Page 1

Service Manual

G424FE LP/Dual Fuel Engine

G

424F LP Engine

G20P-5, G25P-5, G30P-5, G33P-5, G35C-5

GC20P-5, GC25P-5, GC30P-5, GC33P-5

SB4251E00

May. 2007

Page 2

Page 3

1

Important Safety Information

Most accidents involving pr oduct operation, maintenance and repair ar e caused by failure to observe basic

safety rules or precautions. An acc ident can often be avoided by recognizing p otentially hazardous sit uations

before an accident occurs. A person must be alert to potential hazards. This person should also have the

necessary training, skills and tools to perform these functions pr oper ly .

Read and understand all safet y precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the “Safety” section of the Service or Technic al M anual. Additional safety

precautions are list ed in the “Safety” section of the owner/operation/maintenance publication.

Specific safet y warnings for all t hese publicat ions are pr ovided in the des cript ion of oper ations wher e hazard s

exist. WARNING labels have also been put on the product to provide instructions and to identify specific

hazards. If these hazard warnings are not heeded, bodily injury or death could occur to you or other persons.

Warnings in this publication and on the product labels are identified by the f ollowing s y m bol.

WARNING

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could

result in in jur y or de a t h.

Do not operate or perform an y lubrication, main tenance or repair on this product, until you have read

and understood the operation, lubrication, maintenance and repair information.

Operations that may c ause product damage are identified by NOTICE labels on the product and in thi s

publication.

DOOSAN cannot antici pate every possible circumstance that might involve a potential hazard. The warnings

in this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or

operating tec hnique not specifically recommended by DOO SAN is used, you must satisfy yourself that it is

safe for you and others. You should also ensure that the product will not be damaged or made unsaf e by the

operation, lubr ic ation, maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product. Obtain the complete and

most current information before starting any job. DOOSAN dealers have the most current information available.

Page 4

Page 5

G424F(FE) Servi ce Manual Index 3

Index

Chapter 1. GENERAL INFORMATION

Precautions before Service.................................7

Tightening Torque .............................................10

Recommended Lubricants and Capacities.......11

Engine Model and Engine Serial Number.........12

General Specification........................................ 13

G424F/G424FE Engine Power and Torque........15

Chapter 2. RECOMMENDED

MAINTENANCE

General M a in t e na nc e.........................................16

Test Fuel System for Leaks...........................16

Inspect Engine f or Fluid Leak s ...................... 16

Inspect Vacuum Lines and F itt ings................ 16

Inspect Electrical System..............................16

Inspect Foot Pedal Operation........................16

Engine Oil Classification................................17

Checking Engine Oil Level............................18

Replacing Engine Oil and F ilter.....................18

Checking Compressed Pressure...................19

Cooling S y s te m Maintenanc e............................20

Coolant Recommendation.............................20

Check Coolant Level.....................................20

Inspect Coolant Hoses..................................20

Checking coolant leaks.................................21

Specific gravity test.......................................21

Relation between Coolant c onc entration and

Specific Gravity.............................................21

Checking and Adjusting Drive B elt ................ 22

Adjusting.......................................................22

Checking Belt for Damage............................ 22

Ignition System Maintenance............................23

Inspect Battery System................................. 23

Inspect Ig n i ti o n Syste m................................. 23

Inspection of Ignition Timing ......................... 23

Inspection of Spark Plug............................... 24

Fuel System Maintenance ................................. 26

Replace LP Fuel Filter Element..................... 26

Testing Fuel Lock-off Operation .................... 26

Pressure Regulator/Converter Inspection ...... 27

Inspect Air/Fuel Valve Mixer Assembly ......... 27

Inspect for Intake Leak s................................ 27

Inspect Th r o ttl e As se m b l y............................. 27

Checking the TMAP Sensor.......................... 27

Exhaust S y s tem Maintenance........................... 27

Inspect Engine f or Exhaus t Leaks................. 27

Maintenance Schedule...................................... 28

Chapter 3. ENGINE MECHANICAL

SYSTEM

General Informati on ...........................................30

Engine Outline.............................................. 30

Technical Specifications............................... 31

Shells Selection Table.................................. 33

Recommended Torque Values...................... 36

Troubleshooting............................................ 38

Engine Exploded View....................................... 39

Intake manifold and gasket............................... 41

Exhaust Manifold and Gasket........................... 45

Timing Belt......................................................... 47

Timing Belt Tensioner....................................... 51

PCV Valve .......................................................... 52

Camshaft Timing Pulley and/or Seal................. 55

Crankshaft Timing Pulley.................................. 55

Crankshaft Front Seal ....................................... 56

Camshaft Case Cover and Gasket.................... 56

Page 6

G424F(FE) Servi ce Manual Index 4

Crankshaft Accessory P ul ley............................57

Timing Belt Rear Cover .....................................57

Rocker Arms, Linkag e, Valve Lifters With

Cylinder Head and Eegine...............................59

Cooling S y s te m..................................................60

Thermostat Housing..........................................66

Water Pump........................................................67

Lubrication System............................................68

Oil Pan................................................................71

Oil Pump.............................................................72

Oil Pump Assembly ...........................................73

Camshaft Case Assembly .................................74

Cylinder Head.....................................................78

Valve, Spring or Seal......................................... 79

Engine Disassembl y ..........................................81

Engine Assembly...............................................85

Cylinder Block....................................................90

Crankshaft.......................................................... 91

Pistons and/or Connecting Rods ...................... 97

Rings.............................................................. 9999

Chapter 4. ENG INE ELECTRICAL

SYSTEM

Specifications.................................................. 101

Ignition System................................................ 102

Wasted Spark DIS Ignition System..............102

Inspection of Ignition Coil............................ 103

Spark Plug Wire Inspection......................... 104

Spark Plug Wire Replacement .................... 104

Spark Plug Replacement.............................105

Spark Plug Inspection................................. 105

Charging System............................................. 107

General Description .................................... 107

Troubleshooting Proc edur e ......................... 110

STARTING SYSTEM.........................................115

General Description .................................... 115

Diagnosis Procedure ...................................116

Start Relay Tests.........................................118

Troubleshooting...........................................119

Chapter 5. ENGINE MANAGEMENT

SYSTEM (EMS)

General Informati on ..........................................1 2 1

Specifications..............................................121

Service Standard.........................................126

Component Location ....................................127

G424FE EMS (Engine Manag ement System)

Overview...........................................................131

General Description.....................................131

LPG Fuel System Operati o n........................134

MPI Gasoline System Operation..................141

Electronic Throttle System...........................142

Ignition System............................................143

Exhaust System...........................................144

SECM..........................................................146

SECM Wiring Diagrams for G424FE............149

G424F EMS (Engine Management System)

Overview...........................................................152

General Description.....................................152

LPG Fuel System Operati o n........................155

Electronic Throttle System...........................159

Ignition System............................................159

SECM..........................................................159

SECM Wiring Diagrams for G424F LP Engine

....................................................................160

Page 7

G424F(FE) Servi ce Manual Index 5

EMS Inspection and Repair............................. 161

Engine Control Module (SECM ) .................. 161

Camshaft Position Sensor........................... 163

IAT (Intake Air Temperature) Sensor...........167

Oxygen Sensor (Pre-Catalyst)..................... 168

Oxygen Sensor (Post - Catalyst)...................169

ECT (Engine Coolant T em per ature) Sensor 170

LP Fuel Temperature Sensor...................... 172

Angle Sensor-Accelerator........................... 173

Transmission Oil Temperature Switch......... 174

Ground Speed Limit Switch (optional) ......... 175

Electronic Throttle Body..............................176

Chapter 6. LPG FUEL DELIVERY

SYSTEM

G424FE LP System Inspect io n and Repair..... 177

Removal and Installat ion............................. 177

Hose Connections................................ 178

Removal and Installat ion of

N-2007 LP

Regulator.............................................180

Removal and Installat ion of CA100 Mixer

for G424FE.......................................... 181

Tests and Adjustments................................183

N-2007 Regulator Service Testing........183

AVV (Air Valve Vacuum) Testing.......... 185

Connection of the MI-07 S er v ic e Tool...185

Idle Mixture Adjustment........................186

Parts Description......................................... 189

CA100 Mixer for G424FE Engine ......... 189

N-2007 Regulator for G 424FE Engine.. 191

G424F LPG System Inspection and Repair.....193

Removal and Installat ion............................. 193

G424F Fuel System Connect ions......... 194

Removal and Installat ion of N-2001 LP

Regulator/Converter.............................195

Removal and Installat ion of CA100 Mixer

for G424F ............................................ 196

Tests and Adjustments................................198

N-2001 Regulator Service Testing........198

AVV (Air Valve Vacuum) Testing ..........200

Connection of the MI-07 S er v ic e Tool ...200

Idle Mixture Adjustment........................201

Parts Description.........................................203

CA100 Mixer for G424F Engine ............203

CA100 Disassembly and Serv ic e..........205

CA100 Disassembled Servic e...............206

N-2001 Regulator for G 424F Engine.....207

N2001 Regulator Disassembly S teps:...209

N2001 Disassembled Service ...............211

Chapter 7. MPI GASOLINE FUEL

DELIVERY SYSTEM

Specification.....................................................212

Components Location......................................213

Fuel Pressure Test ...........................................214

Injector..............................................................216

Fuel Pump.........................................................219

Chapter 8. BASIC TROUBLESHOOTING

Preliminary Checks ..........................................220

Before Starting............................................220

Visual/Physical check..................................220

Basic Troubleshooting Guide..........................221

Customer Problem A naly s is Sheet...............221

Basic Inspect ion P r oc edur e .........................222

Connector Inspection Procedure..................223

Symptom Troubleshoot ing Guide Chart .......227

Basic Troubleshooting.....................................233

Intermittents.................................................233

Surges and/or St um bles ..............................234

Engine Cranking but Will Not S tart / Difficult to

Start............................................................235

Lack of Power, Slow to Respond / P oor High

Speed Performance / Hesitation During

Page 8

G424F(FE) Servi ce Manual Index 6

Acceleration................................................ 237

Detonation / Spark Knock............................ 239

Backfire...................................................... 240

Dieseling, Run-on ....................................... 240

Rough, Unstable, I nc or r ec t I dle, or Stalling.. 241

Cuts Out, Misses......................................... 243

Poor Fuel Economy / Excess iv e Fuel

Consumption LPG Ex haus t Sm ell ............... 244

High Idle Speed .......................................... 245

Excessive Exhaus t Em is s ions or Odors.......246

Diagnostic Aids for Ric h / Lean O per ation... 247

Chart T-1 Restricted Exhaust System Check248

Chapter 9. ADVANCED DIAGNOSTICS

Reading Diagnostic Fault Codes.....................249

Displaying Fault Codes (DFC) from SECM

Memory............................................................. 249

Clearing Fault (DFC) Codes............................. 249

Fault Action Descrip t ions................................ 250

Fault List Definitions........................................250

Table 1. Fault List Definitions...................... 251

Table 2. Diagnostic Fault Codes (Flash Codes)

................................................................... 261

Appendix

Service Tool Software (MotoView)...................279

Introduction .................................................279

Connection of the Ser v ic e Tool ....................280

MotoView Display Scr eens ..........................281

SECM field update wit h Servic e Tool...........293

Ground Speed Limits (Option).........................297

LPG And LP G Fue l Tanks ................................299

Regulatory Compliance....................................303

Special Co nditions for Sa f e Use......................303

Abbreviations...................................................304

Page 9

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 7

Chapter 1. GENERAL INFORMATION

Precautions before Service

Removal and Disassembly

For prevention of wrong inst allation or reassembly

and for ease of operat ion, put m ating m ar k s to the

parts where no function is adv er s ely aff ec ted.

Special Tool

Be sure to use Special Tools when their use is

specified for t he oper ation.

Use of substitute tools will r es ult in malfunction of

the part or damage it.

Tightening Torque

Tighten the part properly to specified torque.

Sealant

Use specified brand of s ealant.

Use of sealant other than s pec ified sealant may

cause water or oil leaks.

Page 10

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 8

Replacement Part

When oil seal, O-ring, pac k ing and gas k et have

been removed, be sure t o replace t hem with new

parts.

However, rocker cover gasket may be reused if it is

not damaged.

Rubber Parts

Do not stain timing belt and V- belt with oil or water.

Therefore, do not clean the pulley and sprocket with

detergent.

Oil and Grease

Before reassembly , apply s pec ified oil to the rotating

and sliding parts.

Genuine Part

When the part is to be replaced, be s ur e to use

genuine part.

For selection of appropriate parts, refer to the Parts

Catalog.

Electrical System

1. Be sure to disconnect the bat tery cable from the

negative (-) terminal of the battery.

2. Never pull on the wires when dis c onnec ting

connectors.

3. Locking connector s will c lic k when the connector

is secure.

4. Handle sensors and relays c ar efully. Be careful

not to drop them or hit them against other parts.

Page 11

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 9

Precautions for catalytic Converter

CAUTION

If a large amount of unburned gasoline flows

into the con verter, it may overheat and create a

fire hazard. To prevent this, observe the

following precau tions and explain them to your

customer.

1. Use only unleaded gasoline.

2. Do net run the engine while the tr uc k is at rest f or

a long time. Avoid running the engine at fast idle

for more than 5 minutes and at idle speed for

more than 10 minutes.

3. Avoid spark-jum p tests. Do spark-jumps only

when absolutely necessary . Perform this test as

rapidly as possible and, while t es ting, never race

the engine.

4. Do not measure engine compress ion for an

extended time. E ngine c om pr es s ion tests must be

made as rapidly as possible

5. Do not run the engine when the fuel tank is nearly

empty. This may cause the engine to m is fire and

create and extra load on the conv er ter.

6. Avoid coasting with the ignition turned off and

during prolonged braking

7. Do not dispose of a used catalyt ic c onv erter

together with parts contaminated with gasoline or

oil.

