Dometic NDR 1402 Installation And Operating Instructions For Manual And Remote Control Options

Page 1

INSTALLATION AND

OPERATING INSTRUCTIONS

REFRIGERATOR FOR LP-GAS AND ELECTRIC OPERATION

NDR 1402

USA Corporate Office CANADA

Service Office 2320 Industrial Parkway Elkhart, IN 46515 Dometic Distribution Inc.

Dometic Corporation 866 Langs Drive

509 South Poplar Street Cambridge, Ontario

LaGrange, IN 46761 For Service Center Assistance N3H 2N7 Canada

Phone: 260-463-4858 Call: 800-544-4881 Phone: 519-653-4390

825 12 23-00

®

®

Contents:

Page

Installation 4

Operating Instructions 8

Maintenance & Service 12

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Dont touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

WARNING: Improper installation,

adjustment, alteration, service or

maintenance can cause injury or

property damage. Refer to this

manual. For assistance or additional

information consult a qualified

installer, service agency or the gas

supplier.

Pour votre sécurité

Si vous sentez une odeur de gaz:

1. Ouvrez les fenêtres.

2. Ne touchez à aucun interrupteur.

3. Éteignez toute flamme nue.

4. Avertissez immédiatement votre fournisseur de gaz.

Pour votre sécurité

Ne pas entreposer ni utiliser de lessence ni

dautres vapeurs ou liquides inflammables à

proximité de cet appareil ou de tout autre

appareil.

Avertissement: Une installation, un réglage,

une modification, une réparation ou un

entretien non conforme aux normes peut

entraîner des blessures ou des dommages

matériels. Lisez attentivement le mode demploi fourni avec lappareil. Pour obtenir de

laide ou des renseignements supplémentaires, consultez un installateur ou un service

dentretien qualifié ou le fournisseur de gaz.

Page 2

Page 3

3

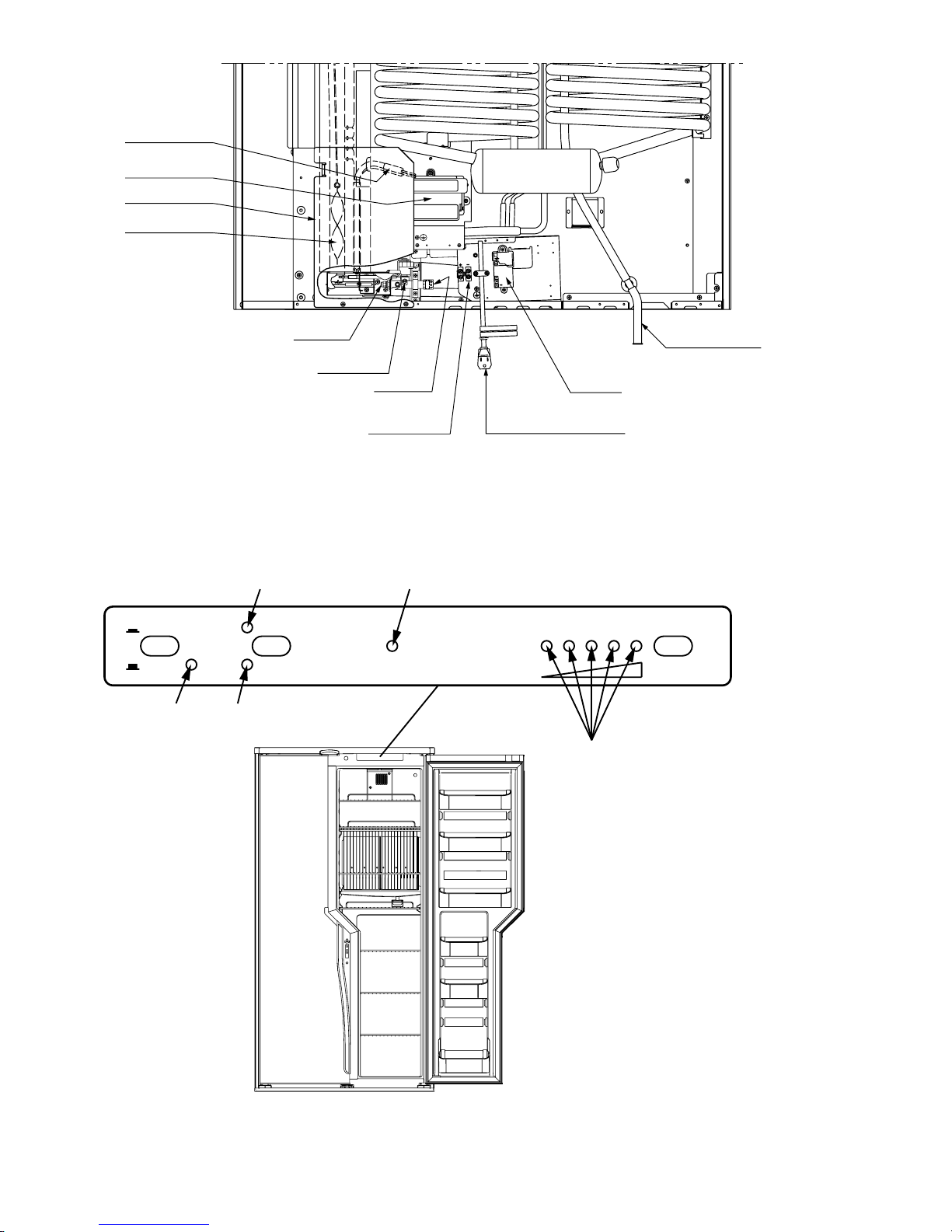

Refrigerator control panel

FIG. 2

GAS

AC

ON

OFF

AES

AUTO

CHECK

COLD

COLDEST

1

2

34

5

12 3

AC

BD

E

LEGEND 2-WAY AES Model

1. Main Power Button ON/OFF

2. AES/AUTO/GAS Mode Selector Button

3. Temperature Selector Button

A. AC Mode Indicator Lamp

B. AES/AUTO Mode Indicator Lamp

C. GAS Mode Indicator Lamp

D. CHECK Indicator Lamp

E. Temperature Indicator Lamps

FIG. 1

12V DC

Heaters

Power module

and fuses

Protection cover

Flue baffle

Burner jet

Manual gas

shutoff valve

Inlet fitting

12 Volt

Terminal block

Reigniter

Flexible cord, Refrigerator

Drain water hose

Page 4

4

INSTALLATION

GENERAL INSTRUCTION

This appliance is designed for storage of foods and

storage of frozen foods and making ice.

