DongFeng DF404G2-6, DF354G2-6, DF304G2-6, DF254G2-6 Service Manual

CONTENTS Service Manual 304G2

Safety |

1 |

Precautions |

…………………………..…………… |

…… |

|

Chapter |

I |

Work safely Always and safety Rules ……………….……………… |

14 |

Chapter |

II |

Technical Specifications of the Tractor ……………...……………… |

18 |

Chapter |

III |

Running-in of the Tractor……………………………………………… |

23 |

Chapter |

IV |

Operating the Tractor ………………………………..………………… |

25 |

Chapter |

V |

Adjustments of the Tractor…………………………..………………… |

31 |

Chapter |

VI |

Lubrication and Maintenance of the Tractor………...……………… |

43 |

Chapter |

VII |

Troubles and Trouble-shooting ……………………………………… |

47 |

Appendix 1 |

Moving Locus Diagram of Lifting Linkages………...………………… |

57 |

|

Appendix 2 |

Moving Locus Diagram of Lifting Linkages………...………………… |

58 |

|

Appendix 3 |

Diagram of Electrical System Principle ……………………………… |

59 |

|

Appendix 4 |

List of Rubber Oil-seal and O-ring |

60 |

|

|

|

Seal…… …………..………… |

|

Appendix 5 |

List of Bearings……………………………………... ………………… |

62 |

|

Appendix 6 |

Tightening Torque Table of Main Bolts and Nuts…..………………… |

63 |

|

Appendix 7 |

Optional Accessories …………...………….…….….………………… |

63 |

|

Appendix 8 |

List of Attached Tools………………………………………... ……… |

64 |

|

Appendix 9 |

Packing |

65 |

|

|

|

List………………………………………... …... ... |

|

|

|

... .. |

|

PRE-DELIVERY SERVICE………………………………………………………………… |

66 |

||

1

Downloaded from www.Manualslib.com manuals search engine

Safety Precautions

Recognize Safety Information

This is a safety—alert symbol When you see this symbol on your machine or in this manual be alert to the Potential for personal injury

Follow recommended precautions and safe operating practices

Understand Signal Words

A signal word—DANGER WARNING or CAUTION—is used with the safety alert symbol DANGER identifies the most serious hazards

DANGER or WARNING safety signs are located near specific hazards General precautions are listed on CAUTION safety signs CAUTION also calls attention to safety messages in this manual

Follow Safety instructions

Carefully read all safety messages in this manual and on your machine safety signs Keep safety signs in good condition Replace missing or damaged safety signs Be sure new equipment components and repair parts include the current safety signs Replacement safety signs are available from your East Wind dealer

Learn how to operate the machine and how to use controls properly Do not let anyone operate without Instruction·

Keep your machine in proper working condition Unauthorized modifications to the machine may impair the function and/or safety and affect machine life·

If you do not understand any part of this manual and need l assistance contact your East Wind dealer

Prevent Machine Runaway

Avoid possible injury or death from machinery runaway Do not start engine by shorting across starter terminals Machine will start in gear If normal circuitry is bypassed NEVER start engine while standing on ground Start engine

only from operator’s seat with transmission in neutral or park

Use Seat Belt and Foldable ROPS Properly—

Open Station

When the ROPS is in the“up”or extended position ALWAYS use your seat belt to minimize chance of injury from an overturn accident

DO NOT use seat belt when ROPS is folded down

2

Downloaded from www.Manualslib.com manuals search engine

This tractor is equipped with a foldable Roll-Over Protective Structure(ROPS) The ROPS(A)should be kept in the“up"or extended position(as pictured)with pins(C)retained with quick—lock pins(B) except when it is necessary to fold it for low clearance operations

A—ROPS

B—Quick-Lock Pins

C——ping

Handle Chemical Products Safely

Direct exposure to hazardous chemicals can cause serious injury Potentially hazardous chemicals used with East Wind equipment include such items as lubricants coolants paints and adhesives

Before you start any job using a

hazardous chemical you should know exactly what the risks are and how to do the job safely Then follow procedures and recommended equipment

Operate Tractor Safely

Features designed into your tractor make operation Safer and let it perform a wide variety of jobs Use your tractor only for specified jobs it was designed to perform implement carrier load mover remote power source or transport Unit—not a recreational vehicle

Careless use or misuse can result in unnecessary accidents Be alert to hazards of tractor operation Understand causes of accidents and take every precaution to avoid them Most common accidents are caused from

·Tractor misuse.

·Improper starting procedures

·Crushing and pinching during hitching

·Collisions with other motor vehicles

·Getting entangled in PTO shafts

·Falls from tractors

Avoid accidents by taking the following precautions

Put transmission in NUETRAL AND APPLY

Downloaded from www.Manualslib.com manuals search engine

HAND BRAKE before dismounting Leaving transmission in gear with engine

stopped will NOT prevent the tractor from moving Be sure everyone is clear of tractor and attached equipment before Starting engine

Never try to get on or off a moving tractor

When tractor is left unattended place In NUETRAL, Apply hand brake lower

implements to the ground stop the engine and remove the key

Use Caution on Hillsides

Always wear seat belt with ROPS in upper position Avoid holes ditches and obstructions which cause the tractor to tip especially on hillsides Avoid sharp uphill turns

Never drive near the edge of a gully or steep embankment-it might cave in

Driving forward out of a ditch or mired condition

or up a steep slope could cause tractor to tip over rearward Back out of these situations if possible

