Page 1

Instruction and Safety Manual

for Gasoline Power Cuts (page 2 - 30)

Manuel d’instructions et de sécurité

de découpeuse thermiques (page 32 - 60)

Manual de instrucciones y de seguridad

para Cortadora de muela de tronzar (pagina 62 - 90)

WARNING!

Read and understand this Manual. Always follow safety precautions in the Instruction and

Safety Manual. Improper use can cause serious injury!

The engine exhaust from this product contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. Preserve this Manual carefully!

ATTENTION!

Suivez toujours les conseils de sécurité du présent manuel d’instructions et de sécurité.

Une utilisation incorrecte de la découpeuse peut entraîner des blessures graves!

Conservez avec soin ce manuel! Les gaz d’échappement émis par ce produit contiennent des produits

chimiques connus par l’Etat de Californie pour provoquer le cancer, des défauts de naissance ou

autres dommages de reproduction. Lisez et comprenez ce manuel.

ADVERTENCIA:

Observe siempre las instrucciones de seguridad contenidas en el manual. Lea y compenétrese con el

contenido del manual. El uso inadecuado de la cortadora puede causar lesiones de gravedad.

Los gases de escape del motor de este producto contienen sustancias químicas conocidas en el Estado

de California como causantes de cáncer, defectos genéticos y otros problemas relacionados con la

reproducción. Conserve este manual cuidadosamente

PC-6430, PC-6435

PC-7330, PC-7335

1

Page 2

EMISSIONS COMPONENT DEFECT WARRANTY COVERAGE

DOLMAR U.S.A, Inc warrant to the initial retail purchaser and each subsequent owner, that this utility equipment was designed,

built, and equipped to conform at the time of initial sale to all applicable regulations of the U.S. Environmental Protection Agency

(EPA), and that the engine is free of defects in materials and workmanship which would cause this engine to fail to conform with

EPA regulations during its warranty period.

For the components listed under PARTS COVERED, the service dealer authorized by DOLMAR will, at no cost to you, make the

necessary diagnosis, repair, or replacement necessary to ensure that the engine complies with applicable U.S. EPA regulations.

EMISSION COMPONENT DEFECT WARRANTY PERIOD

The warranty period for this engine begins on the date of sale to the initial purchaser and continues for a period of 2 years.

PARTS COVERED

Listed below are the parts covered by the Emission Components Defect Warranty. Some of the parts listed below may require

scheduled maintenance and are warranted up to the first scheduled replacement point for that part.

Fuel Metering System Ignition System

Carburetor and internal parts Spark plugs

Fuel filter, if applicable Flywheel Magneto

Throttle stopper, if applicable Ignition Coil

Choke System, if applicable

Air Induction System Miscellaneous Items Used in Above Systems

Air cleaner plate, Air filter Fuel hoses, clamps and sealing gaskets

Air cleaner case, Intake manifold

OBTAINING WARRANTY SERVICE

To obtain warranty service, take your engine to the nearest DOLMAR Service Center authorized by DOLMAR. Bring your sales

receipts indicating date of purchase for this engine. The dealer of service authorized by DOLMAR will perform the necessary

repairs or adjustments within a reasonable amount of time and furnish you with a copy of the repair order. All parts and accessories

replaced under this warranty become the property of DOLMAR.

WHAT IS NOT COVERED

• Conditions resulting from tampering, misuse, improper adjustment (unless they were made by the service dealer authorized by

DOLMAR during a warranty repair), alteration, accident, failure to use the recommended fuel and oil, or not performing required

maintenance services.

• The replacement parts used for required maintenance services.

• Consequential damages such as loss of time, inconvenience, loss of use of the engine or equipment, etc.

• Diagnosis and inspection charges that do not result in warranty-eligible service being performed.

• Any non-authorized replacement part, or malfunction of authorized parts due to use of non-authorized parts.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the required maintenance listed in your owner’s manual.

DOLMAR recommends that you retain all receipts covering maintenance on your engine, but DOLMAR cannot deny warranty

solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the engine owner, you

should however be aware that DOLMAR may deny warranty coverage if your engine or a part has failed due to abuse, neglect,

improper maintenance or unapproved modifications.

You are responsible for presenting your engine to the nearest service dealer authorized by DOLMAR when a problem exists.

If you have any questions regarding your warranty rights and responsibilities, you should contact the DOLMAR Warranty service

Department at 1-888-OPE-PART for the information.

THINGS YOU SHOULD KNOW ABOUT THE EMISSION CONTROL SYSTEM WARRANTY:

MAINTENANCE AND REPAIRS

You are responsible for the proper maintenance of the engine. You should keep all receipts and maintenance records covering the

performance of regular maintenance in the event questions arise. These receipts and maintenance records should be transferred

to each subsequent owner of the engine. DOLMAR reserves the right to deny warranty coverage if the engine has not been

properly maintained. Warranty claims will not be denied, however, solely because of the lack of required maintenance or failure to

keep maintenance records.

MAINTENANCE, REPLACEMENT OR REPAIR OF EMISSION CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED BY

ANY REPAIR ESTABLISHMENT OR INDIVIDUAL; HOWEVER, WARRANTY REPAIRS MUST BE PERFORMED BY A SERVICE

DEALER AUTHORIZED BY DOLMAR. THE USE OF PARTS THAT ARE NOT EQUIVALENT IN PERFORMANCE AND DURABILITY

TO AUTHORIZED PARTS MAY IMPAIR THE EFFECTIVENESS OF THE EMISSION CONTROL SYSTEM AND MAY HAVE A

BEARING ON THE OUTCOME OF A WARRANTY CLAIM.

If other than the parts authorized by DOLMAR are used for maintenance replacements or for the repair of components affecting

emission control, you should assure yourself that such parts are warranted by their manufacturer to be equivalent to the parts

authorized by DOLMAR in their performance and durability.

HOW TO MAKE A CLAIM

All repair qualifying under this limited warranty must be performed by a service dealer authorized by DOLMAR. In the event that

any emission-related part is found to be defective during the warranty period, you shall notify DOLMAR Warranty service Department at 1-888-OPE-PART and you will be advised of the appropriate warranty service dealer or service providers

where the warranty repair can be performed.

2

Page 3

Thank you for purchasing a DOLMAR product!

Congratulations on choosing a DOLMAR Power Cut cutoff saw!

We are confident that you will be satisfied with this modern piece

of equipment. DOLMAR GmbH of Hamburg, Germany is the

world’s oldest manufacturer of gasoline-powered chainsaws - we

got our start in 1927 - giving us very extensive experience with

power hand tools. Like our chain saws, the DOLMAR Power Cuts

feature specially designed high-performance engines with

outstanding power-to-weight ratios, for heavy-duty yet lightweight

tools.

Other advantages of the DOLMAR Power Cuts:

• Sturdy construction and high reliability.

• Maintenance-free electronic ignition, hermetically sealed to

protect against dust and moisture.

• Vibration damping with the DOLMAR 2-mass system (D2M)

for tireless working even when guiding the Power Cut by

hand.

• Five-stage air-filter system for reliable working even under

very dusty conditions.

• Two options for mounting the cutter attachment: Either

centrally, for good balance when guiding the unit manually,

or on the side, for flush cuts along walls or curbsides or

horizontally directly above the ground.

• Extensive range of resin-bonded and diamond grit cutting

discs, trolley with dust catcher, and systems for supplying

water to the disc.

The following industrial property rights apply:

US 08510690, SE 95027298, SE 95027306, IT 95000653,

IT 95000654, GBM 9412558, GBM 9412559.

We want you to be satisfied with your DOLMAR product.

In order to guarantee the optimal function and performance of

your Power Cut and to ensure your personal safety we would

request you to perform the following:

Read this Instruction and Safety Manual carefully before

putting the Power Cut into operation for the first time,

and strictly observe the safety regulations! Failure to

observe these precautions can lead to severe injury or

death!

WARNING!

Some dust created by power sanding sawing,

grinding, drilling, and other construction activities

contains chemicals known (to the State of California)

to cause cancer, birth defects or other reproductive

harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products, and

• arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on

how often you do this type of work.

To reduce your exposure to these chemicals: work in

a well ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic particles.

Table of contents Page

Packing ................................................................................ 3

Delivery inventory .............................................................. 4

Symbols ...............................................................................4

SAFETY PRECAUTIONS

Intended use ................................................................... 5

General precautions........................................................5

Protective equipment .................................................. 5-6

Fuels / Refuelling ............................................................6

Putting into operation ......................................................6

Cutting discs....................................................................7

Kickback and lock-in .......................................................8

Working behavior / Method of working ...........................8

Cutting metal ...................................................................9

Cutting masonry and concrete .................................. 9-10

Transport and storage ..................................................10

Maintenance..................................................................11

First aid .........................................................................11

Technical data ................................................................... 12

Denomination of components......................................... 12

PUTTING INTO OPERATION

Mounting the cutting disc ..............................................13

Tightening the V-belt / Checking V-belt tension ...........14

Installing the pressure water system ...................... 14-15

Fuels / Refuelling .................................................... 15-16

Starting the engine ........................................................ 17

Cold-starting .................................................................. 17

Warm-starting................................................................18

Stop engine ...................................................................18

Adjusting the carburetor .................................................19

MAINTENANCE

Changing the V-belt ......................................................20

Cleaning the protection hood ........................................ 21

Cleaning / changing the air filter ............................. 21-22

Replacing the spark plug ..............................................22

Replacing the suction head .......................................... 23

Replacing the starter cable ..................................... 23-24

Replacing the return spring ..........................................24

Instructions for periodic maintenance........................... 28

Cutting attachment in central / side position .......... 25-26

Repositioning the cutting attachment ..................... 25-26

Replacing/cleaning the spark arrester screen .............. 26

SPECIAL ACCESSORIES

Diamond cutting discs, trolley, water tank

and pressure water system ................................................27

Service, spare parts and guarantee ......................... 28-29

Troubleshooting ............................................................... 29

Extract from spare parts list............................................30

Accessories ................................................................... 30

Service stations ................................................................92

Packing

Your DOLMAR Power Cut is packed in a cardboard box to

prevent shipping damage.

Cardboard is a basic raw material and is consequently reuseable or suitable for recycling (waste paper recycling).

The Emissions Compliance Period referred to on the emission

Compliance label indicates the number of operating hours for

which the engine has been shown to meet federal emissions

requirements.

Category C= 50 hours, B= 125 hours, and A= 300 hours.

RE Y

3

Page 4

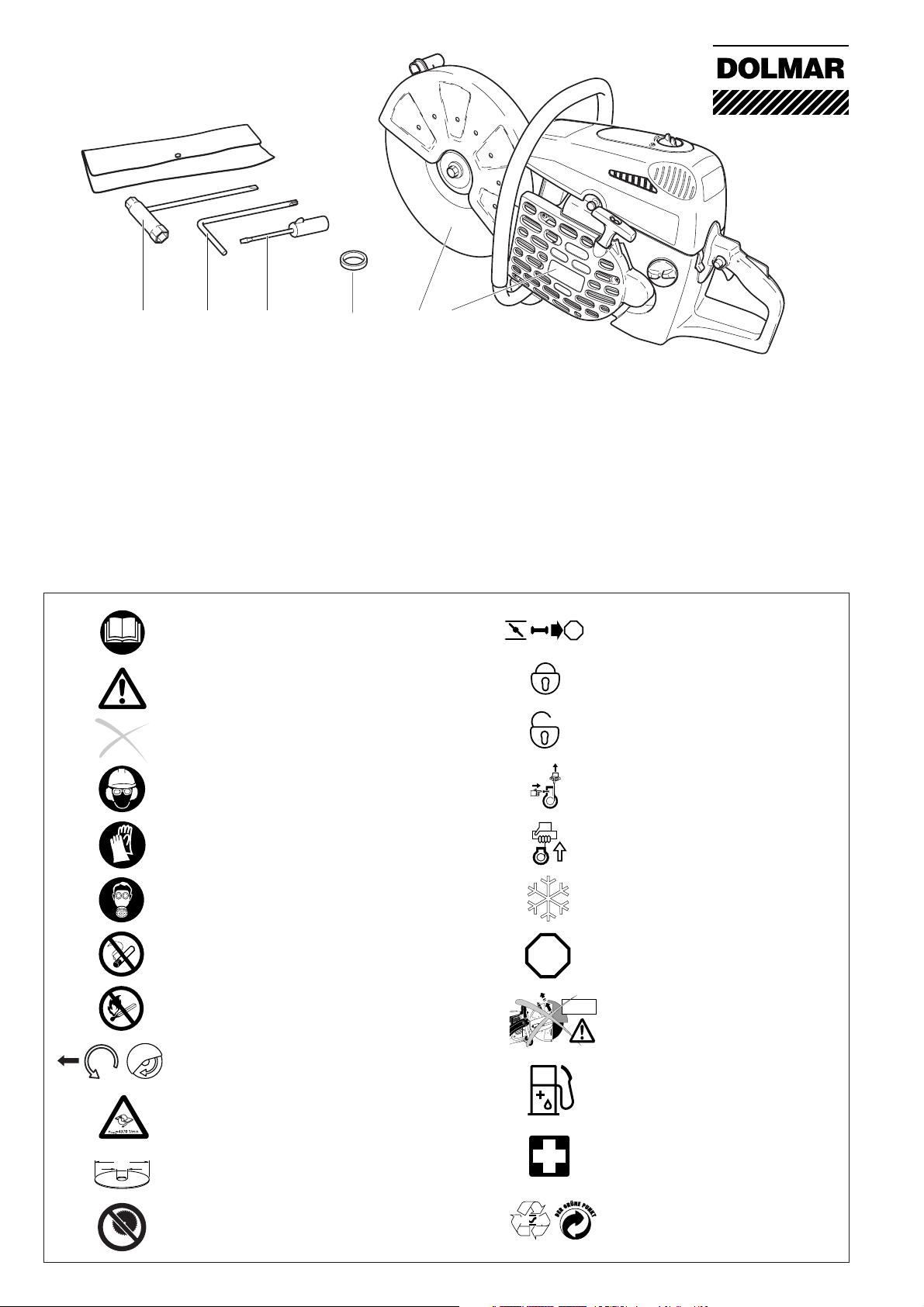

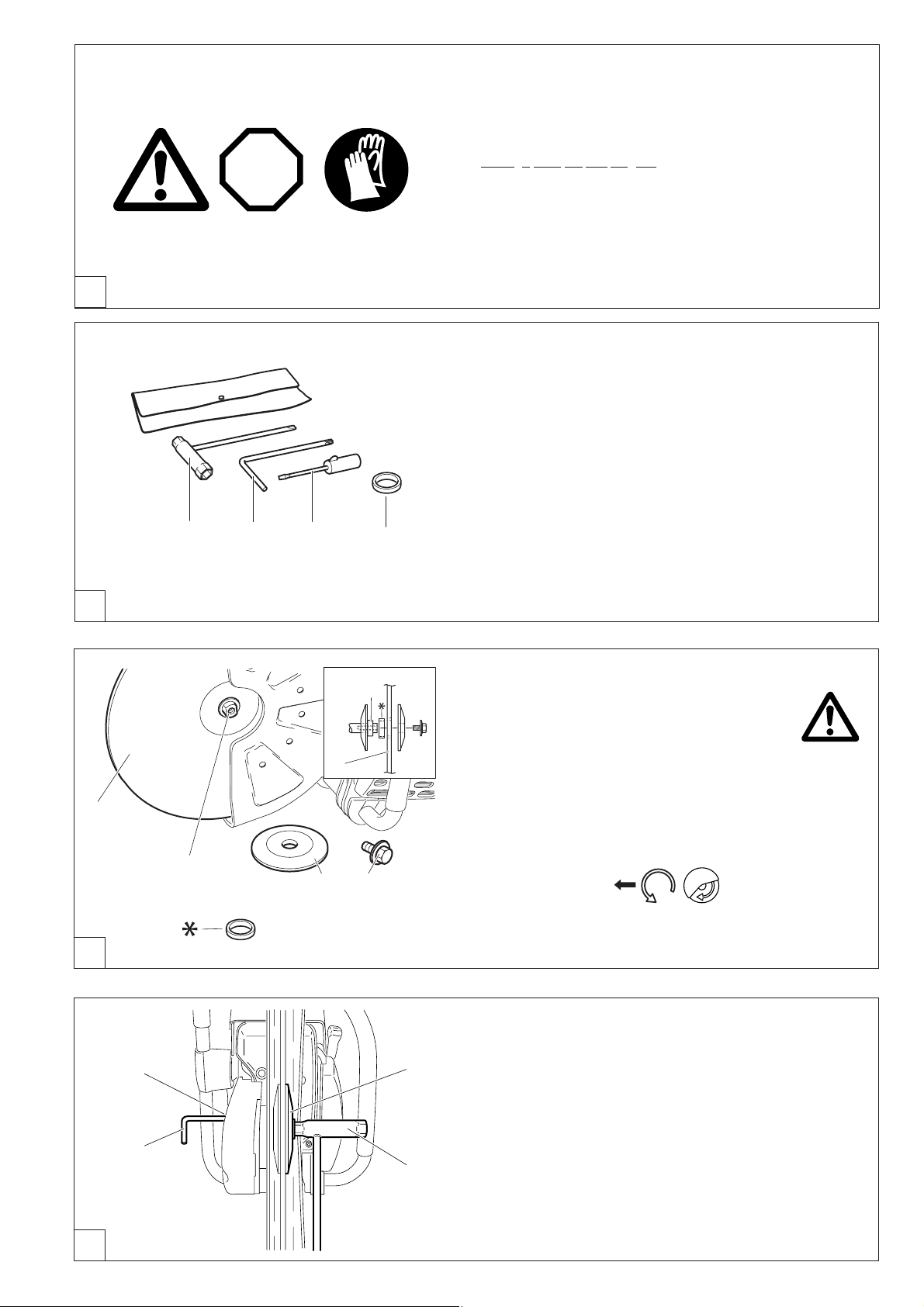

Delivery inventory

STOP

654321

1. Power Cut

2. Cutting disc

3. Adapter ring 0.8"/1.0" (not in the general scope of delivery. Country-specific)

4. Screwdriver (for carburetor adjustment)

5. Offset screwdriver

6. Universal wrench 13/19

7. Instruction manual (not shown)

In case one of the parts listed should not be included in the

delivery inventory, please consult your sales agent.

