Page 1

•Americana /Americana Plus

•Classic

•New Dimensions

•New Generations

Page 2

Home Refrigerators

vs

RV Refrigerators

• Compressor vs Absorption

• Controlled Environment vs

Changing Environment

• Recovery time is vastly

different

30-45 minutes vs

1-2 hours recovery

Page 3

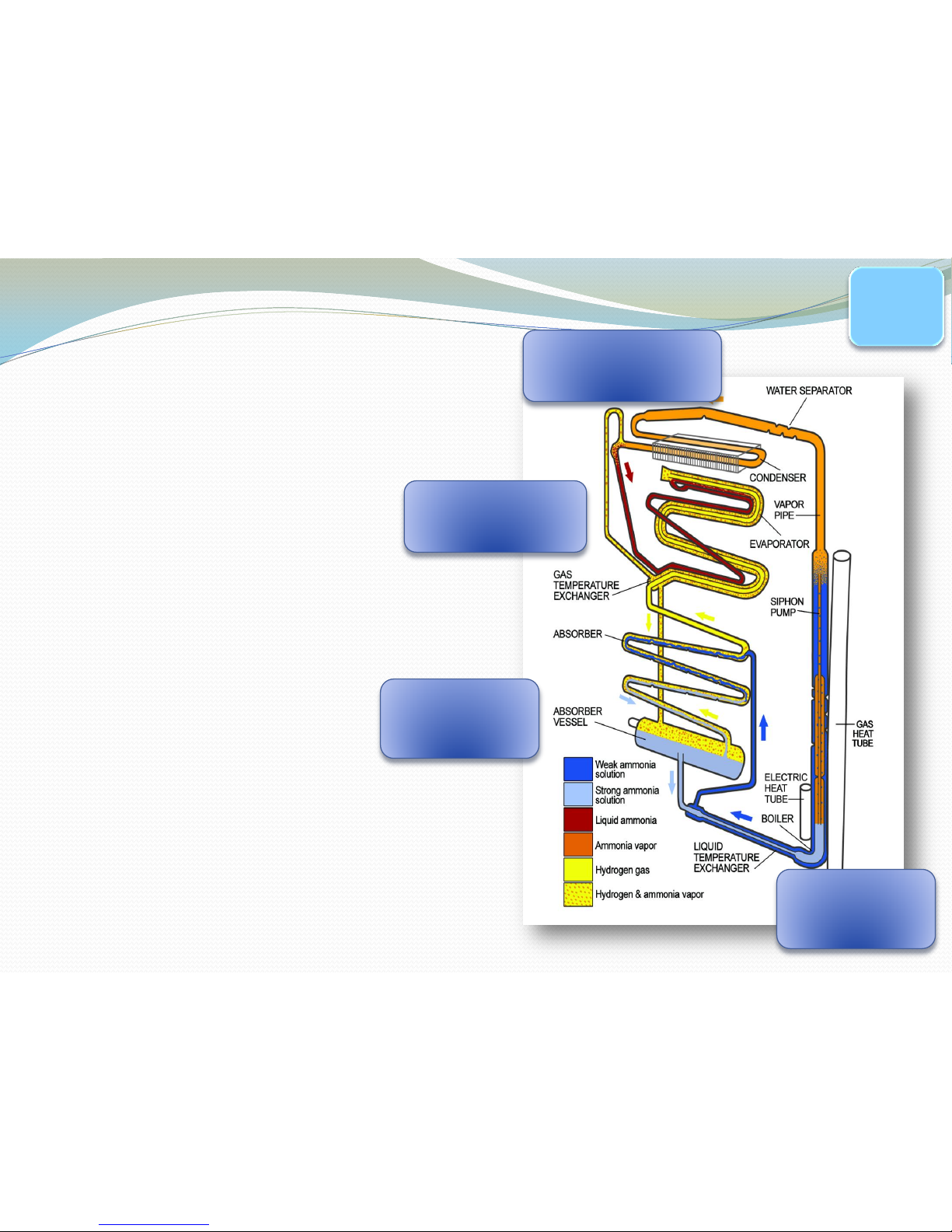

CONDENSER

EVAPORATOR

ABSORBER

BOILER

SOLUTION IS

MADE UP OF:

•AMMONIA

•WATER

•HYDROGEN

•RUST INHIBITOR

The

Absorption

System

PG.