This appliance is certified under the latest edition of

ANSI Z21.19CSA 1.4 Refrigerators using gas fuel.

The installation must conform with local codes, or in

absence of local codes, the following standards as applicable.

In the U.S. the installation must conform with:

1. National Fuel Gas Code, ANSI Z223.1/NFPA 54

(latest edition).

2. Recreational Vehicles Code, ANSI A119.2 (latest

edition)

3. Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280.

If an external electrical source is utilized, the refrigerator, when installed, must be electrically grounded in accordance with local codes or, in the absence of local

codes, the National Electrical Code, ANSI/NFPA 70 - (latest edition).

In CANADA, the installation must conform with:

1. Natural Gas and Propane Installation Code,

CSA B149.1

2. CSA Z240 RV Series, Recreational Vehicles.

3. Current CSA Z240.4, Gas-equipped Recreational

Vehicles and Mobile Housing.

If an external electrical source is utilized, the refrigerator, when installed, must be electrically grounded in accordance with local codes or, in the absence of local

codes, the Canadian Electrical Code, CSA C22.1, Parts

I and II - (latest edition).

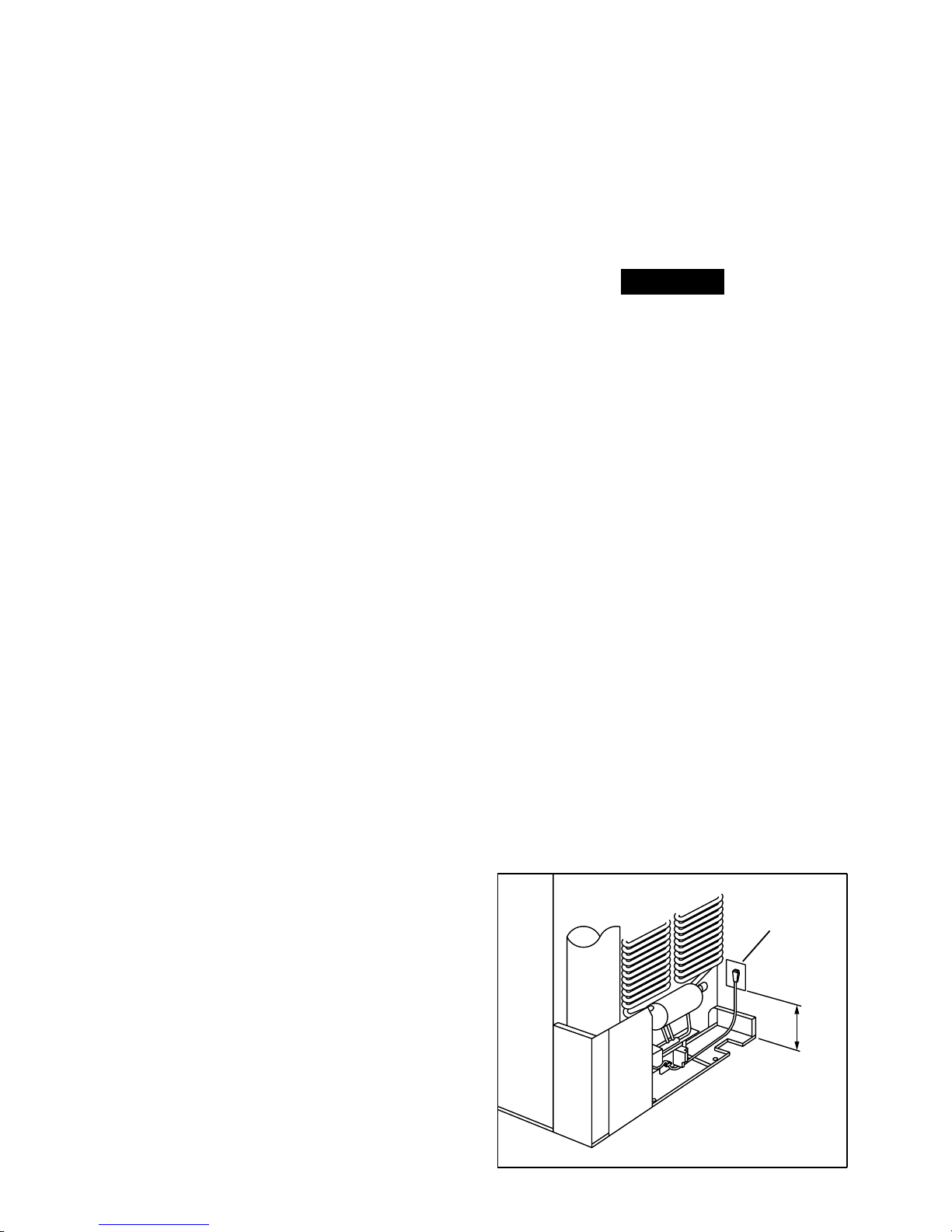

VENTILATION

The installation shall be made in such a manner as to

separate the combustion system from the living space

of the mobile home or recreational vehicle. Openings

for air supply or for venting of combustion products shall

have a minimum dimension of not less than 1/4 inch.

Proper installation requires one lower fresh air intake

and one upper exhaust vent. The ventilation kits shown

in this instruction manual have been certified for use with

the refrigerator models listed in the table. For Certified

Vent System Kits see page 15.

The ventilation kits must be installed and used without

modification. An opening toward the outside at floor level

in the refrigerator compartment must be provided for

ventilation of heavier-than-air fuel gases. The lower vent

of the recommended kits is provided with proper size

openings. The flow of combustion and ventilating air must

not be obstructed.

The lower side vent is fitted with a panel, which provides

an adequate access opening for ready serviceability of

the burner and control manifold of the refrigerator. This

should be centered on the back of the refrigerator.

GAS CONNECTION

Hook up to the gas supply line is accomplished at the

manual gas valve, which is furnished with a 3/8" SAE

(UNF 5/8" -18) male flare connection. All completed connections should be checked for leaks with soapy water.

DO NOT use a flame to check for gas leaks.

The gas supply system must incorporate a pressure regulator to maintain a supply pressure of not more than 11

inches water column.

