Dodge Fuel Service Manual

DR FUEL SYSTEM 14 - 1

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS ....................1

FUEL INJECTION - GAS ...................24

FUEL DELIVERY - GAS

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS

DESCRIPTION ..........................1

OPERATION ............................2

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE ...................2

SPECIFICATIONS

FUEL SYSTEM PRESSURE ..............3

TORQUE - FUEL SYSTEM ...............3

SPECIAL TOOLS

FUEL SYSTEM ........................5

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION ..........................6

OPERATION ............................6

FUEL LEVEL SENDING UNIT / SENSOR

DESCRIPTION ..........................7

OPERATION ............................7

REMOVAL .............................7

INSTALLATION ..........................8

FUEL LINES

DESCRIPTION ..........................8

QUICK CONNECT FITTING

DESCRIPTION ..........................8

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS ............................8

FUEL DELIVERY - DIESEL .................56

FUEL INJECTION - DIESEL ................79

FUEL PUMP

DESCRIPTION .........................12

OPERATION ...........................12

FUEL PUMP MODULE

DESCRIPTION .........................12

OPERATION ...........................12

REMOVAL .............................12

INSTALLATION .........................13

FUEL RAIL

DESCRIPTION .........................13

OPERATION ...........................13

REMOVAL .............................13

INSTALLATION .........................18

FUEL TANK

DESCRIPTION .........................20

OPERATION ...........................20

REMOVAL- EXCEPT DIESEL ..............20

INSTALLATION - EXCEPT DIESEL ..........22

INLET FILTER

REMOVAL .............................23

INSTALLATION .........................23

FUEL DELIVERY - GAS

DESCRIPTION

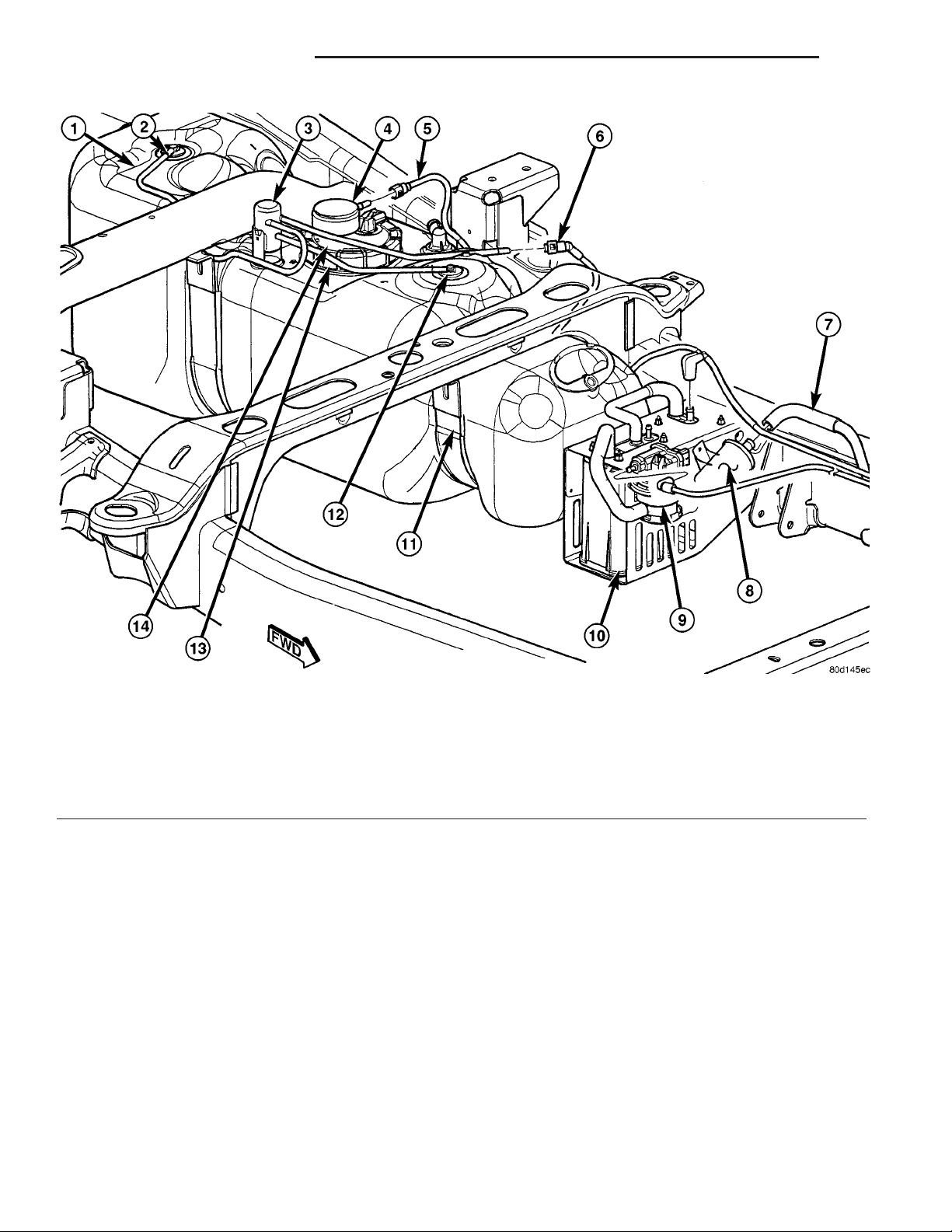

The fuel delivery system consists of:

• a fuel pump module containing the electric fuel

pump, fuel filter/fuel pressure regulator, fuel gauge

sending unit (fuel level sensor) and a secondary fuel

filter located at the bottom of the pump module

• fuel tubes/lines/hoses

• a combination fuel filter/fuel pressure regulator

• quick-connect fittings

• fuel injector rail

• fuel tank

• fuel tank filler/vent tube assembly

• fuel tank filler tube cap

• accelerator pedal

• throttle cable

Certain fuel delivery components can be found in

(Fig. 1).

14 - 2 FUEL DELIVERY - GAS DR

FUEL DELIVERY - GAS (Continued)

Fig. 1 FUEL DELIVERY COMPONENTS

1 - FUEL TANK 8 - LDP FRESH AIR FILTER

2 - CHECK VALVE 9 - LEAK DETECTION PUMP

3 - LIQUID EXPANSION CHAMBER 10 - EVAP CANISTERS (2)

4 - FUEL FILTER / FUEL PRESSURE REGULATOR 11 - FUEL TANK STRAPS (2)

5 - QUICK-CONNECT FITTING AND FUEL LINE (TO ENGINE) 12 - CHECK VALVE

6 - EVAP LINE CONNECTION 13 - FUEL PUMP MODULE LOCK RING

7 - LEAK DETECTION PUMP FRESH AIR LINE 14 - FUEL PUMP MODULE

OPERATION

Fuel is returned through the fuel pump module

and back into the fuel tank through the fuel filter/

fuel pressure regulator. A separate fuel return line

from the engine to the tank is not used.

The fuel tank assembly consists of: the fuel tank,

fuel pump module assembly, fuel pump module locknut/gasket, and fuel tank check valve (refer to Fuel

sphere. The description and function of the Evaporative Control System is found in Emission Control

Systems.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal scheduled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

Tank Check Valve for information).

A fuel filler/vent tube assembly using a pressure/

vacuum, 1/4 turn fuel filler cap is used. The fuel

filler tube contains a flap door located below the fuel

fill cap.

Also to be considered part of the fuel system is the

evaporation control system. This is designed to

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE

Use following procedure if the fuel injector

rail is, or is not equipped with a fuel pressure

test port.

(1) Remove fuel fill cap.

reduce the emission of fuel vapors into the atmo-

DR FUEL DELIVERY - GAS 14 - 3

FUEL DELIVERY - GAS (Continued)

(2) Remove fuel pump relay from Power Distribution Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cylinder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.

(8) Connect other end of jumper wire to positive

side of battery.

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa +/- 34 kPa (49.2 psi +/- 2 psi).

(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-connect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC’s)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBt scan tool must be

used to erase a DTC.

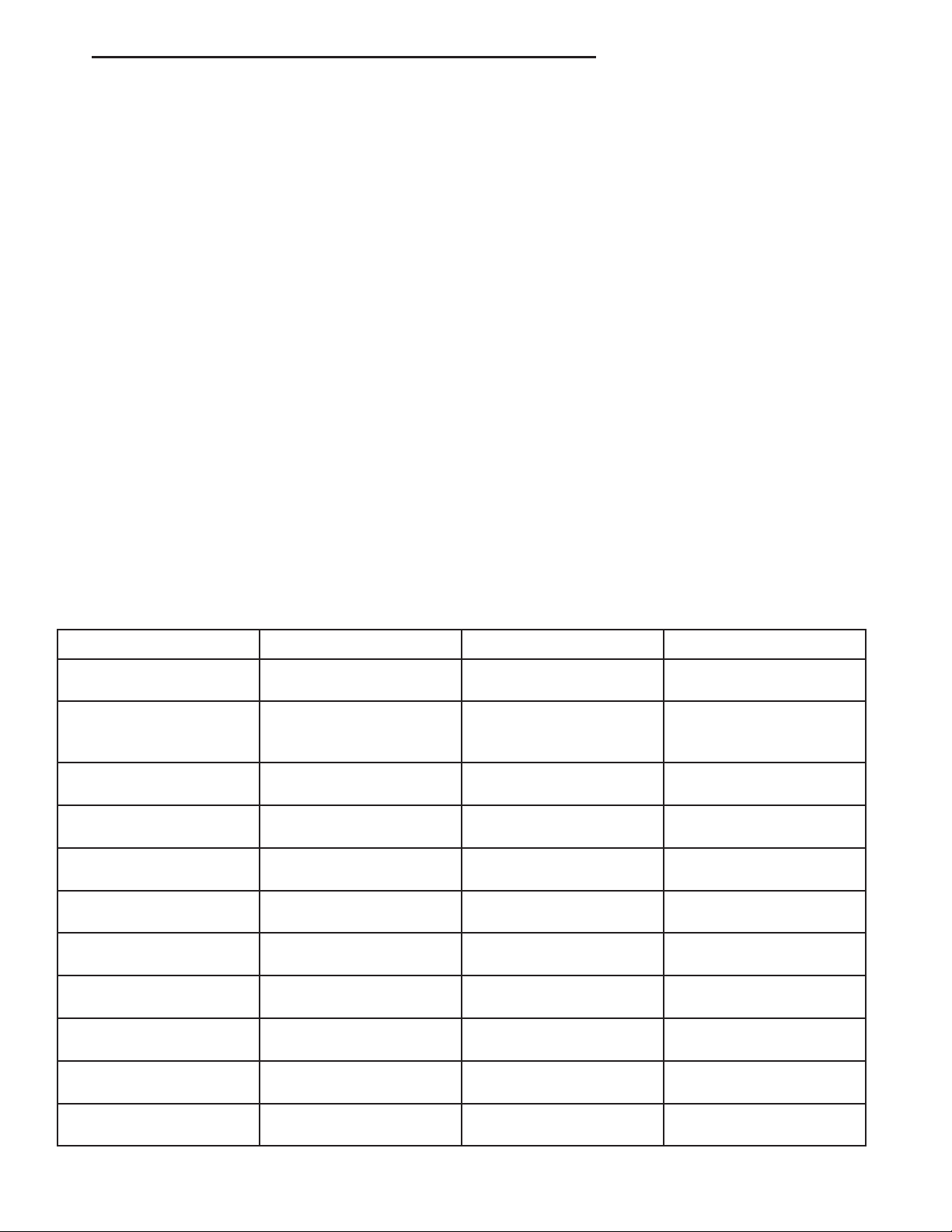

TORQUE - FUEL SYSTEM

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting

Accelerator Pedal Position

Sensor Bracket-to-Battery

Tray Bolts

Crankshaft Position

Sensor - 3.7L

Crankshaft Position

Sensor - 4.7L

Crankshaft Position

Sensor - 5.7L

Crankshaft Position

Sensor - 5.9L

Crankshaft Position

Sensor - 8.0L

Camshaft Position Sensor

- 3.7L

Camshaft Position Sensor

- 4.7L

Camshaft Position Sensor

- 5.7L

Camshaft Position Sensor

- 8.0L

12 - 105

3-30

28 21 -

28 21 -

12 - 105 (+/-20)

8-70

8-70

12 - 106

12 - 106

12 9 105 (+/-) 20

6-50

14 - 4 FUEL DELIVERY - GAS DR

FUEL DELIVERY - GAS (Continued)