26

Page 4

PG.

25

Page 5

To properly test a Cooling Unit

Three criteria have to be met:

•Level ?

•Ventilation ?

•Heat Source?

Page 6

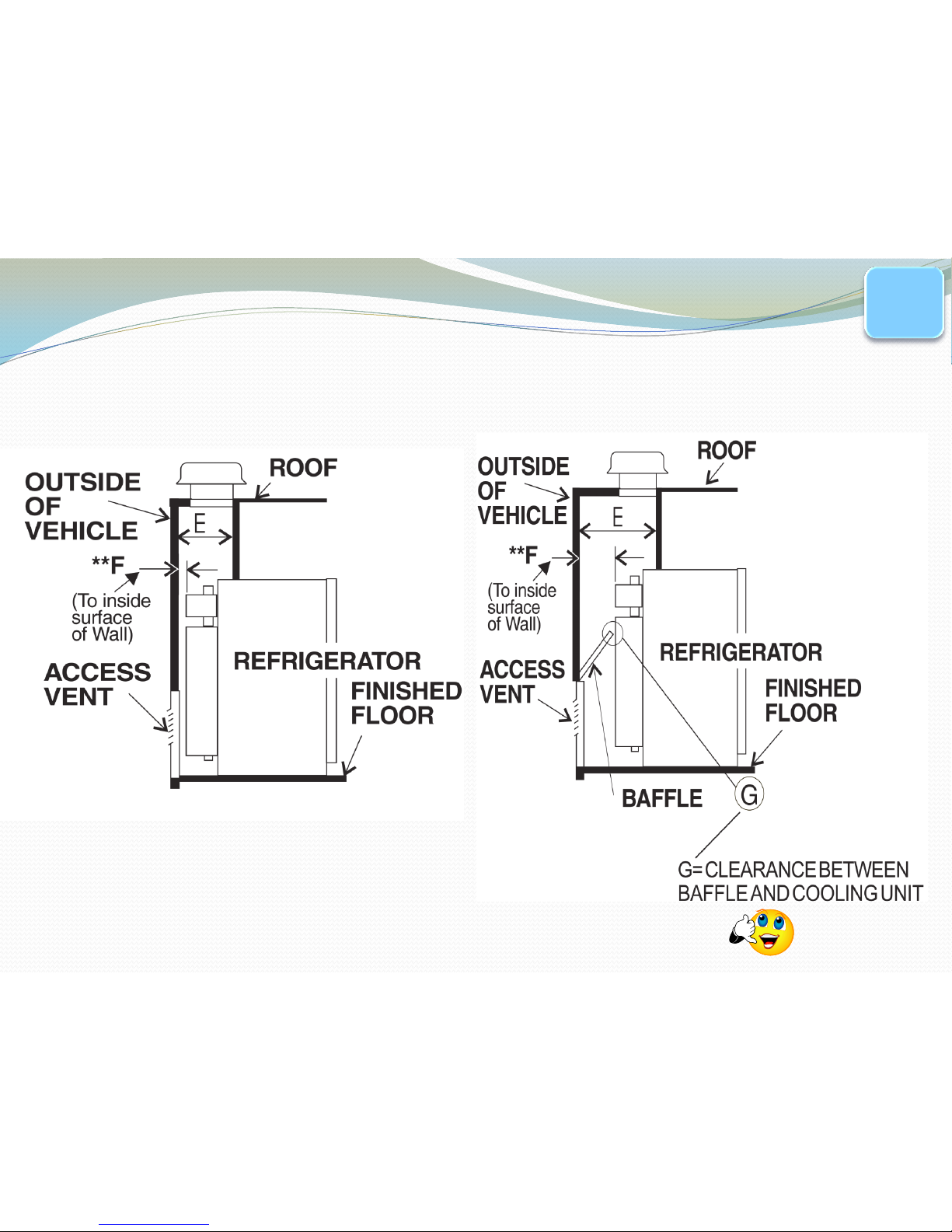

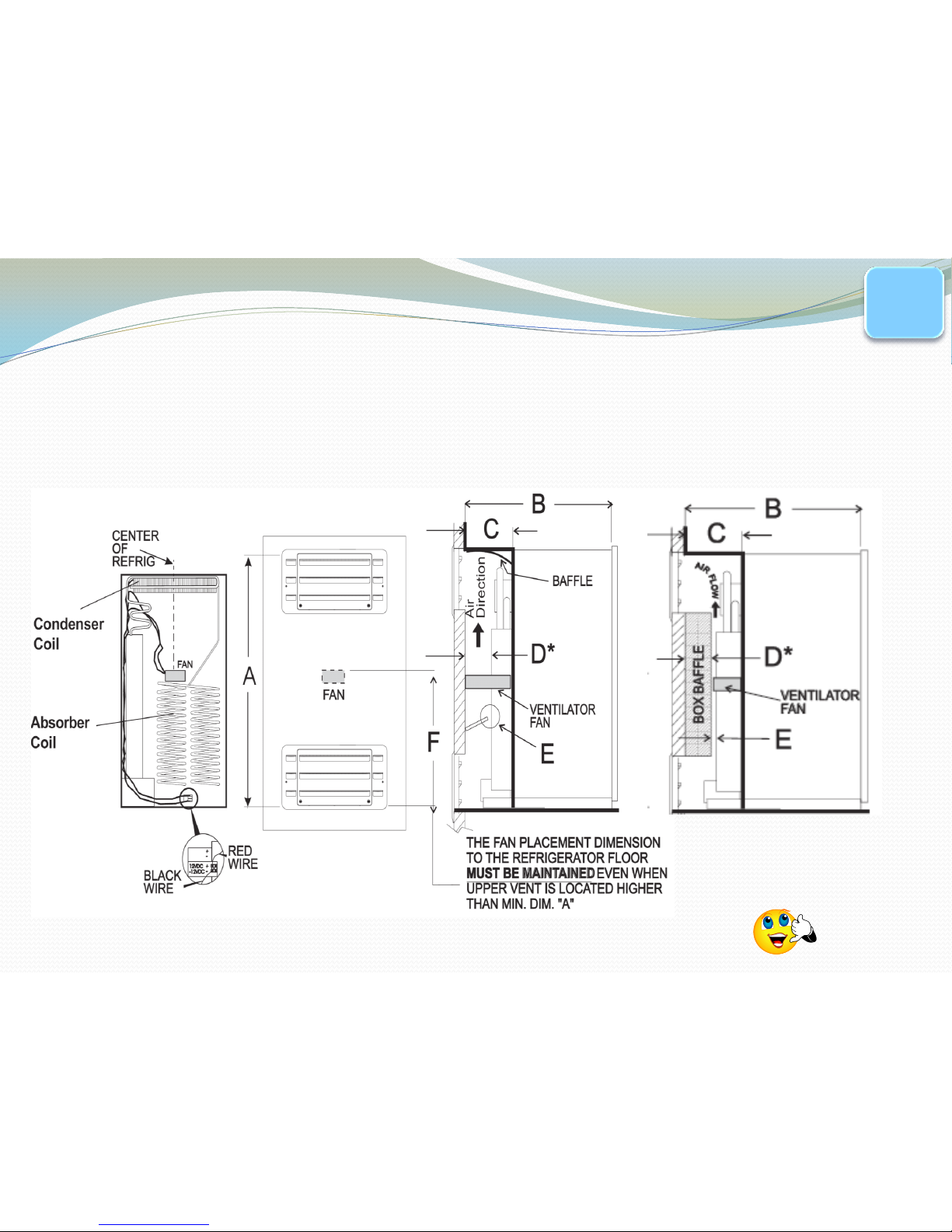

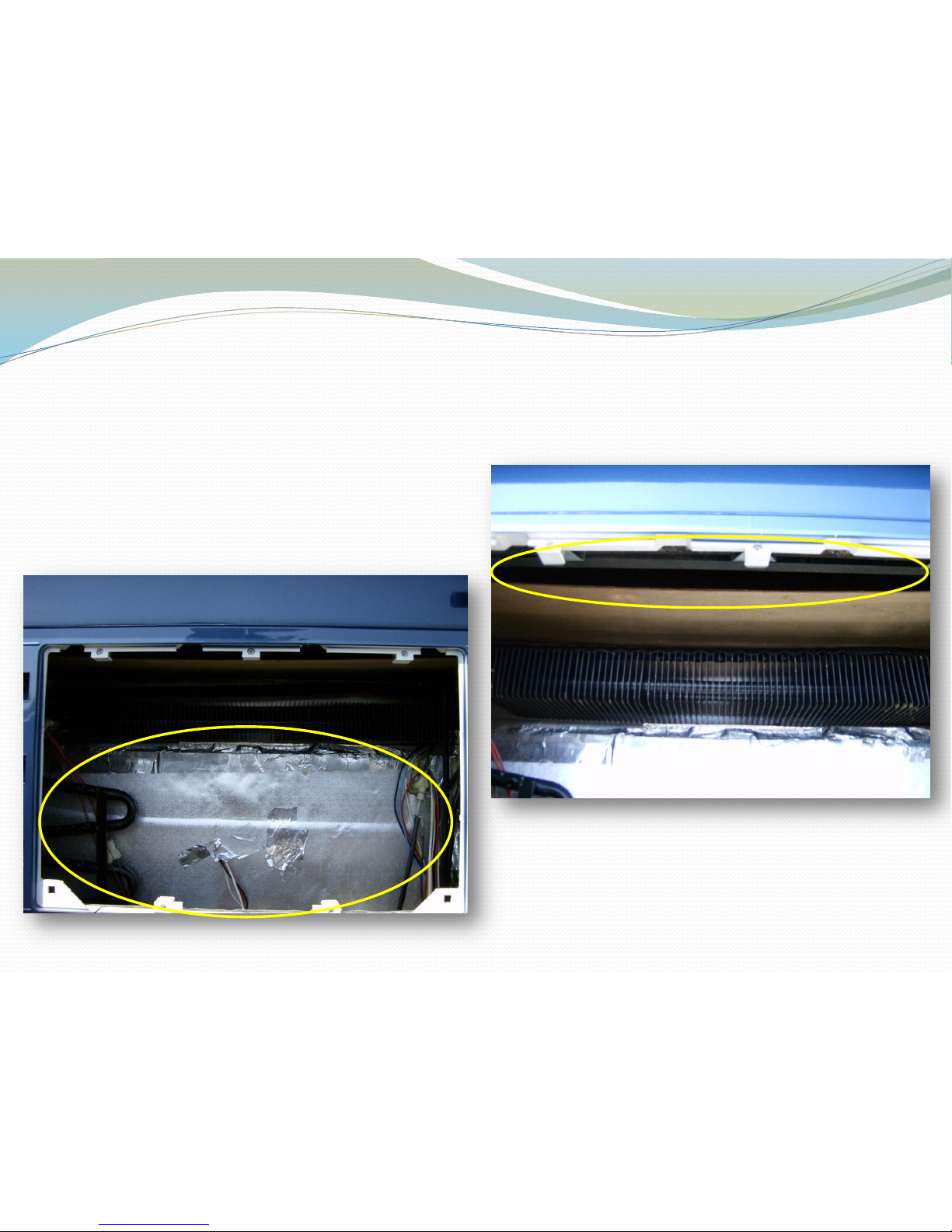

Ventilation

Make sure you check Ventilation and Air Flow

-0” clearance on the sides and top

-No more than 1” from back of CU to

sidewall. (A baffle may need to be installed to

help direct air across coils)

-If there is an auxiliary fan, check that it is

working properly.

PG.

21

Page 7

Typical Double Door Install

0” clearance on the side and

top and less than 1” from CU

to sidewall

Application Guide 3308666.XXX

PG.

21

Page 8

Typical Side by Side Installation

in Slide Out/2 Sidewall Vents

Application Guide 3308666.XXX

PG.

21

Page 9

Symptom: Not Cooling

Air is not being forced through the

condenser – to much space!

Warm air is being trapped around

the refrigerator from a poor

installation.

