Page 1

Disassembly &

Assembly

Lift Trucks Power Train

D20S-3, D25S-3, D30S-3, D32S-3

D20S-3(B3.3), D25S-3(B3.3), D30S-3(B3.3),

D32S-3(B3.3), D33S-3(B3.3)

G20S-3, G25S-3, G30S-3

GC20S-3, GC25S-3, GC30S-3

G20E-3, G25E-3, G30E-3, G32E-3

GC20E-3, GC25E-3, GC30E-3, GC32E-3

G20P-3, G25P-3, G30P-3, G32P-3

GC20P-3, GC25P-3, GC30P-3, GC32P-3

SB2103E01

Jan.2004

Page 2

Important Safety Information

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. A person must be alert to potential hazards. This person should also ha v e the necessary

training, skills and tools to perform these functions properly.

Read and understand all safety precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the “Safety” section of the Service or Technical Manual. Additional safety

precautions are listed in the “Safety” section of the owner/operation/maintenance publication.

Specific safety warnings for all these pub lications are pro vided in the description of operations where hazards

exist. W ARNING labels have also been put on the product to provide instructions and to identify specific hazards.

If these hazard warnings are not heeded, bodily injury or death could occur to you or other persons. W arnings in

this publication and on the product labels are identified by the f ollo wing symbol .

WARNING

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have read and

understood the operation, lubrication, maintenance and repair inf ormation.

Operations that may cause product damage are identified by NOTICE labels on the product and in this

publication.

DAEWOO cannot anticipate every possible circumstance that might involv e a potential hazard. The warnings in

this publication and on the product are therefore not all inclusiv e. If a tool, procedure, work method or operating

technique not specifically recommended by DAEWOO is used, you must satisfy yourself that it is safe for you and

others. Y ou should also ensure that the product will not be damaged or made unsafe by the operation, lubrication,

maintenance or repair procedures you choose.

The information, specifications, and illustration in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product. Obtain the complete

and most current information before starting any job. DAEWOO dealers have the most current inf ormation

available.

1

Page 3

Page 4

Index

Transmission

Assembly Input Shaft ...............................................16

Assembly Output Shaft ............................................19

Assembly Reverse Shaft..........................................11

Assembly Transmission Housing .............................20

Disassembly / Assembly Valve Body .......................26

Disassembly Input Shaft ..........................................14

Disassembly Output Shaft........................................19

Disassembly Reverse Shaft .......................................9

Disassembly Transmission Housing ..........................5

Drive Axle

Adjustment Bevel Pinion ..........................................37

Adjustment Disassembly /

Assembly of Bevel Pinion.........................................39

Assembly Bevel Pinion.............................................39

Assembly Carrier Diff ...............................................45

Assembly Crown wheel/Adjustment .........................42

Assembly Shaft As ...................................................31

Disassembly / Assembly Brake Parts.......................32

Disassembly / Assembly Differential ........................40

Disassembly / Assembly Hub Drive Axle..................33

Disassembly / Differential Assembly ........................34

Disassembly Axle .....................................................27

Disassembly Bevel Pinion ........................................35

Disassembly Shaft As...............................................31

Special Service Tools ...............................................51

Disconnect batteries before performance of any

service work.

WARNING

Power Train Index

3

Page 5

Page 6

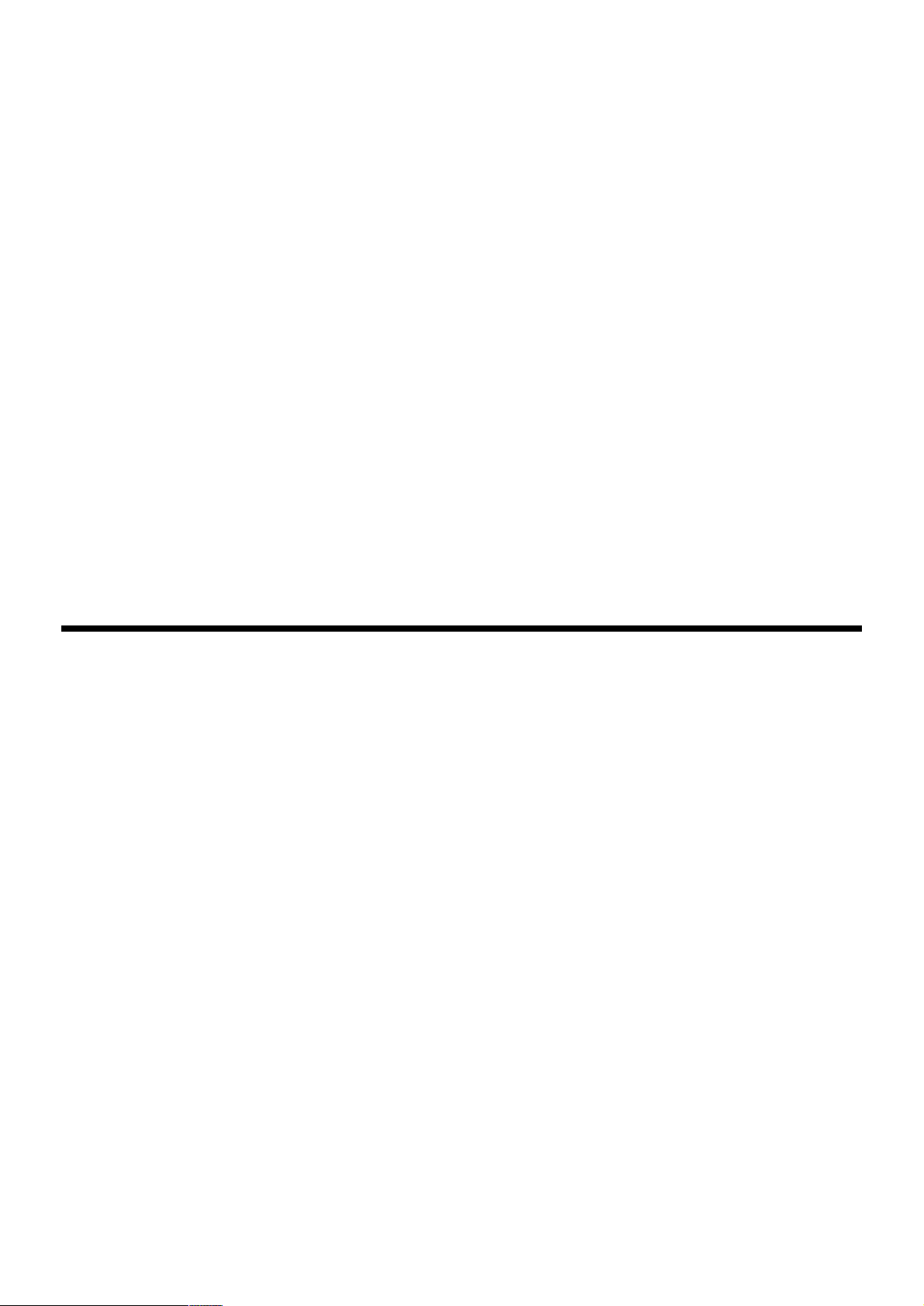

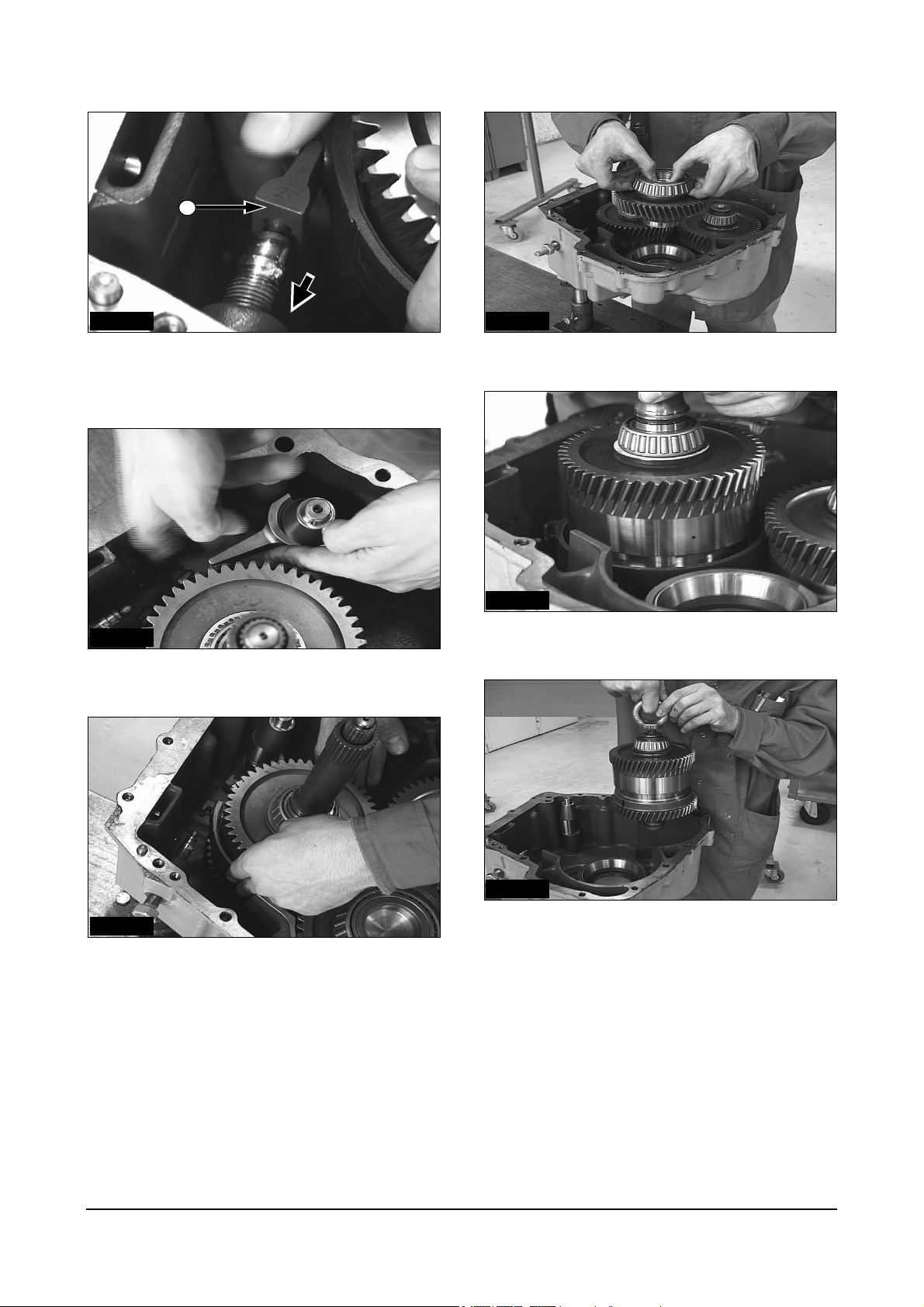

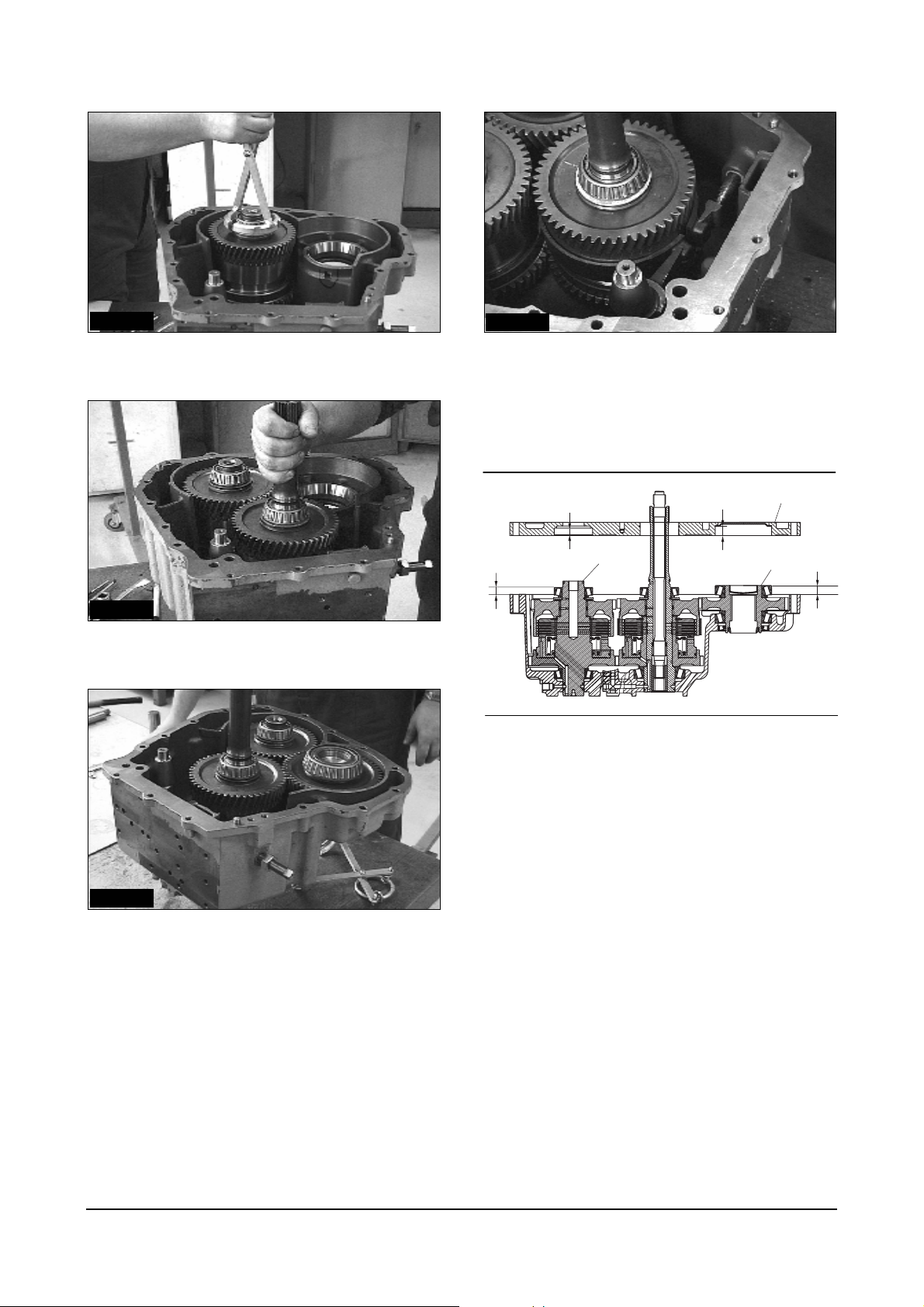

Disassembly

Transmission Housing

IDCD501P

1. Mount the transmission on a suitable jig.

1

1

IDCD502P

2. Disconnect valve body, loosen the screws (1) with

socket head wrench 8 mm.

ATTENTION: Loosen bolts from outside to inwards!

IDCD504P

4. To remove the torque converter housing,

loosen the upper housing screws.

(Hexagonal socket 17 mm)

IDCD505P

5. Loosen the lower housing screws.

(Hexagonal socket 17 mm)

4

IDCD506P

3

6. Install 2 jackbolts (M10, 30mm (1.2in)) in locations

2

(4) until they stop against bearing plate,

alternately tighten bolts to separate the torque

converter housing from the transmission.

