Doosan G420F, G420FE, G15S-5, G18S-5, G20SC-5 Service Manual

...

Service Manual

G420FE LP/Dual Fuel Engine

G

420F LP/Gasoline Dual Fuel Engine

G15S-5, G18S-5, G20SC-5

GC15S-5, GC18S-5, GC20SC-5

G20E-5, G25E-5, G30E-5

GC20E-5, GC25E-5, GC30E-5, GC33E-5

SB4241E00

Apr. 2007

1

Important Safety Information

Most accidents involving pr oduct operation, maintenance and repair ar e caused by failure to observe basic

safety rules or precautions. An acc ident can often be avoided by recognizing p otentially hazardous sit uations

before an accident occurs. A person must be alert to potential hazards. This person should also have the

necessary training, skills and tools to perf or m thes e functions properly.

Read and understand all safet y precautions and warnings before operating or performing lubrication,

maintenance and repair on this product.

Basic safety precautions are listed in the “Saf ety” sect ion of t he Servic e or Technical Manual. Additional s afety

precautions are list ed in the “Safety” section of the owner/operation/maintenanc e public ation.

Specific safet y warnings for all t hese publicat ions are pr ovided in the des cript ion of oper ations wher e hazard s

exist. WARNING labels have also been put on the product to provide instructions and to identify specific

hazards. If these hazard warnings are not heeded, bodily injury or death could occur to you or other persons.

Warnings in this publication and on the product labels are identified by the following sym bol.

WARNING

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could

result in in jur y or de a t h.

Do not operate or perform an y lubrication, main tenance or repair on this product, until you have read

and understood the operation, lubrication, maintenance and repair information.

Operations that may c ause product damage are identified by NOTICE l abels on the product and in this

publication.

DOOSAN cannot antici pate every possible circumstance that might involve a potential hazard. The warnings

in this publication and on the product are therefore not all inclusive. If a tool, procedure, work method or

operating tec hnique not specifically recommended by DOO SAN is used, you must satisfy yourself that it is

safe for you and others. You should also ensure that the product will not be damaged or made unsaf e by the

operation, lubr ic ation, maintenance or r epair proc edur es you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product. Obtain the complete and

most current information before starting any job. DOOSAN dealers have the most current information available.

G420F(FE) Servi ce Manual Index 3

Index

Chapter 1. GENERAL INFORMATION

Precautions before Service.................................7

Tightening Torque .............................................10

Recommended Lubricants and Capacities.......11

Engine Model and Engine Serial Number......... 12

General Specification........................................ 13

Engine Power and Torque................................. 15

Chapter 2. RECOMMENDED

MAINTENANCE

General M a in t e na nc e.........................................16

Test Fuel System for Leaks........................... 16

Inspect Engine f or Fluid Leak s ......................16

Inspect Vacuum Lines and F itt ings................16

Inspect Electrical System..............................16

Inspect Foot Pedal Operation........................16

Engine Oil Classification................................17

Checking Engine Oil Level............................ 18

Replacing Engine Oil and F ilter.....................18

Checking Compressed Pressure...................19

Adjusting Timing Belt Tension.......................20

Cooling S y s te m Maintenanc e............................21

Coolant Recommendation.............................21

Check Coolant Level.....................................21

Inspect Coolant Hoses..................................21

Checking coolant leaks.................................22

Specific gravity test.......................................22

Relation between Coolant c onc entration and

Specific Gravity.............................................22

Checking and Adjusting Drive B elt ................ 23

Adjusting.......................................................24

Checking Belt for Damage............................24

Ignition System Maintenance............................ 25

Inspect Battery System.................................25

Inspect Ig n i ti o n Syste m................................. 25

Inspection of Ignition Timing ......................... 25

Inspection of Spark Plug............................... 26

Fuel System Maintenance ................................. 28

Replace LP Fuel Filter Element..................... 28

Testing Fuel Lock-off Operation .................... 29

Pressure Regulator/Converter Ins pection...... 29

Inspect Air/Fuel Valve Mixer Assembly ......... 30

Inspect for Intake Leak s................................ 30

Inspect Th r o ttl e As se m b l y............................. 30

Checking the TMAP Sensor.......................... 30

Exhaust S y s tem Maintenance........................... 30

Inspect Engine f or Exhaus t Leaks................. 30

Maintenance Schedule...................................... 31

Chapter 3. ENGINE MECHANICAL

SYSTEM

General Informati on ...........................................33

Engine Outline.............................................. 33

Specifications............................................... 34

Specifications............................................... 35

Torque Specification..................................... 38

Special Tools................................................ 39

Troubleshooting............................................ 41

Timing Belt System ........................................... 42

Components................................................. 42

Removal....................................................... 43

Inspection..................................................... 44

Assembly...................................................... 46

PCV Valve .......................................................... 48

Outline and Operat ion P r inc iple .................... 48

Service Procedure........................................ 49

Intake and Exhaust Syst em............................... 50

Intake Manifold............................................. 50

Exhaust Manifold.......................................... 52

Cooling S y s te m................................................. 54

General Description...................................... 54

Testing and Adjust ing ................................... 55

G420F(FE) Servi ce Manual Index 4

Cooling System Recomm endation ................58

Coolant Pipe and Hose .................................60

Water Pum p..................................................61

Thermostat ................................................... 63

Cylinder Head Assembly ...................................65

Lubrication System............................................74

General Description ......................................74

Testing and Adjust ing.................................... 75

Oil Pressure Switch.......................................77

Front Case and Oil Pump..............................78

CAM Shaft, HLA, Timing Chain.........................83

Components .................................................83

Removal ....................................................... 84

Inspection.....................................................85

Crankshaft.......................................................... 90

Flywheel and Housing.......................................94

Piston and Connection Rod .............................. 95

Cylinder Block..................................................110

Chapter 4. ENG INE ELECTRICAL

SYSTEM

Specifications..................................................118

Ignition System................................................ 119

Coil-On-Plug Ignition System ...................... 119

COP Components....................................... 119

Inspection of Ignition Timing........................ 122

Inspection of Ignit ion Coil Dr iv er s ( P ower TR)

...................................................................122

Inspection of Ignition Coil............................123

Inspection of Spark Plug.............................124

Charging System............................................. 126

General Description ....................................126

Troubleshooting .......................................... 128

Disassembly and Installation.......................134

STARTING SYSTEM.........................................139

General Description ....................................139

Diagnosis Procedure................................... 140

Start Relay Tests ........................................ 142

Troubleshooting...........................................143

Starter.........................................................144

Chapter 5. ENGINE MANAGEMENT

SYSTEM (EMS)

General Informati on ..........................................1 5 0

Specifications..............................................150

Service Standard.........................................155

Component Location ....................................156

G420FE EMS (Engine Manag ement System)

Overview...........................................................160

General Description.....................................160

LPG Fuel System Operati o n........................163

MPI Gasoline System Operation..................170

Electronic Throttle System...........................171

Ignition System............................................172

Exhaust System...........................................173

SECM..........................................................175

SECM Wiring Diagrams for G420FE............178

G420F EMS (Engine Management System)

Overview...........................................................180

General Description.....................................180

LPG Fuel System Operati o n........................183

MPI Gasoline System Operation..................187

Electronic Throttle System...........................187

Ignition System............................................187

Exhaust System...........................................187

SECM..........................................................187

SECM Wiring Diagrams for G420F ..............188

EMS Inspection and Repair..............................189

Engine Control Module (SECM )...................189

Camshaft Position Sensor...........................191

Crank Shaft Position Sensor........................ 192

MAP (Manifold Absolute P r es s ur e) Sensor ..193

IAT (Intake Air Temperature) .......................194

G420F(FE) Servi ce Manual Index 5

Sensor........................................................ 194

Oxygen Sensor (Pre-Catalyst)..................... 195

Oxygen Sensor (Post - Catalyst)................... 196

ECT (Engine Coolant T em per ature) Sensor 197

LP Fuel Temperature Sensor...................... 199

Angle Sensor-Accelerator........................... 200

Transmission Oil Temperature Switch......... 201

Ground Speed Limit Switch (optional) ......... 202

Electronic Throttle Body.............................. 203

Chapter 6. LPG FUEL DELIVERY

SYSTEM

G420FE LP System Inspect io n and Repair..... 204

Removal and Installat ion............................. 204

Hose Connections.........................205

Removal and Installat ion of ...........206

N-2007 LP Regulator ....................206

Removal and Installat ion of CA100

Mixer for G420FE.......................... 207

Tests and Adjustments................................ 209

N-2007 Regulator Service Testing. 210

AVV (Air Valve Vacuum) Testing... 211

AVV (Air Valve Vacuum) Testing... 212

Connection of the MI-07 S er v ic e Tool

.....................................................212

Idle Mixture Adjustment.................213

Parts Description......................................... 216

CA100 Mixer for G420FE Engine .. 216

N-2007 Regulator for G 420FE Engine

.....................................................218

G420F LPG System Inspection and Repair..... 220

Removal and Installat ion............................. 220

G420F Fuel System Connect ions.. 221

Removal and Installat ion of N-2001 LP

Regulator/Converter......................222

Removal and Installat ion of CA100

Mixer for G420F............................223

Tests and Adjustments................................ 225

N-2001 Regulator Service Testing .225

AVV (Air Valve Vacuum) Testing....227

Connection of the MI-07 S er v ic e Tool

......................................................227

Idle Mixture Adjustment.................228

Parts Description.........................................230

CA100 Mixer for G420F Engine .....230

N-2001 Regulator for G 420F Engine

......................................................234

Chapter 7. MPI GASOLINE FUEL

DELIVERY SYSTEM

Specification.....................................................239

Special Tools....................................................239

Components Location......................................240

Fuel Pressure Test ...........................................241

Injector..............................................................243

Injector Inspection............................................245

Fuel Pump.........................................................247

Chapter 8. BASIC TROUBLESHOOTING

Preliminary Checks ..........................................248

Before Starting............................................248

Visual/Physical check..................................248

Basic Troubleshooting Guide..........................249

Customer Problem A naly s is Sheet............... 249

Basic Inspect ion P r oc edur e .........................250

Connector Inspection Procedure..................251

Symptom Troubleshoot ing Guide Chart .......255

Basic Troubleshooting.....................................261

Intermittents.................................................261

Surges and/or St um bles ..............................262

Engine Cranking but Will Not S tart / Difficult to

Start............................................................263

Lack of Power, Slow to Respond / P oor High

Speed Performance / Hesitation During

Acceleration.................................................265

G420F(FE) Servi ce Manual Index 6

Detonation / Spark Knock............................ 267

Backfire......................................................268

Dieseling, Run-on .......................................268

Rough, Unstable, I nc or r ec t I dle, or Stalling.. 269

Cuts Out, Misses......................................... 271

Poor Fuel Economy / Excess iv e Fuel

Consumption LPG Ex haus t Sm ell ............... 272

High Idle Speed ..........................................273

Excessive Exhaus t Em is s ions or Odors.......274

Diagnostic Aids for Ric h / Lean O per ation.. . 275

Chart T-1 Restricted Exhaust System Check276

Chapter 9. ADVANCED DIAGNOSTICS

Reading Diagnostic Fault Codes.....................277

Displaying Fault Codes (DFC) from SECM

Memory............................................................. 277

Clearing Fault (DFC) Codes............................. 277

Fault Action Descrip t ions................................ 278

Fault List Definitions........................................278

Table 1. Fault List Definitions...................... 279

Table 2. Diagnostic Fault Codes (Flash Codes)