Page 10

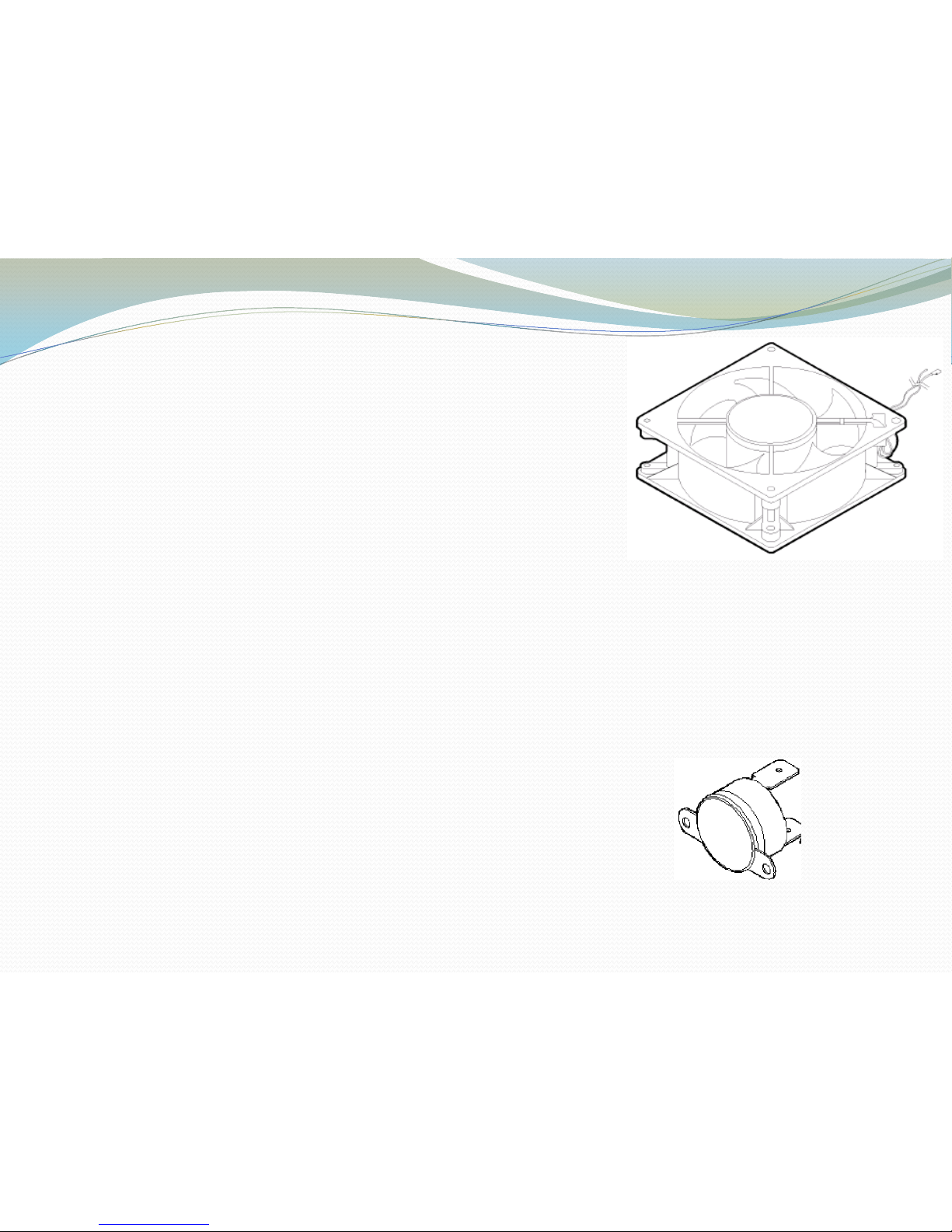

AUXILIARY FANS

Helps with air flow.

3108705.751 for Single Door refers

Fan limit switch will close at 105°F and open at

90°F +/- 10%.

3108705.744 for Double Door refers

Fan limit switch will close at 150°F and open at 120° +/-

10%.

Will draw only .5 amps each.

In-line fuse to protect circuit

Small Fan # 3851183016

Note: Please write these Part #’s down as they are not in the service manual.

Limit Switch only: 3104723.006

Limit Switch only: 3104133.016

Page 11

Heating Elements

The function of the heating element

is to provide the boiler with a

specific amount of BTU’s of Heat

AC Heating Element 6,8,10 cu ft.

Ohms – Approx. 44 +/- 10%

Amps – Approx. 2.7

Watts – 325

Series AC Heating Element for side

wise/side by side

Ohms – Approx. 34.3 +/- 10%

Amps – Approx. 3.5

Watts – 420

DC Heating element (Not shown) 6 cu ft.

Continuity – yes or no

Amps – Approx 18

Watts – Approx. 215

Note: Only use DC heating element

when driving to or from a location.

