Page 1

PETROL BLOWER

SOUFFLEUR À ESSENCE

BENZIN BLASGERÄT

SOFFIATORE A BENZINA

BENZINE BLADBLAZER

SOPLADOR GASOLINA

English / Français / Deutsch

Italiano / Nederlands / Español

PB-252.4

INSTRUCTION MANUAL

(P2~P18)

INSTRUCTIONS D’EMPLOI

(P19~P35)

BETRIEBSANLEITUNG

(P36~P52)

Important:

Read this instruction manual carefully before putting the Blower into operation and strictly

observe the safety regulations! Preserve instruction manual carefully!

Importante:

Lisez attentivement ce manuel utilisateur avant de mettre en route le souffleur et respectez scrupuleusement les consignes de sécurité.

Conservez soigneusement ce manuel.

Wichtig:

Lesen Sie diese Betriebsanleitung sorgfältig durch bevor Sie das Blasgerät in Betrieb

nehmen und beachten Sie die Sicherheitsvorschriften genau!

Bewahren Sie diese Betriebsanleitung sorgfältig aul!

MANUALE D’ISTRUZIONI

(P53~P69)

GEBRUIKSAANWIJZING

(P70~P86)

MANUAL DE INSTRUCCIONES

(P87~P103)

Importante:

Leggere con attenzione il manuale prima di mettere in funzione il soffiatore; le norme di

sicurezza vanno rigorosamente rispettate!

Conservare il manuale delle istruzioni per I’uso.

Belangrijk:

Lees altijd eerst de veiligheidsvoorschriften aandachtig door en neem deze in acht voordat u de machine in gebruik neemt. Bewaar deze gebruiksaanwijzing zorgvuldig.

Importante:

Lea bien este manual antes de poner el soplador en funcionamiento, y observe estrictamente las medidas de seguridad. Conserve este manual de instrucciones.

Page 2

English

Thank you very much for selecting the DOLMAR blower. We are

pleased to be able to offer you the DOLMAR blower which is the result

of a long development programme and many years of knowledge and

experience.

The blower models PB-252.4 combines the advantages of state-of-theart technology with ergonomic design. They are of light weight handy,

compact and represent professional equipment for a great variety of

applications.

Please read, understand and follow this booklet which refers in detail to

the various points that will demonstrate its outstanding performance.

This will assist you to safety obtain the best possible results from your

DOLMAR Blower.

Table of contents

SYMBOLS............................................................................................ 2

SAFETY INSTRUCTIONS ................................................................... 3

EC DECLARATION OF CONFORMITY .............................................. 6

SPECIFICATIONS ............................................................................... 6

DESIGNATION OF PARTS .................................................................. 7

ASSEMBLY INSTRUCTIONS .............................................................. 8

BEFORE START OF OPERATION ...................................................... 9

OPERATION ......................................................................................11

ADJUSTMENT OF IDLING................................................................ 12

OPERATION METHOD...................................................................... 13

INSPECTION AND MAINTENANCE ................................................. 14

STORAGE.......................................................................................... 16

TROUBLESHOOTING....................................................................... 18

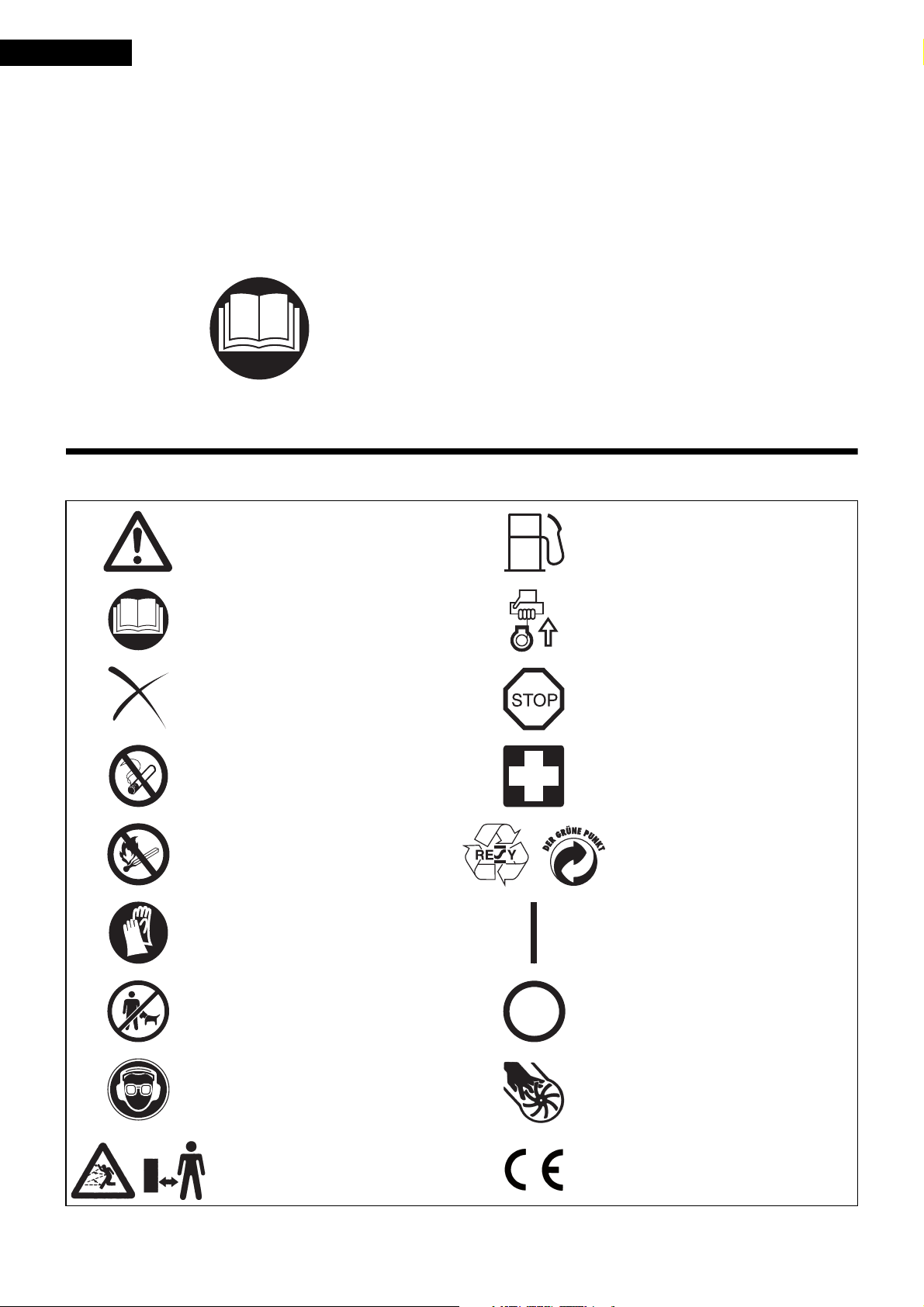

SYMBOLS

It is very important to understand the following symbols when reading this instructions manual.

Page

WARNING/DANGER Fuel (Gasoline)

Read, Understand and Follow Instruction

Manual

Forbidden Emergency Stop

No Smoking First Aid

No Open Flame Recycling

Protective Gloves must be Worn ON/START

Engine-manual Start

Keep the Area of Operation

Clear of All Persons and Pets

Wear Eye and Ear Protection

Keep bystanders away CE-Mark

OFF/STOP

Severing of fingers or hand,

impeller blade

2

Page 3

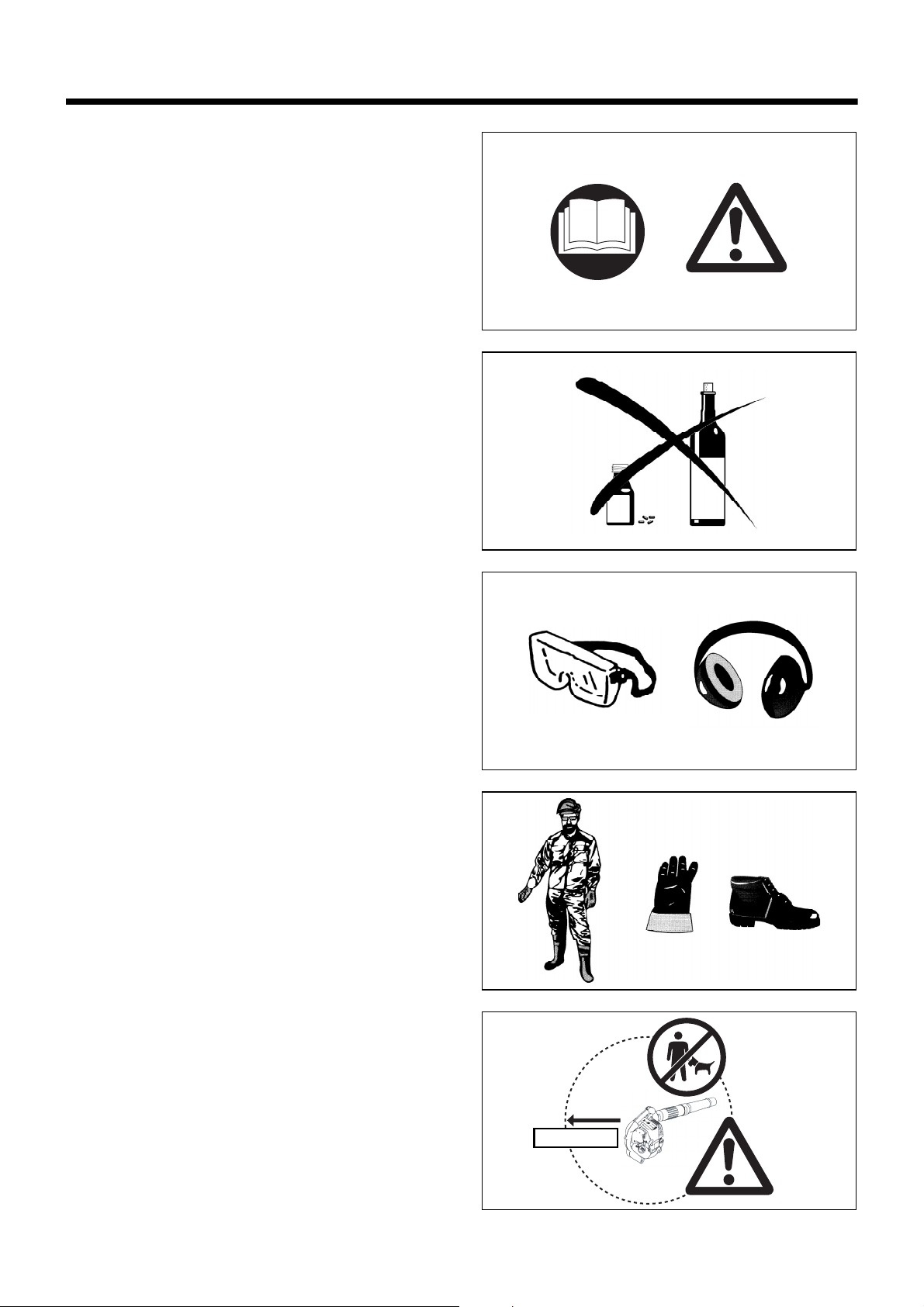

SAFETY INSTRUCTIONS

(1)

(2)

(3)

(4)

(5)

15 meters

General Instructions

• To ensure correct and safe operation, the user must read, understand

and follow this instruction manual to assure familiarity with the handling

of the blower (1). Users insufficiently informed will risk danger to themselves as well as others due to improper handling.

• It is recommended only to loan the blower to people who have proven

to be experienced with blowers.

• Always hand over the instruction manual.

• First-time users should ask the dealer for basic instructions to familiarize oneself with the handling of a blower.

• Children and young persons aged under 18 years must not be allowed

to operate the blower. Persons over the age of 16 years may however

use the tool for the purpose of being trained only while under the direct

supervision of a qualified trainer.

• Use blowers with the utmost care and attention.

• Operate the blower only if you are in good physical condition.

• Perform all work conscientiously and carefully. The user has to accept

responsibility for others.

• Never use the blower while under the influence of alcohol or drugs (2).

• Do not use the unit when you are tired.

• Save these instructions for future referral.

Personal Protective Equipment

• The clothing worn should be functional and appropriate, I. e. It should

be tight-fitting but not cause a hindrance. Do not wear jewelry, clothing

or long hair which could be drawn into the air intake.

• In order to avoid head-, eye-, hand- or foot injuries as well as to protect

your hearing the following protective equipment and protective clothing

must be used during operation of the blower.

Pay particular attention to the following regulations

• Clothing must be sturdy and snug-fitting, but allow complete freedom

of movement. Avoid loose-fitting jackets, flared or cuffed pants, scarf,

unconfined long hair or anything that could be drawn into the air intake.

