Page 1

400 Series XPR

Instructional Safety

Manual

High Performance Rotary Tool

Dremel brand products are manufactured and sold by the

Dremel Division of Robert Bosch

Form No. 2610925455 10/04

1-800-437-3635

http://www.dremel.com

ool Corporation

T

Robert Bosch

ool Corporation © 2004

T

All Rights Reserved

Page 2

POWER TOOL SAFETY RULES

WARNING

!

Read and understand all instructions. Failure to follow all instructions list-

ed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust.

tools create sparks which may ignite the dust

or fumes.

Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Power

Electrical Safety

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install a polarized outlet. Do not

change the plug in any way.

Insulation eliminates the need for the three

wire grounded power cord and grounded

power supply system. Before plugging in the

tool, be certain the outlet voltage supplied is

within the voltage marked on the nameplate.

Do not use “AC only” rated tools with a DC

power supply.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators.

of electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit

Interrupter must be used to supply the power

to your tool. Electrician’s rubber gloves and

footwear will further enhance your personal

safety.

Don't expose power tools to rain or wet

conditions.

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil,

sharp edges or moving parts.

damaged cords immediately

cords increase the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W."

use and reduce the risk of electric shock.

These cords are rated for outdoor

There is an increased risk

Water entering a power tool will

Double

Replace

. Damaged

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication.

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from

moving parts.

long hair can be caught in moving parts.

Keep handles dry, clean and free from oil and

grease.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in.

with your finger on the switch or plugging in

tools that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches

before turning the tool ON.

key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times.

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection.

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

A moment of inattention while

Loose clothes, jewelry, or

Carrying tools

A wrench or a

Proper footing and

Dust mask, non-skid safety

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform.

or against your body is unstable and may

lead to loss of control.

Do not force tool. Use the correct tool for

your application.

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

ON or OFF.

trolled with the switch is dangerous and must

be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

2

Holding the work by hand

The correct tool will do the

Any tool that cannot be con-

Page 3

Store idle tools out of reach of children

and other untrained persons.

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean.

tained tools, with sharp cutting edges are

less likely to bind and are easier to control.

Any alteration or modification is a misuse

and may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using.

are caused by poorly maintained tools.

Develop a periodic maintenance schedule

for your tool.

Use only accessories that are recommended by the manufacturer for your

model.

Accessories that may be suitable for

one tool, may become hazardous when

used on another tool.

Tools are

Properly main-

Many accidents

SAFETY RULES FOR ROTARY TOOL

Accessories must be rated for at least the

speed recommended on the tool warning

label.

Wheels and other accessories running over rated speed can fly apart and

cause injury.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord.

make exposed metal parts of the tool "live"

and shock the operator. If cutting into existing

walls or other blind areas where electrical

wiring may exist is unavoidable, disconnect

all fuses or circuit breakers feeding this worksite.

Do not operate the flexible shaft with a

sharp bend.

generate excessive heat on the jacket or

hand piece. The recommended minimum is

6" radius.

Always disconnect the power cord from

the power source before making any

adjustments or attaching any accessories.

to start leading to serious personal injury.

Be aware of the switch location, when

placing the tool down or when picking the

tool up.

switch.

Always hold the hand piece firmly in your

hands during the start-up.

torque of the motor, as it accelerates to full

speed, can cause the shaft to twist.

Contact with a "live" wire will

Over bending the shaft can

You may unexpectedly cause the tool

You may accidentally activate the

The reaction

Service

Tool service must be performed only by

qualified repair personnel.

maintenance performed by unqualified personnel could result in a risk of injury. For

example: internal wires may be misplaced

or pinched, safety guard return springs may

be improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury. Certain cleaning

agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic

parts.

Always wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and working in

safe environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely tightened.

unexpectedly shift, causing loss of control,

loose rotating components will be violently

thrown.

Do not reach in the area of the spinning

bit.

The proximity of the spinning bit to your

hand may not always be obvious.

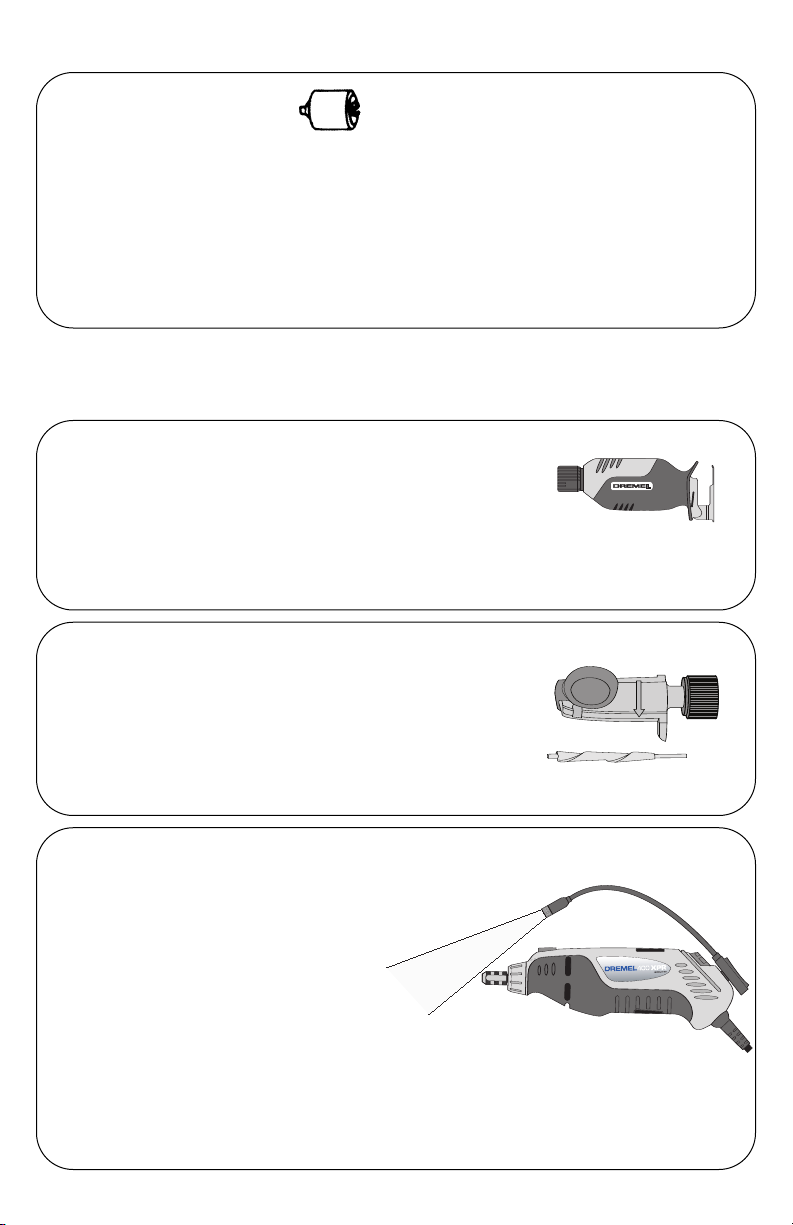

Allow brushes to run at operating speed

for at least one minute before using

wheel. During this time no one is to stand

in front or in line with the brush.

bristles or wires will be discharged during the

run-in time.

Wire and bristle brushes must never be

operated at speeds greater than

15,000/min. Direct the discharge of the

spinning wire brush away from you.

Small particles and tiny wire fragments may

be discharged at high velocity during the

“cleaning” action with these brushes and may

become imbedded in your skin. Bristles or

wires will be discharged from the brush at

high speeds.

Carefully handle both the tool and individual grinding wheels to avoid chipping or

cracking. Install a new wheel if tool is

Loose adjustment device can

Service or

Loose

3

Page 4

SAFETY RULES FOR ROTARY TOOL (CONTINUED)

dropped while grinding. Do not use a

wheel that may be damaged.

from a wheel that bursts during operation will

fly away at great velocity possibly striking you

or bystanders.

Never use dull or damaged bits. Sharp

bits must be handled with care.

bits can snap during use. Dull bits require

more force to push the tool, possibly causing

the bit to break.

Use clamps to support workpiece whenever practical. Never hold a small workpiece in one hand and the tool in the other

hand while in use. Allow for sufficient

space, at least 6", between your hand and

the spinning bit.

dowel rods, pipes or tubing have a tendency

to roll while being cut, and may cause the bit

to “bite” or jump toward you. Clamping a

small workpiece allows you to use both

hands to control the tool.

Inspect your workpiece before cutting.

When cutting irregularly shaped workpieces, plan your work so it will not slip

and pinch the bit and be torn from your

hand.

For example, if carving wood, make

sure there are no nails or foreign objects in

the workpiece. Nails or foreign objects can

cause the bit to jump.

Never start the tool when the bit is

engaged in the material.

edge may grab the material causing loss of

control of the cutter.

Avoid bouncing and snagging the wheel,

especially when working corners, sharp

edges etc.

and kick-back.

The direction of feed with the bit into the

material when carving, routing or cutting

is very important. Always feed the bit into

the material in the same direction as the

cutting edge is exiting from the material

(which is the same direction as the chips

are thrown).

direction, causes the cutting edge of the bit to

climb out of the work and pull the tool in the

direction of this feed.

If the workpiece or bit becomes jammed

or bogged down, turn the tool “OFF” by

the switch. Wait for all moving parts to

stop and unplug the tool, then work to

free the jammed material.

the tool is left “ON” the tool could restart

unexpectedly causing serious personal

injury.

Do not leave a running tool unattended,

turn power off.

Round material such as

This can cause loss of control

Feeding the tool in the wrong

Only when tool comes to a

Fragments

Damaged

The bit cutting

If the switch to

complete stop it is safe to put it down.

Do not grind or sand near flammable

materials.

ignite these materials.

Do not touch the bit or collet after use.

After use the bit and collet are too hot to be

touched by bare hands.

Regularly clean the tool's air vents with

compressed air.

powdered metal inside the motor housing

may cause electrical failures.

Do not allow familiarity gained from frequent use of your rotary tool to become

commonplace.

careless fraction of a second is sufficient to

inflict severe injury.

Do not alter or misuse tool. Any alteration

or modification is a misuse and may result in

serious personal injury.

This product is not intended for use as a

dental drill, in human or veterinary medical applications.

When using the steel saws, cutoff wheels,

high speed cutters or tungsten carbide

cutters, always have the work securely

clamped. Never attempt to hold the work

with one hand while using any of these

accessories.

wheels will grab if they become slightly canted in the groove, and can kickback causing

loss of control resulting in serious injury. Your

second hand should be used to steady and

guide the hand holding the tool. When a cutoff wheel grabs, the wheel itself usually

breaks. When the steel saw, high speed cutters or tungsten carbide cutter grab, it may

jump from the groove and you could lose

control of the tool.

!

construction activities, contains chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically

treated lumber.

our risk from these exposures varies,

Y

depending on how often you do this type of

work. To reduce your exposure to these

chemicals, work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially

designed to filter out microscopic particles.

Sparks from the wheel could

Excessive accumulation of

Always remember that a

Serious injury may result.

The reason is that these

WARNING

Some dust created by

power drilling and other

4

Page 5

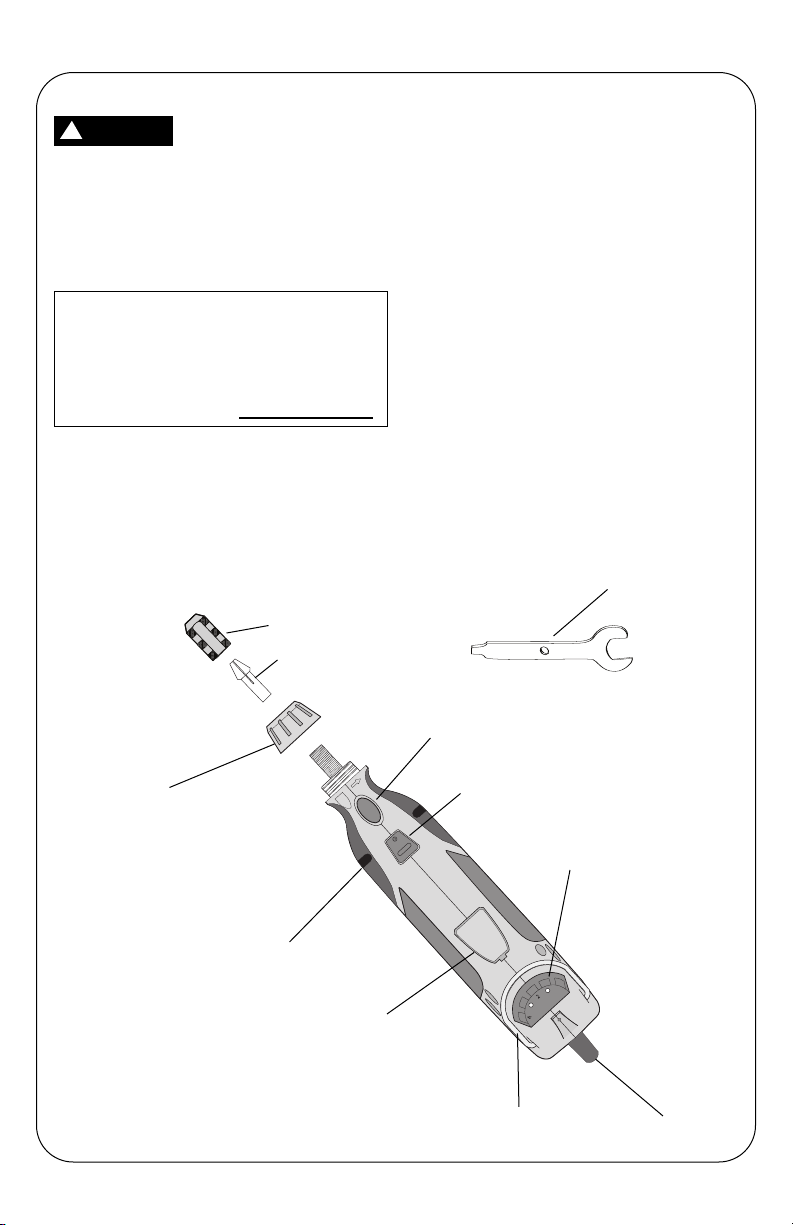

GETTING TO KNOW YOUR ROTARY TOOL

Unpacking & Checking Contents

WARNING

!

cal shock, always remove plug from wall

outlet when tool is not in use.