................................................................... 289

Appendix

Service Tool Software (MotoView) .................. 307

Service Tool Connect ion to SECM.............. 308

Service Tool Display................................... 309

SECM field update wit h Servic e Tool...........313

SECM field update wit h Servic e Tool...........314

Ground Speed Limits (Option)........................ 318

LPG And LP G Fue l Tanks................................ 32 0

Regulatory Compliance................................... 324

Special Co nditions for S a fe Us e..................... 324

Abbreviations................................................... 325

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 7

Chapter 1. GENERAL INFORMATION

Precautions before Service

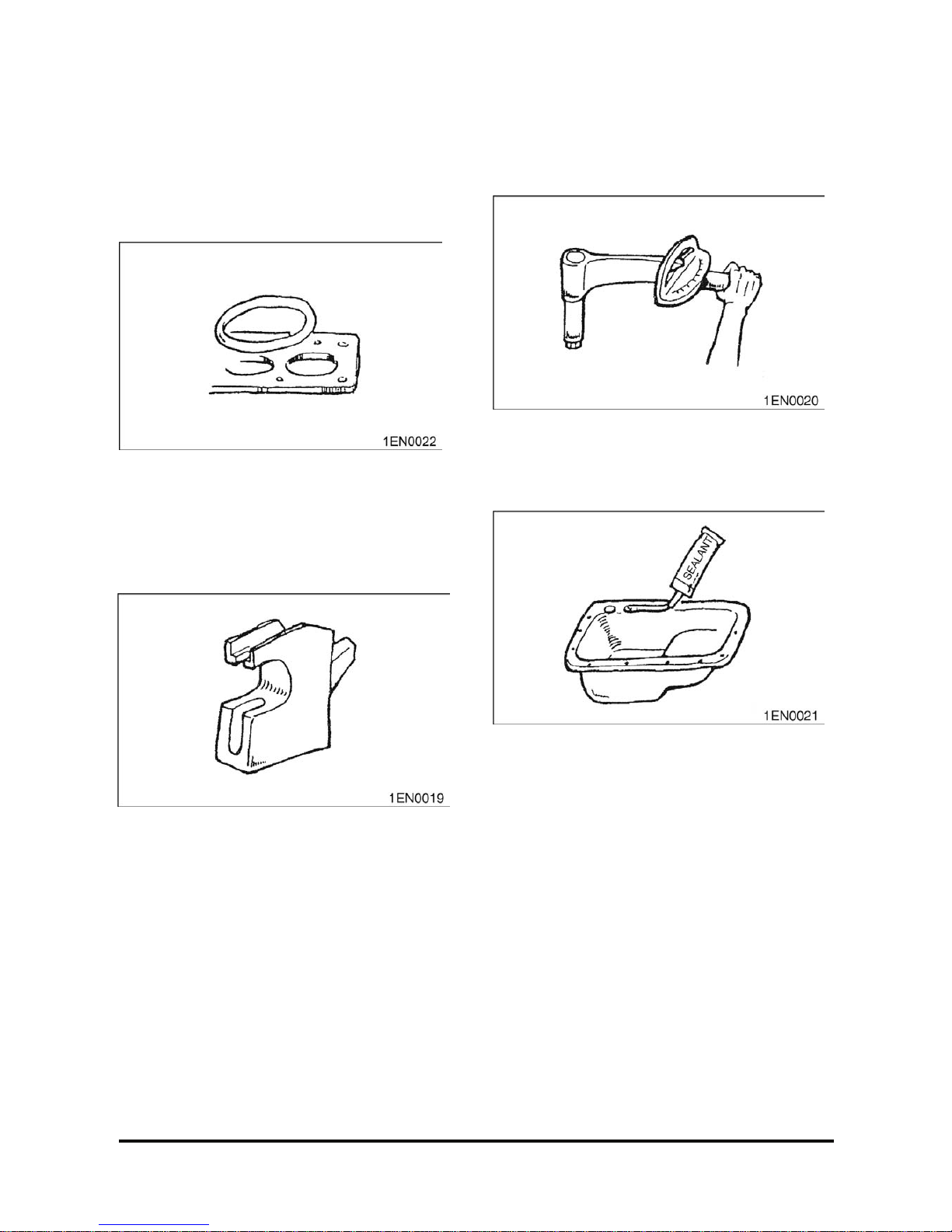

Removal and Disassembly

For prevention of wrong inst allation or reassembly

and for ease of operat ion, put m ating m ar k s to the

parts where no function is adv er s ely aff ec ted.

Special Tool

Be sure to use Special Tools when their use is

specified for t he oper ation.

Use of substitute tools will r es ult in malfunction of

the part or damage it.

Tightening Torque

Tighten the part properly to specified torque.

Sealant

Use specified brand of s ealant.

Use of sealant other than s pec ified sealant may

cause water or oil leaks.

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 8

Replacement Part

When oil seal, O-ring, pac k ing and gas k et have

been removed, be sure t o replace t hem with new

parts.

However, rocker cover gasket may be reused if it is

not damaged.

Rubber Parts

Do not stain timing belt and V- belt with oil or water.

Therefore, do not clean the pulley and sprocket with

detergent.

Oil and Grease

Before reassembly , apply s pec ified oil to the rotating

and sliding parts.

Genuine Part

When the part is to be replaced, be s ur e to use

genuine part.

For selection of appropriate parts, refer to t he Parts

Catalog.

Electrical System

1. Be sure to disconnect the bat tery cable from the

negative(-) terminal of the battery.

2. Never pull on the wires when dis c onnec ting

connectors.

3. Locking connector s will c lic k when the connector

is secure.

4. Handle sensors and relays c ar efully. Be careful

not to drop them or hit them against other parts.

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 9

Precautions for catalytic Converter

CAUTION

If a large amount of unburned gasoline flows

into the con verter, it may overheat and create a

fire hazard. To prevent this, observe the

following precau tions and explain them to your

customer.

1. Use only unleaded gasoline.

2. Do net run the engine while the tr uc k is at rest f or

a long time. Avoid running the engine at fast idle

for more than 5 minutes and at idle speed for

more than 10 minutes.

3. Avoid spark-jum p tests. Do spark-jumps only

when absolutely necessary . Perform this test as

rapidly as possible and, while t es ting, never race

the engine.

4. Do not measure engine compress ion for an

extended time. E ngine c om pr es s ion tests must be

made as rapidly as possible

5. Do not run the engine when the fuel tank is nearly

empty. This may cause the engine to m is fire and

create and extra load on the conv er ter.

6. Avoid coasting with the ignition turned off and

during prolonged braking

7. Do not dispose of a used catalyt ic c onv erter

together with parts contaminated with gasoline or

oil.

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 10

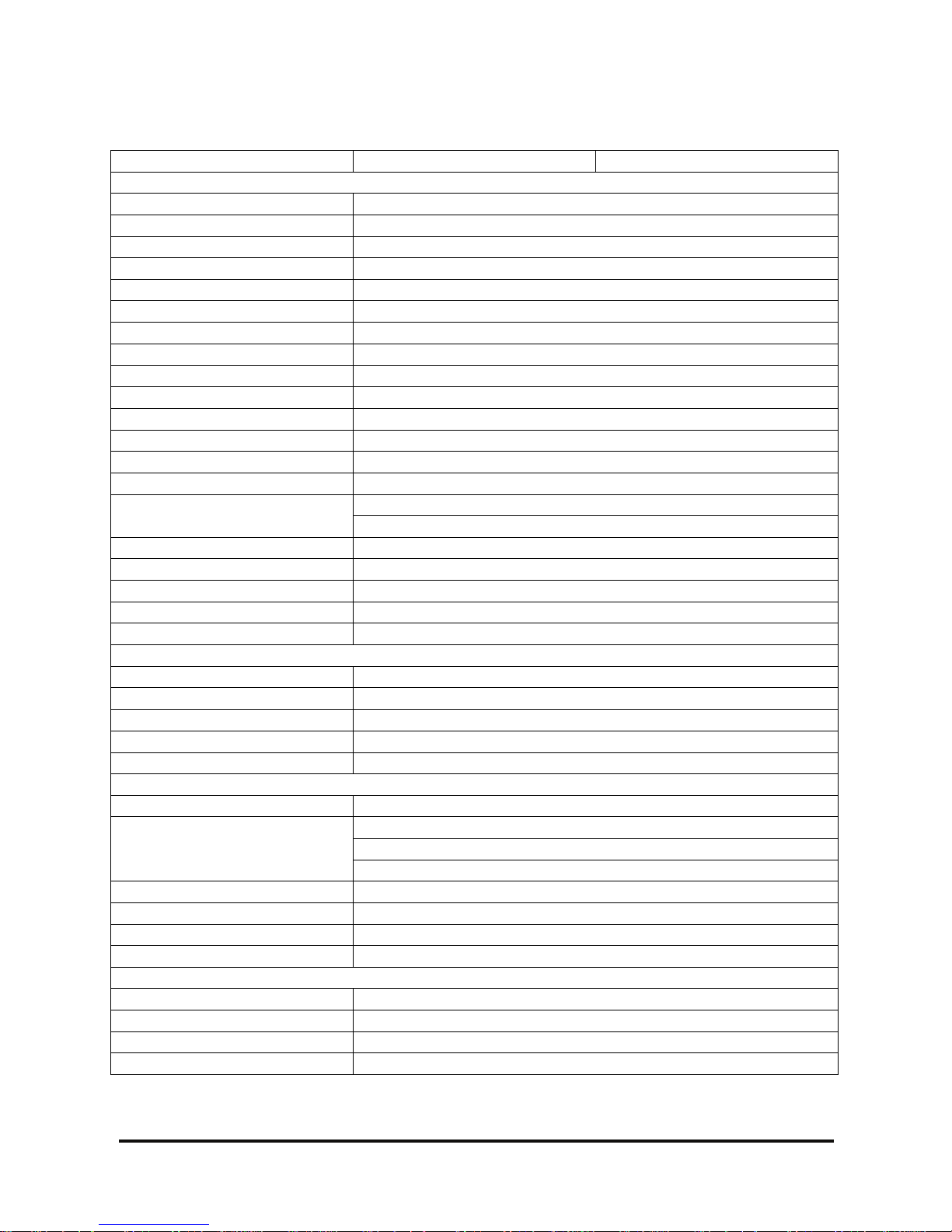

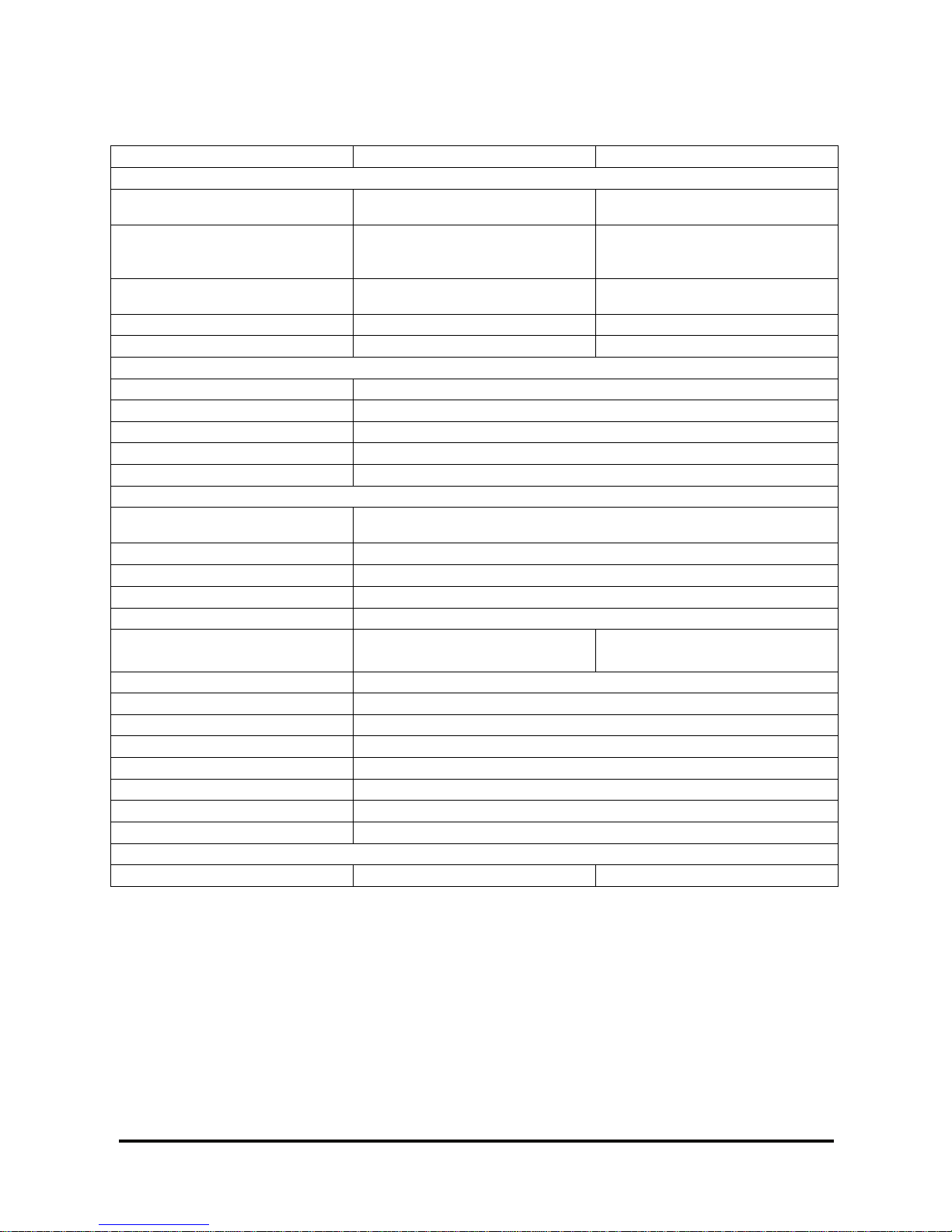

Tighteni ng Torque

Tightening Torque Table of Standard Parts

Torque (kg·m)

Bolt nominal

diameter(mm)

Pitch(mm)

Head mark 4 Head mark 7

M5 0.8 0.3 ~ 0.4 0.5 ~ 0.6

M6 1.0 0.5 ~ 0.6 0.9 ~ 1.1

M8 1.25 1.2 ~ 1.5 2.0 ~ 2.5

M10 1.25 2.5 ~ 3.0 4.0 ~ 5.0

M12 1.25 3.5 ~ 4.5 6 ~ 8

M14 1.2 7.5 ~ 8.5 12 ~ 14

M16 1.5 11 ~ 13 18 ~ 21

M18 1.5 16 ~ 18 26 ~ 30

M20 1.5 22 ~ 25 36 ~ 42

M22 1.5 29 ~ 33 48 ~ 55

M24 1.5 37 ~ 42 61 ~ 70

M5 0.8 0.3 ~ 0.4 0.5 ~ 0.6

M6 1.0 0.5 ~ 0.6 0.9 ~ 1.1

M8 1.25 1.2 ~ 1.5 2.0 ~ 2.5

M10 1.25 2.5 ~ 3.0 4.0 ~ 5.0

NOTE: The torques shown in t he table are s tandard

vales under the following conditions.