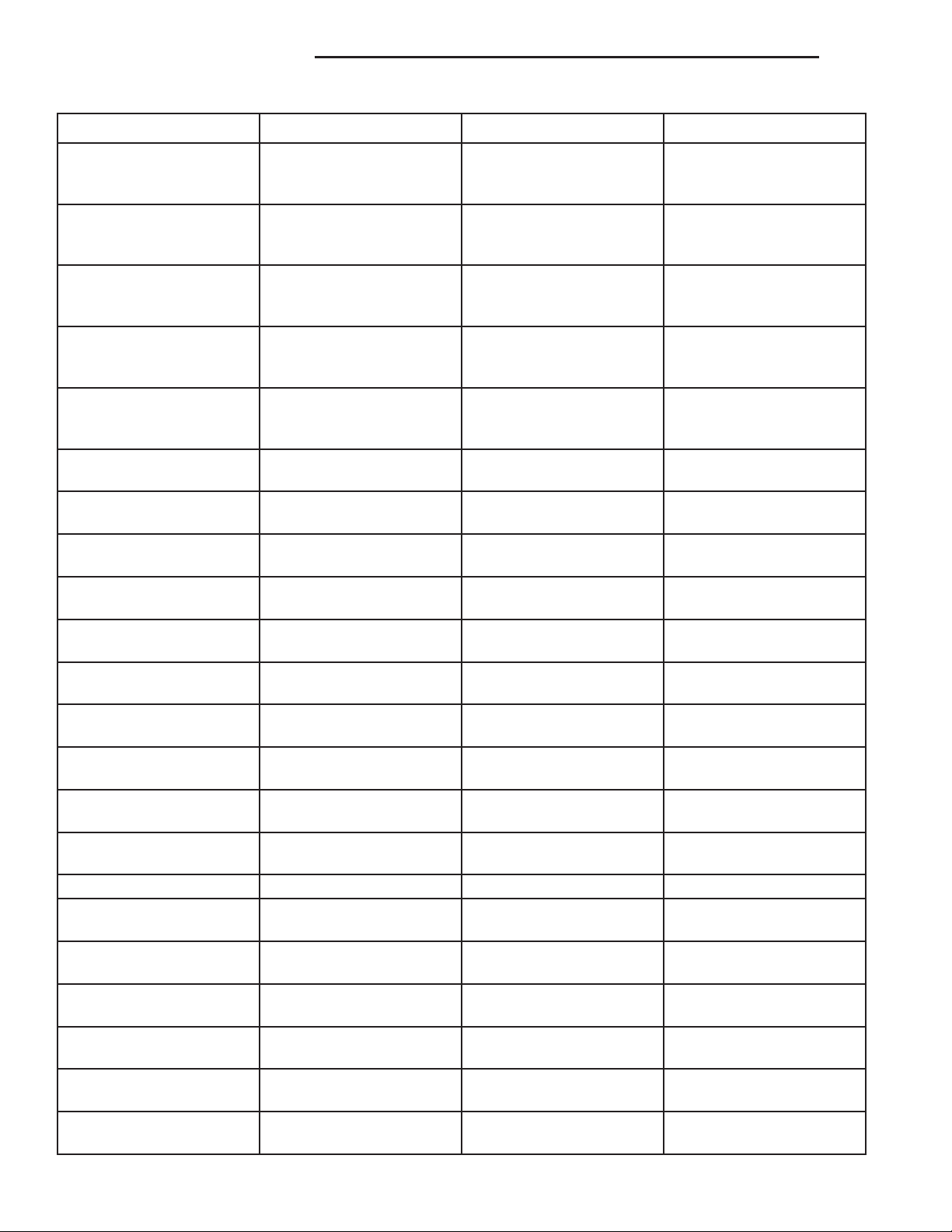

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Engine Coolant

Temperature Sensor -

3.7L

Engine Coolant

Temperature Sensor -

4.7L

Engine Coolant

Temperature Sensor -

5.7L

Engine Coolant

Temperature Sensor -

5.9L

Engine Coolant

Temperature Sensor -

8.0L

EVAP Canister- to-Bracket

Nuts

EVAP Canister-to-frame

bolts

Fuel Filler Hose Clamp at

Tank

Fuel Filler Housing-to-

Body Screws

Fuel Pump Module Lock

Ring

Fuel Rail Mounting Bolts -

3.7L

Fuel Rail Mounting Bolts -

4.7L

Fuel Rail Mounting Bolts -

5.7L

Fuel Rail Mounting Bolts -

5.9L

Fuel Rail Mounting Bolts -

8.0L

Fuel Tank Mounting Straps 41 30 -

IAC Motor Mounting

Screws - 3.7L

IAC Motor Mounting

Screws - 4.7L

IAC Motor Mounting

Screws - 5.9L

IAC Motor Mounting

Screws - 8.0L

Leak Detection Pump

Mounting Bolt

Map Sensor Mounting

Screws - 3.7L

11 - 96

11 - 96

11 - 96

11 - 96

11 - 96

8.5 - 75

34 25

3-30

2-17

54 40 -

11 -

11 - 100

11 - 100

23 - 200

15 - 136

7-60

7-60

7-60

7-60

8.5 - 75

3-25

100

DR FUEL DELIVERY - GAS 14 - 5

FUEL DELIVERY - GAS (Continued)

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Map Sensor Mounting

Screws - 4.7L

Map Sensor Mounting

Screws - 5.9L

Map Sensor Mounting

Screws - 8.0L

PCM-to-Mounting Bracket

Mounting Screws

Power Steering Pressure

Switch - 3.7L

Power Steering Pressure

Switch - 4.7L

TPS Mounting Screws -

3.7L

TPS Mounting Screws -

4.7L

TPS Mounting Screws -

5.9L

TPS Mounting Screws -

8.0L

Throttle Body Mounting

Bolts - 3.7L

Throttle Body Mounting

Bolts - 4.7L

Throttle Body Mounting

Bolts - 5.7L

Throttle Body Mounting

Bolts - 5.9L

Throttle Body Mounting

Bolts - 8.0L

Oxygen Sensors 30 22 -

3-25

3-25

2-20

4-35

14-22 - 124-195

14-22 - 124-195

7-60

7-60

7-60

7-60

11 - 100

12 - 105

12 - 105

23 - 200

22 - 192

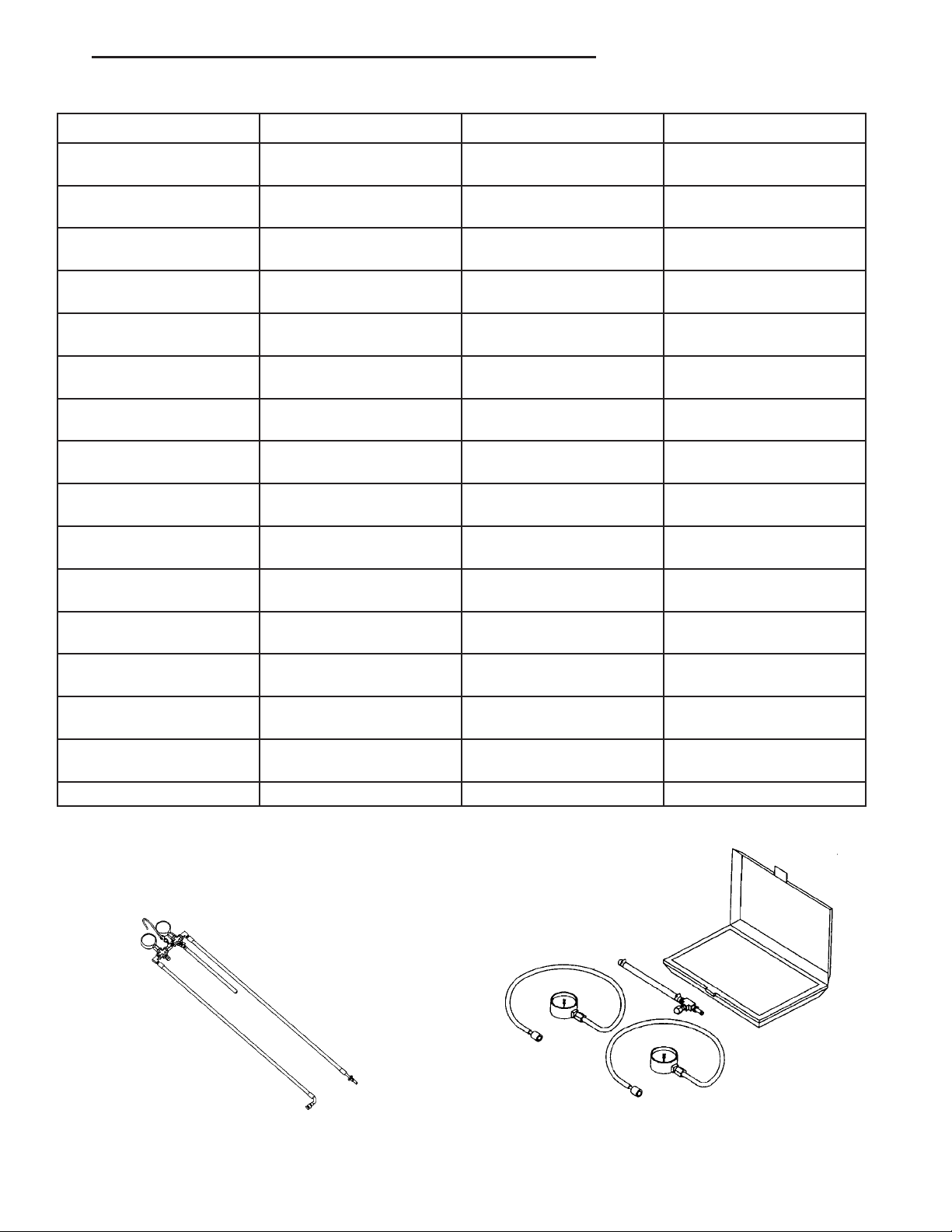

SPECIAL TOOLS

FUEL SYSTEM

FUEL PRESSURE TESTER - #8978

TEST KIT, FUEL PRESSURE, 8.0L ENGINE - #5069

14 - 6 FUEL DELIVERY - GAS DR

FUEL DELIVERY - GAS (Continued)

FUEL FILTER/PRESSURE

REGULATOR

DESCRIPTION

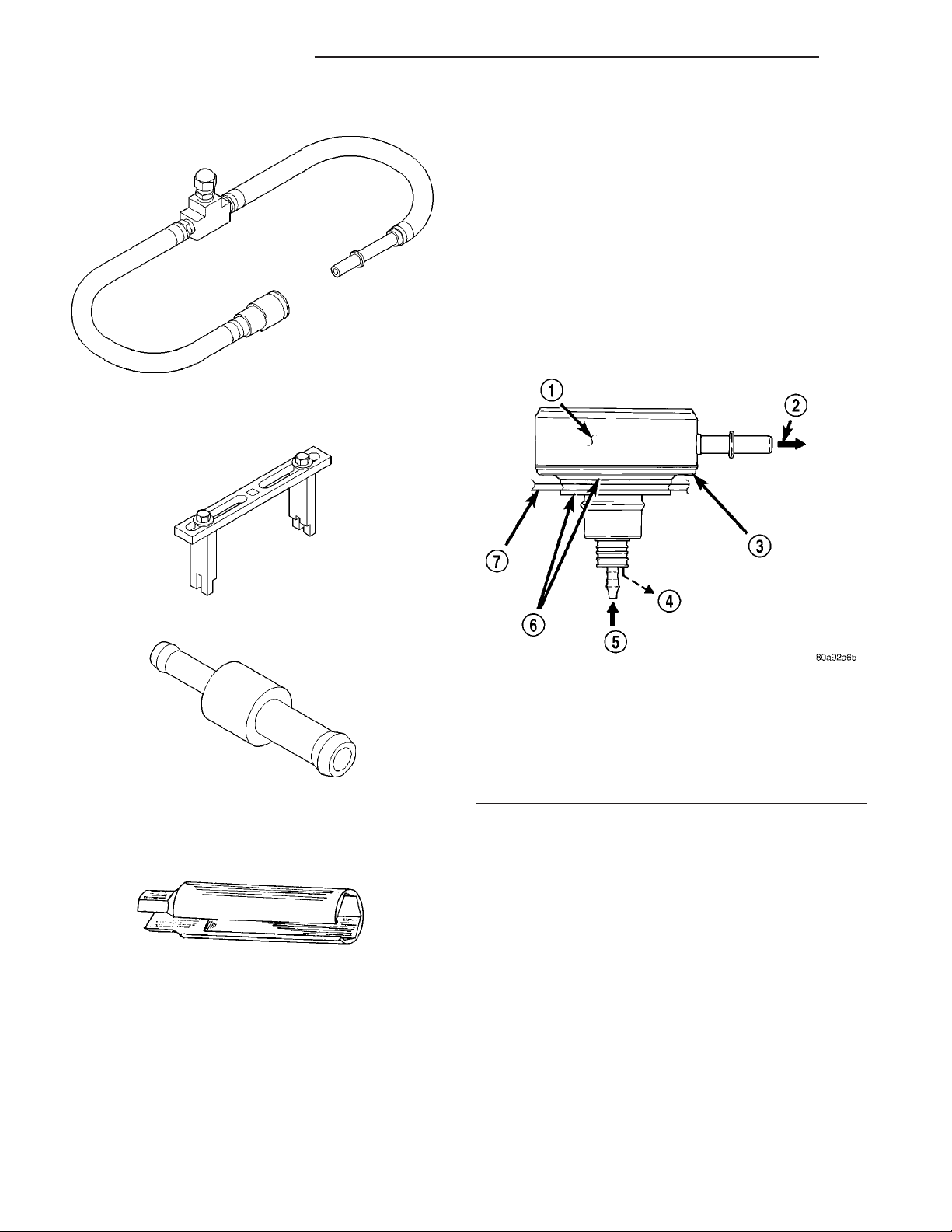

A combination fuel filter and fuel pressure regulator (Fig. 2) is used on all engines. It is located on the

top of the fuel pump module. A separate frame

mounted fuel filter is not used with any engine.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal scheduled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

ADAPTERS, FUEL PRESSURE TEST, 8.0L - #6539

AND/OR #6631

SPANNER WRENCH - #6856

FITTING, AIR METERING - #6714

O2S (OXYGEN SENSOR) REMOVER/INSTALLER -

#C-4907

Fig. 2 SIDE VIEW - FILTER/REGULATOR

1 - INTERNAL FUEL FILTER

2 - FUEL FLOW TO FUEL INJECTORS

3 - FUEL FILTER/FUEL PRESSURE REGULATOR

4 - EXCESS FUEL BACK TO TANK

5 - FUEL INLET

6 - RUBBER GROMMET

7 - TOP OF PUMP MODULE

OPERATION

Fuel Pressure Regulator Operation: The pressure regulator is a mechanical device that is not controlled by engine vacuum or the Powertrain Control

Module (PCM).

