Page 1

DR

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 69

MANUAL TRANSMISSION - GETRAG 238 - SERVICE

INFORMATION

TABLE OF CONTENTS

page page

MANUAL TRANSMISSION - GETRAG 238 -

SERVICE INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - GETRAG 238 . . . . . 70

STANDARD PROCEDURE

DRAIN AND FILL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

SPECIFICATIONS

MANUAL TRANSMISSION - GETRAG 238 . . . . 135

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Page 2

21 - 70 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

DR

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

DIAGNOSIS AND TESTING

MANUAL TRANSMISSION - GETRAG 238

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the result of a leak, inadequate lubricant fill or incorrect lubricant level

check.

Rear transmission leaks will be from the oil seals or transfer case front seal on 4x4.

Front transmission leaks will be from the front input shaft retainer seal. Lubricant may drip from the clutch housing

after extended operation. If leak is severe, it may contaminate the clutch disc.

Lubricant level check can only be made when the vehicle is level and allowing the lubricant to settle for a minute

before checking. This will ensure an accurate check and avoid an under or overfill condition.

HARD SHIFTING

Hard shifting can be caused by low lubricant level, improper or contaminated lubricants. This will cause noise,

excessive wear, internal bind, and hard shifting. Substantial lubricant leaks can result in gear, shift rail, synchro, and

bearing damage. The first indications of component damage is usually hard shifting and noise.

Shift component damage, clutch adjustment, worn pressure plate or disc, can increased shift effort. If clutch problem

is advanced, gear clash during shifts can result. Worn or damaged synchronizer rings can cause gear clash when

shifting into any forward gear. In some new or rebuilt transmissions, new synchro rings may tend to stick slightly

causing hard or noisy shifts. In most cases, this condition will decline as the rings wear-in.

TRANSMISSION NOISE

Most manual transmissions make some noise during normal operation. Rotating gears generate a mild whine that is

audible, but generally only at extreme speeds.

Severe, highly audible transmission noise is generally the initial indicator of a lubricant problem. Insufficient,

improper or contaminated lubricant will promote rapid wear of gears, synchronizer rings, shift rails, forks and bearings. The overheating caused by a lubricant problem, can also lead to gear and bearing damage.

STANDARD PROCEDURE

DRAIN AND FILL

1. Raise and support vehicle.

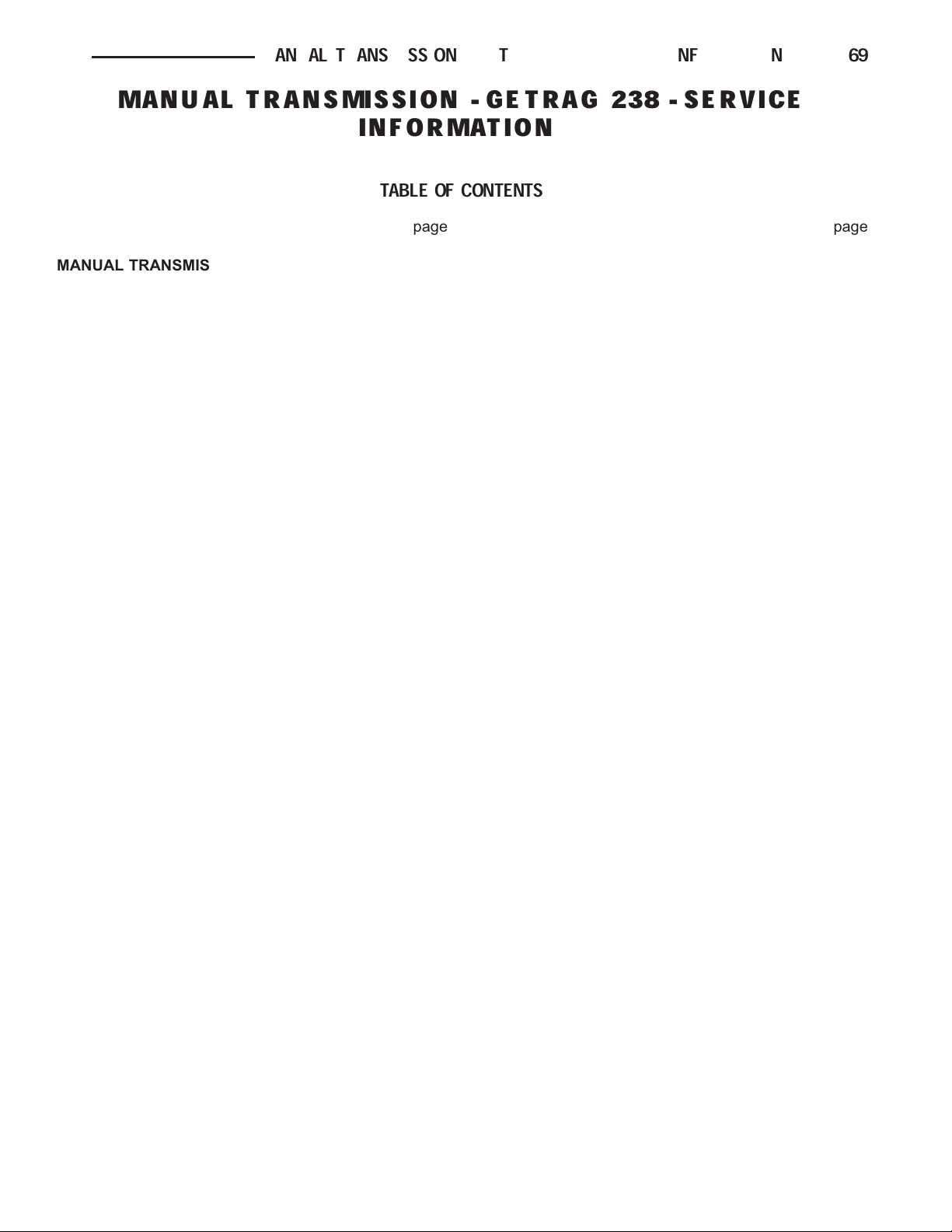

2. Remove drain plug (1) on transmission (2) and

drain fluid.

3. Install drain plug and tighten to 50 N·m (37 ft. lbs.).

Page 3

DR

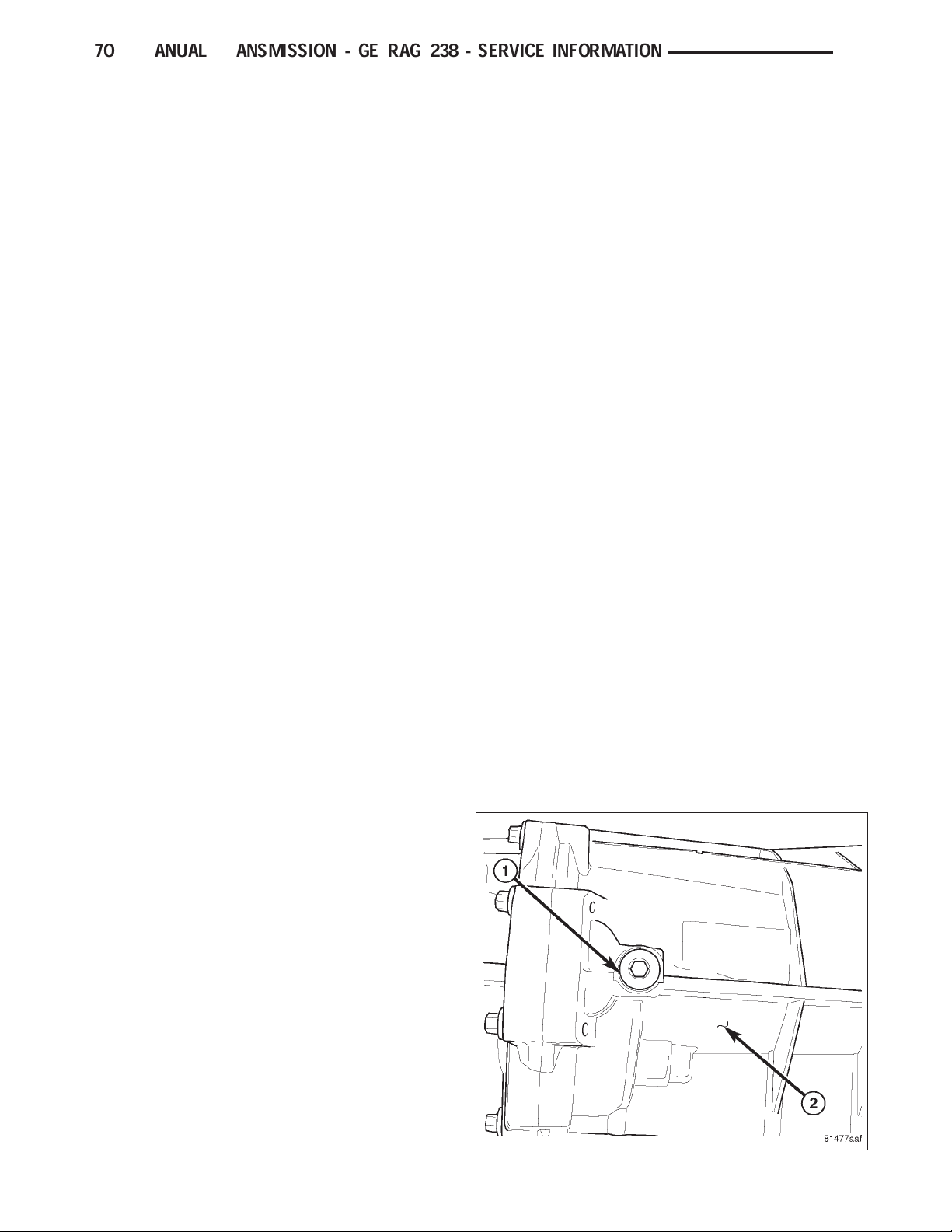

4. Remove fill plug (1) from side of transmission (2).

5. Fill transmission even with the bottom of the fill

hole.

6. Install fill plug and tighten to 50 N·m (37 ft. lbs.).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 71

REMOVAL

1. With vehicle in neutral, position vehicle on hoist.

2. Disconnect battery negative cable.

3. Remove shift boot bezel screws and slide boot

upward on shift lever extension.

4. Remove shift lever extension from the shift tower

and lever assembly.

5. Remove 4WD shift boot if equipped and remove

floor console.

6. Remove skid plate, if equipped.

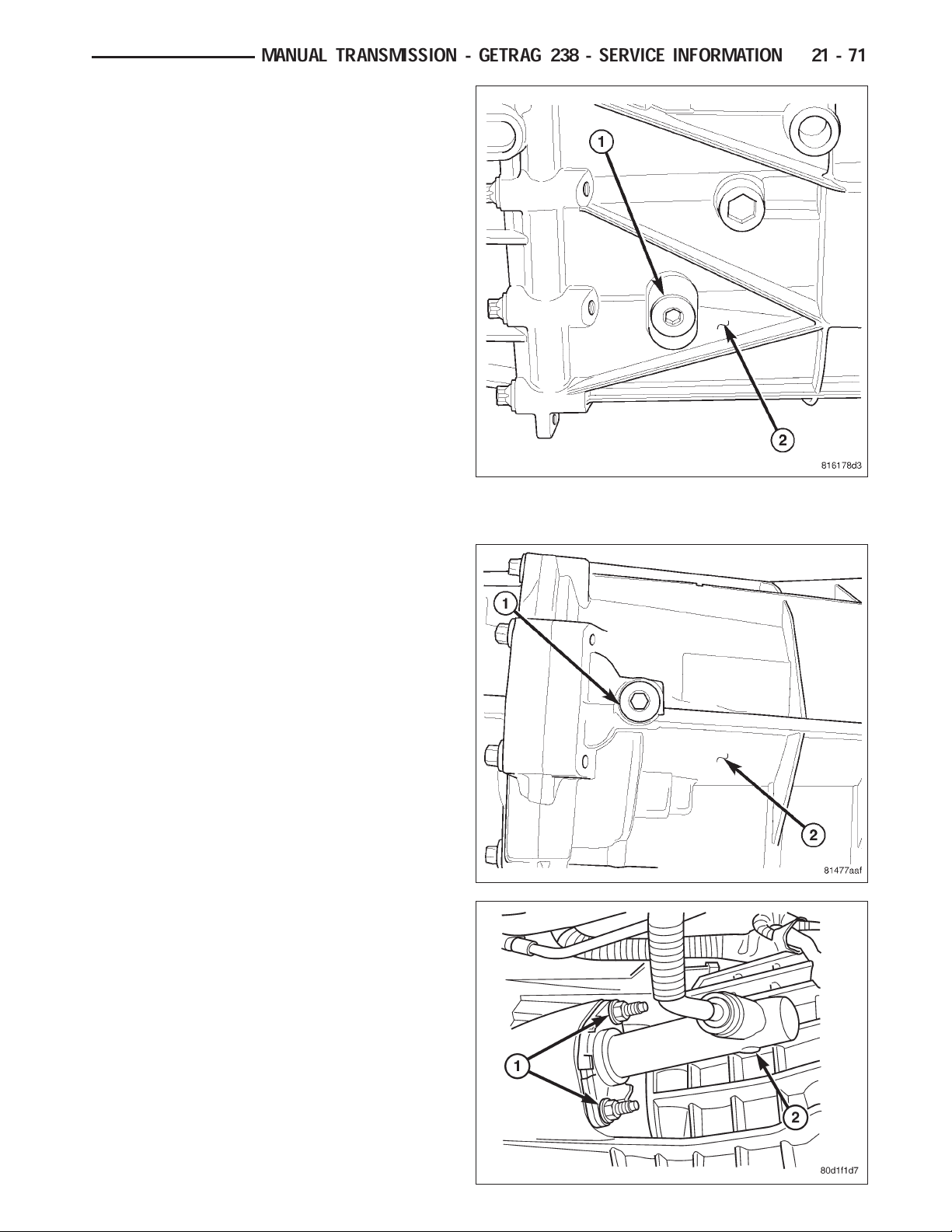

7. Remove drain plug (1) from rear housing (2) and

drain fluid.

