Page 1

Original Instruction Manual

Instructions d’emploi

Betriebsanleitung

Manuale d’istruzioni

Gebruiksaanwijzing

Manual de instrucciones

Manual de instruções

Brugsanvisning

Πρωτότυπο εγχειρίδιο οδηγιών

Orijinal kullanım kılavuzu

Important:

Read this instruction manual carefully before putting the Blower into operation and strictly observe the safety regulations! Preserve

instruction manual carefully!

Importante:

Lisez attentivement ce manuel utilisateur avant de mettre en route le soufeur et respectez scrupuleusement les consignes de sécurité.

Conservez soigneusement ce manuel.

Wichtig:

Lesen Sie diese Betriebsanleitung sorgfältig durch bevor Sie das Blasgerät in Betrieb nehmen und beachten Sie die

Sicherheitsvorschriften genau! Bewahren Sie diese Betriebsanleitung sorgfältig aul!

Importante:

Leggere con attenzione il manuale prima di mettere in funzione il sofatore; le norme di sicurezza vanno rigorosamente rispettate!

Conservare il manuale delle istruzioni per I’uso.

Belangrijk:

Lees altijd eerst de veiligheidsvoorschriften aandachtig door en neem deze in acht voordat u de machine in gebruik neemt. Bewaar

deze gebruiksaanwijzing zorgvuldig.

Importante:

Lea bien este manual antes de poner el soplador en funcionamiento, y observe estrictamente las medidas de seguridad. Conserve este

manual de instrucciones.

Importante:

Leia cuidadosamente este manual de instruções antes de colocar o soprador em funcionamento e observe estrictamente as normas de

segurança. Guarde o manual de instruções.

Vigtig:

Denne driftsvejledning skal læses omhyggeligt igennem, inden blæseapparatet tages i drift og man skal være sarlig opmærksom på de

enkelte sikkerhedsforskrifter! Opbevar denne driftsvejledning omhyggeligt!

Σημαντικό:

Διαβάστε αυτό το εγχειρίδιο οδηγιών προσεκτικά πριν θέσετε τον φυσητήρα σε λειτουργία και τηρήστε αυστηρά τους κανονισμούς

ασφάλειας!Διατηρήστε το εγχειρίδιο οδηγιών προσεκτικά!

Önemli:

Üeme makinesini çalıştırmadan önce bu kullanma kılavuzunu dikkatlice okuyun ve güvenlik kurallarına haryen uyun!Kullanma

kılavuzunu dikkatli bir şekilde saklayın!

PB-7650.4 PB-7650.4 H

Page 2

2

3

English

Thank you very much for selecting the Dolmar blower. We are pleased

to be able to offer you the Dolmar blower, which is the result of a long

development program and many years of knowledge and experience.

Those blower models combine the advantages of state-of-the-art

technology with ergonomic design. They are of lightweight, handy,

compact and represent professional equipment for a great variety of

applications.

Please read, understand and follow this booklet, which refers in detail

to the various points that will demonstrate its outstanding performance.

This will assist you to safety obtain the best possible results from your

Dolmar Blower.

Table of Contents

Symbols ................................................................................................ 2

Safety instructions ................................................................................ 3

EC declaration of conformity ................................................................ 6

Technical data....................................................................................... 7

Designation of parts.............................................................................. 8

Assembly instructions ........................................................................... 9

Before starting the engine .................................................................. 10

Operation ............................................................................................ 12

Adjustment of idling ............................................................................ 14

Prevention from carburetor icing ........................................................ 14

Operation method ............................................................................... 15

Inspection and maintenance............................................................... 17

Storage ............................................................................................... 19

Troubleshooting .................................................................................. 21

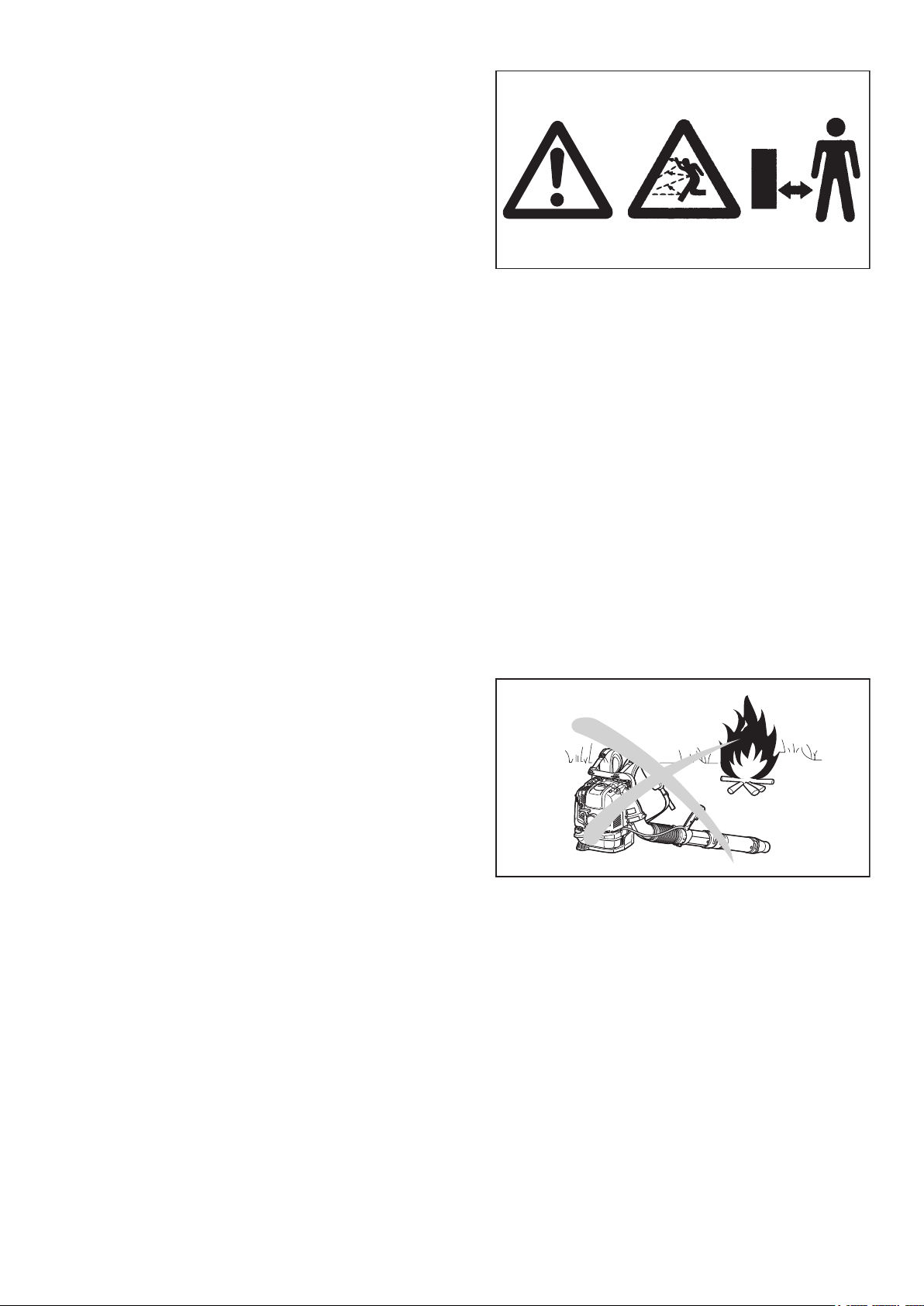

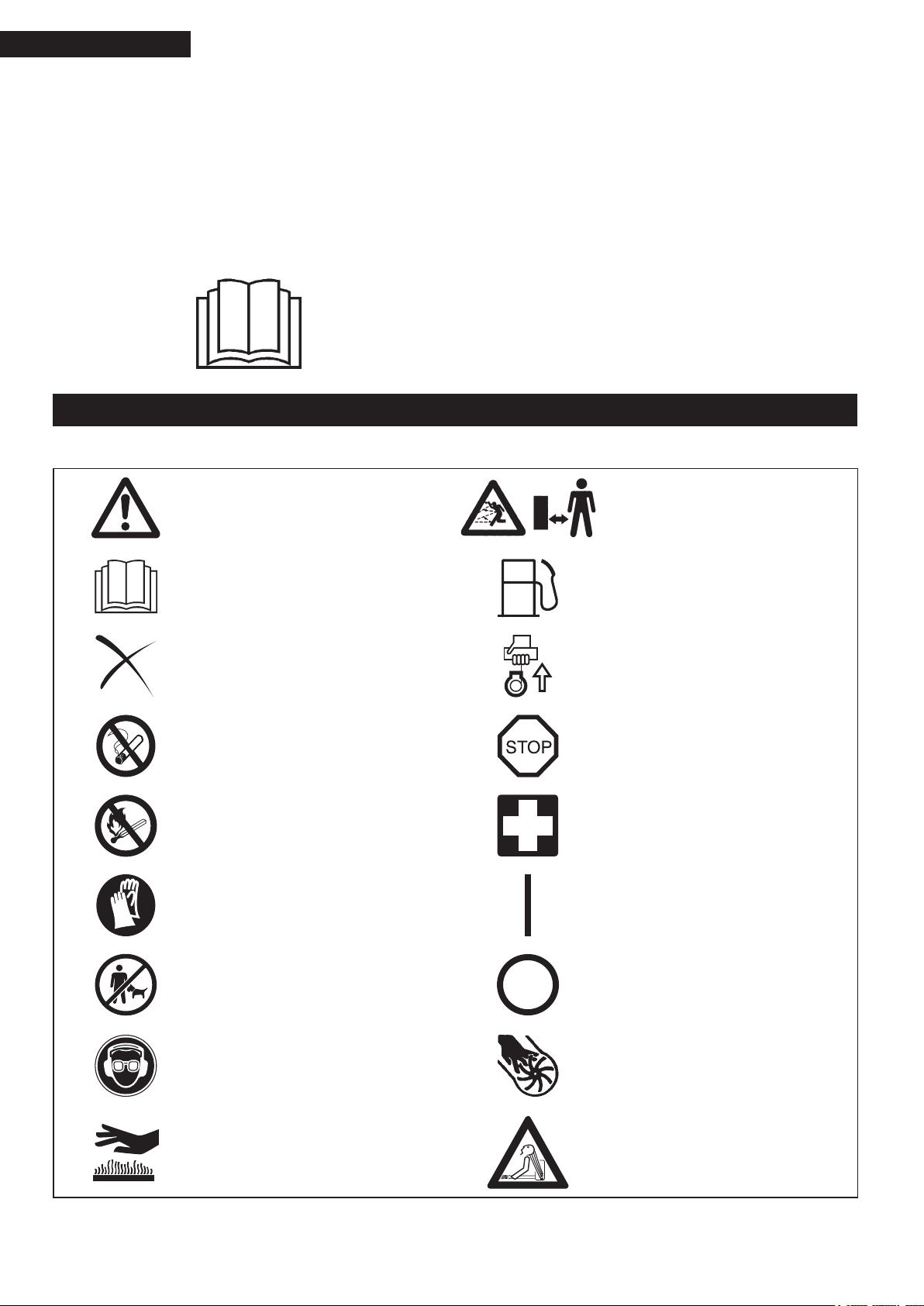

SYMBOLS

It is very important to understand the following symbols when reading this instructions manual.

WARNING/DANGER Keep bystanders away

Page

Read, Understand and Follow Instruction

Manual

Forbidden Engine-manual Start

No Smoking Emergency Stop

No Open Flame First Aid

Protective Gloves must be Worn ON/START

Keep the Area of Operation

Clear of All Persons and Pets

Fuel (Gasoline)

OFF/STOP

Wear Eye and Ear Protection Severing of ngers or hand, impeller blade

Hot surfaces – Burns to ngers or hands

Long hair may cause entanglement

accident.

Page 3

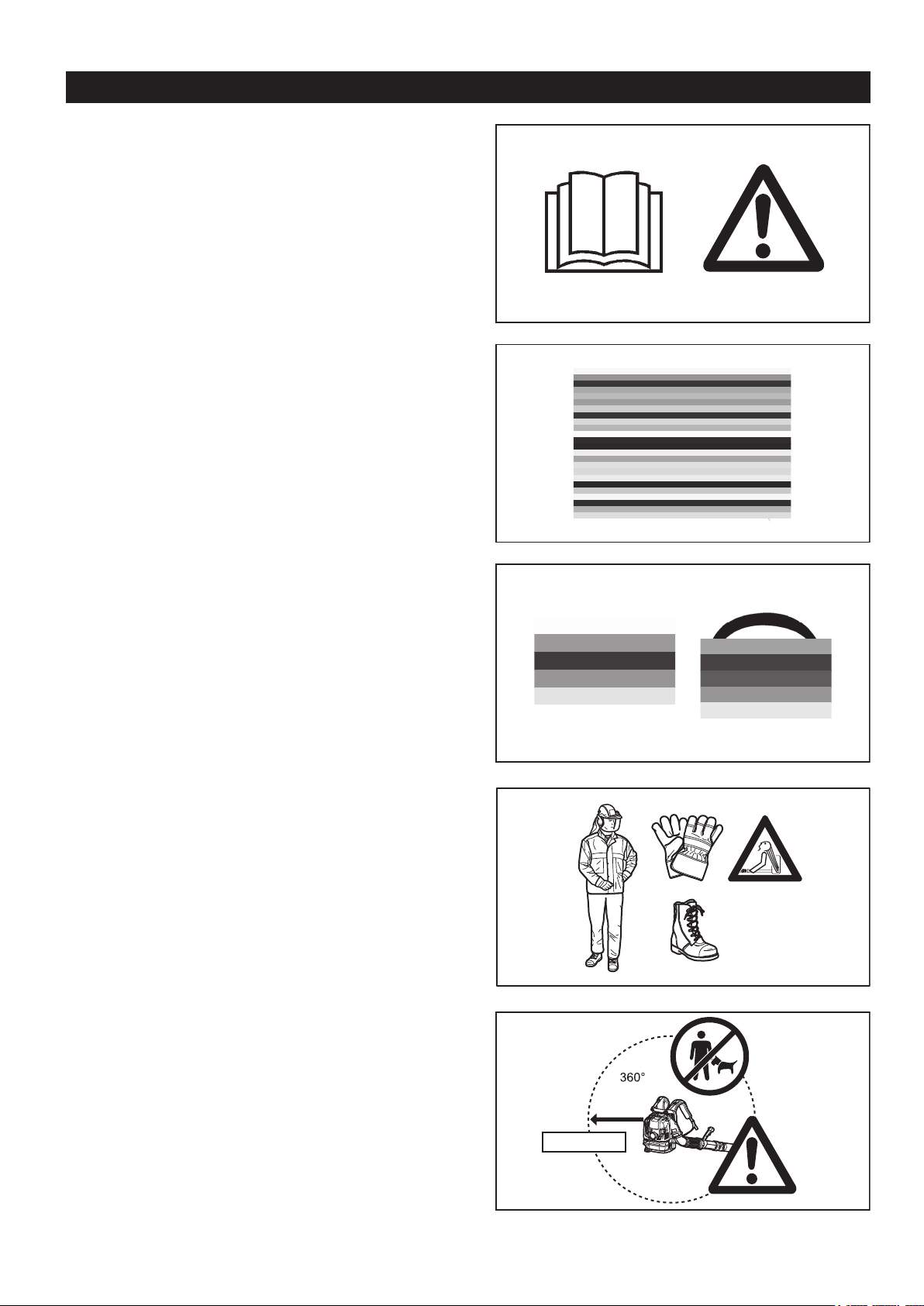

SAFETY INSTRUCTIONS

(1)

(2)

(3)

(5)

(4)

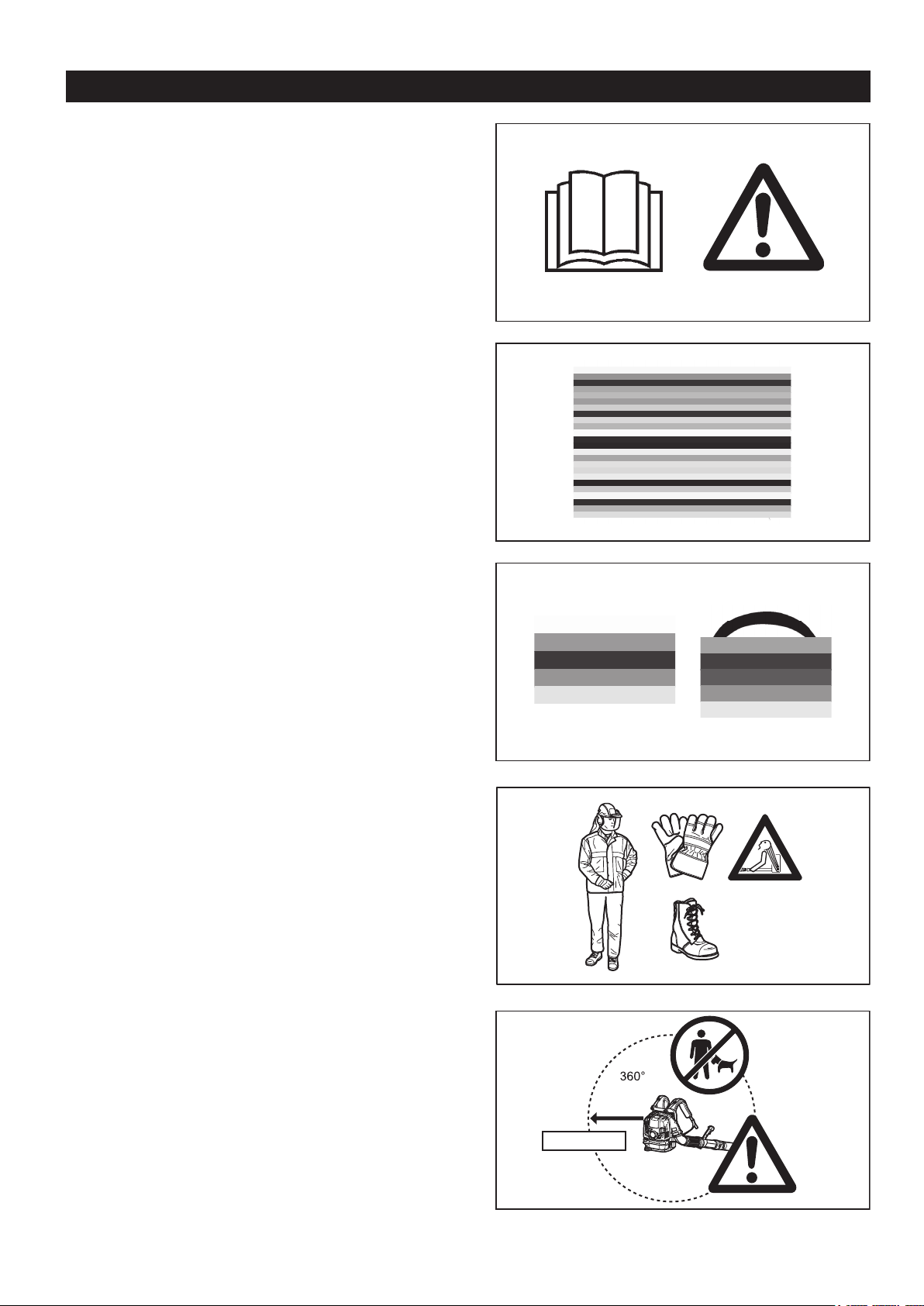

General Instructions

To ensure correct and safe operation, the user must read, understand and

●

follow this instruction manual to assure familiarity with the handling of the

blower (1). Users insufciently informed will risk danger to themselves as

well as others due to improper handling.

●

It is recommended only to loan the blower to people who have proven to

be experienced with blowers.

●

Always hand over the instruction manual.

First-time users should ask the dealer for basic instructions to familiarize

●

oneself with the handling of a blower.