The regulator is calibrated to maintain fuel system

operating pressure of approximately 339 kPa ± 34

kPa (49.2 psi ± 5 psi) at the fuel injectors. It contains

a diaphragm, calibrated springs and a fuel return

valve. The internal fuel filter (Fig. 2) is also part of

the assembly.

Fuel is supplied to the filter/regulator by the electric fuel pump through an opening tube at the bottom of filter/regulator (Fig. 2).

The regulator acts as a check valve to maintain

some fuel pressure when the engine is not operating.

This will help to start the engine. A second check

valve is located at the outlet end of the electric fuel

DR FUEL DELIVERY - GAS 14 - 7

FUEL FILTER/PRESSURE REGULATOR (Continued)

pump. Refer to Fuel Pump - Description and

Operation for more information.

If fuel pressure at the pressure regulator exceeds

approximately 49.2 psi, an internal diaphragm opens

and excess fuel pressure is routed back into the tank

through the bottom of pressure regulator.

Both fuel filters (at bottom of fuel pump module

and within fuel pressure regulator) are designed for

extended service. They do not require normal scheduled maintenance. Filters should only be replaced if

a diagnostic procedure indicates to do so.

FUEL LEVEL SENDING UNIT /

SENSOR

DESCRIPTION

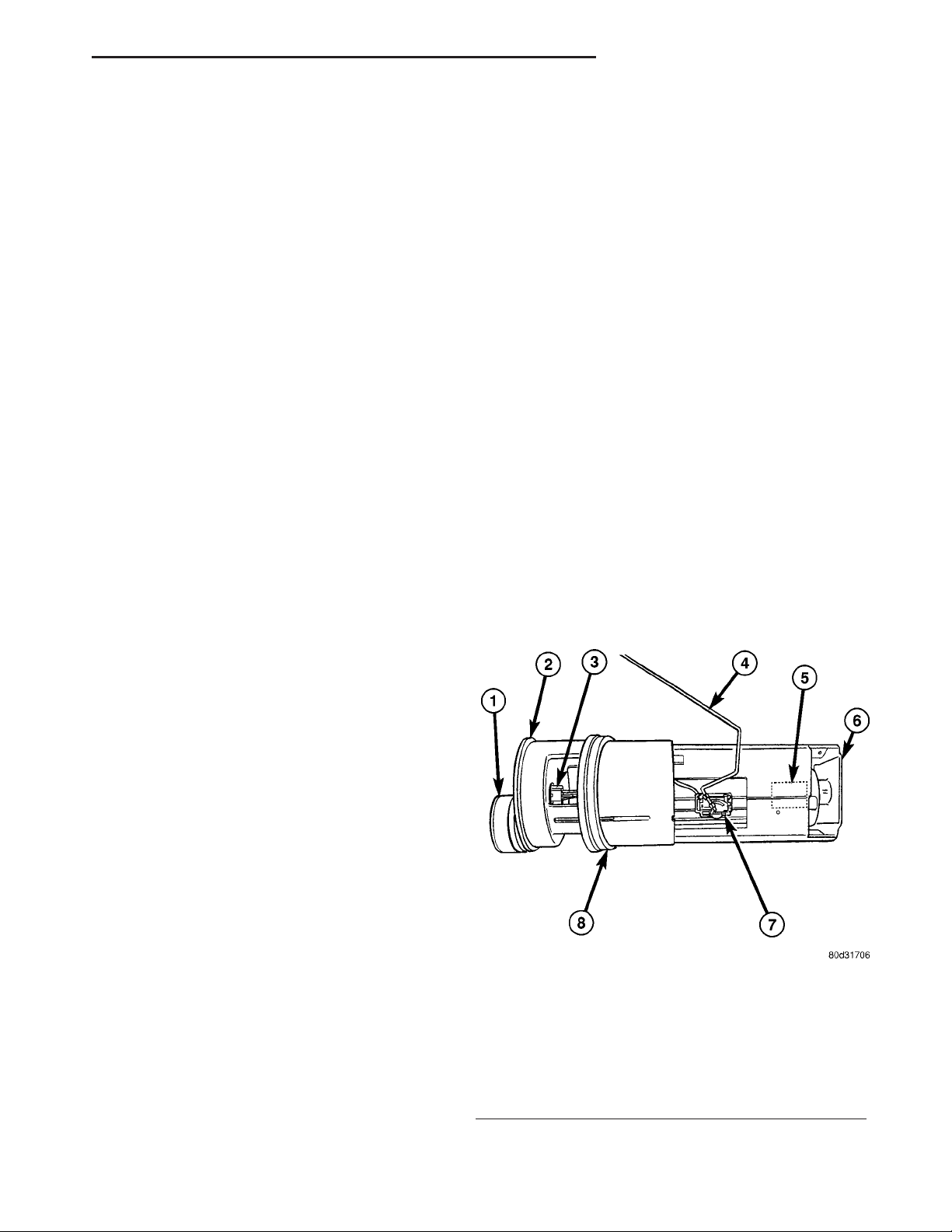

The fuel gauge sending unit (fuel level sensor) is

attached to the side of the fuel pump module. The

sending unit consists of a float, an arm, and a variable resistor track (card).

OPERATION

The fuel pump module has 4 different circuits

(wires). Two of these circuits are used for the fuel

gauge sending unit for fuel gauge operation, and for

certain OBD II emission requirements. The other 2

wires are used for electric fuel pump operation.

For Fuel Gauge Operation: A constant current

source is supplied to the resistor track on the fuel

gauge sending unit. This is fed directly from the

Powertrain Control Module (PCM). NOTE: For

diagnostic purposes, this 12V power source can

only be verified with the circuit opened (fuel

pump module electrical connector unplugged).

With the connectors plugged, output voltages

will vary from about 0.6 volts at FULL, to about

8.6 volts at EMPTY (about 8.6 volts at EMPTY

for Jeep models, and about 7.0 volts at EMPTY

for Dodge Truck models). The resistor track is

used to vary the voltage (resistance) depending on

fuel tank float level. As fuel level increases, the float

and arm move up, which decreases voltage. As fuel

level decreases, the float and arm move down, which

increases voltage. The varied voltage signal is

returned back to the PCM through the sensor return

circuit.

Both of the electrical circuits between the fuel

gauge sending unit and the PCM are hard-wired (not

multi-plexed). After the voltage signal is sent from

the resistor track, and back to the PCM, the PCM

will interpret the resistance (voltage) data and send

a message across the multi-plex bus circuits to the

instrument panel cluster. Here it is translated into

the appropriate fuel gauge level reading. Refer to

Instrument Panel for additional information.

For OBD II Emission Monitor Requirements:

The PCM will monitor the voltage output sent from

the resistor track on the sending unit to indicate fuel

level. The purpose of this feature is to prevent the

OBD II system from recording/setting false misfire

and fuel system monitor diagnostic trouble codes.

The feature is activated if the fuel level in the tank

is less than approximately 15 percent of its rated

capacity. If equipped with a Leak Detection Pump

(EVAP system monitor), this feature will also be activated if the fuel level in the tank is more than

approximately 85 percent of its rated capacity.

REMOVAL

The fuel level sending unit (fuel level sensor) and

float assembly is located on the side of the fuel pump

module (Fig. 3).

(1) Remove fuel pump module from fuel tank.

Refer to Fuel Pump Module Removal/Installation.

(2) To remove sending unit from pump module, lift

on plastic locking tab (Fig. 4) while sliding sending

unit tracks.

(3) Disconnect 4–wire electrical connector (Fig. 3)

from fuel pump module. Separate necessary sending

unit wiring from connector using terminal pick /

removal tool. Refer to Special Tools in 8W Wiring for

tool part numbers.

Fig. 3 LOCATION - FUEL GAUGE SENDING UNIT

1 - FUEL FILTER / FUEL PRESSURE REGULATOR

2 - FUEL PUMP MODULE ASSEMBLY

3 - 4-WAY ELEC. CONNECT.

4 - FLOATARM

5 - ELEC. FUEL PUMP

6 - INLET FILTER

7 - FUEL GAUGE SENDING UNIT

8 - GASKET (SEAL)

14 - 8 FUEL DELIVERY - GAS DR

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

QUICK CONNECT FITTING

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components, lines and

tubes. These are: a single-tab type, a two-tab type or

a plastic retainer ring type. Some are equipped with

safety latch clips. Some may require the use of a special tool for disconnection and removal. Refer to

Quick-Connect Fittings Removal/Installation for more

information.

Fig. 4 FUEL GAUGE SENDING UNIT - R/I

1 - SENDING UNIT

2 - LOCK TAB

3 - TRACKS

4 - NOTCH

INSTALLATION

(1) Connect necessary wiring into electrical connectors. Connect 4–wire electrical connector to pump

module.

(2) Position sending unit to pump module. Slide

and snap into place.

(3) Install fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

FUEL LINES

DESCRIPTION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM MAY BE UNDER A

CONSTANT PRESSURE (EVEN WITH THE ENGINE

OFF). BEFORE SERVICING ANY FUEL SYSTEM

HOSES, FITTINGS, LINES, OR MOST COMPONENTS, FUEL SYSTEM PRESSURE MUST BE

RELEASED. REFER TO THE FUEL SYSTEM PRESSURE RELEASE PROCEDURE.

CAUTION: The interior components (o-rings, clips)

of quick-connect fittings are not serviced separately, but new plastic spacers are available for

some types. If service parts are not available, do

not attempt to repair the damaged fitting or fuel line

(tube). If repair is necessary, replace the complete

fuel line (tube) assembly.

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

Also refer to Fuel Tubes/Lines/Hoses and Clamps.

Different types of quick-connect fittings are used to

attach various fuel system components, lines and

tubes. These are: a single-tab type, a two-tab type or

a plastic retainer ring type. Safety latch clips are

used on certain components/lines. Certain fittings

may require use of a special tool for disconnection.

DISCONNECTING

WARNING: THE FUEL SYSTEM IS UNDER A CONSTANT PRESSURE (EVEN WITH ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSE,

FITTING OR LINE, FUEL SYSTEM PRESSURE MUST

BE RELEASED. REFER TO FUEL SYSTEM PRESSURE RELEASE PROCEDURE.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contaminated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped: The hose clamps used to secure rubber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

CAUTION: The interior components (o-rings, spacers) of some types of quick-connect fitting are not

serviced separately. If service parts are not available, do not attempt to repair a damaged fitting or

fuel line. If repair is necessary, replace complete

fuel line assembly.

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure.

DR FUEL DELIVERY - GAS 14 - 9

QUICK CONNECT FITTING (Continued)

(2) Disconnect negative battery cable from battery.

(3) Clean fitting of any foreign material before disassembly.

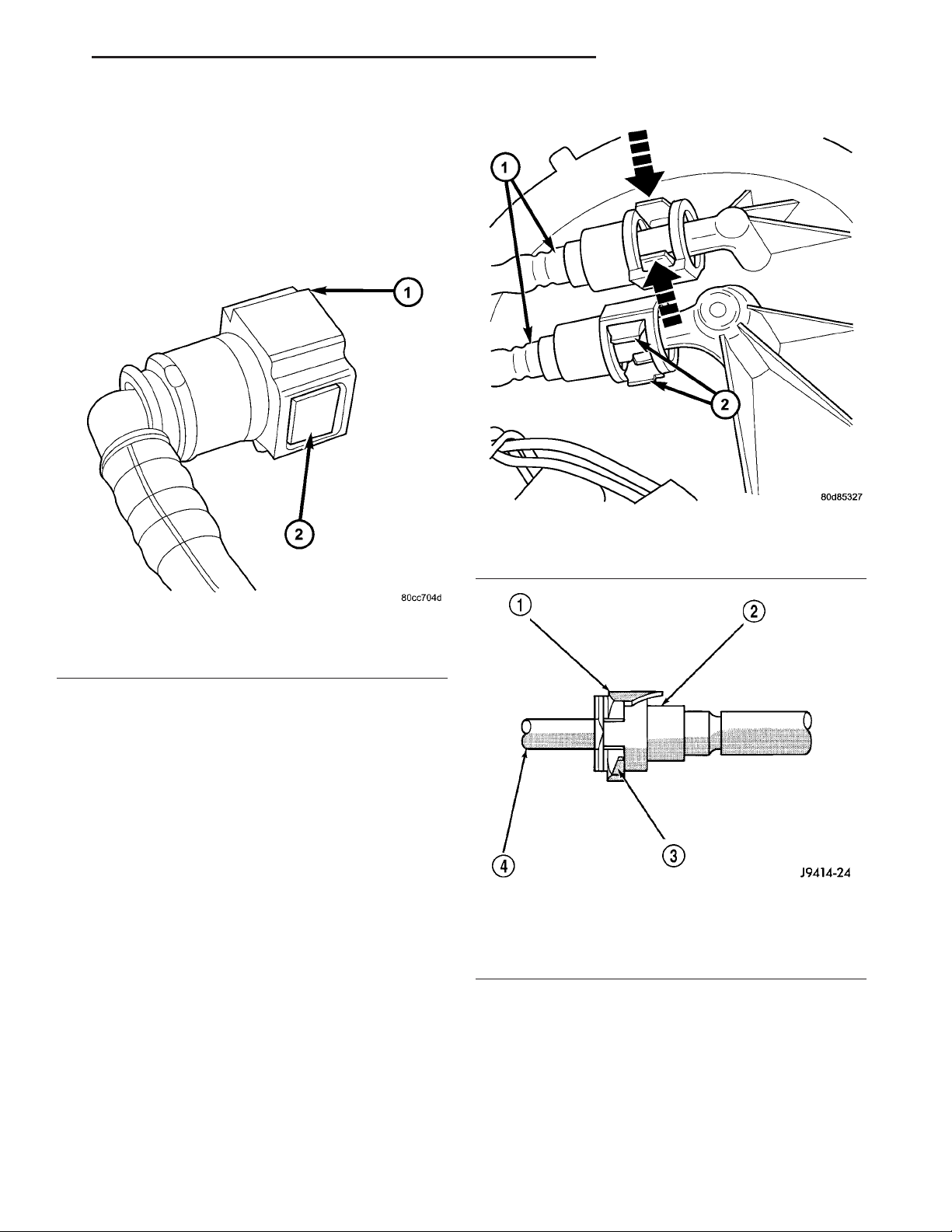

(4) 2–Button Type Fitting: This type of fitting is

equipped with a push-button located on each side of

quick-connect fitting (Fig. 5). Press on both buttons

simultaneously for removal. Special tools are not

required for disconnection.