PG.

10/11

Page 12

To Perform a By-Pass Test of

the Cooling Unit

Disconnect the Thermister from Control Board

(with the thermister unplugged no temperature is

sensed, therefore, it will run continuously).

Place a glass of water in the refrigerator along with

a thermometer.

Plug unit into 115 VAC and allow to run “wide

open” for approximately 12 hours.

DO NOT DIRECT WIRE HEATING ELEMENT!

PG.

26

Page 13

Water/Thermometer

UNPLUG at P2 Terminal

To Perform a By-Pass Test of

the Cooling Unit

PG.

26

Page 14

After 12 hours Check

Liquid Temperature

•Industry Standards with

the thermister plugged IN…

•8 cubic foot and larger should

be 43°F or Less at 110°F

ambient temperature.

•6 cubic foot and smaller

should be 43°F or Less at 90°F

ambient temperature.

•After running “wide open”

for 12 hours with the

thermister unplugged…

•Should be approximately in

the lower 30’s under NORMAL

conditions.

PG.

26

Page 15

Refrigerator Specifications

A MINIMUM of 9.6 VDC at terminal block for controls

to operate properly.

Best from Battery, if not, from battery side of converter

or filtered side.

A MAXIMUM of 6 VAC ripple.

A Dedicated Fused Circuit – Nothing else tied into

circuit!

Must have 11” water column with 50% of all BTU

appliances on.

PG.