Page 12

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 10

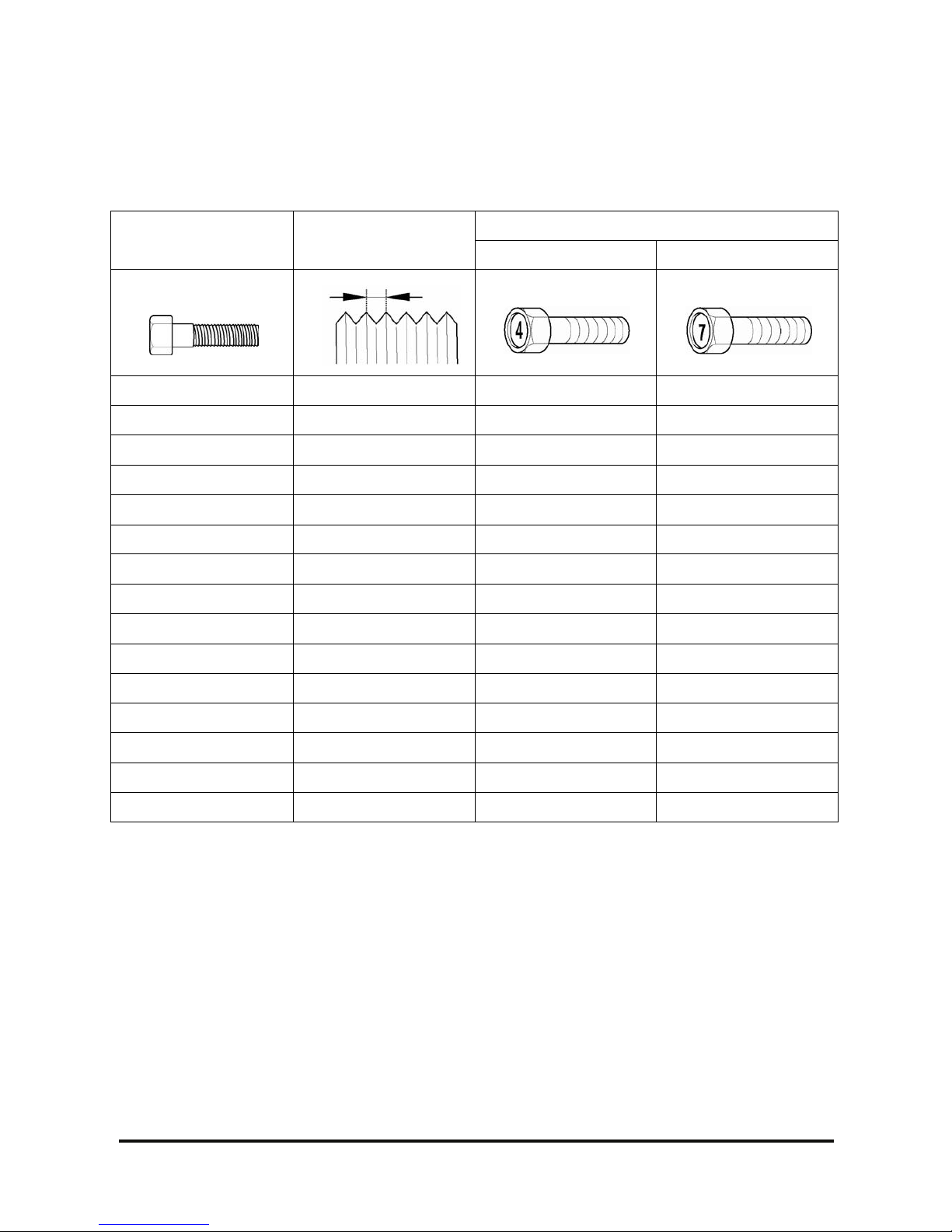

Tighteni ng Torque

Tightening Torque Table of Standard Parts

Torque (kg·m)

Bolt nominal diameter

(mm)

Pitch (mm)

Head mark 4 Head mark 7

M5 0.8 0.3 ~ 0.4 0.5 ~ 0.6

M6 1.0 0.5 ~ 0.6 0.9 ~ 1.1

M8 1.25 1.2 ~ 1.5 2.0 ~ 2.5

M10 1.25 2.5 ~ 3.0 4.0 ~ 5.0

M12 1.25 3.5 ~ 4.5 6 ~ 8

M14 1.2 7.5 ~ 8.5 12 ~ 14

M16 1.5 11 ~ 13 18 ~ 21

M18 1.5 16 ~ 18 26 ~ 30

M20 1.5 22 ~ 25 36 ~ 42

M22 1.5 29 ~ 33 48 ~ 55

M24 1.5 37 ~ 42 61 ~ 70

M5 0.8 0.3 ~ 0.4 0.5 ~ 0.6

M6 1.0 0.5 ~ 0.6 0.9 ~ 1.1

M8 1.25 1.2 ~ 1.5 2.0 ~ 2.5

M10 1.25 2.5 ~ 3.0 4.0 ~ 5.0

NOTE: The torques shown in t he table are s tandard

vales under the following conditions.

1. Nuts and bolt are made of steel bar and

galvanized.

2. Galvanized plain st eel was her s ar e ins er ted.

3. All nuts, bolts, plain washer s ar e dr y .

NOTE: The torques shown in t he table are not

applicable,

1. When spring washers, toothed washers and the

like are inserted.

2. If plastic parts ar e fastened.

3. If oil is applied to thr eads and s urfac es .

NOTE: If you reduce the tor ques in the t able to the

percentage indicated below under the following

conditions, it will be the standard value.

1. If spring washers ar e us ed : 85%

2. If threads and bearing s ur faces are stained with

oil: 85%

Page 13

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 11

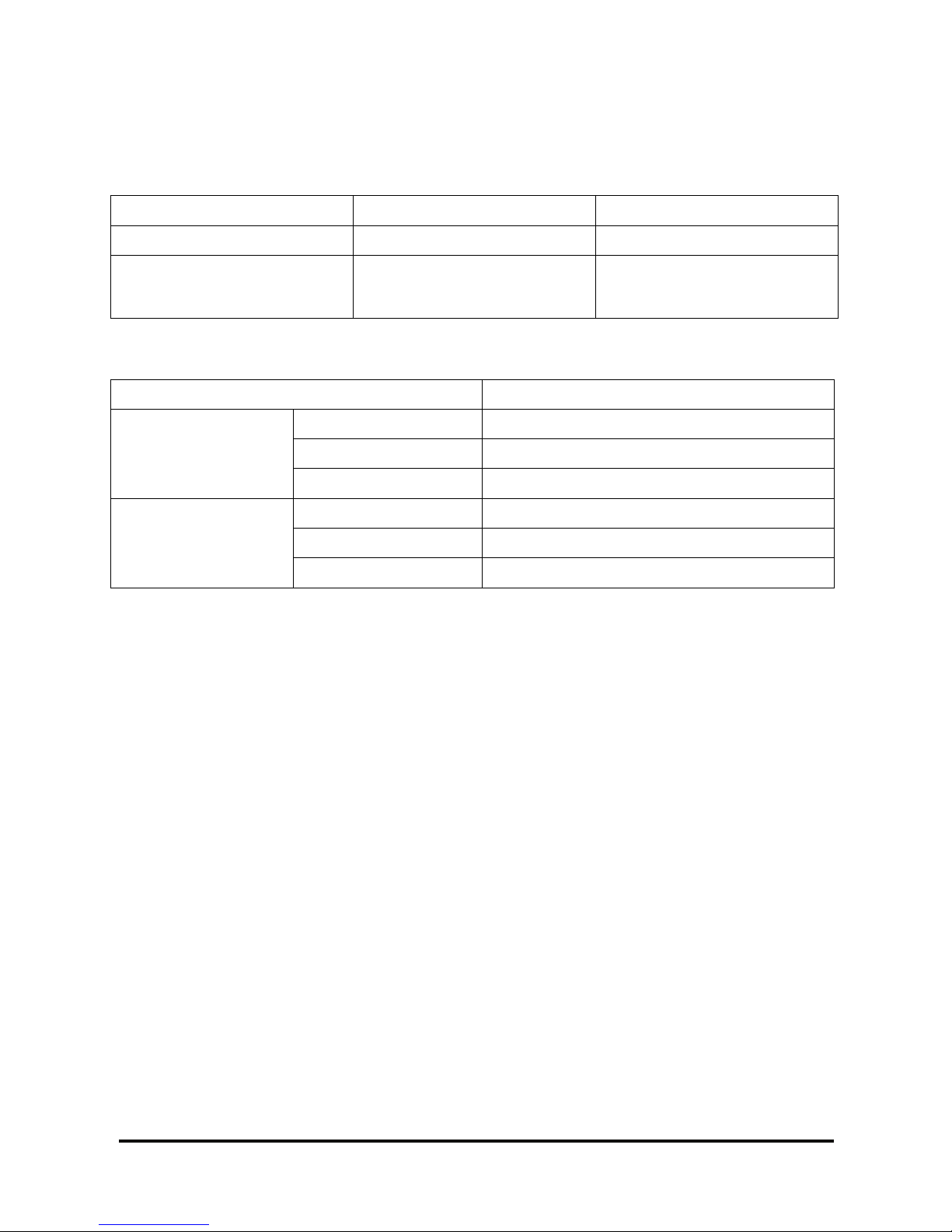

Recommended Lubric a nt s and Capaciti e s

Recommended Lubricants

Lubricant Specification Remarks

Engine Oil API Classification SJ or above SAE 10W30 or SAE 5W30

Coolant (Antifr eez e)

Automotive ant ifreeze

suitable for gasoline engines

having aluminum alloy parts

Concentration level 50%(nor m al)

Concentration level 40%(tropical)

Lubricant Capacities

Description G(C)20/25/30/33P-5

Oil Pan 4.25

Oil Filter 0.3

Engine Oil (liters)

Total 4.5

Engine 3.0

Radiator & Hoses 6.0

Coolant (liters)

Total 9.0

Page 14

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 12

Engine Model and Engine Serial

Number

Engine

Model

Fuel Type

Emission

Regulation

G424FE LP/Dual Fuel

EPA/CARB*

2007

Compliant

G424F LP

* EPA: Environmental Protection Agency

* CARB: California Air Resources Board

G424FE Engine

• Comply with EPA 2007 Emission Regulation

• Electronic Cont r ol by ECM

• Certified LP/ Dual Fuel Sy s tem available

– Closed loop LP Carburetion system

– Closed loop MPI Gasoline system

• 3-way Catalytic Muffler is standard

G424F Engine

• Not comply with EPA 2007 Emiss ion Regulation

• Electronic Cont r ol by ECM

• Standard LP System available

– Open loop LP Carburetion s y stem

• Muffler is standard

Indication of Engine Model and Serial

Number

Engine Model Engine Serial Number

G424FE/G424F 30700001 to 39999999

Features and Benefi t s of G424F E/G424F Engine

• Al head with valve seat inserts

– Aluminum head and valve seat s yst em

• SOHC 8 valve system

• Timing belt system

• Distributorles s Ignition system

• Electronic control system by ECM (Engine control

module)

– Drive-by-wire system

– Higher efficiency and lower fuel consumption

– Min./Max. gover nor c ontrol

– Automatic engine protec tion from overheating

and/or low engine oil pressure

– Automatic trans m is s ion pr otection from

overheating

– Engine diagnostics by ser v ic e-tool software

– Forklift ground speed lim it (optional)

Page 15

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 13

General Specification

G424FE Engine G424F Engine

GENERAL DESCRIPTION

ENGINE TYPE: Water-cooled, Inline 4-Cy c le, 4-Cylinders

COMBUSTION SYSTEM: Squish Combution Chamber

INTAKE MANIFOLD Cast Aluminum (wit h injec tor ports)

EXHAUST MANIFOLD Cast Iron (dual channel)

VALVE CONFIGURATION: SOHC, 2 Valves per Cylinder

VALVE LIFTER/LAS H ADJUSTER Stationary Hydraulic Lash Adjus ters

VALVE ROTATOR Exhaust Rotat or

CAMSHAFT DRIVE Timing belt system ( 20 mm Toothed B elt)

DISPLACEMENT: 2,405 cc (147 cid)

BORE x STROKE 87 mm (3.44 in) x 100 mm (3.94 in)

BLOCK STRUCTURE Grey Cast Iron

HEAD STRUCTURE Aluminum with seat ins er ts

COMPRESSION RATIO: 9.6:1

COMPRESSION PRESSURE: 1,240 kPa (180psi) Minim um

Intake Valve: 17°30' B TDC/ 76°30' ABDC

VALVE TIMING:

Exhaust Valve: 58°30' B B DC/ 35° 30' ATDC

FIRING ORDER: 1-3-4-2

WEIGHT: 120 kg

ENGINE ROTATION: Counter-Clockwise (CCW) when viewed from Flywheel End

FUEL TYPE: LPG, Dual Fuel (LPG or Gasoline)

CRANK VENTILATION Foul Air System with PCV

IGNTION SYSTEM

IGNITION TYPE: Distributorless (waste spark)

IGNITIOIN TIMI NG: Electronic controlled by E CM

IGNITION COIL: 12 V operation volt

SPARK PLUGS: 0.035" (0.8-0.9 mm) Air Gap

LUBRICATION SYSTEM

OIL PRESSURE: 282 - 324 kPa @ 1400 rpm

OIL TEMPERATURE:

Upper Limit: 125 °C (257°F )

Recommended: 99 – 110 °C (210 - 230°F)

Lower Limit:80 °C ( 176 °F)

OIL PAN Cast Aluminum

OIL PAN CAPACITY 4.25 L (EXCLUDES OIL FILTE R)