Fig. 5 2-BUTTON TYPE FITTING

1 - QUICK-CONNECT FITTING

2 - PUSH-BUTTONS (2)

(5) Pinch-Type Fitting: This fitting is equipped

with two finger tabs. Pinch both tabs together while

removing fitting (Fig. 6). Special tools are not

required for disconnection.

(6) Single-Tab Type Fitting: This type of fitting

is equipped with a single pull tab (Fig. 7). The tab is

removable. After tab is removed, quick-connect fitting

can be separated from fuel system component. Special tools are not required for disconnection.

(a) Press release tab on side of fitting to release

pull tab (Fig. 8). If release tab is not pressed

prior to releasing pull tab, pull tab will be

damaged.

(b) While pressing release tab on side of fitting,

use screwdriver to pry up pull tab (Fig. 8).

(c) Raise pull tab until it separates from quickconnect fitting (Fig. 9).

(7) Two-Tab Type Fitting: This type of fitting is

equipped with tabs located on both sides of fitting

(Fig. 10). The tabs are supplied for disconnecting

quick-connect fitting from component being serviced.

(a) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 10) against sides of

quick-connect fitting with your fingers. Tool use is

Fig. 6 PINCH TYPE QUICK-CONNECT FITTING

1 - QUICK-CONNECT FITTINGS

2 - PINCH TABS

Fig. 7 SINGLE-TAB TYPE FITTING

1 - PULL TAB

2 - QUICK-CONNECT FITTING

3 - PRESS HERE TO REMOVE PULL TAB

4 - INSERTED TUBE END

not required for removal and may damage plastic

retainer.

(b) Pull fitting from fuel system component

being serviced.

(c) The plastic retainer will remain on component being serviced after fitting is disconnected.

The o-rings and spacer will remain in quick-connect fitting connector body.

14 - 10 FUEL DELIVERY - GAS DR

QUICK CONNECT FITTING (Continued)

Fig. 8 DISCONNECTING SINGLE-TAB TYPE FITTING

1 - PULL TAB

2 - SCREWDRIVER

3 - QUICK-CONNECT FITTING

Fig. 9 REMOVING PULL TAB

1 - FUEL TUBE OR FUEL SYSTEM COMPONENT

2 - PULL TAB

3 - QUICK-CONNECT FITTING

4 - FUEL TUBE STOP

Fig. 10 TYPICAL 2–TAB TYPE FITTING

1 - TAB(S)

2 - QUICK-CONNECT FITTING

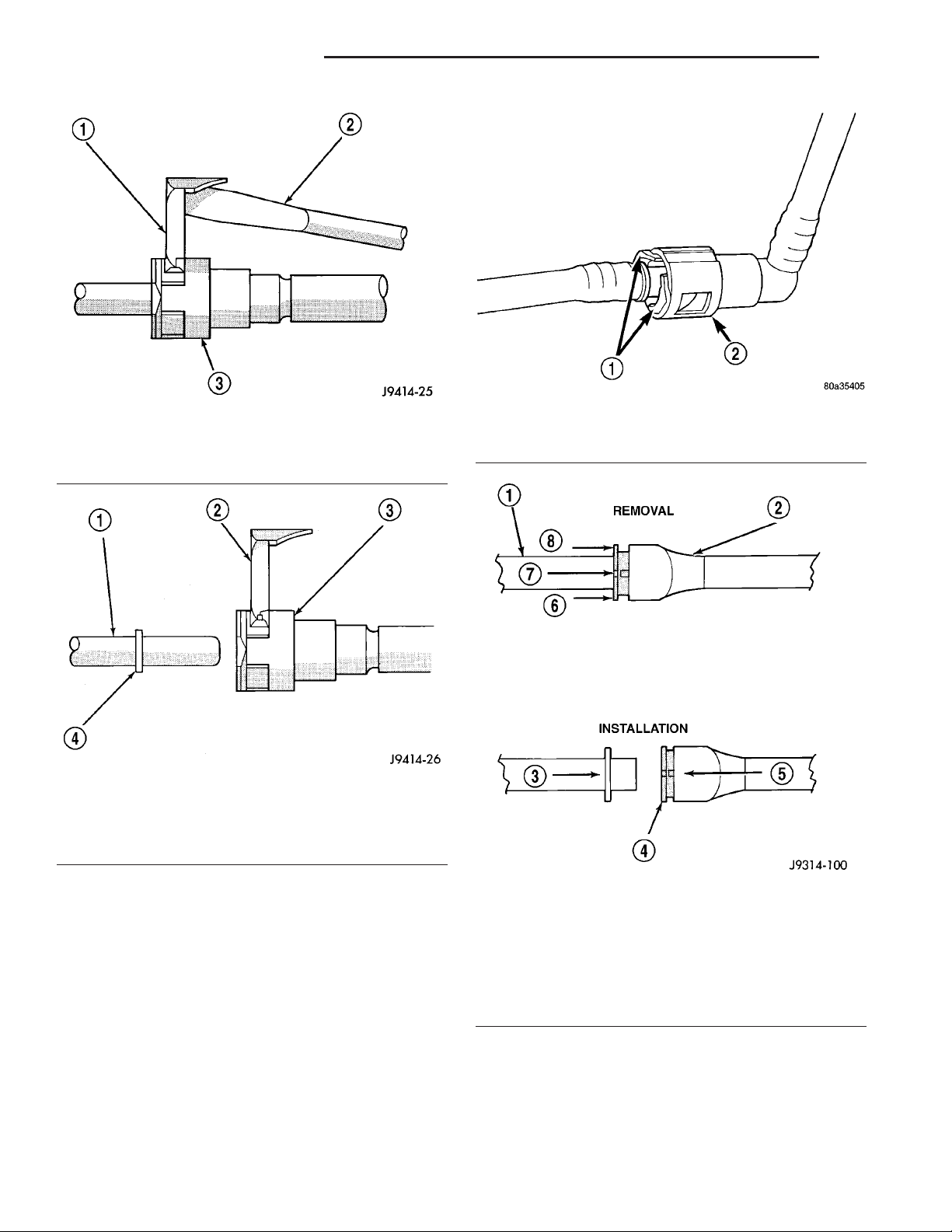

(8) Plastic Retainer Ring Type Fitting: This

type of fitting can be identified by the use of a fullround plastic retainer ring (Fig. 11) usually black in

color.

(a) To release fuel system component from quickconnect fitting, firmly push fitting towards component being serviced while firmly pushing plastic

retainer ring into fitting (Fig. 11). With plastic ring

depressed, pull fitting from component. The plas-

tic retainer ring must be pressed squarely

into fitting body. If this retainer is cocked

during removal, it may be difficult to disconnect fitting. Use an open-end wrench on

shoulder of plastic retainer ring to aid in disconnection.

Fig. 11 PLASTIC RETAINER RING TYPE FITTING

1 - FUEL TUBE

2 - QUICK CONNECT FITTING

3 - PUSH

4 - PLASTIC RETAINER

5 - PUSH

6 - PUSH

7 - PUSH

8 - PUSH

(b) After disconnection, plastic retainer ring will

remain with quick-connect fitting connector body.

(c) Inspect fitting connector body, plastic retainer

ring and fuel system component for damage.

Replace as necessary.

(9) Latch Clips: Depending on vehicle model and

engine, 2 different types of safety latch clips are used

DR FUEL DELIVERY - GAS 14 - 11

QUICK CONNECT FITTING (Continued)

Fig. 12 LATCH CLIP-TYPE 1

1 - TETHER STRAP

2 - FUEL LINE

3 - SCREWDRIVER

4 - LATCH CLIP

5 - FUEL RAIL

Fig. 13 LATCH CLIP-TYPE 2

1 - LATCH CLIP

(Fig. 12) or (Fig. 13). Type-1 is tethered to fuel line

and type-2 is not. A special tool will be necessary to

disconnect fuel line after latch clip is removed. The

latch clip may be used on certain fuel line/fuel rail

connection, or to join fuel lines together.

(a) Type 1: Pry up on latch clip with a screw-

driver (Fig. 12).

(b) Type 2: Separate and unlatch 2 small arms

on end of clip (Fig. 13) and swing away from fuel

line.

Fig. 14 FUEL LINE DISCONNECTION USING

SPECIAL TOOL

1 - SPECIAL FUEL LINE TOOL

2 - FUEL LINE

3 - FUEL RAIL

(c) Slide latch clip toward fuel rail while lifting

with screwdriver.

(d) Insert special fuel line removal tool (Snap-On

number FIH 9055-1 or equivalent) into fuel line

(Fig. 14). Use tool to release locking fingers in end

of line.

(e) With special tool still inserted, pull fuel line

from fuel rail.

(f)

After disconnection, locking fingers will remain

within quick-connect fitting at end of fuel line.

(10) Disconnect quick-connect fitting from fuel sys-

tem component being serviced.

CONNECTING

(1) Inspect quick-connect fitting body and fuel sys-

tem component for damage. Replace as necessary.

(2) Prior to connecting quick-connect fitting to

component being serviced, check condition of fitting

and component. Clean parts with a lint-free cloth.

Lubricate with clean engine oil.

(3) Insert quick-connect fitting into fuel tube or

fuel system component until built-on stop on fuel

tube or component rests against back of fitting.

(4) Continue pushing until a click is felt.

(5) Single-tab type fitting: Push new tab down

until it locks into place in quick-connect fitting.

(6) Verify a locked condition by firmly pulling on

fuel tube and fitting (15-30 lbs.).

(7) Latch Clip Equipped: Install latch clip (snaps

into position). If latch clip will not fit, this indi-

cates fuel line is not properly installed to fuel

rail (or other fuel line). Recheck fuel line connection.

(8) Connect negative cable to battery.

(9) Start engine and check for leaks.

14 - 12 FUEL DELIVERY - GAS DR

FUEL PUMP

DESCRIPTION

The electric fuel pump is located inside of the fuel

pump module. A 12 volt, permanent magnet, electric

motor powers the fuel pump. The electric fuel pump

is not a separate, serviceable component.

OPERATION

Voltage to operate the electric pump is supplied

through the fuel pump relay.

Fuel is drawn in through a filter at the bottom of

the module and pushed through the electric motor

gearset to the pump outlet.

Check Valve Operation: The bottom section of

the fuel pump module contains a one-way check

valve to prevent fuel flow back into the tank and to

maintain fuel supply line pressure (engine warm)

when pump is not operational. It is also used to keep

the fuel supply line full of gasoline when pump is not

operational. After the vehicle has cooled down, fuel

pressure may drop to 0 psi (cold fluid contracts), but

liquid gasoline will remain in fuel supply line

between the check valve and fuel injectors. Fuel

pressure that has dropped to 0 psi on a cooled

down vehicle (engine off) is a normal condition.

The electric fuel pump is not a separate, serviceable component.

BEFORE SERVICING THE FUEL PUMP MODULE, THE

FUEL SYSTEM PRESSURE MUST BE RELEASED.

(1) Drain and remove fuel tank. Refer to Fuel

Tank Removal/Installation.