When testing the gas supply system at test pressures in

excess of 1/2 psi, the refrigerator and its individual shutoff

valve must be disconnected from the gas supply piping

system.

When testing the gas supply system at pressures less

than or equal to 1/2 psi, the appliance must be isolated

from the gas supply piping system by closing its individual manual shutoff valve.

In case detailed instructions on the installation and connection to the gas supply are required, contact your

dealer or distributor.

ELECTRICAL CONNECTION

120 Volts AC Connection

The refrigerator is equipped with a three-prong (grounding) plug for your protection against shock hazards and

should be plugged directly into a properly grounded threeprong receptacle. DO NOT cut or remove the grounding

prong from this plug. The free length of the cord is 2 feet

and therefore recommended that the receptacle be located to the right side of the refrigerator (viewed from

the rear) and approximately 10 inches from the floor (see

FIG. 3). This allows easy access through the vent door.

The cord should be routed to avoid direct contact with

the burner cover, flue cover or any other components

that could damage the cord insulation.

! WARNING

FIG. 3

10

120 Volt AC

receptacle

Page 5

5

12 Volts DC Connection

The refrigerator model NDR 1402 require a continuous

12 volt DC supply (even though 2-way models are designed to operate on 120 volts AC and gas, a 12 volt DC

control is required to maintain the automatic energy system). The connection is made to the positive (+) and

negative (-) terminals of the terminal block on the back

of the refrigerator. (See FIG. 1). Correct polarity must be

observed when connecting to the DC supply.

Do not use the chassis or vehicle frame as one of the

conductors.

Connect two wires at the refrigerator and route to the

DC supply.

The distance the current must travel from the battery to

the refrigerator dictates the AWG wire size to be used.

Should the wire be too small for the distance, a voltage

drop will result.

Recommended wire sizes are shown below.

Caution: Use care when installing the refrigerator. This

refrigerator is equipped with the latest vacuum insulated

panel technology. These insulating panels are located

on the Top, Back, Bottom, Sides and Doors of the refrigerator.

If the surface is punctured, loss of insulation will occur,

resulting in poor refrigerator performance.

NOTE: A wood strip must be in place across the upper

opening of the enclosure. The top frame of the refrigerator will be anchored to the wood strip with screws, see

FIG. 10.

The refrigerator must be installed in a substantial enclosure and must be level. When installing the refrigerator

in the enclosure, all areas within the recess in which the

refrigerator is installed must be sealed.

Make sure that there is a complete seal between the

front frame of the refrigerator and the top, sides and

bottom of the enclosure. A length of sealing strip is applied to the rear surface of the front frame for this purpose, see FIG. 4. The sealing should provide a complete isolation of the appliances combustion system from

the vehicle interior.

NOTE: Be careful not to damage the sealing strip when

the refrigerator is put in place.

The wires from the battery to the refrigerator must be of

large enough size to handle the load. The connections

must be clean, tight and free from corrosion.

INSTALLING REFRIGERATOR IN

ENCLOSURE

The transport support at the rear of the refrigerator can

be removed if necessary for the installation of the refrigerator in the enclosure. (See figure above).

NOTE: DO NOT install the appliance directly on

carpeting. Carpeting must be removed or

protected by a metal or wood panel beneath

the appliance, which extends at least full

width and depth of the appliance.

Securing the Refrigerator

After the refrigerator is put in place, (ensuring a combustion seal at the front frame), the refrigerator is to be

secured in the enclosure with six screws (not included).

The screws have to be installed in the following order:

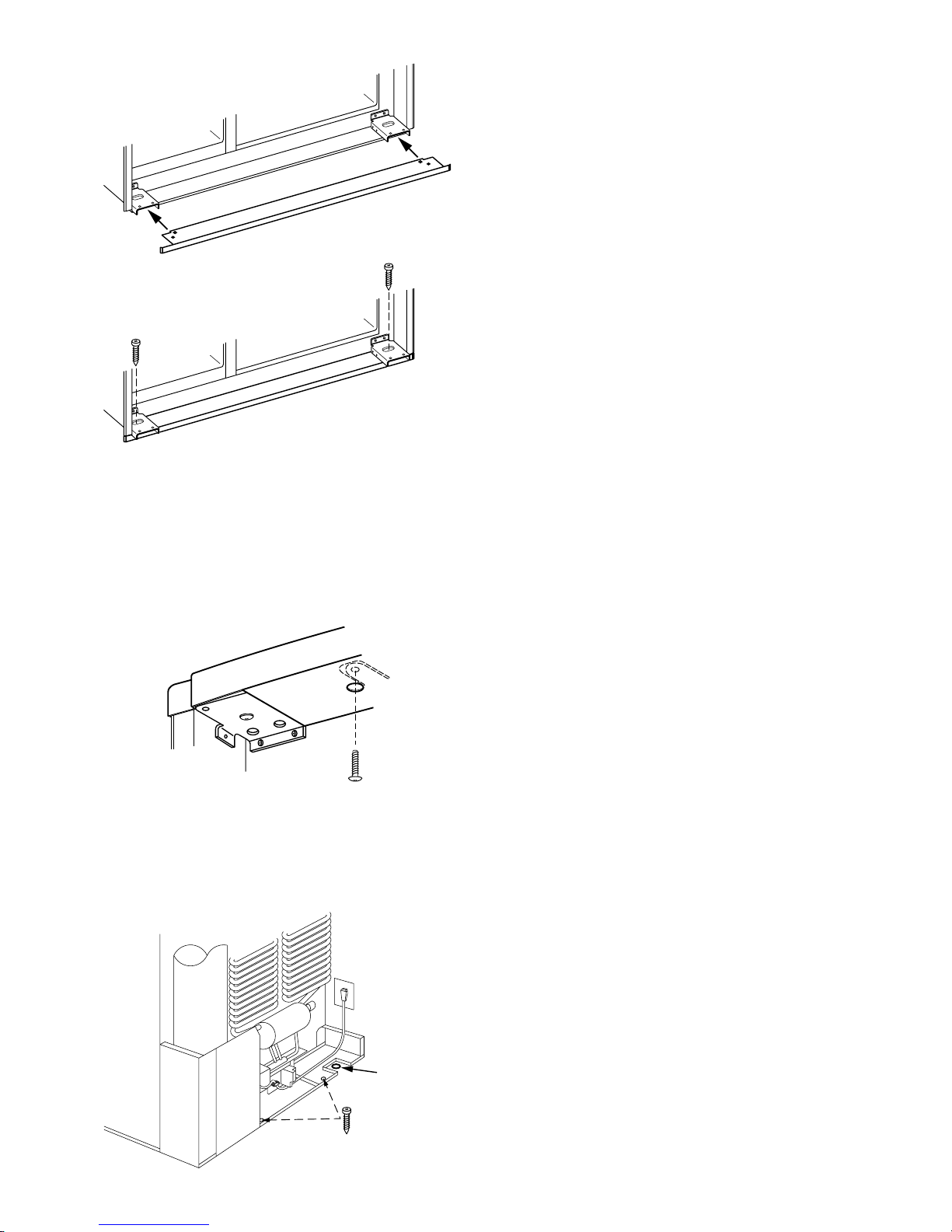

STEP 1: Two screws installed through the front base,

which includes the lower front strip installation.