OIL FILTER: 0.3 L

ENGINE OIL SPECIFICATION: API - SJ, SAE 10W30 or SAE 5W30

Page 16

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 14

G424FE Engine G424F Engine

COOLING SYSTEM

WATER PUMP ROTATION: Toothed Timing Belt Driv e- Cloc k wis e from front of engine

THERMOSTAT:

Opening Temperatur e: 82°C (180°F)

Fully Open Temperatur e: 95°C (203°F)

COOLING WATER CAPACITY: 3.0 L

LP FUEL SYS TEM

LP FUEL SYSTEM

Closed loop LP Carburetion

System

Open loop LP Carburetion

System

MIXER:

Diaphragm Type Air Valv e

Assembly inside, Downdr aft

(Model: CA-100)

Diaphragm Type Air Valv e

Assembly inside, Downdr aft

(Model: CA-100)

REGULATOR:

Two-Stage Negativ e P r es s ur e

Regulator (Model: N-2007)

Two-Stage Negativ e P r es s ur e

Regulator (Model: N-2001)

FUEL TRIM VALVE (FTV): Dual Dither System None

FUEL FILTRATION: 40 Microns Maximum 40 Microns Maximum

GASOLINE FUEL SYSTEM

GASOLINE FUEL SYSTEM Closed loop MPI System and In-Tank Fuel Pump System

Electric Fuel P ump (12V)

Fuel Filter & Strainer

FUEL PUMP MODULE

Gasoline Pressure Regulator (3.5 bar)

FUEL INJECTOR ASS’Y Electric Fuel Injector (12V)

ENGINE ELECTRIC

ENGINE CONTROL

MODULE(ECM):

12 V operation volt, 48 pins of I/O

CRANK SENSOR VR (Variable Reluctanc e)

CAM SENSOR Hall sensor (Dual fuel engine only)

TMAP: Intake Air Temp. & Manifold Absolute Press. Sensor

PEDAL ANGLE SENSOR: Two-O utput Signals (Installed on Accelerator Pedal)

OXYGEN SENSOR: Dual O x y gen S ens or S yst em None

ECT-ECM: Engine Coolant Temperat ur e S ens or for ECM

ECT-GAUGE Engine Coolant Temp. Sens or for GAUGE on Instrument Panel

TPS: Throttle Position Sens or ( built in Throttle Body)

THROTTLE BODY: Electronic Throttle Body

LP FUEL LOCK-OFF: 12 V operation volt

ENGINE OIL PR. S/W: 14-41 kP a

STARTING MOTOR: 12 Volts, 1.4 kW

ALTERNATOR: 13.5 Volts, 80 A

EXHAUST SYSTEM

Muffler Catalytic M uff ler Muffler (wit hout catalyst)

Page 17

G424F(FE) Servi ce Manual Chapter 1. General Info rmat ion 15

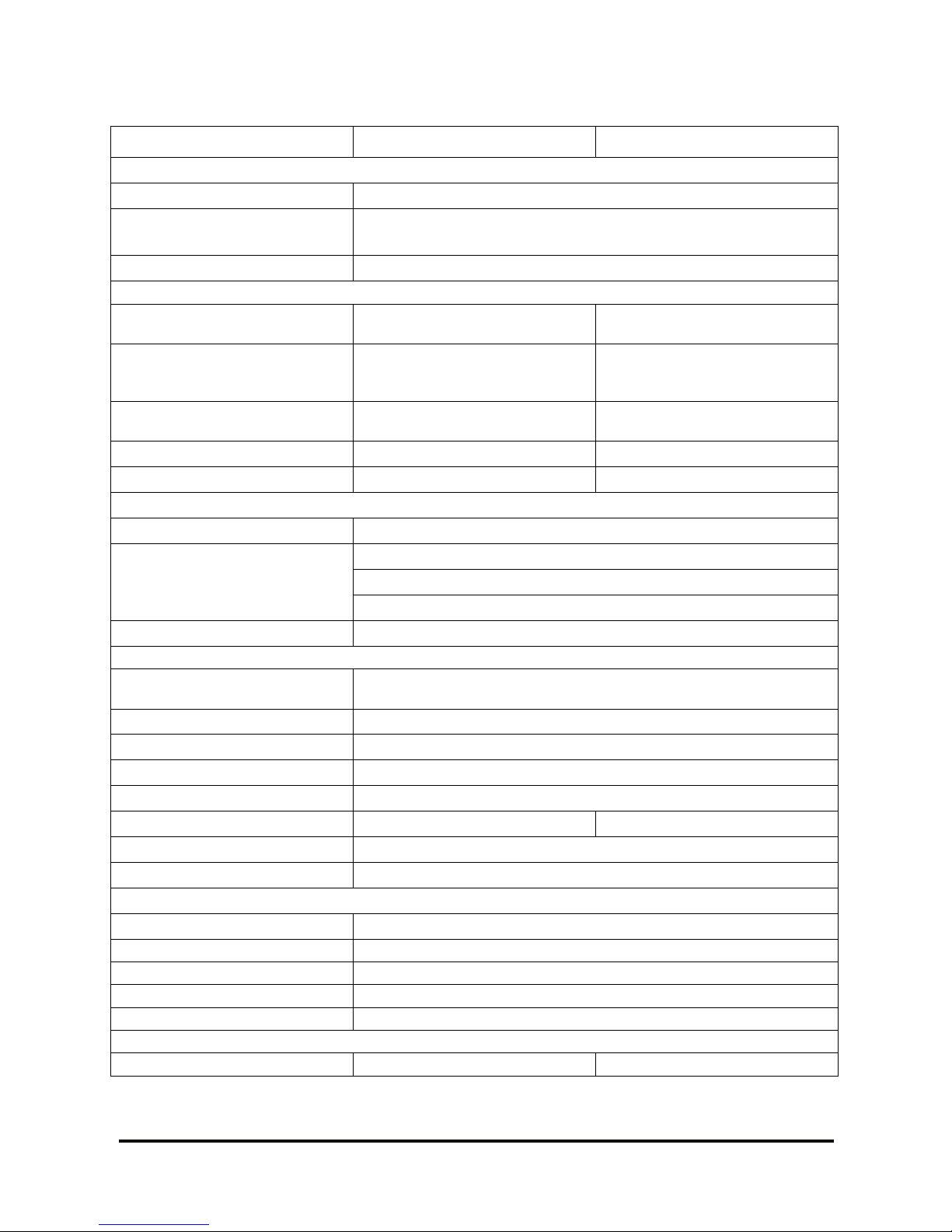

G424F/G424FE Engine Power and Torque

G424FE G424F

ENGINE MODEL unit

G424FE-LP

G424FE-DF(LP)

G424FE-DF(GAS) G424F-LP

kW 46.2 44.7 46.2

hp 62 60 62

PS 62.9 60.8 62.9

RATED POWER

rpm 2,550 2,550 2,550

N-m 181 172 181

ibf-ft 134 127 134

Kgf-m 18.5 17.5 18.5

MAX TORQUE

rpm 2,200 2,200 2,200

GOVERNED SPEED rpm 2,600 2,600 2,600

LOW IDLE rpm 750 750 750

Page 18

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 16

Chapter 2. RECOMMENDED MAINTENANCE

Suggested maintenance r equir em ents for an engine equipped with an MI-07 fuel sy stem ar e contained in this

section. The oper ator should, however, develop a customized maintenance schedule using the requirements

listed in this section and any other requirements listed by the engine manufac turer.

General Mainte na nc e

Test Fuel System for Leaks

• Obtain a leak check squirt bot tle or pump spray

bottle.

• Fill the bottle with an approved leak check solution.

• Spray a generous amount of the solution on the

fuel system fuel lines and connections, start ing at

the storage cont ainer .

• Wait approximately 15-60 seconds, then perform a

visual inspection of the fuel system. Leaks will

cause the solution t o bubble.

• Listen for leaks

• Smell for LPG odor which may indic ate a leak

• Repair any leaks before c ontinuing.

• Crank the engine through s ev er al revolutions. This

will energize the fuel lock- off and allow fuel to

flow to the pressure regulator/converter. Apply

additional leak check s olution to the regulator/

converter fuel c onnec tions and housing. Repeat

leak inspection as list ed abov e.

• Repair any fuel leaks bef or e c ontinuing.

Inspect Engine for Fluid Leaks

• Start the engine and allow it to reac h oper ating

temperatures.

• Turn the engine off.

• Inspect the entir e engine for oil and/or coolant

leaks.

• Repair as necessary before continuing.

Inspect Vacuum Lines and Fittings

• Visually inspect v ac uum lines and fittings for

physical damage such as brittleness, cracks and

kinks. Repair/r eplac e as r equir ed.

• Solvent or oil damage may caus e v ac uum lines t o

become soft, resulting in a collapsed line while

the engine is running.

• If abnormally soft lines ar e detected, replace as

necessary.

Inspect Electrical System

• Check for loose, dirt y or dam aged c onnec tors and

wires on the harness including: fuel lock-off,

TMAP sensor, O2 sensors, elec tronic throttle,

control relays, fuel t r im valves, crank position

sensor, and cam position sensor.

• Repair and/or replace as nec es s ary.

Inspect Foot Pedal Operation

• Verify foot pedal t r av el is smooth without sticking.

Page 19

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 17

Engine Oil Classification

Recommended API clas s ification: Above SJ

Recommended SAE viscosity classification

The following lubricants s hould be s elec ted for all

engines to enhance excellent per formance and

maximum effect.

1. Observe the API classif ic ation guide.

2. Proper SAE classification number should be

selected within ambient temperature ranges. Do

not use the lubricant with SAE classification

number and API grade not identified on the

container.

*1. 10W-30 engine oil is recom m ended

If 10W-30 is not applicable, pr oper engine oil will be possible according to temperat ur e r anges .

Page 20

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 18

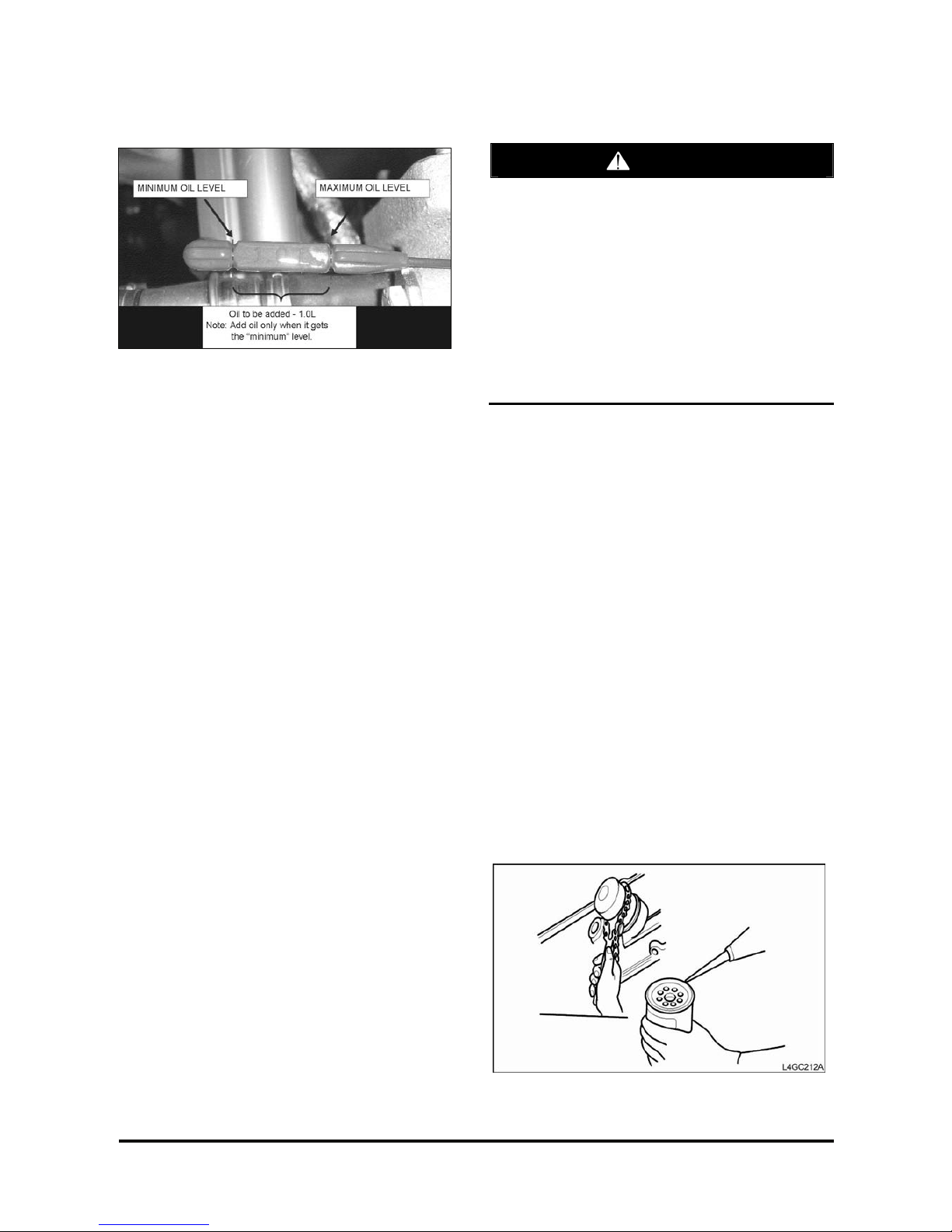

Checking Engine Oil Level

1. Check that the oil level is between “MIN” and

“Max” marks on the engine oil level gauge.

2. If the oil level is below “MIN” m ark, add oil until

the level is within the s pec ified ranges.

3. Check the engine for oil cont am ination and

viscosity and replac e if necessary.

Replacing Engine Oil and Filter

CAUTION

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irri tation and dermat itis.