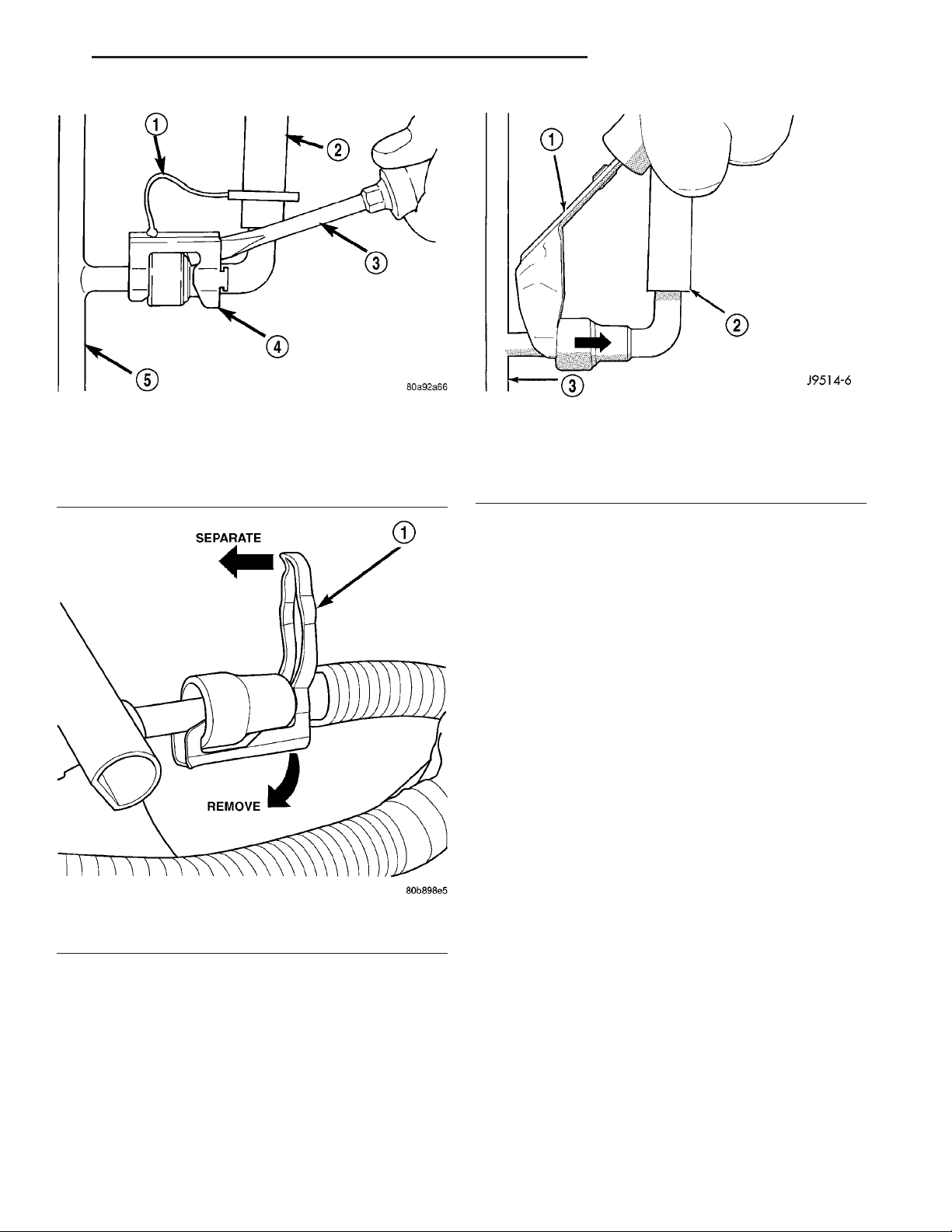

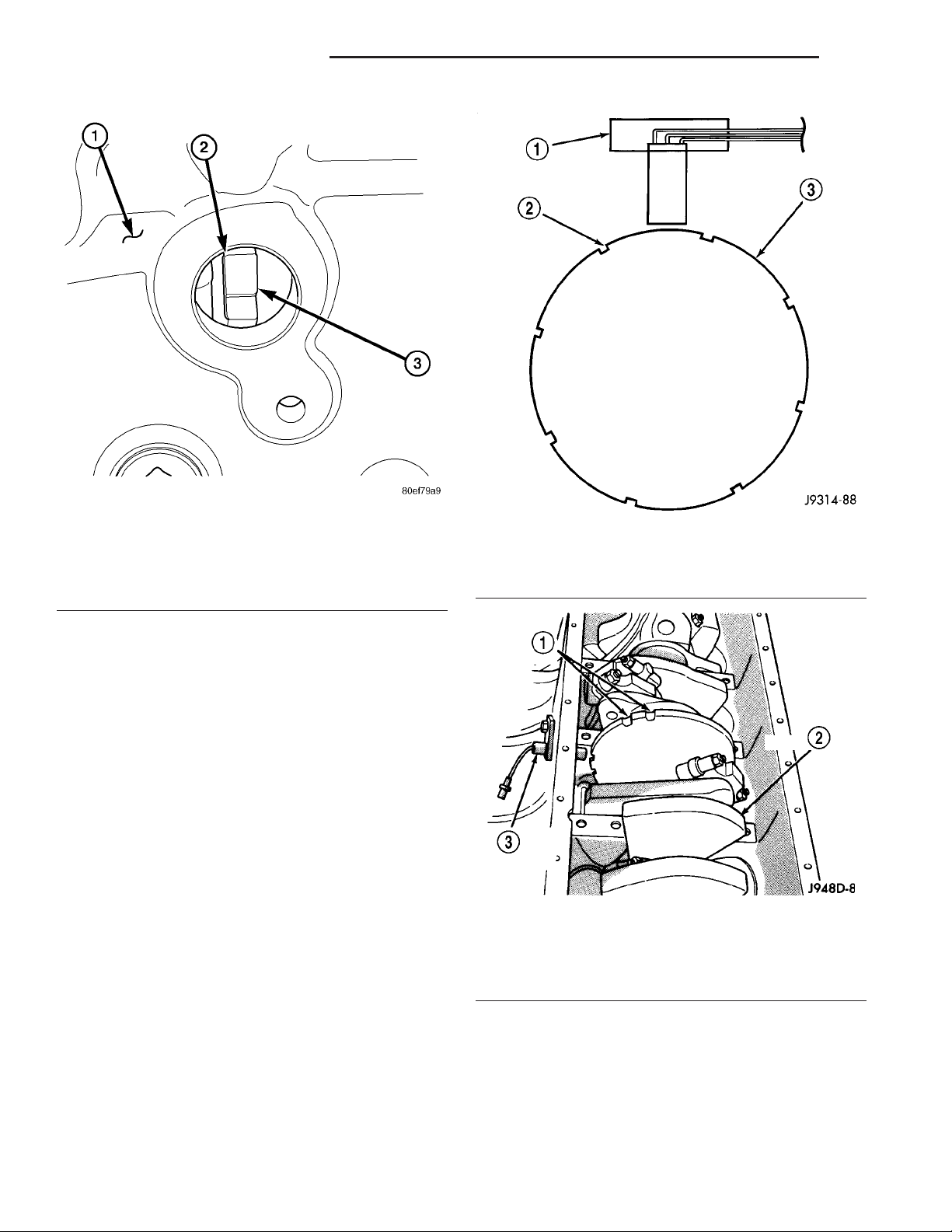

(2) The plastic fuel pump module locknut (Fig. 15)

is threaded onto fuel tank. Install Special Tool 6856

to locknut and remove locknut (Fig. 16). The fuel

pump module will spring up slightly when locknut is

removed.

(3) Remove module from fuel tank.

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module assembly is located on the

top of the fuel tank (Fig. 1). The complete assembly

contains the following components:

• A combination fuel filter/fuel pressure regulator

• A separate fuel pick-up, or inlet filter

• An electric fuel pump

• A lockring to retain pump module to tank

• A soft gasket between tank flange and module

• A fuel gauge sending unit (fuel level sensor)

• Fuel line connection

The fuel gauge sending unit may be serviced separately. If the electrical fuel pump, primary inlet filter,

fuel filter or fuel pressure regulator require service,

the fuel pump module must be replaced.

OPERATION

Refer to Fuel Pump, Inlet Filter, Fuel Filter / Fuel

Pressure Regulator and Fuel Gauge Sending Unit.

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CONSTANT PRESSURE (EVEN WITH THE ENGINE OFF).

Fig. 15 FUEL PUMP MODULE (TOP)

1 - FUEL FILTER / FUEL PRESSURE REGULATOR

2 - ALIGNMENT ARROW

3 - TOP OF PUMP MODULE

4 - LOCKNUT

5 - ALIGNMENT MARKS

Fig. 16 LOCKNUT REMOVAL/INSTALLATION -

TYPICAL

1 - SPECIAL TOOL 6856

2 - LOCKNUT

DR FUEL DELIVERY - GAS 14 - 13

FUEL PUMP MODULE (Continued)

INSTALLATION

CAUTION: Whenever the fuel pump module is serviced, the rubber gasket must be replaced.

(1) Using a new gasket, position fuel pump module

into opening in fuel tank.

(2) Position locknut over top of fuel pump module.

Install locknut finger tight.

(3) Rotate module until embossed alignment arrow

(Fig. 15) points to center alignment mark. This step

must be performed to prevent float from contacting

side of fuel tank. Also be sure fitting on fuel filter/

fuel pressure regulator is pointed to drivers side of

vehicle.

(4) Install Special Tool 6856 (Fig. 16) to locknut.

(5) Tighten locknut. Refer to Torque Specifications.

(6) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL RAIL

DESCRIPTION

The fuel injector rail is used to mount the fuel

injectors to the engine.

OPERATION

High pressure from the fuel pump is routed to the

fuel rail. The fuel rail then supplies the necessary

fuel to each individual fuel injector.

A quick-connect fitting with a safety latch clip is

used to attach the fuel line to the fuel rail.

The fuel rail is not repairable.

CAUTION: The left and right sections of the fuel rail

are connected with either a flexible connecting

hose, or joints. Do not attempt to separate the rail

halves at these connecting hose or joints. Due to

the design of the connecting hose or joint, it does

not use any clamps. Never attempt to install a

clamping device of any kind to the hose or joint.

When removing the fuel rail assembly for any reason, be careful not to bend or kink the connecting

hose or joint.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tubes (Fig. 18). Due to design

of tubes, it does not use any clamps. Never attempt

to install a clamping device of any kind to tubes.

When removing fuel rail assembly for any reason,

be careful not to bend or kink tubes.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove air resonator mounting bracket at

front of throttle body (2 bolts).

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove necessary vacuum lines at throttle

body.

