IMPORTANT

Read Before Using

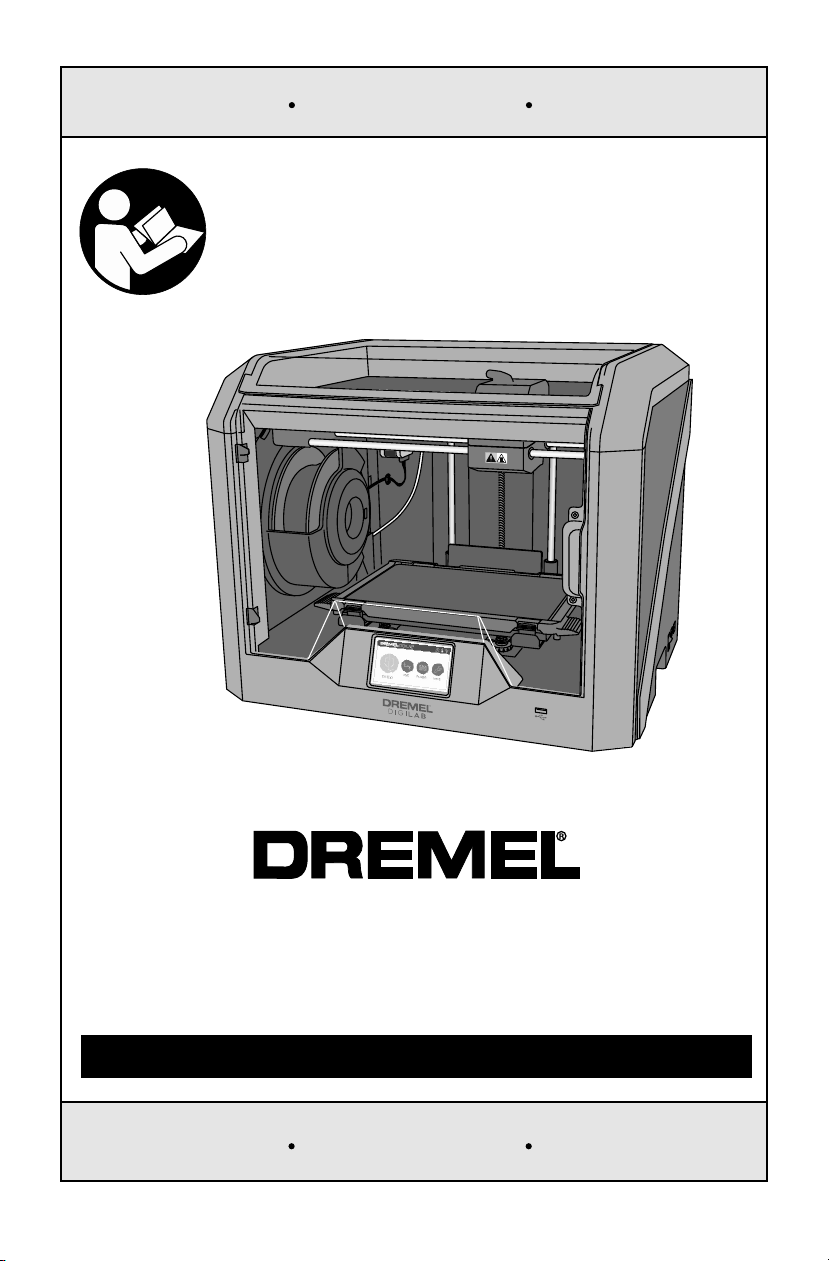

3D45

IMPORTANT

Lire avant usage

IMPORTANTE

Leer antes de usar

Operating/Safety Instructions

Consignes d’utilisation/de sécurité

Instrucciones de funcionamiento y seguridad

P.O. Box 081126 Racine, WI 53408-1126

Call Toll Free for Consumer Information & Service Locations

Pour obtenir des informations et les adresses de nos centres de service après-vente, appelez ce numéro gratuit

Llame gratis para obtener información para el consumidor y ubicaciones de servicio

1-844-4DRML3D (1-844-437-6533) www.digilab.dremel.com

For English Version

See page 2

Version française

Voir page 39

Versión en español

Ver la página 77

2

!

Safety Symbols....................................................................................2

General Safety Warnings..................................................................3-5

Additional Safety Warnings..................................................................5

Symbols ...............................................................................................5

Dremel Remote Services.....................................................................5

FCC Compliance .................................................................................6

Information on Intellectual Property .....................................................6

Specifications.......................................................................................7

Resources............................................................................................8

Glossary of Terms.............................................................................8-9

Introduction ........................................................................................10

Kit Contents .......................................................................................10

Unpacking ..........................................................................................11

Getting To Know Your Dremel 3D45.............................................12-13

Touch Screen................................................................................14-20

Initial Setup ........................................................................................21

Dremel Cloud Platform ......................................................................22

Getting Ready to Build..................................................................23-27

Building.........................................................................................28-30

Removing Your Object .......................................................................31

Using the Camera..............................................................................32

Best Practices....................................................................................33

Maintenance .................................................................................33-34

Troubleshooting............................................................................35-36

Firmware and Open Source Software ...............................................37

®

Dremel

Consumer Limited Warranty ................................................38

Table of Contents

Safety Symbols

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, could result in minor or moderate injury.

General Safety Warnings

3

WARNING

!

instructions may result in fire, equipment damage, property damage, or personal injury.

Read all instructions in this manual and familiarize yourself with the Dremel

3D45 before setup and use. Failure to comply with the warnings and

READ ALL INSTRUCTIONS

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

Keep work area clean and well lit. Cluttered

Work Area Safety

or dark areas invite accidents.

Do not operate Dremel 3D45 in the presence

of flammable liquids, gases or dust. Dremel

3D45 creates high temperatures which may

ignite the dust or fumes.

Store idle 3D45 out of reach of children and

other untrained persons. Injury can occur in

hands of untrained users.

Electrical Safety

Always use the Dremel 3D45 with a properly

grounded outlet. Do not modify Dremel 3D45

plug. Improper grounding and modified plugs

increase risk of electric shock.

Do not use Dremel 3D45 in damp or wet

locations. Do not expose Dremel 3D45 to

rain. Presence of moisture increases risk of

electric shock.

Do not abuse the cord. Never use the cord

for pulling or unplugging the Dremel 3D45.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

Avoid using this product during an electric

storm. There may be a remote risk of a power

surge from lightning that may result in electric

shock hazard.

In case of emergency unplug Dremel 3D45

from outlet.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a

Dremel 3D45. Do not use Dremel 3D45 while

you are tired or under the influence of drugs,

alcohol or medication. A mom ent of

inattention while operating Dremel 3D45 may

result in personal injury.

Use personal protective equipment. The use

of protective equipment such as heat resistant

gloves and safety glasses will reduce the risk of

personal injuries.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

Dremel 3D45 Use and Care

Before every use check Dremel 3D45 for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the Dremel 3D45’s operation.

If damage is suspected have the Dremel

3D45 repaired by authorized Dremel service

center before use. Use of Dremel 3D45 when

damaged may result in poor quality of object

creation, further equipment damage, property

damage or personal injury.

Do not touch the extruder tip or heated build

platform during Dremel 3D45 operation or until

it has cooled down to at least 60°C (140°F).

Contact with the extruder tip or build platform

during or after operation before tip and build plate

has cooled may result in personal injury.

Set up the Dremel 3D45 in a well-ventilated

area. Place Dremel 3D45 printer on flat

nonflammable surface and away from

flammable materal. Provide at least 8 inches

of unobstructed spacing around Dremel

3D45. Dr emel 3D 45 m elts pl astic durin g

building. Plastic odors emitted during Dremel

3D45 operation may irritate eyes and airways.

Locating Dremel 3D45 close to surrounding

objects prevents proper ventilation.

Do not reach inside the Dremel 3D45 while it

is in operation. Contact with Dremel 3D45

moving parts during operation may result in

poor build qu ality, equi pment da ma ge or

personal injury.

Always monitor the Dremel 3D45 during

operation. Use of Dremel 3D45 by persons

unfamiliar with these warnings and instructions

may result in equipment or property damage

and personal injury.

Use only DREMEL filament. Use of filament

not auth orized by Dreme l may result in

equipment, property damage, or personal injury.

Do not adjust extruder/nozzle setting to

exceed the maximum rated temperature of

the filament type being used. Heating filament

abov e reco mmended range can cause

emissions that may result in personal injury.

4

General Safety Warnings

Ensure small objects created by Dremel

3D45 are not accessible to young children.

Small objects are potential choking hazards for

young children.

Do not create illegal or inappropriate objects

using Dremel 3D45.

Do not use Dremel 3D45 to create objects

intended for use with candles, liquid fuels,

and other heat sources. Plastic may melt

when exposed to fire or other heat sources.

Such use of objects created by Dremel 3D45

may resul t in fire, p roperty dama ge and

personal injury.

Do not use Dremel 3D45 to create objects

intended for food or drink applications such

as preparation, decoration, storage, or

consumption. Such use of objects created by

Dremel 3D45 may result in illness or personal

injury.

Do not use Dremel 3D45 to create objects

intended with use with electrical

components or housings of electrical

components. Dremel filament is not suitable

for electrical applications. Such use of objects

created by Dremel 3D45 may result in property

damage and personal injury.

Do not put plastic objects in or around your

mouth. Dremel filament is not suitable for food

or drink preparation and food utensils. Such use

of objects created by Dremel 3D45 may result in

illness or personal injury.

Do not use Dremel 3D45 to create objects

intended for chemical storage. Dremel

filament is not suitable for chemical storage.

Such use of objects created by Dremel 3D45

may result in property damage and personal

injury.

Do not modify Dremel 3D45 or alter factory

settings. Modifications may result in equipment

and property damage, and personal injury.

Do not expose Dremel 3D45 to temperatures

exceeding 70°C (158°F). Dremel 3D45 may

become damaged. Dremel 3D45 is intended to

operate in temperature between 16-29° C (60 85° F).

Do not move or bump Dremel 3D45 or the

extruder during operation. The object may

build incorrectly.

Do not change filament spool unless the

building process is completed, stopped, or

paused. Changing the filament during building

will cancel the object and may damage the

extruder.

Do not pull the filament out. Doing so may

damage the extruder.

Use extra care not to damage the extruder

tip when clearing debris. Dremel 3D45 will not

work properly with damaged extruder tip and will

require replacement.

Before every build make sure that the build

platform is covered with Dremel specified

glue. Use of improper glue may result in

equipment damage and poor object build

quality.

Be aware of your body position when using

hand tools to remove objects from the build

platform. Sudden tool slip and improper body

position during object removal from the build

platform may result in personal injury.

Avoid scratching the build platform when

removing objects. Scratches in the build

platform will result in improper object creation.

Do not drop the build platform. Tempered

glass plate may break and result in personal

injury.

Do not remove tempered glass plate from

plastic holder. Contact with tempered glass

plate edge may result in personal injury.

Do not twist or bend the build platform while

removing objects. Tempered glass plate may

separate from plastic holder and result in

personal injury.

Dremel is not responsible for structural

integrity or utility of objects created using

Dremel 3D45. Structural models created by

inexperienced designers may result in property

damage and personal injury.

Service

Always unplug Dremel 3D45 from its power

before performing any service procedures.

Failure to do so may result in personal injury

and equipment damage.

Have your Dremel 3D45 serviced only by an

authorized Dremel service center using only

Dremel replacement parts. This will ensure

that proper operation and safety of Dremel

3D45 is maintained.

Use only Dremel approved components. Use

of components other than genuine Dremel

components may void warranty.

Use only Dremel approved filament. Damage

to the product resulting from use of filament

other than Dremel approved filament is not

covered under warranty.

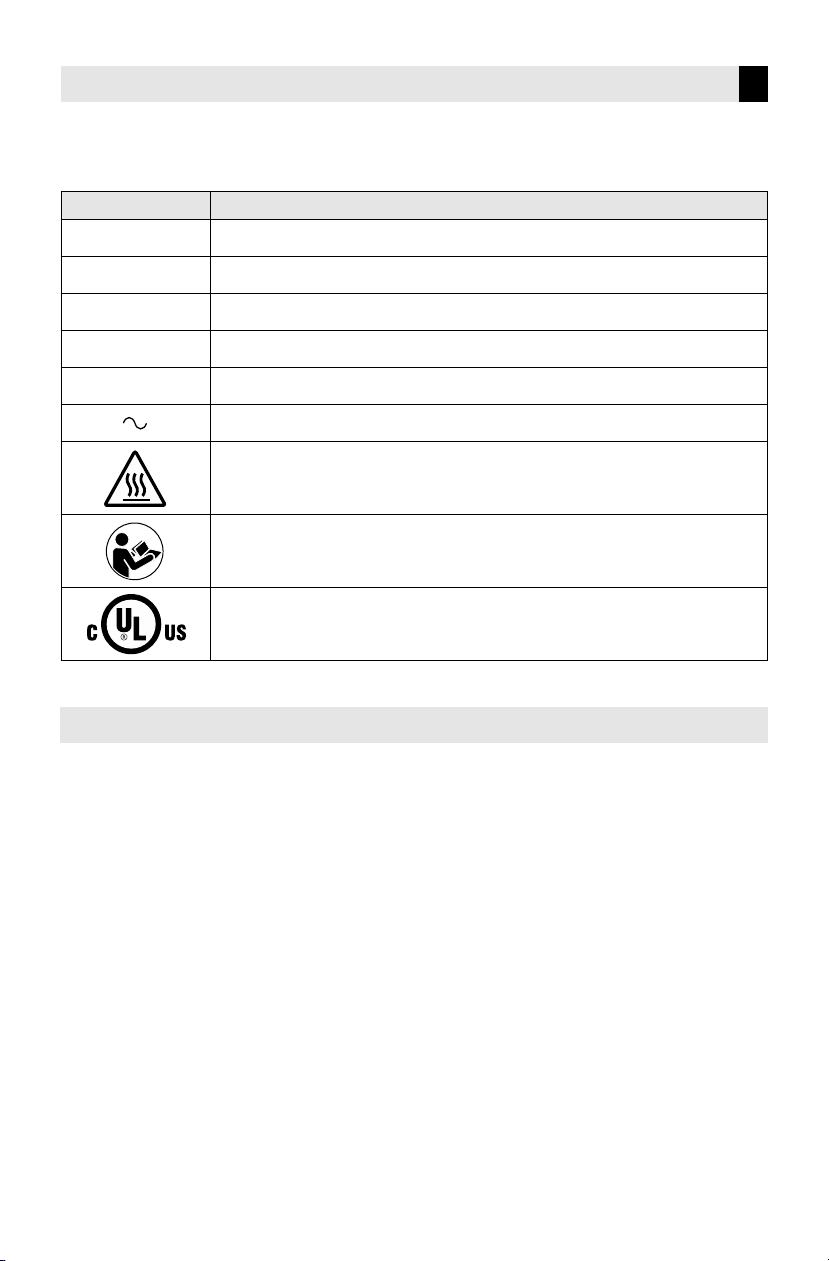

Symbols

5

IMPORTANT: Some of the following symbols may be used on your 3D45. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Designation / Explanation

V Volts (voltage)

A Amperes (current)

Hz Hertz (frequency, cycles per second)

ø

0 Off position

Diameter

Alternating current (type or a characteristic of current)

Hot surface hazard symbol. Contact may cause burn. Allow to cool before

servicing.

