Page 1

PROCEDURE FOR

®

CHANGING COOLING UNIT

IN CARAVAN 95 AND NDR

REFRIGERATORS

Refrigerator

Bulletin R74/6D

March 2002

The following categories have been established predicated on similarity of design and procedure for

replacement of cooling units:

A - CATEGORY #1

RM2193 RM2332 RM2333

RM2452 RM2453 RM2551

RM2552 RM2553 RM2554

RM4223 RM4290 RM4292

B - CATEGORY #2

RM2620 RM2652 RM2820

RM2852 RM3662 RM3663

RM3862 RM3863 NDR1062

C - CATEGORY #3

RM1272 NDR1282

RM1282 NDR1292

NDR1272 NDR1492

GENERAL INSTRUCTIONS TO ALL MODELS

1. Disconnect shore power from coach, the positive lead

from battery, and turn propane OFF at the tank.

These instructions must be read and understood before installation of this kit. This kit must

be installed by a Dometic service center or a

qualified service technician. Modification of this

product can be extremely hazardous and could

result in personal injury or property damage.

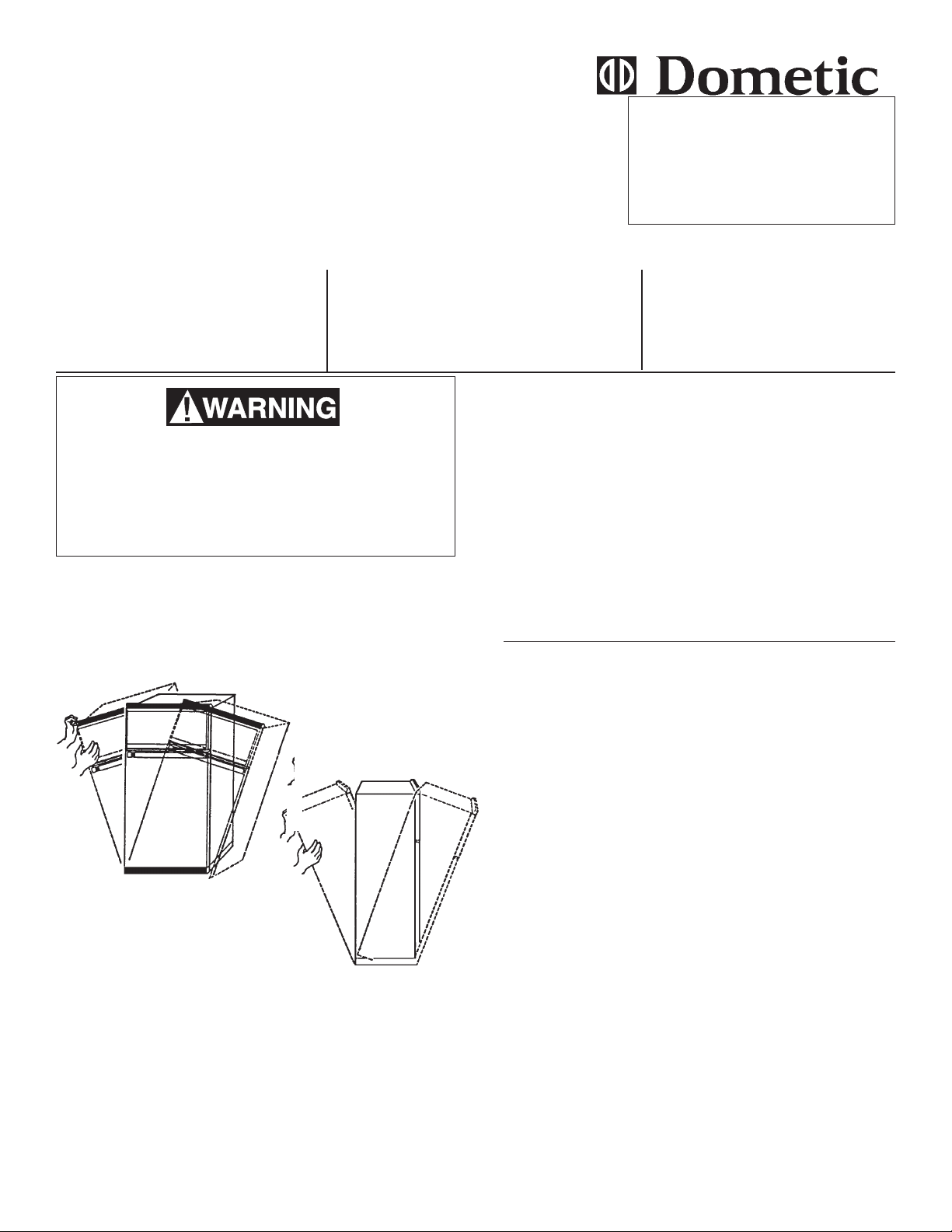

Important: After the cooling unit has been installed,

the initial start-up time can be shortened by tilting the

refrigerator from side-to-side and then from front-toback before the refrigerator is turned on. Hold in each

tilt position for approximately 30 seconds to settle

solution to bottom of cooling unit.

2. Through lower vent, unplug refrigerator 120V AC cord(s)

from wall receptacle. Disconnect 12V DC wires from

terminal block on the refrigerator (if models have 12V

DC). Tape or cap ends.

3. Check again to make sure propane is OFF at tank, then

remove coach gas line from gas cock on refrigerator and

cap coach gas line.

4. For Models with Ice Maker: Turn water OFF to

appliance. Disconnect coach’s water line from water

solenoid (cap end).

5. Remove the refrigerator from alcove.

A. Category #1:

RM2193 RM2332 RM2333 RM4223

RM2452 RM2453 RM2551 RM4290

RM2552 RM2553 RM2554 RM4292

TILT FRONT-TO-BACK

TILT SIDE-TO-SIDE

Run the refrigerator on a bench for 12 hours after the cooling

unit has been installed. The refrigerator should not have food

in it during this test.

REVISION

Form No. 3107154.035 3/02

(Replaces 3107154.027)

