DongFeng DFA1101GZ5AD6J-907 Service Manual

DFA1101GZ5AD6J-907

SERVICE MANUAL

DONGFENG AUTOMOBILE CO.,LTD

2006.05

INDEX

General Principles

Clutch

Gearbox

Propeller Shaft

Steering System

Front Axle

Rear Axle

Suspension System

Brake System

Cab

Electric System

General Principles

GL

Table of Conntents

General Principles...........................................................................................GL-1

Operational Instruction ...................................................................................GL-2

Standard Terms...............................................................................................GL-2

Standard Tightening Torque...........................................................................GL-2

Maintenance Rule ...........................................................................................GL-3

Recommended Fuel and Lubricant.................................................................GL-6

Protective Measures while Repairing .............................................................GL-8

Cleaning..........................................................................................................GL-9

Generic Inspection..........................................................................................GL-9

Trouble Analysis...........................................................................................GL-10

General Principles

General Principles

This manual mainly states maintenance and service methods of DFA1101GZ5AD6J-907 light commercial

truck.

To use vehicles safely and efficiently, you need to read the manual thoroughly and make sure that you are

familiar with the items that mark "Note". This is very important.

Due to continuous improvements on our vehicles, maybe there are some instructions in the manual that do

not accord with the actual vehicles.

Maintenance method varies with different skill level, methods, tools and available parts that serviceman

adopts. Any serviceman should firstly take into consideration no harm personal safety and vehicle safety when

working.

As for the maintenance of engine, please refer to service documents offered by DongFeng Cummins Engine

Co., Ltd.

GL-1

General Principles

Operational Instruction

You can neglect the structural differences between the part in the

manual and the corresponding one of your vehicle, because the manual

is just teaching you principles for your operation.

Standard Terms

Vehicle direction

Vehhicle direction referred in the manual is marked as the right

picture.

Maintenance standard

The matching clearance or standard performance parameter of

components while assembled.

Reparation limit

It means that the component size or component clearance after

repairing must satisfy the specified repair limit;

Wear limit

It means that if a component is overworn or exceeds its wear

limit, it must be replaced;

Unit

Legal measure units are used in this manual.

Standard Tightening Torque

To assure the safety and reliability of key vehicle parts, this

manual makes specific prescriptions to the tightening torque of the

bolts and other fasteners on those parts. As for the bolts and other

fasteners not mentioned, the structures and the sizes of them have been

standardized and they should be fastened with screwing torques

prescribed in the following table.

M6 M8 M10 M12 M14 M16 M18 M20

Ordinary car-

bon steel

High-strength

alloy steel

5~8 16~23 29~42 50~70 80~110 130~170 160~200 260~320

9~12 18~26 34~48 67~95 120~170 165~220 200~250 320~400

GL-2

General Principles

Maintenance Rule

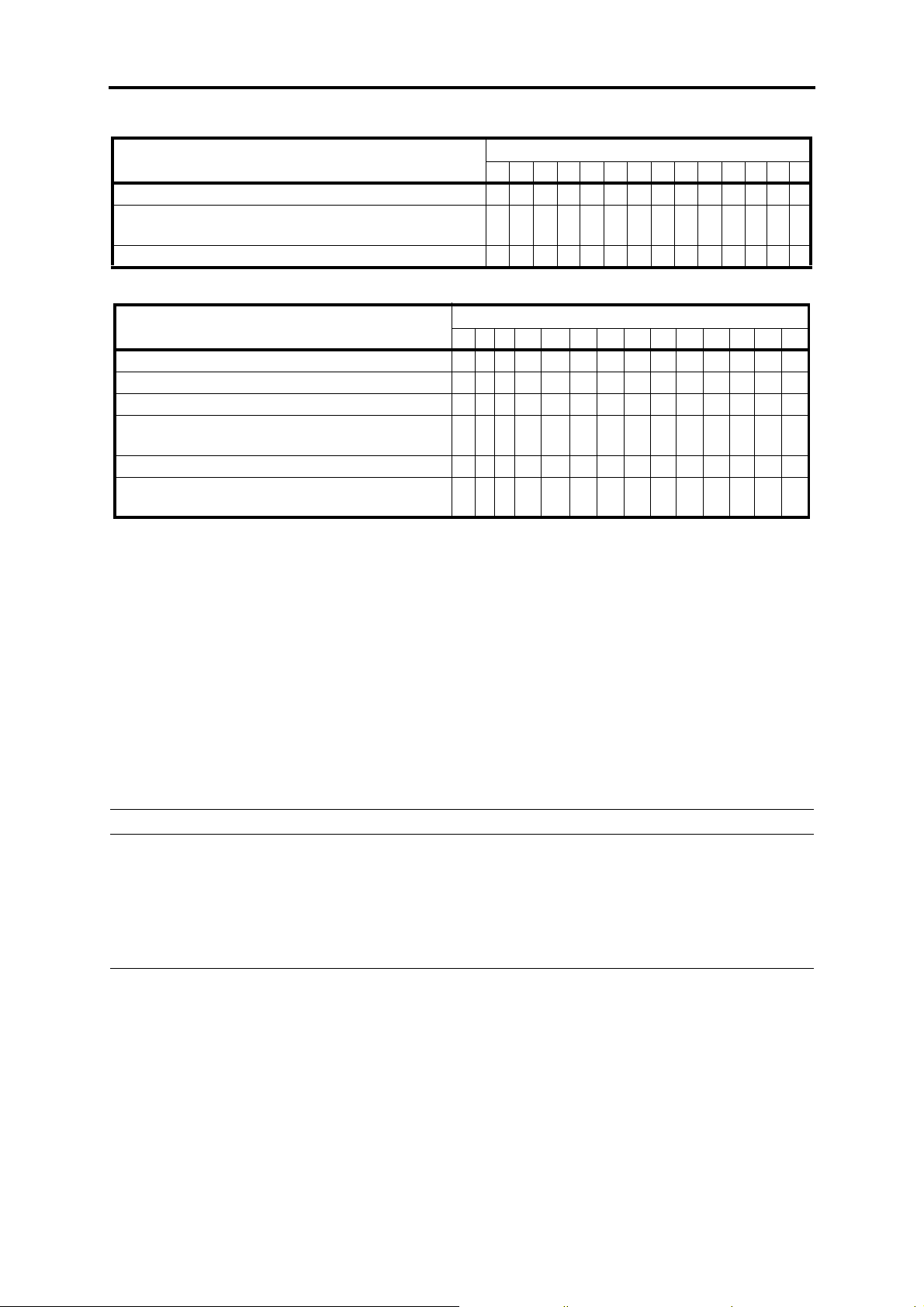

Maintenance Schedule

It's necessary for periodical inspection and maintenance of truck to prolong its service life, improve its power

performance and fuel economy, so periodical inspection and maintenance should be carefully carried out according to the following items. Then it will achieve the max economic and social benefits.

The following schedule is not only for maintenance items of 80,000km, but also for normal maintenance

items after 80,000Km.

△—maintenance mileage at running-in period (1,500~2,500km)

☆—maintenance items at running-in period

★—maintenance items at regular driving period

Note:

Customers should carry out the inspection and maintenance intervals according to the different area

condition. Properly shorten the maintenance intervals can ensure the truck to get the reasonable maintenance and

move reliability. Never prolong the intervals.

Dong Feng Cummins Diesel Engine

Maintenance Item

Clean engine assembly

Check acceleration capability and decelerability

Check exhaust status

Check the leakage of eninge lubricant

Check the cleanness and reserves of lubricant

Check the leakage of fuel

Check the leakage in cooling system

Check the damage of fan belt

Remove the deposit in fuel prefilter

Check and clean air filter element

Replace engine lubricant

Replace oil filter

Check and adjust valve clearance

Replace fule filter and oil & water seperator

Replace air filter element

Check the compression pressure in cylinder

Check the injection pressure of injector

Check injection timing

Check the injection volume of injection pump

Check the working conditions of delivery pump

Check the working conditions of thermostat

Check the working conditions of radiator

Clean the cooling system of engine

Check the working conditions of supercharger,

replace while necessary

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

★★★ ★★★★★★★★★

☆★★★ ★★★★★★★★★

☆★★★ ★★★★★★★★★

☆★★★ ★★★★★★★★★

★★★ ★★★★★★★★★

☆★★★ ★★★★★★★★★

☆★★★ ★★★★★★★★★

☆★★★ ★★★★★★★★★

☆★★★ ★★★★★★★★★

☆★ ★ ★ ★ ★ ★

☆★ ★ ★ ★ ★ ★

☆★ ★ ★ ★ ★ ★

☆★★★★

★★★★

★★

★

★

★

★

★

★

★

★

★★

GL-3

Clutch

General Principles

Maintenance Item

Check the working conditions of clutch

Check the free travel of clutch pedal

Check the leakage of the hydraulic pipeline and

clutch pump

Check the air leakage of clutch booster

Check the reserve of braking fluid in oil reservoir

Replace clutch braking fluid

Propeller Shaft

Maintenance Item

Check the looseness of the linking parts of propeller

shaft

Check the looseness of spider bearing

Check the looseness of middle bearing

Check the wearing conditions of spline

Gearbox

Maintenance Item

Clean gearbox and vent plug

Check the oil reserves in gearbox

Check oil leakage of gearbox

Replace gearbox lubricant

Check the looseness of the linking parts of the control mechanism

Check the working conditions of the bearings in

gearbox

Disassemble and check gearbox

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

★

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★ ★ ★ ★

☆★

☆★

★

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

☆★★

☆★★

★

★

Suspension System

Maintenance Item

Check the leakage of shock absorber and fasten the

bolts of brackets

Clean front and rear leaf spring and shock absorber

Fasten U bolt of leaf spring when fully loaded

Check the damage and looseness of shock absorber

Check the wearing of pin sleeve of rear leaf spring,

replace while necessary

Check if shock absorber is out of service

Disassemble leaf spring, replace spring pin and pin

sleeve

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★★★★★★★ ★ ★ ★★★

★★★★★★★ ★ ★ ★★★

☆★ ★ ★ ★

★★★★

★

★

★

GL-4

Axle and Wheel

General Principles

Maintenance Item

Clean alxes and wheels

Check the oil leakage of final drive

Check the fastening conditions of important

bolts

Check the pressure in tyres

Check the abnormal wearing of wheels

Check lubricant reserves of final drive, clean

vent plug

Clean and adjust hub bearings

Replace the lubricant of final drive

Wheel changing

Check the working conditions of final drive and

the bearings

Disassemble and check final drive and adjust it

Make megnatic examination for axle shaft tube

Steering system

Maintenance Item

Check the oil leakage of steering gear

Clean steering gear

Check free travel and working conditions of hand

wheel

Check the fastening conditions of the ball heads of

steering cross rod and tie rod

Check fastening conditions of steering mechanism

and its brackets

Check fastening conditions of steering arm and steering knuckle arm

Check and adjust front wheel toe-in

Check front wheel alignment

Check and adjust steering gear

Disassemble and check the connectors of steering

cross rod and tie rod

Make magnetic examinations for steering knuckle

Replace the ball head pins in steering system

Check power steeering oil reserves, add while necessary

Replace power steering transmission oil

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

★★★★★★★★★★★★

☆★★★ ★★★★★★★★★

☆★★★ ★★★★★

☆★★★ ★★★★★★★★★

★★★★★★★★★★★★

★★★★

★★★★

☆★★

★★★★

★

★

★

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★

★★★★ ★ ★ ★ ★ ★ ★ ★ ★

☆★ ★ ★ ★

☆★ ★ ★ ★

☆★ ★ ★ ★

☆★ ★ ★ ★

☆★ ★ ★ ★

★

★

★

★

★

☆★★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★

★★

Braking System

Maintenance Item

Check the free travel of brake pedal

Check parking brake and its efficiency

Check the air leakage of braking pipeline

Check and adjust the clearance between brake drum and

friction disc

GL-5

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★

☆★★★★★★★★★★★★★

Braking System

General Principles

Maintenance Item

Check the fastening conditions of brake back plate

Check the wearing of brake drum and shoe, replace while

necessary

Check the working conditions of air compressor

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★★★★

★★

★

Other

Maintenance Item

Check battery liquid reserves, add while necessry

Check the proportion of battery liquid

Check the looseness of the rivets in chassis frame

Check the efficency of locking device of tilting

mechanism

Check the looseness of linking parts of cabin

Check the looseness and damage of cross and side

members of cargo body and the linking parts

Maintenance Mileage Interval( × 1,000km)

4 8 12 16 20 24 28 32 36 40 44 48 80

△

☆★★★ ★ ★ ★ ★ ★ ★ ★ ★ ★

★★★★

★★

★★

☆★★★ ★ ★ ★ ★ ★ ★ ★ ★ ★ ★

★★

Recommended Fuel and Lubricant

The quality of fuel and lubricant can effect the performances, quality and even life of vehicles. Therefor, to

ensure normal operations of vehicles, suitable oil products should be used according to relative prescriptions.