Symbols

You will notice the following symbols on the Power Cut and in the Instruction Manual:

Read instruction manual and

follow the warning- and safety

precautions!

Particular care and caution!

Forbidden!

2

Wear protective helmet, eye and

ear protection!

Wear protective gloves!

Wear respiratory protection!

No smoking!

1

STOP

Combination Start/Stop (I/O)

switch, choke

Locked

Unlocked

Press decompression valve

Engine - manual start

Working in winter

Stop engine!

No open fire!

Warning!

Kickback!

Direction of cutting wheel rotation

Fuel and oil mixture

Warning: the max. peripheral

speed of the cutting disc

is 80 m/s!

First aid

Cutting disc dimensions

Never use circular saw blades!

4

RE Y

Recycling

Page 5

FE

A

B

C

D

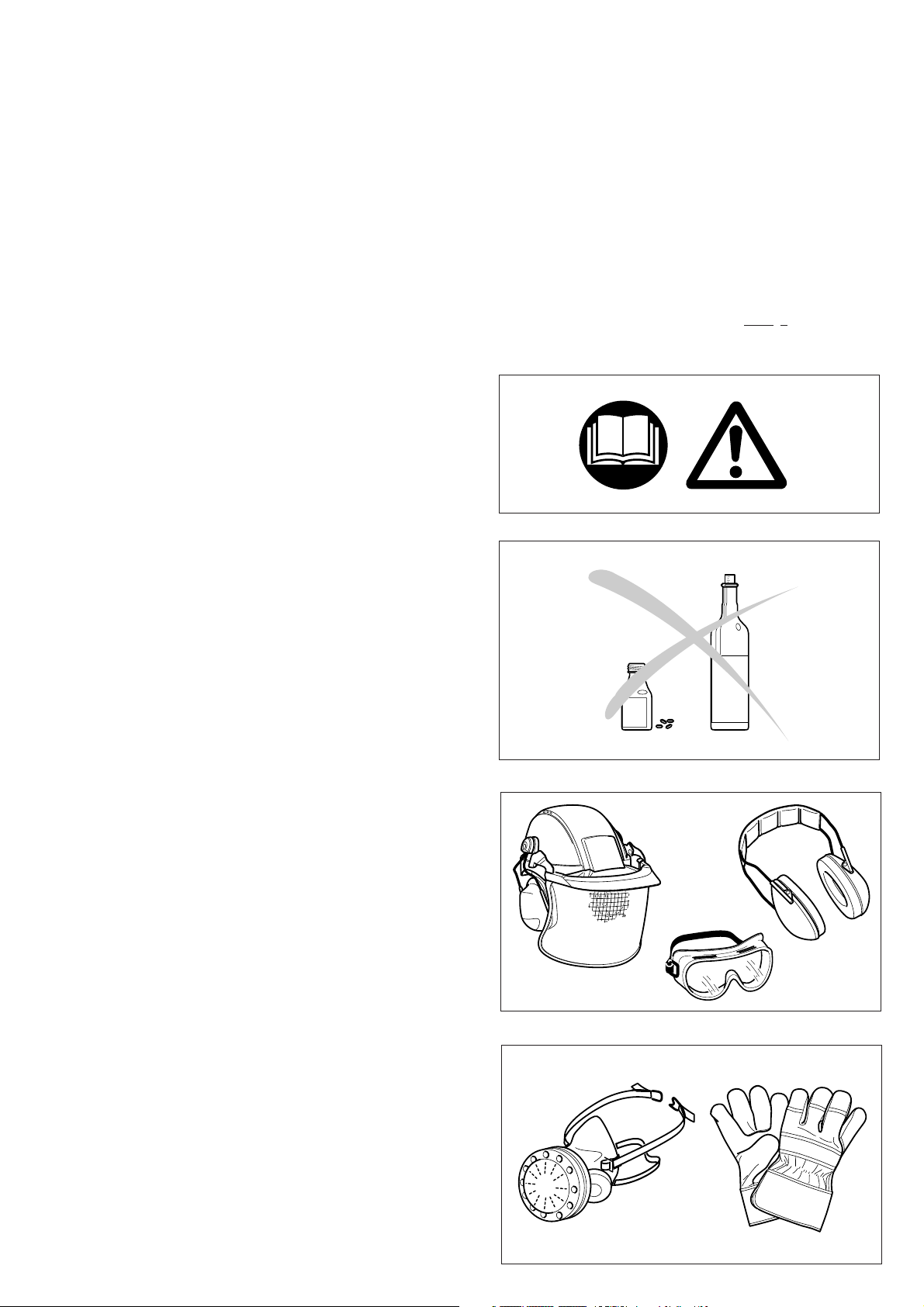

SAFETY PRECAUTIONS

Intended use

Power Cut

Use the Power Cut cutoff saw outdoors only, for trimming and

cutting suitable materials, using cutting discs rated for this machine.

Improper use:

Never use the cutoff saw cutting discs for grinding or sanding

(using the side of the cutting disc to remove material). The disc can

break! Never use the Power Cut with saw blades, cutter blades,

brushes etc.

Unauthorised users:

Persons unfamiliar with the Instruction Manual, children, young

people, and persons under the influence of alcohol, drugs or

medications must not use the Power Cut.

General precautions

- The operator MUST read this instruction manual to ensure

safe operation (even if you already have experience in

using cutoff saws). It is important to be familiar with the

operation of this particular cutoff saw. Users insufficiently

informed will endanger themselves as well as others due to

improper handling.

- Let only persons who have experience in using cutoff saws

work with this unit. When letting another person use the Power

Cut, this instruction manual must be provided along with it.

- First-time operators should ask a specialist to instruct them in

working with gasoline-powered cutoff saws.

- Children and persons under 18 years of age must not be

allowed to use this Power Cut. Persons over the age of 16

years may, however, use the Power Cut for the purpose of

being trained as long as they are under the supervision of a

qualified trainer.

- Working with the Power Cut requires high concentration.

- Operate the Power Cut only if you are in good physical

condition. If you are tired, your attention will be reduced. Be

especially careful at the end of a working day. Perform all work

calmly and carefully. The user has to accept liability for others.

- Never work while under the influence of alcohol, drugs, medication or other substances which may impair vision, dexterity

or judgement.

- A fire extinguisher must be available in the immediate vicinity

when working in easily inflammable vegetation or when it has

not rained for a long time (danger of fire).

- Asbestos and other materials that can release toxins may be

cut only with the necessary safety precautions and after

notification of the proper authorities and under their supervision or that of a person appointed by them.

- The use of dust-reduction devices is urgently recommended

(see Accessories, pressure water tank, water tank).

- The helmet visor (B) protects the face from dust and

material grains. In order to prevent injuries to eyes and

face, always wear protective goggles (C) or visor when

using the Power Cut.

- To prevent hearing damage, always wear suitable personal

hearing protection. (ear muffs (D), ear plugs, etc.). Octave brand analysis upon request.

- When dry-cutting dust-producing materials such as stone

or concrete, always wear approved respiratory protec-

tion (E).

- Work gloves (F) of tough leather are part of the required

work kit of the Power Cut and must always be worn when

working with the Power Cut.

1

2

Protective equipment

- In order to avoid head, eye, hand or foot injuries as well as

to protect your hearing the following protective equipment must be used during operation of the Power Cut:

- The kind of clothing should be appropriate, i. e. it should be

tight-fitting but not be a hindrance. Clothing in which grains of

material can accumulate (trousers with cuffs, jackets and

trousers with wide-open pockets, etc.) must not be worn,

particularly when cutting metal.

- Do not wear any jewellery or clothing that can get caught or

distract from the operation of the Power Cut.

- It is necessary to wear a protective helmet whenever working

with the Power Cut. The protective helmet (A) is to be

checked in regular intervals for damage and is to be replaced

after 5 years at the latest. Use only approved protective

helmets.

3

4

5

Page 6

H

G

- Always wear safety shoes or boots (G) with steel toes,

non-skid soles, and leg protectors when working with the Power

Cut. Safety shoes equipped with a protective layer provide

protection against cuts and ensure a secure footing.

- Always wear a work suit (H) of tough material with sufficient

flame-retardant qualities whenever working with the cutoff saw.

Fuels / Refuelling

- Go to a safe, level place before refuelling. Never refuel while

on scaffolding, on heaps of material, or in similar places!

- Switch off the engine before refuelling the Power Cut.

- Do not smoke or work near open fires (6).

- Let the engine cool down before refuelling.

- Fuels can contain substances similar to solvents. Eyes and skin

should not come in contact with mineral oil products. Always

wear protective gloves when refuelling (not the regular work

gloves!). Frequently clean and change protective clothes. Do

not breathe in fuel vapors. Inhalation of fuel vapours can be

hazardous to your health.

- Do not spill fuel. If a spill occurs, clean off the Power Cut

immediately. Fuel should not come in contact with clothes. If

your clothes have come in contact with fuel, change them at

once.

- Ensure that no fuel oozes into the soil (environmental protection). Use an appropriate base.

- Refuelling is not allowed in closed rooms. Fuel vapors will

accumulate near the floor (explosion hazard).

- Ensure to firmly tighten the screw cap of the fuel tank.

- Before starting the engine, move to a location at least 3 meters

(approx. 10 feet) from where you fuelled the Power Cut (7), but

not within the extended swing range of the cutting disc (direction

of sparks).

- Fuel cannot be stored for an unlimited period of time. Buy only

as much as will be consumed in the near future.

- When making up the gasoline/oil mixture, always put the oil in

the mixing container

- Use only approved and marked containers for the transport and

storage of fuel.

- Keep fuel away from children!

first, and then the gasoline.

5

6

3 meters

7

Putting into operation

- Do not work on your own. There must be someone around

in case of an emergency (within shouting distance).

- Observe all anti-noise regulations when working in residential

areas.

- Never use the Power Cut near inflammable materials or

explosive gases! The Power Cut can create sparks leading

to fire or explosion!

- Make sure that all persons within 30 meters (100 feet), such as

other workers, are wearing protective gear (see "Protective

Equipment") (8). Children and other unauthorized persons must

remain more than 30 meters (100 feet) away from the working

area. Keep an eye out for animals as well (9).

- Before starting work the Power Cut must be checked for

perfect function and operating safety according to the

prescriptions. In particular, make sure that the cutting wheel is

in good condition(replace immediately if torn, damaged or

bent), the cutting wheel is properly mounted, the protective

hood is locked in place, the hand guard is properly mounted, the

V-belt has the proper tension, the throttle moves easily and the

half-throttle lock button functions properly, the grips are clean

and dry, and the combination switch functions properly (Start/

Stop (I/O) switch, choke).

- Start the Power Cut only after complete assembly and inspection. Never use the Power Cut when it is not completely

assembled.

30 m (100 feet)

8

9

= wearing Protective Equipment

6

Page 7

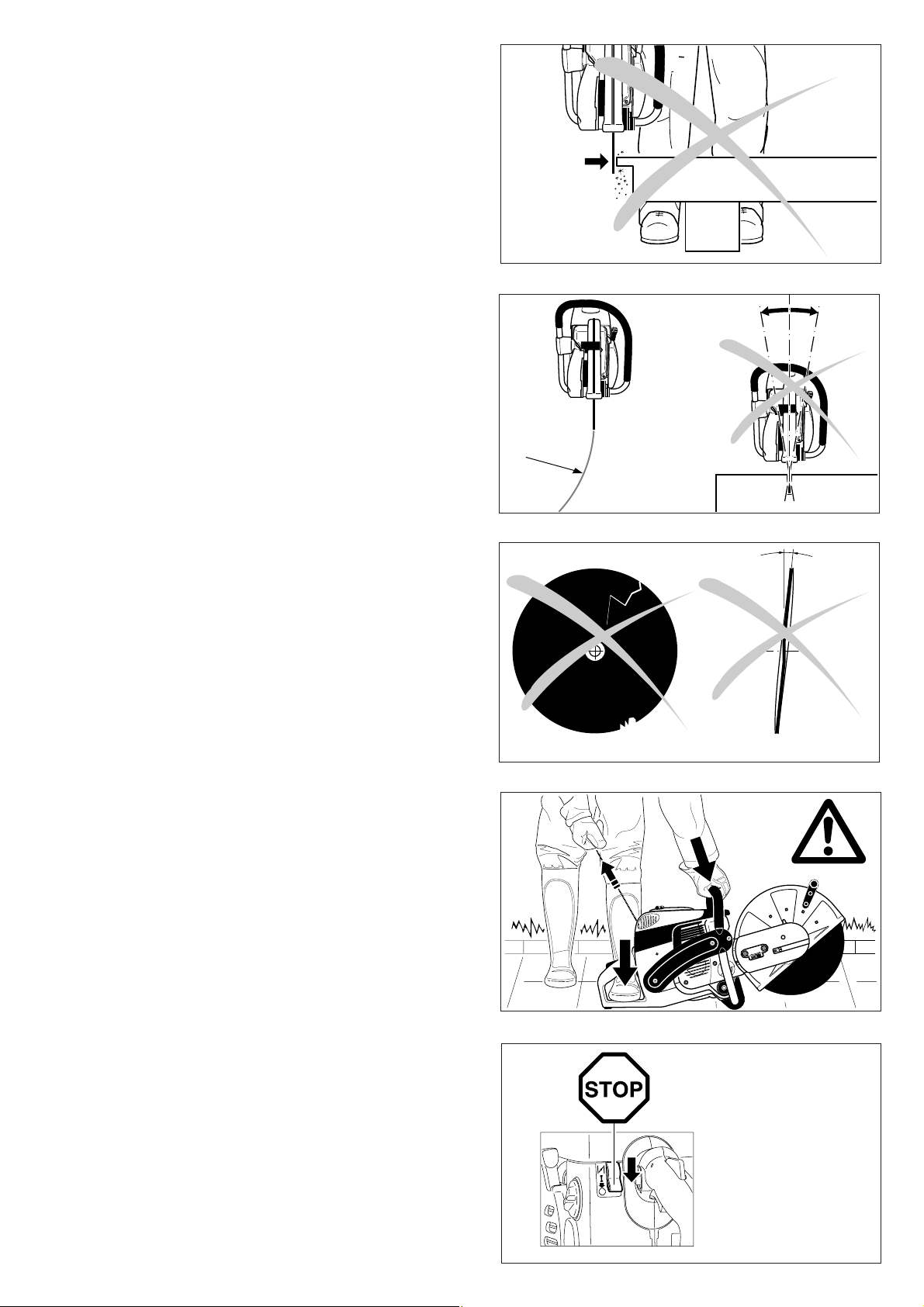

Cutoff discs

S

T

O

P

- The protection hood must always be on! Change discs only

with the engine off!

- There are two basic types of cutoff discs:

- For metal (hot cutting)

- For masonry (cold cutting)

NOTE:

When using diamond cutoff discs, always make sure to observe

the "direction of rotation" markings. Diamond discs should only be

used for cutting masonry/brick/ concrete etc.

- Cutoff discs are intended only for radial loading, i.e. for cutting.

Do not grind with the sides of the cutting disc! This will break the

disc (10)!

Caution!

Never change direction (turning radius less than 5 meters /

16 feet), exert lateral (sideways) pressure, or tip the Power Cut

during cutting (11)!

- Use a cutting disc only for cutting the materials it is intended for.

The proper type of disc must be used, for either metals or

masonry.

- The arbor hole of the cutting disc must be an exact fit with the

arbor or shaft. If the arbor hole is larger, it must be fitted with an

adapter ring (available as an accessory).

- The cutting disc must be rated for freehand cutting at up to 4370

rpm or 80 m/sec for 350 mm discs or up to 5100 rpm or 80 m/

s for 300 mm discs. Use only cutting discs that comply with EN

12413, EN 13236 or der BGV D 12.

- The disc must be free of defects (12). Do not use defective

cutting discs.

Always tighten the cutting disc mounting bolt to a torque of 30

Nm. Otherwise, the cutting disc can twist.

- Before starting the cutting disc, make sure you have a steady

footing.

- Put the Power Cut into operation only as described in this

instruction manual (13). Always place your left foot in the rear

handle and grasp the other handle firmly (with thumb and

fingers). Other starting methods are not allowed.