●

Children and young persons aged under 18 years must not be allowed

to operate the blower. Persons over the age of 16 years may however

use the tool for the purpose of being trained only while under the direct

supervision of a qualied trainer.

●

Use blowers with the utmost care and attention.

Operate the blower only if you are in good physical condition.

●

Perform all work conscientiously and carefully. The user has to accept

●

responsibility for others.

Never use the blower while under the inuence of alcohol or drugs (2).

●

Do not use the unit when you are tired.

●

Save these instructions for future referral.

●

Personal Protective Equipment

The clothing worn should be functional and appropriate, i. e., it should

●

be tight tting but not cause a hindrance. Do not wear jewelry, clothing or

long hair which could be drawn into the air intake.

In order to avoid head-, eye-, hand- or foot injuries as well as to protect

●

your hearing the following protective equipment and protective clothing

must be used during operation of the blower.

Pay particular attention to the following regulations

Clothing must be sturdy and snug-tting, but allow complete freedom of

●

movement. Avoid loose-tting jackets, ared or cuffed pants, scarves,

unconned long hair or anything that could be drawn into the air intake. (4)

Wear overalls or long pants to protect your legs.

Do not wear shorts. (4)

Generally, engine products are noisy and their noise may damage your

●

hearing. Wear sound barriers (ear plugs or ear mufers) to protect your

hearing. Continual and regular users should have their hearing checked

regularly. (3)

Use of gloves when working with the blower is recommended.

●

Wear sturdy shoes with non-slip soles. (4)

Proper eye protection is a must. Even though the discharge is directed

●

away from the operator, ricochets and bounce-backs can occur during

blower operation. (3)

Never operate a blower unless wearing goggles or properly tted safety

●

glasses with adequate top and side protection which comply with EN166

and regulations in your country.

To reduce the risk of injury associated with the inhalation of dust, use

●

face lter mask in dusty conditions.

Starting up the blower

Make sure that there are no children or other people within a working

●

range of 15 meters (5), also pay attention to any animals in the working

vicinity. Never use the blower in urban areas.

Before operating, always check that the blower is safe for operation:

●

Check the security of the throttle lever. The throttle lever should be

checked for smooth and easy action. Check for proper functioning of the

throttle lever lock. Check for clean and dry handles and test the function

of the l-O switch. Keep handles free of oil and fuel.

15 meters

3

Page 4

4

5

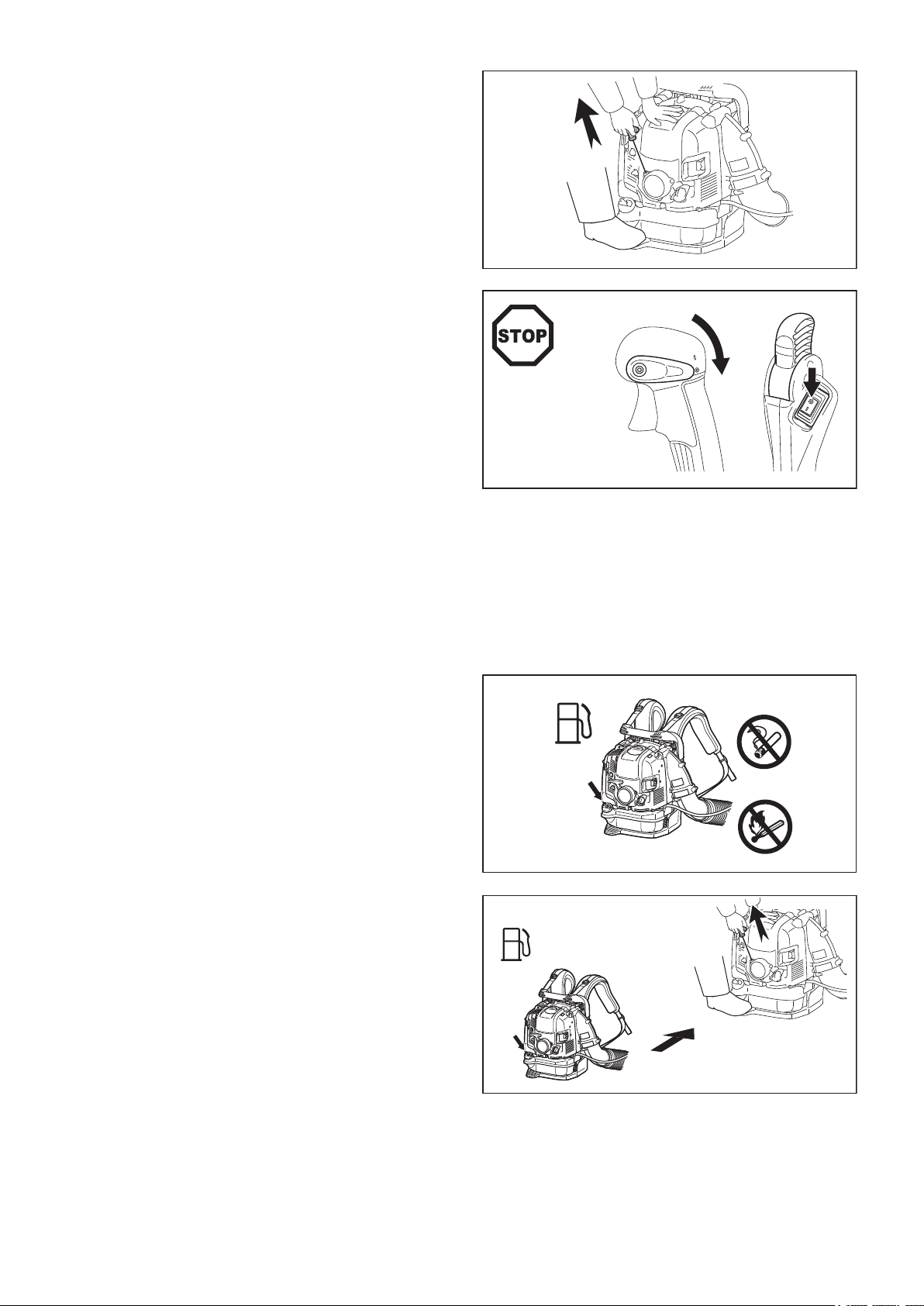

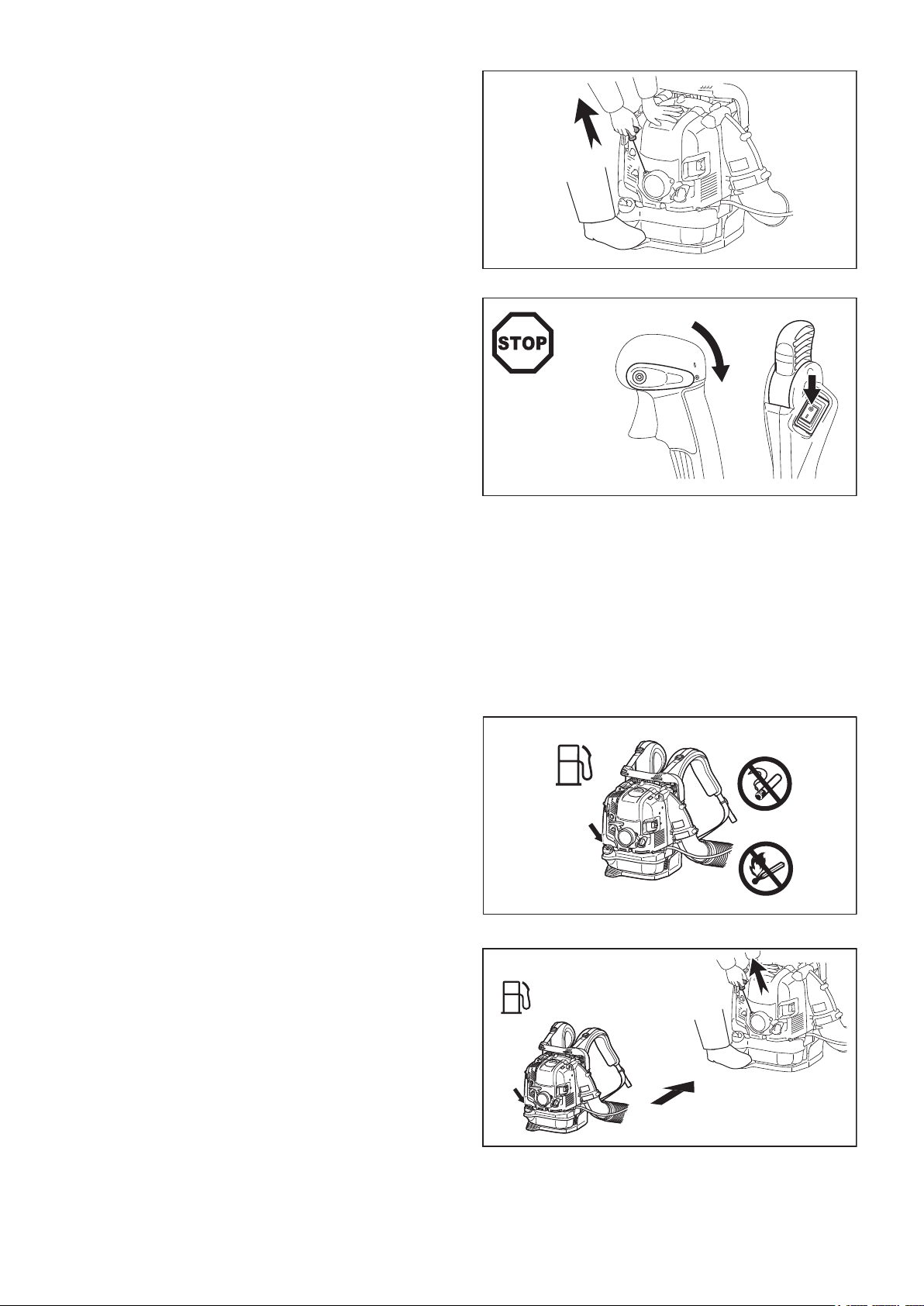

Start the Blower only in accordance with the instructions. Do not use any

(7)

(6)

(8)

(9)

●

other methods for starting the engine (6).

●

Use the blower and the tools supplied only for applications specied.

Start the blower engine only after the entire tool has been assembled.

●

Operation of the tool is permitted only after all the appropriate accessories

are attached.

The engine is to be switched off immediately if there are any engine

●

problems.

When working with the blower, always wrap your ngers tightly around

●

the handle, keeping the control handle cradled between your thumb and

forenger. Keep your hand in this position to have your machine under

control at all times. Make sure your control handle is in good condition

and free of moisture, pitch, oil or grease.

Always ensure a safe, well-balanced footing.

Carry the blower properly on both shoulders during operation. Do not

●

carry the blower with only one shoulder strap. Otherwise personal injury

may result.

Operate the blower in such a manner as to avoid inhalation of the exhaust

●

gases. Never run the engine in enclosed rooms (risk of suffocation and

gas poisoning). Carbon monoxide is an odorless gas.

Always ensure there is adequate ventilation.

Switch off the engine when resting or leaving the blower unattended.

●

Place it in a safe location prevent danger to others, setting re to

combustible materials, or damage to the machine.

Never lay the hot blower onto dry grass or onto any combustible

●

materials.

All protective parts and guards supplied with the machine must be used

●

during operation.

Never operate the engine with a faulty exhaust mufer.

●

Shut off the engine during transport (7).

●

Position the blower safely during car or truck transportation to avoid fuel

●

leakage.

When transporting the blower, ensure that the fuel tank is completely

●

empty.

Carry the blower by its carry handle. Do not drag the blower by nozzle,

●

pipe or other parts.

When transport the blower, bent your knee and make sure you do not

●

damage your shoulder and lower back.

Resting

●

Transport

●

Refuelling

●

Maintenance

●

Tool Replacement

●

Refuelling

Shut off the engine during refuelling (7), keep well away from open ame

●

(8) and do not smoke.

●

Avoid skin contact with petroleum products. Do not inhale fuel vapor.

Always wear protective gloves during refuelling. Change and clean

protective clothing at regular intervals.

Take care not to spill either fuel or oil in order to prevent soil contamination

●

(environmental protection). Clean the blower immediately after fuel has

been spilt. Allow wet cloths to dry before disposing in properly, covered

container to prevent spontaneous combustion.

●

Avoid any fuel contact with your clothing. Change your clothing

immediately if fuel has been spilled on it (re hazard).

●

Inspect the fuel cap at regular intervals making sure that it stays securely

fastened.

●

Carefully tighten the locking screw of the fuel tank. Change locations to

start the engine (at least 3 meters away from the place of refuelling) (9).

●

Never refuel in closed rooms. Fuel vapors accumulate at ground level

(risk of explosions).

●

Only transport and store fuel in approved containers. Make sure stored

fuel is not accessible to children.

●

Do not attempt to refuel a hot or a running engine.

3 meters

Page 5

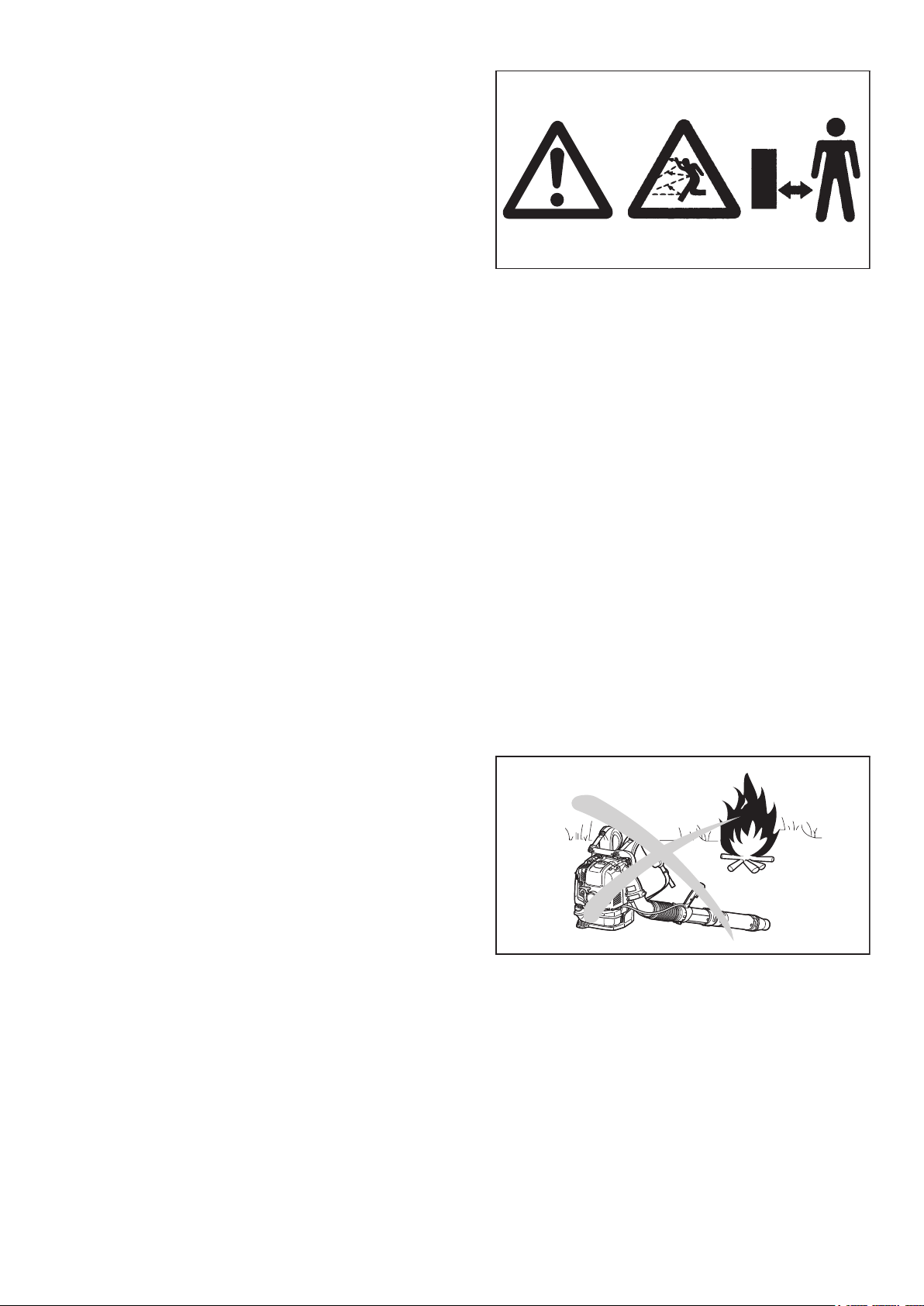

Method of operation

(10)

(11)

Use the blower only in good light and visibility. Beware of slippery or wet

●

areas, ice and snow (risk of slipping) , and narrow space.

Always ensure a safe footing.

Never work on unstable surfaces or steep terrain.

●

Do not work from ladders or high places. Otherwise it may result in

●

personal injury.

To reduce the risk of personal injury, do not direct air blast towards

●

bystanders, since the high pressure of the air ow could injure eyes and

could blow small objects at great speed.

Never insert any foreign object into the air intake of the machine or into

●

the nozzle of the blower. It will damage the fan wheel and may cause

serious injury to the operator or bystanders as a result of the object or

broken parts being thrown out at high speed.

Pay attention to the direction of the wind, i.e., do not work against the

●

wind.

To reduce the risk of stumbling and loss of control, do not walk backward

●

while operating the machine.

Always shut off the engine before cleaning or servicing the unit or

●

replacing parts.

Take a rest to prevent loss of control caused by fatigue. We recommend

●

to take a 10 to 20-minute rest every hour.

Do not operate the machine near the windows, etc.

●

To reduce damage from vibration and/or damage to the ears, operate the

●

machine at low speed if possible and limit the time of operation.

Operate the machine only at reasonable hours. Do not operate the blower

●

in the morning or late at night when people might be disturbed.

It is recommended for using rakes and brooms to loosen debris before

●

blowing.

Before blowing, slightly dampen surfaces in dusty conditions or use

●

water mist sprayer if necessary.

●

Adjust the length of the blower nozzle so that the stream can work close

to the ground.

●

To reduce sound levels, limit the number of pieces of equipment used at

any one time.

After using blowers and other equipment, CLEAN UP! Dispose of debris in

trash receptacles.

Maintenance instructions

●

Be kind to the environment. Operate the blower with as little noise and

pollution as possible. In particular, check the correct adjustment of the

carburetor.

●

Clean the blower at regular intervals and check that all screws and nuts

are securely tightened.