1. Nuts and bolt are made of steel bar and

galvanized.

2. Galvanized plain st eel was her s ar e ins er ted.

3. All nuts, bolts, plain washer s ar e dr y .

NOTE: The torques shown in t he table are not

applicable,

1. When spring washers, toothed washers and the

like are inserted.

2. If plastic parts ar e fastened.

3. If oil is applied to thr eads and s urfac es .

NOTE: If you reduce the tor ques in the t able to the

percentage indicated below under the following

conditions, it will be the standard value.

1. If spring washers ar e us ed : 85%

2. If threads and bearing s ur faces are stained with

oil: 85%

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 11

Recommended Lubric a nt s and Capaciti e s

Recommended Lubricants

Lubricant Specification Remarks

Engine Oil API Classification SJ or above SAE 10W30 or SAE 5W30

Coolant (Antifr eez e)

Automotive ant ifreeze

suitable for gasoline engines

having aluminum alloy parts

Concentration level 50%(nor m al)

Concentration level 40%(tropical)

Lubricant Capacities

Description G(C)18S-5, G(C)20SC-5 G(C)20/25/30E-5

Oil Pan 3.7 3.7

Oil Filter 0.3 0.3

Engine Oil (liters)

Total 4.0 4.0

Engine 3.0 3.0

Radiator & Hoses 5.5 5. 5

Coolant (liters)

Total 8.5 8.5

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 12

Engine Model and Engine Serial

Number

Engine

Model

Fuel Type

Emission

Regulation

G420FE LP/Dual Fuel

EPA/CARB*

2007

Compliant

G420F

LP/Gasoline/Dual

Fuel

* EPA: Environmental Protection Agency

* CARB: California Air Resources Board

G420FE Engine

• Comply with EPA 2007 Emission Regulation

• Elec tronic Control by ECM

• Certified LP/Dual Fuel System available

– Closed loop LP Carburet ion syst em

– Closed loop MPI Gasoline system

• 3-way Catalytic Muffler is standard

G420F Engine

• Not c om ply with E PA 2007 Emission Regulation

• Elec tronic Control by ECM

• Standard LP/Gas/DF/Dual Fuel S y s tem available

– Open loop LP Carburetion system

– Closed loop MPI Gasoline system

• Muff ler is standard

Indication of Engine Model and Serial

Number

Engine Model Engine Serial Number

G420FE/G420F 30700001 to 39999999

Features and Benefi t s of G420F E/G420F Engine

• Al head with valve seat inserts

– Alum inum head and v alv e s eat system

• DO HC 16 valve sy stem

• Durable timing belt system

– Durable timing belt material and r ubber -

sealed cover

• Distributorless I gnition system (coil on plug)

• Electronic control system by ECM

(Engine control module)

– Drive-by-wire system

– Higher efficiency and lower f uel c ons um ption

– Min./Max. governor control

– Aut omatic engine protection f r om ov er heating

and/or low engine oil pressure

– Aut omatic transmission pr otection from

overheating

– Engine diagnostics by service-tool software

– Forklift ground speed limit ( optional)

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 13

General Specification

G420FE Engine G420F Engine

GENERAL DESCRIPTION

ENGINE TYPE: Water - c ooled, Inline 4-Cycle, 4-Cylinders

COMBUSTION SYSTEM: Semi-Rent Roof

INTAKE MANIFOLD Cast Aluminum (wit h injec tor ports)

EXHAUST MANIFOLD Cast Iron, Dry

VALVE CONFIGURATION: DOHC, 4 Valves per Cylinder

VALVE LIFTER/LASH ADJUSTER Hydraulic Lash Adjuster

VALVE ROTATOR Intake/Ex haus t Rot ator

CAMSHAFT DRIVE Timing belt system ( 25.4 mm Toothed Belt)

DISPLACEMENT: 1,975 cc (120.5 cid)

BORE x STROKE 82mm (3.23 in) x 93.5 mm (3.68 in)

BLOCK STRUCTURE Grey Cast Iron

HEAD STRUCTURE Aluminum with seat ins er ts

COMPRESSION RATIO: 9.4:1

COMPRESSION PRESSURE: 1,450 kPa (210 psi)

Intake Valve: 2° BTDC(Open)/ 16° ABDC(Close)

VALVE TIMING:

Exhaust Valve: 6° BBDC(O pen)/ 2° ATDC(Close)

FIRING ORDER: 1-3-4-2

WEIGHT: 170 kg (Dry)

ENGINE ROTATION: Counter-Clockwise (CCW) when viewed from Flywheel End

FUEL TYPE: LPG, Gasoline, Dual F uel ( LPG or Gas oline)

CRANK VENTILATION Foul Air System with PCV

IGNTION SYSTEM

IGNITION TYPE: Distributorless (coil on plug)

IGNITION TIMING: Electronic cont r olled by E CM

POWER TRANSISTOR Ignition coil driver

IGNITION COIL: 12 V operation volt, 4 coils (c oil on plug)

SPARK PLUGS: Platimum Spark Plug (Air Gap: 0.8mm)

LUBRICATION SYSTEM

OIL PRESSURE: 167 kPa (24 psi) @ low Idle (90-100C oil temperature)

Upper Limit: 125°C ( 257°F)

Recommended: 99 - 110°C ( 210 - 230°F)

OIL TEMPERATURE:

Lower Limit:80°C ( 176° F)

OIL PAN Cast Aluminum

OIL PAN CAPACITY 3.7 L (EXCLUDES OIL FILTER)

OIL FILTER: 0.3 L

ENGINE OIL SPECIFICATION: API - SJ, SAE 10W30 or SAE 5W30

COOLING SYSTEM

WATER PUMP ROTATION: V-Belt Drive - Clockwise ( CW) when v iewed from engine front

THERMOSTAT: Opening Temperature: 82° C (180°F)

Fully Open Temperatur e: 95°C (203°F)

COOLING WATER CAPACITY: 3.0 L (block only)

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 14

General Specification

G420FE Engine G420F Engine

LP FUEL SYS TEM

LP FUEL SYSTEM

Closed loop LP Carburetion

System

Open loop LP Carburetion Sy s tem

MIXER:

Diaphragm Type Air Valv e

Assembly inside, Downdr aft

(Model: CA-100)

Diaphragm Type Air Valv e

Assembly inside, Downdr aft

(Model: CA-100)

REGULATOR:

Two-Stage Negativ e P r es s ur e

Regulator (Model: N-2007)

Two-Stage Negativ e P r es s ur e

Regulator (Model: N-2001)

FUEL TRIM VALVE (FTV): Dual Dither System No FTV

FUEL FILTRATION: 40 Microns Maximum 40 Microns Maximum

GASOLINE FUEL SYSTEM

GASOLINE FUEL SYSTEM Closed loop MPI S y stem and In-Tank Fuel Pump System

FUEL PUMP MODULE Electric Fuel Pump (12V)

Fuel Filter & Strainer

Gasoline Pressure Regulator (3.5 bar)

FUEL INJECTOR ASS’Y Electric Fuel Injector (12V)

ENGINE ELECTRIC

ENGINE CONTROL

MODULE(ECM):

12 V operation volt, 48 pins of I/O

CRANK SENSOR Magnetic Inductive type

CAM SENSOR Hall sensor

TMAP: Intake Air Temp. & Manifold Absolute Press. Sensor

PEDAL ANGLE SENSOR: Two-Output Signals ( built in Accelerator Pedal)

Gasoline : One Oxygen sensor

OXYGEN SENSOR: Dual Oxygen Sensor S yst em

LPG: No Oxygen sensor

ECT-ECM: Engine Coolant Temperat ur e S ens or for ECM

ECT-GAUGE Engine Coolant Temp. S ens or for GAUGE on Instrument Panel

TPS: Throttle Pos ition Sens or ( built in Throttle Body)

THROTTLE BODY: Electronic Throttle B ody

LP FUEL LOCK-OFF: 12 V operation volt

ENGINE OIL PR. S/W: 28.4 kPa (4.1 psi)

STARTING MOTOR: 12 Volts, 1.7 kW

ALTERNATOR: 13.5 Volts, 90 Am p

EXHAUST SYSTEM

Muffler Catalytic Muffler Muffler (without cataly s t)

G420F(FE) Servi ce Manual Chapter 1. General Info rmat ion 15

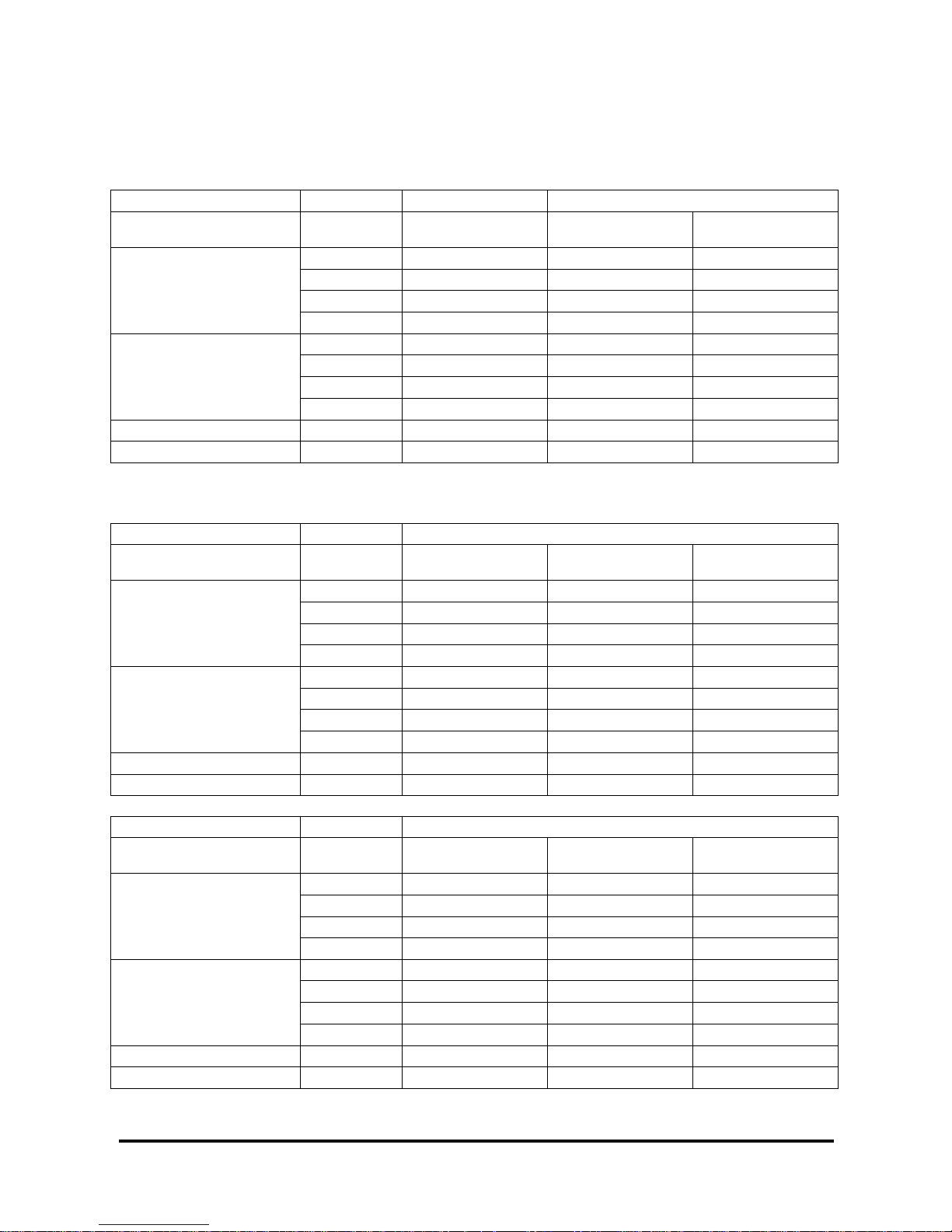

Engine Power and Torque

G420FE Engine Power & Torque

FORKLIFT MODEL G(C)15/18S-5 G(C)20/25/30E-5

ENGINE MODEL G420FE-LP

G420FE-DF(LP)