The refrigerator is provided with a lower front strip

(shipped as a loose part). The front strip is to be attached

after the refrigerator is set into the cutout opening.

1. Install the lower front strip by sliding it under the

bottom hinge plates, as shown in FIG. 5.

MAXIMUM TOTAL CONDUCTOR WIRE LENGTH

(in feet and meters)

Wire length AWG

17 ft.

14

5 m

27 ft.

12

8 m

FIG. 4

Page 6

6

2. Secure the refrigerator and the lower front strip with

two screws: One screw through each hinge. See

FIG 6.

Step 2: Two screws installed in the top frame.

Open the doors and fasten the refrigerator with two

screws through the holes underneath the top decoration

panel. See FIG. 7.

Failure to follow the sequence in securing refrigerator in

enclosure can cause leakage between the frame and

cabinet.

Any space between the counter, storage area or ceiling

and top of the refrigerator greater den 1-1/2 inches should

be blocked. The heat produced at the rear of the refrigerator will become trapped in this space, making the top

of the refrigerator hot and reduce the efficiency of the

refrigerator.

Drain water hose

A hole must be drilled through flooring see FIG. 8.

The hole must be drilled in the cut out opening of the

base plate at the rear of the refrigerator. The installer

MUST make sure that the hose does not kink when run

through the floor. Seal around the hose that goes through

the drilled hole. If a longer hose than supplied is required

to get the water to drain outside of the vehicle, the installer will have to supply the extra length of hose.

TESTING LP GAS SAFETY

SHUTOFF

The gas safety shutoff must be tested after the refrigerator is connected to LP gas supply.

To test the gas safety shutoff, proceed as follows:

1. Start the refrigerator according to the instructions,

and switch to GAS mode. (See start up instructions).

2. Check that the gas flame is lit and the GAS mode

indicator lamp (C) is on.

3. Close the manual gas shutoff valve at the back of

the refrigerator. (See FIG. 1).

4. Wait for one minute. The CHECK indicator lamp

(D) should be on and the GAS mode indicator lamp

(C) should be off.

5. Remove protection cover (see FIG. 1) and open

the manual gas shutoff valve. Do not change any

button positions on the control panel. Apply a noncorrosive commercial bubble solution to the burner

jet orifice.

6. No bubbles should appear at the opening of the

burner jet orifice. The presence of bubbles indicates a defective gas safety shutoff, and service is

required.

7. If no bubbles were present at the burner jet orifice,

it should be rinsed with fresh water. Be careful not

to damage the burner jet orifice. Replace cover and

press the main power ON/OFF button (1) OFF and

back ON. Normal operation of the burner should

return. Allow the burner to operate for a minimum

of five minutes.

STEP 3: Two screws installed in the rear base.

See FIG. 8.

FIG. 5

FIG. 6

FIG. 7

FIG. 8

Hole for drain

water hose

Page 7

7

CERTIFIED INSTALLATION

Certified installations require one roof vent and one lower

side vent.

For Certified Vent System Kits see page 15.

For further information contact your dealer or distributor.