©2002 Dometic Corporation

LaGrange, IN 46761

STEP 1. REMOVAL OF COOLING UNIT

1. See General Instructions on all models.

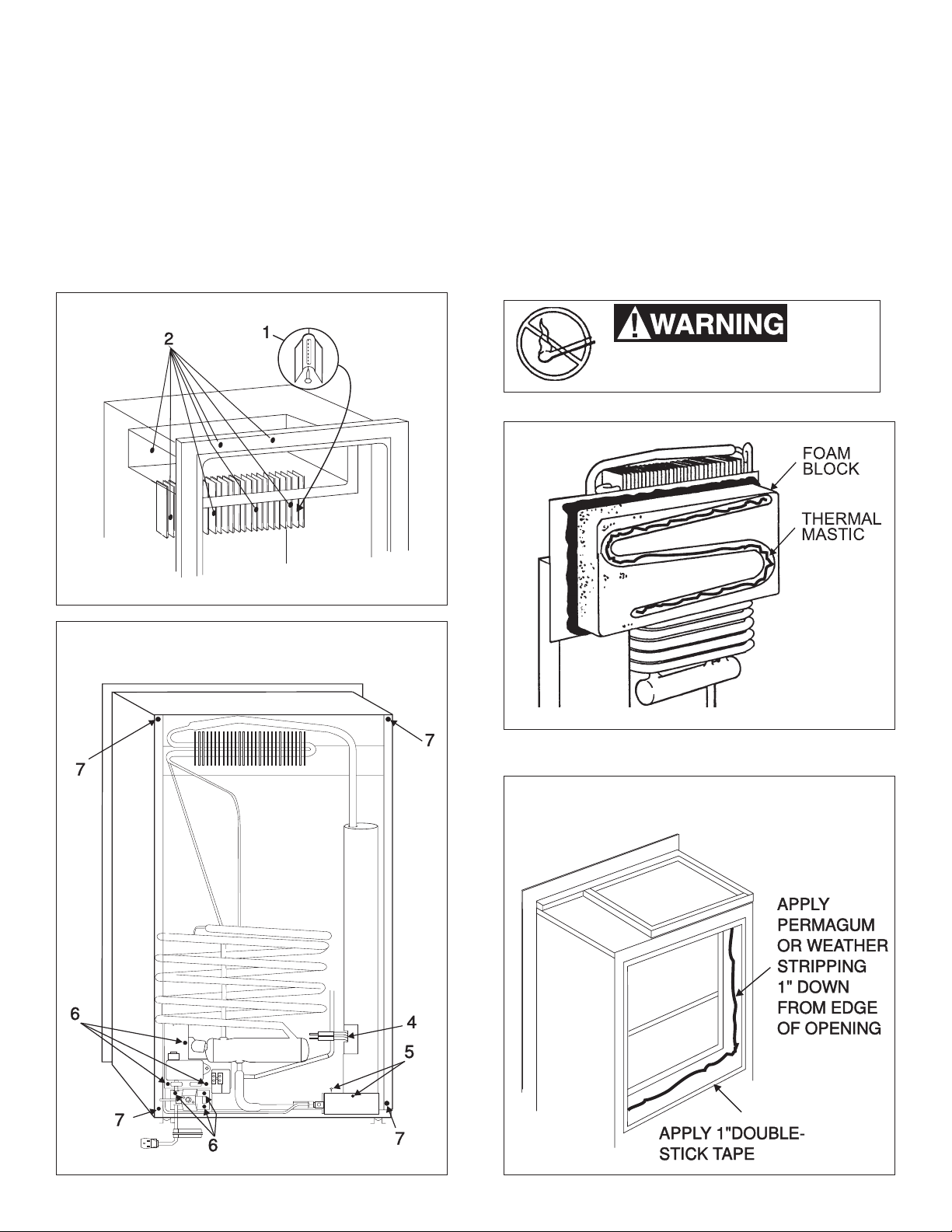

2. Loosen screws holding the thermostat bulb to fins. See

FIG. A1.

Note: Some models have a plastic thermistor bracket

clipped to the fin.

3. Remove the screws from the back wall of the freezer and

the fins.

Note: On models RM2452, RM2453, RM2551, RM2552,

RM2553 and RM2554, the fins are installed on the cooling

unit before it is put in the cabinet. The cooling unit must be

out of the cabinet before the fins can be removed.

4. On all other models remove the fins. See FIG. A1.

5. Lay the refrigerator face down on two 2x4’s to avoid

damaging the refrigerator front.

6. Remove cover from boiler and heating element(s).

7. Remove burner cover and then the burner assembly.

Note: Some models have a bracket that holds the manual

gas cock and/or the electric solenoid valve. Remove the

screws from these brackets and save to be reinstalled.

8. Cut the wire ties along the left side. Remove the

thermostat sensor tube (if required) and position the

burner assembly and wires so they will not be damaged

1

by pulling the cooling unit.

Page 2

STEP 2. INSTALLATION OF COOLING

UNIT

1. Inspect cooling unit for broken welds or bent frame.

2. Trim the foam block portion of cooling unit if it does not

go freely into the refrigerator. Be sure foam does not

cover the evaporator tubes where cooling fins attach.

3. Apply thermomastic on evaporator tubes 1/4” to 3/8”

bead. Apply more if the tubes are recessed in foam

block. (FIG. A3)

4. Apply permagum and double-stick tape to cabinet as

shown in FIG. A4.

FIG. A1

5. If foam block fits loosely into cabinet (1/4” or more of

movement) use 1/2” wide x 3/8” thick closed cell, onesided adhesive weather stripping. Place in the same

location as permagum. Also apply double-stick tape as

shown in FIG. A4.