●

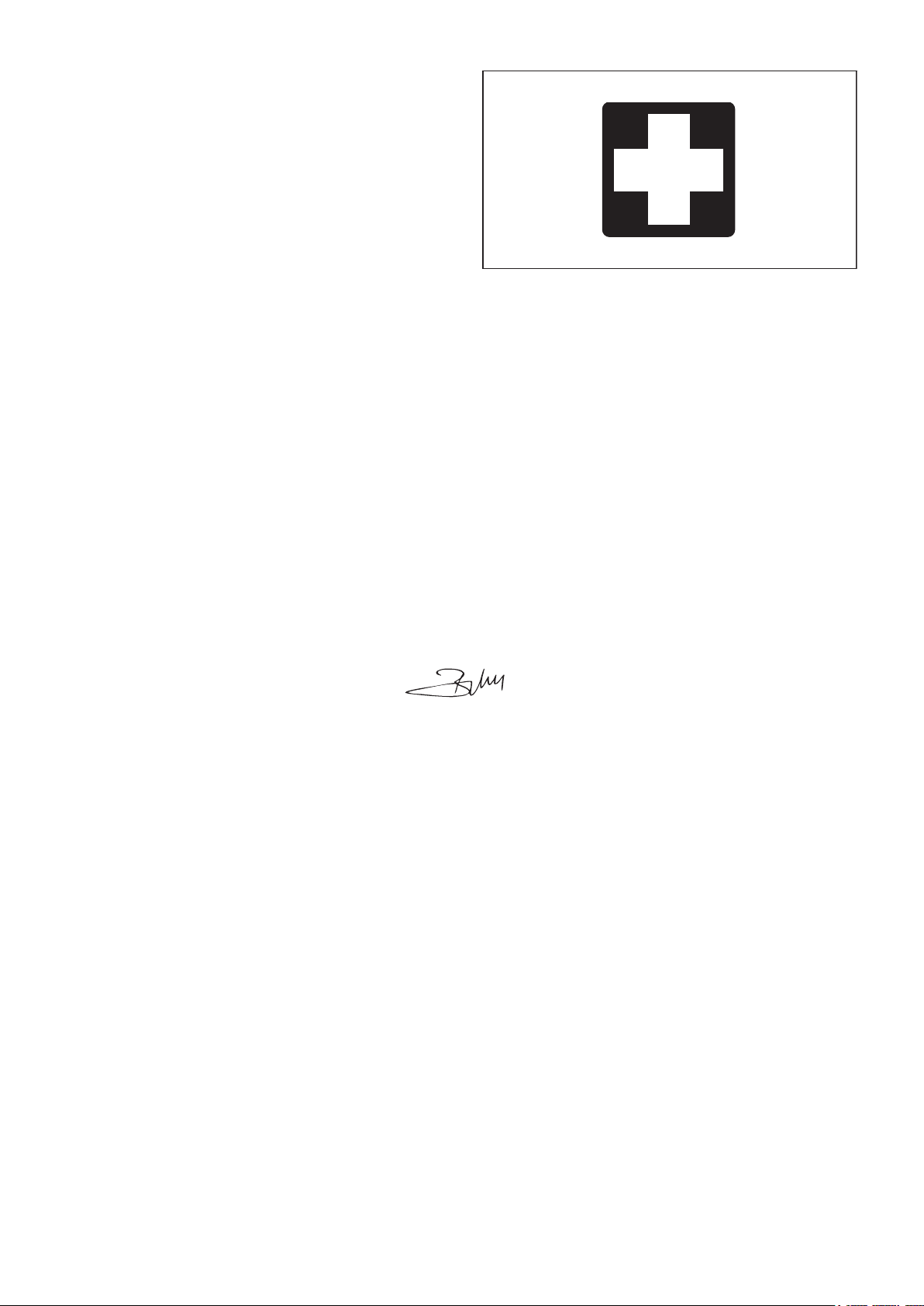

Never service or store the blower in the vicinity of open ames, sparks,

etc. (11).

●

Always store the blower in a well-ventilated locked room and with an

emptied fuel tank.

Observe and follow all relevant accident prevention instructions issued by

the trade associations and by insurance companies. Do not perform any

modications to the blower as this will risk your safety.

The performance of maintenance or repair work by the user is limited to

those activities as described in this instruction manual. All other work is to

be done by Authorized Service Agents.

Use only genuine spare parts and accessories supplied by Dolmar.

Use of non-approved accessories and tools means increased risk of

accidents and injuries. Dolmar will not accept any liability for accidents

or damage caused by the use of any non-approved attachment or

accessories.

Never make modication on the equipment. It may cause dangerous

accidents or personal injury.

5

Page 6

6

7

First Aid

(12)

In case of accident make sure that a well-stocked rst-aid kit is available

in the vicinity of the operations. Immediately replace any item taken from

the rst aid kit.

When asking for help, please give the following information:

Place of accident

●

What happened

●

Number of injured persons

●

Extent of injuries

●

Your name

●

For European countries only

EC Declaration of Conformity

The undersigned, Rainer Bergfeld, as authorized by Dolmar GmbH, declares that the DOLMAR machine(s):

Designation of Machine: Petrol Blower

Model No./ Type: PB-7650.4, PB-7650.4 H

Specications: see “TECHNICAL DATA” table

are of series production and

Conforms to the following European Directives:

2000/14/EC, 2006/42/EC

And are manufactured in accordance with the following standards or standardized documents:

EN15503

The technical documentation is on le at:

Dolmar GmbH,

Jenfelder Straße 38, Abteilung FZ, D-22045 Hamburg

The conformity assessment procedure required by Directive 2000/14/EC was in Accordance with annex V.

Measured Sound Power Level: 110 dB

Guaranteed Sound Power Level: 111 dB

6. 8. 2013

Rainer Bergfeld

Managing Director

Page 7

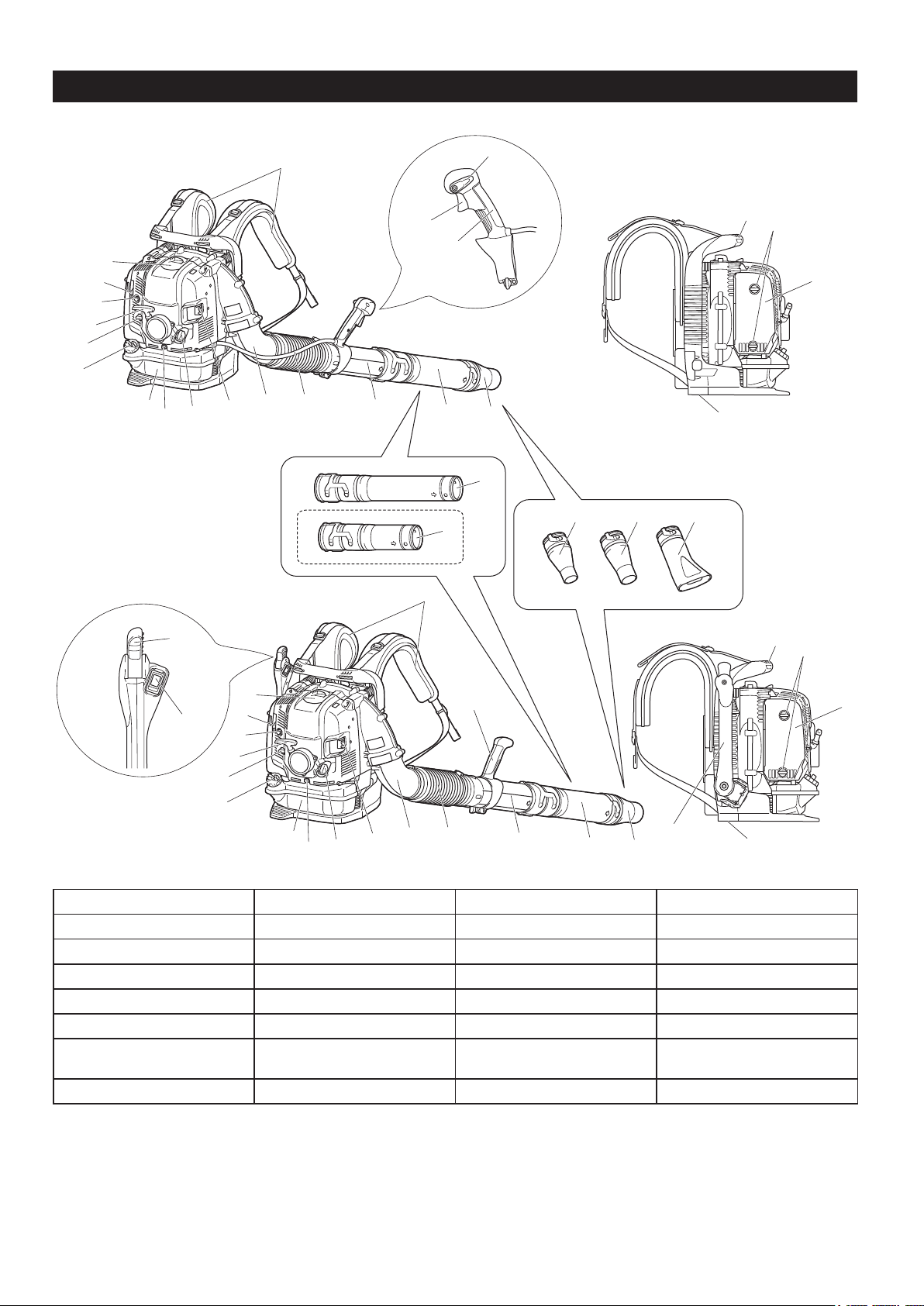

TECHNICAL DATA

Model PB-7650.4 PB-7650.4 H

Throttle type Tube throttle Hip throttle

Mass (without blower pipe) (kg) 10.8 11.0

Dimension (without blower pipe L x W x H) (mm) 332

(with speed nozzle)

(with long pipe)

Air velocity

(with short pipe)

(with volume nozzle) 81

(with at nozzle) 86

(with speed nozzle) 90

(m/s)

(with volume nozzle) 81

(with at nozzle) 87

(with speed nozzle)

(with long pipe)

Air volume ow rate

(with short pipe)

(with volume nozzle) 19

(with at nozzle) 17

(with speed nozzle) 17

(m

3

/minute)

(with volume nozzle) 19

(with at nozzle) 17

Max. engine speed (with speed nozzle) (min

Idling speed (min

Engine displacement (cm

–1

) 7,100

–1

) 2,800

3

) 75.6

Fuel Automobile gasoline

Fuel tank capacity (cm

3

) 1,900

Engine oil

Engine oil volume (cm

3

) 220

Carburetor (type) Diaphragm

Spark plug NGK CMR6A

Electrode gap (mm) 0.7 – 0.8

(with speed nozzle)

(with volume nozzle) 2.3 2.3

(with at nozzle) 4.1 4.8

(with speed nozzle) 3.1 2.7

(with volume nozzle) 2.8 2.3

Right

handle

(with long pipe)

a

hv eq

(with short pipe)

(with at nozzle) 3.7 5.1

Vibration per

EN15503 2009

Left

handle

(control

arm)

Uncertainty K 2.2 3.0

(with speed nozzle) 0.7

(with long pipe)

a

hv eq

(with short pipe)

(with volume nozzle) 0.7

(with at nozzle) 0.9

(with speed nozzle) 0.8

(with volume nozzle) 0.7

(m/s

2

)

(with at nozzle) 0.9

Uncertainty K 0.5

Sound pressure level average to EN15503: 2009

Sound power level average to EN15503: 2009

L

PA eq

Uncertainty K dB(A) 1.5

L

WA eq

Uncertainty K dB(A) 1.0

dB(A) 100

dB(A) 110

x 460 x 480 332 x 510 x 480

89

17

API grade SF class or higher, SAE 10W-30 oil

(automobile 4-stroke engine oil)

2.5 2.7

Notes:

●

Due to our continuing program of research and development, the specications herein are subject to change without notice.

Specications may differ from country to country.

●

7

Page 8

8

9

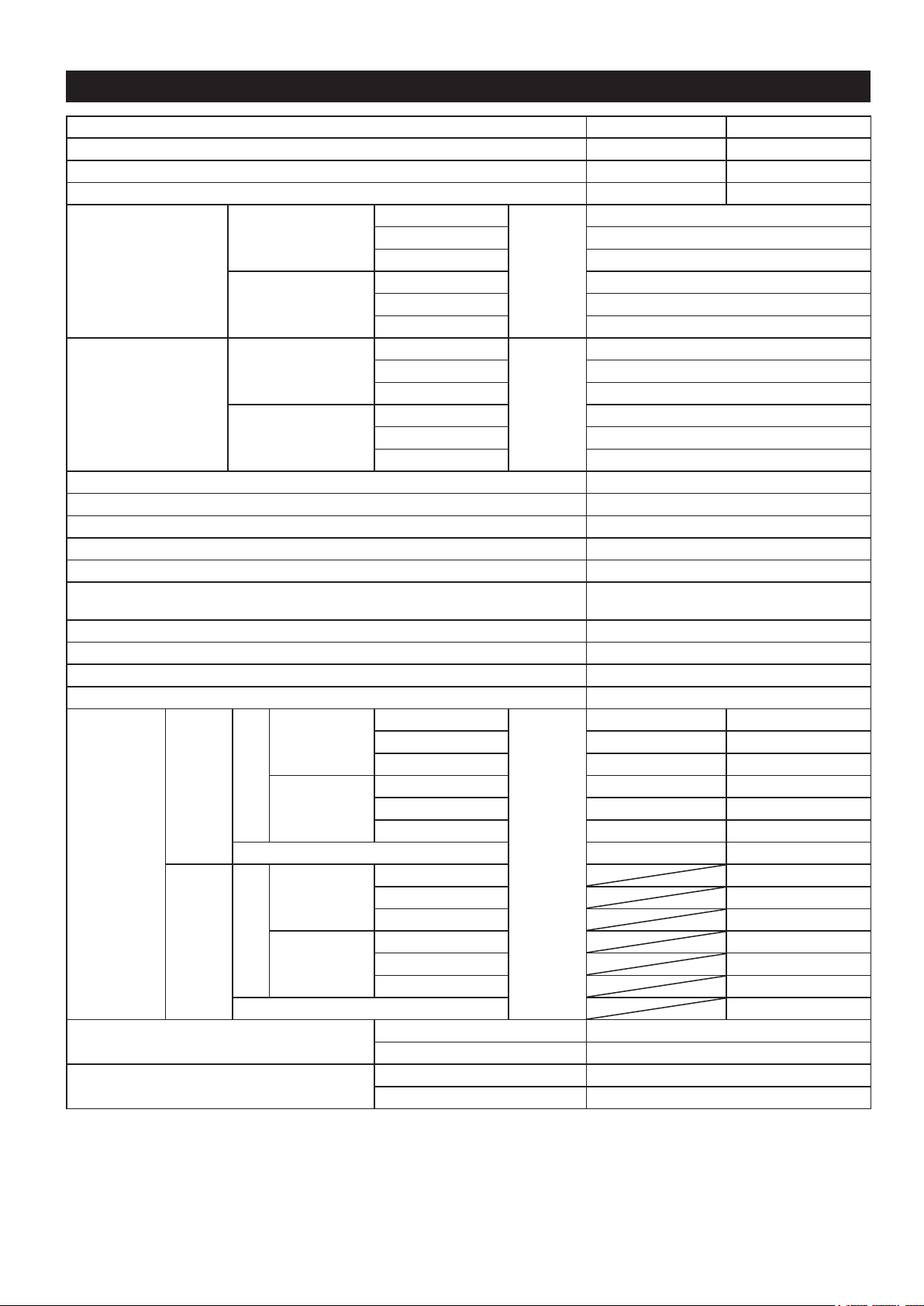

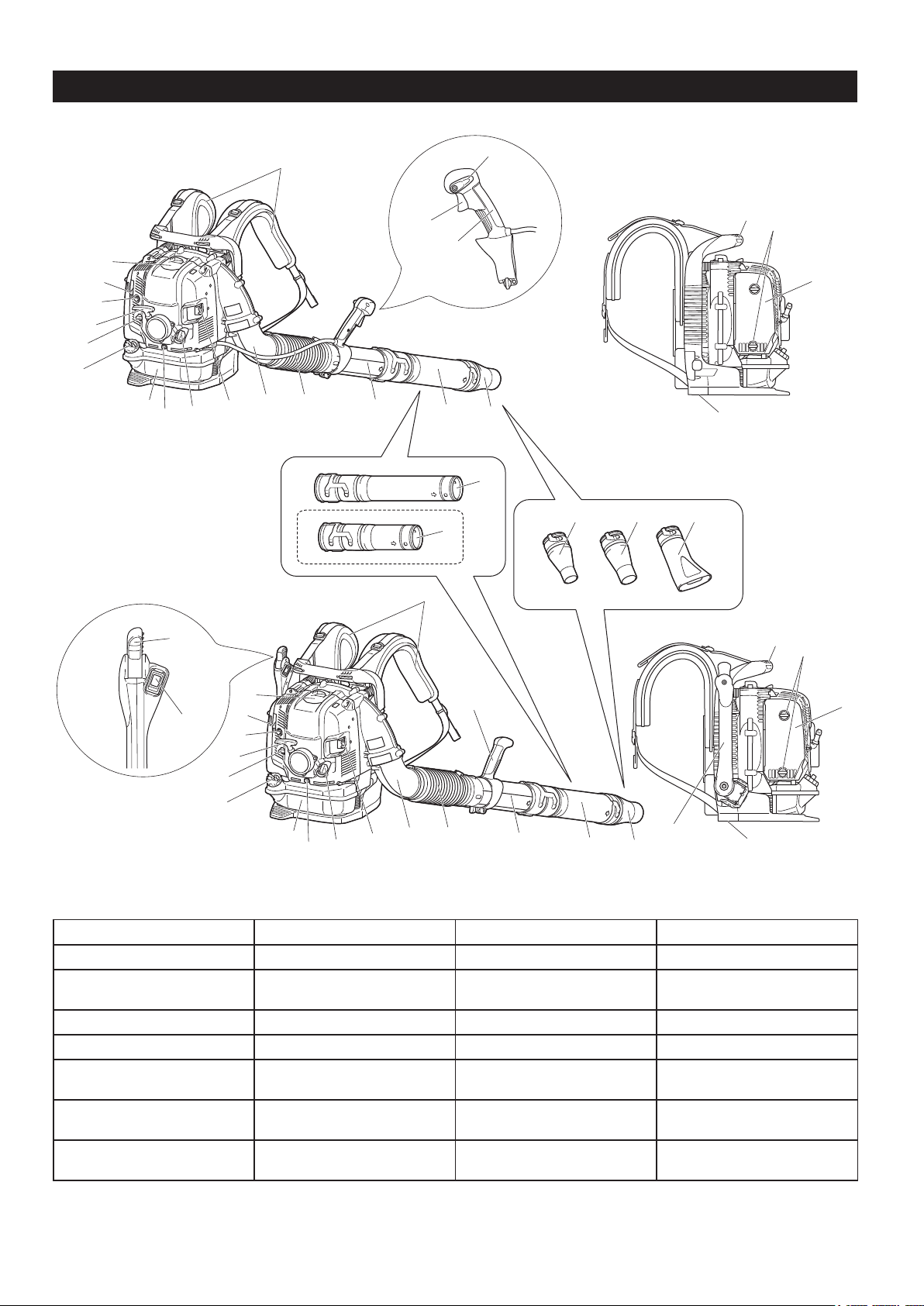

DESIGNATION OF PARTS

1

2

3

4

5

6

8

32

32

7

7

9

10

11

12

14

15

16

17

19

18

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

19

18

20

21

22

23

24

25

26

20

PB-7650.4

PB-7650.4 H

27 28 29

30

31

1. Shoulder strap 9. Oil cap 17. Air inlet net (at the bottom) 25. Stop switch

2. Spark plug cover 10. Mufer 18. Air cleaner cover 26. Control arm

3. Choke lever 11. Elbow 19. Bolt (of air cleaner cover) 27. Speed nozzle

4. Primer pump 12. Flexible pipe 20. Carry handle 28. Volume nozzle

5. Starter knob 13. Handle assembly 21. Stop control lever 29. Flat nozzle

6. Fuel tank cap 14. Swivel 22. Control handle 30. Long pipe

7. Fuel tank 15. Pipe (long/short) 23. Throttle trigger

Oil drain bolt 16. Nozzle 24. Throttle lever 32. Anti icing lever

8.

●

Standard accessories may differ from country to country.