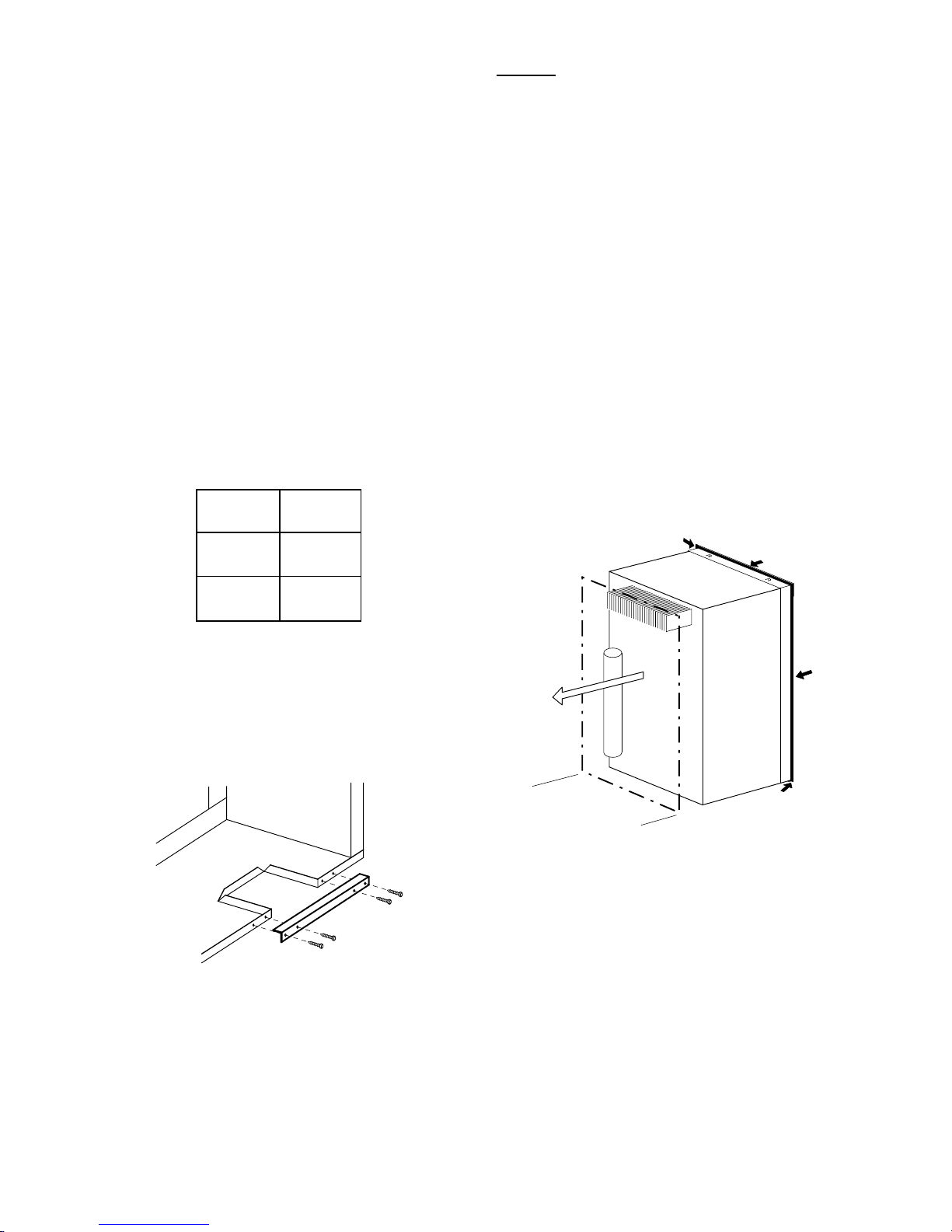

METHODS OF INSTALLATION

The method of installation is shown in FIG. 9. It is essential that all maximum or minimum dimensions are strictly

maintained as the performance of the refrigerator is dependent on adequate flow of air over the rear of the refrigerator.

NOTE: The upper vent should be centered over the

condenser coil at the back of the refrigerator.

VENTILATION HEIGHTS

CLEARANCES

Minimum clearances in inches to combustible materials

are:

G: Top 0

K: Side 0

L: Bottom 0

M: Rear 0

N: See NOTE: Clearance N below.

NOTE: Clearance M is between the rearmost part of

the refrigerator and the wall behind the refrigerator.

NOTE: Clearance N is the distance between the bottom of the lower vent to the roof material. For ventilation

height, see table VENTILATION HEIGHTS

See Figures 9, and 10.

LOWER VENT CUTOUT

13-5/8

28-5/8

FIG. 9

Ventilation

height

Condenser

FIG. 10

Installation with roof Minimum ventilation

vent and lower side vent heights in:

Refrigerator Inches mm

NDR 1402 69-1/8 1756

K

L

NOTE: Wood Strip

MUST be in place

G

K

N

M

Page 8

8

OPERATING

INSTRUCTIONS

IMPORTANCE OF LEVELING A

REFRIGERATOR

In an absorption refrigerator system, ammonia is liquefied in the finned condenser coil at the top rear of the

refrigerator. The liquid ammonia then flows into the

evaporator (inside the freezer section) and is exposed

to a circulating flow of hydrogen gas, which causes the

ammonia to evaporate, creating a cold condition in the

freezer.

When starting this refrigerator for the very first time, the

cooling cycle may require up to four hours of running

time before the cooling unit is fully operational.

The tubing in the evaporator section is specifically sloped

to provide a continuous movement of liquid ammonia,

flowing downward by gravity through this section. If the

refrigerator is operated when it is not level and the vehicle is not moving, liquid ammonia will accumulate in

sections of the evaporator tubing. This will slow the circulation of hydrogen and ammonia gas, or in severe

cases, completely block it, resulting in a loss of cooling.

Any time the vehicle is parked for several hours with the

refrigerator operating, the vehicle should be leveled to

prevent this loss of cooling. The vehicle needs to be

leveled only so it is comfortable to live in (no noticeable

sloping of floor or walls).

When the vehicle is moving, the leveling is not critical,

as the rolling and pitching movement of the vehicle will

pass to either side of level, keeping the liquid ammonia

from accumulating in the evaporator tubing.

OPERATION

Before starting the refrigerator, check that all the manual

gas valves are in the ON position. DO NOT forget the

manual shutoff valve on the rear of the refrigerator see

FIG. 1.

This refrigerator is equipped with an Automatic Energy

Selector (AES) control system, which can automatically

select the most suitable energy source which is available, either 120 Volt AC, or LP gas operation. The system can be set by the user to be fully automatic, or if

desired, LP gas only. The refrigerator controls will work

down to 9.6 volt DC.

Most LP gas appliances used in recreational vehicles are vented to the outside of the vehicle.

When parked close to a gasoline pump, it is possible that the gasoline fumes could enter this

type of appliance and ignite from the burner

flame, CAUSING A FIRE OR AN EXPLOSION.

FOR YOUR SAFETY, when refueling, shut off all

LP gas appliances which are vented to the outside.

! WARNING

Overall Recess

Refrigerator Dimensions Dimensions

Model

Height Width Depth Height Width Depth

AB C H WD

inch 64-17/64 33-11/16 29-5/8 63-3/16 32-3/4 26-1/16

NDR 1402

mm 1632 855 752 1605 832 662

This method of installation and these clearances will give you adequate space for service and proper installation.

FIG. 11

Side view View from above

D

HA

D

W

C

B

Page 9

9

THERMOSTAT

The thermostat on the refrigerator controls both the gas

and electric operation, thereby eliminating the necessity of resetting each time a different energy source is

employed.

After the initial start-up, the thermostat should be moved

from COLDEST to the desired temperature setting,

usually at mid setting.

TO SHUT OFF THE REFRIGERATOR

The refrigerator may be shut off while in any mode of

operation by pressing the main power ON/OFF button

to the UP (OFF) position. This shuts off all DC power to

the refrigerator, including the interior light.

START UP INSTRUCTIONS

A. A continuous 12 volt DC supply must be available for

the electronic control to function.

B. Press the main power ON/OFF button (1) to the

DOWN position.

C. Press the TEMPERATURE SELECTOR button (3)

until the lamp at the desired setting is illuminated.

AES/AUTO MODE

1. Press the AES/AUTO/GAS mode selector button (2)

to turn ON the AES/AUTO lamp (B). If 120 volts is

available, the AC mode indicator lamp (A) will illuminate indicating AC operation. If 120 volts AC is not

available, the GAS indicator lamp (C) will illuminate

indicating the control has automatically switched to

the GAS mode.

2. If the CHECK indicator lamp (D) illuminates and the

GAS mode indicator lamp (C) is off, the controls have

failed to ignite the burner in the GAS mode. GAS

operation may be reset by pressing the main power

ON/OFF button (1) to the OFF then ON position. (See

step 2 under GAS MODE).