Alerts user to read manual.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

Dremel Remote Services

Dr e mel rem o te serv i ces pro vide y o u with

information and services regarding your Dremel

3D products. The type of information provided

by Dremel remote services may change from

ti m e t o t i me. All p rod u c t i nfor m atio n a n d

services are provided for your convenience, “As

is” and “As Available”.

Dremel does not guarantee that the information

or s erv i ces w ill b e ava ila b le, a ccu rat e, or

reliable, or that product information or services

will provide safety in your home. You use all

product information, services, and products at

you r d isc r e tio n a n d ris k . T he pro d uct

information and services are not intended as a

sub s tit u t e fo r dire c t mea n s of o btai n ing

information.

Network connectivity requires an access point

and high speed internet connection. Internet

service provider charges may apply.

Remote printing requires a compatible mobile

device an d data plan. Ca rr ie r char ge s may

apply.

6

FCC and IC Compliance

FCC COMPLIANCE

NOTE: This equipment has been tested and

found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

rea s o nable pr o tecti o n ag ainst ha r m ful

interference in a residential installation. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the instructions,

may cause harmf ul i nterferen ce to rad io

com m u nica t i ons. Ho weve r, th ere is no

guarantee that interference will not occur in a

particular installation. If this equipment does

cau s e harm f ul i n t erfer e n ce t o radi o or

tel e v isio n recep t i on, w h ich ca n be

determined by turning the equipment off and

on, the user is encouraged to try to correct

the int e rfer e n ce by one or more of the

following measures:

Information on Intellectual Property

The Dremel 3D45 is intended for 3D printing

objects from digital files that you create or

own, or have the right to prin t using the

Dremel 3D45. When making objects using

the Dremel 3D45, it is your responsibility to

ensure that you do not infringe any third

party intellectual property rights or violate

any applicable laws or regulations, such as

U.S. or foreign intellectual property laws.

The Dremel 3D45 may not be used to make

objects protected by intellectu al property

rights owned by third parties without such

third parties’ permission. Using the Dremel

3D45 to do any of the following may require

the permission of third parties: to make a

duplicate or facsimile (in whole or in part) of

any object not created by you, to make an

object from a digital file you do not own, or to

make an object from a scan of a physical

obje ct that y ou d id not create. I t is y our

responsibility to obtain such permission. In

• Reorient or relocate the receiving antenna.

• Inc reas e t h e s epar a tion bet ween the

equipment and receiver.

• Connect the equipment into an outlet on a

circ uit diffe rent from th at to w hich the

receiver is connected.

• Co nsu lt the d eal er or an experienced

radio/TV technician for help.

Changes and Modifications not expressly

approved by the manufacturer or registrant of

this equipment can void your authority to

ope r a te this equ i p ment und e r Fe deral

Communications Commission’s rules.

some cases, you may not be able to obtain

such permission. Where such permission

cannot be obtained, you should not 3D print

such object, or you do so at your own risk.

You may not mod i fy, r ever s e e ngine e r,

decompile, or disassemble the Dremel 3D45

or it s so ftwar e or firmwa r e , excep t as

permitted by applicable law.

If you use the Dremel 3D45 in any way other

th an as r eco mmended and d escri bed i n

these Operating/Safety Instructions, you do

so at your own risk. Using the Dremel 3D45

to make objects that infringe any intellectual

property rights owned by third parties could

result in civil or crimin al prosecution and

penalties, and you could be liable for money

damages, fines, or imprisonment.

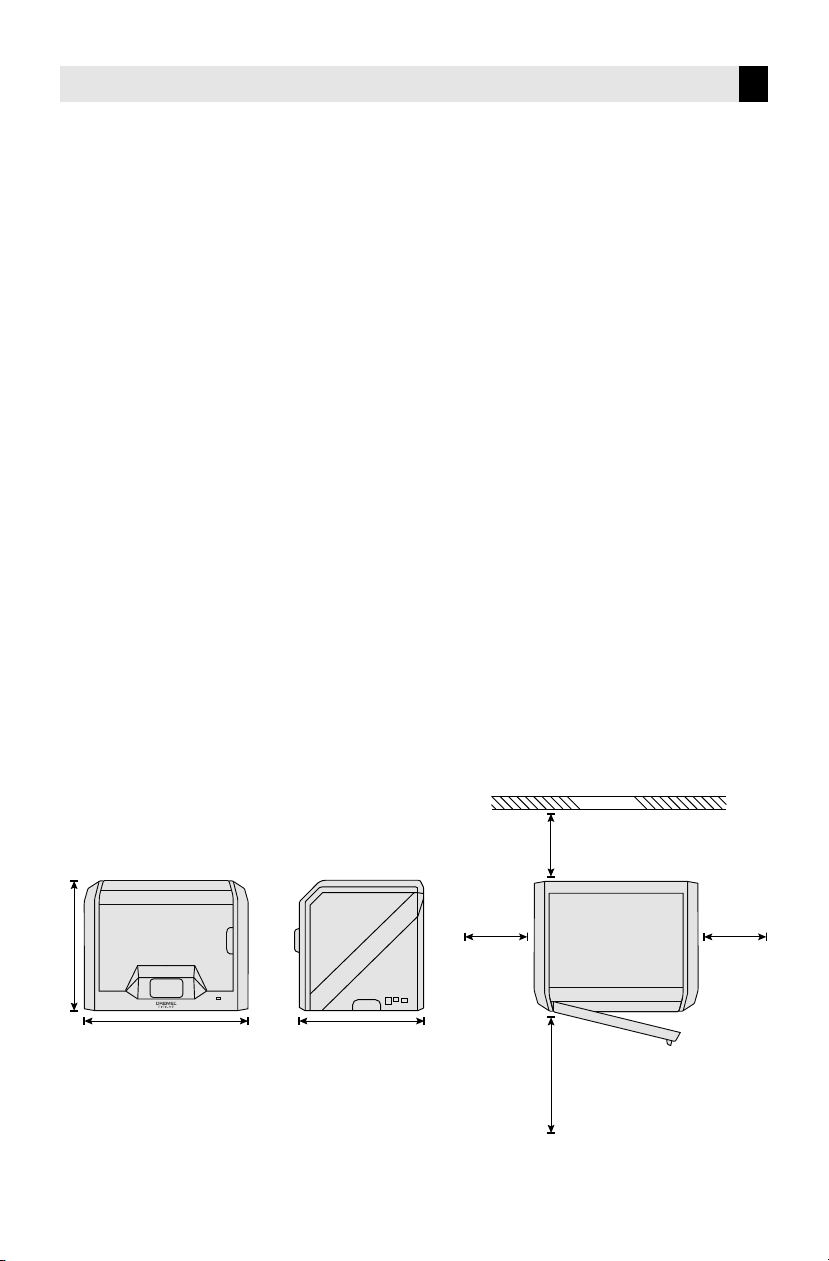

Specifications

16” (406mm)

20.25” (515mm) 15.5” (394mm)

WALL

8” (203mm)

8” (203mm)8” (203mm)

14” (356mm)

7

BUILDING

Extruder: single extrusion

Extruder Temperature: Up to 280 C, 536 F

Build Platform Temperature: Up to 100 C,

212 F

Operating Interface: 4.5” full color IPS touch

screen

Maximum Build Volume: 10” x 6” x 6.7”

(255mm x 155mm x 170mm)

Layer Thickness: 50 microns (0.05 mm)

Filament Types and Colors: See

www.digilab.dremel.com for color choices

Internal Storage: 8GB

External Storage: USB flash Drive

WEIGHT & DIMENSIONS

Weight (without spool): 19.4 kg (42.8 lb)

Dimensions: 20.25” x 16” x 15.9” (515mm x

406mm x 394mm)

FILAMENT

ONLY works with Dremel 1.75mm filament

FILAMENT STORAGE

All polymers degrade with time. Do not

unpack until filament is needed. Filament

should be stored at room temperature:

16-29° C (60-85° F) and in dry conditions.

SUPPORTED OPERATING SYSTEMS

®

• Apple

• Microsoft

Mac®OS®X v10.9 or later

(Mavericks)

®

Windows®7 SP1

• Microsoft®Windows® Window 8, 8.1

• Microsoft®Windows® Window 10

MINIMUM SYSTEM SPECIFICATIONS

FOR PRINT STUDIO

• CPU: 64-bit processor (32-bit not

supported)

• Memory: 3 GB RAM (4 GB or more

recommended)

• Disk space: ~2 GB free disk space for

installation

• Display card: 1,024 MB GDDR RAM or

more. Microsoft

®

Direct3D®11 capable

graphics card or higher

• Pointing Device: three-button mouse

ELECTRICAL REQUIREMENTS

3D45 input rating: 100-240V, 47-60Hz,

0.85-2.3Amps

OPERATING ENVIRONMENT

Room Temperature: 16-29° C (60 - 85° F)

Level workspace

Dry workspace environment

SOFTWARE

Dremel 3D45 comes with complimentary file

slicing software for Windows and Mac OSX.

This application converts your 3D digital files

into buildable files.

8

Resource Description Location

Quick Start Guide

Dremel

Website

Provides illustrated walkthrough of how

to un-box your 3D45 and start building

out of the box.

Provides the latest 3D45 software,

product information, customer support,

and 3D model and project downloads.

Resources

Printed version of the Quick Start

Guide is located in the carton with

the printer. It is also available on

www.digilab.dremel.com

www.digilab.dremel.com

Dremel 3D

Customer Support

File Slicing

Software

Contact Dremel for product support,

maintenance, and service.

Allows you to upload, edit,

and build 3D files.

1-844-4DRML3D (1-844-437-6533)

www.digilab.dremel.com

Install from www.digilab.dremel.com

or from USB flash drive provided

with the Dremel 3D45.

Glossary of Terms

Build Platform The flat surface used by your Dremel 3D45 to build objects. The build platform is

Build Platform Clips Clips located at the front of the build platform base that are used to secure the build

Build Volume The three dimensional (3D) amount of space that an object will use once it is completed.

Door Your Dremel 3D45 has a door located on the front panel. This allows for easy access to

ECO-ABS Natural thermoplastic that provides users with durable and impact resistant parts.

Ethernet Port A local area wired networking technology that allow electronic devices to communicate.

Extruder An assembly that uses gears to pull filament through the extruder intake, heat the filament

Extruder Fans Fans used to cool the outer assembly of the extruder and gear motor.

Extruder Fan Baffle A plastic piece that directs air from the extruder fan onto the build platform to assist in

Extruder Intake An opening located at the top of the extruder where filament is inserted for building.

Extruder Lever A lever located on the side of the extruder that is used to loosen the grip of the extruder

Extruder Tip A nozzle located at the bottom of the extruder where heated filament is forced out for

Filament A threadlike strand of plastic material.

Filament Guide Tube A plastic tube that guides the filament from the spool holder to the extruder of the printer,

comprised of a tempered glass plate with a plastic holder.

platform in place.

Your Dremel 3D45 has a maximum build volume which means that objects with a larger

build volume cannot be built unless they are resized or broken into sub-objects.

the build platform, extruder, filament, and your objects. This door is made with a

transparent material so you can monitor the progress of your objects while keeping the

build environment stable.

to the build temperature, and push the heated filament out of the extruder tip.

cooling the active build.

gear motor.

building.

preventing any snags.

Glossary of Terms

9

Filament Runout Sensor A sensor in the extruder intake that pauses your printer if it runs out of filament

Filament Spool A cylindrical piece on which a long strand of filament is wound for storage and

.g, .gcode and .g3drem Buildable file formats compatible with your Dremel 3D45.

Glue Stick Non-toxic and acid-free stick of glue that is applied to the build platform to help prints

Leveling Knobs Knobs located under the base of the build platform that allow users to easily level the

Leveling Sensor A sensor that detects the height of the build platform and assists in proper leveling.

Lid Your Dremel 3D45 has a pivoting lid on the top. This allows for more access to the

Needle Nose Pliers Common tool used to hold small objects and to grab excess material that may be too

Nylon Synthetic polymer that provides strong and flexible prints with heavy wear resistance.

OBJ File A common digital file format used in a wide range of 3D model software. This file is

Object Removal Tool A tool used to separate your objects from the build platform.

PETG A thermoplastic filament that combines flexibility, strength and durability similar to

PLA A bioplastic derived from renewable resources such as corn starch.

Spool Holder A plastic piece located to the left of the build platform inside your Dremel 3D45 build

Spool Door A removable door which locks the filament spool to the spool holder.

Stepper Motor A brushless DC electric motor used to drive the guide rails and extruder gears.

.STL File A common digital file format used in a wide range of 3D model software. This file is

Touch Screen Full color display that is touch activated. It allows you to monitor your Dremel 3D45

USB Flash Drive A portable memory card used on a wide array of devices.

WIFI A local area wireless networking technology that allow electronic devices to

X-Axis Guide Rails A set of rails on either side of the extruder that allow a stepper motor to move the

Y-Axis Guide Rails A set of rails on either side of the build area that allow a stepper motor to move the

Z-Axis Guide Rails A set of rails located at the back of the build area that allow a stepper motor to move

during a build.

continuous use.

stick.

build platform before each print.

build platform, extruder, filament, and objects when necessary.

hot to touch directly.

created in 3rd party 3D software or downloaded from www.digilab.dremel.com.

Nylon but is easier to print, similar to PLA.

area that is designed to hold a filament spool.

created in 3rd party 3D software or downloaded from www.digilab.dremel.com.

and objects while also providing commands directly to your Dremel 3D45 without the

use of a computer.

communicate.

extruder to the left or right side of the build area.

extruder to the front or back of the build area.

the build platform up or down.

10

I

M

P

ORT

A

NT

Re

a

d

Be

f

o

r

e

Us

i

n

g

I

MP

ORT

A

NT

L

i

r

e

a

va

n

t

u

s

a

g

e

I

M

P

OR

T

A

NT

E

L

e

e

r

a

n

t

e

s

d

e

u

sa

r

F

o

r

E

n

g

l

i

s

h

V

e

r

s

i

o

n

S

e

e

p

a

g

e

2

V

e

r

s

i

o

n

f

r

a

n

ça

i

se

V

o

i

r

p

a

g

e

3

8

Ve

r

si

ó

n

e

n

e

s

p

a

ñ

o

l

Ve

r

l

a

p

á

g

i

n

a

7

5

1

8

4

4

4

D

R

M

L

3

D

(1

8

4

4

4

3

7

-6

5

3

3

)

ww

w

.

d

r

e

m

e

l

.

c

o

m

P

.

O.