- When starting the Power Cut it must be well supported and

securely held. The cutting disc must not be touching anything.

- If the cutting disc is new, test it by running it at least 60 seconds

at top speed. When doing this, make sure that no persons or

body parts are in the extended swing range of the disc, in case

it is defective and flies apart.

- When working with the Power Cut always hold it with both

hands. Take the back handle with the right hand and the tubular

handle with the left hand. Hold the handles tightly with your

thumbs facing your fingers.

- CAUTION: When you release the throttle lever the disc will

keep spinning for a short period of time (free-wheeling

effect).

- Continuously ensure that you have a safe footing.

- Hold the Power Cut such that you will not breathe in the exhaust

gas. Do not work in closed rooms or in deep holes or ditches

(danger of poisoning by fumes).

- Switch off the Power Cut immediately if you observe any

changes in its operating behavior.

- Switch off the engine before inspecting the V-belt tension

or tightening it, replacing the cutting wheel, repositioning

the cutter attachment (side or middle position) or eliminating

faults (14).

- Turn off the engine immediately and check the disc if you hear

or feel any change in cutting behaviour.

- Turn off the Power Cut when taking a break or stopping work

(14). Place the unit in such a way that the disc is not touching

anything and cannot endanger anyone.

- Do not put the overheated Power Cut in dry grass or on any

inflammable objects. The muffler is very hot (danger of fire).

- IMPORTANT: After wet cutting, first turn off the water feed and

then let the disc run at least 30 seconds, to fling off the remaining

water and prevent corrosion.

10

min. 5 m

11

12

13

● Maintenance

● Refuelling

● Changing cutoff discs

● Repositioning the

cutting attachment

● Stopping work

● Transport

● Putting out of function

14

7

Page 8

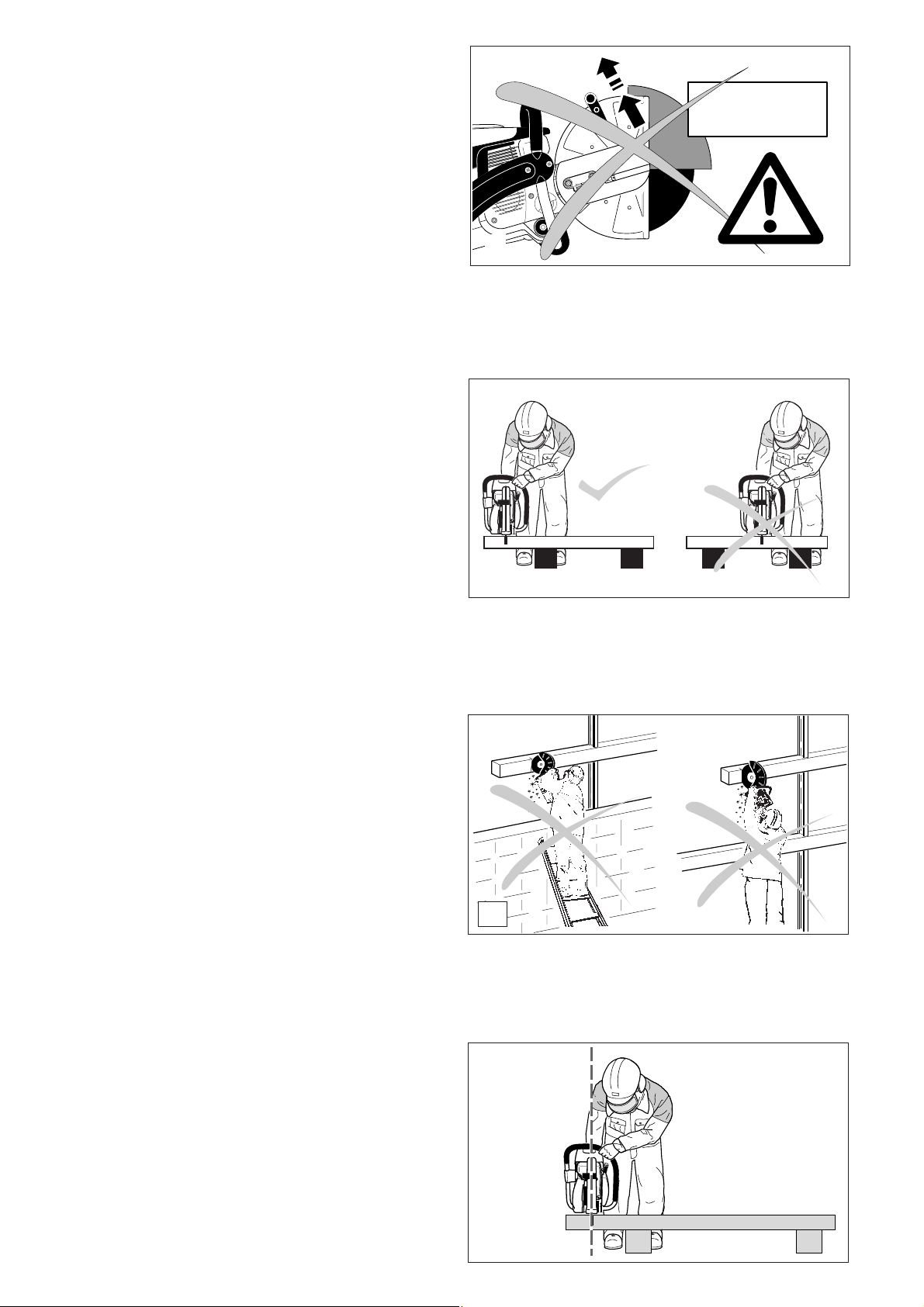

Kickback and lock-in

- When working with the Power Cut there is a danger of kickback

and lock-in.

- Kickback occurs when the top of the cutting disc is used for

cutting (15).

- This causes the Power Cut to be thrown back toward the user

with great force and out of control. Risk of injury!

To prevent kickback, observe the following:

- Never cut with the section of the cutting disc shown in figure 15.

Be especially careful when reinserting the disc into cuts

that have already been started!

- Lock-in occurs when the cut narrows (crack, or workpiece

under stress).

- This causes the Power Cut to suddenly jump forward, out of

control and with great force. Risk of injury!

To prevent lock-in, observe the following:

- When reinserting the disc into previous cuts, have the Power

Cut running at top speed. Always cut at top speed.

- Always support the workpiece so that the cut is under tension

(16), so that the cut does not press together and jam the cutting

disc as it proceeds through the material.

- When starting a cut, apply the disc to the workpiece with care.

Do not just shove it into the material.

- Never cut more than one piece at a time! When cutting, make

sure that no other workpiece comes into contact.

15

Working behavior / Method of working

- Before starting work, check the work area for any hazards

(electrical wires, inflammable substances). Clearly mark the

work area (for example with warning signs or by cordoning off

the area).

- When working with the Power Cut hold it firmly by the front and

rear handles. Never leave the Power Cut unattended!

- Use the Power Cut at high speed as far as possible (see

“Technical Data”).

- Only use the Power Cut during good light and visibility periods.

Be aware of slippery or wet areas, and of ice and snow (risk of

slipping).

- Never work on unstable surfaces. Make sure that there are no

obstacles in the working area, risk of stumbling. Always ensure

that you have a safe footing.

- Never cut above your shoulder height (17).

- Never stand on a ladder to cut (17).

- Never use the Power Cut while standing on scaffolding.

- Do not lean over too far when working. When putting down and

picking up the Power Cut, do not bend over from the waist, but

instead bend in the knees. Save your back!

- Guide the Power Cut in such a way that no part of your body

is within the extended swing range of the disc (18).

- Use cutting discs only for the materials for which they are

designed!

- Use cutting discs only for the materials for which they are

designed. Do not use the Power Cut to lift up and shovel away

pieces of material and other objects.

Important! Before cutting, remove all foreign objects, such as

rocks, gravel, nails etc. from the cutting area. Otherwise, such

objects can be flung away by the disc with great speed. Injury

hazard!

- When cutting workpieces down to length use a firm support. If

necessary, secure the workpiece from slipping, but do not

steady it with your foot or allow another person to hold it.

- When cutting round items, always secure them against rotation.

- When guiding the Power Cut by hand, use the side mounting

position of the cutter attachment only when actually necessary. Otherwise, always use the central position. This gives

the unit a better balance, for reduced operator fatigue.

8

16

17

18

Page 9

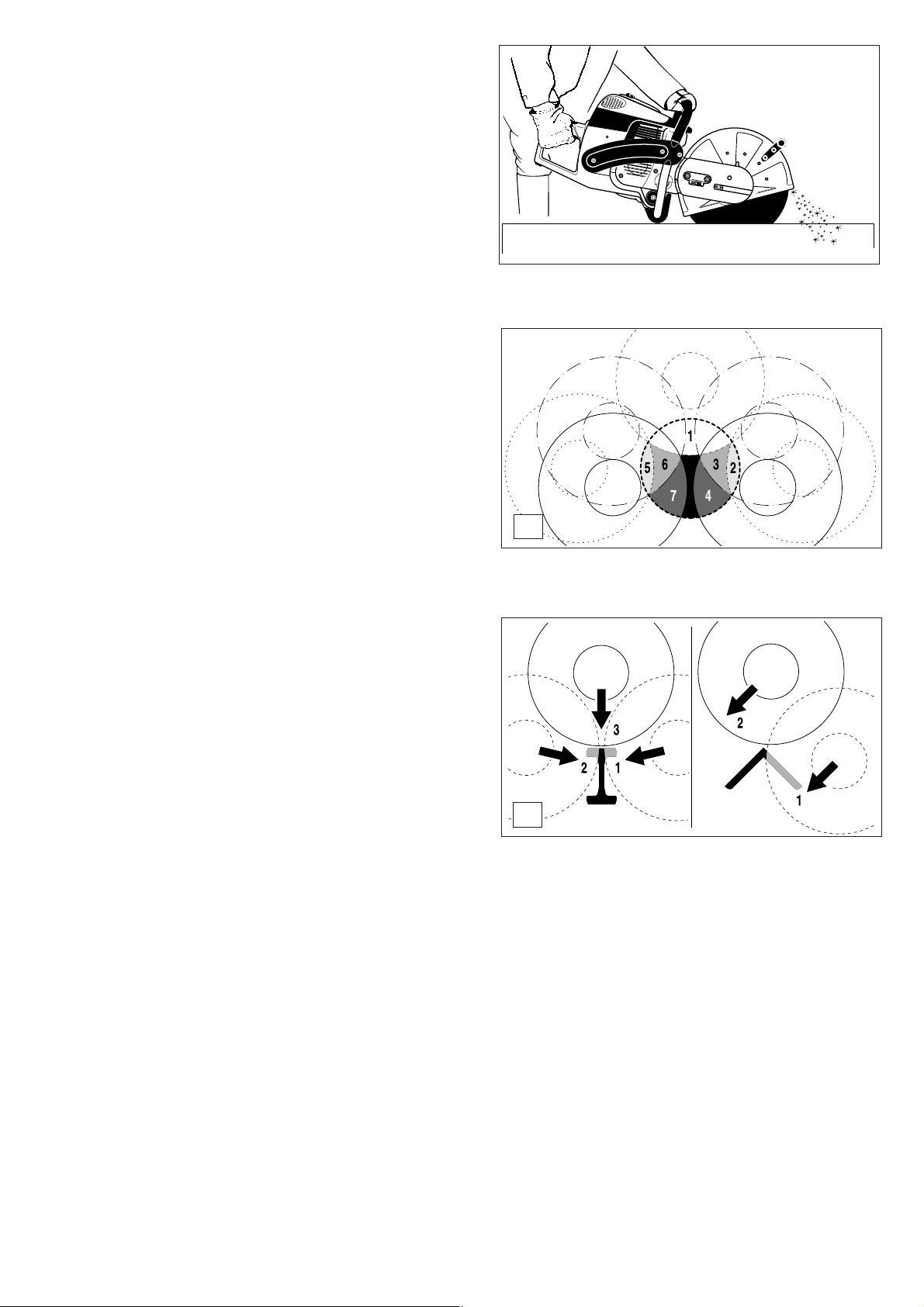

Cutting metals

IMPORTANT!

Always wear approved respiratory protection!

Materials that can release toxic substances may be cut only

after notifying the proper authorities and under their supervision or that of a person appointed by them.

CAUTION!

The rapid rotation of the cutting disc heats metal and melts it

at the point of contact. Swing the guard as far down as

possible (19) in order to direct the stream of sparks forward,

away from the operator (fire hazard).

- Determine the cut line, mark the cut and apply the disc to the

material at moderate speed, to cut a guide groove before going

to top speed and applying more pressure to the Power Cut.

- Keep the disc straight and vertical. Do not tip it, as this can

break it.

- The best way to get a good, clean cut is to pull or move the

Power Cut back and forth. Do not simply press the disc into the

material.

- Thick round stock is best cut in stages (20).

- Thin tubing and pipes can be cut with a simple downward cut.

- Cut large-diameter pipes as for round stock. To prevent tipping

and for better control, do not let the disc sink too deeply into the

material. Instead, always cut shallow around the whole piece.

- Worn discs have a smaller diameter than new discs, so that at

the same engine speed they have a lower effective circumferential speed and therefore do not cut as well.

- Cut I-beams and L-bars in steps; see Figure 21.

- Cut bands and plates like pipes: along the wide side with a long

cut.

- When cutting material under stress (supported material or

material in structures), always make a notch in the thrust

(pressure) side, and then cut from the tension side, so that the

disc does not lock in. Secure cutoff material from falling!

19

20

CAUTION!

If there is a chance that the material is under stress, be

prepared for it to kick back. Make sure you can get out of the

way if you have to!

Be particularly careful in scrap-metal yards, junkyards, at

accident sites, and with haphazard piles of material. Precariously balanced pieces or pieces under stress can act in

unpredictable ways, and may slide, jump out, or burst. Secure cutoff material from falling! Always exercise extreme

caution and use only equipment that is in perfect working

order.

Observe the accident-prevention rules and regulations of

your employer and/or insurance organization.

Cutting masonry and concrete

IMPORTANT!

Always wear approved respiratory protection!

Asbestos and other materials that can release toxic substances may be cut only after notifying the proper authorities

and under their supervision or that of a person appointed by

them. When cutting prestressed and reinforced concrete

piles, follow the instructions and standards of the responsible authorities or the builder of the structural member.

Reinforcement rods must be cut in the prescribed sequence

and in accordance with applicable safety regulations.

21

NOTE:

Mortar, stone, and concrete develop large quantities of dust

during cutting. To increase the lifetime of the cutting disc (by

cooling), to improve visibility, and to avoid excessive dust creation, we strongly recommend wet cutting instead of dry cutting.

9

Page 10

In wet cutting, the disc is wetted at an equal rate on both sides by

a trickle of water. DOLMAR offers the right accessories for all wet

cutting applications (see also "SPECIAL ACCESSORIES").

- Remove foreign objects such as sand, stones and nails found

within the working area. Caution: Watch out for electric

wires and cables!

The rapid rotation of the cutting disc at the point of contact

throws fragments out of the cut groove at high speed. For

your safety, swing the protection hood down as far as

possible (23), so that material fragments are thrown forward,

away from the operator.

- Mark the cut, and then make a groove about 5 mm (just under

1/5") along the entire length of the planned cut. This groove

will then guide the Power Cut accurately guring the actual

cutoff.

NOTE:

For long, straight cuts we recommend using a trolley (24, see also

"SPECIAL ACCESSORIES"). This makes it much easier to guide

the unit straight.

- Perform the cut with a steady back-and-forth motion.

- When cutting slabs to size, you need not cut through the entire

material thickness (creating unnecessary dust). Instead, simply make a shallow groove, and then knock off the excess

material cleanly on a flat surface (25).

CAREFUL!

When cutting into lengths, cutting through material, making

cutouts, etc., always make sure to plan the direction and sequence of cuts in such a way that the disc does not get jammed

by the cut-off piece, and that no persons can be injured by falling

pieces.