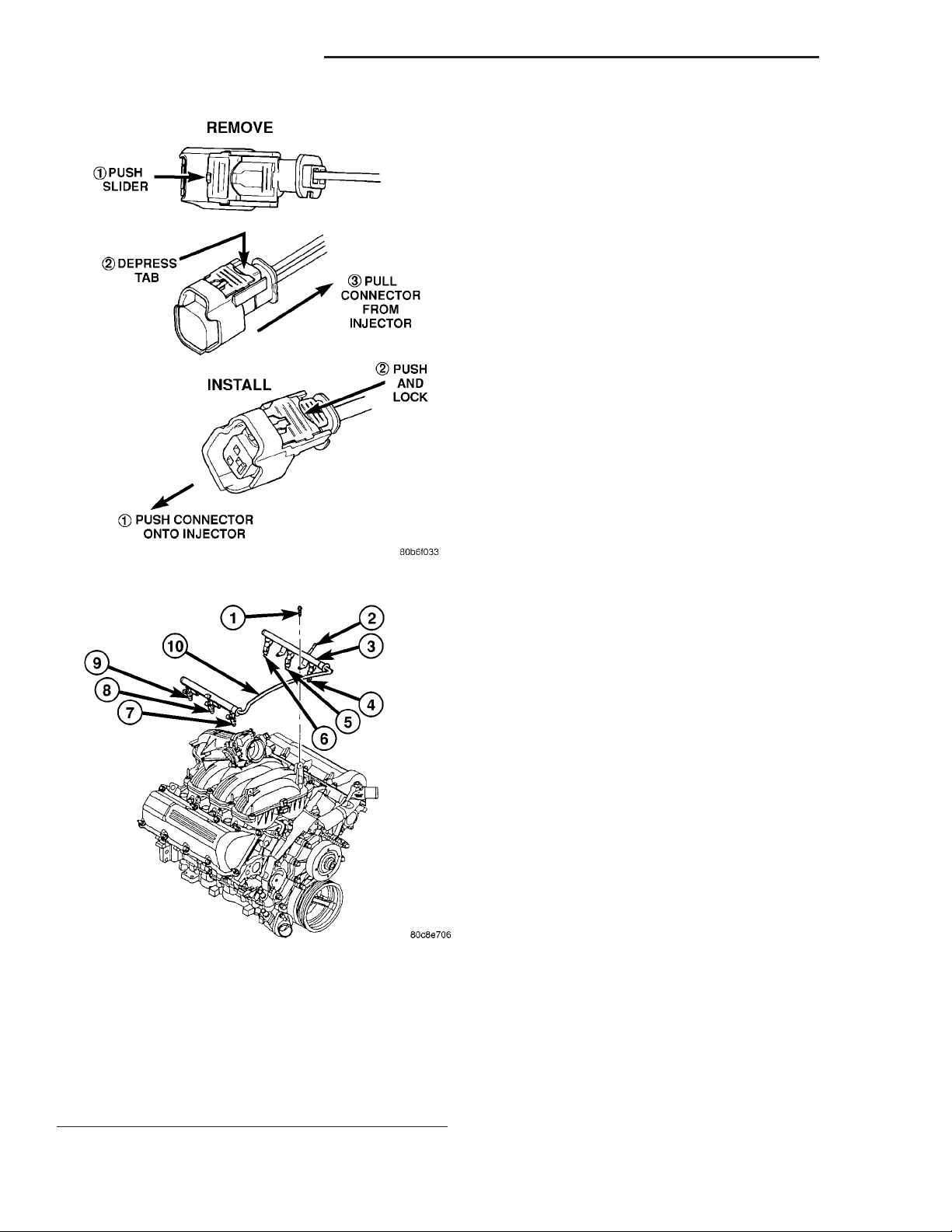

(9) Disconnect electrical connectors at all 6 fuel

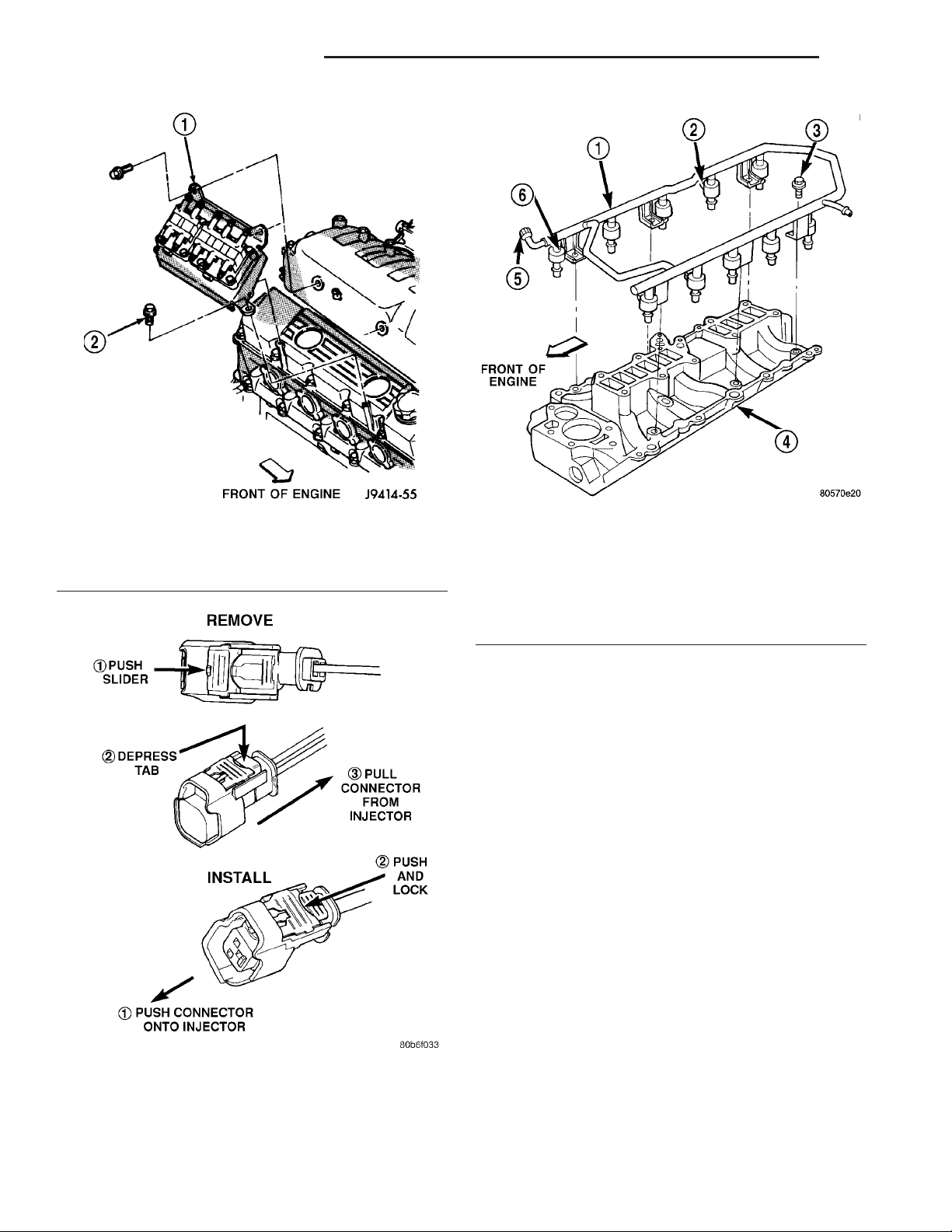

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While pushing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at all throttle

body sensors.

(11) Remove 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(12) Remove 4 fuel rail mounting bolts (Fig. 18).

(13) Gently rock and pull left side of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pull right side of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

4.7L V-8

REMOVAL

3.7L V-6

WARNING: THE FUEL SYSTEM IS UNDER CONSTANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

WARNING: THE FUEL SYSTEM IS UNDER CONSTANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

14 - 14 FUEL DELIVERY - GAS DR

FUEL RAIL (Continued)

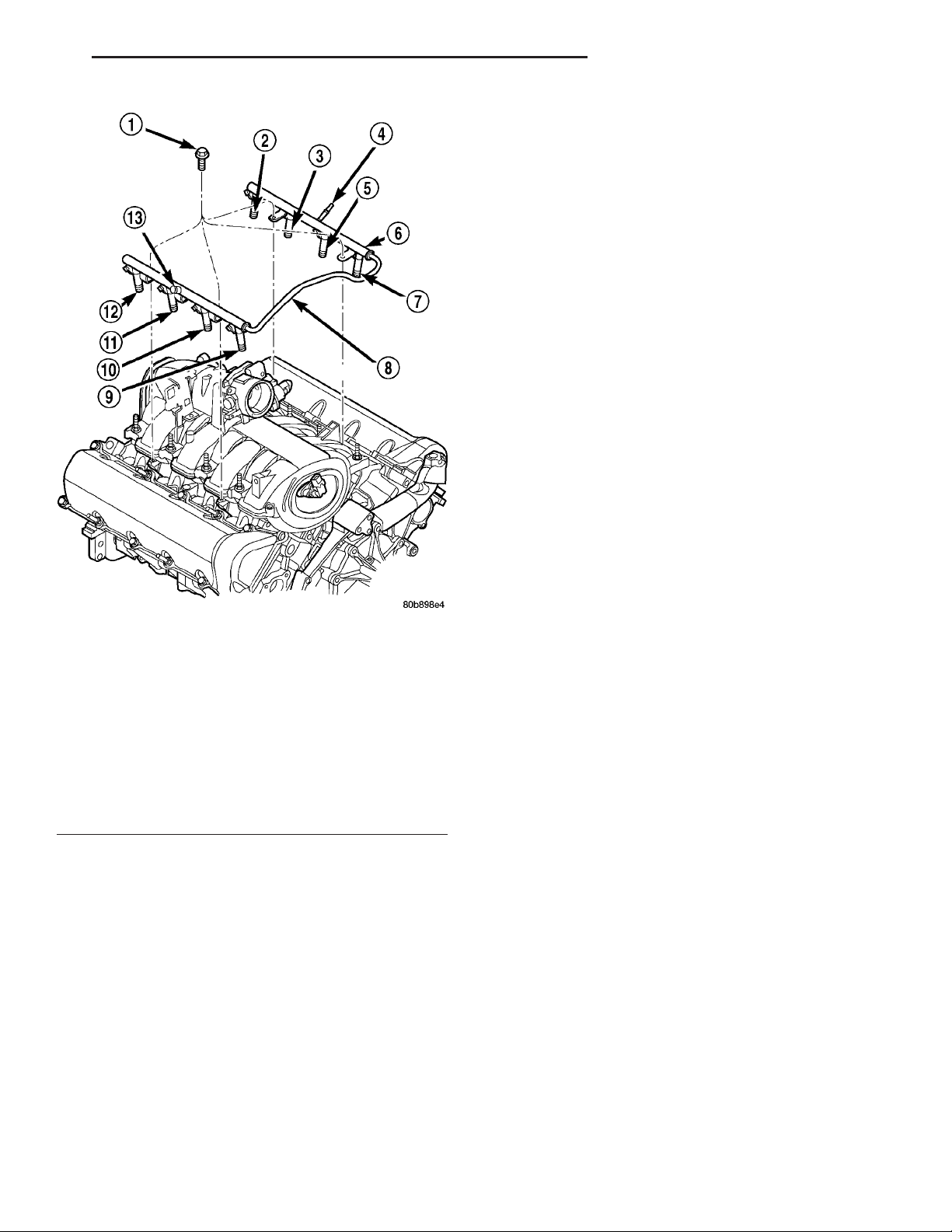

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tubes (Fig. 19). Due to design

of tubes, it does not use any clamps. Never attempt

to install a clamping device of any kind to tubes.

When removing fuel rail assembly for any reason,

be careful not to bend or kink tubes.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Procedure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove air resonator mounting bracket at

front of throttle body (2 bolts).

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove necessary vacuum lines at throttle

body.

(9) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While pushing slider, depress tab (2) and remove connector (3)

Fig. 17 REMOVE/INSTALL INJECTOR CONNECTOR

from injector. The factory fuel injection wiring harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at all throttle

body sensors.

(11) Remove 8 ignition coils. Refer to Ignition Coil

Removal/Installation.

(12) Remove 4 fuel rail mounting bolts (Fig. 19).

(13) Gently rock and pull left side of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pull right side of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

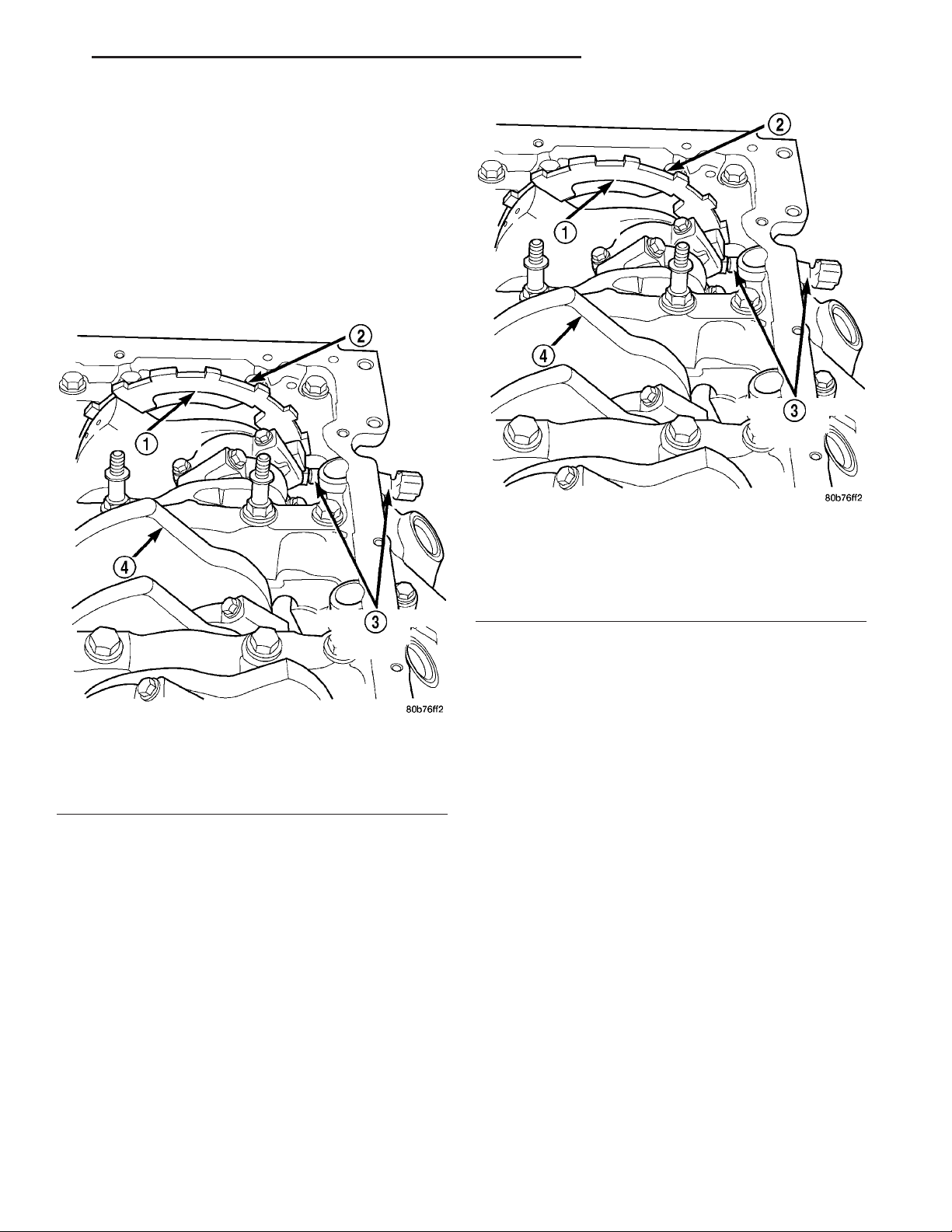

Fig. 18 FUEL RAIL REMOVE/INSTALL - 3.7L V-6

1 - MOUNTING BOLTS (4)

2 - QUICK-CONNECT FITTING

3 - FUEL RAIL

4 - INJ. #1

5 - INJ. #3

6 - INJ. #5

7 - INJ. #2

8 - INJ. #4

9 - INJ. #6

10 - CONNECTOR TUBE

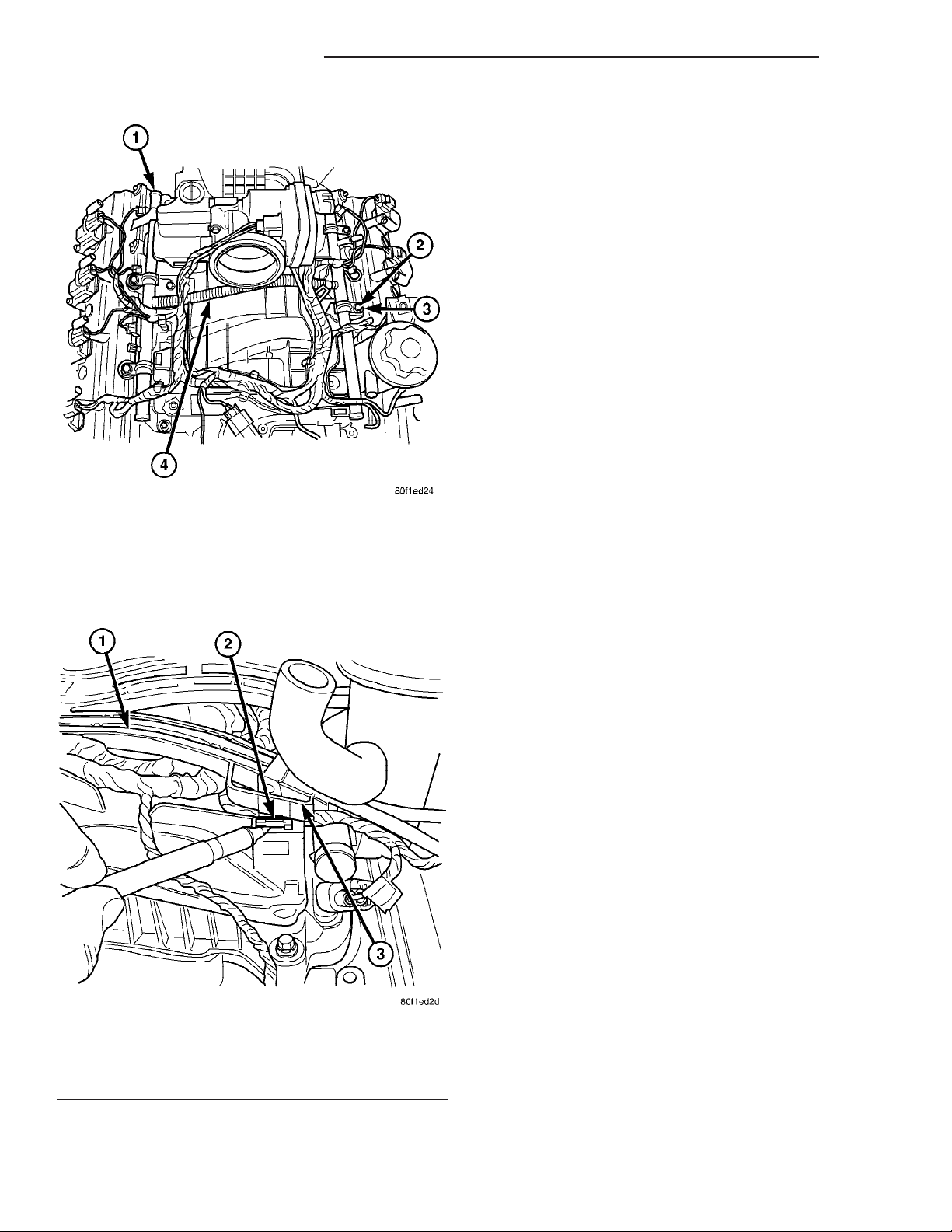

5.7L V-8

WARNING: THE FUEL SYSTEM IS UNDER CONSTANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

DR FUEL DELIVERY - GAS 14 - 15

FUEL RAIL (Continued)

cable routing tray. Note original cable positions while

removing (Fig. 22).