8. Mark propeller shaft/shafts and companion flange

yoke/yokes for installation reference and remove

propeller shaft/shafts.

9. Disconnect harness from clips on transmission

housing.

10. Remove transfer case linkage if equipped.

11. Remove transfer case mounting nuts and remove

transfer case if equipped.

12. Remove slave cylinder (2) mounting nut (1) and

remove cylinder.

Page 4

21 - 72 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

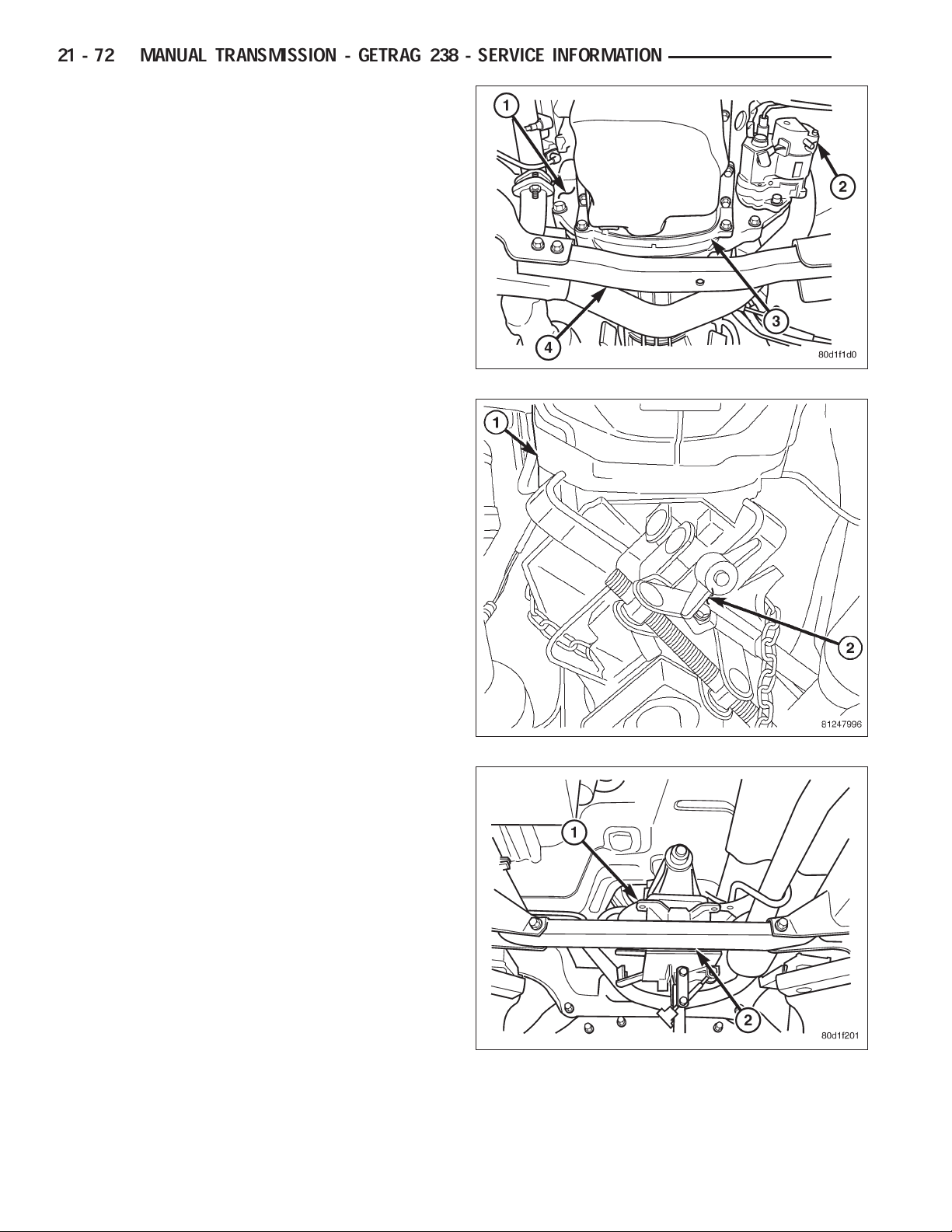

13. Remove starter motor (2), structural dust cover (3)

bolts to clutch housing, dust shield (1) bolt and

suspension crossmember (4).

CAUTION: Do not remove structural dust cover

from engine block. If cover is removed clutch

housing and cover must be aligned with the

engine.

14. Remove exhaust pipe from the exhaust manifolds.

15. Support engine with adjustable jack stand and

wood block.

16. Support and secure transmission (1) to a trans-

mission jack (2) with safety chains.

DR

17. Remove bolts from the rear transmission mount.

18. Remove the rear crossmember (2) and transmis-

sion mount (1).

19. Remove bolts attaching transmission to the

engine.

20. Move transmission rearward until input shaft is

clear of clutch disc and pressure plate. Then

lower jack and remove transmission from under

vehicle.

Page 5

DR

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 73

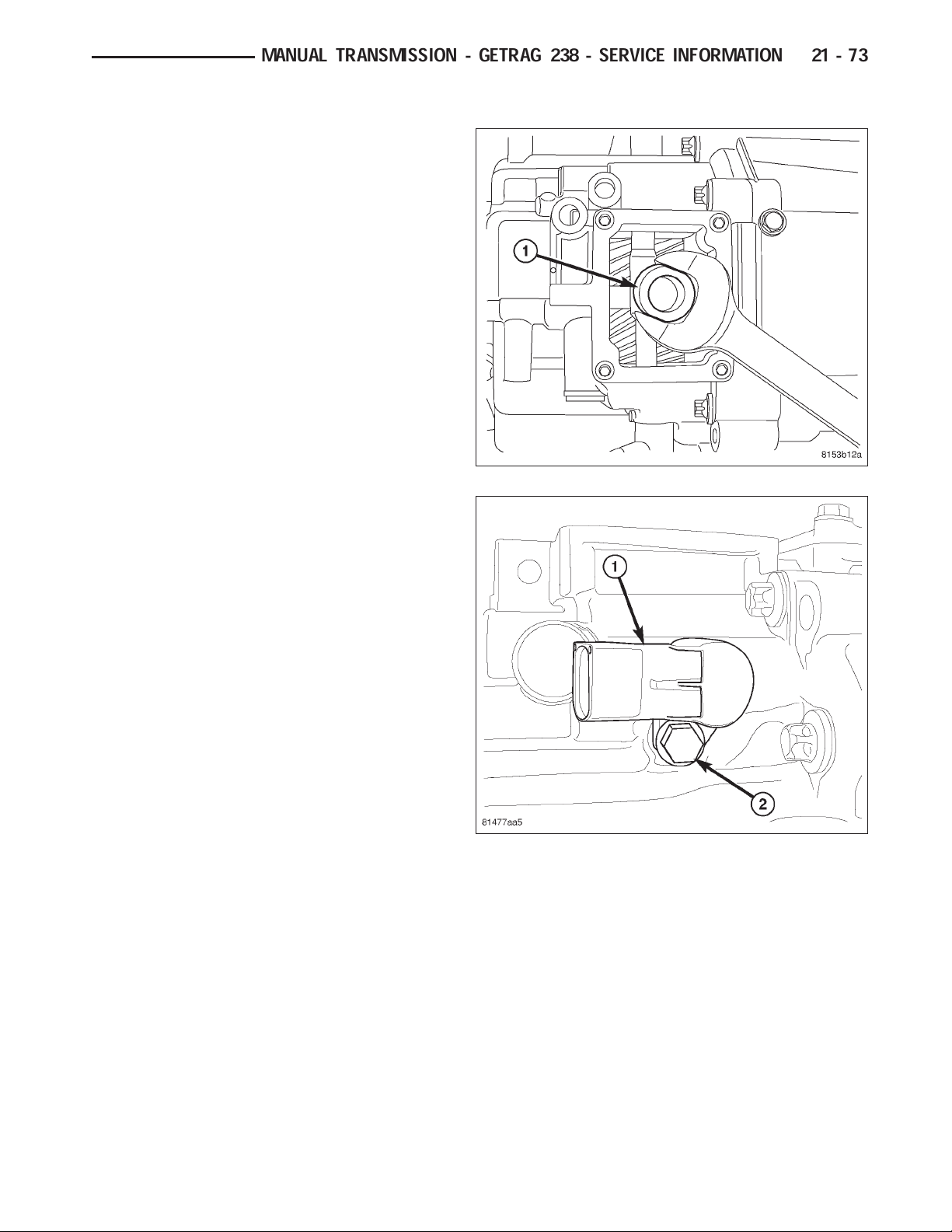

DISASSEMBLY

1. Remove shifter socket (1) from main shift rail.

2. Remove back up lamp switch (1) bolt (2) and

remove switch.

Page 6

21 - 74 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

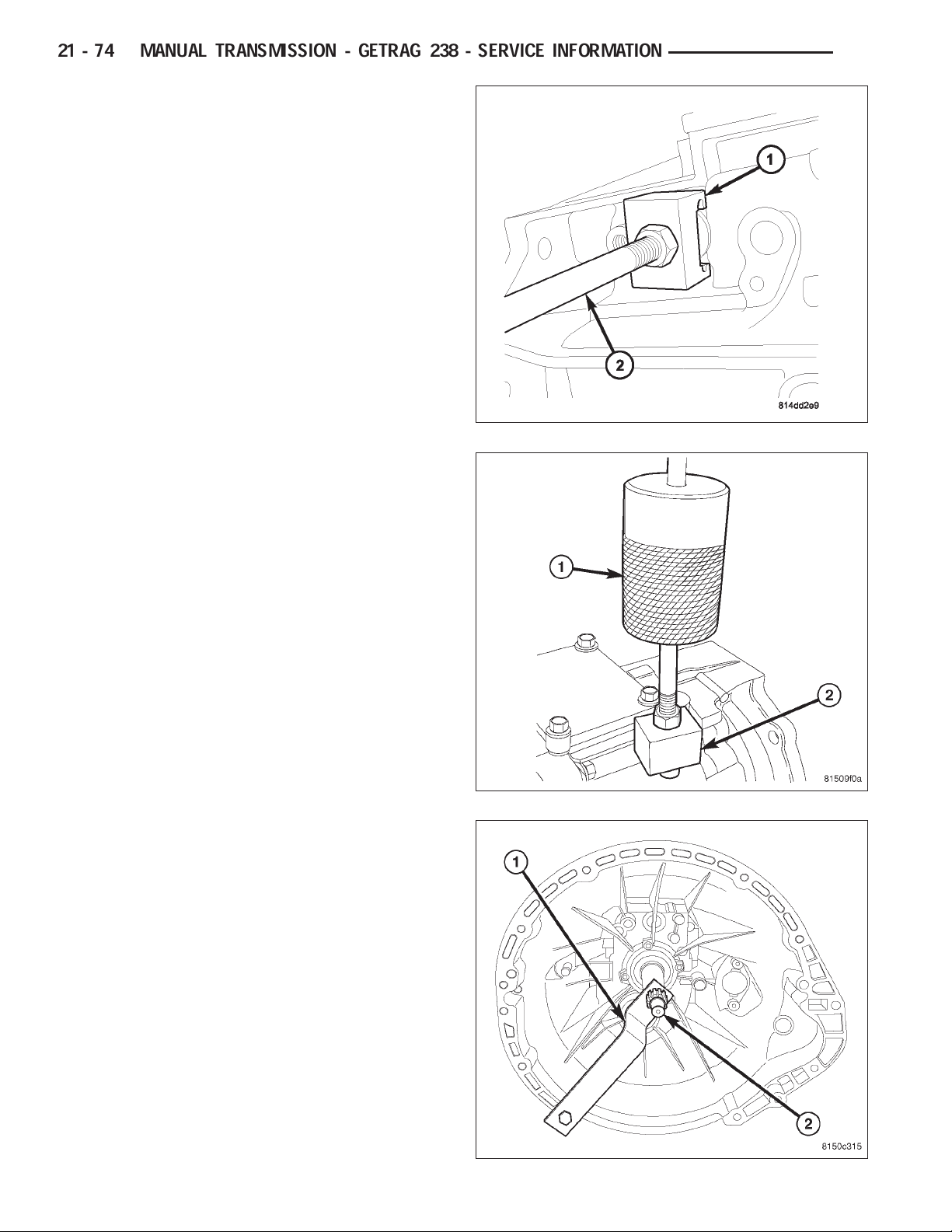

3. Remove large detent plug, next to back up lamp

switch opening with Puller 9583 (1) and Slide Hammer C-3752 (2).

4. Remove two small detent plugs on top of rear

housing with Puller 8870 (2) and Slide Hammer

C-3752 (1).