Wear overalls or long pants to protect your legs. Do not wear

shorts. (4)

• Blower noise may damage your hearing. Wear sound barriers (ear

plugs or ear mufflers) to protect your hearing. Continual and regular

users should have their hearing checked regularly. (3)

• Use of gloves when working with the blower is recommended. Good

footing is most important. Wear sturdy shoes with non slip soles. (4)

• Proper eye protection is a must. Even though the discharge is directed

away from the operator, ricochets and bounce backs can occur during

blower operation. (3)

• Never operate a blower unless wearing goggles or properly fitted

safety glasses with adequate top and side protection which comply

with ANSI Z 87. 1 (or your applicable national standard).

Starting up the blower

• Please make sure that there are no children or other people within a

working range of 15 meters (5), also pay attention to any animals in the

working vicinity. Never use the blower in urban areas.

• Before operating, always check that the blower is safe for operation:

Check the security of the throttle lever. The throttle lever should be

checked for smooth and easy action. Check for proper functioning of

the throttle lever lock. Check for clean and dry handles and test the

function of the l-O switch. Keep handles free of oil and fuel.

360°

3

Page 4

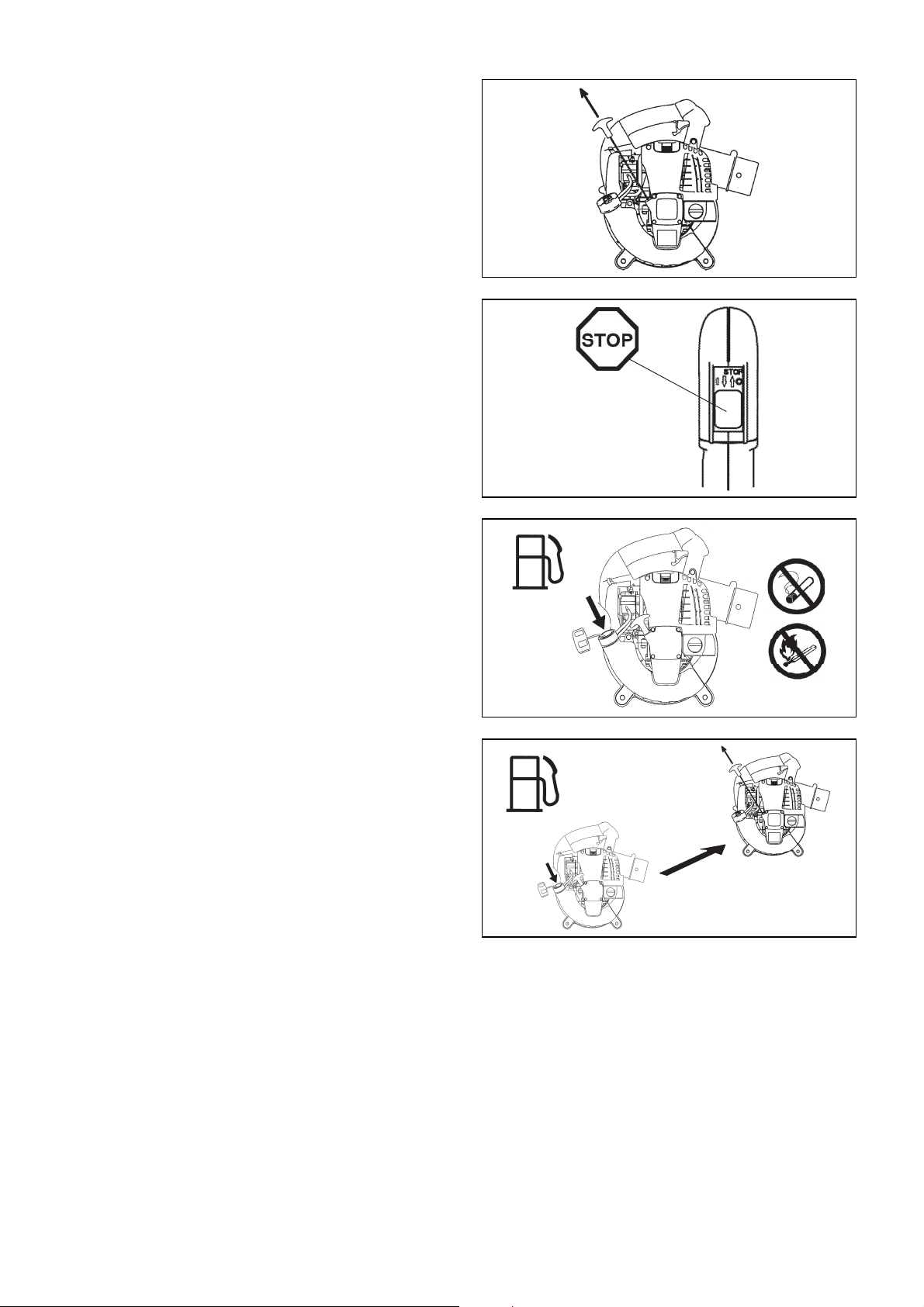

Start the Blower only in accordance with the instructions.

(6)

(7)

(8)

(9)

3 meters

• Resting

• Transport

• Refuelling

• Maintenance

• Tool Replacement

Do not use any other methods for starting the engine (6) !

• Use the blower and the tools supplied only for applications specified.

• Start the blower engine only after the entire tool has been assembled.

Operation of the tool is permitted only after all the appropriate accessories are attached.

• The engine is to be switched off immediately if there are any engine

problems.

• When working with the blower, always wrap your fingers tightly around

the handle, keeping the control handle cradled between your thumb

and forefinger. Keep your hand in this position to have your machine

under control at all times. Make sure your control handle (and grip for

vacuum attachment) are in good condition and free of moisture, pitch,

oil or grease.

Always ensure a safe, well-balanced footing.

• Operate the blower in such a manner as to avoid inhalation of the

exhaust gases. Never run the engine in enclosed rooms (risk of suffocation and gas poisoning). Carbon monoxide is an odorless gas.

Always ensure there is adequate ventilation.

• Switch off the engine when resting and when leaving the blower unattended. Place it in a safe location prevent danger to others, setting fire

to combustible materials, or damage to the machine.

• Never lay the hot blower onto dry grass or onto any combustible materials.

• All protective parts and guards supplied with the machine must be

used during operation.

• Never operate the engine with a faulty exhaust muffler.

• Shut off the engine during transport (7).

• Position the blower safely during car or truck transportation to avoid

fuel leakage.

• When transporting the blower, ensure that the fuel tank is completely

empty.

Refuelling

• Shut off the engine during refuelling (7), keep well away from open

flame (8) and do not smoke.

• Avoid skin contact with petroleum products. Do not inhale fuel vapor.

Always wear protective gloves during refuelling. Change and clean

protective clothing at regular intervals.

• Take care not to spill either fuel or oil in order to prevent soil contamination (environmental protection). Clean the blower immediately after fuel

has been spilt. Allow wet cloths to dry before disposing in properly,

covered container to prevent spontaneous combustion.

• Avoid any fuel contact with your clothing. Change your clothing immediately if fuel has been spilled on it (fire hazard).

• Inspect the fuel cap at regular intervals making sure that it stays

securely fastened.

• Carefully tighten the locking screw of the fuel tank. Change locations to

start the engine (at least 3 meters away from the place of refuelling)

(9).

• Never refuel in closed rooms. Fuel vapors accumulate at ground level

(risk of explosions)

• Only transport and store fuel in approved containers. Make sure stored

fuel is not accessible to children.

• Do not attempt to refuel a hot or a running engine.

4

Page 5

Method of operation

(10)

(11)

(12)

• Use the blower only in good light and visibility. During cold seasons

beware of slippery or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

• Never work on unstable surfaces or steep terrain.

• To reduce the risk of personal injury, do not direct air blast towards

bystanders, since the high pressure of the air flow could injure eyes

and could blow small objects at great speed.

• Never insert any foreign object into the air intake of the machine or into

the nozzle of the blower. It will damage the fan wheel and may cause

serious injury to the operator or bystanders as a result of the object or

broken parts being thrown out at high speed.

• Pay attention to the direction of the wind, i.e., do not work against the

wind.

• To reduce the risk of stumbling and loss of control, do not walk backward while operating the machine.

• Always shut off the engine before cleaning or servicing the unit or

replacing parts.

Maintenance instructions

• Be kind to the environment. Operate the blower with as little noise and

pollution as possible. In particular check the correct adjustment of the

carburetor.

• Clean the blower at regular intervals and check that all screws and nuts

are securely tightened.

• Never service or store the blower in the vicinity of open flames, sparks,

etc. (11).

• Always store the blower in a well-ventilated locked room and with an

emptied fuel tank.

Observe and follow all relevant accident prevention instructions issued

by the trade associations and by insurance companies. Do not perform

any modifications to the blower as this will risk your safety.

The performance of maintenance or repair work by the user is limited to

those activities as described in this instruction manual. All other work is

to be done by Authorized Service Agents.

Use only genuine spare parts and accessories supplied by DOLMAR.

Use of non-approved accessories and tools means increased risk of

accidents and injuries. DOLMAR will not accept any liability for accidents

or damage caused by the use of any non-approved attachment or accessories.

First Aid

In case of accident make sure that a well-stocked first-aid kit is available

in the vicinity of the operations. Immediately replace any item taken from

the first aid kit.

When asking for help, please give the following information:

• Place of accident

• What happened

• Number of injured persons

• Extent of injuries

• Your name

Packaging

The DOLMAR blower is delivered in a protective cardboard box to prevent shipping damage. Cardboard is a basic raw material and is therefore consequently reusable or suitable for recycling (waste paper

recycling).

5

Page 6

For European countries only

EC Declaration of Conformity

The undersigned, Tamiro Kishima and Rainer Bergfeld,

as authorized by Dolmar GmbH, declare that the

DOLMAR machine(s):

Designation of Machine:

Petrol Blower

Model No./ Type: PB-252.4

Specifications: see “SPECIFICATIONS” table

are of series production and

Conforms to the following European Directives:

2000/14/EC, 2006/42/EC

And are manufactured in accordance with the following

standards or standardized documents:

EN15503

The technical documentation is on file at:

Dolmar GmbH,

Jenfelder Straße 38, Abteilung FZ,

D-22045 Hamburg

The conformity assessment procedure required by Directive

2000/14/EC was in Accordance with annex V.

Measured Sound Power Level: 102 dB

Guaranteed Sound Power Level: 106 dB

14th June 2010

Tam i ro K i sh i ma

Managing Director

Rainer Bergfeld

Managing Director

SPECIFICATIONS

Model PB-252.4

Mass (without blower pipe) (kg) 4.5

Dimension (without blower pipe L x W x H) (mm) 350 × 231 × 368

-1

Max. engine speed (min

Idling speed (min

Engine displacement (mL) 24.5

Fuel Automobile gasoline

Fuel tank capacity (L) 0.52

Engine oil

Engine oil volume (L) 0.08

Carburetor (Diaphragm-carburetor) WALBRO WYL

Ignition system Solid state ignition

Spark plug NGK CMR6A

Electrode gap (mm) 0.7 - 0.8

a

Vibration per EN15503

Sound pressure level average to

EN15503

Sound power level average to

EN15503

hv eq

Uncertainty K (m/s

L

PA eq

Uncertainty K dB(A) 1.4

L

WA eq

Uncertainty K dB(A) 1.4

Notes:

1. Use the oil and spark plug specified by DOLMAR.

2. This specification is subject to change without prior notice.

) 7,800

-1

) 3,500

SAE 10W-30 oil of API Classification, Class SF or higher

(4-stroke engine for automobile)

