Page 1

Original instructions 2

EN

Übersetzung der Originalbedienungsanleitung 27

DE

Traduction de la notice originale 54

FR

2610Z07095 01/2015 All Rights Reserved

Page 2

!

GB

ORIGINAL INSTRUCTIONS

GENERAL SAFETY WARNINGS

WARNING

MANUAL AND FAMILIARIZE YOURSELF

WITH THE DREMEL 3D20 BEFORE SETUP

AND USE. FAILURE TO COMPLY WITH THE

WARNINGS AND INSTRUCTIONS MAY RESULT IN

FIRE, EQUIPMENT DAMAGE, PROPERTY DAMAGE,

OR PERSONAL INJURY. SAVE ALL WARNINGS AND

INSTRUCTIONS FOR FUTURE REFERENCE

WORK AREA SAFETY

a. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b. Do not operate Dremel 3D20 in the presence of

ammable liquids, gases or dust. Dremel 3D20

creates high temperatures which may ignite the

dust or fumes.

c. Store idle 3D20s out of reach of children and

other untrained persons. Injury can occur in

hands of untrained users.

ELECTRICAL SAFETY

a. Always use the Dremel 3D20 with a properly

grounded outlet. Do not modify Dremel 3D20

plug. Improper grounding and modied plugs

increase risk of electric shock.

b. Do not use Dremel 3D20 in damp or wet

locations. Do not expose Dremel 3D20 to rain.

Presence of moisture increases risk of electric

shock.

c. Do not abuse the cord. Never use the cord for

pulling or unplugging the Dremel 3D20.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

d. Avoid using this product during an electric

storm. There may be a remote risk of a power

surge from lightning that may result in electric

shock hazard.

e. In case of emergency unplug Dremel 3D20 from

outlet.

PERSONAL SAFETY

a. Stay alert, watch what you are doing and

use common sense when operating a Dremel

3D20. Do not use Dremel 3D20 while you are

tired or under the inuence of drugs, alcohol

or medication. A moment of inattention while

operating Dremel 3D20 may result in personal

injury.

b. Use personal protective equipment. The use of

protective equipment such as heat resistant gloves

and safety glasses will reduce the risk of personal

injuries.

c. Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry

or long hair can be caught in moving parts.

DREMEL 3D20 USE AND CARE

a. Before every use check Dremel 3D20 for

misalignment or binding of moving parts,

breakage of parts and any other condition

READ ALL

INSTRUCTIONS IN THIS

that may affect the Dremel 3D20’s operation.

If damage is suspected have the Dremel 3D20

repaired by autorized Dremel service center

before use. Use of Dremel 3D20 when damaged

may result in poor quality of object creation, further

equipment damage, property damage or personal

injury.

b. Do not touch the extruder tip during Dremel

3D20 operation or until it has cooled down to

at least 60°C (140°F). Contact with the extruder tip

during or after operation before tip has cooled may

result in personal injury.

c. Set up the Dremel 3D20 in a well-ventilated

area. Provide at least 8 inches of unobstructed

spacing around Dremel 3D20. Dremel 3D20

melts plastic during building. Plastic odors emitted

during Dremel 3D20 operation may irritate eyes

and airways. Locating Dremel 3D20 close to

surrounding objects prevents proper ventilation.

d. Do not reach inside the Dremel 3D20 while it is

in operation. Contact with Dremel 3D20 moving

parts during operation may result in poor build

quality, equipment damage or personal injury.

e. Do not leave the Dremel 3D20 unattended

during operation. Use of Dremel 3D20 by persons

unfamiliar with these warnings and instructions may

result equipment or property damage and personal

injury.

f. Use only DREMEL PLA lament. Use of lament

not authorized by Dremel may result in equipment

and property damage.

g. Ensure small objects created by Dremel 3D20

are not accessible to young children. Small

objects are potential choking hazards for young

children.

h. Do not create illegal or inappropriate objects

using Dremel 3D20.

i. Do not use Dremel 3D20 to create objects

intended for use with candles, liquid fuels,

and other heat sources. Plastic may melt when

exposed to re or other heat sources. Such use of

objects created by Dremel 3D20 may result in re,

property damage and personal injury.

j. Do not use Dremel 3D20 to create objects

intended for food or drink applications

such as preparation, decoration, storage, or

consumption. Such use of objects created by

Dremel 3D20 may result in illness or personal

injury.

k. Do not use Dremel 3D20 to create objects

intended with use with electrical components or

housings of electrical components. PLA plastic

is not suitable for electrical applications. Such use

of objects created by Dremel 3D20 may result in

property damage and personal injury.

l. Do not put plastic objects in or around your

mouth. PLA plastic is not suitable for food or drink

preparation and food utensils. Such use of objects

created by Dremel 3D20 may result in illness or

personal injury.

m. Do not use Dremel 3D20 to create objects

intended for chemical storage. PLA plastic is not

suitable for chemical storage. Such use of objects

created by Dremel 3D20 may result in property

damage and personal injury.

n. Do not modify Dremel 3D20 or alter factory

settings. Modications may result in equipment

and property damage, and personal injury.

o. Do not expose Dremel 3D20 to temperatures

exceeding 70°C (158°F). Dremel 3D20 may

become damaged. Dremel 3D20 is intended to

operate in temperature between 16-29° C (60 - 85°

F).

2

Page 3

p. Do not move or bump Dremel 3D20 or the

WARNING

!

extruder during operation. The object may build

incorectly.

q. Do not change color of lament or spool during

building. Doing so will cancel the object and may

damage the extruder.

r. Do not pull the lament out until instructed

by the touch screen. Doing so may damage the

extruder.

s. Use extra care not to damage the extruder tip

when clearing debris. Dremel 3D20 will not work

properly with damaged extruder tip and will require

replacement.

t. Before every build make sure that the build

platform is covered with Dremel specied build

tape. Use of improper build tape may result in

equipment damage and poor object build quality.

u. Be aware of your body position when using

hand tools to remove objects from the build

platform. Sudden tool slip and improper body

position during object removal from the build

platform may result in personal injury.

v. Avoid scratching the build platform when

removing objects. Scratches in the build platform

will result in improper object creation.

w. Dremel is not responsible for structural integrity

or utility of objects created using Dremel

3D20. Structural models created by inexperienced

designers may result in property damage and

personal injury.

SERVICE

a. Always unplug Dremel 3D20 from its power

before performing any service procedures.

Failure to do so may result ion personal injury and

equipment damage.

b. Have your Dremel 3D20 serviced only by an

authorized Dremel service center using only

Dremel replacement parts. This will ensure that

proper operation and safety of Dremel 3D20 is

maintained.

c. Use only Dremel approved materials and

components. Use of object materials, or 3D

objects other than Dremel

materials and genuine Dremel

void warranty.

®

approved object

®

components may

TABLE OF CONTENTS

General safety warnings ......................................2

Table of contents...................................................3

Used symbols ........................................................3

Information on Intellectual Property ................... 3

Functional Description and Specications ........ 4

3D20 Resources .................................................... 5

Glossary of Terms .................................................5

Getting to know your 3D20 .................................. 7

Introduction ............................................................9

Kit Contents and Unpacking ................................ 9

Touch Screen ....................................................... 11

Software Install and Registration ...................... 16

Dremel Software Overview .................................17

Getting Ready to Build ....................................... 19

Building ................................................................21

Building from the SD Card ................................. 21

Building From Your Computer...........................22

Removing Your Object ........................................22

Unloading and Replacing Filament Spool ........23

Maintenance and Service ...................................24

Unclogging the extruder ....................................25

Cleaning the exterior ..........................................25

Cleaning the extruder tip ................................... 25

Cleaning the touch screen ................................. 25

Best practices ......................................................25

®

Consumer Limited Warranty................26

Dremel

USED SYMBOLS

Symbol Name Designation/

!

PRODUCT MAY CAUSE RADIO INTERFERENCE IN

WHICH CASE THE USER MAY BE REQUIRED TO

TAKE ADEQUATE MEASURES.

Warning symbol

Read manual

symbol

WARNING

THIS IS A CLASS A PRODUCT. IN

A DOMESTIC ENVIRONMENT THIS

Explanation

Alerts user to warning

messages

Alerts user to read

manual

INFORMATION ON INTELLECTUAL

PROPERTY

The Dremel 3D20 is intended for 3D printing objects

from digital les that you create or own, or have the

right to print using the Dremel 3D20. When making

objects using the Dremel 3D20, it is your responsibility

to ensure that you do not infringe any third party

intellectual property rights or violate any applicable

laws or regulations, such as U.S. or foreign intellectual

property laws. The Dremel 3D20 may not be used to

make objects protected by intellectual property rights

owned by third parties without such third parties’

permission. Using the Dremel 3D20 to do any of the

following may require the permission of third parties:

to make a duplicate or facsimile (in whole or in part) of

any object not created by you, to make an object from

a digital le you do not own, or to make an object from

a scan of a physical object that you did not create. It is

your responsibility to obtain such permission. In some

cases, you may not be able to obtain such permission.

Where such permission cannot be obtained, you

should not 3D print such object, or you do so at your

own risk. You may not modify, reverse engineer,

decompile, or disassemble the Dremel 3D20 or i ts sof

tware or f irmware, except as permitted by applicable

law. If you use the Dremel 3D20 in any way other than

as recommended and described in these Operating/

Safety Instructions, you do so at your own risk. Using

the Dremel 3D20 to make objects that infringe any

intellectual property rights owned by third parties could

result in civil or criminal prosecution and penalties,

and you could be liable for money damages, nes, or

imprisonment.

This product may contain or discharge chemicals

known to the State of California to cause cancer and

birth defects or other reproductive harm.

3

Page 4

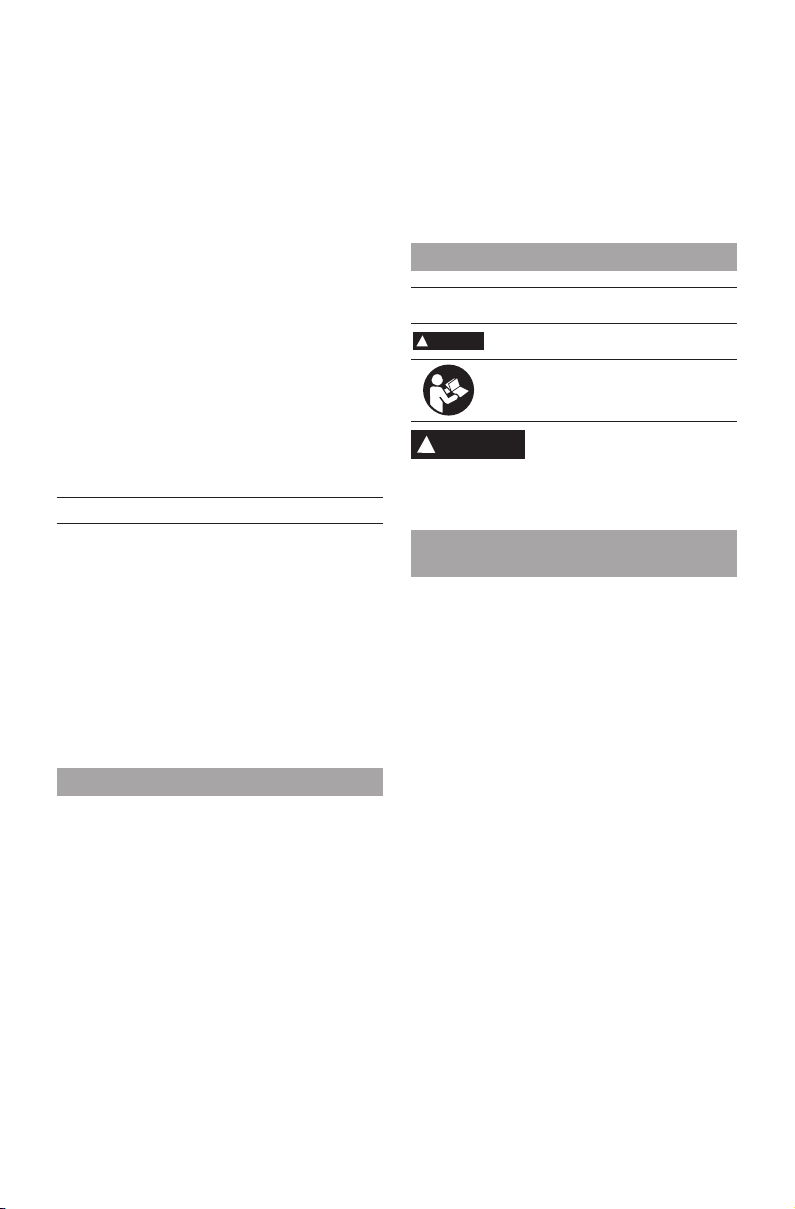

FUNCTIONAL DESCRIPTION AND

14” (356mm)

SPECIFICATIONS

BUILDING

Extruder: Single extrusion

Extruder temperature: Up to 230°C (397°F)

Operating Interface: 3.5” full color IPS touch screen

Maximum Build Volume: 9” x 5.9” x 5.5”

(230mm x 150mm x 140mm)

Layer Thickness: 4 mil | 0.004 inches 100 microns |

0.10 mm

Filament Colors: See Dremel3D.com for color choices

SD Card: Up to 32GB in size (3D20 will not work with

SD cards larger than 32GB)

Internal Storage: 4GB

WEIGHT & DIMENSIONS

Weight (without spool): 8.8kg (19lbs 8oz)

Dimensions: 19.1” x 15.7” x 13.2” (485mm x 400mm

x 335mm)

FILAMENT

ONLY works with Dremel PLA lament

Filament: 1.75mm PLA

(Biodegradable/Renewable)

FILAMENT STORAGE

All polymers degrade with time. Do not unpack until

lament is needed. Filament should be stored at room

temperature: 16-29° C (60-85° F)

SOFTWARE

Dremel 3D20 comes with complimentary Dremel 3D

software for Windows and Mac OSX. This application

converts your 3D digital les into buildable les.

MINIMUM HARDWARE REQUIREMENTS

A PC with these minimum requirements will be required

to run the Dremel

Processor: Multi-core processor - 2 GHz or faster per

core

System RAM: 2 GB

Screen Resolution: 1024x768

USB port

®

3D Software

WINDOWS REQUIREMENTS

Dremel® Software runs on 32 and 64-bit Operating

Systems

Windows Vista or later

MAC OSX REQUIREMENTS

Dremel® Software runs on Mac OSX 10.8 or later

ELECTRICAL REQUIREMENTS

3D20 input rating: 120V, 60Hz, 1.2A

OPERATING ENVIRONMENT

Room Temperature: 16-29° C (60 - 85° F)

Level workspace

Dry workspace environment

15.7” (400mm)

19.1” (485mm) 13.2” (335mm)

WALL

8” (203mm)

8” (203mm)8” (203mm)

4

Page 5

3D20 RESOURCES

GLOSSARY OF TERMS

Resource Description Location

Quick Start

Guide

3D20 Website Provides the

3D20

Customer

Support

Dremel 3D20

Software

Provides

illustrated

walkthrough of

how to un-box

your 3D20 and

start building out

of the box.

latest 3D20

software, product

information, and

customer support.

Contact Dremel

for product

support,

maintenance, and

service.

Allows you to

upload, edit, and

build 3D les.

You can also

change device

settings and order

supplies.

Printed version of

the Quick Start

Guide is located

in the rectangular

component carton.

It is also available

on www.dremel3d.

com

www.dremel3d.com

Installed from

www.dremel3d.com

or from SD card

provided with the

Dremel 3D20.

Term Denition

Build Platform The at surface used by your Dremel

Build Platform

Clip

Build Tape Adhesive tape similar to blue painter’s

Build Volume The three dimensional (3D) amount

Door Your Dremel 3D20 has a door located

Lid Your Dremel 3D20 has a removable

Limit Switch Switch that is activated by the motion

Extruder An assembly that uses gears to

Extruder Fan A fan used to cool the outer assembly

Extruder Intake An opening located at the top of the

Extruder Push

Lever

Extruder Tip A nozzle located at the bottom of the

Filament A threadlike strand of plastic material.