Dong Feng Automobile Co., Ltd. prescribes the most suitable fue and lubricants for its products. The foll-

wing are the fuel and lubricants that should be used in our products.

Fuel

Qualified light diesel in accord with GB252-87 Standard should be used. Users can choose specific class of

light diesel according to the specific temperature in his region.

Recommended temperature scope:

Class Recommended Temperature

0# light diesel

10# light diesel

20# light diesel

35# light diesel

50# light diesel

above 4 ℃

above -5 ℃

between -5 ℃ ~ -14 ℃

between -14 ℃ ~ -29 ℃

between -29 ℃ ~ -44 ℃

Engine lubricant

High-quality lubricant meeting following standards must be used for Dong Feng Cummins engines:

Lowest standard: CF-4/SG 15W-40

Recommended Standard:CG-4/SH 15W-40

Ideal standard: CH-4/SJ 15W-40

Note:

Engine damages for using lubricants below CD15W-40 or CE15W-40 or even lower are not in our warranty

scope.

GL-6

General Principles

Suitable temperature scope:

For 15W-40: -10 ℃ ~-15 ℃; For 10W: -5 ℃ ~-20 ℃ ; For 5W-30: below -25 ℃

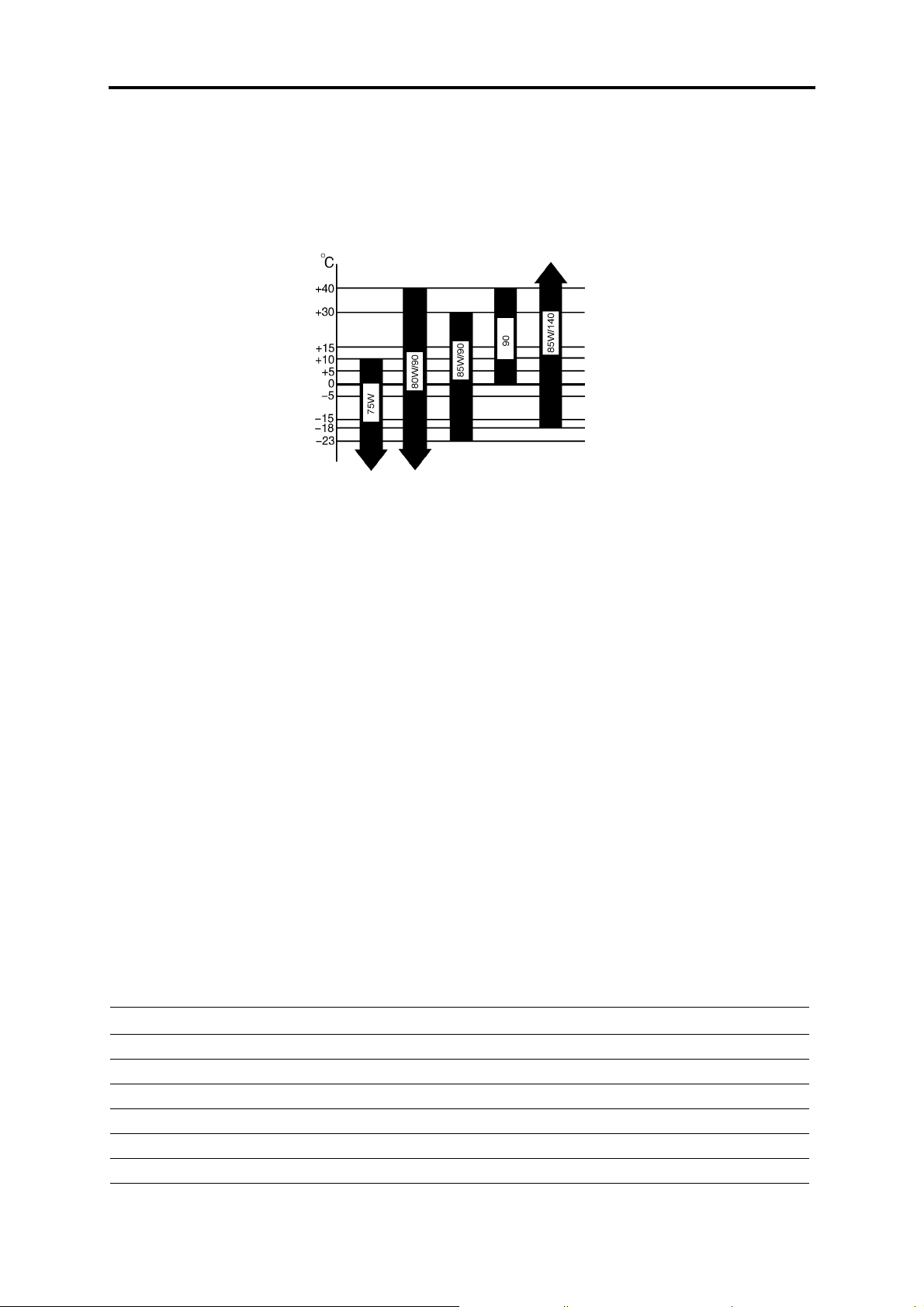

Lubricant for gears in driving axle

Recommend to use sulfur-phosphor API GL-5 gear lubricant for heavy duty vehicle. Applicable

environment temperatures for different classes are as follow:

Gearbox oil

Recommend to use sulfur-phosphor 85W/90 GL-4 gear lubricant for middle duty vehicle.

Lubricating grease

Recommend to use generally-used lithium grease for the lubricating points on hubs and chassis frame.

Shock absorber oil

Recommend to use specially-used shock absorber oil.

Clutch boosting liquid

Recommend to use DOT 4compounded braking liquid. Different classes of braking liquid can not be used

together.

Note:

Braking liquid made by different manufacturers can not be used together.

Engine antifreeze liquid (coolant)

Recommend to use long-term antirust & antifreeze liquid. The freeze point of the antifreeze liquid used

should be 8 ℃ lower than the minimum local temperature. Different classes of antifreeze liquid can not be used

together.

Volume Data

Part

Fuel tank 102

Engine lubrication system 9

Engine cooling system 14.5

Gearbox 4.2

Rear axle Add till the oil overflow from the inspection hole

Clutch Add to the scale of "MAX" of clutch oil reservoir

GL-7

Vo l u m e (L)

Volume Data

General Principles

Part

Power steering gear Add between the upper and lower scale of oil tank

Vo l u m e (L)

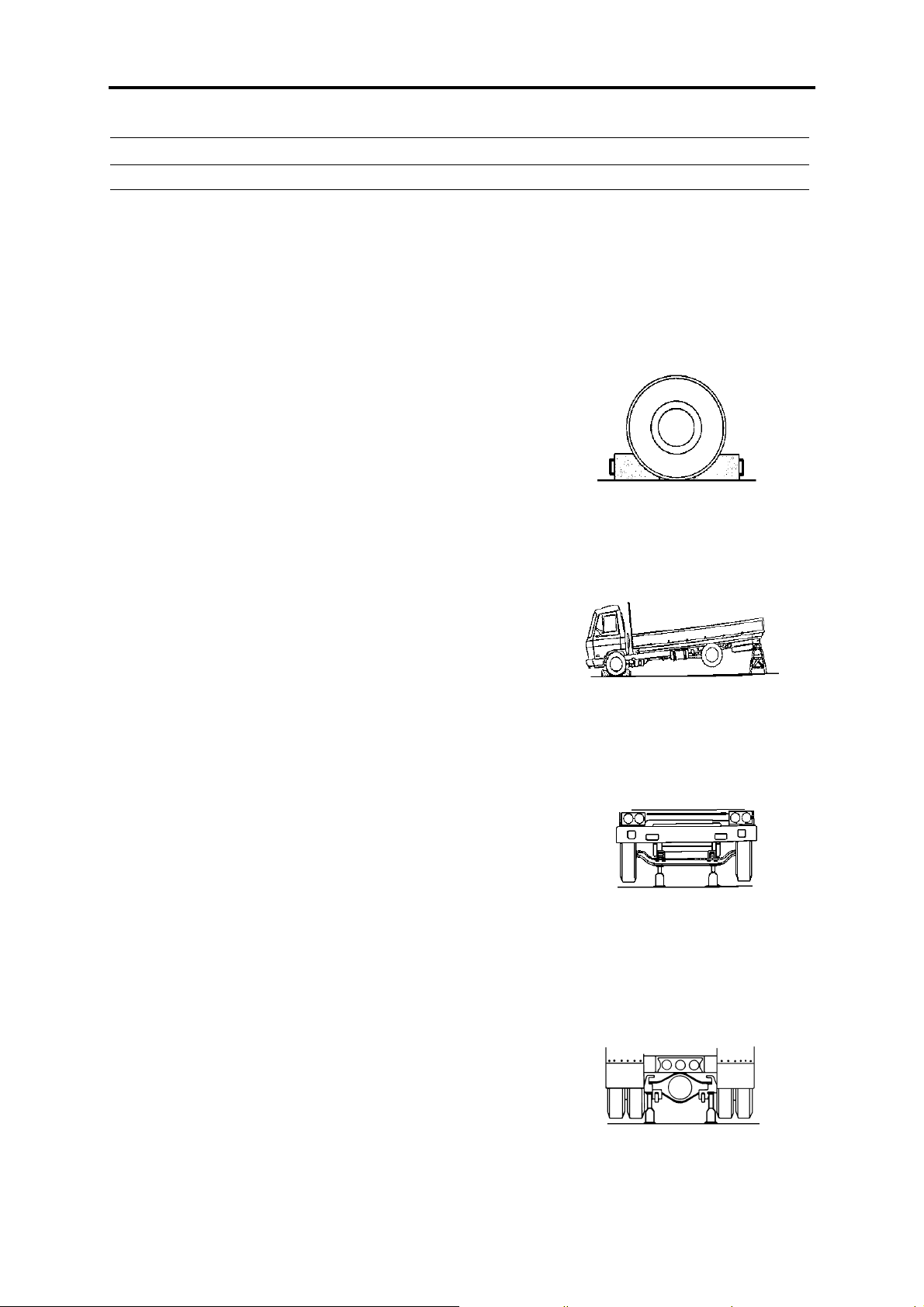

Protective Measures while Repairing

To assure safety in repairing, the following protective measures

should be taken all the way:

1) Before reparation, you should ensure that the wheels can not

turn. The measure to lock wheels is as the sketch map.

2) Ensure that the gearbox is at neutral position.

3) Ensure that the ignition switch is at "off" postion.

4) When repairing electric circuit, the negative pole should be

disconnected.

5) The jacks and brackets used should be strong enough for the

load acting on them.

Method of mounting brackets is as the sketch map.

The supporting points of front axle for mounting jacks is as the

sketch map.

The supporting points of rear axle for mounting jacks is as the

sketch map.

6) When disassemble or assemble the assemblies that have been

taken down, you should ensure that they are on a solid worktable to

avoid they would drop or turn over.

GL-8

General Principles

Cleaning

Because the parts may be covered by dirty oil and mud, cleaning is compulsive.

Applicable cleaning methods include steam cleaning, pressure cleaning, light oil cleaning, acid or alkali

cleaning, neutral medium cleaning, trichlorethylene steam cleaning, Magnus solution cleaning, etc. Part damages

may be revealed during the cleaning, so great attention should be paid while cleaning.

Metal parts

Light oil: in contrast with other solutions, light oil can't penetrate or dissolve mud. Therefore, except for

finished surface, mud should be removed by wire brush or other tools and should be cleaned in this way for two

times.