3. Press the TEMPERATURE SELECTOR button (3)

until the lamp at the desired position is illuminated.

GAS MODE

1. Press the AES/AUTO/GAS mode selector button (2)

to turn OFF the AES/AUTO lamp (B). The GAS mode

indicator lamp (C) will illuminate. Within 45 seconds

the burner should be ignited and operating normally.

2. On the initial refrigerator start-up, it may take longer

than 45 seconds to allow air to be purged from the

gas line. If the gas does not ignite within 45 seconds

the CHECK indicator lamp (D) will illuminate and the

GAS mode indicator lamp (C) will go off.

To reset when the CHECK indicator lamp (D) is illuminated, press the main power ON/OFF button (1)

to the OFF and then ON position.

NOTE: Do not continue to reset GAS operation if the

CHECK indicator lamp continues to be illuminated

after several tries.

3. Press the TEMPERATURE SELECTOR button (3)

until the lamp at the desired position is illuminated.

DISPLAY PANEL

GAS

AC

ON

OFF

AES

AUTO

CHECK

COLD

COLDEST

1

2

345

12 3

AC

BD

E

Page 10

10

DESCRIPTION OF OPERATING

MODES

AES/AUTO MODE

When operating in the AES/AUTO mode, the AES/AUTO

mode indicator lamp (B) will illuminate. The control system will automatically select between AC and GAS operation with AC having priority over GAS. Either the AC

indicator lamp (A) or the GAS indicator lamp (C) will

illuminate depending on the energy source selected by

the control system. If the control system is operating

with AC energy and it then becomes unavailable, the

system will automatically switch to GAS. As soon as AC

becomes available again the control will switch back to

AC regardless of the status of GAS operation.

GAS MODE

When operating in the GAS mode the AES/AUTO mode

indicator lamp (B) will be off and the GAS mode indicator lamp (C) will be illuminated. This mode provides LP

gas operation only. The control system will activate the

ignition system and will make three attempt to light the

burner for a period of approximately 45 seconds with

two minutes interval. If unsuccessful, the CHECK indicator lamp (D) will illuminate and the GAS mode indicator lamp (C) will turn off.

To restart GAS operation, press the main power ON/

OFF button (1) to the OFF and then ON position. The

control system will attempt a new ignition sequence.

If the refrigerator has not been used for a long time or

the LP tanks have just been refilled, air may be trapped

in the supply lines. To purge the air from the lines may

require resetting the main power ON/OFF button (1) three

or four times. If repeated attempts fail to start the LP gas

operation, check to make sure that the LP gas supply

tanks are not empty and all manual shutoff valves in the

lines are open. If the problem is still not corrected, contact a service center for assistance.

If the control is switched to AC operation while the CHECK

indicator lamp is on, it will function properly, but the

CHECK indicator lamp will not go off until the main power

ON/OFF button is pressed to the OFF then ON position.

LIMP MODE OF OPERATION

This control system contains a feature where it will continue to operate the cooling system in the event of a failure of a major operating component. Two different modes

of operation can occur in this category.

If for some reason the display module becomes non functional, the control system will revert to full automatic

operation selecting the best energy source available with

AC, GAS priority. The temperature of the refrigerator

will be maintained at the MID position within normal temperature tolerances. The power module will continually

attempt to reestablish operation of the display module.

The second limp mode of operation will execute when a

failure of the temperature sensing device or associated

electronic circuitry occurs. If this should occur, the control system will operate on the energy source selected

via the control panel. The cooling unit will run continuously on the selected energy source. The refrigerator

will continue to operate in this mode indefinitely or until

a new sensor is installed and the system is reset.

DISPLAY PANEL

E

GAS

AC

ON

OFF

AES

AUTO

CHECK

COLD

COLDEST

1

2

345

12 3

AC

BD

Page 11

11

HOW TO USE THE REFRIGERATOR

FOOD STORAGE COMPARTMENT

The food storage compartment is completely closed and

unventilated, which is necessary to maintain the required

low temperature for food storage. Consequently, foods

having a strong odor or those that absorb odors easily

should be covered. Vegetables, salads etc. should be

covered to retain their crispness. The coldest positions

in the refrigerator are under the cooling fins and at the

bottom of the refrigerator. The warmer areas are on the

upper door shelves. This should be considered when

placing different types of food in the refrigerator.

When the refrigerator is heavily loaded, it will take a

longer time to lower the temperature; therefore, to get

maximum efficiency the refrigerator and food items

should be precooled prior to loading. The shelves should

not be covered with paper or plastic, and the food items

should be arranged so air can circulate freely.

If you need more space in the refrigerator you can lift up

the front of the second shelf from the top and push the

shelf in, the shelf will fall down against the finned evaporator. This shelf cannot be relocated to a different position within the refrigerator.

The middle shelf is a sliding shelf, to slide out grasp the

front of the shelf and pull forward. Push the shelf in to

return to original position. This shelf cannot be relocated

to a different position within the refrigerator.

The lower door shelf is designed for large containers or

bottles (1/2-gallon milk or juice).

FROZEN FOOD STORAGE

COMPARTMENT

Quick frozen soft fruits and ice cream should be placed

in the coldest part of the compartment, which is on the

top freezer shelf. Frozen vegetables, may be stored in

any part of the compartment.

This compartment is not designed for deep or quickfreezing of food. Meat or fish, whether raw or prepared,

can be stored in the frozen food storage compartment

provided they are precooled first in the refrigerator. They

can be stored about three times longer in the frozen food

compartment as compared to the fresh food compartment. To prevent food from drying out, keep it in covered dishes, containers, plastic bags or wrapped in aluminum foil.

Total Refrigerated Volume 13.2 cu.ft.

Ice making

Ice cubes can be made in ice trays placed in the freezer

compartment. For faster ice making, the trays should be

placed in direct contact with the aluminum shelf.

Ice will be made more rapidly if the thermostat is set at

its highest position. It is a good idea to do this a few

hours before the anticipated need for ice, but be sure to

move the thermostat back to normal setting, usually

about mid setting when the ice is formed. Food in the

fresh food compartment may be frozen if the setting is

left on COLDEST position.

Freezer door

The freezer door has three wire door baskets for frozen

food items, such as bagged vegetable.