& G420FE-LP

G420FE-DF(Gas)

RATED POWER Kw 33.6 39.5 39.5

hp 45 53 53

PS 46 54 54

rpm 2,400 2,550 2,550

MAX TORQUE N-m 147 157 157

lbf-ft 108 116 116

kgf-m 15,0 16.0 16.0

rpm 1600 1600 1600

GOVERNED SPEED rpm 2450 2600 2600

LOW IDLE rpm 750 750 750

G420F Engine Power & Torque

FORKLI FT M ODEL G(C)15/1 8 S -5

ENGINE MODEL

G420F-DF(LP)

& G420F-LP

G420F-DF(Gas) G420F-GAS

RATED POWER Kw 33.6 35.8 36.5

hp 45 48 49

PS 45.6 48.7 49.7

rpm 2,400 2,400 2,400

MAX TORQUE N-m 147 152 154

lbf-ft 108 112 114

kgf-m 15,0 15.5 15.7

rpm 1600 1600 1600

GOVERNED SPEED rpm 2450 2450 2450

LOW IDLE rpm 750 750 750

FORKLI FT M ODEL G(C)20/2 5 /3 0E-5

ENGINE MODEL

G420F-DF(LP)

& G420F-LP

G420F-DF(Gas) G420F-GAS

RATED POWER Kw 39.5 39.5 40.3

hp 53 53 54

PS 53.7 53.7 54.7

rpm 2,550 2,550 2,550

MAX TORQUE N-m 157 157 160

lbf-ft 116 116 118

kgf-m 16.0 16.0 16.3

rpm 1600 1600 1600

GOVERNED SPEED rpm 2600 2600 2600

LOW IDLE rpm 750 750 750

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 16

Chapter 2. RECOMMENDED MAINTENANCE

Suggested maintenance r equir em ents for an engine equipped with an MI-07 fuel system ar e contained in this

section. The oper ator should, however, develop a customized maintenance schedule using the requirements

listed in this section and any other requirements lis ted by the engine manufacturer .

General Mainte na nc e

Test Fuel System for Leaks

• O btain a leak check squirt bottle or pump spr ay

bottle.

• Fill the bott le with an approved leak check s olution.

• Spr ay a gener ous amount of the solution on the

fuel system fuel lines and connections, start ing at

the storage cont ainer .

• W ait approx imately 15-60 seconds, then perform a

visual inspection of the fuel system. Leaks will caus e

the solution to bubble.

• Listen for leaks

• Sm ell for LPG odor which may indicate a leak

• Repair any leak s before continuing.

• Crank the engine through several r ev olutions. This

will energize the fuel lock- off and allow fuel to flow to

the pressure regulat or /converter. Apply additional

leak check solution t o the regulator/ convert er fuel

connections and housing. Repeat leak inspection as

listed above.

• Repair any fuel leaks before cont inuing.

Inspect Engine for Fluid Leaks

• Start the engine and allow it to reach operat ing

temperatures.

• T ur n the engine off.

• I ns pec t t he entire engine for oil and/or coolant

leaks.

• Repair as nec es s ary before continuing.

Inspect Vacuum Lines and Fittings

• Vis ually ins pec t vacuum lines and fittings for

physical damage such as brittleness, cracks and

kinks. Repair/r eplac e as r equir ed.

• Solv ent or oil damage may cause vacuum lines to

become soft, resulting in a collapsed line while the

engine is running.

• I f abnorm ally s oft lines are detected, replac e as

necessary.

Inspect Electrical System

• Check for loose, dirty or damaged connectors and

wires on the harness including: fuel lock-off, TMAP

sensor, O2 sensors, electronic throttle, c ontrol

relays, fuel trim v alv es , cr ank pos ition sensor, and

cam position sensor.

• Repair and/or replace as necessary.

Inspect Foot Pedal Operation

• Ver ify foot pedal travel is smoot h without stic king.

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 17

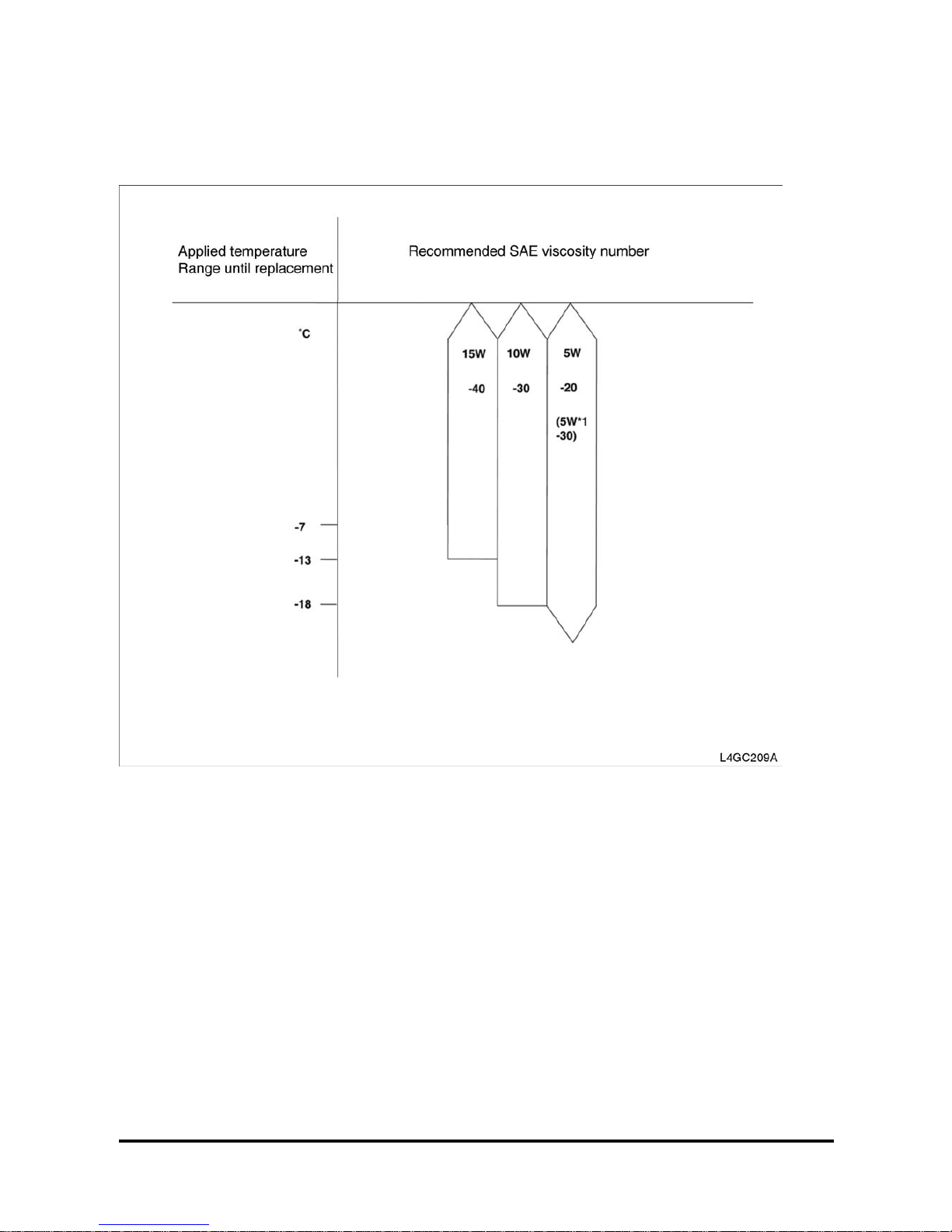

Engine Oil Classification

Recommended API clas s ification: Above SJ

Recommended SAE viscosity classification

The following lubricants s hould be s elec ted for all

engines to enhance excellent per formance and

maximum effect.

1. Observe the API classif ic ation guide.

2. Proper SAE classification number should be

selected within ambient temperature ranges. Do

not use the lubricant with SAE classification

number and API grade not identified on the

container.

*1. 10W-30 engine oil is recom m ended

If 10W- 30 is not applic able, proper engine oil will be possible ac c or ding to temperature ranges.

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 18

Checking Engine Oil Level

1. Check that the oil level is between “MIN” and

“Max” marks on the engine oil level gauge.

2. If the oil level is below “MIN” m ark, add oil until

the level is within the s pec ified ranges.

3. Check the engine for oil cont am ination and

viscosity and replac e if necessary.

Replacing Engine Oil and Filter

CAUTION

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irri tation and dermat itis.

In addition, used engine oil contains potentially

harmful contaminants which may cause skin

cancer.

Exercise caution in order to minimize the leng th

and frequency of contact of your skin to used oil.

In order to preserve the environment, used oil

and used oil filter must be disposed of only at

designated di sposal sites.

1. Drain engine oil.

1) Remove the oil filler c ap.

2) Remove the oil drain plug, and dr ain the oil into

a container.

2. Replace oil filter.

1) Remove the oil filt er.

2) Check and clean the oil filter installation

surface.

3) Check the part number of the new oil filter is as

same as old one.

4) Apply clean engine oil to the gas k et of a new

oil filter.

5) Lightly screw t he oil filt er into place, and

tighten it until the gasket contacts the seat.

6) Tighten it an additional 3/4 turn.

3. Refill with engine oil filter.

1) Clean and install the oil drain plug wit h a new

gasket.

Torque

39.2~44.1N.m(4.0~4.5kgf.m,

28.9~32.5lb-ft)

2)Fill with fres h engine oil.

Capacity Drain

and refill

4.0L(4.23US qts , 3. 52Lm p qts)

Oil filter 0.3L(0.32US qts , 0. 26Lm p qts)

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 19

3) Install the oil filler c ap.

4. Start engine and check for oil leaks.

5. Recheck engine oil level.

Checking Compressed Pressure

1. Prior to inspection, check that the engine oil,

starter motor and batt er y are normal.

2. Start the engine and run it unt il the engine coolant

temperature reac hes 80 ~ 95° C.

3. Stop the engine and disconnect the ignition coil

and air cleaner element.

4. Remove the spark plug.

5. After opening the t hr ott le v alv e c om pletely, crank

the engine to remove f or eign m aterial from the

cylinder.

CAUTION

At this time, necessarily screen the spark plug

hole with a rag. Because ho t cool ant, oil, fuel,

and other fore ign materia l, being penet r a te d in

the cylinder throug h cracks can come into the

spark hole during ch eckin g co mpressed

pressure.

When cranking the engine to t est compressed

pressure, necessarily open the throttle val ve before cranking.

6. Install the compr es s ion gauge to the spark plug

hole.

7. With the thrott le valve opened, c r ank the engine

to measure the compress ed pr es s ure.

Standard 15kg/㎠

Standard(250~400rpm)

Limit 14kg/㎠

8. Follow the procedur es ( no.6-7) to each cylinder

and check that compress ed pr es s ur e v alues of all

cylinders are within t he lim it.

Limit 1.0kg/㎠

9. If any of all cylinders is out of lim it, add a small

amount of engine oil to t he spark plug hole, and

re-proceed the procedur es ( no.6-7) to the c y linder .

At this time, if the compressed pressur e is increased,

it means that the piston, pis ton ring or cylinder

surface are worn or damaged, and if the

compressed pressur e is dec r eas ed, it means that

the valve is clogged, the valve contact is faulty, or

the pressure leaks through gasket.

CAUTION

If a large amo unt of incomple t e combust ion

gaso-line comes in to the cat alytic converter,

emergency such as a fire can occu r du e to

overheating. So this job should be done quickly

with the engine not operated.