DR

5. Install Wrench 9586 (1) on input shaft (2).

Page 7

DR

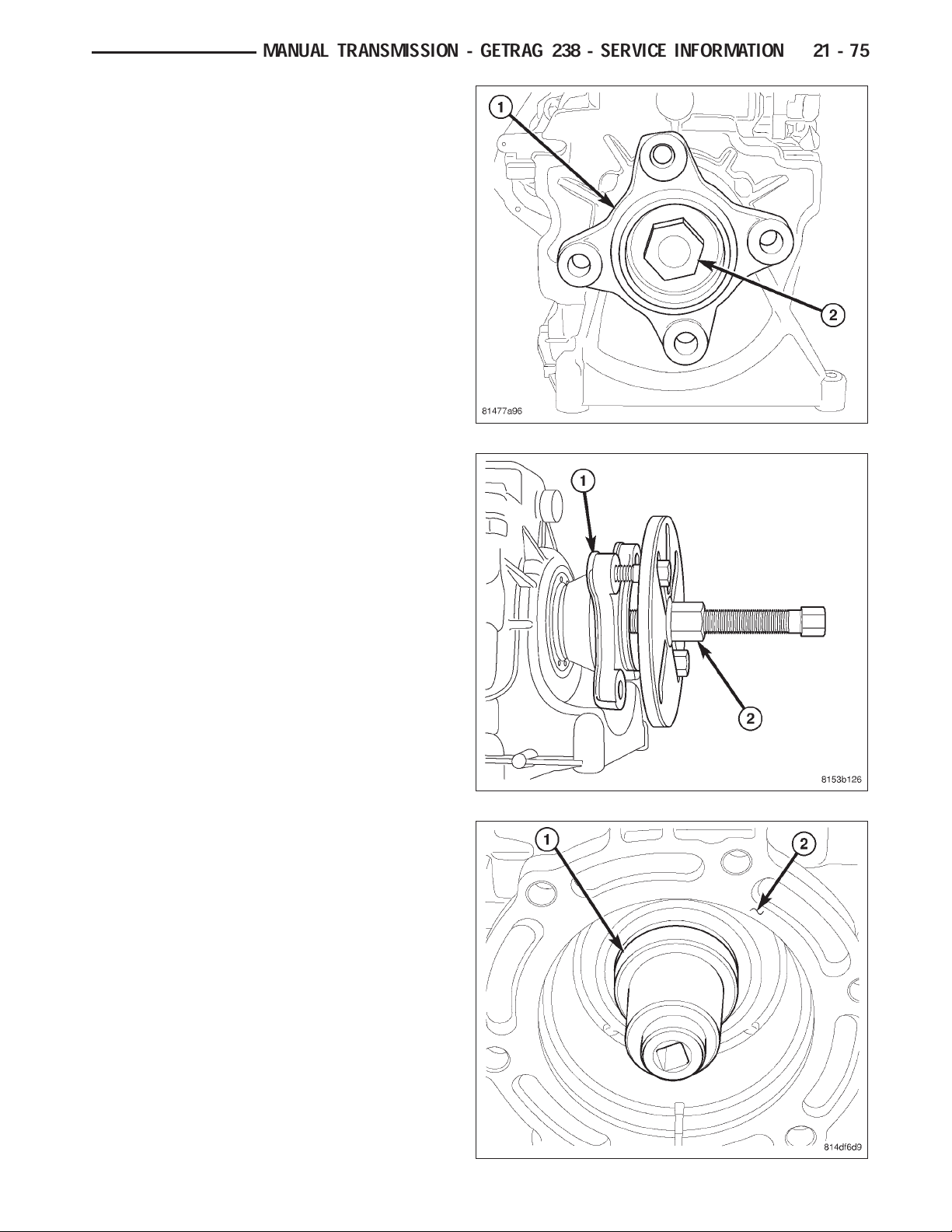

6. Remove output flange (1) nut (2) on 4x2 transmission.

7. Remove output flange (1) on 4x2 transmission with

Puller 8992 (2) and Button 9618-2.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 75

8. Remove output shaft nut with Socket 9584 (1) on

4x4 transmission (2).

9. Remove Wrench 9586 from input shaft.

Page 8

21 - 76 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

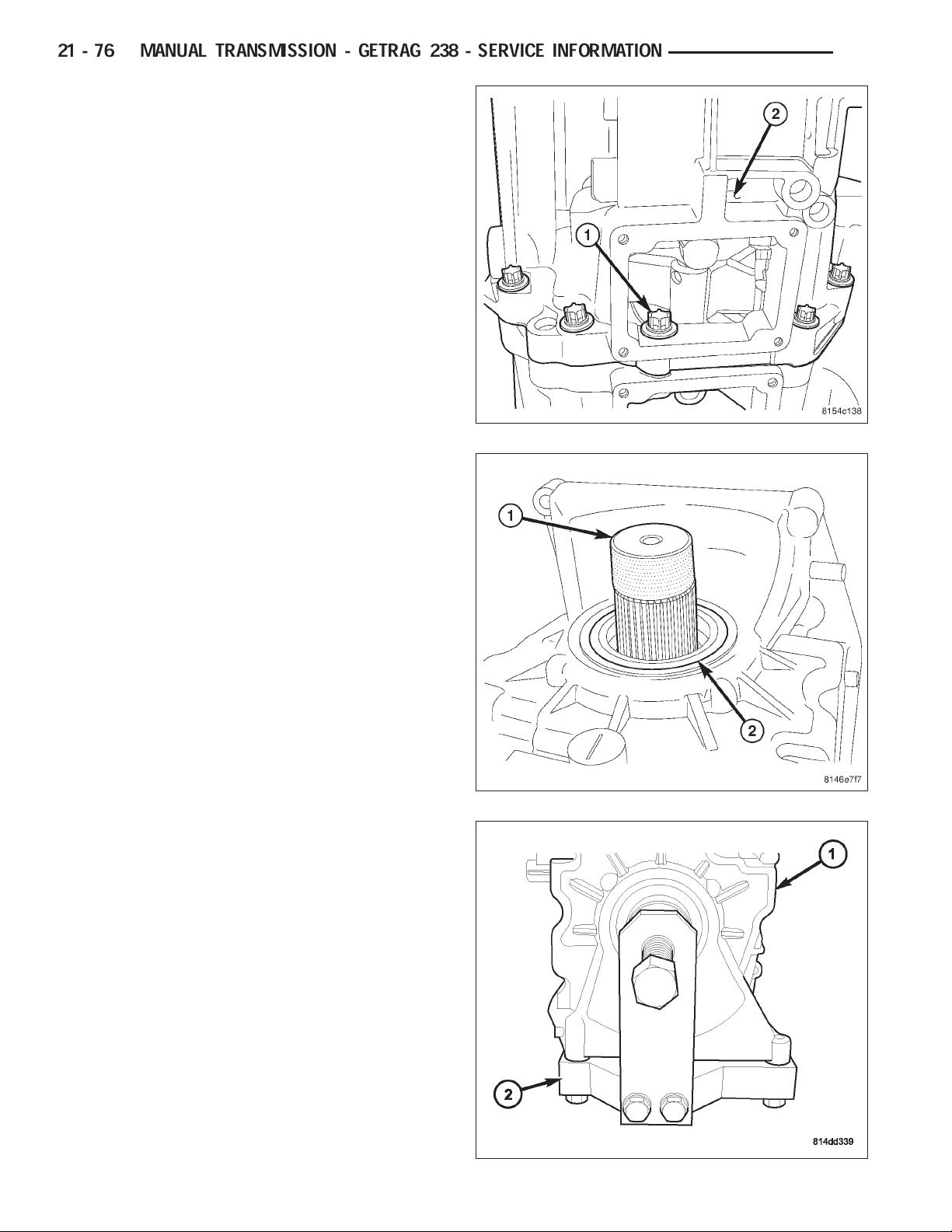

10. Place transmission on front housing and remove

rear housing (2) bolts (1). If necessary, remove

the cover plate to access the one rear housing (2)

bolt (1) located in the opening.

11. Install Button 9618-2 (1) into output shaft (2).

DR

12. Separate rear housing (1) from mainshaft with

Puller 9621(2). Bolt puller to the bottom of the

rear housing, then turn puller bolt to push mainshaft out of the housing.

Page 9

DR

13. Remove reverse shift fork roll pin (1) from reverse

shift rail (2).

14. Slide reverse shift rail (1) down out of the shift

fork (2) and remove reverse shift fork. Then slide

shift rail up and out of the front housing.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 77

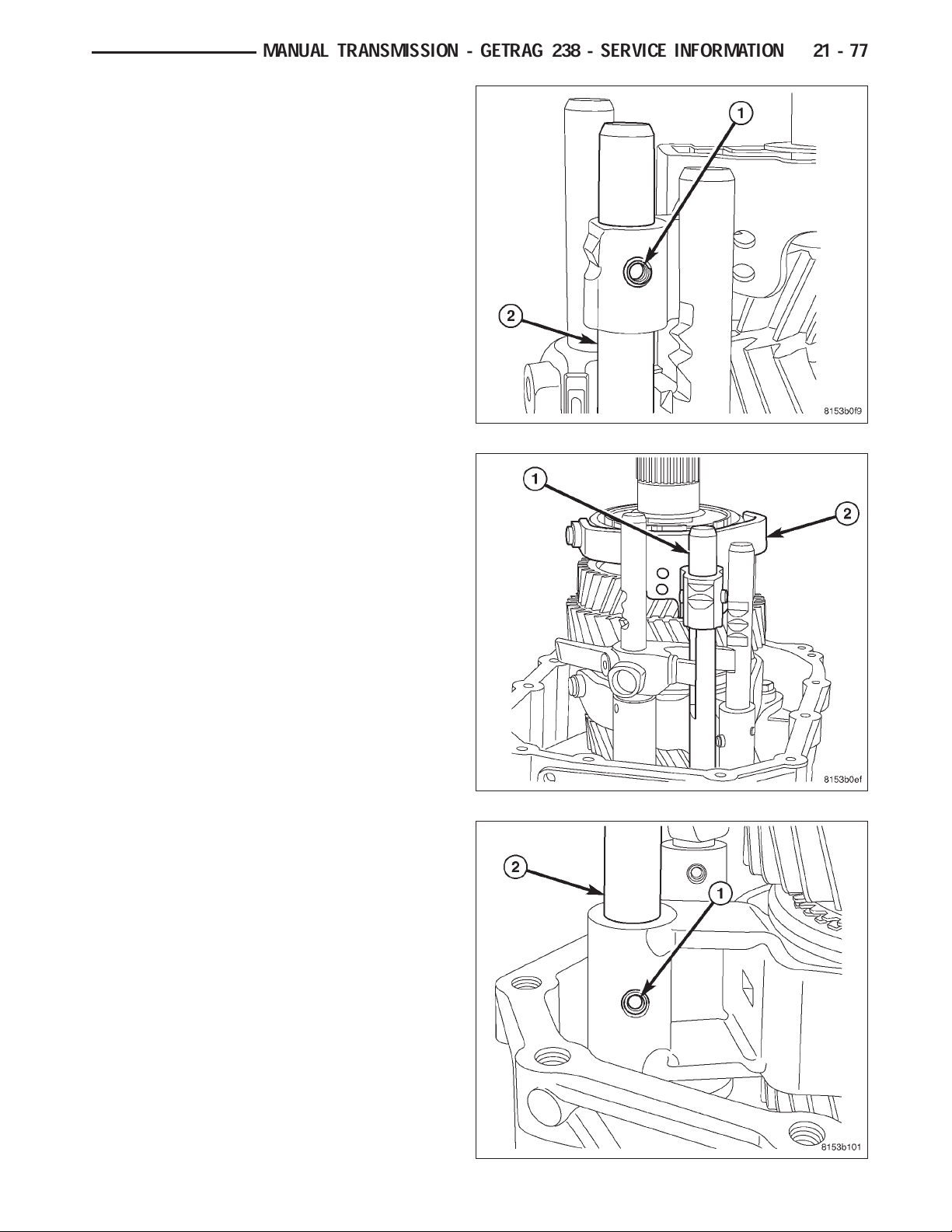

15. Remove 1-2 shift fork roll pin (1) from shift rail (2).

Slide shift rail up out of shift fork and rear housing. Remove 1-2 shift fork.

Page 10

21 - 78 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

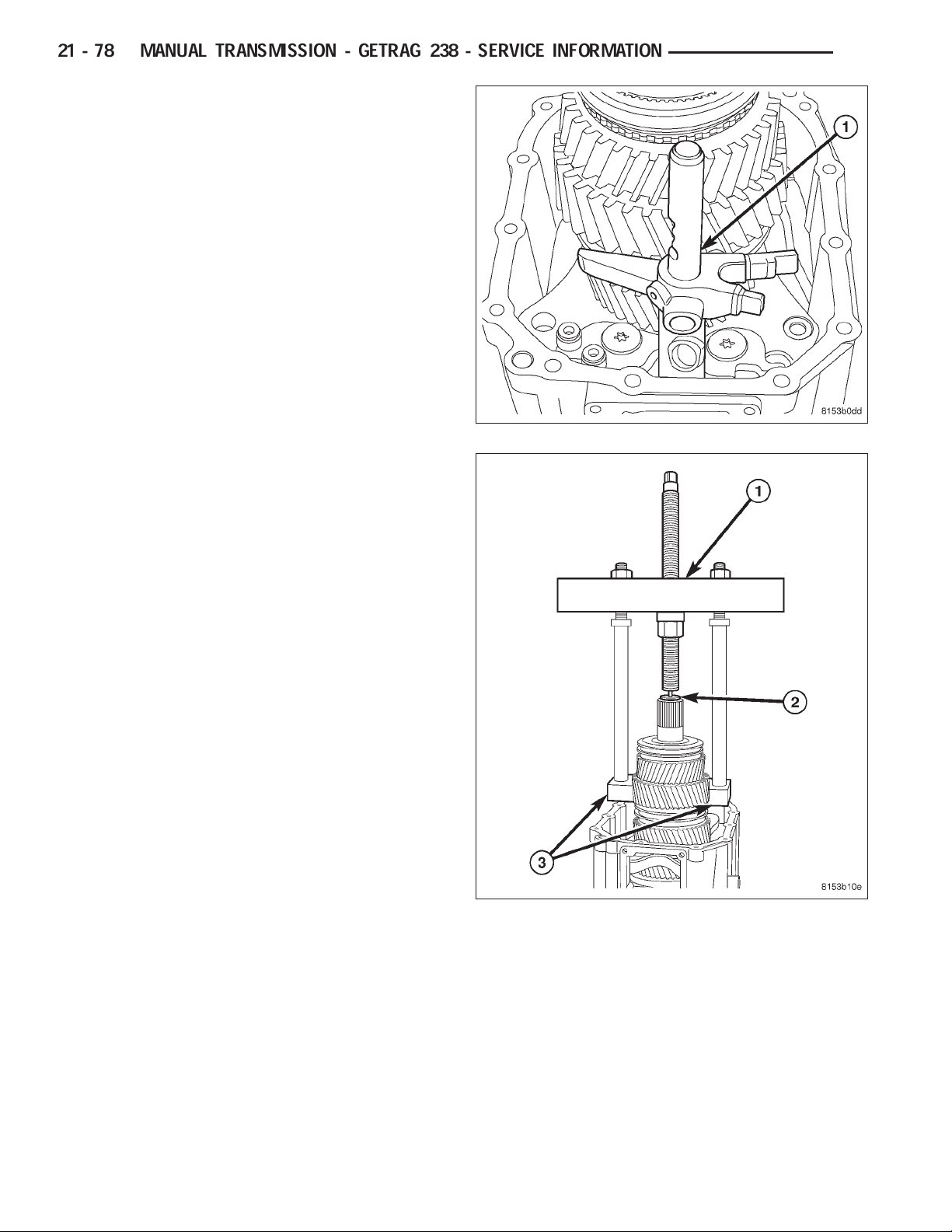

16. Rotate main shift rail (1) clockwise and pull up

and out of the front housing.