IDCD503P

3. Remove the Gasket (2) and oil dipstick (3).

Power Train Disassembly & Assembly

5

Page 7

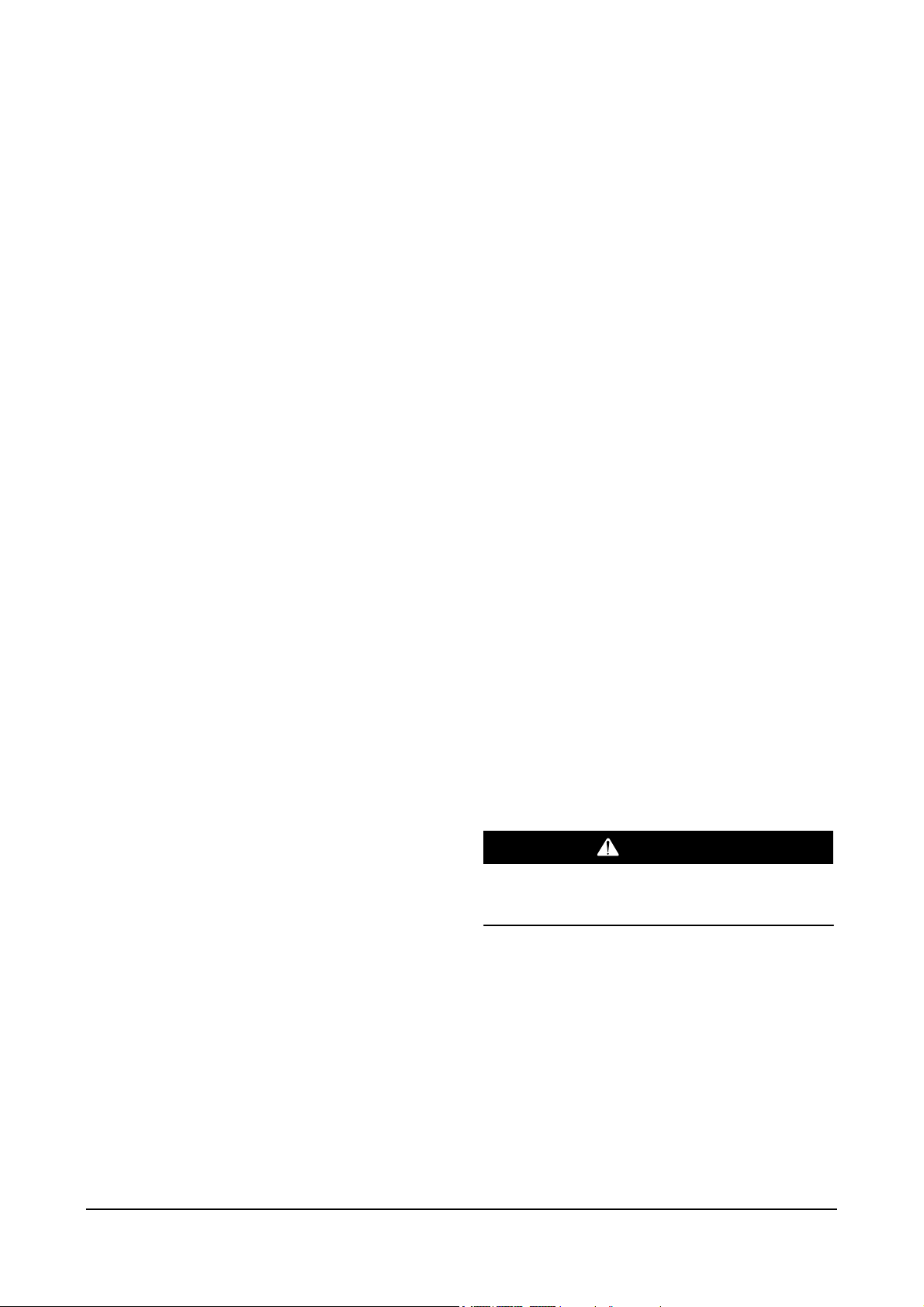

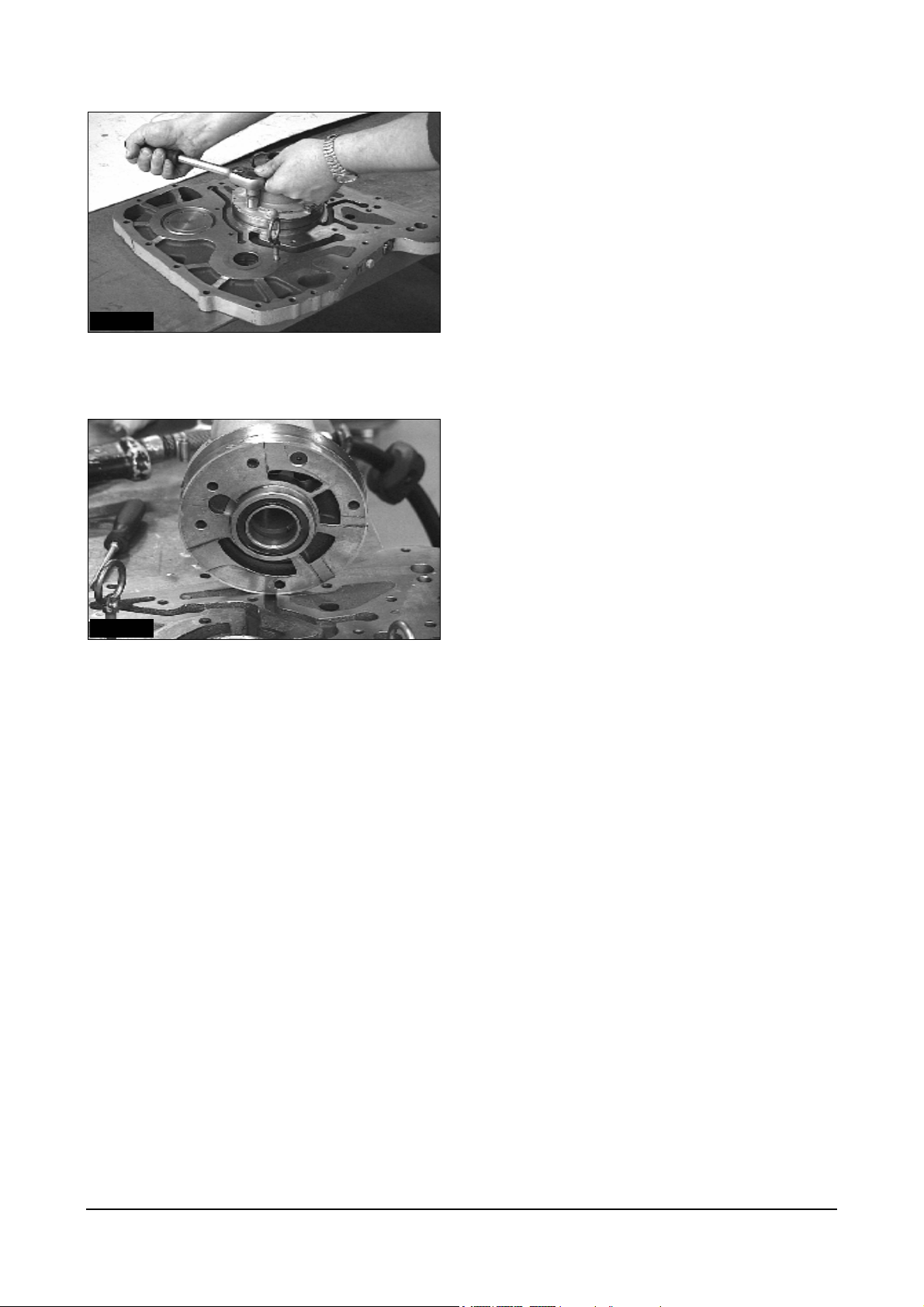

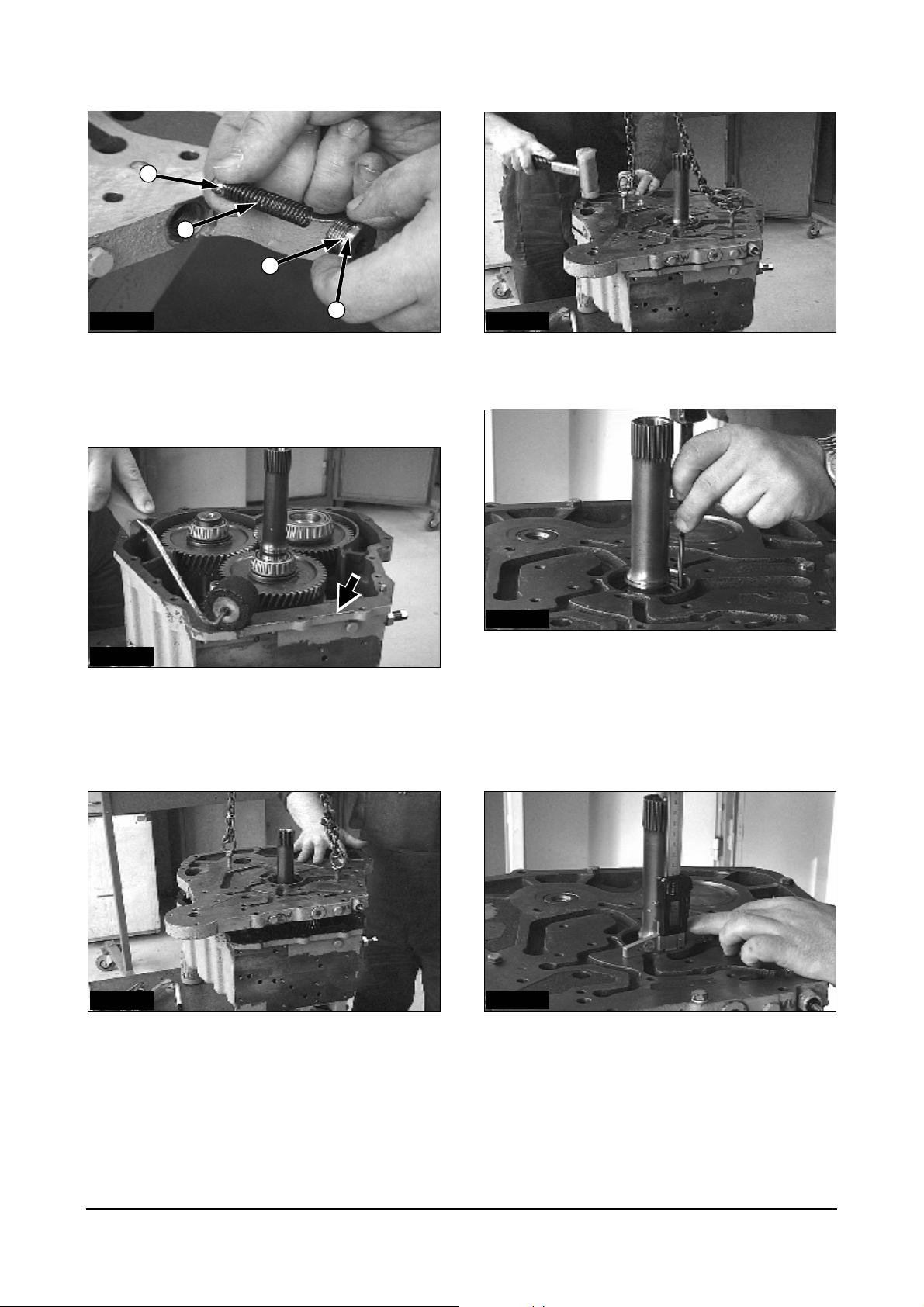

IDCD507P

7. To remove strainer, loosen the screw with an allen

head wrench.

IDCD510P

10. Remove the remaining screws between the T/M

bearing plate and the torque converter housing.

(Hexagonal socket 17 mm).

IDCD508P

8. Lift the torque converter housing from the T/M

bearing plate.

IDCD509P

9. Secure the eyebolts M10 to remove the torque

converter housing.

IDCD511P

11. Secure the eyebolts M10 to remove the T/M

bearing plate.

1

2

IDCD512P

12. Loosen the jam nut (1) to loosen the hand brake

adjustment with the ring spanner (22 mm) and the

threaded bolt (2) with the open ended spanner (10

mm).

Power Train Disassembly & Assembly

6

Page 8

1

13. Turn the adjustment bolt until the strut (1) can be

removed from the brake band.

IDCD516PIDCD513P

16. Remove the output shaft.

IDCD517P

IDCD514P

17. Remove the input shaft with forward clutch.

14. Remove the brake struts from the eccentric shaft.

IDCD518P

IDCD515P

15. Lower the loosened brake band into the housing.

Remove after dismounting the shaft.

18. Use the eyebolt M18 to lift the reverse shaft.

Power Train Disassembly & Assembly

7

Page 9

IDCD592P

19. Remove the lube pump. (Hexagonal socket 13

mm)

