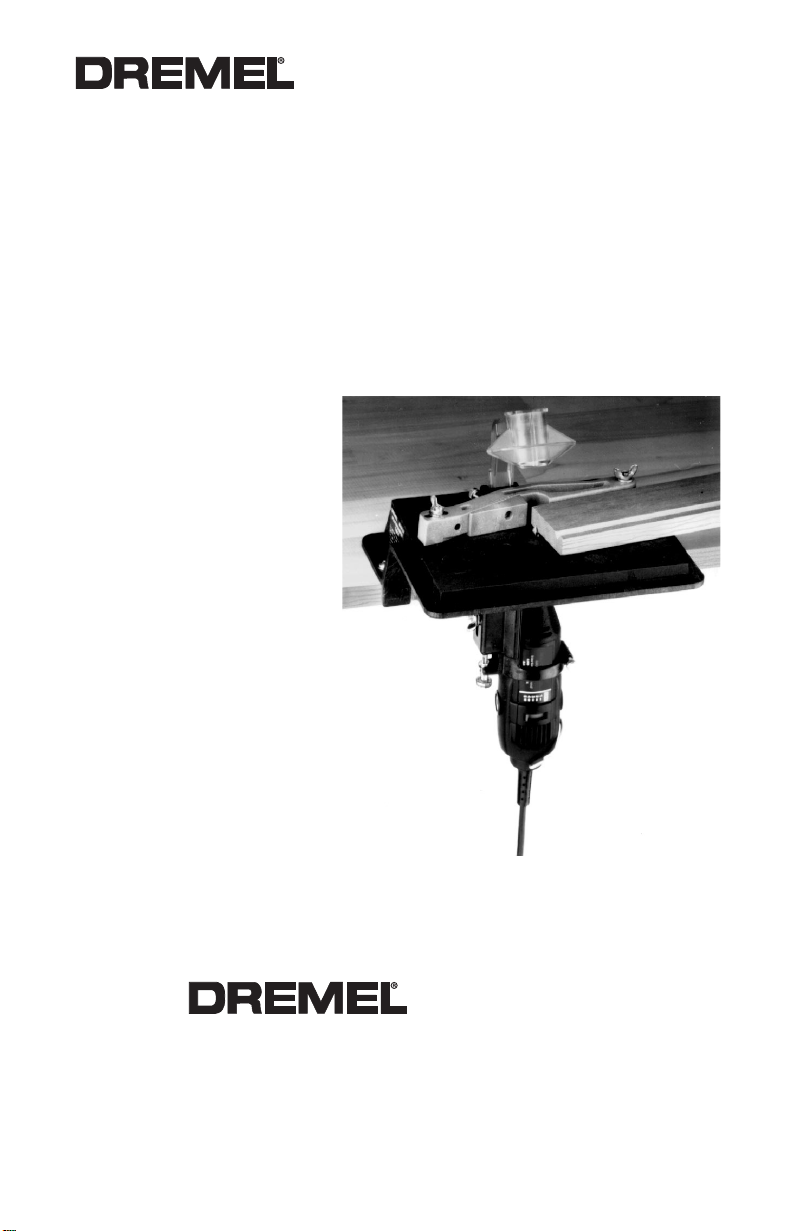

Shaper/Router Table

Owner’s Manual Model 5000231

HONESTLY NOW … Have you read

this OWNER’S MANUAL?

Parlez-vous français?

Voir page 8

¿Habla español?

Vea página 14

• Safety

• Assembly

• Operation

• Service Parts

P.O. Box 1468

Racine, Wisconsin 53401

1-800-437-3635

http://www.dremel.com

2615302562 9/00 ©1998 S-B Power Tool Co. PRINTED IN U.S.A.

Page 2

Power Tool Safety Rules

WARNING

!

Read and understand all instructions. Failure to follow all instructions listed

below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in

any way. Double Insulation eliminates the

need for the three wire grounded power cord

and grounded power supply system. Before

plugging in the tool, be certain the outlet

voltage supplied is within the voltage marked

on the nameplate. Do not use “AC only” rated

tools with a DC power supply.

Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician’s rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil, sharp

edges or moving parts. Replace damaged

cords immediately. Damaged cords increase

the risk of electric shock.

When operating a power tool outside, use an

outdoor extension cord marked "W-A" or

"W." These cords are rated for outdoor use and

reduce the risk of electric shock.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

Dress properly. Do not wear loose clothing

or jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair can

be caught in moving parts. Keep handles dry,

clean and free from oil and grease.

Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with

your finger on the switch or plugging in tools

that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches before

turning the tool “ON”. A wrench or a key that

is left attached to a rotating part of the tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used

for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

“ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of reach of children and

other untrained persons. Tools are dangerous

in the hands of untrained users.

-2-

Page 3

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools,

with sharp cutting edges are less likely to bind

and are easier to control. Any alteration or

modification is a misuse and may result in a

dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools. Develop a

periodic maintenance schedule for your tool.

Use only accessories that are recommended

by the manufacturer for your model. Access-

ories that may be suitable for one tool, may

become hazardous when used on another tool.

Safety Rules for Router/Shaper Tables

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning agents

such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

Unplug tool before setting up in table, making

adjustments or changing bits. Accidental

start-up of the tool can cause injury.

Securely fasten table to a stable platform or

workbench. During operation unstable

platforms or workbenches may shift or tip

causing loss of control and injury.

Securely fasten tool to table before operating.

If tool loosens during operation it will tend to

ìwalkî down from clamp and tool may fall while

bit is still spinning.

Know how to shut off the tool! Position the

tool under the table so that switch is readily

accessible to quickly shut off in an emergency.

Route the cord away from the bit or cutting

area. Cutting into live electrical wires may result

in a shock, burn or electrocution.

Wear eye protection and dust mask. Use

only in well-ventilated area. Using personal

safety devices and working in safe environment

reduces risk of injury.

Match the appropriate bit and its speed to

your application. Do not use bits that have a

cutting diameter that exceed the capacity of

the tool. The shaper/router table is intended

primarily for light duty use on wood.

Overloading the tool can lead to personal injury

or tool failure.

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits can

snap during use. Dull bits require more force to

push the workpiece, possibly causing the bit to

break.

Always make sure the workpiece is free from

nails and other foreign objects. Cutting into a

nail will damage the bit and can cause the

workpiece to jump causing loss of control.

Use guard in all cutting applications except

for sanding and certain rabbeting operations.

If any portion of the spinning bit is contacted

injury will occur.

Use the adjustable fence in straight cutting

applications. When routing along an entire

edge of the work the fence and adjustable

support wedge will help maintain stability and

prevent forming concave shape or snipe on the

edge.

Only piloted bits can be used without the

fence. Piloted bits are used when routing

internal and external contours on the

workpiece. Piloted bits assist in maintaining

control of the workpiece when the fence is not in

use.

Never start the tool when the bit is engaged

in the material. The bit cutting edge may grab

the material causing loss of control of the

workpiece.

Never place hands near the spinning bit. Use

a push stick or fixture to guide small or thin

workpieces when shaping/routing these

pieces. Guiding the material with both hands,

push sticks or fixtures is preferred to avoid

contact with the spinning bit.

Feed the workpiece against the rotation of

the bit. The bit rotates counter-clockwise as

viewed from the top of table. Feeding the

work in the wrong direction will cause the

workpiece to ìclimbî up on the bit and may lead

to loss of control during operation.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely

tightened. Loose adjustment device can

unexpectedly shift, causing loss of control, loose

rotating components will be violently thrown.

Never touch the bit during or immediately

after the use. Contact with a spinning bit will

cause injury and after use the bit is too hot to be

touched by bare hands.

-3-

Page 4

ATTACHMENT FOR USE WITH DREMEL

ROTARY MODELS 275, 285, 395, AND

398

ATTENTION: Read entire instruction

manual carefully before using your Dremel

Shaper/Router Table. Retain instructions for

future reference. This attachment will

convert Dremel Corded Rotary Tools to a

Shaper/Router Table for edge forming,

routing, grooving, shaping, sanding edges,

jointing, etc.

NOTE: Not for use with cordless rotary

tools. Not for use in conjuction with the tile

cutting bit, model 562.