Alkali solution: if the parts are made of alloy, don't use alkali solutions for the cleaning. Instead, alkali

solutions are very effective for the cleaning of steel and cast iron.

Note:

If alkali solutions are being used, you should make some correctives such as boric acid solution. Once your

eyes or skin touch the alkali solution, you should use the corrective to clean.

Rubber parts

Don't use mineral oil for the cleaning. Use alcohol or clean cloth to remove the mud.

Oil duct

Make a metal wire to get through the oil duct to ensure it is not jammed. Wash the oil duct with cleaning

solution with high-pressure nozzle.

Antirust

After removing the oil grease on the parts, clean grease should be applied to prevent the rusting of the parts.

General Inspection

Check parts and components with special gauges or tools. Decide whether a component can continue to

serve according to specified maintenance standards. Damaged components should be repaired or replaced as

required. If one of a pair of components fitted together is worn so much that the fit clearance exceeds the specified

range, replace the pair of components together.

Out of consideration of preventive maintenance, some components should be replaced before them reaching

service limit.

Carefully inspect the surface of components by outlook or red check method. Repair or replace the component if its surface has the following abnormal signs: uneven wear, biased wear, scratch, crack, distortion, malfunction or becoming weak (spring), bended, loose, abnormal noise (bearing), distortion, malfunction or becoming

weak (spring), bended, loose, abnormal noise (bearing), discolored, seized, eroded, deteriorate (friction lining),

etc.

All the rubber pieces, such as O-rings, oil seals and washers cannot be further used after disassembled.

GL-9

General Principles

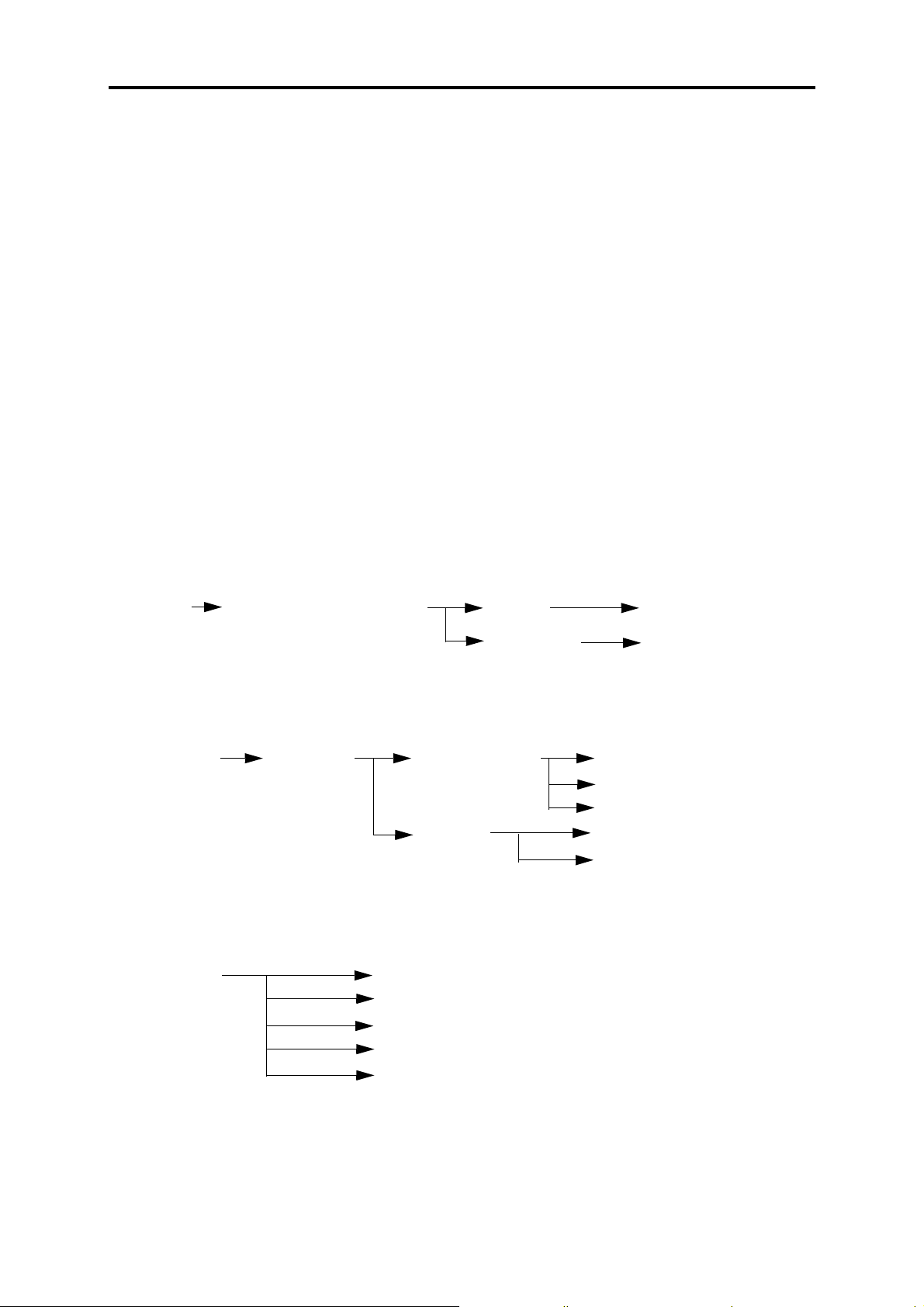

Trouble Analysis

In a vehicle, a part is made up of many components. Some parts like clutch, transmission and rear axle are

interactive functioning. Therefore, in order to find and examine trouble exactly, it is necessary to know the structure of each part as well as the functional connection between various parts.

To resolve a problem of the vehicle, you must first know the nature of the trouble. To achieve this, you must

get some exact knowledge of the trouble from the customer, including the parts that effect using conditions and

the date of the happening of the trouble.

A trouble may be caused by one or many reasons in most cases. Therefore, to examine and repair requires

the ability of systematic thinking and resolving problems step by step. For example, when the steering wheel turns

unstable, you should first examine the connection mechanism of the pitman arm instead of disassembling the

steering gear rashly, then decide whether the trouble belongs to the steering gear or to the connection mechanism.

When disassembling the part to find the cause of the trouble, proceed systematically and start from easy

problem.

It is a very important way to find out the cause of the trouble according to the manifestation of the trouble

such as abnormal noise, vibration and failure. Listed below are some common trouble signs and their reasons. As

for the detailed trouble analysis, please refer to chapter of each assembly.

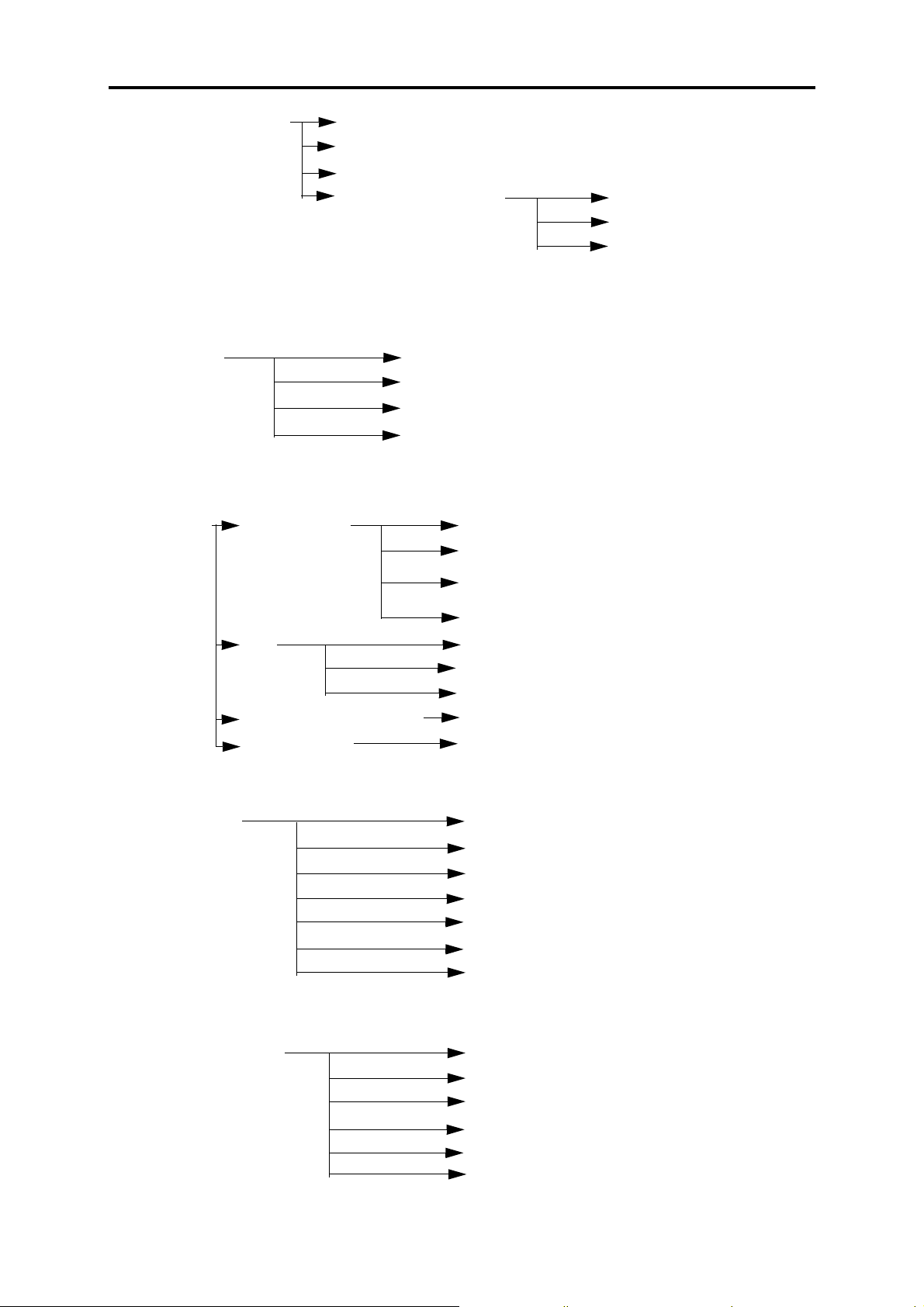

1. During starting of the engine (neutral position)

Engine can

not start

Listen to the sound of the gear of the

gear of the starter Folo-tru drive

No sound Trouble in starting system

Having sound Engine troubled

2. After engine started

Abnormal sound Engage a gear Sound does not stop Clutch cover troubled

Engine troubled

Exhaust system troubled

Sound stops Clutch driven disc troubled

Transmission troubled

3. During starting of vehicle

Abnormal sound Clutch troubled

Transmission troubled

Propeller shaft troubled

Rear axle troubled

Engine drive belt slipped

GL-10

General Principles

Unstable running of vehicle Engine troubled

Incomplete release of parking brake

Incomplete release of brake

Bumpy running of vehicle Clutch troubled

4. During vehicle running

Poor acceleration Clutch slipped

Incomplete release of brake

Incomplete release of parking brake

Engine fuel system troubled

Overload of propeller shaft

Engine rubber mounting failed

Abnormal noise Continuous noise Transmission troubled (oil insufficient or deteriorate)

Reductor gear troubled (oil insufficient or deteriorate)

Wheel hub bearing troubled (grease insufficient or

improper)

Over-low tyre pressure

Noise Transmission troubled

Reductor gear troubled

Propeller troubled

Noise when run on road bend Differential gear troubled

Noise when brake Brake troubled

Too heavy vibration Front and rear leaf spring troubled

Shock absorber troubled

Propeller shaft troubled

Engine troubled

Uneven wear of tyre or imbalance of tyres

Engine mounting troubled

Cab mounting troubled

Unstable running (straight) Incorrect front wheel alignment

Front axle troubled

Suspension spring troubled

Steering system troubled

incomplete release of brake

Uneven tyre pressure

GL-11

General Principles

Abnormal steering operation Heavy steering Steering system troubled

Incorrect front wheel alignment

Front axle troubled

Over low pressure of front wheel

Turning wheels not return Steering system troubled

Incorrect front wheel alignment

Front axle troubled

Insufficient steering angle Steering system troubled

Front axle troubled

Abnormal gear shift Difficult gear shift Abnormal clutch disengagement

Transmission troubled

Transmission handling mechanism troubled

Gear disengaged Transmission troubled

Transmission handling mechanism troubled

Abnormal braking operation Weak braking Brake system troubled

Overwear of tyres

Hub bearing clearance too large

Brake can't be released completely Brake system troubled

Hub bearing clearance too large

GL-12

Clutch

CL

Table of Contents

Main Parameter............................................................................................... CL-1

Trouble Analysis............................................................................................. CL-2

Clutch Mechanical System ............................................................................. CL-3

Adjustment of Clutch Pedal............................................................................ CL-4

Clutch Cover and Flywheel ............................................................................ CL-6

Usage and Maintenance.................................................................................. CL-7

Clutch

Clutch

Main Parameter

Distributing diameter (mm)

Bolt install hole size

Positioning pin hole size

Angle between positioning hole and installing bolt hole

Friction lining size D×d

Working pressure force 10250

Release bearing stroke (mm) 10

Pressure plate lift range (mm)

Height of release finger (mm) 56±1

Unbalance static of the cover assembly (g.cm)

Unbalance static of the driven disc assembly (g.cm)

Torque (N.m) Max=770

Note:

The DOT4 compound brake fluid is recommended to the clutch.