In addition, used engine oil contains potentially

harmful contaminants which may cause skin

cancer.

Exercise caution in order to minimize the leng th

and frequency of contact of your skin to used oil.

In order to preserve the environment, used oil

and used oil filter must be disposed of only at

designated di sposal sites.

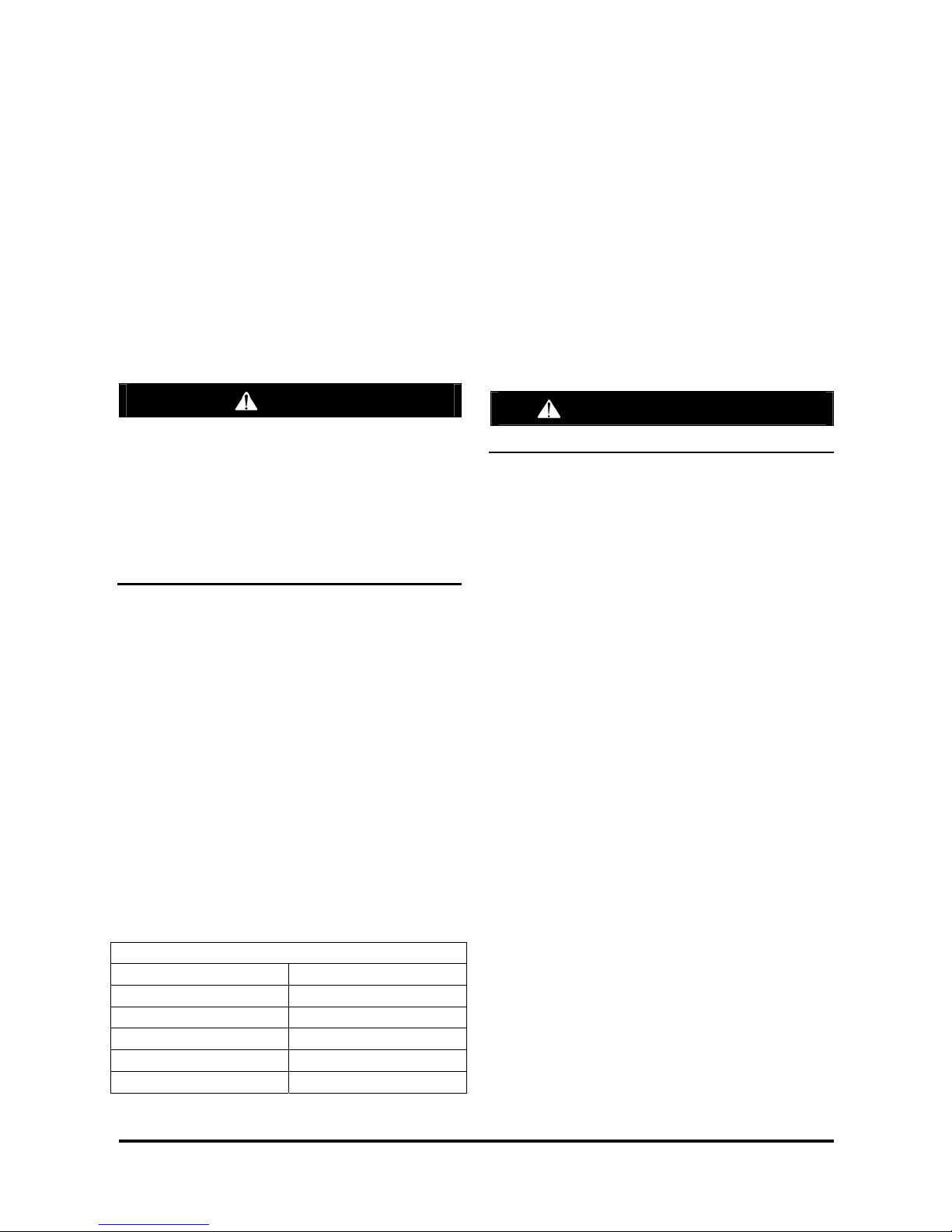

1. Drain engine oil.

1) Remove the oil filler c ap.

2) Remove the oil drain plug, and dr ain the oil into

a container.

2. Replace oil filter.

1) Remove the oil filt er.

2) Check and clean the oil filter installation

surface.

3) Check the part number of the new oil filter is as

same as old one.

4) Apply clean engine oil to the gas k et of a new

oil filter.

5) Lightly screw t he oil filt er into place, and

tighten it until the gasket contacts the seat.

6) Tighten it an additional 3/4 turn.

Page 21

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 19

3. Refill with engine oil filter.

1) Clean and install the oil drain plug wit h a new

gasket.

Torque 40~70 N·m

2)Fill with fres h engine oil.

Capacity Drain and refill 4.3 L

Oil filter 0.3 L

3) Install the oil filler c ap.

4. Start engine and check for oil leaks.

5. Recheck engine oil level.

Checking Compressed Pressure

1. Prior to inspection, check that the engine oil,

starter motor and batt er y are normal.

2. Start the engine and run it unt il the engine coolant

temperature reac hes 80 ~ 95° C.

3. Stop the engine and disconnect the ignition coil

and air cleaner element.

4. Remove the spark plug.

5. After opening the t hr ott le v alv e c om pletely, crank

the engine to remove f or eign m aterial from the

cylinder.

CAUTION

At this time, necessarily screen the spark plug

hole with a rag. Because hot coolant, oil, fuel,

and other foreign material, being penetrated in

the cylinder through cracks can come into the

spark hole during checking compressed

pressure.

When cranking the engine to test compressed

pressure, necessaril y open the throttle valve before cranking.

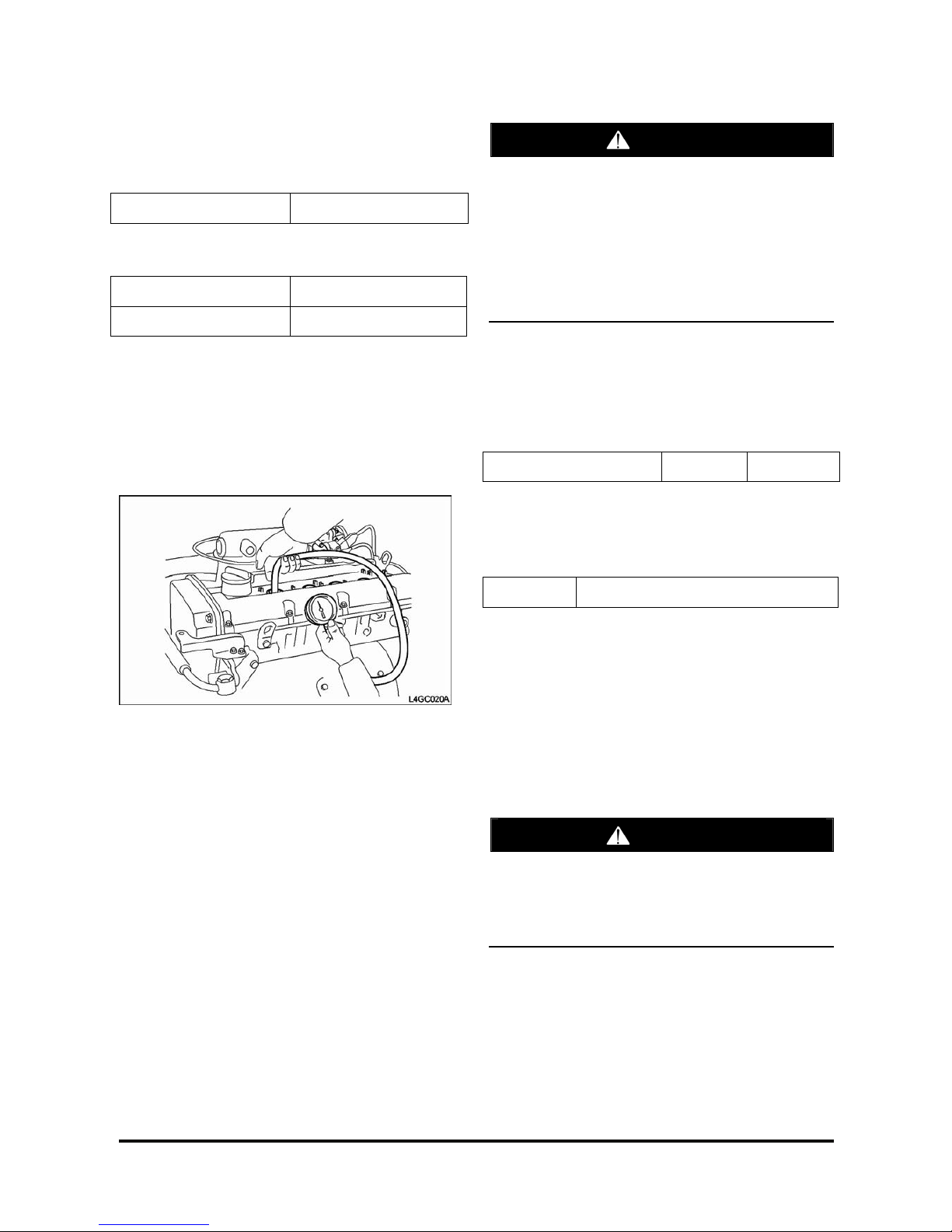

6. Install the compr es s ion gauge to the spark plug

hole.

7. With the thrott le valve opened, c r ank the engine

to measure the compress ed pr es s ure.

Standard (250~400 r pm ) Limit 1,240 kPa

8. Repeat steps ( no.6-7) over all c ylinders, ensur ing

that the pressure differential for each of the

cylinders is within t he lim it.

Limit 100 kP a ( between cylinders)

9. If any of all cylinders is out of lim it, add a small

amount of engine oil to t he spark plug hole, and

re-proceed the procedur es ( no.6-7) to the cylinder.

At this time, if the compressed pressur e is increased,

it means that the piston, pis ton ring or cylinder

surface are worn or damaged, and if the

compressed pressur e is dec r eas ed, it means that

the valve is clogged, the valve contact is faulty, or

the pressure leaks through gasket.

CAUTION

If a large amount of incomplete combustion

gasoline comes into the catalytic converter,

emergency such as a fire can occur due to

overheating. So this job should be done quickly

with the engine not operated.

Page 22

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 20

Cooling System Mai ntena nc e

Coolant Recommendation

The engine cooling system is provided with a

mixture of 50% ethylene glyc ol anti-freeze and 50%

water (For the vehicles of t r opic al area, the engine

cooling system is provided with a mixture of 40%

ethylene glycol anti-freeze and 60% water at the

time of manufactur e.)

Since the cylinder head and wat er pum p body ar e

made of aluminum alloy casting, be sure to use a 30

to 60% ethylene glycol ant ifreeze coolant to assure

corrosion protection and freezing prevention.

CAUTION

If the concentration of the antifreeze is below

30%, the anticorrosion property will be adversely

affected. In addition, if the concentration is

above 60%, both the antifreeze and engine

cooling properties will decrease, adversely

affecting the engine. For th ese reasons, be sure

to maintain the concentration level within the

specified range.

Coolant Water

Hard water, or water wit h high lev els of calc ium and

magnesium ions, encourages the formation of

insoluble chemical compoun ds by c om bining with

cooling system additives such as silicates and

phosphates.

The tendency of silicat es and phos phates to

precipitate out- of-solution increases with increasing

water hardness. Har d water, or water with high

levels of calcium and magnes ium ions enc our ages

the formation of insoluble c hem ic als , especially after

a number of heating and cooling cycles.

DOOSAN prefers the use of distilled water or

deionized water to reduce the potential and severity

of chemical insolubility .

Acceptable Water

Water Content Limits (ppm)

Chlorides (CI) 40 maximum

Sulfates (SO4) 50 maximum

Total Hardness 80mg/ℓ maximum

Total Solids 250 maximum

pH 6.0 ~ 8.0

ppm = parts per million

Antifreeze

DOOSAN recommends select ing automotive

antifreeze suit able for gasoline engines using

aluminum alloy parts. The antifreeze should meet

ASTM-D3306 standard.

Check Coolant Level

• The items below are a general guideline f or

system checks. Refer to the engine

manufacturer’s s pec ific recommendations for

proper procedures.

• Engine must be off and cold.

WARNING—PROPER USE

Never remove the pressu re cap on a hot engin e.

• The coolant level should be equal to the “COLD”

mark on the coolant recover y tank.

• Add approve coolant t o the spec ified level if the

system is low.

Inspect Coolant Hoses

• Visually inspect c oolant hoses and clamps.

Remember to check the two coolant lines that

connect to the pressur e r egulator/converter.

• Replace any hose that shows signs of leakage,

swelling, cracking, abr as ion or deterioration.

Page 23

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 21

Checking coolant leaks

1. After the coolant t em per ature drops below 38°C

loosen the radiator cap.

2. Check that the coolant level r eac hes filler neck.

3. Install the radiat or c ap tester to the radiator filler

neck and apply a pressure of 1.4kg/cm2 .

While maintaining it f or 2 m inutes, check the radiator,

hose, and connecting part for leak.

CAUTION

Because the coolant in the radiator is too hot,

never open the cap when it hot, or injury may

occur due to an outburst of hot water.

Dry out the inspection p art .

When removing th e tester, take care not to spill

the coolant.

When removing/installing the tester as well as

testing, take care not to deform the fille r neck.