6. Install cooling unit back in the cabinet. Replace screws

holding cooling unit to cabinet. Replace components

removed in Step 1, 587. (FIG. A2)

7. Stand refrigerator upright. Transfer flue baffle to new

cooling unit. Replace the inside parts removed in Step 1,

2–4. (See “Important” on Page 1).

8. Install refrigerator back into coach and leak check all gas

fittings. Repair all gas leaks.

Do not use a flame

to check for gas leaks.

FIG. A3

FIG. A2

FIG. A4

2

Page 3

B. Category #2

RM2620 RM2652 RM2820 RM2852

*RM3662 *RM3663 *RM3862 *RM3863

*NDR1062

* Optional Ice Maker Cycle

STEP 1. REMOVAL OF COOLING UNIT

1. See General Instructions for all models.

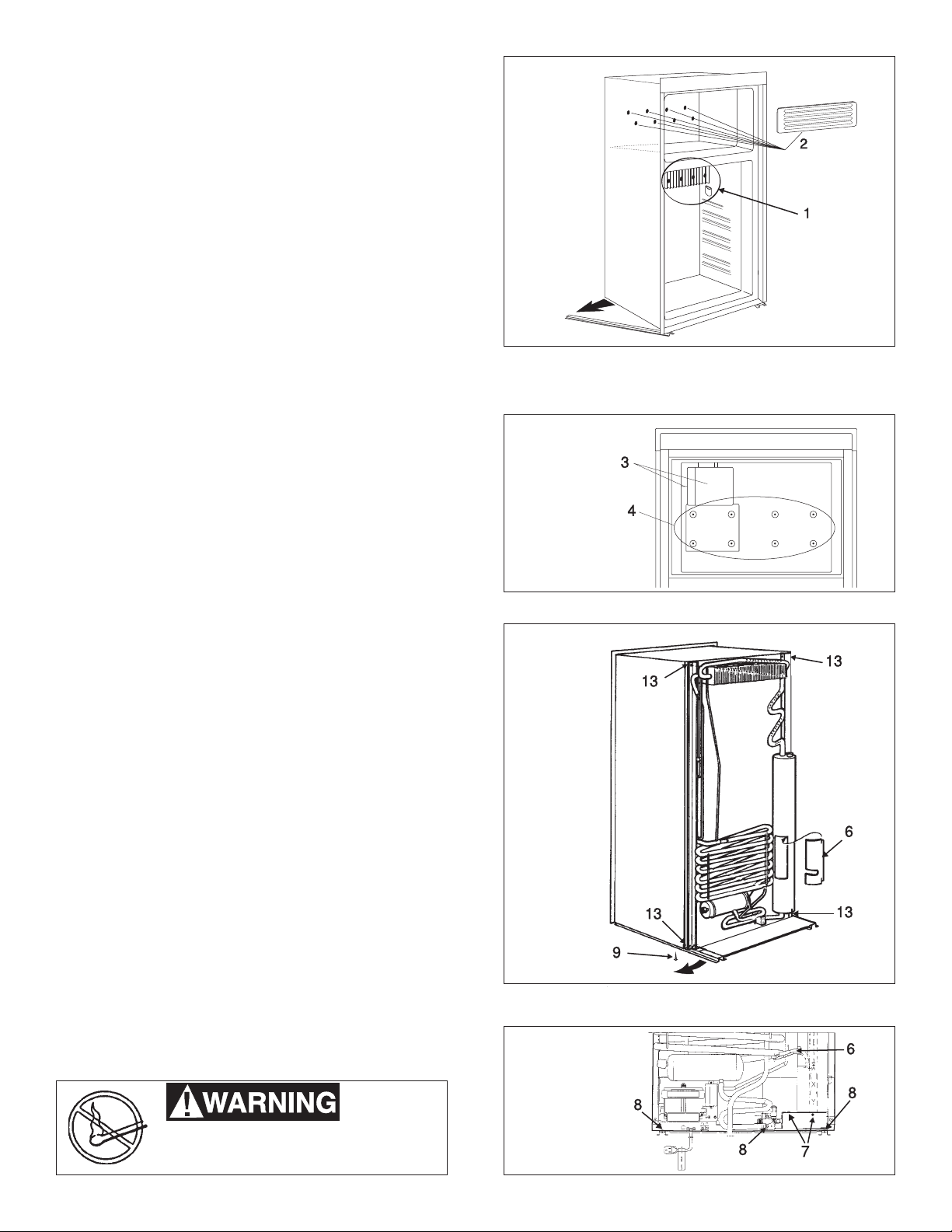

2. Remove thermistor bracket and 4 screws from fins (FIG.

B1). DO NOT remove fins. They are taped to the rear of the

cabinet liner.

3. In the freezer, remove shelves and grill covering screws.

Pull out center of grill to allow right or left side to pop out

of slot (FIG. B1).

4. Models with Ice Maker: Remove the cover of cycle and

the 2 screws holding cycle to the side wall (FIG. B2).

5. Remove 4 screws holding cycle bracket. Be careful not to

drop. Unplug electrical connection and take cycle out of

freezer. Remove the remaining screws. (FIG. B2)

6. Lay the refrigerator face down on two 2x4’s to protect the

face of the appliance.

7. Remove heater cover and heater(s) (FIG. B3 & B4). Also

disconnect ice wire harness leads from electrical connections on the refrigerator.

Note: NDR models - pull wire harness out of the cooling unit

from the inside of freezer. Pull water fill tube from rear of

refrigerator. Disconnect water line from water solenoid valve.

8. Remove burner cover (1 screw) and screw holding the

burner to flue tube. Pull burner down and off tube (FIG. B4).

9. Remove 2 screws holding control panel to runner and 2

screws holding gas solenoid valve to cooling unit (FIG. B4).

10. Take out screws (1 on each side) where runner fastens to

the rear of cabinet. Swing runners out to the side to clear