Separate all loose parts from packing materials and check each item with the contents

listed on the carton to make sure all items are

accounted for before discarding any packing

material.

IMPORTANT! If any parts are missing, or if

you require any assistance with these

instructions, please contact the Dremel™

Consumer Service at:

To avoid injury from unexpected starting or electri-

1-800-437-3635

or check our website at www.Dremel.com.

Description

The 400 Series XPR™ Rotary Tool incorporates both high-speed and performance to

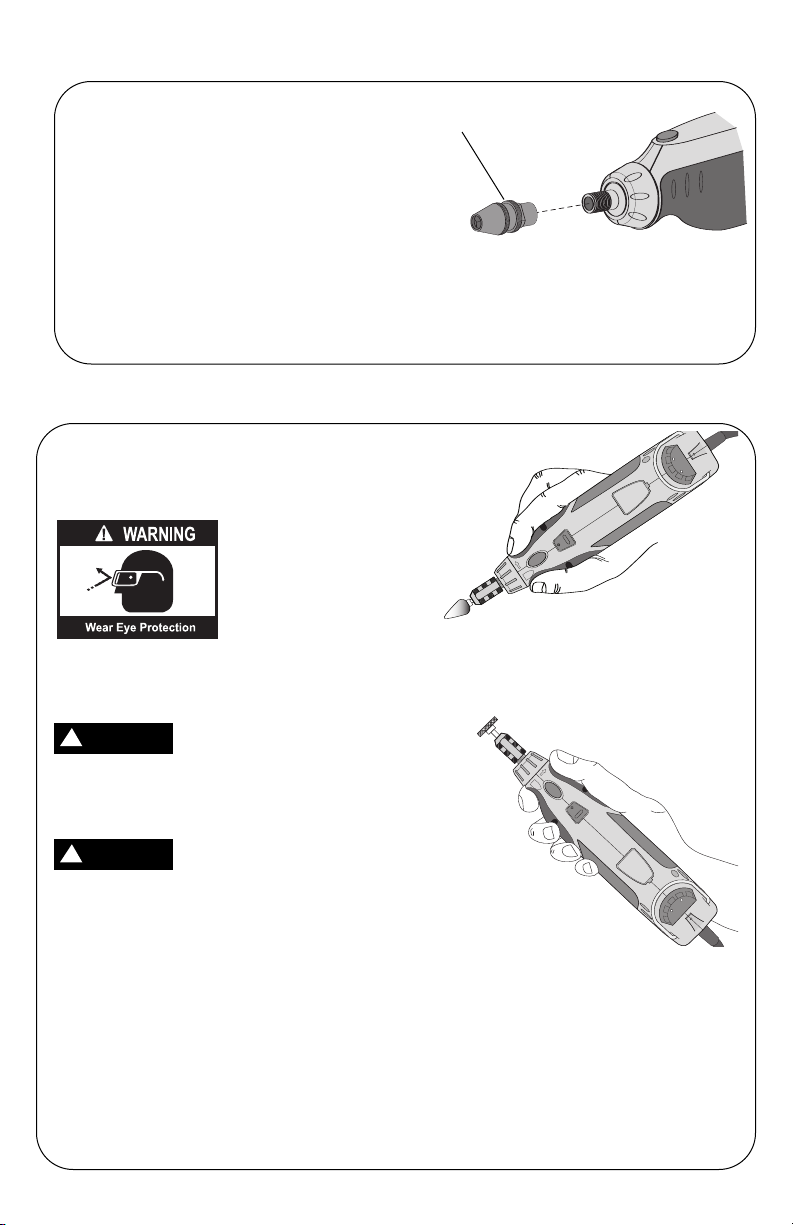

Collet Nut

Collet

serve as a carver

, grinder, polisher, sander,

cutter, power brush, drill, and more.

The tool utilizes a small, but effective DC

motor. The large variety of available

Dremel™ accessories includes abrasive

wheels, drill bits, wire and nylon brushes,

engraving and carving cutters, router bits,

polishing points and more. The ability to add

different Dremel™ attachments adds to the

multi-faceted uses of the tool. The variety of

projects you can do with the tool is limitless.

The 400 Series XPR Rotary Tool is a highspeed tool and operates at speeds 5,000 to

35,000 RPM. (A typical electric drill operates

only up to 2500 RPM!). When used with

Dremel™ accessories and attachments, the

400 Series XPR rotary tool’s high speed performance allows you to work on even the

most demanding projects without having to

exert undue pressure on the tool. The tool

does the work for you.

Collet Wrench

Housing Cap

Ventilation Openings

Brush Cover

(one each side)

Shaft Lock Button

5

On/Off Switch

Hanger

Variable Speed Dial

Power Cord

Page 6

SPECIFICATIONS

General Specifications

Voltage Rating . . . . . . . . . .120 V, 50-60 Hz

Amperage Rating . . . . . . . . . . . . . . . . .2.0 A

No Load Speed . . . . . . . . . .No35,000/min

Collet Capacity . . . .1/32", 1/16", 3/32", 1/8"

Motor Specifications

This Rotary Tool utilizes a variable highspeed RPM motor. It is wired for operation on

110-120 volts, 50-60 Hz. alternating current.

Before connecting the motor cord to wall outlet, make certain the power switch is in the

OFF position and be sure the electric current

is of the same characteristics as stamped on

the Rotary Tool nameplate.

Connection To A Power Source

DANGER

!

prongs on the plug when installing or

removing the plug to or from the outlet.

DANGER

!

have it replaced immediately to avoid

shock or fire hazard.

To avoid electric shock,

do not touch the metal

If power cord is worn, cut

or damaged in any way,

Extension Cords

If an extension cord is necessary, a cord

with adequate size conductors that is

capable of carrying the current necessary

for your tool must be used.

vent excessive voltage drop, loss of power or

overheating.

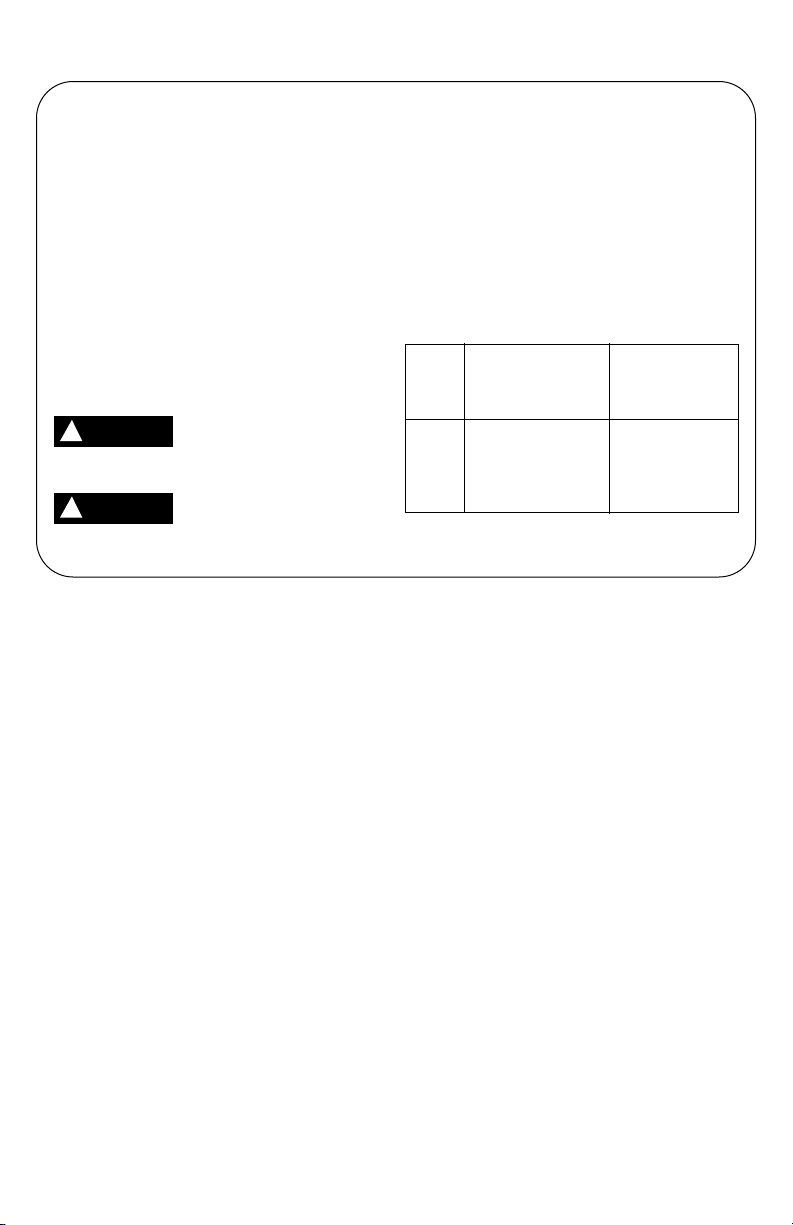

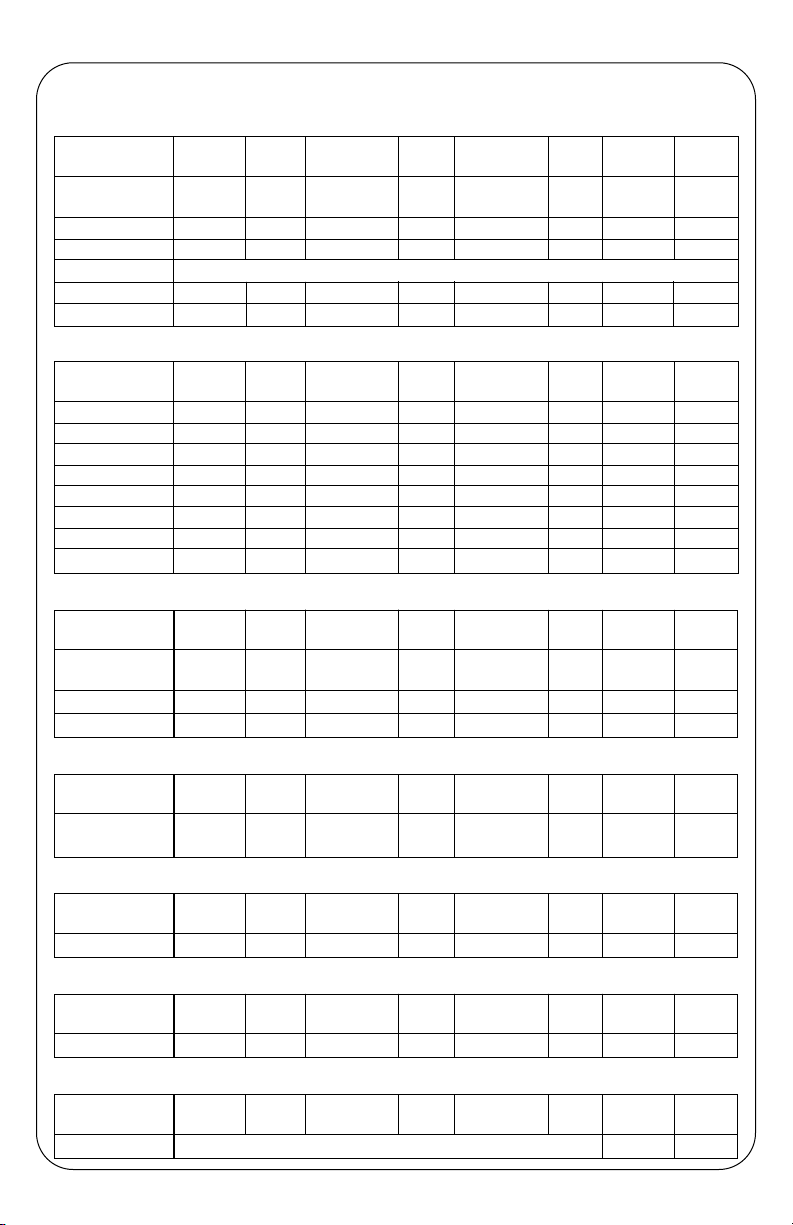

RECOMMENDED SIZES

OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

NOTE: The smaller the gauge number, the

heavier the cord.

ool’

T

Ampere

Rating

2-6

6-8

8-10

10-12

12-16

Cord Size in A.W.G.