4. Replace parts if leak is detected.

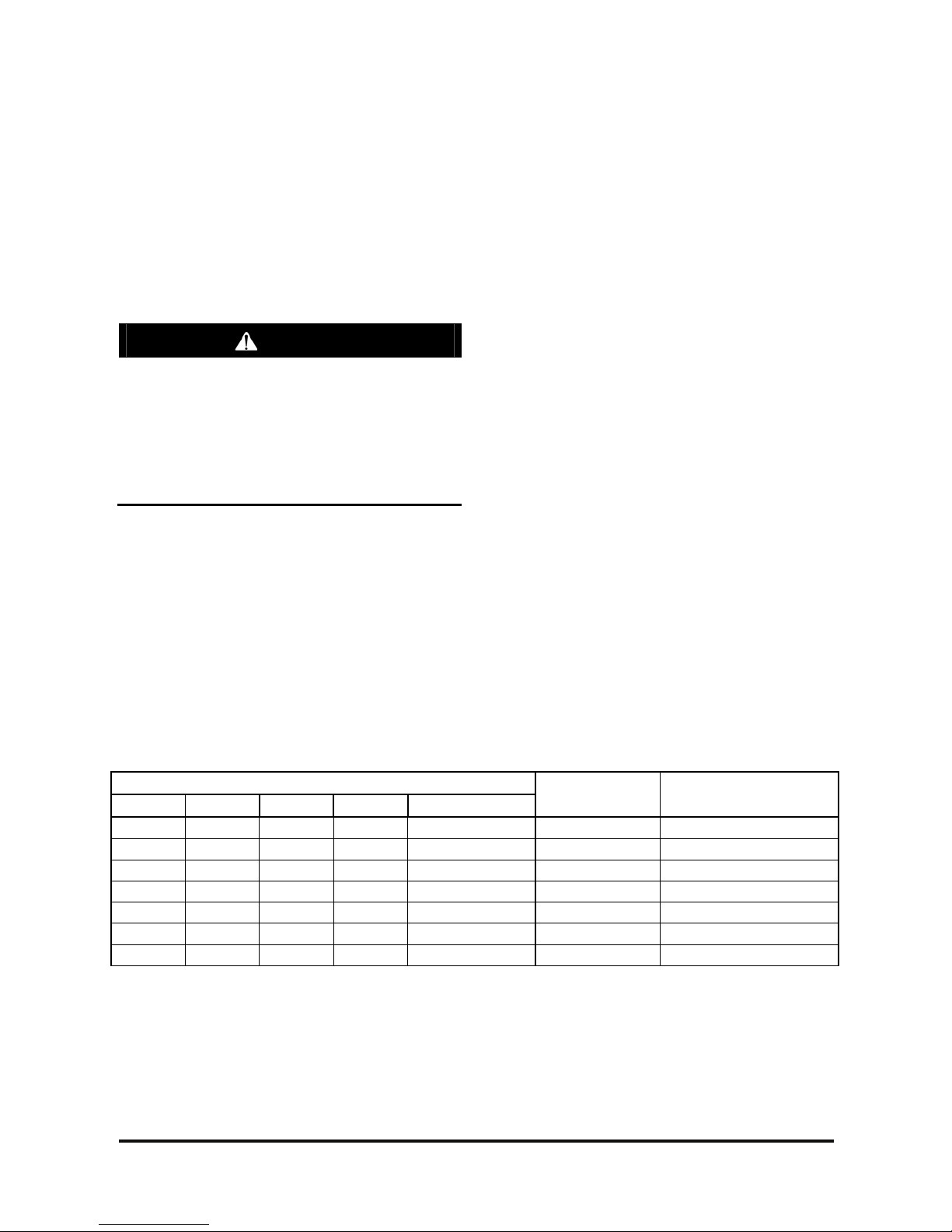

Specific gravity test

1. Measure specif ic gravity of the coolant using a

hydrometer.

2. After measuring the coolant temperature,

calculate specific gr av ity using the following table.

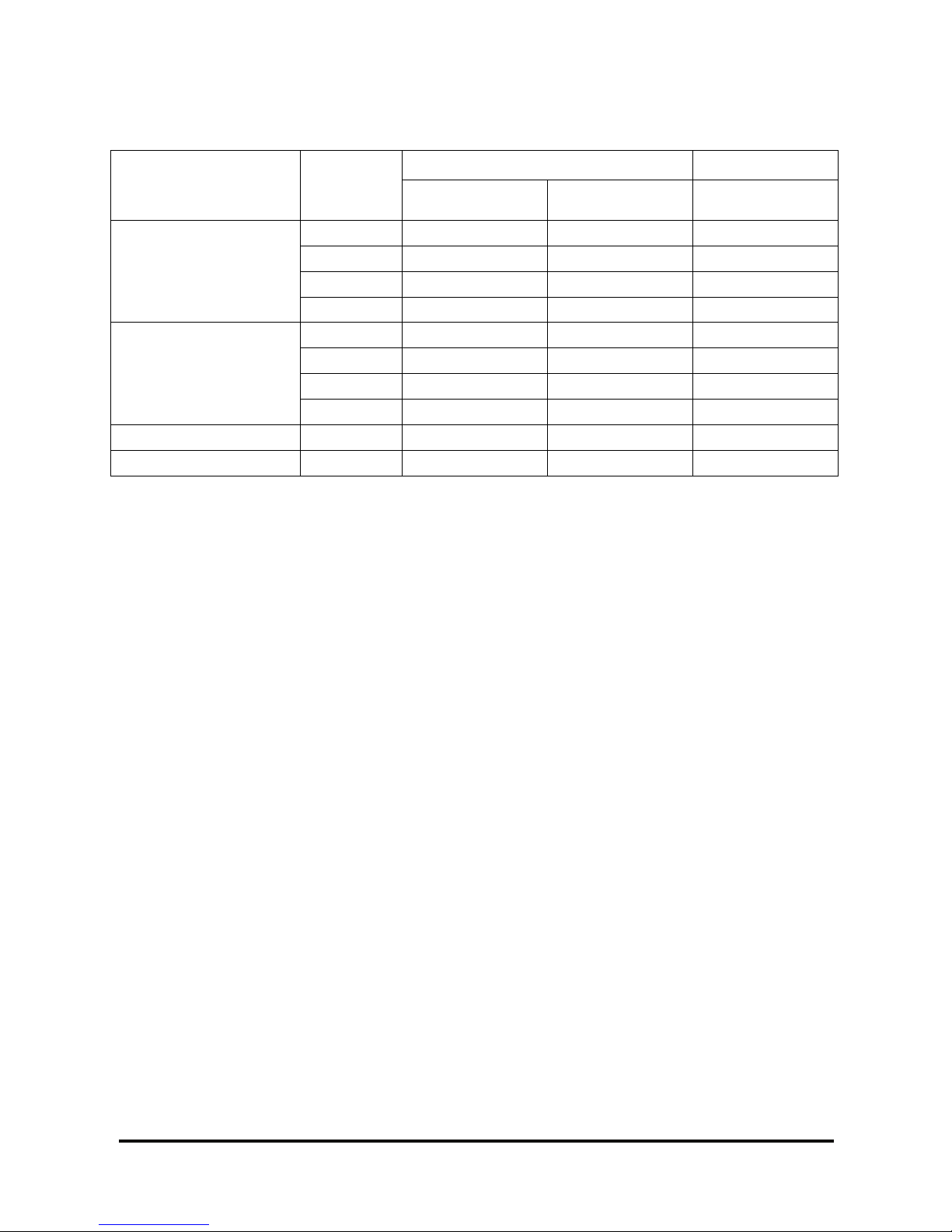

Relation between Coolant concentration and Specific Gravity

Temperature and Sp ecific gravity of coolant (Temp.:℃)

10 20 30 40 50

Freezing

temp(℃)

Coolant Concentration

Specific Volume

1.054 1.050 1.046 1.042 1.036 -16 30%

1.063 1.058 1.054 1.049 1.044 -20 35%

1.071 1.067 1.062 1.057 1.052 -25 40%

1.079 1.074 1.069 1.064 1.058 -30 45%

1.087 1.082 1.076 1.070 1.064 -36 50%

1.095 1.090 1.084 1.077 1.070 -42 55%

1.103 1.098 1.092 1.084 1.076 -50 60%

Page 24

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 22

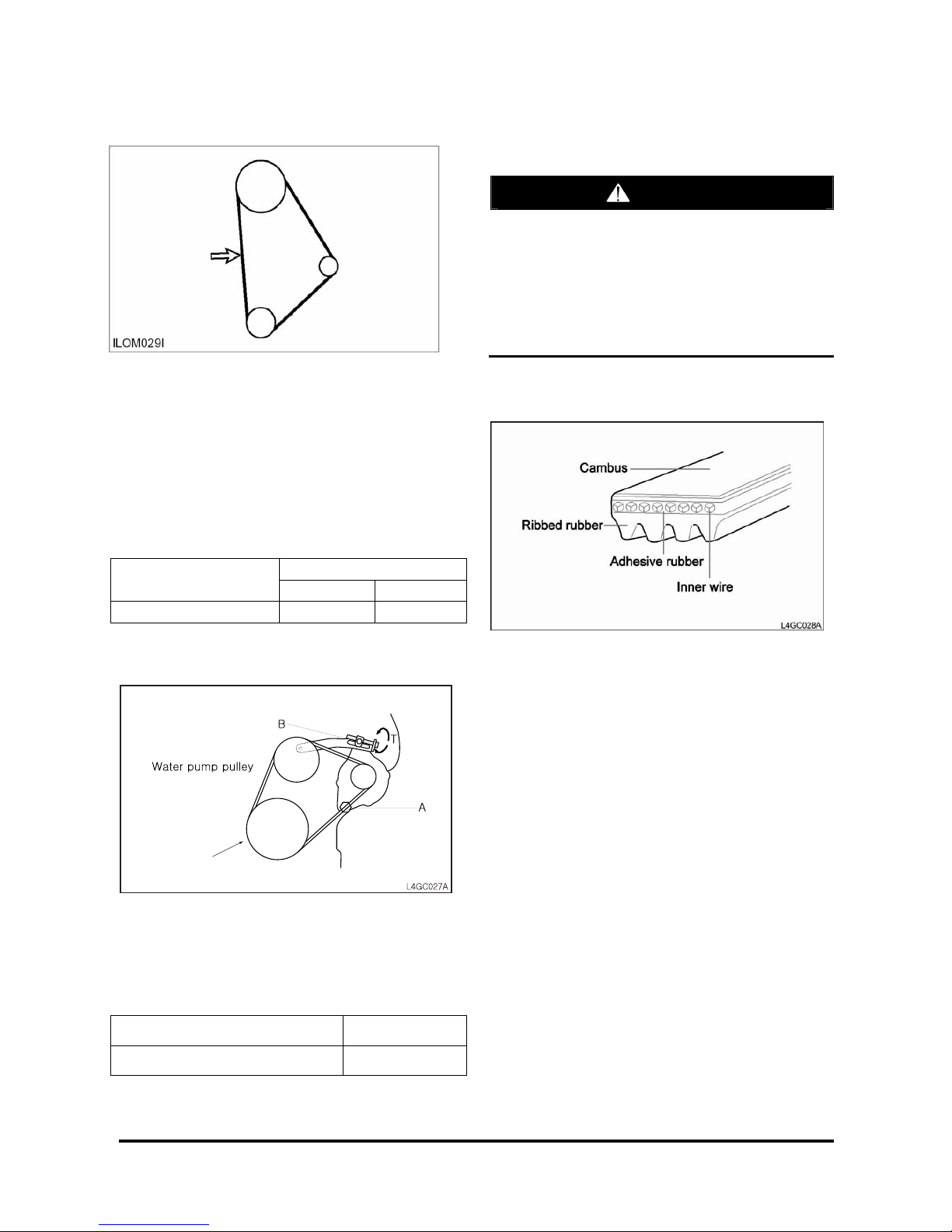

Checking and Adjusting Drive Belt

1. Checking tension

1) Press the middle of the water pum p pulley and

alternator pulley wit h 10k gf.

2) Inspect the belt deflection by pressing it.

3) If the belt deflection is out of the standard,

adjust it as follows.

Standard

Item

New belt Used belt

Drive belt deflect ion ( L) 4.0~4.4mm 5.1~ 5.7mm

Adjusting

1. Loosen the alternator support bolt “A” nut and

adjusting lock bolt “B ” .

2. Adjust the belt tension by m ov ing the alternator

brace adjusting bolt t o “ T” dir ec tion.

Alternator adjusting lock bolt “B” 1.2~1.5kg·m

Alternator suppor t bolt “A” 2~2.5kg·m

3. Tighten the bolt “A ” and then tighten “B” to the

specified torque.

CAUTION

If the belt tension is too excessive, noise as well

as early wear of belt occurs and the water pu mp

bearing and altern at or bearing are damaged.

If the belt is too loose, due to early wear of belt

and insufficient power of alternator, battery and

water pump become inefficient and finally

engine is over he ated or dama ged.

