DongFeng DFA1101GZ5AD6J-907 Operational Manual

DFA1101GZ5AD6J-907

Light Commercial Truck

Operation Manual

DONGFENG AUTOMOBILE CO., LTD.

2006, 05

Foreword

Foreword

Thank you for purchasing the DFA1101GZ5AD6J-907 light

commercial truck that manufactured by DONGFENG AUTOMOBILE

CO., LTD of the People's Republic of China.

This manual contains necessary procedures and instructions for the

operation, inspection and maintenance for your DFA1101GZ5AD6J-907

truck.

This vehicle is equipped with the EQB140-20 DONGFENG Cum-

mins diesel engine which could reach the European II displacement

standard.

To obtain the optimum performance from your new vehicle is the

common goal for all of us, and it depends largely on your care and

familiarity of the operation and maintenance of the vehicles. We

sincerely hope that you read this manual thoroughly, and make sure that

you are familiar with the operation and maintenance before you using

the new truck.

The manual is a part of your vehicle. Please keep it with your truck.

The information and figures in this manual are correct when publishing.

Due to continuous improvement on our vehicles, maybe there are some

instructions in the manual that does not accord with the actual vehicles.

Please inquire when you get some problem.

The Application Section of Testing Department, Commercial product

R&D Institute of DONGFENG AUTOMOBILE CO., LTD. is in charge of

compiling this manual. DFAC reserve the right to make changes at any

time without notice

As for vehicle saling, maintaining or spare parts purchasing, please

consult with the local agency

The manual uses the legal unit.

.

.

DONGFENG AUTOMOBILE CO., LTD.

2006. 05

1

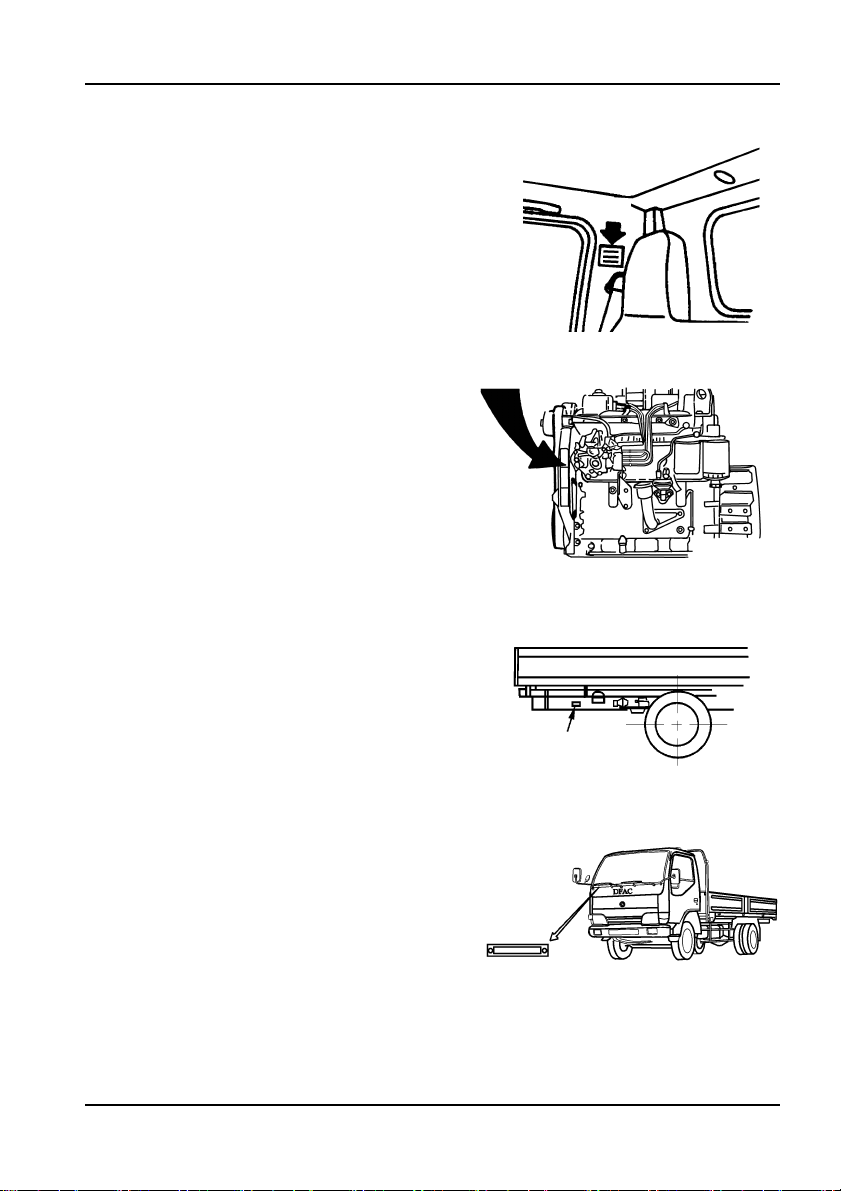

Truck Nameplate

Truck Nameplate Position

Engine Nameplate Position

Truck Nameplate

VIN Position

1—1

Table of Content

Table of Content

Truck Nameplate......................................................................1-1

Truck Nameplate Position ........................................................ 1-1

Engine Nameplate Position...................................................... 1-1

VIN Position............................................................................... 1-1

Main Technical Specifications ............................................2-1

Main Technical Specifications and Structure Features......... 2-1

Operational Data ....................................................................... 2-2

Engine Parameter...................................................................... 2-2

Chassis Type and Structure Parameter ................................. 2-3

Construction and Operation ...............................................3-1

Arrangement of the Cab .......................................................... 3-1

Doors.......................................................................................... 3-2

Seats.......................................................................................... 3-3

Instruments................................................................................ 3-4

Indicators ................................................................................... 3-6

Keys............................................................................................ 3-9

Key Switch................................................................................. 3-9

Light Combination Switch...................................................... 3-10

Power Switch........................................................................... 3-13

Exhaust Brake Switch............................................................. 3-13

Air Horn and Electric Horn Shift Switch ............................... 3-14

Air Drier Switch ....................................................................... 3-14

Dome Lamp and Glove Box ................................................... 3-14

Cab Skylight ............................................................................ 3-15

Air Conditioning System ........................................................ 3-15

Levers, Steering Wheel and Accessories............................. 3-16

Tilting Cab................................................................................ 3-21

Vehicle Starting......................................................................4-1

Engine Starting.......................................................................... 4-1

Engine Starting (when the cab is tilted) ................................. 4-2

1

Running-in and Maintenance of New Vehicle ............... 5-1

Before Running-in .....................................................................5-1

Running-in Period......................................................................5-2

After Running-in.........................................................................5-2

Driving Recommendations................................................. 6-1

Driving on a slope .....................................................................6-2

Clutch Operation .......................................................................6-2

Double-foot-clutch Method for Shifting...................................6-3

The Use of Warning Triangle ....................................................6-3

Parking........................................................................................6-4

Vehicle Inspection ............................................................ 7-1

Driver's Daily Inspection ..........................................................7-1

Vehicle External Inspection .....................................................7-2

General Maintenance ......................................................... 8-1

Air Filter ......................................................................................8-1

Diesel Oil Prefilter......................................................................8-2

Fuel Filter and Fuel-water Separator........................................8-2

Oil Filter ......................................................................................8-2

Fuel Tank Draining.....................................................................8-3

Fuel Pump .................................................................................8-3

Exhaust GasTurbo Supercharger.............................................8-4

Air Drier ......................................................................................8-6

Check the Oil Level, and Refill the Clutch Oil Reservior .......8-6

The Transmission Lubricating Oil........................................... 8-6

The Rear Axle Main Reductor Lubricating Oil ....................... 8-7

Power Steering Lubricating Oil ................................................8-8

Battery Checking and Maintenance ........................................ 8-9

Fuse ..........................................................................................8-10

Suspension ..............................................................................8-10

Tire Rotation............................................................................ 8-11

Clean and Replace the Wiper Blades.....................................8-12

General Adjustment............................................................ 9-1

2

Table of Content

Using Engine in a Environmental Protection Standard........ 9-1

Drain Water Out from the Cooling System ............................. 9-2

Check the Opening Temperature of the Thermostat.............. 9-2

Adjustment of Fan Belt............................................................ 9-3

Pump Fuel Manually and Bleed Air Out of Fuel Supply System

9-4

Water-leak Hole of the Water Pump......................................... 9-4

Air Valve Clearance Adjustment .............................................. 9-4

Adjustement of Clutch.............................................................. 9-5

Air Release of Clutch............................................................... 9-6

Adjustment of Brake Clearance.............................................. 9-7

Brake system............................................................................ 9-9

Adjustment of wheel hub bearing .......................................... 9-9

Adjustment for the front wheel hub bearing ....................... 9-10

Adjustment for the front wheel hub bearing ........................ 9-10

Adjustment of Free Play of Steering Wheel.......................... 9-10

Adjustment for Toe-in ............................................................. 9-11

Maintenance Schedule ..................................................... 10-1

Engine ..................................................................................... 10-1

Clutch ....................................................................................... 10-2

Transmission ........................................................................... 10-3

Brake System .......................................................................... 10-3

Steering System ...................................................................... 10-4

Suspension System................................................................ 10-5