Bo

x

0

8

1

1

2

6

Ra

c

i

n

e

,

W

I

5

3

4

0

8

1

1

2

6

3

D

4

5

Op

e

r

a

t

i

n

g

/

S

a

f

e

t

y

I

n

s

t

r

u

c

t

i

o

n

s

C

o

n

s

i

g

n

e

s

d

’u

t

i

l

i

s

a

t

i

on

/

d

e

s

é

c

u

r

i

t

é

I

n

s

t

r

u

c

c

i

on

e

s

d

e

f

u

n

c

i

on

a

m

i

e

n

t

o y

s

e

g

u

r

i

d

a

d

C

a

l

l

T

o

l

l

F

r

e

e

f

o

r

C

o

n

s

u

m

e

r

I

n

f

o

r

m

a

t

i

o

n

&

S

e

r

v

i

c

e

L

o

c

a

t

i

o

n

s

P

o

u

r

o

b

t

e

n

i

r

d

e

s

i

n

f

o

r

ma

t

i

o

n

s

e

t

l

e

s

a

d

r

e

s

s

e

s

d

e

n

o

s

c

e

n

t

r

e

s

d

e

s

e

r

v

i

c

e

a

p

r

è

s

v

e

n

t

e

,

a

p

p

e

l

e

z

c

e

n

umé

r

o

g

r

a

t

ui

t

L

l

a

m

e

g

r

a

t

i

s

p

a

r

a

o

bt

e

n

e

r

i

n

f

o

r

m

a

c

i

ó

n

pa

r

a

e

l

c

o

n

s

u

m

i

d

o

r

y

u

bi

c

a

c

i

o

n

e

s

d

e

s

e

r

v

i

c

i

o

Introduction

Welcome to the world of Dremel Digilab. Our

mission is to mentor you through the digital

fabrication process and share best practices

for bringing your ideas to life.

3D bu ilding is a process that will involve

experimentation and persistence. Thankfully,

the Dremel experts are here to make your

job easier with online tips and live support.

Dremel 3D45 brings new functionality, such

as network connectivity and remote printing.

To get started with 3D45 follow the initial

setup routine on the touch screen to connect

and register the printer.

Kit Contents*

Dremel 3D45 Instruction Manual Quick Start Guide

You can create a user profile by going to

www.digilab.dremel.com. Your profile gives

you access to high-quality models, support

and software downloads, and remote printing

services powered by 3DPrinterOS. Once

setup and registration is complete you are

ready to start building.

Filament Spool** Power Cable USB Cable

Glue Stick Object Removal Tool USB Flash Drive

*Quantities may vary depending on kit.

**Do not store in moist or hot environment.

Unclog Tool

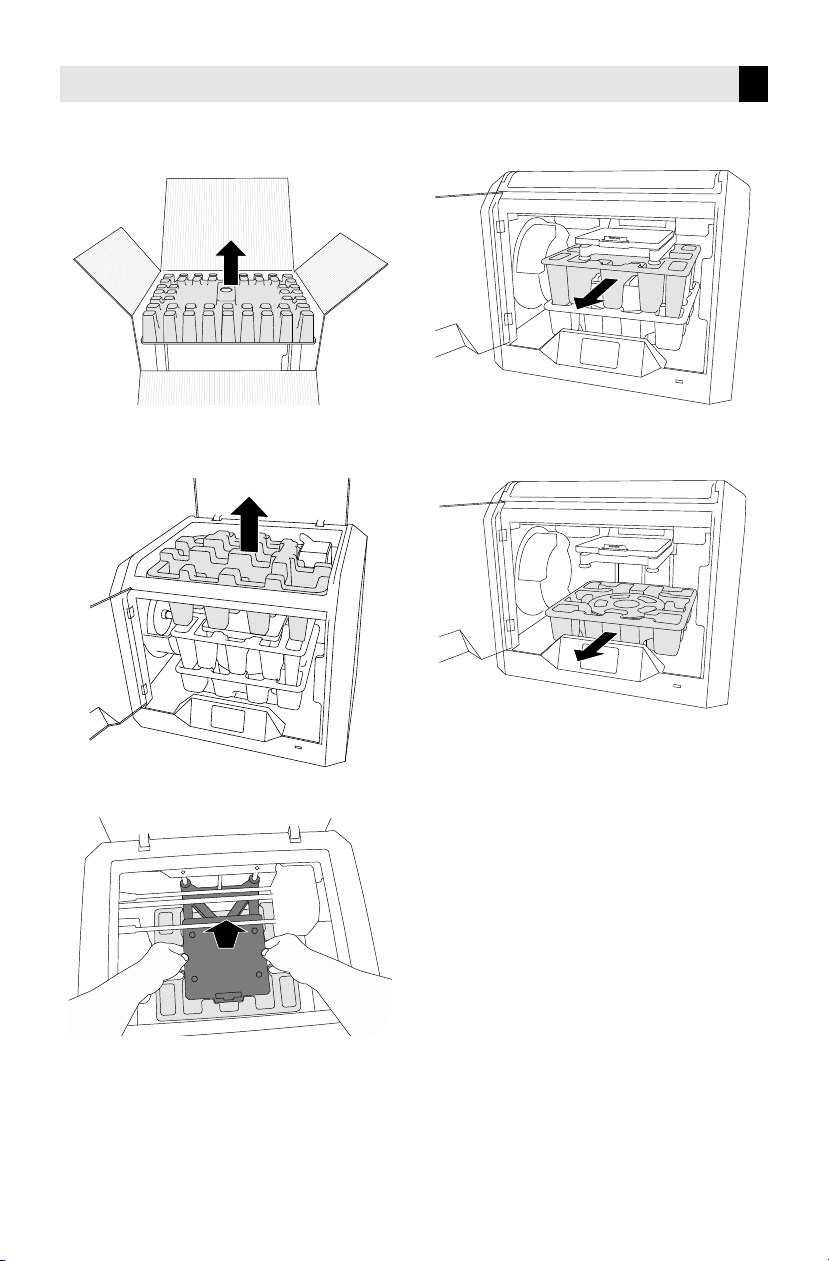

Unpacking

11

1. Place box on table, cut tape, and open.

2. Remove top insert.

3. Remove 3D45 and place on table.

4. Open lid and remove top insert.

6. Open door and remove middle insert.

7. Remove bottom insert.

5. Raise build platform by lifting from both sides.

Tip: Keep packaging for future transportation

and storage.

12

Getting To Know Your 3D45

14

13

12

15

1

2

3

4

5

6

1. Lid

2. Extruder

3. Z-Axis Guide rail

4. Door

5. Build Platform Tabs

6. Gripping Handles

7. USB A Port

8. Leveling Knobs

9. Build Platform

10. Touch Screen

11. Build Platform Clips

12. Filament Spool Holder

11

10

13. RFID Reader

14. Filament Spool

15. Camera

16. Y-Axis Guide Rail

17. Stepper motor

18. Filament Guide Tube

19. Extruder Lever

20. Filament Guide Clip

21. Extruder Intake

22. Chamber Fan

(With optional filtration

hook-up)

9

7

8

23. Ribbon Cable

24. X-Axis Guide Rail

25. Leveling Sensor

26. Extruder Tip

27. Power Switch

28. USB B Port

29. Ethernet Port

30. Nameplate

31. Power Input

Getting To Know Your 3D45

M

o

d

e

l

3

D

4

5

F

0

1

3

3

D

4

5

0

0

1

0

0

V

–

2

4

0

V

~

4

7

–

6

3

H

z

0

.

8

–

1

.

8

A

Ø

1

.

7

5

m

m

(

0

.

0

6

9

"

)

L

I

S

T

E

D

3

D

P

R

I

N

T

E

R

E

4

6

9

3

1

1

1

U

1

S

N

K

O

N

I

J

N

E

N

B

E

R

G

6

0

,

4

8

2

5

B

D

B

R

E

D

A

-

N

L

M

M

/

Y

Y

Y

Y

X

X

X

X

X

X

X

X

X

D

r

e

m

e

l

M

o

u

n

t

P

r

o

s

p

e

c

t

,

I

L

M

a

d

e

i

n

C

h

i

n

a

13

16

15

17 18 19 22

20

21

24

23

25

27 28 29 31

30

26

14

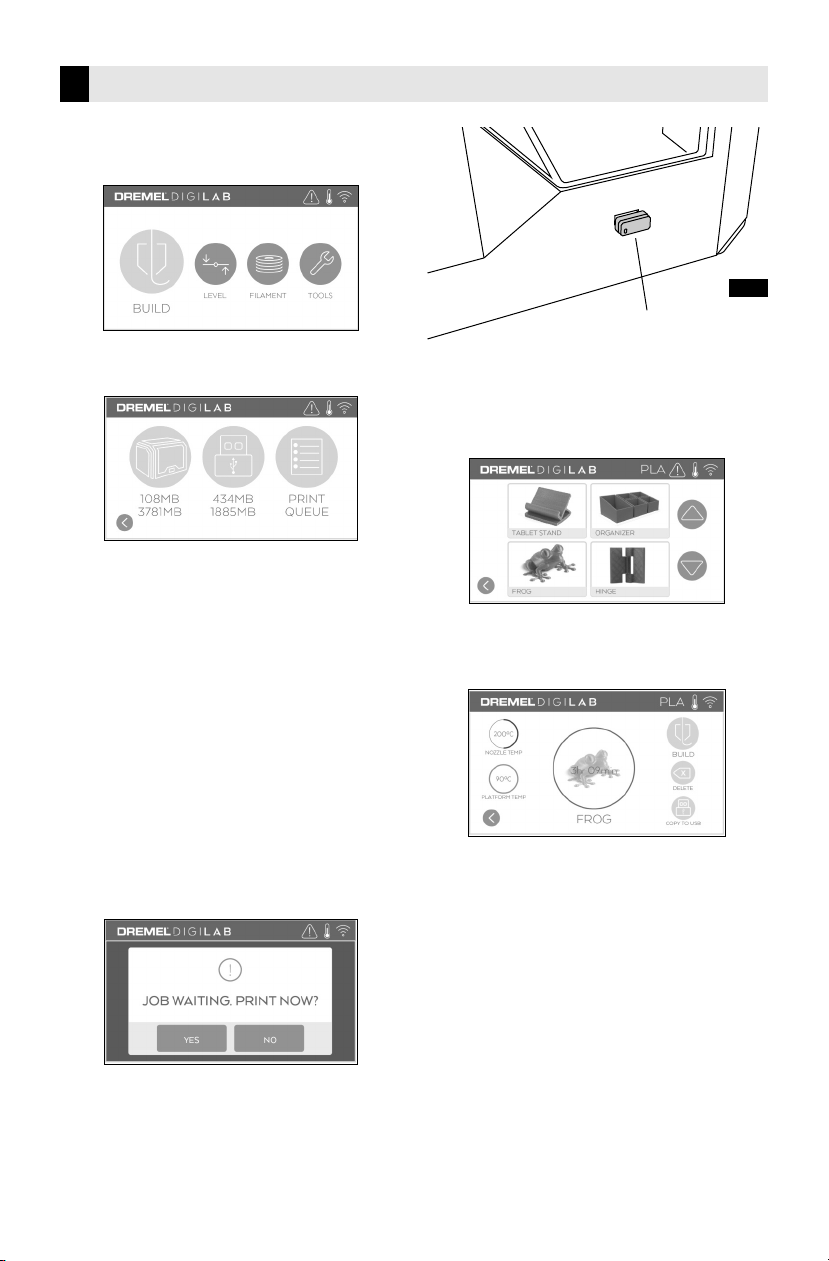

Using your Dremel 3D45 without a computer is easy with the onboard software and full color

touch screen.

Before building your model we want to familiarize you with the touch screen menu structure

and options.

WARNING

!

damage or personal injury.

Observe all provided warnings and safety instructions when using the

Dremel 3D45. Failure to do so may result in fire, equipment damage, property

Touch Screen

BUILD

Tap to select a 3D model and begin build process.

(see page 28 for detailed build instructions)

BUILD MENU

Tap Printer, USB Flash Drive, or Print Queue to

choose the destination of your desired file.

MODEL MENU

Tap to select the desired model or use arrows to

scroll through pages to find your model.

Touch Screen

FILE DETAILS

Noz z l e and pl a tfor m t e mpera t u res se t ting s

referenced for the current build.

BUILD – Tap to begin build process.

DELETE – Tap to remove model file from on-printer

storage or USB flash drive.

COPY TO PRINTER – From USB flash drive, tap to

copy model file to on-printer storage.

BUILD STATUS

PAUSE/PLAY – Tap to pause or resume the current

build process. Pause will allow you to access the

filament button.

STOP – Tap to cancel the current build process.

15

PRINT QUEUE MENU

YES – Tap to proceed to print file.

NO – Tap to cancel printing of file.