cabinet (FIG. B3).

11. Cut wire ties holding cables and thermistor to frame of

cooling unit.

12. Disconnect climate control and interior (red wires) from J2

on circuit board and black wires from ground.

13. Cut red and black wires from interior light. Strip back 3/8”

to reconnect using butt connectors after cooling unit has

been installed.

14. Remove 4 screws holding cooling unit to cabinet (2 on top

and 2 on bottom). (FIG. B3). Lift cooling unit out of cabinet.

FIG. B1

FIG. B2

FIG. B3

STEP 2. INSTALLATION OF COOLING UNIT

1. Refer to Step 2, Category A, 1–5.

2. Install cooling unit back in cabinet. Replace screw holding

unit.

3. Replace the components removed in Step 1, 2-14.

4. Stand refrigerator upright. Transfer the flue baffle to new

cooling unit. Replace inside parts removed in Step 1, 2–5.

5. Check for proper cooling before installing refrigerator back

into the coach. (See “Important” on Page 1).

6. Install refrigerator back into coach and leak check all gas

fittings. Repair all gas leaks.

Do not use a flame

to check for gas leaks.

FIG. B4

3

Page 4

STEP 3. PREPARING THE COOLING UNIT

SPREAD ATHIN

LAYER OF

THERMOMASTIC

ON ICE MAKER SHELF

FOR THE ICE MAKER (For only models with ice maker)

Note: Models that have the water fill for the ice maker entering

through the top do no require drilling of cooling unit

(RM3652, RM3653, RM3862, and RM3863). The cooling unit has been installed in the refrigerator, proceed to

number 2.

1. Before the shelves and other interior parts are placed into

the cabinet, the opening for the ice maker water lines and

power cords must be made through the foam block of the

cooling unit. Look at the defective cooling unit to determine

the approximate location and angle to drill the hole in the

new cooling unit. The two holes are drilled from the interior

of the cabinet out through the rear of the refrigerator. Use

a 1/2” and 3/4” by 8” long drill bit to make the two holes. Be

careful not to drill into any refrigerant lines, causing a leak.

See FIG. B5.