17. Remove first gear, reverse gear, reverse bearing,

reverse gear bearing race and reverse synchronizer with Bridge 938 (1), Button 9618-2 (2) and

puller Adapters 9628 (3). Position puller Adapters

9628 (3) under first gear.

DR

Page 11

DR

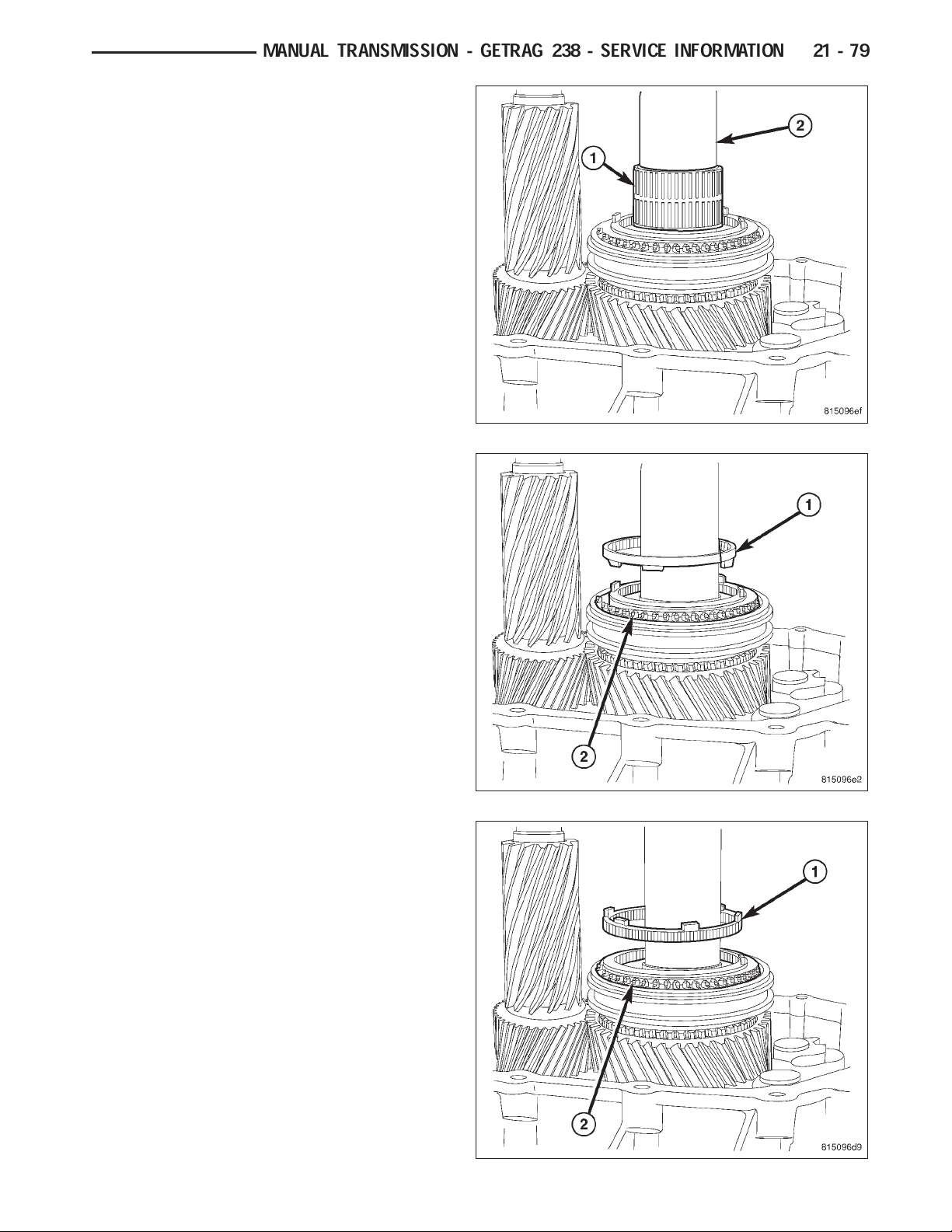

18. Remove first gear bearing (1) from mainshaft (2).

19. Remove first gear synchronizer inner friction ring

(1) from 1-2 synchronizer hub (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 79

20. Remove first gear synchronizer outer friction ring

(1) from 1-2 synchronizer hub (2).

Page 12

21 - 80 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

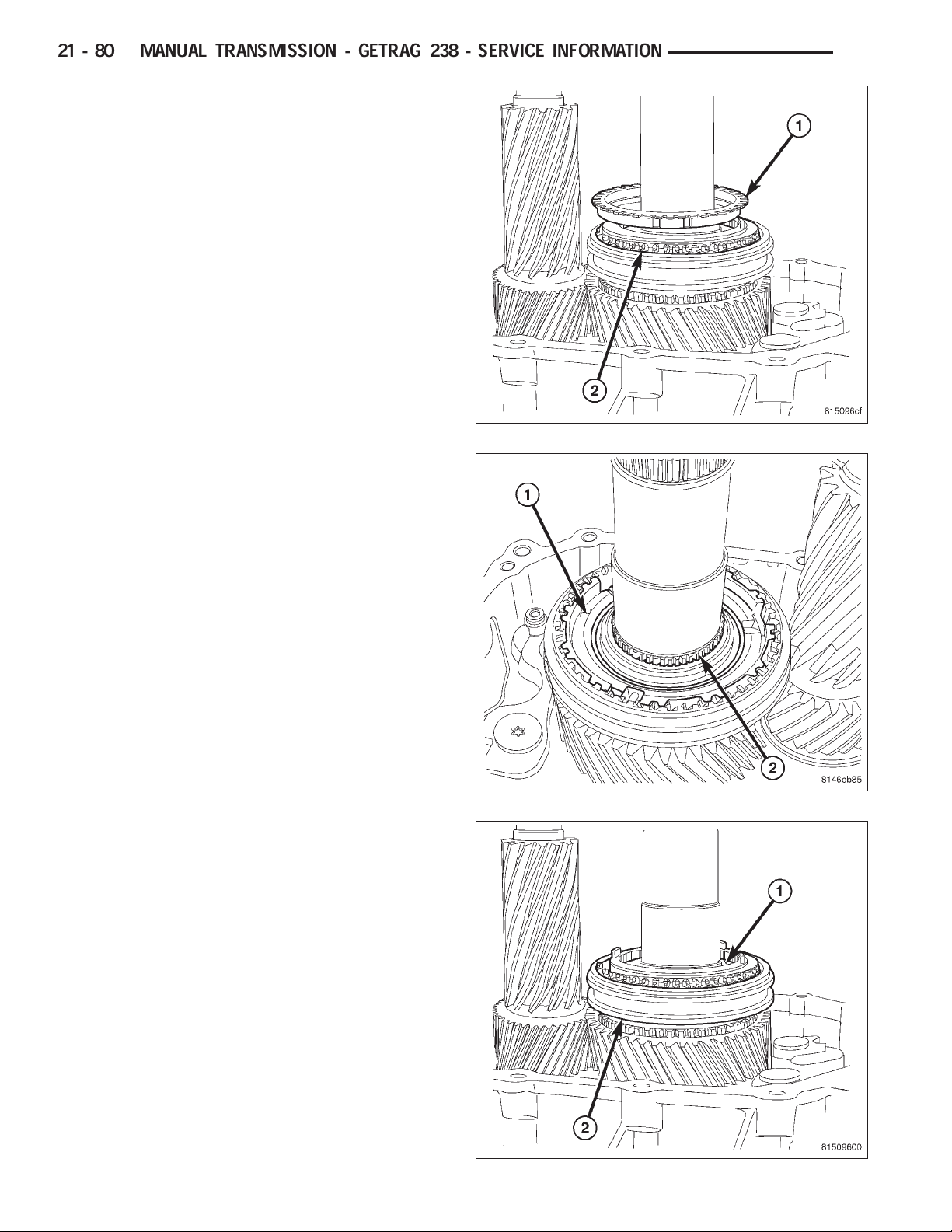

21. Remove first gear synchronizer blocker ring (1)

from 1-2 synchronizer hub (2).

22. Remove 1-2 synchronizer hub (1) snap ring (2).

DR

23. Remove 1-2 synchronizer sleeve (1) from 1-2 syn-

chronizer hub (2).

Page 13

DR

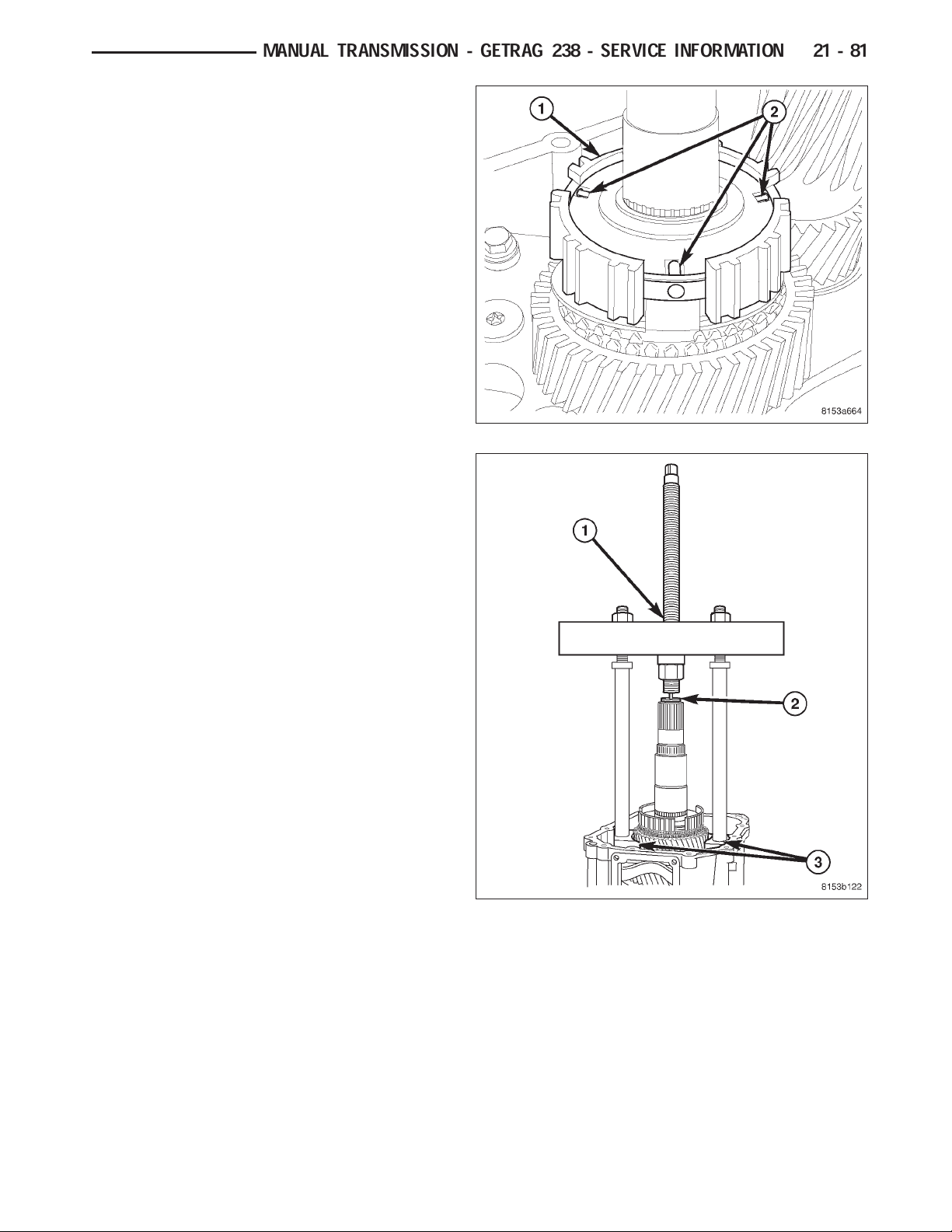

24. Remove 1-2 synchronizer hub (1) detents (2).

25. Remove second gear and 1-2 synchronizer hub

with Bridge 938 (1), Button 9618-2 (2) and Adapters 9627 (3).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 81