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 20

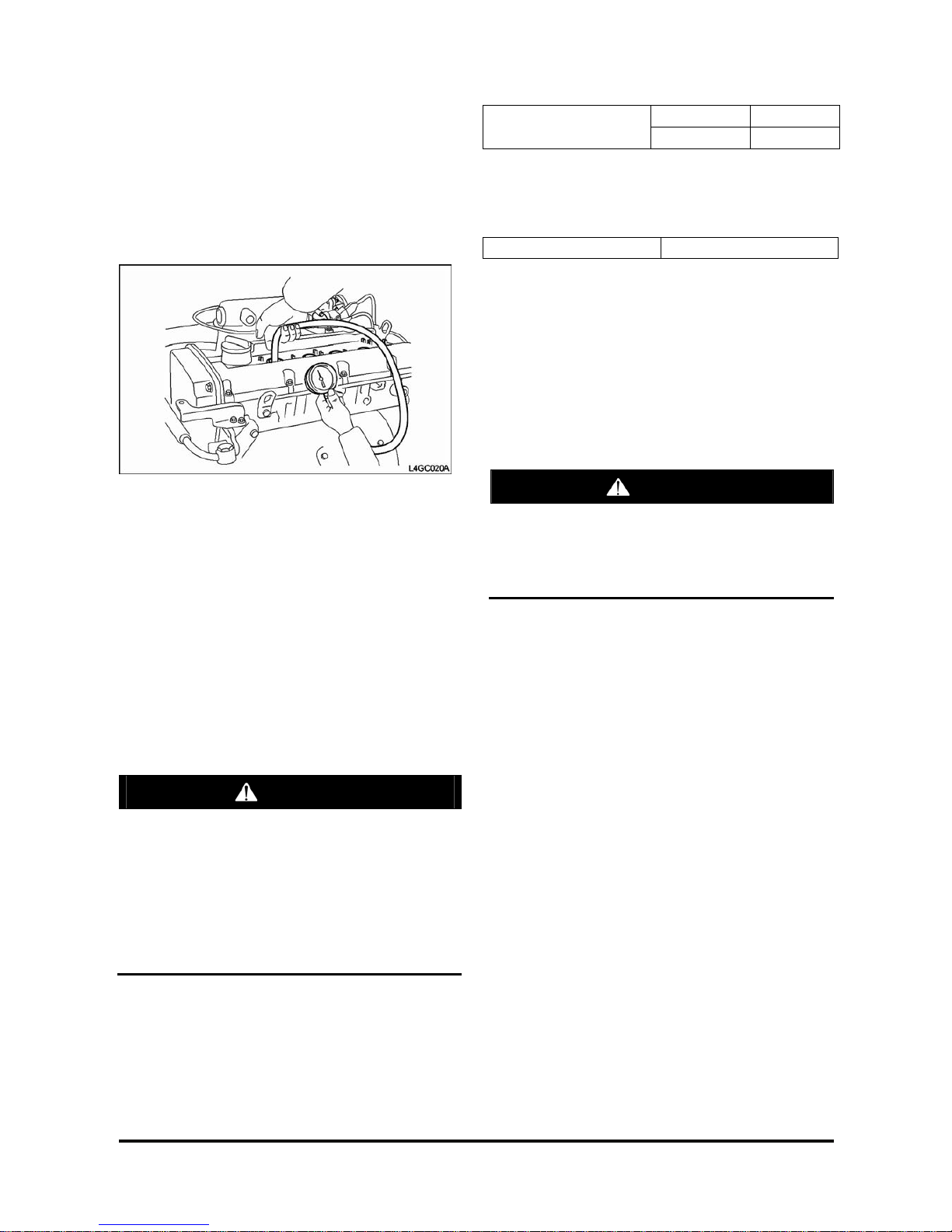

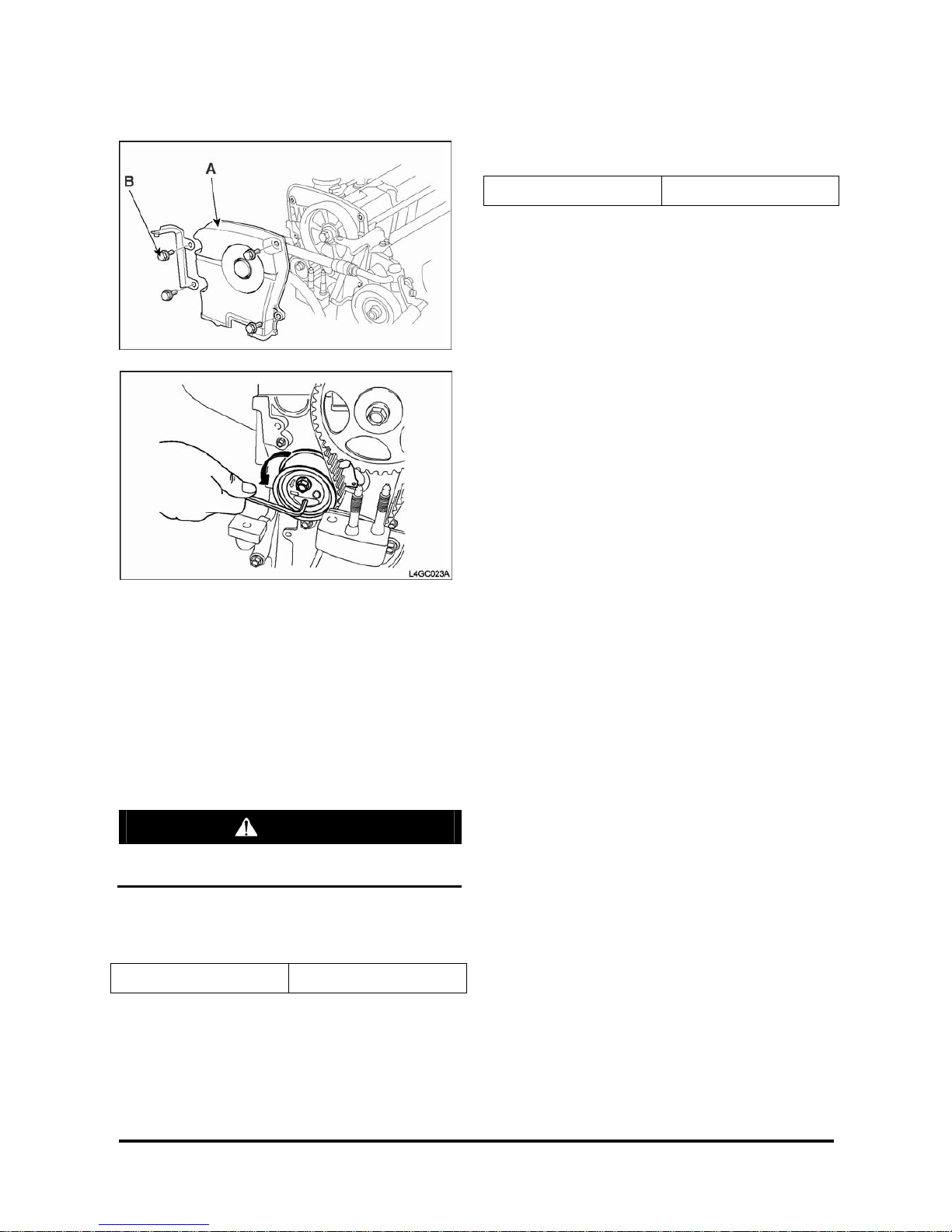

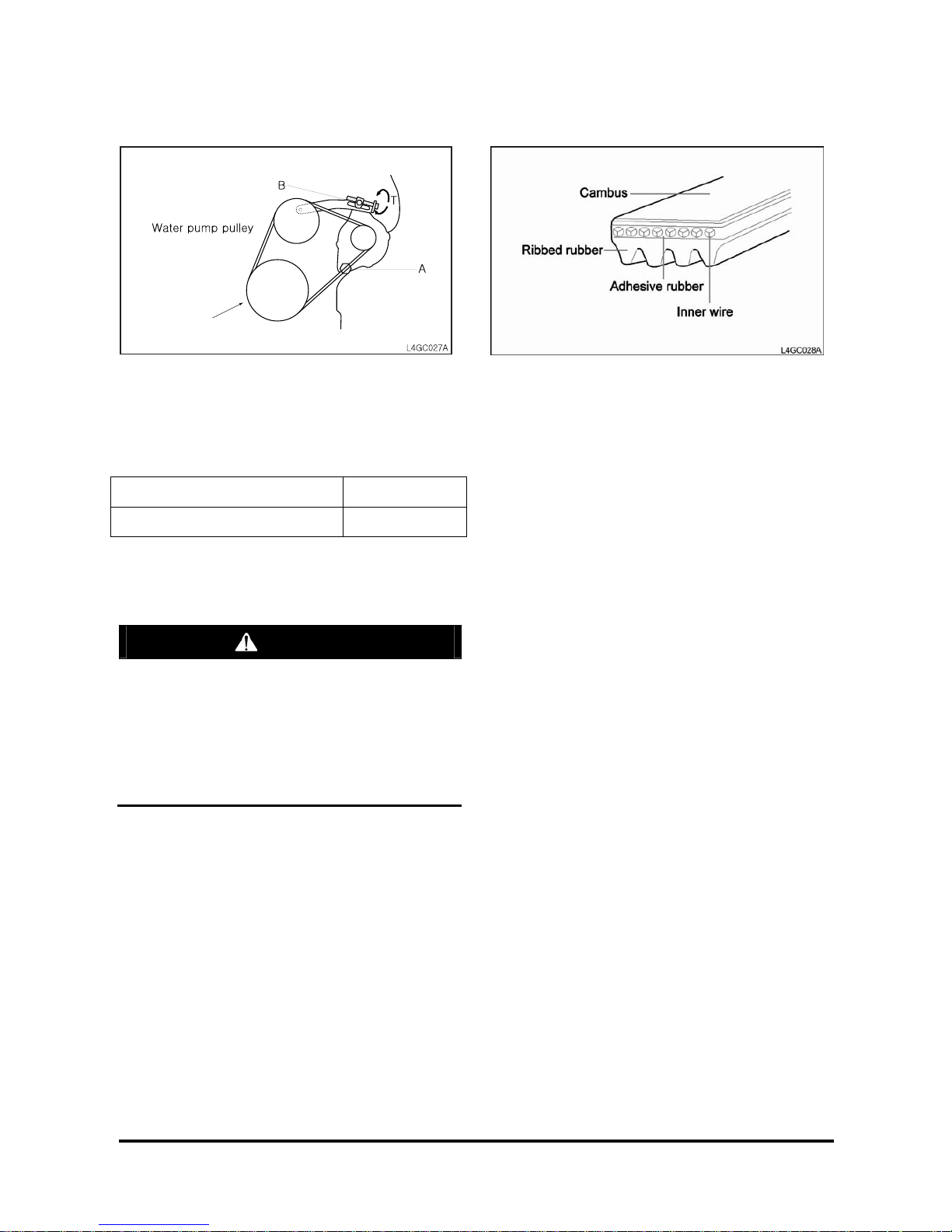

Adjusting Timing Belt Tension

Adjust the tension as t he following order .

1. Remove the fan driv e br ac k et.

2. Loosen the timing belt upper cover bolt (B) and

disconnect the upper c ov er (A).

3. As the illustrat ion, insert the hex wrench to the

adjuster groove and tur n it counterclockwise to

move the arm indi-cator in the middle of the base

groove.

CAUTION

If it is turned in reverse di rect io n, be su re th at

the tensioner may function abnormally.

4. Tighten the tensioner fixing bolt with the arm

indicator fixed.

Tightening torque 2. 3~2.9kgf·m

5. Rotate the cranks haft 2 turns c loc k wis e and make

sure the auto tensioner arm indic ator is placed in

the middle of the base gr oov e.

6. If the arm indicator is out of the m iddle, loosen the

bolt and repeat the prev ious pr oc edur e.

7. Install the tim ing belt upper cover (A) and tighten

the bolt(B).

Tightening torque 0.8~1.0k g·m

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 21

Cooling System Mai ntena nc e

Coolant Recommendation

The engine cooling system is provided with a

mixture of 50% ethylene glyc ol anti-freeze and 50%

water (For the vehicles of t r opic al area, the engine

cooling system is provided with a mixture of 40%

ethylene glycol anti-freeze and 60% water at the

time of manufactur e.)

Since the cylinder head and wat er pum p body ar e

made of aluminum alloy casting, be sure to use a 30

to 60% ethylene glycol ant ifreeze coolant to assure

corrosion protection and freezing prevent ion.

CAUTION

If the concentration of the antifreeze is below

30%, the anticorrosion property will be adversely

affected. In addition, if the concentration is

above 60%, both the antifreeze and engine

cooling properties will decrease, adversely

affecting the engine. For th ese reasons, be sure

to maintain the concentration level within the

specified range.

Coolant Water

Hard water, or water wit h high lev els of calc ium and

magnesium ions, encourages the formation of

insoluble chemical compoun ds by c om bining with

cooling system additives such as silicates and

phosphates.

The tendency of silicat es and phos phates to

precipitate out- of-solution increases with increasing

water hardness. Har d water, or water with high

levels of calcium and magnes ium ions enc our ages

the formation of insoluble c hem ic als , especially after

a number of heating and cooling cycles.

DOOSAN prefers the use of distilled water or

deionized water to reduce the potential and severity

of chemical insolubility .

Acceptable Water

Water Content Lim its (pps)

Chlorides (CI) 40 maximum

Sulfates (SO4) 50 maximum

Total Hardness 80mg/ℓ maximum

Total Solids 250 maximum

pH 6.0 ~ 8.0

ppm = parts per million

Antifreeze

DOOSAN recommends select ing automotive

antifreeze suit able for gasoline engines using

aluminum alloy parts. The antifreeze should meet

ASTM-D3306 standard.

Check Coolant Level

• T he items below are a general guideline for

system checks. Refer to the engine manufacturer’s

specific recomm endations for proper procedures .

• Engine m us t be off and cold.

WARNING—PROPER USE

Never remove the pressu re cap on a hot engin e.

• T he c oolant level should be equal to the “COLD”

mark on the coolant recover y tank.

• Add appr ov e c oolant to the specified level if the

system is low.

Inspect Coolant Hoses

• Vis ually ins pec t coolant hoses and clamps.