23

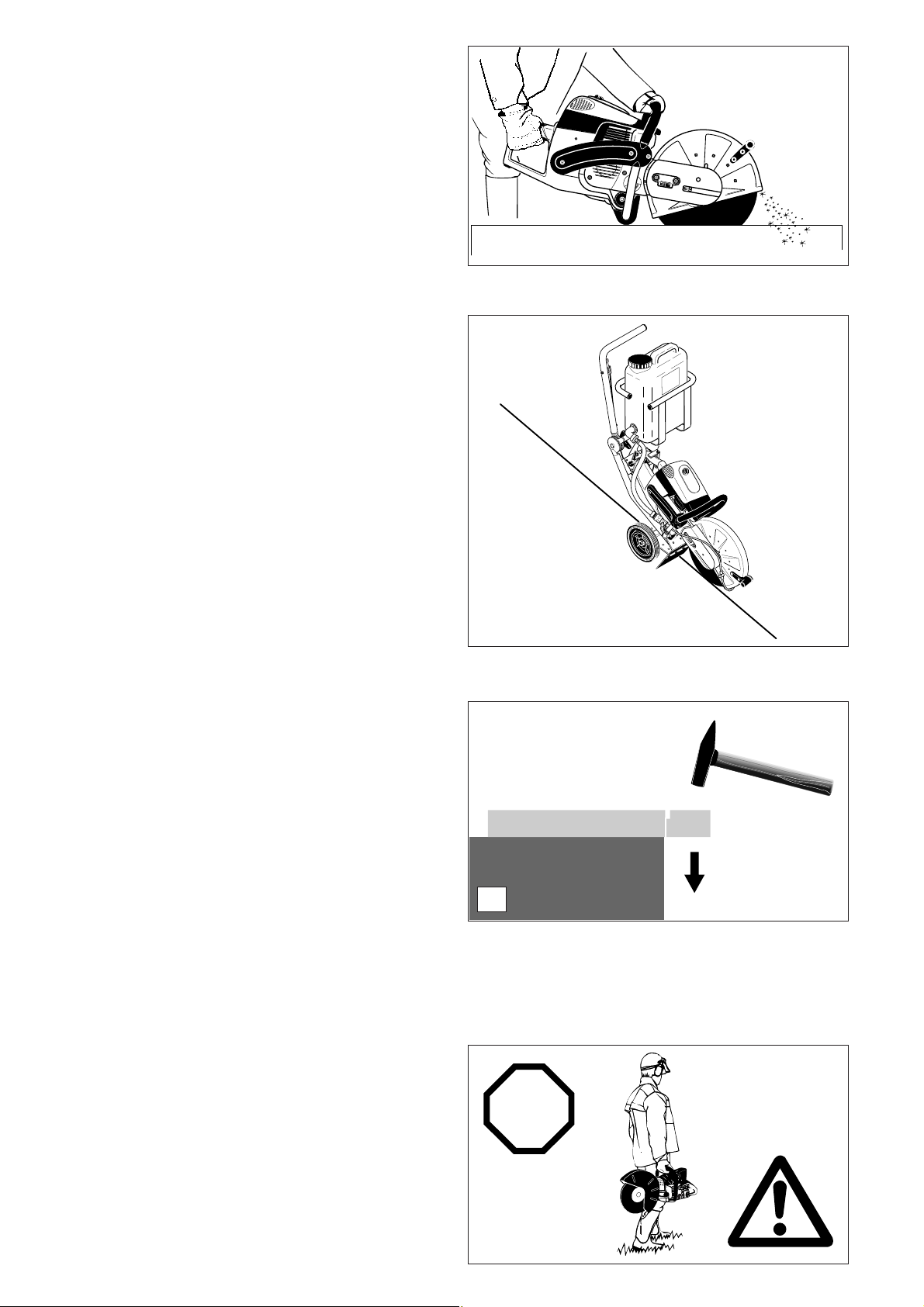

Transport and storage

- Always turn off the Power Cut when transporting it or

moving it from place to place on a site (26).

- Never carry or move the unit with the engine on or the disc

moving!

- Carry the unit only by the tubular (middle) handle with the

cutting disc pointing behind you (26). Avoid touching the

exhaust muffler (burn hazard!)

- When moving the Power Cut over longer distances, use a

wheelbarrow or wagon.

- When transporting the Power Cut in a vehicle, make sure it is

securely positioned in such a way that no fuel can leak out.

Always remove the cutting disc before transporting the unit in

a vehicle.

- The Power Cut should be stored safely in a dry place. It must

not be left outdoors! Always dismount the cutting disc before

storage. Keep the Power Cut away from children.

- Before long-term storage and before shipping the Power

Cut, follow the instructions in the chapter on "Periodic

care and maintenance". ALWAYS empty the fuel tank and

run the carburetor dry.

- When putting cutting discs in storage, be careful to:

- Clean and dry them well.

- Store them lying down flat.

- Avoid dampness, freezing temperatures, direct sunshine,

high temperatures and temperature fluctuations, as these can

cause breakage and splintering.

- Always check new cutting discs or cutting discs that

have been in storage to make sure that they are free of

defects

for at least 60 seconds. Keep body parts and people well away

out of range of the direction of the cutting disc during this test.

and before the first cut test-run the tool at top speed

24

25

STOP

10

26

Page 11

Maintenance

- Before performing maintenance work switch off the Power

Cut (27) and pull out the plug cap.

- Always check the Power Cut before using it to make sure that

it is in good working order. In particular, make sure that the

cutting disc is properly mounted. Make sure that the cutting

wheel is undamaged and suitable for the job it will be used for.

- Operate the Power Cut only at a low noise and emission level.

For this ensure the carburetor is adjusted correctly.

- Clean the Power Cut regularly.

- Check the fuel tank cap regularly for good sealing.

Observe the accident prevention instructions issued by

trade associations and insurance companies. NEVER

make any modifications to the Power Cut! You will only

be putting your own safety at risk!

Perform only the maintenance and repair works described in

the instruction manual. All other work must be carried out by

DOLMAR Service.

Use only original DOLMAR spares and accessories.

The use of non-DOLMAR spares, accessories, or cutting

discs increases the risk of accident. We cannot accept any

responsibility for accidents or damage occurring in association with the use of cutting discs or accessories other than

original DOLMAR.

STOP

27

SERVICE

28

First aid

For the event of a possible accident, please make sure that a

first aid kit is always immediately available close by. Immediately replace any items used from the first aid box.

When calling for help, give the following information:

- Place of the accident

- What happened

- Number of injured people

- Kind of injuries

- Your name!

NOTE

Individuals with poor circulation who are exposed to excessive

vibration may experience injury to blood vessels or the nervous

system.

Vibration may cause the following symptoms to occur in the

fingers, hands or wrists: ”Falling asleep” (numbness), tingling,

pain, stabbing sensation, alteration of skin colour or of the skin.

If any of these symptoms occur, see a physician!

29

11

Page 12

Technical data

PC-6430 PC-6435 PC-7330 PC-7335

Displacement cu in (cm3) 3.9 (64) 4.5 (73)

Bore in (mm) 1.85 (47) 1.97 (50)

Stroke in (mm) 1.46 (37) 1.46 (37)

Max. power hp (kW) 4.4 (3.2) 5.6 (4.2)

Max. torque Nm 4.0 5.0

Idling speed 1/min 2,500 2,500

Clutch engagement speed 1/min 3,800 3,800

Engine speed limitation 1/min 9,350 9,350

Max. spindle speed 1/min 4,300 4,300

Sound pressure level at the operators ear

1)

dB (A) 97 104

Sound pressure level at the bystander’s position (50 ft)1)dB (A) 84 86

Vibration acceleration a

- Tubular handle (idle/rated spindle speed) m/s

- Rear handle (idle/rated spindle speed) m/s

Carburetor

(diaphragm carburetor) Type TILLOTSON HS-273 A

per EN 1454

h,w

2

2

6 / 5 7 / 6

8 / 6 8 / 7

Ignition system (with speed limitation) Type electronic

Spark plug Type

NGK BPMR 7A / BOSCH WSR 6F / CHAMPION RCJ 6Y

Electrode gap in (mm) .020 (0.5) .020 (0.5)

Fuel consumption at max. load per ISO 8893 kg/h 1.65 2.1

Specific consumption at max. load per ISO 8893 g/kWh 500 500

Fuel tank capacity fl oz (l) 37 (1.1) 37 (1.1)

Mixture ratio (fuel/two-stroke oil)

- when using DOLMAR HP 100 high-performance oil 100:1 100:1

- when using DOLMAR oil 50:1 50:1

Cutting disc for 80 m/sec.

Cutting disc for 80 m/sec.

2)

2) 4)

in

in

12" / 0.8" / 0.2"

14" / 1" / 0.2"

3)

14" / 0.8" / 0.2"

3)12" / 0.8" / 0.2"

3)

14" / 1" / 0.2"

3)

14" / 0.8" / 0.2"

Arbor diameter in 0.8" 0.8" / 1.0" 0.8" 0.8" / 1.0"

V-belt (DOLMAR no.) 965 300 470 965 300 470

Overall weight (tanks empty, without cutting disc) lb 21.38 21.82 21.6 22.04

1)

According to UL-test requirement under full load (cutting concrete).

2)

Circumference speed at max. engine speed

3)

Outside diameter / arbor hole / thickness

4)

Country-specific

3)

3)

Denomination of components

PC-7335

EMI OFB

973108

DOLMAR GmbH, 22045 Hamburg, Germany

0410 123456

394.100. 256

Typ 394

1 Handle

2 Filter cover for air filter and spark plug cap

3 Cover lock

4 Tubular handle

5 Muffler

6 Protection hood

7 Grip

8 V-belt tension adjusting screw

9 Retaining nuts

10 Stand

11 Carburetor adjustment opening

12 Identification plate

13 Fuel tank with handle

14 Decompression valve

15 Starter grip

16 Air intake

17 Combination Start/Stop (I/O) switch, choke

18 Stop knob for halfway throttle

19 Safety locking button

20 Throttle lever

21 Tank cap (fuel)

22 Starter housing with starter

23 Cutting disc

24 Disc bolt

25 Spring washer

26 Hold opening

12

Identification plate (12)