Mount Table to Workbench

The SHAPER/ROUTER TABLE comes

assembled ready to mount to the

workbench. After determining table

location, predrill the bench using a 1/8”

diameter drill at the four MOUNTING HOLE

locations. Secure table to the bench using

the (4) #10 x 1” WOOD SCREWS, and

WASHERS. (Included with the

Shaper/Router Table). (See Fig. 1)

Install Rotary Tool to Table

1. Check the model number of your rotary

tool and use the listing below to

determine which bushing to use when

adapting your tool to the Shaper/Router

table.

2. Loosen the two CLAMPS NUTS several

turns. Insert the tool into both clamps

then align the switch to the split in the

clamps (switch will be to the right —

giving a front to rear motion for

turning motor off). Be sure nose is

seated all the way in small clamp.

Secure tool by tightening the two clamp

nuts. (See Fig. 2 & 3)

Fig. 1

MOUNTING

HOLE

Fig. 2

(4) #10 X 1”

WOOD SCREWS

& WASHERS

GUARD

FENCE

CLAMPS

CLAMP NUTS

SWITCH IS TO THE

RIGHT SO FRONT TO

REAR MOTION WILL

TURN UNIT OFF

ROTARY TOOL MODEL BUSHING REQUIRED

275, 285, 395 (Type I, II, IV, V) . . . . . . . . USE: Black Bushings in small clamp.

398 Professional

-4-

Page 5

Installing Router Bits

1. When installing router bits, be sure the

power cord is unplugged, then remove

the tool from the Shaper/Router Table.

Fit the ROUTER BIT SHANK into the

collet allowing a maximum of 5/8” to

protrude past the collet nut. Use the

spindle lock and wrench to secure the

bit. (See Fig. 3)

2. Loosen the WING NUT on HEIGHT

STAND and turn the DEPTH

ADJUSTING SCREW to set cutting

depth. Depth of cut will be the amount

the bit extends above the

SHAPER/ROUTER TABLE. After

setting cutting depth, retighten wing nut.

Cutting Depth Adjustment

Adjustment markings on the back of

adjusting bracket are marked in inches and

millimeters. Each line on the fractional side

represents 1/16 of an inch. Each line on the

metric side represents one millimeter. View

the markings prior to starting your project.

Loosen the clamp knob and turn the

adjusting screw counterclockwise (lowering

the adjusting bracket), set to desired depth

and tighten clamp knob. To insure proper

settings, rout and measure cut on scrap

material.

Fig. 3

HEIGHT

STAND

WING NUT

DEPTH

ADJUSTING

SCREW

DEPTH

OF CUT

ROUTER BIT

TABLE

SMALL CLAMP

LARGE CLAMP

Router Feed Direction

The router spindle turns in a counter

clockwise direction when viewed from

above the table. For best control and quality

of cut, feed the work into the bit in the

direction that the bit will tend to pull the

work to the fence. (Incorrect feed direction

will result in the bit trying to pull the wood

thru faster than you want.) Feed the

workpiece from right to left as shown. Feed

direction is extremely important when using

a pilot bit freehand on the edge of a

workpiece as well as when using the fence

with all bits. (See Fig. 4)

Fig. 4

ROUT

END

GRAINS

FIRST

Feed directions for outside and inside routing.

Note the sequence of the cuts for routing around

all four edges of a rectangle or square board.

ROUTER FEED DIRECTION

BIT ROTATION

-5-

Page 6

Fig. 5

Routing Using the Fence

1. Unplug the rotary tool before making

any fence adjustments or bit changes.

Feed the work against the rotation of the

bit as shown. Most fence cutting is done

with the SUPPORT WEDGE adjusted to

the right, where it is in line with the

fence. (See Fig. 5)

2. CENTER CYLINDER of the GUARD can

be adjusted up when making cuts using

the fence. Loosen THUMB NUT, lift the

cylinder up and secure by tightening

thumb nut. (See Fig. 6)

3. When shaping small pieces or when

finishing the cut on narrow, long pieces,

use a PUSH STICK. Use 1/4” x 2” x 8”

piece of lumber notched as shown to

make this push stick. (As shown) It will

enable you to keep your hands away

from the cutting area.

