Page 1

INSTALLATION INSTRUCTIONS

B

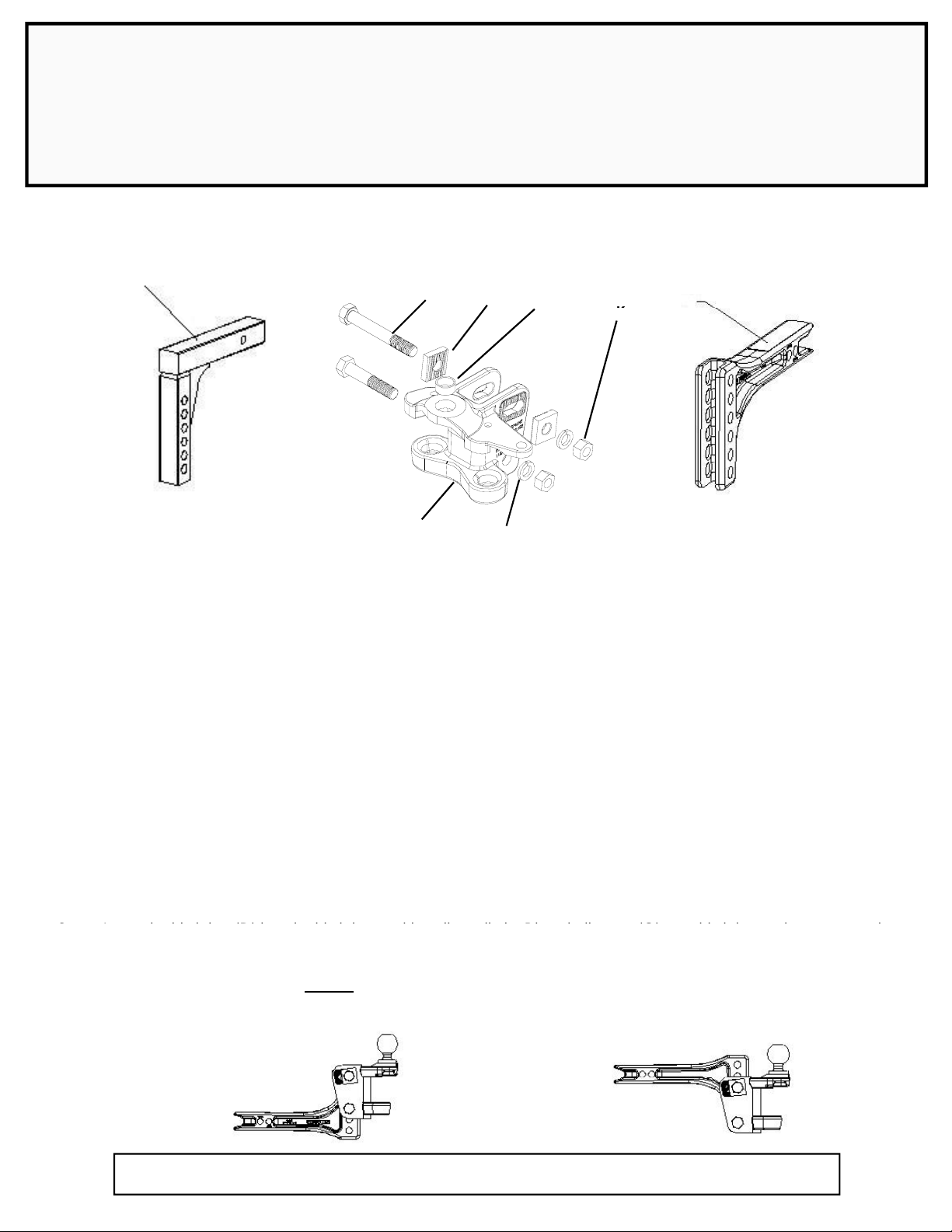

K

2.Level the trailer and measure and record the distance from the ground to the top of the ball socket (X dimension Fig.1)

6. I

(D) i

(G)

Trunnion Style

Weight Distributing Kits

PLYMOUTH, MI.