Indicate when ordering spare parts

Serial number

Year of manufacture

25

24

23

3 4 5 6 7

2

1

26

8

9

12 1113

10

14 15 16

17

18

19

20

2122

Page 13

A

STOP

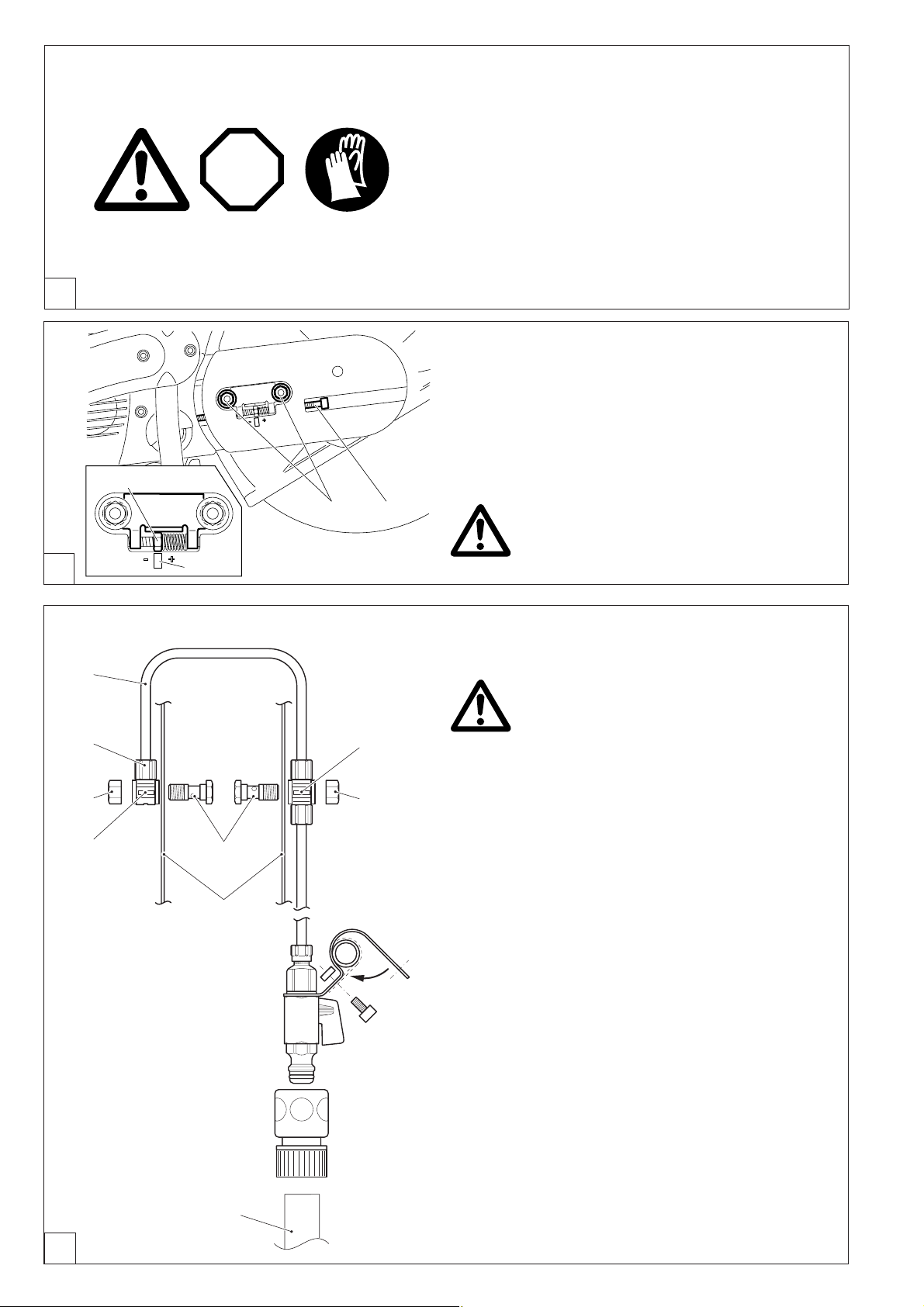

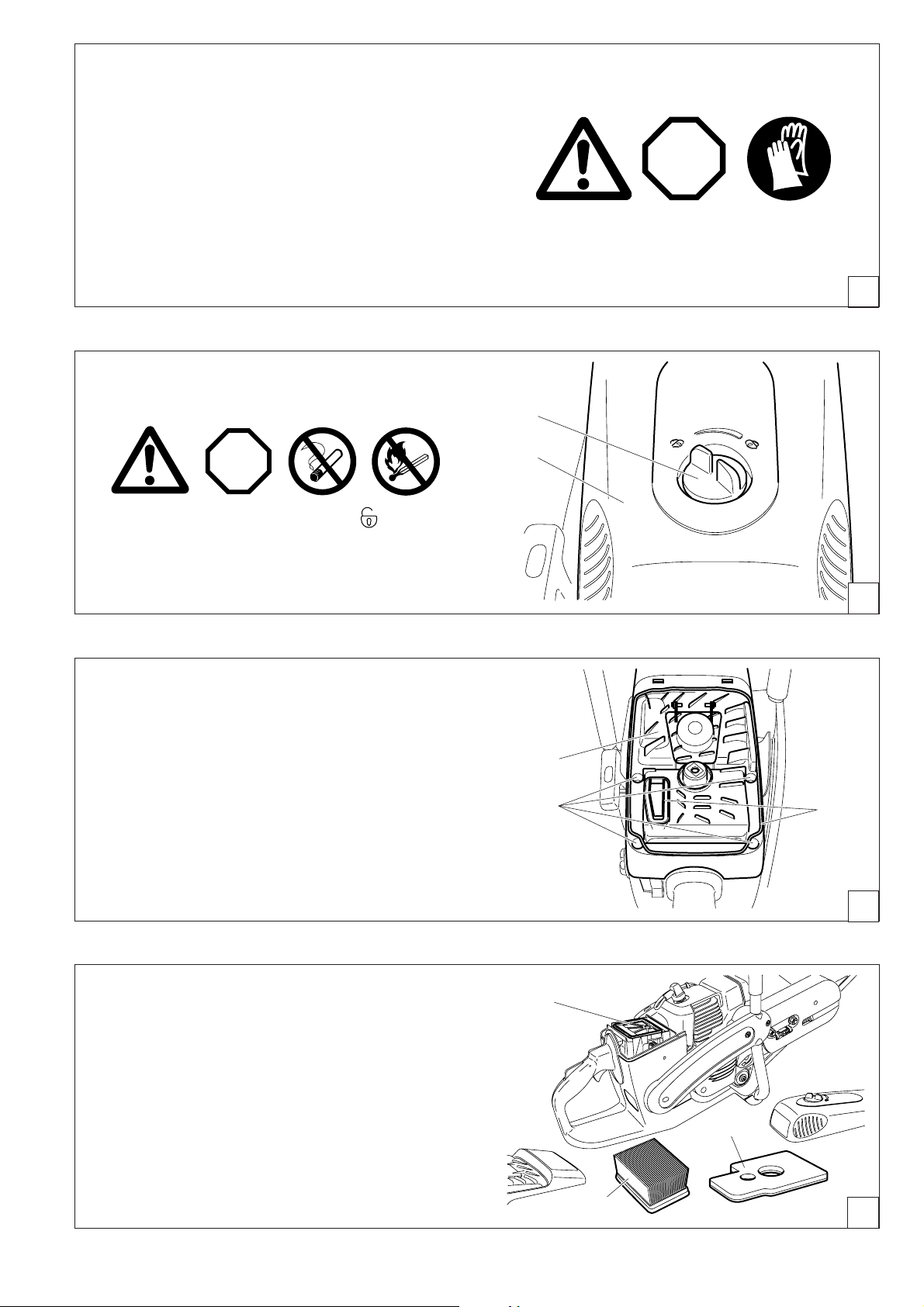

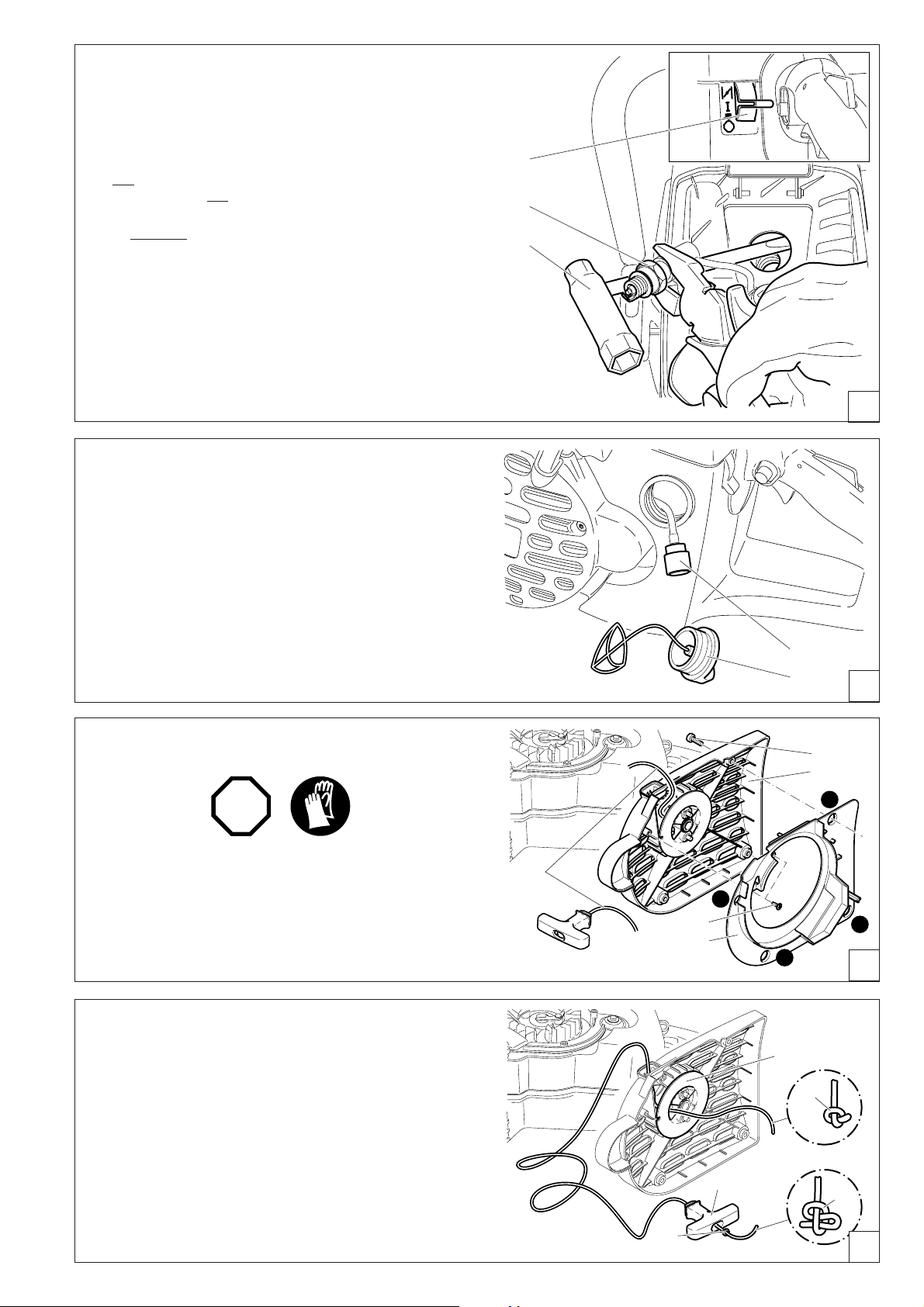

PUTTING INTO OPERATION

CAUTION:

Always turn off the engine and pull off the spark plug cap

before doing any work on the Power Cut! Always wear

protective gloves!

CAUTION:

Start the Power Cut only after complete assembly and

inspection.

For the the following work, use the assembly tools included

with delivery:

1. 13/19 AF combination wrench

2. Allen key

3. Carburetor adjustment screwdriver

4. Adapter ring (not in the general delivery inventory)

B

C

1

2

34

Schematic drawing

7

5

5

Place the Power Cut on a stable surface and carry out the

following assembly steps:

Mounting the cutting disc

Inspect the disc for damage.

See SAFETY INSTRUCTIONS, Page 7.

Unscrew screw (9) and remove the spring washer (8).

Place the cutting disc (5) on the arbour (7).

Hinweis: The arbor hole of the cutting disc must be an exact

fit with the arbor or shaft. If the arbor hole is larger, it must be

fitted with an adapter ring (*).

7

98

Make sure the cutting disc is installed so it turns in the

right direction, if a direction is marked on the disc.

D

10

Place the spring washer (8) on the arbour and insert the screw

(C/9) and tighten by hand.

8

2

Turn the disc slowly until the stop hole of the V-belt pulley is

visible in the cutting arm cover (10).

Insert the Allen key (2) as far as it will go. The shaft is now

blocked.

Tighten the screw with the combination wrench (1)

1

NOTE: Tighten the screw firmly (30 ± 2 Nm), as otherwise

the cutting wheel may slip during cutting.

13

Page 14

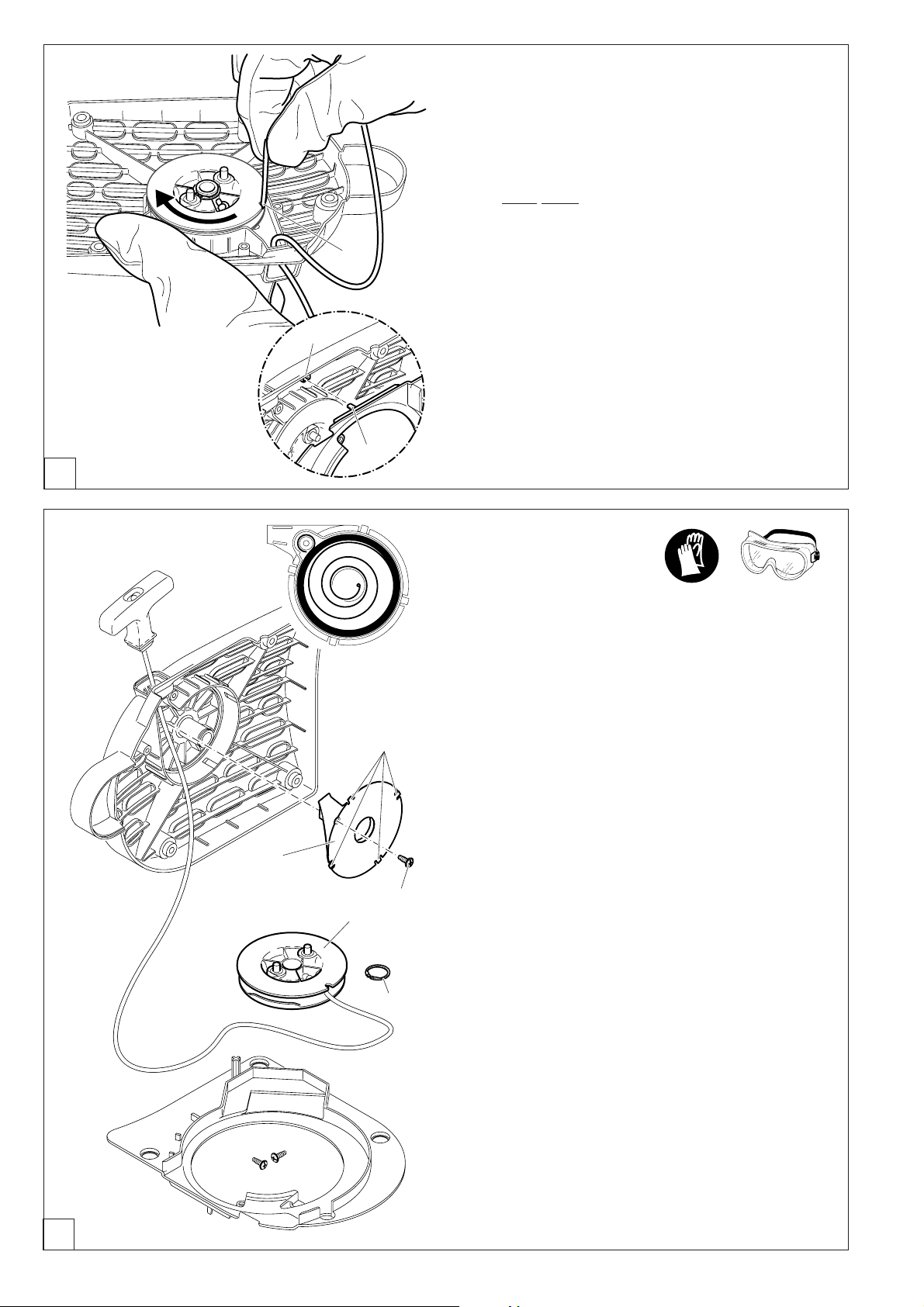

Tightening the V-belt /

Checking V-belt tension

F

E

13

STOP

14

11 12

IMPORTANT

Exact V-belt tension is essential for maximum cutting

performance with minimum fuel consumption. Improper

V-belt tension will result in premature wear to the V-belt

and V-belt wheel or damage to the clutch bearing.

If the Power Cut is new or the V-belt has been replaced,

retighten the V-belt after the first hour of operation!

NOTE: The two fastening nuts (11) must be loosened before

tightening the V-belt or checking the tension.

To increase the belt tension, turn the tightening screw (12) to

the right (clockwise) with the combination wrench included with

the Power Cut.

The belt tension is correctly adjusted when the nut (13) is

centred on the mark (14).

:

IMPORTANT:

After tightening/inspection, make certain to tighten

the fastening nuts (11) (30 ± 2 Nm).

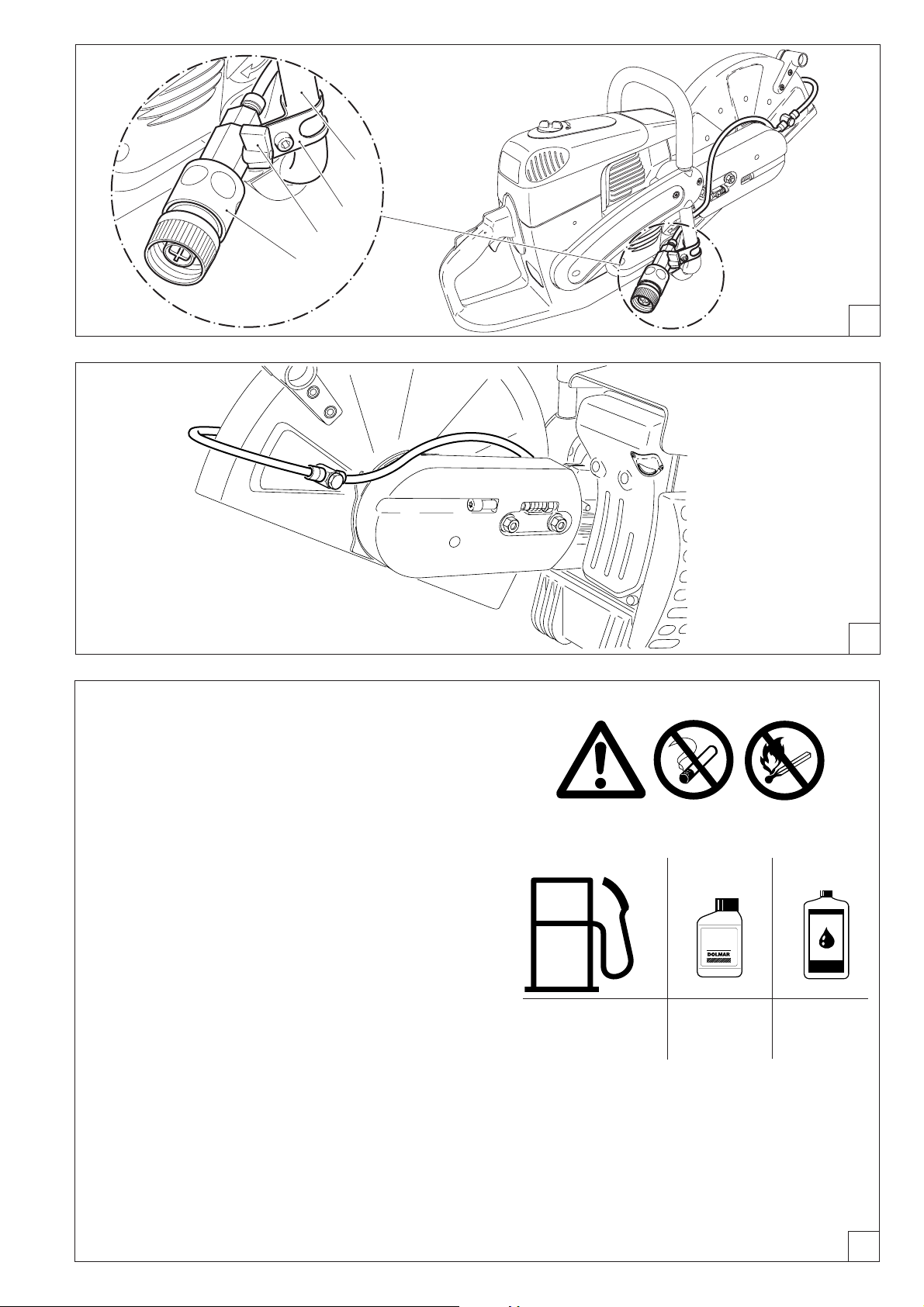

Installing the pressure water system

1

2

7

3

7

3

5

6

Not in the general scope of delivery. Country-specific!

CAUTION: Before doing any work on the Power Cut, always switch off the engine and

disconnect the spark plug cap!

NOTE: When using a protective hood for a maximum disk diameter

of 300 mm (12"), always shorten hose (1) to 180 mm (7").

To do this unscrew sleeve (2) and carefully pull tube (1) off

coupling (3) and cut to 180 mm. Then push the tube end back

over the coupling and tighten the sleeve all the way.

- Install the water connection as shown in Figure H. Push

clamp (H/8) around the front grip (H/9) and fasten with the

bolt and square nut.

- Pull the quick-release coupling (H/10) from the water

connection and connect it to the 1/2" supply line (4).

- Remove the cutting disk (see instruction manual).

- Tube routing with the cutting assembly in the middle

position, see Fig. H.

- Tube routing with the cutting assembly in the outside

position, see Fig. I.

- Insert the nozzles (5) through the protective hood (6) from

the inside and put on couplings (3). Screw on and tighten

the coupling caps (7).

14

G

4 *

IMPORTANT:

To avoid bending the tubes, be sure to position the couplings

(3) in accordance with Fig. H or I as appropriate.

- Install the cutting disc (see instruction manual).

- Connect the quick-release coupling (H/10) to the supply

tube.

NOTE:

The water flow rate can be precisely adjusted with valve (H/11).

Page 15

10

9

8

11

H

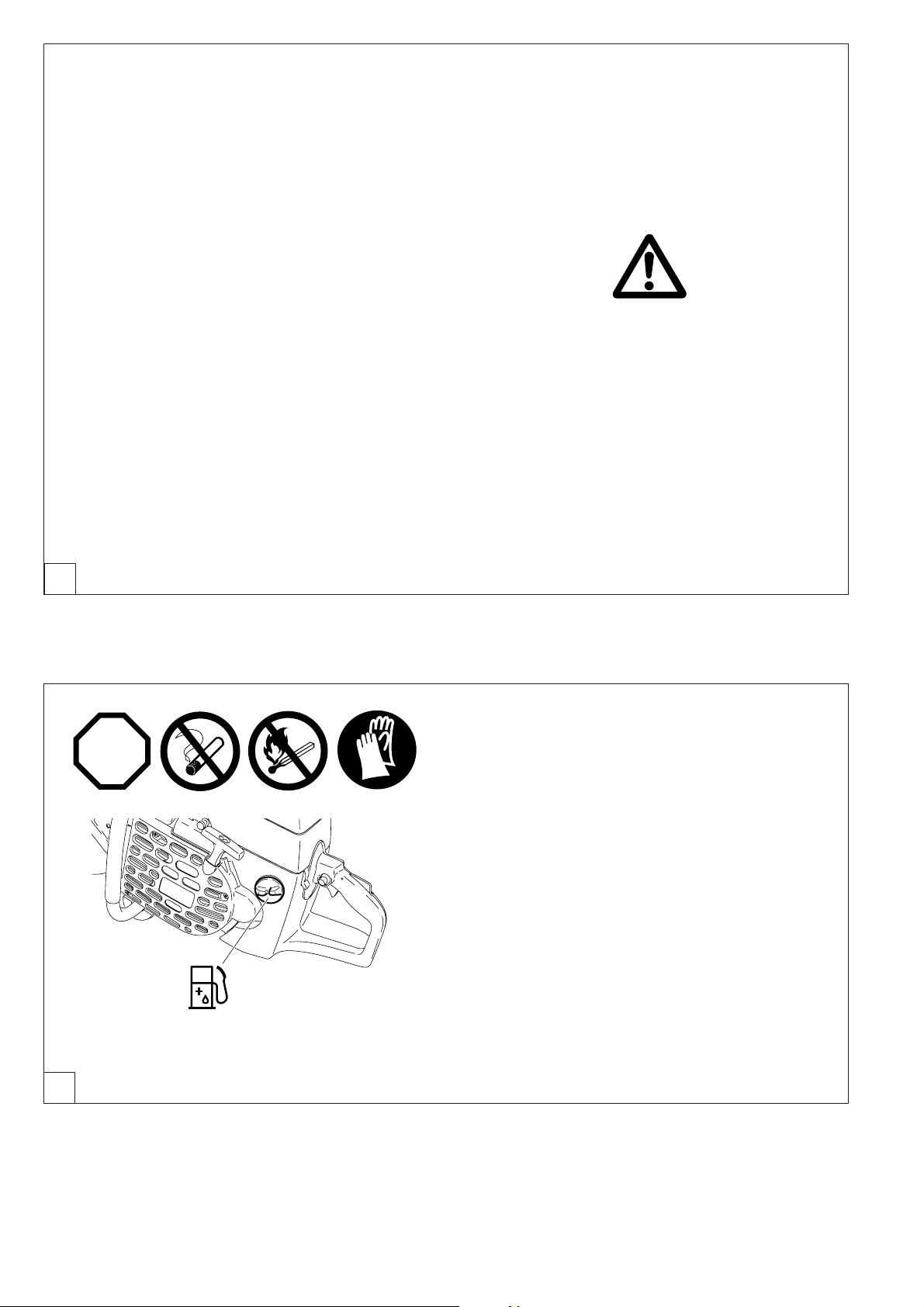

Fuels

Caution:

The Power Cut uses mineral-oil products (gasoline and oil).