Propeller Shaft........................................................................ 10-5

Axle and Wheel....................................................................... 10-6

Others...................................................................................... 10-6

Main Adjusting Data ............................................................... 10-7

Fuel.......................................................................................... 10-8

Grease Application Place and Schedule.............................. 10-8

Lubricant and Vehicle Used Fluid.......................................... 10-9

Engine Lubricant................................................................... 10-10

Gear Oil .................................................................................. 10-11

Transmission Gear Oil ......................................................... 10-11

Lubricating Grease .............................................................. 10-11

Shock Absorber Oil............................................................... 10-11

3

Clutch Boost Liquid...............................................................10-11

Engine Anti-freeze Fluid (cooling fluid).............................. 10-11

Capacity Data .........................................................................10-12

Tightening Torque .............................................................. 11-1

Engine...................................................................................... 11-1

Chassis .................................................................................... 11-2

Attached Drawing .............................................................. 12-1

Electric System Drawings...................................................... 12-1

4

Main Technical Specifications

Main Technical Specifications

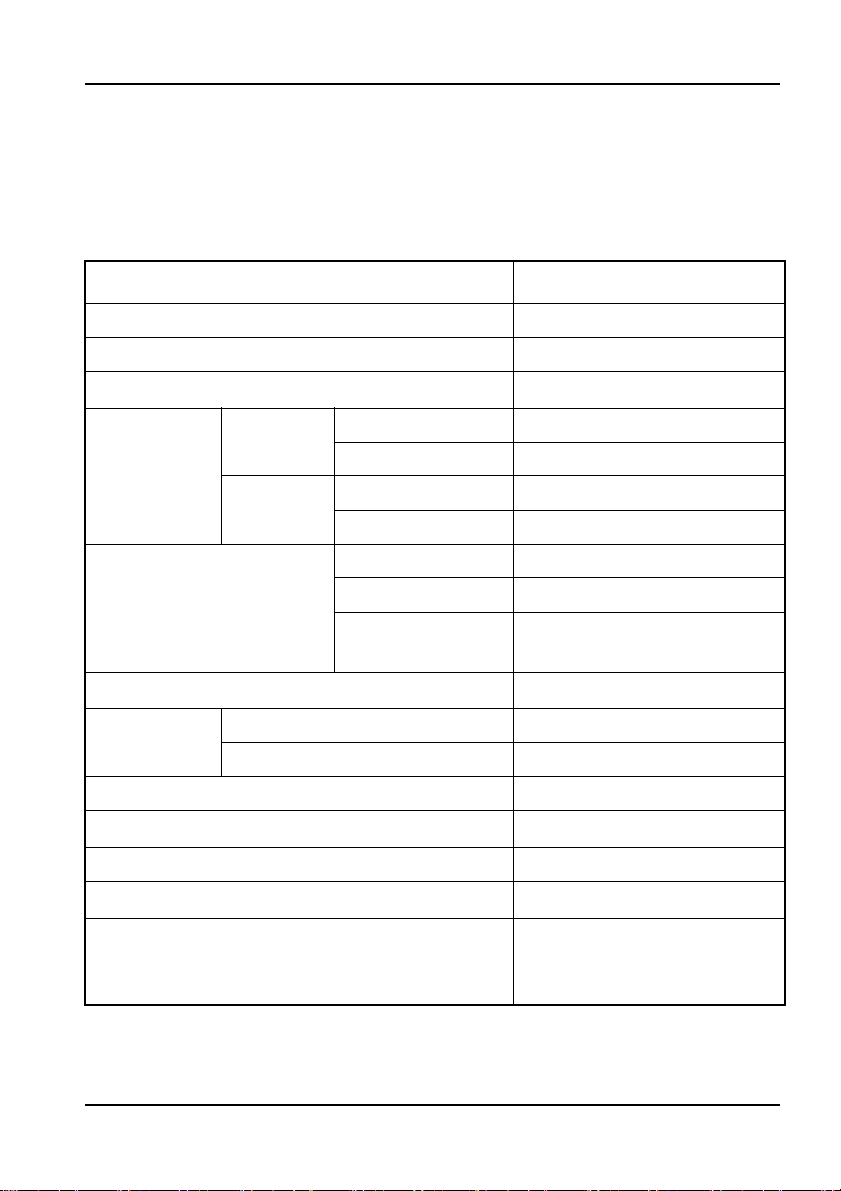

Main Technical Specifications and Structure Features

●

General Data

Vehicle Model 5ADDFA1101GZ 6J-907

Rated Loading Weight (kg) 4990

Curb Weight (kg) 4420

Gross Weight (kg)

Load Distribution (kg)

Overall Dimension (mm)

Wheel Base (mm)

Wheel

Tread (

Front/Rear Overhang (mm) 1270/2380

Approach angle/Departure angle

Min. Ground Clearance (mm) (Full-load) 240

Min. Turning Diameters (m)

Structure Features

mm)

Front axle

Rear axle

Front wheel 1831

Rear wheel 1640

No-load 2235

Full-load 3195

No-load 2185

Full-load 6410

Length 8350

Width 2330

Height (no-load,

to cab top)

Cab over engine, single

row, equipped with

EQB140-20 engine

9605

2395

4700

5.5 2 °/ 11°

19

2—1

Main Technical Specifications

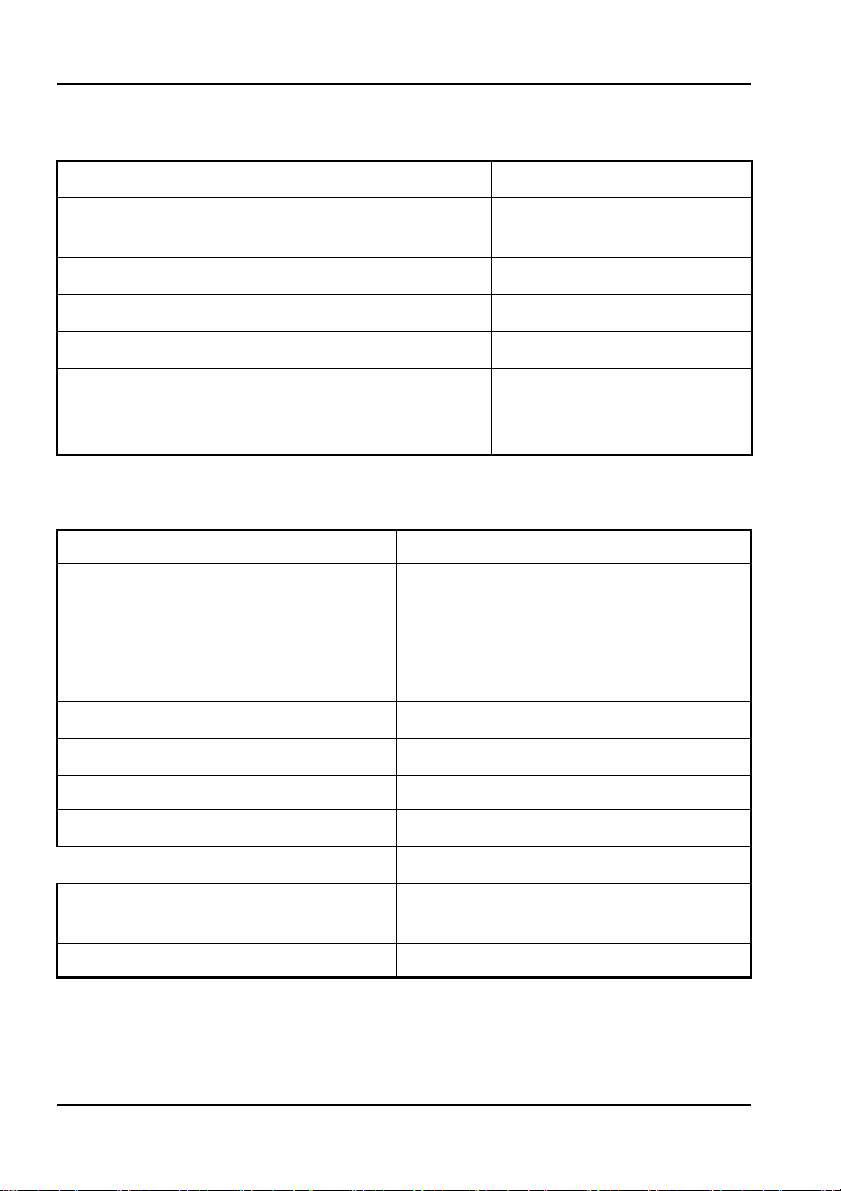

Operational Data

(km/h)Max speed

Max gradability (Full-load on dry and hard

road, the slope length is over 15m)

Ability of parking on the slope

105

≥ 30%

≥ 20%

100km fuel consumption (L) ≤ 13

Max continuous running distance (km)

500

RC-0#(summer), RC-

Fuel type

10#(

winter) vehicle used

light diesel oil

Engine Parameter

Model EQB140-20

4 in-line cylinders, supercharging

and intercooling, direct injecting

Type

× Stroke (mm × mm)Bore 102 × 120

Displacement (L)

DONGFENG Cummins diesel

engine, reach the European II

displacement standard

3.92

Compression ratio 17.3:1

Rated power (kW/rpm)

Rated torque (N.m/r/min)

Min. specific fuel consumption

(g/kW.h)