16

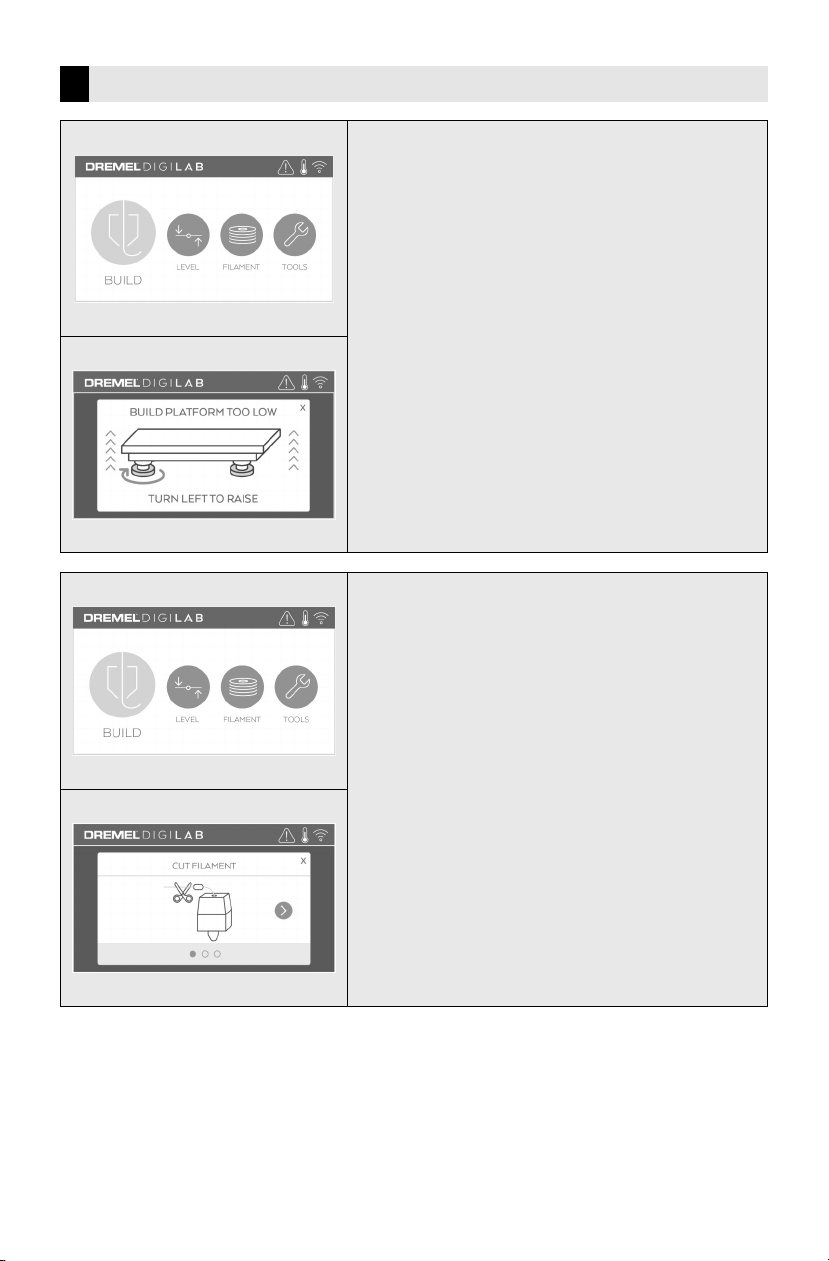

Touch Screen

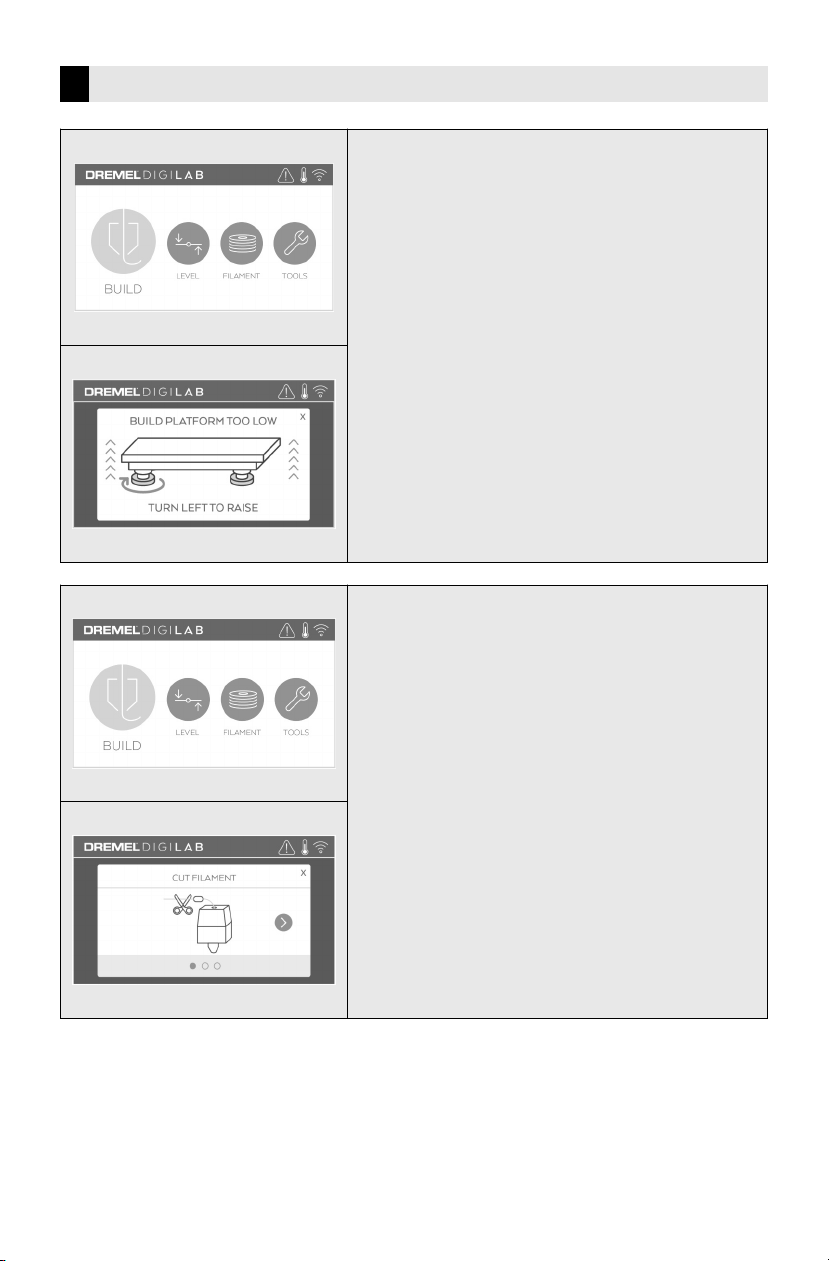

LEVEL

Tap to begin build platform leveling process. (see

pa g e 27 for ins truc tion s on leve ling t he buil d

platform)

FILAMENT

Tap to begin heating and start filament load/change

process. (See page 23 for instructions on filament

load/change process)

Touch Screen

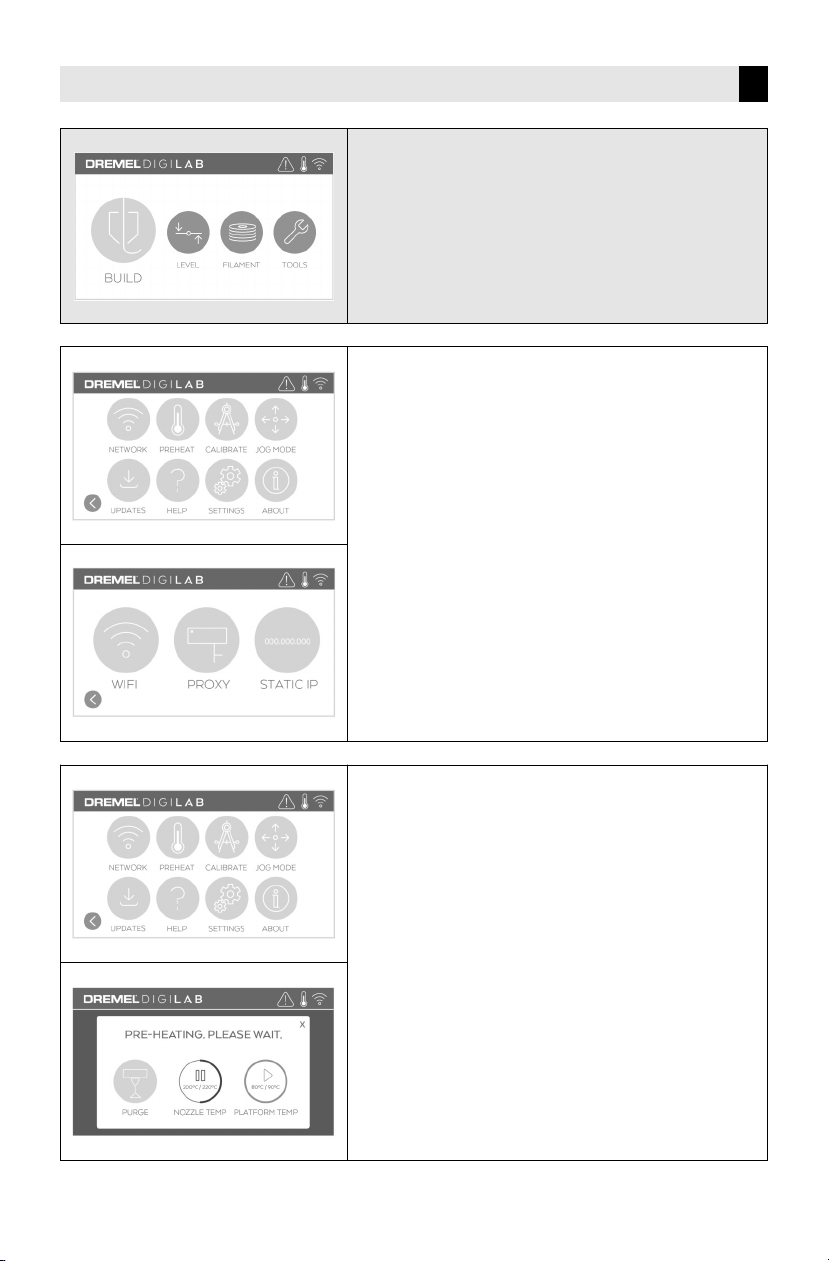

TOOLS

Tap t o a cce s s t he foll owin g i ndiv idua l p rint er

functions and settings.

NETWORK

Tap to enter Network menu to connect or disconnect

WiFi and Set Proxy.

CONNECT WIFI – Tap to connect to WiFi.

SET PROXY – Tap to set manual proxy.

SET STATIC IP – Tap to setup static IP.

17

PREHEAT

Tap "N o z zle Temp" to auto m a tica l l y be gin

preheating the extruder for building or removing

excess debris. Once your optimal temperature is

achieved, tap "Plate Temp" to begin preheating the

build platform.

PURGE – Once extruder is hot, tap to manually

extrude filament.

18

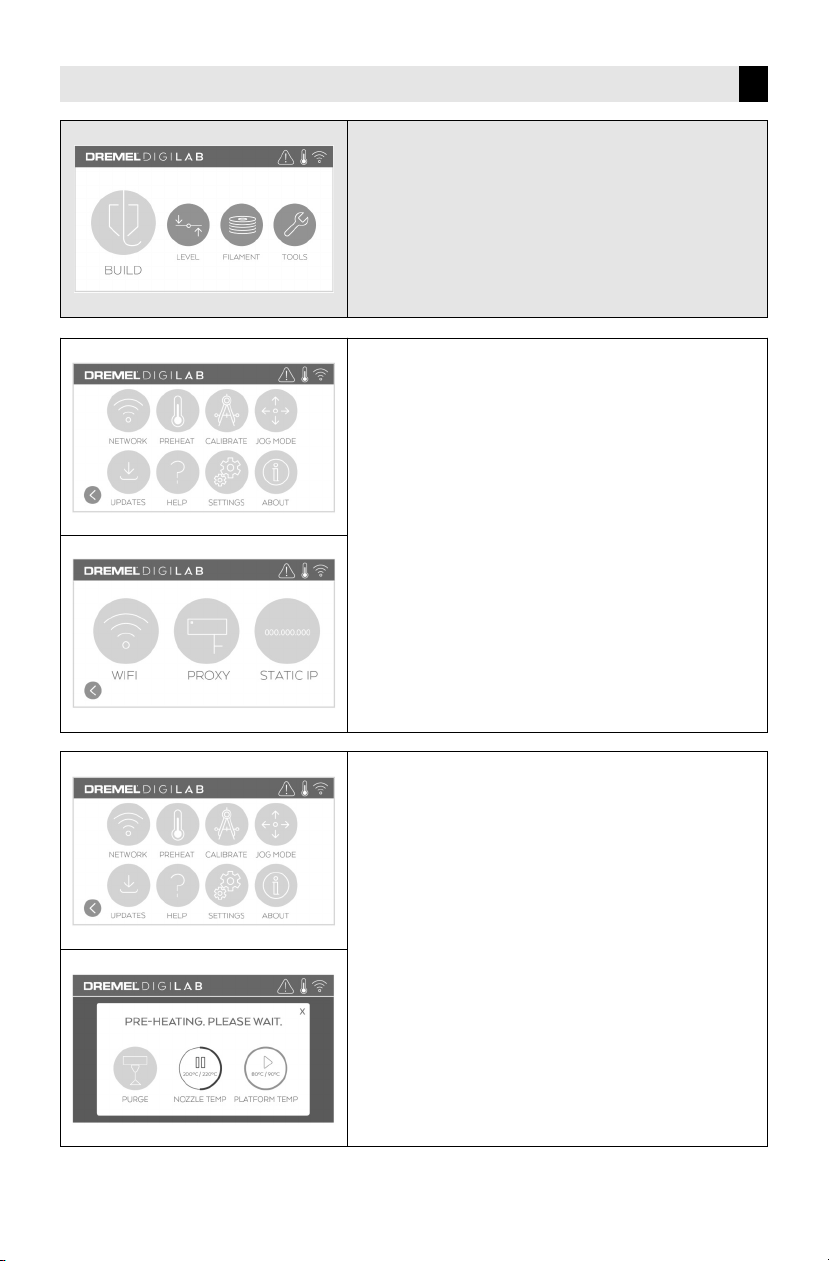

Touch Screen

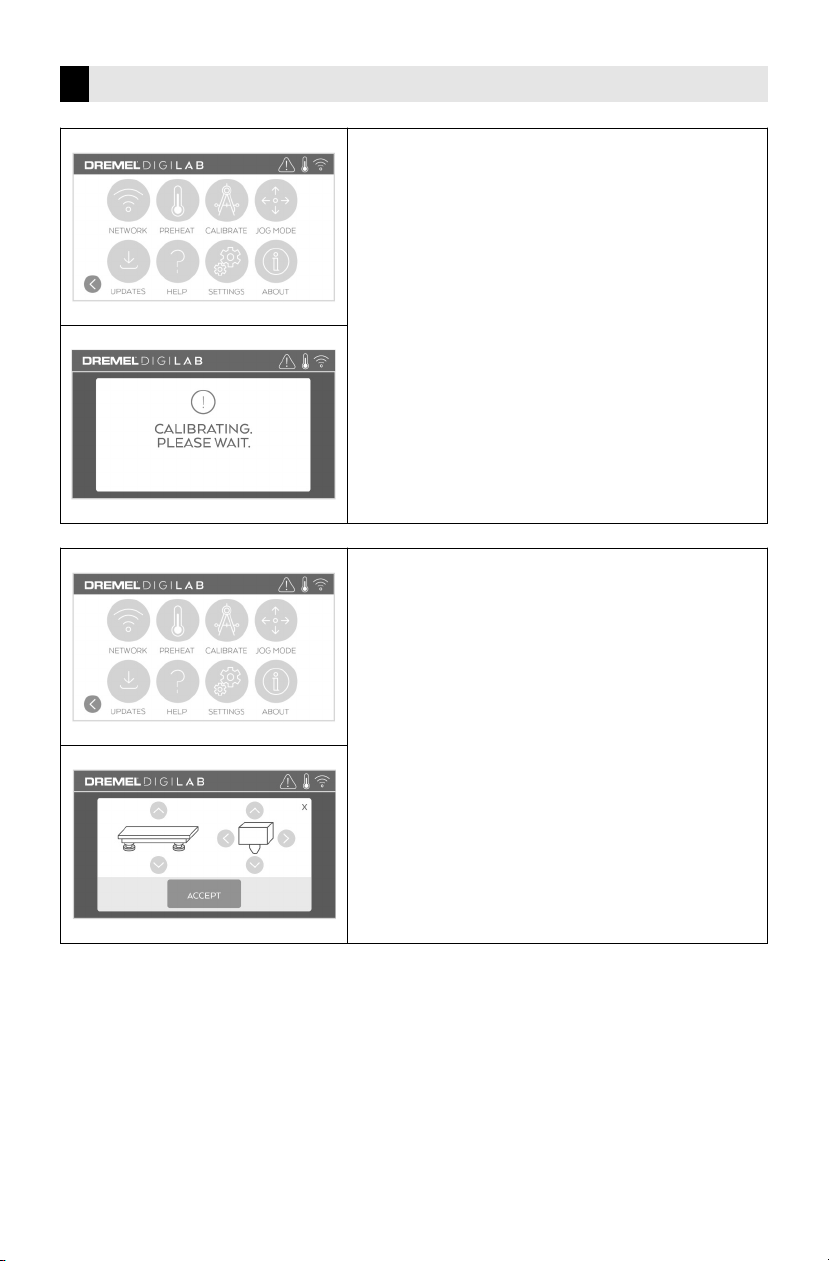

CALIBRATE

Tap to move extruder and build platform to zero

position.

JOG MODE

Tap to display options to move extruder and build

platform along the X, Y, and Z-axis.