Be especially careful when handling gasoline.

Do not smoke. Do not allow gasoline to come near flames,

sparks or fire (explosion hazard).

Fuel mixture

The Power Cut is powered by a high-performance two-stroke

engine. It runs on a mixture of gasoline and two-stroke engine

oil.

The engine is designed for unleaded regular gasoline with a min.

octane value of 91 ROZ. In case no such fuel is available, you

can use fuel with a higher octane value. This will not affect the

engine.

In order to obtain an optimum engine output and to protect

your health and the environment use unleaded fuel only.

Gasoline which contens alcohol should not used in DOLMAR

products.

To lubricate the engine, use a high-performance two-stroke

engine oil (quality grade JASO FC or ISO EGD), which is added

to the fuel. The engine is designed for the use of DOLMAR HP

100 high-performance two-stroke engine oil at a mixture ratio of

only 100:1 to protect the environment. In addition, this ensures

a long service life and reliable operation with minimum exhaust

emissions.

Gasoline

+

1.0 Us-gal. (3.7 l) 1.25 floz. (37 cm3) 2.5 floz. (75 cm3)

2.5 Us-gal. (9.4 l) 3.2 floz. (94 cm3) 6.4 floz. (189 cm3)

5.0 Us-gal. (18.9 l) 6.4 floz. (189 cm3) 12.8 floz. (378 cm3)

The correct mixture ratio:

100:1 When using DOLMAR HP 100 high-perfor-

mance two-stroke engine oil, i. e. 100 parts

gasoline to 1 part oil.

50:1 When using DOLMAR high-performance two-

stroke engine oil, i. e. 50 parts gasoline to 1

part oil.

100:1

HP 100

50:1

OIL

50:1

DOLMAR

I

J

15

Page 16

DOLMAR HP 100 high-performance two-stroke engine oil is

available in the following sizes to suit your individual requirements:

50 ml order number 980 008 105

0,5 l order number 980 008 113

DOLMAR high-performance two-stroke engine oil (50:1) is

available in the following sizes to suit your individual requirements:

100 ml order number 980 008 106

1 l order number

5 l order number 980 008 118

NOTE: For preparing the fuel-oil mixture first mix the entire oil

quantity with half of the fuel required, then add the remaining

fuel. Shake the finished mixture thoroughly before pouring it

into the Power Cut tank.

Caution: Open the tank cap carefully, as pressure might

have built up inside!

It is not wise to add more engine oil than specified to

ensure safe operation. This will only result in a higher

production of combustion residues which will pollute

the environment and clog the exhaust channel in the

cylinder as well as the muffler. In addition, fuel consumption will rise and performance will decrease.

980 008 112

The Storage of Fuel

Fuels have a limited storage life. Fuel and fuel mixtures age.

Therefore fuel and fuel mixtures, which have been stored

for too long, can cause starting problems. Purchase only

that amount of fuel, which will be consumed over the next

few months.

Store fuel safely in a dry place in approved containers

only.

AVOID SKIN AND EYE CONTACT

Mineral oil products degrease your skin. If your skin comes in

contact with these substances repeatedly and for an extended period of time, it will dry out. Various skin deseases

may result. In addition, allergic reactions are known to occur.

Eyes can be irritated by contact with oil. If oil comes into your

eyes, immediately wash them with clear water.

If your eyes are still irritated, see a doctor immediately!

A

STOP

Refuelling

IMPORTANT:

FOLLOW THE SAFETY PRECAUTIONS!

Be careful and cautious when handling fuels.

The engine must be turned off and cooled down!

Carefully clean the area around the fuel-tank filler neck to keep

dirt from getting in the tank.

Place the unit on its side on an even surface.

Unscrew the tank cap and fill tank with fuel mixture. Take care

to avoid spilling.

Screw the tank cap back on hand-tight.

Clean screw cap and tank after refuelling. Never start or

operate the Power Cut in the same place as it was fuelled!

Fuel mixture

If fuel gets on your clothing, change clothes immediately.

16

B

Page 17

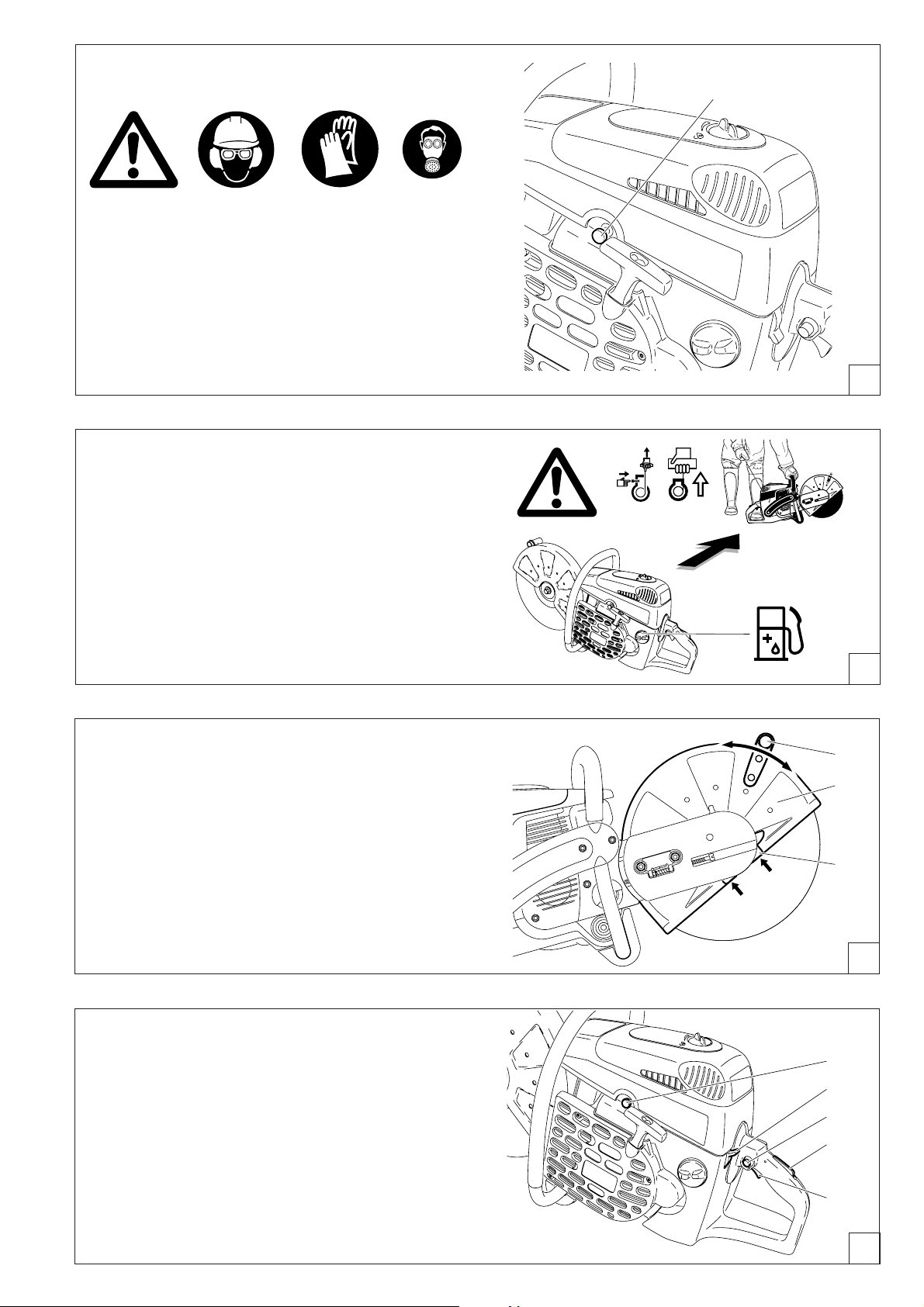

Starting the engine

6

5

7

8

9

if

necessary

This model is fitted with a semiautomatic decompression valve

(1) to make starting easier. Depressing it reduces the force

needed for compression, so little force is needed to accelerate

the engine to its starting speed.

The high pressure in the combustion chamber after the first

ignition automatically closes the decompression valve (button

pops out).

CAUTION:

Observe the SAFETY INSTRUCTIONS on page 5 and 6!

Start the Power Cut only after complete assembly and

inspection!

Move at least 10 feet (3m) away from the place where you

fuelled the Power Cut.

Make sure you have a good footing, and place the Power

Cut on the ground in such a way that the cutting disc is not

touching anything.

1

C

2

1

3 meters

Move the protective hood (3) into the proper position for the

work you intend to do (see illustration).

Grasp the grip (2). The hood (3) can swing in both ways within

its range of motion.

Caution:

Always make sure that the straight outer edge of the impact

plate (4) and the edge of the hood are parallel (see arrows).

If this is not the case, take the tool to a service center.

Cold-starting

Move the combination switch (6) up (choke position).

Grasp handle (hand pressure actuates the grip throttle lever lock

(8)).

Push the throttle (9) in all the way and hold it.

Press the throttle lock (7) and release the throttle (9) (the

throttle lock will hold the throttle at half-throttle position).

NOTE: If the Power Cut is in a trolley, bring the control lever to

the third or fourth detent.

Depress decompression valve (5).

D

2

3

4

E

F

17

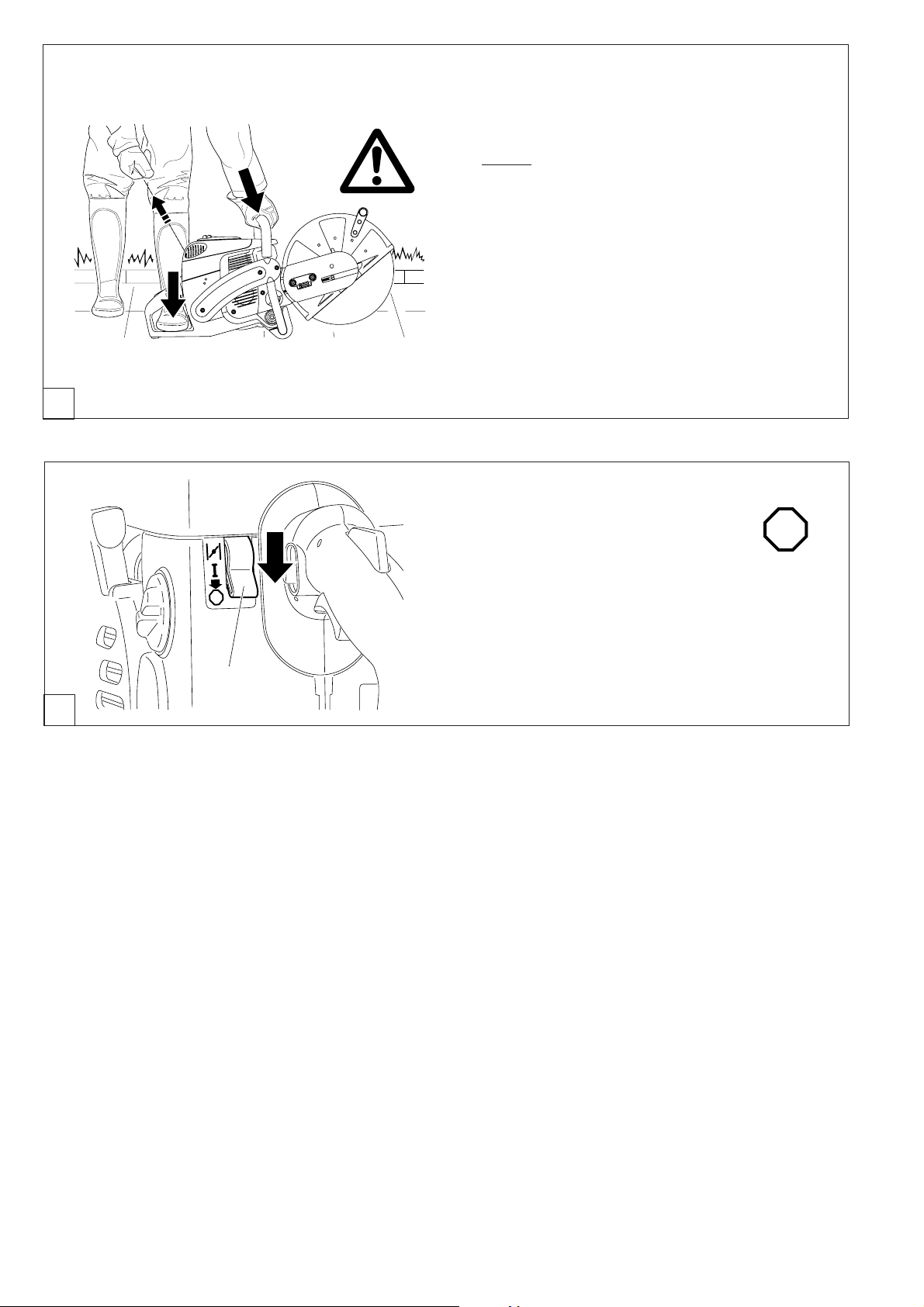

Page 18

G

Grasp the tubular handle firmly with one hand and press the

Power Cut against the ground.

Place the tip of your left foot in the rear handle.

Pull the starter cable strong and rapidly until you hear the

audible ignition.

first

CAUTION: Do not pull out the starter cable more than approx.

20" (50 cm), and lead it back by hand.

Depress decompression valve (F/5) again.

Put the combination switch (F/6) in position “I”.

Keep pulling the starter cable until the engine catches.

As soon as the engine is running, press the throttle (F/9) to

release the half-throttle lock (F/7), allowing the engine to idle.

Warm-starting

As described under ”Cold starting”, except without putting the

combination switch (F/6) in choke position.

Stopping the engine

Push the combination switch (1) down to position .

STOP

H

P

TO

S

10

18

Page 19

Adjusting

the carburetor

NOTE: The grinding parts are equipped with an electronic

ignition to limit the speed. The carburetor also has a fixed

jet which cannot be adjusted.

At the factory the idling speed has been set to approx.

2,500 1/min., but the running-in process of a new engine

may require slight readjustment of the idling speed.

For correct adjustment of the idling speed the following

steps must be carried out:

A

Start the engine and run it until it is warm

(about 3 - 5 minutes).

Adjust the carburetor with the screwdriver (1, Order No. 944

340 001) included with the Power Cut. It has a lug that helps

with adjustment.

Readjust the idling speed.

If the cut-off disc is still turning when the engine is running,

unscrew the adjusting screw of the throttle valve (2) until the

cut-off disc is no longer turning. When the engine is left

running at idling speed, loosen the screw a little.

2

1

B

1

Switch off the engine

STOP

2

C

19

Page 20

A

STOP

SERVICE

MAINTENANCE

CAUTION:

Before doing any work on the Power Cut turn off the

engine, remove the cutting disc, pull the plug cap off the

spark plug and wear protective gloves!

CAUTION:

Start the Power Cut only after complete assembly and

inspection.

IMPORTANT:

Because many of the parts and assemblies not mentioned

in this Instruction Manual are vital to the safety of the unit,

and because all parts are subject to a certain amount of

wear and tear, it is important for your own safety that you

have the unit checked and maintained regularly by a

DOLMAR service center.

IMPORTANT:

If the cutting wheel breaks during cutting, the

Power Cut must be repaired by a DOLMAR service center before being used again!

B

C

7

65

8

4

3

2 1

9

10

Changing the V-belt

Loosen nuts (3).

Loosen the tightening screw (1) (counter-clockwise) until the

end of the screw (2) is visible in the gap.

Unscrew the nuts (3) and remove the cover (4).

Remove the screws (5) and (7) and remove the side piece (6).

NOTE:

Screw (5) is longer than screws (7). Make sure to

put them back in the right places during

reassembly!

Unscrew the screws (8) and remove the crankcase housing

cover (9).

Remove the old belt (10) or belt pieces.

Clean out the inside of the drive arm with a brush.

Put in a new V-belt.