While mechanical front wheel drive greatly increases traction it DOES NOT increase stability of the tractor With mechanical front wheel drive engaged the tractor can climb steeper slopes but it does not become more stable When this option is used extra caution is needed on slopes Compared to a 2-wheeI drive a front Wheel drive tractor maintains traction on steeper slopes increasing the possibility of a tip over

Danger of overturn increases greatly with narrow tread setting at high speed

Hitch towed loads only to drawbar. When using a chain, take up the slack slowly

Protect Against Noise

Prolonged exposure to loud noise can cause impairment or loss of hearing

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable loud noises

Shift to Low Gear on Hills

Shift to a low gear before descending a

Downloaded from www.Manualslib.com manuals search engine

steep hill to improve your control of the tractor with little or no braking Use engine braking to reduce speed before applying tractor brakes Run-away tractors often tip over Never coast downhill

When driving on icy wet or graveled surfaces reduce speed and be sure tractor is properly ballasted to avoid skidding and loss of steering control For best control engage mechanical front wheel drive(if equipped) Additional ballast may be needed for transporting heavy hitch mounted implements When implement is raised drive slowly over rough ground regardless of how much ballast is used

Keep Riders Off Machine

Only allow the operator on the machine Keep riders off Riders on machine are subject to injury such as being struck by foreign objects and being thrown off of the machine Riders also obstruct the operator’s view resulting in the machine being operated in an unsafe manner

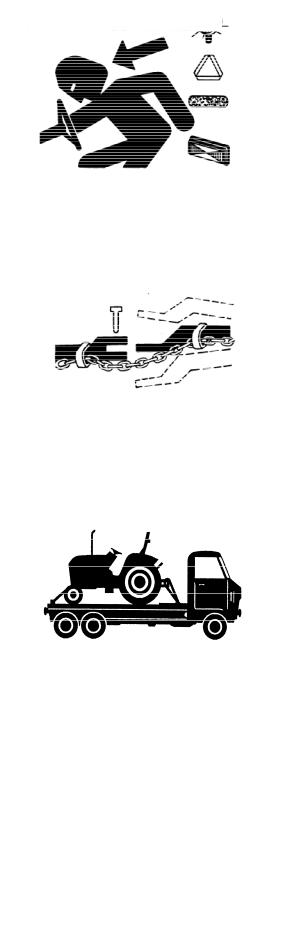

Freeing a Mired Machine

Attempting to free a mired machine can involve safety hazards such as the mired tractor tipping rearward the towing tractor overturning and the tow chain or tow bar (Actable is not recommended) failing and recoiling from its stretched condition

Back your tractor out if it gets mired down in mud Unhitch any towed implements Dig mud from behind the rear wheels Place boards behind the wheels to provide a solid base and try to back out slowly

If necessary dig mud from the front of all wheels and drive slowly ahead

If necessary to tow with another unit use a tow bar or a long chain(a cable is not recommended) Inspect the chain for flaws Make sure all parts of towing devices are of adequate size and strong enough to handle the load Always hitch to the drawbar of the towing unit Do not hitch to the front push bar attachment point Before

moving clear the area of people Apply power smoothly to take up the slack a sudden pull could snap any towing device causing it to whip or recoil dangerously

Avoid High-Pressure Fluids

Escaping fluid under pressure can penetrate the skin

5

Downloaded from www.Manualslib.com manuals search engine

causing serious injury

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines Tighten all connections before applying pressure

Search for leaks with a piece of cardboard Protect hands and body from high pressure fluids

If an accident occurs see a doctor immediately Any fluid injected into the skin must be surgically removed within a few hours or gangrene may result Doctors unfamiliar with this type of injury should reference a knowledgeable medical source

Park Tractor Safely

To park tractor safely

·Disengage PTO

·Lower equipment to the ground

·Put gear shift lever in NUETRAL

·Apply hand brake

·STOP the engine

·Remove key

Before you leave the operator's seat wait for engine and attachment parts to stop moving

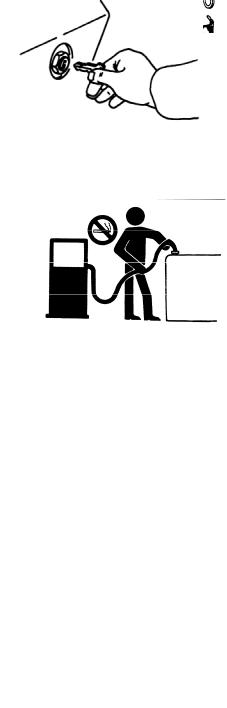

Handle Fuel Safely-Avoid Fires

Handle fuel with care it is highly flammable Do not refuel the machine while smoking or when near open flame or sparks

Always stop engine before refueling machine Fill fuel tank outdoors

Prevent fires by keeping machine clean of accumulated trash grease and debris Always clean up spilled fue1

Prepare for Emergencies

Be prepared if a fire starts

Keep a first aid kit and fire exitinguisher handy Keep emergency numbers for doctors ambulance

service hospital and fire department near your telephone

Do Not Use Starting Fluid

DO NOT use starting fluid in tractors equipped with an intake air heater system

Tractors are equipped with an intake air heater system

Wear Protective Clothing

Wear close fitting clothing and safety equipment

6

Downloaded from www.Manualslib.com manuals search engine

appropriate to the job

Prolonged exposure to loud noise can cause

Impairment or loss of hearing

Wear a suitable hearing protective device such as earmuffs or earplugs to protect against objectionable or uncomfortable Loud noises