Filament Spool A cylindrical piece on which a long

Filament Guide

Tube

Leveling

Knobs

3D20 to build objects.

Clip located at the front of the build

platform base that is used to secure

the build platform in place.

tape that improves the consistency of

your objects and helps them stick to

the build plate surface.

of space that an object will use once

it is completed. Your Dremel 3D20

has a maximum build volume which

means that objects with a larger build

volume cannot be built unless they

are resized or broken objects with a

larger build volume cannot be built

unless they are resized or broken into

sub-objects.

on the front panel. This allows for

easy access to the build platform,

extruder, lament, and your objects.

This door is made with a transparent

material so you can monitor the

progress of your objects while keeping

the build environment stable.

lid on the top. This allows for more

access to the build platform, extruder,

lament, and objects when necessary.

of the extruder or build platform when

the end of travel is reached.

pull lament through the extruder

intake, heat the lament to the build

temperature, and push the heated

lament out of the extruder tip.

of the extruder and gear motor.

extruder where lament is inserted for

building.

A lever located on the side of the

extruder that is used to loosen the

grip of the extruder gear motor.

extruder where heated lament is

forced out for building.

strand of lament is wound for storage

and continuous use.

A plastic piece that guides the

lament from the lament spool

through a passage in the outer

housing of your Dremel 3D20.

Knobs located under the build

platform base that are used to create

proper spacing between the extruder

tip and the build platform.

5

Page 6

Leveling Tool Calibrated leveling pad with detailed

PLA A bioplastic derived from renewable

Needle Nose

Pliers

Object

Removal Tool

SD Card A portable memory card used on

Spool Holder A plastic piece located to the left of

Spool Lock A plastic piece which locks the

Stepper Motor A brushless DC electric motor used

.STL File A common digital le format used in

.3dremel File Dremel’s digital le format that is used

.G3Drem File A buildable le format compatible with

Touch Screen Full color display that is touch

Unclog Tool A tool used to clear the extruder of

X-Axis Guide

Rails

Y-Axis Guide

Rails

Z-Axis Guide

Rails

markings and directions for use.

resources such as corn starch.

Common tool used to hold small

objects and to grab excess material

that may be too hot to touch directly.

A tool used to separate your objects

from the build platform.

a wide array of devices such as

cameras.

the build platform inside your Dremel

3D20 build area that is designed to

hold a lament spool.

lament spool to the spool holder.

This piece is inserted through the

center of the lament spool, into the

spool holder, and turned to lock.

to drive the guide rails and extruder

gears.

a wide range of 3D model software.

This le is created in 3rd party

3D software or downloaded from

Dremel3D.com.

by your Dremel 3D20 to properly

process models.

your Dremel 3D20.

activated. It allows you to monitor

your Dremel 3D20 and objects while

also providing commands directly to

your Dremel 3D20 without the use of

a computer.

excess debris.

A set of rails on either side of the

extruder that allow a stepper motor to

move the extruder to the left or right

side of the build area.

A set of rails on either side of the

build area that allow a stepper motor

to move the extruder to the front or

back of the build area.

A set of rails located at the back of

the build area that allow a stepper

motor to move the build platform up

or down.

6

Page 7

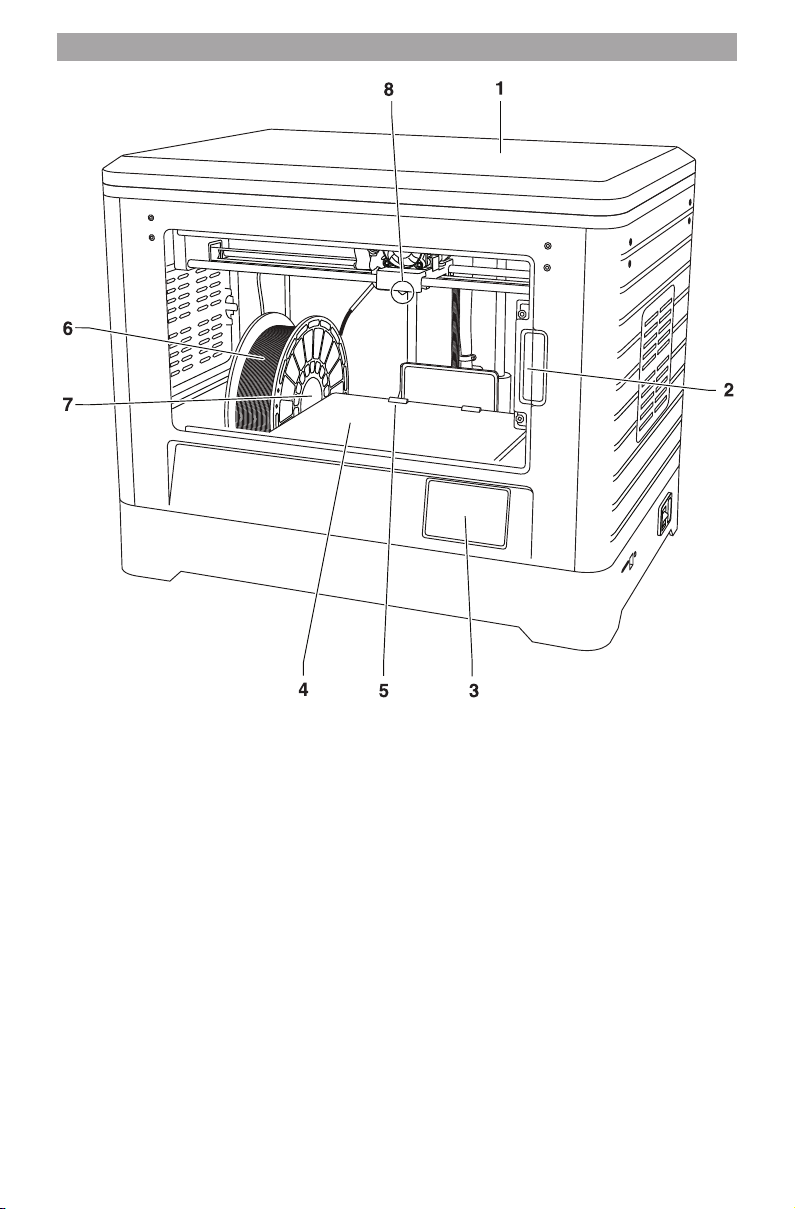

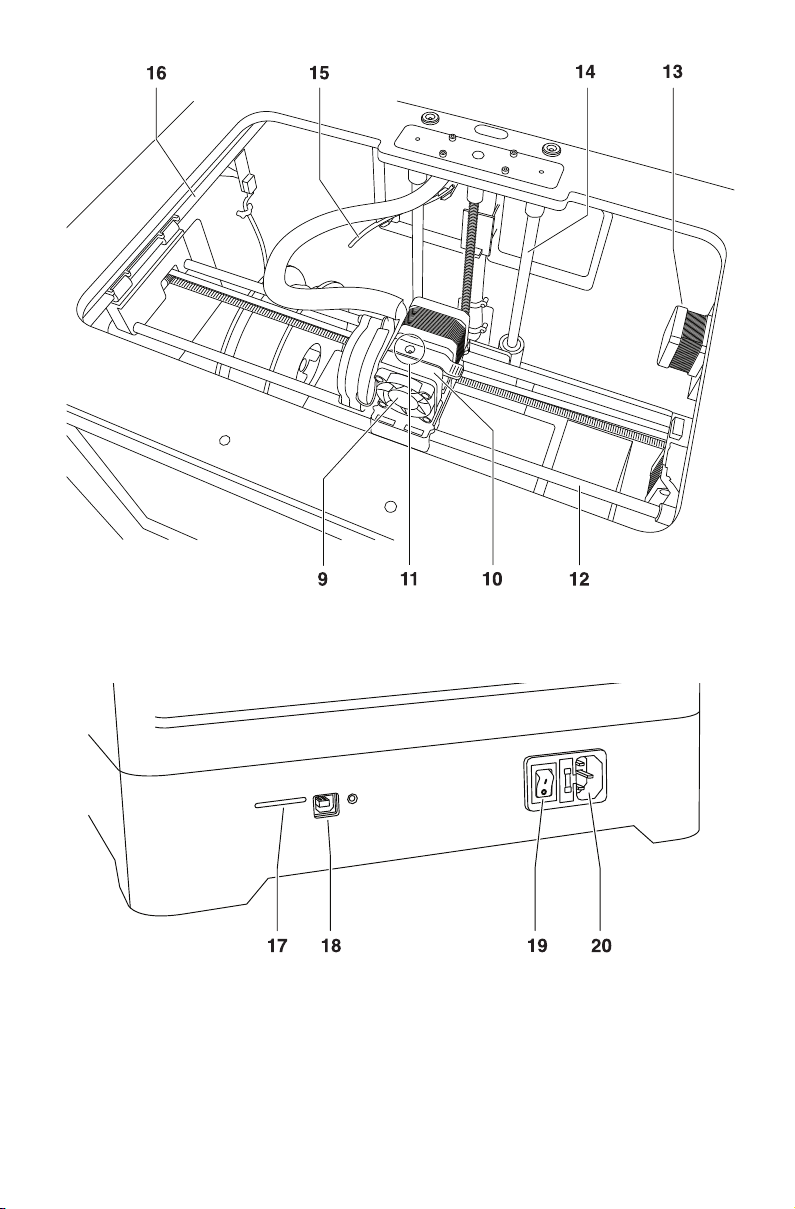

GETTING TO KNOW YOUR 3D20

1. Lid

2. Door

3. Touch Screen

4. Build Platform

5. Build Platform Clips

6. Filament Spool

7. Filament Spool Holder/Lock

8. Extruder Tip

9. Extruder Fan

10. Extruder

11. Extruder Entry

12. X-Axis Guide Rails

13. Stepper motor (1 of 3)

14. Z-Axis Guide rail

15. Filament Guide Tube

16. Y-Axis Guide Rails

17. Power Input

18. Power Switch

19. USB Input

20. SD card Input

7

Page 8

8

Page 9

INTRODUCTION

KIT CONTENTS AND UNPACKING

Welcome to the world of Dremel 3D. Our mission is

to mentor you through the 3D building process and

share best practices for bringing your ideas to life. 3D

building is a process that will involve experimentation

and persistence. Thankfully, the Dremel experts are

here to make your job easier with online tips and live

support. Kick-start your success by registering your

Dremel 3D20 on Dremel3D.com giving you access

to hundreds of high-quality models and innovative

projects. With Dremel, you can build on your own

ideas, build them better and make them yours.

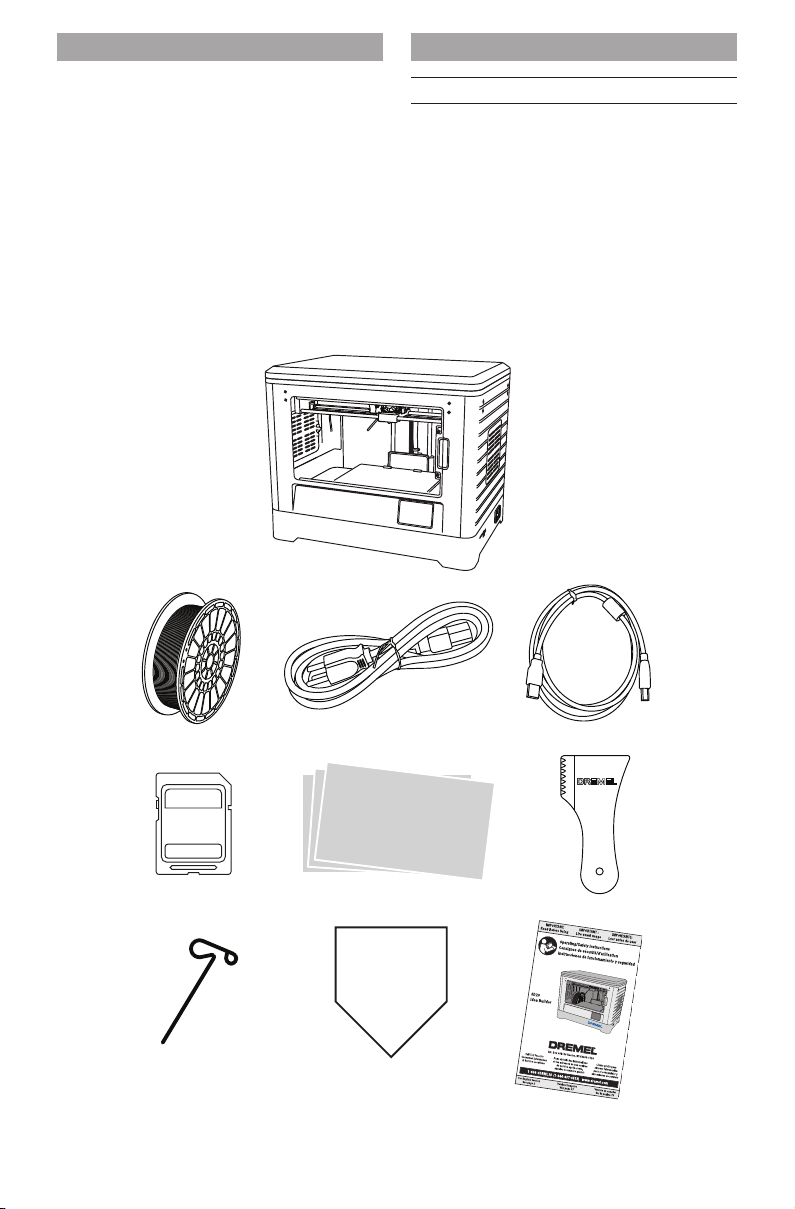

KIT CONTENTS

• Dremel 3D20

• 1 Filament Spool

(Do not store in moist or hot environment)

• Quick Start Guide

• Instruction Manual

• Power Cable

• USB Cable

• SD Card

(Containing Sample Model Files)

• Build Tape

• Object Removal Tool

• Unclog Tool

• Leveling Tool

Leveling tool

9

Page 10

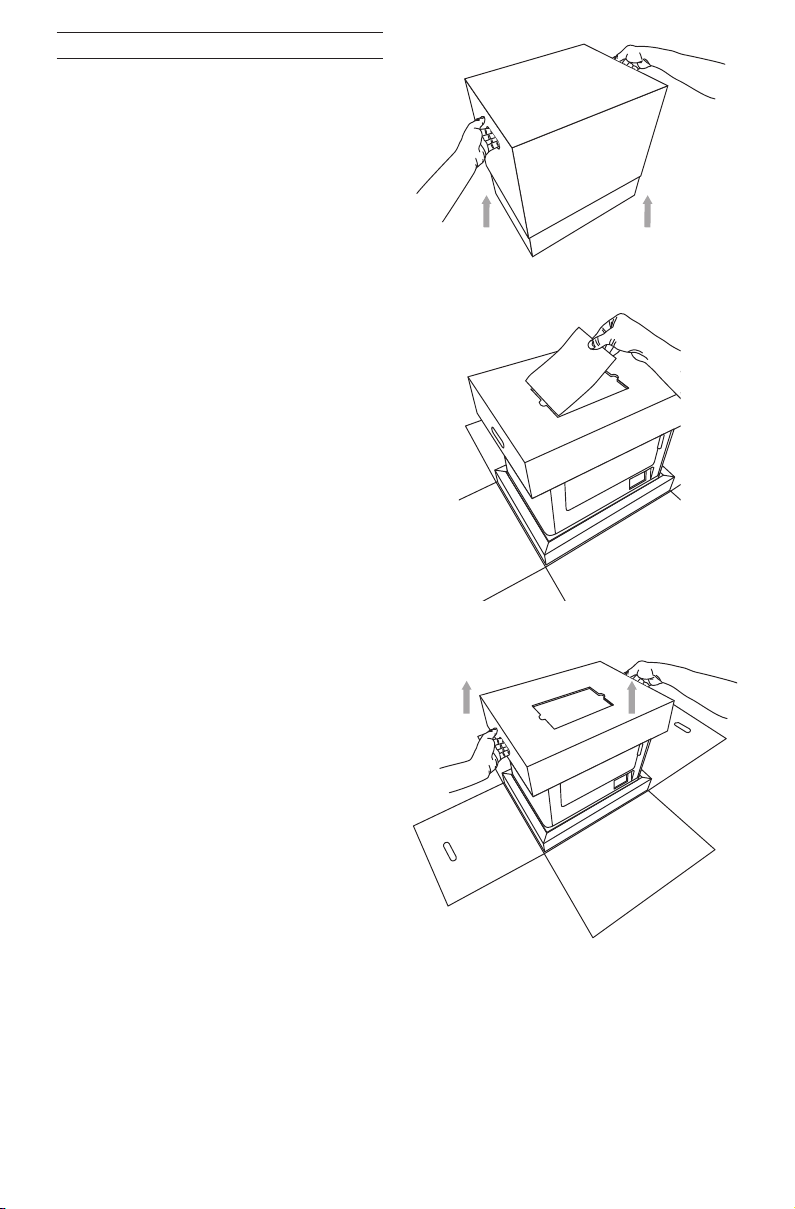

UNPACKING

1. Place box on table and cut tape.

2. Lift outer box and allow inner box to open.

3. Remove carton lid from top of your Dremel 3D20

4. Rectangular carton on top of your Dremel 3D20

contains product manual, quick-start guide, and

set-up pieces. Remove the kit contents located

inside.