Remember to check the two coolant lines that

connect to the pressur e r egulator/convert er.

• Replace any hos e that shows signs of leakage,

swelling, cracking, abr as ion or deterioration.

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 22

Checking coolant leaks

1. After the coolant t em per ature drops below 38°C

loosen the radiator cap.

2. Check that the coolant level r eac hes filler neck.

3. Install the radiat or c ap tester to the radiator filler

neck and apply a pressure of 1.4kg/cm2 .

While maintaining it f or 2 minutes , check the

radiator, hose, and c onnec ting part for leak.

CAUTION

Because the coolant in th e radi ator is too hot,

never open the cap when it hot, or inj ury may

occur due to an outburst of hot water.

Dry out the inspection p art .

When removing the tester, take care not to spill

the coolant.

When removing/in st all in g the tester as well as

testing, take care not to deform the filler neck.

4. Replace parts if leak is detected.

Specific gravity test

1. Measure specif ic gravity of the coolant using a

hydrometer.

2. After measuring the coolant temperature,

calculate specific gr av ity using the following table.

Relation between Coolant concentration and Specific Gravity

Temperature and Sp ecifiv gravity of coolant (Temp.:℃)

10 20 30 40 50

Freezing

temp(℃)

Coolant Concentration

(Specific Volume)

1.054 1.050 1.046 1.042 1.036 -16 30%

1.063 1.058 1.054 1.049 1.044 -20 35%

1.071 1.067 1.062 1.057 1.052 -25 40%

1.079 1.074 1.069 1.064 1.058 -30 45%

1.087 1.082 1.076 1.070 1.064 -36 50%

1.095 1.090 1.084 1.077 1.070 -42 55%

1.103 1.098 1.092 1.084 1.076 -50 60%

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 23

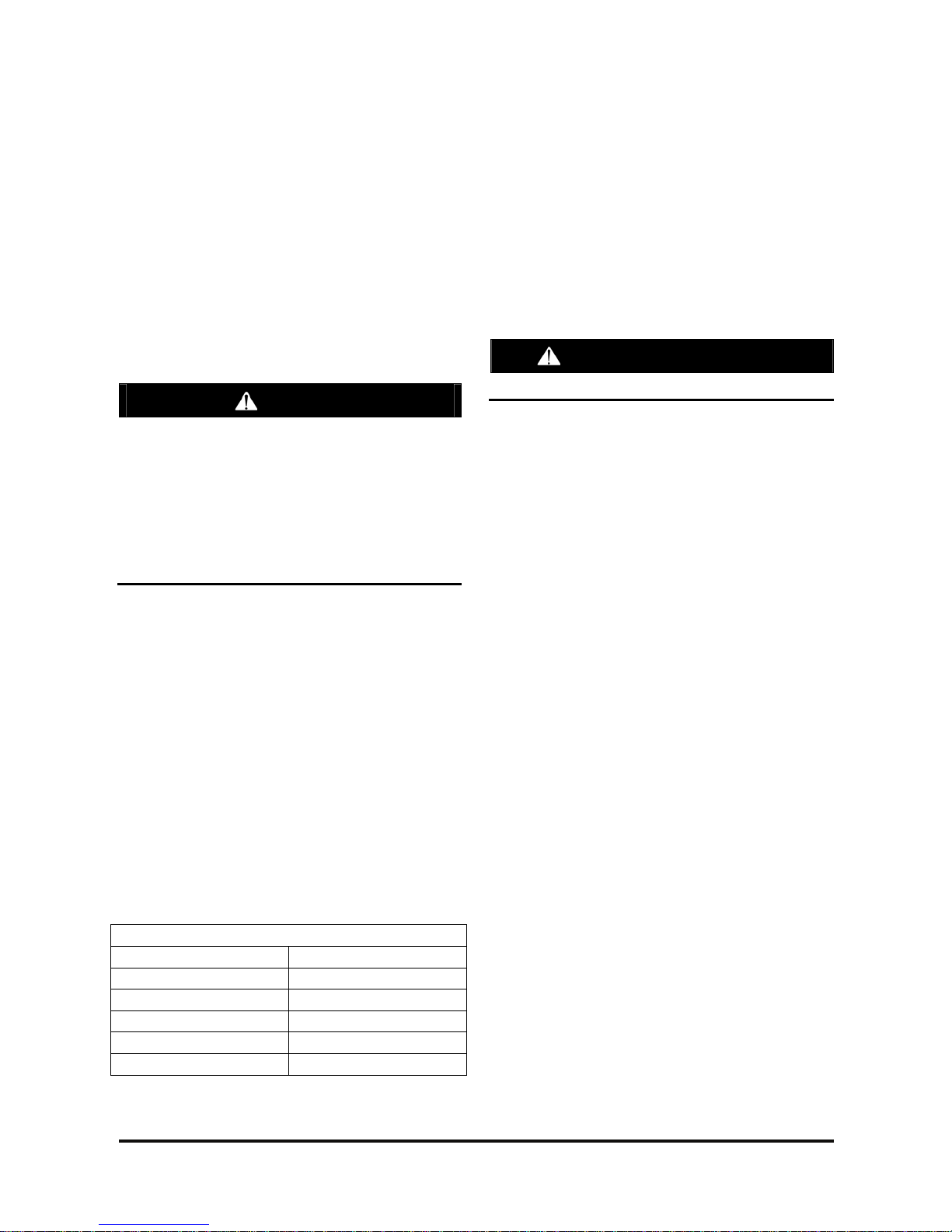

Checking and Adjusting Drive Belt

1. Checking tension

1) Press the middle of the water pum p pulley and

alternator pulley wit h 10k gf.

2) Inspect the belt deflection by pressing it.

3) If the belt deflection is out of the standard,

adjust it as follows.

Standard

Item

New belt Used belt

Drive belt deflect ion ( L) 4.0~4.4mm 5.1~5.7mm

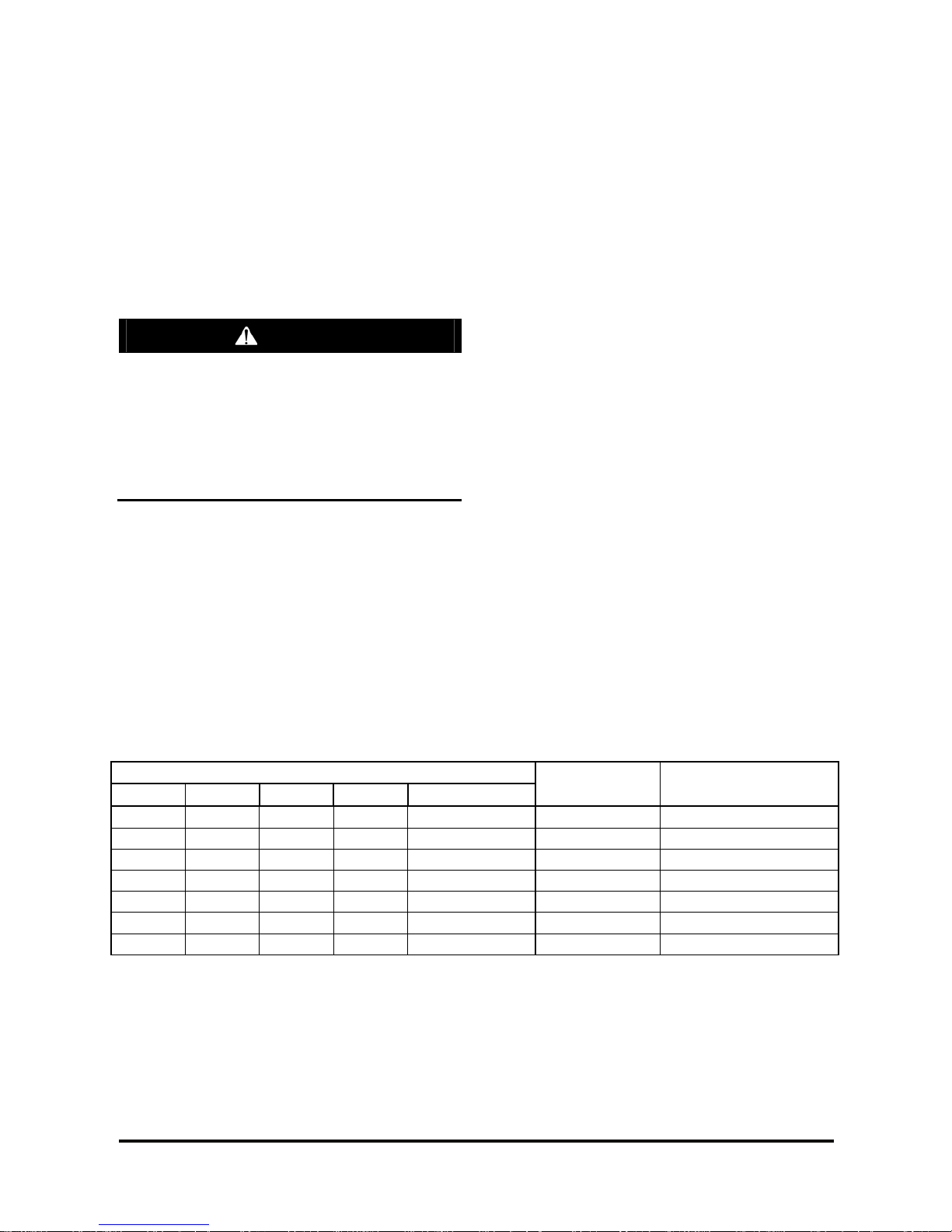

2. Using a tension gauge

1) Type

• BORROUGHS BT - 33 - 73F

• NIPPONDENSO BTG – 2

2) How to use

• Insert the belt between the gauge hook and

spindle and press the tens ion gauge handle.

• Leave the handle and read the gauge.

Standard

New belt Used beltTension(T)

65~75kg 40~50kg

CAUTION

The belt used over 5 minutes should be adjusted as used belt of st and ard

Check that the belt is installed correctly.

When the belt is loosened, sli p no ise is heard.

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 24

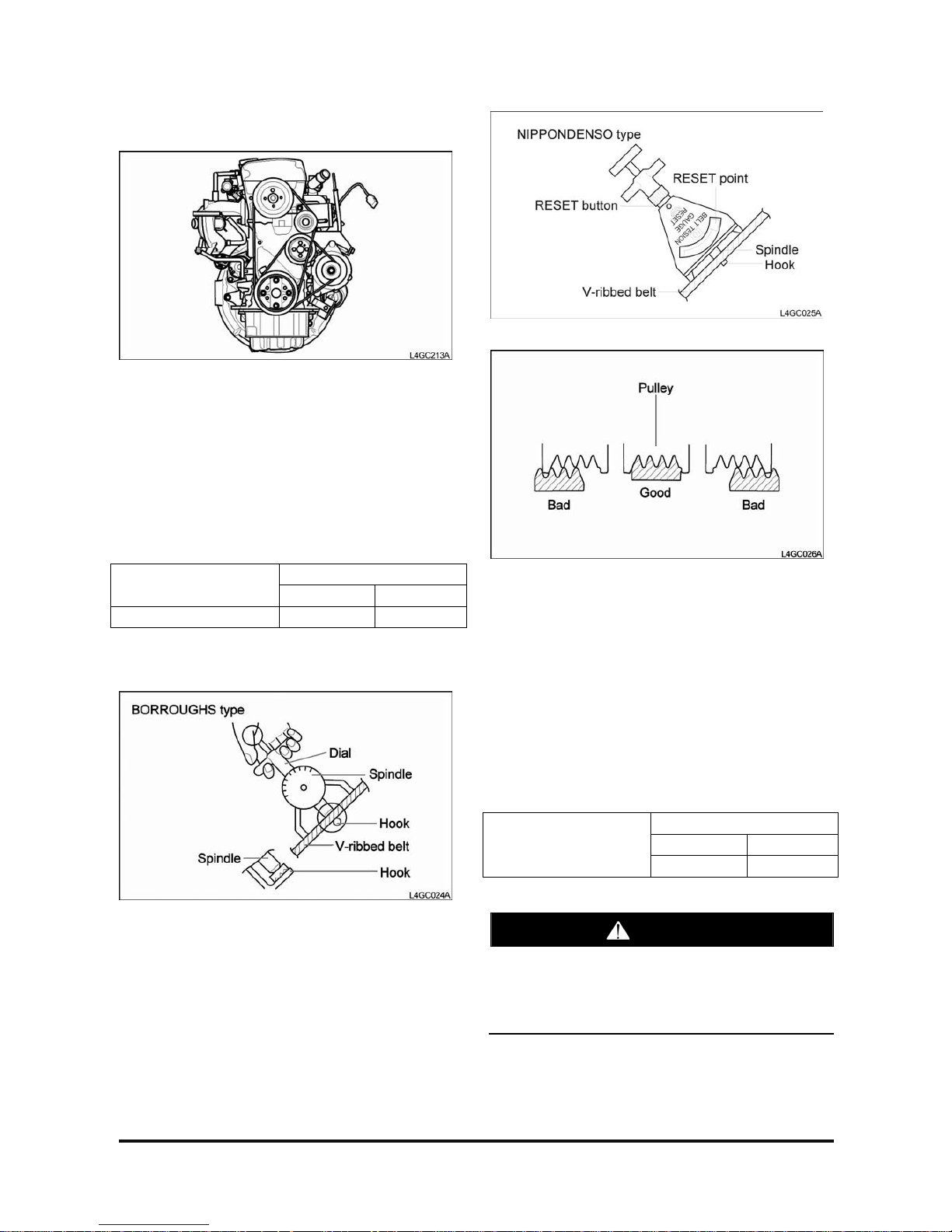

Adjusting

1. Loosen the alternator support bolt “A” nut and

adjusting lock bolt “B ” .