IDCD593P

20. Lift the lube pump with 2 screw drivers.

Power Train Disassembly & Assembly

8

Page 10

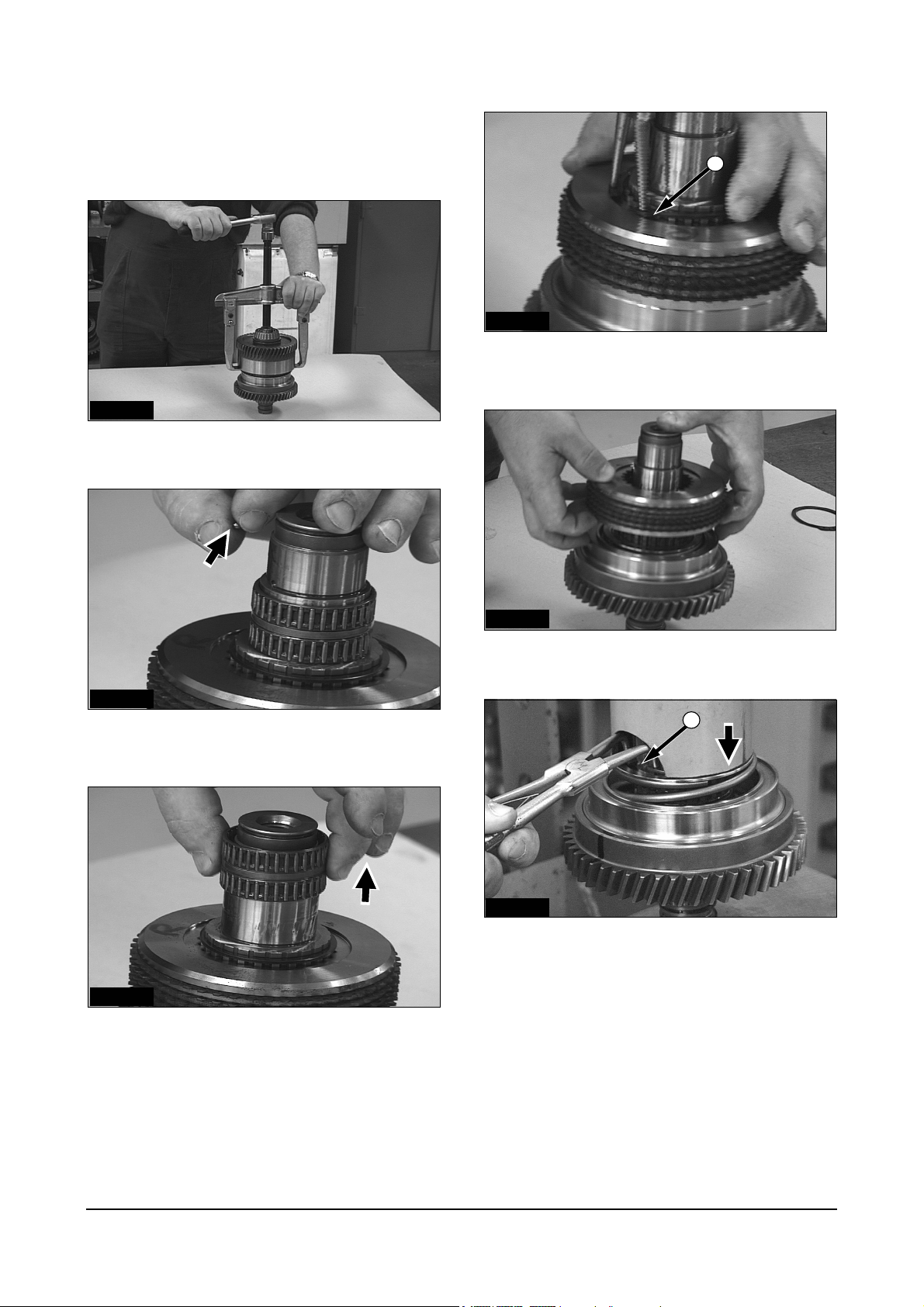

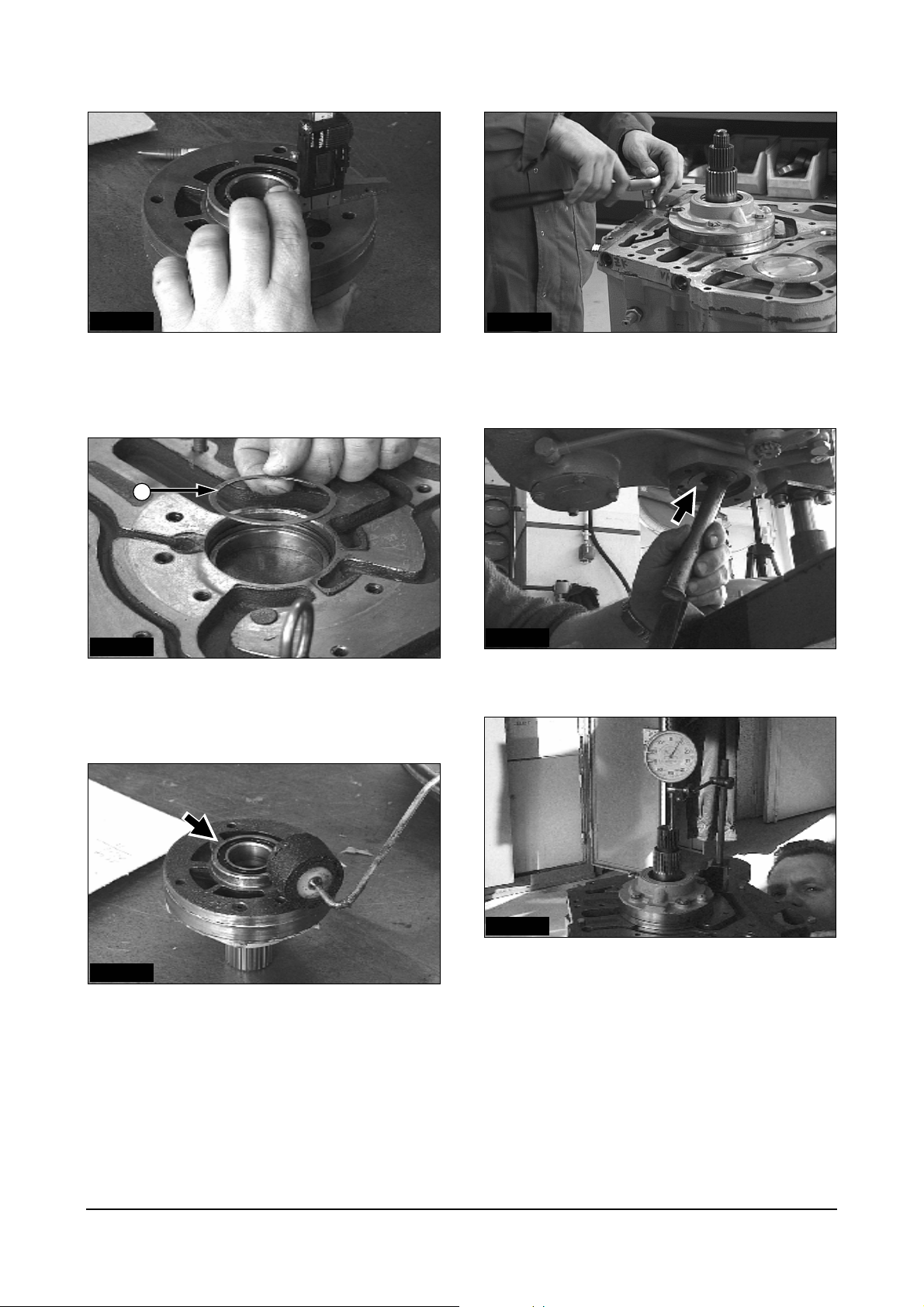

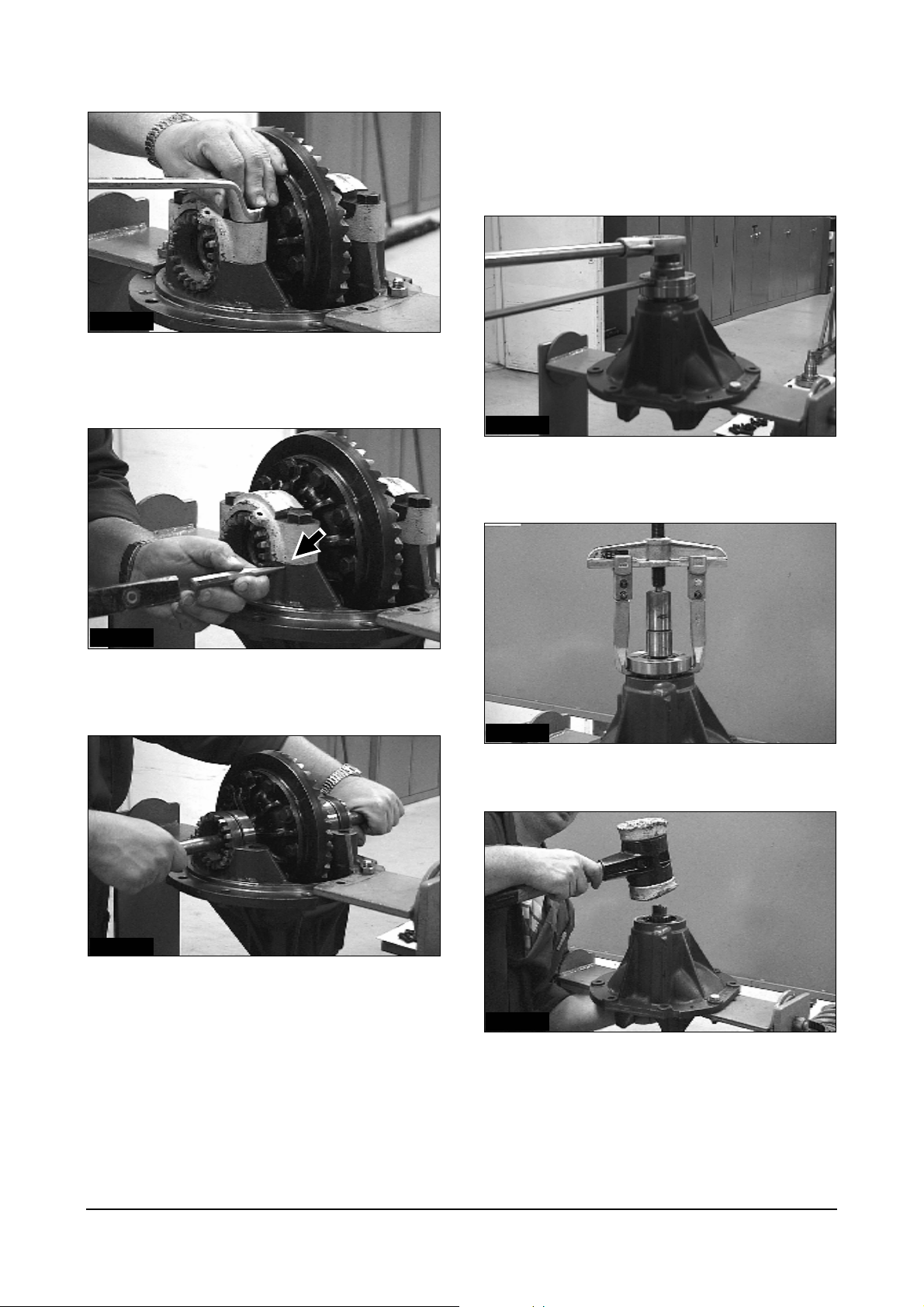

Disassembly

Reverse Shaft

1

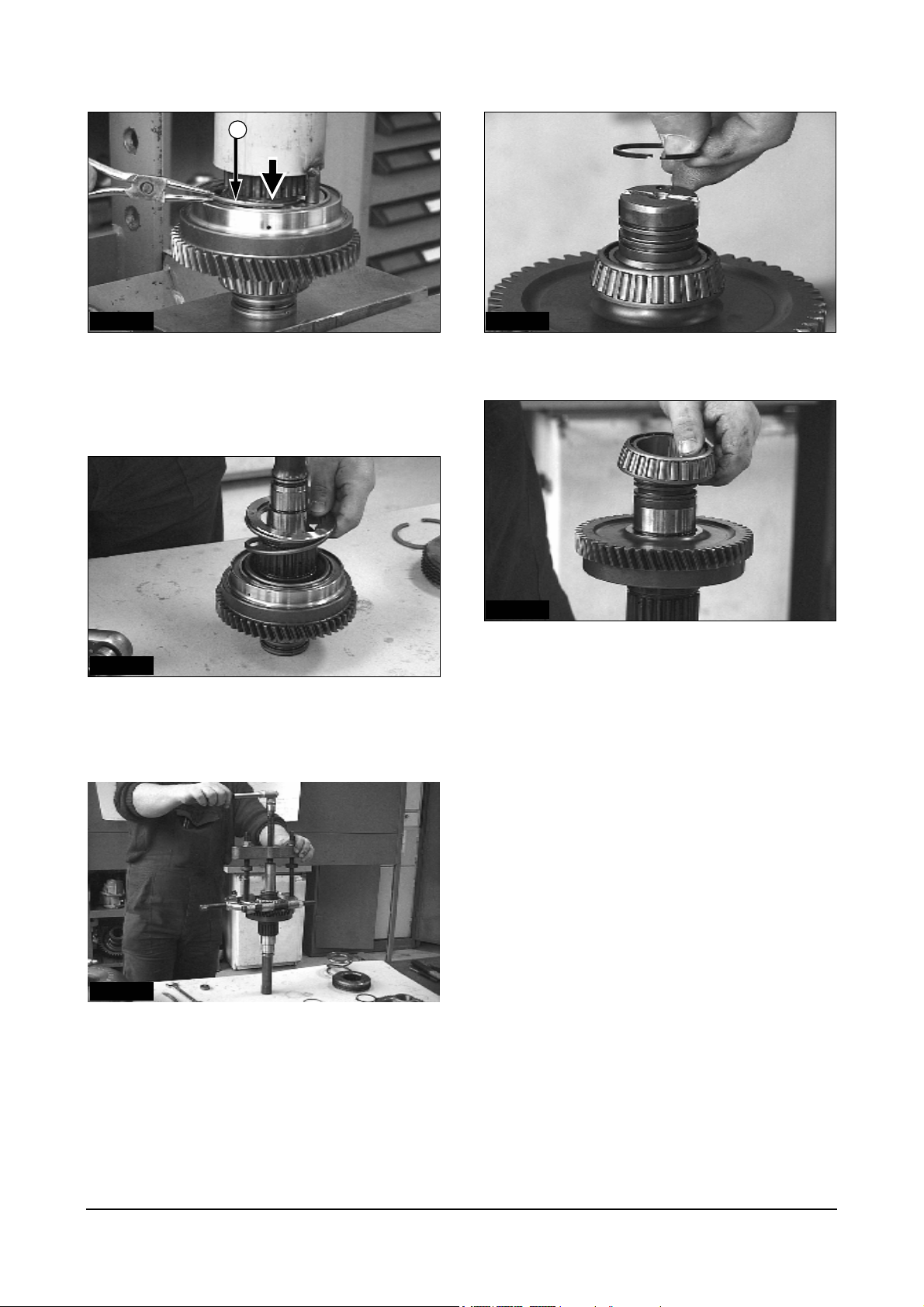

IDCD521P

1. Disassemble the shaft with the 2-leg puller.

IDCD522P

2. Remove the safety ball from the seat with a screw

driver.

IDCD524P

4. Remove the snap ring (1) from the support disk

with the circlip pliers.

IDCD525P

5. Lift the multiple disk body.

2

IDCD526P

6. Remove the snap ring (2) while pressing the

return spring on the spring retainer with a

IDCD523P

3. Remove the double needle bearing.

Power Train Disassembly & Assembly

9

hydraulic press. Slowly relieve the tension of the

spring. (Tool Ref. No 1)

Page 11

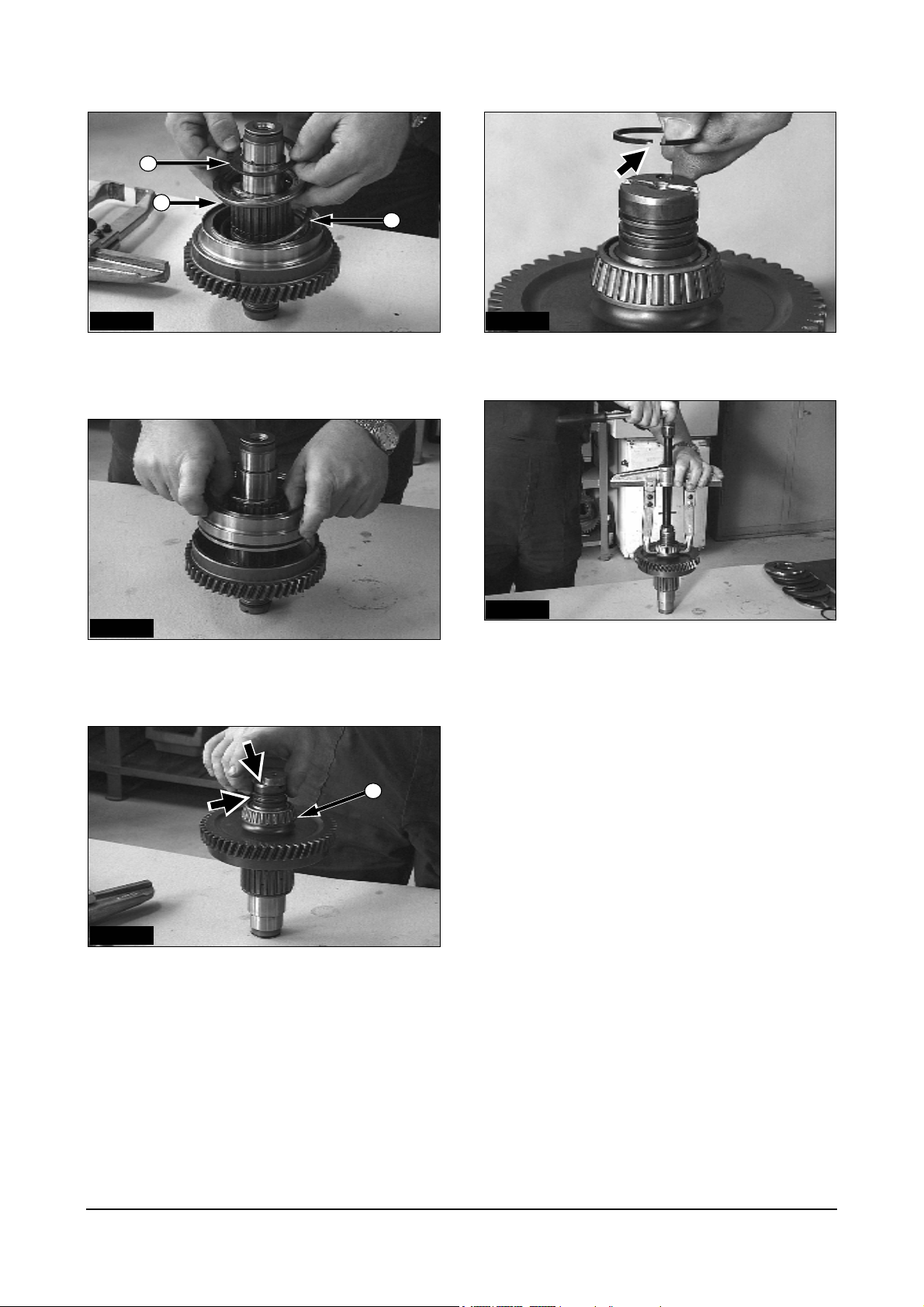

1

2

3

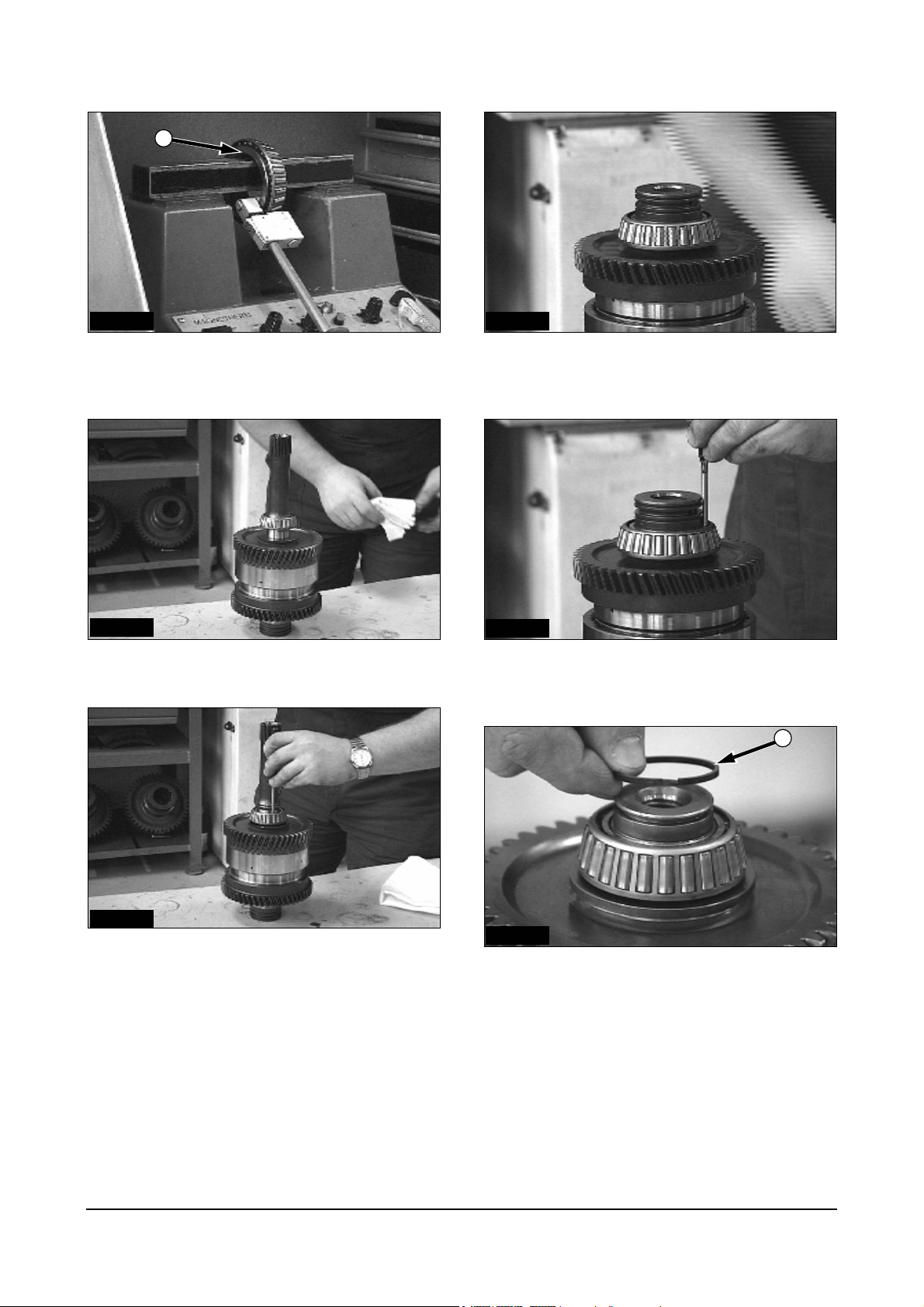

IDCD527P IDCD530P

7. Remove the parts - snap ring (1), spring

retainer(2) and return spring (3)

10. ATTENTION: Open the R-rings before lifting!

IDCD531P

IDCD528P

8. Lift the piston by using compressed air in the

lower bore.

11. Remove the bearing from the shaft with a 2-leg

puller.