Unclean or dirty brake fluid is forbidden to use.

Do not splash the brake fluid down to the paint. (It may erode the paint.)

You must make use of the tools to disassemble and assemble the clutch pipeline system.

Make use of the clean brake fluid to clean the master cylinder, booster and the fluid reservior.

The mining oil such as gasoline, kerosene, etc, it will erode the rubber parts in the hydraulic pressure system.

After clean the clutch pressure plate, dry it with the suction cleaner, not the compression air.

Aperture (mm)

Number of holes 8 (4 pairs)

Distributing diameter (mm)

Aperture (mm)

Number of holes 2

Φ 368.3

Φ 10.3 (+0.25)

Φ 363.53

Φ 7.92 (0.03)

Φ 9.52 (+0.03)

15°

Φ 325× Φ 200

≥ 1.4

≤ 50

≤ 25

CL-1

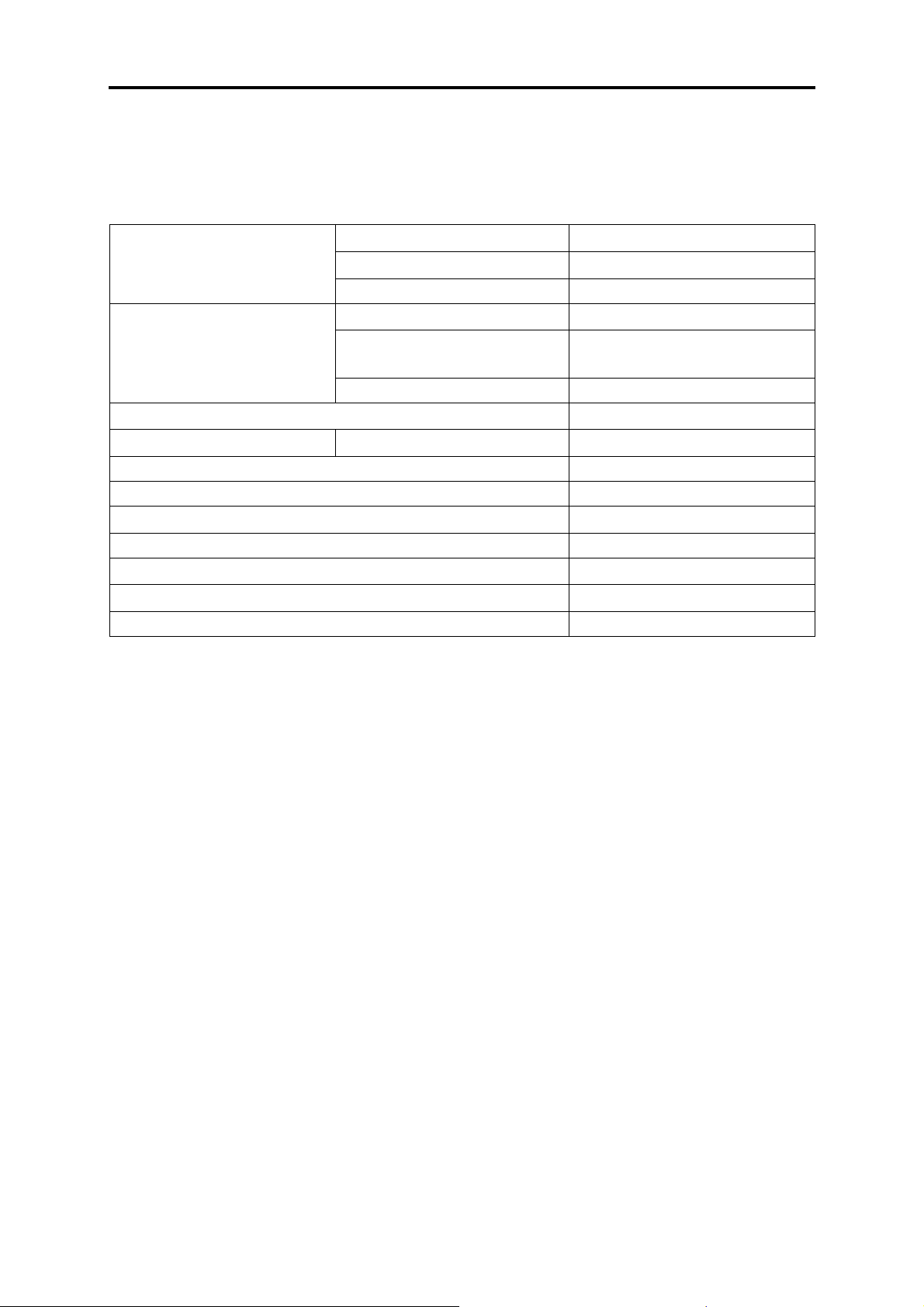

Trouble Cause Method

Clutch disengaged incomplete or vehicle started

unstably

Clutch slipped

Abnormal sound of clutch

Clutch pedal can't be

stepped down

Changes in clutch pedal

Too large clutch pedal

force

Clutch

Trouble Analysis

Clutch pressure plate or driven disc lining distorted or cracked

Release lever improper adjusted

Air in clutch hydraulic pressure controlling system pipe

Too large clutch pedal free travel

Clutch master cylinder or booster

worked abnormally

Clutchdriven disc friction lining or

pressure plate worn

Oil stain on clutch driven disc or

pressure plate

Too small clutch pedal free travel

Clutch booster push rod has no free

stroke.

Clutch booster push rod can't return.

Clutch pressure plate spring failed

Clutch release bearing worn

Clutch booster push rod adjusted

improperly

Clutch release bearing worn or

improper lubricated

Clutch pressure plate or driven disc distorted

Transmission input shaft or driven disc

spline worn

Clutch pedal shaft bush worn

Clutch out of control

Cylinder of clutch hydraulic pressure

system blocked

Release lever worn

Air in hydraulic pressure pipeline

Master cylinder oil pipeline blocked

Clutch booster troubled

Release shaft bushing blocked or

improper lubricated

Release bearing flange blocked

Release lever bush improper lubricated

Change the pressure plate or driven disc

lining

Disassemble and repair

Exhaust the air in the pipe

Readjust accord to the standard

Disassemble and repair

Replace driven disc friction lining or

pressure plate

Clean driven disc friction lining and

pressure plate

Disassemble and repair

Readjust accord to the standard

Check master cylinder push rod and

booster oil seal

Change the pressure platespring

Replace the release bearing

Disassemble and repair

Replace the release bearing release bearing

Change the pressure plate or driven disc

Replace input shaft or driven disc

Replace the bushing

Adjust

Adjust

Replace

Exhaust air in the pipe

Clean or replace

Disassemble, repair and clean

Replace bush or lubricate

Correct or replace the bearing flange

Lubricate

CL-2

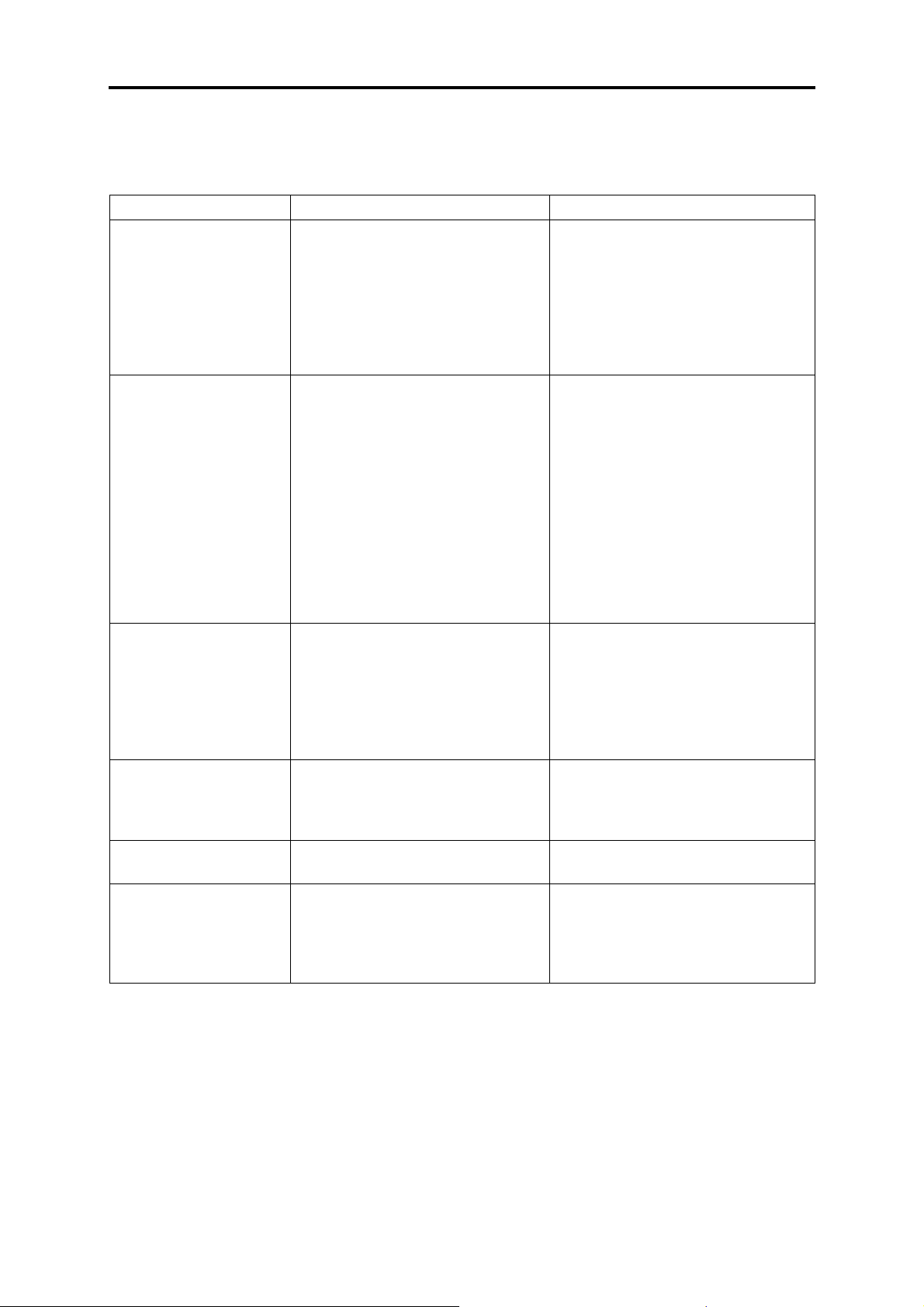

Clutch

Clutch Mechanical System

1.Clutch pedal bracket assy

2.Lower fixed plate--pedal bracket

3.Hose assy--oil reservior to master cylinder

4.Clutch pedal welding assy

5.Pedal sleeve

6.Clutch pedal shaft

7.Clutch pedal return spring

8.Bush--pedal assy

9.Pin

10.Clutch master cylinder assy

11.Oil reservior assy

12.Front oil pipe assy

13.Free flowing coupling

14.Front hose assy--clutch

15.Rear oil pipe assy--clutch master cylinder to

booster

16.Clutch rear oil pipe bracket

17.Rear hose assy

18. Booster assy

19.Nylon pipe assy (air pipe to four-way protective

valve)

20.Bracket set--clutch booster

CL-3

Clutch

Adjustment of Clutch Pedal

1.Adjust the height of the clutch pedal by adjusting the pedal setting bolt. The height of clutch pedal is about

160~170mm.