Freezer compartment

The freezer compartment has two sliding wire baskets

for more convenient access to the frozen foods.

DEFROSTING

Shut off the refrigerator by pressing the main power ON/

OFF button to the UP (OFF) position.

Empty the refrigerator, leaving the drip tray under the

finned evaporator, and the cabinet and freezer doors

open. Filling ice trays with hot water and placing them

on the freezer shelves can reduce defrosting time.

When all the frost has melted, dry the interior of the refrigerator and freezer with a clean cloth. Replace all food

and set the thermostat to the COLDEST temperature

setting for a few hours. Then reset the thermostat to the

desired setting, usually at mid setting.

Page 12

12

DO NOT use a hot air blower. Permanent damage

could result from warping the metal or plastic parts.

DO NOT use a knife or an ice pick, or other sharp

tools to remove frost from the freezer shelves. They

can create a leak in the ammonia system.

CLEANING

Cleaning the refrigerator is usually done after it is defrosted or put into storage. To clean the interior liner of

the refrigerator, use lukewarm weak soda solution. Use

only warm water to clean the finned evaporator, ice trays

and shelves. NEVER use strong chemicals or abrasives

to clean these parts, as the protective surfaces will be

damaged. It is important to always keep the refrigerator

clean.

SHUT OFF - STORAGE PROCEDURE

Shut off the refrigerator by pressing the main power ON/

OFF button to the UP (OFF) position.

If the refrigerator will not be in operation for a period of

weeks, it should be emptied, defrosted, cleaned and the

doors left ajar. The ice trays should also be dried and

kept outside the cabinet.

FUSES

This model is equipped with 2 fuses, one for the refrigerator control system and one for AC cartridge heater.

(See table below).

To replace fuses proceed as follows.

1. Disconnect the wall plug, and the 12 volt wires.

2. Remove the power module cover. See FIG. 1.

3. Snap the fuse out of the fuse holder.

4. Fit a new fuse in to the fuse holder.

5. Replace the power module cover.

! CAUTION

! WARNING

DO NOT store explosive substances in the refrigerator, such as cigarette lighter gas, gasoline, ether

or the like.

NOTE: Sodium chromate is used for corrosion protec-

tion (less than 2-weight % of the coolant).

ELECTRIC EQUIPMENT

HEATERS

The heat necessary for the operation of an absorption

cooling unit is supplied by an electric heater mounted in

a pocket of the boiler system.

This model is equipped with a series connected twin

heater.

To replace the heater proceed as follows:

1. Disconnect the wall plug, and the 12 volt wires.

2. Remove the protection cover see FIG. 1

3. Remove the power module cover see FIG. 1

4. Disconnect the heater leads.

5. With a pair of pliers unfold the lug holding the lid

of the boiler casing and open the lid.

6. Remove some insulation wool so that the heater

is accessible.

7. Turn and lift the heater out of its pocket.

8. Fit the new heater into the pocket.

9. Connect the leads and put on the power module

cover.

10. Reset the insulation and close the lid of the boiler.

11. Replace the protection cover.

Control system 3 Amp

AC heater 5 Amp

MAINTENANCE & SERVICE

The user should be aware of service that must be

done on a regular schedule to keep the refrigerator

operating properly. The service should only be performed by a qualified technician who is familiar with

LP gas systems and refrigerators.

1. REFRIGERATOR REMOVAL

Before working on the refrigerator, make sure the AC

voltage and DC voltage leads are disconnected. Shut

off the gas supply. Disconnect the gas supply line at

the rear of the refrigerator see FIG. 1. Always use a

back up wrench when loosening and tightening this

connection. Cap the gas supply line loosen the screws

anchoring the refrigerator to the enclosure and slide

the refrigerator out of the compartment.

When replacing the refrigerator make sure that the

sealing strips are properly positioned.

Replacement is the reverse of removal. Check all connections for gas leaks.

Refer to section INSTALLATION, page 4 to 8.

2. PERIODIC MAINTENANCE

To keep your Dometic refrigerator operating efficiently

and safely, periodic inspection and cleaning of several components once or twice a year is recommended.

A. It is important to keep the area at the back of the

refrigerator clean. Check the lower vent, upper vent

and area between these openings for any obstructions such as bird/insect nests, spider webs, etc.

Clean the coils on the back of the refrigerator. Use

a soft bristled brush to dust off the coils.

It is important to keep the refrigerator area free from

combustible material, gasoline and other flammable

vapors or liquids.

Page 13

13

NOTE: The following maintenance is required once or

twice a year, but should only be done by a qualified serviceman who is familiar with LP gas systems and refrigerators.

B. Check all connections in the LP gas system (at the

back of the refrigerator) for gas leaks. The LP gas

supply must be turned on. Apply a noncorrosive

bubble solution to all LP gas connections. The appearance of bubbles indicates a leak and should be

repaired immediately by a QUALIFIED SERVICEMAN

WHO IS FAMILIAR WITH GAS SYSTEM AND REFRIGERATORS.

6. Remove the burner mounting screws and remove the

burner assembly. (See FIG. 12).

7. Remove the wire and the flue baffle from the top of

flue tube. Clean the flue from the top using a flue

brush. Blowing compressed air into the flue will not

properly clean soot and scale out of the flue tube.

Replace the flue baffle.

8. Clean burner tube with a brush. Blow out burner with

compressed air.

9. Before removing burner jet, clean burner area of soot

and scale that fell out of flue tube. Remove the burner

jet. Soak the jet in wood alcohol and blow it out with

compressed air. Reinstall and tighten burner jet.

NOTE: The color of the flame shall be clear blue

over the slots of the burner. (See FIG. 13).

! WARNING

DO NOT use a wire or pin when cleaning the burner

jet as damage can occur to the precision opening.

This can cause damage to the refrigerator or create

a fire hazard.

FIG. 13

Clear blue color

of flame

GAS EQUIPMENT ASSEMBLY

SOLENOID VALVE

INLET FITTING

MANUAL SHUTOFF VALVE

Shown in open position

PRESSURE TEST PORT

BURNER JET

SPARK ELECTRODE

BURNER TUBE .

THERMOCOUPLE

BURNER MOUNTING

SCREWS

FIG. 12

! WARNING

DO NOT use a flame to check for gas leaks.

C. Check the AES control system by connecting/discon-

necting 120 volt AC power, start/stop the engine, etc.