(m/s2)9.3

2

)0.5

dB(A) 90.8

dB(A) 103.7

6

Page 7

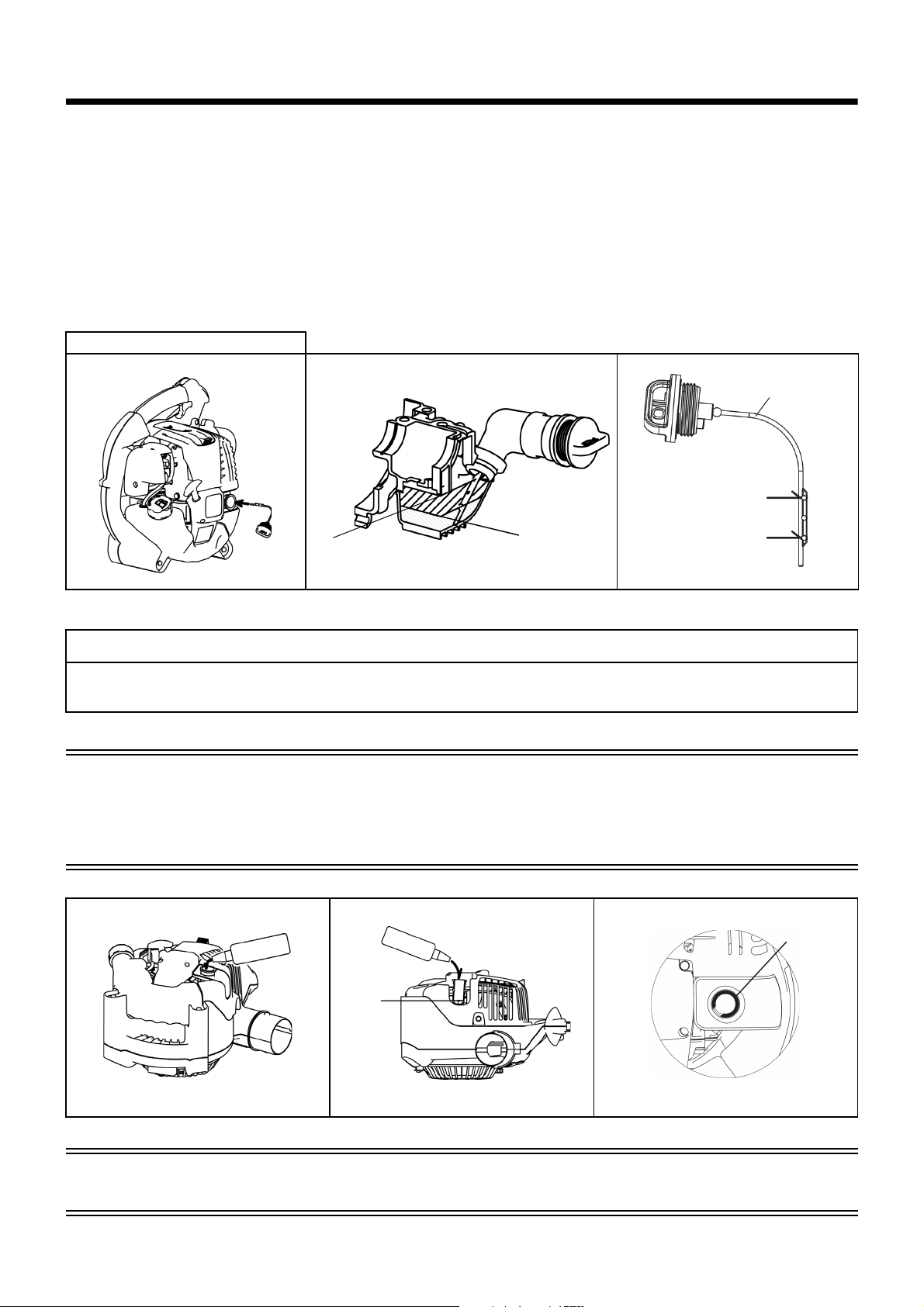

DESIGNATION OF PARTS

Optional

Vacuum set (Optional)

DESIGNATION OF PARTS DESIGNATION OF PARTS DESIGNATION OF PARTS DESIGNATION OF PARTS

1. Stop switch 8. Fuel Tank 15. Plug Cover 22. Vacuum Pipe

2. Main Handle 9. Fuel Tank Cap 16. Spark Plug 23. Arrow Mark

3. Trigger Lever 10. Muffler 17. Oil Cap 24. Dust Bag

4. Primer Pump 11. Assist Handle 18. Blower Tube

5. Air Cleaner Cover 12. Throttle lock button 19. Blower Nozzle A

6. Choke Lever 13. Screw 20. Blower Nozzle B

7. Starter Handle 14. Protector 21. Elbow

7

Page 8

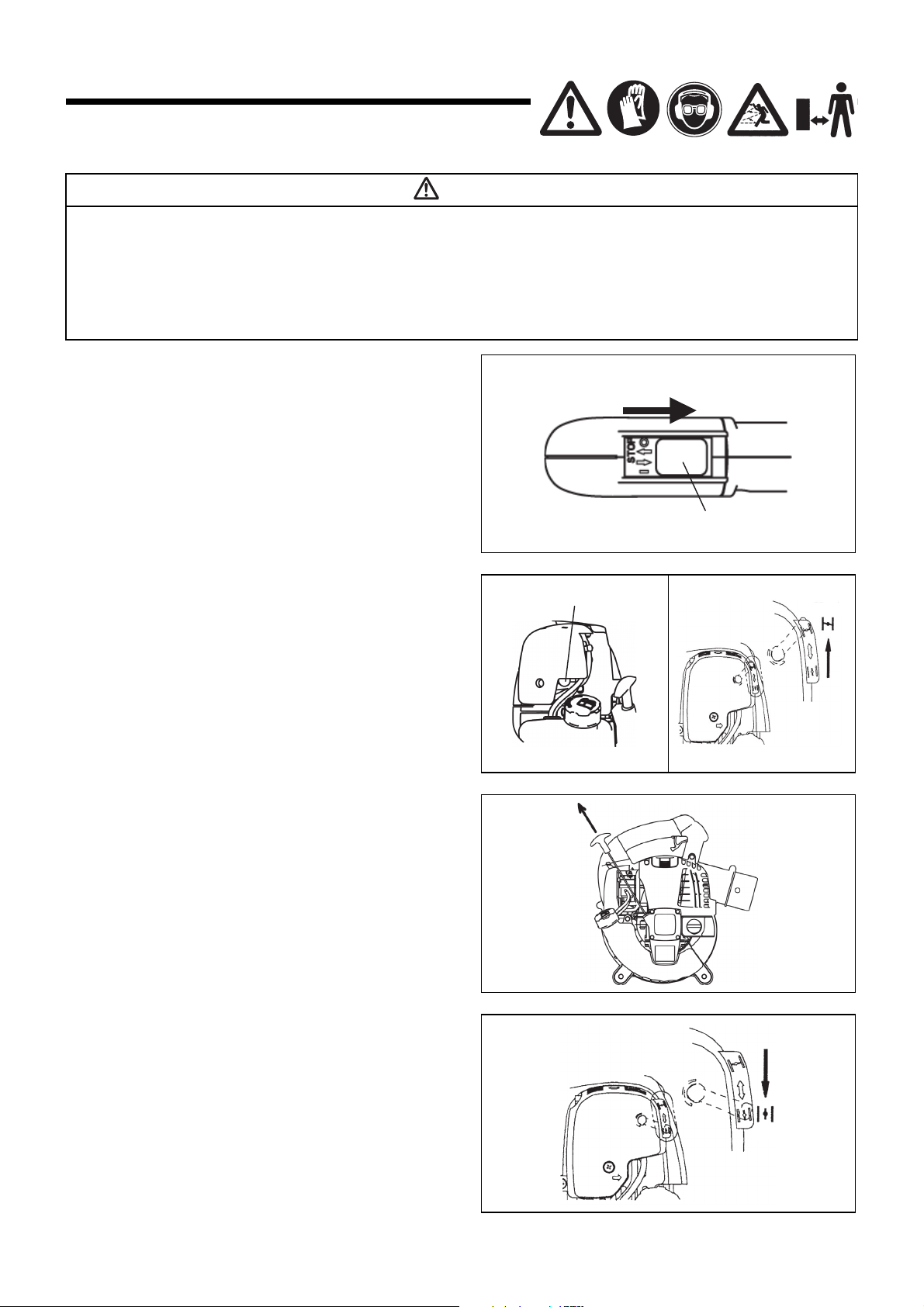

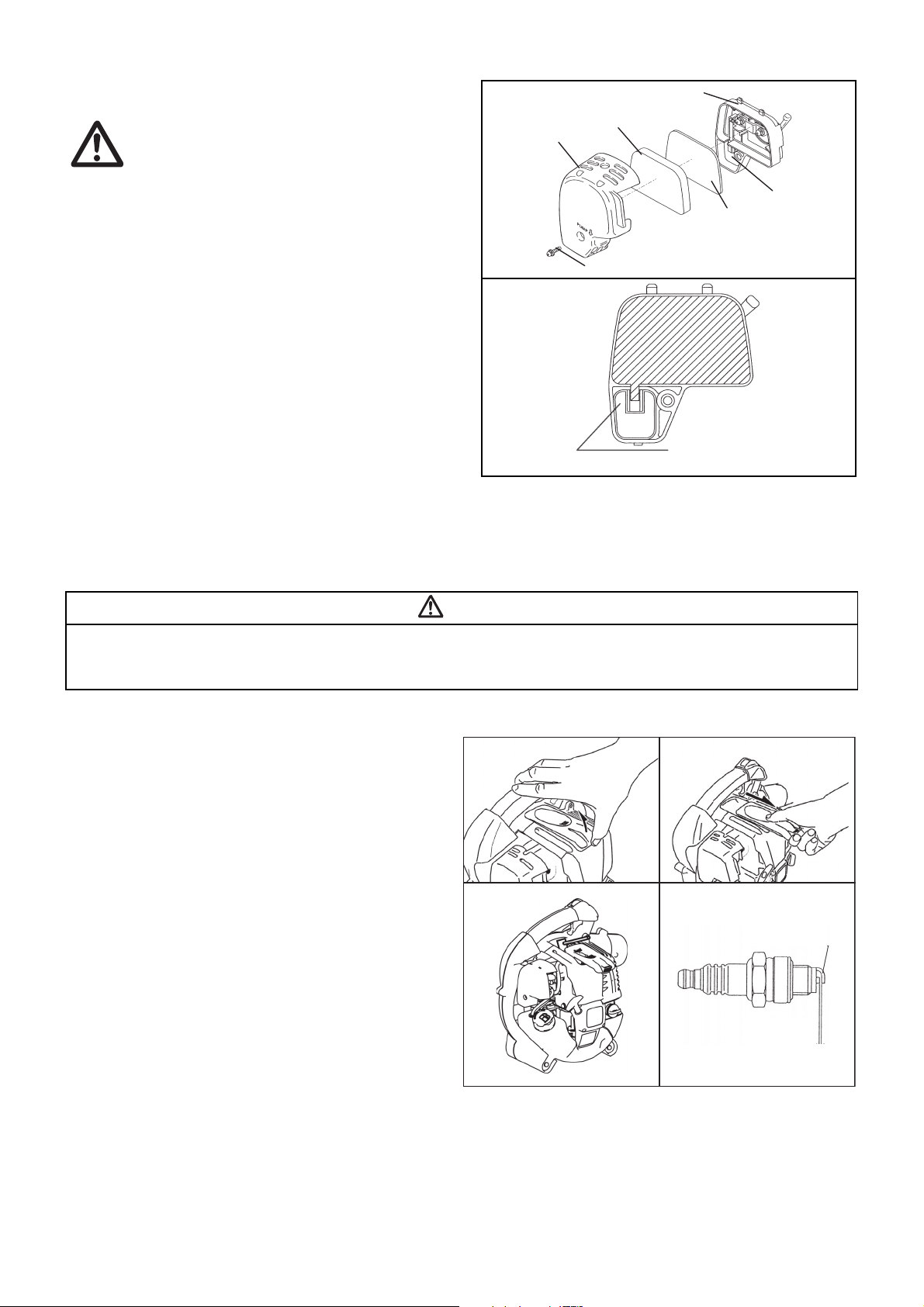

ASSEMBLY INSTRUCTIONS

CAUTION : Before performing any work on the blower, always stop

the engine and pull the spark plug connectors off the

spark plug.

Always wear protective gloves!

CAUTION : Start the blower only after having assembled it com-

pletely.

1. ASSEMBLY OF BLOWER PIPES

1) Align grooves in the blower pipe with pegs on the blower

housing and slide the pipe onto housing.

2) Turn the blower pipe clockwise to lock it into place.

3) Place clamp around the opening of the blower pipe. Fasten securely with bolt and nut .

2. ASSEMBLY OF VACUUM ATTACHMENT

1) Installing Vacuum pipe (nozzle)

(1) Loosen the screw and open the protector .

WARNING!

When using this machine as a blower, be sure to confirm

that the screw is not loosened at each time of startup. If

the screw is loosened, retighten it.

It is dangerous to operate the machine with the screw loosened.

The operator’s finger or clothing may be caught in the impeller, which will

result in a serious accident.

Caution : The engine will not start unless the protector is closed

completely.

(2) Align the indicated on the vacuum pipe with the “ ” indi-

cated on the blower. Then insert the vacuum pipe into the

blower.

(3) Turn the vacuum pipe until the is aligned with the “ ”

indicated on the blower to lock the vacuum pipe.

(4) Fasten the vacuum pipe securely to the blower with screw

and bracket .