Touch Screen

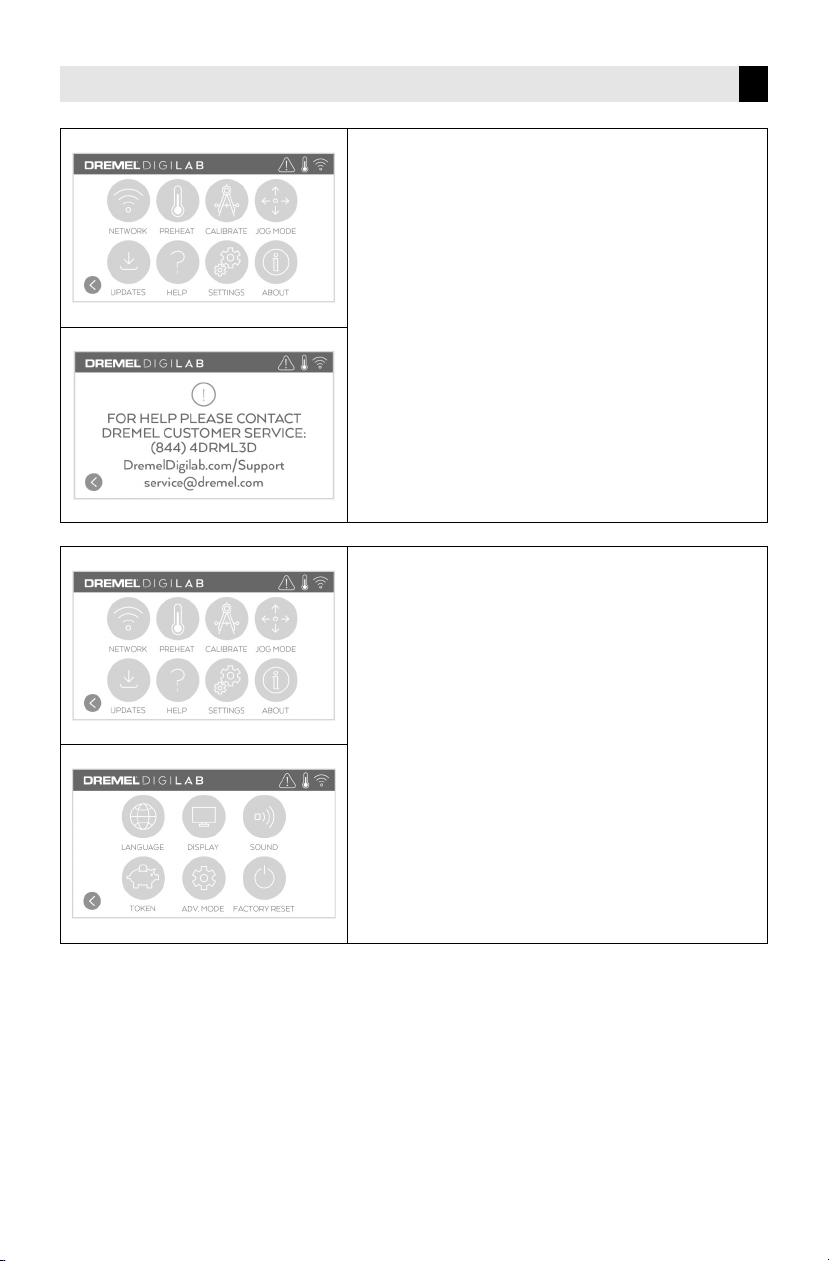

HELP

Tap to enter service menu to see customer service

contact information.

SETTINGS

LANGUAGE – Tap to pick alternate menu language.

DISPLAY – Tap to customize cabinet LEDs or main

menu hotkeys.

SOUNDS – Tap to turn 3D45 sounds On/Off.

TOKEN – Tap to release current token and get a

new token when connected to Wifi or Ethernet.

ADVANCED MODE – Tap to manually prioritize G-

Code settings.

FACTORY RESET – Tap to remove all information

stored on 3D45 and return it to factory defaults.

19

20

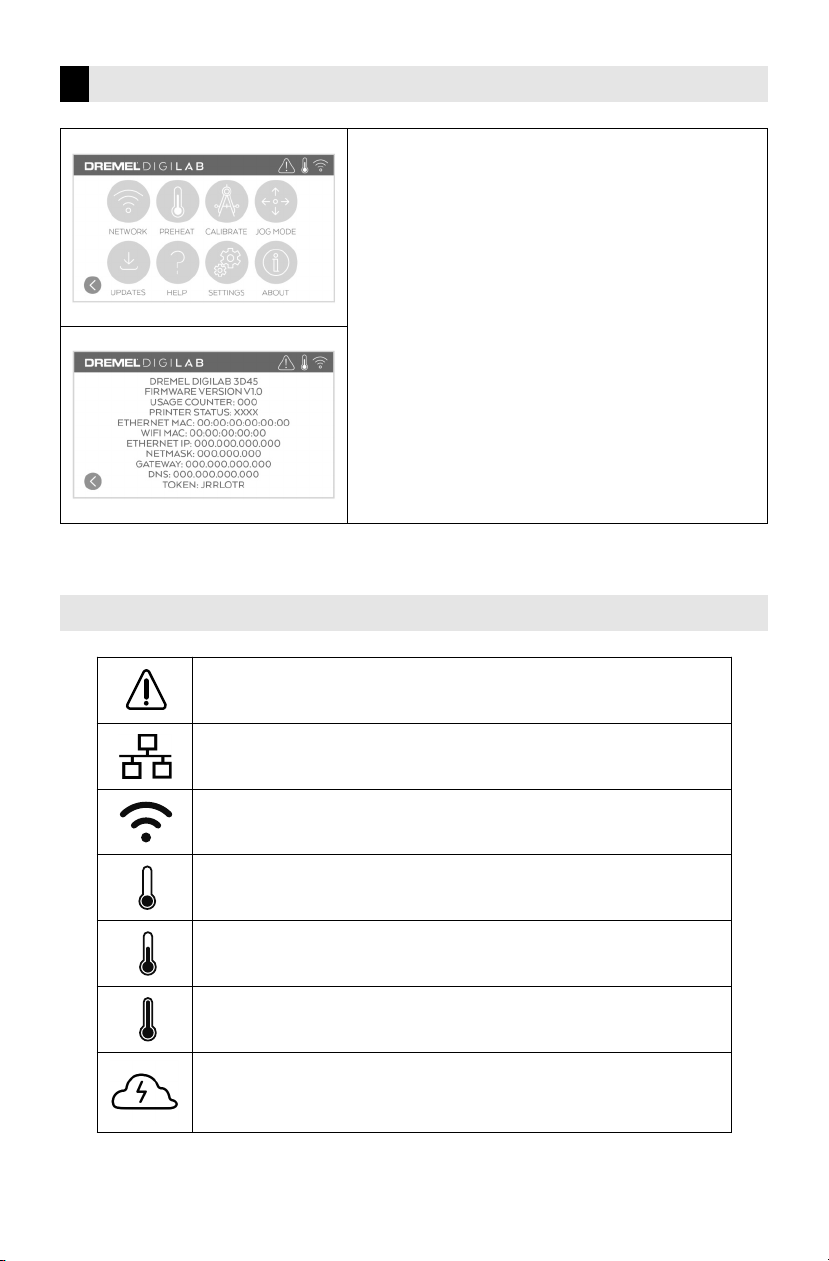

Touch Screen

ABOUT

Tap to see 3 D45 informati on s uch as firm ware

ver s i on, usa g e counte r, pr i n ter sta t u s, MAC

address, and token.

Touch Screen Icons

Indicates that there is an error such as filament empty or door open.

Indicates that Ethernet is connected.

Indicates WiFi signal strength and connected status.

Indicates that the extruder and build platform is cool.

Indicates that the extruder and build platform is warm.

Indicates that the extruder and build platform is hot.

Indicates that the printer is connected to 3DPrinterOS printing

services and that it can receive remote commands.

Initial Setup

21

The first time you power on your Dremel

3D45 you will be prompted to perform an

init ial s etup of ne twork . Compl eting this

process will give you access to features

such as printing wirelessly from your PC or

Dr emel3 D clo ud based pr ogr am, p rinte r

sharing amongst your friends and family,

noti f i c a tions o f f i r m w are u p d ates, a nd

printer status monitoring. You will then be

walked through how to loading your first roll

of filament and how to properly level the

build plate.

NOTE: Dremel3D cloud based software can

be accessed on www.digilab.dremel.com.

1. To complete initial setup, tap "Start" when

prompted on the initial setup screen. If you

decline this setup you can always setup

network later.

2. If y o u c h o ose “Star t ” , 3 D 45 w ill

automatically connect to your ethernet (if

pl ugged in to route r ski p to step 5) or

search for available wireless networks.

3. Choose your wireless network using the

touch screen. Use the arrows to scroll

th r oug h t he list o f a vail able wir eles s

networks. Tap on your network name to

accept it.

4. Enter your wireless network password and

tap “Done”.

5. Write down the token displayed at th e

bottom of the touch screen. This token will

be used to link your printer to your Dremel

account.

6. Visit www.digilab.dremel.com and follow

the prompts to complete your user profile

creation and printer registration.

22

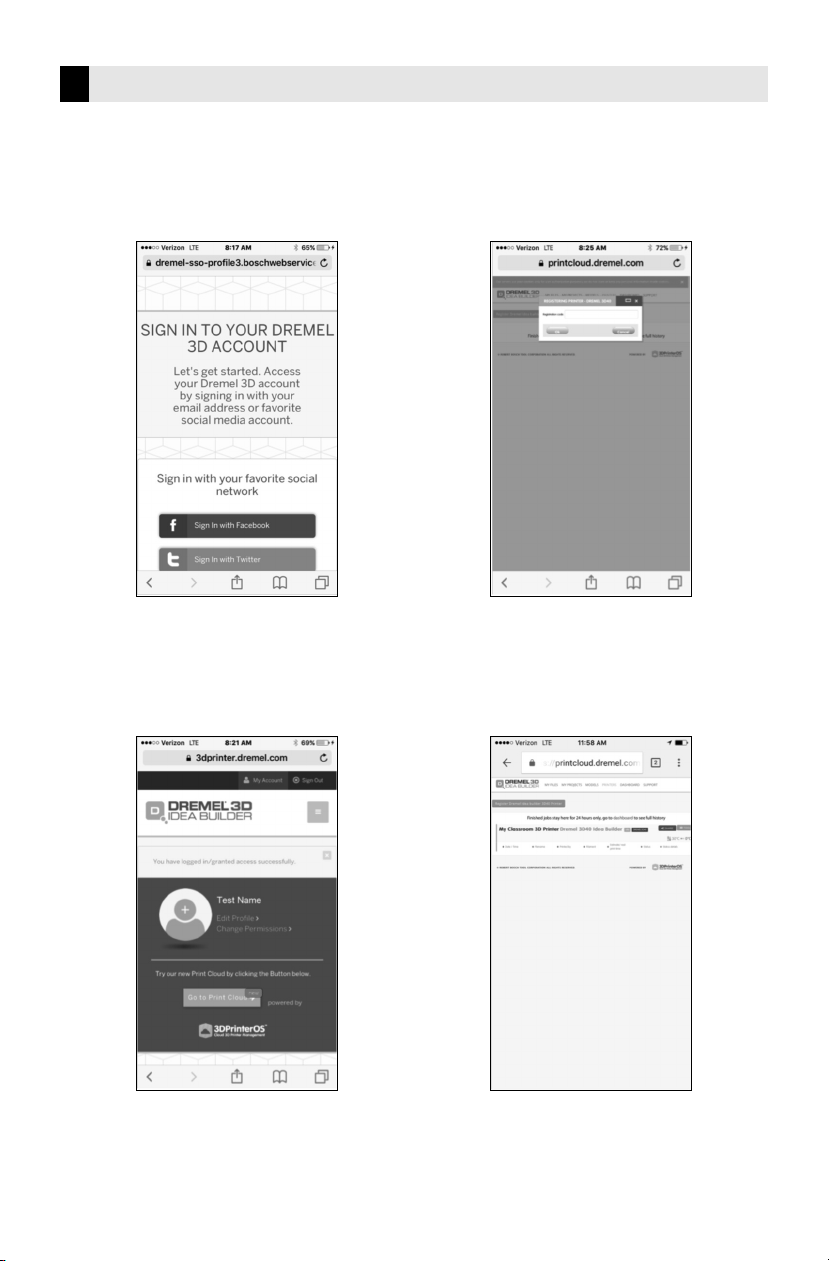

Dremel’s cloud-based platform allows you to connect to your 3D45 from any web browser. In

the platform, you can view models and projects in the Dremel 3D library, send, pause and

cancel builds, monitor build status, receive push notification updates, and more. Create a user

profile on www.digilab.dremel.com and follow the setup steps below to get started.

Note: This feature is currently only available in the United States.

Dremel Cloud Platform

1. After launching the Dremel cloud platform

in your web browser, you will need to Log

In wi th your e x i sting D r emel us e r

information or Social Log In or Sign Up to

create a new account.

2. Click on the “Go To Print Cloud” button to

launch the new cloud platform.

3. When you enter the cloud platform, click

on printers on the top toolbar to register

you r 3D45. R egis t e r you r 3D45 b y

entering the token number where it says

“Registration code” and clicking “OK”.

4. Your mobile device is now connected to

your 3D45.

Getting Ready to Build

Open

Close

23

WARNING

!

instructions when using the Dremel 3D45.

Failure to do so may result in fire, equipment

damage, property damage or personal injury.

WARNING

!

during Dremel 3D45 operation or until it

has cooled down to at least 60°C (140°F).

Contact with the extruder tip or build platform

during or after operation before tip and build

plate has cooled may result in personal injury.

WARNING

!

au t hori z ed by Dre m el may r e sult i n

equipment, property damage, or personal

injury.

WARNING

!

ma ximum rated temperature of the

filament type being used. Heating filament

ab o ve reco m mend e d range ca n cause

emissions that may result in personal injury.

CAUTION

!

the extruder.

Obs erve all provide d

war nings and safety

Do not touch the extruder

tip or heated build platform

Use only DREMEL filament.