5. Using a rm grip, lift your Dremel 3D20 out of

packaging and place gently on stable work surface.

6. Remove plastic lid from top of your Dremel 3D20.

7. Remove tape from your Dremel 3D20 door.

8. Remove inserts from inside of your Dremel 3D20.

Tip: Keep packaging for future transportation

and storage.

10

Page 11

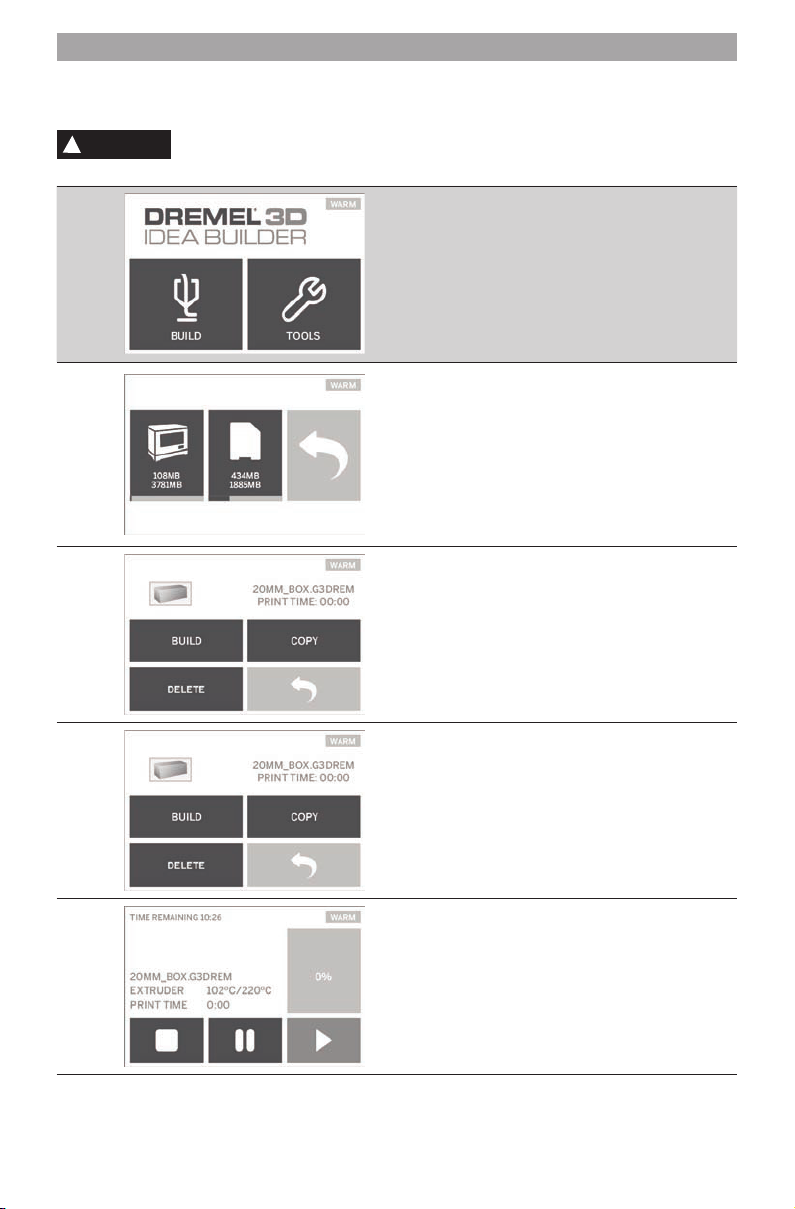

TOUCH SCREEN

!

Using your Dremel 3D20 without a computer is easy with the onboard software and full color touch screen.

Before building your model we want to familiarize you with the touch screen menu structure and options.

WARNING

PROPERTY DAMAGE OR PERSONAL INJURY.

OBSERVE ALL PROVIDED WARNINGS AND SAFETY INSTRUCTIONS WHEN USING THE

DREMEL 3D20. FAILURE TO DO SO MAY RESULT IN FIRE, EQUIPMENT DAMAGE,

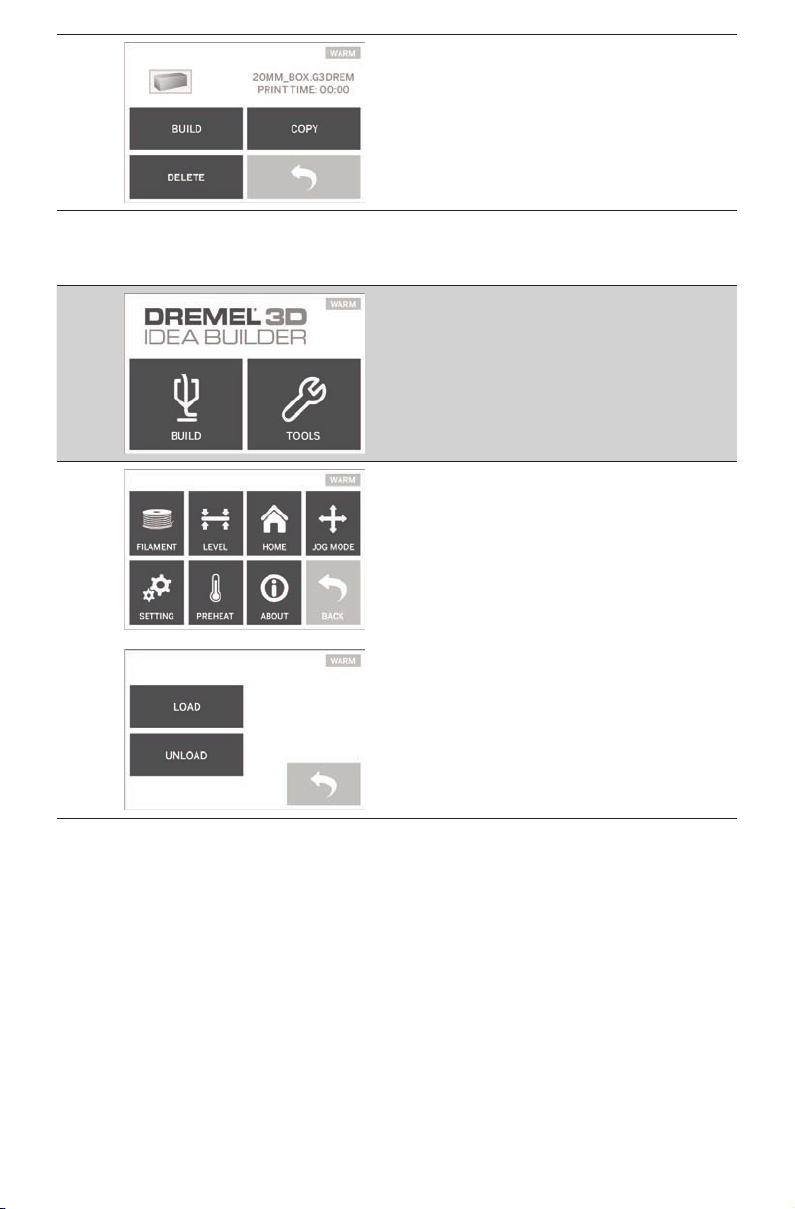

BUILD

Select a model le from your Dremel 3D20‘s

onboard memory by tapping the Dremel 3D20

icon or select a model le from SD card by

tapping the SD card icon.

After a model is selected, a pop-up window will

appear on the touch screen with the following

options:

BUILD

Tapping this option will begin the building

process while displaying useful information and

object status.

STOP – Tapping this option will cancel the

object.

You will be asked whether to cancel building or

continue building.

PAUSE – Tapping this option will pause the

building process. This will allow you to access

the “Tools” menu to unload or load lament.

PLAY – Tapping this option will exit the pause

mode and resume building your object.

11

Page 12

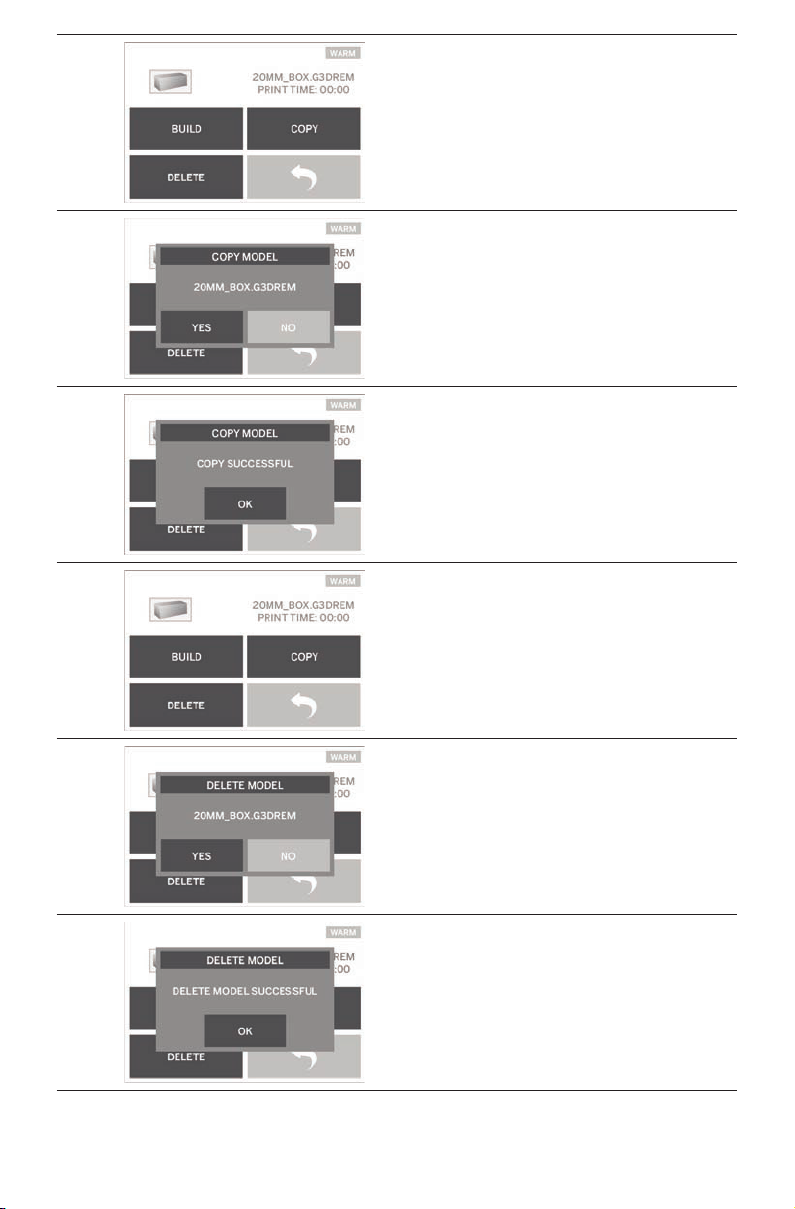

COPY

Tapping this option will allow you to copy a

model le from an SD card to your Dremel 3D20

onboard memory. You cannot copy a model le

from your Dremel 3D20 to an SD card.

COPY MODEL

Tapping this option will conrm your decision to

copy your model le from your Dremel 3D20’s

onboard memory or an SD card.

COPY MODEL SUCCESSFUL

A pop-up alert notifying you that the model le

has been successully copied.

DELETE

Tapping this button to permenantly delete the

selected model le from the onboard Dremel

3D20

memory drive or an SD card.

DELETE MODEL

A pop-up will ask you to conrm that you want to

permenantly delete a model le from your

Dremel

3D20’s onboard memory or an SD card.

DELETE MODEL SUCCESSFUL

A pop-up alert notifying you that the model le

has been successully deleted.

12

Page 13

RETURN

Return to previous menu.

TOOLS

FILAMENT

Load – Tapping this option will instruct your

Dremel 3D20 to begin heating the extruder for

loading lament (see page 19 for instructions

on loading lament). The touch screen will

display a status bar and will let you know when

it is time to load the lament.

Unload - Tapping this option will instruct your

Dremel 3D20 to begin heating the extruder

for unloading lament (see page 23 for

instructions on unloading lament). The touch

screen will display a status bar and will let you

know when it is time to unload the lament.

13

Page 14

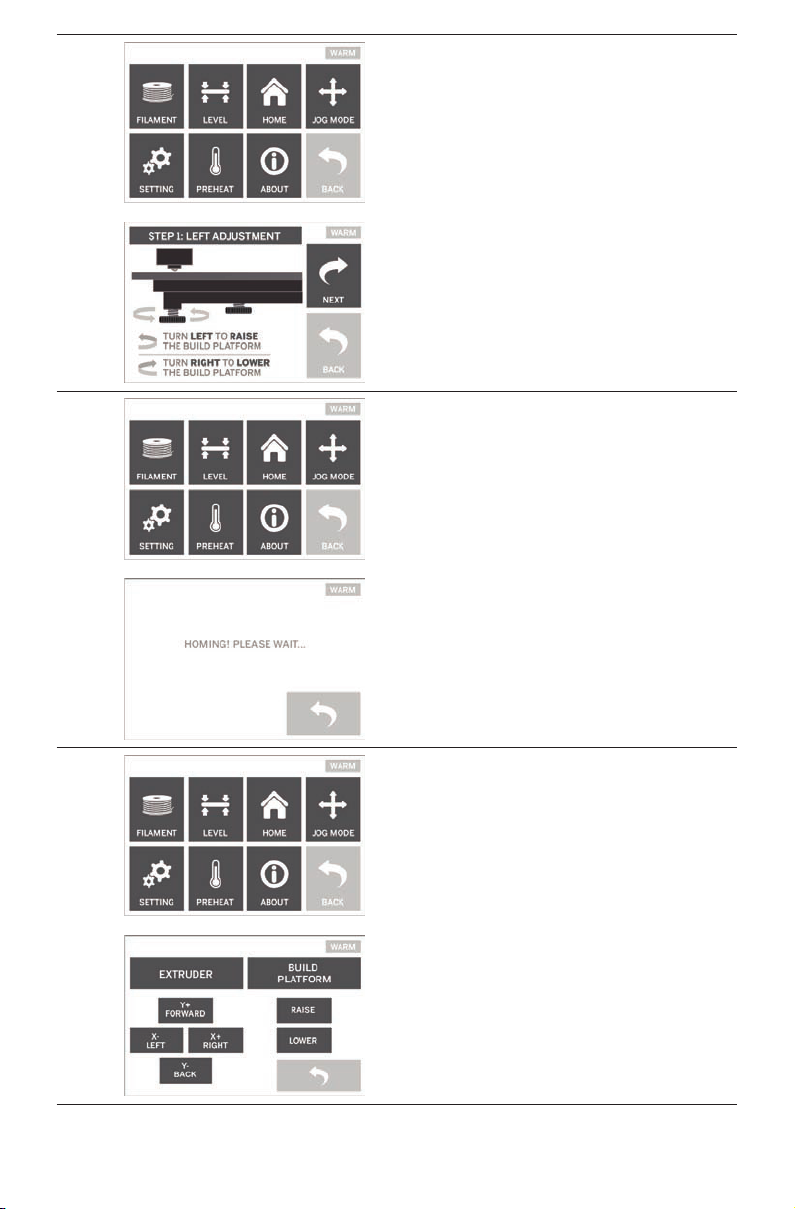

LEVEL

Tapping this option will begin the build platform

leveling process (see page 20 for instructions

on leveling the build platform). The touch screen

will display instructions on how to level the build

platform.