HIGH-PERFORMANCE BALLMOUNT

D*

INITIAL SET-UP

1. Line up tow vehicle and trailer on level pavement, in straight-ahead position, uncoupled.

3. Select a hitch ball with a diameter that matches the trailer coupler size. The three most common sizes are 1-7/8", 2",

and 2-5/16". Select ball with 1-1/4" or 1" threaded shank that is V-5 rated equal to or greater than trailer gross vehicle

weight rating (GVWR). A thin jam nut (.72” thick) should be used on standard ballmount to prevent interference with

spring bar trunnion.

J

G

E

L

**

D*

*D not included in all kits

**B not included in all kits

.

WARNING: Raised balls usually have reduced load ratings. Ball rating MUST equal or exceed trailer GVWR.

4. Attach hitch ball to the ballmount (G). Standard height hitch balls with 1-1/4" shanks are supplied with lockwashers and

nuts (If you must use a 1” shank ball, use bushing 58184 (B) to reduce hole size in ballmount (G) to 1”). Always use a

lockwasher and place washer next to nut. Unless otherwise specified by ball manufacturer torque ball nut to 450 ft/lbs for

1-1/4" nut, 250 ft/lbs for 1" nut.

5. Some installations may require a longer hitch bar (D). Extended bumper guards, pickup truck "caps", or rear mounted

spare tires can limit turn angles unless a longer bar is used. Individual hitch bars (D) are available in various sizes.

nsert the hitch bar

for proper height. Hitch bar may be used in either the up or down position (see below).

NOTE: Ball height should be greater

(approximately 3/4” to 1”).

nto the hitch box and install a pull pin. Place ballmount

than coupler height (measured in step 1) to compensate for vehicle "squat”

HIGHEST POSITION

onto hitch bar and move up or down

LOWEST POSITION

For Installation Assistance or Technical Help, Call 1-888-521-0510

66006IN-13JAN06H PCN7968 ©2006 TOWING PRODUCTS, INC Litho in USA

Page 2

For vehicles with air springs, air shocks or automatic leveling system, check vehicle owners manual. Unless otherwise

)

()

* ADD 1” TO Y DIMENSION FOR NON

INTEGRATED CAM SPRING BARS

specified, level the vehicle with the vehicle loaded as it will be when towing before setting ball height and attaching

trailer.