103/2700

502/1500

210

Injecting order 1-3-4-2

2—2

Main Technical Specifications

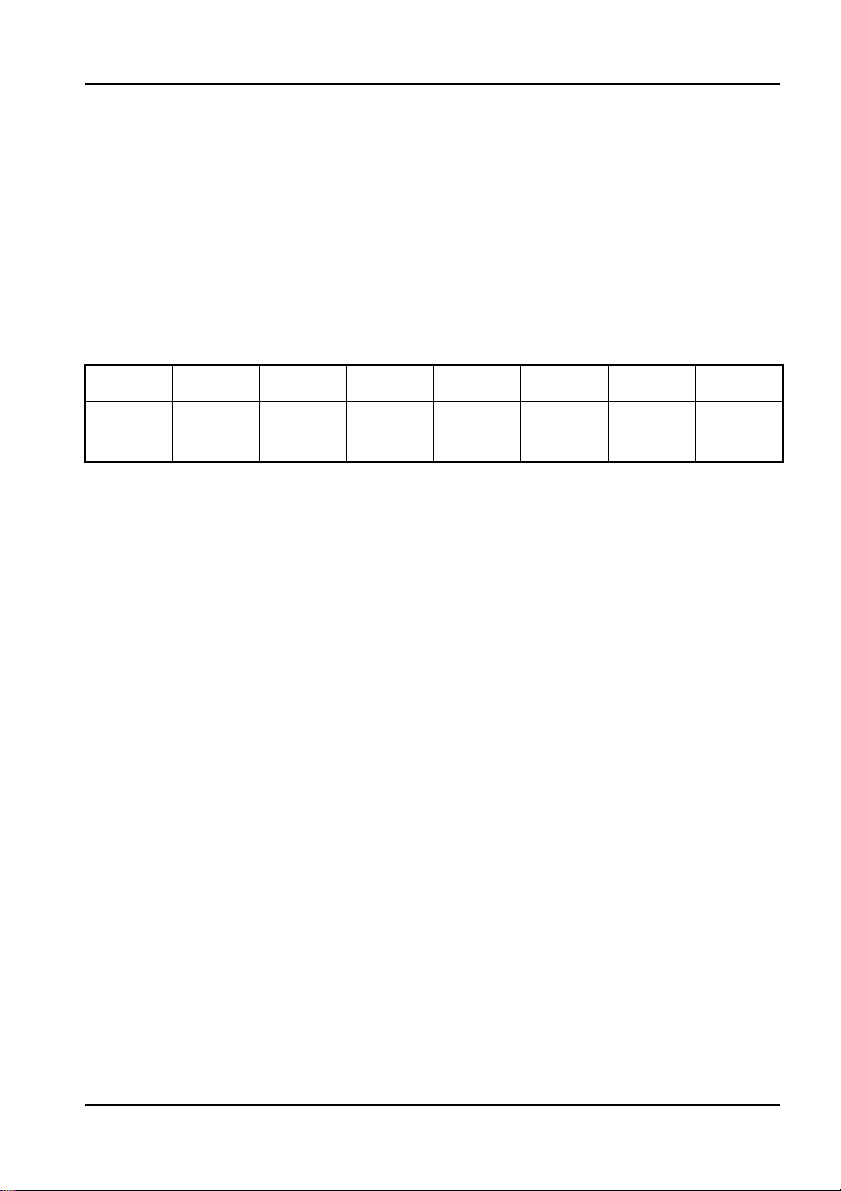

Chassis Type and Structure Parameter

1.Clutch

Ø350 mm single , dry disc, hydraulic remote control.

2.Transmission

Manual mechanical transmission, six gears forward, one reverse,

ynchronizers on 2nd to 6th gear. There is a take-off window on the

with s

right side, controlled by flexible shaft.

Speed ratio:

Gear

Speed

ratio

Ⅰ

Ⅱ Ⅲ Ⅳ Ⅴ Ⅵ

7.454 4.823 3.075 1.976 1.480 1.000 6.709

R

3.Propeller shaft

Cardan universal joint, depart into two parts..

4.Front axle

Forging, I-beam axle.

Front wheel aligner:kingpin inclination 7°

caster 2°

camber 1°

toe-in 0~5mm

5.Drive axle

Founding axle housing, single-stage and double-curved gear

reductor, fully floating axle shaft

.

Final drive: 4.33

6.Suspension system

Both front and rear suspension are dependent, laminated leaf-

spring, with an auxiliary spring on rear suspension.

Hydraulic telescopic damper: Equipped on the front suspension

Number of spring leaf: Front: 11, Rear 13+8.

7.Wheel

2—3

Main Technical Specifications

Single tyre on the front axle, double tyre on the rear tyre, and a

spare tyre on the spare tyre carrier hang under the rear end of the

frame.

Tyre:8.25-20

Tyre inflating pressure:

Front wheel is 490kPa and rear wheel is 560kPa, while the allow-

able inflating pressure is 630kPa.

8.Steering system

Circulating ball type with power steering.

Max front wheel turning angle (inside/outside): 40°/32°

9.Brake system

Service brake:dual-circuit, air brake system, and front and rear

brake are self-adjustable, cam, air-operated, drum brake with the

exhaust auxiliary brake system.

Parking brake:spring brake controlled by manual-operated valve

through air pipes.

10.Frame

Ladder type, longitudinal is grooving section and riveted by several

crossbeams, part of the frame has stiffening plate.

11.Electric equipment and instruments

Single, negative earthed line, 24V.

Battery:6-QW-90DF

Starter:24V, 3.7kW

Alternator:45A, 28V

Main switches:

Power switch, combined switch, ignition switch, assistant starting

switch, heater switch, etc.

Instruments:

Speedometer and odometer, water temperature gauge, fuel gauge,

air-pressure gauge, oil pressure gauge, etc.

Indicators:

Water temperature indicator, oil pressure indicator, fuel level warn-

ing indicator, oil pressure warning indicator, turning signal indicator,

2—4

Main Technical Specifications

charge warning indicator, parking indicator, water overheat or level over

low warning indicator, reversing warning indicator, electric horn,

etc.

Lamps:

Head lamp, front combined lamp, fog lamp, turning signal lam p,

license lamp, tail

combined lamp, front clearance lamp, rear clearance

lamp, side marker lamp, etc.

12.Cab

New developed, all metal structure, tilting, wide cab with single row

and a sleeper. Interior trimming has two types: standard and luxury. The

driver's seat can be adjusted for ward and backward. The driver and the

assistant's seats are fitted with 3 point-seat belt, the middle seat is fitted

with 2 point-seat belt. The cab is equipped with full-scope windshield,

sun shield, inner rear view mirror, and radio cassette, etc.

13.Tools equipment

Every commercial vehicle is equipped with a set of tools.