Caution : Do not perform the fastening operation in (4) above if the

blower is to be used in a country or region where the CE mark

is not applicable.

Caution : The screw do not tighten strongly too much.

Caution : The engine will not start unless the vacuum pipe is mounted

WARNING!

Always hold the mounting end of the vacuum pipe when attaching/

detaching the vacuum pipe.

Caution : Do not perform the fastening operation in (4) above if the

Always mount the protector/vacuum pipe in the right way before operation. Operation without the protector/vacuum pipe is dangerous, the

impeller may catch the operator’s fingers or clothes and it can result in

serious injury.

Do not attempt to remove the screw (1) or disassemble the vacuum pipe.

Regulation requires safety distance of at least 900 mm between the

impeller and the top of the pipe.

completely.

2) Installing Elbow and Dust Bag

(1) Open the fastener of the dust bag.

(2) Insert the elbow into the dust bag and take it out through the

bag’s entry.

(3) Install the elbow on the blower.

(4) Place clamp around the opening of the elbow. Fasten

securely with bolt and nut .

blower is to be used in a country or region where the CE mark

is not applicable.

WARNING!

Do not attempt to pick up large wood chips, metals,

glass, stones, liquids, lighted cigarettes, fire works or

the like.

8

Page 9

BEFORE START OF OPERATION

Figure 1

Figure 2

Lower limit

Upper limit

Figure 3

Upper limit

Lower limit

Oil level indicator

Figure 4

Figure 5

Shelf

Figure 6

Shelf

1. Inspection and Refill of Engine Oil

(1) Perform the following procedure when the engine is cool.

Assure engine is on a flat horizontal surface as shown in Figure 1.

• Inspection: Remove the oil cap. Wipe clean the oil level indicator. Reinstall the oil cap (Figure 2) and remove. Confirm if the oil is

• Refill: After inspection if the oil is below the lower limit add oil through the same opening that the oil cap was removed. See

(2) You may need to refill oil approximately every 10 hours of use (every 10 refuellings).

(3) If the oil changes in color or mixes with dirt, replace the oil. (For the interval and method of replacement, refer to P. 14)

Recommended oil: SAE 10W-30 oil of API Classification, Class SF or higher (4-stroke engine for automobile)

Oil volume: Approx. 0.08 L

Inspection method of engine oil

between the lower or upper limit of the oil indicator.

Figure 4 on how to orient the engine to refill the oil.

NOTE

• If the engine is not positioned as in Figure 1 on a horizontal surface, an inaccurate indication of oil level may occur.

• If the oil is filled above the limit, oil may be contaminated or may catch fire with white smoke.

Replacement of Oil “Oil Gauge”

• Remove dust or dirt near the oil refill port, and detach the oil gauge.

• Keep the detached oil gauge free of sand or dust. Otherwise, any sand or dust adhering to the oil gauge may cause irregular oil circulation or

wear on the engine parts, which will result in troubles.

• As an example to keep the oil gauge clean, it is recommended to insert the oil gauge on its knob side into the engine cover.

After refilling oil

• Wipe with a rag any spilled oil.

9

Page 10

2. Fuel supply

WARNING

• When refuelling the unit, be sure to observe the following instructions to prevent ignition or fire:

- Fuel supply must be made in a place free of fire. Never bring the fire (smoking, etc.) near the place of fuel supply.

- Stop the engine and allow the engine to cool down before refuelling.

- Open the fuel tank cap slowly. The fuel may be spilled out under internal pressure.

- Take care not to spill the fuel. Any spilled fuel must be wiped clean.

- Carry out fuel supply in a well-ventilated place.

• Handle the fuel with care.

- Fuel sticking to the skin or entering an eye may cause allergies or irritation. When any physical abnormality is detected, consult the medical

specialist immediately.

• DO NOT put oil in the fuel tank.

STORAGE PERIOD OF FUEL

Fuel should be used within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shaded area.

If a special container is not used or if the container is not covered, fuel may deteriorate in one day.

Storage of machine and refill tank

• Keep the machine and tank at a cool place free from direct sunshine.

• Never keep the fuel in a car.

FUEL

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

Points for Fuel

• Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles.

• Use of deteriorated oil will cause irregular startup.

When refuelling, be sure to stop the engine and confirm that the engine cools down.

REFUELLING METHOD

• Loosen the tank cap a little to release the tank pressure.

• Detach the tank cap, and refuel, discharging air by tilting the fuel tank so that the refuel port will be oriented upward.

(DO NOT fill fuel up to the top of the tank.)

• After refuelling, securely tighten the tank cap.

• If there is any flaw or damage on the tank cap, replace it.

• The tank cap wears out in course of time. Replace it every two to three years.

• DO NOT put fuel in the oil fill port.

10

Page 11

Figure 1

Stop Switch

Figure 2

Close

Figure 4

Figure 5

Open

Figure 3

Primer pump

OPERATION

1. Starting

WARNING

• Never attempt engine start in a place where the fuel has been supplied.

- If may cause ignition or fire. When starting the engine, keep a distance of at least 3 m.

• Exhaust gas from the engine is toxic. Do not operate the engine in a poorly-ventilated place, such as in a tunnel, building, etc.

- Operating the engine in the poorly-ventilated place may cause poisoning by exhaust gas.

• In case of detection of any abnormality in sound, odor, vibration after start, stop the engine immediately and carry out inspection.

- If the engine is operated without attending such abnormality, an accident may occur.

• Confirm that the engine stops when the stop switch is set to “O” position.

1) When the engine is cold or after refuelling

(1) Set this machine on a flat space.

(2) Set the stop switch to “ I ” position (Figure 1).

(3) Continue to push the primer pump until fuel comes into the

primer pump (Figure 2).

• In general, fuel enters into the carburetor by 7 to 10 pushes.

• If the primer pump is pushed excessively, an excess of gasoline returns to the fuel tank.

(4) Lift the choke lever to the closed position (Figure 3).

(5) Hold the main handle with left hand to prevent the engine from

moving.

(6) Pull out slowly the starter handle till a certain resistance is felt.

Return the starter handle backward once from this position,

then pull it out with force (Figure 4).

• Never pull the rope to the full extension.

• Once the start knob is pulled, never release your hand

immediately. Hold the start knob until it returns to its original

point.

(7) When the engine starts, open the choke lever (Figure 5).

• Open the choke lever progressively while checking the

engine operation. Be sure to open the choke lever to the full

in the end.

• In cold or when the engine is cooled down, never open the

choke lever suddenly. Otherwise, the engine may stop.

(8) Continue warm-up operation for 2 to 3 minutes.

(9) Warm-up is complete when there is quick engine acceleration

from low rpm to full throttle.

11

Page 12

NOTE

Stop Switch

Adjusting screw

Carburetor

• The engine may be damaged if the choke lever is moved further beyond the “CLOSE” position.

• If the engine fires and stops, return this lever to the “OPEN” position and pull the starter handle several times to start the engine again.

• If the operator keeps pulling the starter handle several times with the choke lever left in the “CLOSE” position, the engine may be difficult to

start because of flooding of the fuel.

• In case of flooding of the fuel, remove the spark plug and pull the handle several times rapidly to discharge any excess fuel. Dry the spark

plug electrode.

• When the throttle valve does not return to a position in contact with the idling adjusting screw even if the throttle lever is set to the low speed,

correct the control cable catching state to ensure proper return of the valve.

2) When the engine is warm

(1) Place the engine on a flat ground.

(2) Press the primary pump several times.

(3) Confirm that the choke lever is open.

(4) Hold the main handle with left hand to prevent the engine from moving.

(5) Pull out slowly the starter handle till a certain resistance is felt. Return the starter handle backward once from this position, then pull it

out with force.

(6) When the engine is difficult to start, open the throttle valve by about 1/3.

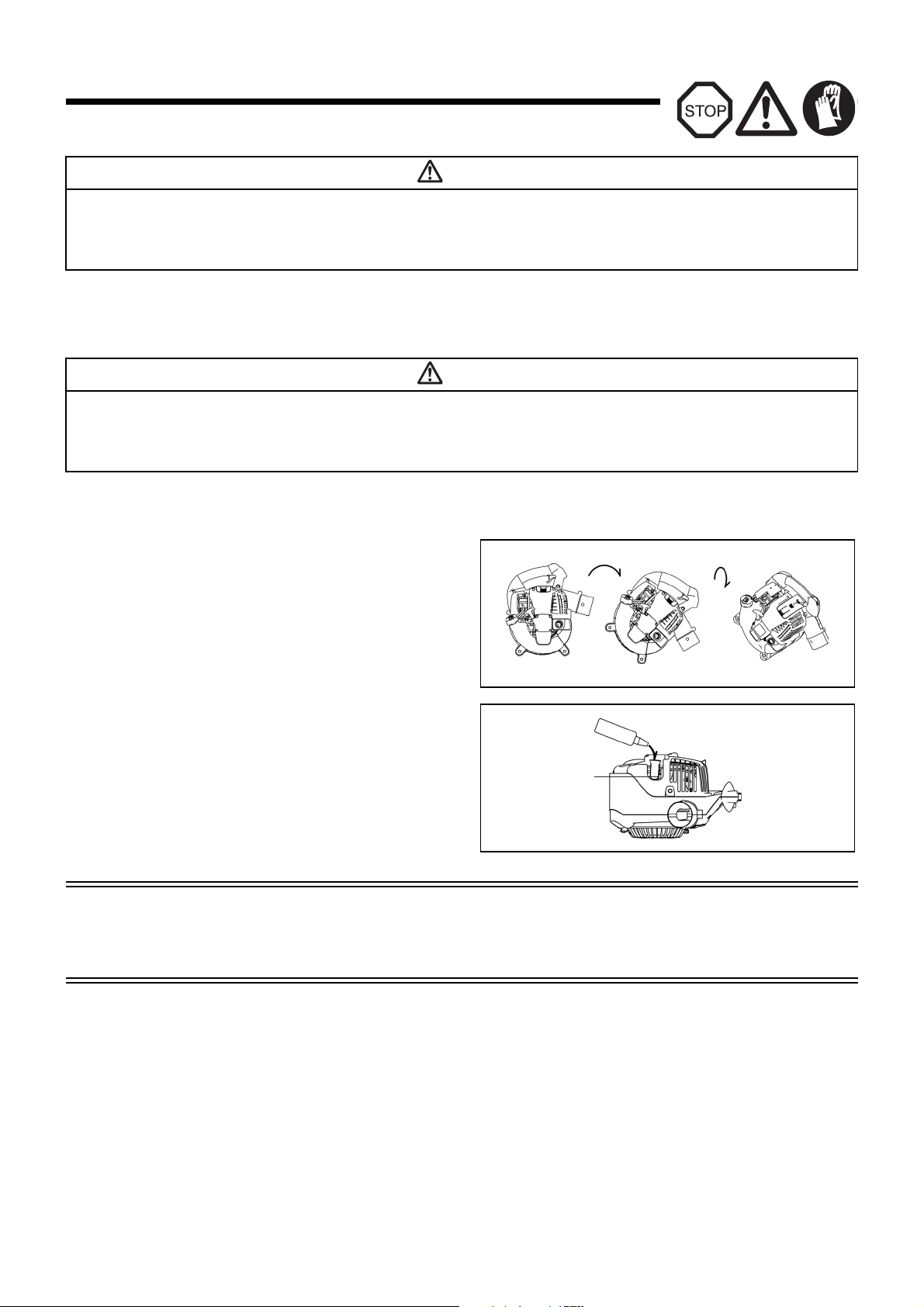

2. Stopping

Release the trigger lever to reduce the engine speed, and set the stop

switch to the “O” position.

(Release throttle lever lock if it is locking the trigger lever in the fully open

position.)

ADJUSTMENT OF IDLING

DANGER

The carburetor is factory adjusted. Please do not adjust other than idling adjusting. When adjustment becomes necessary, please consult your

dealership or an authorized service agent.

Checkup of low-speed rotation

Set the low-speed rotation to 3500 rpm (min–1).

• If it is necessary to change the rotation speed, regulate the adjusting

screw, with Phillips screwdriver.

• Turn the adjusting screw to the right, and the engine speed will

increase. Turn the adjusting screw to the left, and the engine speed will

drop.

12

Page 13

OPERATION METHOD

1. Blower operation

• Hold the machine firmly during operation.

• Direct the nozzle end toward the object to be dusted and pull the trigger lever.

• Fully pull the trigger lever, hold down the throttle lock button and

release finger from the trigger lever to lock the trigger lever at full throttle.

• Pull the trigger lever again to release the throttle lock.

• The lower portion of the fuel tank acts as an assist handle, which

enables operation with both hands. In this case, be sure to hold the

assist handle with a right hand.