PRELIMINARY BALLMOUNT ADJUSTMENT

1. Install hardware in lower hole of ballmount as shown. Tighten nut enough to prevent easy rotation of ballmount.

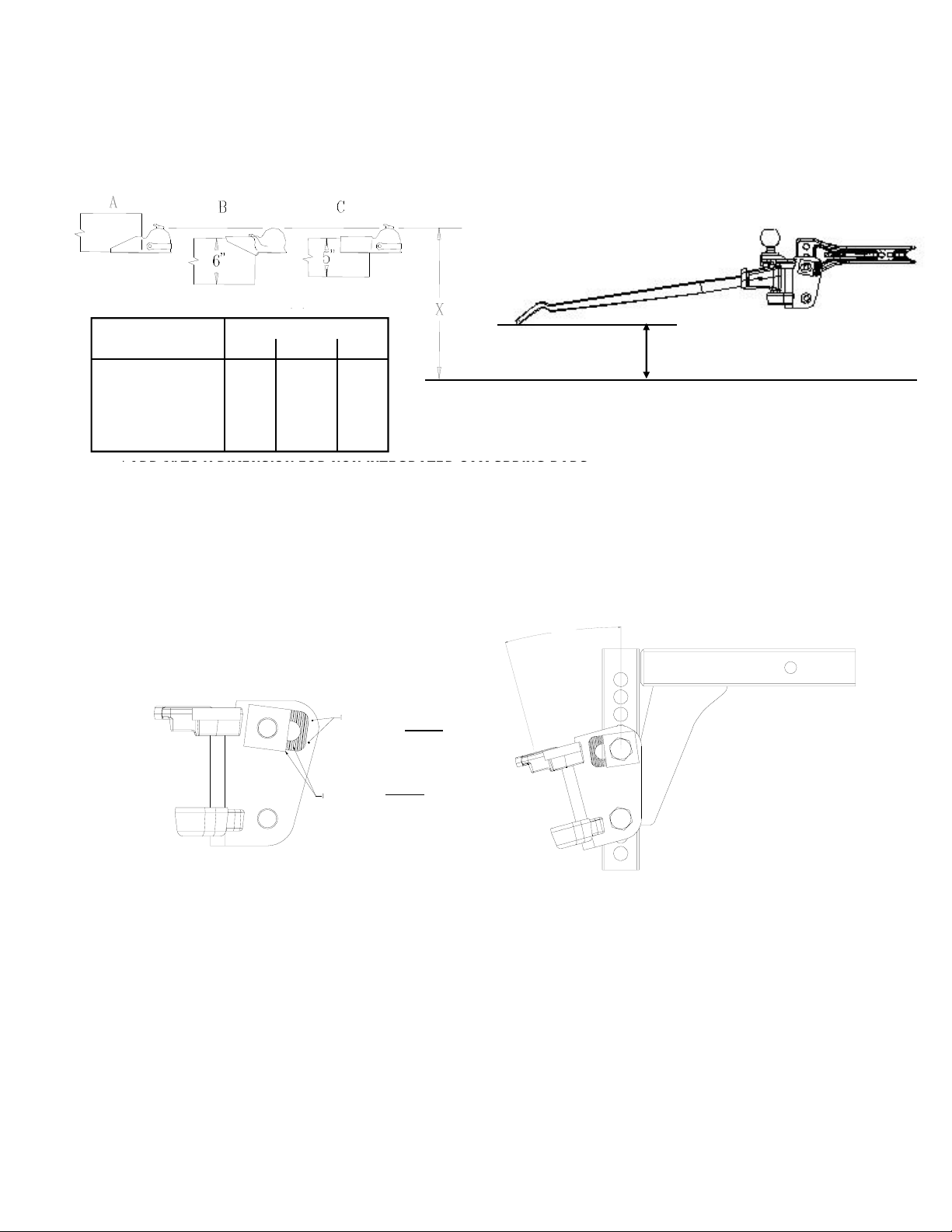

2. Determine spring bar height "Y" using table below. Insert spring bar and trunnion into the ball mount. Swing bar

outward to the same angle as when connected to trailer. Lift up on bar to remove slack. Tilt ball mount for proper "Y”

dimension at end of spring bar.

SPRING BAR HEIGHT (Y

COUPLER HEIGHT

X

COUPLER STYLE

A B C

Y

15" TO 18"

18" TO 20"

20" TO 22"

22" TO 24"

24" TO 26"

3. The ballmount (G) is adjustable through a 15° angle range for proper spring bar adjustment. See chart above.

HIGH-PERFORMANCE BALLMOUNT ADJUSTMENT

7" 4-1/2" 5-1/2"

8" 5-1/2" 6-1/2"

9" 6-1/2" 7-1/2"

10" 7-1/2" 8-1/2"

11' 8-1/2" 9-1/2"

-

EQUAL NUMBER OF

TEETH MUST

SHOW

15°

.

Install longer 3/4” bolt (J) with two serrated washers (E) as shown. Install lockwasher (L) and nut (K), but allow space

for washers to be positioned and aligned. Align the washers as shown, hold in position, and tighten nut. Torque the

two nuts (K) to 300 ft/lbs. If proper torque wrench is not available, torque nuts to 150 ft/lbs then turn nuts an additional

1/4 turn. Do not lubricate the threads.

CAUTION: Washer MUST BE aligned parallel with teeth on ballmount. Re-check washer alignment after nut is

tightened. Equal number of teeth must show at top and bottom. Teeth can be stripped when loaded if not properly

aligned.

66006IN-13JAN06H PCN7968 ©2006 TOWING PRODUCTS, INC Litho in USA

TEETH MUST

BE PARALLEL

2

Page 3

INITIAL HOOK UP

3. Usi

the spring bar is approximately vertical

7. L

ll

Check to see if trailer is level, if not, you may need to re

adjust ballmount angle and / or position

NOTE: Car and trailer should be loaded and ready for travel before final leveling.

1. Pick reference points on front and rear wheel wells. Measure and record distance to pavement.

Front wheel well to pavement ___________________ Rear wheel well to pavement __________________.

2. Attach chains to spring bars using U-bolts, flat washers, and locknuts. Let 2-3 threads protrude below locknut. Chain

must not bind.

STANDARD SPRING BAR INTEGRATED CAM SPRING BAR

ng tongue jack lower coupler onto ball and close coupler latch.