s

Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

18 16 16 14 .75 .75 1.5 2.5

18 16 14 12 .75 1.0 2.5 4.0

18 16 14 12 .75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 — —————

This will pre-

Wire Sizes in mm

2

6

Page 7

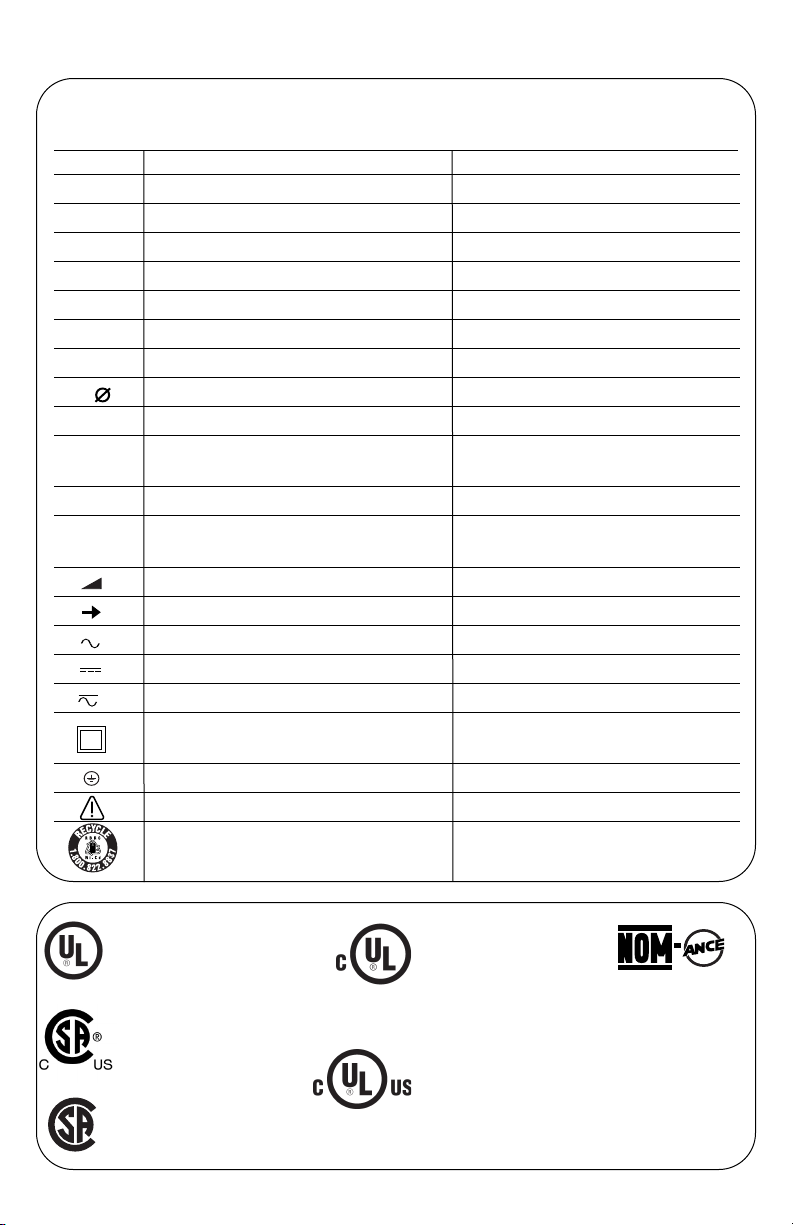

SYMBOLS

0

IMPORTANT! Some of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels,etc.

n

0

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

No load speed Rotational speed, at no load

per minute orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates

that this tool is listed by

the Canadian Standards

Association, and is listed

to US Standards by CSA.

This symbol designates

that this tool is listed by

the Canadian Standards

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters

Laboratories.

This symbol designates that

this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

This symbol

designates

that

this tool complies

to NOM

Mexican

Standards.

Association.

7

Page 8

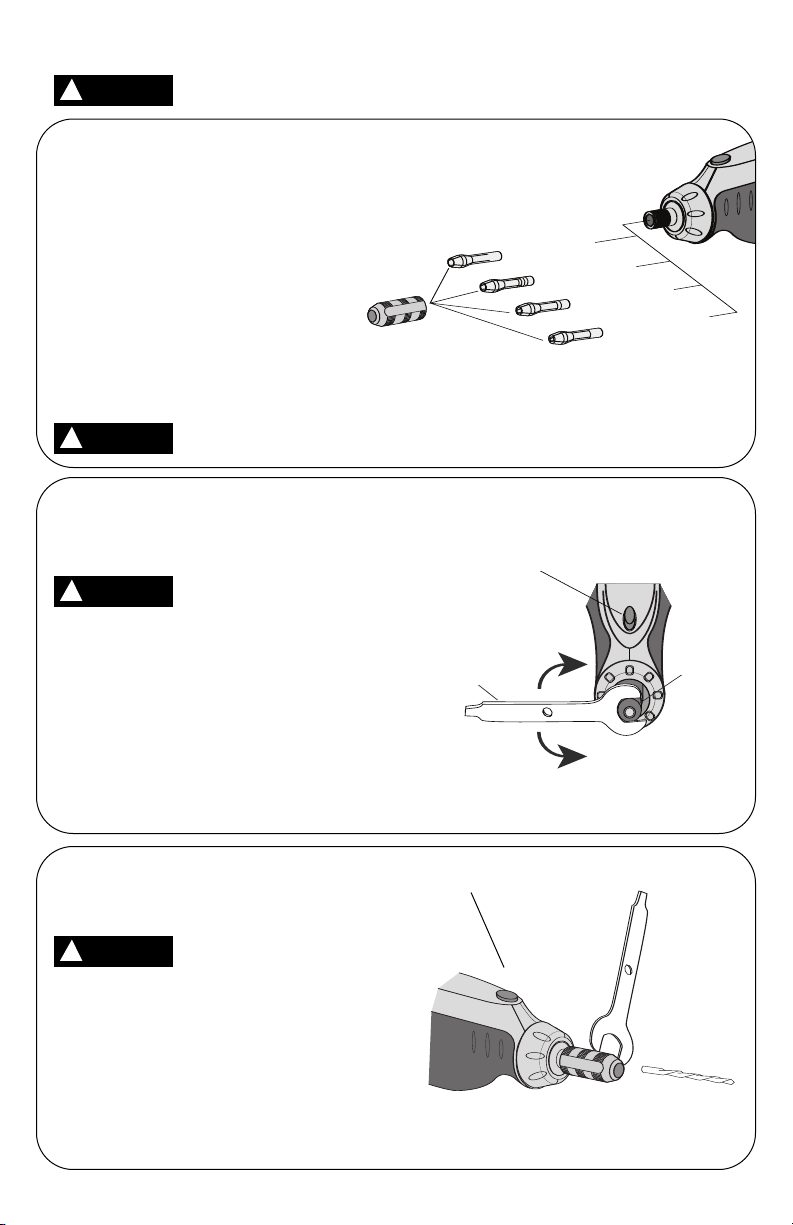

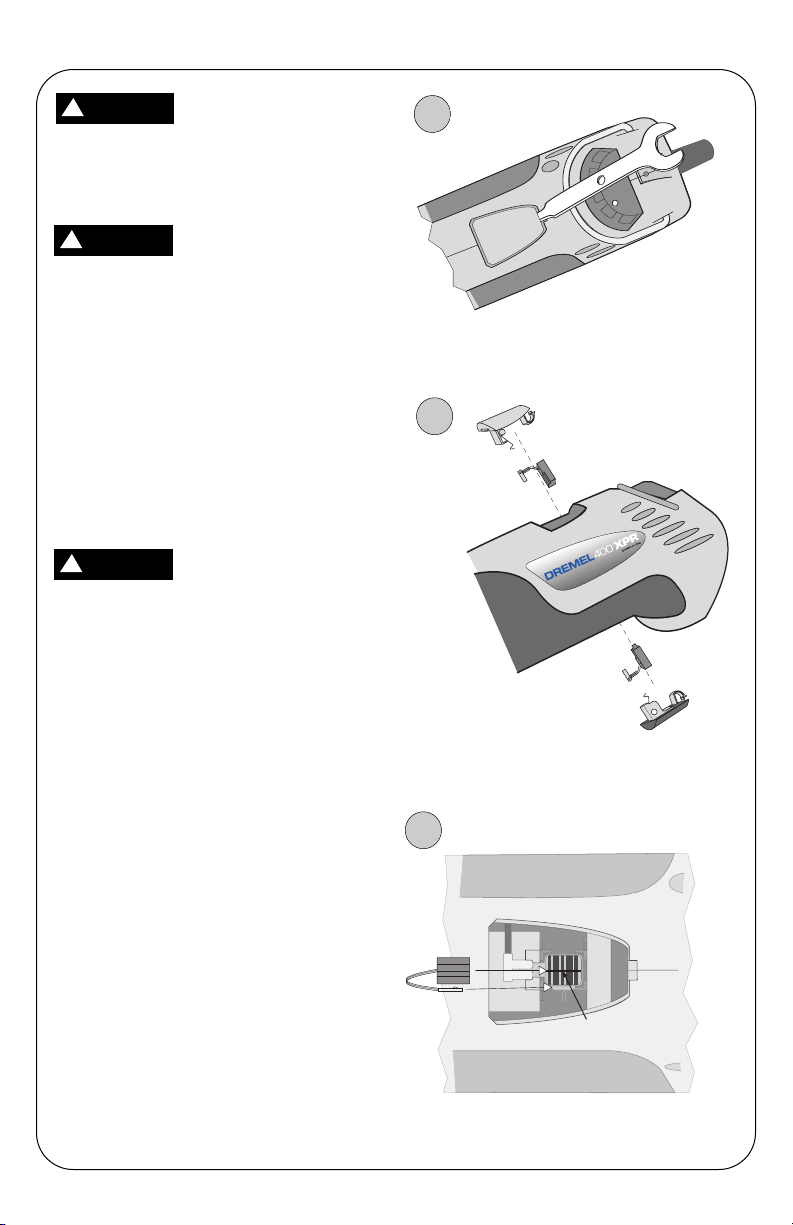

Shaft Lock Button

Collet Wrench

To

Tighten

To

Loosen

Collet Nut

1/8" Collet (480)

3/32" Collet (481)

1/16" Collet (482)

1/32" Collet (483)

Collet Nut

ASSEMBLY

WARNING

!

The Dremel™ accessories available for the

rotary tool come with various shank sizes.

Four size collets are available to accommodate

the different shank sizes. Collet sizes are identified by the rings on the back of the collet:

• 1/32" collet has 1 ring (No. 483)

• 1/16" collet has 2 rings (No. 482)

• 3/32" collet has 3 rings (No. 481)

• 1/8" collet has no rings (No. 480)

NOTE: Some rotary tool kits may not include all

four collet sizes. Collets are available separately.

Always unplug rotary tool before changing accessories, changing

collets, or servicing the tool.

Collets

1. Press the shaft lock button, hold down

tool is running.

2. With the shaft lock button engaged,

3. Remove the collet by pulling it free from

4. Install the appropriate size collet fully

1. Press the shaft lock button and rotate

tool is running.

2. With the shaft lock button engaged,

3. Insert the bit or accessory shank fully

4. With the shaft lock button engaged, fin-

CAUTION

!

Always use the collet which matches the shank size of the accessory you

plan to use. Do not force a larger diameter shank into a smaller collet.

Changing Collets

and rotate the shaft by hand until it

engages the shaft.

WARNING

!

Do not engage the shaft

lock button while rotary

loosen and remove the collet nut. Use

the collet wrench if necessary.

the shaft.

into the shaft and reinstall the collet nut

finger tight. Do not fully tighten the nut

when there is no bit or accessory

installed.

Changing Accessories

the shaft by hand until it engages the

shaft lock.

WARNING

!

loosen (do not remove) the collet nut.

Use the collet wrench if necessary.

into the collet.

ger tighten the collet nut until the bit or

accessory shank is gripped by the collet.

Do not engage the shaft

lock button while rotary

Shaft Lock Button

NOTE: Be sure to read the instructions

supplied with your Dremel™ accessory for

further information on its use.

8

Page 9

ASSEMBLY (CONTINUED)

2

4

2

4

Keyless Chuck

The keyless chuck is used in place of the stan

dard collet and collet nut to easily and quickly

remove and install some accessories.

The keyless chuck holds various accessories

with shank sizes 1/32" to 1/8" and is intended

for light duty accessories such as drill bits,

sanding drums, polishing accessories, wire

and bristle brushes and cut-off wheels.

1. See steps 1—3, Changing Collets on

page 7 to install the keyless chuck.

2. Thread the keyless chuck onto the rotary

tool shank.

OPERATION

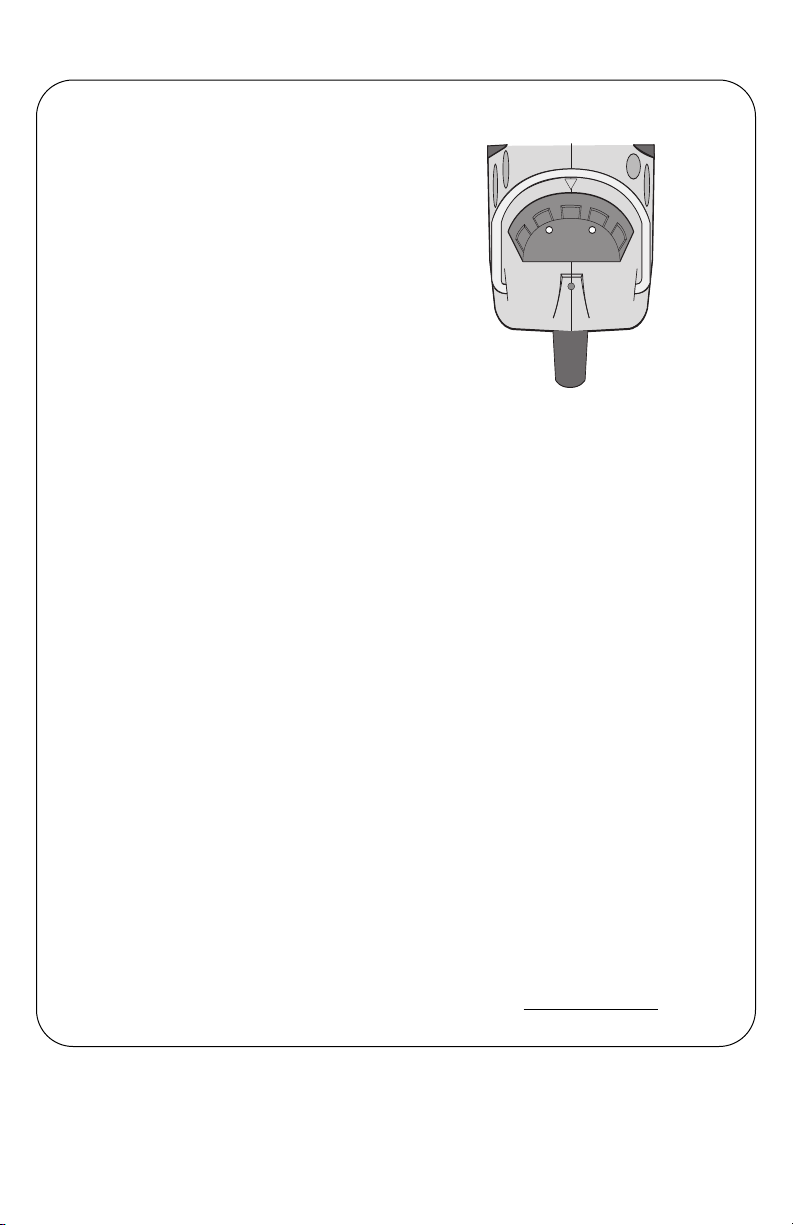

Learning To Use the Rotary Tool

Getting the most out of your rotary tool is a

matter of learning how to let the speed and

the feel of the tool in your hands work for you.