Operating equipment safely requires the full attention of the operator Do not wear radio or music headphones while operating machine

Work In Ventilated Area

Engine exhaust fumes can cause sickness or death If it is necessary to run an engine in an enclosed area remove the exhaust fumes from the area with an exhaust pipe extension

If you do not have an exhaust pipe extension open the doors and get outside air into the area

Avoid Contact with Pesticides

Enclosed cab does not protect against inhaling harmful pesticides If pesticide use instructions require respiratory protection wear an appropriate respirator inside the cab

Before leaving the cab wear personal protective equipment as required by the pesticide use instructions

When re-entering the cab remove protective equipment and store either outside the cab in a closed box or some other type of sealable container or inside the cab in a pesticide resistant container such as a plastic bag Clean your shoes or boots to remove soil or other contaminated particles prior to entering the cab

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious Injury or death

Keep tractor master shield and driveline shields in place at all times Make sure rotating shields turn freely Wear close fitting clothing Stop the engine and be sure PTO driveline is stopped before making adjustments connections or cleaning out PTO driven equipment

7

Downloaded from www.Manualslib.com manuals search engine

Use Safety Lights and Devices

Prevent collisions between other road users slow moving tractors with attachments or towed equipment and self-propelled machines on public roads Frequently check for traffic from the rear especially in turns

and use turn signal lights

Use headlights flashing warning lights and turn Signals day and night Follow local regulations for Equipment lighting and marking Keep lighting and marking visible clean and in good working order Replace or repair lighting and marking that has been damaged or lost An implement safety lighting kit is Available from your East Wind dealer

Use a Safety Chain

A safety chain will help control drawn equipment should it accidentally separate from the drawbar

Using the appropriate adapter parts attach the chain to the tractor drawbar support or other specified anchor location Provide only enough slack in the chain to permit turning

See your East Wind dealer for a chain with a strength rating equal to or greater than the gross weight of the towed machine Do not use safety chain for towing

Safely Transporting the Tractor

A disabled tractor is best transported on a flatbed carrier Use chains to secure the tractor to the carrier

Never tow a tractor at a speed greater than 16 km/h(10mph) An operator must steer and brake the tractor under tow

Tow Loads Safely

Stopping distance increases with speed and weight of towed loads and on slopes Towed loads with or without brakes that are too heavy for the tractor or are

towed too fast can cause loss of control Consider the total weight of the equipment and its load

Observe these recommended maximum road speeds or local speed limits which may be lower

·If towed equipment does not have brakes do not travel more than 20 km h(12.5 mph ) and do not tow loads more

8

Downloaded from www.Manualslib.com manuals search engine

than 1.5 times the tractor weight

·If towed equipment has brakes do not travel more than 30 km h(25 mph)and do not tow loads more than 3 times the tractor weight

Ensure the load does not exceed the recommended weight ratio Add ballast to recommended maximum for

tractor lighten the load or get a heavier towing unit The tractor must be heavy and powerful enough with adequate braking power for the towed load Use additional caution when towing loads under adverse surface conditions when turning and on inclines

Keep ROPS Installed Properly

Make certain all parts are reinstalled correctly if the roll-over protective structure(ROPS)is loosened or removed for any reason Tighten mounting bolts to proper torque

The protection offered by ROPS will be impaired if ROPS is subjected to structural damage is involved in an overturn incident or is in any way altered by welding bending drilling or cutting A damaged ROPS should be replaced not reused

Practice Safe Maintenance

Understand service procedure before doing work Keep area clean and dry

Never lubricate service or adjust machine while it is moving Keep hands feet and clothing from power-driven parts Disengage all power and operate controls to relieve pressure Lower equipment to the ground Stop the engine Remove the key Allow machine to cool

Securely support any machine elements that must be raised for service work

Keep all parts in good condition and properly installed Fix damage immediately Replace worn or broken parts Remove any buildup of grease oil or debris

On self-propelled equipment disconnect battery ground Cable ( ) before making adjustments on electrical systems or welding on machine

On towed implements disconnect wiring harnesses from tractor before servicing electrical system components or welding on machine

Service Cooling System Safely

Explosive release of fluids from pressurized cooling system can cause serious burns

9

Downloaded from www.Manualslib.com manuals search engine

Add make-up coolant through the external container not directly to the radiator

If radiator cap must be removed do not remove when engine is hot Shut engine off and wait until cap is cool enough to touch with bare hands Slowly loosen cap to first stop to relieve pressure before removing completely

Service Tractor Safely

Do not service the tractor while it is in motion or while the engine is running

When servicing front-wheel-drive-equipped tractor with rear wheels supported off ground and rotating wheels by engine power always support front wheels in a similar manner Engaging front-wheel drive will pull rear wheels off support if front wheels are not raised

Tighten wheel hardware to correct torque as specified in Wheels Tires and Tread section Torque at intervals shown in Break-In Period and Lubrication and Maintenance sections to ensure that wheel hardware does not loosen

Reinstall protective covers removed during service

Support Machine Properly

Always lower the attachment or implement to the ground before you work on the machine If you must work on a lifted machine or attachment securely support the machine or attachment If left in a raised position hydraulically supported devices can settle or leak down