4

IDCD529P

9. Remove both R-rings before lifting the bearing (4).

Power Train Disassembly & Assembly

10

Page 12

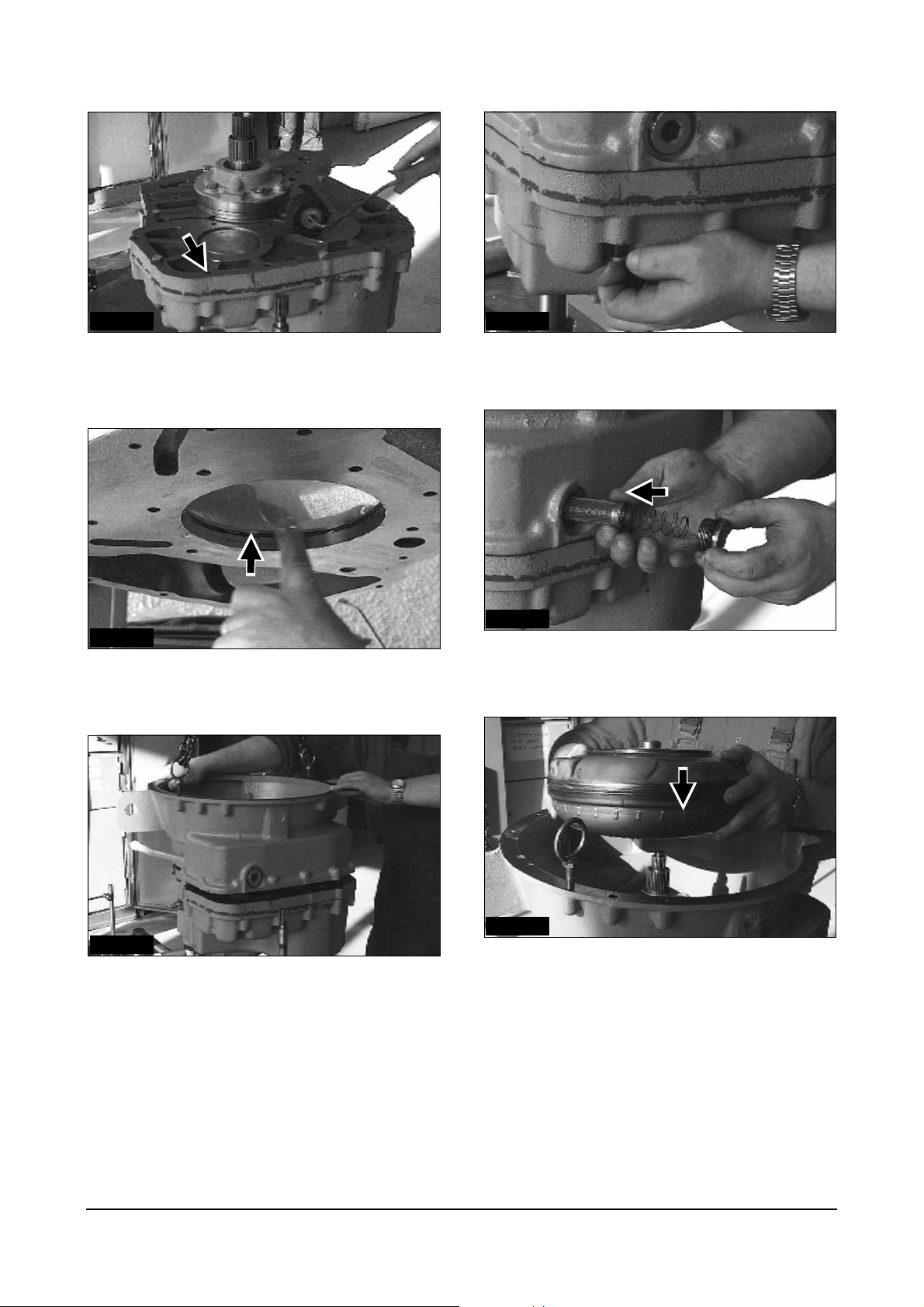

Assembly

Reverse Shaft

3

IDCD532P

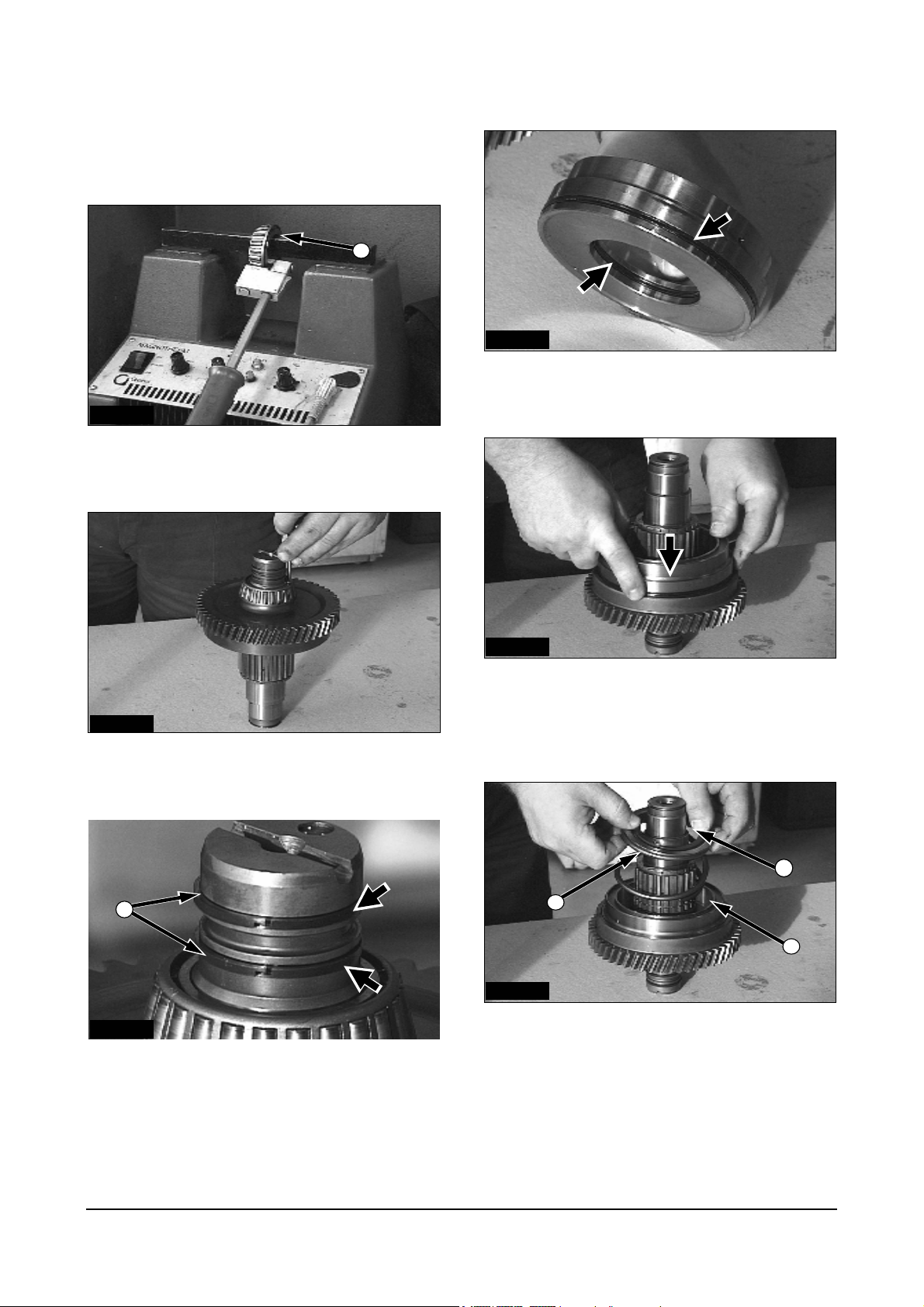

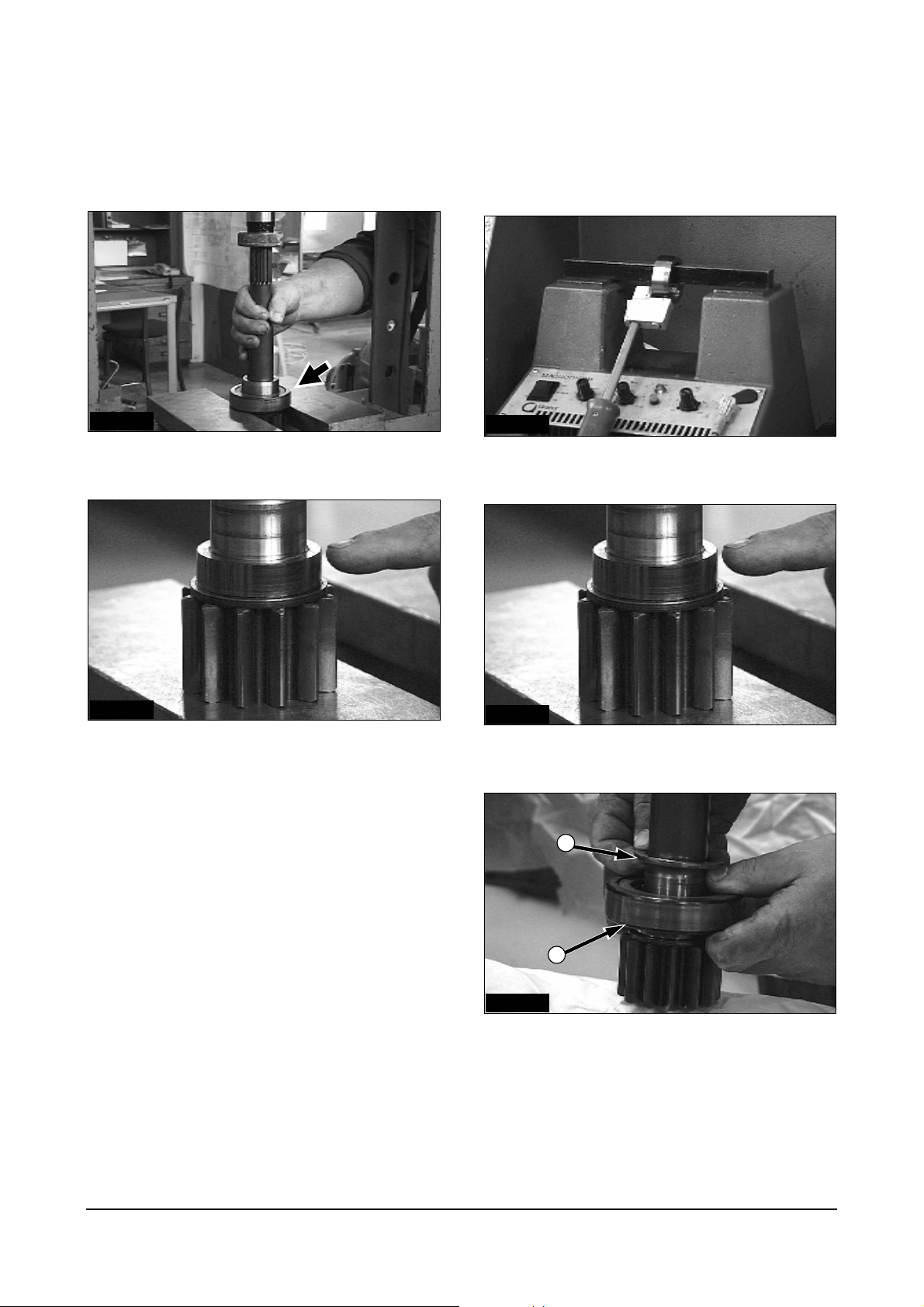

12. Heat bearing (1) to a temperature of 120°C

(248°F) and install it on the shaft.

IDCD533P

13. After the bearing has cooled, the inner bearing

ring must be tapped into position.

IDCD535P

15. Inner and outer piston rings must be lubricated

with transmission oil.

IDCD536P

16. Insert the piston.

ATTENTION: Canting the piston can cause damage.

5

2

IDCD537P

IDCD534P

14. Install both R-rings (2) in their grooves.

Power Train Disassembly & Assembly

17. Install return spring (3), spring retainer (4) and

11

4

3

snap ring (5).

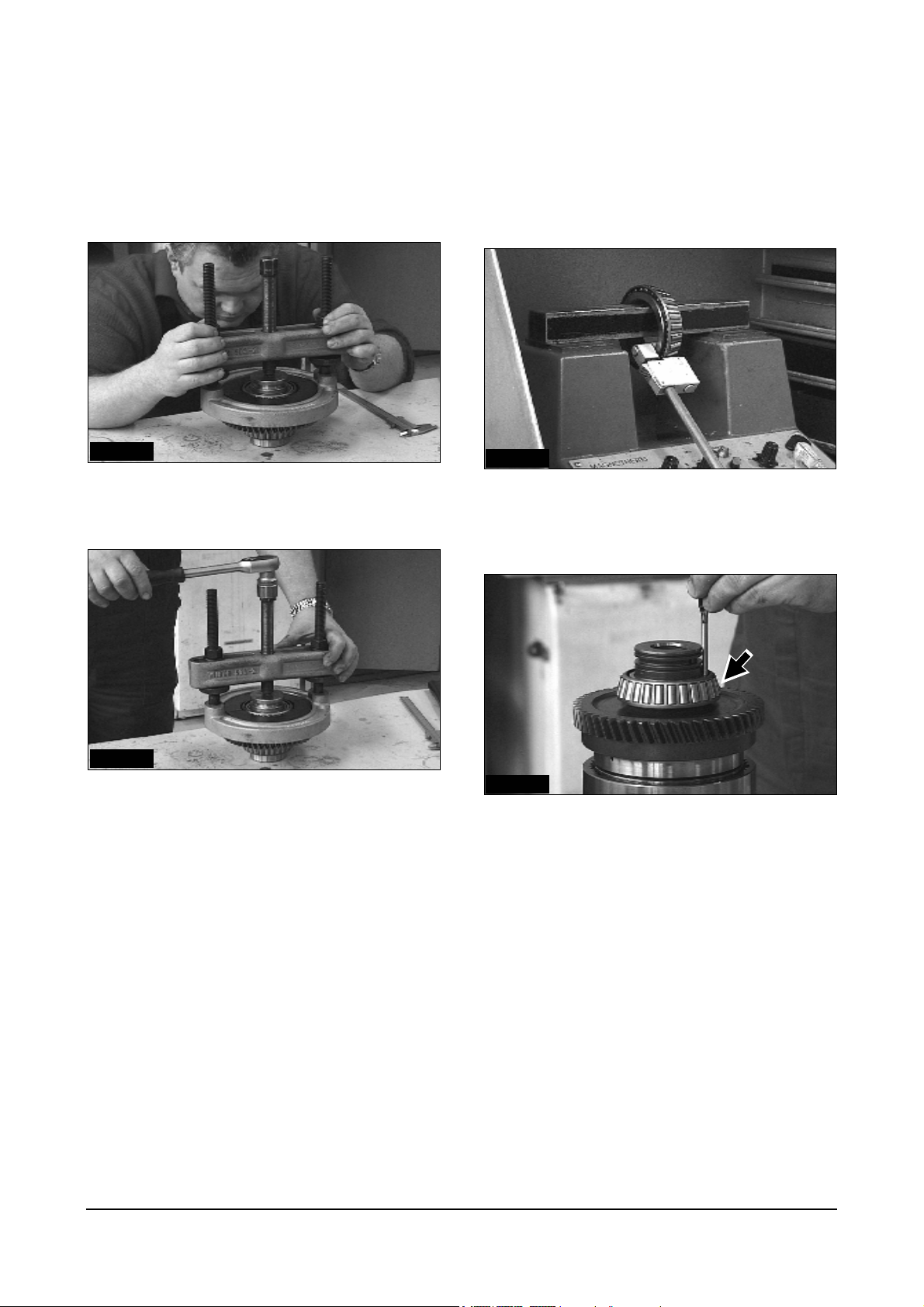

Page 13

1

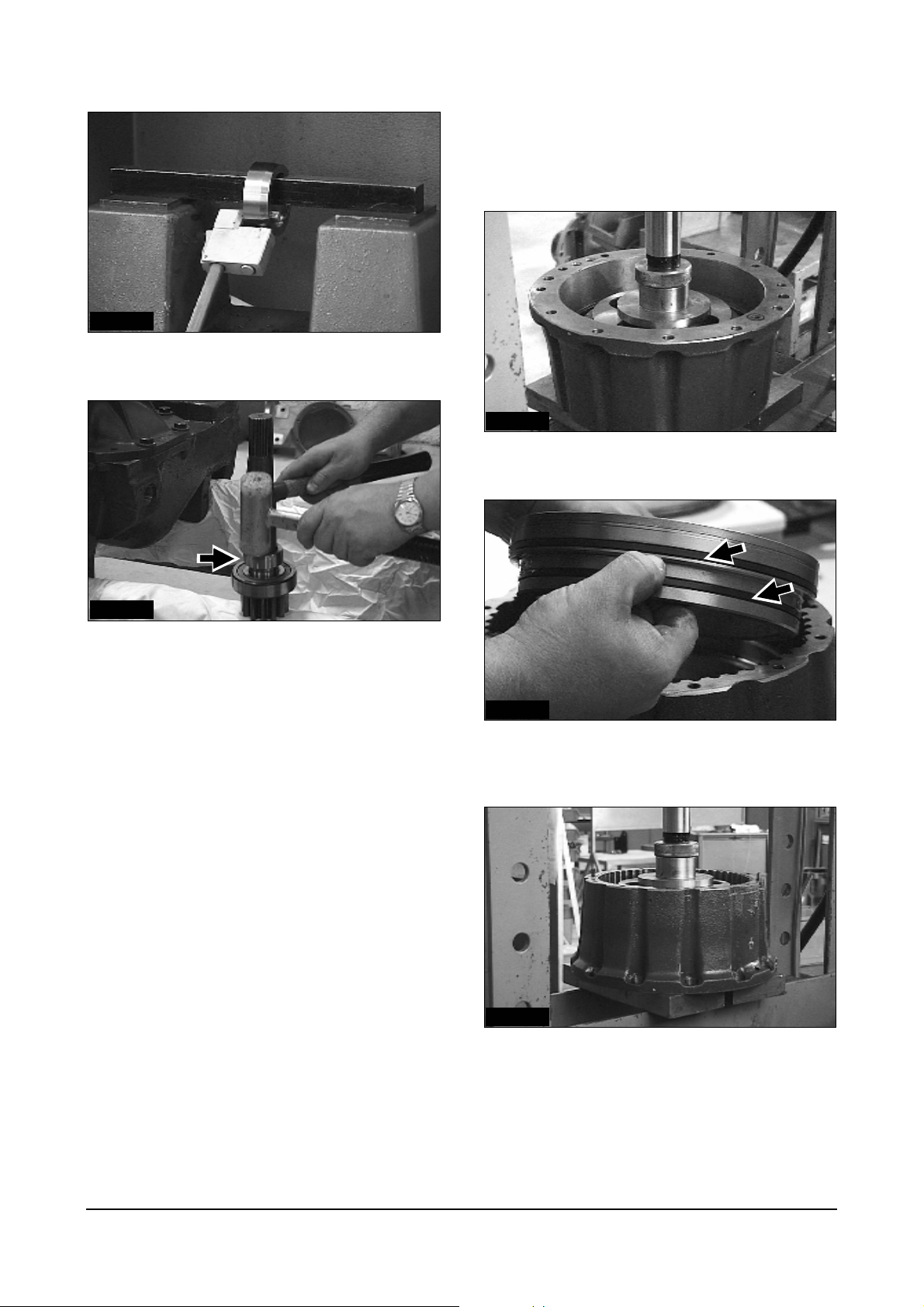

18. Install snap ring (1) by pressing the return spring.

(Tool Ref. No 1)

IDCD541PIDCD538P

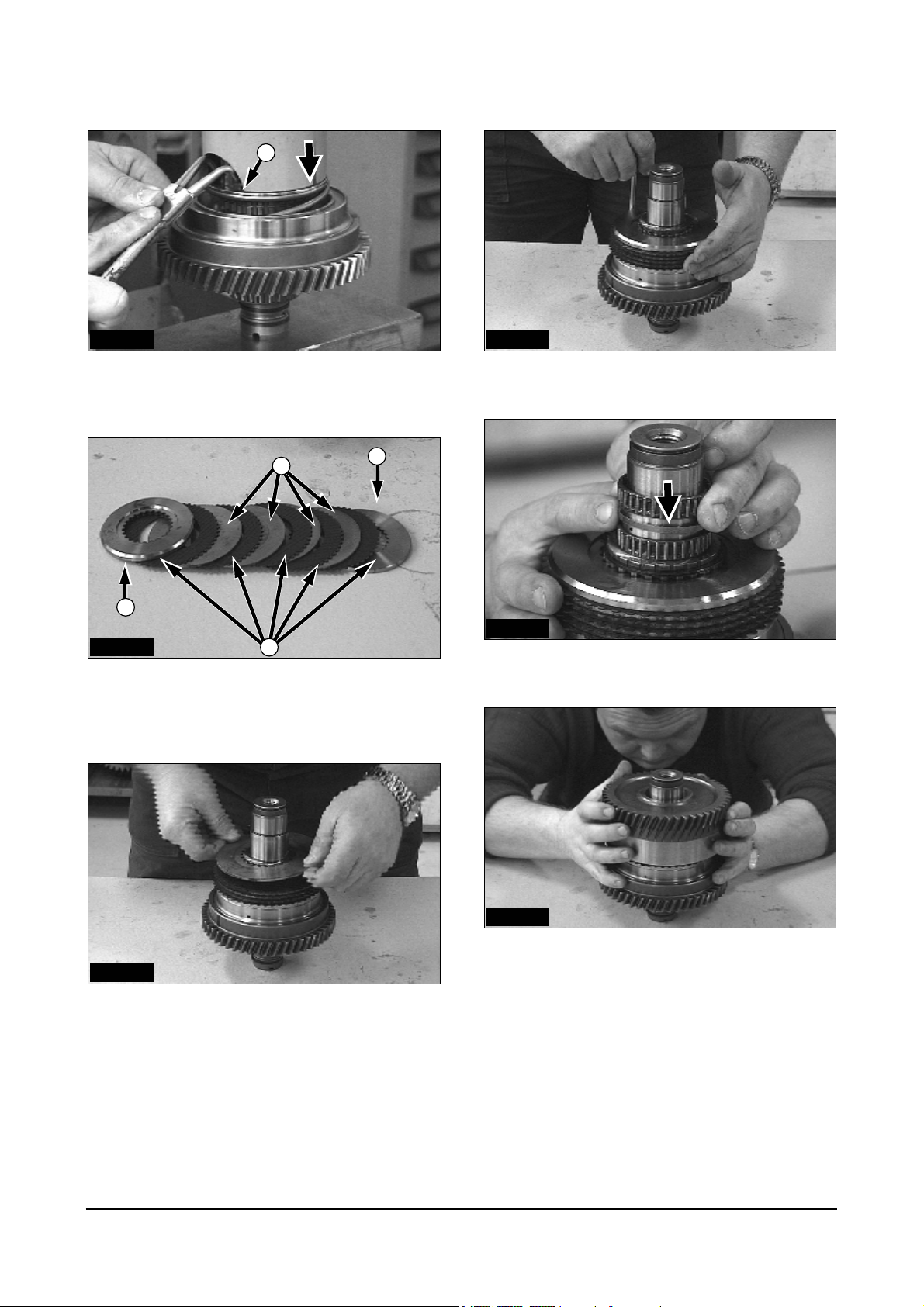

21. Align the teeth of the clutch disks.

2

5

IDCD539P

3

4

19. Elements of the multiple disk body: (2) pressure

disk, (3) inner separater disks, (4) outer clutch

disks, (5) support disk

IDCD542P

22. Install the needle bearing.

IDCD543P

IDCD540P

20. Put the multiple disk body on the gear and install

the snap ring.