The first step in learning to use the rotary

tool is to get the “feel”

of it. Hold it in your

hand and feel its

weight and balance.

housing. This taper permits the tool to be

grasped much like a pen or pencil. The

unique comfort grip on the nose allows for

added comfort and control during use.

WARNING

!

Accessories can be damaged during

handling and can fly apart as they come

up to speed. This is not common, but it

does happen.

CAUTION

!

your hand. Blocking the air vents could

cause the motor to overheat.

IMPORTANT!

Practice on scrap material first

to see how the tool’s high-speed action performs. Keep in mind that your rotary tool will

perform best by allowing the speed, along

with the correct Dremel™ accessory and

attachment, do the work for you. Do not put

pressure on the tool during use, if possible.

Instead, lower the spinning accessory lightly

to the work surface and allow it to touch the

point at which you want to begin.

Concentrate on guiding the tool over the

work using very little pressure from your

hand. Allow the accessory to do the work.

Feel the taper of the

Always hold the tool

away from your face.

When holding tool, do not

cover the air vents with

-

Keyless Chuck

3. Use the supplied wrench to completely tighten the keyless chuck if you are

unable to apply sufficient tightening

pressure to hold the bit or accessory.

For best control in close work, grip the rotary

tool like a pencil between your thumb and

forefinger.

The “golf” grip method is used for more aggressive operations such as grinding or cutting.

Usually it is better to make a series of pass

es with the tool rather than to do the entire

job with one pass. A gentle touch gives the

best control and reduces the chance for

error.

9

-

Page 10

2

4

OPERATION (CONTINUED)

Operating Speeds

To achieve the best results when working

with different materials, set the variable

speed control to suit the job. To select the

right speed for the accessory in use, practice

with scrap material first.

NOTE: Speed is affected by voltage changes. A

reduced incoming voltage will slow the RPM of the

tool, especially at the lowest setting. If your tool

appears to be running slowly, increase the speed

setting accordingly. The tool may not start at the

lowest switch setting in areas where outlet voltage

is less than 120 volts. Simply move the speed setting to a higher position to begin operation.

The 400 Series XPR Rotary Tool switch settings are marked on the speed control dial.

Refer to the Speed Settings chart on pages

11 thru 13 to help determine the proper

speed for the material being worked on and

the accessory to use.

Most jobs can be accomplished using the

tool at the highest setting. However, certain

materials (some plastics and metals) can be

damaged by high-speed generated heat and

should be worked on at relatively slow

speeds.

Slow speed operation (15,000 RPM or less)

is usually best for polishing operations

employing the felt polishing accessories, delicate wood carving and fragile model parts.

All brushing applications require lower

speeds to avoid wire discharge from the

holder. Let the performance of the tool do the

work for you when using lower speed settings.

Higher speeds are better for drilling, carving,

cutting, routing, shaping, cutting dadoes or

rabbets in wood. Hardwoods, metals and

glass require high speed operation also.

The settings for approximate RPM’s are:

Switch Setting Speed Range RPM

2 5,000-8,000

4 9,000-11,000

6 12,000-17,000

8 18,000-24,000

10 25,000-35,000

Set the Speed Control to the desired setting.

Some guidelines regarding tool speed:

• There is no accessory for the Dremel

Rotary tool that will drill or cut glass.

• Plastic and other materials that melt at low

temperatures should be cut at low speeds.

• Polishing, buffing and cleaning with a wire

brush must be done at speeds not greater

than 15,000 RPM to prevent damage to the

brush and your material.

• Wood should be cut at high speed.

• Iron or steel should be cut at high speed.

• If a high speed steel cutter starts to vibrate,

it usually indicates that it is running too

slow.

• Aluminum, copper alloys, lead alloys, zinc

alloys and tin may be cut at various

speeds, depending on the type of cutting

being done. Use a paraffin (not water) or

other suitable lubricant on the cutter to prevent the cut material from adhering to the

cutter teeth.

NOTE: Increasing pressure on the tool is not

the answer when it is not performing properly. Try a different accessory or speed setting

to achieve the desired result. Please refer to

the following Speed Setting charts or simply

contact Dremel Consumer Service at:

1-800-437-3635

or at www.Dremel.com.

10

Page 11

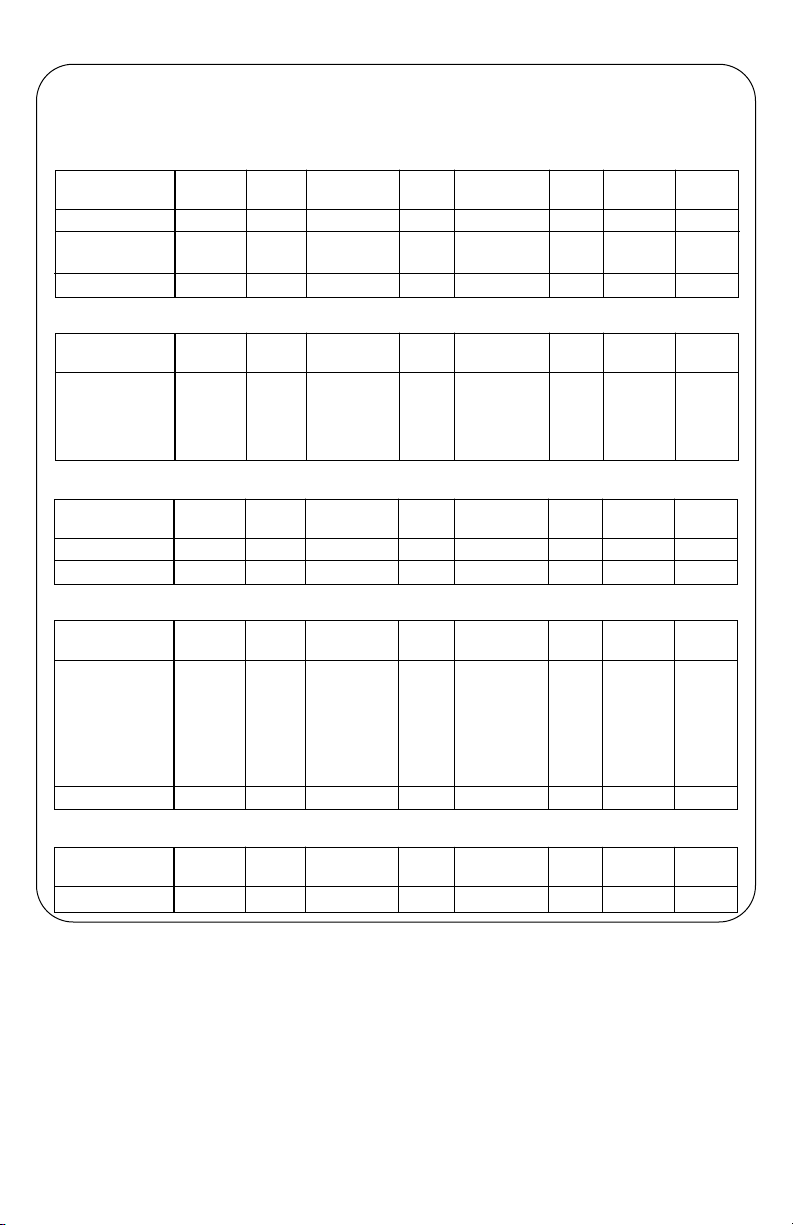

SPEED SETTINGS

Use only Dremel™ tested, high performance accessories.

* Speed for light cuts; Caution - burning on deep grooves.

• Depending on cutting direction relative to grain.

High Speed Cutters

Catalog

Number

100, 121, 131

114, 124,

134, 144

190

118, 191, 192,

193, 194

116, 117,

125, 196

115

198

199

Catalog

Number

105, 108

106, 109

107, 110

111

112

113

Catalog

Number

7103, 7105,

7117, 7120,

7122, 7123,

7134, 7144

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

810 5 5 6 - - 86 4 5 6 - - -

810 4 7 8 - - 810 4 5 8 - - -

86 4 5 6 - - -

810 4 5 6 - - 88 4 5 6 - - 88 4 5 6 - - -

Engraving Cutters

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

810 6 4 6 - - 8 10 54 6--810 5 4 6 - - 8* 10* 6* 4 6 - - 8* 10* 5* 4 6 - - 8* 10* 5* 4 6 - - -

Diamond Wheel Points

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

10 8 - - - 10 10 10

Catalog

Number

9931, 9932,

9933, 9934,

9935, 9936

Catalog

Number

9901, 9902,

9903, 9904,

9905, 9906,

9909, 9910,

9911, 9912

Structured Tooth Tungsten Carbide Cutters

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

88 4 - 6 - - -

Tungsten Carbide Cutters

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

8

8

4 8-10 6 8 8-10 8-10

11

Page 12

SPEED SETTINGS (CONTINUED)

Use only Dremel™ tested, high performance accessories.

* Speed for light cuts; Caution - burning on deep grooves.

• Depending on cutting direction relative to grain.

High Speed Router Bits

Catalog

Number

612, 640

615, 617, 618,

650, 652

654

Catalog

Number

83142, 83322,

83702, 84922,

85422, 85602,

85622

Catalog

Number

516, 517, 518,

500

Catalog

Number

903, 911, 921,

932,941, 945,

952, 953, 954,

971, 997,

8153, 8175,

8193, 8215

541

Catalog

Number

453, 454, 455

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

10* 8• - - - - - 10* 8• - - - - - -

10* 8• - - - - - -

Silicon Carbide Grinding Stones

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

- - 6 10 4 6 10 10

Abrasive Points

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

4-6 4-6 - 8 6 - - 4-6 4-6 - 8 6 - - -

Aluminum Oxide Grinding Stones

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

10 10 - 8 4 6 10 -

10 10 - 8 4 610 -

Chain Saw Sharpening Stones

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

-- - 8 - ---

12

Page 13

SPEED SETTINGS (CONTINUED)

Use only Dremel™ tested, high performance accessories.

* Speed for light cuts; Caution - burning on deep grooves. • Depending on cutting direction relative to grain.

Cutting Accessories

Catalog

Number

409, 420, 426,

540

542

545

560

561

562

Catalog

Number

461, 462, 463

414, 422, 429

425, 427

423

403, 404, 405

530, 531, 532

428, 442, 443

535, 536, 537

Catalog

Number

430, 431, 438

439, 440, 444

407, 408, 432

411, 412, 413

Catalog

Number

502, 503, 504,

505

Catalog

Number

511

Catalog

Number

150

Catalog

Number

569, 570

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

- - 2-4 10 10 10 10 -

10 8-10 2-4 10 10 10 10 -

8-10 8 - - - - - -

For use on drywall. For best results, use at 35,000 rpm.

6-10 6-10 2-4 - 10 - - -

-- - - - -10-

Polishing Accessories

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

-- - 8 8 888

-- - 6 6 666

-- -8 8---

- - - 6-8 6-8 6-8 6-8 6-8

4 4 2-4 6 6 - - -

- 4-4---4 4 2 4 - --44 - 4 4 4 - -

Sanding Bands and Discs

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

2-10 2-10 2-6 10 10 2-10 2-10 2-10 2-10 2-6 10 10 2-10 2-10 2-10 2-10 2-6 10 10 2-10 2-10 -

8 8 2-4 - 2-4 - - -

Flapwheels

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

6-8 8 2 10 8-10 - - -

Finishing Abrasive Buffs

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

66 4 6 6 - - -

Drill Bit

Soft Hard Laminates Steel Aluminum, Shell Ceramic Glass

Wood Wood Plastic Brass, etc. Stone

10

8-10

2-4

-

6---

Grout Removal Bits

Ceramic Glass

Soft

Wood

Aluminum,

Laminates

Hard

Wood Plastic Brass, etc. Stone

For use on wall and floor grout. 6-8 -

Steel

Shell

13

Page 14

"V" Notch

MAINTENANCE

2

4

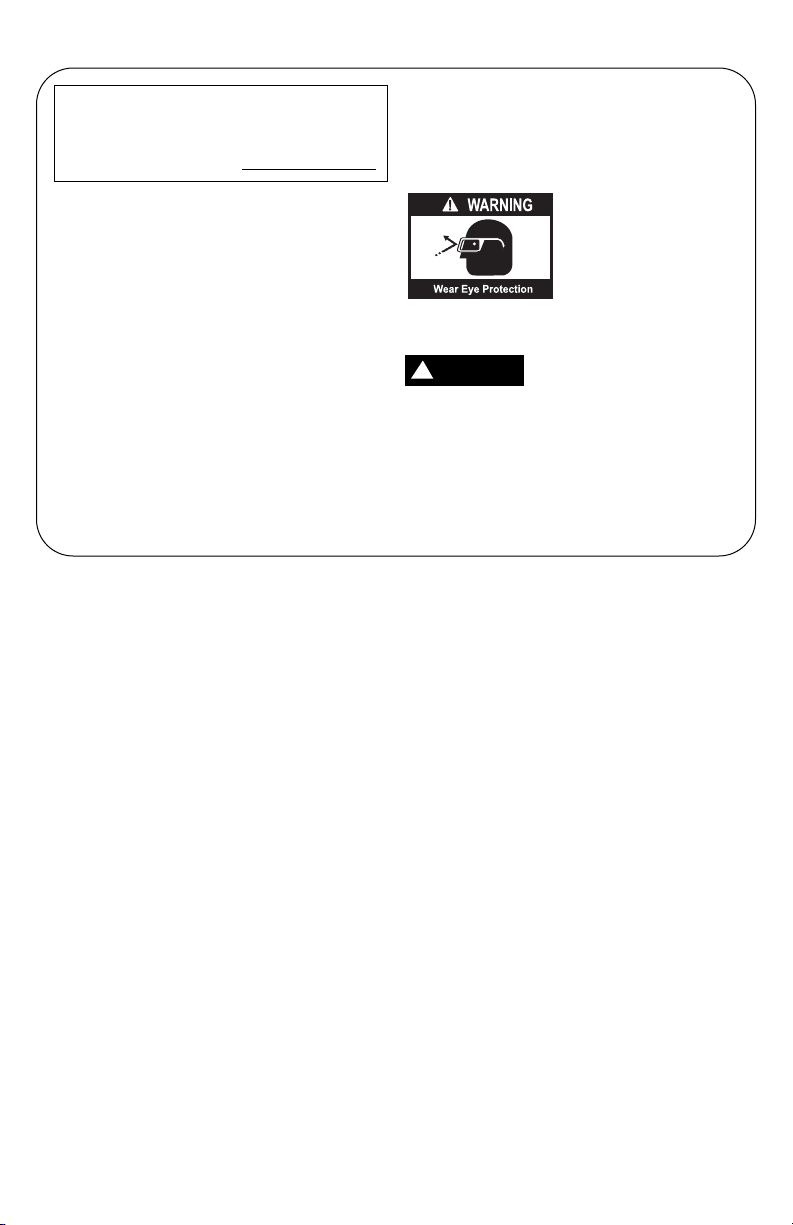

WARNING

!