Do not support the machine on cinder blocks hollow tiles or props that may crumble under continuous load Do not work under a machine that is supported solely by a jack Follow recommended procedures in this manual

When implements or attachments are used with a tractor always follow safety precautions listed in the implement operator's manual

Remove Paint Before Welding or Heating

Avoid potentially toxic fumes and dust

Hazardous fumes can be generated when paint is heated by welding soldering or using a torch

Do all work outside or in a well ventilated area Dispose of paint and solvent properly

Remove paint before welding or heating

·lf you sand or grind paint avoid breathing the dust

10

Downloaded from www.Manualslib.com manuals search engine

Wear an approved respirator

·lf you use solvent or paint stripper remove stripper with soap and water before welding Remove solvent or paint stripper containers and other flammable material from area Allow fumes to disperse at least 15 minutes before welding or heating

Avoid Heating Near Pressurized Fluid Lines

Flammable spray can be generated by heating near pressurized fluid lines resulting in severe burns to yourself and bystanders Do not heat by welding soldering or using a torch near pressurized fluid lines or other flammable materials Pressurized

lines can be accidentally cut when heat goes beyond the Immediate flame area

Store Attachments Safely

Stored attachments such as dual wheels cage wheels and loaders can fall and cause serious injury or death Securely store attachments and implements to prevent

falling Keep playing children and bystanders away from storage area

Prevent Acid Burns

Sulfuric acid in battery electrolyte is poisonous It is strong enough to burn skin eat holes in clothing and cause blindness if splashed into eyes

Avoid the hazard by

1 Filling batteries in a well-ventilated area 2 Wearing eye protection and rubber gloves 3 Avoiding breathing fumes when electrolyte is added 4 Avoiding spilling or dripping electrolyte

5 Use proper jump start procedure If you spill acid on yourself 1.Flush your skin with water

2 Apply baking soda or lime to help neutralize the acid 3 Flush your eyes with water for 15—30 minutes

Get medical attention immediately If acid is swallowed

1 Do not induce vomiting

2 Drink large amounts of water or milk but do not exceed 2 L(2 quarts)

3 Get medical attention immediately

11

Downloaded from www.Manualslib.com manuals search engine

Service Tires Safely

Explosive separation of a tire and rim parts can cause serious injury or death

Do not attempt to mount a tire unless you have the proper equipment and experience to perform the job ’

Always maintain the correct tire pressure Do not inflate the tires above the recommended pressure Never weld or heat a wheel and tire assembly The heat can cause an increase in air pressure resulting in a tire explosion Welding can structurally weaken or deform the wheel When inflating tires use a clip—on chuck and extension hose long enough to allow you to stand to one side and NOT in front of or over the tire assembly Use a safety cage if available

Check wheels for low pressure cuts bubbles damaged rims or missing lug bolts and nuts

Dispose of Waste Properly

Improperly disposing of waste can threaten the environment and ecology Potentially harmful waste used with equipment include such items as oil fuel coolant brake fluid filters and batteries

Use leak proof containers when draining fluids Do not use food or beverage containers that may mislead someone into drinking from them

Do not pour waste onto the ground down a drain or into any water source

Air conditioning refrigerants escaping into the air can damage the Earth's atmosphere Government regulations may require a certified air conditioning service center to recover and recycle used air conditioning refrigerants Inquire on the proper way to recycle or dispose of waste from your local environmental or recycling center or from you r East Wind dealer

12

Downloaded from www.Manualslib.com manuals search engine

Chapter Work Safely Always and Safety Rules

Safety First

This warning sign alerts you about important messages involving your safety.

Read these safety rules attentively and strictly follow suggested precautions to avoid any potential danger and safeguard your health and personal safety.

Important Notices

This tractor has been designed and manufactured specifically and solely for agricultural use.

Any other application will be considered non-compatible with the use envisaged by the manufacturer who, consequently, shall not be held responsible for any damage to things or to the machine itself or for any physical injury to people deriving from the uses other

than agricultural ones. Always consider that you would assume the personal responsibility for any consequence associated with the improper use of this tractor.

The respect of the rules for tractor use, maintenance and repair given in this operation manual is an essential element qualifying the correct use of the tractor as envisaged by the Manufacturer. The tractor must be used, serviced or prepared only by those people who are well trained beforehand in the handling features and safety rules besides being specifically authorized to

13

Downloaded from www.Manualslib.com manuals search engine

operate it.

The users of the tractor are always responsible for the strict observance of general safety and accident prevention rules as well as of the traffic regulations if driving the tractor on public or open roads.

Any un-authorized and arbitrary modification made on the tractor will relieve the manufacturer of all responsibilities for any damage or injury deriving from such modification.

The Manufacturer and all the Organizations associated with its distribution network, including but not limited to national, regional or local distributors, shall decline any and all responsibilities for damages that may derive from the abnormal performance and behavior of those machine parts or components not specifically authorized by the Manufacturer of the tractor, including those used ones for the maintenance and/or repair again though they were fabricated or distributed by the Manufacturer before.

In any case, no warranty of any sort is issued or prescribed for damages deriving from abnormal behavior of those parts and/or components not authorized by the Manufacturer of the tractor.

Caution

Read the Operator’s Manual carefully before starting, using, maintaining, refueling or making other service interventions on the tractor.

Comply strictly with the safety regulation and follow the suggested precautions in order to safeguard yourselves.