31. Short pipe (optional

accessory)

Page 9

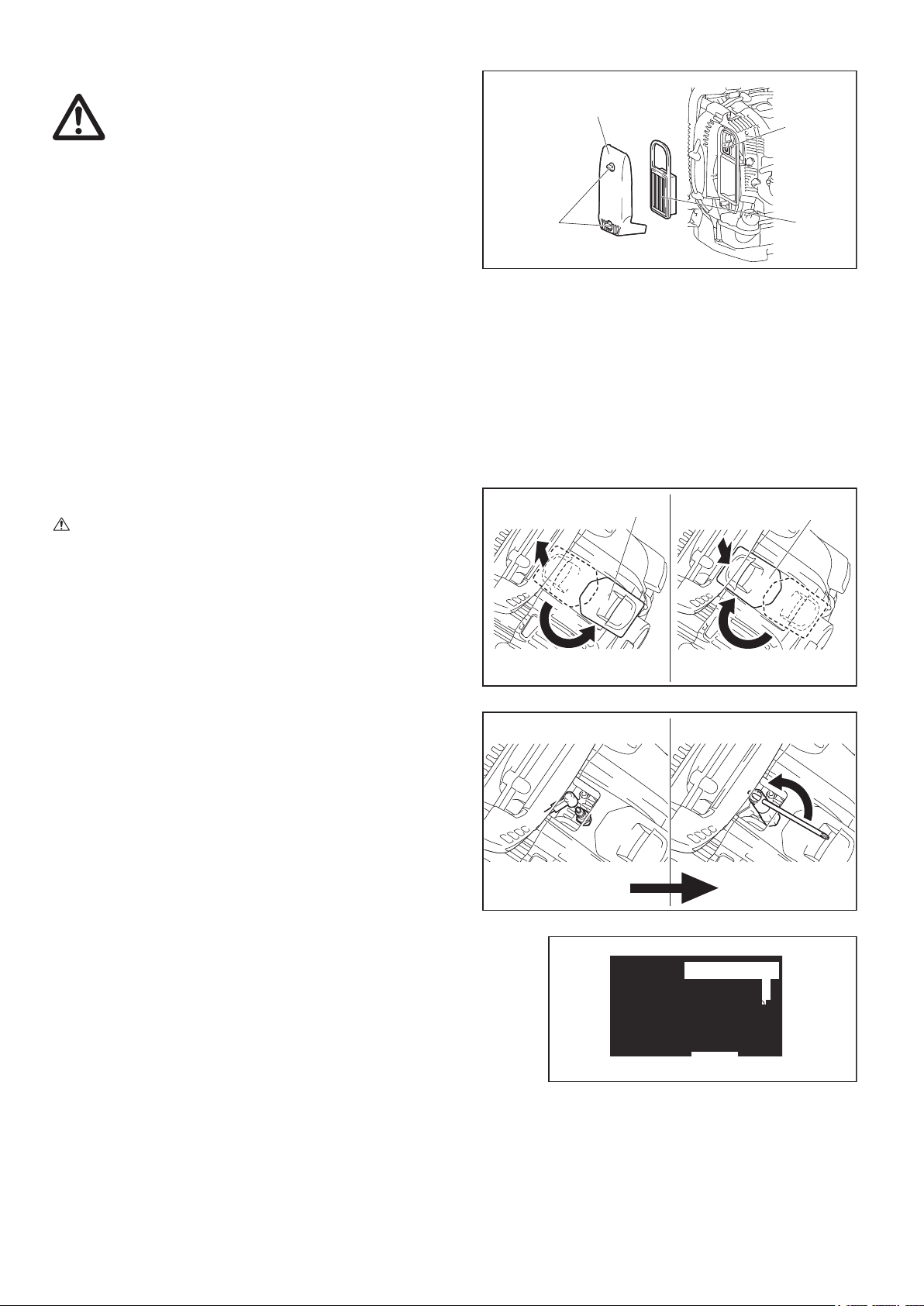

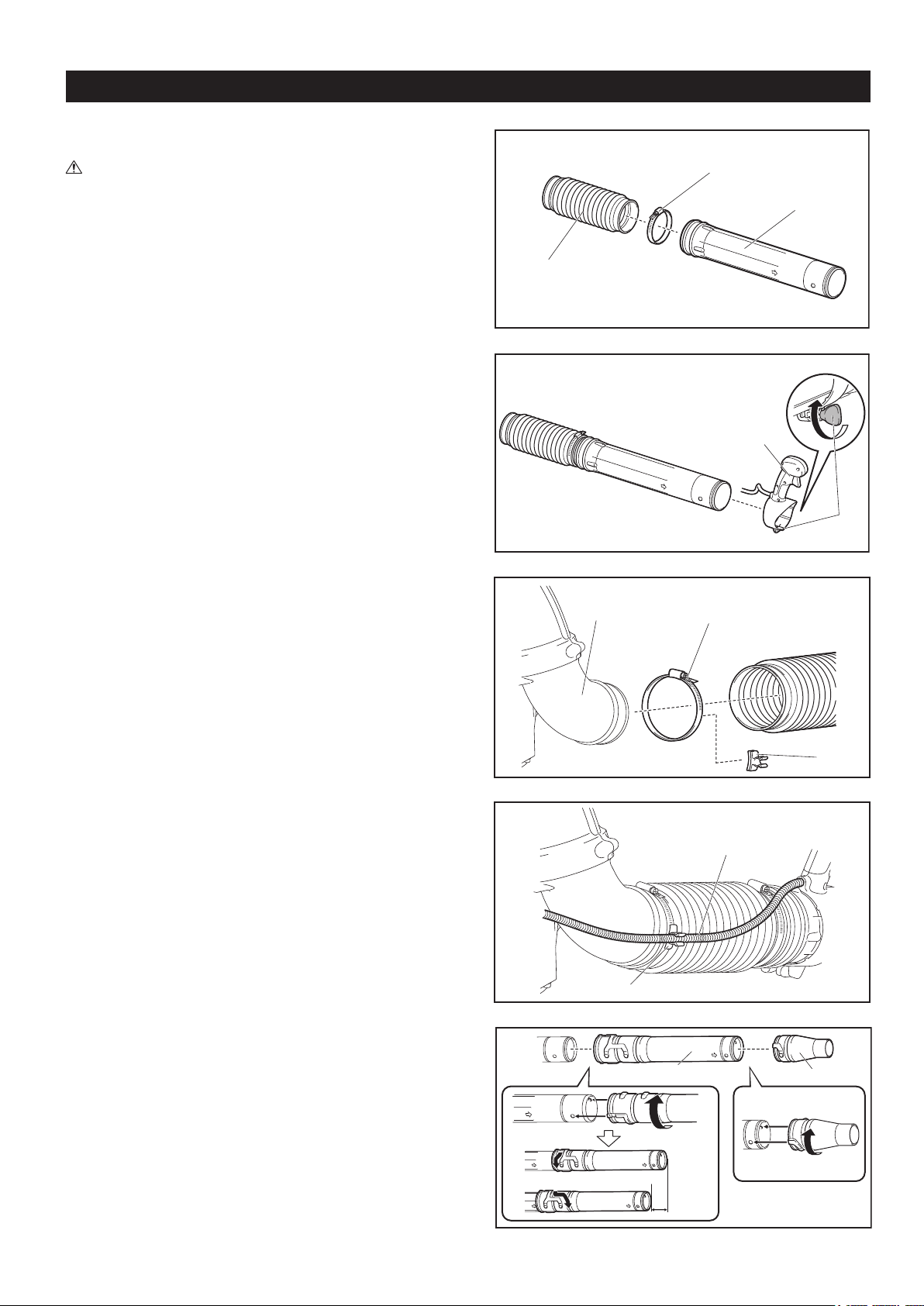

ASSEMBLY INSTRUCTIONS

(1)

(2)

(3)

(5)

(4)

(10)

(11)

(6)

(8)

(7)

(9)

(7)

ASSEMBLY OF BLOWER PIPES

CAUTION:

Before performing any work on the blower, always stop the engine

●

and pull the spark plug connectors off the spark plug.

Always wear protective gloves!

Start the blower only after having assembled it completely.

●

Always wear protective gloves!

●

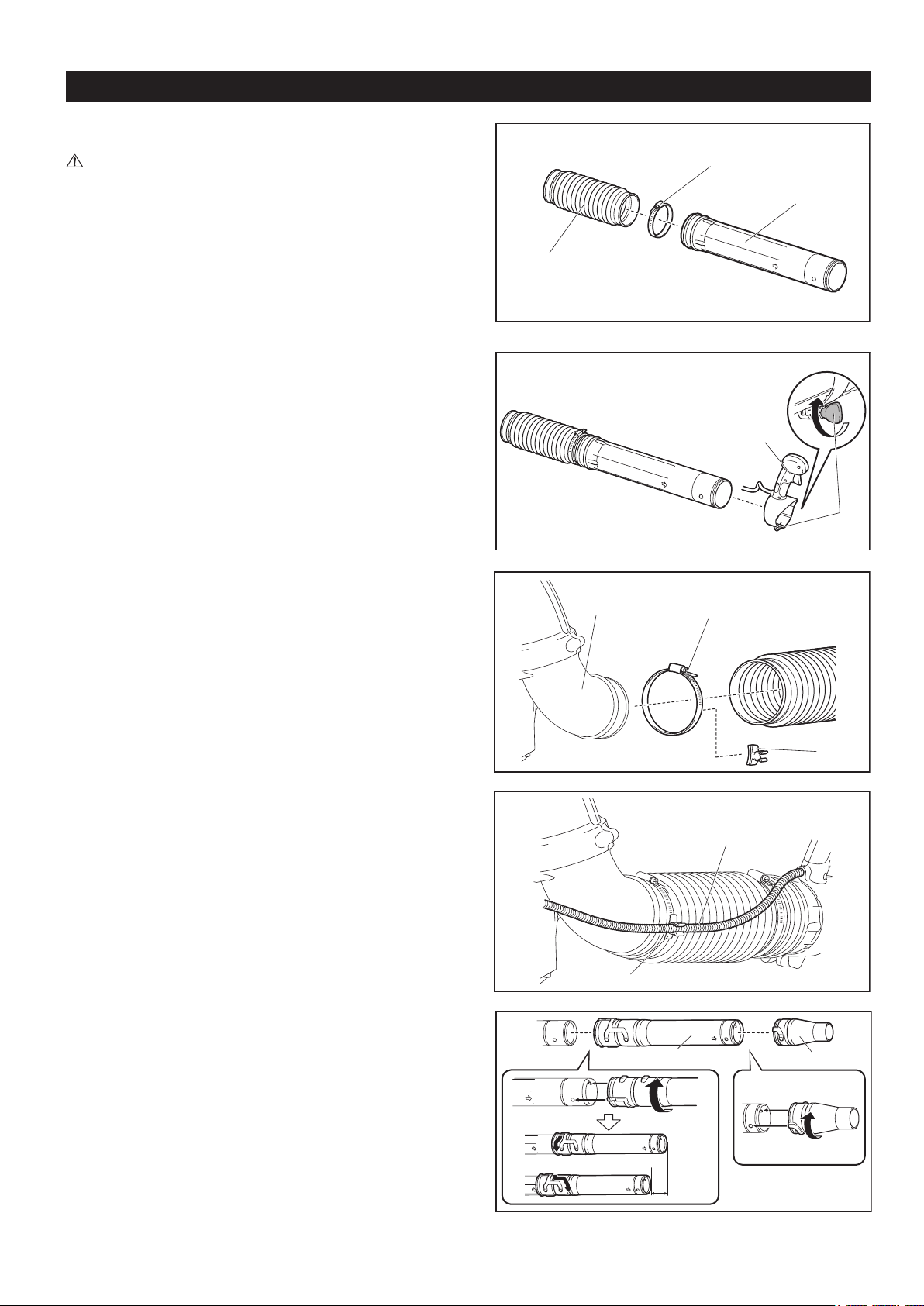

1. Insert the swivel (3) into the exible pipe (1) and tighten them with hose

band (2).

2. Install the control handle / handle assembly (4) onto the swivel and

tighten them with the clamp screw (5).

3. For tube throttle model

Insert the exible pipe to elbow (6) of the blower.

Attach the cable holder (7) between the hose band (8) and the elbow.

Tighten the cable holder, exible pipe and elbow with the hose band.

Set the control cable (9) onto the cable holder (7).

For hip throttle model

Insert the exible pipe to elbow (6) of the blower.

Tighten the exible pipe and elbow with the hose band (8).

Attach the long/short pipe (10) with the swivel. Turn the long/short pipe

4.

clockwise to lock it into place.

Then attach the blower nozzle (11) with the long/short pipe. Turn the

blower nozzle clockwise to lock it into place.

5.

Make sure all clamps are tight.

9

Page 10

10

11

BEFORE STARTING THE ENGINE

(1)

(2)

(4)

(3)

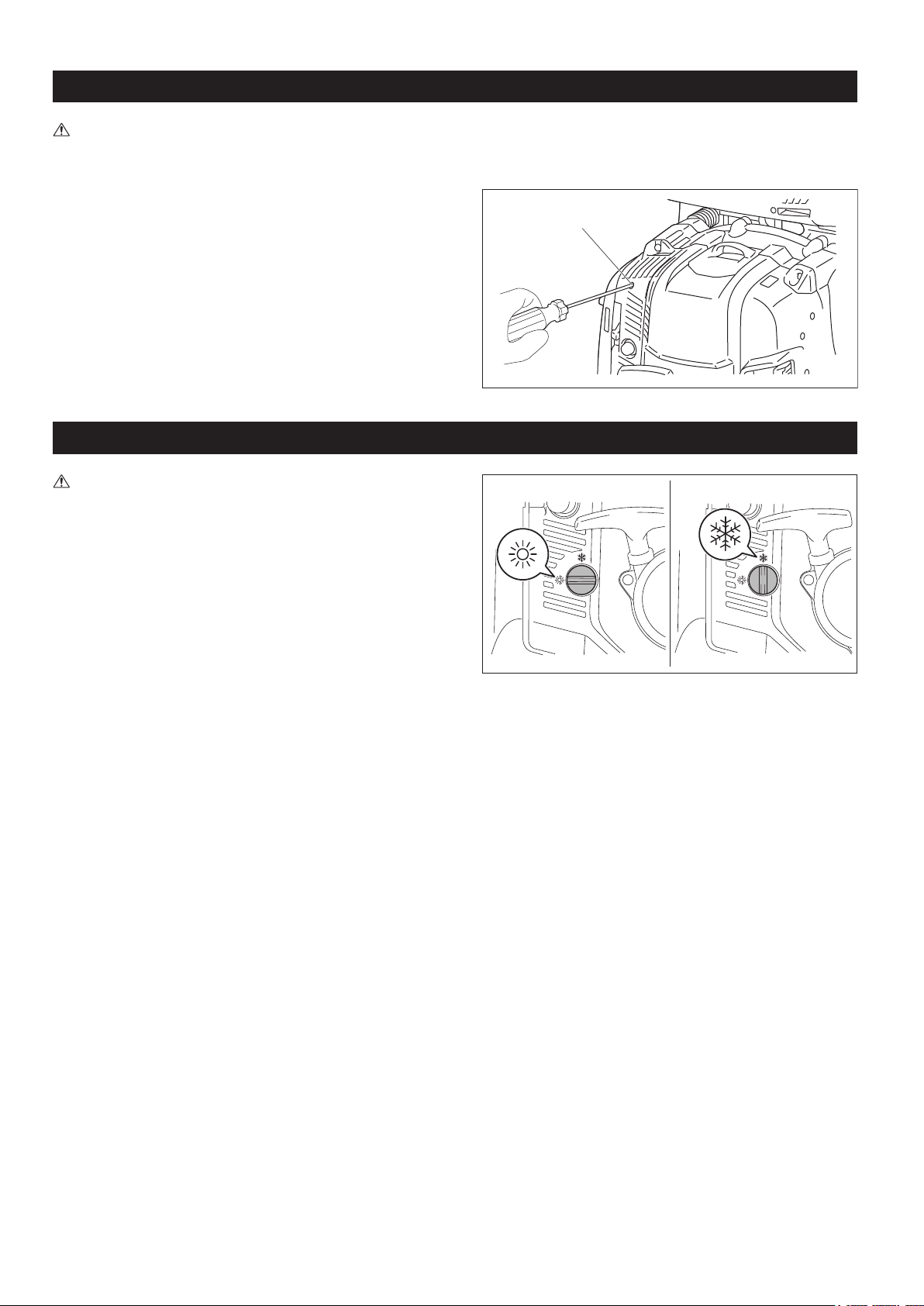

1. Checking and Relling Engine Oil

1) Perform the following procedure, with the engine cooled down.

Otherwise skin burn may result.

●

Inspection: Put the blower on a at surface and remove the oil

cap.

Check the oil gauge (1). Make sure that the oil level is

within the upper (2) and lower (3) limit marks. If the oil

is not up to the 100 ml level (4), ll up with new oil.

Filling oil:

●

2) On average, engine oil needs to be added after every 20 hours of

operation (every 10 – 15 refuellings).

Change the oil whenever it becomes dirty or signicantly changes

3)

color. (Refer to “Replacement of engine oil” for the oil change

procedure and frequency.)

Recommended oil: Dolmar genuine oil or SAE10W-30 oil of API type SF grade or better (4 stroke motor oil for automobiles)

Oil capacity: Approximately 0.22 L (220 ml)

Put the blower on a at surface and remove the oil

cap.

Fill the oil up to the upper limit of the oil level gauge.

NOTE:

If the blower is not stored in an upright position, the oil may ow from the level gauge into the engine and give a false reading when checking the

●

oil level. This may result in inadvertently overlling whenever adding engine oil. Always store the blower in an upright position.

●

If the engine oil is exceeded, the oil may spill from the breather of the air cleaner and make surrounding parts dirty, or white smoke may appear

due to burning excessive oil.

Replacement of Oil “Oil cap”

●

Remove dust or dirt near the oil rell port, and detach the oil cap.

●

Keep the detached oil cap free of sand or dust. Otherwise, any sand or dust adhering to the oil cap may cause irregular oil circulation or wear on

the engine parts, which will result in troubles.

After relling oil

●

Wipe with a rag any spilled oil.

Page 11

2. Fuel supply

WARNING:

When refuelling the unit, be sure to observe the following instructions to prevent ignition or re or personal injury:

●

Fuel supply must be made in a place free of re. Never bring the re (smoking, etc.) near the place of fuel supply.

–

Stop the engine and allow the engine to cool down before refuelling.

–

Refuel on at surface. Do not refuel on unstable or bad ventilated place.

–

Refuel in good light and visibility.

–

Refuel at open clear place.

–

Open the fuel tank cap slowly. The fuel may be spilled out by internal pressure.

–

Take care not to spill the fuel. Any spilled fuel must be wiped clean.

–

Carry out fuel supply in a well-ventilated place.

–

Handle the fuel with care.

●

Fuel sticking to the skin or entering an eye may cause allergies or irritation. When any physical abnormality is detected, consult the medical

–

specialist immediately.

DO NOT put oil in the fuel tank.

●

STORAGE PERIOD OF FUEL

Fuel should be used within a period of 4 weeks, even if it is kept in a special container in a well-ventilated and shaded area.

Otherwise, fuel may deteriorate in one day.

Storage of machine and rell tank

Keep the machine and tank at a cool place free from direct sunshine.

●

Never keep the fuel in a car.

●

FUEL

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for Fuel

Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles.

●

Use of deteriorated oil will cause irregular start-up.

●

When refuelling, stop the engine and wait for the engine to cool down.

REFUELLING METHOD

Loosen the tank cap a little to release the tank pressure.

●

Detach the tank cap, and refuel, discharging air by tilting the fuel tank so that the refuel port will be oriented upward. DO NOT ll fuel up to the

●

top of the tank.

After refuelling, securely tighten the tank cap.

●

If there is any aw or damage on the tank cap, replace it.

●

The tank cap wears out in course of time. Replace it every two to three years.

●

DO NOT put fuel in the oil ll port.

●

11

Page 12

12

13

OPERATION

(1)

PB-7650.4 PB-7650.4 H

(2)

(1)

(4)

(3)

(6)

1. Starting

WARNING:

Never attempt engine start in a place where the fuel has been

●

supplied.

–

It may cause ignition or re. When starting the engine, keep a distance

of at least 3 m.