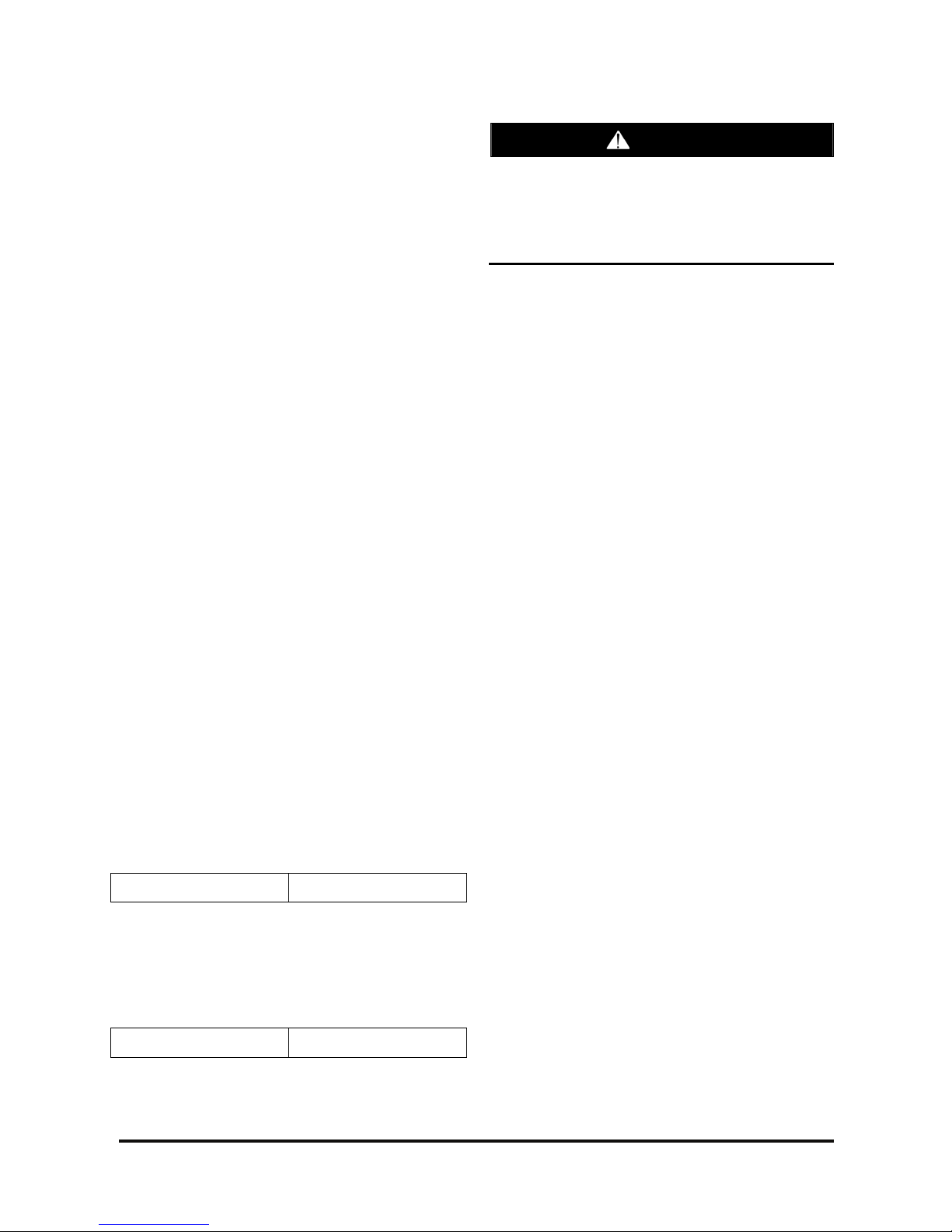

Checking Belt for Damage

Check the following item s and r eplac e the belt if

defective.

1. Check the belt surf ac e for dam age, wear and

crack.

2. Check the belt surf ac e for oil or grease

contamination.

3. Check the rubber part for wear or hardening.

4. Check the pulley surfac e for crack or damage.

Crank

pulley

Page 25

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 23

Ignition Syst em Mai nt e nance

Inspect Battery System

• Clean battery out er surfaces with a mixture of

baking soda and water.

• Inspect batter y outer surfaces for damage and

replace as necessary.

• Remove battery cables and c lean, repair and/or

replace as necessary.

Inspect Ignition System

• Remove and inspect the spark plugs . Replace as

required.

• Inspect the ignition coil for cracks and heat

deterioration. V is ually ins pec t the coil heat sink

fins. If any fins are br oken replace as requir ed.

Inspection of Ignition Timing

1. Inspection c ondition

Coolant temperatur e : 80-90°C(At normal

Temperature)

Lamp and all accessories : OFF

Transmission : In neutral position

Parking brake : ON

2. Inspection

1) Connect the timing light.

2) Measure RPM.

RPM

Low Idle 750±15rpm

NOTE: If RPM is not normal, it is impos s ible to

measure the proper ignit ion timing, so measure it at

a normal RPM.

3) Inspect the standard ignit ion timing.

BTDC 5˚±5˚

4) If ignition timing is out of the standard, inspect

sensors concerned wit h ignition timing.

CAUTION

Because ignition timing is fixed by set data

value in ECU, it is impossible to control on

purpose.

Fist, check that sensors send output properly to

help determine ignition timing control.

NOTE: Affectiv e ECU input to Ignition timing control

• Coolant temperat ur e s ens or

• Oxygen sensor

• Battery voltage

• MAP sensor (Engine load)

• Crankshaft position s ens or

• Throttle position s ens or

• Intake Air Temperature sensor

5) Check that actual ignit ion timing is changed

with engine RPM increased.

Page 26

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 24

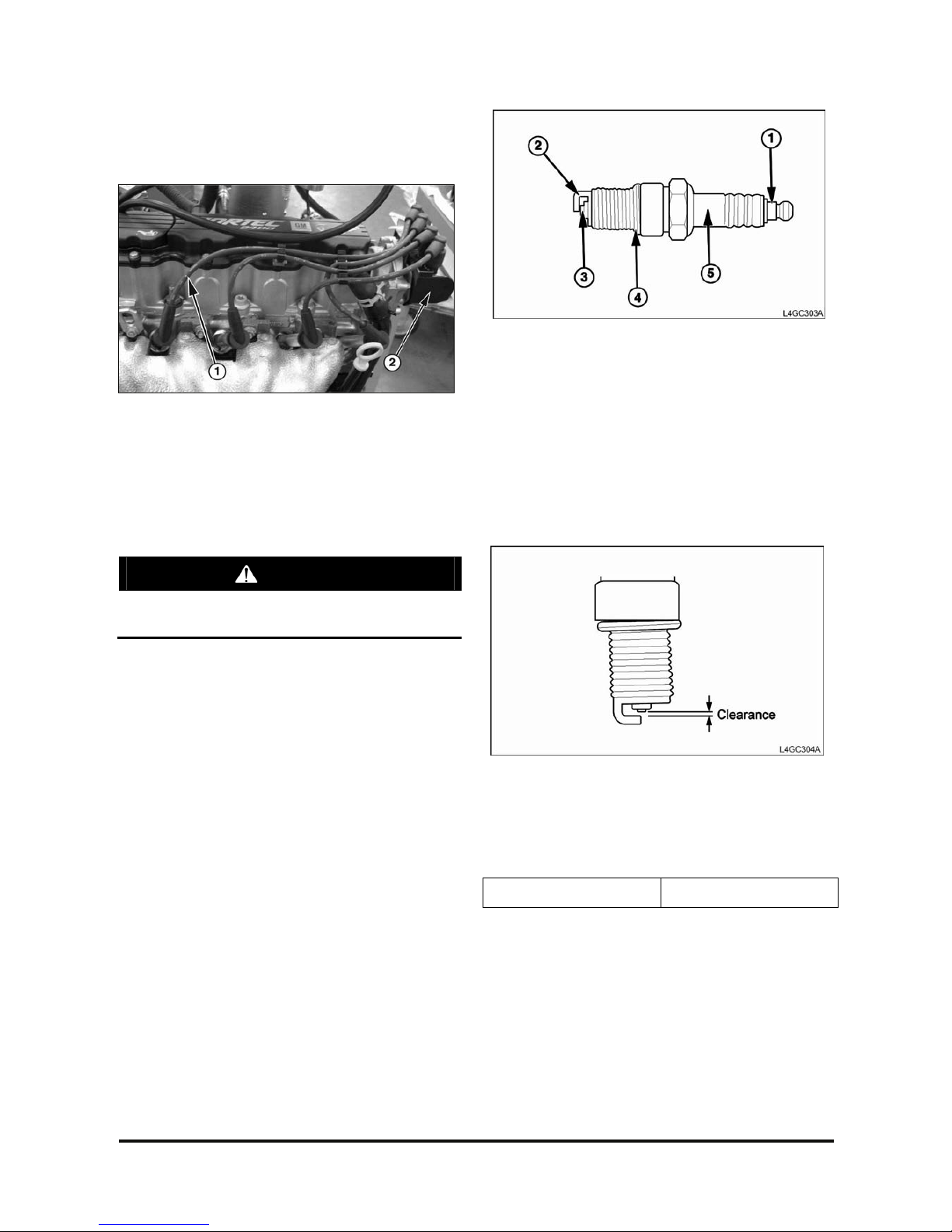

Inspection of Spark Plug

Inspection and clean

1) Ignition cable

2) Ignition coil

1. Disconnect t he ignition cables from ignition coil

ass’y.

2. Remove all spark plugs from the cy linder head

using a sparkplug wrench.

CAUTION

Take care not to come foreign materials into

spark-plug mounting hole.

3. Check the spark plug as below.

1) Insulator brok en

2) Terminal worn

3) Carbon deposit

4) Gasket damaged or broken

5) Porcelain insulator of spark plug clearance

4. Check the plug clearance using a plug clear anc e

gauge and if the value is not within the specified

values, adjust it by bending the gr ound c lear anc e.

When installing a new sparkplug, install it after

checking the uniform plug c lear anc e.

Spark plug clearance 0.8~0.9mm

Page 27

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 25

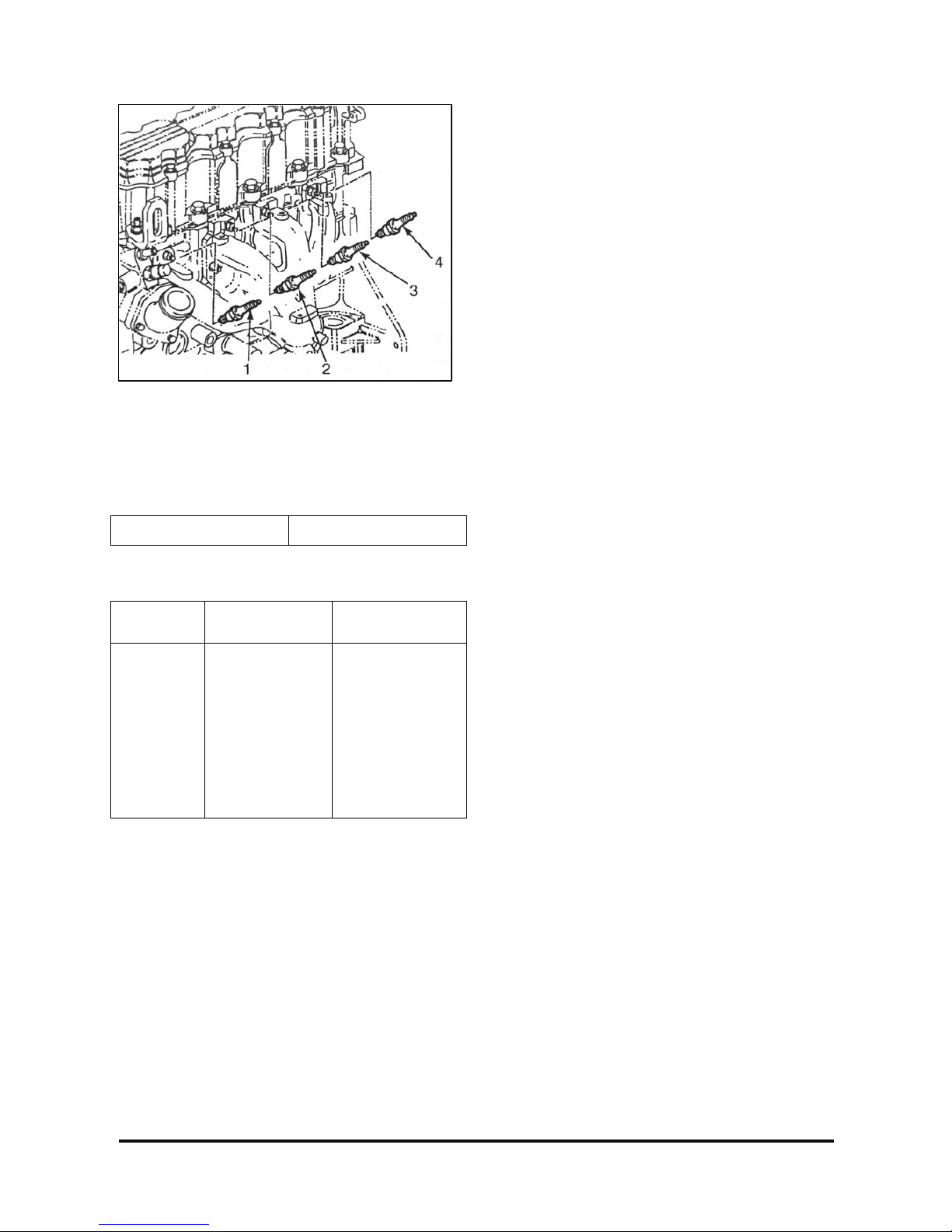

Spark Plugs

5. Install the spark plug and tighten it to the specified

torque.

Take care not to over tight en it t o pr ev ent cy linder

head threads from dam age.

Tightening torque 2 ~ 2.5 kg·m

SPARK PLUG ANALYSIS

State

Contact point is

black

Contact point is

white

Description

• Density of the

fuel mixture is

thick

• Density of the

fuel mixture is

thin

• Lack of air

intake

• Ignition timing is

fast

• Spark plug is

tight

• Lack of torque

Page 28

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 26

Fuel System Maintena nc e

Replace LP Fuel Filter Element

Park the lift truck in an authorized refueling area with

the forks lowered, park ing br ak e applied and the

transmission in Neut r al.

1. Close the fuel shutof f valv e on the LP-fuel tank.

Run the engine until the fuel in the system runs

out and the engine stops.

2. Turn off the ignition switch.

3. Scribe a line across the filt er hous ing c ov er s ,

which will be used for alignment pur pos es when

re-installing the f ilter cover.

FUEL FILTER DISASSEMBLY (Steps 4-7)

4. Remove the cover retaining screws (1).

5. Remove top cover (2), magnet (3), spring (4), and

filter element ( 7) from bottom cover (5).