Power Train Disassembly & Assembly

23. Put the gear wheel on the shaft.

12

Page 14

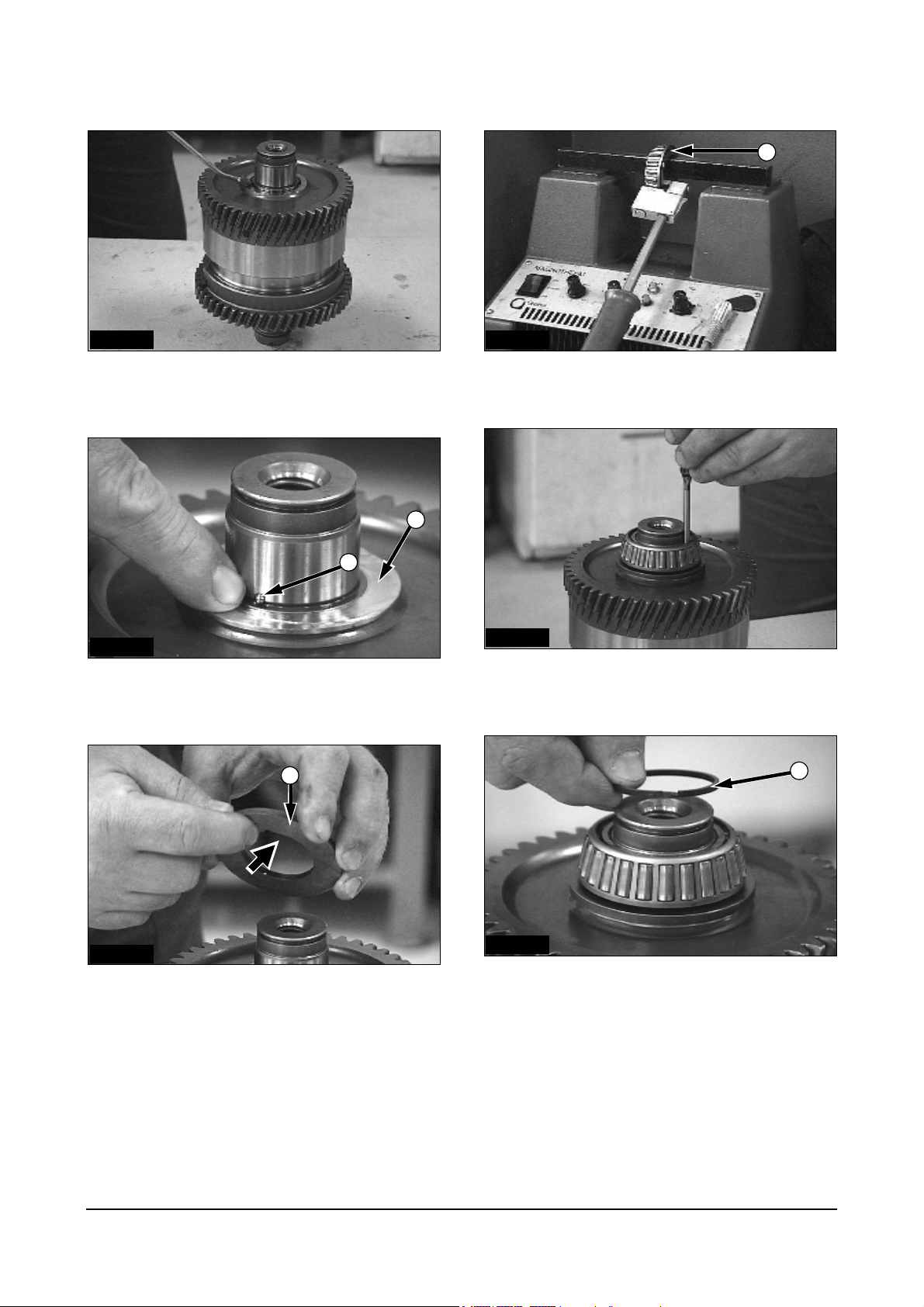

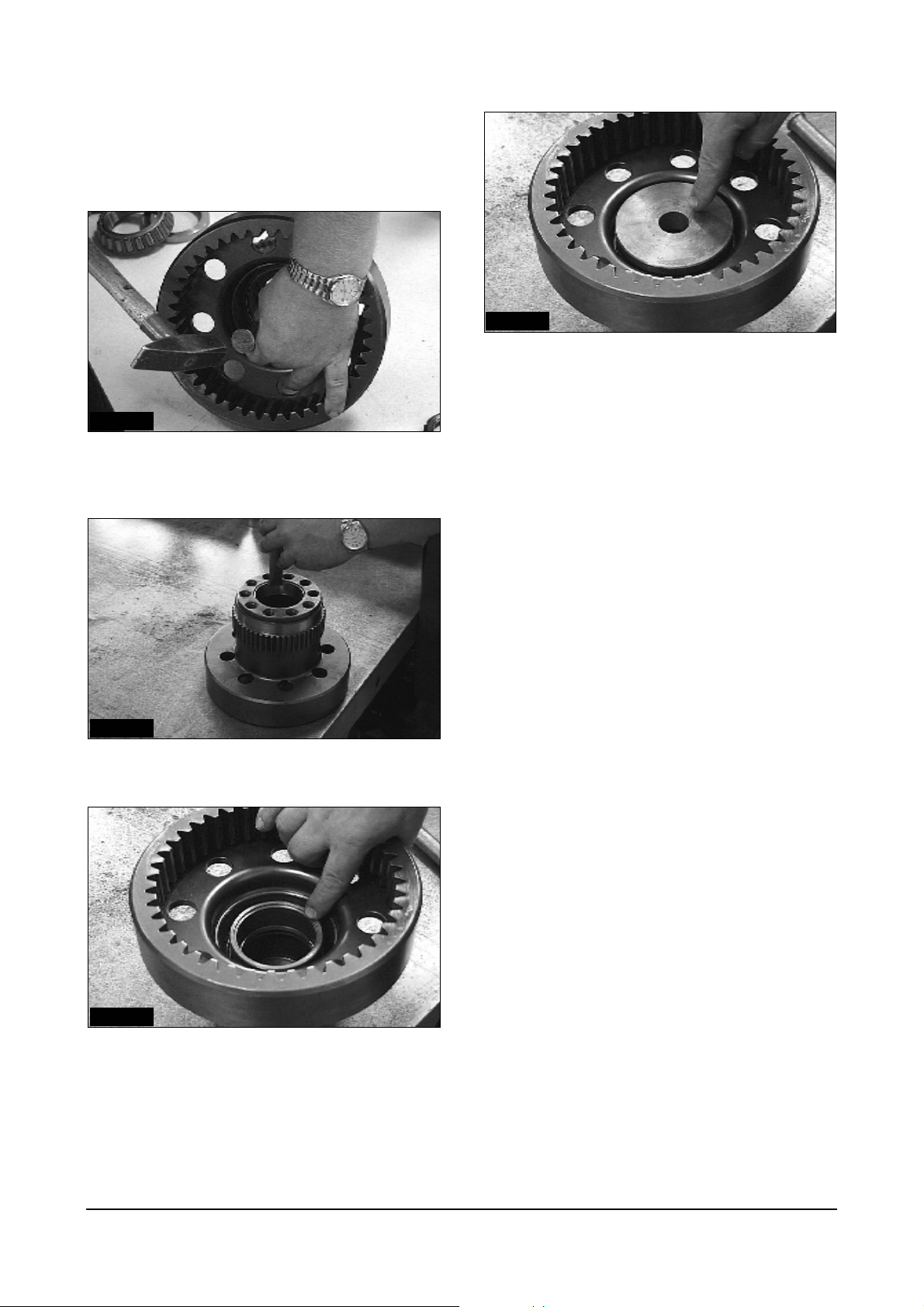

24. Lubricate the needle bearing before installing the

washer.

1

2

IDCD547PIDCD544P

27. Heat bearing (4) to a temperature of 120°C

(248°F) and install it on the shaft.

4

IDCD545P

25. After installing the washer (1), put the ball (2) in

the hole.

3

IDCD546P

26. Install the steel-washer (3).

ATTENTION: The ball must engage the notch!

IDCD548P

28. After cooling the bearing, the inner bearing ring

must be tapped to set bearing.

IDCD549P

29. Install the R-ring (5).

5

Power Train Disassembly & Assembly

13

Page 15

Disassembly

Input Shaft

IDCD550P

1. Disassemble the shaft with a 2-leg puller.

Remove R-ring before lifting the bearing.

2

3

1

IDCD551P

2. After lifting the gear wheel (1), remove bearing (2)

and washer (3).

IDCD553P

4. Remove the ball from the seat with a magnet.

IDCD554P

5. Remove the double needle bearing (4) and the

brass washer (5).

6

4

5

IDCD555P

6. Remove the snap ring (6) from the support disk

with the circlip pliers and remove the disks.

IDCD552P

3. Lift the gear wheel.

Power Train Disassembly & Assembly

14

Page 16

1

IDCD556P IDCD530P

7. Remove the snap ring (1) while pressing the

return spring on the spring retainer with a

10. ATTENTION : Open the R-rings before lifting.

hydraulic press. Slowly relieve the tension of the

spring. (Tool Ref. No 1)

IDCD559P

IDCD557P

11. Lift the back bearing.

8. Lift the piston by using compressed air in a lower

bore, after removing the spring retainer and return

spring.

IDCD558P

9. Remove both R-rings before lifting the bearing.

Power Train Disassembly & Assembly

15

Page 17

Assembly

Input Shaft

1

IDCD560P

12. Ring (1) and inner needle bearing (2).

IDCD561P

13. Drive the ring and bearing with an puncher

(Ø25mm, length 400 mm) (Ø 1.0 in X 15.75 in

length) into the shaft.

2

IDCD563P

15. Insert the piston.

ATTENTION: Canting the piston can cause damage.

IDCD564P

16. Install snap ring by pressing the return spring.

(Tool Ref. No 1)

IDCD565P

17. Put the multiple disk body on the gear.

IDCD562P

14. Inner and outer piston rings must be lubricated

with the transmission oil.

Power Train Disassembly & Assembly

16

Page 18

1

IDCD566P

18. Mount the snap ring (1) on the support disk with

the circlip pliers.

IDCD567P

19. Lubricate the support disk area.

IDCD569P

21. Align the teeth of the clutch disks and put gear

wheel on the shaft.

IDCD570P

22. Lubricate the washer.

IDCD571P

IDCD568P

20. Install the washer and needle bearings.

23. Put the ball in the hole of the shaft and the notch

in the washer.

ATTENTION: The ball must engage the notch!

Power Train Disassembly & Assembly

17

Page 19

1

IDCD572P IDCD575P

24. Heat bearing (1) to a temperature of 120°C

(248°F) and install it on the shaft.

IDCD573P

25. Install the bearing on the shaft.

27. Install the heated back bearing (120°C, 248°C) on

the shaft.

IDCD576P

28. After mounting and cooling, the inner bearing ring

must be tapped into position.

2

IDCD574P

26. After the bearing has cooled, the inner bearing

ring must be tapped into position. Install the R-ring.

IDCD577P

29. Mount and hook the R-ring (2).

Power Train Disassembly & Assembly

18

Page 20

Disassembly

Output Shaft

Assembly

Output Shaft

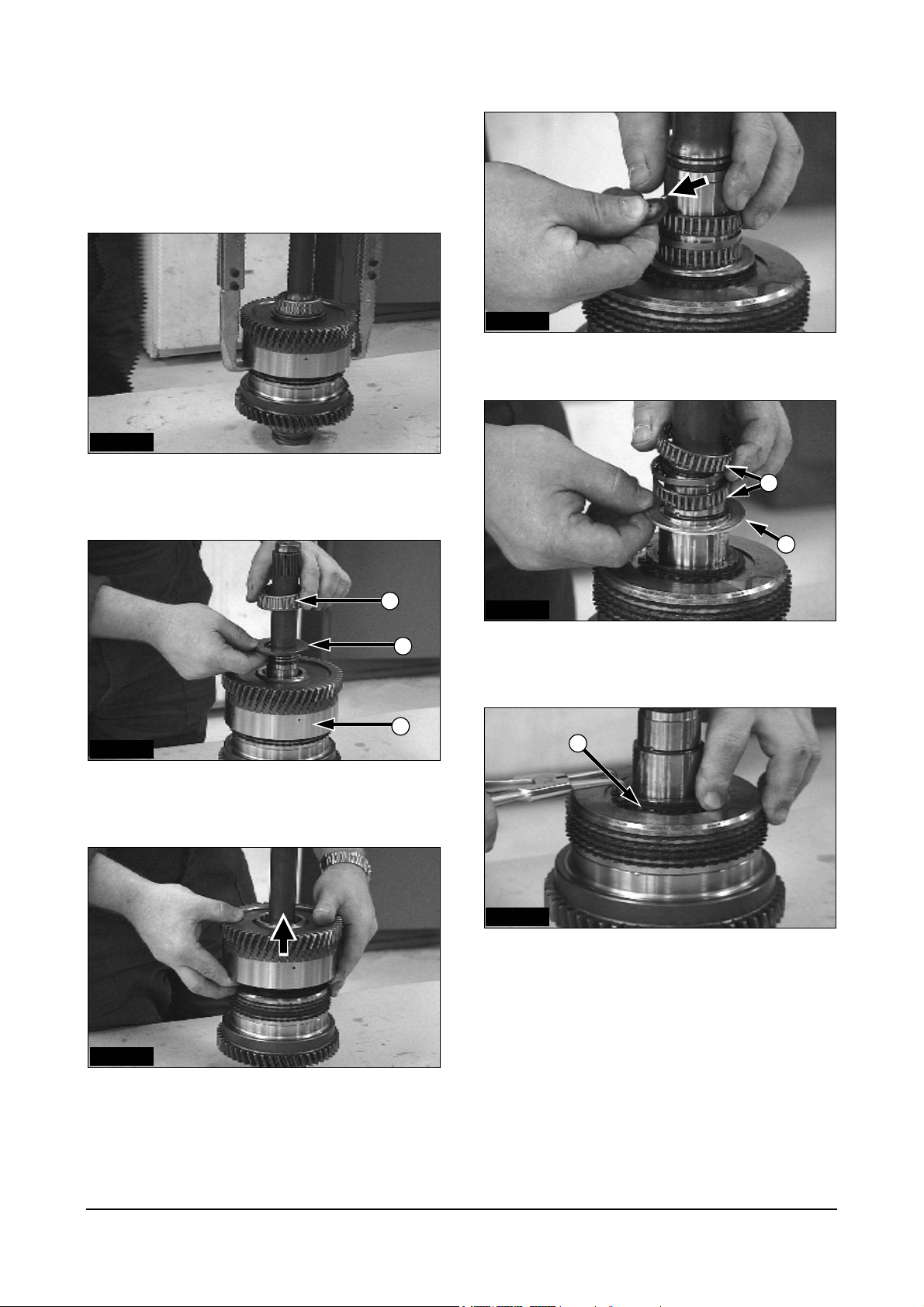

IDCD578P

1. ATTENTION: Set the puller on the inner bearing

ring!

IDCD579P

2. Remove the shaft with suitable puller device.

This can be done from either end of shaft.

IDCD580P

3. Heat bearing (1) to a temperature of 120°C

(248°F) and install it on the shaft.

IDCD581P

4. After cooling, the inner bearing ring must be

tapped into position.