2. Dust Collection Operation

WARNING

• Do not allow kerosene, gasoline, or lighted cigarette to be sucked into the machine.

- Otherwise, fire may occur.

• Do not allow foreign materials, such as large wood chips, metals, glass, pebbles, etc., to be sucked into the machine.

- Otherwise, failure may occur.

• Overfilling of the dust bag may cause its overflow toward the engine side. Empty the bag before it becomes completely full.

- Otherwise, fire may occur.

• Carry the dust bag belt on the shoulder and adjust the belt length to ensure easy operation.

• Confirm that the dust bag is not twisted and pull the trigger lever to start dust collection.

• When the dust bag is full, remove the dust bag from the machine and open the fastener to empty the

bag.

NOTE

If this machine is operated with the protector oriented upwards or the main handle downwards, white smoke may appear, oil may be contaminated or oil may leak.

13

Page 14

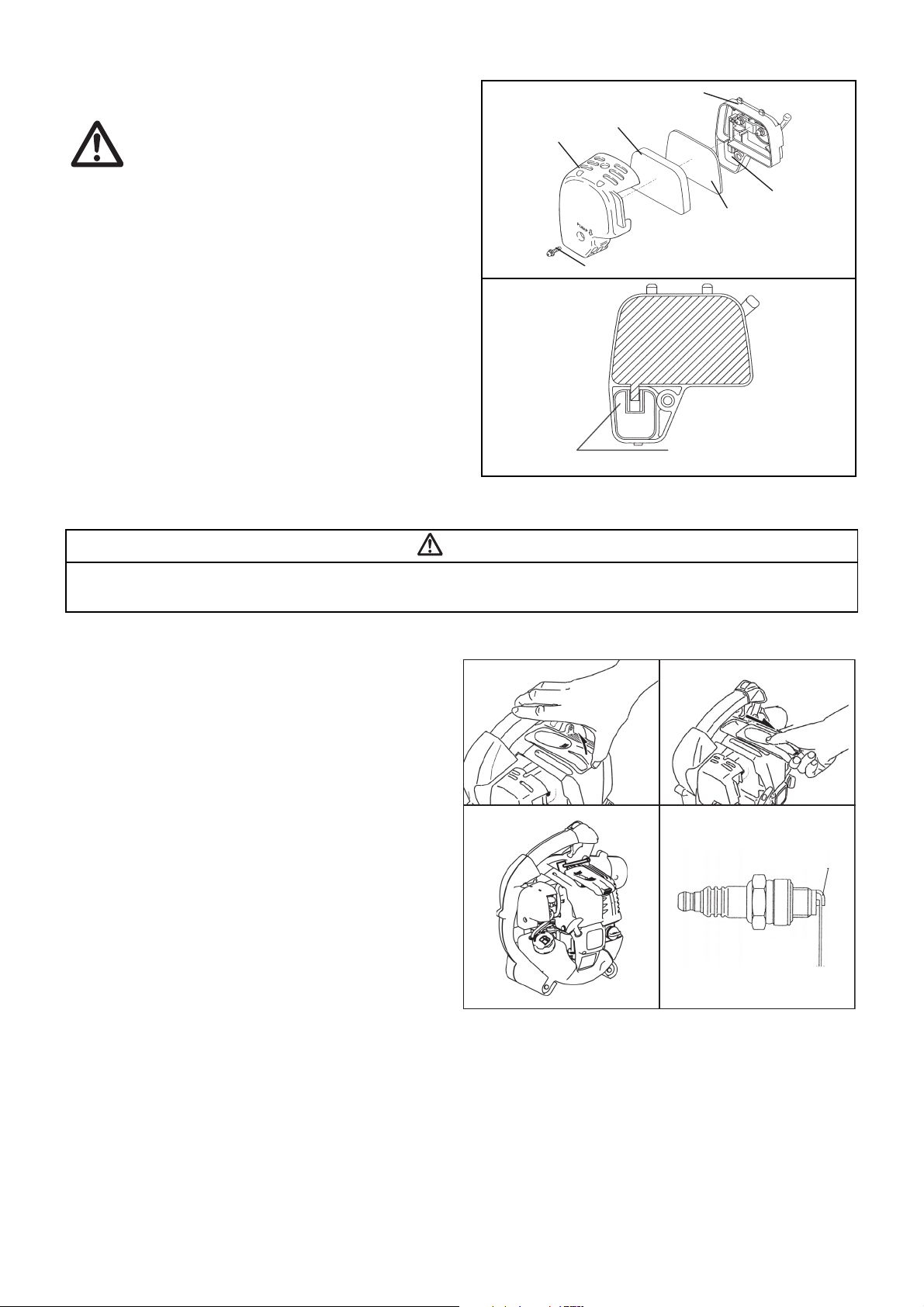

INSPECTION AND MAINTENANCE

Figure 1

Figure 2

Shelf

DANGER

• Before inspection and maintenance, stop the engine and allow it to cool. Remove the spark plug and plug cap.

- If inspection or maintenance is attempted immediately after engine stop or with the plug cap left attached, the operator may suffer burn or

an accident due to careless startup.

• After inspection and maintenance, be sure to confirm that all parts are assembled. Then, proceed to operation.

1. Replacement of engine oil

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of replacement.

DANGER

• In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil, confirm that the engine

main unit and engine oil are sufficiently cooled down. Otherwise, there may remain a risk of scald. Allow sufficient time after stopping engine

for the engine oil to return to the oil tank to ensure accurate reading of the oil level indicator.

• If the oil filled above the limit, it may be contaminated or may catch fire with white smoke.

Interval of replacement:After first 20 operating hours, followed by every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classification SF Class or higher (4-stroke engine oil for automobile)

In replacement, perform the following procedure.

(1) Confirm that the tank cap is tightened securely.

(2) Detach the oil cap.

• Keep the oil gauge free from dust or dirt.

(3) Tilt the machine in order as shown in Figure 1.

• Drain the oil in a container.

(4) Orient the machine as shown in Figure 2 and refill oil to the

shelf inside the oil pipe.

(5) After refill, securely tighten the oil gauge. Insufficient tightening

of the oil gauge will lead to oil leakage.

Points in replacement of engine oil

• Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the relevant

laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

• Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6 months).

14

Page 15

2. Cleaning of air cleaner

Plate

Element

(sponge)

Air cleaner

cover

Breather Part

Element

(felt)

Fixing bolt

Pick this part and remove the

element (felt).

Figure 1

Figure 3

Lateral electrode (–)

Figure 2

Figure 4

Electrode clearance

0.7 - 0.8 mm

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of Cleaning and Inspection: Daily (every 10 operating

hours)

(1) Remove the air cleaner cover-fixing bolts.

(2) Pull the cover lower side and detach the air cleaner cover.

(3) Turn the choke lever to the full close side, and keep the carbu-

retor off from dust or dirt.

(4) If oil adheres to the element (sponge), squeeze it firmly.

(5) For heavy contamination:

• Remove the element (sponge), immerse it in warm water or

in water-diluted mild detergent, and dry it completely.

• Clean the element (felt) with gasoline, and dry it completely.

(6) Before attaching the element, be sure to dry it completely.

Insufficient drying of the element may lead to difficult startup.

(7) Wipe out with waste cloth, oil adhering around the air cleaner

cover and plate breather.

(8) Immediately after cleaning is finished, attach the air cleaner

cover and tighten it with fixing bolts. (In remounting, first place

the upper claw, and then the lower claw.)

DANGER

• Clean the element several times a day, if excessive dust adheres to it.

• If operation continues with the element remaining not cleared of oil, oil in the air cleaner may fall outside, resulting in oil contamination.

3. Checking the spark plug

(1) Opening/closing the plug cover

When opening the cover, apply fingers to the main handle

and plug cover projection (Figure 1). Push up the projection

and slide the cover in the “OPEN” direction (Figure 2).

When closing the cover, slide the cover in the “CLOSE”

direction till the click under the plug cover projection rides

over the engine cover. Finally, push in the projection.

(2) Removing the spark plug

Use an attached box wrench to remove or install the spark

plug (Figure 3).

(3) Checking the spark plug

The clearance between two electrodes of spark plug is 0.7

to 0.8 mm (Figure 4). Adjust to the correct clearance when it

is too wide or too narrow.

Clean thoroughly or replace the spark plug if it has accumulated carbon or contaminated.

(4) Replacing the spark plug

For replacement, use NGK-CMR6A.

15

Page 16

4. Cleaning the fuel filter

Hose clamp

Fuel filter

Fuel tank cap

• Clogged fuel filter may cause difficulty of startup or failure of engine

speed increase.

• Check the fuel filter regularly as follows:

(1) Remove the fuel tank cap, drain the fuel to empty the tank.

Check the tank inside for any foreign materials. If any, wipe

clean such materials.

(2) Pull out the fuel filter with wire through the oil filling port.

(3) If the fuel filter surface is contaminated, clean it with gasoline.

The gasoline used for the cleaning must be disposed of

according to the method specified by each local authority.

Excessively contaminated filter must be replaced.

(4) Reset the fuel filter in the fuel tank and tighten firmly the fuel

tank cap. For replacement, contact your dealership or an

authorized service agent.

5. Inspection of bolts, nuts and screws

• Retighten loose bolts, nuts, etc.

• Check for fuel and oil leakage.

• Replace damaged parts with new ones for safety operation.

6. Cleaning of parts

• Keep engine clean by wiping down with a cloth rag.

• Keep the cylinder fins free of dust or dirt. Dust or dirt adhering to the fins will cause seizure.

7. Replacement of gaskets and packings

Replace gaskets and packings if the engine is disassembled.

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Agents.

STORAGE

WARNING

• When draining the fuel, be sure to stop the engine and confirm that the engine cools down.

- Failure to do so may cause burns or fire.

DANGER

• When you store the machine for a long time, drain all fuel from the fuel tank and carburetor, and keep it at a dry and clean place.

Drain fuel from the fuel tank and carburetor according to the following

procedure:

(1) Remove the fuel tank cap, and drain fuel completely.

If there is any foreign matter remaining in the fuel tank, remove

it completely.

(2) Pull out the fuel filter from the refill port using a wire.

(3) Push the primer pump until fuel is drained from there, and

drain fuel coming into the fuel tank.

(4) Reset the filter to the fuel tank, and securely tighten the fuel

tank cap.

(5) Then, continue to operate the engine until it stops.

(6) Remove the spark plug, and drip several drops of engine oil

through the spark plug hole.

(7) Gently pull the starter handle so that engine oil will spread over

the engine, and attach the spark plug.

(8) Keep the machine with its handle upside.

(9) Keep the drained fuel in a special container in a well-ventilated

shade.

16

Page 17

Fault location

Fault System Observation Cause

Engine not starting or

with difficulty

Warm start problems Tank filled ignition spark

Engine starts but dies Fuel supply Tank filled Incorrect idling adjustment, carburetor contaminated

Insufficient performance Several systems may

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark STOP-switch operated, wiring fault or short circuit, spark plug

or connector defective, ignition module faulty

Fuel supply Fuel tank filled Incorrect choke position, carburetor defective, fuel supply line

bent or blocked, fuel dirty.

Compression No compression when

pulled over

Cylinder bottom gasket defective, crankshaft seals damaged,

cylinder or piston rings defective or improper sealing of spark

plug

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

Carburetor contaminated, have it cleaned

existing

Fuel tank vent defective, fuel supply line interrupted, cable or

STOP-switch faulty

Engine idling poor Air filter contaminated, carburetor contaminated, muffler

simultaneously be

clogged, exhaust duct in the cylinder clogged

affected

Operating time

Item

Engine oil

Tightening parts (bolt, nut) Inspect 16

Fuel tank

Throttle lever Check function –

Stop switch Check function 12

Low-speed rotation Inspect/adjust 12

Air cleaner Clean 15

Ignition plug Inspect 15

Cooling air duct Clean/inspect 16

Fuel pipe

Fuel filter Clean/replace 16

Clearance between air intake

valve and air discharge valve

Oil tube Inspect *

Engine overhaul *

Carburetor Drain fuel *

Inspect/clean 9

Replace *

Clean/inspect –

Drain fuel *

Inspect 16

Replace *

Adjust *

Before

operation

After

lubrication

Daily (10h) 30h 50h 200h

1

2

2

2

2

Shutdown/

rest

3

3

Corresponding

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request Authorized Service Agent or a machine shop.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

Page

14

16

–

–

–

–

16

17

Page 18

TROUBLESHOOTING

Run engine at idling, and set choke lever to

CLOSE.

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description of

this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump Push 7 to 10 times.

Low pulling speed of starter rope Pull strongly.

Lack of fuel Feed fuel.