6. Replace the filt er elem ent (7) .

7. Check bottom cover O- r ing s eal ( 6) f or damage.

Replace if necessary.

8. Re-assemble the filt er as s em bly aligning the

scribe lines on the top and bott om c ov er s.

9. Install the cover r etaining sc r ews , tightening the

screws in an opposite sequenc e ac r os s the cov er .

10. Open the fuel valve by slowly t ur ning the valve

counterclockwise.

11. Crank the engine sever al r ev olutions to open the

fuel lock-off. DO NOT START THE ENGINE.

Turn the ignition key s witch to the off position.

12. Check the filter hous ing, fuel lines and fittings for

leaks. Repair as necess ar y .

Testing Fuel Lock-off Operation

• Start engine.

• Locate the electrical c onnector for the fuel lock (A) .

• Disconnect the elec tric al c onnec tor.

• The engine should run out of fuel and s top within a

short period of time.

NOTE

The length of time the engine runs on trapped fuel

vapor increases with any increase in distance

between the fuel lock-off and the pressure

regulator/converter.

• Turn the ignition key switch off and re-connect the

fuel lock-off connect or .

Page 29

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 27

Pressure Regulator/Converter

Inspection

• Visually inspect the pressure regulator/converter

(B) housing for coolant leaks.

• Refer to Chapter 5 if the pres s ure

regulator/conver ter requires replacement.

Fuel Trim Valve Inspec tion (FTV)

• Visually inspect the fuel trim valves (C) for

abrasions or cracking. Replace as necessary.

• To ensure a valve is not leaking a blow-by t es t can

be performed.

1. With the engine off, dis c onnec t the electrical

connector to the FTVs.

2. Disconnect t he vacuum line from the FTVs to the

pressure regulator/converter at the converter’s

tee connection.

3. Lightly blow through the vacuum line connected to

the FTVs.

Air should not pass through t he FT V s when deenergized.

If air leaks past the FTVs when de-ener giz ed,

replace the FTVs.

Inspect Air/Fuel Valve Mixer Assembly

• Refer to Chapter 5 for proc edur es r egar ding the

LP mixer (D).

Inspect for Intake Leaks

• Visually inspect the intake throttle assembly (E),

and intake manifold for loos enes s and leak s .

Repair as necessary.

Inspect Throt tl e Ass em bly

• Visually inspect the throttle assembly motor

housing for coking, c r ac k s, and m issing cov erretaining clips. Repair and/or replace as

necessary.

NOTE: Refer to Chapter 5 for pr oc edur es on

removing the mixer and ins pec ting the throttle plate.

Checking the TMAP Sensor

• Verify that the TMAP sensor (F) is mount ed tightly

into the manifold or m anifold adapter (E), with no

leakage.

• If the TMAP is found to be loose, remov e the

TMAP retaining screw and the TMAP sensor from

the manifold adapter.

• Visually inspect the TMAP O-ring seal for damage.

Replace as necessary.

• Apply a thin coat of an approved silicon lubr ic ant

to the TMAP O-ring seal.

• Re-install the TMAP sensor into the manifold or

manifold adapter and secur ely tighten the

retaining screw.

Exhaust System Maint ena nc e

Inspect Engine for Exhaust Leaks

• Start the engine and allow it to reac h oper ating

temperatures.

• Perform visual inspection of exhaust system from

the engine all the way to the tailpipe. Any leaks,

even after the post- c atalyst oxygen sensor, can

cause the sensor out put t o be eff ected ( due to

exhaust pulsation ent r aining air ups tream).

Repair any/all leaks found. Ensure the length

from the post-catalyst sensor to tailpipe is the

same as original fact or y .

• Ensure that wire rout ing for the oxygen sensors is

still keeping wires away f r om the exhaus t system.

Visually inspect t he ox y gen s ens or s to det ect any

damage.

Page 30

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 28

Maintenanc e Schedule

NOTE: The MI-07 fuel system was des igned for use with LPG fuel that complies with HD5 or HD10 LPG fuel

standards. Use of non-c om pliant LPG fuel may require more frequent servic e intervals and will disqualify the

user from warranty c laim s.

Page 31

G424F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 29

Page 32

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 30

Chapter 3. ENGINE MECHANICAL SYSTEM

General Information

Engine Outl ine

Page 33

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 31

Technical Specifications

CRANKSHAFT

Maximum saddle taper..................................................................................................................... 0.005 mm

Maximum saddle out-of-roundness .................................................................................................. 0.004 mm

Crankshaft maximum warping............................................................................................................0.03 mm

Trunnion diameter........................................................................................................57.9820 – 57.9950 mm

Journal diameter................................................................................................................48971 – 49987 mm

Maximum clearance bet ween trunnion and shell ..................................................................0.015 – 0.041 mm

Clearance between journal and c onnec ting rod shell............................................................0.012 – 0.062 mm

Connecting rod journal end clearance ..................................................................................0.070 – 0.242 mm

Reboring number........................................................................................................................................... 2

Crankshaft end clear anc e ...................................................................................................... 0.02 – 0.352 mm

Shells: See color def initions below, under “Table of Spare Shells”

CYLINDERS AND PISTONS

Clearance between piston and cy linder ( s k ir t lower area).....................................................0.010 a 0.030 mm

Maximum saddle out-of-roundness .................................................................................................. 0.127 mm

Crankshaft maximum warping ........................................................................................................ 0.127 mm

Piston stroke....................................................................................................................................... 100 mm

Piston bore........................................................................................................................................ 87.5 mm

Distance between pist on head in the TDC and block surface....................................................0.11 a 0.43 mm

Angle between the compres s ion r ing openings..........................................................................................100°

Gap between compress ion r ing tips ............................................................................. 1st groove 0.25 – 0.45

....................................................................................................................................2nd groove 0. 15 – 0.45

Gap between compress ion r ings and grooves

– Upper groove .......................................................................................................................0.005 – 0.085

– Lower groove.......................................................................................................................0.035 – 0.008

Gap between the oil scr aper - type c ontrol oil....................................................................................0.20 – 0.55

Page 34

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 32

CYLINDER HEAD

Valve seat angle (all) .......................................................................................................................... 90° ± 1°

INTAKE AND EXHAUST VALVES

Seat angle ........................................................................................................................................ 92° ± 15°

Stem lash in the guides........................................................................................... 0.015 a 0.042 mm (intake)

e 0.030 a 0.060 mm (exhaust)

Available oversize...................................................................................................0.075 a 0.150 e 0.250 mm

Valve seat eccent r ic ity tolerance (between maximum and minimum readings).................................. 0.050 mm

Valve seat widths:

– Intake....................................................................................................................................1.3 – 1.4 mm

– Exhaust ...............................................................................................................................1. 7 – 1.8 mm

CAMSHAFT

End clearance..........................................................................................................................0.04 – 0.16 mm

Camshaft maximum warping..............................................................................................................0.04 mm

OIL PUMP

Clearance between:

– Driven gear and case ........................................................................................................0.11 a 0.19 mm

– Drive gear and crescent.....................................................................................................0.35 a 0.45 mm

– Gear and cover..................................................................................................................0.03 a 0.10 mm

Pressure @ 1400 RPM..............................................................................................................282 – 324 kPa

(41 – 47 lbf·pul²)

Page 35

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 33

Shells Selection Table

MAIN BEARINGS – STANDARD SIZE (*)

(*) ALL MEASURES ARE IN MILLIMETERS

Page 36

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 34

MAIN BEARINGS – 0.50 UNDERSIZE (*)

Page 37

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 35

CONNECTING ROD BEARINGS CONNECTING ROD BEARINGS

0.25 UNDERSIZE 0.50 UNDERSIZE

Page 38

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 36

Recommended Torque Values

nuts N•m

Starter to cylinder bloc k 45

Exhaust manifold to cylinder head 18-22 1)

Dipstick oil tube t o cylinder bloc k 20-30

DIS Ignition Module to camshaft housing carrier 8

Throttle body to int ak e manifold 11-13

Pressure plate t o camshaft housing 8

Intake manifold to cylinder head 18-22 1)

Crankshaft position sensor 6

Rear toothed belt cov er bolts 8

Rear toothed belt cov er nuts 7

Heat shield to exhaust m anifold 6-8

bolts N•m

V–belt tensioner t o alternator support 25

Fuel distributor tube to intake manifold 22-30

Fuel supply and return line to throttle valve guards 15

Water pump to cylinder block 25

Coolant pipe to cylinder block 20

Crankshaft main bear ing c ap to cylinder block 50 N•m + 45° + 15°

Oxygen sensor to exhaust manifold 35-44

Crankcase oil baffle plate and bridge bolts 20

Camshaft housing cov er to cam s haft hous ing 8

Camshaft sprocket to camshaft 45

Oil drain bolt to oil pan 40-70

Oil pressure swit c h to oil pump 30-50

Oil filter to oil pump Hand Tight

Oil pump to cylinder block 10

Oil pump cover to oil pump 6

Oil intake pipe to oil pump 10

Oil intake pipe to cy linder bloc k 8

Oil baffle plate to oil pan 8

Oil pan to transmission 40

Page 39

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 37

bolts N•m

Oil pan to cylinder block 18-22

Con–rod bearing cap to con–rod 30-40+40°+45°

Flywheel to cranks haft 35 + 30 ° + 15° 2)

Coolant temperatur e s ens or to thermostat housing 20

Thermostat housing t o c y linder head 15

Carrier plate (DIS ignition module) to camshaft housing 12

Relief valve plug to oil pump 45 - 60

Toothed belt cover , lower par t to rear toothed belt cover 4

Toothed belt tens ion r oller to oil pump 20

Spark plug to cylinder head 25

Cylinder head and camshaft hous ing to cylinder block 25 + 180°+ 10° 2)

1. Use new nuts.

2. Use new bolts.

3. Rectum thread befor e r eus e and ins er t bolt s with

screw locking compound (r ed) . The installation

time including the tor que c hec k is maximum 10

minutes.

4. Insert bolts with mounting paste (white).

Page 40

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 38

Troubleshooting

Symptom Possible cause Remedy

Low compression

Cylinder head gasket damaged

Worn or damaged piston r ing

Worn piston or cylinder

Worn or damaged valve seat

Replace gasket

Replace ring

Repair or replace piston and cy linder bloc k

Repair or replace valve and seat r ing

Low oil pressure

Insufficient engine oil

Oil pressure switch defective

Oil filter clogged

Worn oil pump gear or cover

Thin or diluted engine oil

Oil relief valve clogged( Open)

Excessive bearing clear anc e

Check engine oil level

Replace oil pressure switc h

Install new filt er

Replace

Replace engine oil

Replace or inspect

Replace bearing

High oil pressure Oil relief v alv e c logged( Clos ed) Repair relief valve

Noisy valve

Thin or diluted engine oil

Faulty HLA

Worn belt stem or valve guide

Replace engine oil

Replace HLA

Replace belt stem or valve guide

Noisy connecting rod

or timing belt

Insufficient engine oil

Low oil pressure

Thin or diluted engine oil

Excessive bearing clear anc e

Check engine oil level

Refer to too low oil pressure

Replace engine oil

Replace bearing

Noisy timing belt Incorrect belt tens ion Correct belt tension

Low coolant level

Coolant leak from Heat er or radiat or

hose

Defective radiat or c ap

Thermostat housing

Radiator

Water pump

Repair or replace parts

Retighten clamp or replac e

Replace gasket or housing

Replace

Replace parts

Radiator clogged Foreign material into c oolant Replace coolant

Abnormally high

coolant temperat ur e

Thermostat defec tive

Radiator cap defect iv e

Abnormal flow in cooling system

Loose or missing driving belt

Loose water pump

Water temperatur e wir ing defective

Cooling pan defective

Radiator or thermos tat switch defective

Inefficient c oolant

Replace parts

Replace parts

Clean or replace parts

Correct or replace

Replace

Repair or replace

Repair or replace

Replace

Add coolant

Abnormally low

coolant temperat ur e

Thermostat defec tive

Water wiring defec tive

Replace

Repair or replace

Oil cooling system

leak

Loose connecting part

Cracked or damaged hose, pipe, and oil

cooler

Retighten Replace

Exhaust gas leak

Loose connecting part

Pipe or muffler damaged

Retighten

Repair or replace

Abnormal noise

Breakaway exhaust plate in muffler

Rubber hanger damaged

Pipe or muffler with body Interfered

Pipe or muffler damaged

Catalytic conver ter damaged

Each connecting gasket damaged

Replace

Replace

Repair

Repair or replace

Replace

Replace

Page 41

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 39

Engine Explode d View (1 of 2)

1) RING KIT 2) PISTON 3) BEARING KIT 5) ROD 6) BOLT

13) INDICATORK,OIL LVL 14) HOSE 16) GASKET 17) BOLT 20) PLUG

21) ENGINE 22) SEAL 23) BOLT 24) GEAR 25) GEAR

26) SEAL 27) COVER 28) BOLT 41) PAN,OIL 42) BOLT

47) CAP 57) BEARING 58) BOLT 59) CRANKSHAFT 60) RING

61) KEY 62) BEARING KIT 80) FILTER 81) FITTING 86) VALVE

87) SENSOR 90) BOLT 91) BOLT 92) SEAL 97) PIN

98) BEARING KIT 99) PLATE 100) CAP 101) BOLT 102) PUMP

103) SEAL 104) PIN 105) GASKET 106) PUMP 107) BOLT

108) SEAL 109) SEAL 110)PIPE 111) BOLT 112) BOLT

113) BAFFLE 114) SEAL 115) PLUG 117) CLAMP 118) HOSE

120) SPRING 121) PLUG 122) SEAL 123) PLUG 124) VALVE

125) GASKET 126) PIN 129) SEAL 130) SWITCH 131) BOLT

132) PLATE 133) BOLT 134) STARTER 135) SENSOR 136) PLUG

139) BOLT 143) BOLT 145) BOLT

Page 42

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 40

Engine Explode d View (2 of 2)