4. To cut a straight groove, use 5000650

(1/8”) or 5000654 (1/4”). Install the bit

and set the depth of cut using adjusting

screw as shown in Fig. 3. Loosen WING

NUT on left end of fence and swing

fence assembly to proper distance from

bit to give desired groove location.

Retighten wing nut. Take a trial cut on

scrap lumber to check depth and

location of groove.

5. When trimming the entire edge of a

workpiece, adjust the SUPPORT

WEDGE for support of the workpiece on

the left side of the cutter. First, adjust

the fence to control the amount of cut.

Take a trial cut of about 2” long and

check the amount of cut. Turn rotary

tool off. Loosen WEDGE CLAMP NUT

and slide wedge to left until wedge

contacts workpiece. Retighten clamp

nut to secure wedge to fence.

Workpiece will not have support on both

sides of the cutter. (See Fig. 5)

WEDGE CLAMP NUT

SUPPORT WEDGE

CENTER CYLINDER

WING NUT

Fig. 6

THUMB NUT

(NOT SHOWN)

PUSH STICK

-6-

Page 7

Fig. 7

1 1/2" SLOT TO CLEAR GUARD

16"

12"

3/8" PLYWOOD

Routing Using Pilot Bits

1. When bits with pilots are to be used

(such as 5000612 or 5000615), move

the fence back only enough to allow the

amount of cut to be made. Keeping the

fence close to the bit allows the fence to

serve as a rear guard. In special cases

when the fence must be removed from

the table, adjust the center sleeve of the

guard down the rear bit protection.

2. Only piloted bits can be used without

the fence. If the workpiece being cut is

between the cutter and the operator,

then feed from right to left. If the cutter

is between the operator and the

workpiece being cut, feed from left to

right.

3. Feed the workpiece past the cutter

without stopping, with a consistent

speed. A change in feed or a dwell will

cause an irregular cut.

1 1/2"

RECTANGULAR HOLE

TO FIT OVER TABLE

1 1/2”HIGH SUPPORTS

ON BOTH ENDS WILL REST ON BENCH

Drum Sanding

The Shaper/Router Table is also ideal for

drum sanding irregular shaped parts as

shown. Use Drum Sander 5000407 (1/2”) or

5000430 (1/4”), with or without the fence

assembly. (See Fig. 8)

Fig. 8

Expanded Table Work Surface

The shaper/router table is designed to make

it easy to expand the size of the working

surface. Use 3/8” thick solid core plywood.

Cut a rectangular hole in the plywood to fit

over the table and secure using (8) #10

wood screws, 1/2” in length. Support the

table at both ends by securing 1 1/2” high

lumber supports to the plywood base. (See

Fig. 7)

-7-

Page 8

MODEL MODÈLE MODELO

5000231

-20-

Page 9

ORDER BY PART NUMBER, NOT CODE NUMBER

CODE NO. PART NO. DESCRIPTION

01 2615296101 *Guard & Sleeve

02 2615296100 *Fence & Wedge

03 2615294998 *Shaper Table

04 *Thumb Nut

05 2615294999 *Guard & Pin

06 2615294956 *Adjustable Bracket Clamp Screw

07 2615294223 *Clamp Screw Nut #6-32

08 2615294205 *Clamp Screw #6-32 x 3/4"

09 2615296105 *Wedge Clamp Screw #6-32 x 1-1/4"

10 *Clamp Rivet Burr #9

11 2615294959 *Clamp Screw Wing Nut

12 2615294227 *3/16" Rivet Burr

13 2615296106 *Shaper Mounting Screw

14 2615294960 *Housing Screw #8 x 15/16

15 2615294951 *Holder Adj. Bracket

16 2615294953 *Depth Adj. Screw

17 2615294952 *Tool Holder

18 2615297216 *Type 1, 4 and 5 Nose Bushing

19 2615294962 *Small Body Bushing Set

20 2615294964 *Top Plate Nut

WRITE FOR CURRENT PRICES

NO C.O.D.'S

3 Req’d

4 Req’d

3 Req’d

2 Req’d

3 Req’d

2 Req’d

-21-

Loading...

Loading...