2—5

Construction and Operation

Construction and Operation

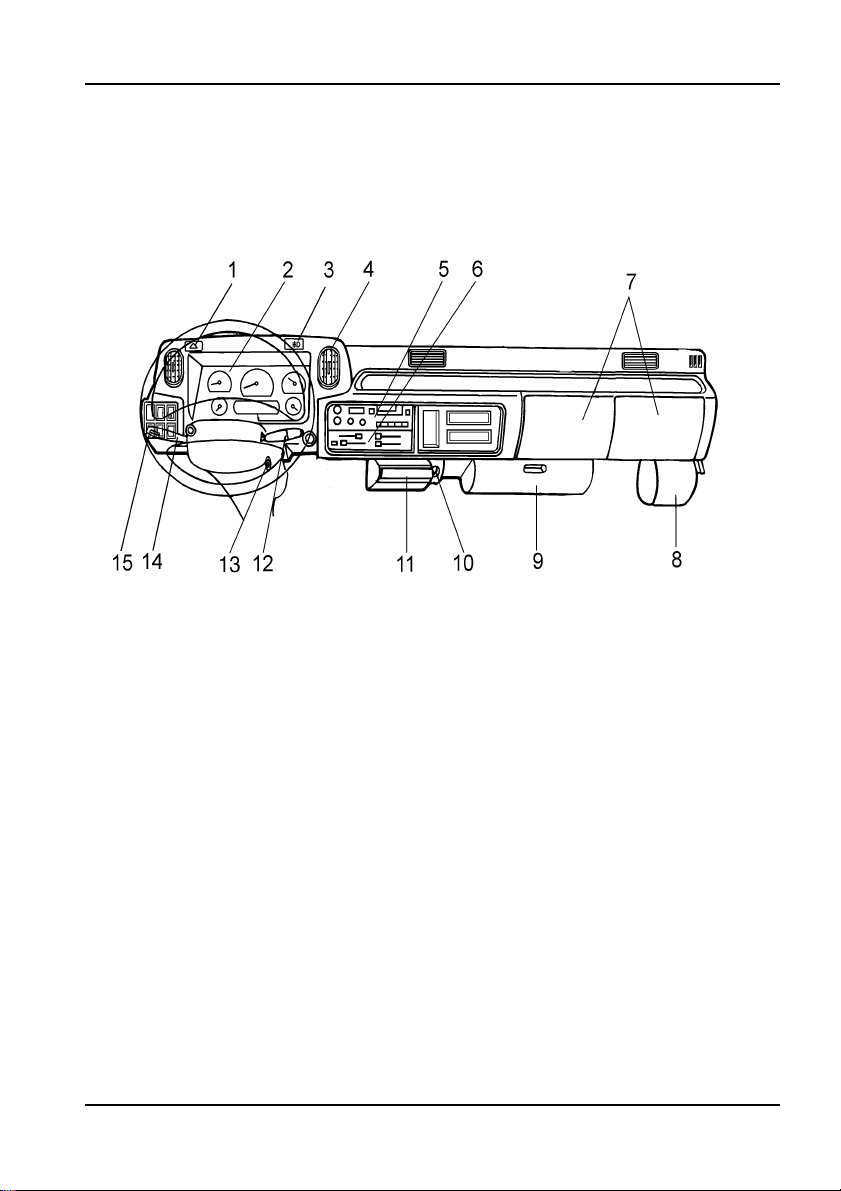

Arrangement of the Cab

1. Hazard waring lamp switch

2. In strument panel

3. Front fog lamp switch

4. Wind channel

5. Radio cassette

6. Heater and air-conditioner switch

7. Glove box

8. Windshield washer fluid reservoir

9. Fuse box

10. Cigarette lighter

11. Ash tra y

12. Windshield wiper and washer controlling rod

13. Ignition lock

14. Combined light switch

15. Combination switch

3—1

Doors

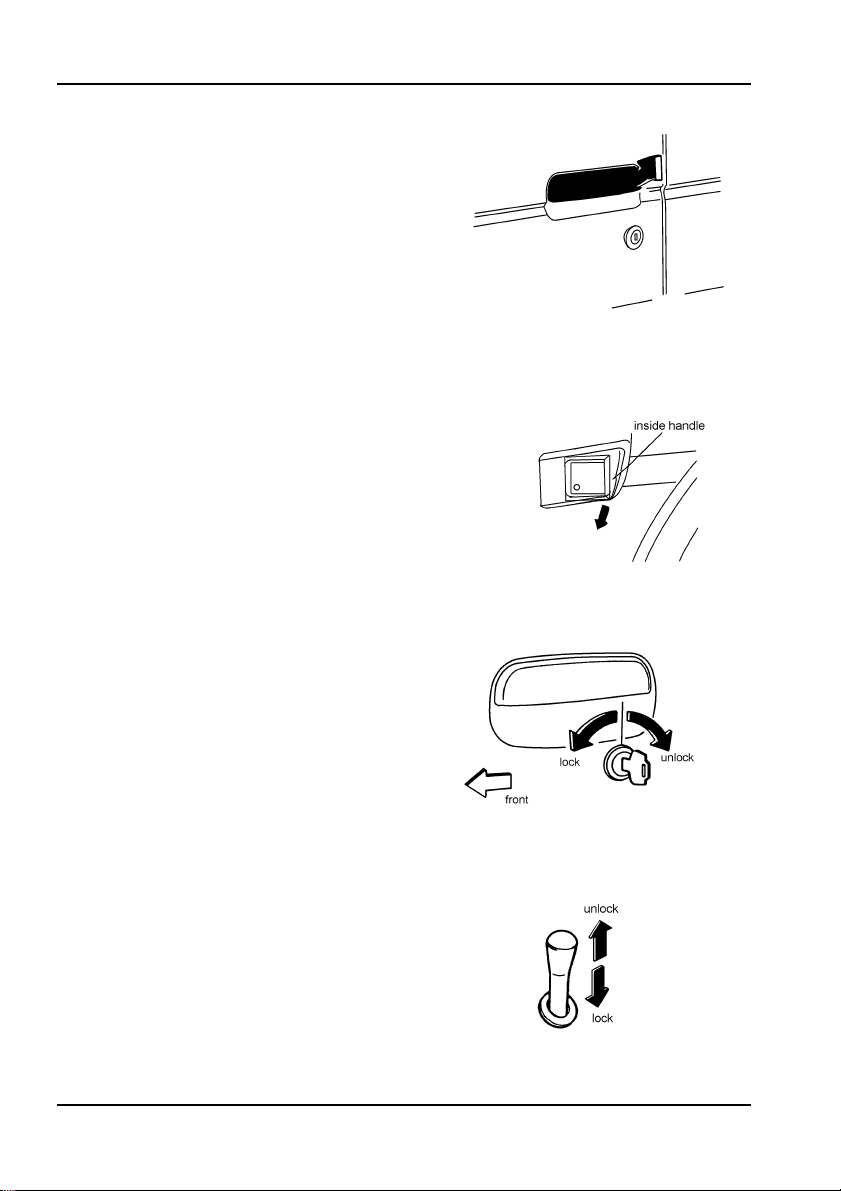

● Opening doors

From the outside

From the inside

Note:

After closing the door,please double check

whether the door is really closed. Driving with

the door half closed can be very dangerous.

● Closing doors

From the outside

Turn the key forward to lock the

door, while turn it backward to unlock

the door.

Construction and Operation

From the inside

Set the lock ball to the locked

place, and pull the door handle to close

the door.

3—2

Construction and Operation

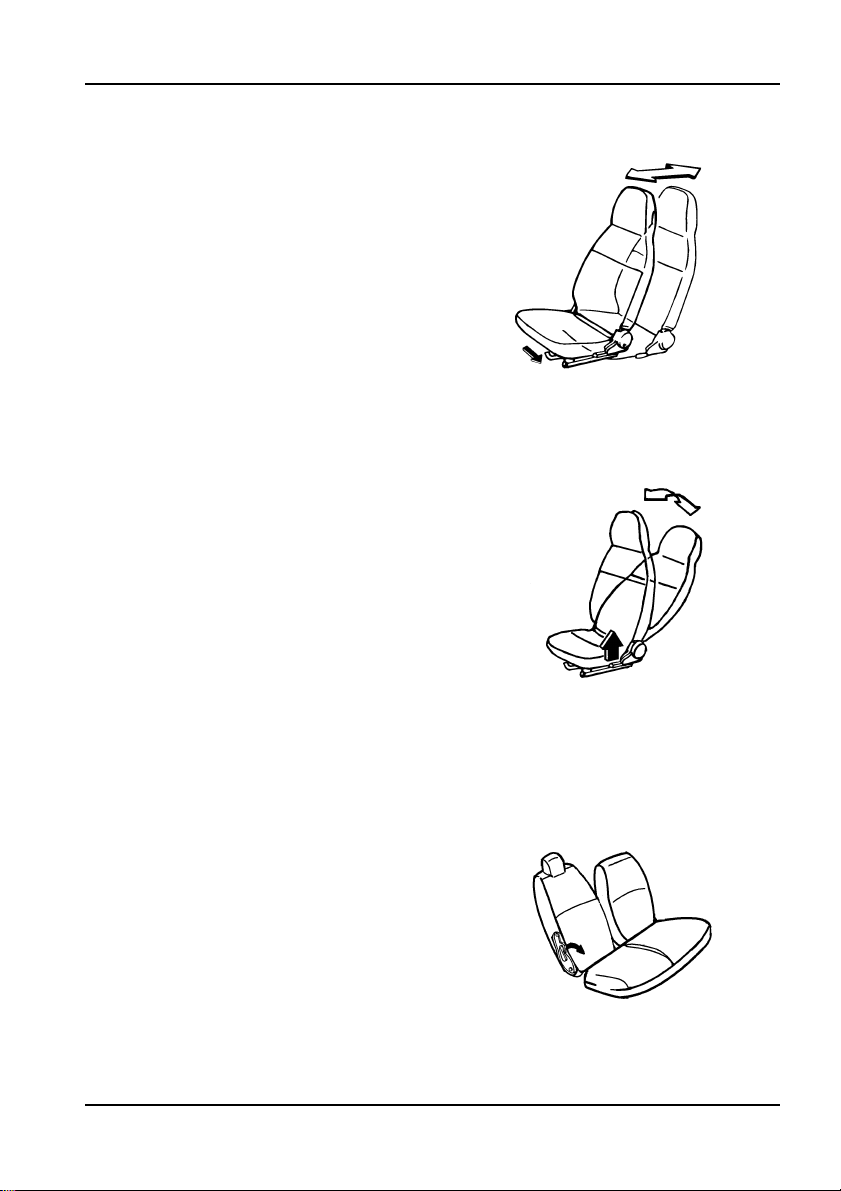

Seats

● Driver's seat forward and back-

ward adjustment

Raise the adjusting lever on the

front side of the seat, and move the

forward and backward till to the

seat

optimum, then release the adjusting

lever and

position.

lock the seat in the desired

● Driver's seat back angle adjust-

ment

Raise the adjusting lever on the left

side of the seat,

back to an angle most appropriate for

holding the steering wheel

elease the lever to lock the seatback in

r

the desired position.

and adjust the seat

, then

● Assistant's seat back adjustment

Turn the knob located on the right

side of the seat

adjusted to the desired position or

putted down face to the seat.