●

Exhaust gas from the engine is toxic. Do not operate the engine in a

poorly-ventilated place, such as in a tunnel, building, etc.

–

Operating the engine in the poorly-ventilated place may cause

poisoning by exhaust gas.

●

In case of detection of any abnormality in sound, odor, vibration after

starting, stop the engine immediately and carry out inspection.

–

If the engine is operated without attending such abnormality, an

accident may occur.

●

Do not touch hot engine cover. Otherwise skin burn may result.

●

Make sure that there are no fuel leakage before starting the engine.

Make sure that the engine stops when the stop switch is set to “O”

●

position.

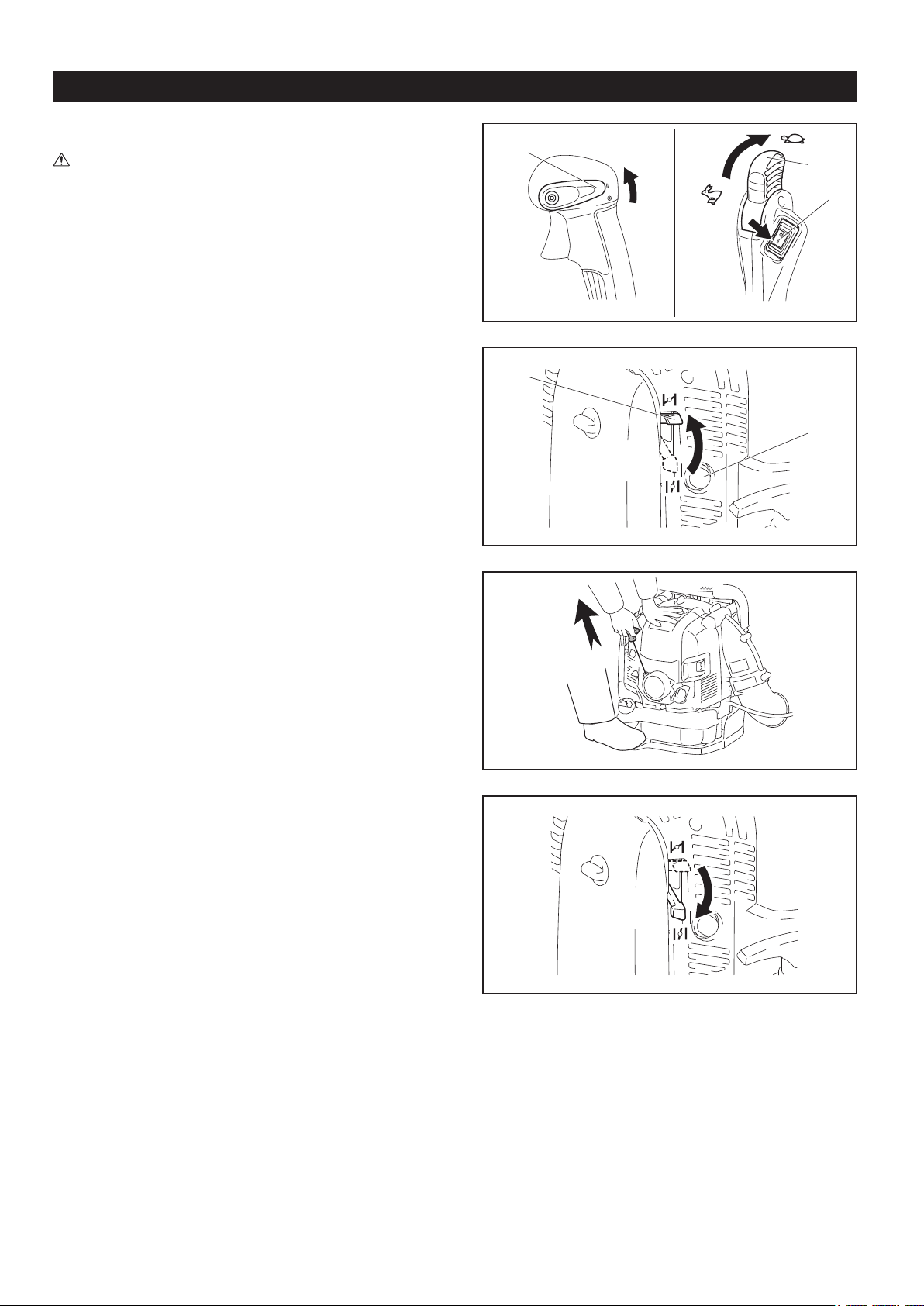

1) When the engine is cold or after refuelling (cold start)

(1) Put the blower on a at surface.

(2) For tube throttle model

Set the stop control lever (1) to “I” position.

For hip throttle model

(2)

Set the stop switch (1) to “I” position.

And make sure that the throttle lever (2) is set to low speed

position.

(3)

Continue to push the primer pump (3) until fuel comes into the

primer pump.

●

In general, fuel comes into the carburetor by 7 to 10 pushes.

Even the primer pump is pushed excessively, an excess of

●

gasoline returns to the fuel tank.

(4)

Lift the choke lever (4) to the closed position.

(5) Stump the pedal with your right foot, and hold the top of the unit

cover with left hand to prevent the engine from moving.

Pull out slowly the starter handle till feeling compression.

(6)

Then pull it strongly.

Never pull the rope to the full extension.

●

Return the starter knob gently into the housing. Otherwise

●

released starter knob may hit your body or it may not rewind

appropriately.

(7)

When the engine starts, down the choke lever to open position.

Open the choke lever fully when checking the engine

●

operation.

In cold temperature or when the engine is not warm enough,

●

never open the choke lever suddenly. Otherwise, the engine

may stop.

(8)

Continue warm-up operation for 2 to 3 minutes.

(9) Warm-up is complete when quick engine acceleration from low

rpm to full throttle is felt.

Page 13

NOTE:

(1)

(2)

(3)

(1)

(2)

PB-7650.4 PB-7650.4 H

O

O

(2)

(1)

The engine may be damaged if the choke lever is moved further beyond

●

the “CLOSE” position.

●

If the engine res and stops, return this lever to the “OPEN” position and

pull the starter handle several times to start the engine again.

●

If the operator keeps pulling the starter handle several times with the

choke lever left in the “CLOSE” position, the engine may be difcult to

start because of ooding of the fuel.

In case of ooding of the fuel, remove the spark plug and pull the handle

●

several times rapidly to discharge any excess fuel. Dry the spark plug

electrode.

When the throttle valve (1) does not return to a position in contact with

●

the idling adjusting screw (2) even if the throttle lever is set to the low

speed, correct the control cable (3) catching state to ensure proper

return of the valve.

2) When the engine is warm (warm start)

(1) Put the engine on a at surface.

(2) Push the primer pump several times.

(3) Make sure that the choke lever is open.

(4) Stump the pedal with your right foot, and hold the top of the unit

with left hand to prevent the engine from moving.

(5)

Pull slowly the starter handle till feeling compression. Then pull

it strongly.

(6)

When the engine is difcult to start, open the throttle valve by

about 1/3.

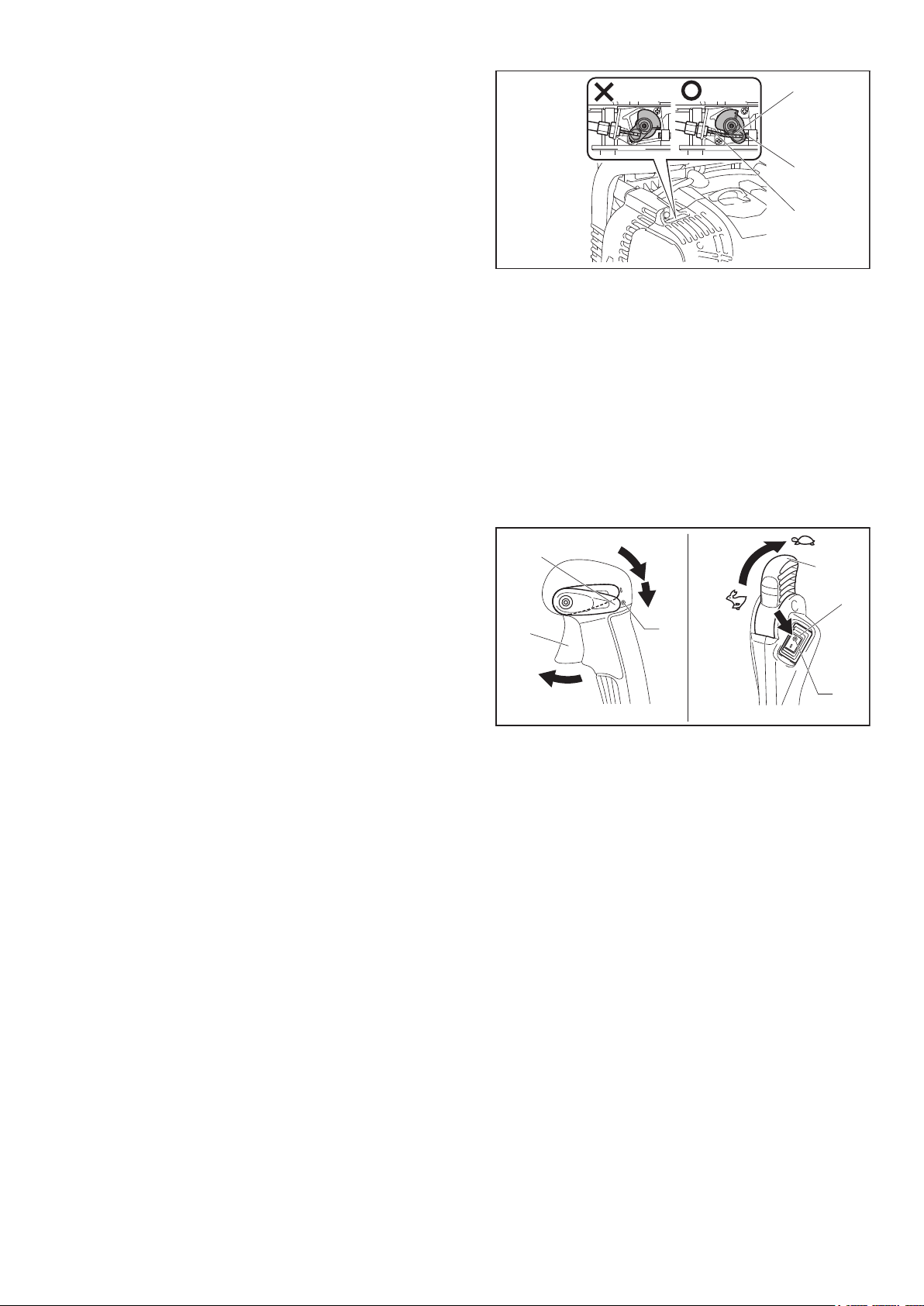

2. Stopping

For tube throttle model

Release the throttle trigger (2) and then set the stop control lever (1) to

“O” position.

For hip throttle model

Set the throttle lever (1) to the low speed position to reduce the engine

speed. Then set the stop switch (2) to “O” position.

13

Page 14

14

15

ADJUSTMENT OF IDLING

(1)

CAUTION:

The carburetor is factory adjusted. Never adjust other than idling

●

adjusting. For other adjustments, ask Dolmar authorized service

center.

Checkup of low-speed rotation

Set the low-speed rotation to 2,800 rpm (/min).

●

If it is necessary to change the rotation speed, regulate the idling

adjusting screw (1), with Phillips screwdriver.

●

Turn the adjusting screw to the right, and the engine speed will increase.

Turn the adjusting screw to the left, and the engine speed will drop.

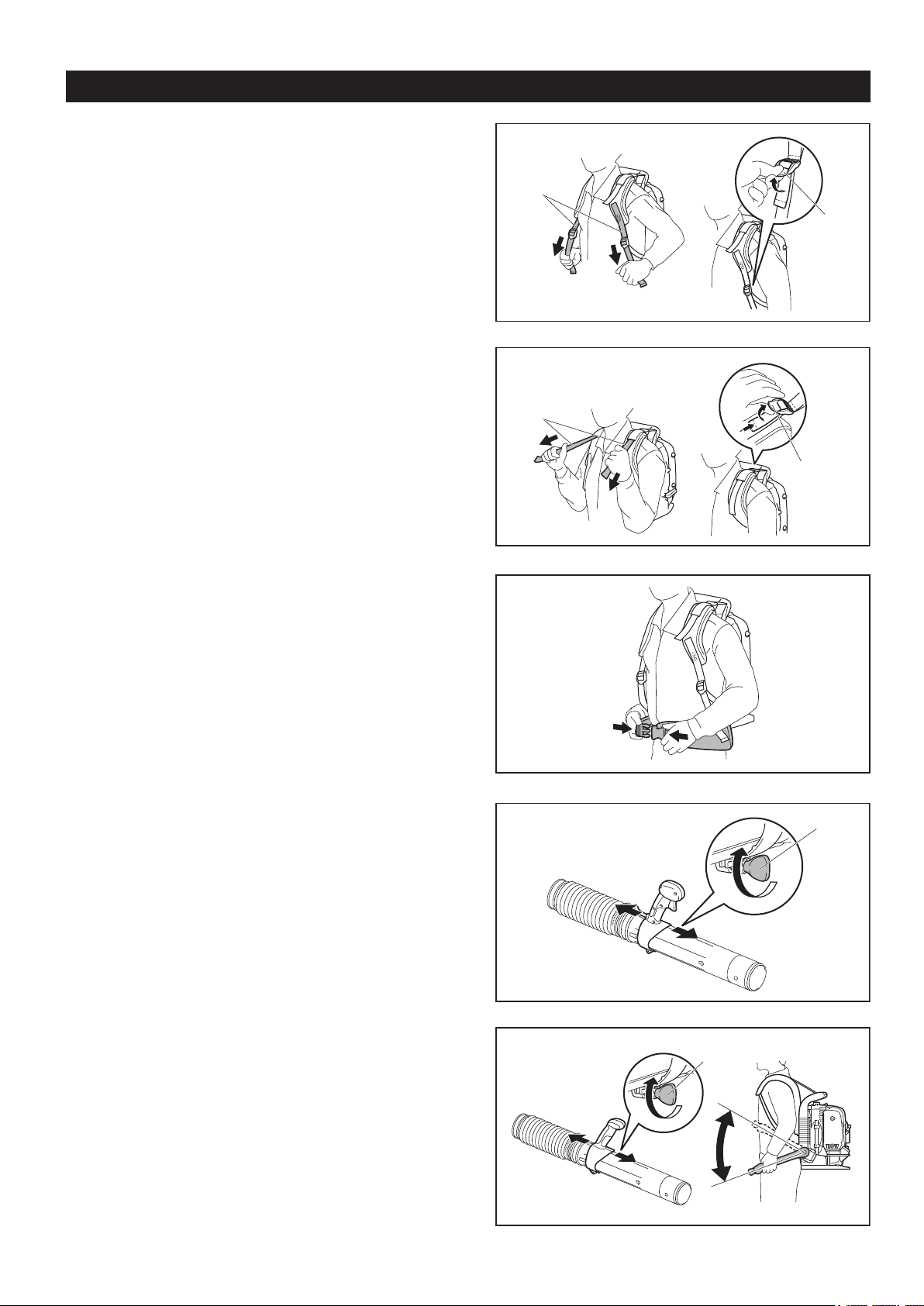

PREVENTION FROM CARBURETOR ICING

CAUTION:

When environmental temperature is higher than 10°C, always return

●

the lever to normal (sun mark) setting. Otherwise the engine may be

damaged by overheating.

When the environmental temperature is low and humidity is high, water

vapor may freeze inside the carburetor and the engine drives unsteadily

(carburetor icing). Change the setting of the anti icing lever as follows if

necessary.

Environment temperature is higher than 10°C: Turn the lever to normal

–

position (sun mark).

Environment temperature is equal or lower than 10°C: Turn the lever to

–

anti-icing position (snow mark).

Page 15

OPERATION METHOD

(1)

(2)

(A) (B)

(1)

(1)

(3)

(4)

(C) (D)

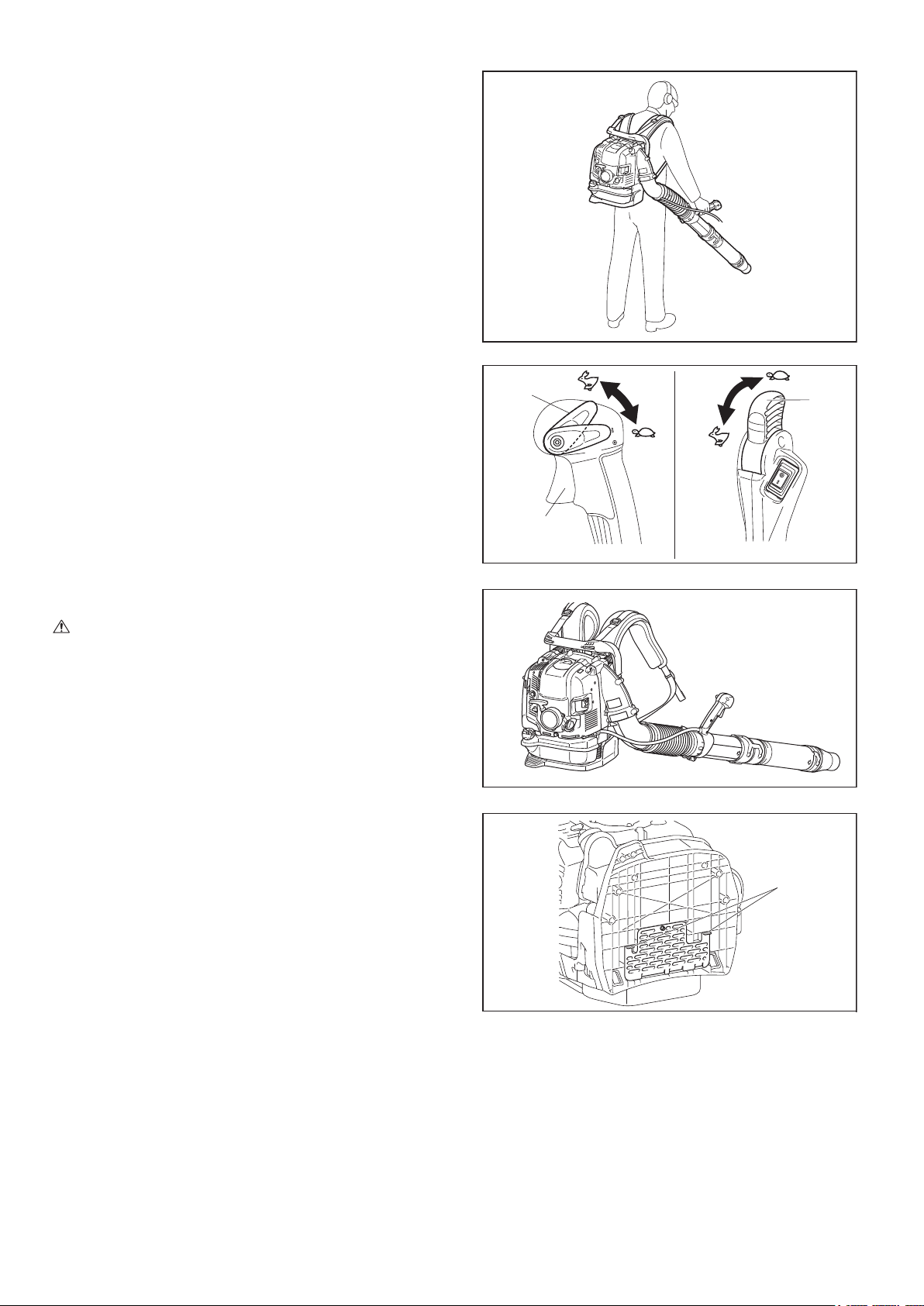

1. Adjusting Shoulder strap

Adjust the shoulder strap (1) to a length that is comfortable to work while

carrying the blower. To fasten (A) the strap, pull the end of the strap

downwards. To loosen (B) the strap, pull up the end of the fastener (2).