2. Adjust the belt tension by m ov ing the alternator

brace adjusting bolt t o “ T” dir ec tion.

Alternator adjusting lock bolt “B” 1.2~1.5kg·m

Alternator suppor t bolt “A” 2~2.5kg·m

3. Tighten the bolt “A ” and then tighten “B” to the

specified torque.

CAUTION

If the belt tension is too excessive, noise as well

as early wear of belt occurs and the water pu mp

bearing and altern at or bearing are damaged.

If the belt is too loose, due to early wear of belt

and insufficient power of alternator, battery and

water pump become inefficient and finally engine is overheated or damaged.

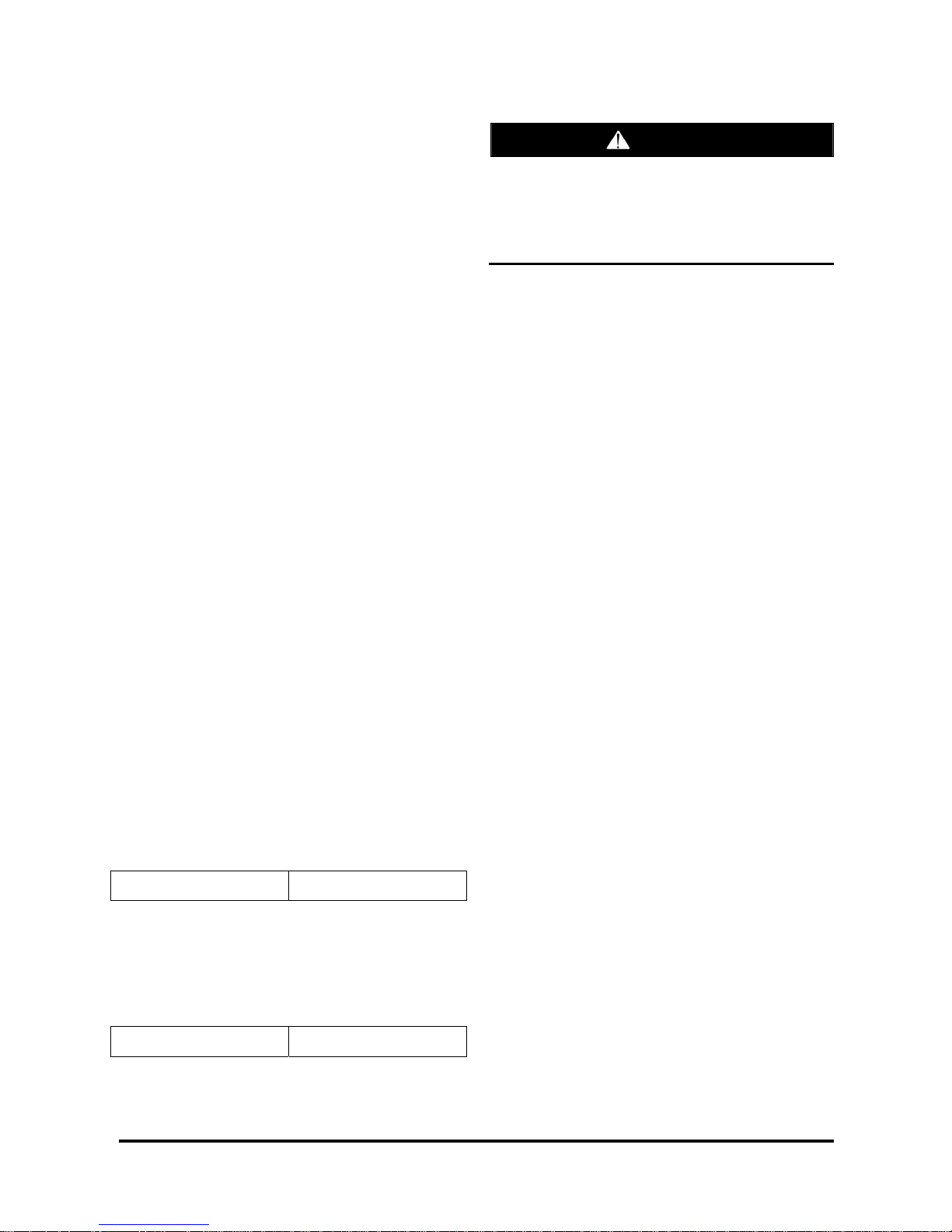

Checking Belt for Damage

Check the following item s and r eplac e the belt if

defective.

1. Check the belt surf ac e for dam age, wear and

crack.

2. Check the belt surf ac e for oil or grease

contamination.

3. Check the rubber part for wear or hardening.

4. Check the pulley surfac e for crack or damage.

Crank

pulley

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 25

Ignition Syst em Mai nt e nance

Inspect Battery System

• Clean bat tery outer surfaces wit h a mixt ur e of

baking soda and water.

• I ns pec t bat tery outer surfaces for damage and

replace as necessary.

• Remov e battery cables and clean, r epair and/or

replace as necessary.

Inspect Ignition System

• Remov e and ins pec t the spark plugs. Replace as

required.

• I nspect t he ignition coil for cracks and heat

deterioration. V is ually ins pec t the coil heat sink

fins. If any fins are br oken replace as required.

Inspection of Ignition Timing

1. Inspection c ondition

Coolant temperatur e : 80-90°C(At normal

Temperature)

Lamp and all accessories : OFF

Transmission : In neutral position

Parking brake : ON

2. Inspection

1) Connect the timing light.

2) Measure RPM.

RPM

Low Idle 750±15rpm

NOTE: If RPM is not normal, it is impos s ible to

measure the proper ignit ion timing, so measure it at

a normal RPM.

3) Inspect the standard ignit ion timing.

BTDC 5˚±5˚

4) If ignition timing is out of the standard, inspect

sensors concerned wit h ignition timing.

CAUTION

Because ignition timing is fixed by set data

value in ECU, it is impossible to control on

purpose.

Fist, check that sensors send output properly to

help determine ignition timing control.

NOTE: Affectiv e ECU input to lgnition timing control

• Coolant temperature sensor

• Oxygen sensor

• Battery voltage

• MA P sensor (Engine load)

• Crank s haft position sensor

• T hr ott le pos ition sensor

• Intake Air Temperature sensor

5) Check that actual ignit ion timing is changed

with engine RPM increased.

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 26

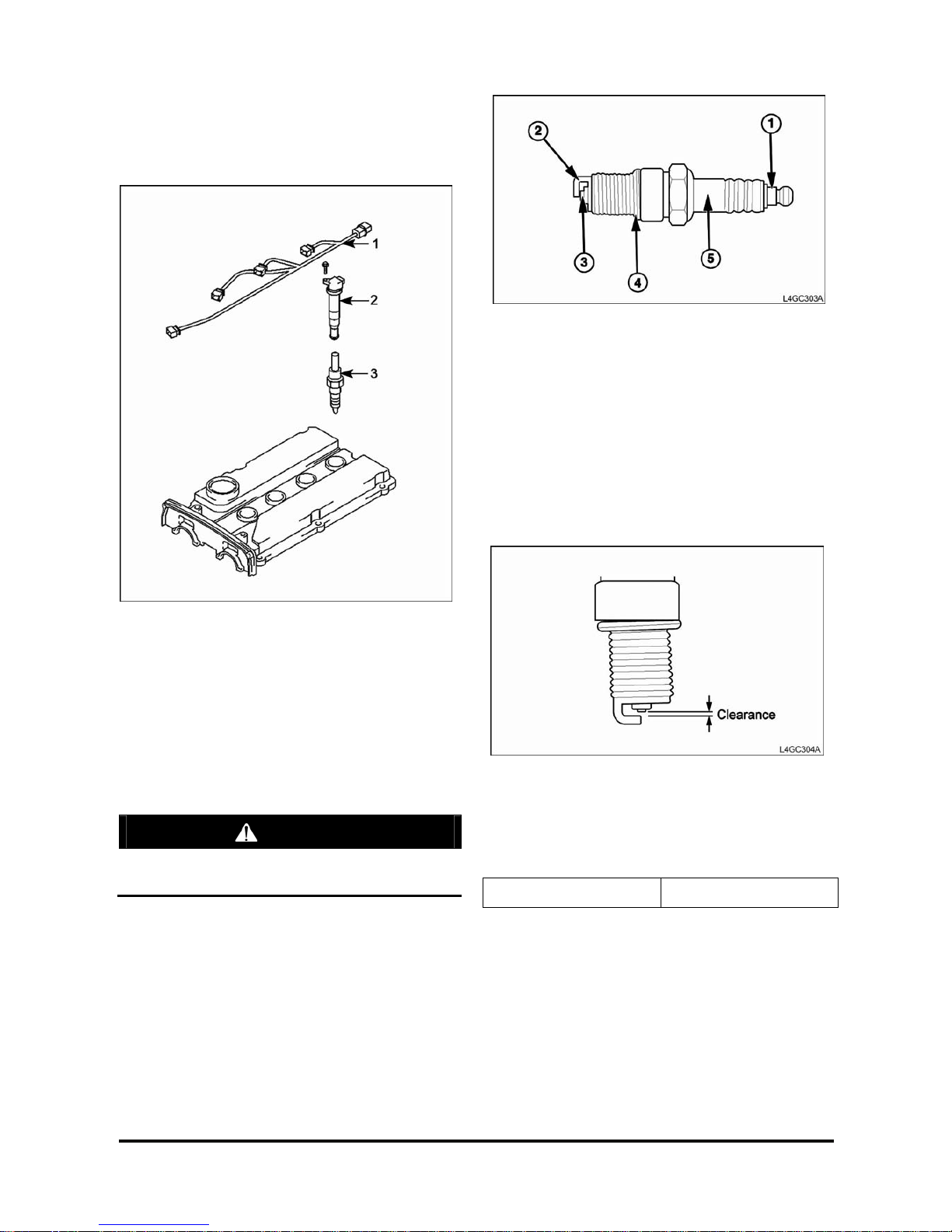

Inspection of Spark Plug

Inspection and clean

1) Ignition wire Ass’y

2) Ignition coil Ass’y

3) Spark plug

1. Disconnect t he ignition wire as s ’y from ignition

coil ass’y.

Remove the ignition coil ass ’y by pulling the ignition

coil hand.

2. Remove all spark plugs from the cy linder head

using a sparkplug wrench.

CAUTION

Take care not to come foreign materials into

spark-plug mounting hole.

3. Check the spark plug as below.

1) Insulator brok en

2) Terminal worn

3) Carbon deposit

4) Gasket damaged or broken

5) Porcelain insulator of spark plug clearance

4. Check the plug clearance using a plug clear anc e

gauge and if the value is not within the specified

values, adjust it by bending the gr ound c lear anc e.

When installing a new sparkplug, install it after

checking the uniform plug c lear anc e.