, the seatback will be

3—3

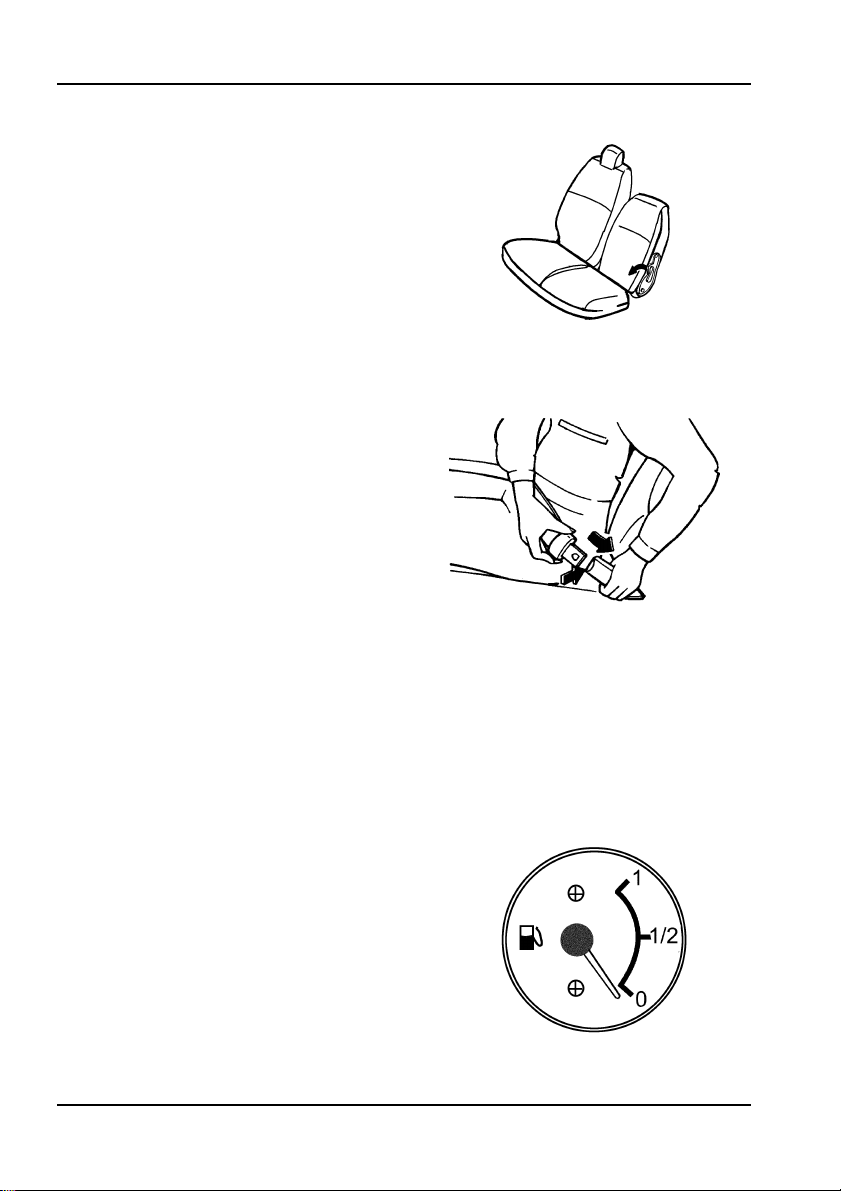

● Center seat back adjustment

Turn the knob located on the left

side of the seat, the seatback will be

adjusted to the desired position or

putted down face to the seat

.

● Safety belts

Slowly pull out the safety belt and

make it throught your body from the left

side of your neck to the right side of

your waist and press the button, then

insert the locking hook into the latch

hook. Adjust the length of the safty belt

to the optimum.

Note:

Adjust the position of the seat correctly;

Make sure that the safty belt is not winded

or rubbed by hard edge, and far away from the

chemical and battery acid;

One belt for one person;

After being overused, invalid or damaged,

the whole belt should be changed;

If the safty belt retractor does not work well,

the whole belt should be changed immediately.

Construction and Operation

Instruments

1.Fuel Gauge

The fuel gauge use to indicate the

approximate level of fuel remaining in

the fue tank. The needle will change

because of vehicle braking, turning,

accelerating or climbing.

3—4

Construction and Operation

Note:

Do remember refill the fuel tank with clean

fuel before the gauge indicates that the fuel has

been used up.

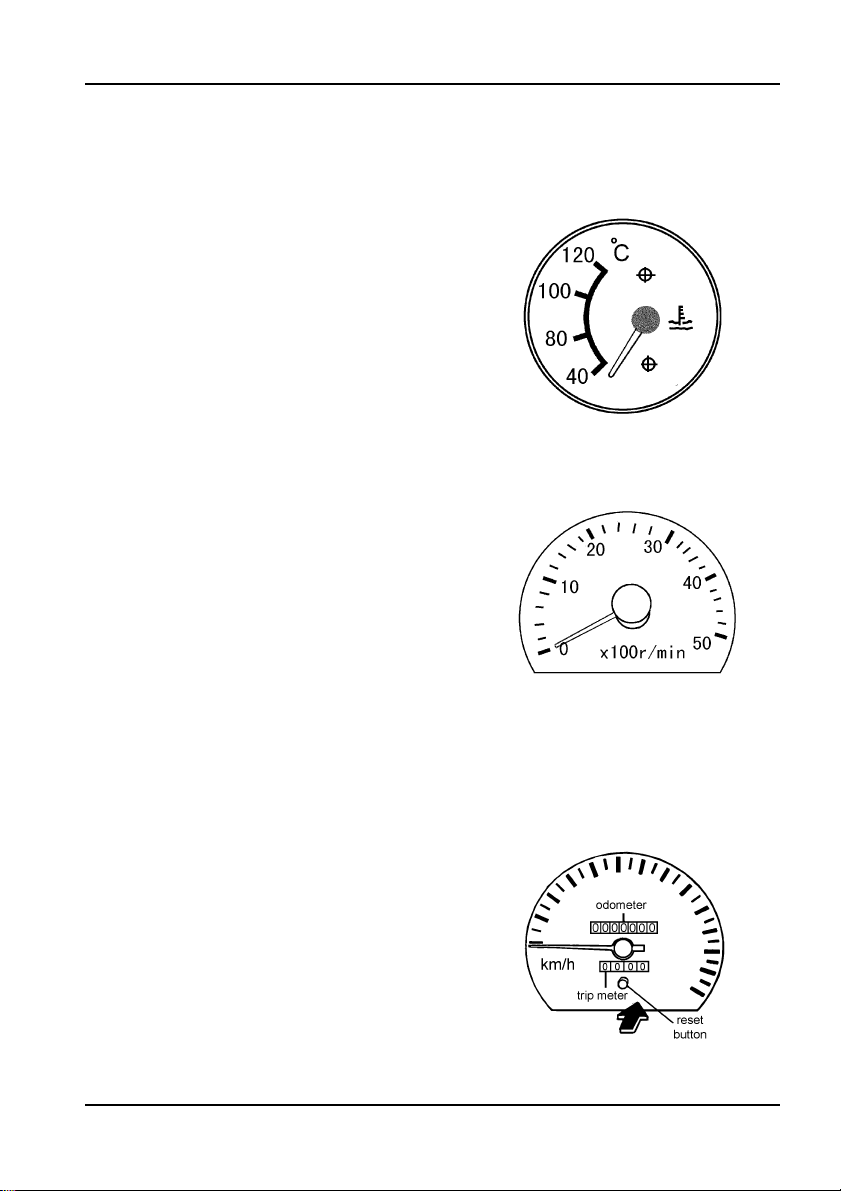

2.Water Temperature Gauge

The gauge indicates the engine

water

temperature. Its needle will

change

because of atmospheric

temperature and driving condition.

Note:

Be sure to stop the vehicle as soon as

possible when the needle of the gauge beyond

the normal range.To run the vehicle with a

overheated engine is extremely harmful to the

engine.

3.Tachometer

The needle of the tachometer

indicates the engine speed in

revolutions per minute. The red zone

indicates a range of critical engine

speed. Be sure to always keep the

indictor below this critical zone. The

green zone indicates the range for the

most economical engine operation.

Driving under this green zone will save

fuel and extend the sevice life of the

engine.