Power Train Disassembly & Assembly

19

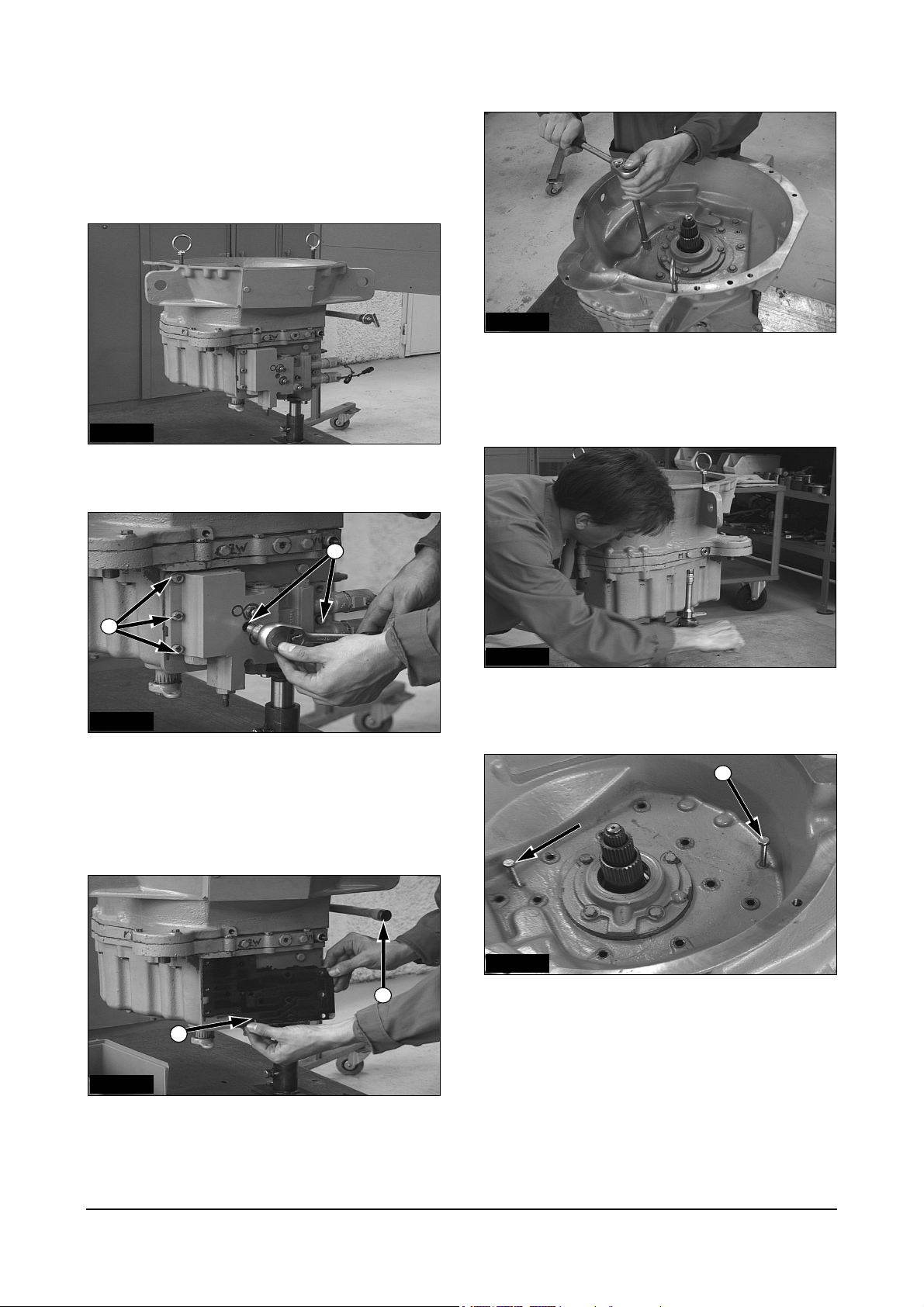

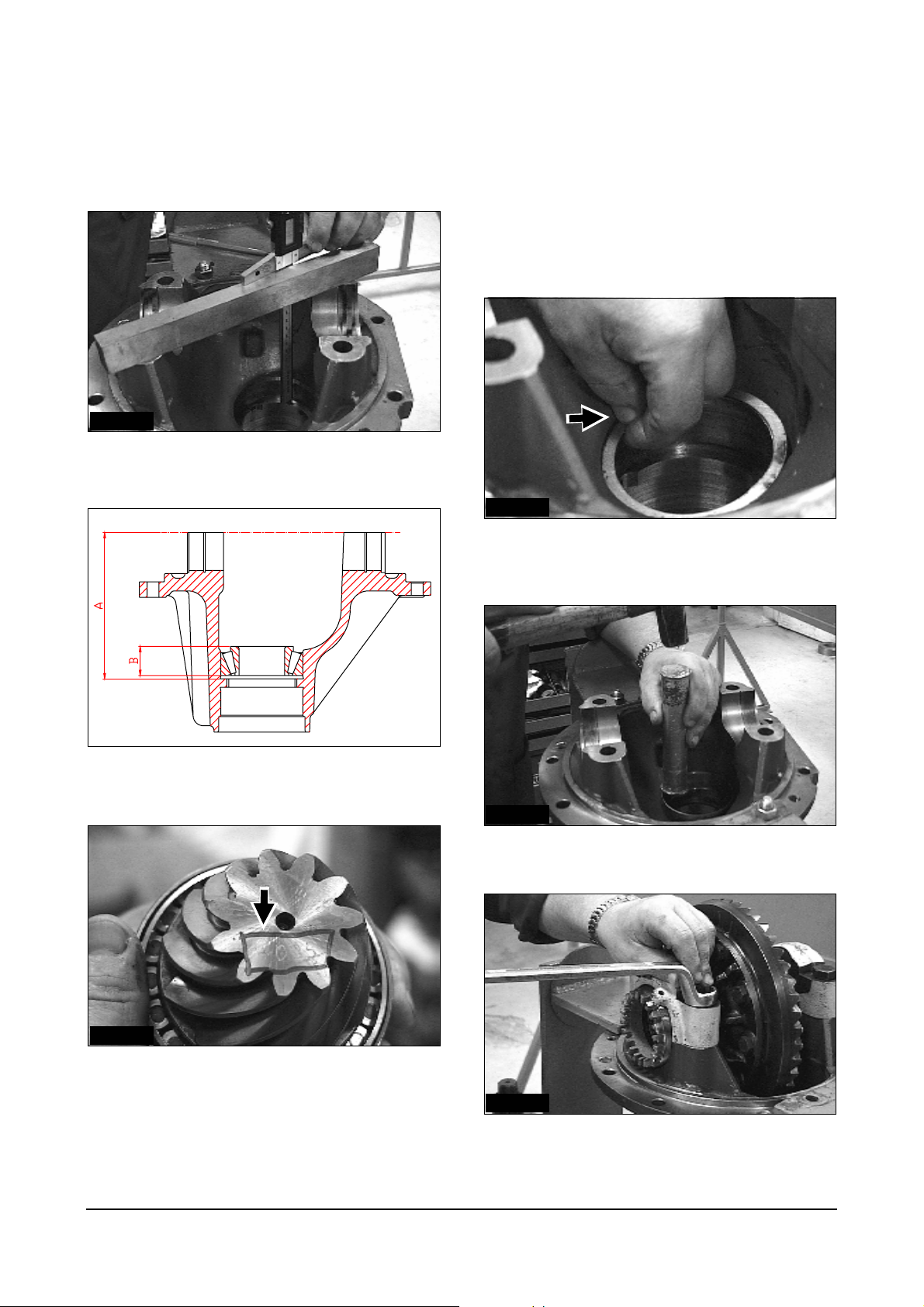

Page 21

Assembly

Transmission Housing

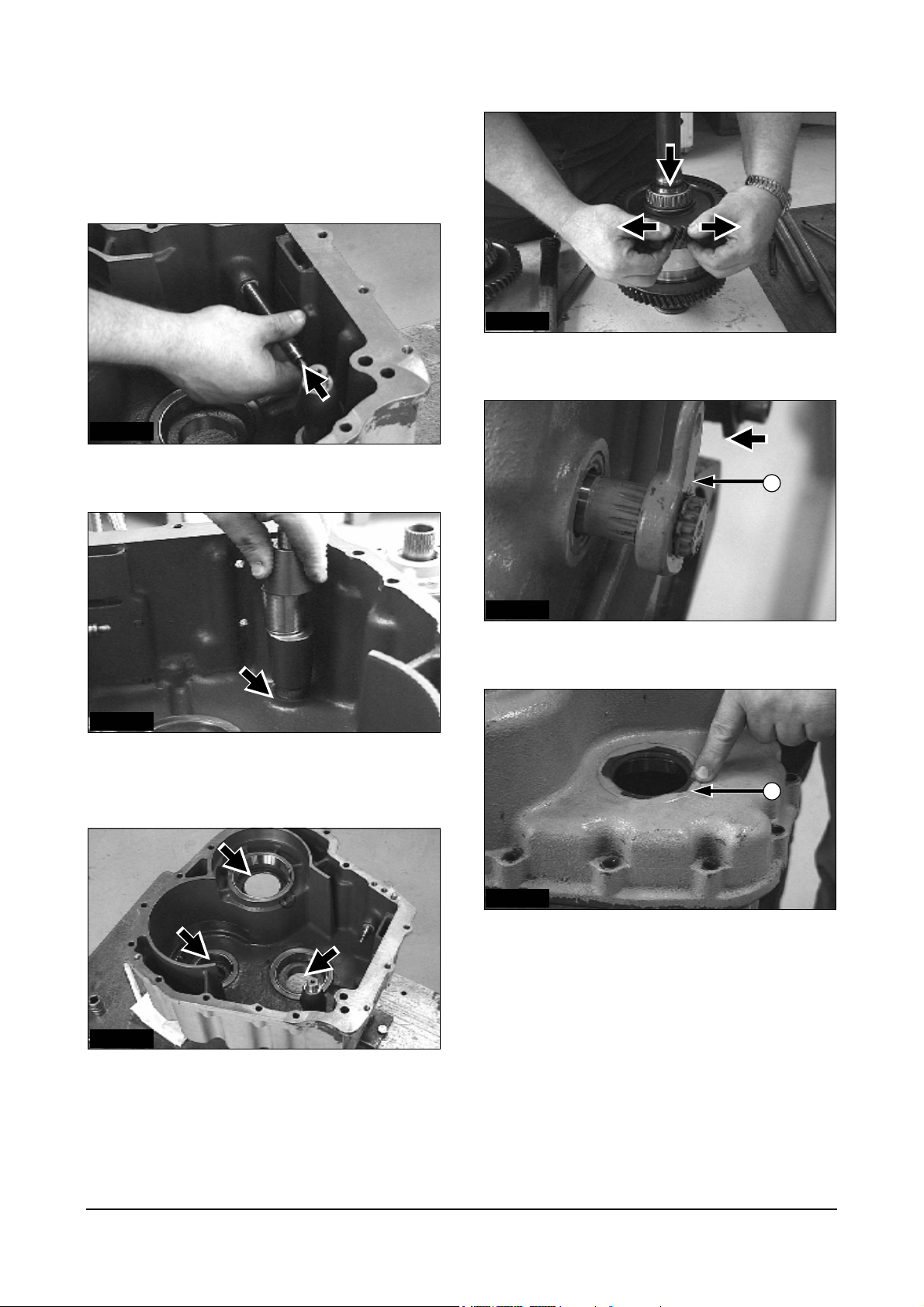

IDCD582P

1. Mount the parking brake adjustment bolt.

IDCD583P

2. Eccentric shaft for parking brake.

Check the free-movement.

IDCD585P

4. Mount the brake band.

IDCD586P

5. Mount the snap ring of the park brake lever (1).

1

2

IDCD587P

6. Oil Seal of output gear wheel (2) must be set flush

with the housing surface.

IDCD584P

3. Check the bearing parts for damages.

Be sure all surfaces are clean.

Power Train Disassembly & Assembly

20

Page 22

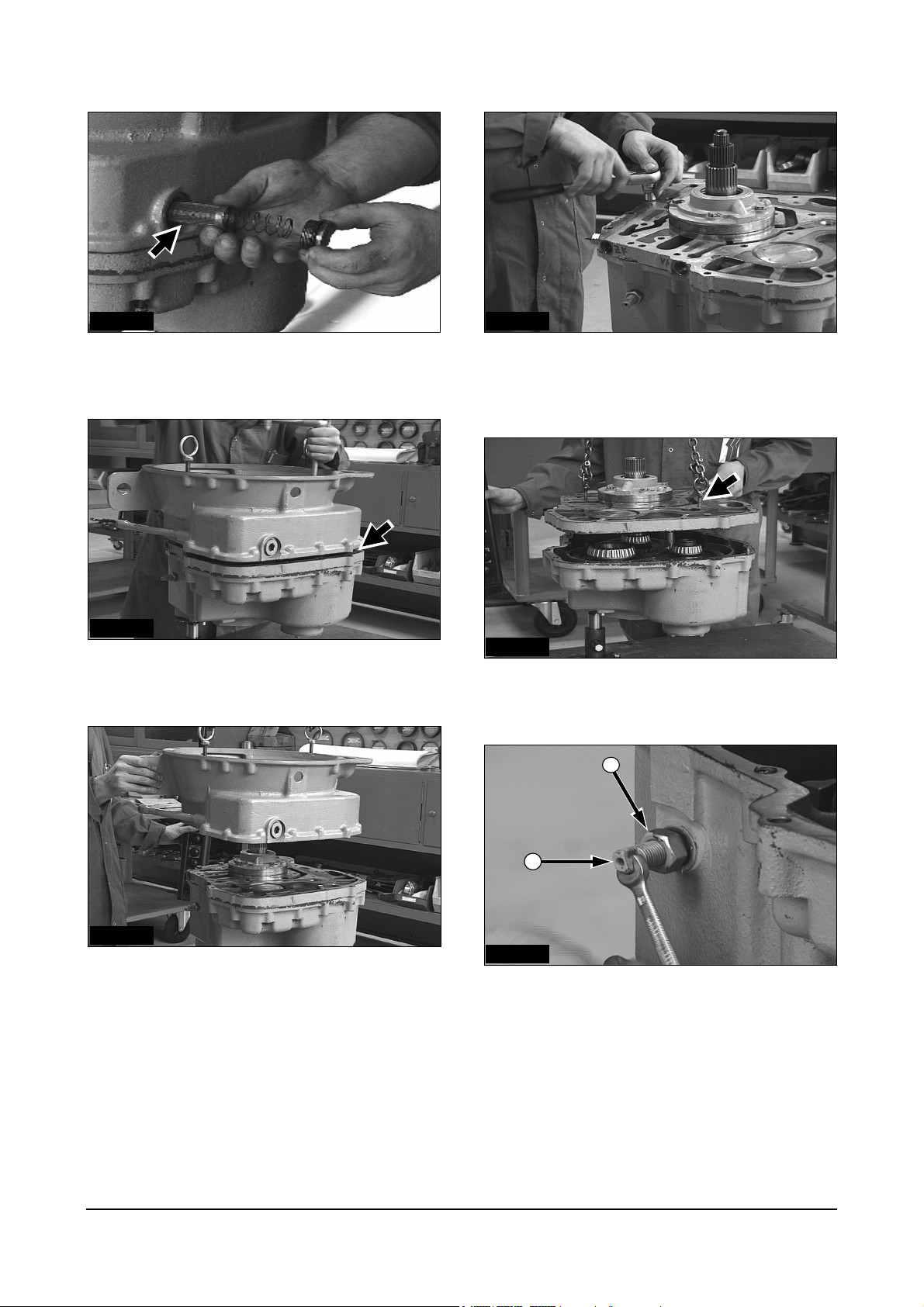

IDCD588P

7. Install the reverse shaft.

IDCD591P

10. Assemble the struts for the parking brake band.

Adjust after assembly.

11. Install each bearing cup on the reverse shaft

assembly and the output shaft assembly.

IDCD589P

8. Install the lnput shaft. Check for free rotation.

IDCD590P

9. Install output shaft last.

Check for free rotation.

A

B

Reverse

Shaft

B’

12. Measure the height from the surface of

transmission housing to the top of the each

bearing cup (A or A‘ dimension)

* To minimize the measuring error measure at

least three places and average them.

13. Measure the depth from the bearing plate surface

to the shoulder of the hole for the bearing of each

shaft, reverse and output (B or B’ dimension)

* For the output shaft, measurement should be

done with the cover installed

14. Caculate the required shimpack thickness (Z) with

the following formula.

Z = B-A+(0.05~0.08mm) or (0.002~0.003in)

For reverse shaft

= B’-A’+(0.05~0.08mm) or (0.002~0.003in)

For output shaft

15. Insert shims according to the calculated thickness

above behind the bearing cup of each shaft. And

assemble bearing cups into the bearing plate.

Bearing Plate

Output

Shaft

A’

Power Train Disassembly & Assembly

21

Page 23

1

2

3

IDCD594P

4

16. Valves in the bearing plate consist of: ball(1),

spring(2), seal ring (3) and plug (4).

Tighten the plug with allen head wrench 6 mm.

IDCD595P

17. The housing areas must be cleaned and

degreased. Apply sealing compound (LOCTITE

17430) to coat on one side.

IDCD597P

19. Tap the bearing plate into position over dowel pins

and tighten all bearing plate mounting bolts.

IDCD598P

20. Using a punch, tap bearing cone down against

input shaft. Install bearing cup against cone in the

same manner.

ATTENTION: Check for free rotation.

IDCD596P

18. Lower the bearing plate.

IDCD599P

21. Measure the depth of the bearing cup below

bearing plate surface at three places.

Average this dimension and record as Dim. A

Power Train Disassembly & Assembly

22

Page 24

IDCD600P

22. Measure the height of pump pilot surface above

mounting surface at three places.

Average this dimention and record as Dim. B.

1

IDCD510P

25. Assemble the lube pump with screws M8, torque

32 ± 3 N·m (23.5 ± 2.0 lb·ft) (Hexagonal socket 13

mm).

IDCD601P

23. Select shim thickness by subtracting B Dim. from

A Dim. Shim thickness = A-B+0.0-0.05mm (+0.0-

0.002 in)

IDCD602P

24. The sealing area of the lube pump must be

cleaned and degreased. Apply sealing compound

(LOCTITE 17430) to pump flange.

IDCD604P

26. Tap the outer front bearing ring back.

IDCD605P

27. Check the shaft end play by moving the shaft up

and down.

Dial indicator should not exceed 0.05mm

(0.002 in)

Power Train Disassembly & Assembly

23

Page 25

IDCD606P IDCD609P

28. The housing areas must be cleaned and

degreased. Apply sealing compound (LOCTITE

17430) on one side of bearing plate.

31. Install the housing screws with a torque of

55 ± 5 N·m (41 ± 4 lb·ft).

IDCD610P

IDCD607P

29. Before joining torque converter housing to bearing

plate, apply lubricant to lube pump ring.

32. Install the oil filter screen.

Tighten the plug with an allen head wrench.

IDCD611P

IDCD608P

30. Install the torque converter housing.

33. Install the torque converter.

Power Train Disassembly & Assembly

24

Page 26

IDCD612P

34. Mount the valve block.

ATTENTION: Tighten the screws from inner to outer

with the tightening torque of 45 ± 3 N·m (33 ± 2.2

lb·ft).