Preventative maintenance

performed by unauthorized personnel may result in misplacing

of internal wires and components which

could cause serious hazard. We recommend that all tool service be performed

by a Dremel™ Service Facility.

WARNING

!

To avoid injury from unex-

pected starting or electrical shock, always remove plug from wall

outlet before performing service or cleaning.

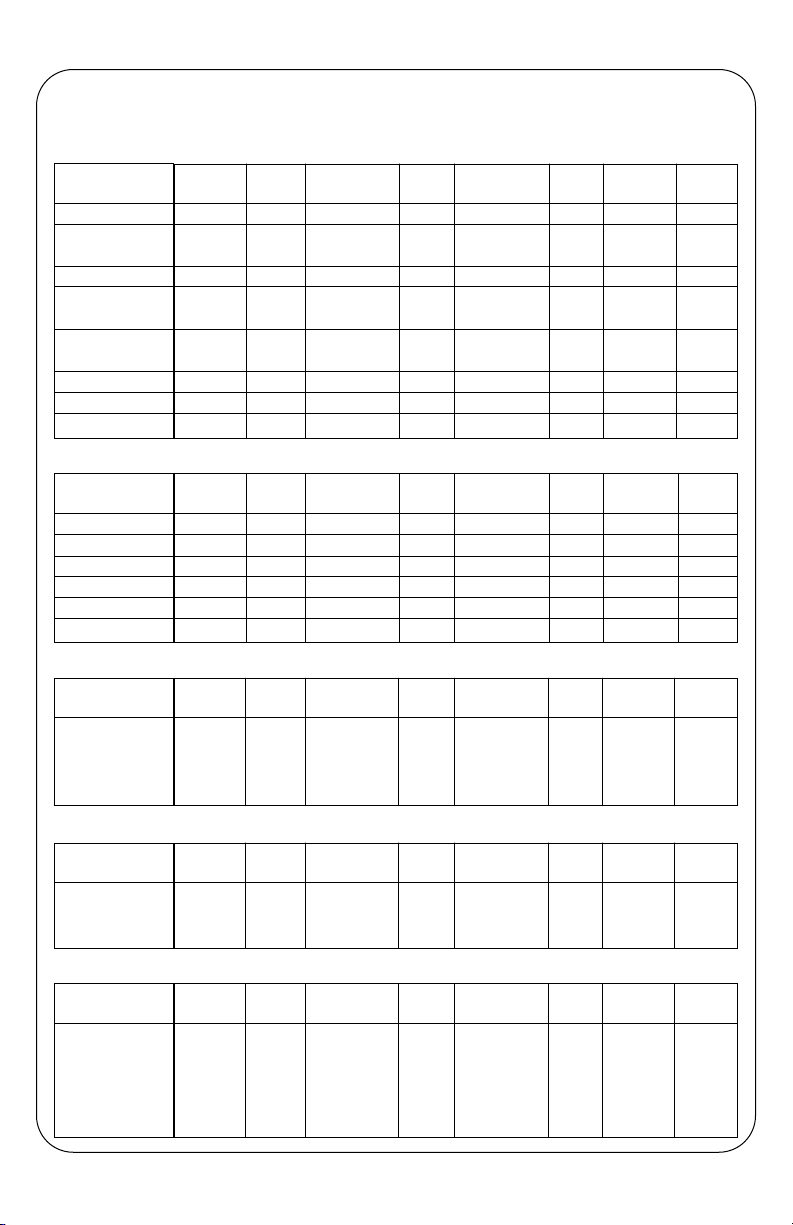

Carbon Brushes

The brushes in your tool have been engineered for many hours of dependable service.

To prepare the brushes for use, run the tool

at full speed for 5 minutes under no load.

This will properly “seat” the brushes, and

extend the life of the tool.

To maintain peak efficiency of the motor,

examine the brushes for wear every 40-50

hours.

CAUTION

!

damage the motor.

Use only original Dremel™ replacement

brushes.’

Inspect the rotary tool brushes after 40-50

hours of use. If the rotary tool runs erratically, loses power, or makes unusual noises

check the brushes for wear and possible

replacement. Remember: brushes in the

rotary tool are similar to oil in a car; the more

you check/service, the better the performance.

Follow these steps to check/change the

rotary tool brushes.

1. With the power cord unplugged, place

the tool on a clean surface. Use the tool

wrench to pry up and release the clip on

the brush cover (Figure A).

2. Remove the brushes from the tool by

pulling the shunt and brass clip which

are attached to the brush (Figure B).

NOTE: Be sure to note how the brass clip

slides out of the slot next to the brush pock

et. Also, note how the detent on brass clip fits

into brush pocket slot, which secures the

brass clip into proper position.

3. Check each brush for wear

less than 3/8" long, or if contact end is

rough or pitted, replace the brush.

Using the tool with worn

brushes will permanently

. If brush is

A

Removing Brush Cover

B

Removing/Inspecting Brushes

C

-

Installing Brushes

14

Page 15

For questions or replacement brushes,

please call Dremel’s Consumer Service

or check our website at www.Dremel.com.

4. Install existing or new brushes so the

NOTE: The detent on the brass clip must fit

into the slot on the side of the brush pocket,

which secures the brass clip in the proper

position (Figure C).

5. Reinstall brush covers by angling the

6. Plug power cord into a wall outlet. Run

at

1-800-437-3635

curved surface of the brush end matches the curvature of the motor commutator (as seen through the brush opening).

non-clip end into the opening. Make certain brush spring is centered in the “V”

notch on the brush, then snap closed

the clip end of the brush cover.

the rotary tool at full speed for 5 minutes

under no load. This will properly seat the

brushes and extend the life of the tool.

Cleaning The Tool

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointed

objects through openings.

The tool may be

cleaned with compressed air. Always

wear safety goggles

when cleaning tool

with compressed air.

There is no need to lubricate the Dremel™

rotary tool.

CAUTION

!

plastic parts. Some of these are: gasoline,

carbon tetrachloride, chlorinated cleaning solvents, ammonia and household

detergents that contain ammonia.

Clean the “soft grip” areas of the tool using a

damp cloth. Tougher soiled areas may

require more than one wipe application to get

clean.

Certain cleaning agents

and solvents will damage

15

Page 16

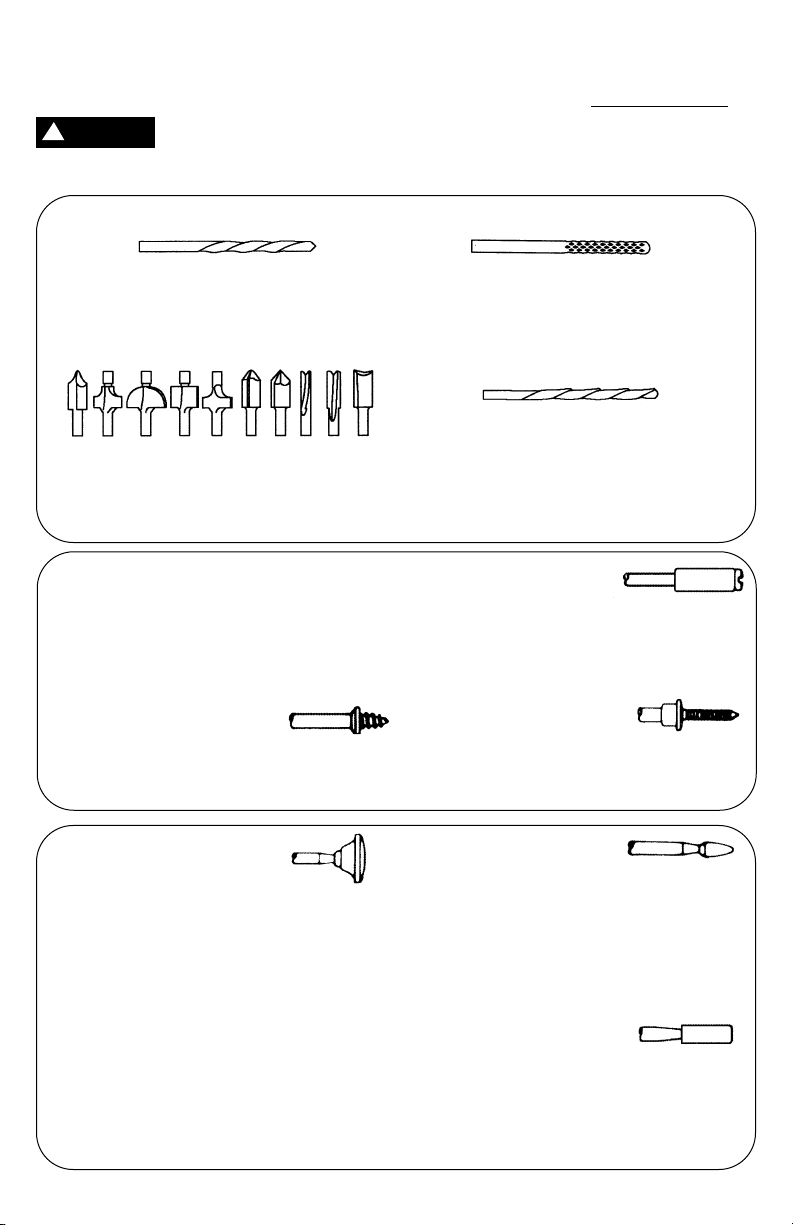

ACCESSORIES

For availability of all accessories and attachments, refer your local hardware, hobby or home

center. Or contact Dremel Consumer Service at:

WARNING

!

damage.

Use only Dremel™, high-performance accessories. Other accessories are

not designed for this tool and may lead to personal injury or property

1-800-437-3635 or at www.Dremel.com.

Drywall Cutting Bit

When using a template (outlet box) behind

the drywall, cut in a counterclockwise direction.

High Speed Router Bits

For routing, inlaying and mortising in wood

and other soft materials. Use only with

Dremel™ Router Attachment #330 or

Shape/Router Table #231.

Mandrels

A mandrel is a shank with a threaded or

screw head used with polishing accessories,

cutting wheels, sanding discs and polishing

points. The mandrel is a permanent shank,

allowing for replacement of the worn head

when necessary.

Screw Mandrel

For use with the felt polishing

tip and felt polishing wheels.

1/8" shank

Tile Cutting Bit

For use wall tile, cement board and plaster.

Start the bit into the material at a 45° angle

and then slowly bring it to a 90° angle to

begin the cut.

Multipurpose Cutting Bit

For use in wood, plastics, drywall, fiberglass,

vinyl or aluminum siding, acoustical tile and

laminates.

Start the bit into the material at a 45° angle

and then slowly bring it to a 90° angle to

begin the cut.

Small Screw Mandrel

Mandrel has a small screw

at the tip and is used with

emery and fiberglass cutting

wheels, sanding discs and

polishing wheels.

1/8" shank

Threaded Tip Mandrel

Mandrel has a threaded tip

which threads into the polishing point accessory #427.

1/8" shank

Aluminum Oxide Grinding

Stones (red/brown)

These grinding stones

come round, pointed or flat

and are made of aluminum

oxide. Use them for every possible grinding

operation: sharpening lawn mower blades,

screwdriver tips, knives, scissors, chisels and

other cutting tools. Use to remove flash from

metal castings, deburring any kind of metal.

These grinding stones can be resharpened

with a dressing stone. In machine shops,

high speed drills and cutters are normally

ground with aluminum oxide wheels.

1/8" shank

Silicon Carbide Grinding

Stones (blue/green)

Tougher than aluminum oxide

points, these are made especially for use on

hard materials such as glass and ceramics.

1/8" shank

Diamond Wheel Points

Used for fine detail work on

wood, jade, ceramic, glass and

other hard material. Bits are

covered with diamond parti

cles.