1) ENGINE 3) SPARK PLUG 4) ARM 5) SEAT 6) ADJUSTER 7) KEY

8) CAP 9) SPRING 10) SEAL 11) SEAT 12) GUIDE 28) STUD

29) NUT 31) MANIFOLD 32) GASKET 33) VALVE 34) SEAT 35) VALVE

36) SEAT 37) GASKET 38) HEAD 40) BOLT 49) STUD 66) PIN

67) HOUSIN G 69) WASHER 71) CA MSHAFT 72) PIN 73) ST UD 74) CAP

75) SEAL 76) COVER 77) GASDET 78) BAFFLE 79) TUBE 80) BOLT

81) BRACKET 82) BRACKET 83) BRACKET 86) BOLT 87) BRACKET 88) COVER

89) SEAL 90) BOLT 91) RETAINER 92) RETAINER 93) RETAINER 94) RETAINER

95) WIRE 96) WIRE 97) WIRE 98) WIRE 99) WIRE KIT 100) STRA P

104) COIL 105) BOLT 107) GASKET 108) MANIFOLD 113) HOSE 115) COVER

116) BOLT 117) ADAPTER 118 ) BOLT 119 ) COV ER 120) BOLT 121) SPROCKE T

122) WASHER 123) BOLT 124) BELT 125) TENSIONER 126) BOLT 128) SPACER

129) KEY 130) SEAL 131) SPROCKET 132) WASHER 133) BOLT 134) SEAL

135) HOUSING 136) SENSOR 137) BOLT 140) SEAL 141) THERMOSTAT 142) BOLT

143) INJECTOR 144) SEAL 145) INJETOR 146) REGULATOR 148) SEAL 149) SEAL KIT

150) CLIP 151) BOLT 152) BOLT 153) COVER 154) GASKET 160) TUBE

161) TUBE 162) FITTING 164) BOLT 165) INLET 166) STUD 167) SEAL

168) VALVE 169) HOSE 170 ) CLA MP 171) CLAMP 172) HOSE 173) BA LA NCER

174) BOLT 175) PIPE 176) BOLT 177) TUBE 180) ADAPTER 181) WASHER

183) STUD 184) NUT

Page 43

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 41

Intake manifold and gasket

Components

1) Gasket 2) Intake Manifold Assy 3) Stud Bolt 4) Nut 5) Fitting

6) Tmap 7) Bolt 8) Bracket-Stay 9) Washer 10) Bolt

11) Washer 12) Bolt 13) Pipe 14) Plug 15) Hose

16) Hose 17) Clamp 18) Washer 19) Bolt 20) Hose

21) Clamp 22) Washer 23) Bolt 24) Hose 25) Clamp

26) Block 27) Brack et 28) Fit ti ng 29) Plug

Page 44

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 42

Removal

Remove or Disconnect

1. Relieve of fuel line pres s ur e:

• Fuel-off solenoid valv e dis c onnec t.

• Run the engine and leave it running until

stopping by lack of fuel.

• Run the engine for about 5 seconds s o as to fully

depressurize the f uel s y stem .

• Fuel pump electric connec tion, from the tank

upper area

• Run the engine and let it idle until it s tops by lack

of fuel.

• Start the engine for about 5 seconds, so as to

obtain full pressure r elief in the fuel system.

2. Disconnect t he wiring harness from electronic

components.

3. Battery negativ e c able.

4. Drain the coolant, releas ing the radiator lower

hose.

5. Disconnect t he fitting of gasoline fuel hose from

the fuel tank. (G424FE DF)

6. Disconnect t he fuel hose and balanc e line, air

hose.

7. Disconnect car bur etor assembly by using 5mm

hex-bit socket wr enc h handle.

8. Disconnect t he PCV hose by using a sc r ew driver.

9. Remove bracket attaching bolts by using 17mm

spanner.

10. If necessary, rem ov e the f uel r ain from intake

manifold by using 12mm soc k et wrenc h and

extension.

11. If necessary, rem ov e TM AP sens or att ac hing

screws by using E-8 socket wrenc h with

extension.

12. Remove all hose clamps and hos e by using

screw driver.

13. Remove coolant pipe at taching bolts by using

13mm spanner and 10mm sock et wrenc h.

14. Remove manifold at taching bolts from the head

by using 13mm wrench.

15. Remove the intake manifold.

Clean

• Gasket residues from the int ak e m anifold and

cylinder head, taking c ar e not to scratch the

gasket mating surfac es .

Page 45

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 43

Installation

Install or connect

1. Coolant pipe attac hing bolt with cylinder block in

its place.

2. With 13mm torque s panner , proper torque; tighten.

Tighten

• Bolts: 18 – 22 N·m (13 – 16 lb·ft.).

3. Hose clamp with torque driv er ; tighten.

Tighten

• Clamps: 1.5 – 2 N·m (1.1 – 1.5 lb·ft.).

4. A new gasket between intak e m anifold and

cylinder head.

5. Intake manifold and it s att ac hing nuts, without

tightening.

6. With a 13-mm socket wrench, ext ens ion and

proper torque wrench; tighten.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.).

Obs.: Tighten t he intake manifold nuts in a

crisscross sequence, from the center to the ends.

7. Put the pipe on the manifold.

8. With a 10-mm socket wr enc h, extension and

proper torque wrench; tighten.

Tighten

• Bolts: 5 – 6 N·m (3.7 – 4.4 lb·ft.).

9. Insert the TMAP onto manifold with greased oring.

10. With an E-8 socket wrenc h, extension and

proper torque wrench; tighten.

Tighten

• Bolts: 6– 7 N·m (4.4 – 5.2 lb·ft.).

11. MAP sensor electr ic connector in the intake

manifold rear area.

12. Insert the fuel rail wit h injec tors in the hole of

manifold and paste oil and grease to o-ring of

injector. (G 424FE)

13. With a 12-mm socket wrench, ext ens ion and

proper torque wrench; tighten.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.).

Page 46

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 44

14. Connect wiring to the injectors.

15. Connect the PCV hose bet ween P CV and fitt ing.

16. Hose clamp with torque driv er ; tighten.

Tighten

• Clamps : 1. – 1.5 N·m (0.75 – 1.1 lb·ft.).

17. Bracket-st ay and its att ac hing nuts, without

tightening.

18. With a 17-mm torque spanner ; tighten.

Tighten

• Nuts: 35– 40 N·m (25.8 – 29.5 lb·ft.).

19. A new gasket between mixer assembly and

intake manifold.

20. Mixer assembly and its att ac hing nuts, without

tightening.

21. With a 5mm hex-bit sock et wrenc h and tor que

wrench; tighten by us ing thread loc k er .

Page 47

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 45

Exhaust Manifold and Gasket

Components

1) Gasket 2) Adapter-Exhaust Manifold 3) Bolt

4) Washer 5) O2 Sensor 6) Stud Bolt

7) Washer 8) Bolt 9) Exhaust Manifold

10) Shield 11) Gasket

Page 48

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 46

Removal

Remove or disconnect

1. Spark plug cable ter m inals ;

2. Exhaust manifold heat s hield and r em ov e dips tick

tube (to allow removal of #3 plug wire) .

3. Oxygen sensor (O2) electric connection.

4. Adapter-Manifold

5. Remove attaching bolts of adapter with 6 mm hex

– bit socket.

6. Exhaust manifold-to-cylinder head attaching nuts,

with a 13-mm socket wrench, extension and

handle.

7. Exhaust manifold and gask et.

Clean

• Exhaust manifold and cy linder head gas k et

residues, taking c ar e not t o scr atch the gasket

mating surfaces .

Installation

Install or connect

1. New gasket between the exhaus t manifold and

cylinder head.

2. Exhaust manifold and at taching nuts, without

tightening.

3. With a 13-mm socket wrench, ext ens ion and

torque wrench; t ighten.

Tighten

• Nuts: 18 – 22 N·m (13 – 16 lb·ft.)

4. New gasket between the exhaus t manifold and

adapter.

5. Exhaust adapter and at taching bolts Without

tightening.

6. With a 6mm hex-bit socket, extension and torque

wrench; tighten.

• Tighten : 25 ~ 30N.m

7. Oxygen sensor to the adapt er , wit h 22m m torque

spanner tighten.

8. Washer and plug to the exhaus t manifold, with

19mm socket wrench, extens ion and Torque

wrench; tighten.

• Torque : 60 ~ 70N.m

9. Heat shield and att aching bolts , wit hout tightening.

10. With a T30 socket wrench and tor que

Wrench; tighten.

• Tighten: 6 ~ 8N.m

11.Spark plug cables, obs er v ing their sequence.

Page 49

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 47

Timing Belt

Components

1) Cover 2) Bolt 3) Adapter

4) Bolt 5) Cover 6) Bolt

7) Sprocket 8) Washer 9) Bolt

10) Belt-t im in g 11) Te ns io ner-Timing Belt 12) Bolt

13) Spacer 14) Key 15) Seal

16) Sprocket 17) Washer 18) Bolt

19) Bolt 20) Stud 21) Nut

Page 50

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 48

Removal

Remove or disconnect

1. Crankshaft pulley; s ee “ Cr ank s haft P ulley –

Removal”, in this s ection.

2. V pulley belt autom atic Tensioner ; see “V Pulley

Belt Automat ic Tens ioner – Rem ov al” , in t his

section.

3. Timing belt front cover att ac hing bolt, with an E10

Torx socket wrench, extension and handle

4. Timing belt front cover.

Important

• Note the camshaft pulley alignm ent with the

timing mark on the tim ing belt cover.

• Turn the crankshaft until aligning the timing

pulley mark with the oil pum p c as e flange, in the

no. 1 cylinder combustion stroke.

5. Loosen the timing belt Tensioner bolt with a 13mm combination wrench, releasing belt tension.

6. Timing belt, mark ing the running direction/front

edge of the belt in case of using the sam e belt.

Timing Belt

Inspection

1. Check the belt for oil or dust depos it and replace

it if necessary. In cas e of sm all am ount of oil or

dust, clean it with a rag or paper instead of a

solvent.

2. After overhauling t he engine or r eadjus ting the

belt, inspect the belt in detail and replace it with a

new one if the following defec ts are detected.

CAUTION

Do not bend or twist the timing belt.

Take care not to contact the timing belt with oil,

water, grease and st eam.

Page 51

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 49

Description Specification

1. Back side rubber is hardened

Glossy back side. Due to

non-elasticity and har dening,

when pressing it with t he tip of

a finger, there is no sign of it.

2. Back side rubber is crac k ed

3. Canvas is cracked or det ac hed

4. Tooth is excessiv ely wor n out (initial step)

Tooth loaded from c anv as is

worn (elastic canvas fiber rubber

is worn, color is faded in white,

canvas structure is deformed)

5. Tooth is excessiv ely wor n out (final step)

Tooth loaded from c anv as is

Worn and rubber is worn off

(tooth width is nar r owed)

6. Tooth bottom is crac k ed

7. Tooth is missing

8. The side of belt is severely wor n out

9. The side of belt is cracked

NOTE: In case of normal

belt, it is cut precisely as

if cut with a sharp cutter

Page 52

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 50

Installation

Install or connect

Important

• Align the camshaft tim ing pulley m ar k with the

timing belt rear cov er mark.

• Align the cranks haft timing pulley m ar k with the

oil pump case flange, in t he no. 1 cy linder

combustion str ok e.

1. Timing belt

2. Belt Tensioner adjust m ent: with a 6-mm Allen

wrench, so as to keep steady t he Tensioner s haft,

loosen the Tensioner shaft attaching bolt until the

same becomes steady.

With a 6-mm Allen wrench, tur n c loc kwise the

Tensioner installat ion s haft up to the “NEW”

marking point (± mm) (Det ail B ). The needle may

move from the right side up t o the f inal adjus ting

position. Tight en the bolt. For used timing belts,

follow the same procedur e, but with the belt

adjustment in the “ USED” pos ition.

This change is suggest ed due to the used belt

presenting a differ ent course of action regarding

the new belt.

3. Timing belt front cover.

4. Timing belt front cover att ac hing bolts, with a 10-

mm socket wrench and handle.

5. V pulley belt autom atic Tensioner ; see “V Pulley

Belt Automat ic Tens ioner – Installation”, in this

Section.

6. Crankshaft pulley; s ee “ Cr ank s haft P ulley –

Installation”, in this section.

Page 53

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 51

Timing Belt Tensi oner

Removal

Remove or disconnect

1. Timing belt; see instructions under “Timing Belt –

Removal”, in this s ection.

2. Timing belt Tensioner bolt, in the oil pump case,

with a 13-mm socket wrench and handle.

3. Timing belt Tensioner.

Install or connect

1. Tensioner in the oil pum p c as e.

Important

• The lug (1) in the Tensioner base should be

lodged in the hole (2) of the oil pum p c as e.

2. Tensioner attaching bolt, without tightening.

3. Timing belt; see “Timing B elt – Installation”, in this

section.

Page 54

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 52

PCV Valve

Outline and Operation Principle

Engine condition No operating Engine condition At idle or decelerat ion

PCV valve No operating PCV valve Full operating

Vacuum path Clogged Vacuum path Small

Engine condition Proper operating Engine condit ion High speed and overload

PCV valve Proper oper ating PCV valve Light operating

Vacuum path Big Vacuum path Very big

Page 55

G424F(FE) Servi ce Manual Chapter 3. Engine Mechani cal System 53

Crankcase Ventilation

Cam

Carrier

Cylinder

Head

Engine

Block

Cover Assy

Oil Pan Baffle

Oil Pump

Assy

Secondary Vent

(Fresh Air Port) Primary Vent

to PCV

Oil Drai n backs (7 to tal)

(2 at front, 2 at rear, &