Page 14

21 - 82 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

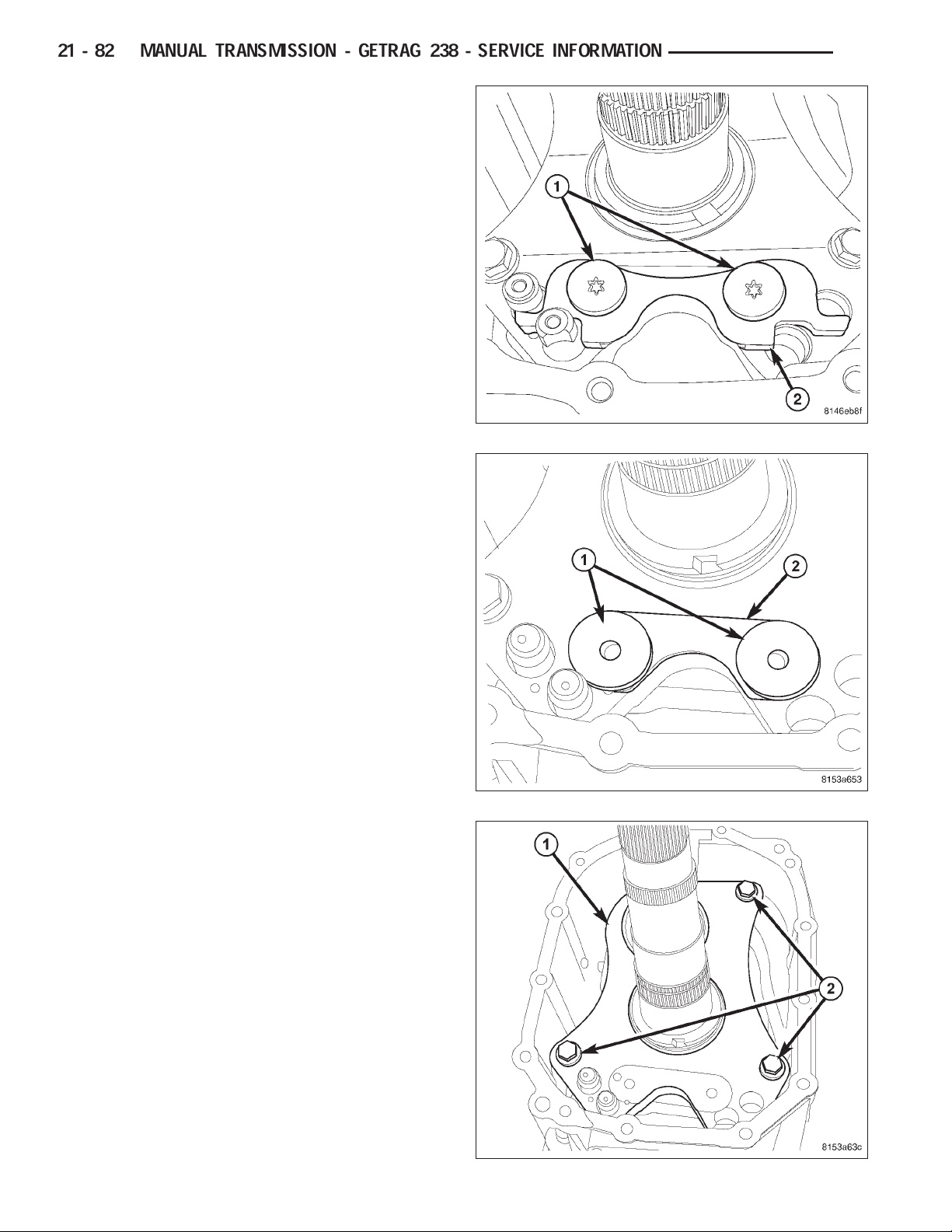

26. Remove interlock plate bolts (1) and remove inter-

lock plate (2).

27. Remove washers (1) from intermediate plate (2).

DR

28. Remove intermediate plate (1) bolts (2).

Page 15

DR

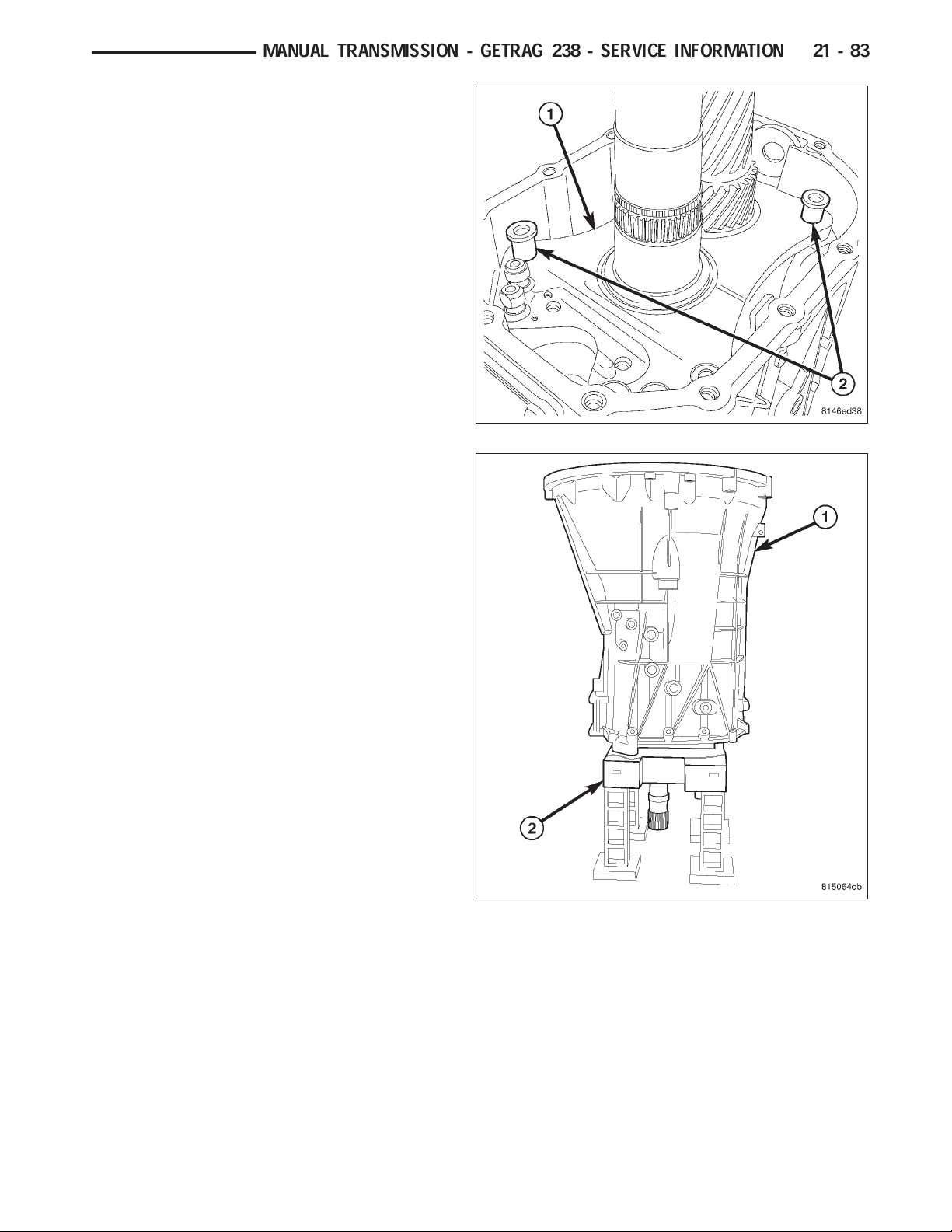

29. Remove intermediate plate (1) dowels (2) with a

suitable tool and remove intermediate plate.

30. Install Fixture 9626 (2) on main/countershaft and

shift rails. Turn fixture (2) with transmission (1)

over onto the fixture.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 83

Page 16

21 - 84 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

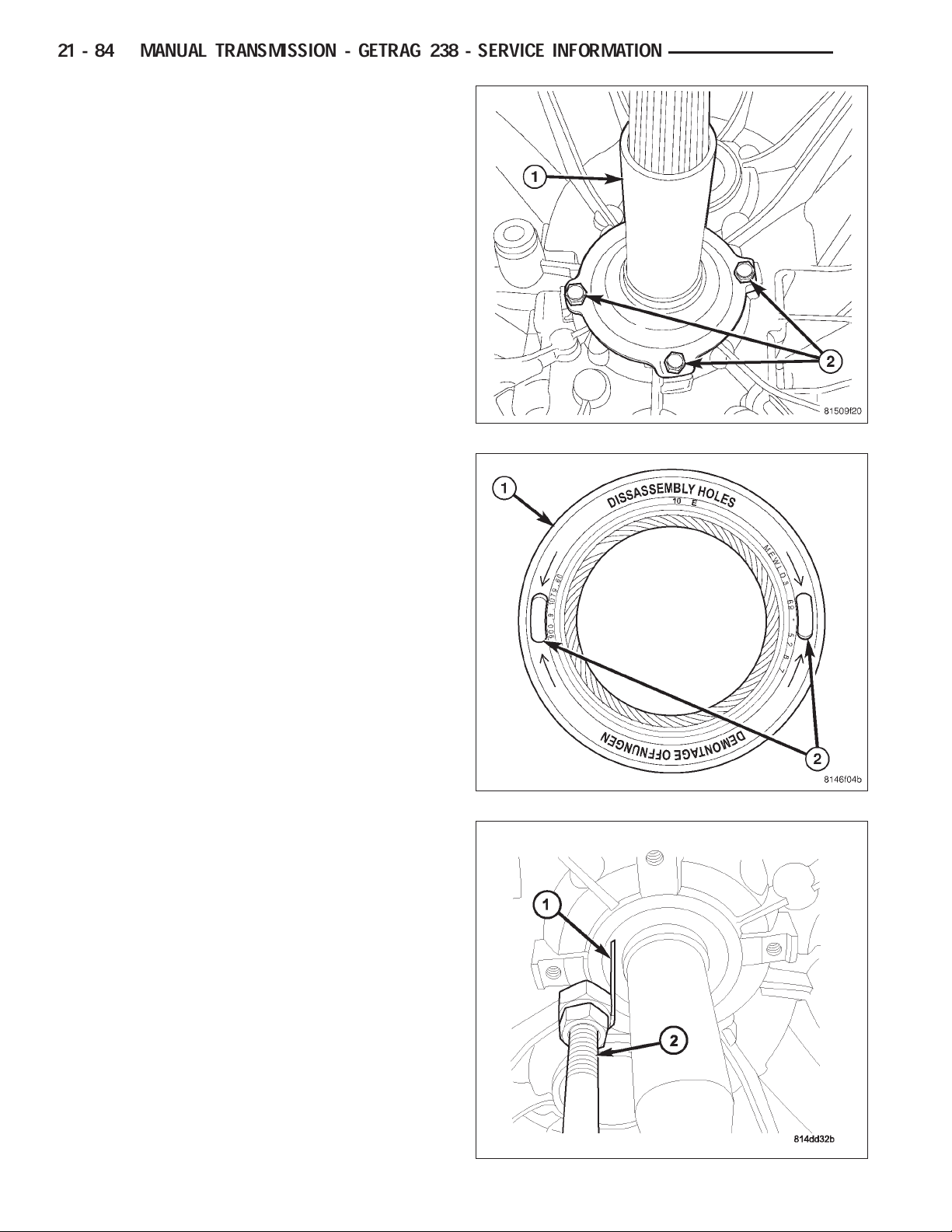

31. Remove clutch release bearing support bolts (2)

and retainer (1).

32. Insert seal Puller 9667 through one input shaft

seal (1) disassembly hole (2).

DR

33. Remove input shaft seal with Remover 9667 (1)

and Slide Hammer C-3752 (2).

Page 17

DR

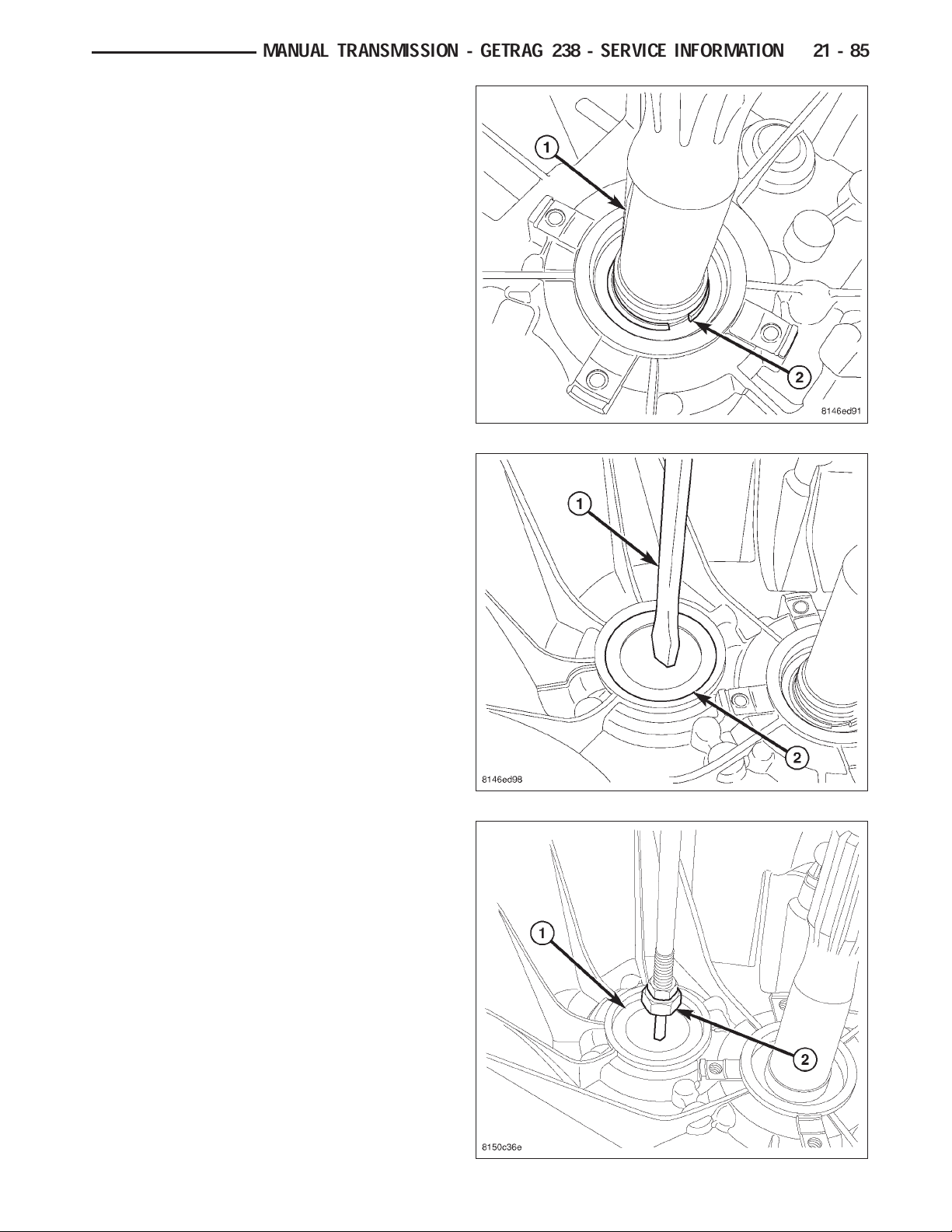

34. Remove input shaft (1) snap ring (2).

35. Put a hole in the center of the countershaft plug

(2) with a punch (1).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 85

36. Remove countershaft plug (1) from front housing

with Puller 9667 (2) and Slide Hammer C-3752.