Clogged fuel filter Clean

Broken fuel tube Straighten fuel tube

Deteriorated fuel makes starting more difficult.

Deteriorated fuel

Engine does not start

Engine stops soon

Engine speed does not increase

Engine does not stop. Detached connector Attach securely

Excessive suction of fuel

Detached plug cap Attach securely

Contaminated spark plug Clean

Abnormal clearance of spark plug Adjust clearance

Other abnormality of spark plug Replace

Abnormal carburetor Make request for inspection and maintenance.

Starter rope cannot be pulled Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Insufficient warm-up Perform warm-up operation

Choke lever is set to “CLOSE” although engine

is warmed up

Clogged fuel filter Clean

Contaminated or clogged air cleaner Clean

Abnormal carburetor Make request for inspection and maintenance.

Abnormal drive system Make request for inspection and maintenance.

Detached throttle wire Attach securely

Abnormal drive system Make request for inspection and maintenance.

Abnormal electric system Make request for inspection and maintenance.

Replace with new one. (Recommended

replacement: 1 month)

Set throttle lever from medium speed to high

speed, and pull starter handle until engine

starts. If engine will not start still, remove

spark plug, make electrode dry, and

reassemble them as they originally are. Then,

start as specified.

Set to “OPEN”

When the engine does not start after warm-up operation:

If there is no abnormality found for the check items, open the throttle by about 1/3 and start the engine.

18

Page 19

Nederlands

Hartelijk dank voor uw aankoop van deze DOLMAR-bladblazer. Wij zijn

ervan verzekerd dat deze u zal bevallen, daar deze het resultaat is van

jarenlange research en onze know-how en ervaring.

De DOLMAR PB-252.4 kombineert de voordelen van de huidige stand

dertechniek met ergonomisch design; zij zijn licht in gewicht, handig,

compacte en staan voor professionele inzet van tal van verschillende

gebruiksvormen.

Lees, begrijp en volg de in deze gebruiksaanwijzing omschreven

punten om zodoende volledig gebruik te maken van de mogelijkheden

die deze machine u biedt. Dit biedt u de garantie zo goed en veilig

mogelijk te werken met de DOLMAR-bladblazer.

Inhoudstabel

SYMBOLEN ....................................................................................... 70

VEILIGHEIDSVOORSCHRIFTEN ..................................................... 71

EU-VERKLARING VAN CONFORMITEIT......................................... 74

TECHNISCHE GEGEVENS .............................................................. 74

BENAMING VAN ONDERDELEN...................................................... 75

OPBOUWINSTRUCTIES................................................................... 76

VOOR GEBRUIK................................................................................ 77

BEDIENING ....................................................................................... 79

AFSTELLINGEN ................................................................................ 80

BEDIENINGSMETHODE................................................................... 81

INSPECTIE EN ONDERHOUD ......................................................... 82

MACHINE-OPSLAG........................................................................... 84

OPLOSSEN VAN PROBLEMEN........................................................ 86

SYMBOLEN

Het is erg belangrijk de volgende symbolen te herkennen en begrijpen wanneer u deze gebruiksaanwijzing doorleest.

Pagina

WAARSCHUWING/GEVAAR Brandstof (Benzine)

Lees, begrijp en volg gebruiksaanwijzing Handstart motor

Verboden Noodstop

Niet roken Eerste Hulp

Geen open vuur Recycling

Beschermende handschoenen dragen AAN/START

Houd werkomgeving vrij

van personen en dieren

Draag oog- en oorprotectie

Houd omstanders uit de buurt CE-merk

UIT/STOP

Gevaar verlies vinger/hand,

impeller

70

Page 20

VEILIGHEIDSVOORSCHRIFTEN

(1)

(2)

(3)

(4)

(5)

15 meter

Algemene instructies

• Om verzekerd te zijn van een correcte en veilige bediening moet de

gebruiker de gebruiksaanwijzing lezen, begrijpen en opvolgen om

vertrouwd te raken met de blazer (1). Niet volledig geïnstrueerde

gebruikers riskeren ongelukken voor zichzelf en voor anderen door niet

correct gebruik.

• Het is aan te bevelen de machine enkel uit te lenen aan mensen die

vertrouwd zijn met de werking hiervan.

• Reik altijd de gebruiksaanwijzing over.

• Onervaren gebruikers moeten zich door de dealer op de hoogte laten

stellen van het correcte gebruik van de blazer.

• Kinderen en personen onder de 18 jaar mogen niet werken met de

machine. Personen boven de 16 jaar mogen enkel onder begeleiding

van deskundigen met de machine werken.

• Gebruik de blazer met de meeste zorg en waakzaamheid.

• Gebruik de blazer enkel wanneer u in een goede, lichamelijke conditie

verkeerd.

• Werk met de grootste waakzaamheid. De gebruiker is verantwoordelijk

voor derden.

• Gebruik de blazer nooit indien de gebruiker onder invloed van alcohol

of medicijnen is (2).

• Werk niet met de machine indien u zich moe voelt.

• Bewaar deze instructies voor later naslagwerk.

Persoonlijke beschermingsmiddelen

• De te dragen kleding moet functioneel zijn en afdoende bescherming

bieden. De kleding mag de werkzaamheden niet hinderen. Draag nooit

kettingen, loszittende kledingstukken of lang haar wat door de

aanzuigtrechter kan worden ingezogen.

• Om hoofd-, oog-, of voetverwondingen te voorkomen evenals uw

gehoor te beschermen moet u tijdens de werkzaamhen de volgende

beschermende maatregelen nemen:

Geef de volgende voorschriften extra aandacht:

• Kleding moet nauwaansluitend en afgekleed zitten, maar moet

voldoende bewegingsruimte bieden. Draag geen loszittende jassen,

broeken met brede pijpen of omgeslagen zomen, sjaal, loshangend

lang haar of iets anders dat in de luchtinlaat kan worden gezogen.

Draag beschermende lange broeken, geen korte broeken. (4)

• Het uitlaatgeluid kan uw gehoor beschadigen. Draag oorbescherming

zoals oorproppen of gehoorbeschermers. Regelmatige gebruikers

moeten hun gehoor regelmatig laten testen. (3)

• Het gebruik van handschoenen is aangeraden. Goed schoeisel is erg

belangrijk. Draag beschermende schoenen met anti-slipzolen. (4)

• Deugdlijke oogbescherming is een must. Alhoewel de luchtstroom van

u af gericht is, kunnen steentjes of takjes terug kaatsen tijdens de

werkzaamheden. (3)

• Nooit een blazer gebruiken zonder een veiligheidsbril of een goed

passende, beschermende bril te dragen met afdoende bescherming

aan de boven- en zijkanten, die voldoet aan ANSI Z 87.1 (of de van

toepassing zijnde nationale norm).

Het starten van de blazer

• Verzeker u ervan dat er geen kinderen of andere personen zich

bevinden binnen een straal van 15 meter (5), let ook op eventuele

aanwezigheid van dieren. Gebruik de blazer niet in druk bevolkte

gebieden.

• Controleer voor gebruik altijd of de blazer veilig is om te gebruiken:

Controleer de juiste werking van de gashendel. De gashendel moet

worden gecontroleerd op soepele werking en gemakkelijke bediening.

Controleer de juiste werking van de gashendelvergrendeling.

Controleer of de handgrepen schoon en droog zijn en test de werking

van de stopschakelaar. Voorkom dat olie of brandstof op de

handgrepen komt.

360°

71

Page 21

Start de blazer enkel volgens de instructies.

(6)

(7)

(8)

(9)

3 meter

• Pauze

• Transport

• Bijtanken

• Onderhoud

• Delen Vervangen

Probeer de machine niet op een andere manier te starten (6) !

• Gebruik de blazer en de toebehoren enkel waarvoor zij bedoeld zijn.

• Start de motor alleen nadat de machine op de juiste wijze is

gemonteerd. Het gereedschap mag uitsluitend worden gebruikt nadat

alle toepasselijke toebehoren zijn gemonteerd.

• De motor moet direct worden uitgeschakeld, indien zich hier

problemen mee voor doen.

• Wanneer u met de machine werkt, sla uw vingers altijd losjes om de

handgreep zodat u volledige controle heeft over de gashendel en de

aan/uitschakelaar. Houd uw hand op deze plaats om de machine te

allen tijde onder controle te houden. Zorg ervoor dat uw

bedieningshendel (en de handgreep voor het vacuümhulpstuk) zich in

goede staat bevinden en er geen vocht, vuil, olie of vet op zit.

Verzeker u er altijd van dat u veilig en in evenwicht kunt staan.

• Werk zo met de machine dat u voorkomt dat u uitlaatgassen inademt.

Werk nooit met de machine in afgesloten ruimten (gevaar van

vergiftiging). Koolmonoxyde is een geur- en kleurloos gas. Zorg altijd

voor voldoende ventilatie.

• Schakel de motor altijd uit tijdens werkpauzes of wanneer de blazer

even niet gebruikt wordt. Berg deze zonodig veilig op voor gevaar voor

derden, brandgevaar door licht ontvlambaar materiaal of beschadiging

van de machine.

• Zet de machine nooit neer in droog gras of andere licht-ontvlambare

materialen.

• Alle benodigde beschermingsmiddelen moeten worden gebruikt

tijdens de werkzaamheden.

• Werk nooit met een dichtgekoolde (vervuilde) uitlaat.

• Schakel de motor uit bij transport (7).

• Plaats de machine veilig tijdens transporteren om brandstof-lekkage te

voorkomen.

• Overtuig u ervan dat bij transporteren van de blazer de tank geledigd

is.

Bijtanken

• Schakel de motor uit bij tanken (7), houd de machine weg bij open vuur

en rook beslist niet.

• Voorkom huidcontact met benzine. Inhaleer geen benzinedampen.

Draag altijd beschermende handschoenen bij het tanken. Wissel en

reinig regelmatig beschermende kleding.

• Voorkom het spillen van benzine en olie uit veiligheids- en milieu

overwegingen. Veeg gemorste benzine direct af en reinig de machine.

Laat natte doeken eerst drogen voordat u ze weggooit in een geschikte

en gesloten container om te voorkomen dat ze spontaan ontbranden.

• Voorkom ieder contact van benzine op uw kleding. Trek direct kleding

uit indien deze in contact is geweest met de brandstof om brandgevaar

en huidcontact te voorkomen.

• Controleer met regelmaat de benzinetankdop op lekkage en of deze

goed afdicht.

• Draai de benzinetankdop altijd goed aan en start de machine op een

andere plaats (min. 3 meter verder) dan waar u heeft bijgetankt (9).

• Tank nooit bij in afgesloten ruimten. Benzinedampen vormen zeer

brandbare gassen op grondniveau (gevaar voor explosies).

• Transporteer en sla de benzine enkel op in goedgekeurde cans.

Verzeker u dat de benzine volgens voorschriften is opgeslagen en

geen toegang heeft voor derden.

• Tank nooit een hete of nog draaiende motor bij.

72

Page 22

Bedieningsinstructie

(10)

(11)

(12)

• Gebruik de blazer enkel bij goed zicht en goede belichting. Tijdens de

koude seizoenen, let op een natte en gladde ondergrond met ijs en

sneeuw (gevaar tot uitglijden).

Sta altijd stabiel.

• Werk nooit op instabiele plaatsen of een steile ondergrond.

• Om de kans op persoonlijk letsel te verkleinen, mag u geen

luchtstroom richten op omstanders aangezien de hoge druk van de

luchtstroom oogletsel kan veroorzaken en kleine voorwerpen met een

hoge snelheid kan wegwerpen.

• Steek nooit een vreemd voorwerp in de luchtinlaat van de machine of

in het mondstuk van de luchtblazer. Hierdoor zal de ventilator worden

beschadigd, en kan ernstig letsel worden veroorzaakt bij de gebruiker

en omstanders doordat het voorwerp of kapotte onderdelen op hoge

snelheid uit de machine worden geworpen.

• Let op de windrichting; werk niet tegen de windrichting in.

• Om het gevaar van struikelen en vallen te voorkomen, werk nooit

lopend in achterwaartse richting.

• Schakel de motor altijd uit indien u de machine onderhoudt of reinigt of

indien u onderdelen vervangt.

Onderhoudsinstructies

• Wees milieubewust. Werk met zo min mogelijk lawaai en belasting van

het milieu als mogelijk. Controleer de afstelling van de carburateur.

• Reinig de blazer met regelmaat en controleer alle bouten, moeren en

schroeven op hun bevestiging.

• Onderhoud of plaats de blazer nooit in nabijheid van open vuur,

vonken, etc. (11).

• Sla de blazer altijd op met een lege tank in een goed geventileerde

ruimte.