Pull the stabilizer strap (3) until there are no space left between your back

and the blower housing. To fasten (C) the strap, pull the end of the strap

downwards. To loosen (D) the strap, pull up the end of the fastener (4).

The hip belt (optional accessory) enables the operator to carry the tool

more stably.

2. Adjusting the control lever

For tube throttle model

Move the control handle along the swivel pipe to the most comfortable

position. Then tighten the control handle with the screw (1).

For hip throttle model

Move the handle assemble along the swivel to the most comfortable

position. Then tighten the handle with the screw (1).

Adjust the angle of the control arm for comfortable operation.

15

Page 16

16

17

3. Blower Operation

(1)

PB-7650.4 PB-7650.4 H

(2)

(1)

(1)

1) While operating the blower, adjust the throttle trigger / throttle lever

so that the wind force is appropriate for the work location and

conditions.

2) Adjusting engine speed.

For tube throttle model

Engine speed increases by pulling the throttle trigger (1). To decrease

the engine speed, loosen the throttle trigger.

Adjusting engine speed with the cruise control function:

The cruise control function allows the operator to maintain a constant

engine speed without operating the trigger lever.

To increase the engine speed, turn the stop control lever (2) to high

speed.

To decrease the engine speed, turn the stop control lever to low

speed.

For hip throttle model

To increase the engine speed, turn the throttle lever (1) to high

speed.

To decrease the engine speed, turn the throttle lever to low speed.

TRANSPORTING AND STORING THE BLOWER

CAUTION:

When transporting the blower, be sure to stop the engine.

●

Do not sit or stand on the blower nor put an heavy object on it. It may

damage the tool.

Maintain the blower in an upright position whenever transporting or

storing.

Transporting or storing in a position that is not upright may cause oil to spill

inside the blower engine. This may result in oil leaks and white smoke from

burning oil, and the air cleaner may become dirty with oil.

Do not drag the blower when transporting. Otherwise the blower housing or

air inlet net may be damaged, and it may cause rust.

*

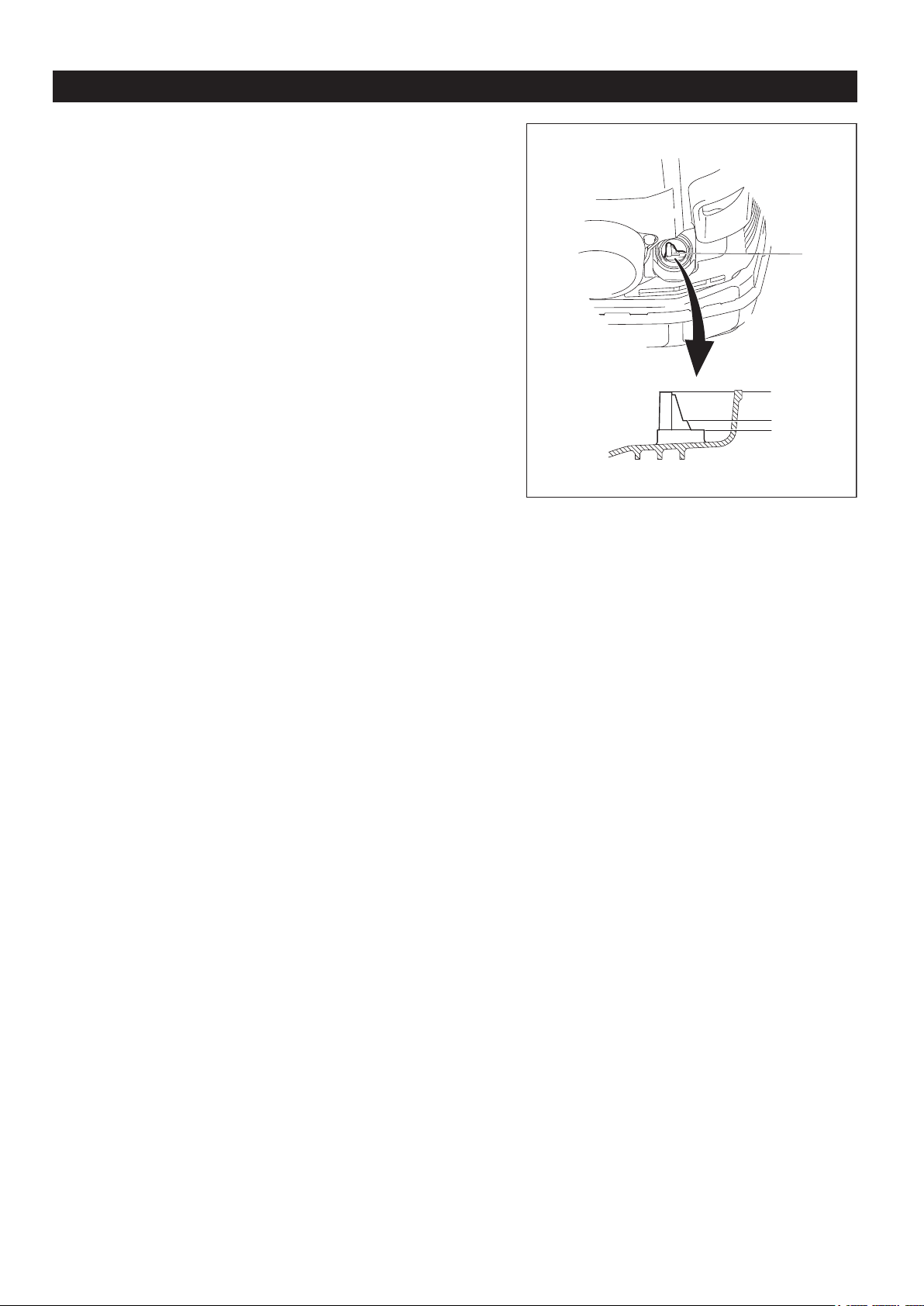

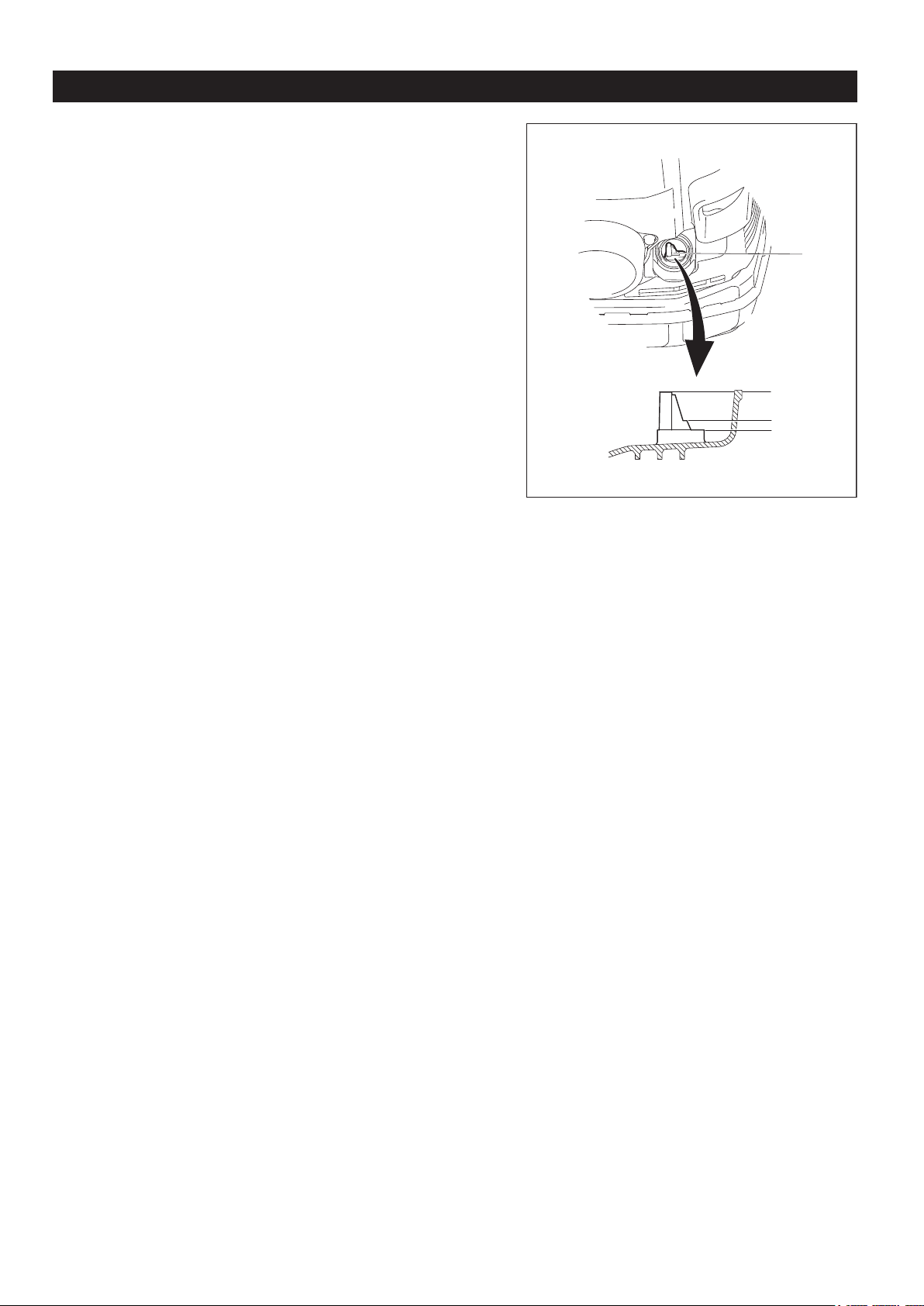

On the air inlet net there are ground contacts (1) which discharges

electrostatic to the ground.

Page 17

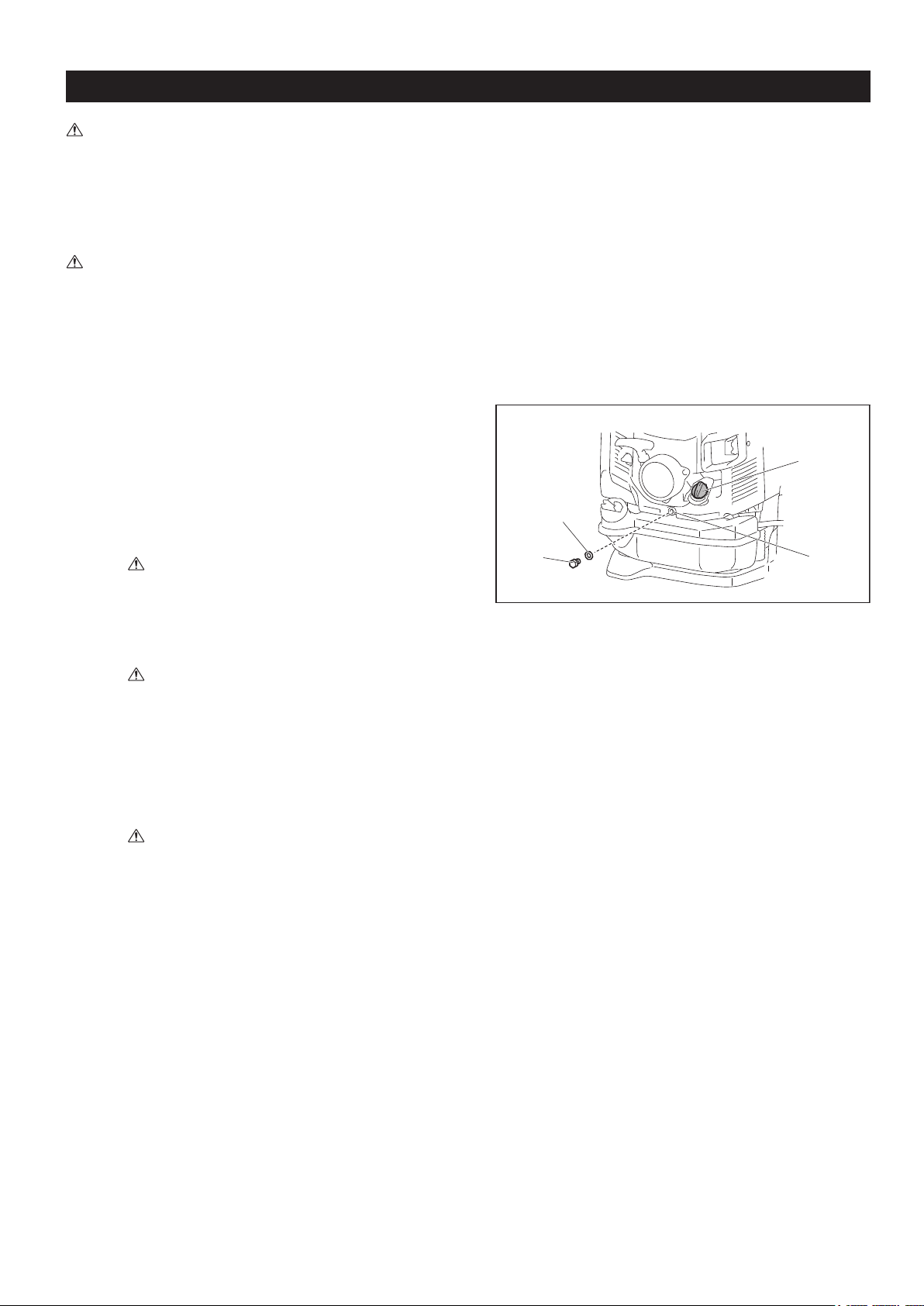

INSPECTION AND MAINTENANCE

(2)

(3)

(4)

(1)

CAUTION:

Before inspection and maintenance, stop the engine and allow it to cool down. Remove the spark plug and plug cap.

●

Otherwise the operator may suffer burn or serious injury due to an accidental start-up.

–

After inspection and maintenance, make sure that all parts are assembled. Then, proceed to operation.

●

1. Replacement of engine oil

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of

replacement.

CAUTION:

The engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil, make sure that the engine main unit and

●

engine oil are sufciently cooled down. Otherwise, there may remain a risk of scald. Allow sufcient time after stopping engine for the engine oil

to return to the oil tank to ensure accurate reading of the oil level indicator.

If the oil lled above the limit, it may become dirty or may catch re with white smoke.

●

Interval of replacement: After rst 20 operating hours, followed by every 50 operating hours

Recommended oil: SAE10W-30 oil, API Classication SF Class or higher (4-stroke engine oil for automobile)

Oil Change Procedure

Please follow these steps when changing the oil:

(1) Set the blower down on a level surface.

(2) Put a waste oil container under the drainage hole (1) to catch

the oil as it drains out. The container should have a capacity of

at least 220 ml to be able to catch all of the oil.

Loosen the oil drain bolt (2) to let the oil drain out. Be careful not

(3)

to allow oil to get on the fuel tank or other parts.

CAUTION:

Be careful not to lose the gasket (aluminum washer) (3). Put

●

the oil drain bolt (2) in a location where it will not accumulate

dirt.

(4) Remove the oil cap (4). (Removing the oil cap (4) allows the oil

to drain easily.)

CAUTION:

●

Be sure to set the oil cap (4) down in a location where it will

not accumulate dirt.

(5) As the level of the oil being drained decreases, tilt the blower

over on to the side with the drain so that the oil will completely

drain out.

(6)

After the oil has completely drained out, tighten the oil drain bolt

(2) securely. If the bolt is not tightly fastened, this may result in

an oil leak.

CAUTION:

●

Do not forget to put the gasket (aluminum washer) (3) back

on when reattaching the drain plug.

(7) Adding oil during the oil change procedure is performed in the

same manner as the separately explained procedure for adding

oil whenever the level is insufcient. Always add oil by lling

from the opening under the oil cap.

(Specied oil level: Approximately 220 ml)

(8)

After lling with oil, tighten the oil cap (4) securely to prevent oil

leaks.

Points in replacement of engine oil

Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the relevant

●

laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

●

Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6 months).

17

Page 18

18

19

2. Cleaning of air cleaner

(1)

(A) (B)

(1)

0.7 - 0.8 mm

(2)

(3)

(4)

(1)

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating hours)

Loosen the bolts (1).

(1)

(2) Remove the air cleaner cover (2).

(3) Remove the element (3) and clean off any dirt from the element

with the brush.

Note:

The element is a dry type and should not get wet. Never wash

●

with water.

(4) Replace the element with a new one if it is damaged or very

dirty.

(5)

Wipe off any oil that has come in to contact with the breather (4)

with a rag or cloth.

(6)

Install the element in the air cleaner case.

(7) Attach the air cleaner cover and tighten the knob bolt.

NOTICE:

Clean the element several times a day, if excessive dust adheres to it.

●

If operation continues with the element remaining not cleared of oil, oil in

●

the air cleaner may fall outside, resulting in oil contamination.

3. Checking the spark plug

CAUTION:

Do not touch the spark plug while the engine is running. Otherwise

●

electrical shock may result.

Set the stop control lever/stop switch to OFF “O” position.

●

Check the spark plug cord regularly. If it is damaged or torn, replace it.

●

Otherwise electrical shock may result.

When removing the spark plug, clean the spark plug and cylinder head

●

rst, so that no dirt, sand, etc will enter the cylinder.

Remove the spark plug after the engine has cooled down in order to

●

avoid damaging the threaded hole in the cylinder.

Install the spark plug properly into the threaded hole. If installed at an

●

angle, the threaded hole in the cylinder will get damaged.

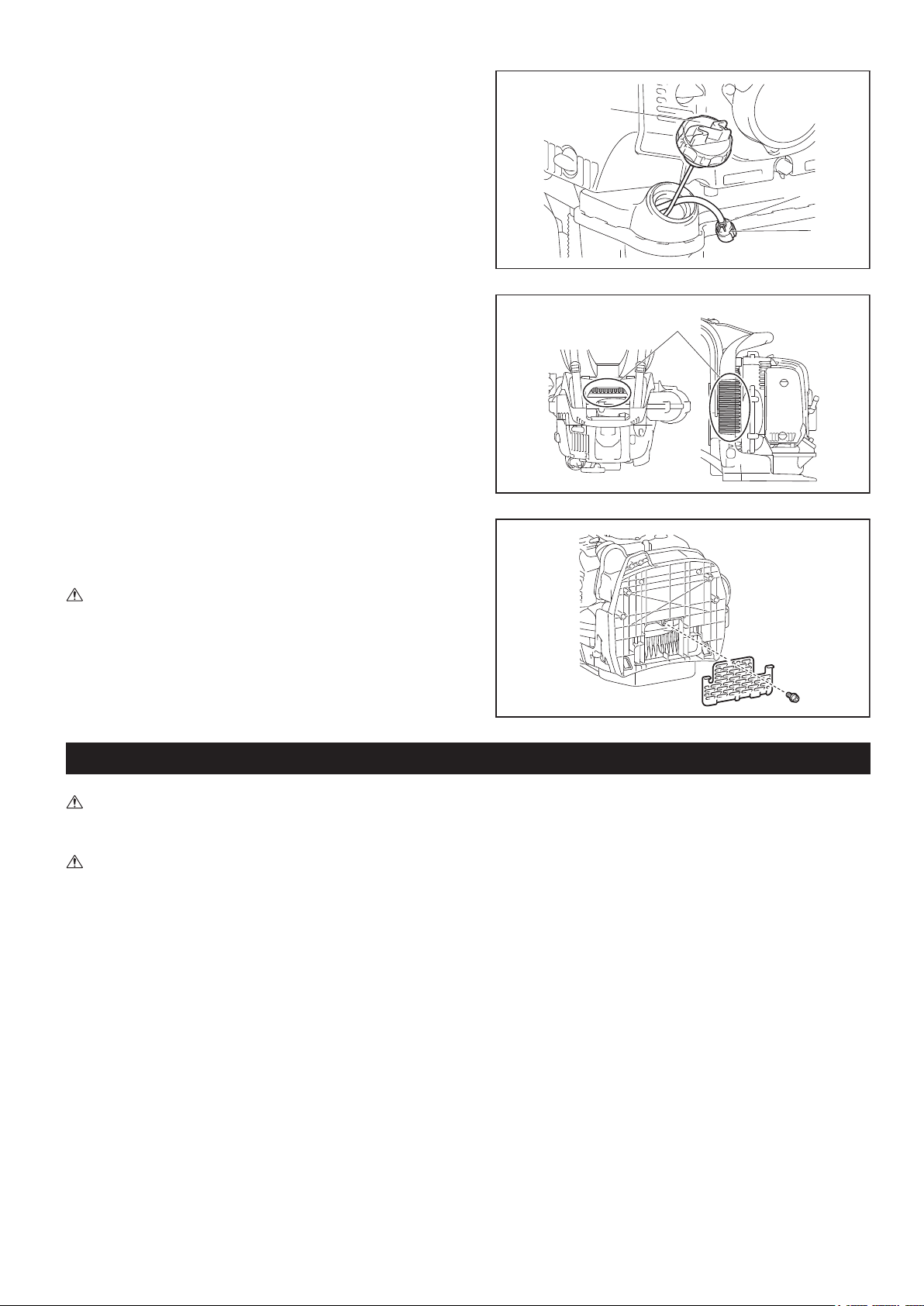

(1) Opening/closing the plug cover

To open (A) the plug cover (1), lift it and make a half turn of it. To

close (B) the plug cover, make a half turn of it, and press around

the dented part.