Page 18

21 - 86 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

37. Install Wrench 9586 (1) on input shaft (2).

38. Remove countershaft allen bolt (1).

39. Remove input shaft wrench.

DR

40. Remove two detent plugs from the side of the

housing with Puller 8870 (1) and Slide Hammer

C-3752 (2).

Page 19

DR

41. Remove 3-4 (2) and 5-6 (1) shift fork pivot bolts

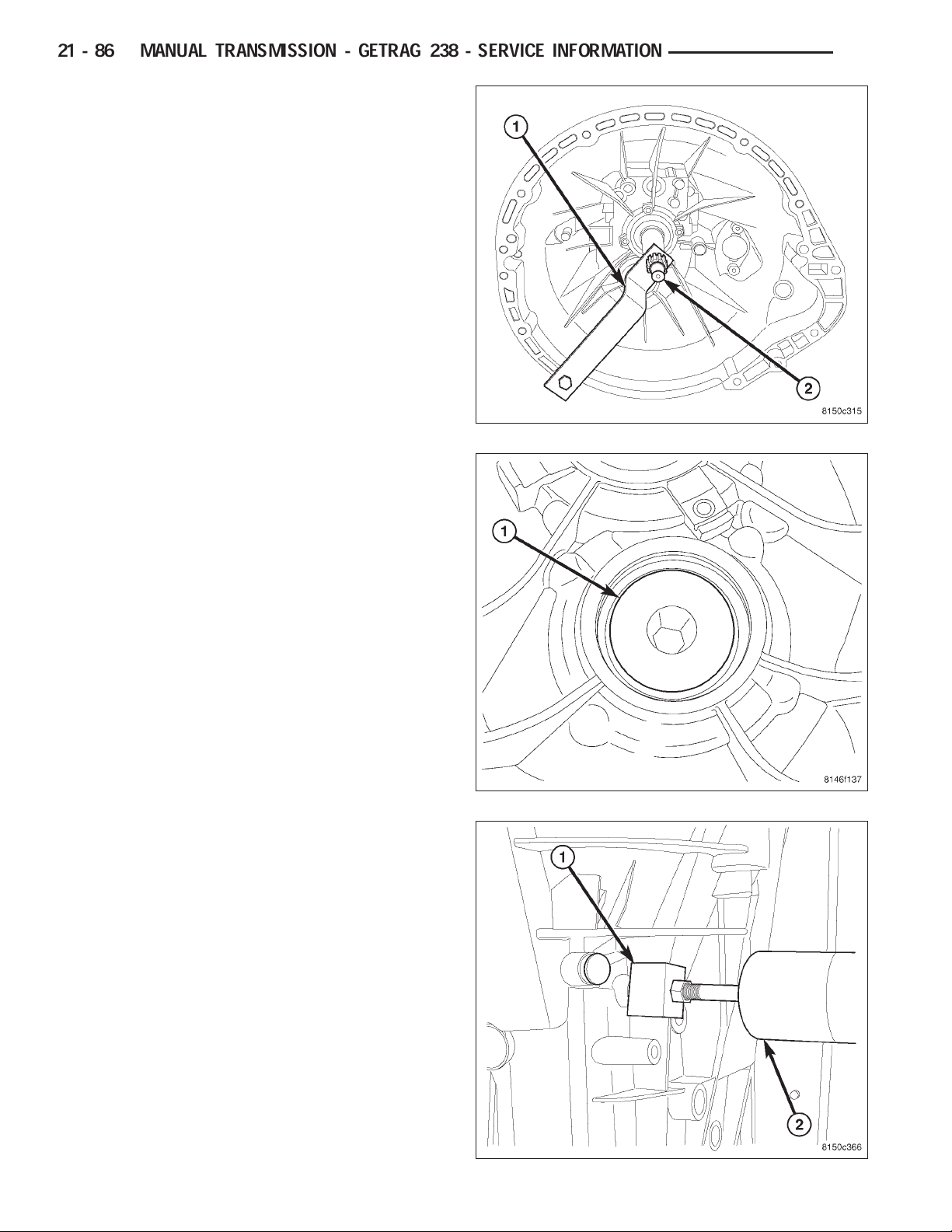

from both sides of the front housing.

42. Install Puller 9621(1) with puller Plug 9621-2 (2)

on front housing. Tighten puller bolts evenly and

remove front housing from the mainshaft and

countershaft.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 87

Page 20

21 - 88 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

43. Remove 5-6 shift fork (3) and 3-4 shift fork (4).

Then remove 5-6 shift rail (1) and 3-4 shift rail (2)

from Fixture 9626.

DR

44. Remove input shaft (1) from mainshaft (2).

Page 21

DR

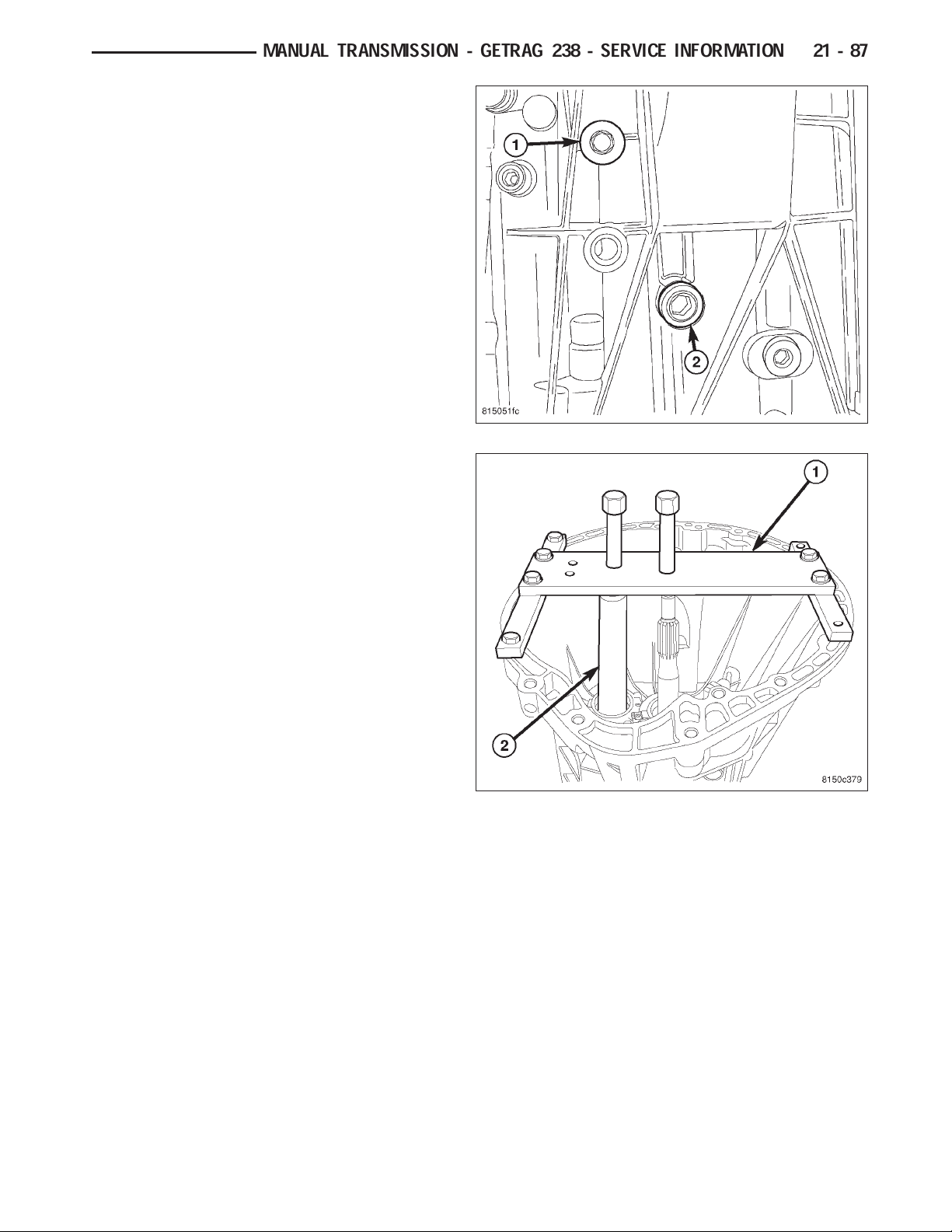

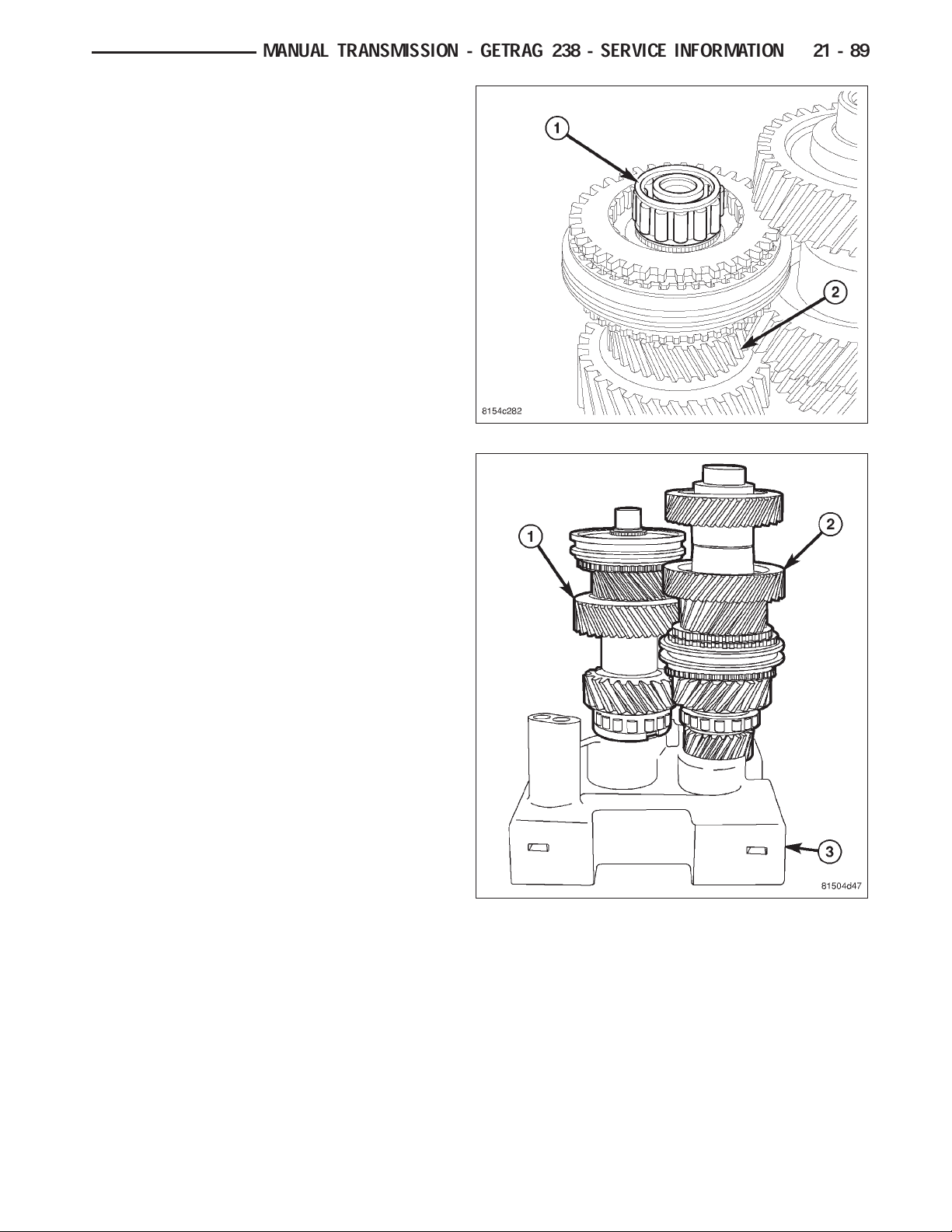

45. Remove input shaft bearing (1) from mainshaft

(2).