Power Train Disassembly & Assembly

25

Page 27

Disassembly/Assembly

Valve Body

IDCD613P

1. Dismount/mount the solenoid valves of the

forward and reverse clutch.

IDCD614P

2. Dismount / mount the main valve.

IDCD616P

4. Dismount / mount the selection valve.

IDCD617P

5. Dismount the modulation valve with an allen head

wrench.

IDCD618P

6. Dismount / mount the modulation valve.

IDCD615P

3. Dismount / mount the inching valve.

Power Train Disassembly & Assembly

26

Page 28

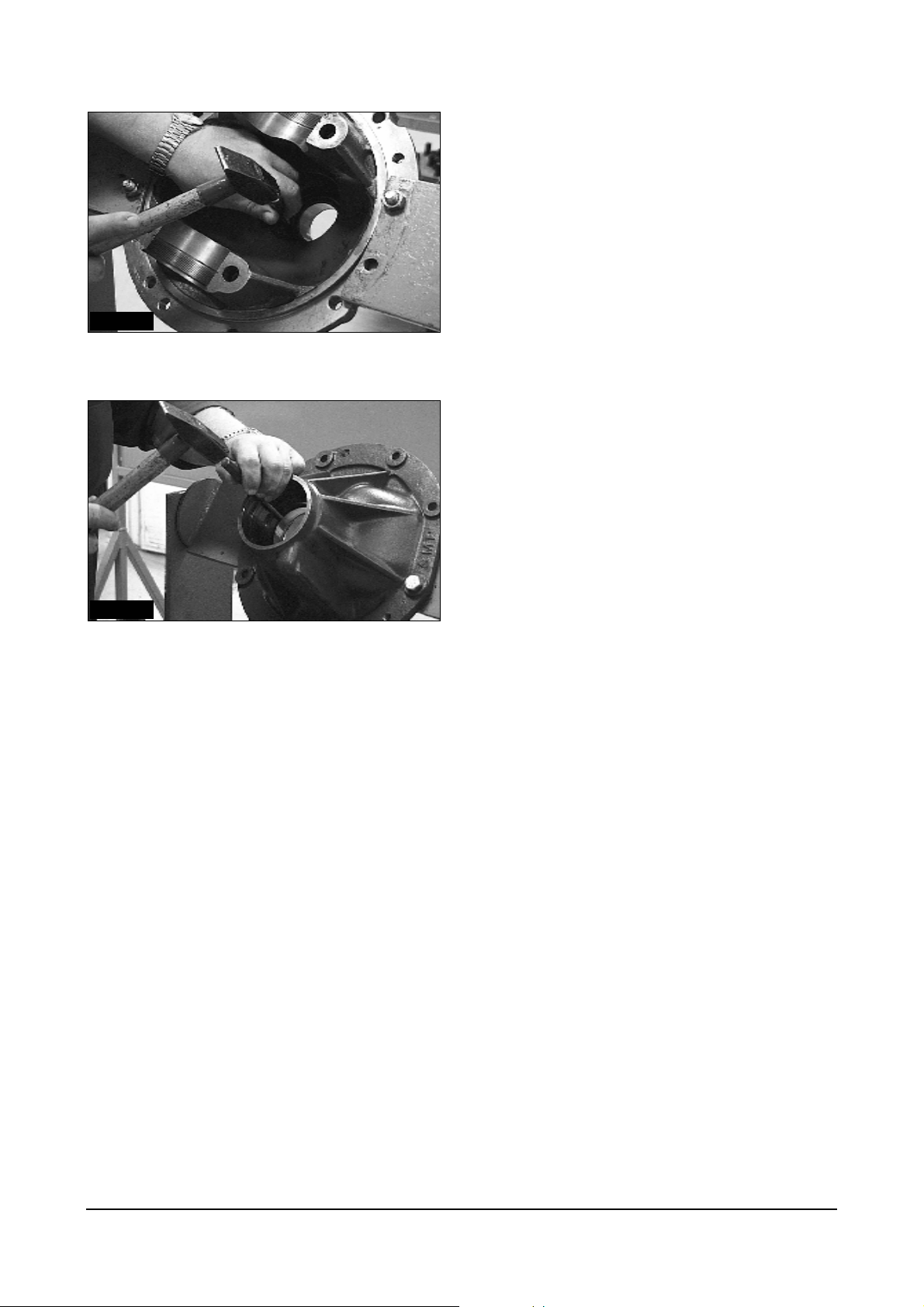

Disassembly

Axle

IDCD619P

7. Tighten the screw to fix the inner working piston of

the inching valve

IDCD620P

8. Adjust the main pressure with the shims in the

screw of main valve

IDCD621P

1. Poision the axle on a suitable support.

IDCD622P

2. Remove the disk brake adapter.

IDCD623P

3. Remove the cover-end

(Hexagon socket 13 mm)

Power Train Disassembly & Assembly

27

Page 29

IDCD624P

4. Loosen the end cover with a plastic hammer

before removing.

IDCD627P

7. Remove the gear cover.

IDCD628P

IDCD625P

5. Remove the friction disks and separater disks.

8. Loosen the gear cover by using a plastic hammer.

1

IDCD629P

IDCD626P

6. Brake parts : (1) sepratater disks,

(2) friction discs.

Power Train Disassembly & Assembly

2

9. Force the gear cover with 2 tire irons.

28

Page 30

IDCD630P

10. Straighten the lock tab with a punch.

IDCD633P

13. Remove the hub.

1

IDCD631P

11. Remove spindle nut with a special tool.(Ref. No 2)

IDCD634P

14. Remove the inner wheel bearing (1).

IDCD632P

1

12. Remove the nut (1), washer (2), shield (3) and

outer hub bearing.

Power Train Disassembly & Assembly

3

2

IDCD635P

15. Remove the spindle with a hexagon socket 19 mm.

29

Page 31

IDCD636P

16. Remove the spindle from the axle housing.

IDCD639P

19. Parts overview of the disassembled axle without

the differential and axle housing.

IDCD637P

17. Pull the axle shaft assembly with a pry bar and a

spindle mounting bolt.

IDCD638P

18. Remove the shaft assembly from the axle housing.

Power Train Disassembly & Assembly

30

Page 32

Disassembly

Shaft As

Assembly

Shaft As

IDCD640P

1. Remove the roller bearing and the ring.

IDCD641P

2. Pull off the inner bearing ring with an suitable 2leg puller.

IDCD642P

1. Heat bearing to a temperature of 120°C (248°F).

IDCD643P

2. Install the heated inner bearing ring on the shaft.

2

1

IDCD644P

3. Mount the bearing (1) and the washer (2).

Power Train Disassembly & Assembly

31

Page 33

Disassembly/Assembly

Brake Parts

IDCD645P

4. Heat the ring to a temperature of 135°C (275°F).

IDCD646P

5. Mount the heated ring with the plastic hammer.

IDCD647P

1. Remove the brake piston.

IDCD648P

2. Lubricate the seal and sliding surface with

transmission oil.

IDCD649P

3. Mount the brake piston using a press.

Power Train Disassembly & Assembly

32

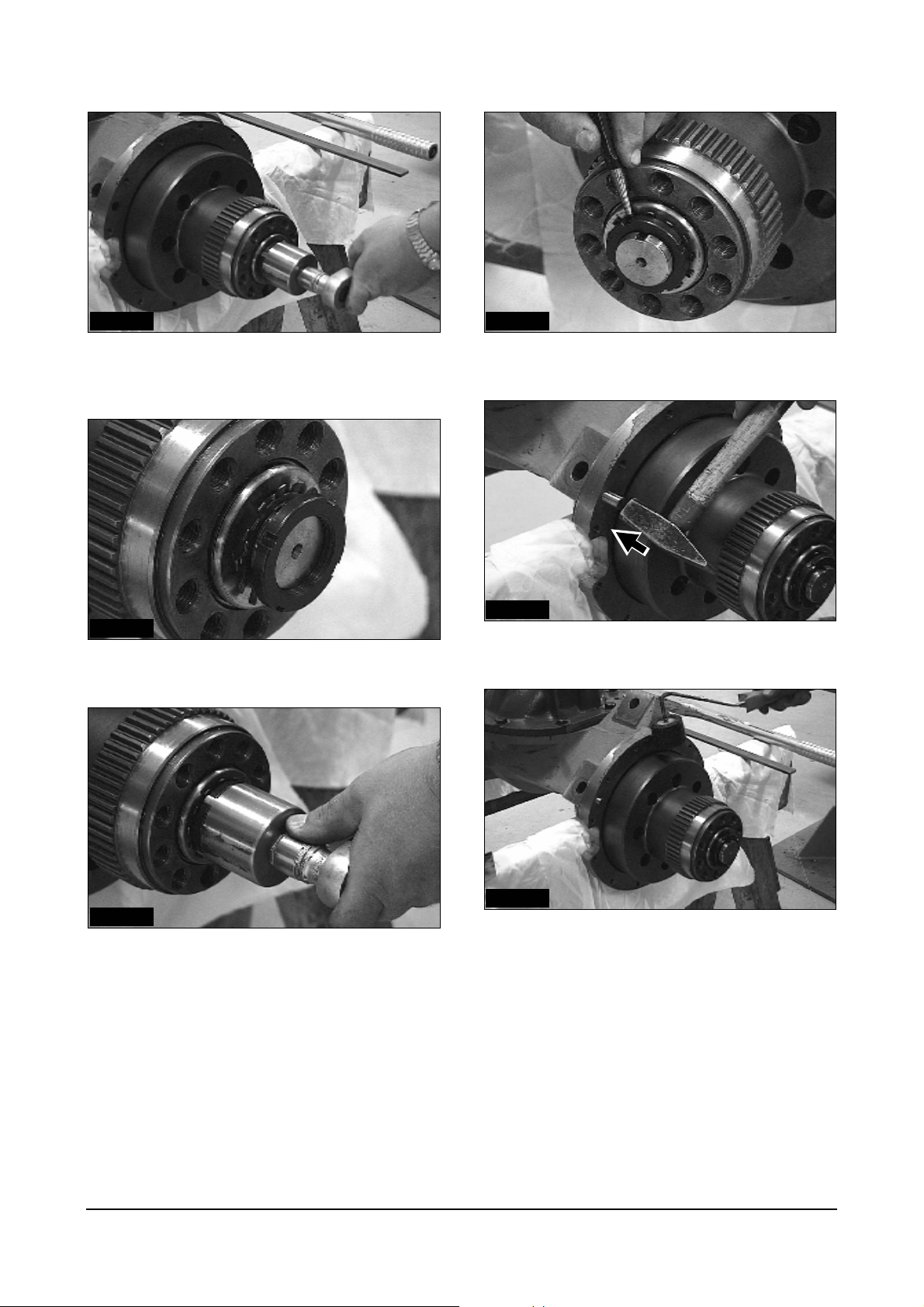

Page 34

Disassembly/Assembly

Hub Drive Axle

IDCD650P

1. Remove the inner bearing cup with hammer and

punch.

IDCD651P

2. Remove the outer bearing cup.

IDCD653P

4. Press in the outer bearing cup. (Tool Ref. No 3)

IDCD652P

3. Install seal with a special tool. (Tool Ref. No 7)

Power Train Disassembly & Assembly

33

Page 35

Disassembly

Differential Assembly

IDCD654P

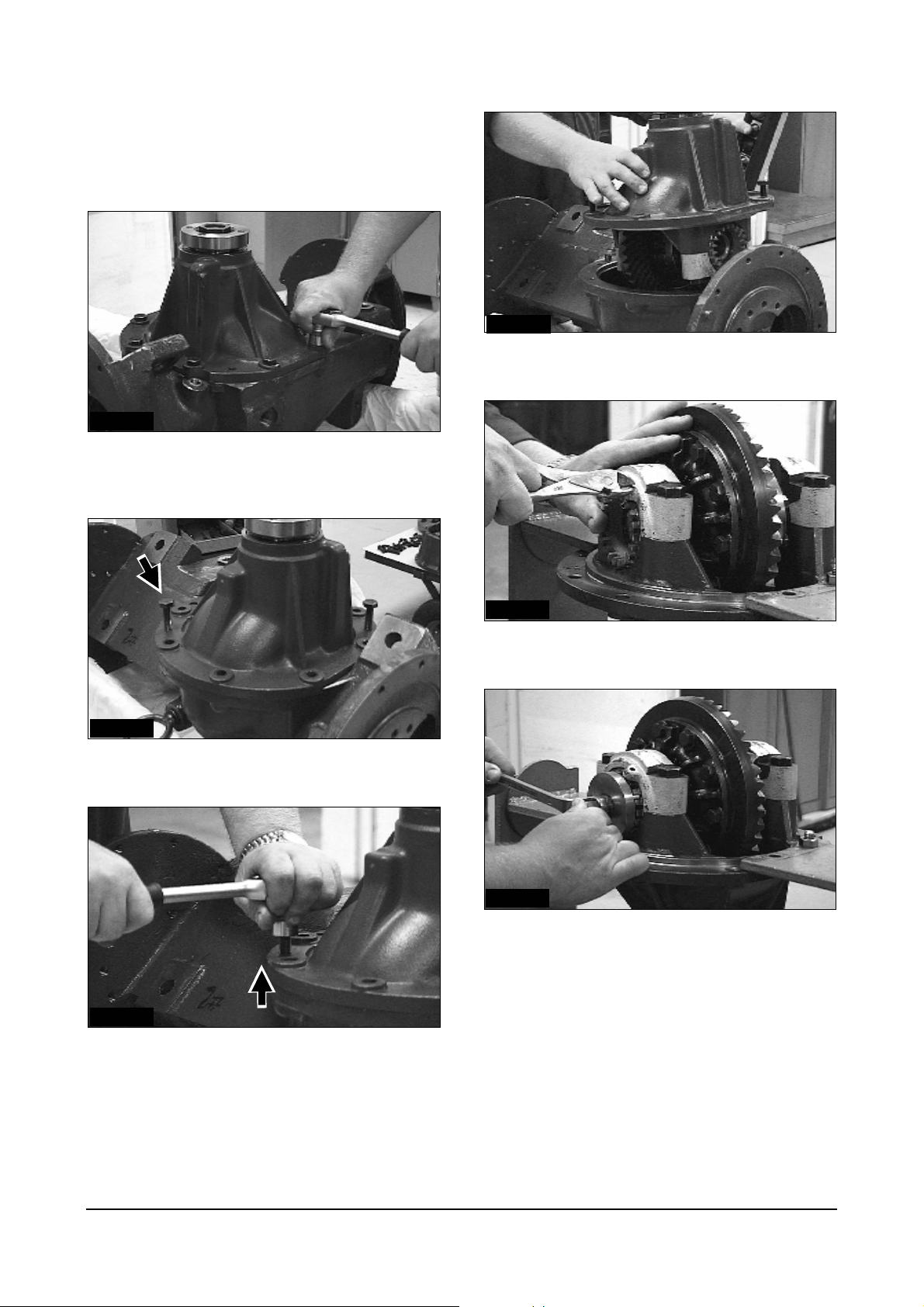

1. Remove all differential carrier mounting bolts.

(hexagon socket 19mm)

IDCD655P

2. Install 2 jackbolts to carrier flange.

IDCD657P

4. Lift the differential carrier out of the axle housing.

IDCD658P

5. Remove the locking cotter pins.

IDCD659P

6. Loosen the retainer with special tool on both sides.

(Tool Ref. No 4)

IDCD656P

3. Press off the axle drive from the axle housing.

Alternately tighten jackbolts to separate carrier

from axle housing.

Power Train Disassembly & Assembly

34

Page 36

Disassembly

Bevel Pinion

IDCD660P

7. Loosen the bearing bolts.

(ring spanner 19mm)

IDCD661P

8. Mark the bearing parts with hammer and centre

punch to guarantee correct side mounting.

IDCD663P

1. Loosen yoke retaining nut with a special tool.

(Tool Ref. No 7) (Hexagon socket 42mm)

IDCD664P

2. Pull off the yoke with a suitable gear puller.

IDCD662P

9. Lift the differnential assembly out of the axle

housing.

Power Train Disassembly & Assembly

IDCD665P

3. Remove pinion from inside carrier while gently

tapping pinion shaft from yoke end using a soft

face mallet.

35

Page 37

IDCD666P

4. Remove the bevel pinion bearing cup and seal.

IDCD667P

5. Carefully drive out the internal bevel pinion

bearing cup.

Power Train Disassembly & Assembly

36

Page 38

Adjustment

Bevel Pinion

4. Calaulate the shimpack thickness according to the

following formula.

Shimpack thickness = A-(127+B+C)

Example) if A=160.50, B=32.00, C=+0.05

Then, shimpack thickness

= 160.50-(127+32.00+0.55) = 1.45mm

* To minimize the measuring error, measure

three places at least and average them.

IDCD668P

1. Measure the depth from center of diff. carrier to

the seat of pinion bearing cup. (Dimension A)

2. Measure the width of pinion bearing.

(Dimension B)

IDCD671

5. Shims of calculated thickness laid into bearing

seat.

IDCD672P

6. Install bearing cup.

IDCD670P

3. Check the etched value on the pinion face.

(Dimension c)

*unit : mm

Power Train Disassembly & Assembly

IDCD673P

7. Install crown gear, differential assy and lightly

torque bridge bilts.

37

Page 39

8. Install bearing nuts for correct bridge position and

lightly torque them to achieve bearing preload.

11. When drag is correct, mark position of nuts both

on nuts and bridge.

9. Tap on differential on both sides to achieve correct

bearing cone position, rotate differential (3-5

times).

10. Check drag 19.6 N.m (14.5 lb.ft) on rotating

differential.

12. After marking of position remove differential assy.

Power Train Disassembly & Assembly

38

Page 40

Adjustment

Disassembly/Assembly of

Bevel Pinion

Assembly

Bevel Pinion

IDCD679P

1. Pull the tapered roller bearing of the bevel pinion

using a two leg puller.

IDCD680P

2. Install the roller bearing with a press.

IDCD681P

1. Install cup of rear pinion bearing

IDCD682P

2. Install spacer and shims on pinion (basic

thickness 1.5mm (0.059 in)).

IDCD683P

3. Install bearing cone.

Power Train Disassembly & Assembly

39

Page 41

Disassembly/Assembly

Differential

IDCD684P

4. Tap bearing cone to correct position(Rotate pinion

3-5 times)

IDCD685P

5. Assemble yoke and nut and tighten flange nut to

180 ±15 N∙m (133±11 lb ∙ft)

IDCD687P

1. Loosen differential housing bolts to disassemble

differential.