Maintenance

Use genuine DF Brand parts only. Failure to do this will:

—Cost you more

—Not result in complete satisfaction.

—Seriously risk improper functioning of the tractor

The tractors were designed with the owner in mind and effort has been made to simplify maintenance.

The purpose of this handbook is to familiarize the operator with the operation and regular servicing of the tractor. Remember that the time spent on maintenance extends the life of your tractor.

Pay particular attention to the instructions covering fuel filtering, air cleaner maintenance and lubrication. Remember that badly filtered fuel results in injection system deterioration and irregular air cleaner maintenance leads to premature engine wear. Please keep in mind that the lube oil should be replaced thoroughly after every 1000 working hours, but at least once a year.

14

Downloaded from www.Manualslib.com manuals search engine

Safety Precautions

General

■Your tractor was designed with safety very much in mind. However, there is no real substitute for caution and attention in preventing accidents. Once an accident has happened, it is too late to think about what you should have done.

■Read this manual carefully before attempting to start, operate, service, refuel or carry on other operating involving you tractor. A few minutes dedicated to reading will save time and trouble later.

■Remember that your tractor was designed and produced exclusively for agricultural use. If the owner of the tractor is to use it for any other purposes, he has to get the prior authorization from the Manufacturer in advance.

■Keep a first aid tool handy.

■Do not work with loose garments that could get caught in moving parts. Check that all rotating parts connected to the power take-off shaft are properly shielded.

■This tractor has to be operated by the people who were trained on the use and maintenance of it, and they also have to be duly authorized to operate it in advance.

■Do not attempt to increase the maximum engine rpm by altering the setting of the fuel injection system.

■Do not alter the pressure relief valve settings of the different hydraulic circuits hydraulic lift and remote control valves.

■Do not operate tractor if you feel unwell or physically unfit, in which case you should stop working.

■Always operate with the cab and rollover safety frame undamaged, complete of all components and correctly installed on the tractor; periodically check fastenings for tightness and frame and structures to make sure they are free from damages consequent on accidental impacts.

Starting the Tractor

■Prior to starting the engine, check that the parking brake is on and transmission and PTO are in neutral.

■Make sure all implements are fully lowered down to ground before starting the engine.

■Make sure, before starting the engine, that all guards, shields and protections are correctly installed on your tractor.

■Do not attempt to start or drive the tractor unless sitting in the operator’s seat.

■Always make sure, before starting the tractor in motion, that there are no people or obstacle within range.

■Do not run the engine inside closed premises without adequate ventilation, as exhaust fumes are harmful to health or may even become deadly.

Tractor Operation

■Select the track width setting best suitable to work, always keeping tractor stability in mind.

■Engage clutch gradually: abrupt engagements, particularly if pulling out of a rough area, a ditch or muddy grounds, or driving over a steep gradient, may cause dangerous tractor pitching.

15

Downloaded from www.Manualslib.com manuals search engine

Immediately disengage the clutch if front wheels tend to come off the ground.

■When coasting downhill, keep a transmission gear engaged. Never disengage the clutch and never drive your tractor in neutral.

■With tractor in motion, the operator should be correctly seated on driver’s seat.

■Do not get on or off a moving tractor.

■Always press the brake pedal gently.

■Do not corner at high speed.

■Always operate the tractor at a safe speed for the type of ground being worked. When operating on rough ground, use proper caution to assure tractor stability.

■When working on sloping grounds, as for example on hillsides, drive at moderate speed, slow down the tractor particularly when steering.

■Proceed with extreme caution when driving with wheels close to the edge of a ditch or bank.

■Never carry passengers.

■When driving on public roads, be sure to respect traffic rules and regulations.

■Do not override brake and clutch pedals.

■When driving on roads, latch the brake pedals together by using the latch plate. Braking with pedals unlatched may cause side skidding of the tractor. Moreover, avoid overworking the brakes.

Towing and Transport

■To assure tractor stability at work, correctly adjust the towing attachment depending on the towed trailer or drawn implement.

■For your personal safety, trailers should not be towed unless equipped with an independent braking system.

■Always use drawbar and towing equipment to pull heavy loads and avoid in any case hooking or connecting equipment to the 3-point hitch lower links or to the top link, because even in the last case pitching danger subsists.

■When towing, never negotiate bends with a locked differential because you might not be able to steer the tractor.

Using Agricultural Implements and Machinery

■Do not connect implements or machinery requiring a higher power rating than your tractor class.

■Never stand between tractor and implement to facilitate hitching while the tractor is being back up.

■Never actuate the power take-off shaft connected to an operating machine without making sure in advance that no one is within operating range of the same machine.

Stopping the Tractor

■Never leave implements in the raised position while the tractor is stationary, lower down the farm implements before shutting the engine off.

■Before leaving the tractor seat, be sure to move transmission control lever to neutral position, disengage the power take-off shaft, get the hand brake in working status by pulling its handle

and shut the engine off at last.

16

Downloaded from www.Manualslib.com manuals search engine

Besides, when leaving tractor unattended, always remove the key from the starter switch.

■When parking, look for level grounds if any, shift into a gear and lock the hand brake. On sloping grounds, besides locking the hand brake, shift into first forward gear if heading uphill or into first reverse gear if heading downhill. For more safety, also use the specific stopping wedge (available upon request). Be sure to do so if parking your tractor with a trailer.

Tractor Maintenance

■Allow engine to cool off sufficiently before removing the radiator cap. After the engine is shut down for some time, slowly turn the cap to release pressures before removing it completely.