46. Remove countershaft (2) from fixture (3).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 89

Page 22

21 - 90 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

MAINSHAFT

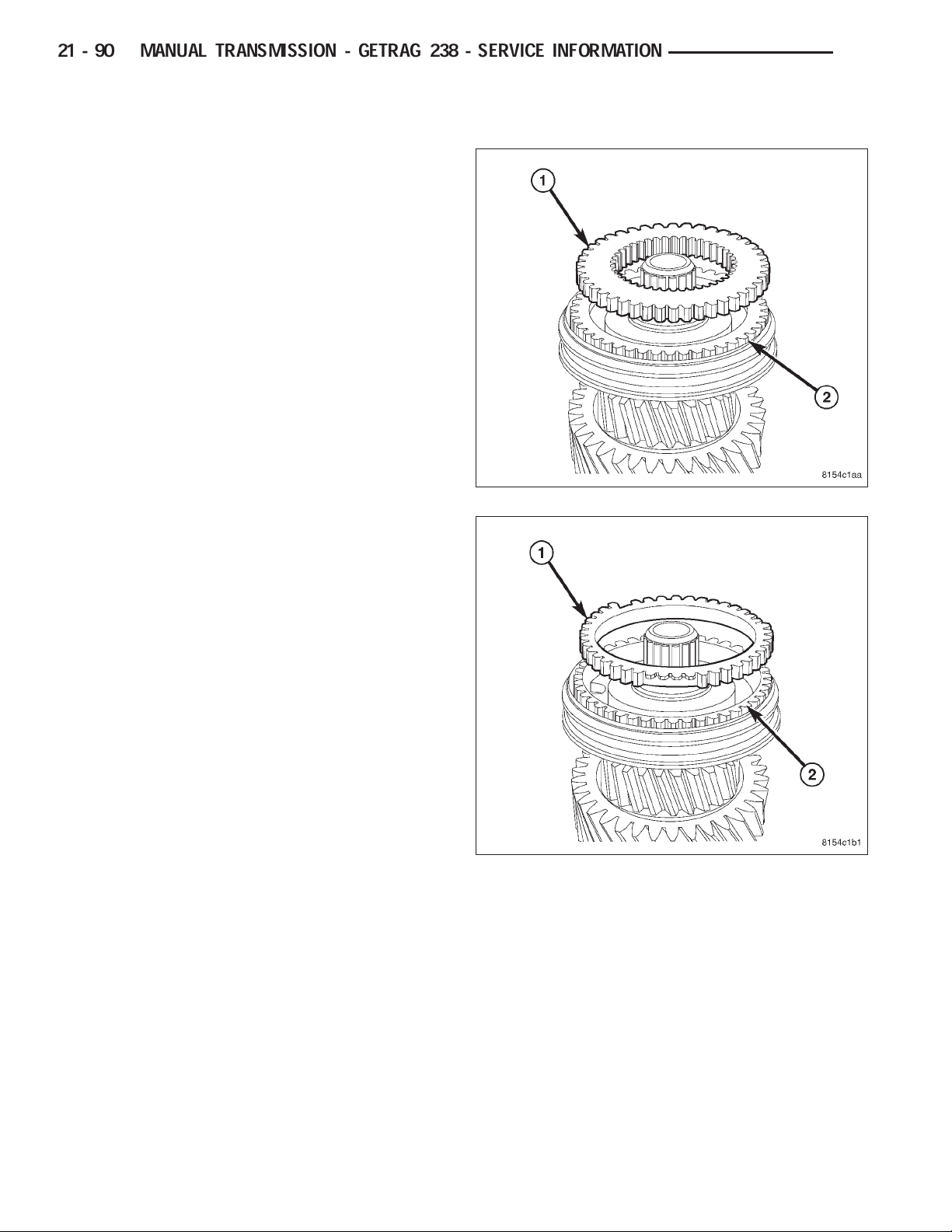

1. Remove fifth gear synchronizer clutch body (1)

from 5-6 synchronizer hub (2).

DR

2. Remove fifth gear synchronizer friction ring (1) from

5-6 synchronizer hub (2).

Page 23

DR

3. Remove 5-6 synchronizer sleeve (1) from hub (2).

4. Remove 5-6 synchronizer detents (1) from hub (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 91

5. Remove 5-6 synchronizer hub (1) snap ring (2).

Page 24

21 - 92 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

6. Remove 5-6 synchronizer hub (1) with three jaw

puller (2) and Button 9618-2 (3). Position jaws

under sixth gear clutch body (4).

DR

7. Remove sixth gear (1) from mainshaft (2).

Page 25

DR

8. Remove sixth gear bearing (1) from mainshaft (2).

9. Remove mainshaft center support bearing (1) from

mainshaft (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 93

Page 26

21 - 94 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

COUNTERSHAFT

1. Remove countershaft center support bearing (1)

from counter shaft (2).

NOTE: Countershaft with 3-4 synchronizer, is serviced as an assembly except bearings.

DR

CENTER SUPPORT PLATE

1. Remove center support (1) roller bearing race

retainer (2).

Page 27

DR

2. Remove mainshaft center support (1) bearing race

with Remove/Installer 9668 (2) and Handle C4171.

3. Remove countershaft center support (1) bearing

race with Remove/Installer 9617 (2) and Handle

C4171.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 95

Page 28

21 - 96 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

FRONT HOUSING

1. Remove mainshaft bearing retainer (1) and countershaft bearing retainers (2).

2. Remove mainshaft bearing and countershaft bearing with hammer and driver.

DR

REAR HOUSING

1. Remove reverse idler gear shaft bolt (1) from housing (2).

Page 29

DR

2. Remove reverse idler gear shaft (1) from idler gear

(2).

3. Remove reverse idler gear (1) shaft support (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 97

4. Remove reverse idler gear (1) and bearing (2).

Page 30

21 - 98 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

5. Remove mainshaft bearing (1) retainer (2) bolts

and remove retainer.

6. Remove bearing from housing with a hammer and

driver.

7. Break plastic countershaft roller bearing cage with

a screw driver. Then remove cage and roller bearing.

8. Insert Puller 9585 through the countershaft roller

bearing shell (1) and expand the tool (2) to grab

the bottom (3) of the bearing shell (1).

DR

9. Remove countershaft roller bearing shell (1) from

the rear housing with Puller 9585 (2) and Slide

Hammer C-637.

Page 31

DR

10. Remove shift rail roller bearing from rear housing

(3) with Puller 9609 (1) and Slide Hammer C-637

(2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 99

CLEANING

Clean gears, shafts, shift components and transmission housings with a standard parts cleaning solvent. Do not use

acid or corrosive base solvents. Dry all parts except bearings with compressed air.

Clean shaft bearings with a mild solvent such as MOPART degreasing solvent, GunkT or similar solvents. Do not

dry the bearings with compressed air. Allow the bearings to either air dry or wipe them dry with clean shop towels.

INSPECTION

NOTE: Minor corrosion, nicks, or pitting can be

smoothed with 400 grit emery and polished out

with crocus cloth.

Bearings: Inspect roller bearings for wear, chips,

cracks, flat-spots or brinnelling. Inspect sealed bearings, and verify bearings roll smoothly.

Gears: Inspect for worn, chipped, or cracked teeth.

Inspect bearing surfaces for wear or flat-spots.

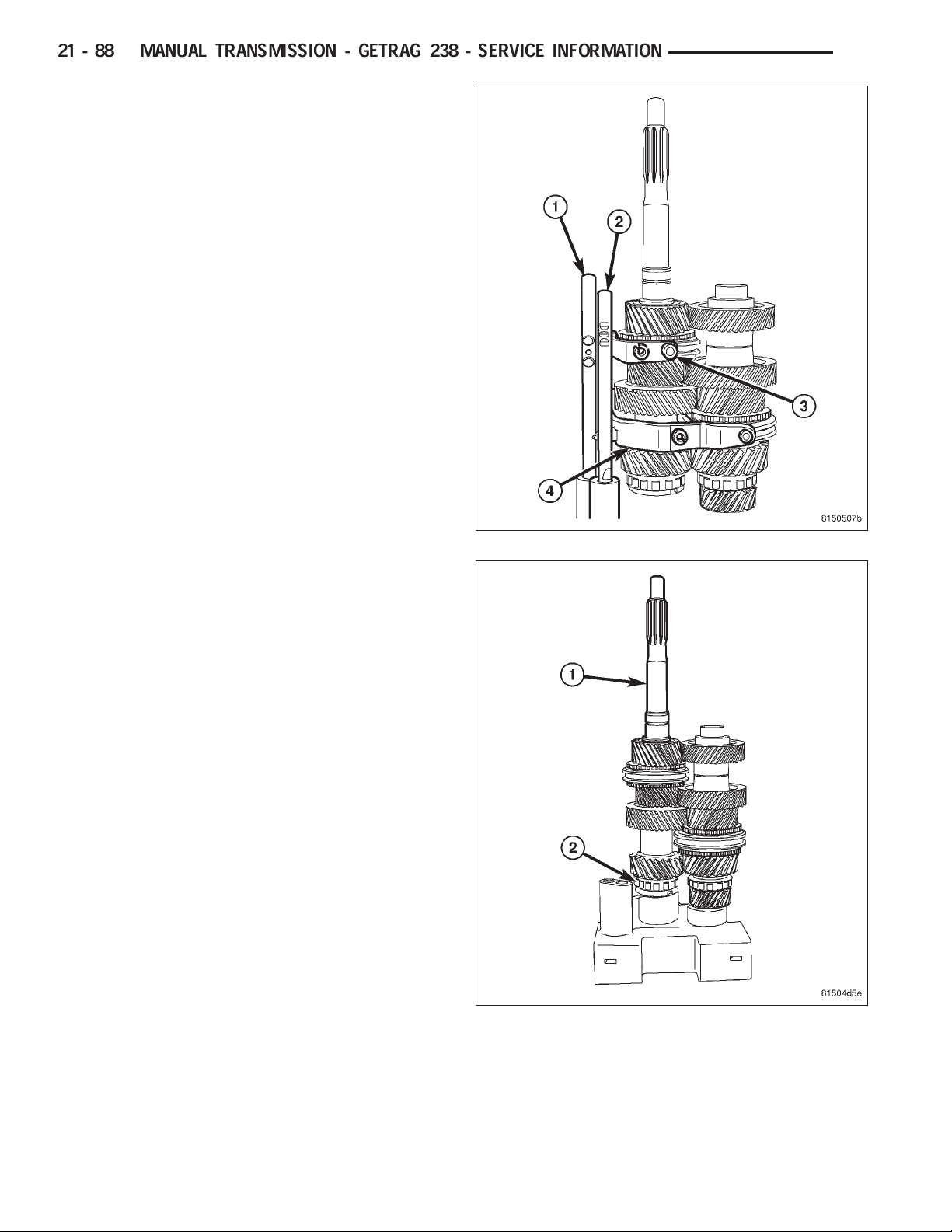

Mainshaft: Inspect for worn splines (1), snap ring

grooves (2) and worn, chipped or cracked teeth (3).

Inspect all bearing surfaces (4) for wear or flat-spots.

Third and fourth gear (3) are serviced with

mainshaft.

Page 32

21 - 100 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

Countershaft: Inspect all gears for worn, chipped or

cracked teeth (1). Inspect 3-4 synchronizer assembly

for wear (2). Inspect center support bearing surfaces

(3) for wear or flat-spots. The countershaft with 3-4

synchronizer is serviced as an assembly, except

for bearings.

Synchronizer components: Inspect for worn,

chipped, or cracked teeth and burned or flaking off

friction material. Synchronizers are serviced as an

assembly.

Input Shaft: Inspect input shaft bearing (1) and bear-

ing surfaces for wear or flat-spots. Inspect input shaft

splines (2) for wear. Inspect snap ring groove (3) for

wear. Inspect fifth gear (4) for worn, chipped, or

cracked teeth.

DR

Shift forks: Inspect shift forks (1) for distortion.

Inspect fork shoes (2) for wear and fit shoes in synchronizer sleeve to ensure parts fit and work smoothly.

Page 33

DR

Shift Rails: Inspect shift rails, bushings, and bearing

for wear. Verify main shift rail (1) bearings (2) roll

smoothly.

Clutch Release Bearing Support: Inspect clutch

release bearing support (1) release bearing slide surface (2) for damage.

Housing/Tail housing: Inspect sealing and mating

surfaces are free of burrs and nicks. Inspect alignment

dowels are tight and in good condition. Inspect shift

rail bushings for wear.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 101

Page 34

21 - 102 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

ASSEMBLY

MAINSHAFT

1. Install mainshaft center support bearing (1) on

mainshaft (2).

DR

2. Install sixth gear bearing (1) on mainshaft (2).

Page 35

DR

3. Install sixth gear (1) on mainshaft (2).

4. Install sixth gear clutch body (1) on sixth gear (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 103

5. Install sixth gear friction ring (1) on clutch body (2).

Page 36

21 - 104 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

6. Install 5-6 synchronizer hub (1) on mainshaft with

Installer W-262 (2).

DR

7. Install 5-6 synchronizer hub (1) snap ring (2).

Page 37

DR

8. Install 5-6 synchronizer detents (1) in hub (2).

9. Install 5-6 synchronizer sleeve (1) on hub (2).

NOTE: Align grooves in the sleeve with detents in

hub.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 105

10. Install fifth gear synchronizer friction ring (1) on

5-6 synchronizer hub (2).

Page 38

21 - 106 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

11. Install fifth gear synchronizer clutch body (1) on

5-6 synchronizer hub (2).

COUNTERSHAFT

1. Install countershaft center support bearing (1) on

countershaft (2).

DR

Page 39

DR

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 107

CENTER SUPPORT

1. Install center support (1) countershaft roller bearing

race with Installer/Remover 9617 (2) and Handle

C-4171.

2. Install center support (1) mainshaft roller bearing

race with Installer/Remover 9668 (2) and Handle

C-4171.