IDCD688P

2. After loosening the bolts, lift the differential

housing carefully.

IDCD686P

6. Measure the rolling torque. The value of rolling

torque should be 1.5~2.0 N∙m (1.1~1.5 lb∙ft)

7. If the rolling torque exceeds 2 N∙m, add one shim

and if it is lower than 1.5 N∙m, subtract one shim

8. When the adjustment is correct, disassemble the

nut and the yoke.

Assemble the oil seal and yoke again and then

tighten the nut to 180 ±15 N∙m (133±11 lb∙ft).

Power Train Disassembly & Assembly

IDCD689P

3. Overview of the differential parts.

40

Page 42

IDCD690P IDCD693P

4. Grease all sliding surfaces with Molycote BR-2

also during assembly.

7. Check the greasing of all sliding surfaces and

position of the cross shaft.

IDCD691P

5. Assemble cross shaft with small differential bevel

gears and thrust washers and place into half the

differential housing.

IDCD692P

6. CAUTION : The thrust washer and cross shafts

have flats to prevent washer rotation with bevel

gears.

Power Train Disassembly & Assembly

IDCD694P

8. The flat side of the shaft must be on top. Join

differential housing halves so marks are aligned.

IDCD695P

9. Secure the bolts with Loctite 242 before installing.

41

Page 43

Assembly

Crown wheel/Adjustment

IDCD696P

10. Secure the bolts to the instructed torque (85 ± 6

N·m (63 ± 4.5 lb·ft).

IDCD697P

1. Torque of the crown wheel bolts 80 ± 6 N·m

(60 ± 4 lb·ft).

IDCD698P

2. Assemble the crown wheel with bearing support

and retainers.

First turn the retainers to the marked position (for

adjusting turn both retainers on the same side to

keep the constant bearing preload of the crown

wheel !) (Tool Ref. No 4)

Power Train Disassembly & Assembly

42

Page 44

IDCD699P IDCD702P

3. Strike the crown wheel left and right to insure

position.

6. Rotate gears and examine contact pattern.

IDCD700P

4. Rotate the axle drive through 100° and check the

tooth backlash at several points of the crown

wheel using a dial gauge. The tooth backlash

should be 0.15 - 0.25mm. (0.006 - 0.010 in)

IDCD703P

7. Depth of engagement of the bevel pinion is

correctly set, when the contact pattern appears as

shown in diagram.

IDCD704P

IDCD701P

5. In order to check the depth of engagement of the

bevel pinion, apply a coating of a gear tooth

pattern checking material.

8. The contact pattern in diagram shows too great a

depth of engagement.

Power Train Disassembly & Assembly

43

Page 45

IDCD705P

9. With a contact pattern as shown in diagram the

bevel pinion has too little an engagement. The

shim of the bevel pinion should be rechecked if

the contact pattern as shown in fig. 7 is not

achieved.

IDCD708P

12. Before assembling the yoke, coat the seal with

grease.

IDCD709P

13. Heat the yoke to 130°C (266°F).

IDCD706P

10. If the depth of engagement is correct secure the

retainers with locking cotter pins.

IDCD710P

14. Install the yoke.

IDCD707P

11. Install the seal flush with carrier housing.

(Tool Ref. No 6)

CAUTION : Take care that the sealing lips will not be

damaged !

Power Train Disassembly & Assembly

44

Page 46

Assembly

Carrier Diff

IDCD711P

15. Apply Loctite 242 to the yoke retaining nut.

IDCD712P

16. Tighten the nut to the instructed torque of

180 ± 15 N·m (133 ±11 lb·ft). (Tool Ref. No 8)

IDCD713P

1. Install the dowels for the carrier housing.

IDCD714P

2. Degrease the flange area and apply with Loctite

17430 sealant.

IDCD715P

3. Install the differential carrier assembly.

Power Train Disassembly & Assembly

45

Page 47

IDCD716P IDCD719P

4. Tighten the carrier assembly housing on the axle

housing to the instructed torque 115 ± 15 N·m

7. Drive the plug flush with axle housing.

(85 ± 11 lb·ft).

IDCD717P

5. Coat the plug with Loctite 17430.

IDCD718P

6. Install the plug.

IDCD720P

8. Insert the pre-assembled shaft assembly.

IDCD721P

9. Tap the shaft assembly into the differential and

axle housing.

Power Train Disassembly & Assembly

46

Page 48

IDCD722P IDCD725P

10. Install the spindle into the drive axle. Apply Loctite

242 to secure bolts.

13. Fully pack outer roller bearing into grease and

install into hub. Install shield and nut.

IDCD723P IDCD726P

11. Tighten all bolts of the spindle to a torque of

115 ± 15 N·m (85 ± 11 lb·ft).

IDCD724P

12. Install the inner tapered roller bearing.

14. Tighten the hub nut to 135 N·m (100 lb·ft).

(Tool Ref. No 2)

IDCD727P

15. Knock with the percussion drive and rotate the

hub drive axle to insure the seating of the

bearings.

Power Train Disassembly & Assembly

47

Page 49

IDCD728P IDCD731P

16. Loosen the nut of the hub drive axle to install the

safety washer. (Tool Ref. No 2)

19. Lock the nut with a punch.

IDCD729P

17. Install the safety washer and the nut.

IDCD730P

18. Tighten the nut to 50 ± 5 N·m (37 ± 11 lb·ft).

(Tool Ref. No 2)

IDCD732P

20. Install 2 dowels on both sides.

IDCD733P

21. Degrease the contact area and seal with Loctite

17430.

Power Train Disassembly & Assembly

48

Page 50

IDCD734P IDCD737P

22. Install and tighten the gear cover to 55 ± 10 N·m

(41 ± 7.5 lb·ft).

25. Put on the end cover.

IDCD738P

IDCD735P

23. Install the friction discs and plates in the gear

cover. First mount a plate outer.

26. Tighten the end cover with 28 ± 7 N·m (21 ± 5

lb·Ift)

IDCD739P

IDCD736P

24. Degrease and seal the gear cover to end

coverwith Loctite 17430.

Power Train Disassembly & Assembly

27. Install the adapter for wheels.

49

Page 51

IDCD740P

28. Tighten the adapter to 285 N·m (210 lb·ft).

Power Train Disassembly & Assembly

50

Page 52

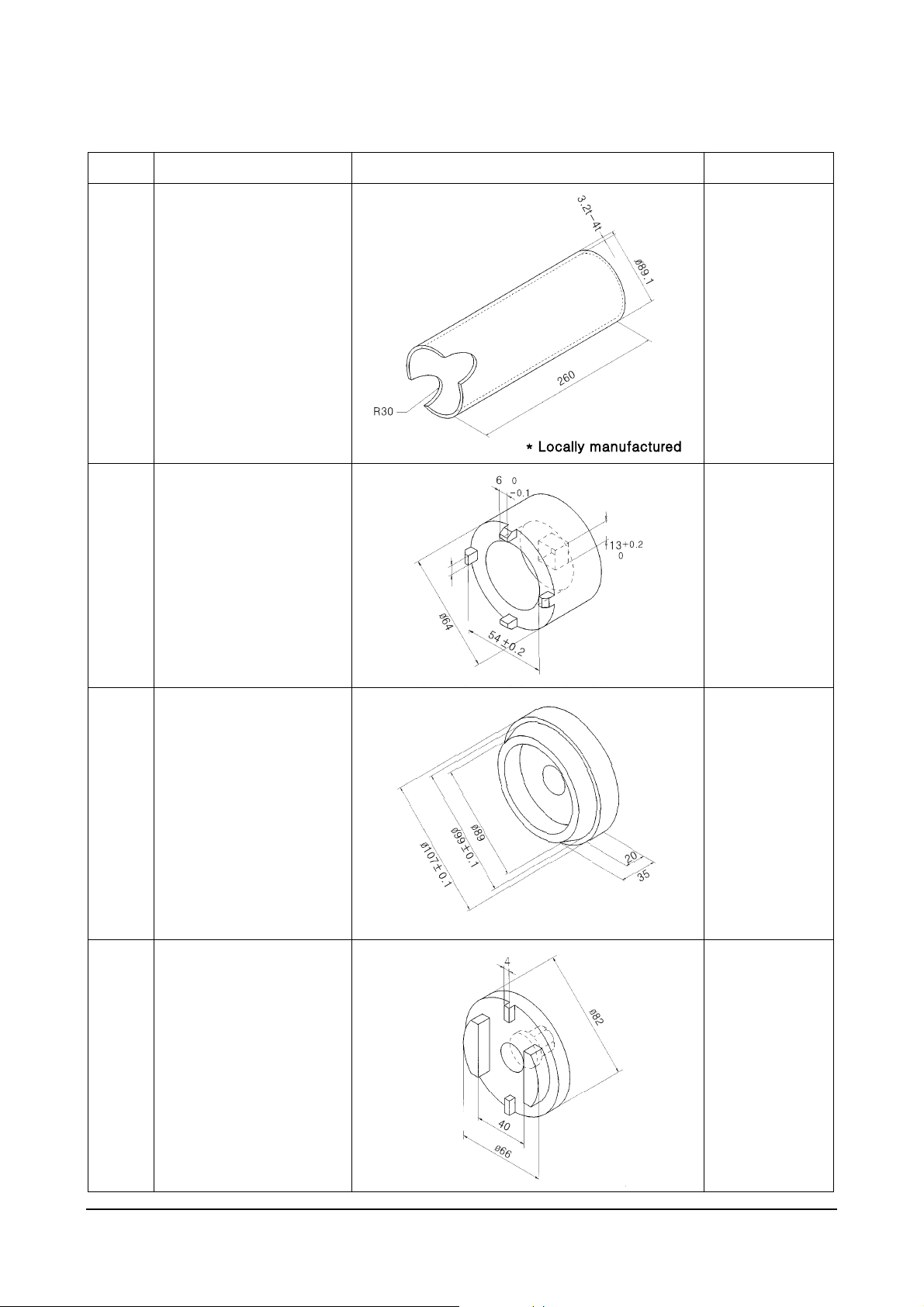

Special Service Tools

Ref.No Tool Name Illustration Remark

Transmission

1

2

Piston return spring

Compressor

Drive Axle

Hub Bearing Lock

Nut Installer

DAEWOO Tool

No.: T059

Drive Axle

3

4

Hub Bearing Cup

Installer

Drive Axle

Differential

Retainer Installer

DAEWOO Tool

No.: T020

DAEWOO Tool

No.: T001

Power Train Disassembly & Assembly

51

Page 53

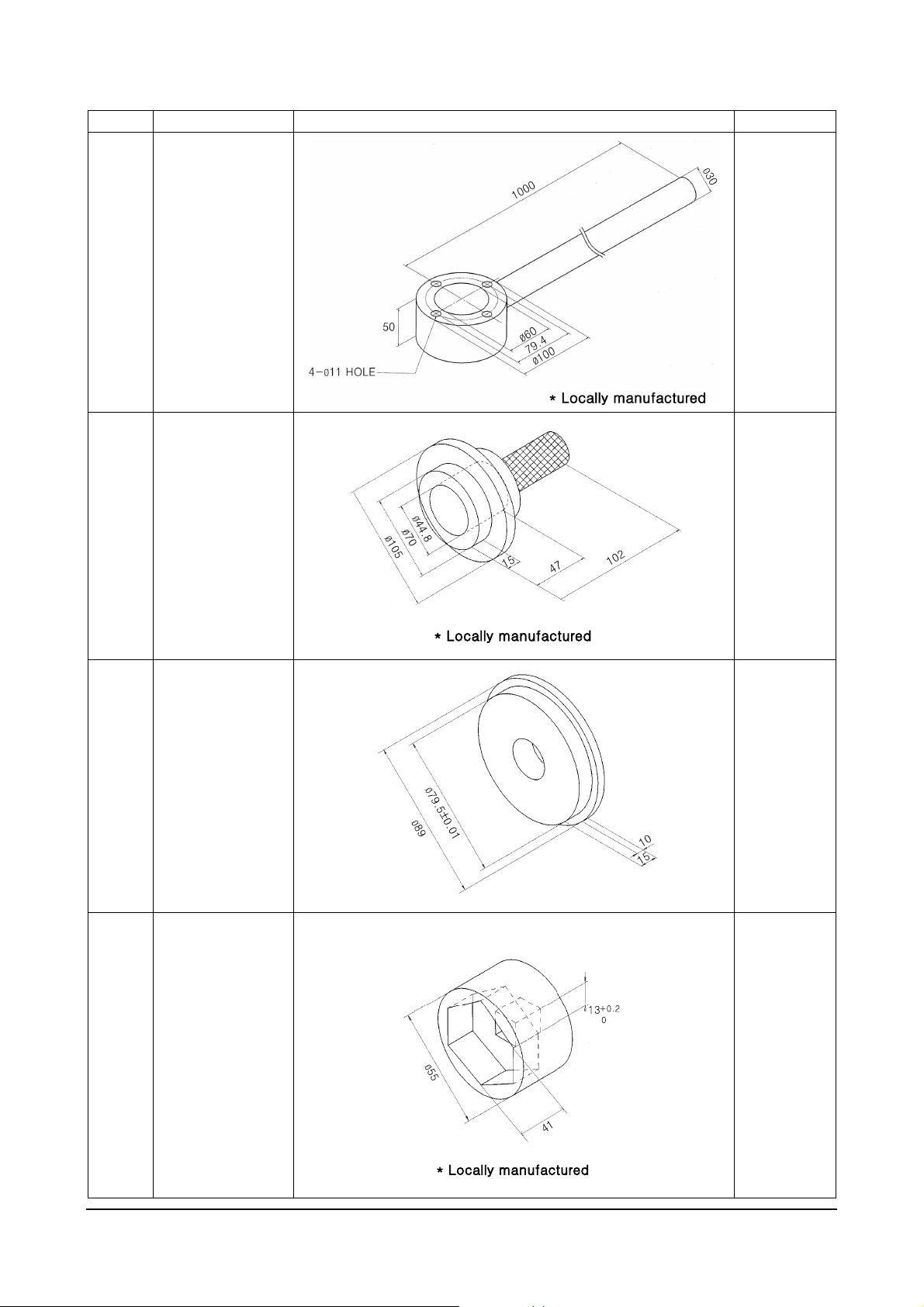

Ref.No Tool Name Illustration Remark

Drive Axle

5

Yoke N ut

Installer

Drive Axle

Input Shaft

6

7

Lip-seal

Installer

Drive Axle

Hub Lip-seal

Installer

DAEWOO

Tool

No.: T022

Drive Axle

8

Power Train Disassembly & Assembly

Yoke N ut

Installer

52

Loading...

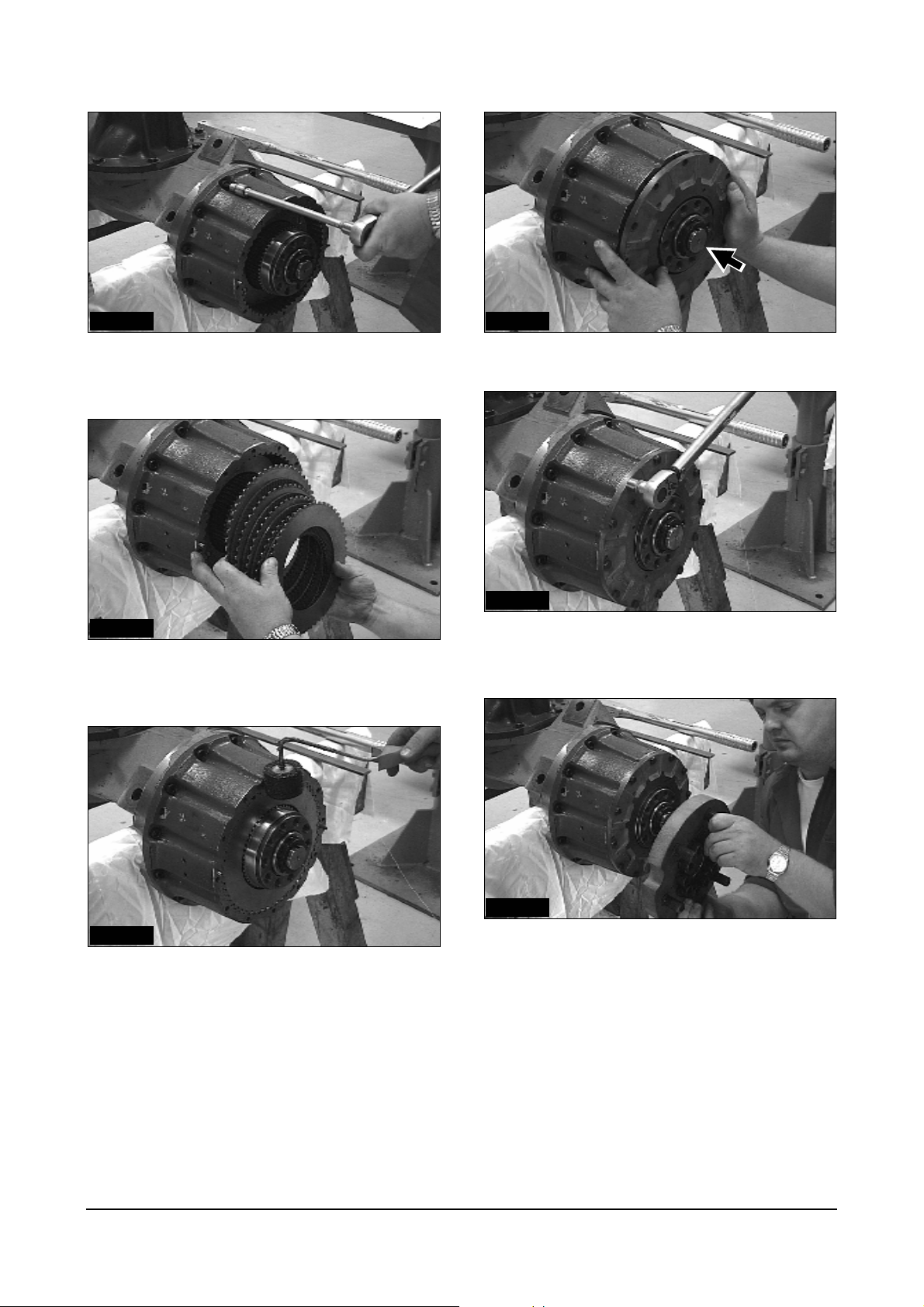

Loading...