Houd u zich aan en volg alle relevante veiligheidsinstructies, uitgegeven

door overheidsinstellingen en verzekeraars. Voer geen enkele

wijzigingen uit aan uw blazer, omdat dit uw veiligheid in gevaar brengt.

Het uitvoeren van onderhoud of reparaties door de gebruiker is beperkt

tot de in deze gebruiksaanwijzing omschreven punten. Alle andere

werkzaamheden dienen door de erkende vakman/dealer uitgevoerd te

worden.

Gebruik enkel originele DOLMAR-onderdelen.

Gebruik van niet originele onderdelen of toebehoren verhoogt de kans

op verwondingen en ongelukken. DOLMAR accepteert geen enkele

claim die voortvloeit uit het gebruik van niet-originele onderdelen of

toebehoren.

Eerste Hulp

In geval van ongelukken dient een goed gevulde Eerste hulp-koffer

volgens DIN 13164 aanwezig te zijn. Vul direct na gebruik van de inhoud

de koffer weer volledig aan.

Wanneer u hulp inroept, geef altijd de volgende informatie:

• Plaats van ongeluk

• Wat er gebeurt is

• Aantal verwonde mensen

• Aard van verwondingen

• Uw naam

Verpakking

De DOLMAR-blazer wordt geleverd in een beschermende kartonnen

doos. Karton is geschikt voor hergebruik en geschikt voor recycling.

73

Page 23

Alleen voor Europese landen

EU-verklaring van conformiteit

Ondergetekenden, Tamiro Kishima en Rainer Bergfeld, als

erkende vertegenwoordigers van Dolmar GmbH, verklaren

dat de DOLMAR-machine(s):

Aanduiding van de machine:

Benzine bladblazer

Modelnr./Type: PB-252.4

TECHNISCHE GEGEVENS: zie de tabel “TECHNISCHE

GEGEVENS”.

in serie zijn geproduceerd en

Voldoen aan de volgende Europese richtlijnen:

2000/14/EC, 2006/42/EC

En zijn gefabriceerd in overeenstemming met de volgende

normen of genormaliseerde documenten:

EN15503

De technische documentatie wordt bewaard door:

Dolmar GmbH,

Jenfelder Straße 38, Abteilung FZ,

D-22045 Hamburg

De conformiteitsbeoordelingsprocedure vereist door Richtlijn

2000/14/EC was in Overeenstemming met annex V.

Gemeten geluidsvermogenniveau: 102 dB

Gegarandeerd geluidsvermogenniveau: 106 dB

14. 6. 2010

Tam i ro K i sh i ma

Hoofddirecteur

Rainer Bergfeld

Hoofddirecteur

TECHNISCHE GEGEVENS

Model PB-252.4

Droog gewicht (zonder pijpen) (kg) 4,5

Afmetingen (zonder pijpen) (totaal l x b x h) (mm) 350 × 231 × 368

Max. toerental (min

Stationair toerental (min

Cilinderverplaatsing (mL) 24,5

Brandstof Autobenzine

Inhoud brandstoftank (L) 0,52

Motorolie

Olievolume van de motor (L) 0,08

Carbureteur (Membraan-type) WALBRO WYL

Ontsteking Transistorontsteking

Bougie NGK CMR6A

Elektrode-afstand (mm) 0,7 – 0,8

a

Trillingen volgens EN15503

Gem. Geluidsdruk volgens EN15503

Gem. Geluidsniveau volgens EN15503

hv eq

Onzekerheid K (m/s

L

PA eq

Onzekerheid K dB(A) 1,4

L

WA eq

Onzekerheid K dB(A) 1,4

Opmerkingen:

1. Gebruik uitsluitend de door DOLMAR gespecificeerde olie en bougie.

2. Deze technische gegevens kunnen zonder kennisgeving vooraf gewijzigd worden.

-1

) 7.800

-1

) 3.500

SAE10W-30 olie van API Classificatie SF Klasse of hoger

(4-takt olie voor auto’s)

(m/s2)9,3

2

)0,5

dB(A) 90,8

dB(A) 103,7

74

Page 24

BENAMING VAN ONDERDELEN

Los verkrijgbaar

Stofkit (Los verkrijgbaar)

BENAMING VAN ONDERDELEN BENAMING VAN ONDERDELEN BENAMING VAN ONDERDELEN BENAMING VAN ONDERDELEN

1. Stopschakelaar 8. Benzinetank 15. Bougiekap 22. Zuigmond

2. Hoofdgreep 9. Benzinetankdop 16. Bougie 23. Pijlteken

3. Trekker 10. Uitlaat 17. Oliedop 24. Stofzak

4. Opvoerpomp 11. Hulpgreep 18. Blaaspijp

5. Afdekking luchtfilter 12. Throttle vergrendelknop 19. Blaasmond A

6. Chokehendel 13. Schroef 20. Blaasmond B

7. Trekstarter 14. Beschermrooster 21. Elleboog

75

Page 25

OPBOUWINSTRUCTIES

LET OP: Altijd voordat u werkzaamheden aan de blazer uitvoert,

de motor uitschakelen en de bougiedop lostrekken.

LET OP: Start de blazer enkel wanneer deze volledig is

1. Bevestiging van de pijpen

1) Lijn de groeven van de blazerpijpen uit met de nokken op het

2) Draai nu de pijp met de richting van de klok mee en schroef

3) Plaats de klem rond de opening van de pijp van de blazer.

2. Bevestiging van de zuigtoebehoren.

1) Monteer opzuigpijp (nozzle)

Het is gevaarlijk de machine te gebruiken terwijl schroef los zit.

Degene die met de machine werkt zou zo met een vinger of met zijn of

haar kleding de impeller kunnen raken, hetgeen zal leiden tot ernstige

ongevallen.

Let op: De motor zal niet starten als de beschermkap niet volledig

Let op: Voer de handelingen voor het bevestigen zoals beschreven

Let op: Draai schroef niet te strak aan.

Let op: De motor zal niet starten als de vacuümbuis niet volledig

WAARSCHUWING!

Houd altijd het bevestigingseind van de opzuigpijp vast wanneer u deze

monteert of demonteert.

2) Bevestiging van elleboog en opvangzak.

Let op: Voer de handelingen voor het bevestigen zoals beschreven

Monteer het beschermrooster en/of de vacuümpijp op de juiste wijze

vóór gebruik. Het gebruik zonder het beschermrooster en/of de

vacuümpijp is gevaarlijk. De ventilator kan de vingers of kleding van de

gebruiker raken, waardoor ernstig letsel kan worden veroorzaakt.

Verwijder niet de schroef (1) en demonteer niet de opzuigpijp.

Veiligheidsnormen vereisen een minimale afstand van 900 mm tussen

de ventilator en het einde van de pijp.

Draag altijd beschermende handschoenen.

opgebouwd.

ventilatorhuis en plaats deze over elkaar.

deze aan elkaar.

Zet goed vast met bout en moer .

(1) Draai schroef los en open het beschermrooster .

WAARSCHUWING!

Wanneer u deze machine als blazer gebruikt, moet u elke

keer voor de machine gestart wordt controleren of de

schroef niet los zit. Als de schroef los zit, moet u deze

weer vast draaien.

gesloten is.

(2) Lijn de afgetekend op de opzuigpijp uit met het “ ”

teken op de blazer. Plaats nu de opzuigpijp in de opening van

de blazer.

(3) Draai de opzuigpijp totdat de is uitgelijnd met het “ ”

teken op de blazer, zodat deze vastgedraaid zit.

(4) Zet de opzuigpijp goed vast aan de blazer met schroef en

beugel .

onder (4) hierboven niet uit als de blazer wordt gebruikt in een

land of gebied waar het CE keurmerk niet van toepassing is.

gemonteerd is.

(1) Open de sluiting van de opvangzak.

(2) Voer de elleboog door de opvangzak en leid deze door de

opening. Zet de elleboog vast met het klittenband.

(3) Bevestig de elleboog op de blazer.

(4) Plaats klem rond de opening van de elleboog. Zet goed

vast met bout en moer .

onder (4) hierboven niet uit als de blazer wordt gebruikt in een

land of gebied waar het CE keurmerk niet van toepassing is.

WAARSCHUWING!

Zuig geen grote stukken hout, metalen, glas, stenen,

vloeistoffen, brandende sigaretten of andere brandende

voorwerpen op.

76

Page 26

VOOR GEBRUIK

Afbeelding 1

Afbeelding 2

Onderste oliepeil

Maximum oliepeil

Afbeelding 3

Maximum oliepeil

Onderste oliepeil

Oliepeilstok

Afbeelding 4

Afbeelding 5

Plank

Afbeelding 6

Plank

1. Inspectie en bijvullen van motorolie

(1) Volg de onderstaande procedure wanneer de motor koud is.

Zorg ervoor dat de motor op een vlakke, horizontale ondergrond staat, zoals aangegeven in afbeelding 1.

• Inspectie: Verwijder de oliedop. Veeg de oliepeilstok af. Plaats de oliedop terug (afbeelding 2) en verwijder hem weer. Controleer

• Bijvullen: Als na inspectie blijkt dat het oliepeil onder het onderste merkteken staat, vult u olie bij via dezelfde opening waaruit de

(2) Het kan nodig zijn olie bij te vullen na iedere 10 bedrijfsuren (na iedere 10 keer brandstof bijvullen).

(3) Als de olie van kleur verandert of met vuil is vermengd, ververst u de olie. (Raadpleeg pagina 82 voor informatie over het

verversingsinterval en de verversingsprocedure.)

Aanbevolen olie: SAE10W-30 olie van API Classificatie SF Klasse of hoger (4-takt olie voor auto’s)

Hoeveelheid olie: Ongeveer 0,08 L

of het oliepeil tussen de onderste en bovenste merktekens staat.

oliedop werd gedraaid. Zie afbeelding 4 voor hoe de motor moet worden gehouden om olie bij te vullen.

De methode van de inspectie van

motorolie

OPMERKING

• Als de motor niet in de stand wordt gehouden zoals aangegeven in Afbeelding 1 op een horizontale ondergrond, kan het oliepeil

onnauwkeurig worden aangegeven.

• Als er teveel olie in het carter gedaan is, kan de olie verontreinigd raken, of verbranden met een witte rook als resultaat.

Olie verversen, “oliepeilstok”

• Verwijder stof en vuil rond de olievul-opening en draai de oliepeilstok los.

• Houd de losgemaakte oliepeilstok vrij van zand en stof. Doet u dat niet, dan kan vuil dat aan de oliepeilstok blijft kleven de circulatie van de

olie door de motor belemmeren of het binnenwerk beschadigen, wat kan leiden tot problemen.

• Een manier om de oliepeilstok schoon te houden is om de draaiknop van de oliepeilstok in de motorafdekking te steken.

Na het bijvullen van olie

• Veeg gemorste olie af met een poetsdoek.

77

Page 27

2. Brandstofvoorziening

WAARSCHUWING

• Let bij het bijvullen van brandstof op de volgende punten om te voorkomen dat brand uitbreekt:

- Werk met brandstof en tank op een plek waar geen vuur of hittebron in de buurt is. Breng in geen geval vuur of hittebronnen (door te roken

bijvoorbeeld) in de buurt van de brandstof.

- Zet de motor uit en laat de motor afkoelen voordat u brandstof bijvult.

- Draai de brandstofvuldop langzaam los. De brandstof kan eruit komen als gevolg van inwendige druk.

- Wees voorzichtig dat u geen brandstof morst. Veeg eventueel gemorste brandstof onmiddellijk weg.

- Tank alleen op een goed geventileerde plek.

• Ga voorzichtig om met brandstof.

- Wanneer brandstof op de huid of in een oog terecht komt, kan dit leiden tot allergische reacties of irritatie. Roep onmiddellijk medische

assistentie in wanneer u een fysieke afwijking bespeurt.

• Giet GEEN olie in de brandstoftank.

OPSLAGTERMIJN VAN BRANDSTOF

Brandstof hoort binnen 4 weken opgebruikt te worden, zelfs al wordt het bewaard in een speciale container in een goed geventileerde, donkere

ruimte.

Als u geen speciale container gebruikt, of als de container open is, kan brandstof binnen een dag onbruikbaar worden.

Opslag van de machine en de tank

• Bewaar de machine en de tank op een koele plek, uit de zon.

• Bewaar brandstof nooit in een auto.

BRANDSTOF

De gebruikte motor is een 4-takt motor. Let er op dat u benzine voor auto’s gebruikt (normaal of super).

Opmerkingen over brandstof

• Gebruik nooit een benzine-olie mengsel. Doet u dit toch, dan kan er zich een koolstof afzetting vormen en kunnen er mechanische problemen

op gaan treden.

• Als verslechterde olie wordt gebruikt, zal dat leiden tot onregelmatig starten.