16

3/32" shank

-

Page 17

ACCESSORIES (continued)

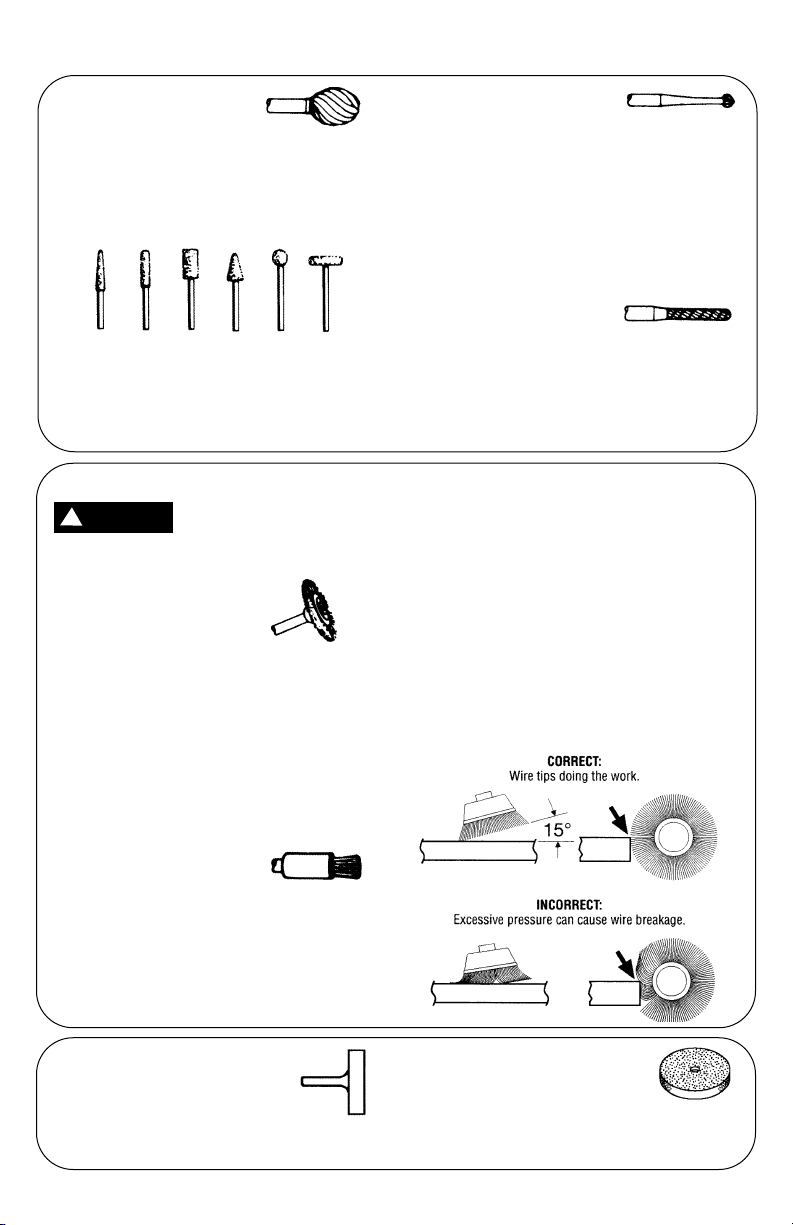

High Speed Cutters

High speed cutters are

used in carving, cutting

and slotting wood, plastics

and soft metals (such as aluminum, copper

and brass). Made of high quality steel.

1/8" shank

Structured Tooth Tungsten Carbide Cutters

1/8" shank

These cutters feature fast cutting needlesharp teeth for greater material removal with

minimum loading. Use on fiberglass, wood,

plastic, epoxy and rubber.

Wire Brushes

CAUTION

!

15,000 rpm. Refer to Speed Settings

(pages 10-12) for proper tool and setting.

Three different shapes

of wire brushes are

available in three different materials: stainless

steel, brass and carbon

wire. Stainless steel

brushes perform well on pewter, aluminum,

stainless steel and other metals, without

leaving rust. Brass brushes are non-sparking

and softer than steel, making them good for

use on soft metals like gold, copper and

brass. Carbon wire brushes are good for

general purpose cleaning.

Never use wire brushes at

speeds greater than

1/8" shank

Engraving Cutters

Engraving cutters come in a

wide variety of sizes and

shapes and are used for intricate work on

ceramics (greenware), wood carvings, jewelry and scrimshaw. They are often used in

making complicated printed circuit boards.

They should not be used on steel and very

hard materials, but are good for use on

wood, plastic and soft metals.

3/32" shank

Tungsten Carbide Cutters

Tungsten carbide cutters

are long-lived cutters for

use on hardened steel, fired

ceramics and other very hard materials. They

can be used for engraving on tools and garden equipment.

1/8" shank

Brushing Pressure

•. The tips of a wire brush do the work.

Operate the brush with the lightest pressure so only the tips of the wires come in

contact with the work surface.

•. If heavier pressure is used, the wires will

become overstressed, resulting in a wiping action. If this continues, the life of the

brush will be shortened by fatigue.

•. Apply the brush to the work surface so

the majority of the brush face makes full

contact. Applying the edge or side of the

brush to the work surface will result in

wire breakage and shortened brush life.

Bristle Brushes

Bristle brushes are

used for cleaning tools on

silverware, jewelry and antiques. The three

shapes make it possible to get into tight corners and other difficult spaces. They can be

used with polishing compound for faster

cleaning or polishing.

1/8" shank

Aluminum Oxide Abrasive

Wheels

Used to remove paint, deburr

metal, polish stainless steel

and other metals. Available in

medium grit.

1/8" shank

Grinding Wheel

Used for deburring, removing

rust, and general purpose grinding. Use with Mandrel #402.

17

Page 18

ACCESSORIES (continued)

Sanding Accessories

Sanding discs in fine,

medium and coarse

grades are made to fit

mandrel #402. They can be

used for nearly any small sanding job from

model making to fine furniture finishing.

In addition, the drum sander makes it possible to shape wood, smooth fiberglass, sand

inside curves and other difficult places. Drum

bands are replaceable and come in fine and

coarse grades.

1/8" shank

Flapwheels grind and polish flat or contoured

surfaces.

finishing sander, after heavier surface sanding and material removal is completed.

Flapwheels come in fine and coarse grades.

Buffs are a great finishing accessory for

cleaning and light sanding. They work effectively on metal, glass, wood, aluminum and

plastics. Buffs are available in medium and

coarse grades.

They are used most effectively as a

ATTACHMENTS

The following attachments are part of the Dremel Rotary Tool System; increasing the versatility

of your rotary tool.

XPR MultiSaw

The Dremel XPR MultiSaw turns your rotary tool into a multipurpose saw that will allow you to make straight and curved cuts in

a variety of materials. Scroll cutting patterns is now fast and easy.

Using standard jigsaw blades, you can cut soft & hard wood, plywood, metal, PVC, plastic, and much more!

Use with model 400 Series XPR only.

XPR Planer

Convert your corded rotary tool into a planer.

• The planer is designed for two types of planing: straight

planing and 45° planing, up to 2-1/8".

• In addition, the straight planing technique can be used for

limited shaping and carving.

• Ideal for fixing a warped or stuck door!

Use with model 400 Series XPR only.

Flex Light

The flex light uses Lithium Ion batteries (batteries included).

• LED lighting provides visibility in dimly lit

areas and increases light on detailed projects

• Easy to attach, no confusing wires or connections

• Attaches to Workstation 220 and Plunge

Router 335

Use with model 400 Series XPR only

.

18

Page 19

ATTACHMENTS (continued)

7 6 5 4 3

3 2

1

3/4

1/2

1/4

0

Flex Shaft

Ideal for hard-to-reach places and fine detail work.

• Quick connect attach system

• 36" long cable with new 5" bend radius provides more flexibility

• Comfort grip hand piece

• Integrated shaft lock button

• Holds up to 1/8" shank

Use with models: 275, 285, 395, 398, 780, 800, 400 Series XPR.

5" Radius

Converts you corded rotary tool into a plunge router.

• Clear base

• Two depth stop

• Includes edge guide and circle guide

• Rout circles, parallel to edge, signs, inlay work, and

lettering template adapters

Use with models: 275, 285, 395, 398, 800, 400 Series XPR.

Grout Removal

Fast and easy way to regrout any room or replace a

broken tile!

• Multiple side depth adjustment

• 30° angle for control cutting

• Guides 180° apart to keep bit centered between

tiles

• Easy screw mounting

• Includes 1/16" grout removal bit

Use with models: 275, 285, 395, 398, 770, 780, 800, 400 Series XPR.

Plunge Router

Cutting Guide

Provides controlled cutting in a variety of materials

• Allows for sturdy controlled cuts with maximum visi

bility

• Easy depth adjustment. Set to the correct cutting

depth for the project material.

Use with models: 275, 285, 395, 398, 770, 780, 800, 400 Series XPR.

19

-

Page 20

ATTACHMENTS (continued)

30

o

30

o

GAGE

Lawn / Garden Sharpener

The fastest, easiest, safest way to sharpen your lawn mower

blade and other garden tools.

• Guide provides optimum sharpening angle

• Sharpens most rotary lawn mower blades

• Includes sharpening stone

Use with models: 275, 285, 395, 398, 770, 780, 800, 400 Series XPR.

Chain Saw Sharpener

• Easily sharpen the dullest of chains

• Contains: sharpening attachment, 3 sharpening stones,

gauge, 2 spacers, wrench, instruction manual

Use with models: 275, 285, 395, 398, 770, 780, 800, 400 Series XPR.

Right Angle

Enhances the versatility of the rotary tool by allowing you to

get into hard-to-reach places.

• Ball bearings and spiral gears provide smooth and cool

operation

• Coupling system allows you to orient the attachment on

your tool in 12 different directions

• Quick disconnect system easily attaches to your rotary tool

in place of the housing cap, no wrenches required

Use with models: 275, 285, 395, 398, 780, 800, 400 Series XPR.

Dremelite

• Provides visibility in dimly lit areas and increases light on

detailed projects

• Two extremely long lasting and durable LED lights

• Uses a magnet threaded onto the tool’s output shaft to provide a clever and simple power source—no wires!

Use with models: 275, 285, 395, 398, 770, 780, 800, 400 Series XPR.

20

Page 21

ATTACHMENTS (continued)

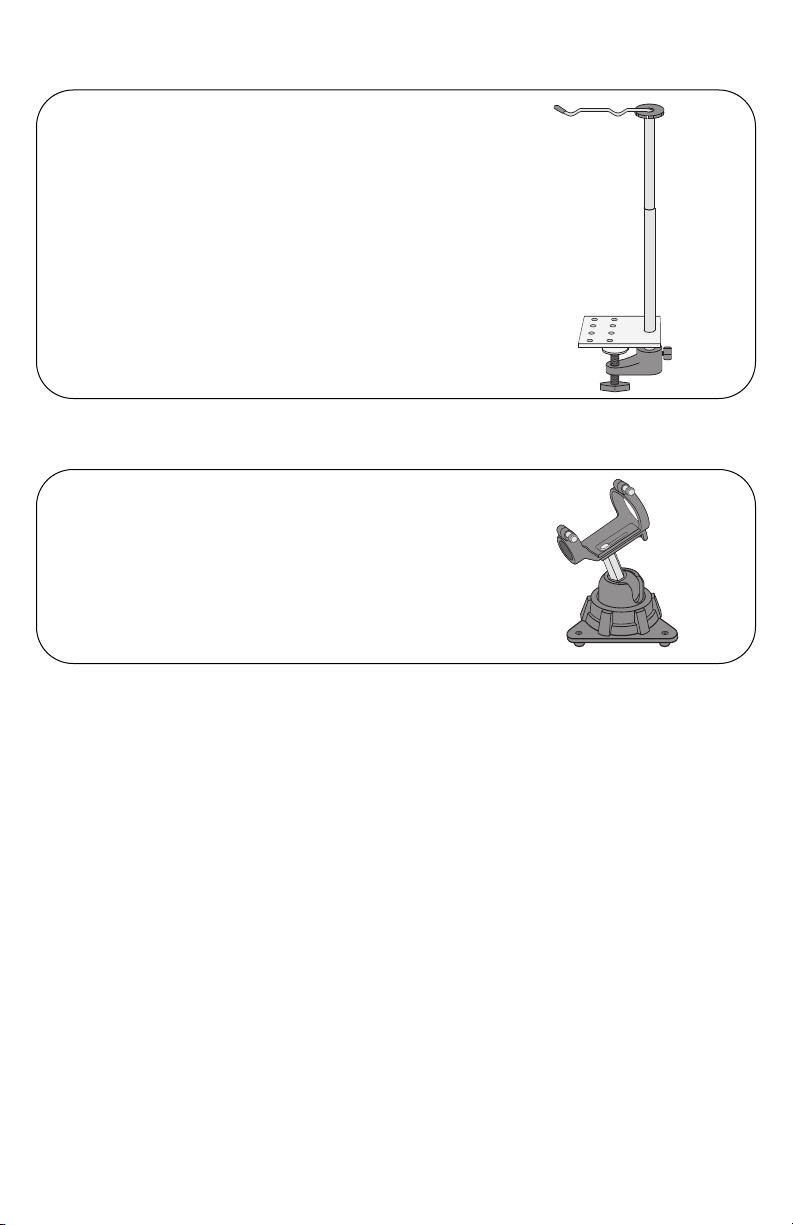

Flex Shaft Tool Holder

Conveniently suspends any Dremel rotary tool above your workbench.

• Perfect for use with the Flex-Shaft attachment

• Clamps to workbenches up to 1-3/4" thick, and adjusts in height

from 12" to 42"

• Store extra bits on base

Use with models: 275, 285, 395, 398, 400 Series XPR.