■Disconnect the ground cable of storage battery before starting to work on any of the electrical system parts or component.

■Before disconnecting any hydraulic line or hose, make sure the system is pressure-free.

■Hydraulic oil escaping under pressure could cause serious personal injury. Consequently, when searching for or detecting oil leaks, make sure to use adequate safety protections such as shields, goggles and gloves.

■Prior to inspect, clean, adjust or carry on maintenance of the tractor or of any other mounted or connected implement, always make sure that engine is shut down, transmission is in neutral, brake are locked, power take-off is disengaged and all other moving parts are stationary.

■Do not operate on tyres unless suitable tools and the necessary experience are available. Any wrong tire installation may seriously involve your personal safety. If any doubt subsists, call on qualified persons.

■Do not fill up the fuel tank completely when expecting to work in full sunlight as the fuel might expand and escape. In such case, promptly wipe off any fuel stain.

■Tractor fuel may be dangerous. Never refuel while engine is running, or still hot, or near an open flame or when smoking.

Chapter Technical Specifications of the Tractor

2.1Parameters of the tractor

Tractor Model |

DF254G2-6 |

DF304G2-6 |

DF354G2-6 |

DF404G2-6 |

||||

|

|

|

|

|

|

|

|

|

|

Length |

|

|

3350 |

3350 |

3453 |

3453 |

|

Overall |

|

|

|

|

|

|

|

|

Width |

|

|

1480 |

1480 |

1588 |

1588 |

||

dimensions |

|

|

|

|

|

|

|

|

|

|

To steering |

1524 |

1540 |

1500 |

1581 |

||

(mm) |

|

|

||||||

|

|

wheel |

||||||

|

Height |

|

|

|

|

|||

|

To the top of |

2220 |

2240 |

2250 |

2275 |

|||

|

|

|

||||||

|

|

|

exhaust pipe |

|||||

|

|

|

|

|

|

|

||

Wheel base (mm) |

|

|

1732 |

1732 |

1900 |

1900 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Front track |

1100 |

1100 |

1200 |

1200 |

Wheel track (mm) |

|

|

|

|

|

|

||

|

Rear track |

1100 1200 |

1100 1200 |

1200 |

1200,1300, |

|||

|

|

|

|

1300 |

1300 |

1300,1400 |

1400 |

|

|

|

|

|

|

||||

Ground clearance (mm) |

|

|

290 |

310 |

358 |

405 |

||

|

|

|

|

|

|

|

|

|

Construction mass (kg) |

|

|

1650 |

1650 |

1780 |

1780 |

||

|

|

|

|

|

|

|

||

Ballast (kg) |

|

Front wheel |

120 |

120 |

120 |

120 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17 |

|

|

|

Downloaded from www.Manualslib.com manuals search engine

|

|

|

Rear |

wheel |

112 |

160 |

160 |

160 |

|

|

|

|

(Optional) |

||||||

|

|

|

|

|

|

|

|||

Rated |

traction |

In paddy field |

4200 |

4950 |

5160 |

4970 |

|||

force (N) |

|

|

|

In dry field |

6300 |

6940 |

7230 |

7856 |

|

|

|

|

|

|

|

|

|||

Theoretic speed (km/hr) |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Gear |