Us e of fil a ment not

Do n ot adj ust extruder

se tting to ex ceed the

Do not pull the filament

out. Doing so may damage

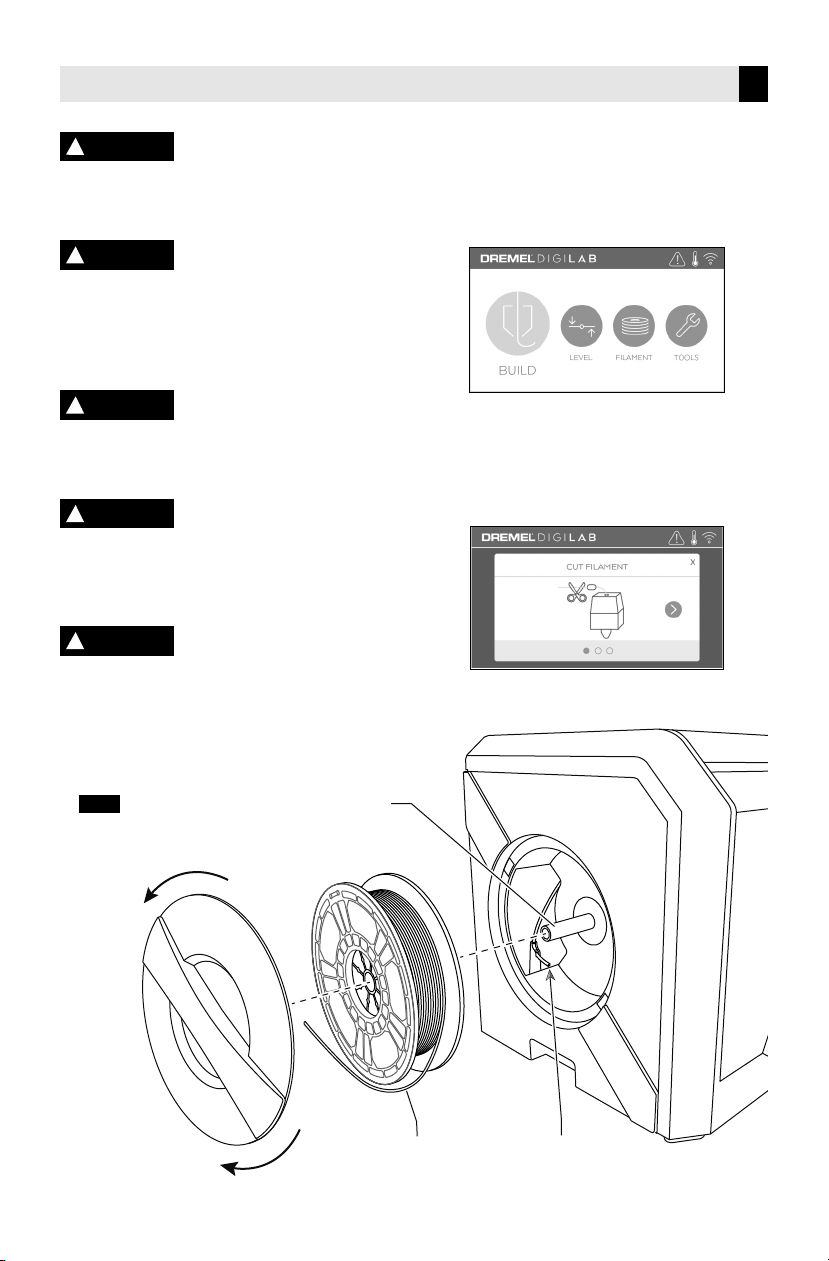

LOADING/CHANGING FILAMENT

1. Start filament load/change proc es s by

tapping “Filament” button on touch screen.

Extruder will move to front right corner of

print area and extruder tip will begin to heat.

2. After extruder s tops moving, open t he

3D45 Lid for better access to extruder.

3. If existing filament is loaded, cut existing

filament near extruder intake and tap the

arrow button on touch screen.

FIG. 1

Spool

Holder

Filament

Filament

Guide Tube

24

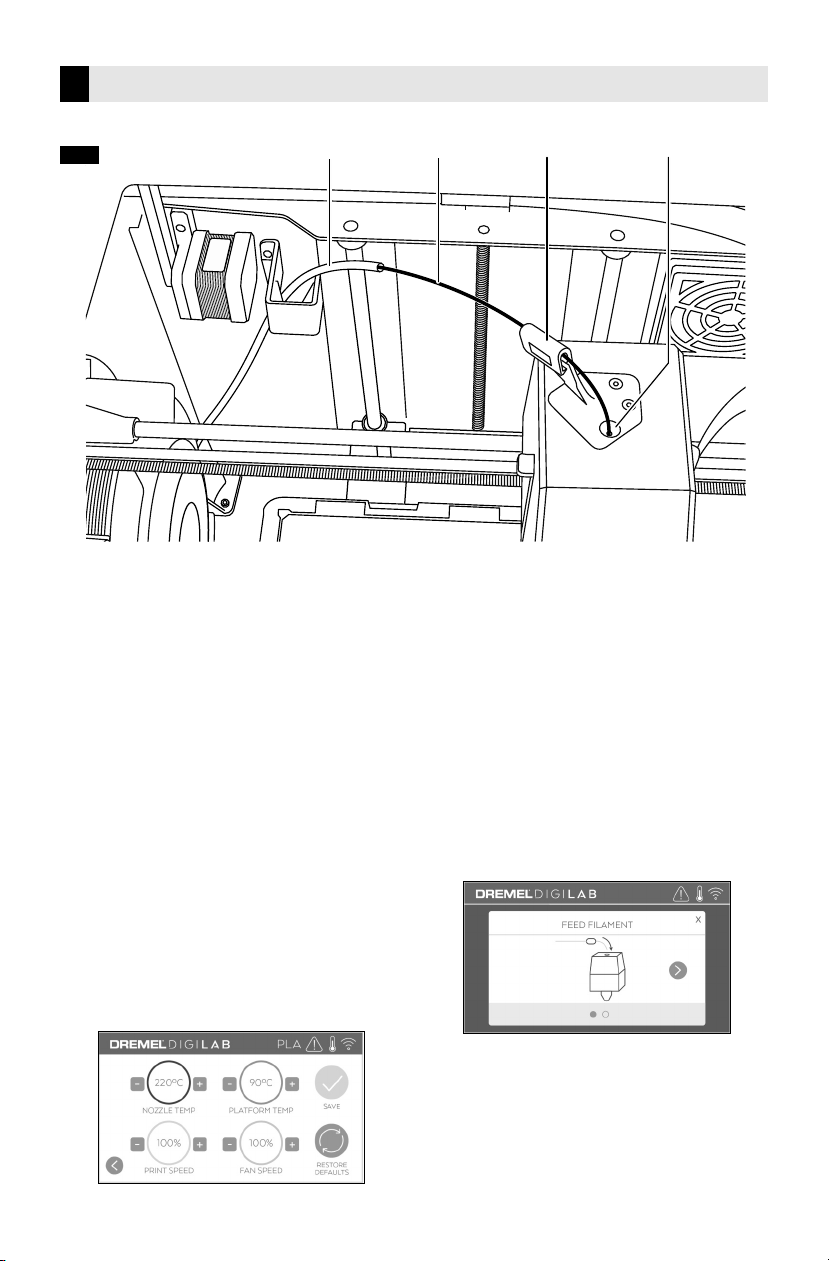

Getting Ready to Build

FIG. 2

Guide Tube

4. Remove Spool door by rotating it counter

clockwise, see figure 1. Remove existing

spool if one is present.

5. Thread tip of new filament through guide

tube, place spool on spool holder, replace

spool door by aligning locking tabs and

rotating clockwise, see figure 1.

6. When you place a roll of Dremel filament

into the spool holder, the printer will autorecognize the filament type and adjust the

printer settings to be optimized for the

filament you are using (This will bypass any

print settings loaded in your sliced file).

NOTE: You have the opti o n t o e nter

advanced printer mode to manually alter

print settings after you change filament.

Plea se chec k all set tings (if m anually

entered) as improper settings may cause

prints to fail or damage the equipment,

see “Filament Type and Settings” or on

digilab.dremel.com for the latest chart.

Filament

Filament

Guide

Extruder

Intake

NOTE: You also have the option to pull

print settings from the saved sliced file.

This will prevent the printer from altering

its print settings. Please check all settings

prior to printing as improper settings may

cause prints to fail, property damage, or

personal injury.

7. If changing existing filament, 3D45 will

automatically purge existing filament.

8. When Feed Filament screen appears, tap

the arrow on touch screen and thread

fi lam ent coming f rom gu ide tu be int o

ext r u der i n take u ntil f ilame n t fee d s

through on its own, see figure 2.

NOTE: Ensure the gears inside of the

ext r u der hav e pr operl y gr abbed th e

filament befo re you finish the filament

change. You will feel a tug and see the

fil a m ent star t to fe e d it s elf into th e

extruder when this occurs.

Getting Ready to Build

9. Filament will be drawn into the extruder

and begin to exit from the hot extruder tip.

NOTE: Your Dremel 3D45 was tested by

building objects before leaving the factory.

These test objects may have been made

with a different filament color than you are

usi n g . T heref o r e, a s m a ll amoun t of

filament may be remaining in the extruder.

10. When n e w fila m e nt appe a r s from

extruder tip, tap “done” on touch screen

to com plet e f ilam e nt load pr o cess ,

re turn t o m ain me n u, and ca libr ate

ext r uder. Caref u lly remo v e e x cess

filament without touching hot extruder

tip. If necessary, carefully remove debris

fr o m e xtru der tip with ne e dle nose

pliers.

FILAMENT TYPEANDSETTINGS

25

CAUTION

!

Use e x t ra care n o t t o

dam a g e the e xtrud e r tip

when clearing debris. Dremel 3D45 will not

work properly with a damaged extruder tip

and will require replacement.

11. Close 3D45 lid and door.

Filament Type

Nozzle Temperature Range

Optimal Nozzle Temperature

Build Platform Temperature Range

Optimal Build Platform Temperature

Print Speed Multiplier

Recommended Speed Multiplier

Fan Range

Object cooling fan setting

NOTE: Please check website digilab.dremel.com for latest filament settings.

PLA ECO-ABS Nylon PETG

200 -240 C 200 -240 C 220 – 280 C 240-260 C

230 C 230 C 255 C 250 C

0 – 70 C 0 – 70 C 0 – 100 C 70 – 90 C

60 C 60 C 80 C 80 C

0 – 100% 0 – 100% 0 – 100% 0 – 100%

100% 100% 90% 100%

0 – 100% 0 – 100% 0 – 100% 0 – 100%

100% 100% 50% 30%

26

FIG. 3

Getting Ready to Build

Rear ClipRear Clip

Tab

Front Clip

PREPARING BUILD PLATFORM

WARNI

!

during Dremel 3D45 operation or until it

has cooled down to at least 60°C (140°F).

Contact with the extruder tip or build platform

during or after operation before tip and build

plate has cooled may result in personal injury.

WARNING

!

plate may break and result in personal injury.

WARNING

!

holder. Contacting with tempered glass plate

edge may result in personal injury.

CAUTION

!

covered with glue from the supplied glue

stick. If glue is not used, it may cause poor

object build quality.

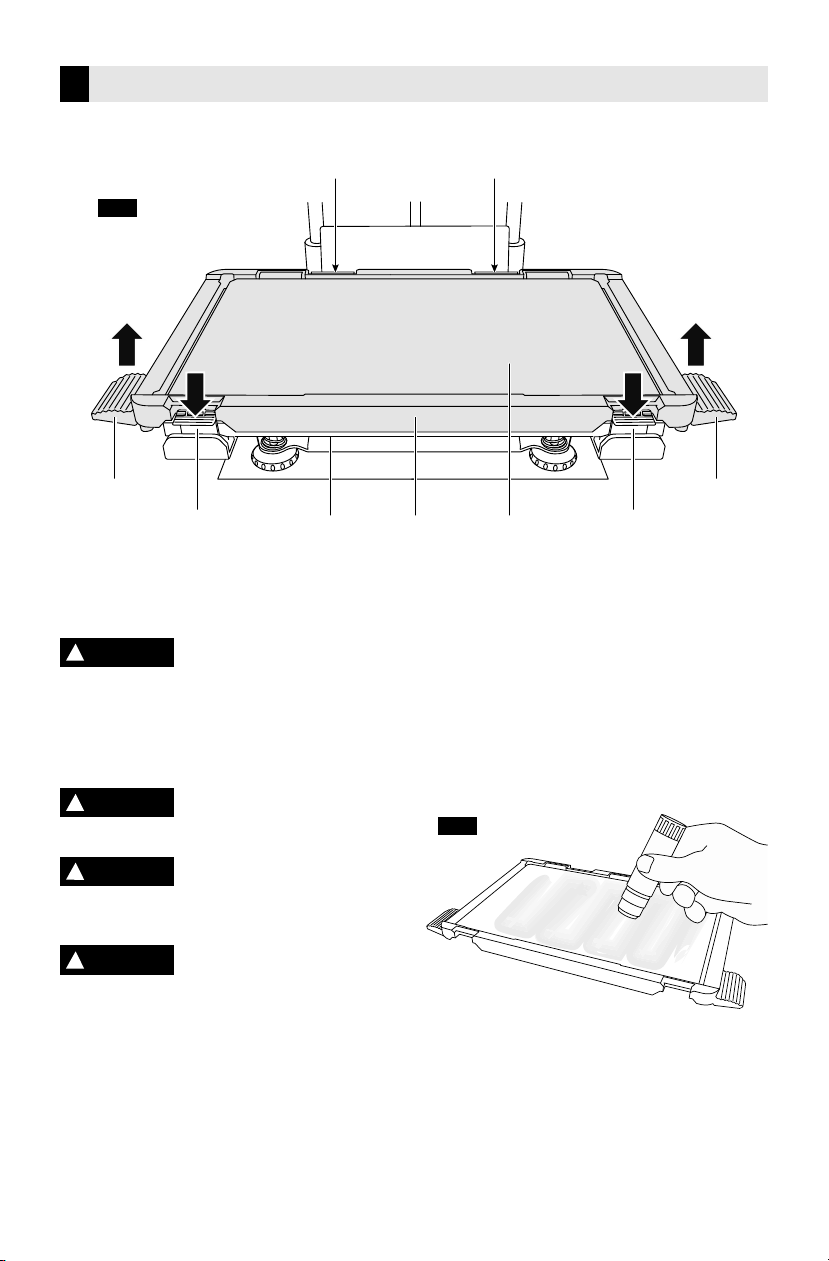

1. Remove build platform by first pressing

down and releasing the two clips located

at the front of the build platform, then lift

the build platform off the base using the

build platform tabs (figure 3).

Do not touch the extruder

N

G

tip or heated build platform

Do not drop t he build

platform. Tempered glass

Do not remove tempered

glass plate fro m plas tic

Bef o r e ever y bu ild m a k e

sure that the build platform is

Base

Platform

Build

Tempered

Glass

2. Apply the glue in two overlapping layers to

ensure that the entire b ui ld s ur face i s

properly covered. You can apply glue to

the perimeter of the build plate first, and

the n zi g zag u p an d do w n wh i le

overlapping the entire area. Wait for 10

seconds and then apply another layer

zigzagging left to right. This ensures a

uniform layer over the entire build area.

FIG. 4

NOTE: To clean the build platform, rinse

the platform with warm water and dry with

a towel.

3. Install the build platform by first inserting

the rear of the platform onto the rear clips,

the n pres s down on the front of the

platform until it snaps in place.

Front Clip

Glue

Stick

Tab

Getting Ready to Build

27

LEVELING BUILD PLATFORM

WARNING

!

during Dremel 3D45 operation or until it

has cooled down to at least 60°C (140°F).

Contact with the extruder tip or build platform

during or after operation before tip and build

plate has cooled may result in personal injury.

It is important you level the build platform

every time you reinstall the build platform to

en sur e tha t the bu ild pl atf orm i s evenly

spaced from the extruder head. Not leveling

the build platform may cause objects to not

build properly.