(2)

Removing the spark plug

Use an attached box wrench to remove or install the spark

plug.

(3)

Checking the spark plug

The clearance between two electrodes of spark plug is 0.7 to

0.8 mm. Adjust to the correct clearance when it is too wide or

too narrow.

Clean thoroughly or replace the spark plug if it has accumulated

carbon or contaminated.

(4)

Replacing the spark plug

For replacement, use NGK-CMR6A.

Page 19

4. Cleaning the fuel lter

(2)

(3)

(1)

(1)

Clogged fuel lter may cause difculty of start-up or failure of engine

●

speed increase.

●

Check the fuel lter regularly as follows:

(1) Remove the fuel tank cap (1), drain the fuel to empty the tank.

Check the tank inside for any foreign materials. If any, wipe

clean such materials.

(2)

Pull out the fuel lter (2) with wire through the oil lling port.

(3) If the fuel lter surface is contaminated, clean it with gasoline.

The gasoline used for the cleaning must be disposed of

according to the method specied by each local authority.

Excessively contaminated lter must be replaced.

After checking, cleaning or replacing, insert the fuel lter into the

(4)

fuel pipe and x it by the hose clamp (3). Reset the fuel lter in

the fuel tank and tighten rmly the fuel tank cap.

Make sure there is no damage on the fuel tank.

●

5. Inspection of bolts, nuts and screws

Retighten loose bolts, nuts, etc.

●

Check for fuel and oil leakage.

●

Replace damaged parts with new ones for safety operation.

●

6. Cleaning of parts

Keep engine clean by wiping down with a cloth rag.

●

Keep the cylinder ns free of dust or dirt. Dust or dirt adhering to the ns

●

will cause seizure.

Blowing air is taken in from the air inlet vent and the air inlet net (1). When

●

airow drops down during operation, stop engine and inspect the air

inlet vent and the air inlet net for any blockages. Clean it if necessary.

Check the air inlet net at the bottom. Remove the screw and the air inlet

●

net. Check if there are any blockages. Clean it if necessary.

Such a blockage may cause overheat and damage the engine.

●

WARNING:

Never use the blower without the net of the blower. Before each use,

●

check that the net is attached in place and is free from any damage.

7. Replacement of gaskets and packings

Replace gaskets and packings if the engine is disassembled.

Any maintenance of adjustment work that is not included and described in

this manual is only to be performed by Authorized Service Agent.

STORAGE

WARNING:

When draining the fuel, stop the engine and wait for the engine to cool down.

●

Failure to do so may cause burns or re.

–

CAUTION:

When you store the machine for a long time, drain all fuel from the fuel tank and carburetor, and keep it at a dry and clean place.

●

Drain fuel from the fuel tank and carburetor according to the following procedure:

Remove the fuel tank cap, and drain fuel completely.

(1)

If there is any foreign materials remaining in the fuel tank, remove it completely.

(2)

Pull out the fuel lter from the rell port using a wire.

(3) Push the primer pump until fuel is drained from there, and drain fuel coming into the fuel tank.

(4) Reset the lter to the fuel tank, and securely tighten the fuel tank cap.

(5) Then, continue to operate the engine until it stops.

(6) Remove the spark plug, and drip several drops of engine oil through the spark plug hole.

(7) Gently pull the starter handle so that engine oil will spread over the engine, and attach the spark plug.

(8) Keep the machine with its handle upside.

(9) Keep the drained fuel in a special container in a well-ventilated shade.

19

Page 20

20

21

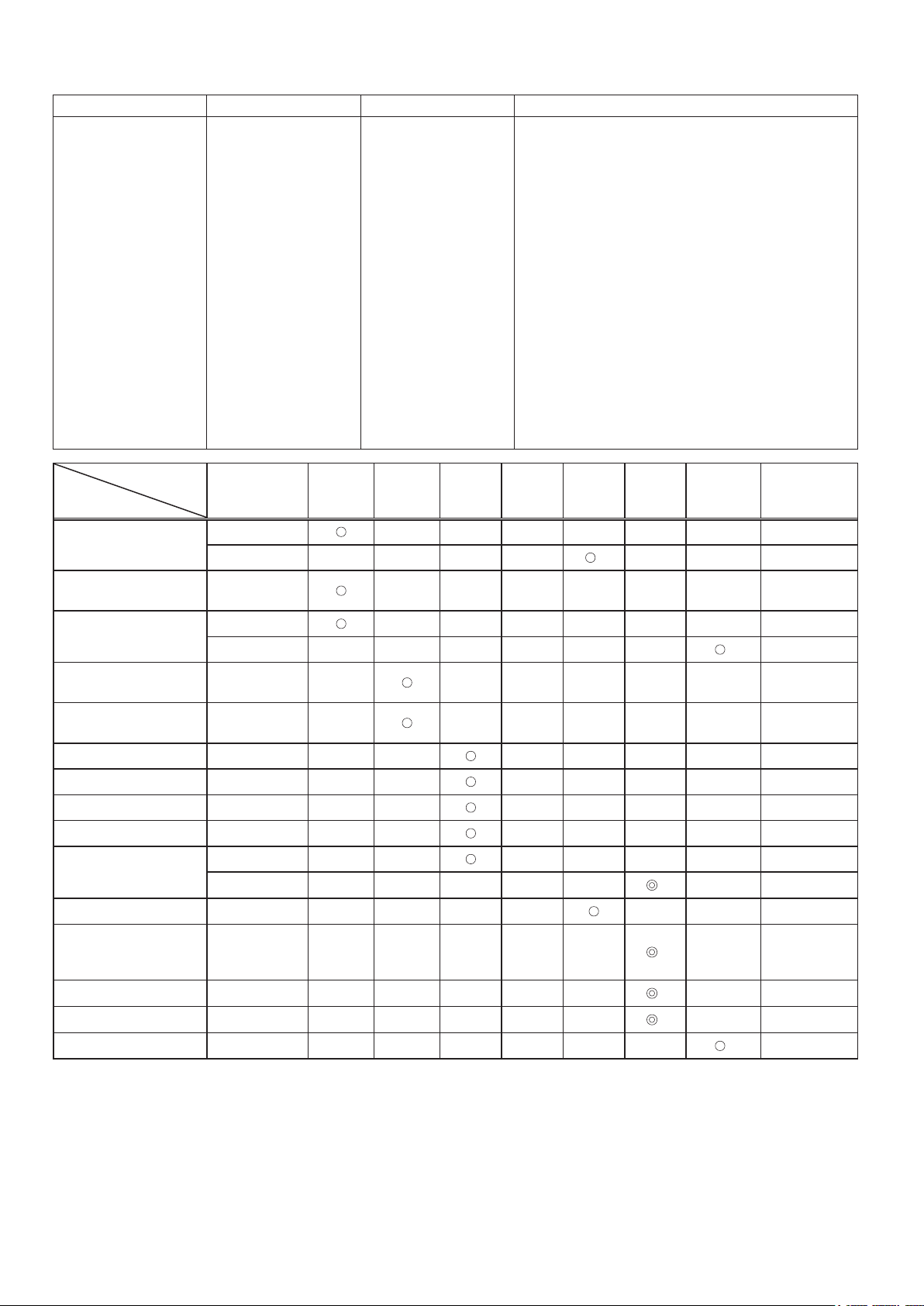

Fault location

Fault System Observation Cause

Engine not starting or

with difculty

Warm start problems Tank lled ignition spark

Engine starts but dies Fuel supply Tank lled Incorrect idling adjustment, carburetor contaminated

Insufcient performance Several systems may

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Fuel supply Fuel tank lled Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty.

Compression No compression when

pulled over

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

Carburetor contaminated, have it cleaned

existing

Fuel tank vent defective, fuel supply line interrupted, cable

or STOP-switch faulty

Engine idling poor Air lter contaminated, carburetor contaminated, mufer

simultaneously be

clogged, exhaust duct in the cylinder clogged

affected

Operating time

Item

Inspect/clean

Engine oil

Replace

Tightening parts (bolt,

nut)

Inspect

Clean/inspect

Fuel tank

Drain fuel

Throttle trigger/

throttle lever

Stop control lever/

stop switch

Check function

Check function

Low-speed rotation Inspect/adjust

Air cleaner Clean

Ignition plug / plug cord Inspect

Cooling air duct Clean/inspect

Inspect

Fuel pipe

Replace

Fuel lter Clean/replace

Clearance between

air intake valve and air

Adjust

discharge valve

Oil tube Inspect

Engine overhaul

Carburetor Drain fuel

Before

operation

After

lubrication

Daily

(10h)

30h 50h 200h

*1

*2

*2

*2

*2

Shutdown/

rest

*3

*3

Corresponding

Page

10

17

19

—

19

—

13

14

18

18

19

19

—

19

—

—

—

19

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

Page 21

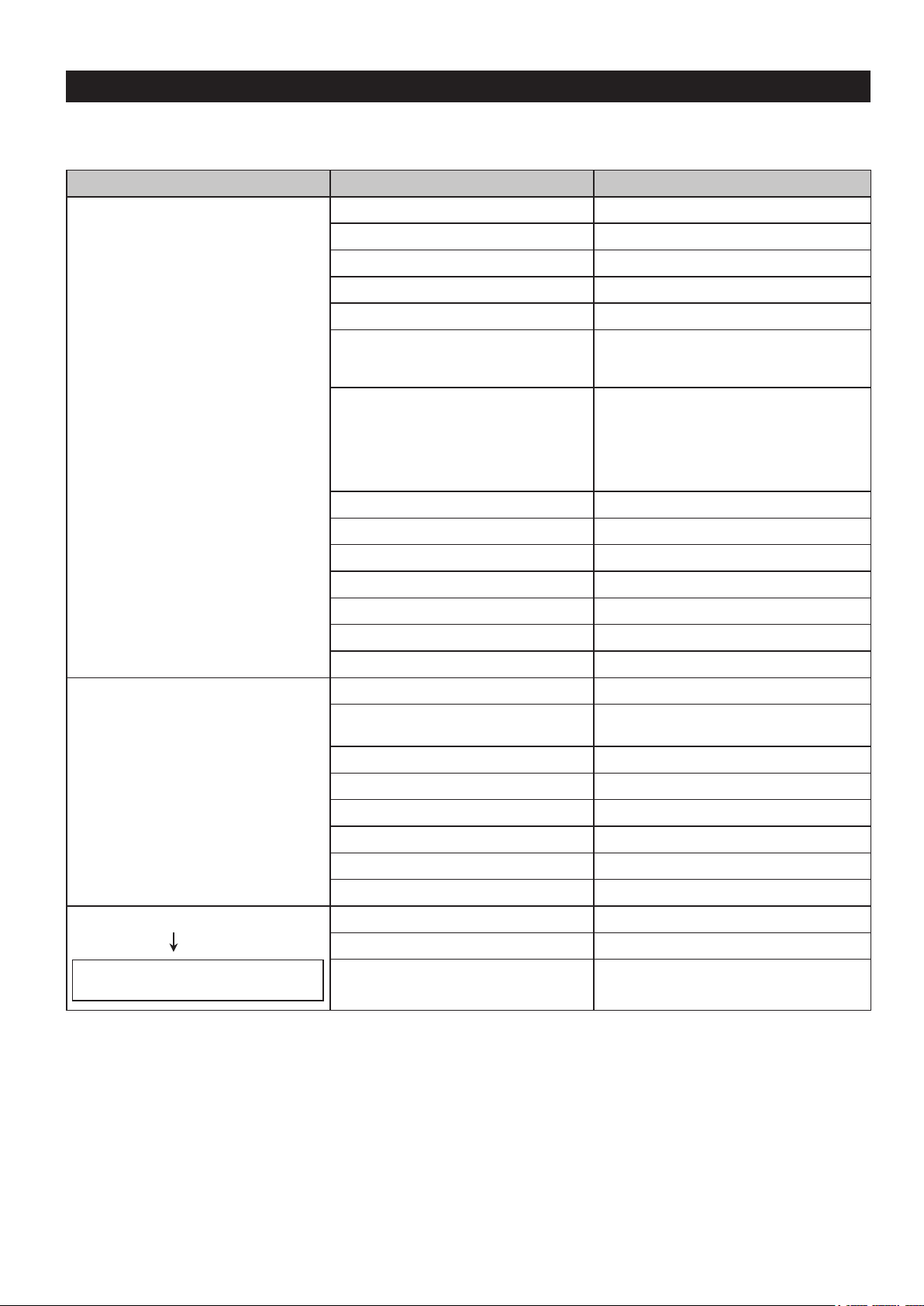

TROUBLESHOOTING

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description of this

manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times.

Low pulling speed of starter rope Pull strongly.

Lack of fuel Feed fuel.

Clogged fuel lter Clean

Bent fuel tube Straighten fuel tube

Deteriorated fuel Deteriorated fuel makes starting more difcult.

Replace with new one. (Recommended

replacement: 1 month)

Excessive suction of fuel Set throttle lever from medium speed to high

speed, and pull starter handle until engine

Engine does not start

Detached plug cap Attach securely

Contaminated spark plug Clean

starts.

If engine will not start still, remove spark plug,

make electrode dry, and reassemble them as

they originally are. Then, start as specied.

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Cannot pull the starter knob Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Insufcient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although

engine is warmed up

Clogged fuel lter Clean

Engine stops soon

Engine speed does not increase

Engine does not stop. Detached connector Attach securely

Run engine at idling, and set choke lever to

“CLOSE”.

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Detached throttle wire Attach securely

Abnormal electric system Make request for inspection and maintenance.

Set to “OPEN”

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

21

Page 22

23

Français

Nous vous remercions d’avoir choisi un soufeur Dolmar, fruit d’un

important programme de développement et d’années de connaissances

et d’expérience accumulées.

Ces modèles de soufeur allient les avantages d’une technologie

de pointe à une conception ergonomique. Ces outils de qualité

professionnelle sont légers, pratiques, compacts, et utilisés dans de

nombreuses applications.

Lisez, assimilez et respectez les instructions gurant dans ce manuel, qui

traite en détail des différents points permettant de tirer le meilleur parti

possible des performances de votre soufeur Dolmar, en toute sécurité.

Table des matières

Symboles ............................................................................................ 22

Consignes de sécurité ........................................................................ 23

Déclaration de conformité CE............................................................. 26

Caractéristiques techniques ............................................................... 27

Nomenclature ..................................................................................... 28

Instructions de montage ..................................................................... 29

Avant de démarrer le moteur .............................................................. 30

Fonctionnement .................................................................................. 32

Réglage du ralenti .............................................................................. 34

Prévention du givrage du carburateur ................................................ 34

Mode opératoire ................................................................................. 35

Inspection et entretien ........................................................................ 37

Remisage ........................................................................................... 39

Dépannage ......................................................................................... 41

SYMBOLES

Lors de la lecture des instructions gurant dans ce manuel, prêtez une attention particulière aux symboles suivants.

AVERTISSEMENT/DANGER Éloignez les personnes présentes

Page

Lisez, assimilez et respectez les

instructions gurant dans ce manuel

Interdit Démarrage manuel du moteur

Interdiction de fumer Arrêt d’urgence

Flamme nue interdite Premiers secours

Port de gants de protection obligatoire ON/Marche

Maintenez les personnes et les animaux

domestiques à l’écart de la zone de travail

Carburant (essence)

OFF/Arrêt

Port de protections des yeux et des oreilles

obligatoire

Surfaces chaudes - Risque de brûlures

22

Pales en rotation - Risque de

sectionnement des doigts ou de la main

Les cheveux longs risquent de se prendre

dans les pièces en mouvement.

Page 23

CONSIGNES DE SÉCURITÉ

(1)

(2)

(3)

(5)

(4)

Généralités

Pour garantir un fonctionnement en toute sécurité, vous devez lire,

●

assimiler et respecter les instructions gurant dans ce manuel pour vous

familiariser avec la manipulation du soufeur (1). Les utilisateurs mal

informés risquent, par des manipulations inappropriées, de se blesser

ou de blesser leur entourage.

Il est conseillé de ne prêter cet appareil qu’aux personnes ayant déjà une

●

certaine expérience des soufeurs.

Fournissez-leur aussi le manuel d’instruction.

●

Les utilisateurs novices doivent demander au vendeur les explications

●

de base leur permettant de se familiariser avec le soufeur.

Les enfants et les jeunes gens de moins de 18 ans ne doivent pas être

●

autorisés à utiliser le soufeur. Les personnes âgées de plus de 16 ans

peuvent cependant utiliser l’outil pour apprendre à s’en servir, mais

uniquement sous le contrôle direct d’un formateur qualié.

Utilisez toujours le soufeur avec prudence.

●

N’utilisez la machine que si vous êtes en bonne condition physique.

●

Faites très attention à tout ce que vous faites. En tant qu’utilisateur, vous

●

êtes responsable des autres.

N’utilisez jamais le soufeur lorsque vous êtes sous l’inuence d’alcool

●

ou de médicaments (2).

N’utilisez pas l’appareil lorsque vous êtes fatigué.

●

Conservez soigneusement ce manuel an de pouvoir vous y référer

●

ultérieurement.

Équipement de protection personnelle

Portez des vêtements fonctionnels et adaptés, c’est-à-dire ajustés,

●

mais n’entravant pas vos mouvements. Ne portez pas de bijoux ou de

vêtements qui pourraient être happés par l’entrée d’air, attachez les

cheveux longs.

Pour éviter les blessures à la tête, aux yeux, aux mains, aux pieds et

●

les blessures auditives, portez les équipements et les vêtements de

protection suivants lorsque vous utilisez le soufeur.

Prêtez une attention particulière aux consignes

suivantes

Les vêtements doivent être résistants et ajustés, sans toutefois entraver

●

la liberté de mouvement. Évitez les vestes amples, les pantalons à

jambes larges, les écharpes, les cheveux longs non attachés, ou tout ce

qui pourrait être happé par l’arrivée d’air. (4) Portez un bleu de travail ou

un pantalon long pour protéger vos jambes.