10

Page 16

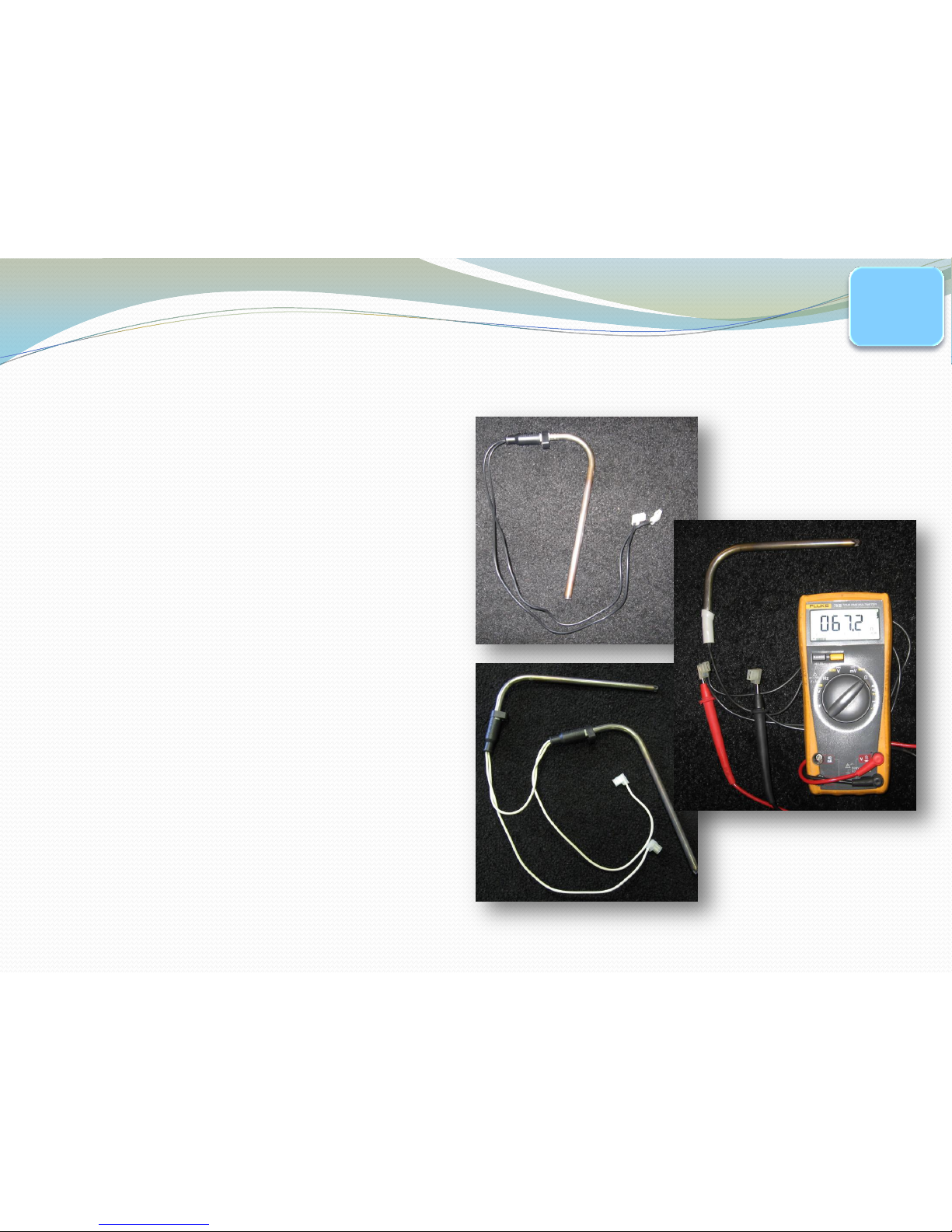

Thermister

The function of the thermister

is to monitor the temperature

inside the refrigerator box

using resistance.

Symptom: Over Cooling or

Under Cooling.

Check Ohms Value of

thermister. In a glass of ice

water at approx. 34°F you

should see between 8500

and 9500 Ohms.

Note: NDA 1402 has different

value. At approx 34°F you

should see between 5000 to

6000 Ohms.

PG.

11

Page 17

UPPER CONTOL BOARD

The function of the Upper Control

Board is to send commands to the

Lower Control Board

Symptom: No LED lights or no operation

1

st

check for DC voltage at the 5/6 wire Harness

plugged into the P1 terminal on Lower Board.

Check between terminal 5 – red and terminal 4 +

orange wire. This is the DC voltage going to the upper

control board. Note: If no voltage, check

3 amp fuse

and then at the terminal block.

PG.

13

Page 18

5/6 Wire

Harness

The Function of the 5/6 Wire

Harness is to connect from the

lower board to the upper control

board .

Allows the upper board to

communicate with the Lower

Board.

Symptom: No LED lights, No

operation.

Check Continuity through each

wire to chassis ground.

Page 19

5/6 Wire Harness in P1

Connector

- Red to + Orange (UP)

- Red to + Green (GAS Down)

- Red to + Black (ELECT. Down)

Should see approximately:

9.6 VDC to 22 VDC

With no more than 1.5 volt

difference

•Turn on refrigerator.

•Check DC voltage coming from upper control board on P1 connector

•Check from - red to + Green and – red to + Black

Page 20

Lower Control Board

Minimum of 9.6 VDC to Maximum of 22 VDC

Minimum of 9.6 VDC for initial opening of Gas Valve

Note: Upper control board will stay lit at 4 VDC, but no

commands will be sent to lower control board

ALL TESTS ARE TO BE DONE WITH THE

REFRIGERATOR IN THE COOLING MODE

Unplug the thermister from the control board during

lower board testing to assure unit is calling for cooling.

PG.

17

Page 21

No AC Operation-works on LP?

OPERATION

INCOMING AC VOLTAGE

5 AMP FUSE

HEATING

ELEMENT

WIRING

LOWER

BOARD

Page 22

GAS COMPONENTS

Gas Solenoid

Gas Valve

Orifice

Igniter

Electrode

Burner

Thermocouple

Flue Baffle

Page 23

Gas Solenoid

The Function of the Gas Solenoid is to allow gas to

flow through the gas valve assembly.

Symptom:

Check Light or

NO LP (gas)

Needs at least

9.6 VDC to open

OHMS

49 +/- 10 %

PG.

11

Page 24

Manual Shut-Off Valve

The Gas Valve is responsible for allowing gas to the

burner chamber.

Symptom:

Check Light or

NO LP

Check manual

shutoff valve

(horizontal)

Manual

Shutoff

valve

PG.

19

Page 25

Orifice

The orifice provides a pre-determined amount of gas

to the burner. The orifice has a man-made ruby inset

that allows LP to mix with air in order to get

combustion.

Symptom: Check

Light or NO LP

Check orifice for Debris

Use ONLY alcohol based

solvent to clean. Soak in

solvent and allow to air dry

PG.

19

Page 26

IGNITER

The function of the re-igniter is to sense resistance through the flame

between the electrode and the burner. If there is no flame, the igniter

will spark to light the burner.