2. The wire harness is routed from the inside of the freezer

compartment through the 1/2” hole. Pull the wire harness

through the back wall of the freezer compartment. Leave

sufficient length of wires (approx. 8”) to connect to the

cycle. Follow the same path that was used before by the

wire harness and reconnect it to the solenoid and power

cord.

3. Route the water line from the water solenoid up the rear of

the refrigerator. Insert the fill tube from the rear through the

3/4” hole. Use permagum to make an air tight seal around

the wire harness and water fill tube. If water line is not

attached to the fill tube it should be connected now. Make

sure that the same routing is followed between the water

solenoid and fill tube. If the water line has heat tape, be

sure it is in place. Use aluminum foil tape to cover and seal

the water line and wire harness to the back of the cabinet.

See FIG. B6.

4. Spread a thin layer of thermomastic on ice maker shelf.

See FIG. B7. Plug the wire harness to the ice cycle. Install

the cycle using the screws removed. Make sure the end

of the water fill tube will allow water to enter the cycle inlet,

and is free from touching the sides or bottom. This will

allow the water to drain completely out of the fill tube and

prevent freezing.

5. Return to Step 2 (Installation of cooling unit), #3 of this

section.

FIG. B5

FIG. B6

FIG. B7

SPREAD ATHIN

LAYER OF

THERMOMASTIC

ON ICE MAKER SHELF

4

Page 5

C. Category #3

NDR1272 **NDR1282 NDR1292

NDR1492 RM1272 **RM1282

** (Ice Maker Cycle/Compressor Operated)

STEP 1. REMOVAL OF COOLING UNIT

1. See General Instructions for all models.

2. Remove the two top shelves and drip tray. Disconnect

interior light from side of refrigerator. Remove thermistor

with bracket from fins (FIG. C1).

3. Remove cooling fins - right side first (6 screws). Pull

out drain cup and remove tube (FIG. C1).

4. Models with Ice Maker: Remove cycle from shelf

plate (3 screws) (FIG. C2). Lift cycle off shelf. Unplug

the cable and move out of cabinet until you are ready

to reinstall. Disconnect the electrical cable from back

of refrigerator and pull out from inside.

5. All Models: Follow Steps 5 – 11.

6. Remove freezer plates (FIG. C3).

A.Two screws with nuts (hexagon)

B.Two screws (side)

C.Two screws (top)

D.Two screws (side)

7. After freezer plates are re moved, take out 4 screws

holding the cooling unit to circulation tube (FIG. C3).

Remove plastic cover plate on the back of freezer.

8. Lay refrigerator face down on two 2x4’s to protect

handles and frame from damage.

9. Removal of controls at rear of refrigerator (FIG. C4).

A.Two screws (plate protections)

B.Two screws (mounting plate circuit board

- (not shown)

C.Three screws (gas valve bracket)

D.Three screws (burner assembly -

not shown)

10. Remove heater cover, heaters (2) and any

other parts that interfere with the removal

of cooling unit.

Note: Before cooling unit is placed in the

refrigerator cabinet, check the tapped screw

holes. See FIG C3 #6. Paint can fill the

holes and make replacement of screws

impossible. See FIG. C4.

11. Remove screws holding cooling unit to the

cabinet (5).

12. Apply leverage as shown and pull out (FIG. C4).

13. Remove the ground wire (white) from bottom of old

cooling unit and place on new one.

STEP 2. INSTALLATION OF COOLING UNIT

1. Refer to section A Category #1, Step 2, 1–5.

2. Place cooling unit in cabinet and replace screws.

3. Replace components removed in Step 1, 9–11, FIG.

C4.

4. Stand refrigerator upright. Transfer flue baffle to the

new cooling unit. Replace inside parts removed in

Step 1, 2–4.

5. Check for proper cooling before installing refrigerator

back into coach. (See “Important” on Page 1).

6. Install refrigerator back into coach and leak check all

gas fittings. Repair all gas leaks.

Do not use a flame

to check for gas leaks.