NOTE:

Reassemble the crankcase housing cover (9), side piece (C/6)

and cover (C/4) in the reverse order.

To tighten the V-belt see ”Tightening the V-belt / Checking

V-belt tension”.

20

D

Page 21

Cleaning the protection hood

13

14

15

16

17

18

Over time, the inside of the protective hood can become caked

with material residue (especially from wet cutting), which if

allowed to accumulate can hinder the free rotation of the

cutting disc. For this reason the hood must be cleaned out from

time to time.

Take off the cutting wheel with spring washer and remove the

accumulated material from inside the hood with a strip of wood

or similar implement.

Clean the shaft and all removed parts.

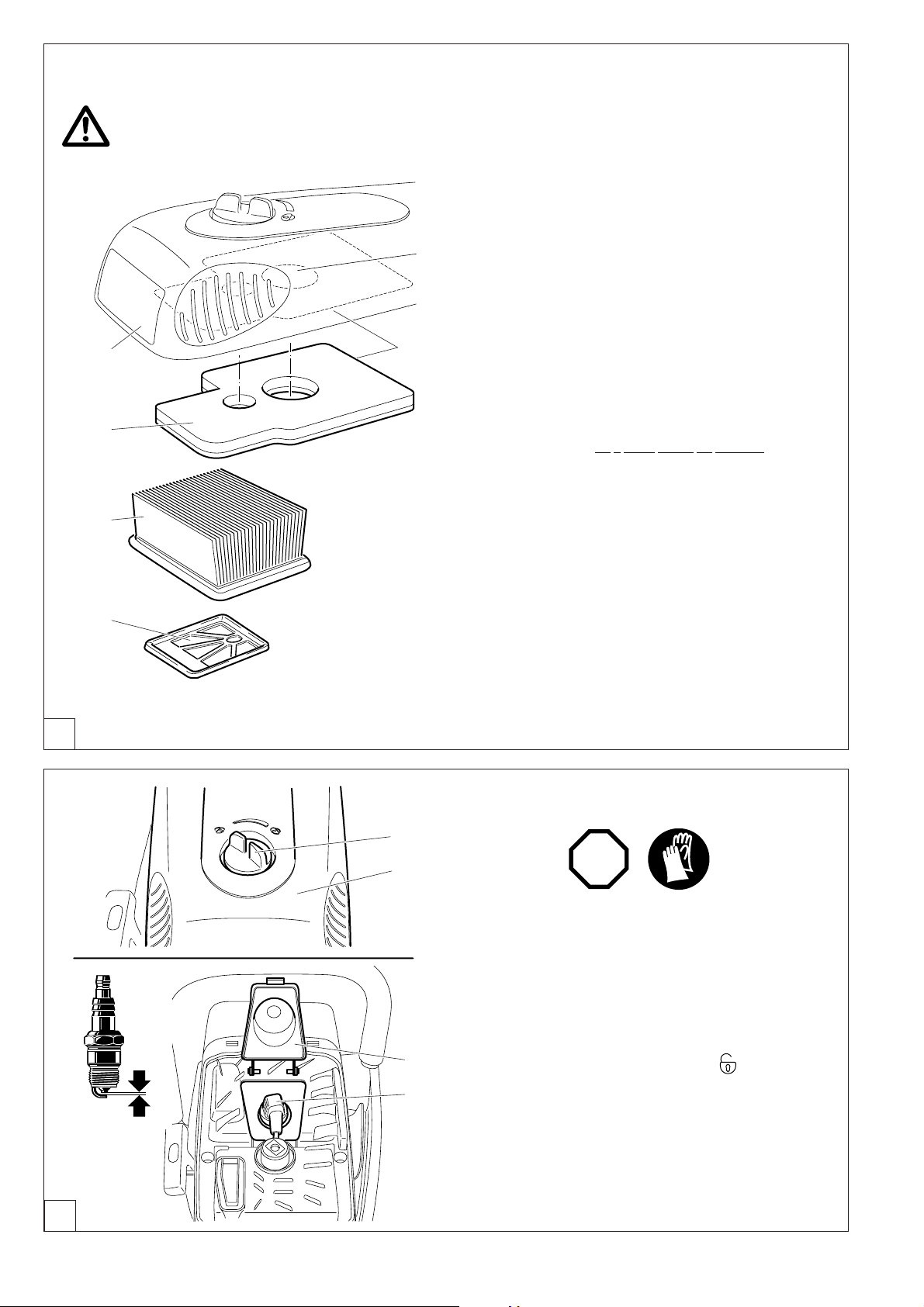

Cleaning / changing the air filter

STOP

NOTE: To install the cutting wheel see ”Mounting the cutting

wheel”.

E

11

STOP

Turn the cover lock (11) to the ”Unlocked ” position and

carefully remove the filter cover (12).

There are two O-rings (G/15) between the filter cover (12) and

the air filter hood (G/14).

Remove screws (13) and take off the cover (14).

Clean the O-ring (15) with a brush and inspect for damage.

12

F

Take the pre-filter (foam, 17) out of the filter cover.

Pull the air filter insert (paper cartridge, 18) out of the cover.

Remove the inner filter (16) from the intake opening.

Note:

Do not allow dirt to get into the carburetor!

Switch the combination switch to ”Choke” or cover the

carburetor with a clean cloth.

G

H

21

Page 22

CAUTION:

Never clean out the air filter with compressed

air! Do not clean the pre-filter and inner filter

with fual.

4

1

2

3

Pre-filter (foam) and inner filter

If the pre-filter (1) and inner filter (3) are dirty, wash them out in

lukewarm water with regular dishwashing liquid.

Dry pre-filter and inner filter thoroughly.

NOTE: The pre-filter needs cleaning at least daily, or more

often if the Power Cut is used in very dusty conditions. If

cleaning on-site is not possible, keep a replacement pre-filter

on hand.

Replace the pre-filter after every 20 operating hours at the

latest.

To improve filtration, wet the pre-filter with air filter oil. Before

doing this, carefully clean the pre-filter with air filter cleaner. Be

sure to follow manufacturer’s instructions.

5

When inserting the pre-filter in the filter cover, align it with the

cover opening and press it into the cover (5).

Filter insert (paper cartridge)

The air filter insert (2) filters the intake air through a very fine

paper fan filter system, so it must never be washed. Clean the

filter insert once weekly.

To do so, open it slightly and carefully tap it out against a clean

surface.

Replace the filter insert every 100 operating hours. Replace it

immediately if there is loss in power, loss in speed, or smoke

develops in the exhaust.

Before installing the filter system, check the intake opening for

any dirt particles that may have fallen in. If so, remove them.

CAUTION:

If the air filter becomes damaged, replace immediately!

Pieces of cloth or large dirt particles can destroy the

engine!

A

0,5 mm

Replacing the spark plug

6

7

STOP

CAUTION:

Do not touch the spark plug or plug cap if the engine is

running (high voltage).

Switch off the engine before starting any maintenance

work.

A hot engine can cause burns. Wear protective gloves!

The spark plug must be replaced in case of damage to the

insulator, electrode erosion (burn) or if the electrodes are very

dirty or oily.

8

Turn the cover lock (6) to the ”Unlocked ” position and

carefully remove the filter cover (7).

9

Flip up the spark-plug cover (8).

Pull the plug cap (8) off the spark plug. Use only the combination

wrench supplied with the saw to remove the spark plug.

Electrode gap

The electrode gap must be .020" (0.5 mm).

22

B

Page 23

22

23

19

21

20

STO

P

9

10

11

Checking the ignition spark

15

18

14

17

16

A

B

C

D

Insert the combination wrench (9) between the hood and

cylinder only as shown.

CAUTION!

Do not insert the combination tool into the spark plug hole,

but make contact only with the cylinder (otherwise you may

damage the engine).

Using insulated pliers, hold the spark plug (10) (unscrewed but

with the plug cap on) against the combination tool (away from

the spark plug hole!).

Switch the combination switch (11) to ”I”.

Pull the starter cable hard.

If the function is correct, an ignition spark must be visible near

the electrodes.

CAUTION: Use only BOSCH WSR 6F spark plug, CHAMPION

RCJ-6Y or NGK BPMR 7A.

Replacing the suction head

The felt filter (13) of the suction head can become clogged. It is

recommended to replace the suction head once every three

months in order to ensure unimpeded fuel flow to the carburetor.

Unscrew the tank cap (12), pull the retainer out of the opening.

Empty fuel tank.

Use a wire hook to pull the suction out of the tank opening for

replacement.

Caution: Do not allow fuel to come into contact with skin!

E

13

12

F

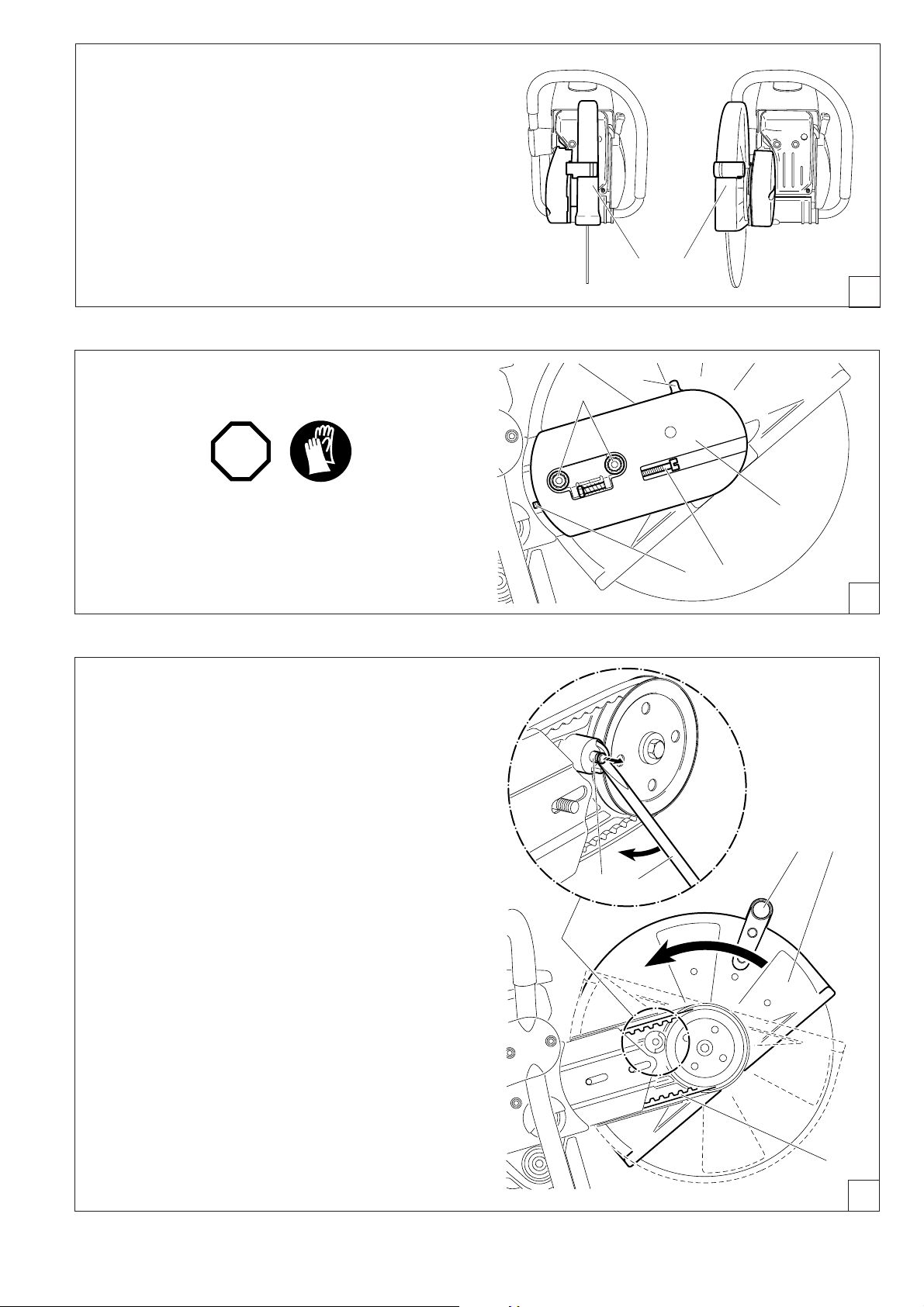

Replacing the starter cable

STOP

Remove four screws (14). Remove starter housing (15).

Unscrew two screws (16) and carefuly remove the air guide

(17) from the starter housing (15). Proceed in the order (A - B

- C - D).

Remove all pieces of cable (18).

G

Thread in a new starter cable (dia 0.16" (4.0 mm), length 39.5"

(1000 mm)) as shown (don’t forget the disc (19)) and knot both

ends.

Pull knot (20) into the cable pulley (21).

CAUTION: Do not let the knots or the cable ends protrude from

the outside of the cable pulley.

Pull knot (22) into the cable grip (23).

H

23

Page 24

A

26

24

25

Guide the cable into the recess (24) on the cable drum and use

the cable to turn the drum two turns in the direction shown by

the arrow.

Holding the cable drum in your left hand, straighten out the twist

in the cable with your right hand, pull the cable tight, and hold.

Release the cable drum. The drum´s spring force will now wind

the cable around the drum.

Repeat

starter housing.

NOTE: With the cable pulled all the way out, it must still be

possible to turn the pulley another 1/4 turn against the return

spring.

three times. The starter grip must be upright on the

CAUTION!

Injury hazard! When you pull out the starter cable hold the

starter handle firmly. It will whip back if the cable pulley is

released by accident.

Install the air guide in reverse order (see figure G, page 23).

Make sure that the nub (25) fits into the slot (26) in the starter

housing.

When putting the starter housing back on, it may be necessary

to pull the starter handle slightly until the starting mechanism

engages.

Replacing the return spring

Remove the starter housing (see “Replacing the starter cable”).

Take the air guide off the starter housing (see “Replacing the

starter cable”).

Take off circlip (1) (circlip pliers, see “Accessories”).

Remove the cable pulley (2).

5

4

3

2

1

Unscrew screw (3).

Evenly lever the return spring (4) out of the catch using a

screwdriver or similar tool. Be extremely careful - the return

spring is under tension and can pop out of its housing!

CAUTION! Injury hazard! Wear eye protection and work

gloves when performing this work!

Replacement return springs are delivered already tensioned in

the housing. CAREFUL - the spring can pop out. If it does, it

can be put back in as shown in the diagram (observe the

direction of rotation).

Before installing the new return spring (4) in the starter housing, grease it lightly with multipurpose grease, Order No. 944

360 000. Then position it and press it until the tabs (5) engage

in the slots.

Do not grease the cable drum (2) or bearing journal!

Screw in bolt (3) but do not tighten it hard.

Turn the cable pulley slightly when putting it back on, until you

hear it catch. Put the circlip back on.

Wind on the starter cable (see above under “Replacing the

starter cable”).

Reinstall the air guide (see Fig. A)

When putting the starter housing back on, it may be necessary

to pull the starter handle slightly until the starting mechanism

engages.

24

B

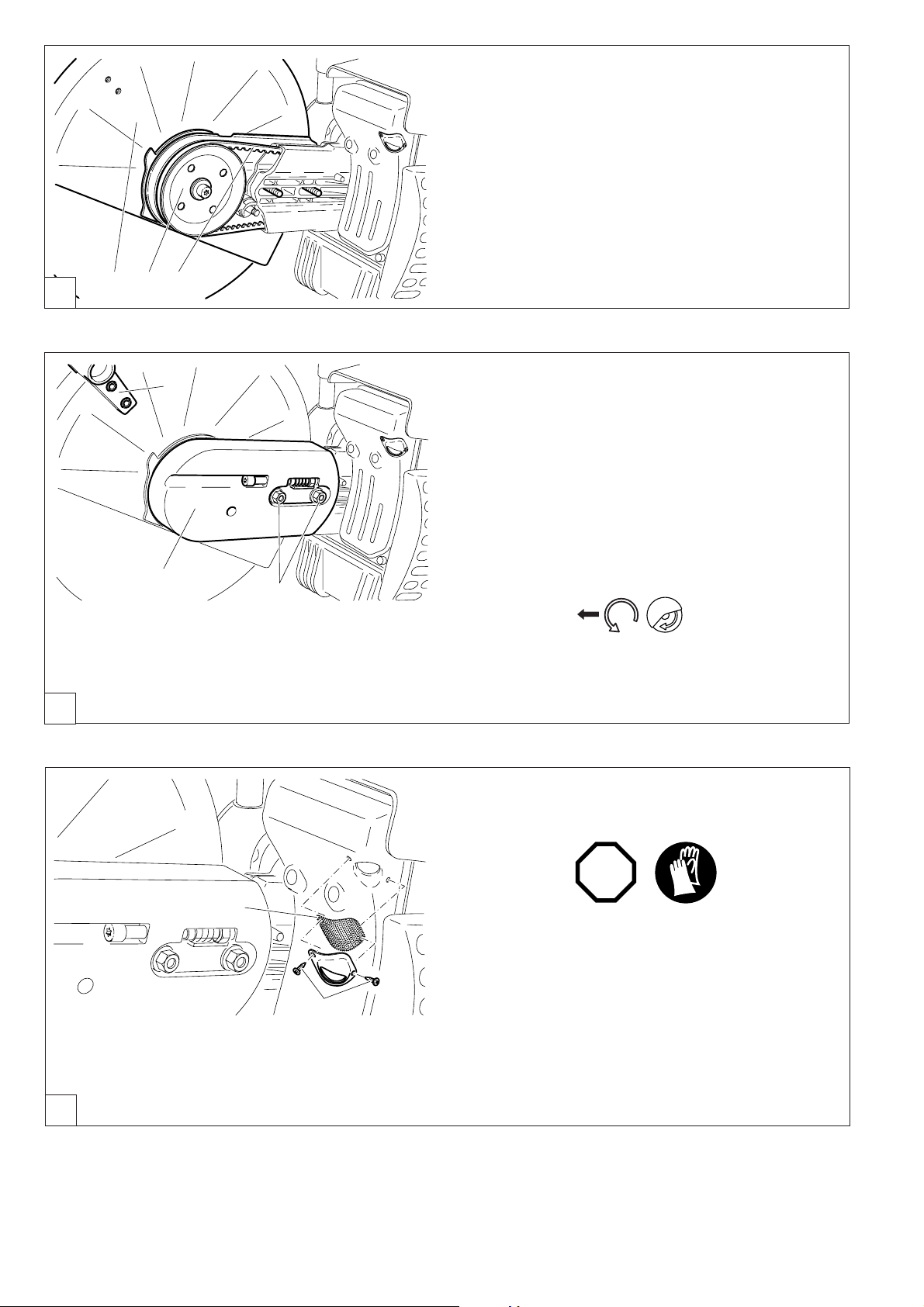

Page 25

34

5

6

7

Cutting attachment in

1 2

11

9

7 8

10

central / side position

NOTE: The Power Cut is delivered with the cutting attachment

mounted in the middle position (1). For cutting up against

obstacles, such as curbs or walls, the cutting attachment can

be mounted to one side (2). Use this position only when

actually necessary, and afterwards return the cutting attachment to the middle position. In this position the Power Cut has

better balance, is easier to guide, and is not as fatiguing for the

operator.