HOME

Tapping this option moves the extruder and build

platform to the zero position.

JOG MODE

Tapping this option will display the options for

positioning the extruder and build platform along

the X-axis, Y-Axis, and Z-axis.

14

Page 15

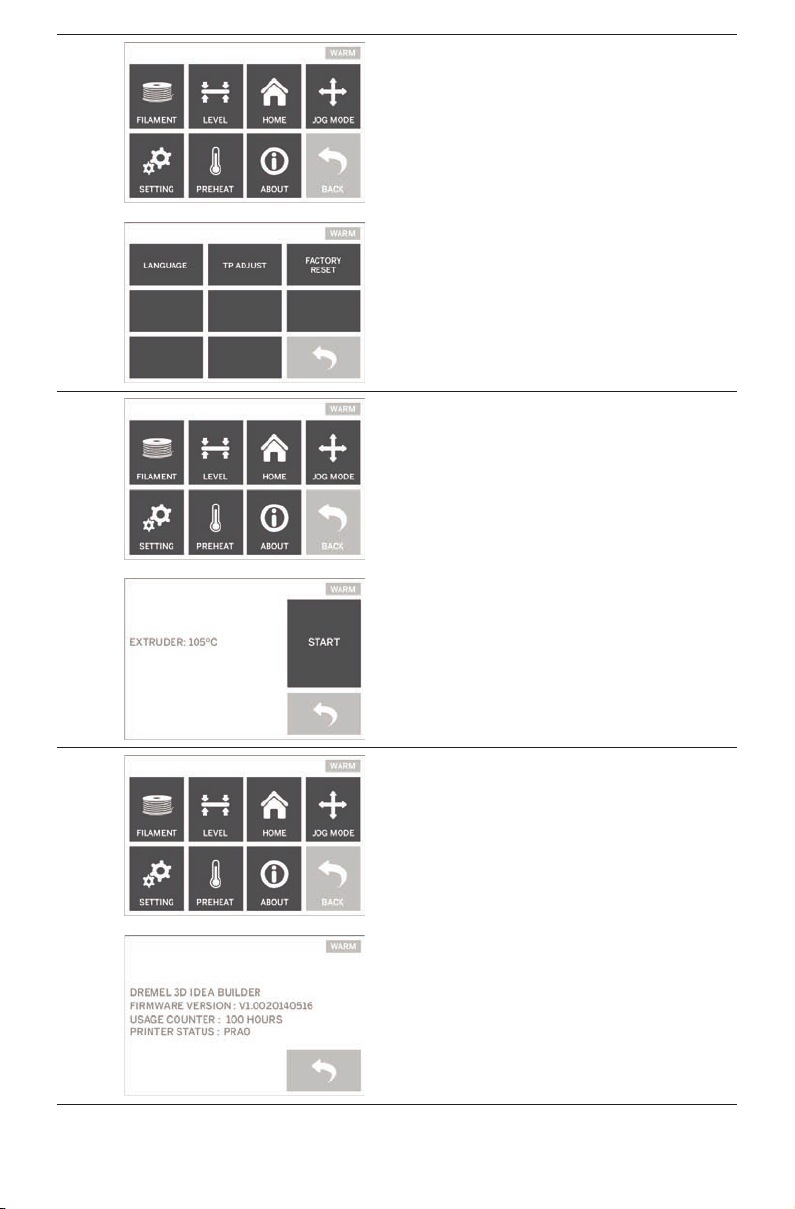

SETTING

Tapping this option will allow you to change the

manufacturer settings for language or revert

back to manufacturer settings.

PREHEAT

Tapping this option will begin preheating the

extruder for building or excess debris removal.

The touch screen will display the approximate

extruder temperature. You can use the touch

screen to START or STOP the preheating

process at any time.

ABOUT

Tapping this option will display your Dremel

3D20 serial number, current rmware version,

usage (hours), and the Dremel 3D20 status.

15

Page 16

SOFTWARE INSTALL AND

REGISTRATION

Creating an account on Dremel3D.com is easy and

gives you access to all of the great designs and

collections that will drive and inspire your creativity.

INSTALLING SOFTWARE FROM DREMEL3D.COM

1. Go to Dremel3D.com.

2. From a PC: Download and install software onto

your PC.

a. Download the Dremel 3D software from

Dremel3D.com.

b. Click on Dremel 3D_(version number).exe in the

folder location that you downloaded the le. The

install wizard will open.

c. Follow the prompts in the install wizard to load

the software on your computer.

3. From a MAC: Download and install software onto

your MAC.

a. Click Downloads and select Dremel 3D software.

Double click on the zip le and the Dremel 3D

INSTALLER.DMG will appear.

b. Double cl ick on Dremel 3D INSTALLER.DMG to

make a new window open. Drag the install le to

the APPLICATIONS folder.

c. If the “Drag to Install” window did not open,

locate the Dremel 3D driver in you device panel.

Click on Dremel 3D to download software.

NOTE: Safari users will not have to unzip the

INSTALLER.DMG le.

d. Click NEXT to launch the setup wizard. The

Dremel 3D software setup wizard will guide

you through the steps to install the software on

your computer. Click NEXT to launch the setup

wizard.

4. Create Dremel maker account on Dremel3D.com to

begin downloading Dremel 3D20 models.

RETURN

Rerurn to previous menu.

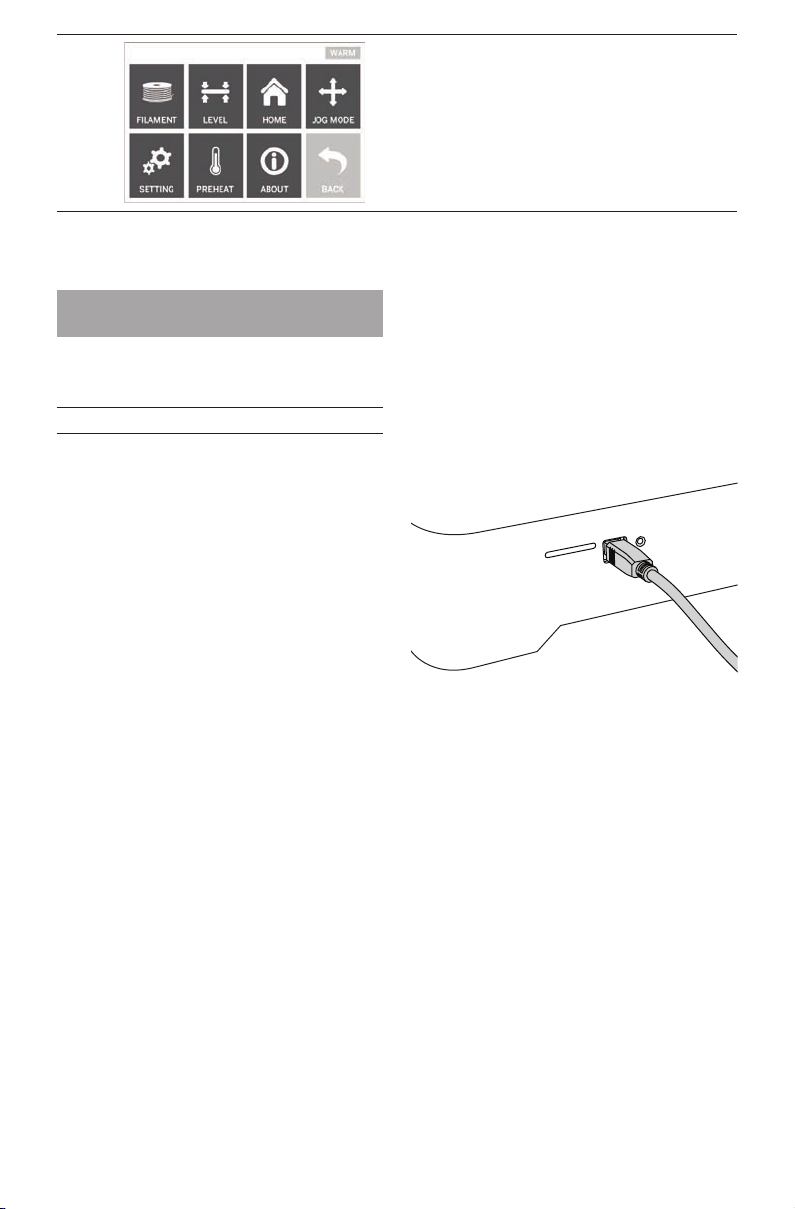

CONNECTING USB CABLE

1. Ensure power switch is in the off position.

2. Plug your Dremel 3D20 into the computer with the

USB cable.

3. Open software.

4. Turn your Dremel 3D20 on using the power switch

to sync your computer to your Dremel 3D20.

16

Page 17

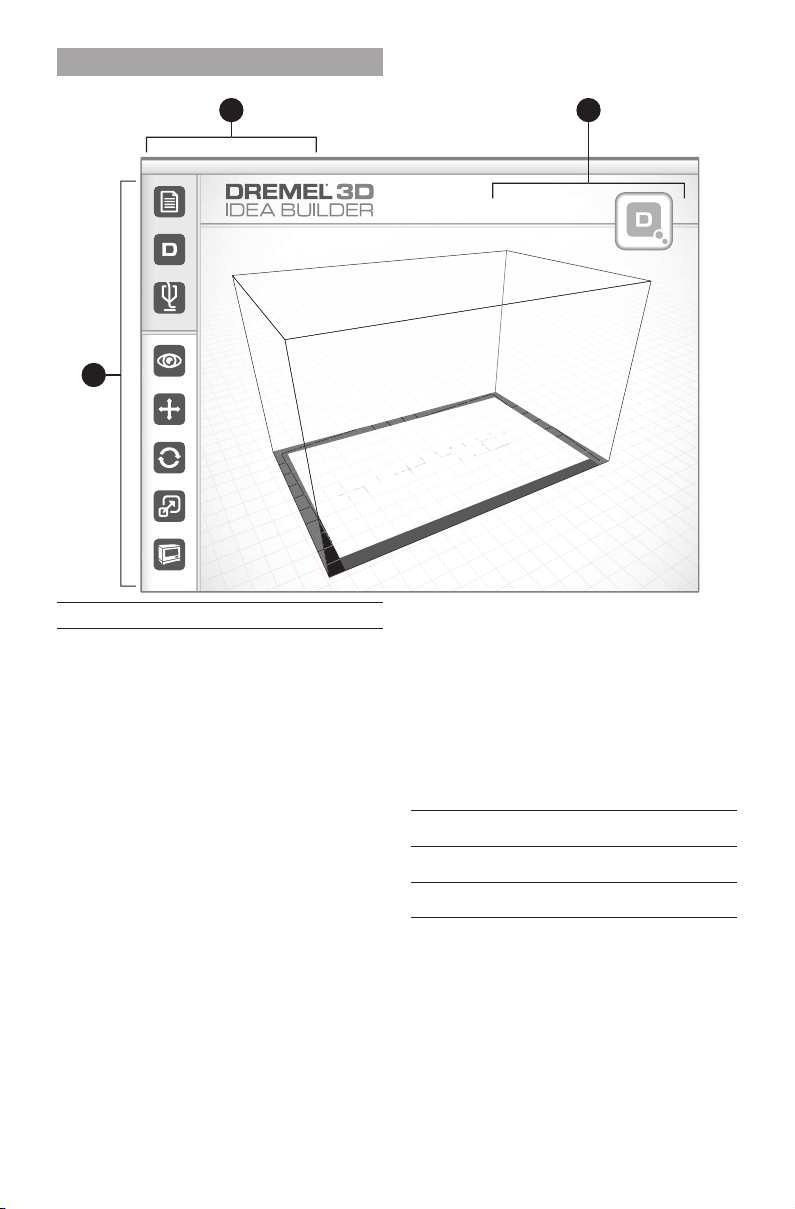

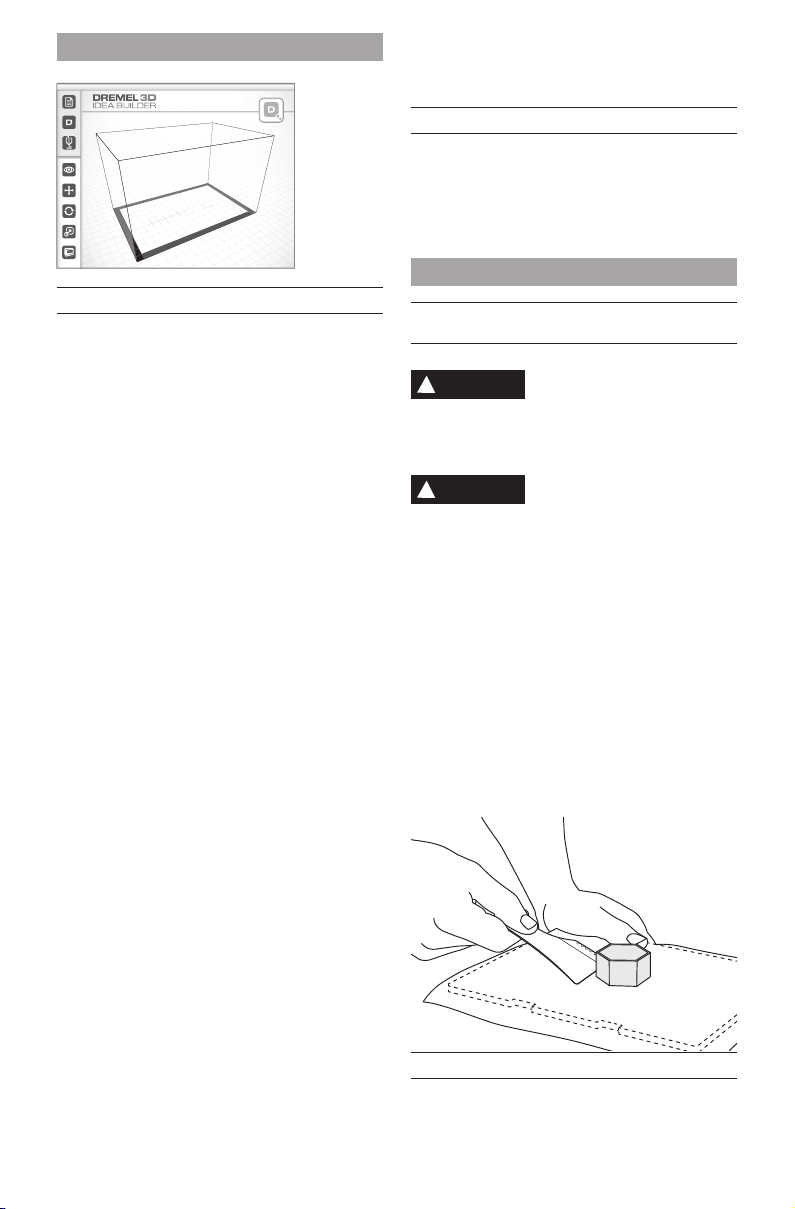

DREMEL SOFTWARE OVERVIEW

3 2

FILE EDIT BUILD VIEW TOOLS HELP

LOAD

3D ONLINE

BUILD

1

VIEW

MOVE

ROTATE

SCALE

IDEA BUILDER

TOOLBAR ICONS

The toolbar icons in the Dremel 3D Software lets you

load, share, build, view, move, rotate, and scale your

objects.