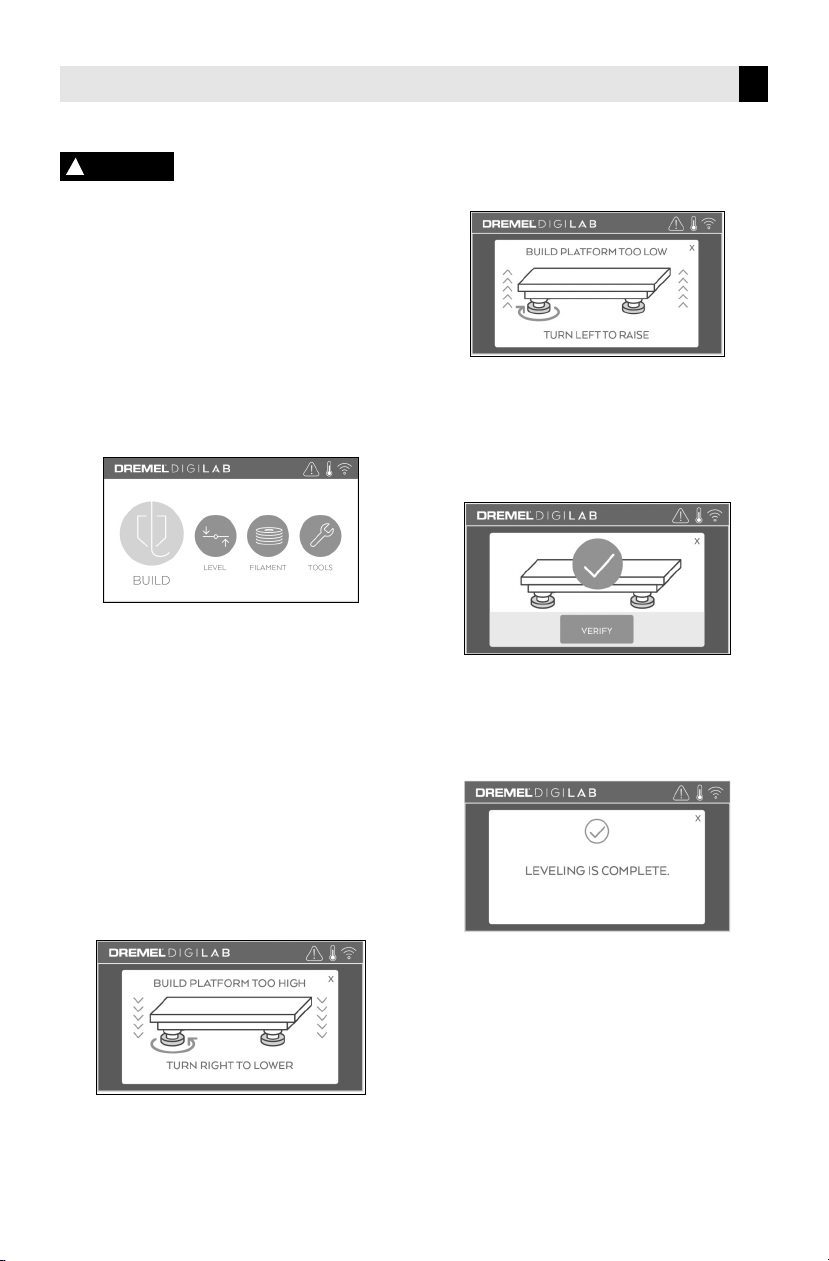

1. Tap “Level” on 3D45’s touch screen.

2. The extruder and build platform will move

into position to level the build platform.

3D45 will first check leve l at t he bac k

ce nte r o f the build pla tfo rm. The t wo

knobs under the build platform are used to

raise and lower the build platform on the

left and right. The extruder contai ns a

sensor that detects if the bed is level, no

additional tools are necessary.

3. The touch screen will indicate if your build

platform is too high or too low. If the build

platform is too high, adjust the appropriate

knob by rotating r ight until you hear a

“beep” and the touch screen indicates that

it is ready to verify that the bed is level.

Do not touch the extruder

tip or heated build platform

4. If the build platform is too low, adjust the

kn ob by rot ati ng lef t unt il you h ear a

“beep” and the touch screen indicates that

it is ready to verify that the bed is level.

5. Tap “Verify” to c heck the bed level. If

further adjustment is needed the touch

screen will indicate the direction, if the

level is correct, the extruder will move to

the next point and the level process can

be repeated.

6. Repeat steps 3-5 for the second position,

when you bed is fully level the extruder

will automatically move to the calibration

pos i t ion a n d com p l ete t h e lev e l ing

process.

28

Getting Ready to Build

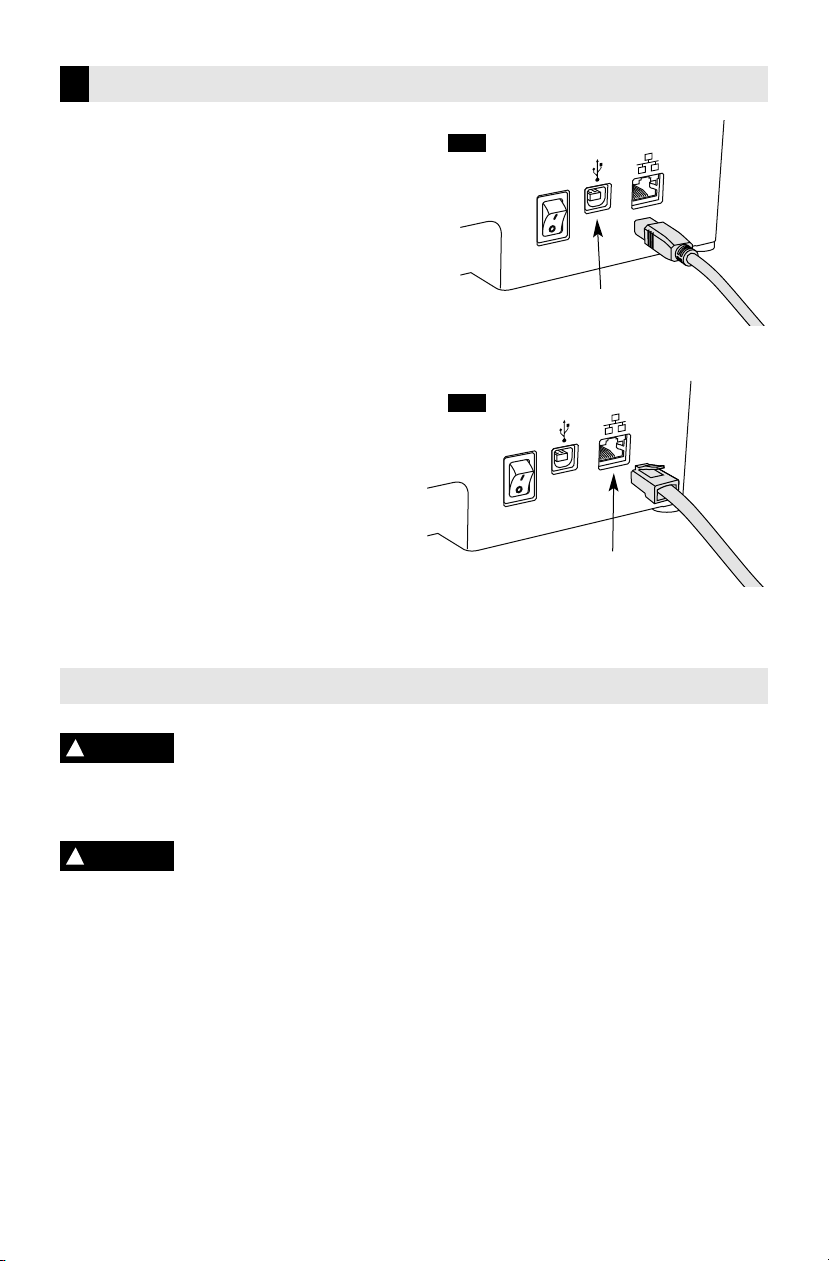

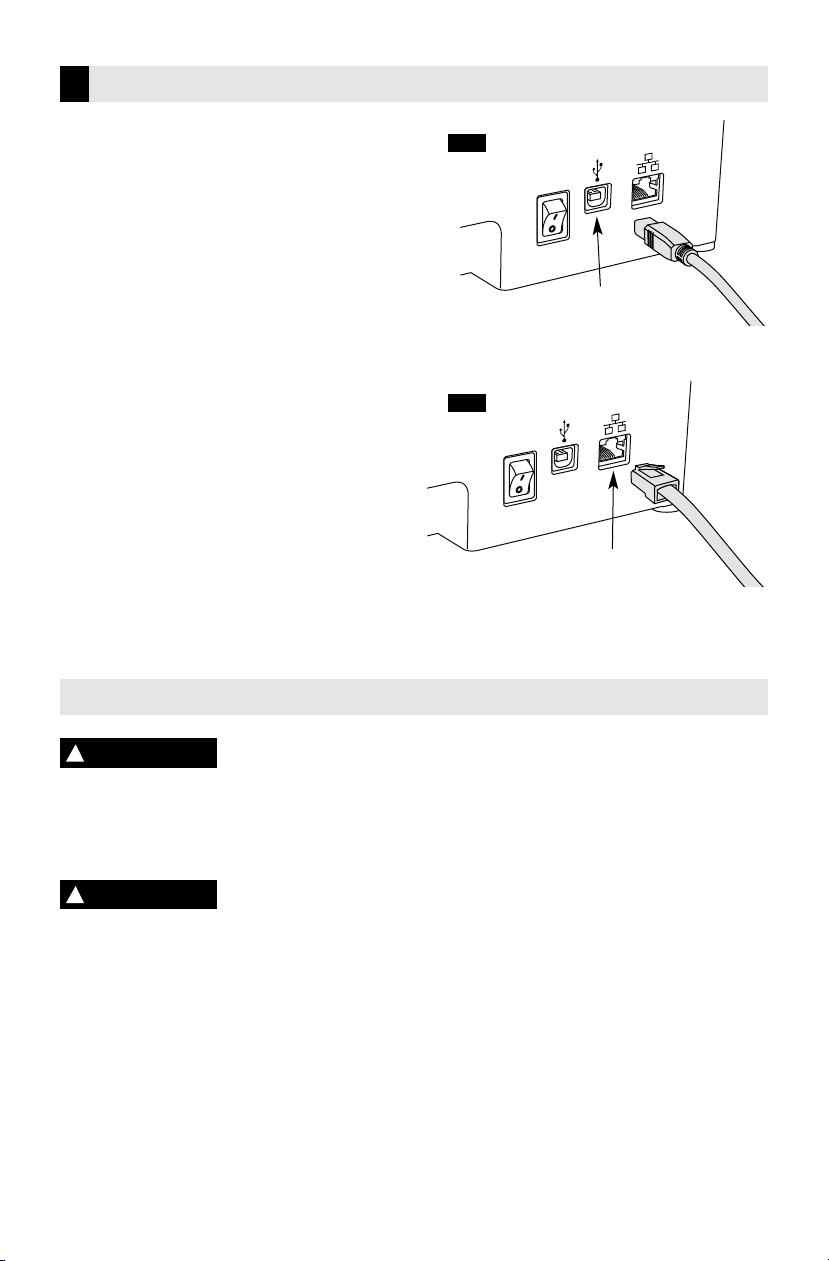

CONNECTING USB CABLE

1. Ensure 3D45 power switch is in the off

position.

2. Connect the included USB cable to your

3D45 and computer, figure 5.

3. Open software.

4. Tur n your D reme l 3D45 o n usin g the

power switch to sync your computer to

your Dremel 3D45.

CONNECTING ETHERNET

1. Ensure 3D45 power switch is in the off

position.

2. Pl ug e t herne t cab l e int o your 3D45 ,

figure 6.

3. Tur n your D reme l 3D45 o n usin g the

power switch. Ethernet connection should

be detected automatically. Tap “Accept” to

confirm connection.

Building

FIG. 5

USB

FIG. 6

Ethernet

WARNING

!

instructions when using the Dremel 3D45.

Failure to do so may result in fire, equipment

damage, property damage or personal injury.

WARNING

!

operation. Contact with Dremel 3D45 moving

parts during operation may result in poor build

quality, equipment damage or personal injury.

NOTE: Your Dremel 3D45 will bu ild test

objects before leaving the factory. These test

objects may have been made with a different

filament color than you are using. Therefore,

Obs erve all provide d

war nings and safety

Do not reach inside the

Dremel 3D45 while it is in

a small amount of filament may be remaining

in the extruder. The start of your first object

may have some of this filament color until it

transitions over to your filament color.

You have several options when building on

your 3D45:

1) On-Printer Storage

2) USB Flash Drive

3) Online Print Queue

4) Computer

Building

29

BEFORE YOU BUILD

1. Ensure an adequate amount of filament is

loaded (see page 23).

If 3D45 runs out of filament during a build,

it will pause until more filament is added.

2. Ensure glue is applied, build platform is

level and clear of objects.

3. Ensure the extruder and build platform

tem p e ratu r e is se t accor d i ng to the

fil a m ent type u sed, see page 25 f o r

details.

BUILDING FROM

ON-PRINTER STORAGE

1. On the main menu tap “Build”.

2. On the build menu tap the printer icon.

4. In the model detail page tap “Build” to

begin building process.

5. Your 3D45 will first align the extruder and

build platform to their zero positions then

the level sensor will lightly touch the build

pl atf orm t o complete ali gnm ent . Your

extruder tip and build plate will begin to

heat which may take a few minutes. Once

the proper temperature is reached your

model will begin to build.

6. Once your object is finished your 3D45 will

automatically align the extruder and build

platform to their calibration positions and

cool the extruder tip and build platform.

7. Wait until the touch screen indicates that

the extruder and build platform is “cool” to

rem o v e y our obje c t . S ee sect i o n

“Removing Object from Build Platform” for

object removal instructions.

3. Tap the model file you would like to build.

(Use arrows to scroll through pages)

30

BUILDING FROM USB FLASH DRIVE

. On main menu tap “Build”.

1

2. Tap USB icon to access contents of USB

flash drive.

3. Follow s teps 3-7 fro m Build fr om On Printer storage to c omplete build from

USB flash drive.

BUILDING FROM PRINT QUEUE

If your 3D45 is registered and added to your

Dremel3D profile, you can send Builds from

your web browser at www.digilab.dremel.com

or by using the Dremel3D cloud slicer (see

page 22).

1. If your 3D45 is displaying the Print Queue

notification tap “YES” in the notification

window to access the Print Queue. If you

choose “NO” you can later access your

Print Queue by tapping “Build” then “Print

Queue”.

Building

FIG. 7

USB Flash

Drive

2. In the Print Queue menu you can choose

to “Build” the next model in the queue or

“Delete” it and advance to the next model.

3. In M ode l D etai ls tap “Bu ild” t o b egin

building process or “Delete” to remove the

file.

BUILD FROM COMPUTER

Dremel 3D45 is compatible with Print Studio

fro m A u todes k , D reme l ' s c loud - b ased

platform, and will included plug-ins for Cura

and Simplified 3D. Follow the instructions

that came with this software to complete a

Build from your computer.

CANCELING YOUR BUILD ON 3D45

To cancel your object during preheating or

building, tap “Stop” on the touch screen. If

you confirm “Yes” the extr uder and build

pla t f orm w ill m ove to th eir calibr a t ion

positions.

Removing Your Object

REMOVING YOUR OBJECT FROM THE

BUILD PLATFORM

WARNING

!

during Dremel 3D45 operation or until it

has cooled down to at least 60°C (140°F).

Contact with the extruder tip or build platform

during or after operation before tip and build

plate has cooled may result in personal injury.

WARNING

!

protective equipment such as heat resistant

glo v e s and safet y gl a s ses will re d u ce

personal injuries.