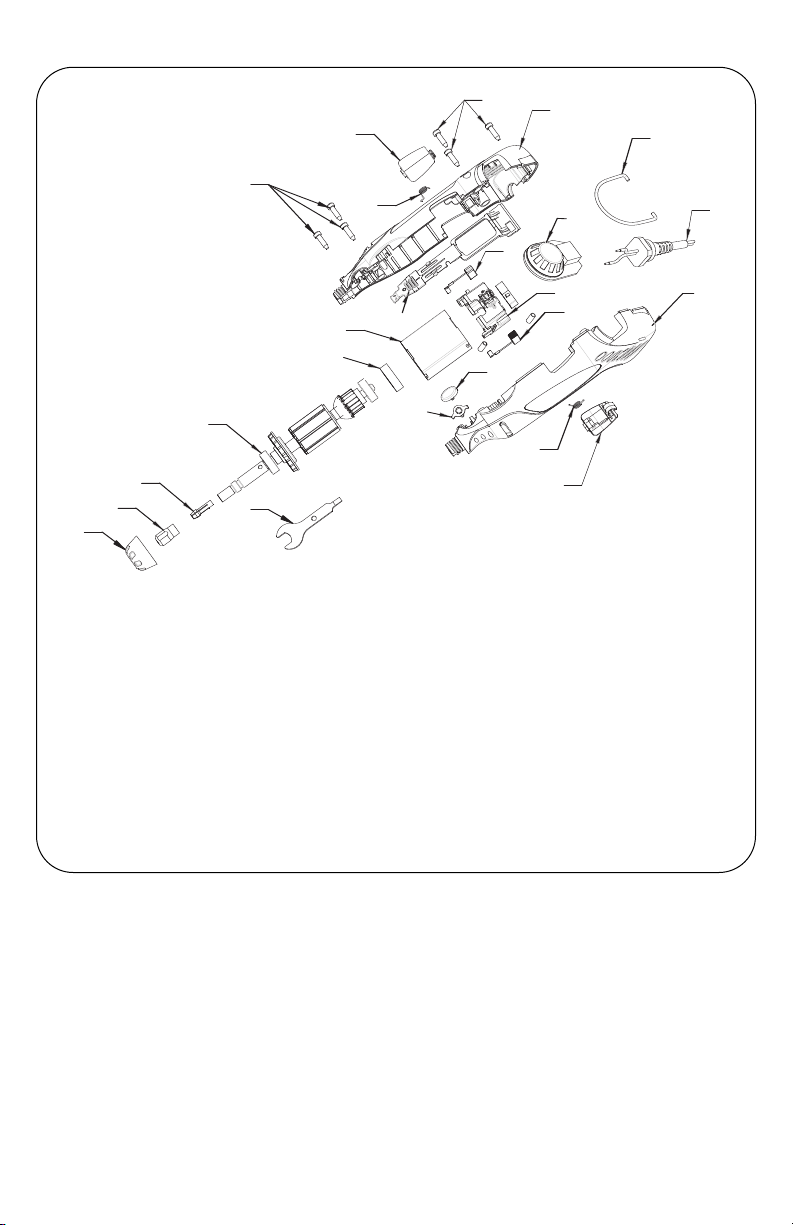

Tool Holder and Base

• Firmly holds rotary tools in any position

• Control workpiece (hands free) for better results

Use with models: 275, 285, 395, 398, 780, 400 Series XPR.

21

Page 22

1

1

2

5

3

10

10

16

17

18

19

20

25

25

22

24

23

25

25

30

28

27

24

4

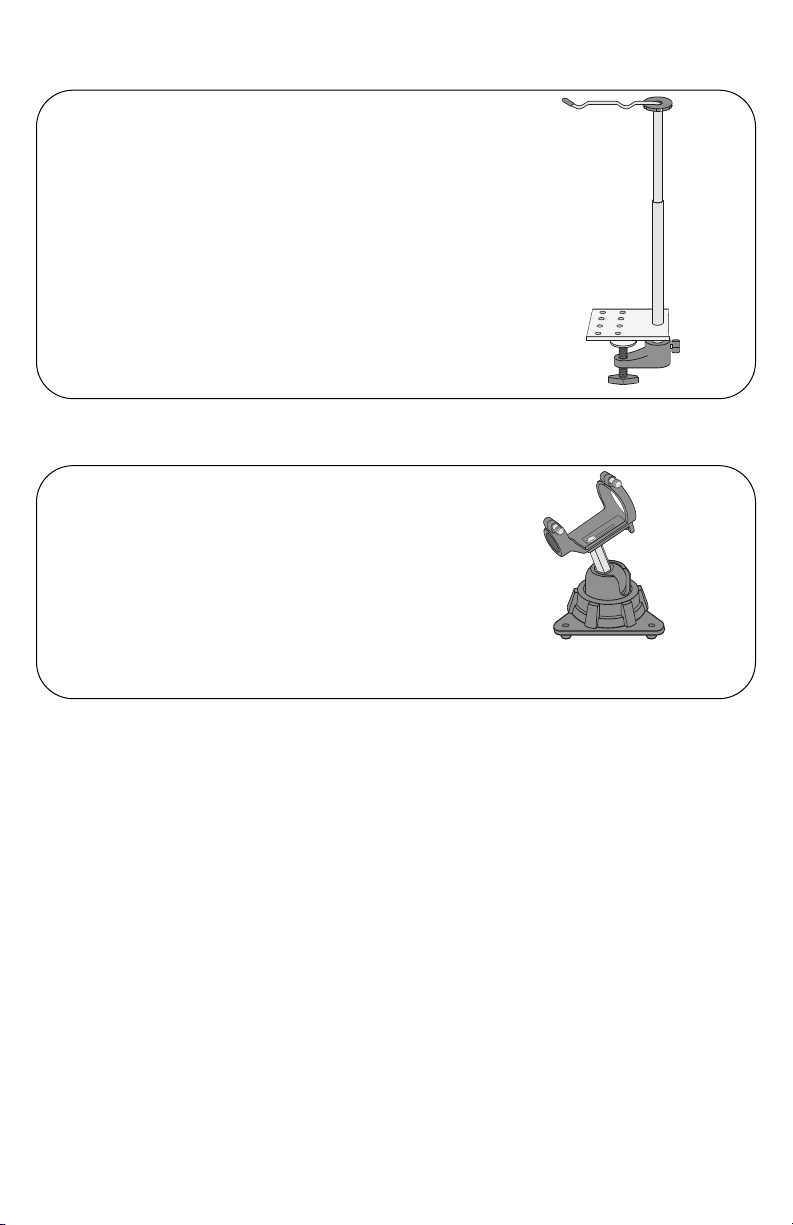

SERVICE PARTS & DIAGRAM

Ref. Part No. Description

1 2610920980 Housing Set

2 2610920701 Field Assembly

3 2610920702 Armature and

Bearing Assembly

4 2615990962 Wrench

5 2615294041 Cord

10 2610920705 Brush Spring (Pair)

16 261920709 Brush Holder

Assembly

17 2610920972 Collet Lock & Spring

Ref. Part No. Description

18 2610922763 Collet Nut

19 2615110480 1/8" Collet (In Tool)

20 2610920710 Switch Assembly

22 2610914379 Rubber Bearing

Sleeve

23 2610920718 Hanger

24 2615294035 Screws (Individual)

25 2610921563 Brush Door (Pair)

27 2610920716 Glamour Cap

28 2640920711 Speed Control

30 2610920717 Housing Cap

22

Page 23

DREMEL™ LIMITED WARRANTY

Your Dremel™ product is warranted against defective material or workmanship for a period of five

years from date of purchase. In the event of a failure of a product to conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid,

along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center Dremel Service Center

4631 E. Sunny Dune, Palm Springs, CA 92264

53406

We recommend that the package be insured against loss or in transit damage for which we cannot be responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT

RESULTING FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED

REPAIRS OR ALTERATIONS, UNAPPROVED ATTACHMENTS OR OTHER CAUSES UNRELATED TO PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY THIS

WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of

Dremel. If Dremel inspection shows that the problem was caused by problems with material or

workmanship within the limitations of the warranty, Dremel will repair or replace the product free

of charge and return product prepaid. Repairs made necessary by normal wear or abuse, or

repair for product outside the warranty period, if they can be made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR

IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH EXCEED THE ABOVE MENTIONED OBLIGATION ARE HEREBY

DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state

to state. The obligation of the warrantor is solely to repair or replace the product. The warrantor is

not liable for any incidental or consequential damages due to any such alleged defect. Some states

do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

4915 21st Street, Racine, WI 53406 OR

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write to

Scarborough, Ont., Canada M1C 4A7 Dremel, 4915 21st Street, Racine, WI

23

Page 24

NOTE

24

Page 25

Série XPR

Manuel d'instructions

et de sécurité

Outil rotatif haute performance

1-800-437-3635

http://www.dremel.com

Les produits Dremel sont fabriqués et vendus par

ool Corporation

la division Dremel de la Robert Bosch

T

Robert Bosch

ool Corporation © 2004

T

ous droits réservés

T

Page 26

POWER TOOL SAFETY RULES

AVERTISSEMENT

!

Vous devez lire et comprendre toutes les instructions. Lenonrespect, même partiel, des instructions ci-après entraîne un

risque de choc életrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

Veillez à ce que l'aire de travail soit propre et bien éclairée.

Le désordre et le manque de lumière favorisent les accidents.

N'utilisez pas d'outils électriques dans une atmosphère

explosive, par exemple enprésence de liquides, de gaz ou

de poussières inflammables.

des étincelles qui pourraient enflammer les poussières ou les

vapeurs.

Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillezavec un outil électrique.

pourraient vous distraire et vous faire faire une fausse

manoeuvre.

Les outils électriques créent

Sécurité électrique

Aire de travail

Les outils à double isolation sont équipés d'une fiche

polarisée (une des lames est pluslarge que l'autre), qui ne

peut se brancher que d'une seule façon dans une prise

polarisée. Si la fiche n'entre pas parfaitement dans la prise,

inversez sa position ; si elle n'entre toujours pasbien,

demandez à un électricien qualifié d'installer une prise de

courant polarisée. Ne modifiez pas la fiche de l'outil.

double isolation élimine le besoin d'un cordon

d'alimentationà trois fils avec mise à la terre ainsi que d'une

prise de courant mise à la terre. Avant de brancher l'outil,

assurez-vous que la tension de la prise correspond, à celle

indiquée sur la plaque signalétique. N'utilisez pas d'outils

prévus pour courant alternatif seulement avec une source de

courant continu.

Évitez tout contact corporel avec des surfaces mises à la

terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs,

etc.).

Le risque de choc électrique est plus grand si votre corps

est encontact avec la terre.Si l'utilisation de l'outil électrique

dans un endroit humide est inévitable, un disjoncteur de fuite à

la terre doit être utilisé pour alimenter votre outil. Des

chaussures et des gants en caoutchouc d'électricien

contribueront à accroître davantage votre sécurité personnelle.

N'exposez pas les outils électriques à la pluie ou à l'eau. La

présence d'eau dans un outil électrique augmente le risque de

choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil par

son cordon et ne débranchez pas la fiche en tirant sur le

cordon. N'exposez pas le cordon à la chaleur, à des huiles,

à des arêtes vives ou à des pièces en mouvement.

Remplacez immédiatement un cordon endommagé.

cordon endommagé augmente le risque de choc électrique.

Lorsque vous utilisez un outil électrique à l'extérieur

employez un prolongateur pour l'extérieur marqué « W

ou « W ».

Ces cordons sont faits pour être utilisés à l'extérieur

et réduisent le risque de choc électrique. Reportez-vous aux «

Dimensions recommandées des cordons de rallonge » dans la

section Accessoires de ce manuel.

Sécurité des personnes

Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. N'utilisez pas un outil électrique si

vous êtes fatigué ou sous l'influence de drogues, d'alcool

ou de médicaments.

Un instant d'inattention suf

fit pour

entraîner des blessures graves.

Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs.

N'approchez jamais les cheveux, les vêtements ou les

gants des pièces en mouvement.

des bijoux ou des cheveux longs risquent d'être happés par

des pièces en mouvement. Gardez les poignées sèches,

propres et exemptes d'huile et de graisse.

Méfiez-vous d'un démarrage accidentel. Avant de brancher

l'outil, assurez-vous que son interrupteur est sur ARRÈT.

Ils

Le fait de transporter un outil avec le doigt sur la détente ou de

brancher un outil dont l'interrupteur est en position MARCHE

peut mener tout droit à un accident.

Enlevez les clés de réglage ou de serrage avant de

démarrer l'outil.

l'outil peut provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un bon

appui et restez en équilibre entout temps.

vous permet de mieux réagir à une situation inattendue.

Utilisez des accessoires de sécurité. Portez toujours des

La

lunettes ou une visière.

masque antipoussière, des bottes de sécurité antidérapantes,

un casque protecteur et/ou un appareil antibruit.

Une clé laissée dans une pièce tournante de

Utilisation et entretien des outils

Immobilisez le matériau sur une surface stable au moyen

de brides ou de toute autre façon adéquate.

la pièce avec la main ou contre votre corps offre une stabilité

insuffisante et peut amener un dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la tâche.

L'outil correct fonctionne mieux et de façon plus sécuritaire.

Respectez aussi la vitesse de travail qui lui est propre.

N'utilisez pas un outil si son interrupteur est bloqué. Un

outil que vous ne pouvez pas commander par son interrupteur

est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un réglage,

de changer d'accessoire oude ranger l'outil.

mesures préventives de sécurité réduisent le risque de

démarrage accidentel de l'outil.

Rangez les outils hors de la portée des enfants et d'autres

personnes inexpérimentées.

les mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils. Les outils de

Un

coupe doivent être toujours bien affûtés et propres.

outils bien entretenus, dont les arêtes sont bien tranchantes,

,

sont moins susceptibles de coincer et plus faciles à

»

-A

diriger.Toute altération ou modification constitue un usage

erroné et peut causer un danger.

Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre

condition préjudiciable au bon fonctionnement de l'outil.

Si vous constatez qu'un outil est endommagé, faites-le

réparer avant de vous en servir.

causés par des outils en mauvais état. Élaborez un calendrier

d'entretien périodique de votre outil.

Des vêtements flottants,

Un bonne stabilité

Selon les conditions, portez aussi un

Le fait de tenir

De telles

Les outils sont dangereux dans

Des

De nombreux accidents sont

26

Page 27

N'utilisez que des accessoires que le fabricant

recommande pour votre modèle d'outil.

accessoires peuvent convenir à un outil, mais être dangereux

avec un autre.

Certains

Réparation

La réparation des outils électriques doit être confiée à un

réparateur qualifié.

électrique par un amateur peut avoir des conséquences

graves. Ainsi, des fils internes peuvent être mal placés ou

pincés, des ressorts de rappel de protecteur peuvent être

montés erronément.