(7) Remove spark plug cable tray from engine by

releasing 4 retaining clips (Fig. 21). Remove tray and

cables from engine as an assembly.

(8) Disconnect electrical connectors at all 8 ignition coils. Refer to Ignition Coil Removal/Installation.

(9) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(10) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While pushing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(11) Disconnect electrical connectors at all throttle

body sensors.

(12) Remove 4 fuel rail mounting bolts and holdown clamps (Fig. 20).

(13) Gently rock and pull left side of fuel rail until

fuel injectors just start to clear machined holes in

intake manifold. Gently rock and pull right side of

rail until injectors just start to clear intake manifold

head holes. Repeat this procedure (left/right) until all

Fig. 19 FUEL RAIL REMOVE/INSTALL - 4.7L V-8

1 - MOUNTING BOLTS (4)

2 - INJ.#7

3 - INJ.#5

4 - QUICK-CONNECT FITTING

5 - INJ.#3

6 - FUEL INJECTOR RAIL

7 - INJ.#1

8 - CONNECTOR TUBE

9 - INJ.#2

10 - INJ.#4

11 - INJ.#6

12 - INJ.#8

13 - PRESSURE TEST PORT CAP

injectors have cleared machined holes.

(14) Remove fuel rail (with injectors attached)

from engine.

(15) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

5.9L V-8

WARNING: THE FUEL SYSTEM IS UNDER A CONSTANT PRESSURE (EVEN WITH ENGINE TURNED

OFF). BEFORE SERVICING FUEL RAIL ASSEMBLY,

FUEL SYSTEM PRESSURE MUST BE RELEASED.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tube (Fig. 20). Due to design of

tube, it does not use any clamps. Never attempt to

install a clamping device of any kind to tube. When

removing fuel rail assembly for any reason, be careful not to bend or kink tube.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove flex tube (air cleaner housing to

engine).

(5) Remove air resonator box at throttle body.

(6) Disconnect all spark plug cables from all spark

plugs and ignition coils. Do not remove cables from

To release fuel pressure, refer to Fuel System Pressure Release Procedure found in this group.

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate the rail

halves at the connecting hose (Fig. 24). Due to the

design of this connecting hose, it does use any

clamps. Never attempt to install a clamping device

of any kind to the hose. When removing the fuel rail

assembly for any reason, be careful not to bend or

kink the connecting hose.

(1) Remove negative battery cable at battery.

(2) Remove air cleaner.

(3) Perform fuel pressure release procedure.

(4) Remove throttle body from intake manifold.

Refer to Throttle Body Removal/Installation.

14 - 16 FUEL DELIVERY - GAS DR

FUEL RAIL (Continued)

(6) Disconnect electrical connectors at all fuel

injectors. To remove connector refer to (Fig. 17). Push

red colored slider away from injector (1). While pushing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(7) Disconnect fuel tube (line) at side of fuel rail.

Refer to Quick-Connect Fittings for procedures,

(8) Remove the remaining fuel rail mounting bolts.

(9) Gently rock and pull the left fuel rail until the

fuel injectors just start to clear the intake manifold.

Gently rock and pull the right fuel rail until the fuel

injectors just start to clear the intake manifold.

Repeat this procedure (left/right) until all fuel injectors have cleared the intake manifold.

(10) Remove fuel rail (with injectors attached)

from engine.

8.0L V-10

Fig. 20 5.7L FUEL RAIL

1 - FUEL RAIL

2 - MOUNTING BOLT

3 - HOLDOWN CLAMPS

4 - CONNECTOR TUBE

Fig. 21 5.7L SPARK PLUG CABLE ROUTING TRAY

1 - SPARK PLUG CABLES

2 - RETAINING CLIP

3 - SPARK PLUG CABLE ROUTING TRAY

(5) If equipped with air conditioning, remove the

A-shaped A/C compressor-to-intake manifold support

bracket (three bolts) (Fig. 23).

WARNING: THE FUEL SYSTEM IS UNDER A CONSTANT PRESSURE EVEN WITH THE ENGINE OFF.

BEFORE SERVICING FUEL RAIL, FUEL SYSTEM

PRESSURE MUST BE RELEASED.

(1) Remove negative battery cable at battery.

(2) Remove air cleaner housing and tube.

(3) Perform fuel pressure release procedure. Refer

to Fuel Delivery System section of this group.

(4) Disconnect throttle body linkage and remove

throttle body from intake manifold. Refer to Throttle

Body removal in this group.

(5) Remove ignition coil pack and bracket assembly (Fig. 25) at intake manifold and right engine

valve cover (four bolts).

(6) Remove upper half of intake manifold. Refer to

Engines for procedures.

(7) Disconnect electrical connectors at all fuel

injectors. To remove connector refer to (Fig. 26). Push

red colored slider away from injector (1). While pushing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification.

(8) Disconnect fuel line quick-connect fitting at

left-rear end of fuel rail. A special 3/8 inch fuel line

disconnection tool will be necessary.

(9) Remove the six fuel rail mounting bolts from

the lower half of intake manifold (Fig. 27).

(10) Gently rock and pull the left fuel rail until

the fuel injectors just start to clear the intake manifold. Gently rock and pull the right fuel rail until

the fuel injectors just start to clear the intake manifold. Repeat this procedure (left/right) until all fuel

injectors have cleared the intake manifold.

DR FUEL DELIVERY - GAS 14 - 17

FUEL RAIL (Continued)

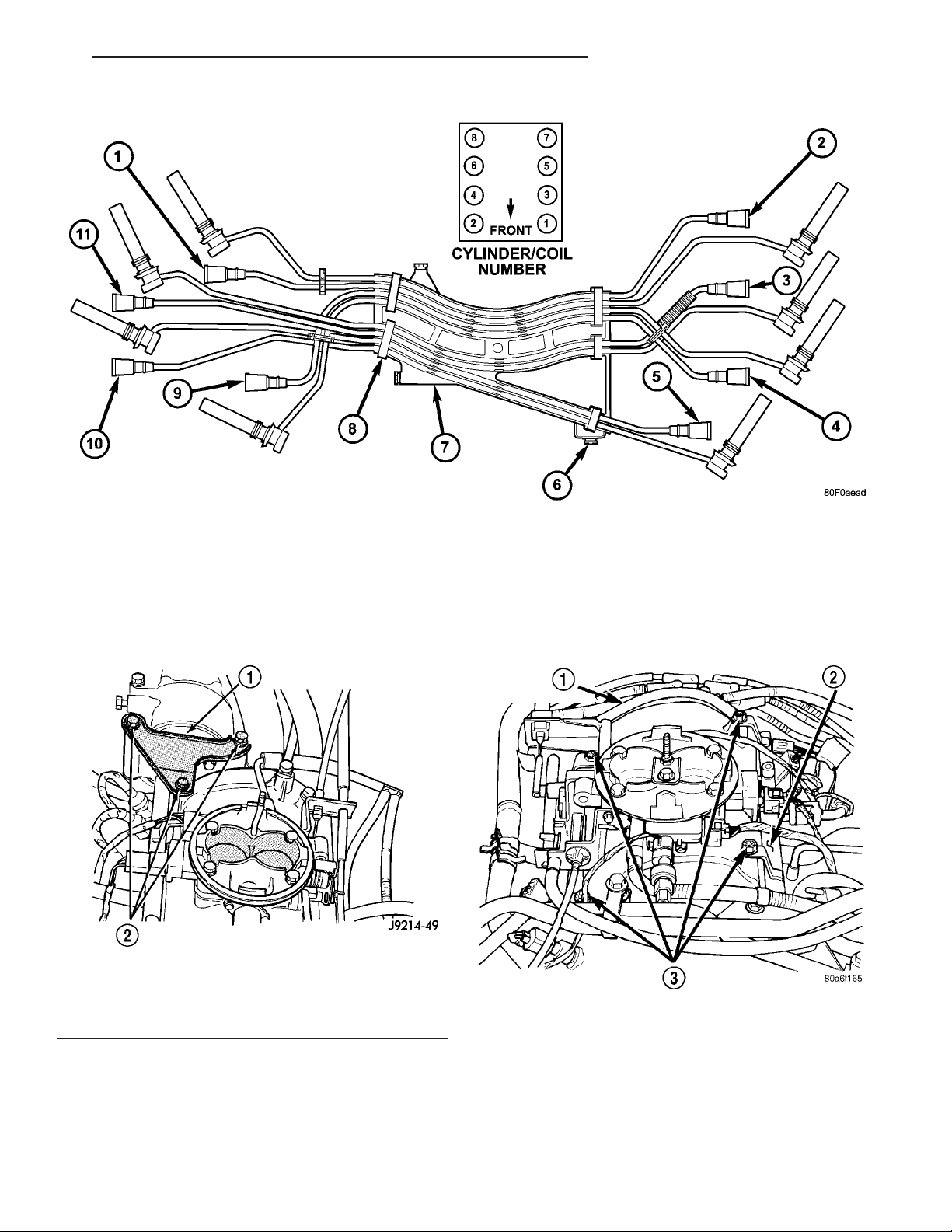

Fig. 22 5.7L SPARK PLUG CABLE ROUTING

1 - #8 COIL-TO- #5 SPARK PLUG (MARKED 5/8) 7 - CABLE TRAY

2 - #5 COIL-TO- #8 SPARK PLUG (MARKED 5/8) 8 - CLIPS (SPARK PLUG CABLE-TO-TRAY- RETENTION)

3 - #7 COIL-TO- #4 SPARK PLUG (MARKED 4/7) 9 - #2 COIL-TO- #3 SPARK PLUG (MARKED 2/3)

4 - #3 COIL-TO- #2 SPARK PLUG (MARKED 2/3) 10 - #6 COIL-TO- #1 SPARK PLUG (MARKED 1/6)

5 - #1 COIL-TO- #6 SPARK PLUG (MARKED 1/6) 11 - #4 COIL-TO- #7 SPARK PLUG (MARKED 4/7)

6 - CLIPS (TRAY-TO-MANIFOLD RETENTION)

Fig. 23 A/C COMPRESSOR SUPPORT BRACKET -

5.9L V-8

1 - AIR CONDITIONING COMPRESSOR SUPPORT BRACKET

2 - MOUNTING BOLTS

(11) Remove fuel rail (with injectors attached)

Fig. 24 FUEL RAIL REMOVE/INSTALL - 5.9L V-8

1 - FUEL RAIL CONNECTING HOSE

2 - FUEL RAIL

3 - MOUNTING BOLTS (4)

from engine.

(12) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

14 - 18 FUEL DELIVERY - GAS DR

FUEL RAIL (Continued)

Fig. 25 IGNITION COIL PACK AND MOUNTING

BRACKET - 8.0L V-10

1 - COIL PACKS AND BRACKET

2 - MOUNTING BOLTS (4)

Fig. 26 REMOVE/INSTALL FUEL INJECTOR

CONNECTOR

Fig. 27 FUEL RAIL MOUNTING BOLTS - 8.0L V-10 -

TYPICAL

1 - FUEL RAIL

2 - ELECTRICAL CONNECTOR

3 - MOUNTING BOLTS (6)

4 - INTAKE MANIFOLD LOWER HALF

5 - FUEL PRESSURE TEST PORT

6 - FUEL INJECTORS (10)

INSTALLATION

3.7L V-6

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be careful not to tear injector o-rings.

(6) Push right side of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.

Push left fuel rail down until injectors have bottomed on cylinder head shoulder.

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 6 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injectors. To install connector, refer to (Fig. 17). Push connector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injector by lightly tugging on connector.

DR FUEL DELIVERY - GAS 14 - 19

FUEL RAIL (Continued)

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

4.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in cylinder head.

(5) Guide each injector into cylinder head. Be care-

ful not to tear injector o-rings.

(6) Push right side of fuel rail down until fuel

injectors have bottomed on cylinder head shoulder.

Push left fuel rail down until injectors have bottomed on cylinder head shoulder.

(7) Install 4 fuel rail mounting bolts and tighten.

Refer to torque specifications.