WARNING

!

tools to remove objects from the build

platform. Sud de n tool slip and impr oper

body position during object removal from the

build platform may result in personal injury.

WARNING

!

plate may break and result in personal injury.

WARNING

!

removing objects. Tempered glass plate

may separate from plastic holder and result

in personal injury.

CAUTION

!

objects. Scratches in the build platform will

result in improper object creation.

Do not touch the extruder

tip or heated build platform

Use personal protective

equ ipment . The us e o f

Be awar e of yo ur body

position when using hand

Do not drop th e build

platform. Tempered glass

Do not twist or bend the

bui ld pl atform while

Avoid scratc hi ng t he b uild

pla t f orm w h en r e m ovin g

31

FIG. 8

Removal

Tool

1. Wait for the extruder or build platform to

cool before removing your object.

2. With the object still attached, remove build

platform from the build area.

3. Peel your object from the build platform. If

needed, gently use the object removal tool

to rem ove obj ect fro m b uild p l atf o rm

(figure 8).

REMOVING SUPPORTS

(IF REQUIRED)

Use needle nose pliers to remove supports

that are inside your object or hard to reach.

32

Using the Camera

Your 3D45 is equipped with a camera that

can be used to remotely monitor prints as

lon g as you r print e r is c o n nect e d to a

network. There are two ways to access the

camera: through the Dremel Cloud Platform

or directly via a web browser.

Dremel Cloud Platform

1.Cre a t e a Dreme l Cl oud a c c ount an d

register your 3D45. See page 22, Dremel

Cloud Platform, for detailed instructions.

2.Log in to your Dremel Cloud account.

3.Click on your registered printer, or click on

Add a Printer if you need to register your

printer.

4.You will be directed to the Printers page of

the Dremel Print Cloud. Here, you can click

on Live View to see the camera view of

any camera currently online.

Direct through Web Browser

1.Make sure the device you want to view the

cam e ra o n i s c o nnect e d t o t h e s a me

network as the 3D printer. This could be

via Wi-Fi or via Ethernet.

2.On th e main menu o f your 3D45 t a p

“Tools”

3.In the tools menu tap “About”

4.Locate the IP address of your printer. If

your printer is connected to the network via

Eth e r net, this i s the ad dress next to

“Ethernet IP”. If it is connected via Wi-Fi

this is the address next to “WiFi IP”. It will

be a sequence of three or four numbers

separated by dots.

5.Open any web browser on the device you

want to view the camera on.

6.In th e ad dress ba r, en t er the st r ing:

http ://IPADD RESS: 10123/s tream _simp

le.html

For example:

http://000.000.000.000:10123/stream_simp

le.html

7.Press enter and you will see a screen with

a view of the camera as below.

Best Practices

33

1. ALWAYS USE PROVIDED GLUE STICK.

2. Ensure your build platform is level before

every print.

3. For proper adhesion of filament to the

build platform, regularly wash the glue

from the build platform with warm water,

dry the build platform, re-apply a fresh

layer of glue and re-level.

4. Ensure spool is installed properly and

can rotate freely.

5. When using your Dremel 3D45 for the

first time or after changing filament, allow

Dremel 3D45 to extrude until material is

cons isten t with the ins talled filam ent

color.

6. It is important to watch your Dremel 3D45

begin building objects. Your object is

most likely to experience difficulty in the

beginning. Thankfully, this is also the

mos t con v e nien t tim e to cance l the

object, clean the build platform, and start

yo u r o bjec t a g ain. Rem ain near the

Dremel 3D45 during the building process.

Maintenance

7. It is important to save your Dremel 3D45

packaging as it will make re-boxing and

transporting your Dremel 3D45 easier.

8. Ensure that you store filament spools in

an environment that is not moist or too

hot. It is recommended that you do not

remove the filament spool from its airtight

packaging until use.

9. Use object removal tool gently to avoid

damaging the build platform or object.

10. Whenever possible, it is best to locate

your obj ec t in t he center o f the build

platform. Using the best orientation for

your object is critical. Ensure that your

object is located on the build platform

and that y ou ar e usi n g the best

orientation for building.

11. For steep over h angs (Les s tha n 45

degree angle) it is recommended to build

with support.

12. Always remove the build platform before

removing the object.

UNCLOGGING THE EXTRUDER

Use the unclogging tool to clean the extruder

and unclog built up filament, fig 9.

1. Click on the filament change button on the

screen and wait for extruder to heat up. As

filament starts to purge, insert the unclog

tool into the extruder intake (top).

2. Clogged debris will be pushed down and

will ext rude fr om t he extr uder ti p. You

should push the unclog tool all the way

down to ensure all filament is purged. You

do not need to push with excessive force,

as this may damage the extruder.

FIG. 9

34

Maintenance

UPDATING FIRMWARE VIA NETWORK

If your 3D45 is registered and connected to

WiFi, it should check for firmware updates

each time it boots up. You can also update its

firmware directly from the touch screen. To

update firmware:

1. Tap “Tools”, then tab “Updates”.

2. Your 3D45 will check to see if it has the

latest firmware installed and ask if you

would like to update if one is needed.

3. Choose accept to download and install the

latest firmware.

4. When the 3D45 starts up and returns to

the Home Screen, f irmware u pdate is

complete.

UPDATING FIRMWARE MANUALLY

If your 3D45 is not connected to a network,

you can update firmware directly from a USB

flash drive.

1. On your web br owser go to

www.digilab.dremel.com and download

the latest 3D45 firmware file.

2. Add the 3D45 firmware file to an empty,

FAT32 formatted, USB flash drive.

3. Turn off yo ur 3D45 using the ON/OFF

switch.

4. Insert the USB flash drive into the USB-A

port.

5. Turn on y o u r 3D 4 5 an d it sho u l d

automatically detect and install the new

firmware.

6. Turn your 3D45 OFF, remove the USB

flash drive, and turn ON again to complete

the update.

CLEANING THE EXTERIOR

Clean the 3D45’s exterior with a lint free

cloth. Clear the outer surfaces of any debris

that is visible.

To avoid damaging your Dremel 3D45 do not

use water, chemicals or other cleaners on

the 3D45.

CLEANING THE EXTRUDER TIP

CAUTION

!

when clearing debris. Dremel 3D45 will not

work properly with damaged extruder tip and

will require replacement.

WARNING

!

during Dremel 3D45 operation or until it

has cooled down to at least 60°C (140°F).

Contact with the extruder tip or build platform

during or after operation before tip and build

plate has cooled may result in personal injury.

Using small needle nose pliers, pull away

any plastic debris from the extruder tip.

If the debris is stubborn, the extruder may

need to be heated.

CLEANING THE TOUCH SCREEN

Wipe the touch screen with the soft, lint-free

cloth. Do not spray cleaners on the touch

screen.

Use e x tra ca r e not to

dam a g e th e extr u der ti p

Do not touch the extruder

tip or heated build platform

PROBLEM CAUSE CORRECTIVE ACTION

Filament is not extruding or

sticking to the build plate

properly.

Troubleshooting

This can be caused by the build

platform not being leveled with

the extruder head.

35

Leveling the build platform will align

the extruder head and ensure a better

object quality. Cancel your object,

clear build platform, level the build

platform, and restart the object.

Dremel 3D45 froze before my

object started.

Support material does not

break away during cleaning and

results in decreased quality of

the final object.

Spaghetti mess at end of build. A layer of your object did not

Part only built halfway. Filament ran out.

No filament coming out. Clogged extruder.

Extruder will not home. Contact customer service.

Dremel 3D45 may have

received conflicting commands.

Orientation of the part is not

optimized.

stick properly, model was saved

with minimal surface area

contacting the build platform,

or object was built floating

above the build platform with

no support selected.

Z-Gap offset may not be correct

and the extruder tip is not

properly spaced with the build

plate.

Filament clogged during build.

Filament not properly loaded.

Turn power switch off, wait 30

seconds, and turn power switch on.

Reorient the position of the 3D file in

Print Studio to minimize the support

material or place the support material

on a non-critical surface.

Use the preview feature in Print

Studio to see the first layer height and

position. Build with supports when

necessary.

Contact customer service on how to

calibrate the Z-Gap Offset.

Replace filament and resume build.

See “No filament coming out”.

Contact customer service.

Try running a filament change again

to ensure the extruder gears have

properly caught the filament.

Stringy or fraying plastic layers

on steep overhangs.

3D45 will not find my Wi-Fi

network.

Object overhangs are too far

apart or too steep (<45 degree

angle).

Printer too far from wireless

router.

Build with supports.

Reposition 3D45 to be closer to your

router.

Connect to network with Ethernet

36

PROBLEM CAUSE CORRECTIVE ACTION

3D45 will not connect to my

network.

Troubleshooting

Printer too far from wireless

router.

Reposition 3D45 to be closer to your

router.

Network password or SSID

incorrect

3D45 will not retrieve a token. Network password incorrect. Re-enter your password or verify

Network has a firewall. Enter network proxy information.

Cloud slicer will not connect to

3D45 or shows "printer offline".

Token invalid. Verify the current 3D45 token

Build did not start when sent

over network.

3D45 not connected to network. Check 3D45 network settings and

using "Tools/About" and retry.

Filament ran out. Load additional filament and resume

Doors open. Doors must be closed to start builds

Model was already building The build plate must be clear to start

Re-enter your password/SSID or

verify your password with your

network owner.

your password with your network

owner.

retry connection.

Use "Get new token" to generate a

new token and retry connection.

Note this will remove any users that

are sharing your printer.

build.

over your network, start build from

print queue.

a build over your network, clear the

build plate and start build from print

queue.

Firmware & Open Source Software

Firmware Updates

Dremel recommends that firmware be updated whenever Dremel provides an update.

Dremel will provide firmware updating to improve performance and add additional features for

the 3D45 throughout the life of the product. There are two ways of updating the 3D45: (1)

Download update from www.digilab.dremel.com and install using USB memory drive. (2)

Connect the 3D45 to the internet and update from the 3D45 touch screen.

Open Source Software used in this Dremel product

This product contains software components that are licensed by the holder of the rights under

any version of the GNU General Public License (GPL), GNU Lesser General Public License

(LGPL) or any other open source software license which requires that source code be made

available. You can receive a complete machine-readable copy of the corresponding source

code by sending a written request to:

Dremel

Attn: Open Source Software Officer

P.O Box 081126

Racine, WI USA 53408-1126

Your request should include: (i) the name of the Dremel product, (ii) the serial number (if

applicable), (iii) the software version (if applicable), (iv) your name, (v) your company name (if

applicable) and (vi) your return mailing and email address (if available).

We may charge you a nominal fee to cover the cost of the physical media and distribution.

You may send your request (i) within three (3) years of the date you received the product that

included the software which is subject of your request or (ii) in the case of code licensed

under the GPL version 3 for as long as Dremel offers spare parts or customer support for that

product.

37

Warranty regarding further use of the Open Source Software:

DREMEL provides no warranty for the Open Source Software programs contained in this

device, if such programs are used in any manner other than the program execution intended

by DREMEL. The licenses listed below define the warranty, if any, from the authors or

licensors of the Open Source Software. DREMEL specifically disclaims any warranties for

defects caused by altering any Open Source Software program or the product´s configuration.

You have no warranty claims against DREMEL in the event that the Open Source Software

infringes the intellectual property rights of a third party. Technical support, if any, will only be

provided for unmodified software.

38

Dremel®Limited Warranty

If used for non-commercial or educational purposes, your Dremel 3D45 is warranted against

defective materials or workmanship for a period of one year from the date of purchase. If the Dremel

3D45 is used for commercial purposes, this warranty will apply for 60 days from the date of purchase.

In the event of the product fails to conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Please contact customer service

3. Carefully package the product by itself, in original packaging, with no other items, and

return it, freight prepaid, along with:

a. A copy of your dated proof of purchase (please keep a copy for yourself).

b. A written statement about the nature of the problem.

c. Your name, address and phone number to:

CONTINENTAL UNITED STATES CANADA

Dremel Service Center

4915 21st Street

Racine, WI 53406

Phone: 1 (800) 437-3635

Giles Tool Agency

47 Granger Av.

Scarborough, ON M1K 3K9

Phone:1-416-287-3000

West Coast Tool

4008 Myrtle Street

Burnaby, B.C. V5C 4G2

Phone: 1-604-873-5394

OUTSIDE CONTINENTAL UNITED STATES

See your local distributor or write to Dremel, 4915 21st Street Racine, WI 53406.

We recommend that the package be insured against loss or in-transit damage, for which we cannot

be responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT

RESULTING FROM TAMP ER IN G, ACC ID EN T, ABU SE , NEGLIGENCE, UNAUTHO RI ZE D

REPAIRS OR ALTERATIONS, PRODUCT USE IN VIOLATION OF THE “GENERAL SAFETY

WARNINGS,” UNAPPROVED ATTACHMENTS, USE OF FILAMENT OTHER THAN DREMEL

APPROVED FILAMENT, OR OTHER CAUSES UNRELATED TO PROBLEMS WITH MATERIAL

OR WORKMANSHIP ARE NOT COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel.

If Dremel inspection shows that the problem was caused by problems with material or workmanship

within the limitations of the warranty, Dremel will repair or replace the product free of charge and

return the product prepaid. Repairs made necessary by normal wear or abuse, or repair for products

outside of the warranty period, if they can be made, will be charged at regular factory prices.

DISCLAIMER OF IMPLIED WARRANTIES: DREMEL MAKES NO OTHER WARRANTY OF ANY

KI N D W HATE V ER, EXP R ESSE D O R IMPL IED, A N D ALL I M PLI E D WA R RANT IES OF

MER C HAN TA B ILIT Y AN D FI TNES S FO R A PAR TICU L AR PURPO S E AR E HE REB Y

DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. The obligation of the warrantor is solely to repair or replace the product. The

warrantor is not liable for any incidental or consequential damages due to any such alleged defect.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact a Dremel service

location.

®

Imported for Dremel

in the U.S. by:

Robert Bosch Tool Corporation

1800 West Central Road

Mount Prospect, Illinois 60056

Table des matières

!

AVERTISSEMENT

!

!

MISE EN GARDE

Symboles relatifs à la sécurité ...........................................................................39

Avertissements généraux concernant la sécurité..........................................40-41

Avertissements de sécurité supplémentaires.....................................................42

Symboles...........................................................................................................42

Services à distance et mobiles Dremel...............................................................42

Conformité aux règlements de la FCC ................................................................43

Informations concernant la propriété intellectuelle ............................................43

Spécifications.....................................................................................................44

Ressources........................................................................................................45

Glossaire terminologique..............................................................................45-47

Introduction .......................................................................................................48

Contenu du kit....................................................................................................48

Déballage ...........................................................................................................49

Familiarisez-vous avec votre équipement Dremel 3D45................................50-51

Écran tactile..................................................................................................52-58

Configuration initiale..........................................................................................59

Plateforme nuage Dremel...................................................................................60

Préparez-vous en vue de la construction......................................................61-66

Construction.................................................................................................66-68

Retrait de votre objet..........................................................................................69

Utiliser la caméra ...............................................................................................70

Meilleures pratiques...........................................................................................71

L’entretien.....................................................................................................71-72

Dépannage....................................................................................................73-74