2.Adjust the free stroke of the clutch pedal.

Release bearing

Check the release bearing for any crack or wear. The release bearing must be smooth and turn without noise.

Replace it if necessary.

Check the release sleeve and release fork for wear, damage or erode, and replace if necessary.

Bearing lubricating

Make use of the recommended lubricant for the connecting surface and the attrition surface of bearing and

fork.

Note:

Overmuch lubricant may cause clutch driven disc damaged.

Clutch driven disc and pressure plate

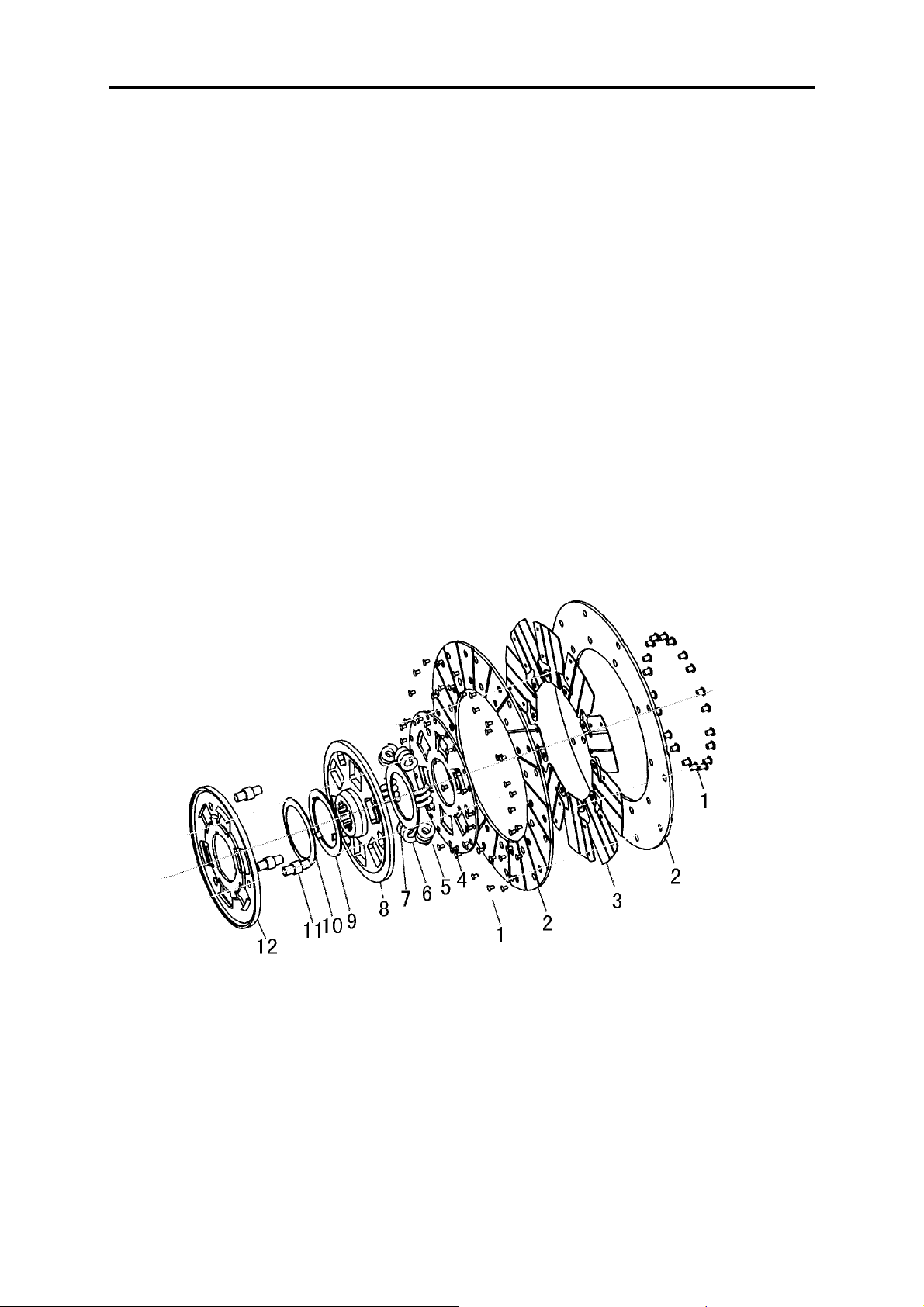

Clutch driven disc

1.Friction lining rivet

2.Friction lining

3.Wave spacer

4.Front damping disc

5.Wave spacer rivet

6.Damping spring

7.Damping spacer

8.Disc hub

9.Damping impact spacer

10.Damping spring spacer

11.Limiting pin

12.Rear damping disc

CL-4

Clutch

Check

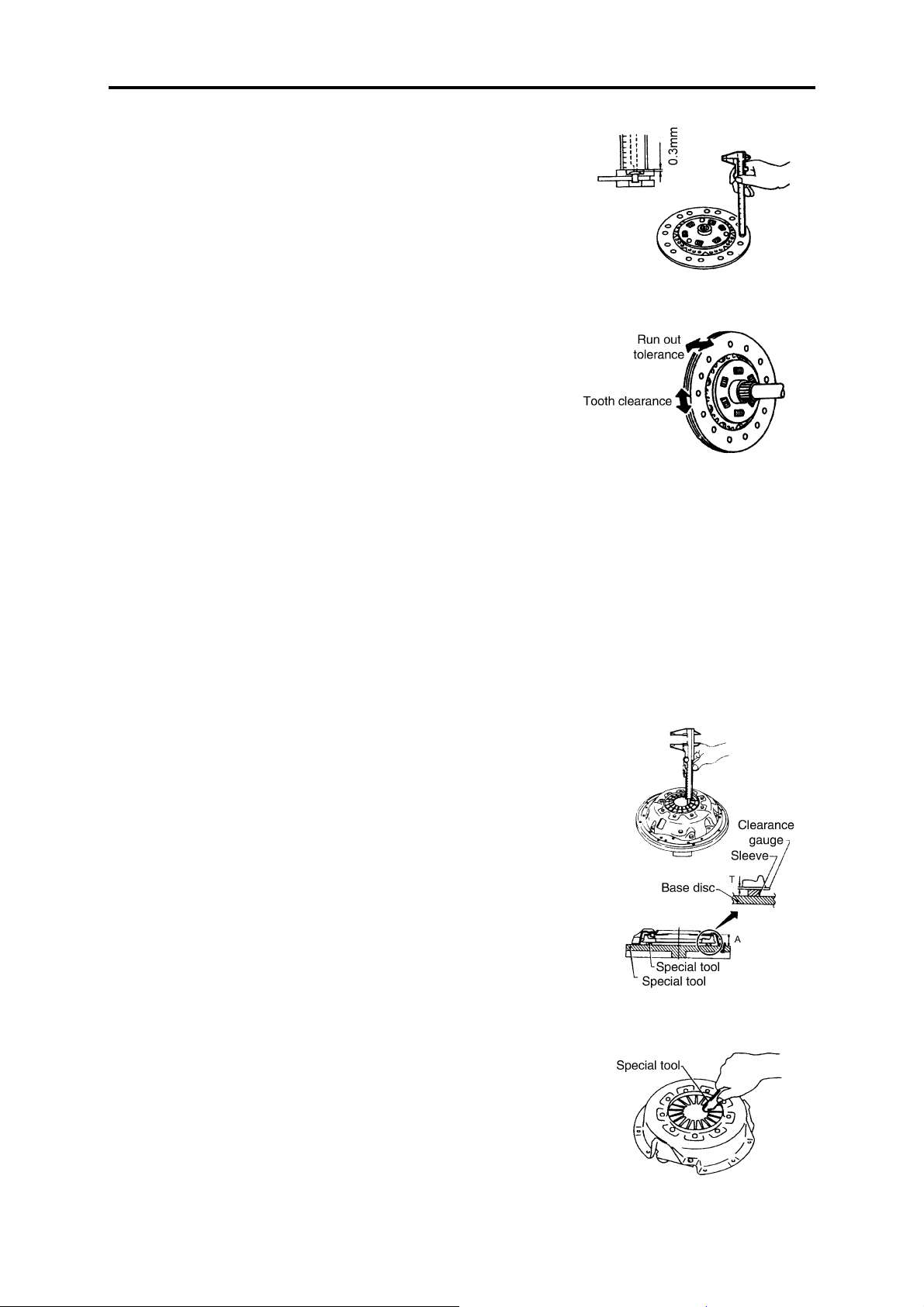

Check the degree of wear of the driven disc surface.

Wear limit:(from friction surface to the rivet head) 0.3mm.

Check the spline tooth clearance and the run out tolerance of driven

disc.

Check the driven disc for ablation, color changed, or contaminated

by oil or grease. Replace if necessary.

Installation

Smear some grease on the connecting surface and the spring.

Overmuch grease may damage the surface of the driven disc.

Clutch pressure plate

Check and adjust

Check the height and plainness of the diaphragm.

When checking the height of the diaphragm, set a clearance

gauge(T=0.2mm) on the distance bushing.

Height of the diaphragm: 41~43mm (base disc to the top of the diaphragm)

If the height is not in the range of the specific range, you need to

replace the pressure plate.

Shake the pressure plate gently, listening and check the wear or damage of the diaphragm supporting ring. Or you can knock the rivet head

gently to find if there is cracks. Replace the pressure plate if necessary.

Check the surface of the pressure plate for any ablation or dirt, make

use of the corundum paper to get rid of them if necessary.

Check the connecting side of the pressure plate and the driven disc for

any distorsion or damage, and replace them if necessary.

Adjust the plainness of the diaphragm by tools.

Plainness: <0.7mm

When install the clutch pressure plate and driven disc, insert the special tool into the clutch driven disc spline(used to align and orient).

Screw down the fixing bolt of the clutch cover.

Screw down the bolt in an acrossed sequence, following two steps.