L'entretien ou la réparation d'un outil

Consignes de sécurité pour outils rotatifs

Pour la réparation d'un outil, n'employez que des pièces

de rechange d'origine. Suivez les directives données à la

section « Réparation » de ce manuel.

autorisées ou le non-respect des instructions d'entretien peut

créer un risque de choc électrique ou de blessures. Certains

agents nettoyants tels qu'essence, tétrachlorure de carbone,

ammoniac, etc., peuvent abîmer les pièces en plastique.avant

l’entretien ; avant de changer les lames, les mèches, les

couteaux, etc.

L'emploi de pièces non

Les accessoires doivent être prévus pour au moins la

vitesse recommandée sur l'étiquette d'avertissement de

Les meules et les autres accessoires utilisés à une

l'outil.

vitesse supérieure à la vitesse nominale peuvent se détacher et provoquer des blessures.

Tenez l'outil par les surfaces isolées de prise en exécutant une opération lorsque l'outil de coupe peut venir en

contact avec des fils cachés ou son propre cordon.

contact avec un fil sous tension rendra les parties

métalliques exposées de l'outil sous tension et causera des

secousses électriques à l'opérateur. Pour couper dans des

murs existants ou autres endroits aveugles pouvant dissimuler des fils électriques, débranchez tous les fusibles ou

les disjoncteurs alimentant ce lieu de travail.

L’avertissement suivant s’applique aux outils à arbre

flexible et à leurs accessoires : ne faites pas fonctionner

l’arbre flexible avec une courbe prononcée.

pliage, l’arbre peut produire une chaleur excessive sur la

gaine ou la partie maniable. Le rayon minimum recommandé

est de 6 po.

Débranchez toujours le cordon de la prise de courant

avant d'effectuer quelque réglage que ce soit ou de

poser des accessoires.

par mégarde et causer des blessures graves.

Connaissez l'emplacement de l'interrupteur lorsque

vous déposez l'outil ou lorsque vous le reprenez.

pouvez actionner l'interrupteur par mégarde.

L’avertissement suivant s’applique aux outils à arbre

flexible et à leurs accessoires : maintenez toujours fermement la partie maniable dans vos mains pendant le

démarrage.

régime, le couple à réaction du moteur peut entraîner une

torsion de l’arbre.

Portez toujours des lunettes de sécurité et un masque

anti-poussières.

L'utilisation de dispositifs de sécurité personnelle et le travail

dans un environnement sûr réduisent les risques de

blessures.

Après avoir changé les lames ou effectué quelque

réglage que ce soit, assurez-vous que l'écrou de la

douille et tout autre dispositif de réglage sont bien serrés.

ment et causer ainsi une perte de contrôle avec projection

violente des composants en rotation.

Ne placez pas la main à proximité de la mèche qui

tourne.

proximité.

Lors de son accélération pour atteindre le plein

Un dispositif de réglage lâche peut bouger soudaine

Vous ne vous rendrez pas toujours compte de cette

L'outil pourrait se mettre en marche

N'utilisez l'outil qu'à un endroit bien aéré.

Lors du

Vous

Laissez les brosses tourner à la vitesse de fonctionnement pendant au moins une minute avant d’utiliser la

meule. Durant cette période, personne ne doit se tenir

devant la meule ou en ligne avec celle-ci.

ode de rodage, les poils ou fils de fer seront éjectés de la

brosse.

Les brosses (à poils standards ou métalliques) ne doivent

Le

jamais être utilisées au-dessus de 15 000 tr/min.

décharge de la brosse métallique en rotation en sens

opposé à vous.

ments de fil peuvent être déchargés à grande vitesse durant

l'action de « nettoyage » de ces brosses et peuvent se loger

dans votre peau. À haute vitesse, les poils ou fils de fer mal

attachés seront éjectés.

Portez des gants protecteurs et un masque de soudeur

avec les brosses métalliques ou en soie de porc.

Appliquez légèrement les brosses métalliques ou en

soie de porc sur votre ouvrage, puisque seules les

extrémités du fil métallique/des brosses font le travail.

Une « lourde » pression sur les brosses entraînera une surcharge du fil métallique ou de la brosse, résultant en une

action d’essuyage, et entraînera une décharge des brosses/du fil métallique.

Maniez soigneusement l'outil aussi bien que les meules

individuelles pour éviter les éclats ou les fissurations.

Posez une nouvelle meule si l'outil tombe pendant la

rectification. N'utilisez pas une meule qui peut être

endommagée.

le fonctionnement seront projetés à grande vitesse et pourraient frapper des personnes présentes ou vous-même.

N'utilisez jamais de lames émoussées ou abîmées. Les

lames affilées doivent être maniées soigneusement. Les

mèches abîmées peuvent se rompre brusquement durant

l'usage. Les lames émoussées nécessitent plus de force

pour pousser l'outil, causant éventuellement un bris de la

lame.

Utilisez des pinces pour supporter l'ouvrage autant que

possible. Ne tenez jamais un petit ouvrage d'une main et

l'outil de l'autre main pendant que celui-ci est en usage.

Prévoyez un espace suffisant, d'au moins 150 mm, entre

votre main et la mèche qui tourne.

telles que tiges cylindriques, tuyaux ou tubes, ont tendance

à rouler pendant qu'on les coupe et, de ce fait, la mèche peut

« mordre » ou sauter vers vous. En fixant un petit ouvrage,

vous pourrez utiliser vos deux mains pour contrôler l'outil.

Inspectez l'ouvrage avant de le couper. Avant de couper

un ouvrage de forme irrégulière, planifiez votre travail de

Des petites particules et des petits frag-

Les fragments d'une meule qui éclate durant

Pendant la péri-

Les pièces rondes,

Dirigez la

27

Page 28

Consignes de sécurité pour outils rotatifs

manière à ce que l'ouvrage ne glisse pas et ne vienne

pas pincer la mèche qui sera arrachée de votre main.

Ainsi, si vous taillez du bois, assurez-vous de l'absence de

clous ou de corps étrangers dans l'ouvrage. Sous l'effet du

contact avec des clous ou corps étrangers, la mèche peut

sauter.

Ne mettez jamais l'outil en marche alors que la lame est

enfoncée dans le matériau.

coincer dans le matériau et vous faire perdre le contrôle du

couteau.

Évitez de faire rebondir et de heurter la meule, surtout en

travaillant des coins, des arêtes vives, etc.

causer une perte de contrôle et un rebond.

Le sens d'avance de la mèche dans l'ouvrage lorsque

vous taillez, détourez ou coupez est très important.

Avancez toujours la mèche dans l'ouvrage dans le sens

dans lequel le tranchant sort de l'ouvrage (ce qui correspond au sens d'éjection des copeaux).

dans le mauvais sens fait sortir le tranchant de la mèche de

l'ouvrage et tire l'outil dans le sens de cette avance.

Si le matériau ou la mèche se grippe ou se bloque, mettez l'outil hors tension « OFF » par l'interrupteur.

Attendez que toutes les pièces mobiles s'immobilisent

et débranchez l'outil, procédez ensuite à débloquer l'ouvrage bloqué.

de marche « ON », l'outil pourrait se remettre en marche par

mégarde et causer ainsi des blessures graves.

Ne laissez pas un outil en marche sans surveillance,

mettez hors tension.

rité uniquement lorsqu'il s'est arrêté complètement.

Ne rectifiez et ne poncez pas à proximité de matières

inflammables.

raient enflammer ces matières.

Ne touchez pas la mèche ou la douille après usage.

Après usage, la mèche et la douille sont trop chaudes pour

être touchées à mains nues.

Nettoyez régulièrement les prises d'air de l'outil à l'aide

d'air comprimé.

poudre à l'intérieur du carter du moteur peut causer des

défaillances électriques.

Si l'interrupteur de l'outil est laissé en position

Les étincelles provenant de la meule pour-

Une accumulation excessive de métal en

Le tranchant de la lame peut se

Ceci peut

L'avance de l'outil

L'outil peut être déposé en toute sécu-

Ne soyez pas dupé par la familiarité acquise par un

usage fréquent de votre outil rotatif.

fraction de seconde d'insouciance suffit à infliger des

blessures graves.

Ne modifiez pas l'outil et n'en faites pas un usage

erroné.

Toute altération ou modification constitue un usage

erroné et peut provoquer des blessures graves.

Ce produit n’est pas destiné à être utilisé comme fraise

dentaire dans des applications médicales humaines ou

vétérinaires.

Lorsque vous utilisez les scies en acier, les disques de

découpage, les couteaux à grande vitesse ou les

couteaux au carbure de tungstène, assurez-vous que la

pièce est toujours bien assujettie. Ne tentez jamais de

tenir la pièce d’une seule main tout en utilisant l’un de

ces accessoires.

lorsqu’elles sont le moindrement inclinées dans la rainure, et

elles peuvent alors rebondir, vous faisant ainsi perdre le contrôle et causant des blessures graves. Votre autre main doit

servir à stabiliser et guider la main qui tient l’outil. Lorsqu’un

disque de découpage grippe, on peut généralement s’attendre à ce qu’il se brise. Lorsque la scie en acier, les couteaux

à grande vitesse ou le couteau au carbure de tungstène grippent, ils peuvent sauter hors de la rainure et vous pouvez

perdre le contrôle de l’outil.

!

travaux du bâtiment peuvent créer des poussières contenant des produits chimiques qui sont des causes reconnues de cancer, de malformation congénitale ou d’autres

problèmes reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du ciment et

d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités chimique-

ment

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire l’exposition à

ces produits chimiques, il faut travailler dans un lieu bien ventilé et porter un équipement de sécurité approprié tel que certains masques à poussière conçus spécialement pour filtrer les

particules microscopiques.

Des blessures graves peuvent s’ensuivre.

La raison en est que ces roues grippent

AVERTISSEMENT

N'oubliez pas qu'une

Les travaux à la machine tel

que ponçage, sciage, meulage, perçage et autres

28

Page 29

FAMILIARISATION AVEC L'OUTIL ROTATIF

Déballage et contrôle du contenu

!

AVERTISSEMENT

causées par le démarrage intempestif de

l'outil ou une décharge électrique,

débranchez toujours l'outil de la prise

murale lorsqu'il n'est pas utilisé.

Séparez toutes les pièces non fixées des

matériaux d'emballage et pour chaque article, pointez sur la liste de colisage qui figure

sur le carton pour vous assurer que rien ne

manque avant de jeter les matériaux d'emballage.

IMPORTANT! S'il manque la moindre

pièce ou si vous comprenez mal ces

instructions, contactez le service clientèle Dremel™ au : 1-800-437-3635 ou visitez notre site Web www.Dremel.com.

Pour écarter tout

risque de blessures

1-800-437-3635

Description

L'outil rotatif SÉRIE XPR™ associe haut

régime et performance pour servir de

Écrou de la bague de serrage

Bague de serrage

machine à ciseler

, meuleuse, cône à polir,

ponceuse, fraise, brosse, perceuse et plus

encore.

L'outil utilise un moteur à courant continu,

petit mais efficace. La grande variété d'accessoires Dremel™ disponibles inclut des

meules abrasives, des forets, des brosses

métalliques et en nylon, des fraises à graver

et à ciseler, des arêtes tranchantes, des

pointes à polir et plus encore. L'ajout possible de différents accessoires Dremel™ augmente d'autant la polyvalence de l'outil. La

variété des projets réalisables avec l'outil est

infinie.

L'outil rotatif SÉRIE XPR est un outil à haut

régime qui fonctionne entre 5 000 et 35 000

tr/min. (Une perceuse électrique typique

fonctionne uniquement jusqu'à 2 500 tr/min !)

Associés aux accessoires Dremel™, le haut

régime et la performance de l'outil rotatif

série XPR vous permettent de travailler sur

les projets les plus contraignants, sans avoir

à appliquer la moindre pression sur l'outil.

L'outil se charge de faire le travail.

Capuchon du boîtier

Bouches d'aération

Couvercle de brosse

(un de chaque côté)

Dispositif de suspension

29

Clé (serrage de la bague)

Bouton de blocage de l'arbre

Interrupteur de marche/arrêt

Régulateur de régime

Cordon d'alimentation

Page 30

CARACTÉRISTIQUES TECHNIQUES

Caractéristiques générales

Tension nominale . . . . . . . .120 V, 50-60 Hz

Intensité nominale . . . . . . . . . . . . . . . .2.0 A

Régime à vide . . . . . . . . . . . .No35,000/min

Bagues de serrage

compatibles 1/32 po (0,7 mm), 1/16 po (1,6

mm), 3/32 po (2,4 mm), 1/8 po (3 mm)

Caractéristiques techniques du moteur

Cet outil rotatif utilise un moteur à haut

régime variable. Il a été conçu pour fonctionner sur du courant alternatif de 110-120 volts

et 50-60 Hz. Avant de brancher le cordon du

moteur sur la prise murale, assurez-vous que

l'interrupteur d'alimentation est sur position "

arrêt " et que les caractéristiques du courant

électrique correspondent exactement à

celles estampillées sur la plaque signalétique

de l'outil rotatif.

Branchement sur l'alimentation

DANGER

!

touchez pas les lames métalliques de la

fiche en installant ou retirant la fiche de la

prise.

DANGER

!

endommagé d'une quelconque manière,

faites-le remplacer immédiatement pour

éviter une électrocution ou un risque d'incendie.

Pour écarter tout risque

d'électrocution, ne

Si le cordon d'alimentation est usé, coupé ou

Rallonges

Si une rallonge est nécessaire, un cordon

doté de conducteurs de calibre adéquat

et capable de transporter le courant

nécessaire pour votre outil devra être utilisé. Ceci empêchera les chutes de tension excessives, les coupures d'alimentation et les surchauffes.

DIMENSIONS RECOMMANDÉES

POUR LES RALLONGES

OUTILS 120 VOL

REMARQUE: Plus le numéro de calibre est

petit, plus le cordon est lourd.

Calibre du cordon en

Intensité

nominale

de l'outil

2-6

6-8

8-10

10-12

12-16

A.W

Longueur du cordon en pieds

25 50 100 150 15 30 60 120