Compare the operation with the operation described

in description of operating modes. Page 10.

D. The LP gas pressure should be checked and the main

regulator readjusted if pressure is incorrect.

The correct operating pressure is 11 inches of water

column. The correct place to take the LP gas pressure is at the test port just ahead of the burner jet.

(See FIG. 12).

E. Inspect the flue baffle. It should be reasonably clean

and free of soot. Heavy soot formation indicates improper functioning of the burner. The flue and burner

both require cleaning in the following manner:

1. Unplug the refrigerator power cord from the 120 volt

AC outlet. (See FIG. 3).

2. Disconnect or shut off the 12 volt power to the refrigerator.

3. Turn manual shutoff valve to OFF. (See FIG. 1).

4. Remove cover from the burner housing. (See FIG. 1).

5. Disconnect the wire from the high voltage electrode.

Page 14

14

10. Reinstall burner, being careful that the end of the

burner fits into the slot on the burner bracket. Check

to make sure slots are centered under the flue tube

and the thermocouple is positioned properly (tip of

thermocouple extends over two slots of burner).

11. Be sure to reconnect the wire to high voltage elec-

trode. Check the electrode for proper location and

gap. (See FIG. 14).

TROUBLESHOOTING

The Refrigerator Does Not Cool Properly

A. Burner jet clogged.

Clean. (See section Maintenance & Service, Item

2. Periodic Maintenance, Paragraph E. Item 1-14.)

B. Check level of refrigerator.

C. Venting problem.

Restriction in air flow across cooling unit.

D. Heavy frost buildup on evaporator fins.

Defrost.

E. Flue baffle not inserted properly in flue tube.

F. Improperly set thermostat.

(See section Operating Instructions, part Start Up

Instructions.)

G. Burner dirty.

Clean. (See section Maintenance & Service, Item

2. Periodic Maintenance, Paragraph E. Item 1-14.)

H. LP gas pressure low at burner.

Set main regulator so pressure does not drop

below 11 inches water column at pressure tap.

I. Burner not located properly under flue tube.

Relocate.

J. Burner damaged.

Replace.

K. Odors from fumes.

1. Dislocated burner.

2. Damaged burner.

3. Dirty flue tube.

L. FUSES

1. Refrigerator AC Supply.

2. Control system. See page 12, part Fuses.

NOTE: AVOID SPRAYING WATER THROUGH THE

REFRIGERATOR VENTS WHILE WASHING YOUR RV.

All the above instructions are to be followed closely. The

refrigerator is quality-guaranteed. However, we are not

responsible for any failures caused by improper adjustments and unfavorable installation conditions. Contact

service point or distributor service dept. for assistance.

FIG. 14

Electrode

Burner tube

1/8 to 3/16

(3-5 mm)

12. Turn on manual gas shutoff valve and check all fittings for leaks.

13. Connect 120 volt power cord to the outlet and reconnect or turn on the 12 volt DC power.

14. Check LP gas safety shutoff. See page 6.

3. REPLACING A HALOGEN LAMP

Turn off the refrigerator before replacing the lamp.

Wear gloves as protection against hot lamp, broken

glass and as protection of the new lamp.

Refrigerator

The lamp is located at the top of the refrigerator compartment.

To replace the lamp proceed as follows:

unhook the tab on the lamp cover by pressing in

with the thumb on the side of the lamp cover.

remove the lamp cover.

with gloves, pull out the lamp from the socket and

replace it with a new 12V, 10-watt halogen lamp

base G4.

replace the lamp cover by placing the two tabs into

the corresponding slots of the lamp house and

press the tab into place.

Freezer

The lamp is located on the right side of the freezer compartment.

To replace the lamp proceed as follows:

unhook the tab on the lamp cover by pressing in

with the thumb on the side of the lamp cover.

remove the lamp cover.

with gloves, pull out the lamp from the socket and

replace it with a new 12V, 5-watt halogen lamp

base G4.

replace the lamp cover by placing the two tabs into

the corresponding slots of the lamp house and

press the tab into place.

! CAUTION

Page 15

15

CERTIFIED VENT SYSTEM KITS

REFRIGERATOR KIT

MODEL NO. COMPONENTS PART NO.

NDR 1402 5A Roof Base 3103633.XXX*

Roof Cover 3103634.XXX*

Lower Side Vent 3109349.XXX*

Power Vent Asm. 3108705.744**

* Fill in XXX with color code numbers. For color codes, contact your supplier.

** Alternate instructions forwarded with the Ventilator Kit.

For further information contact your dealer or distributor.

SPARE PARTS

The following list is a list of commonly used parts, which

should be available, if required, from your Dometic Service Center.

Part No. Description

17 37 72-01/3 Heater, 120V, 420W

(2x 60V, 210W)

95 50 01-67/2 Burner pipe, cpl.

200 74 19-33/2 Jet, No. 76

293 11 32-02/7 Spark ignition device

293 27 81-02/0 Electrode, with conductor

293 18 26-02/4 Thermocouple

385 04 52-01/6 Lamp cover

385 04 55-01/9 Halogen lamp, food compartment

12V, 10W with base G4

385 04 55-02/7 Halogen lamp, freezer compartment

12V, 5W with base G4

293 25 83-04/6 Doorshelf, 3 pieces (upper)

293 25 77-03/0 Doorshelf, 2 pieces

385 04 45-01/0 Doorshelf, (lower)

385 04 46-01/8 Doorshelf, 2 pieces freezer (upper)

385 04 42-01/7 Crisper, 2 pieces

293 26 58-01/2 Bottle holder, 5 pieces

293 26 67-05/4 Baffle

Replacement Parts Suppliers: See page 1.

Contact an authorized service center for

parts and repairs as needed.

Page 16

16

Put a screwdriver into the slot of the shelf lock.

Turn the screwdriver counterclockwise.

Remove the shelf locks from the wire shelf.

Slide the wire shelf to the left.

The right-hand side of the shelf will come loose.

Lower the right-hand side of the wire shelf and

let the left-hand side slide out of the holes in the

wall.

Slide the plastic plugs into the holes of the wall.

Snap the shelf locks onto the wire shelf.

Slide the shelf into the holes on the right-hand

side.

Insert the ends of the wire shelf on the left-hand

side at the desired position.

Positioning of shelves

Page 17

17

Page 18

18

Page 19

19

Page 20

20

MO-FO 0305

Loading...

Loading...