Load – Click on “Load” and select a le from the

model les downloaded from Dremel3D.com. The

model that you selected will appear on the Dremel

3D20 home screen. The software’s home screen is a

simulation of your Dremel 3D20’s build platform.

3D Store – Clicking on “3D Store” will connect you to

Dremel3D.com with your default internet browser.

Build – Dremel 3D Software gives you the ability

to select build quality settings. This allows you to

customize both the build quality and build time.

a. Export Option – Saves your model le to local

drive or portable memory drive for building later.

b. Resolution Options – Models set to Standard

resolution will be built using the default settings.

“Standard” resolution builds will build quickly and

have good surface quality. Models set to “Fast”

resolution will be built with thicker layers and will

build faster. Models set to “Detailed” resolution

will have ner layers and will build more slowly.

c. Support – Select this checkbox to have your

object built with support structures. Dremel

3D20 software will automatically generate

supports for any overhanging sections of your

object. Supports will be easily removable once

your nished object is removed from the build

platform.

View – Changes your view of the Dremel 3D20 home

STATUS : PRINTING

screen to one of six viewing angles.

TIP: You can view the Dremel 3D20 home screen

from any angle by holding the right click button of your

mouse and moving the mouse. You can also use your

mouse wheel to zoom in and out.

Move – Change your object location on the build

platform using X, Y, and Z axis positioning. You can

also center your object in the build area and ensure

that your object is located on the platform. You can

choose to enter a custom axis position value.

Moves the model to the left or right side of

X

the build area.

Moves the model to the front or back side of

Y

the build area.

Moves the model up and down in relation to

Z

the build platform.

a. On Platform – Places the model onto the build

platform.

b. Center – Centers the model on the 3D build

area.

c. Reset – Resets the model position to the

original position.

Rotate – Changes the orientation of your object on

the build platform using X, Y, and Z axis positioning.

You can choose to rotate your object +/- 90 degrees or

enter a custom axis position value. You can reset the

model to the original orientation.

Scale – Change the size of your object on the build

platform using X, Y, and Z positioning. You can choose

17

Page 18

to enter a custom scale value in X,Y, and Z. You can

also increase the size of your object by a percentage

of its original design.

Rotates the model towards or away from the

X

front of the build area.

Rotates the model towards the left or right

Y

side of the build area.

Rotates the model clockwise or

Z

counterclockwise in the build area.

a. Maximize - Uniformly scale the model to the

largest size possible for building.

b. Reset – Undo all scale changes. Model reverts

back to original size.

TIP: If your object was designed in using inches

(Imperial Units), you can convert to mm (metric) units

by increasing your object by 2540%.

Idea Builder – Check the status of your Dremel 3D20.

As long as your Dremel 3D20 is connected to your

computer you can see whether your Dremel 3D20 is

ready to build or currently building an object. You can

also see the temperature of your extruder.

BUILD STATUS

Dremel 3D software continuously provides you with the

status of your Dremel 3D20.

a. The top panel displays the current status of both

your Dremel 3D20 and your object.

b. The status circle located in the top right corner

provides a graphical representation of your

progress.

MENUS

File Menu

a. Load File – Select this option to load a model le

(.STL or .3dremel) from your computer or external

storage device connected to your computer. Once

you have loaded the model le you can begin

editing the le as desired.

NOTE: You cannot load a model le to your

computer from an SD card connected to your

Dremel 3D20. SD card must be connected direct ly

to your computer.

b. Save Build Platform – Saves all of the objects

and layout of the current build platform to a

.3dremel le. Select this opt ion to save a model

f i le to your computer or external storage device

connected to your computer.

NOTE: You cannot save a model le to an SD card

connected to your Dremel 3D20. SD card must be

connected directly to your computer.

c. Save as… - Saves current build platform with new

name. This will not overwrite the original .3dremel

le.

d. Examples – Select this option to view a list of

free model les that are included with your Dremel

3D software. These model les are excellent test

objects to ensure your Dremel 3D20 is working

properly.

e. Recent Files – Select this option to view a list of

recently viewed model les.

f. Preferences – Select this option to set the

language of your Dremel 3D software and change

the automatic update setting.

g. Quit – To close the Dremel 3D software, click on

the “X” in the upper right corner. If you have a

model le open the software will ask you if you

want to save your model le before closing.

Edit Menu

a. Undo – Select this option to undo the most recent

edit you made to your model le. Selecting this

option multiple times will continue to undo edits in

reverse order in which they were performed.

b. Redo – Select this option to redo the most recent

edit you have undone to your model le. Selecting

this option multiple times will continue to redo edits

in reverse order in which they were removed.

c. Select All – Select this option to select all of the

model les that you have loaded to the 3D Build

Home Screen.

d. Duplicate – Select this option to duplicate a

selected model le.

e. Delete – Select this option to delete a selected

model le.

Build Menu

NOTE: The power to your Dremel 3D20 must be

turned on for your Dremel 3D20 to be recognized.

a. Disconnect – Select this option to disconnect your

Dremel 3D20 from your computer.

b. Build – Select this option to convert your work to a

buildable le. You will be asked to save your model

in a .3dremel le format so that your Dremel 3D20

can begin building.

View Menu

a. Change your view of the 3D Build home screen to

one of seven viewing angles.

b. Show Model Outline – This view will highlight the

outer surfaces of your model le to improve viewing

of your model.

c. Show Steep Overhang – This view will highlight

areas of your object that have steep angles that

may require supports.

Tools Menu

a. Control Panel – Select this option for manual

diagnostics of your Dremel 3D20. Your Dremel

3D20 must be connected to your computer to view

this menu.

b. Update Firmware – Al lows you to update your

Dremel 3D20 with the latest rmware. To update

the Dremel 3D20 rmware, connect a USB cord

to the computer and Dremel 3D20. Click the latest

version of the rmware and choose upload. The

rmware will update on the Dremel 3D20. After the

rmware has successfully updated, you need to

reboot (turn off and back on) the machine.

Note: Firmware updates will be automatically

downloaded when the Dremel 3D software is

started. You will be informed that a new version of

the rmware is available.

Help Menu

a. Help Contents – Select this option to be directed

to www.Dremel3D.com help and support contents.

b. Check for Update – Select this option to manually

check for Firmware and Software updates.

c. About – Select this option to review the current

software version you are running for Dremel 3D.

18

Page 19

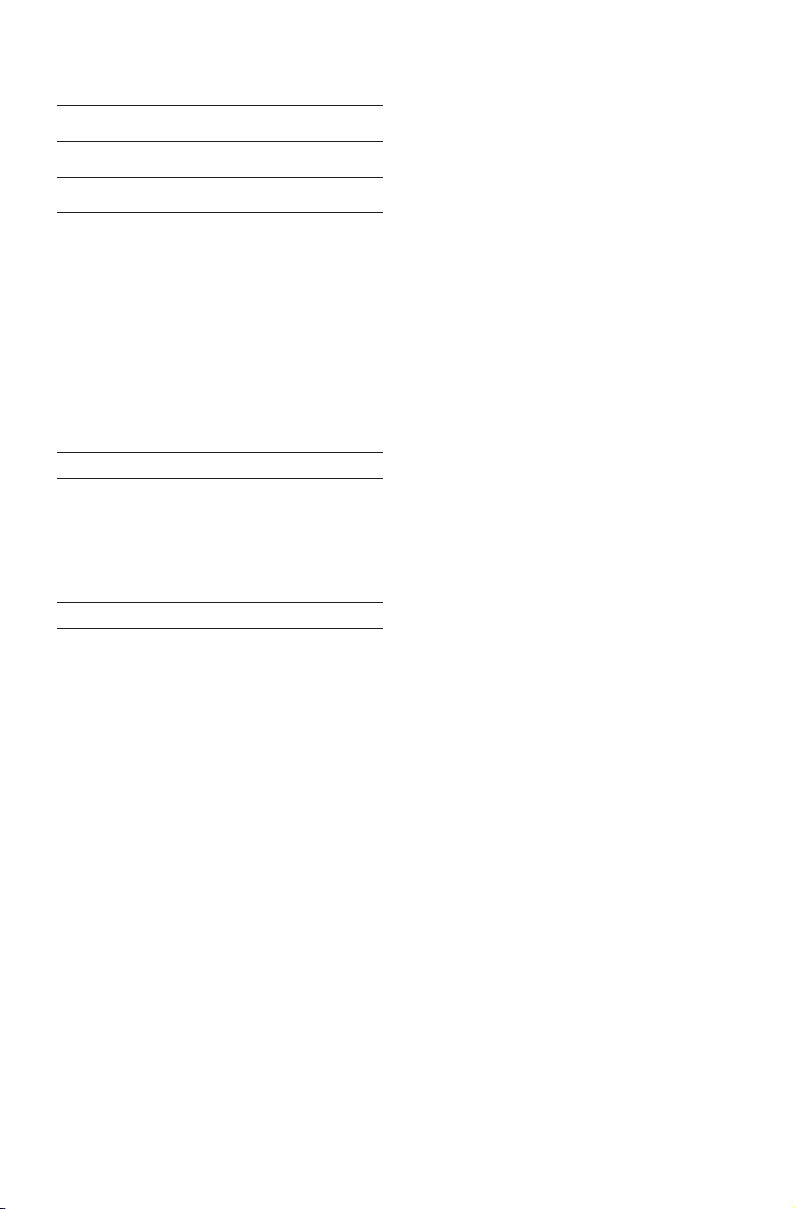

GETTING READY TO BUILD

WARNING

!

INSTRUCTIONS WHEN USING THE DREMEL 3D20.

FAILURE TO DO SO MAY RESULT IN FIRE,

EQUIPMENT DAMAGE, PROPERTY DAMAGE OR

PERSONAL INJURY.

1. Ensure the power switch is in the off position.

2. Remove the Dremel 3D20 lid for better access to

extruder and build platform.

3. If build platform is installed, remove by pinching the

clamp located at the front of the build platform and

lifting the build platform off the base.

OBSERVE ALL PROVIDED

WARNINGS AND SAFETY

PRESS

LEFT

b. Insert spool lock into spool holder and rotate 90

degrees to lock in place.

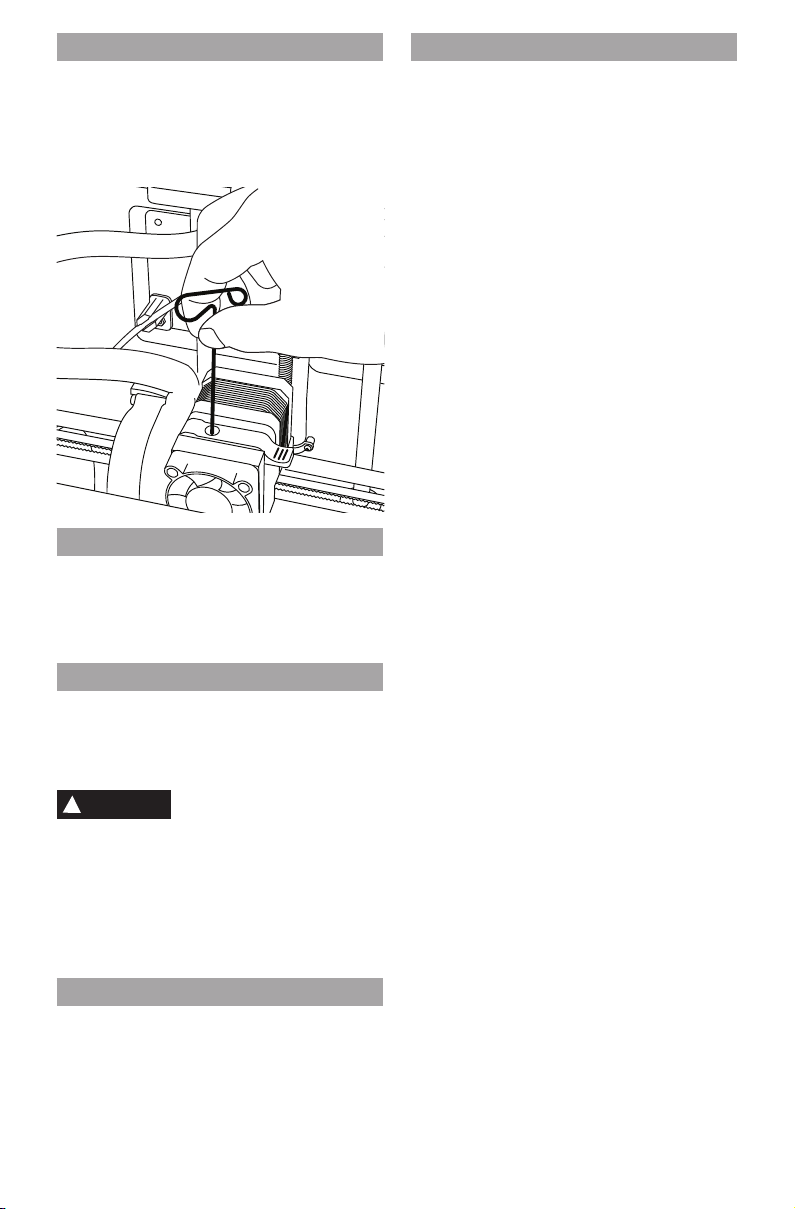

5. Thread lament through lament guide tube. The

lament can then be inserted into the extruder

intake (Manual Image 8-10). This will ensure the

extruder experiences minimal resistance while

building.

Filament guide

6. Place Build Tape over Build Platform.

4. Mount lament spool to spool holder and secure

with with spool lock.

a. Place lament spool onto spool holder with

spool being fed from the bottom towards the

back of the Dremel 3D20.

End of lament

7. Install the build platform using the build platform

clip to secure.

8. Plug power cord into outlet and turn on Power

Switch (Dremel 3D20 will take approximately

30 seconds to properly warm up).

9. Tap “Tools” on your Dremel 3D20’s touch screen

then tap “Filament”, then tap “Load Filament”.

10. Insert the lament coming from the lament guide

tube into the extruder intake (top). Tap “Next”.