Symptom: Check

Light or No Flame.

No sparking sound or

there is continuous

sparking.

Verify voltage at

+ Yellow and

– black (ground)

Note: 2 versions, igniter on board and separate

PG.

11

Page 27

ELECTRODE

The electrode passes the spark to the burner to light

the burner.

Symptom:

Check Light or

No Spark

Check for cracks

or breaks in ceramic.

Proper location on Burner

Note: 3rd slot on burner and 3/16 above burner

3/16”

3 slots

PG.

12

Page 28

THERMOCOUPLE

The thermocouple’s function is to tell the control

board that a flame is present.

Symptom:

Check Light or

won’t stay lit.

Check wiring, leads

may be reversed.

Milli-volts test while in

flame, should produce 25-35 – milli-volts

PG.

20

Page 29

Flue Tube and Flue Baffle

The Flue Baffle helps slow the process of heat rise in

the flue tube. The Flue Tube is where heat is

transferred to the boiler.

Symptom:

Cools on AC

but not on LP.

Check that baffle

is present

Clean flue tube/baffle of Carbon Build up

Check water column (gas pressure)

PG.

20

Page 30

CLIMATE CONTROL/LAT SWITCH

Turning on the ambient temperature switch “ON” allows

the interior light to turn on so that it will cause the

refrigerator to cycle in cold temperatures. This will

prevent frozen foods from thawing. .5 amps

Turning the climate control switch on will turn on the

frame heater to prevent condensation around the frame.

.5 amps 24 ohms +/- 10%

Note: Not on

ALL models.

PG.

18

Page 31

Air Leak?

Air leaks can

cause a

situation like

this!

Over stocking

and not allowing

air flow on the

sides and back

of refrigerator

can also cause

excessive

frost.

Page 32

Troubleshooting a Check Light

DC Power Supply

Gas Supply

Grounds

Thermocouple

Burner

Reignitor

Electrode

Solenoid

Power Module

Control Panel

Installation of wire

harness

• DC – If DC voltage drops below 9.6VDC – AC ripple

on DC line (Dirty Voltage)

• Gas Supply - see components and discuss

* Grounds- a bad or loose ground can cause a Check

Light! A loose ground can create negative millivolts

☺ Discuss

• If a lower control board has recently been replaced

and the check light comes on at start up – review wiring

diagram of new control board and review installation

instructions – in some cases, a wiring harness needs to

be replaced and a ground wire needs to be removed.

(see next slide for example)

Page 33

P3 harness needs to be replaced

Ground wire needs to be removed

Page 34

New Universal Board

Page 35

Icemaker Operation

All icemakers require

120 volts AC to

operate.

Allow refrigerator to

Pre-Cool before

starting the icemaker.

Make sure Manual

Shut-Off valve is

“OPEN”.

Make sure that the

Bail Arm is in the

“DOWN” position.

PG.

27

Page 36

Mold Thermostat

This is a bi-metal switch. It

starts an ejection cycle by

closing at 12°F +/- 3°. The

reset temperature is

50°F +/- 5.

Symptom: Icemaker

is not making ice.

Test: Put a glass of

water or anti-freeze on the

shelf by the icemaker. Take

liquid temperature.

Page 37

Adjusting the Water Fill

Turn screw as

necessary toward the

“+” or the “-” side.

One FULL turn either

way will make an 18cc

change in the amount

of water.

DO NOT turn the

screw more than one

full turn at a time.

Page 38

Icemaker Water Valve

Valve is Solenoid Operated

Ohms Value is 200 to 500.

10-15 watts will energize the coil.

Note: When the solenoid is

energized, a voltage drop may occur.

Symptom: No water in mold. Have

already manually cycled icemaker.

Test: Check ohms on solenoid coil,

see if solenoid is energized when

icemaker is calling for water.

Page 39

How to Drain the Icemaker

Close the Shutoff Valve.

Place a pan under the

solenoid valve.

Remove the inlet fitting

from the water solenoid

valve. Drain water from

water line.

Remove the plastic nut

and water line from the

outlet side. Drain.

Cycle icemaker several

times while blowing

compressed air through

solenoid.

Note: Up to 40 PSIG.

Page 40

You are the reason we are here!

Loading...

Loading...