CL-5

Clutch

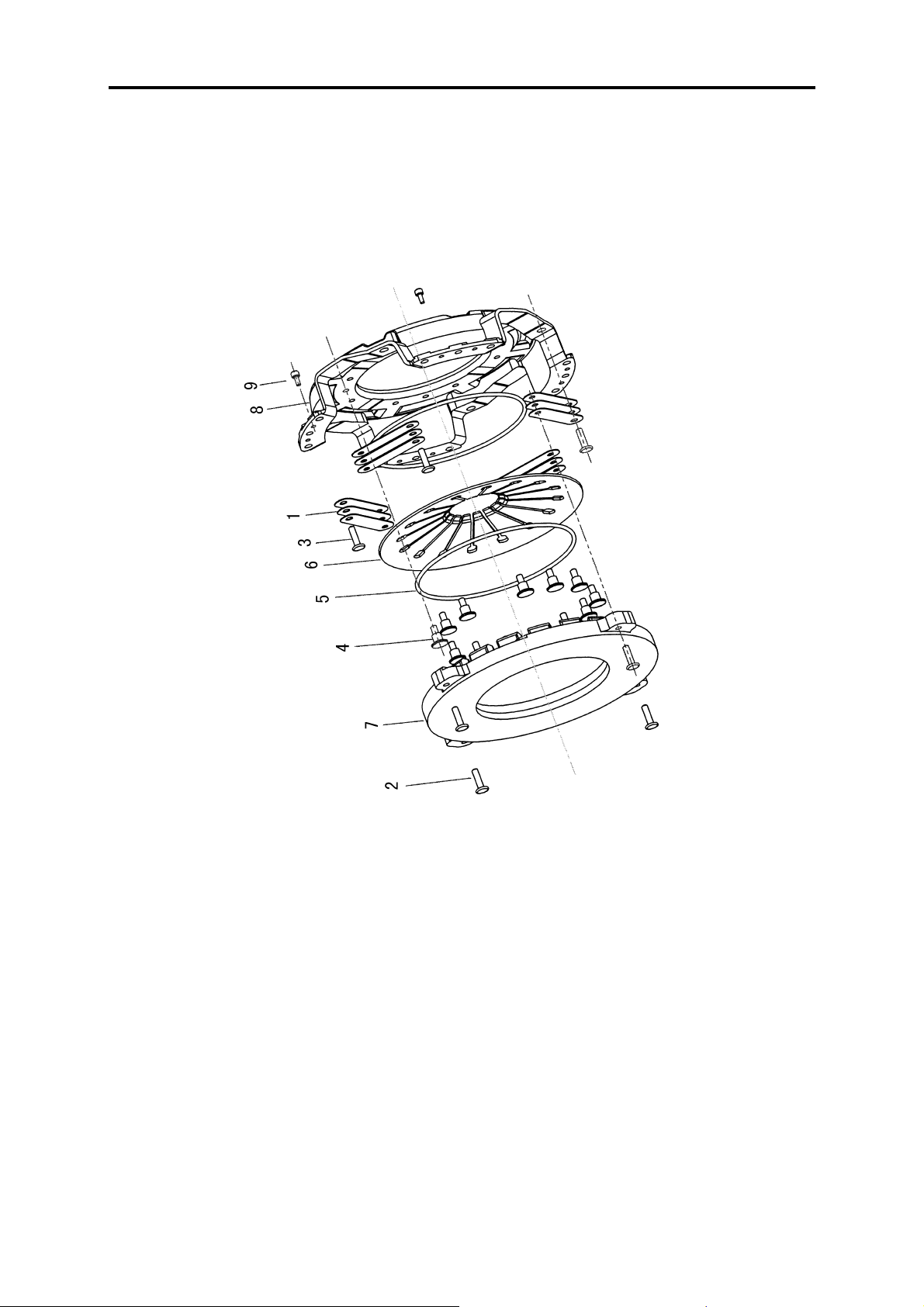

Clutch Cover and Flywheel

1.Driving blade

2.Rivet--pressure plate

3.Rivet--cover

4.Rivet--supporting ring

5.Supporting ring

6.Diaphragm spring

7.Pressure plate

8.Clutch cover

9.Balancing rivet

CL-6

Clutch

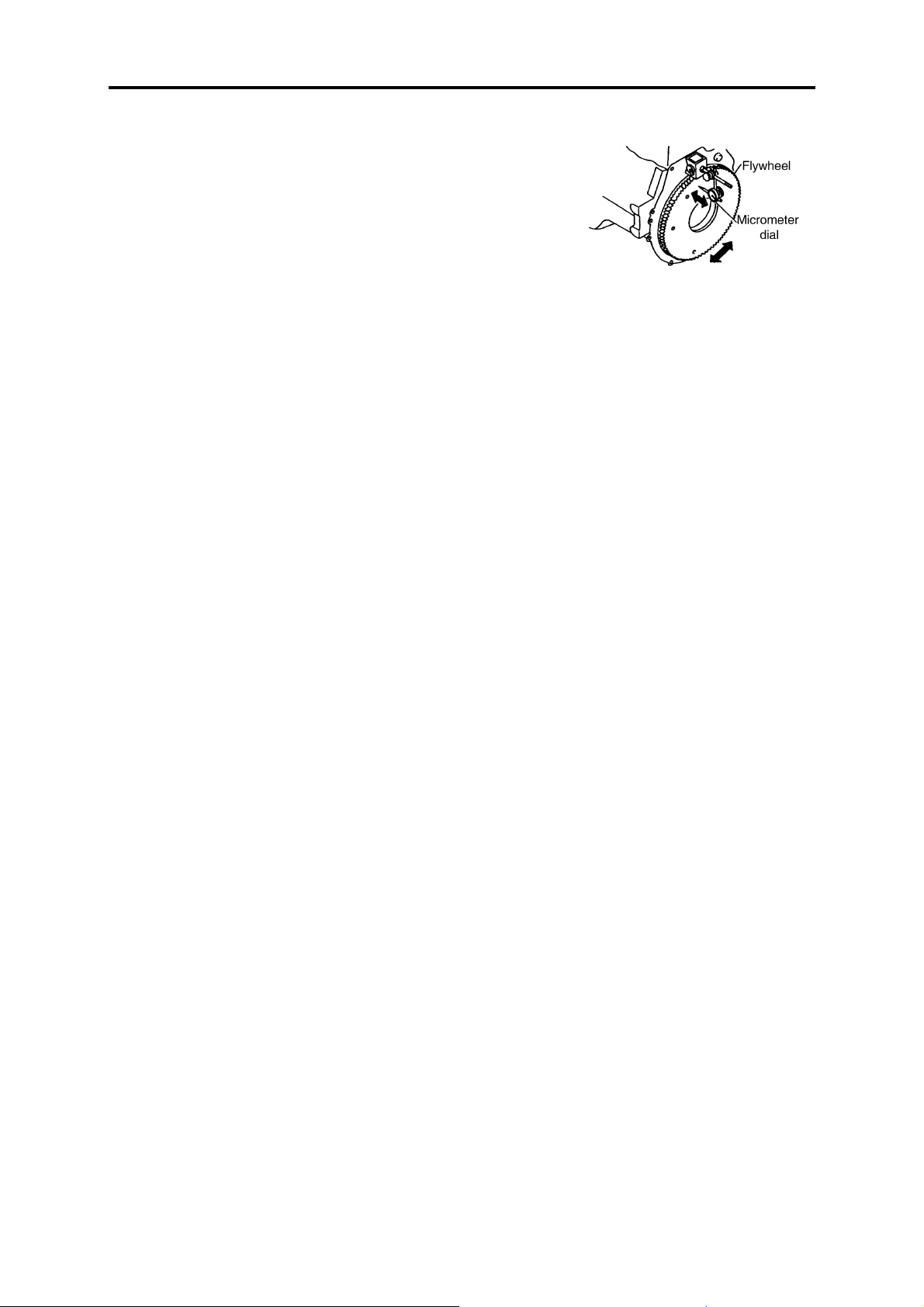

Flywheel check

Check the working face of the flywheel for ablation or color changed,

make use of the corundum paper to get rid of them if necessary.

Check the plainness of the flywheel surface: <0.1mm

Usage and Maintenance

The diaphragm clutch which has two positioning holes and been connected by 8 M10 bolts, is made up by cover assy and driven disc assy.

The drive blade is used to transmit the engine torque between the

pressure plate and clutch cover. Two ends of the drive blade are riveted to

the clutch cover and the pressure plate. When disengaged, the drive blade

may have the axial deformation, and there is no friction between clutch

cover and pressure plate. Therefore, the clutch will has a higher drive efficiency, lower noise, and stable engage.

The working pressure force is caused by the diaphragm. The original

height of the clutch release finger is 56±1mm. During the usage, it will be

heigher because of wearing. The wear limit of the two pieces of the

friction lining is 2×1.8mm. During the wearing time, the distance between

the toppest point of the release finger and the release bearing end has to be

adjusted to 3~4mm, and the largest release stroke of the release finger is

10mm.

The outside diameter of the driven disc friction lining isΦ325mm. Its

material may adopt to asbestos or non-asbestos according to the need of

the customer. The original thickness of the driven disc working surface is

9.7±0.3mm. The assembly is equipped with big and small shock-absorber

spring and damping spacer which is good to absorb the impact and

vibration from the chassis.

The involute spline is used to connect the driven disc and

transmission.

The working surface of the driven disc can't be stained with oil soil

during the assembling and storage.

When the friction lining is in trouble, such as the rivet loose or come

out or cracked, the driven disc must be replaced immediately.

During the assembling and instorage, the working surface of the

clutch cover assembly must haven't any scuffing and rust. If the release

finger is broken or the pressure plate reached to its wear limit and the

diaphragm is broken, you must replace the assembly immediately.

CL-7

Clutch

CL-8

Transmission

MT

Table of Contents

Maintenance Standard ................................................................................... MT-1

Transmission Dismount................................................................................. MT-2

Transmission Disassembly ............................................................................ MT-3

Cleaning....................................................................................................... MT-20

Check ........................................................................................................... MT-20

Reassembly.................................................................................................. MT-24

Transmission Mount .................................................................................... MT-37