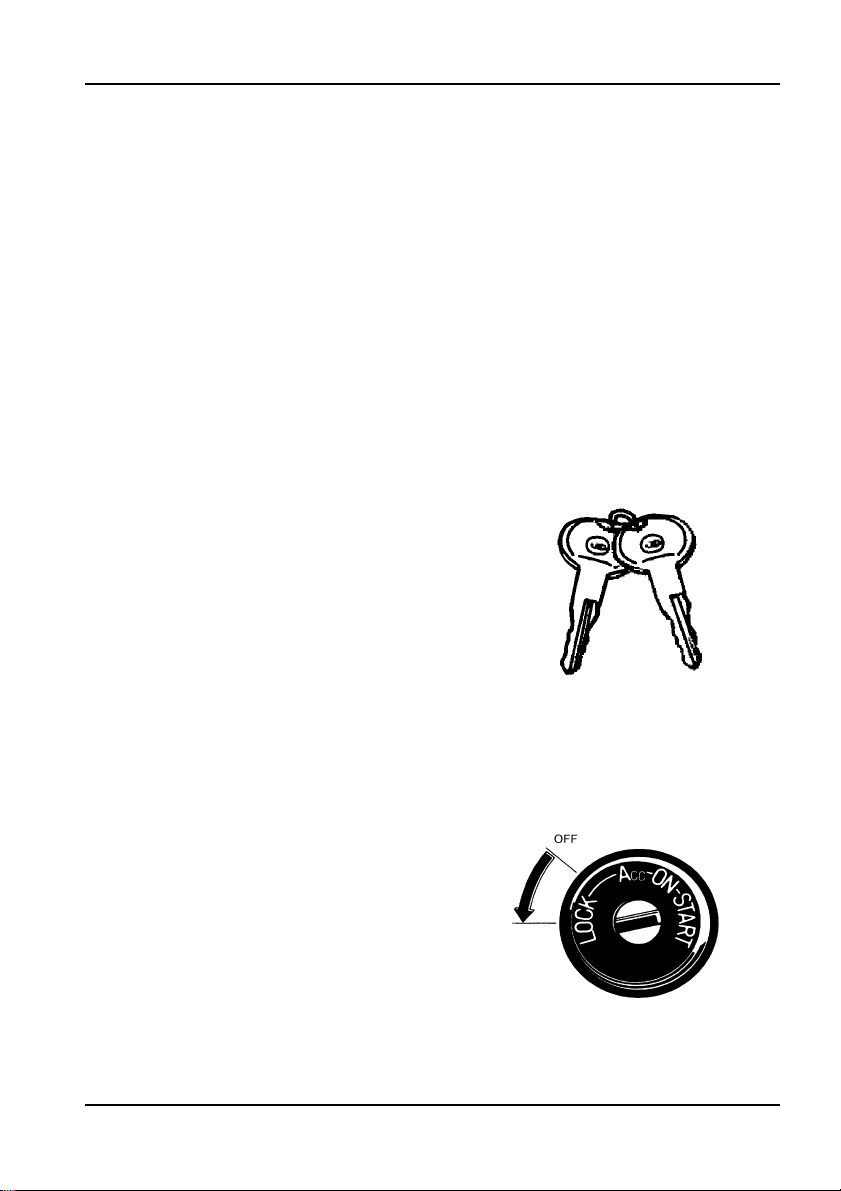

4.Speedometer

The speedometer indicates the

speed of the vehicle in kilometers per

hour. The odometer indicates the

accumulated driving distance in

kilometers.

The trip meter is used to represent

the running distance of a day or a

trip.Do remember to press the reset

button to delete the numbers before

3—5

you use it. The most right number has a

unit of 0.1km.

Note:

Do not press the reset button during the

driving period.

Do not pull or turn the reset button when

press it.

5.Air-pressure Gauge

There are two gauges here, one for

front brake system, the other for rear

brake system. The range of the

indicator is from 0~12x100kPa

, while

0~4x100kPa is in red zone, and under

that condition the vehicle cannot be

started. Only when the indications of

the two needles all over 4x100kPa can

the vehicle be started.

Indicators

Construction and Operation

1.Taillamp Warning Indicator

The indicator will lighten when any

of the tail

lamp (exclude the turning

lamp) is in trouble.

3—6

Construction and Operation

2.Exhaust Brake Indicator

The indicator wil lighten when the

exhaust brake is switched on.

3.High Beam Indicator

The indicator will lighten when the

high beam is used, and if the passing

light is used, the indicator will

en.

lighte

also

4.Charge Warning Indicator

The light will lighten when the key

switch is turned on, and will extinguish

when the engine is started and

charging is initiated. If charging is

stopped due to the failure of the

charging system during engine

operation, the light will lighten.

Note:

Never run the vehicle with the warning light

on. This will run down the battery.

5.Fuel-water Separator Indicator

If the sensor of the fuel-water sepa-

rator indicates that the water level is

too high, this indicator will lighten and

remind the driver to drain water.

6.Parking Brake Warning Indicator

The light will lighten when the

parking brake is actuated to aware the

driver that the vehicle is in the braking

condition. The light wil extinguish when

the parking brake stops operating.

Before moving the vehicle, make sure

the light is off.

7.Safety Belt Indicator

The indicator will flash for 7

seconds to aware the driver and

3—7

passengers to use the safty belts when

the ignition lock is placed at "ON"

position.

8.Fuel Warning Indicator

The indicator will lighten when the

remaining fuel is too little to assure the

normal driving. It is used to aware the

driver to refill the tank.

9.Rear Fog Indicator

The light will lighten when the rear

fog lamp is used.

10.Water Temperature Warning

ndicator

I

The light will lighten when the

temperature of the water is over 101 ℃

. At the same time, a buzzer will sound

to make the driver aware that the

engine is in dangerous situation. The

buzzer stops when the key switch is

turned off with the engine stopped.

Construction and Operation

11.Oil Pressure Warning Indicator

The light will lighten when the key

switch is turned on, and will extinguish

after the engine starts. It will be lighted

again when the oil pressure is too low

during the operation of the engine.

Note:

The low pressure of the engine will cause

the damage of the engine.

Never run the vehicle with the warning light

on.

12.Brake-down Warning Indicator

The light will lighten when the level

of the brake fluid drops or the front

3—8

Construction and Operation

brake lining is worn out. Do remember

to refill with brake fuid or chang the

brake lining.

13.Air Filter Block Warning Indicator

When the air filter is blocked, the

indicator will lighten to remind the driver

to clean it.

14.Turning Signal Indicator

This indicator is used to indicate

the working condition of the turning

signal lamp. Switch on it and both the

left and right indicator are flashing.

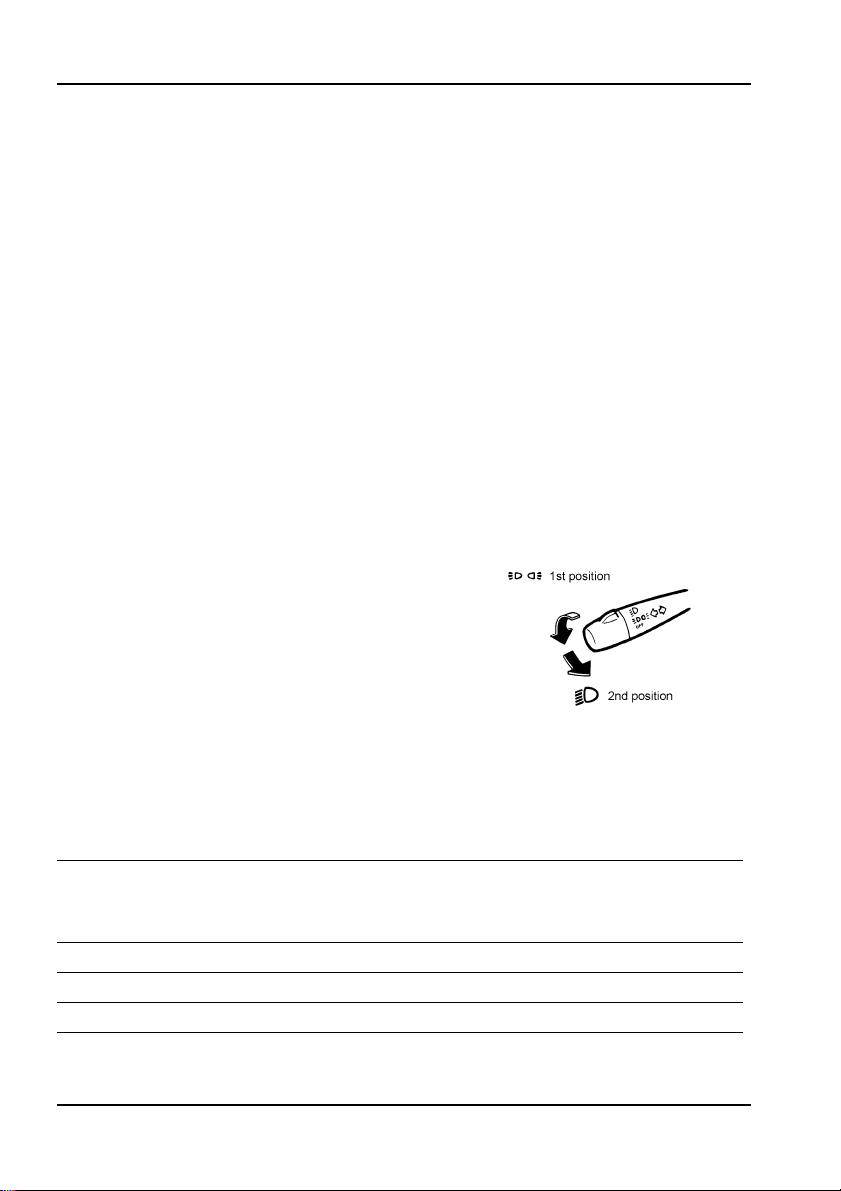

Keys

There are two keys provided that

used to start the vehicle, open or lock

the door.

Key Switch

LOCK: Only the key is set on the

LOCK position can it be inserted or pull

out.

OFF: Turn the key from ON to OFF

to shut-down the engine.

ACC: Set the key at the ACC

position

(such as

cigarette lighter, etc), while the engine

is not operating.

to use any of the accessories

radio cassette, wiper,

3—9

ON: After the engine starting, the

key return from START to ON and the

engine is started normally.

Never turn

the key to any other position while the

engine is running.

START: Set the key to the START

position to start the engine. The key will

return automatically to the ON position

when released from the START

position.