Let er bij het bijvullen van brandstof op dat de motor is uitgezet en controleer of de motor is afgekoeld.

METHODE VAN BRANDSTOF BIJVULLEN

• Draai de brandstofvuldop een klein stukje los en de druk in de brandstoftank af te laten.

• Draai de brandstofvuldop eraf, vul brandstof bij en laat de lucht uit de brandstoftank stromen door de brandstoftank iets te kantelen zodat de

brandstofvulopening recht omhoog wijst.

(NIET bijvullen tot in de vulopening van de brandstoftank.)

• Na het bijvullen van brandstof draait u de brandstofvuldop weer stevig vast.

• Als enige onvolkomenheid of schade aan de brandstofvuldop wordt geconstateerd, moet deze worden vervangen.

• De brandstofvuldop is na verloop van tijd versleten. Vervang de brandstofvuldop iedere twee of drie jaar.

• GEEN brandstof bijvullen in de olievulopening.

78

Page 28

BEDIENING

Afbeelding 1

Stopschakelaar

Afbeelding 2

Close

Afbeelding 4

Afbeelding 5

Open

Afbeelding 3

Opvoerpomp

1. Starten

WAARSCHUWING

• Start de motor in geen geval op dezelfde plek als waar u getankt heeft.

- Hierdoor kan ontbranding of brand ontstaan. Blijf bij het starten van de motor op een afstand van ten minste 3 meter.

• Het uitlaatgas uit de motor is giftig. Gebruik de motor niet op een slecht geventileerde plek, bijvoorbeeld in een tunnel, in een gebouw enz.

- Gebruik van de motor op een slecht geventileerde plek kan leiden tot vergiftiging door uitlaatgassen.

• Stop en inspecteer de motor onmiddellijk wanneer u na het starten iets abnormaals bespeurt, zoals een vreemd geluid, geur, of trilling.

- Als u de motor blijft gebruiken terwijl zich een dergelijk abnormaal verschijnsel voordoet, kan dat leiden tot een ongeval.

• Controleer of de motor inderdaad stopt wanneer de stopschakelaar op de “O” stand wordt gezet.

1) Als de motor koud is of na het bijvullen van brandstof

(1) Plaats de machine op een vlakke ondergrond.

(2) Zet de stopschakelaar op “ I ” (Afbeelding 1).

(3) Blijf op de opvoerpomp drukken tot er brandstof in de

opvoerpomp komt. (Afbeelding 2)

• In het algemeen zal er na 7 tot 10 keer drukken brandstof in

de opvoerpomp komen.

• Als u de opvoerpomp te intensief gebruikt, zal het teveel

aan benzine teruggevoerd worden naar de brandstoftank.

(4) Til de chokehendel op naar de gesloten stand (Afbeelding 3).

(5) Houd de hoofdgreep vast met uw linkerhand om te voorkomen

dat de motor beweegt.

(6) Trek de hendel van de trekstarter voorzichtig uit tot u

weerstand voelt. Laat de trekstarter vervolgens terugkeren en

trek er dan krachtig aan (Afbeelding 4).

• Trek nooit door tot aan het einde van het trekstartkoord.

• Laat nooit direct los nadat u de trekstarter heeft

uitgetrokken. Houd de trekstarter vast totdat deze

terugkeert naar zijn oorspronkelijke positie.

(7) Zet de chokehendel open wanneer de motor start. (Afbeelding

5)

• Zet de chokehendel steeds verder open terwijl u controleert

hoe de motor loopt. Vergeet niet dat de chokehendel

uiteindelijk helemaal open moet staan.

• Als het koud is of wanneer de motor is afgekoeld, mag u

nooit de chokehendel ineens helemaal open zetten. Doet u

dit toch, dan kan de motor stilvallen.

(8) Laat de motor 2 a 3 minuten opwarmen.

(9) Het opwarmen is klaar wanneer de motor snel accelereert van

een laag toerental naar volledig geopend gas.

79

Page 29

OPMERKING

Stopschakelaar

Stelschoef

Carburateur

• De motor kan beschadigd raken als de chokehendel verder gezet wordt dan de “CLOSE” (Dicht) stand.

• Als de motor aanslaat en afslaat, zet u deze hendel terug in de stand “OPEN” en trekt u meerdere keren aan de trekstarter om de motor

opnieuw te starten.

• Als de gebruiker meerdere keren aan de trekstarter blijft trekken met de chokehendel in de stand “CLOSE”, kan de motor moeilijk worden

gestart omdat te veel brandstof is toegevoerd ("verzopen").

• In het geval de motor door te veel brandstof is verzopen, verwijdert u de bougie en trekt u meerdere keren snel aan de trekstarter om het

overschot aan brandstof te verwijderen. Droog de elektroden van de bougie.

• Wanneer de gasklep niet terugkomt in een stand waarin deze de stationair stelschroef raakt, zelfs niet wanneer het gas helemaal dicht staat,

stel dan de kabel opnieuw af zodat de klep terugkeert in de correcte stand.

2) Wanneer de motor warm is.

(1) Plaats de motor op een vlakke ondergrond.

(2) Druk een paar keer op de opvoerpomp.

(3) Controleer of de chokehendel open staat.

(4) Houd de hoofdgreep vast met uw linkerhand om te voorkomen dat de motor beweegt.

(5) Trek de hendel van de trekstarter voorzichtig uit tot u weerstand voelt. Laat de trekstarter terugkeren naar de uitgangspositie en trek er

vervolgens stevig aan.

(6) Wanneer de motor moeilijk te starten is, kunt u proberen het gas ongeveer 1/3 open te zetten.

2. Stop

Laat de aan/uit-schakelaar los om het motortoerental te verlagen en zet

de stopschakelaar in de stand “O”.

(Ontgrendel de gashendelvergrendeling als deze de gashendel in de

volledig geopende stand vergrendelt.)

AFSTELLINGEN

GEVAAR

De carburateur is in de fabriek afgesteld. Stel niet af, anders dan het stationaire toerental. Als het nodig is om hem bij te stellen, dient u

contact op te nemen met uw erkende onderhoudsmonteur.

Controleren van het stationaire toerental

Stel het stationaire toerental in op 3500 rpm (min–1).

• Wanneer het noodzakelijk is het stationaire toerental bij te stellen,

dient u de stelschroef op de carburateur bij te stellen, met een

kruiskopschroevendraaier.

• Draai de stelschroef rechtsom om het motortoerental te verhogen.

Draai de stelschroef linksom om het motortoerental te verlagen.

80

Page 30

BEDIENINGSMETHODE

1. Gebruik als blazer

• Houd de machine stevig vast tijdens gebruik.

• Richt het uiteinde van het mondstuk op de plek waar u wilt blazen en

haal de trekker over.

• Knijp de trekker helemaal in, houdt de throttle vergrendelknop

ingedrukt en laat met uw vinger de trekker los zodat de trekker is

vergrendeld op volledig geopend gas.

• Knijp de trekker nogmaals in om de gashendelvergrendeling te

ontgrendelen.

• Het onderste deel van de brandstoftank fungeert tevens als hulpgreep

zodat u de machine met beide handen kunt gebruiken. Houd in dit

geval de hulpgreep met uw rechterhand vast.

2. Zuigen

WAARSCHUWING

• Zorg ervoor dat er geen dingen zoals kerosine, benzine of brandende sigaretten de machine in gezogen worden.

- Als u dat niet doet, kan brand ontstaan.

• Zorg ervoor dat er geen ongeschikte materialen zoals grote houtsnippers, stukken metaal, glas, kiezelstenen enz. in de machine gezogen

worden.

- Hierdoor kunnen namelijk gemakkelijk storingen ontstaan.

• Door de stofzak te ver te vullen, kan deze overstromen aan de kant van de motor. Leeg de stofzak voordat deze helemaal vol zit.

- Als u dat niet doet, kan brand ontstaan.

• Draag de schouderriem voor de stofzak en stel de riem op een comfortabele lengte in.

• Controleer of de stofzak niet gedraaid zit en haal de aan/uit-schakelaar over om uw werk te

beginnen.

• Als de stofzak vol zit, verwijdert u de stofzak van de blazer en opent u de sluiting om de stofzak te

legen.

OPMERKING

Als de blazer wordt bediend terwijl het beschermrooster omhoog gericht is of de hoofdgreep omlaag gericht is, kan witte rook worden

uitgestoten, kan de olie verontreinigd worden of kan olie eruit lekken.

81

Page 31

INSPECTIE EN ONDERHOUD

Afbeelding 1

Afbeelding 2

Plank

GEVAAR

• Stop de motor en laat deze afkoelen voor u inspectie en onderhoud gaat uitvoeren. Verwijder de bougie en de bougiekap.

- Als u inspectie of onderhoud uitvoert direct nadat de motor gestopt is of wanneer de bougiekap nog op zijn plaats zit, kunt u zich branden

of een ongeval oplopen omdat de motor onverwacht opstart.

• Controleer of alle onderdelen goed op hun plek zitten na inspectie of onderhoud. Ga pas daarna de machine opnieuw gebruiken.

1. Verversen van de motorolie

Te lang gebruikte motorolie zal de levensduur van de heen en weer bewegende en roterende onderdelen flink bekorten. Vergeet niet te

controleren wanneer en hoeveel olie ververst moet worden.

GEVAAR

• In het algemeen zullen de motor zelf en de motorolie nog enige tijd heet blijven ook al is de motor gestopt. Als u de olie wilt gaan verversen,

moet u eerst controleren of de motor zelf en de motorolie daarin voldoende zijn afgekoeld. Doet u dat niet, dan bestaat het gevaar dat u zich

zult branden. Wacht nadat de motor is uit gezet voldoende lang om de motorolie te laten terugstromen naar de olietank voor een

nauwkeurige controle van het oliepeil.

• Als er teveel olie in het carter gedaan is, kan de olie verontreinigd raken, of verbranden met een witte rook als resultaat.

Verversingsinterval: Na de eerste 20 bedrijfsuren en vervolgens na iedere 50 bedrijfsuren.

Aanbevolen olie: SAE10W-30 olie van API Classificatie SF Klasse of hoger (4-takt olie voor auto’s)

Voer de volgende procedure uit bij het verversen van de olie.

(1) Controleer of de tankdop goed dicht zit.

(2) Maak de oliedop los.

• Houd de oliepeilstok vrij van stof of vuil.

(3) Kantel de blazer in de volgorde aangegeven in afbeelding 1.

• Vang de olie op in een daarvoor geschikte bak.

(4) Richt de blazer zoals aangegeven in afbeelding 2 en vul olie bij

tot aan de rand in de oliebuis.

(5) Doe de oliepeilstok weer terug en zet hem goed vast na het

verversen van de olie. Als u de oliepeilstok niet goed vast

maakt, zal er olie gaan lekken.

Opmerkingen bij het verversen van de motorolie

• Gooi afgewerkte motorolie niet weg met het normale vuilnis en loos het niet in de natuur of in een sloot. Het afvoeren van olie is wettelijk

geregeld. Volg altijd de geldende wetten en regelgeving wanneer u zich van afgewerkte motorolie wilt ontdoen. Neem contact op met een

erkende onderhoudsmonteur als u hieromtrent vragen hebt.

• Ook wanneer u olie gewoon bewaart zal de olie op den duur bederven. Controleer regelmatig of de olie die u wilt gebruiken nog goed is

(vervang de olie minstens elke 6 maanden).

82

Page 32

2. Reinigen van het luchtfilter

Plaat

Element

(spons)

Afdekking

luchtfilter

Luchtinlaat

Element

(vilt)

Bevestigingsbout

Pak dit gedeelte vast en

verwijder het element (vilt)

Afbeelding 1

Afbeelding 3

Laterale elektrode (–)

Afbeelding 2

Afbeelding 4

Elektrodespeling

0,7 - 0,8 mm

WAARSCHUWING: ONTVLAMBARE MATERIALEN

TEN STRENGSTE VERBODEN

Interval voor reiniging en inspectie: Dagelijks (om de 10

bedrijfsuren)

(1) Verwijder de bevestigingsbout(en) van het deksel van het

luchtfilter.

(2) Trek het deksel naar beneden en haal het los.

(3) Doe de chokehendel helemaal dicht en zorg ervoor dat er

verder geen stof en vuil in de carburateur terecht kan komen.

(4) Als er nog olie aan het element (spons) zit, dient u het stevig

uit te knijpen.

(5) Bij zware verontreiniging:

• Verwijder het filterelement (spons), dompel het in warm

water of in een oplossing van een mild schoonmaakmiddel

in water, en droog het grondig.

• Reinig het element (vilt) met benzine en laat het goed

drogen.

(6) Voor u het element weer terugzet, moet u controleren of het