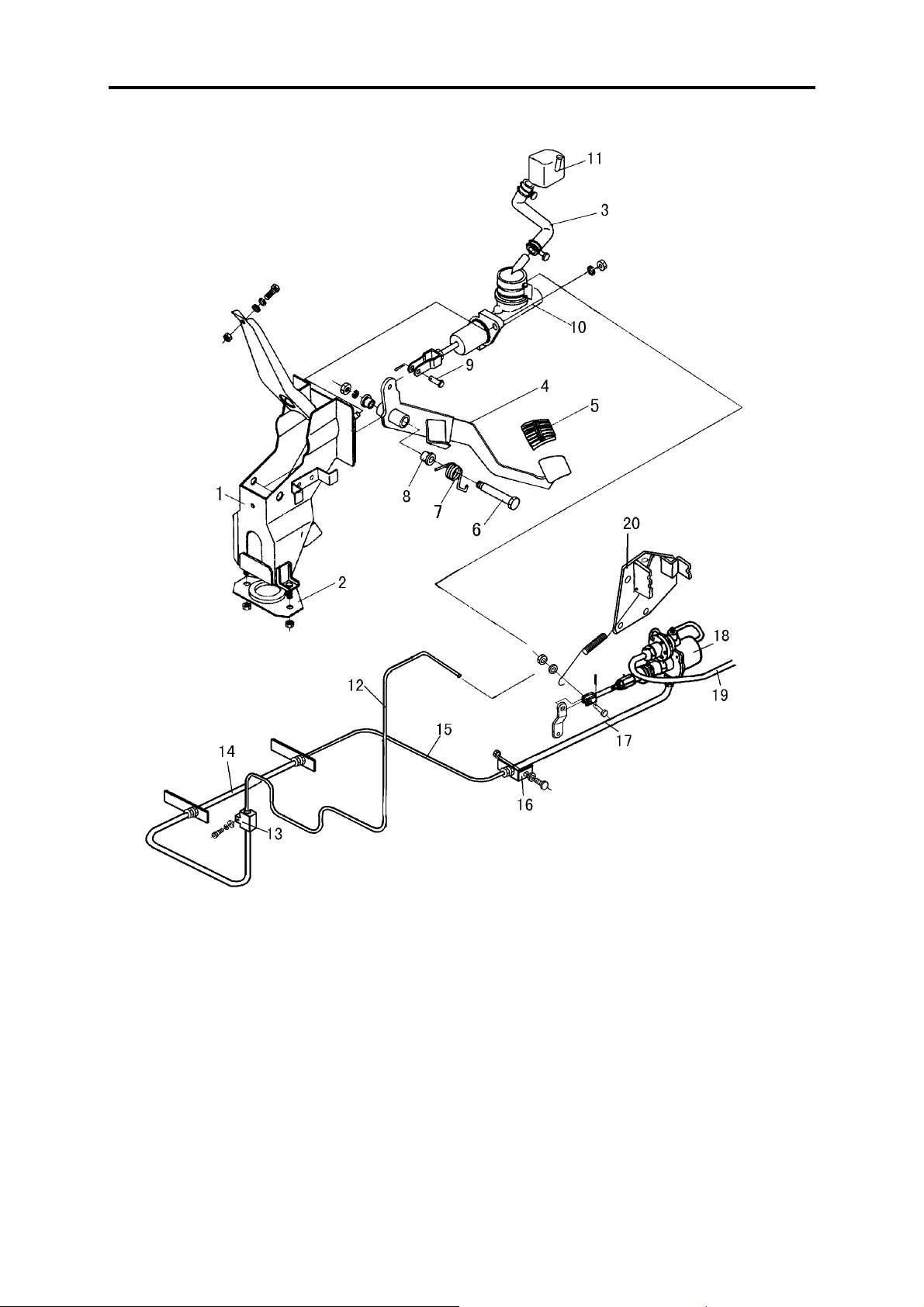

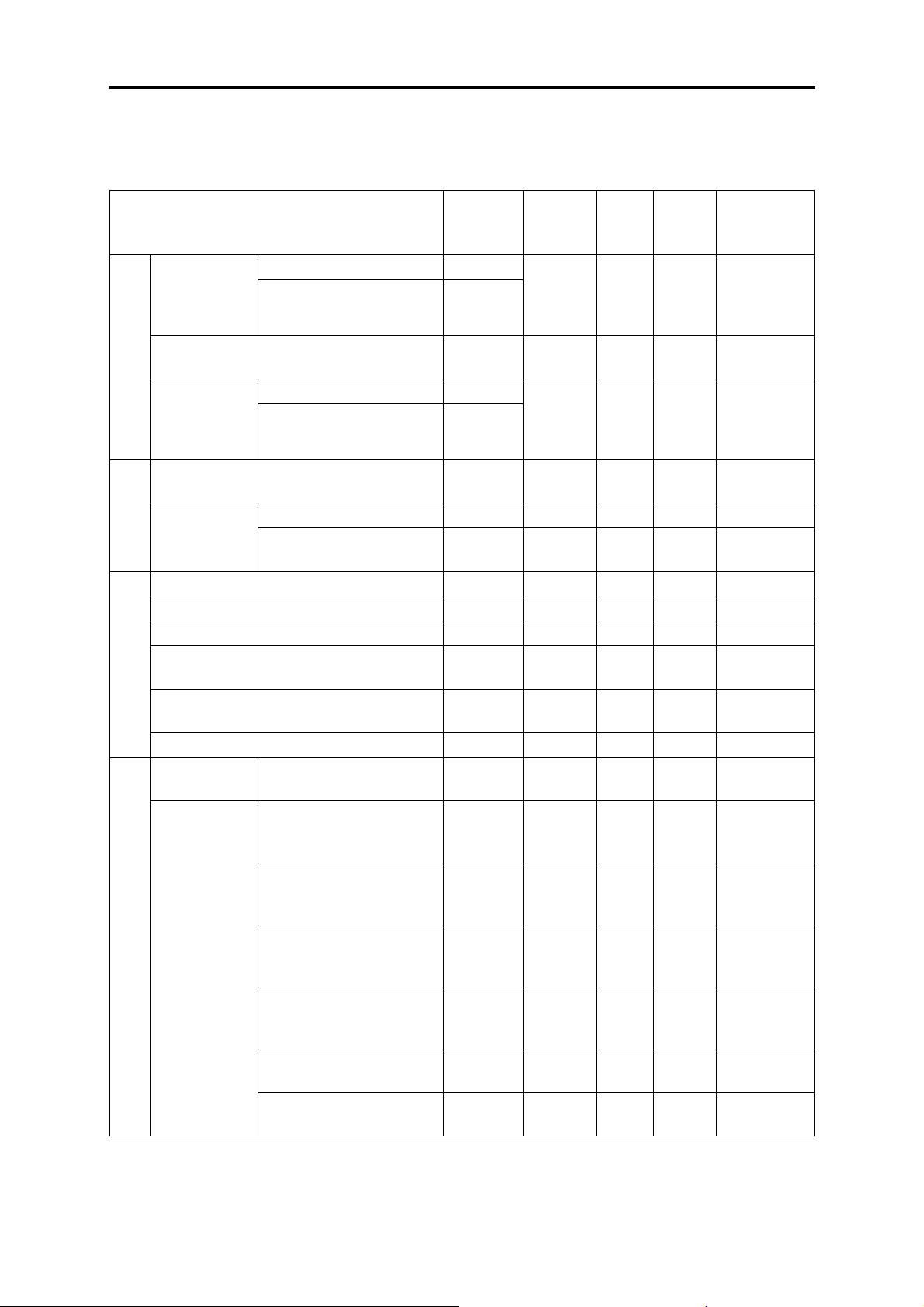

Maintenance Standard

Transmission

Maintenance Standard

Item

Clearance

between gear

shift lever and

select lever

Radial clearance between gear shift lever and

its spline

Clearance

between gear

Transmission top cover

shift lever and

guide block

Clearance between gear shift fork and slide

sleeve

Gear shift fork

shaft self-

upper cover

Transmission

locked spring

Backlash between mainshaft and countershaft

Axial clearance of the 2nd gear

Axial clearance of the reverse gear

Radial clearance between mainshaft spline

hub and mainshaft

Radial clearance between slide sleeve and

coupling gear

Transmission body

Axial clearance of ball bearing

Lockpin type

Slide block

type

Synchronizer

Gear shift lever

Gear select lever

Gear shift lever

Each guide block

Free length

Pressure force

Pretravel of synchronizer

conical ring and conical disc

Clearance between baulk

ring and synchronizer conical ring

Radial clearance between

baulk ring and fixed tooth

seat

Axial clearance between

fixed seat and synchronizer

closing ring

Axial clearance between

fixed seat and synchronizer

backing block

Free length of the backing

block spring

Packing force of the backing block spring

Nominal

Dimension

(mm)

-

-

-

-

-

-

-

-

-

-

-

-

-

---

-

-

-

-

-

15

-

Sevice

Standard

(mm)

0.1~0.4

0.05~0.11

0.1~0.4

0.10~0.29

34.0~36.0

140~190

N

0.15~0.25

0.3~0.5

0.3~0.6

0.2~0.3

0.45~0.55

0~0.5

1.5~2.5

5.3~5.7

> 0.5

0.05~0.35

---

6~10N

Repair

Limit

(mm)

-

-

-

-

--

-

—

-

-

-

-

-

-

--

--

--

-

Wear

Limit

(mm)

0.8

0.5

1.0

1.0

110N

0.5

0.7

1.0

0.5

1.0

0.5

2.0

0

4N

Remark

When press to

25mm

When press to

12.5mm

MT-1

Tightening Torque

Transmission

Item

Clutch housing connecting bolt 142~186

fasten nut of propeller shaft connecting flange 333~549

Transmission upper cover fixed bolt and nut 32~42

Transmission cover fasten bolt 20~26

Reversing lamp switch and neutral position switch 20

Power take-off housing connecting bolt Standard 47~63

Countershaft rear bearing cover fixed bolt 59~79

Fixed bolt of mainshaft rear bearing seat

Fixed bolt of drive gear shaft bearing cover 33~44

Reverse gear shaft locking plate bolt 20~26

Mainshaft front locking nut 300

Oil drain screw plug and filler port screw plug 120~140

Gear shift guide bolt 40

Countershaft rear locking nut 300

M12 59~79

M14 93~124

Tightening Torque (N.m)

Transmission Dismount

Before disassemble the assembly, switch the ignition key to OFF, and wedge up the front and rear wheel to

ensure the safety.

1.Screw off the drain plug screw, drain off the lubricant oil from the underpart of the transmission;

2.Disassemble the driving shaft assembly and central support bearing;

3.Remove the speedometer flexible shaft;

4.Disassemble transmission control system

5.Remove the return spring and dowel pin of the clutch slave cylinder then safely put the clutch slave cylinder

assembly onto the frame;

6.Remove wire and tube.

7.Disassemble the transmission with transmission jack and steel wire.

MT-2

Transmission

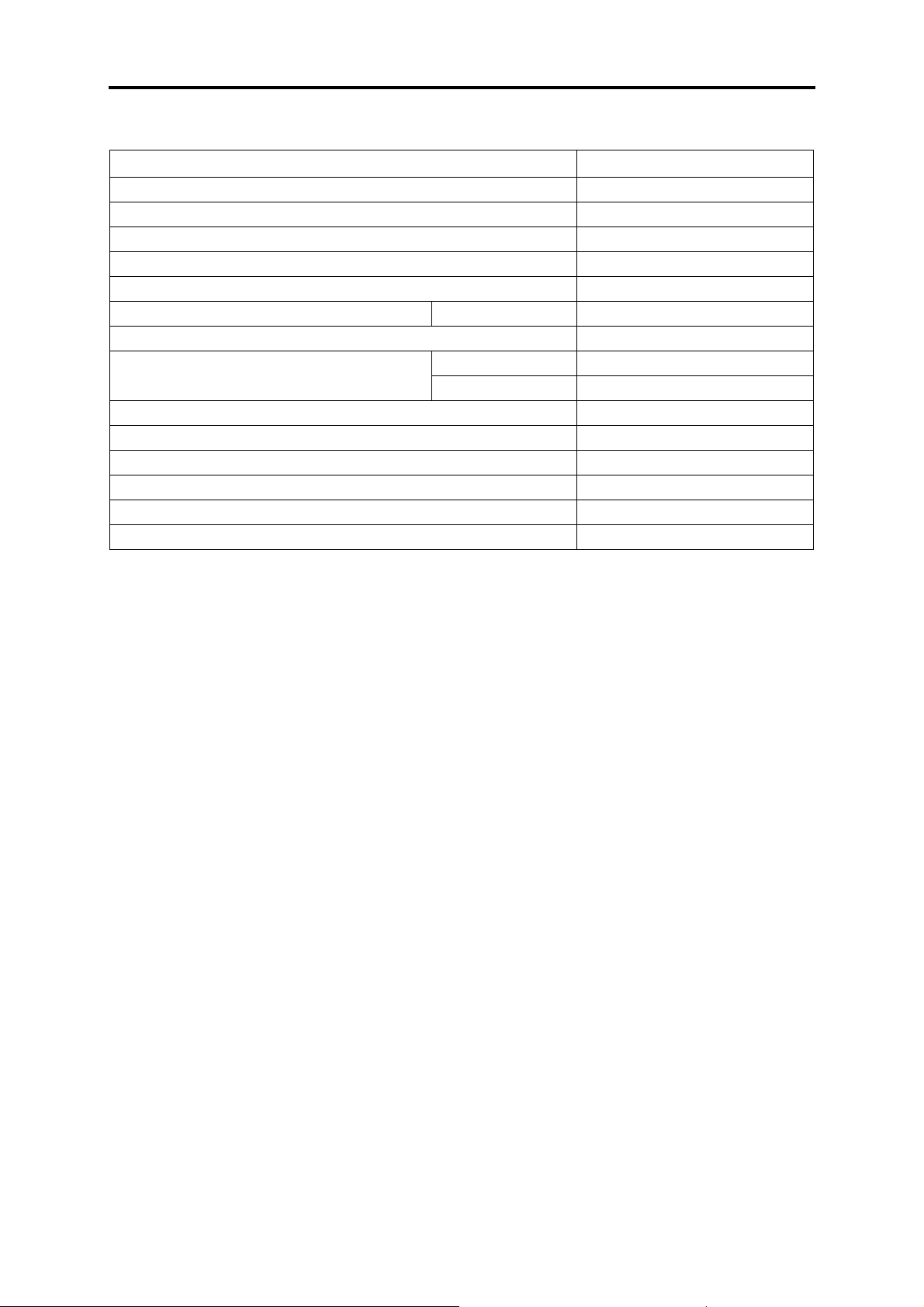

Transmission Disassembly

Transmission housing and drive gear shaft

1.Small hex guide bolt

2.Spring washer

3.Bearing cover--drive gear shaft

4.Bearing cover spacer--drive

gear shaft

5.Oil seal --transmission drive

gear shaft

6.Snap ring for shaft

7.Staved steel ring for shaft

8.Rear bearing--transmission

drive gear shaft

9.Transmission drive gear shaft

10.Spring washer

11.Hex bolt

Set the transmission on the working table carefully. If there is not a working table, make use of a simple table

to support the transmission housing first, and then carefully do the disassembly.