Ne portez pas de pantalon court. (4)

●

Les appareils à moteur sont généralement bruyants et leur bruit risque

d’altérer votre audition. Portez des protections antibruit (bouchons

d’oreille, serre-tête antibruit). Si vous utilisez le soufeur de façon

régulière et continue, faites vérier votre ouïe régulièrement. (3)

●

Le port de gants est recommandé lorsque vous utilisez le soufeur.

Portez des chaussures solides à semelles antidérapantes. (4)

●

Protégez-vous soigneusement les yeux. Même si l’évacuation est dirigée

à l’opposé de l’utilisateur, des ricochets et des rebonds peuvent se

produire en cours de fonctionnement. (3)

●

N’utilisez jamais le soufeur sans porter des lunettes de sécurité munies

d’une protection supérieure et latérale appropriées et conformes à la

norme EN166 et à la réglementation en vigueur dans votre pays.

●

An de réduire le risque de lésions liées à l’inhalation de poussière,

portez un masque ltrant dans les milieux poussiéreux.

Démarrage du soufeur

●

Assurez-vous que personne (et a fortiori aucun enfant) ne se trouve dans

une zone d’action de 15 mètres autour de l’appareil (5). Faites aussi

attention aux animaux. N’utilisez jamais le soufeur dans des zones

urbaines.

●

Avant le démarrage, vériez que le soufeur est en bon état de

:

marche

Vériez le bon fonctionnement du levier de commande d’accélération.

Celui-ci doit pouvoir être manipulé facilement et sans à-coup. Vériez le

bon fonctionnement du système de verrouillage du levier de commande

d’accélération. Assurez-vous que les poignées sont propres et sèches

et vériez le fonctionnement du commutateur de marche/arrêt. Les

poignées ne doivent pas présenter de traces d’huile ou de carburant.

15 m

23

Page 24

25

Mettez le soufeur en marche en respectant les instructions. N’utilisez

(6)

(7)

(8)

(9)

●

pas d’autres méthodes de mise en marche du moteur (6).

●

Utilisez le soufeur et les outils fournis uniquement pour les applications

spéciées.

●

Ne mettez le moteur du soufeur en marche qu’une fois l’outil entièrement

assemblé. L’outil ne fonctionne que lorsque tous les accessoires

appropriés sont montés.

En cas de problème, arrêtez immédiatement le moteur.

●

Lorsque vous travaillez avec le soufeur, tenez fermement la poignée

●

en plaçant vos doigts autour de celle-ci, et en serrant la poignée de

commande entre le pouce et l’index. Maintenez la main dans cette

position pour garder le contrôle de l’appareil en permanence. Vériez

que la poignée de commande est en bonne condition et qu’elle est

exempte d’humidité, de goudron, d’huile ou de graisse.

Gardez une bonne position d’équilibre et une prise ferme au sol.

Portez le soufeur correctement sur les deux épaules lors de son

●

utilisation. Ne portez pas le soufeur avec une seule courroie d’épaule.

Le non-respect de cette consigne peut entraîner des blessures.

Utilisez le soufeur de manière à éviter toute inhalation des gaz

●

d’échappement. Ne mettez jamais le moteur en marche dans des

locaux fermés (risques d’asphyxie et d’empoisonnement par les gaz

d’échappement). Le monoxyde de carbone est un gaz inodore.

Assurez-vous toujours que la ventilation est sufsante.

Coupez le moteur pendant les pauses ou lorsque vous laissez le soufeur

●

sans surveillance.

Mettez-le en lieu sûr pour éviter de blesser l’entourage, de mettre le feu

aux matériaux combustibles, ou d’endommager l’appareil.

Ne posez jamais le soufeur chaud sur de l’herbe sèche ou des

●

matériaux combustibles.

Le soufeur doit être utilisé avec tous les dispositifs et les pièces de

●

protection fournis.

Ne faites jamais fonctionner l’appareil avec un silencieux défectueux.

●

Arrêtez le moteur pendant le transport (7).

●

Mettez le soufeur dans une position sûre pendant le transport en camion

●

ou en voiture pour éviter les fuites de carburant.

Lors du transport du soufeur, assurez-vous que le réservoir de carburant

●

est totalement vide.

Portez le soufeur en le tenant par sa poignée de transport. Ne tirez pas

●

le soufeur par la buse, le tube ou une autre partie.

Lorsque vous portez le soufeur, pensez à plier les genoux et faites

●

attention à vos épaules et à vos lombaires.

●

Repos

●

Transport

Plein de carburant

●

Entretien

●

Remplacement d’outil

●

Plein de carburant

Coupez le moteur lors du remplissage du réservoir. (7) Tenez-vous à

●

distance de toute amme nue. (8) Ne fumez pas.

Évitez tout contact de la peau avec les produits pétroliers. N’inhalez pas

●

les vapeurs de carburant.

Portez toujours des gants de protection. Changez et nettoyez

régulièrement les vêtements de protection.

●

Veillez à ne pas déverser de carburant ou d’huile, pour éviter de

contaminer le sol (protection de l’environnement). En cas de déversement

de carburant, nettoyez immédiatement le soufeur. Laissez sécher les

chiffons humides avant de les jeter dans un conteneur approprié et

couvert, pour éviter tout risque de combustion spontanée.

Évitez tout contact du carburant avec vos vêtements. Changez-vous

●

immédiatement en cas de déversement de carburant sur vos vêtements

(risque d’incendie).

Vériez régulièrement que le bouchon du réservoir est bien fermé.

●

Serrez soigneusement la vis de verrouillage du réservoir de carburant.

●

Éloignez-vous d’au moins 3 m de l’endroit où vous avez fait le plein avant

de mettre le moteur en marche. (9)

Ne faites jamais le plein dans des locaux fermés : les vapeurs de

●

carburant s’accumulent au niveau du sol (risque d’explosion).

Le carburant doit être transporté et stocké uniquement dans des

●

conteneurs approuvés. Veillez à ce que les enfants n’aient pas accès au

carburant stocké.

Ne faites jamais le plein lorsque le moteur est chaud ou en marche.

●

3 m

24

Page 25

Fonctionnement

(10)

(11)

Utilisez le soufeur uniquement dans des endroits bien éclairés, où la

●

visibilité est bonne. Faites attention aux zones glissantes ou humides, au

verglas et à la neige (risque de chute) ainsi qu’aux espaces restreints.

Conservez toujours un bon appui au sol.

●

N’utilisez jamais le soufeur sur une surface instable ou sur une pente

abrupte.

●

Ne travaillez pas sur une échelle ou une zone en hauteur. Le non-respect

de cette consigne peut entraîner des blessures.

●

Pour réduire le risque de blessure, ne dirigez pas le jet d’air vers les

personnes présentes ; la pression élevée de l’air peut causer une

blessure aux yeux ou projeter des petits objets à très grande vitesse.

●

Ne mettez jamais de corps étrangers dans l’entrée d’air ou dans la

buse du soufeur. Cela endommagerait le ventilateur. De plus, l’éjection

à grande vitesse des corps étrangers ou de pièces cassées risque de

blesser l’utilisateur ou les personnes présentes.

●

Tenez compte de la direction du vent, de façon à ne pas travailler contre

le vent.

●

Pour éviter de chute et de perte le contrôle de l’appareil, ne reculez

jamais pendant son utilisation.

●

Coupez toujours le moteur avant tout nettoyage, entretien ou

remplacement de pièces de l’appareil.

●

Faites des pauses an d’éviter toute perte de contrôle due à la fatigue.

Nous vous recommandons une pause de 10 à 20 minutes toutes les

heures.

●

N’utilisez pas l’appareil près des fenêtres, etc.

●

Pour réduire les dommages corporels dus aux vibrations et au bruit,

faites fonctionner l’appareil à vitesse lente si possible et limitez la durée

d’utilisation.

Utilisez l’appareil uniquement à des heures raisonnables. N’utilisez pas

●

le soufeur tôt le matin ou tard le soir lorsque vous risquez de déranger

le voisinage.

Il est recommandé de décompacter les débris à l’aide d’un râteau ou

●

d’un balai avant soufage.

Dans les milieux poussiéreux, humidiez légèrement les surfaces avant

●

soufage, ou utilisez un pulvérisateur d’eau si nécessaire.

Réglez la longueur de la buse du soufeur an que le jet d’air soit soufé

●

près du sol.

●

An de réduire le niveau sonore, limitez le nombre d’équipements utilisés

simultanément.

NETTOYEZ après utilisation du soufeur ou d’autres équipements ! Mettez

les débris dans des poubelles.

Instructions d’entretien

●

Respectez l’environnement. Limitez autant que possible le bruit et la

pollution lorsque vous utilisez le soufeur. Vériez en particulier que le

carburateur est réglé correctement.

●

Nettoyez régulièrement le soufeur et vériez que toutes les vis et tous

les écrous sont bien serrés.

●

Le soufeur doit toujours être entretenu et stocké à l’écart des ammes

nues, des étincelles, etc (11).

●

Remisez toujours le soufeur dans un local bien ventilé et fermant à clé,

et videz le réservoir.

Respectez toutes les consignes de prévention d’accidents des associations

professionnelles et des compagnies d’assurances. Ne modiez pas le

soufeur, sous peine de compromettre votre sécurité.

N’effectuez aucune opération d’entretien ou de réparation qui ne soit pas

prévue par ce manuel. Toutes les autres opérations doivent être effectuées

par des techniciens agréés.

Utilisez uniquement des pièces de rechange et des accessoires d’origine,

fournis par Dolmar.

L’utilisation d’accessoires et d’outils non agréés augmente les risques

d’accident et de blessure. Dolmar décline toute responsabilité en cas

d’accident ou de dommage provoqué par l’utilisation de pièces ou

d’accessoires non agréés.

Ne modiez jamais l’équipement. Le non-respect de cette consigne peut

entraîner des accidents ou des blessures graves.

25

Page 26

27

Premiers secours

(12)

Veillez à avoir toujours à portée de la main une trousse de premiers secours

complète. Remplacez immédiatement tout article utilisé.

En cas d’accident, appelez les services de secours et

fournissez-leur les informations suivantes :

lieu de l’accident

●

circonstances de l’accident

●

nombre de personnes blessées

●

gravité des blessures

●

votre nom

●

Pour l’Europe uniquement

Déclaration de conformité CE

Le soussigné, Rainer Bergfeld, tel qu’autorisé par Dolmar GmbH, déclare que les outils DOLMAR :

Désignation de la machine : Soufeur à essence

N° de modèle/type : PB-7650.4, PB-7650.4 H

Spécications : voir le tableau « CARACTÉRISTIQUES TECHNIQUES »

est un produit de série et

est conforme aux directives européennes suivantes :

2000/14/CE, 2006/42/CE

et est fabriqué conformément aux normes ou aux documents normalisés suivants :

EN15503

La documentation technique se trouve dans les locaux de l’entreprise sise :

Dolmar GmbH,

Jenfelder Straße 38, Abteilung FZ, D-22045 Hamburg

La procédure d’évaluation de la conformité requise par la Directive 2000/14/CE a été réalisée en conformité avec l’annexe V.

Niveau de puissance acoustique mesuré : 110 dB

Niveau de puissance acoustique garanti : 111 dB

6. 8. 2013

Rainer Bergfeld

Directeur général

26

Page 27

CARACTÉRISTIQUES TECHNIQUES

Modèle PB-7650.4 PB-7650.4 H

Type de commande d’accélération

d’accélération sur le

tube

Poids (sans le tube du soufeur) (kg) 10,8 11,0

Commande

Dimensions (sans le tube du soufeur) (L x l x H) (mm) 332

(avec buse haute vitesse)

(avec tube

long)

Vitesse de l’air

(avec tube

court)

(avec buse haut débit) 81

(avec buse plate) 86

(avec buse haute vitesse) 90

(m/s)

(avec buse haut débit) 81

x 460 x 480 332 x 510 x 480

89

(avec buse plate) 87

Débit volumétrique d’air

(avec tube

long)

(avec tube

court)

(avec buse haute vitesse)

(avec buse haut débit) 19

(avec buse plate) 17

(avec buse haute vitesse) 17

(m

minute)

3

/

(avec buse haut débit) 19

17

(avec buse plate) 17

–1

Vitesse max. du moteur (avec buse haute vitesse) (min

Vitesse au ralenti (min

Cylindrée du moteur (cm

) 7 100

–1

) 2 800

3

) 75,6

Carburant Essence automobile

3

Capacité du réservoir de carburant (cm

) 1 900

huile SAE 10W-30 de classe SF ou supérieure,

Huile moteur

Capacité du réservoir d’huile moteur (cm

selon la norme API (huile pour moteur automobile

4

3

) 220

temps)

Carburateur (type) Carburateur à diaphragme

Bougie NGK CMR6A

Distance entre électrodes (mm) 0,7 – 0,8

Vibrations

selon

EN15503

009

2

Poignée

droite

Poignée

gauche

(bras de

commande)

(avec tube

long)

a

hv eq

(avec tube

court)

(avec buse haut débit) 2

(avec buse plate) 4,1 4,8

(avec buse haute vitesse) 3

(avec buse haut débit) 2

(avec buse plate) 3

(avec buse haute vitesse)

Incertitude (K) 2

(avec buse haute vitesse) 0,7

(avec tube

long)

a

hv eq

(avec tube

court)

(avec buse haut débit) 0,7

(avec buse plate) 0,9

(avec buse haute vitesse) 0,8

(avec buse haut débit) 0,7

(m/s

2

)

2,5 2,7

,3 2,3

,1 2,7

,8 2,3

,7 5,1

,2 3,0

(avec buse plate) 0,9

Incertitude (K) 0,5

Niveau de pression acoustique moyen selon EN15503:

009

2

Niveau de puissance acoustique moyen selon EN15503:

2

009

L

PA eq

Incertitude (K) dB(A) 1,5

L

WA eq

Incertitude (K) dB(A) 1,0

dB(A) 100

dB(A) 110

Commande

d’accélération à

la hanche

Notes :

Étant donné l’évolution constante de notre programme de recherche et développement, les spécications contenues dans ce manuel sont sujettes

●

à modication sans préavis.

●

Les spécications peuvent varier suivant les pays.

27

Page 28

29

NOMENCLATURE

1

2

3

4

5

6

8

32

32

7

7

9

10

11

12

14

15

16

17

19

18

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

19

18

20

21

22

23

24

25

26

20

PB-7650.4

PB-7650.4 H

27 28 29

30

31

1. Courroie d’épaules 9. Bouchon du réservoir d’huile 17. Crépine de l’entrée d’air 25. Interrupteur d’arrêt

2. Cache de bougie 10. Silencieux 18. Couvercle du ltre à air 26. Bras de commande

3. Levier du dispositif de

démarrage à froid

4. Pompe d’amorçage 12. Tuyau exible 20. Poignée de transport 28. Buse haut débit

5. Poignée de démarrage 13. Poignée de montage 21. Levier de commande d’arrêt 29. Buse plate

6. Bouchon du réservoir de

7. Réservoir de carburant 15. Tube (long/court)

8. Boulon de vidange d’huile 16. Buse

●

Les accessoires standard peuvent varier d’un pays à l’autre.

carburant

11. Coude

14. Tube rotatif 22. Poignée de commande 30. Tube long

19. Boulon

23. Gâchette de commande

24. Levier de commande

28

(du couvercle du ltre à air)

d’accélération

d’accélération

27. Buse haute vitesse

31. Tube court

(accessoire en option)

32. Levier du dispositif antigivrage

Page 29

INSTRUCTIONS DE MONTAGE

(1)

(2)

(3)

(5)

(4)

(10)

(11)

(9)

(7)

(6)

(8)

(7)

MONTAGE DES TUBES DU SOUFFLEUR

ATTENTION :

Avant toute opération sur le soufeur, coupez toujours le moteur et

●

débranchez les connecteurs de bougie.

Portez toujours des gants de protection !

Ne mettez le soufeur en marche que lorsqu’il est complètement

●

monté.

Portez toujours des gants de protection !

●

1. Insérez le tube rotatif (3) dans le tuyau exible (1) et assemblez-les avec

le collier de serrage (2).

2. Installez la poignée de commande/de montage (4) sur le tube rotatif et

assemblez-les avec la vis de blocage (5).

3. Modèle à commande d’accélération sur le tube

Insérez le tuyau exible dans le coude (6) du soufeur.

Montez le support de câble (7) entre le collier de serrage (8) et le

coude.

Assemblez le support de câble, le tuyau exible et le coude avec le

collier de serrage.

Montez le câble de commande (9) sur le support de câble (7).

Modèle à commande d’accélération à la hanche

Insérez le tuyau exible dans le coude (6) du soufeur.

Assemblez le tuyau exible et le coude avec le collier de serrage (8).

Montez le tube long/court (10) sur le tube rotatif. Tournez le tube long/

4.

court dans le sens des aiguilles d’une montre pour le verrouiller.

Montez ensuite la buse du soufeur (11) sur le tube long/court. Tournez

la buse du soufeur dans le sens des aiguilles d’une montre pour la

verrouiller.

Vériez que tous les dispositifs de xation sont serrés.

5.

29

Page 30

31

AVANT DE DÉMARRER LE MOTEUR

(1)

(2)

(4)

(3)

1. Vérication du niveau d’huile moteur et ajout d’huile

1) Suivez la procédure ci-dessous. Le moteur doit être froid. Le nonrespect de cette consigne peut entraîner des brûlures cutanées.

●

Vérication : Placez le soufeur par terre sur une surface plane et

retirez le bouchon du réservoir d’huile.

Vériez le niveau d’huile (1). Assurez-vous que le

niveau d’huile se trouve entre les repères supérieur

(2) et inférieur de (3) l’indicateur de niveau d’huile. Si

niveau est inférieur à 100 ml (4), ajoutez de l’huile

le

neuve.

Ajout d’huile : Placez le soufeur par terre sur une surface plane et

●

retirez le bouchon du réservoir d’huile.

Remplissez avec de l’huile jusqu’au repère supérieur

de l’indicateur de niveau d’huile.

2) En moyenne, le niveau d’huile moteur doit être ajusté toutes

les 20 heures d’utilisation, ce qui correspond à 10 – 15 pleins de

carburant.

Changez l’huile lorsqu’elle est sale ou lorsque sa couleur change de

3)

manière signicative (Voir « Replacement de l’huile moteur » pour

la procédure et la fréquence de l’opération.)

Huile recommandée : huile Dolmar ou huile SAE10W-30 de classe SF ou supérieure, selon la norme API (huile pour moteur 4 temps)

Capacité du réservoir d’huile : environ 0,22 l (220 ml)

NOTE :

Si le soufeur n’est pas rangé verticalement, l’huile risque de passer de l’indicateur de niveau dans le moteur et donner une fausse indication de

●

niveau lors de la vérication. Ceci peut entraîner un remplissage excessif lors de l’ajout d’huile. Rangez toujours le soufeur verticalement.

●

En cas de remplissage excessif, l’huile peut jaillir du reniard du ltre à air et encrasser les pièces voisines, ou bien la combustion du surplus

d’huile risque de brûler en dégageant une fumée blanche.

Démontage/remise en place du bouchon du réservoir d’huile

●

Nettoyez autour de l’orice de remplissage avant de retirer le bouchon.

●

Le bouchon démonté doit rester exempt de terre et de sable. Sinon, la terre et le sable collés au bouchon du réservoir d’huile peuvent entraîner

une circulation d’huile irrégulière et une usure du moteur, et provoquer des dysfonctionnements.

Après l’ajout d’huile

●

Nettoyez avec un chiffon tout déversement d’huile.

30

Page 31

2. Plein de carburant

AVERTISSEMENT :

Lors du plein, assurez-vous que les instructions suivantes sont respectées pour éviter toute inammation, tout incendie et toute blessure :

●

Le plein de carburant doit se faire en absence de source d’incendie. N’approchez jamais de source d’incendie (cigarette allumée, etc.) du lieu

–