19

Page 20

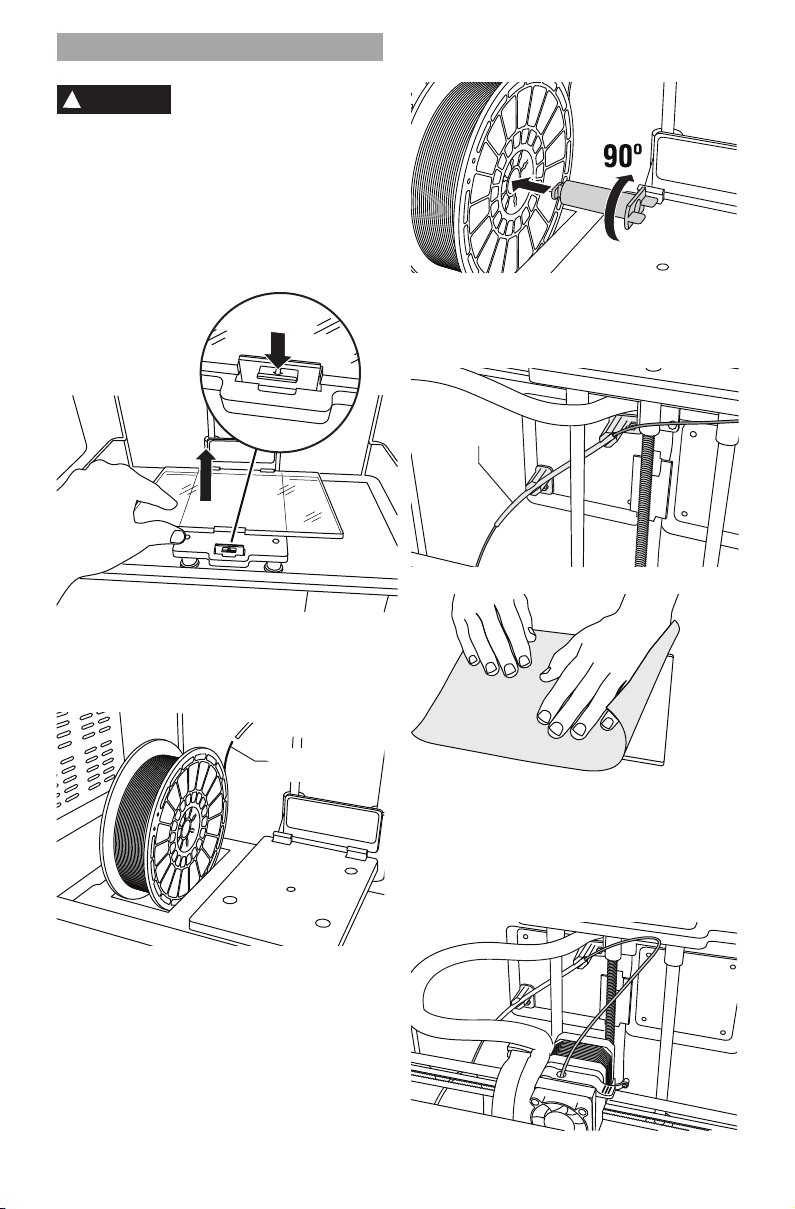

11. Your Dremel 3D20 will begin to heat the extruder.

The Dremel 3D20 touch screen display will update

you when extruder is “HOT” and ready to load.

12. Once your Dremel 3D20 is ready to begin

extruding, gently guide the lament into the

extruder until it feeds through on its own.

WARNING

!

OPERATION OR UNTIL IT HAS COOLED DOWN TO AT

LEAST 60°C (140°F). CONTACT WI TH THE

EXTRUDER TIP DURING OR AFTER OPERATION

BEFORE TIP HAS COOLED MAY RESULT IN

PERSONAL INJURY.

13. Filament will then be drawn into the extruder and

begin to exit from the heated tip at the bottom of

the extruder. After the lament has extruded from

the heated tip, press the return arrow to complete

the loading process. Carefully remove excess

lament without touching the hot extruder tip.

NOTE: Your Dremel 3D20 was tested by building

objects before leaving the factory. These test

objects may have been made with a different

lament color than you are using. Therefore, a

small amount of lament may be remaining in the

extruder. When loading lament for the rst time

make sure to allow lament to exit the extruder

until your lament color is consistently visible.

CAUTION: Use extra care to not damage the

extruder tip when clearing debris. Dremel 3D20 will

not work properly with damaged extruder tip and

will require replacement.

14. After lament has been loaded, ensure the extruder

tip is clear of any debris. Carefully remove debris

with needle nose pliers to ensure the extruder tip

is clean.

15. If lament does not get pulled into the extruder or

does not come out of the extruder tip, tap “Cancel”.

Tap “Setup” then tap “Unload Filament”. Once your

Dremel 3D20 alerts you it is ready, gently remove

the lament from the top of the extruder and repeat

the lament installation steps above. Reference

troubleshooting section for further advice.

DO NOT TOUCH THE EXTRUDER

TIP DURING DREMEL 3D20

BUILD PLATFORM PREPARATION

WARNING

!

OPERATION OR UNTIL IT HAS COOLED DOWN TO

60°C (140°F). CONTACT WITH THE EXTRUDER TIP

DURING OR AFTER OPERATION BEFORE TIP HAS

COOLED MAY RESULT IN PERSONAL INJURY.

DO NOT TOUCH THE EXTRUDER

TIP DURING DREMEL 3D20

CAUTION: Before every build make sure that the build

platform is covered with Dremel specied build tape.

Use of improper build tape may result in equipment

damage and poor object build quality.

LEVELING BUILD PLATFORM

It is important you level the build platform every time

you replace the build tape or reinstall the build platform

to ensure that the build platform is evenly spaced

from the extruder head. Make sure to remove any air

bubbles from between the build platform and the build

tape. Not leveling the build platform or eliminating air

bubbles may cause objects to not build properly.

Wait for the extruder head to cool to at least 60C

(140F) before leveling build platform. Extruder

temperature can be monitored on the touch screen.

(See page 11.)

1. Make sure you have placed build tape over the

build platform. Applying build tape to the build

platform after leveling may effect the consistency

of your object.

2. Tap “Tools” on your Dremel 3D20’s touch screen

and tap “Level”. (See page 14.)

3. The extruder and build platform will move into

position to level the build platform. You will rst

level the front left section of the build platform. The

three knobs under build platform are used to raise

or lower the build platform on the left, right, and

rear of the build platform.

4. Place the level ing tool between the extruder and

build platform. If the leveling tool cannot slide

between the extruder and build platform, adjust

the appropriate knob (turning counterclockwise)

until you can slide the leveling tool between the

extruder and build platform with some resistance.

If the leveling tool can slide between the extruder

and build platform too easily, adjust the appropriate

knob (turning clockwise) until you can slide the

leveling tool between the extruder and build

platform with some resistance.

20

Page 21

TIP: Standard printer paper can also be used to

!

level the build platform in the same manner as the

leveling tool.

5. Tap “Next” to move the build platform toward the

right knob and repeat step 4 above.

6. Tap “Next” to move the build platform toward the

rear knob and repeat step 4 above.

7. Tap “Finish” to complete the leveling process.

8. Repeat steps 1 through 6 above to ensure that

build platform is completely level.

BUILDING

BUILDING FROM THE SD CARD

1. Insert SD card containing your model into the

SD port located on the right side of your Dremel

3D20. Your Dremel 3D20 comes with an SD

card containing free model les ready to be built.

Additionally, you can save new .G3Drem les to

your SD card from the accompanying Dremel 3D

software.

WARNING

INSTRUCTIONS WHEN USING THE DREMEL 3D20.

FAILURE TO DO SO MAY RESULT IN FIRE,

EQUIPMENT DAMAGE, PROPERTY DAMAGE OR

PERSONAL INJURY.

NOTE: Your Dremel 3D20 will build test objects before

leaving the factory. These test objects may have been

made with a different lament color than you are

using. Therefore, a small amount of lament may be

remaining in the extruder. The start of your rst object

may have some of this lament color until it transitions

over to your lament color.

You have 2 options when building on your Dremel

3D20:

1. SD Card - Build directly from the SD card. The

SD card comes wi th model les installed at the

factory. You can plug this directly into your builder

and begin building right away. Additionally, you can

save new .G3Drem les to your SD card from the

Dremel 3D software.

2. Computer – Build direct ly from your computer

through the USB cable.

FILE EDIT BUILD VIEW TOOLS HELP

LOAD

3D ONLINE

BUILD

VIEW

MOVE

ROTATE

SCALE

IDEA BUILDER

OBSERVE ALL PROVIDED

WARNINGS AND SAFETY

STATUS : PRINTING

2. Ensure an adequate amount of lament is loaded

(see page 19).

TIP: You can determine whether you have enough

lament to complete your object before building by

weighing the lament and spool then subtracting

the weight of the empty spool. The Dremel 3D

software will display the approximate weight of

each model.

NOTE: You cannot edit model les directly on

the Dremel 3D20. Ensure that you are building

.G3Drem les when building directly from SD card.

3. Ensure build tape is applied and build platform is

leveled (see page 20).

4. Tap “Build” on the touch screen, tap the SD card

option, and use the up/down arrows to scroll.

5. Tap on the model le you would like to build.

6. Your Dremel 3D20 will rst align the extruder and

build platform. Your Dremel 3D20 will then begin

the heating process which may take a few minutes.

During the heating process, the extruder will reach

the temperature required for proper building with

PLA. Once this temperature is reached, your model

will begin to build.

7. Once the object is nished building, your touch

screen will display “Object Finished”. Tap the check

box to conrm.

8. Wait until the touch screen indicates that the

extruder temperature is “COOL” to remove you

object . See section for removing you object

from the build platform below for object removal

instructions.

CANCELLING YOUR OBJECT ON DREMEL 3D20

To cancel your object during warm up or building, tap

the “STOP” button on touch screen. The next screen

will read, “Cancel build now?” Tap the “Yes” to cancel

or tap “No” box to abort the cancel command. Wait

until the extruder and build platform completely cools

before reaching inside the build area.

21

Page 22

BUILDING FROM YOUR COMPUTER

!

FILE EDIT BUILD VIEW TOOLS HELP

LOAD

3D ONLINE

BUILD

VIEW

MOVE

ROTATE

SCALE

IDEA BUILDER

BUILDING DIRECTLY FROM COMPUTER

1. Install Dremel 3D software to your computer. See

“Software install and Registration” on page 16 for

details. Ensure that you have administrative rights

to your computer to properly install the Dremel 3D

software.

2. Connect your Dremel 3D20 to your computer with

the USB cable supplied with your Dremel 3D20.

3. Ensure an adequate amount of lament is loaded

(see page 19).

TIP: You can determine whether you have enough

lament to complete your object before building by

weighing the lament and spool then subtracting

the weight of the empty spool. The Dremel 3D

software will display the approximate weight of

each model.

4. Prepare build platform (see page 20).

5. Open Dremel 3D Software. Your computer is now

connected to your Dremel 3D20.

6. Click on “Load” and select a le from the model

les downloaded from Dremel3d.com or approved

STL or G3DREM le. The object that you selected

will appear on the Dremel 3D software home

screen. The Dremel 3D software’s home screen is

a simulation of your Dremel 3D20’s build platform.

7. In the software you can view, move, rotate, and

scale your object to ensure that you obtain the

optimum results.

8. To prepare your model le, click on “Build” and

save your model le. Immediately after you have

completed build setup and saved the le, the

Dremel 3D software will being preparing your

model le.

9. After your model le has been prepared, click

“Build” to begin building process.

a. If the Dremel 3D software has not already

detected your Dremel 3D20, then you will be

prompted to select the USB port being used by

your Dremel 3D20. Select the correct port and

click “OK”.

b. Click “Rescan” if the USB port your Dremel

3D20 is using is not shown. Repeat step 10-a.

10. Your Dremel 3D20 will rst align the extruder and

build platform. Your Dremel 3D20 will then begin

the heating process which may take a few minutes.

During the heating process, the extruder will reach

the temperature required for proper building with

PLA. Once this temperature is reached, your model

will begin to build.

11. Once the object is nished building, your touch

screen will display “Object Finished”. Tap the check

box to conrm.

12. Wait until the touch screen indicates that the

STATUS : PRINTING

extruder temperature is “COOL” to remove your

object. See “Removing your object from the

build platform” section below for object removal

instructions.

CANCELLING YOUR OBJECT ON DREMEL 3D20

To cancel your object during warm up or building, tap

the “STOP” button on touch screen. The next screen

will read, “Cancel build now?” Tap the “Yes” to cancel

or tap “No” box to abort the cancel command. Wait

until the extruder and build platform completely cools

before reaching inside the build area.

REMOVING YOUR OBJECT

REMOVING YOUR OBJECT FROM THE BUILD

WARNING

PROTECTIVE EQUIPMENT SUCH AS HEAT

RESISTANT GLOVES AND SAFETY GLASSES WILL

REDUCE PERSONAL INJURIES.

WARNING

!

TOOLS TO REMOVE OBJECTS FROM THE BUILD

PLATFORM. SUDDEN TOOL SLIP AND IMPROPER

BODY POSITION DURING OBJECT REMOVAL FROM

THE BUILD PLATFORM MAY RESULT IN PERSONAL

INJURY.

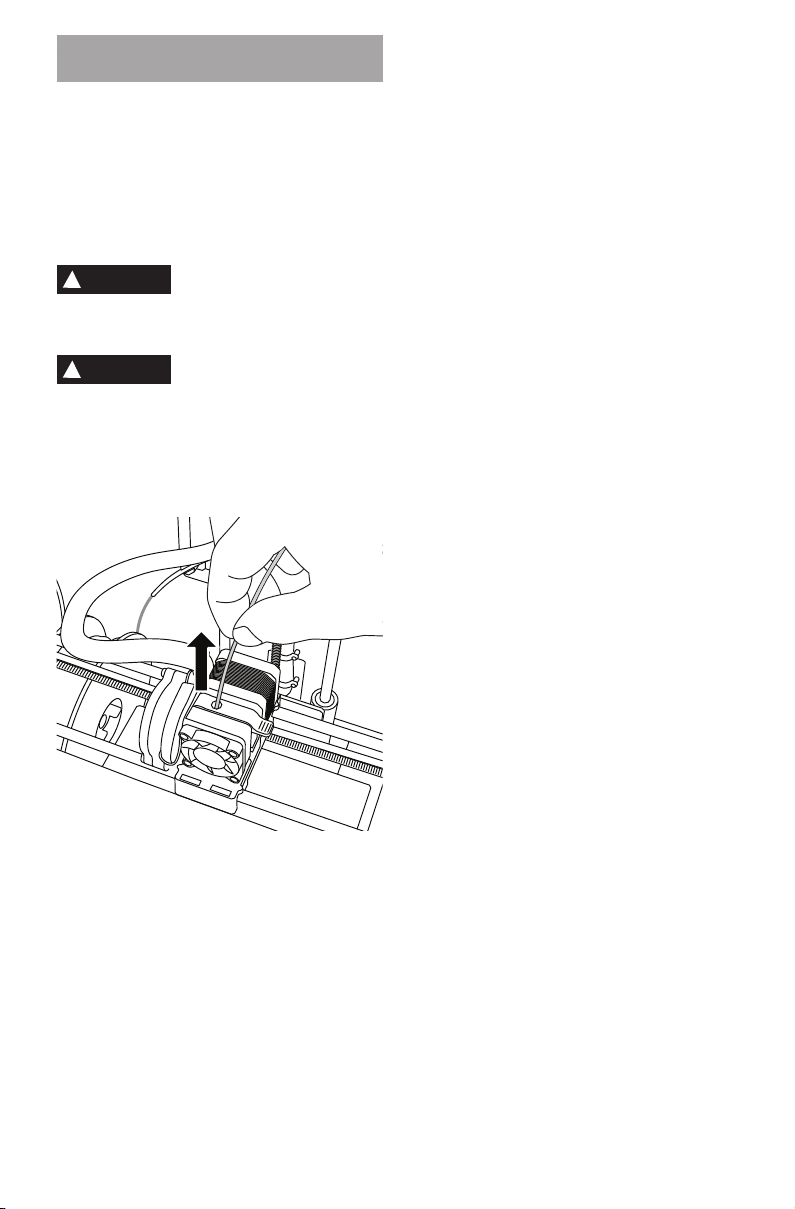

CAUTION: Avoid scratching the build platform when

removing objects. Scratches in the build platform will

result in improper object creation.

1. Wait for the extruder to cool before removing your

object.

2. With the object still attached, remove build platform

from the build area.

3. Peel your object from the build platform. If needed,

gently use the object removal tool to remove object

from build platform. If desired, remove the build

tape from the build platform while separating the

object from the build platform. The build tape can

then be removed from the object.

REMOVING SUPPORTS (IF REQUIRED)

Use small needle nose pliers to remove supports. In

places where the supports are inside your object and

are hard to reach.