FIG. C1

FIG. C3

FIG. C4

FIG. C2

5

Page 6

STEP 3. PREPARING THE COOLING UNIT

APPLY

THERMO

MASTIC

TO TOP

FOR THE ICE MAKER (Models with

ice makers)

1. Models with compressor assist ice making, require a

groove to be cut in the foam block to allow a path for the

refrigerant line and wire harness. This groove needs to

be present before the cooling unit can be fitted into the

cabinet. Models without the compressor should proceed to number 6.

2. The cooling unit frame is manufactured with a notch cut

into it. This notch is where the refrigerant line and wire

harness will pass through once the foam block is cut

away. Use a hacksaw and make the groove on the right

hand side of the foam block. The groove should be the

same dimensions as the notch in the frame. See FIG.

C5 & C7.

3. The cooling unit can be installed into the refrigerator.

See Section A, Category #1, Step 2, 1-5.

4. Before the shelves and other interior parts are placed into

the cabinet, the opening for the ice maker water line must

be made through the foam block of the cooling unit. Look

at the defective cooling unit to determine the approximate location and angel to drill the hole in the new

cooling unit. The hole is drilled from the interior of the

cabinet out through the rear of the refrigerator. Use a 3/

4” by 8” long drill bit to make the hole. Be careful no to

drill into any refrigerant lines, causing a leak. See FIG.

C6.

5. Proceed to number 8.

6. Models without compressor, the cooling unit can be

installed into the refrigerator. Before the shelves and

other interior parts are placed into the cabinet, the

opening for the ice maker water lines and power cords

must be made through the foam block of the cooling unit.

Look at the defective cooling unit to determine the

approximate location and angel to drill the hole in the new

cooling unit. The two holes are drilled from the interior of

the cabinet out through the rear of the refrigerator. Use

a 1/2” and 3/4” by 8” long drill bit to make the two holes.

Be careful not to drill into ant refrigerant lines, causing a

leak. See FIG. C6.

7. The wire harness is routed from the inside of the freezer

compartment through the 1/2” hole. Pull the wire

harness through the back wall of the freezer compartment. Leave sufficient length of wires (about 8”) to

connect to the cycle. Follow the same path that was

used before by the wire harness and reconnect it to the

solenoid and power cord.

8. Route the water line from the water solenoid up the rear

of the refrigerator. Insert the fill tube from the rear through

the 3/4” hole. Use permagum to make an air tight seal

around the wire harness and water fill tube. Seal both the

outside and inside. If the water line is not attached to the

fill tube it should be connected now. Make sure that the

same routing is followed between the water solenoid and

fill tube. If the water line has heat tape, be sure it is in

place. Use aluminum foil tape to cover and seal the water

line and wire harness to the back of the cabinet. See

FIG. C7.

9. Spread a thin layer of thermomastic on top of the ice

maker shelf. See FIG. C8. Plug the wire harness to the

ice cycle. Install the cycle using the screws removed.

Make sure the end of the water fill tube will allow water

to enter the cycle inlet, and is free from touching the

sides or bottom. This will allow the water to drain

completely out of the fill tube and prevent freezing.

10. Return to Section C, Category #3, Step 2, #3.

FIG. C5

FIG. C6

FIG. C7

FIG. C8

APPLY

THERMO

MASTIC

TO TOP

6

Page 7

This manual has been provided courtesy of

DARREN KOEPP - OWNER, MY RV WORKS, INC.

www.myrvworks.com

You can find more RV service manuals here:

www.myrvworks.com/manuals

My RV Works, Inc.

Over the years of running a mobile RV repair service, having a dedicated place

to access service manuals for all the different appliances and components

found on RVs was something that I always had a desire to create.

I hope this resource makes your RV repairs easier, as it has mine, but please

be careful and follow proper safety practices when attempting to repair

your own RV.

If in doubt, please consult with a professional RV technician!

All service manuals provided on www.myrvworks.com are believed to be

released for distribution and/or in the public domain.

Loading...

Loading...