Note:

Never turn the key to the START position

while the engine is running, or else it makes the

starter damage

can the engine be started again.

d. Only after the engine stops

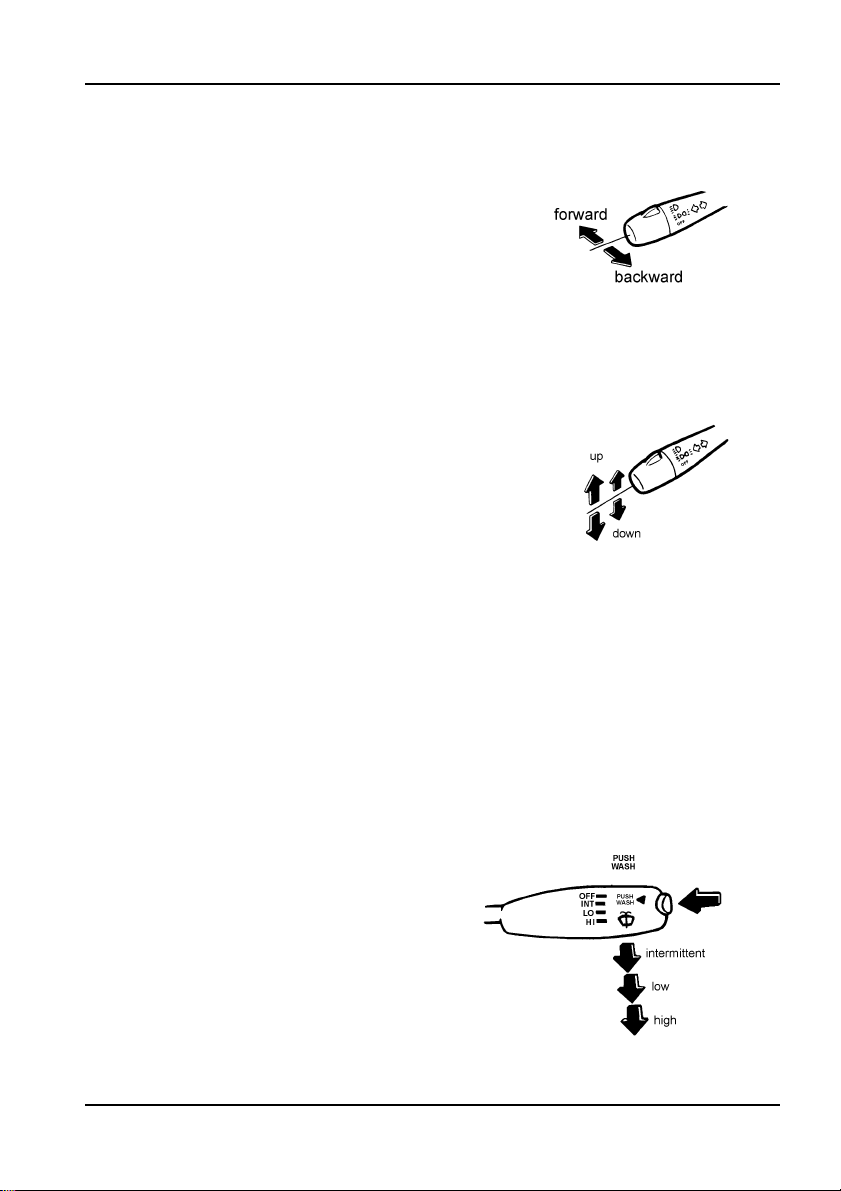

Light Combination Switch

This combined switch is used for

front lamp, tail lamp, head lamp, instru-

ment lamp, licence lamp, passing lamp,

dimmer and turning lamp, etc.

Construction and Operation

1.Light switch

Turn the end knob of the combina-

tion switch lever forward, the lamps

represented in the below chart will illu

-

minate depending on the position of the

switch.

○ ON xOFF

Knob

position

OFF x x x x x x x x

1st position x

2nd position

3—10

Head

Front

lamp

lamp

○ ○ ○ ○ ○ ○ ○ ○

Ta il

Licence

lamp

○ ○ ○ ○ ○ ○ ○

lamp

Instru

ment

lamp

Front

clearan

ce lamp

Rear

clearance

lamp

Side

clearance

marker

Construction and Operation

2.Turn signal light switch

Put the control lever forward and

backward to make the left or right turn

signal lamp blinked.

3.Dimmer switch

Put the combined switch control

lever up and down to change from the

high beam to low beam or from the low

beam to high beam. If there is a coming

vehicle, do remember to use it.

4.Passing light switch

The head light high beam will

lighten as long as the lever is being

pulled from the low beam position, and

when releasing the lever, it will auto

-

matically return back to the low beam

position. You can use this to tell front

vehicles that you're going to pass them.

During the normal running condition of

the vehicle, no matter other lights' con

-

dition, if you use the passing light, it will

be on.

5.Windshield Wiper and Washer Switch

When the front windshield is dirty

and needs to wash, press the button on

top of the windshield washer lever, the

washer will operate and the washer

fluid will be sprayed out

continuously.

At the same time, the equipped

intermitted wiper (3-speedtype) is also

3—11

operating. The wiper should be moved

two or three more times after the

washer stop

s. The wiper starts after

pulling the lever backward. It has

intermittent, low and high three speeds.

Release the

button, the washer stops.

Pull the lever to the end of the front, the

wiper stops

Note:

Use of the wiper alone will scratch the

windshield. Be sure to operate it with the washer

when the weather is well.

Do not use the washer without washer

otherwise the washer motor will be

fluid,

damage.

.

6.Hazard Warning Indicator Switch

Use this switch to warn other

drivers when your vehicle becomes a

traffic hazard

trouble.

urning signal lights are lightened, and

t

the turning signal

source due to mechanical

If switch on it, all left and right

indicator will flash

simultaneously.

Construction and Operation

7.Front Fog Lamp Switch

When this switch is pushed, the

lamps, front lamps and tail lamps all

fog

come on. Use this switch to control the

lights

when driving in a thick fog.

3—12

Construction and Operation

8.Rear Fog Lamp Switch

In the condition that the front fog

light is on, switch on this and the rear

fog lights come on, while switch off, the

rear fog lights will be off.

Power Switch

The rocker switch is used to control

the electromagnetic power switch in the

circuit system

position to turn-on the vehicle circuit

system, and set it to the OFF position

to cut-off the circuit system.

should be

electrical equipments in case the circuit

system is checked or repaired.

Note:

Don't turn off the power switch when the

engine is running.

. Set the switch to the ON

The circuit

switched off to protect other

Exhaust Brake Switch

It is used to control the exhaust

.

brake

3—13

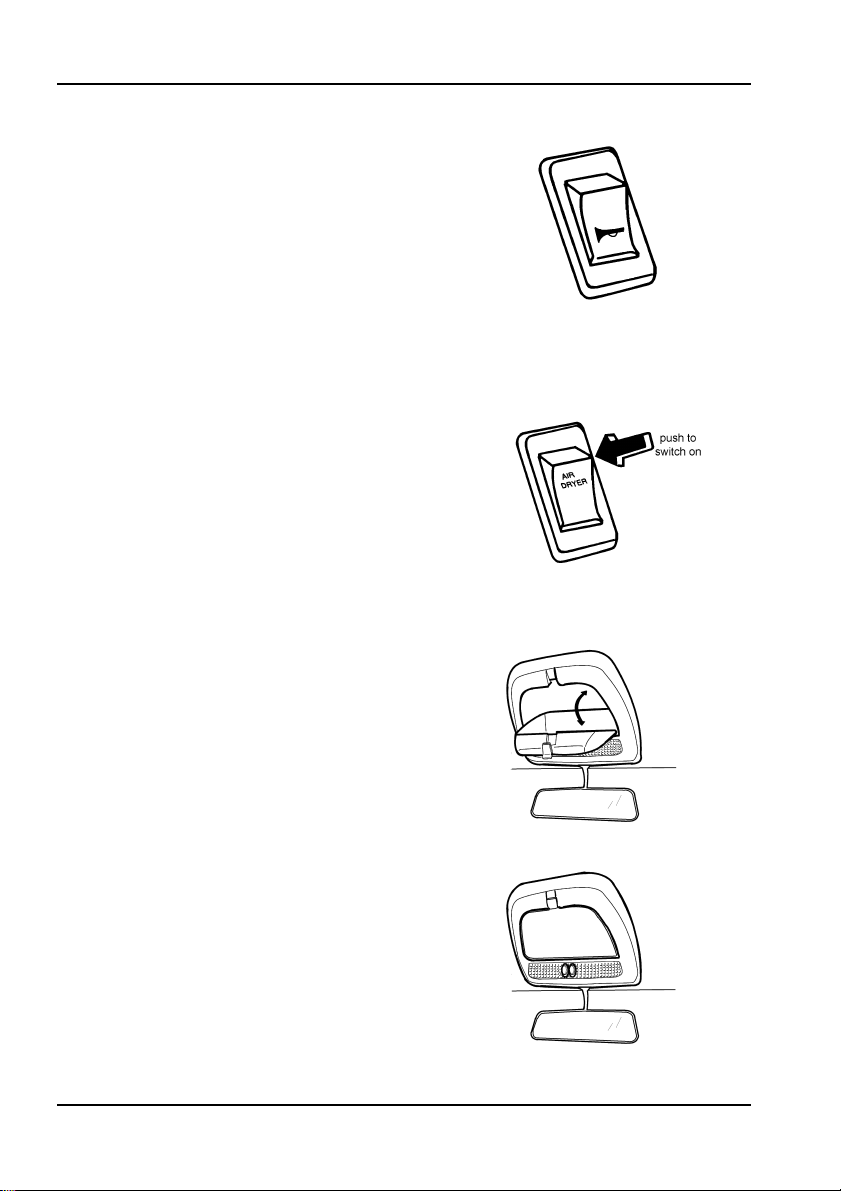

Air Horn and Electric Horn Shift Switch

Choose the air horn or electric horn

as you need.