|

1.40 |

1.48 |

1.35 |

1.41 |

|

|

|

|

Gear |

|

2.12 |

2.23 |

2.03 |

2.14 |

|

|

|

|

Gear |

|

3.40 |

3.58 |

3.26 |

3.43 |

|

Forward |

|

|

Gear |

|

4.92 |

5.18 |

4.73 |

4.96 |

|

|

|

Gear |

|

7.27 |

7.65 |

6.98 |

7.33 |

||

|

|

|

|||||||

|

|

|

Gear |

|

10.98 |

11.56 |

10.54 |

11.07 |

|

|

|

|

Gear |

|

17.62 |

18.54 |

16.92 |

17.76 |

|

|

|

|

Gear |

|

25.50 |

26.84 |

24.49 |

25.7 |

|

|

|

|

Gear |

|

1.41 |

1.49 |

1.36 |

1.42 |

|

|

|

|

Gear |

|

2.13 |

2.25 |

2.05 |

2.15 |

|

|

|

|

Gear |

|

3.92 |

3.60 |

3.29 |

3.45 |

|

Reverse |

|

|

Gear |

|

4.96 |

5.22 |

4.76 |

5.0 |

|

|

|

Gear |

|

7.32 |

7.71 |

7.09 |

7.38 |

||

|

|

|

|||||||

|

|

|

Gear |

|

11.06 |

11.64 |

10.62 |

11.15 |

|

|

|

|

Gear |

|

17.75 |

18.68 |

17.04 |

17.89 |

|

|

|

|

Gear |

|

25.69 |

27.03 |

24.66 |

25.89 |

|

18

Downloaded from www.Manualslib.com manuals search engine

2.2Main technical specifications of the engine

Tractor Model |

254G2-6/304G2-6 |

354G2-6/404G2-6 |

|||||

|

|

|

|

|

|

|

|

Engine Model |

|

390 |

|

490 |

|||

|

|

|

|

|

|

||

Type |

|

Vertical, Water cooling, |

Vertical, Water cooling, |

||||

|

Four-stroke |

Four-stroke |

|||||

|

|

||||||

Number of cylinders |

|

3 |

|

4 |

|||

|

|

|

|

|

|

|

|

Cylinder bore mm |

|

90 |

|

90 |

|||

|

|

|

|

|

|

|

|

Piston stroke (mm) |

|

95 |

|

100 |

|||

|

|

|

|

|

|

|

|

Piston displacement (L) |

|

1.813 |

|

2.543 |

|||

|

|

|

|

|

|

|

|

Compression ratio |

|

22 |

|

22 |

|||

|

|

|

|

|

|

|

|

Cylinder sleeve type |

|

wet |

|

wet |

|||

|

|

|

|

|

|

|

|

Rated power (kW ) |

18.4 |

|

22.4 |

25.8 |

|

29.4 |

|

|

|

|

|

|

|

|

|

Rated |

fuel consumption |

|

≤275 |

|

≤275 |

||

(g/kW. h) |

|

|

|||||

|

|

|

|

|

|

||

Rated speed (rpm) |

2400 |

|

2400 |

2400 |

|

2400 |

|

|

|

|

|

|

|

|

|

Max. Torque (N. m) |

≥89 |

|

≥96.8 |

≥117.8 |

|

≥134.5 |

|

|

|

|

|

|

|

|

|

Net weight (kg) |

|

195 |

|

200 |

|||

|

|

|

|

|

|

||

Overal |

Length |

|

587 |

|

729 |

||

l |

|

|

|

|

|

|

|

Width |

|

492 |

|

512 |

|||

dimens |

|

|

|||||

|

|

|

|

|

|

|

|

ions |

Height |

|

650 |

|

650 |

||

(mm) |

|

|

|||||

|

|

|

|

|

|

|

|

2.3Drive system

Tractor |

DF/254G2-6/304G2-6/354G2-6/404G2-6 |

|

Model |

||

|

||

Clutch |

Linkage type, double-acting clutch |

|

|

|

|

Gearbox |

(4+1)×2 , planar 3-shaft for main transmission, epicyclic gearing for |

|

Hi-Lo speed range transmission |

||

|

||

Main drive |

One pair of spiral bevel gears |

|

|

|

|

Differential |

Bevel gear |

|

|

|

|

Final |

Spur gear, external gearing |

|

transmissions |

19

Downloaded from www.Manualslib.com manuals search engine

2.4Traveling and Steering System

|

|

Tractor Model |

|

|

DF254G2-6/304G2-6 |

|

DF354G2-6/404G2-6 |

|||||

|

|

|

|

|

|

|

|

|

|

|||

Front wheel drive axle |

|

|

|

Bevel gear drive axle |

||||||||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Front wheel toe-in (mm) |

|

|

|

|

5 10 |

|

|

|||

Front |

|

|

|

|

|

|

|

|

|

|

|

|

|

Outward camber |

|

|

|

|

|

3.5° |

|

|

|||

axle |

|

|

|

|

|

|

|

|

|

|

|

|

|

King pin caster |

|

|

|

|

|

0° |

|

|

|||

aligning |

|

|

|

|

|

|

|

|

||||

|

|

King pin inclination |

|

|

|

|

7.5° |

|

|

|||

|

|

|

|

|

|

|

|

|

||||

Steering gear |

|

|

|

Full hydraulic steering gear |

||||||||

|

|

|

|

|

|

|

|

|

|

|||

Brake |

|

|

|

|

|

|

Disc brake |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Traveling wheel |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|||||

Specifications of front |

|

6.00-16 |

|

6.5-16 |

6.50-16 |

|

7.5-16 |

|||||

tyre |

|

|

|

|

|

|

|

|

|

|

|

|

Air pressure of front tyre |

|

|

|

|

160 200 kPa (1.6 2 kg/cm2) |

|||||||

Specification of front tyre |

|

28x9-15 |

|

10-16.5 |

|

|

||||||

Optional against order) |

|

Industrial tyre) |

Industrial tyre) |

|||||||||

Air pressure of front tyre |

|

|

|

|

300 340 kPa(3 3.4 kg/cm2) |

|||||||

Specification of front tyre |

|

26×7.5-12-4 |

|

7.5-16 |

|

|

||||||

(Optional |

against order) |

|

|

|

|

|||||||

|

|

(Turf tyre) |

(Turf tyre) |

|

|

|||||||

(Turf tyre) |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||

Air pressure of front tyre |

|

|

|

|

160 180 kPa |

|

|

|||||

|

|

|

|

|

|

|||||||

Specification of rear tyre |

|

9.5-24 |

|

11.2-24 |

11.2-24 |

|

12.4-24 |

|||||

|

|

|

|

|

|

|||||||

Air pressure of rear tyre |

|

100 150 kPa (1 1.5 kg/cm2) |

100 150 kPa (1 1.5 kg/cm2) |

|||||||||

Specification of rear tyre |

|

8.3-24(Stripe pa |

9.5-24 |

12.4-24 |

|

11.2-24 |

||||||

(Optional against order) |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|||

Air pressure of rear tyre |

|

100 150 kPa (1 1.5 kg/cm2) |

|

|

|

|

|

|||||

Specification of rear tyre |

|

15-19.5NHS |

16.5-22.5NHS |

|||||||||

(Optional against order) |

|

(Industrial |

|

tyre) |

(Industrial |

tyre) |

||||||

Air pressure of rear tyre |

|

|

|

|

260 310 kPa |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

||

Specification of rear tyre |

|

11.2-20-4(Turf tyre) |

12.4-24(Turf tyre) |

|||||||||

(Optional against order) |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|||