12.Cover board--power take-off

hole

13.Cover board spacer--power

take-off hole

14.Oil screw plug assy

15.Sealing washer

16.Transmission housing

17.O-ring--transmission countershaft

18.Rear bearing seat spacer-mainshaft

19.Speedometer oil seal assy

20.Speedometer flexible joint

21.Sealing washer

22.Speedometer driven gear

23.Rear bearing seat--mainshaft

24.Skeleton oil seal assy

25.Small hex guide bolt

26.Spring washer

27.Bolt--for bearing cover

28.Spring washer

29.Countershaft rear bearing

cover

30.Spacer--countershaft rear bearing cover

31.Sealing washer

32.Oil screw plug assy

MT-3

Transmission

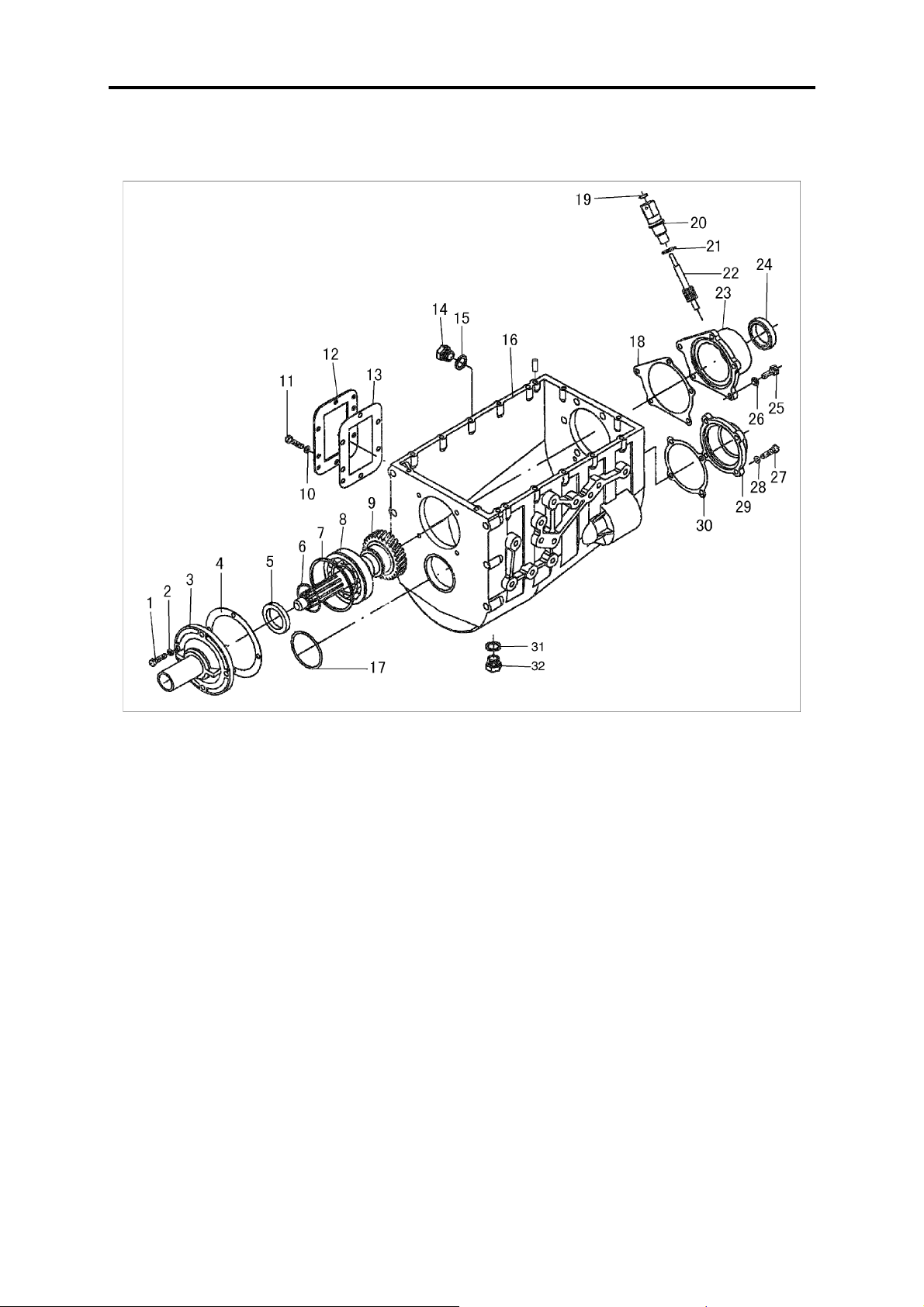

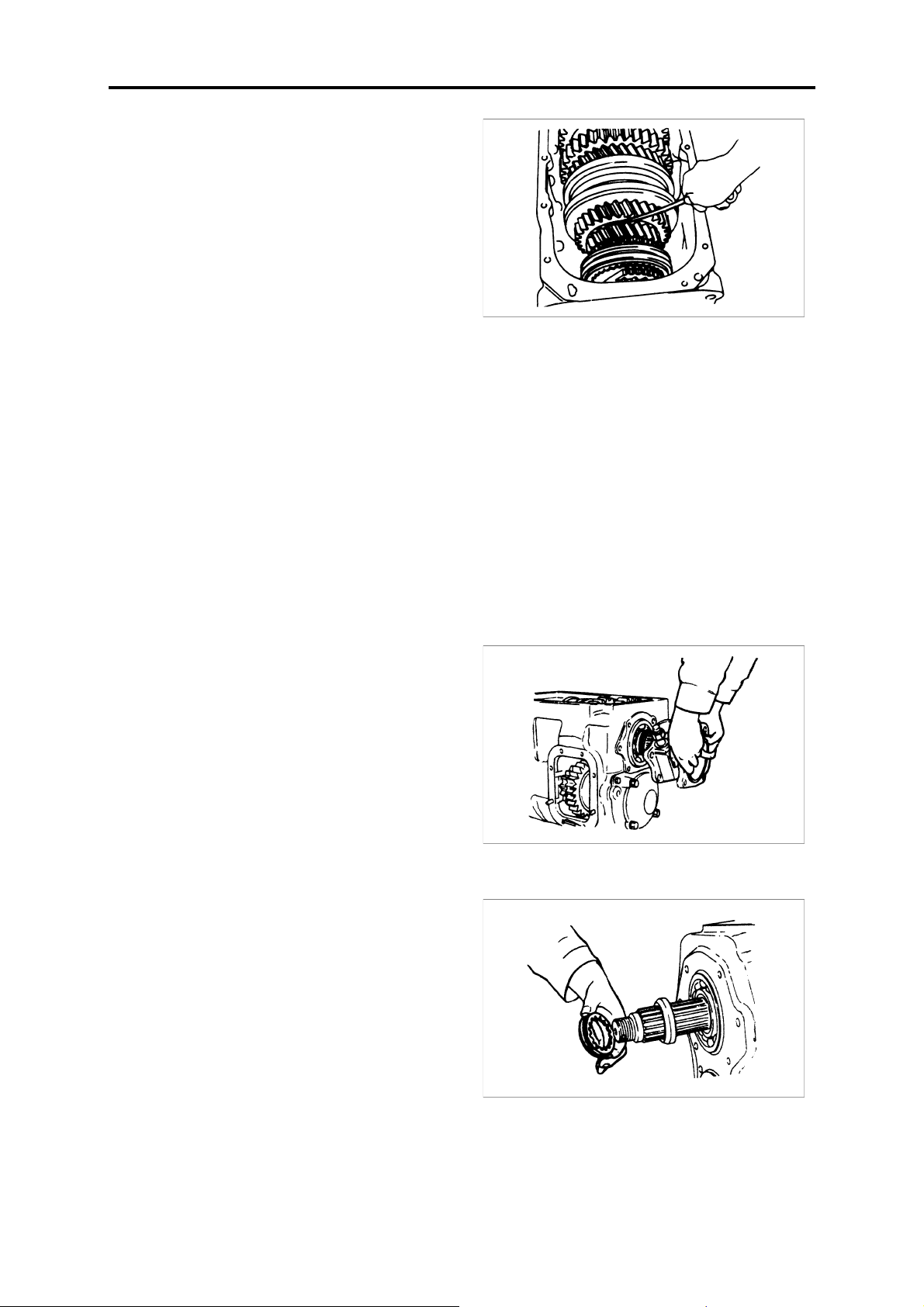

Disassembly of transmission accessories

1.Remove the clutch housing assembly;

2.Remove the transmission upper cover assembly and

spacer;

3.Dismantle the power take-off cover and spacer;

4.Measure the backlash of every pair of gear and take the records;

Note: Take three points of every pair of gear to measure.

MT-4

Transmission

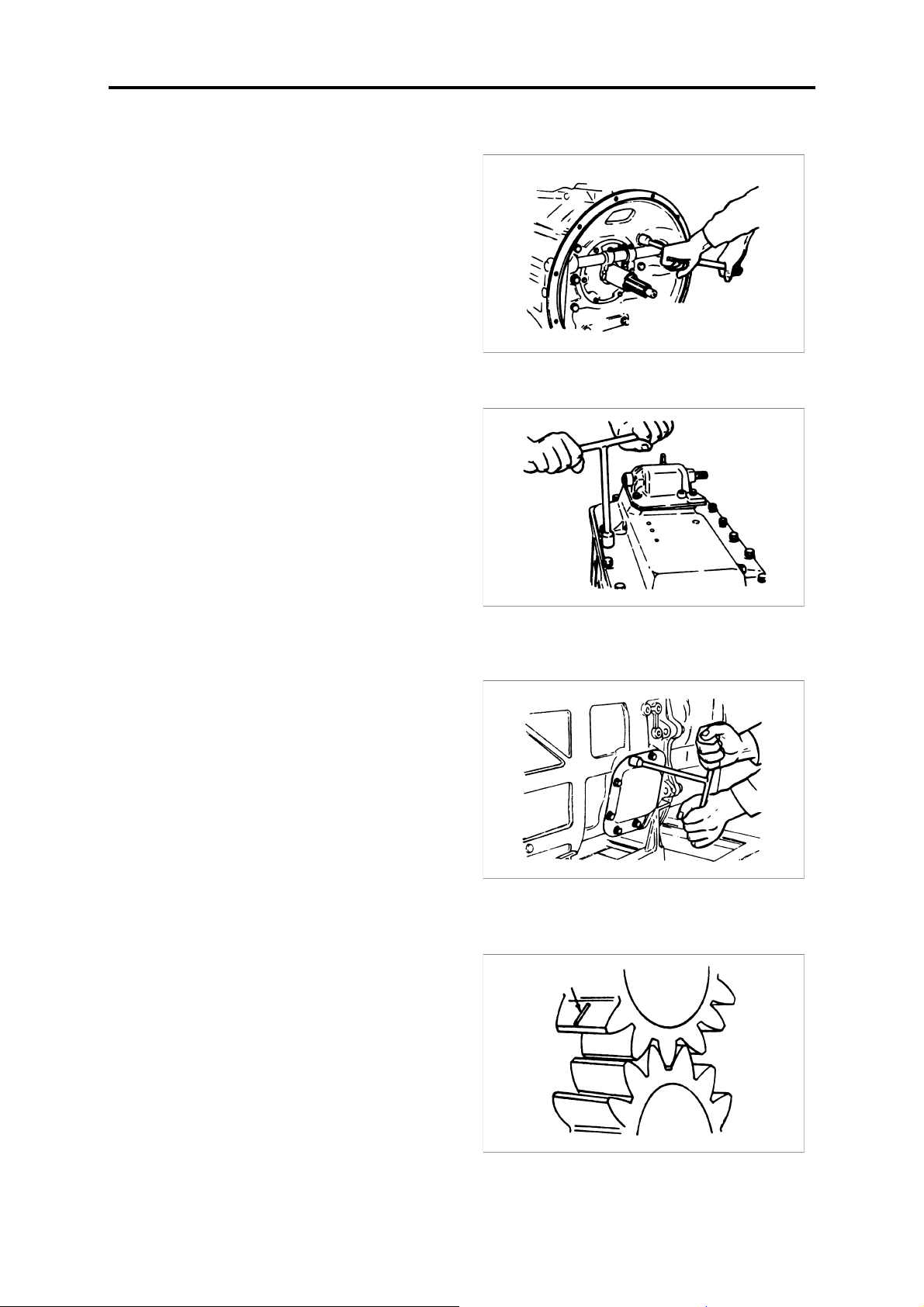

5.Measure the axial clearance of every gear and take the

records.

Check point

1.Clearance between 6th speed gear and 6th speed gear thrust ring;

2.Clearance between 4th speed gear and 6th speed gear thrust ring;

3.Clearance between 3rd speed gear and 3rd and 4th speed gear fixed seat;

4.Clearance between reverse gear and reverse gear fixed seat;

5.Clearance between 2nd speed gear and 3rd speed gear thrust ring;

6.Clearance between 1st speed gear and reverse gear seat.

Transmission body

1.Remove the rear bearing cover of the mainshaft;

2.Remove the speedometer drive gear and spacer;

MT-5

Loading...

Loading...