Air Drier Switch

During raining or snowing days,

switch on the air drier to dry the air in

the brake system to assure the vehicle

brake performance.

Construction and Operation

Dome Lamp and Glove Box

There are one glove box and two

lamps on the inner front of the cab. If

you want to use the glove box, just pull

down the lid.

As for two dome lamps, press the

left button they will lighten no matter the

door is open or not; press the right but

ton they will lighten if any of the door is

opened.

3—14

-

Construction and Operation

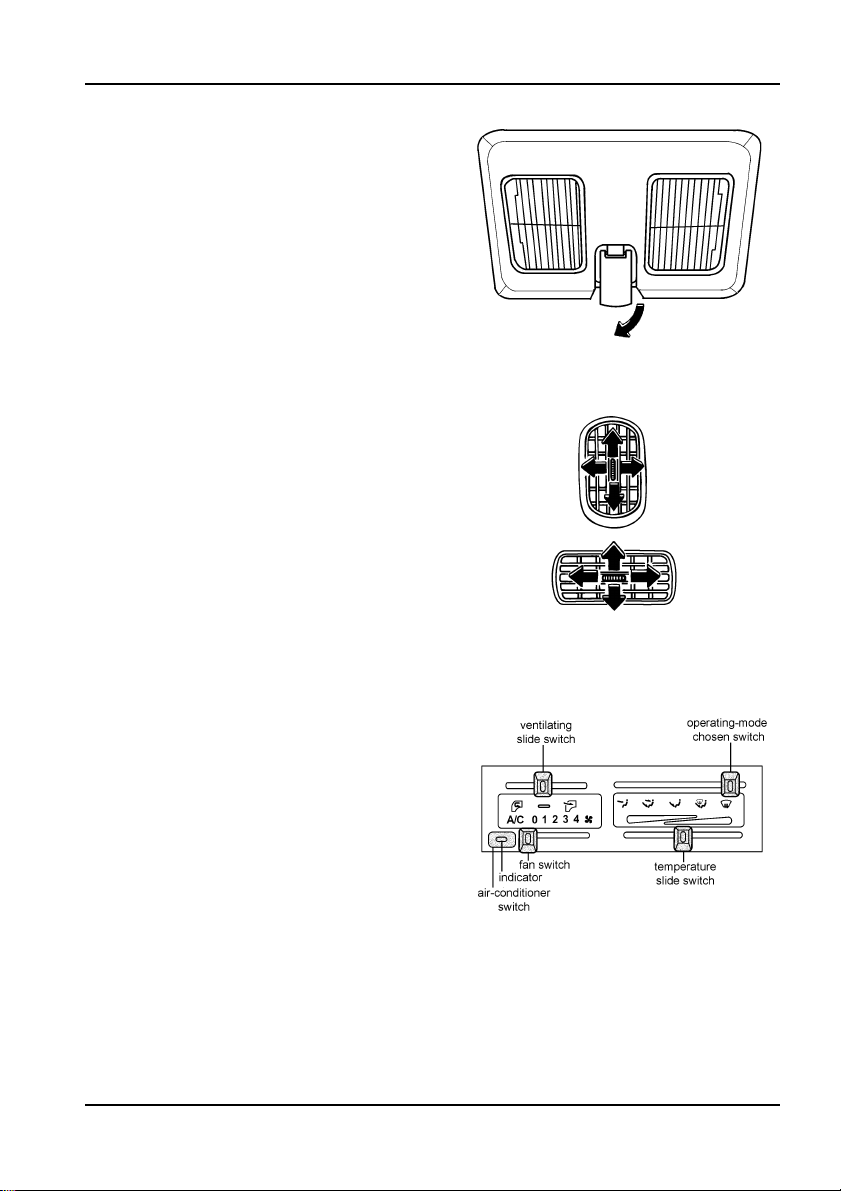

Cab Skylight

When you want to introduce some

fresh air into the cab, just push up the

switch of the skylight.

Air Conditioning System

1.Ventilator

Turn the central roller to change

the direction of the airflow.

2.Air-conditioner

Air-conditioner switch

When the air-conditioner is

needed, press this switch and the

indicator light goes on which means the

connection of power supply.

Fan switch

There are five speeds provided,

from 0 to 4. At 0 position, the fan stops,

and the wind will become even stronger

from 1 to 4 speed successively.

Temperature slide switch

It is used to adjust the inside

temperature. Move the slide switch

from left to right and the temperature

will be adjusted from low to hight.

3—15

Ventilating slide switch

-- introducing external air

--circulating internal air

Operating-mode chosen switch

--blowing to your head

--blowing to your feet

--blowing both to your head

and feet

--inside heating and defogging

--inside defogging

Note:

The warm air is heated by the cooling liquid

of the engine. Its temperature depends on the

temperature of the cooling liquid.

Please do not use the heating device too

long when the engine is stop or idle, otherwise it

will wear out the battery and influence the

normal driving.

Do not forget to reduce the transmission

speed and raise the engine revolution during

low speed running, or climbing the long slope, to

reduce the engine load.

You have to wait for 2-3 minutes before

you restart the air-conditioner to extend the

sevice life of the compressor.

You also have to operate the air-

conditioner for 10 or more minutes every month

even in winter to extend its service life.

Construction and Operation

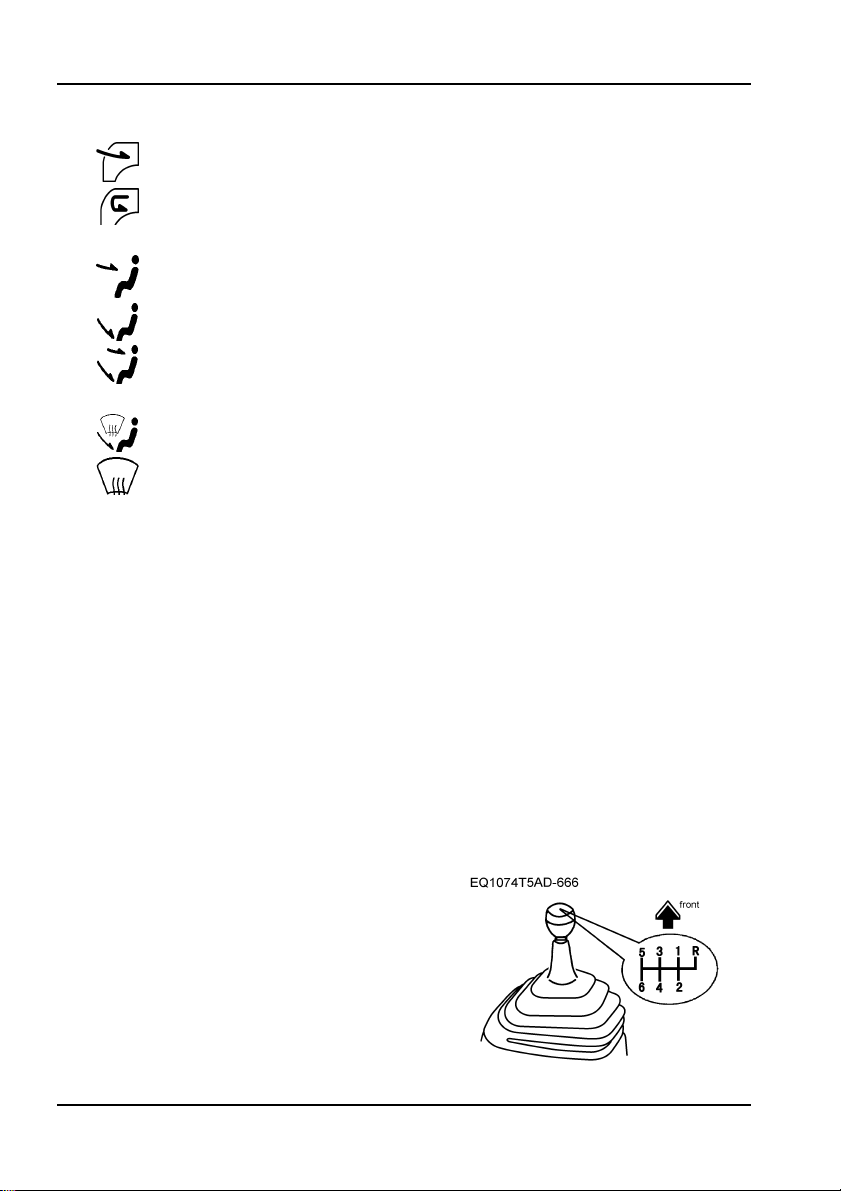

Levers, Steering Wheel and Accessories

1.Transmission gear shift lever

When shifting gears, be sure to

fully

trample down the clutch pedal.

3—16

Loading...

Loading...