Repositioning the cutting attachment

STOP

Loosen nuts (5).

Loosen the tightening screw (3) (counter-clockwise) until the

end of the screw (4) is visible in the gap.

Unscrew the nuts (5) and remove the cover (6).

C

Use the combination tool (8) to lever out the stop pin (7) as

shown in the illustration, until the protective hood (10) can be

turned.

NOTE: The turn stop (D/7) is deactivated when the stop pin (7)

is removed. This permits the hood (10) to be turned farther than

the turn stop (D/7).

Unscrew the grip (9) and turn the protective hood (10) as

shown in the illustration.

Disengage the V-belt (11) and remove the cutting attachment.

D

E

25

Page 26

Press the cutting attachment (12) onto the drive arm in the side

position.

Guide the V-belt (13) over the V-belt pulley (14).

F

G

1412 13

17

15

Put the guard plate (15) on.

Screw on nuts (16) and tighten by hand.

To tighten the V-belt see ”Tightening the V-belt / Checking V-

belt tension”.

Tighten the nuts (16) firmly with the combination wrench.

Replace the grip (17) as shown.

IMPORTANT:

When you reposition the cutting attachment, the direction

of rotation of the cutting wheel changes.

16

If a rotation direction is marked on the cutting disc, make

sure the disc turns in the right direction.

H

18

17

Replacing/cleaning the spark arrester screen

STOP

The spark arrester screen should be checked and cleaned

regularly.

Loosen the 2 screws (18) and remove the spark arrester

screen (19).

Reassembly the spark arrester screen and tighten the screws.

CAUTION:

Do not use sharp or pointed objects for screen cleaning.

Damaged or misformed screen wires may result.

26

Page 27

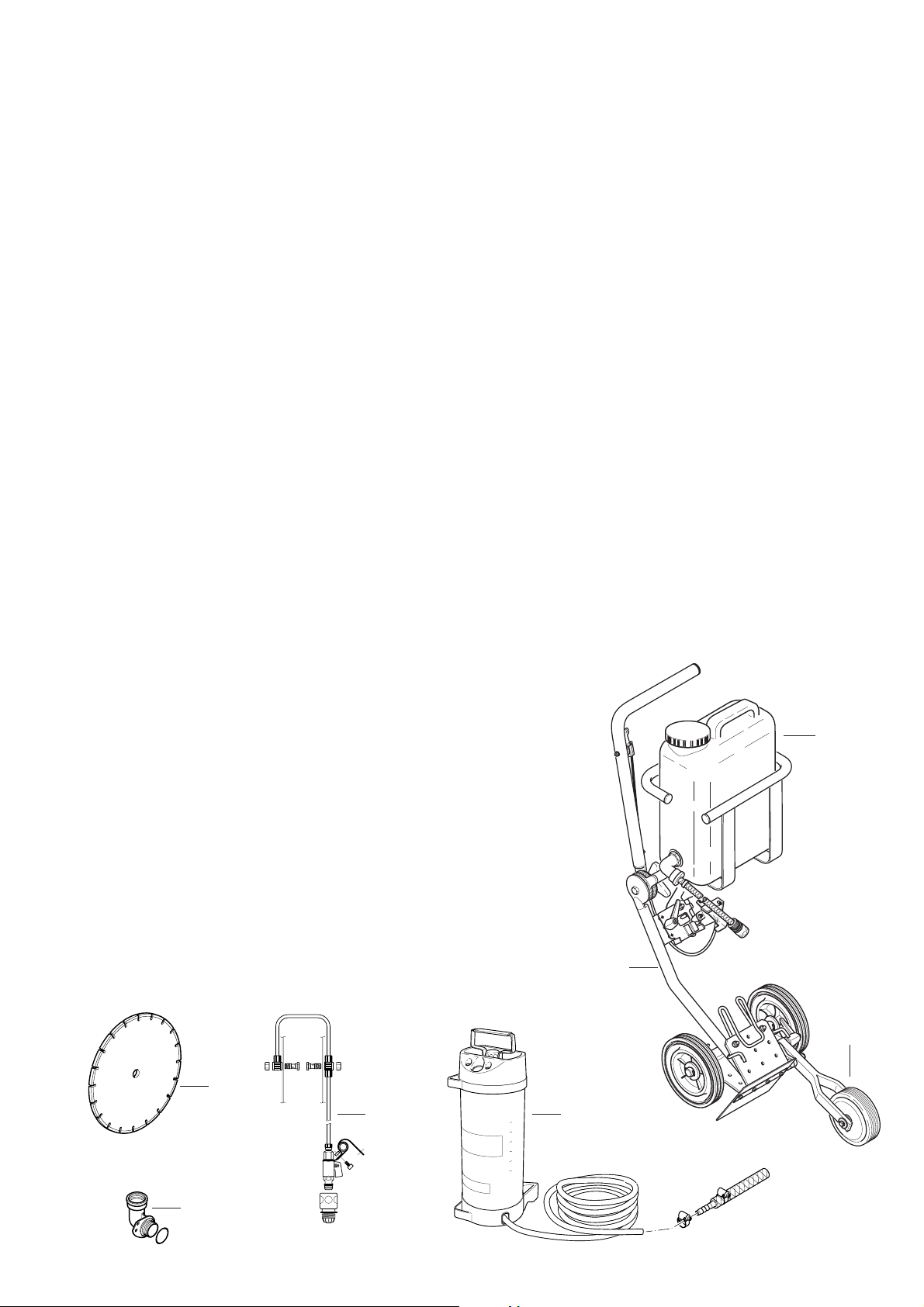

SPECIAL ACCESSORIES

Diamond cutting discs (1)

DOLMAR diamond cutting discs meet the highest demands in

working safety, ease of operation, and economical cutting

performance. They can be used for cutting all materials

except metal.

The high durability of the diamond grains ensures low wear

and thereby a very long service life with almost no change in

disc diameter over the lifetime of the disc. This gives consistent

cutting performance and thus high economy. The outstanding

cutting qualities of the discs make cutting easier.

The metal disc plates give highly concentric running for minimal vibration during use.

The use of diamond cutting discs reduces cutting time significantly. This in turn leads to lower operating costs (fuel consumption, wear on parts, repairs, and last but not least environmental damage).

Guide trolley (2)

The DOLMAR guide trolley makes it much easier to do straight

cuts, while simultaneously enabling almost untiring working. It

can be adjusted for the operator´s height, and can be operated

with the cutting attachment mounted in the middle or on the

side.

Water tank (5)

The water tank is designed to be mounted on the guide trolley.

Its high capacity makes it especially suitable for situations

involving frequent site changes. For filling or for fast changing

to reserve tanks, the tank can be simply lifted off the trolley.

The water tank comes with all necessary connections and

hoses. Mounting to the trolley and Power Cut are very fast and

simple.

Mains/pressure water system (6)

The mains/pressure water system is designed to be mounted

on the Power Cut. It can be used with or without the trolley, but

is especially suitable for applications involving hand-held,

stationary cutting. The water line has a fast-release connection, and can be fed either from a mains supply or from a

pressure tank (7).

The water system comes with all necessary connections and

lines. It can be quickly and easily mounted on the Power Cut.

See “Accessories” for order number.

For easier refuelling when using the trolley, we recommend

adding an angled tank filler neck (3).

A depth limiter can be added for still easier and more accurate

cutting. It makes it possible to maintain a precise predetermined cut depth (4).

To keep down dust and for better cutting-disc cooling, DOLMAR

offers several options for wetting the disc during operation.

1

5

2

4

6

7

3

27

Page 28

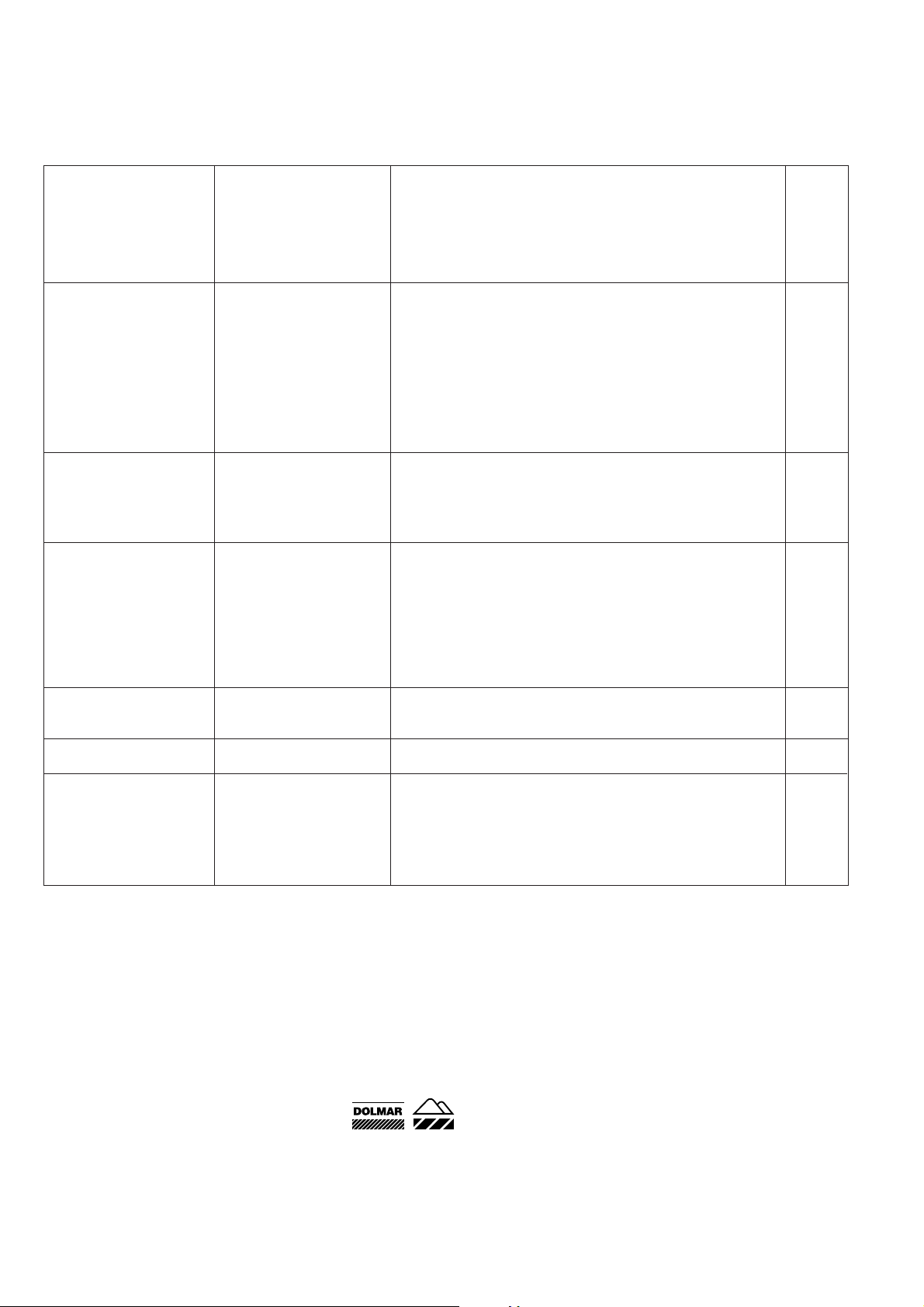

Instructions for periodic maintenance

To ensure long life, prevent damage and ensure the full functioning of the safety features the following maintenance must be

performed regularly. Guarantee claims can be recognized only if this work is performed regularly and properly. Failure to perform

the prescribed maintenance work can lead to accidents!

Users of the Power Cut must not perform any maintenance work not described in this Instruction Manual. All such work must be

carried out by a DOLMAR service center.

General Entire Power Cut Clean exterior, check for damage. In case of damage,

have repaired by a qualified service center immediately

Cutting disc Inspect regularly for damage and wear. 7

Clutch Have inspected at a service center.

Protection hood Clean, Check position (impact plate) 17

Before each start Cutting disc Inspect for damage and make sure the cutting wheel is 7

right for the job

V-belt Check V-belt tension 14

Protective hood Adjust position

Combination switch, Functional check

Safety locking button, Functional check

Throttle lever Functional check 17

Tank cap Check for tightness

Page

Every day Air filter Clean,

Idle speed Check (cutting disc must not turn on idle) 19

Extreme dust Clean filter insert (paper cartridge) 21

Every week Starter housing Clean to ensure proper air cooling 12

Starter cable Check for damage 23

V-belt Check V-belt tension, inspect for damage and wear 20

Air filter insert

Spark plug Check and replace if necessary 22-23

Muffler Check tightness of mounting 12

Every 3 months Suction head Replace 23

Fuel tank Clean

Annually Entire Power Cut Check at an authorized service center

Storage Entire Power Cut Clean exterior, check for damage. In case of damage,

Cutting disc Remove and clean 13

Fuel tank Empty and clean

Carburetor Run empty

(poss. more often), replace foam pre-filter after

20 hours of operation 21

Clean, replace after 100 operating hours 22

have repaired by a qualified service center immediately

Service, spare parts and guarantee

Maintenance and repair

The maintenance and repair of modern cutoff saws and their safety-related components requires qualified technical training and a

workshop equipped with special tools and testing devices.

We therefore recommend that you consult a DOLMAR service center for all work not described in this instruction manual.

The DOLMAR service centers have all the necessary equipment and skilled and experienced personnel, who can work out costeffective solutions and advise you in all matters.

Please contact your nearest service center (list enclosed) or the general trading company or importer (see last page), who will gladly

provide you with the address of your nearest DOLMAR service center.

Spare parts

Reliable long-term operation, as well as the safety of your Power Cut, depend among other things on the quality of the spare parts

used. Use only original DOLMAR parts, marked

Only original parts are from the same production line as the original unit and therefore ensure the highest possible quality of materials,

dimensions, functioning and safety.

Only original spare parts and accessories guarantee the highest quality in material, dimensions and function.

Original spare parts and accessories can be obtained from your local dealer. He will also have the spare part lists to determine the

required spare part numbers, and will be constantly informed about the latest improvements and spare part innovations.

Please bear in mind that if parts other than original DOLMAR spare parts are used, this will automatically invalidate the DOLMAR

product guarantee.

We will furthermore not accept any liability damages arising from the use of non-DOLMAR spare parts.

28

Page 29

Guarantee

DOLMAR guarantees the highest quality and will therefore reimburse all costs for repair by replacement of damaged parts resulting

from material or production faults occurring within the guarantee period after purchase. Please note that in some countries particular

guarantee conditions may exist. If you have any questions, please contact your salesman, who is responsible for the guarantee of the

product.

Please note that we cannot accept any responsibility for damage caused by:

• Disregard of the instruction manual.

• Non-performance of the required maintenance and cleaning.

• Incorrect carburetor adjustment.

• Normal wear and tear.

• Obvious overloading due to permanent exceeding of the upper performance limits.

• The use of other than original DOLMAR cutting discs.

• Use of force, improper use, misuse or accidents.

• Damage from overheating due to dirt on the fan housing.

• Work on the Power Cut by unskilled persons or inappropriate repairs.

• Use of unsuitable spare parts or parts which are not original DOLMAR parts, insofar as they have caused the damage.

• Use of unsuitable or old oil.