4. Hold the spring bar away from you (trunnion ribbed side up). Set the bottom knob of the trunnion into the lower socket of

the ballmount (G) and slide the knob into the top slot of the ballmount. The spring bars will fit on either side as they are

not made right or left handed.

5. Position the snap up brackets on trailer

"A" frame so that the chain on the end of

.

Turn 1/2 X 3-1/2 bolt until it contacts frame.

Then tighten 1/4 turn with wrench. DO NOT

OVERTIGHTEN.

6. Raise trailer tongue and rear of car with

jack. Lower yoke of snap up bracket until

it is parallel with the ground, and slip the

closest link over the hook (If there are

less than 5 links between hook and u-bolt

adjust ballmount angle rearward, and repeat

procedure). With the snap up bracket

handle over the yoke, raise until yoke

has passed “over-center”. Slide the safety

pin through the small hole to lock the yoke

in place. Repeat for other side.

ower jack. Re-measure front and rear wheel we

Fig.2

reference points (vehicle should settle evenly, within

about 1/2 inch). If front has settled more than rear,

increase the number of chain links between yoke hook and spring bar. If there are no more links, the angle of the head

assembly must be decreased. The trailer must be uncoupled and the upper bolt loosened to adjust serrated washers.

The head assembly is then pivoted up as appropriate. Reassemble. If rear has settled more than front, reduce the

number of links between hook and spring bar. It is preferred that rear of vehicle settle the same or more than the front.

-

.

Check to see that there is room for the bar and chain to move when turning a corner.

NOTE: Some surge brakes will not work with weight distributing hitches. Check with manufacturer. Do not use

sway control with surge brakes.

PLACE CLOSEST

LINK ON HOOK

SNAP UP

HANDLE

LUBRICATION

1. Lubricate the ballmount sockets and spring bar trunnions to prevent rapid wear. When hooking-up, place one drop of oil

on the top and a second drop on forward side of upper trunnion. Place a third drop on the rear side of lower trunnion

before inserting trunnion into ballmount. Use a heavy oil or grease. Don't forget to lubricate the hitch ball with one or

two drops also. Trunnions should be lubricated each towing day. It is not necessary to unhook the spring bars however,

as there are two oil holes in the ballmount top plate for upper trunnion lubrication. Lubricate lower trunnions with one

drop at contact point between trunnion and lower socket. Excess oil, dirt, and grit should be wiped out whenever trailer

is uncoupled.

66006IN-13JAN06H PCN7968 ©2006 TOWING PRODUCTS, INC Litho in USA

3

Page 4

WARNINGS: LOADED BALL HEIGHT SHOULD NEVER BE GREATER THAN UNCOUPLED BALL HEIGHT. Front wheel overload and loss of rear wheel traction can

Towi

ill

FREE OF CHARGE

result, and can lead to unstable handling, reduced braking ability, and a tendency to "jackknife" when turning and braking at the same time. IF LOADED BALL HEIGHT IS

GREATER THAN UNCOUPLED HEIGHT, reduce take-up on spring bar chains and re-measure until proper height is obtained.

DO NOT TOW MULTIPLE TRAILERS: Do not attempt t o tow any t ype of t railer behind another tr ailer. Towing mult iple trailer s may cause sev er e instabilit y, loss of

control and/or structural failure, and may result in vehicle accident, property damage and personal injury. Towing multiple trailers is illegal in many jurisdictions.

FRONT-WHEEL-DRIVE VEHICLES: DO NOT ATTEMPT TO HOOK-UP OR TOW WI TH REAR WHEELS OF TOWING VEHICLE REMOVED. Severe structural damage

to towing vehicle, hitch, and trailer may result. A towing vehicle/trailer combination cannot be controlled adequately unless t he towing vehicle's rear wheels are carrying

their share of the load.

MAINTENANCE: Keep trunnions and sockets in head assembly free of dirt and well lubricated. Excessive wear in this area may indicate overload or inadequate

lubrication. Some elongation of socket openings "seat in" is normal.

Keep head assembly exterior clean, especially the trunnion sockets. Do not allow dirt or stones to lodge between trunnions and head.

Keep hitch painted to prevent rust and maintain a good appearance. (Do not paint over labels)

AT THE BEGINNING OF EVERY TOWING DAY:

• Add drop of oil at trunnion contact areas with ball mount.