22

PLATFORM

USE PERSONAL PROTECTIVE

EQUIPMENT. THE USE OF

BE AWARE OF YOUR BODY

POSITION WHEN USING HAND

Page 23

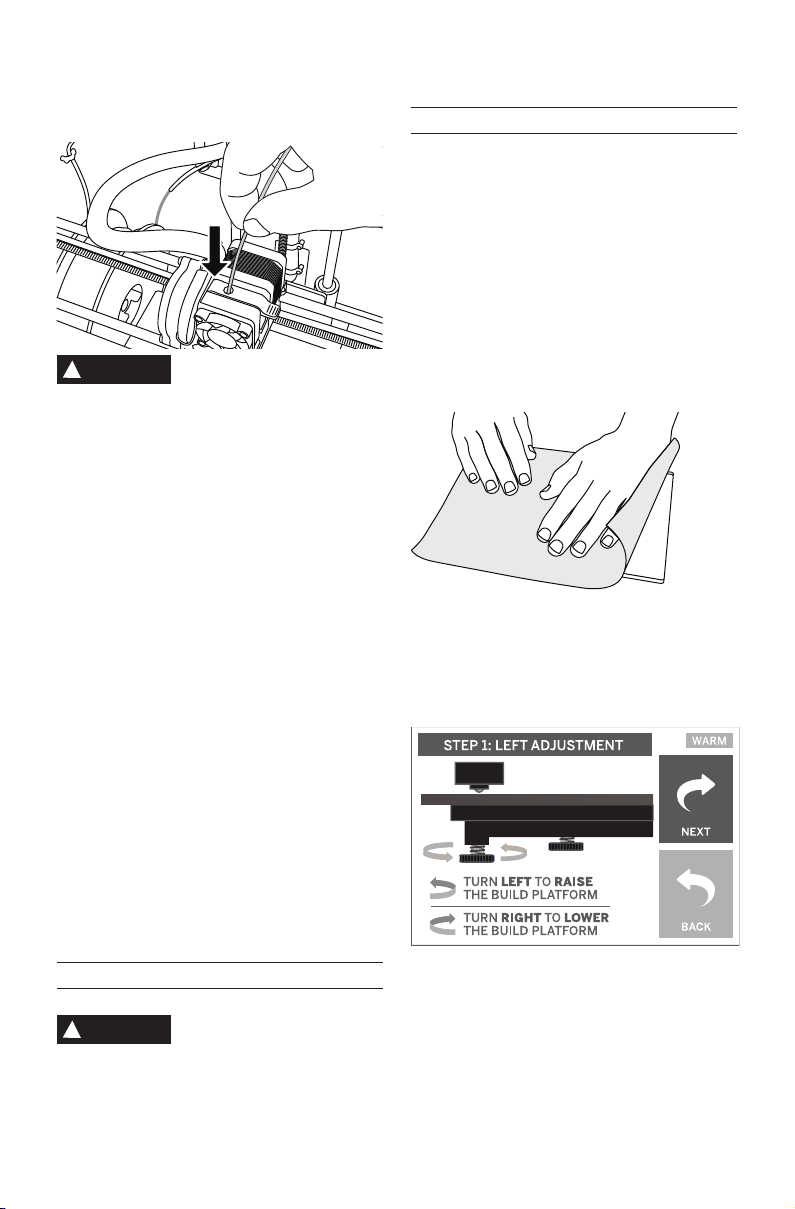

UNLOADING AND REPLACING

FILAMENT SPOOL

CAUTION: Do not change color of lament or spool

during building. Doing so will cancel the object and

may damage the extruder.

1. Tap “Setup” on your Dremel 3D20’s touch screen

then tap “Filament”.

2. Tap “Unload”.

3. Your Dremel 3D20 will begin to heat the extruder

and will play an alert tone when it is ready to

unload the lament.

WARNING

!

TOUCH SCREEN. DOING SO MAY DAMAGE THE

EXTRUDER.

DO NOT PULL THE FILAMENT

OUT UNTIL INSTRUCTED BY THE

lament is present, it will exit from the extruder tip.

6. See “Filament Installation” instructions on page

19 to install replacement lament spool.

WARNING

!

OPERATION OR UNTIL IT HAS COOLED DOWN TO AT

LEAST 60°C (140°F). CONTACT WITH THE EXTRUDER

TIP DURING OR AFTER OPERATION BEFORE TIP

HAS COOLED MAY RESULT IN PERSONAL INJURY.

4. Once your hear the alert tone, gently pull the

lament out of the extruder until it is completey

separated from the extruder.

NOTE: A small amount of lament may be

remaining in the extruder. The start of your next

object may have some of this lament color until

it transitions over to your lament color. Allow

replacement lament to fully extrude before

beginning next object to ensure consistent color.

5. If lament cannot be easily pulled out of the

extruder, tap the return arrow. Tap “Setup” then tap

“Preheat”. Select maximum temperature and al low

15 minutes to heat. After 15 minutes of heating,

tap the “Arrow” button and repeat steps 1 through

5 above.

NOTE: After the lament is pulled out from the

extruder, lament may be visible at the extruder tip.

The lament debris remaining should be removed

using the unclog tool to prevent clogging. To

remove the remaining lament insert the unclog

tool’s point into the extruder intake (top); if any

DO NOT TOUCH THE EXTRUDER

TIP DURING DREMEL 3D20

23

Page 24

MAINTENANCE AND SERVICE

Problem Cause Corrective Action

Extruder head building off center Dremel 3D20 has lost track of the

PLA is not extruding or sticking to

the build tape properly

Dremel 3D software froze during

use or computer froze.

Dremel 3D20 froze before my

object started.

3D le loads with a warning stating

that the le is not closed.

Support material does not break

away during cleaning and results

in decreased quality of the nal

object.

Spaghetti mess at end of build. A layer of your object did not stick

Part only built halfway. Filament ran out.

No lament coming out Clogged extruder Use unclog tool to push through

Extruder will not home Limit switch wire failure Contact customer service.

Stringy or fraying plastic layers on

steep overhangs

extruder head’s exact location and

is failing to build.

This can be caused by the build

platform not being leveled with the

extruder head.

Sometimes software isn’t as smart

as you are and locks up.

Dremel 3D20 may have received

conicting commands.

3D le has not been properly

designed and has open surfaces.

Orientation of the part is not

optimized.

properly, model was saved with

minimal surface area contacting the

build platform, or object was built

oating above the build platform

with no support selected.

Filament clogged during build.

Object overhangs are too far apart

or too steep (<45degree angle).

Sending the extruder head to the

home position will recalibrate the

Dremel 3D20. Cancel your object,

clear build platform, send the

extruder head to the home position,

and restart the object.

Leveling the build platform will align

the extruder head and ensure a

better object quality. Cancel your

object, clear build platform, level

the build platform, and restart the

object.

Save any open les if possible

and either restart the Dremel 3D

software or your computer.

Turn power switch off, wait 30

seconds, and turn power switch on.

Open 3D le in a CAD editing

software to close all the open

surfaces.

Reorient the position of the 3D

le in Dremel 3D to minimize

the support material or place the

support material on a non-critical

surface.

Use the preview future in Dremel

3D to see the rst layer height and

position. Build with supports when

necessary.

Replace lament and start build

over.

See “No lament coming out”.

lament.

Contact customer service.

Build with supports.

24

Page 25

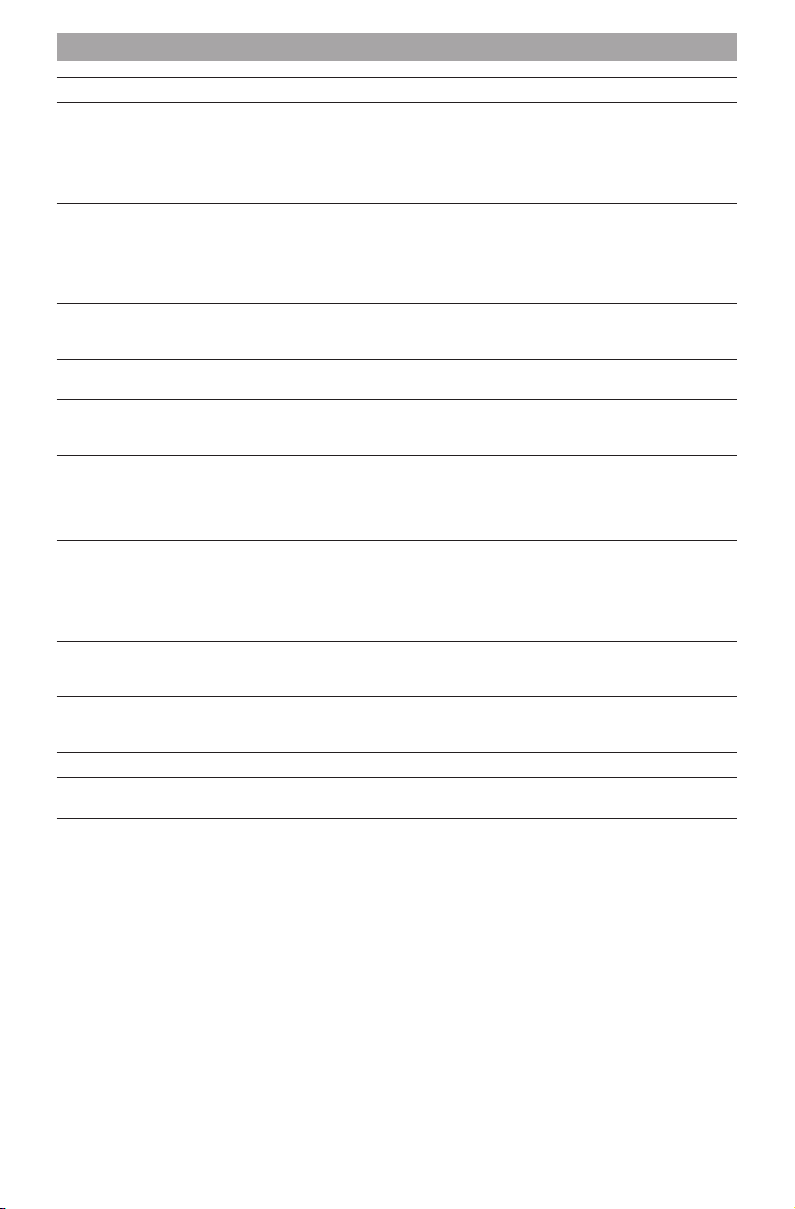

UNCLOGGING THE EXTRUDER

!

BEST PRACTICES

Use the unclogging tool to clean the extruder and

unclog built up lament.

1. Wait for extruder to heat up insert the unclog tool

into the extruder intake (top).

2. Clogged debris will be pushed down and will

extrude from the extruder tip.

CLEANING THE EXTERIOR

Clean the 3D20’s exterior with a lint free cloth. Clear

the outer surfaces of any debris that is visible.

To avoid damaging your Dremel 3D20 do not use

water, chemicals or other cleaners on the 3D20.

CLEANING THE EXTRUDER TIP

CAUTION: Use extra care not to damage the extruder

tip when clearing debris. Dremel 3D20 will not work

properly with damaged extruder tip and will require

replacement.

WARNING

OPERATION OR UNTIL IT HAS COOLED DOWN TO

60°C (140°F). CONTACT WITH THE EXTRUDER TIP

DURING OR AFTER OPERATION BEFORE TIP HAS

COOLED MAY RESULT IN PERSONAL INJURY.

Using small needle nose pliers, pull away any plastic

debris from the extruder tip.

If the debris is stubborn, the extruder may need to be

heated to make the debris soft enough to remove.

DO NOT TOUCH THE EXTRUDER

TIP DURING DREMEL 3D20

1. ALWAYS USE BUILD TAPE.

2. Ensure your build platform is level before every

object.

3. Ensure spool is installed properly and can rotate

freely.

4. When using your Dremel 3D20 for the rst time

or after changing lament, allow Dremel 3D20 to

extrude until material is consistent with the installed

lament color.

5. It is important to watch your Dremel 3D20 begin

building objects. Your object is most likely to

experience difculty in the beginning. Thankfully,

this is also the most convenient time to cancel

the object, clean the build platform, and start your

object again. Remain near the Dremel 3D20 during

the building process.

6. It is important to save you Dremel 3D20 packaging

as it will make re-boxing and transporting your

Dremel 3D20 easier.

7. Ensure that you store lament spools in an

environment that is not moist or too hot. It is

recommended that you do not remove the lament

spool from its airtight packaging until use.

8. Use object removal tool gently to avoid damaging

the build platform or object.

9. Whenever possible, it is best to locate your object

in the center of the build platform. Using the best

orientation for your object is critical. Ensure that

your object is located on the build platform and that

you are using the best orientation for building.

10. For steep overhangs (Less than 45 degree angle) it

is recommended to build with support.

11. To prevent build tape from peeling during the build,

wrap the build tape underneath the build platform.

12. Always remove the build platform before removing

the object.

13. Use the home feature before unloading and

loading a lament spool. Also, it is recommended

to remove the bui ld platform before unloading or

loading a lament spool.

14. Low speed sanding is recommended to prevent

remelting of the object.

15. The Dremel 3D software will display the weight of

each model. You can determine whether you have

enough lament to complete your object before

building by weighing the lament and spool then

subtracting the weight of the spool.

CLEANING THE TOUCH SCREEN

Wipe the touch screen with the soft, lint-free cloth. Do

not spray cleaners on the touch screen.

25

Page 26

®

DREMEL

CONSUMER LIMITED

WARRANTY

This DREMEL product is guaranteed in accordance

with statutory/country-specic regulations; damage due

to normal wear and tear, overload or improper handling

are excluded from the warranty.

In the event of the product fails to conform to this

written warranty, please take the following action:

1. DO NOT return your product to the place of

purchase.

2. Please contact customer service via

www.dremel.com for further instructions.

DISPOSAL

The machine, accessories and packaging should be

sorted for environmental-friendly recycling.

ONLY FOR EC COUNTRIES

Do not dispose of power tools with household

waste!

According the European Guideline 2012/19/

EC for Waste Electrical and Electronic

Equipment and its implementation into national law,

power tools that are nolonger usable must be collected

separately and disposed of in an environmentally-

correct manner.

CONTACT DREMEL

For more information on the Dremel product range,

support and hotline, go to www.dremel.com.

Dremel Europe, P.O. Box 3267, 4800 DG Breda, The

Netherlands.

26

Page 27

ÜBERSETZUNG DER

!

ORIGINALBEDIENUNGSANLEITUNG

ALLGEMEINE WARNHINWEISE

WARNUNG

SICHERHEITSHINWEISE IN DIESEM

HANDBUCH DURCH UND MACHEN SIE

SICH MIT DEM DREMEL 3D20 VERTRAUT, BEVOR SIE

DAS GERÄT EINRICHTEN UND VERWENDEN. DAS

NICHTBEACHTEN VON WARNHINWEISEN UND

ANWEISUNGEN KANN ZU FEUER, GERÄTE- UND

ANDEREN SACHSCHÄDEN SOWIE ZU

PERSONENSCHÄDEN FÜHREN BEWAHREN SIE ALLE

WARNHINWEISE UND ANWEISUNGEN ZUM

SPÄTEREN EINSEHEN AUF.

SICHERHEIT AM ARBEITSPLATZ

c. Halten Sie Ihren Arbeitsbereich sauber und

aufgeräumt. Unordnung und unbeleuchtete

Arbeitsbereiche können zu Unfällen führen.

d. Arbeiten Sie mit dem Dremel 3D20 nicht in

explosionsgefährdeter Umgebung, in der sich

brennbare Flüssigkeiten, Gase oder Stäube

benden. Bei der Arbeit mit dem Dremel 3D20

entstehen hohe Temperaturen, durch die sich

Stäube und Gase entzünden können.

e. Bewahren Sie den 3D20 außerhalb der

Reichweite von Kindern und nicht in der

Verwendung des Gerätes geschulten Personen

auf. Die Verwendung durch nicht geschulte

Personen kann zu Verletzungen führen.