Spark plug clearance 0.7~0.8mm

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 27

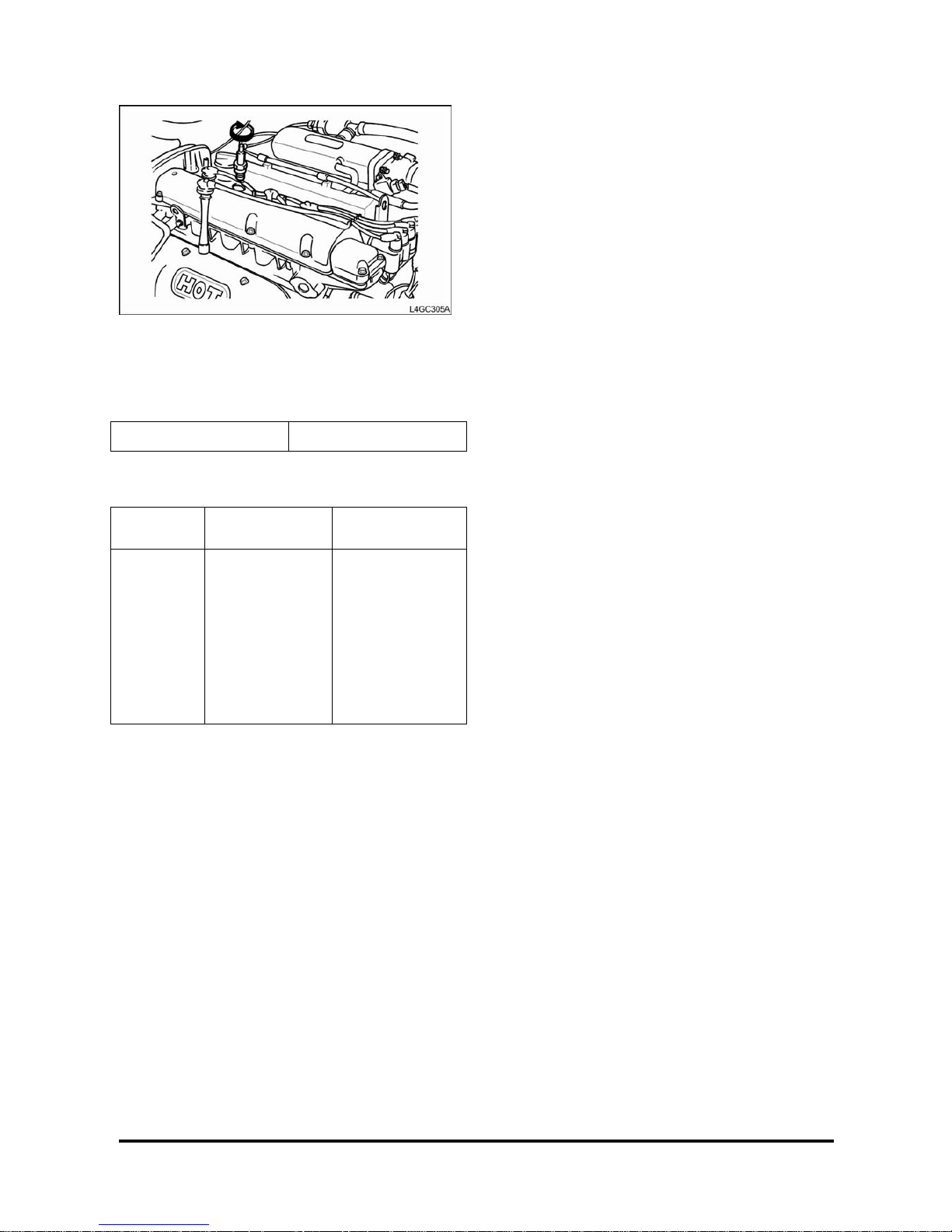

5. Install the spark plug and tighten it to the specified

torque.

Take care not to over tight en it t o pr ev ent cy linder

head threads from dam age.

Tightening torque 2~3kg·m

SPARK PLUG ANALYSIS

State

Contact point is

black

Contact point is

white

Description

• Density of the

fuel mixture is

thick

• Density of the

fuel mixture is thin

• Lack of air

intake

• I gnition timing is

fast

• Spar k plug is

tight

• Lack of torque

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 28

Fuel System Maintena nc e

Replace LP Fuel Filter Element

Park the lift truck in an authorized refueling area with

the forks lowered, park ing br ak e applied and the

transmission in Neut r al.

1. Close the fuel shutof f valv e on the LP-fuel tank.

Run the engine until the fuel in the system runs

out and the engine stops.

2. Turn off the ignition switch.

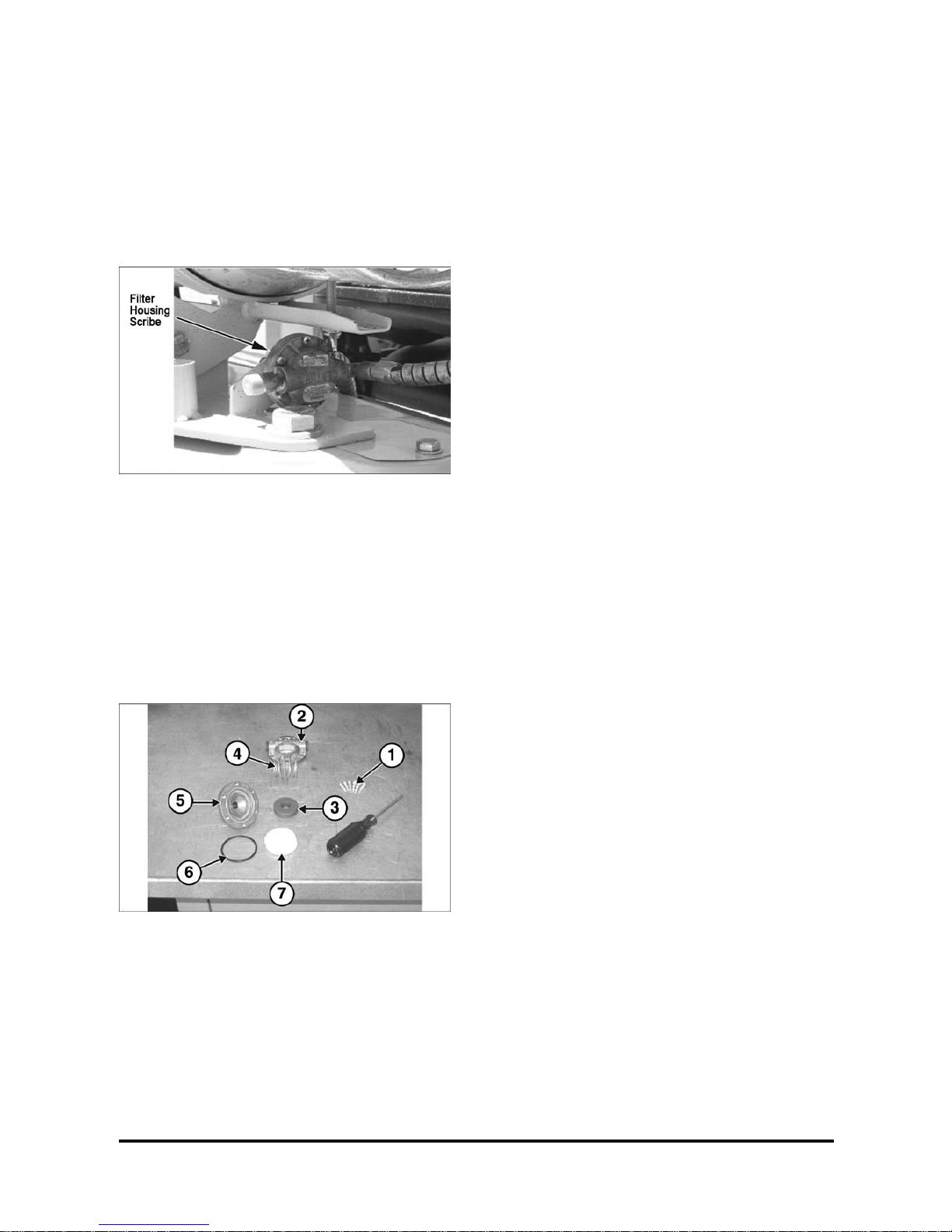

3. Scribe a line across the filt er hous ing c ov er s ,

which will be used for alignment pur pos es when

re-installing the f ilter cover.

FUEL FILTER DISASSEMBLY (Steps 4-7)

4. Remove the cover retaining screws (1).

5. Remove top cover (2), magnet (3), spring (4), and

filter element ( 7) from bottom cover (5).

6. Replace the filt er elem ent (7) .

7. Check bottom cover O- r ing s eal ( 6) f or damage.

Replace if necessary.

8. Re-assemble the filt er as s em bly aligning the

scribe lines on the top and bott om c ov er s.

9. Install the cover r etaining sc r ews , tightening the

screws in an opposite sequenc e ac r os s the cov er .

10. Open the fuel valve by slowly t ur ning the valve

counterclockwise.

11. Crank the engine sever al r ev olutions to open the

fuel lock-off. DO NOT START THE ENGINE.

Turn the ignition key s witch to the off position.

12. Check the filter hous ing, fuel lines and fittings for

leaks. Repair as necess ar y .

G420F(FE) Servi ce Manual Chapter 2. Recommended Maintenance 29

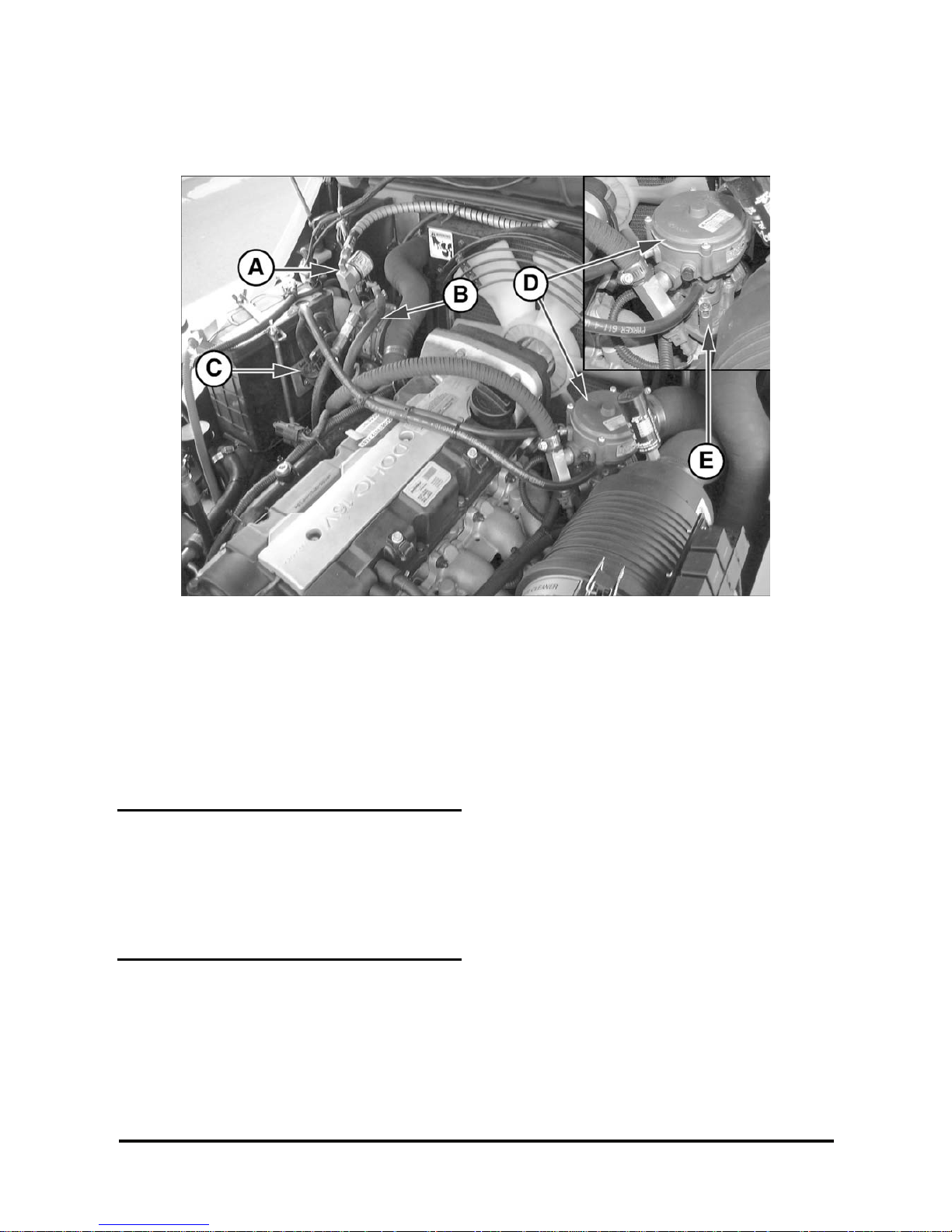

Testing Fuel Lock-off Operation

• Start engine.

• Locate t he electr ical connect or for the f uel lock (A).

• Disc onnec t the electrical connect or .

• T he engine s hould r un out of fuel and stop within a

short period of time.

NOTE

The length of time the engine runs on trapped fuel

vapor increases with any increase in distance

between the fuel lock-off and the pressure

regulator/converter.

• T ur n the ignit ion k ey switch off and re-connect the

fuel lock-off connect or .

Pressure Regulator/Converter

Inspection

• Vis ually ins pec t the pressure regulator /converter

(B) housing for coolant leaks.

• Ref er to Chapt er 5 if the pressure

regulator/conver ter requires replacem ent.

Fuel Trim Valve Inspec tion (FTV)

• Vis ually ins pec t the fuel trim valves (C) for

abrasions or cracking. Replace as necessary.

• T o ens ur e a valve is not leaking a blow-by test can

be performed.

1. With the engine off, dis c onnec t the electrical

connector to the FTVs.

2. Disconnect t he vacuum line from the FTVs to the

pressure regulator/converter at the c onverter’s

tee connection.

3. Lightly blow through the vacuum line connected to

the FTVs.

Air should not pass through t he FT V s when deenergized.

Loading...

Loading...