• Clean ball and coupler socket and coat ball lightly with grease.

• Check spring bar chains and U-bolts for wear. Replace before they become worn halfway through.

• Check to see that all bolts are properly tightened and hitch pin and clip are securely in place.

• Check to see that electrical hookups are in working order, and that safety chains are connected.

TOWING TIPS

DRIVING: Good habits for normal driving need extra emphasis when towing. The additional weight affects acceleration and braking, and extra time should be allowed for

passing, stopping, and changing lanes. Signal well in advance of a maneuver to let other drivers know your intentions. Severe bumps and badly undulating roads can

damage your towing vehicle, hitch, and trailer, and should be negotiated at a slow steady speed. IF ANY PART OF YOUR TOWING SYSTEM "BOTTOMS" OUT, OR IF

YOU SUSPECT DAMAGE MAY HAVE OCCURED IN ANY OTHER WAY, PULL OVER AND MAKE A THOROUGH INSPECTION. CORRECT ANY PROBLEMS

BEFORE RESUMING TRAVEL.

CHECK YOUR EQUIPMENT: Periodically check the condition of all your towing equipment and keep it in top condition.

TRAILER LOADING: Proper trailer loading is important. Heav y items should be placed close to the floor near the trailer axle. The load should be balanced side-to-side

and firmly secured to prevent shifting. Tongue weight should be about 10-15 percent of the gross trailer weight for most trailers. Too low a percentage of tongue weight

will often produce a tendency to sway. Excess weight on the tongue can also lead to sway and damage hitch and / or tow vehicle.

SWAY CONTROLS: A sway control can help minimize the affects of sudden maneuvers, wind gusts, and buffeting caused by other vehicles. Use of a sway control is

recommended for trailers with large surface areas, such as travel trailers.

TIRE INFLATION: Unless specified otherwise by the towing vehicle or trailer manufacturer, tires should be inflated to their maximum recommended pressure.

TOWING VEHICLE AND TRAILER MANUFACTURERS' RECOMMENDATIONS: Review the owners' manuals for your towing vehicle and trailer for specific

recommendations, capacities, and requirements.

POLE TONGUE TRAILERS: If your trailer has a straight tongue (inst ead of an A-fram e t ongue), it will be necessary to use a pole tongue adapter. This adapter attaches

to the trailer tongue, providing a place to attach the snap up brackets.

PASSENGERS IN TRAILERS: Trailers should NOT be occupied while being towed, under any circumstances.

TRAILER LIGHTS, TURN SIGNALS, AND ELECTRIC BRAKES: Always hook up trailer lights, turn signals, electric brakes and break- away switch connection (if so

equipped) even for short trips.

REMOVE HITCH WHEN NOT TOWING: Remove hitch from towing vehicle receiver when not towing, to prevent contamination of head sockets, reduce chance of

striking hitch on driveway ramps or other objects, and minimize damage in the event of a r ear-end collision.

Towing Products warrants its Hitches, Custom Hitch Receivers, and Sway Controls from date of purchase against defects in material and workmanship under

Hitches - Custom Receivers - Sway Controls

normal use and service, ordinary wear and tear excepted, for the ownership life of the original consumer purchaser.

LIMITED WARRANTY

ng Products w

Towing Products Warehouse or return to factor y. TRANSPORTAION CHARGES PREPAID, at the address below.THIS W ARRANTY IS LIMITED TO DEFECTIVE

PARTS REPLACEMENT ONLY. LABOR CHARGES AND/OR DAMAGE INCURRED IN INSTALLATION OR REPLACEMENT AS WELL AS INCIDENTAL AN

CONSEQUENTIAL DAMAGES CONNECTED THEREWITH ARE EXCLUDED.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

Any damage to the Hitch, Custom Hitch Receiver, and Sway Control as a result of misuse, abuse, neglect, accident, improper installation, or any use violative of

instructions furnished by us, WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. In the event of a problem with warranty service or

performance, you may be able to go to a small claims court, or a federal district court.

66006IN-13JAN06H PCN7968 ©2006 TOWING PRODUCTS, INC Litho in USA

replace

any part which proves defective in material or workmanship when presented to any Towing Products dealer,

Towing Products

47774 Anchor Court West

Plymouth, Mi. 48170

4

Loading...

Loading...