Air pressure of rear tyre |

|

|

|

|

100 130 kPa(1 1.3 kg/cm2) |

|||||||

2.5 |

Working devices |

|

|

|

|

|

|

|

|

|

|

|

Tractor Model |

254G2-6/304G2-6 |

354G2-6/404G2-6 |

||

|

|

|

|

|

|

|

|

Pump type |

CBN-E310B |

||

|

|

HLCB-D04/04F1BR |

|||

|

|

|

|||

Hydraulic |

Plowing-depth control |

Predetermined and simple adjusting |

|||

|

|

|

|||

system |

|

|

|

|

|

|

Theoretic flow |

10ml/r |

|

|

|

|

|

|

|

||

|

|

4ml/r hydraulic steering |

|||

|

|

|

|||

|

|

Response pressure of the safety valve |

14ml/r |

|

16 MPa |

|

|

|

|

|

|

Mounting system |

Rear mounted ball socket type |

||||

|

(GB /T1593.1-1996) |

||||

|

|

|

|

||

|

20 |

|

|

|

|

Downloaded from www.Manualslib.com manuals search engine

Max. lifting weight at the point of 610 mm |

4960 N |

|

6650N |

||

beyond the mounting point |

|

||||

|

|

|

|||

Lifting time |

|

|

≤3 s |

||

|

|

|

|

||

Pin hole diameter of uppermounting point |

|

19.5 mm |

|||

|

|

|

|

||

Pin hole diameter of bottommounting point |

|

22.5 mm |

|||

|

|

|

|

|

|

Traction |

|

Hitch pin diameter |

|

30 mm |

|

device |

|

Ground clearance of drawbar frame |

|

390 |

|

|

|

|

|

|

|

|

|

Type |

|

Linkage |

|

|

|

|

|

||

|

|

Rotating speed |

540 rpm and 1000 rpm |

||

PTO shaft |

|

|

|

||

|

Spline size |

6-tooth Ø35 Rectangular spline |

|||

|

|

|

|

|

|

|

|

Rotating direction |

|

Clockwise |

|

|

|

(face to PTO shaft) |

|

||

|

|

|

|

|

|

2.6Electric apparatus and instrument

Tractor Model |

254G2-6/304G2-6/354G2-6/404G2-6 |

|||||

|

|

|

|

|

|

|

Electric circuit |

|

|

|

|

12V Single phase & negative ground |

|

|

|

|

|

|

|

|

Battery |

|

|

6-QW-80L 80Ah |

|

||

|

|

|

|

|

|

|

Starter |

|

|

QD1332C |

|

||

|

|

|

|

|

|

|

Generator |

|

|

JF11 350 W |

|

||

|

|

|

|

|

|

|

Preheat plug |

|

|

10-12-55 12 V |

|

||

|

|

|

|

|

|

|

Measuring |

|

Tachometer |

|

|

0 3000r/min |

|

range of |

|

|

|

|

|

Combination |

|

Water thermometer |

|

|

40 120 |

||

combination |

|

|

|

meter |

||

|

|

|

|

|

||

|

Oil pressure gauge |

|

|

0 1MPa |

||

meter |

|

|

|

|

||

|

|

|

|

|

|

|

|

Fuel gauge |

0 |

1 |

1(Fuel tank capacity) |

|

|

|

|

|

||||

|

|

|

|

|||

|

|

|

2 |

|

|

|

Electric switch |

|

|

|

|

JK406B |

|

|

|

|

|

|

|

|

Horn button |

|

|

|

|

JK938A |

|

|

|

|

|

|

|

|

Turning indicator switch |

|

|

JK938A |

|

||

|

|

|

|

|

|

|

Lamp switch* |

|

|

|

|

JK938A |

|

|

|

|

|

|

|

|

Braking lamp switch |

|

|

|

|

JK231B |

|

|

|

|

|

|

|

|

Klaxon horn |

|

|

|

|

DL-124D |

|

|

|

|

|

|

|

|

Fuse block |

|

|

|

|

AX102 |

|

|

|

|

|

|

|

|

Voltage regulator |

|

|

|

|

FT111 |

|

|

|

|

|

|

|

|

Flasher |

|

|

|

|

SG152 |

|

|

|

|

|

|

|

|

Socket for trailer |

|

|

|

|

QLCZ-1 |

|

|

|

|

|

|

|

|

Headlamp |

|

|

|

|

60/55 W |

White color |

|

|

|

|

|

|

|

Front signal |

Marker lamp |

|

|

10W |

Orange color |

|

lamp |

Turning indicator lamp |

|

|

21 W |

Orange color |

|

|

|

|

|

|

|

|

Rear |

Brake indicator lamp |

|

|

21 W |

Red color |

|

combination |

Marker lamp |

|

|

10 W |

Orange color |

|

light |

|

|

|

|

|

|

Turning indicator lamp |

|

|

21 W |

Orange color |

||

|

|

|

||||

|

|

|

|

|

|

|

Rear working light |

|

|

|

|

50 W |

White color |

|

|

|

|

|

|

|

Caution light |

|

|

|

|

10W |

Orange color |

|

|

|

|

|

|

|

|

|

|

21 |

|

|

|

Downloaded from www.Manualslib.com manuals search engine

Loading...

Loading...