ELEKTRISCHE SICHERHEIT

a. Verwenden Sie den Dremel 3D20 nur mit

ordnungsgemäß geerdeten Steckdosen.

Nehmen Sie keine Änderungen am Stecker

des Dremel 3D20 vor. Durch eine falsche Erdung

oder veränderte Stecker wird die Gefahr von

Stromschlägen erhöht.

b. Verwenden Sie den Dremel 3D20 nicht in

feuchten oder nassen Umgebungen. Setzen

Sie den Dremel 3D20 keinem Regen aus. Durch

Feuchtigkeit wird die Gefahr von elektrischen

Schlägen erhöht.

c. Nutzen Sie das Netzkabel ausschließlich

für seinen bestimmungsgemäßen Zweck.

Verwenden Sie das Netzkabel nicht, um

den Dremel 3D20 zu ziehen. Ziehen Sie den

Netzstecker nicht am Kabel aus der Steckdose.

Halten Sie das Kabel fern von Hitze, Öl,

scharfen Kanten und sich bewegenden

Geräteteilen. Beschädigte oder verwickelte Kabel

erhöhen das Risiko eines elektrischen Schlages.

d. Verwenden Sie das Gerät nach Möglichkeit

nicht während eines Gewitters. Es besteht

geringe Gefahr einer Überspannung durch

Blitzeinschlag, die zu elektrischen Schlägen führen

kann.

e. Ziehen Sie im Notfall den Netzstecker des

Dremel 3D20.

SICHERHEIT VON PERSONEN

a. Seien Sie bei der Arbeit mit dem Dremel 3D20

stets aufmerksam, achten Sie darauf, was Sie

tun, und handeln Sie mit Vernunft. Benutzen Sie

LESEN SIE ALLE

BETRIEBS- UND

den Dremel 3D20 nicht, wenn Sie müde sind

oder unter dem Einuss von Drogen, Alkohol

oder Medikamenten stehen. Ein Moment der

Unachtsamkeit beim Gebrauch des Gerätes kann

zu ernsthaften Verletzungen führen.

b. Tragen Sie persönliche Schutzausrüstung.

Durch Schutzausrüstung wie hitzebeständige

Handschuhe und eine Schutzbrille wird die

Verletzungsgefahr reduziert.

c. Tragen Sie geeignete Kleidung. Tragen Sie

keine weite Kleidung oder Schmuck. Halten Sie

Haare, Kleidung und Handschuhe fern von sich

bewegenden Teilen. Lose Kleidung, Schmuck und

lange Haare können von bewegten Teilen erfasst

werden.

DREMEL 3D20 – SORGFÄLTIGER UMGANG UND

a. Kontrollieren Sie vor jedem Einsatz, ob die

beweglichen Teile des Dremel 3D20 einwandfrei

funktionieren und nicht klemmen, und ob Teile

gebrochen oder so beschädigt sind, dass

die Funktion des Gerätes beeinträchtigt ist.

Wenn der Dremel 3D20 beschädigt ist, muss

er vor der nächsten Verwendung in einem

autorisierten Dremel-Servicezentrum repariert

werden. Die Verwendung des Dremel 3D20 im

beschädigten Zustand kann zu Objekten von

mangelhafter Qualität, zu weiteren Geräteschäden

sowie zu Sach- und Personenschäden führen.

b. Berühren Sie die Druckkopfdüse nicht,

während der Dremel 3D20 in Betrieb ist oder

die Temperatur über 60 °C (140 °F) liegt.

Das Berühren der Druckkopfdüse während des

Betriebs oder vor dem Abkühlen der Düse kann zu

Personenschäden führen.

c. Stellen Sie den Dremel 3D20 an einem gut

belüfteten Ort auf. Lassen Sie rings um den

Dremel 3D20 einen Freiraum von mindestens

20 cm. Während des Druckens schmilzt der

Dremel 3D20 Kunststoff. Die während des Betriebs

des Dremel 3D20 austretenden Kunststoffgerüche

können eine Reizung der Augen und Atemwege

verursachen. Wenn der Dremel 3D20 zu dicht

an anderen Objekten aufgestellt ist, wird eine

ordnungsgemäße Belüftung verhindert.

d. Fassen Sie während des Betriebs nicht in das

Innere des Dremel 3D20. Das Berühren von

beweglichen Teilen des Dremel 3D20 während

des Betriebs kann zu Objekten von mangelhafter

Qualität, weiteren Geräteschäden, Sachschäden

und Personenschäden führen.

e. Lassen Sie den Dremel 3D20 während des

Betriebs nicht unbeaufsichtigt. Die Verwendung

des Dremel 3D20 durch Personen, die nicht mit

diesen Warnungen und Anweisungen vertraut

sind, kann zu Geräteschäden, Sachschäden und

Personenschäden führen.

f. Verwenden Sie nur DREMEL PLA-Filamente. Die

Verwendung von nicht von Dremel zugelassenen

Filamenten kann zu Geräte- und Sachschäden

führen.

g. Mit dem Dremel 3D20 erstellte kleine

Objekte müssen außerhalb der Reichweite

von Kleinkindern aufbewahrt werden.

Kleine Gegenstände stellen eine potenzielle

Erstickungsgefahr für Kleinkinder dar.

h. Erstellen Sie mit dem Dremel 3D20 keine

illegalen oder ungeeigneten Objekte.

i. Erstellen Sie mit dem Dremel 3D20 keine

Objekte, die für den Einsatz mit Wärmequellen

wie Kerzen oder üssigen Kraftstoffen bestimmt

GEBRAUCH

27

DE

Page 28

sind. Kunststoffe können schmelzen, wenn sie

Feuer oder anderen Wärmequellen ausgesetzt

werden. Eine derartige Verwendung von mit dem

Dremel 3D20 erstellten Objekten kann zu Feuer,

Sach- und Personenschäden führen.

j. Erstellen Sie mit dem Dremel 3D20 keine

Objekte, die für den Einsatz mit Lebensmitteln

oder Getränken bestimmt sind (Zubereitung,

Dekoration, Lagerung oder Verzehr). Eine

derartige Verwendung von mit dem Dremel

3D20 erstellten Objekten kann zu Krankheit und

Personenschäden führen.

k. Erstellen Sie mit dem Dremel 3D20 keine

Objekte, die für den Einsatz mit elektrischen

Komponenten oder deren Gehäuse bestimmt

sind. PLA-Kunststoffe sind nicht für die

Verwendung mit elektrischen Geräten geeignet.

Eine derartige Verwendung von mit dem Dremel

3D20 erstellten Objekten kann zu Sach- und

Personenschäden führen.

l. Nehmen Sie Kunststoffobjekte nicht in den

Mund, und vermeiden Sie Kontakt mit dem

Mundbereich. Objekte aus PLA-Kunststoff sind

nicht für den Einsatz mit Lebensmitteln geeignet.

Eine derartige Verwendung von mit dem Dremel

3D20 erstellten Objekten kann zu Krankheit und

Personenschäden führen.

m. Erstellen Sie mit dem Dremel 3D20 keine

Objekte zur Lagerung von Chemikalien.

PLA-Kunststoffe sind nicht für die Lagerung von

Chemikalien geeignet. Eine derartige Verwendung

von mit dem Dremel 3D20 erstellten Objekten kann

zu Sach- und Personenschäden führen.

n. Nehmen Sie keine Änderungen am Dremel 3D20

oder an den Werkseinstellungen vor. Derartige

Änderungen können zu Geräte-, Sach- und

Personenschäden führen.

o. Setzen Sie den Dremel 3D20 keinen

Temperaturen über 70 °C (158 °F) aus.

Andernfalls kann der Dremel 3D20 beschädigt

werden. Der Dremel 3D20 wurde für den Betrieb

bei einer Umgebungstemperatur von 16 bis 29 °C

(60 bis 85 °F) konzipiert.

p. Bewegen Sie den Dremel 3D20 und den

Druckkopf während des Betriebs nicht, und

stoßen Sie sie nicht an. Andernfalls kann es zu

Druckfehlern kommen.

q. Ändern Sie die Farbe des Filaments oder der

Spule nicht während des Drucks. Andernfalls

wird der Druckvorgang abgebrochen, und es kann

zu Schäden am Druckkopf kommen.

r. Ziehen Sie das Filament erst heraus, wenn eine

entsprechende Meldung auf dem Bildschirm

angezeigt wird. Andernfalls kann es zu Schäden

am Druckkopf kommen.

s. Achten Sie beim Entfernen von Restmaterial

besonders darauf, die Druckkopfdüse nicht

zu beschädigen. Wenn die Druckkopfdüse

beschädigt ist, funktioniert der Dremel 3D20 nicht

ordnungsgemäß. Defekte Düsen müssen daher

ausgetauscht werden.

t. Achten Sie vor jedem Druck darauf, dass die

Druckplattform gemäß den Angaben von Dremel

mit Druckband bedeckt ist. Die Verwendung von

ungeeignetem Druckband kann zu Geräteschäden

und Objekten von mangelhafter Qualität führen.

u. Achten Sie auf Ihre Körperhaltung, wenn

Sie Objekte mit einem Werkzeug von der

Druckplattform entfernen. Das Abrutschen mit

dem Werkzeug während des Entfernens des

Objekts von der Druckplattform kann bei falscher

Körperhaltung zu Personenschäden führen.

v. Achten Sie darauf, die Druckplattform beim

28

Entfernen von Objekten nicht zu zerkratzen.

Kratzer auf der Druckplattform führen zu

Druckfehlern.

w. Dremel übernimmt keine Verantwortung für die

strukturelle Integrität oder Verwendbarkeit von

mit dem Dremel 3D20 erstellten Objekten. Von

unerfahrenen Konstrukteuren erstellte strukturelle

Modelle können zu Sach- und Personenschäden

führen.

REPARATUREN

a. Trennen Sie den Dremel 3D20 vor der

Durchführung von Wartungsarbeiten stets von

der Stromversorgung. Andernfalls kann es zu

Personen- und Geräteschäden kommen.

b. Lassen Sie den Dremel 3D20 nur in

autorisierten Dremel-Servicezentren und nur

mit Original-Ersatzteilen von Dremel warten und

reparieren. Nur so bleiben die ordnungsgemäße

Funktion und Sicherheit des Dremel 3D20 weiterhin

gewährleistet.

c. Verwenden Sie nur von Dremel zugelassene

Materialien und Komponenten. Die

Verwendungen von anderen Objektmaterialien oder

3D-Objekten als den von Dremel

Materialien und Dremel

zu einem Erlöschen der Garantie führen.

®

®

zugelassenen

-Originalkomponenten kann

INHALTSVERZEICHNIS

Allgemeine Warnhinweise ..................................27

Inhaltsverzeichnis ...............................................28

Verwendete Symbole ..........................................29

Informationen zu geistigem Eigentum ..............29

Funktionsbeschreibung und technische Daten ...

30

Informationsquellen zum 3d20 ..........................31

Begriffsglossar ....................................................31

Einführung in den 3D20 .....................................33

Einführung ...........................................................35

Lieferumfang und Auspacken ............................35

Touchscreen ........................................................37

Installieren und Registrieren der Software ......42

Überblick über die Dremel-Software .................43

Druckvorbereitung ..............................................45

Druckvorgang läuft .............................................47

Drucken von SD-Karte ........................................48

Drucken vom Computer .....................................48

Entnehmen fertiger Objekte ...............................49

Entfernen und Ersetzen der Filamentspule .....49

Wartung und Problembehebung .......................51

Beseitigen von Verstopfungen aus dem

Druckkopf .............................................................52

Reinigen der Außenächen ................................52

Reinigen der Druckkopfdüse .............................52

Reinigen des Touchscreens...............................52

Tipps .....................................................................52

Page 29

VERWENDETE SYMBOLE

!

Symbol Bezeichnung Beschreibung

WARNUNG

Warnsymbol

Handbuchsymbol

Weist den Benutzer

auf Warnmeldungen

hin

Weist den Benutzer

darauf hin, das

Handbuch zu

konsultieren

WARNUNG

!

UMFELD KANN DIESES PRODUKT

FUNKSTÖRUNGEN VERURSACHEN. IN DIESEM FALL

MUSS DER BENUTZER GEEIGNETE

GEGENMASSNAHMEN TREFFEN.

DIES IST EIN PRODUKT DER

KLASSE A. IM HÄUSLICHEN

INFORMATIONEN ZU GEISTIGEM

EIGENTUM

Der Dremel 3D20 ist für das Drucken von 3D-Objekten

von digitalen Dateien bestimmt, die Sie entweder

selbst erstellt haben oder für die Sie eine Berechtigung

zum Drucken mit dem Dremel 3D20 verfügen. Beim

Erstellen von Objekten mit dem Dremel 3D20 liegt

es in Ihrer Verantwortung, sicherzustellen, dass Sie

keine Urheberrechte von Dritten oder einschlägige

Gesetze oder Vorschriften wie beispielsweise das USamerikanische Gesetz oder Gesetze anderer Länder

zum Schutze von geistigem Eigentum verletzen. Der

Dremel 3D20 darf nicht zur Erstellung von Objekten

verwendet werden, die Urheberrechten Dritter

unterliegen, sofern keine Genehmigung seitens dieser

Dritten vorliegt. Für die Verwendung des Dremel 3D20

zu einem der folgenden Zwecke ist unter Umständen

die Genehmigung Dritter erforderlich: Erstellen eines

Duplikats oder einer Kopie (ganz oder teilweise)

eines Objektes, das nicht von Ihnen entworfen

wurde, Erstellen eines Objekts auf Grundlage einer

digitalen Datei, die nicht Ihnen gehört, oder Erstellen

eines Objekts auf Grundlage eines Scans oder eines

materiellen Gegenstandes, den Sie nicht selbst

entworfen haben. Es liegt in Ihrer Verantwortung, eine

derartige Genehmigung einzuholen. Möglicherweise

wird Ihnen eine solche Genehmigung nicht immer

erteilt. In diesen Fällen sollten Sie keinen 3D-Druck

von den entsprechenden Objekten anfertigen. Wenn

Sie dies dennoch tun, erfolgt dies auf eigene Gefahr.

Sie sind nicht befugt, den Dremel 3D20 oder die

zugehörige Software oder Firmware zu verändern,

zurückzuentwickeln, zu dekompilieren oder zu

demontieren, sofern dies nicht durch geltende Gesetze

erlaubt ist. Wenn Sie den Dremel 3D20 auf eine

andere als die empfohlene und in diesen Betriebs- und

Sicherheitshinweisen beschriebene Art und Weise

verwenden, geschieht dies auf eigene Gefahr. Die

Verwendung des Dremel 3D20 zur Herstellung von

Objekten unter Verletzung der Urheberrechte Dritter

kann eine zivil- und strafrechtliche Verfolgung und

Strafen einschließlich nanziellen Entschädigungen,

Geldstrafen und Gefängnisstrafen nach sich ziehen.

Dieses Produkt kann Chemikalien enthalten oder

freisetzen, die dem US-Bundesstaat als Ursache

für Krebs und Geburtsschäden sowie andere

Fortpanzungsstörungen bekannt sind.

29

Page 30

FUNKTIONSBESCHREIBUNG UND

14” (356mm)

TECHNISCHE DATEN

DRUCKEN

Druckkopf: Einzelextrusion

Druckkopftemperatur: Bis zu 230 °C (397 °F)

Benutzerschnittstelle: 3,5-Zoll-IPS-Farb-Touchscreen

Maximales Druckvolumen:

230 mm × 150 mm × 140 mm

(9" × 5,9" × 5,5")

Schichtstärke: 4 mil | 0,004 Zoll 100 Mikron | 0,10 mm

Filamentfarben: für verfügbare Farben siehe