Page 40

21 - 108 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

3. Install center support (1) race retainer screw (2)

and tighten to 22 N·m (16 ft. lbs.).

REAR HOUSING

1. Install mainshaft bearing (1) in rear housing with

hammer and driver.

2. Install mainshaft bearing (1) retainer (2). Apply

MoparT Lock & Seal Adhesive or equivalent to

retainer bolts and tighten to 10 N·m (88 in. lbs.).

DR

Page 41

DR

3. Install shift rail roller bearing (1) with Installer 8475

(2).

4. Install countershaft bearing with Installer 9624 (1)

and Handle C-4171 (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 109

5. Install idler gear (1) in rear housing (2).

Page 42

21 - 110 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

6. Install idler gear bearing (1) in idler gear (2).

7. Install idler gear (1) shaft support (2).

DR

8. Install idler gear (2) shaft (1).

Page 43

DR

9. Install shaft bolt and align idler gear shaft (1) with

shaft bolt (2).

10. Apply MoparT Lock & Seal Adhesive or equivalent

to idler shaft bolt. Tighten bolt (1) in housing (2) to

25 N·m (18 ft. lbs.).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 111

Page 44

21 - 112 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

FRONT HOUSING

1. Install mainshaft and countershaft bearings in front

housing with hammer and driver.

2. Install mainshaft bearing retainer (1) and countershaft bearing retainers (2). Apply MoparT Lock &

Seal Adhesive or equivalent to retainer bolts and

tighten to 10 N·m (88 in. lbs.).

DR

3. Install mainshaft (1) and countershaft (2) in build

Fixture 9626 (3).

Page 45

DR

4. Install input shaft bearing (1) on mainshaft (2).

5. Install input shaft (1) on mainshaft (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 113

Page 46

21 - 114 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

6. Install 5-6 shift rail (1) and 3-4 shift rail (2) in build

Fixture 9626. Then install 5-6 shift fork (3) and 3-4

shift fork (4)

DR

WARNING: Use tongs when handling heated components. Failure to follow these instructions will

result in personal injury.

CAUTION: A bearing heater (3) is used to heat

Plug 9625 (1) and Plug 9619-1 (2). Use only a bearing heater/hot plate and follow manufacture’s

instructions. Heat components to 100 - 177 Celsius (212° Min. - 350° Max Fahrenheit). Never use

an open flame to heat components. Never leave

components on heater for an extended amount of

time. If component is discolored after heating, the

component has been overheated and must not be

used. Failure to follow these instructions will

result in component damage.

7. Heat Plug 9625 (1) and Plug 9619-1 (2) to a maximum of 177 Celsius (350° Fahrenheit) with bearing

heater (3).

Page 47

DR

8. With tongs place heated Plug 9625 in countershaft

bearing and heated Plug 9619-1 into mainshaft

bearing. Allow plugs to heat bearings for two

minutes.

9. Remove Plug 9625 and Plug 9619 with welding

gloves or tongs, then install front housing (1) on

mainshaft and countershaft in fixture (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 115

Page 48

21 - 116 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

10. Apply MoparT Lock & Seal Adhesive or equivalent

to shift fork pivot bolts. Install 5-6 (1) and 3-4 (2)

shift fork pivot bolts, in both sides of the front

housing and tighten to 35 N·m (26 ft. lbs.).

NOTE: Verify shift fork pivot holes are aligned with

pivot bolt holes before installing bolts.

11. Install two detents (1) in the side of the front hous-

ing (2).

DR

Page 49

DR

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 117

FINAL ASSEMBLY

1. Turn front housing (1) with fixture (2) over onto the

front housing and remove fixture.

2. Install intermediate plate (1) and two dowels (2).

Page 50

21 - 118 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

3. Install intermediate plate (1) bolts (2) and tighten to

22 N·m (16 ft. lbs.).

4. Install interlock plate washers (1) on support (2).

DR

5. Install interlock plate (2) and tighten bolts (1) to 10

N·m (88 in. lbs.).

Page 51

DR

6. Install second gear bearing (1) on mainshaft (2).

7. Install second gear (1) on mainshaft (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 119

8. Install second gear inner friction ring (1) on second

gear (2).

Page 52

21 - 120 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

9. Install second gear outer friction ring (1) on second

gear (2).

10. Install second gear blocker ring (1) on second

gear (2).

DR

Page 53

DR

11. Align 1-2 synchronizer hub (1) with blocker ring on

mainshaft and install hub with Installer D-389 (2).

NOTE: If 1-2 synchronizer hub is installed incorrectly the snap ring groove will not be visible.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 121

12. Install 1-2 synchronizer hub (1) snap ring (2).

Page 54

21 - 122 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

13. Install 1-2 synchronizer hub (1) detents (2).

14. Install 1-2 synchronizer sleeve (2) on 1-2 hub (1).

NOTE: Align grooves in the sleeve with detents in

hub.

DR

15. Install first gear blocker ring (1) on 1-2 hub (2).

Page 55

DR

16. Install first gear outer friction ring (1) on 1-2 hub

(2).

17. Install first gear inner friction ring (1) on 1-2 hub

(2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 123

18. Install first gear bearing (1) on mainshaft (2).

Page 56

21 - 124 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

19. Install first gear (1) on mainshaft (2).

WARNING: Use welding gloves or tongs when

handling heated components. Failure to follow

these instructions will result in personal injury.

DR

CAUTION: A bearing heater is used to heat reverse

bearing race (1). Use only a bearing heater/hot

plate and follow manufacturer’s instructions. Heat

components to 100 - 177 Celsius (212° Min. - 350°

Max Fahrenheit). Never use an open flame to heat

components. Never leave components on heater

for an extended amount of time. If component is

discolored after heating, the component has been

overheated and must not be used. Failure to follow these instructions will result in component

damage.

20. Heat reverse bearing race (1) with bearing heater

(2) to a maximum of 177 Celsius (350°

Fahrenheit).

21. With welding gloves or tongs install reverse bear-

ing race (1) on mainshaft (2).

Page 57

DR

22. Install reverse gear bearing (1) on bearing race

(2).

23. Install reverse gear (1) on mainshaft (2).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 125

24. Install reverse gear friction/blocker ring (1) on

reverse gear (2).

Page 58

21 - 126 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

25. Install reverse synchronizer detents (1) in reverse

hub (2).

26. Install reverse synchronizer sleeve (1) on reverse

hub (2).

NOTE: Align grooves in the sleeve with detents in

hub.

DR

27. Install reverse gear synchronizer hub (1) with

Installer D-389 (2).

Page 59

DR

28. Install main shift rail (1) bearings (2) on main shift

rail.

29. Install main shift rail (1) through rail support (2)

and housing, then rotate counterclockwise into

place.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 127

30. Install 1-2 shift fork then, install 1-2 shift rail (2)

into shift fork and housing. Install shift fork roll pin

(1).

Page 60

21 - 128 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

31. Install reverse shift rail (1) into the housing. Then

install reverse shift fork (2) and pull shift rail (1)

up into the shift fork.

32. Install reverse shift fork roll pin (1).

DR

WARNING: Use tongs when handling heated components. Failure to follow these instructions will

result in personal injury.

CAUTION: A bearing heater (2) is used to heat

Plug 9619-2 (1). Use only a bearing heater/hot

plate and follow manufacturer’s instructions. Heat

components to 100 - 177 Celsius (212° Min. - 350°

Max Fahrenheit). Never use an open flame to heat

components. Never leave components on heater

for an extended amount of time. If component is

discolored after heating, the component has been

overheated and must not be used. Failure to follow these instructions will result in component

damage.

33. Heat Plug 9619-2 (1) with bearing heater (2) to a

maximum of 177 Celsius (350° Fahrenheit).

Page 61

DR

34. With tongs place Plug 9619-2 in rear housing

mainshaft bearing (2). Allow plug to heat bearing

for two minutes.

35. Apply a bead of MoparT Gasket Maker or equiv-

alent to the front housing sealing surface.

36. Remove plug and install rear housing (1) on front

housing (2).

37. Install housing bolts and tighten to 22 N·m (16 ft.

lbs.).

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 129

38. Install output shaft seal in rear housing (1) with

Installer 9629 (2).

Page 62

21 - 130 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

39. Install 4x4 transmission output shaft nut with

Socket 9584 and tighten to 200 N·m (147 ft. lbs.).

Then loosen nut and tighten to 170 N·m (125 ft.

lbs.).

40. Drive output shaft flange onto the output shaft

with Installer D-389.

41. Install 4x2 transmission output shaft flange (1)

and tighten bolt (2) to 200 N·m (147 ft. lbs.). Then

loosen bolt and tighten to 170 N·m (125 ft. lbs.).

Remove Wrench 9586 from input shaft.

DR

42. Install two detent plugs in the top of the rear

housing.

43. Install large detent plunger (1) and spring (2) in

the side of the rear housing.

Page 63

DR

44. Install large detent plug (1) in the side of the rear

housing (2).

45. Install back up lamp switch (1) and tighten bolt (2)

to 10 N·m (88 in. lbs.). Then lay transmission

down on bench.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 131

46. Install input shaft (1) snap ring (2).

Page 64

21 - 132 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

47. Install input shaft seal in front housing with

Installer 9620 (1) and Tube C-3717 (2).

48. Install clutch bearing release support (1) and

tighten bolts (2) to 10 N·m (88 in. lbs.).

DR

49. Install Wrench 9586 (1) on input shaft (2).

Page 65

DR

50. Install countershaft bolt (1) in front housing.

Tighten bolt (1) to 90 N·m (66 ft. lbs.).

51. Install countershaft plug in front housing (1) with

Installer 9622 (2) and Handle C-4171.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 133

52. Install the cover plate for the second shift tower

location, if necessary.

53. Apply MoparT Lock & Seal or equivalent to shifter

socket threads and install shifter socket (1).

Page 66

21 - 134 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

INSTALLATION

1. Clean transmission front housing mounting surface.

2. Apply light coat of Mopar high temperature bearing

grease or equivalent to contact surfaces of following components:

• release fork (1) ball stud (2)

• release bearing slide surface (3)

• input shaft splines (4)

• release bearing bore (5)

• propeller shaft slip yoke.

3. Support and secure transmission to jack.

4. Raise and align transmission input shaft with clutch

disc, then slide transmission into place.

5. Verify front housing is fully seated. Install transmission bolts without washers (1) and tighten bolts into

the engine to 41 N·m (30 ft. lbs.). Tighten the bolts

with washers (2) into the transmission to 68 N·m

(50 ft. lbs.).

6. Install rear crossmember (1) and tighten nuts to

102 N·m (75 ft. lbs.).

7. Install transmission rear mount (2) bolts and tighten

to 68 N·m (50 ft. lbs.).

DR

Page 67

DR

8. Install front dust shield (1) tighten bolt to 4.5 N·m

(40 in. lbs.).

9. Install structural cover (3) to transmission bolts and

tighten to 54 N·m (40 ft. lbs.).

10. Install starter motor (2).

11. Install suspension crossmember (4) and tighten

nuts to 102 N·m (75 ft. lbs.).

12. Connect transmission harnesses to clips on case

and connect switches.

13. Install slave cylinder (2) and tighten cylinder nuts

(1) to 23 N·m (200 in. lbs.).

14. Install transfer case and transfer case linkage if

equipped.

15. Remove transmission jack.

16. Install propeller shaft/shafts with reference marks

aligned.

17. Install exhaust on the exhaust manifolds.

18. Fill transmission with lubricant. Correct fill level is

to bottom edge of fill plug hole.

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 135

SPECIFICATIONS

MANUAL TRANSMISSION - GETRAG 238

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Drain Plug 50 37 -

Fill Plug 50 37 -

Shift Tower Bolts 10 - 88

Back Up Lamp Switch Bolt 10 - 88

4x2 Output Flange Bolt

4x4 Output Shaft Nut

Housing Bolts 22 16 -

Interlock Plate Bolts 10 - 88

Intermediate Support Bolts 22 16 -

Intermediate Support Race

Retainer Bolt

Countershaft Bolt 90 66 -

200 then loosen and

tighten to 170

200 then loosen and

tighten to 170

22 16 -

147 then loosen and

tighten to 125

147 then loosen and

tighten to 125

-

-

Page 68

21 - 136 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Reverse Idler Gear Shaft

Bolt

Mainshaft, Countershaft

Bearing Retainer Bolts

Input Shaft Retainer Bolts 10 - 88

Shift Fork Pivot Bolts 35 26 -

Support Braket to Trans

Bolts

GEAR SPECIFICATIONS

GEAR RATIO

FIRST 4.23

SECOND 2.53

THIRD 1.67

FOURTH 1.23

FIFTH 1.00

SIXTH 0.79

REVERSE 3.84

25 18 -

10 - 88

54 40 -

DR

Page 69

DR

SPECIAL TOOLS

INSTALLER C-3717

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 137

INSTALLER W-262

SLIDE HAMMER C-3752

SLIDE HAMMER C-637

INSTALLER 8475

PULLER 8870

INSTALLER D-389

PULLER 8992

Page 70

21 - 138 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

DR

BRIDGE 938

PULLER 9583

WRENCH 9586

PULLER 9609

SOCKET 9584

PULLER 9585

REMOVER/INSTALLER 9617

PULLER 9618

Page 71

DR

MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION 21 - 139

BUTTON 9618-2

HEAT PLUG 9619-1 & 9619-2

INSTALLER 9622

INSTALLER 9624

INSTALLER 9620

PULLER 9621

HEAT PLUG 9625

FIXTURE 9626

Page 72

21 - 140 MANUAL TRANSMISSION - GETRAG 238 - SERVICE INFORMATION

DR

PULLER ADAPTER 9627

PULLER ADAPTER 9628

REMOVER/INSTALLER 9668

INSTALLER 9629

REMOVER 9667

Loading...

Loading...