(8) Install 8 ignition coils. Refer to Ignition Coil

Removal/Installation.

(9) Connect electrical connectors to throttle body.

(10) Connect electrical connectors at all fuel injectors. To install connector, refer to (Fig. 17). Push connector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injector by lightly tugging on connector.

(11) Connect necessary vacuum lines to throttle

body.

(12) Install air resonator mounting bracket near

front of throttle body (2 bolts).

(13) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(14) Install air box to throttle body.

(15) Install air duct to air box.

(16) Connect battery cable to battery.

(17) Start engine and check for leaks.

5.7L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Clean out fuel injector machined bores in

intake manifold.

(3) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(4) Position fuel rail/fuel injector assembly to

machined injector openings in intake manifold.

(5) Guide each injector into intake manifold. Be

careful not to tear injector o-rings.

(6) Push right side of fuel rail down until fuel

injectors have bottomed on shoulders. Push left fuel

rail down until injectors have bottomed on shoulders.

(7) Install 4 fuel rail holdown clamps and 4 mounting bolts. Refer to Torque Specifications.

(8) Position spark plug cable tray and cable assembly to intake manifold. Snap 4 cable tray retaining

clips into intake manifold.

(9) Install all cables to spark plugs and ignition

coils.

(10) Connect electrical connector to throttle body.

(11) Install electrical connectors to all 8 ignition

coils. Refer to Ignition Coil Removal/Installation.

(12) Connect electrical connector to throttle body.

(13) Connect electrical connectors at all fuel injectors. To install connector, refer to (Fig. 17). Push connector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injector by lightly tugging on connector.

(14) Connect fuel line latch clip and fuel line to

fuel rail. Refer to Quick-Connect Fittings.

(15) Install air resonator to throttle body (2 bolts).

(16) Install flexible air duct to air box.

(17) Connect battery cable to battery.

(18) Start engine and check for leaks.

5.9L V-8

(1) If fuel injectors are to be installed, refer to Fuel

Injector Removal/Installation.

(2) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(3) Clean out fuel injector machined bores in

intake manifold.

(4) Position fuel rail/fuel injector assembly to injector openings on intake manifold.

(5) Guide each injector into intake manifold. Be

careful not to tear injector o-ring.

(6) Push the right fuel rail down until fuel injectors have bottomed on injector shoulder. Push the

left fuel rail down until fuel injectors have bottomed

on injector shoulder.

(7) Install fuel rail mounting bolts. Refer to Torque

Specifications.

(8) Connect electrical connector to intake manifold

air temperature sensor.

(9) Connect electrical connectors at all fuel injectors. To install connector, refer to (Fig. 17). Push connector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injector by lightly tugging on connector.

(10) Install fuel tube (line) at side of fuel rail.

Refer to Quick-Connect Fittings for procedures.

(11) Install air cleaner resonator to throttle body.

(12) Connect battery cable to battery.

14 - 20 FUEL DELIVERY - GAS DR

FUEL RAIL (Continued)

(13) Start engine and check for leaks.

8.0L V-10

(1) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(2) Install injector(s) and injector clip(s) to fuel

rail.

NOTE: The fuel injector electrical connectors on all

10 injectors should be facing to right (passenger)

side of vehicle (Fig. 27).

(3) Position fuel rail/fuel injector assembly to injec-

tor openings on intake manifold.

(4) Guide each injector into intake manifold. Be

careful not to tear injector o-ring.

(5) Push the right fuel rail down until fuel injectors have bottomed on injector shoulder. Push the

left fuel rail down until fuel injectors have bottomed

on injector shoulder.

(6) Install six fuel rail mounting bolts into lower

half of intake manifold. Tighten bolts to 15 N·m (136

in. lbs.) torque.

(7) Connect electrical connectors at all fuel injectors. To install connector, refer to (Fig. 26). Push connector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injector by lightly tugging on connector. The injector wiring harness is numerically tagged.

(8) Install upper half of intake manifold. Refer to

Engines for procedures.

(9) Connect main fuel line at fuel rail. Refer to

Quick-Connect Fittings for procedures.

(10) Install ignition coil pack and bracket assembly at intake manifold and right engine valve cover

(four bolts).

(11) Install throttle body to intake manifold. Refer

to Throttle Body Removal / Installation.

(12) Install throttle body linkage to throttle body.

(13) Install air cleaner tube and housing.

(14) Install negative battery cable at battery.

(15) Start engine and check for leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for placement of the fuel pump module, and (if equipped) certain ORVR components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank connections.

Two check (control) valves are mounted into the

top of the fuel tank. Refer to Fuel Tank Check Valve

for additional information.

An evaporation control system is connected to the

fuel tank to reduce emissions of fuel vapors into the

atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP) and/or an On-Board Refueling

Vapor Recovery (ORVR) system. Refer to Emission

Control System for additional information.

REMOVAL- EXCEPT DIESEL

Fuel Tank Draining

WARNING: THE FUEL SYSTEM MAY BE UNDER

CONSTANT FUEL PRESSURE EVEN WITH THE

ENGINE OFF. THIS PRESSURE MUST BE

RELEASED BEFORE SERVICING FUEL TANK.

Two different procedures may be used to drain fuel

tank: through the fuel fill fitting on tank, or using

the DRBt scan tool. Due to a one-way check valve

installed into the fuel fill opening fitting at the tank,

the tank cannot be drained conventionally at the fill

cap.

The quickest draining procedure involves removing

the rubber fuel fill hose.

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of special test hose tool number 6541,

6539, 6631 or 6923 at fuel rail disconnection (tool

number will depend on model and/or engine application). Position opposite end of this hose tool to an

approved gasoline draining station. Activate fuel

pump and drain tank until empty.

If electric fuel pump is not operating, fuel must be

drained through fuel fill fitting at tank. Refer to following procedures.

(1) Release fuel system pressure.

(2) Raise vehicle.

(3) Thoroughly clean area around fuel fill fitting

and rubber fuel fill hose at tank.

(4) If vehicle is equipped with 4 doors and a 6 foot

(short) box, remove left-rear tire/wheel.

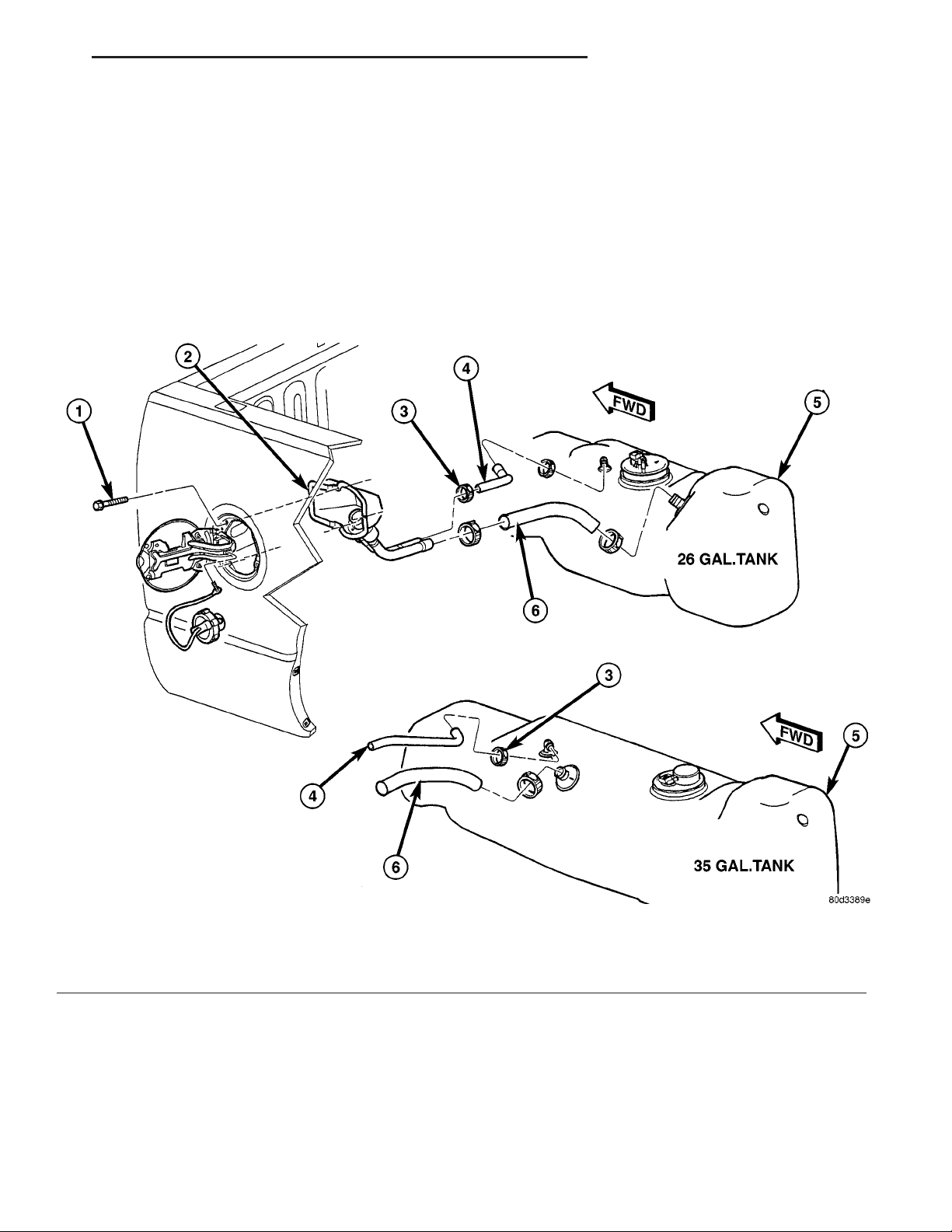

(5) Loosen clamp (Fig. 28) and disconnect rubber

fuel fill hose at tank fitting. Using an approved gas

holding tank, drain fuel tank through this fitting.

DR FUEL DELIVERY - GAS 14 - 21

FUEL TANK (Continued)

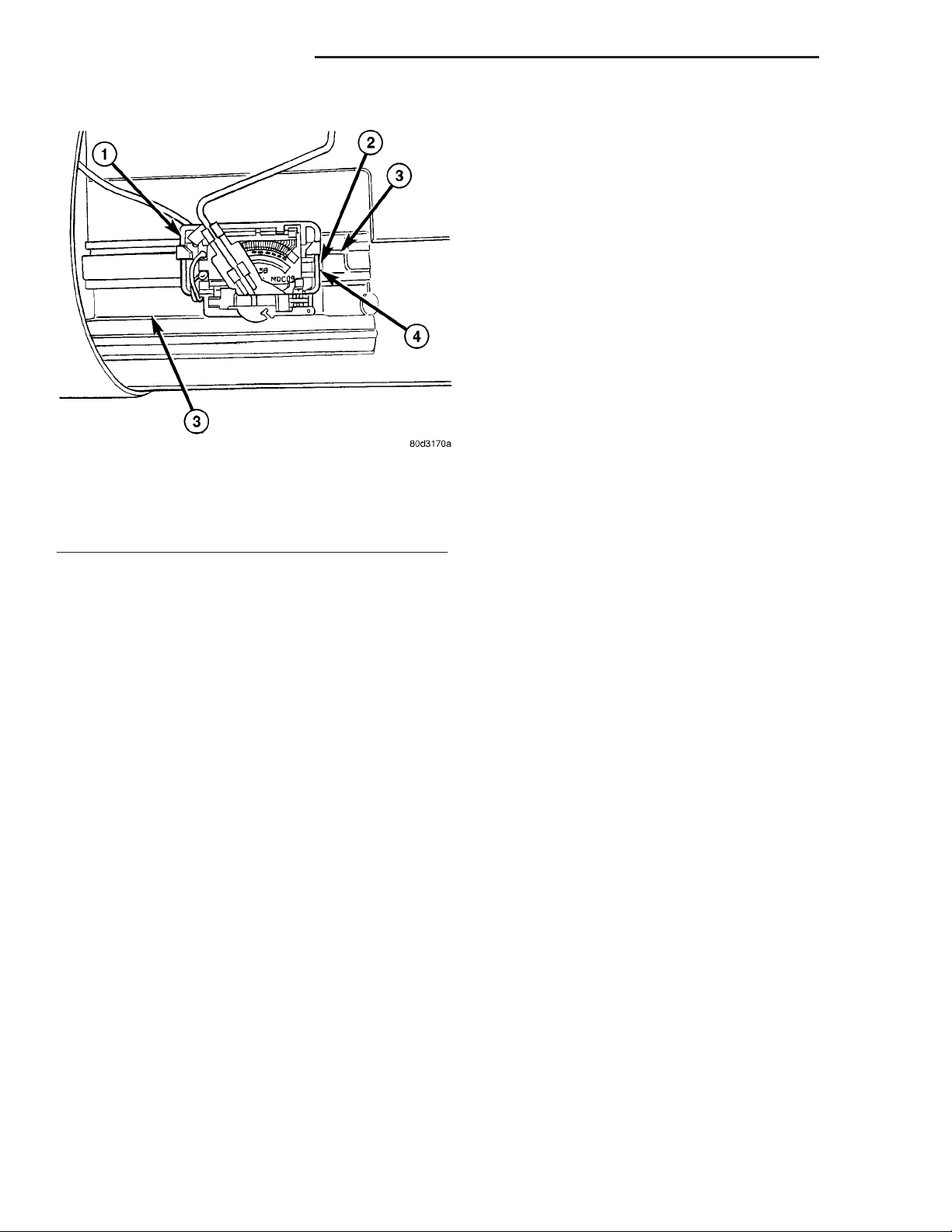

Tank Removal

(1) Loosen clamp and disconnect rubber fuel vent

hose (Fig. 28) at tank fitting.

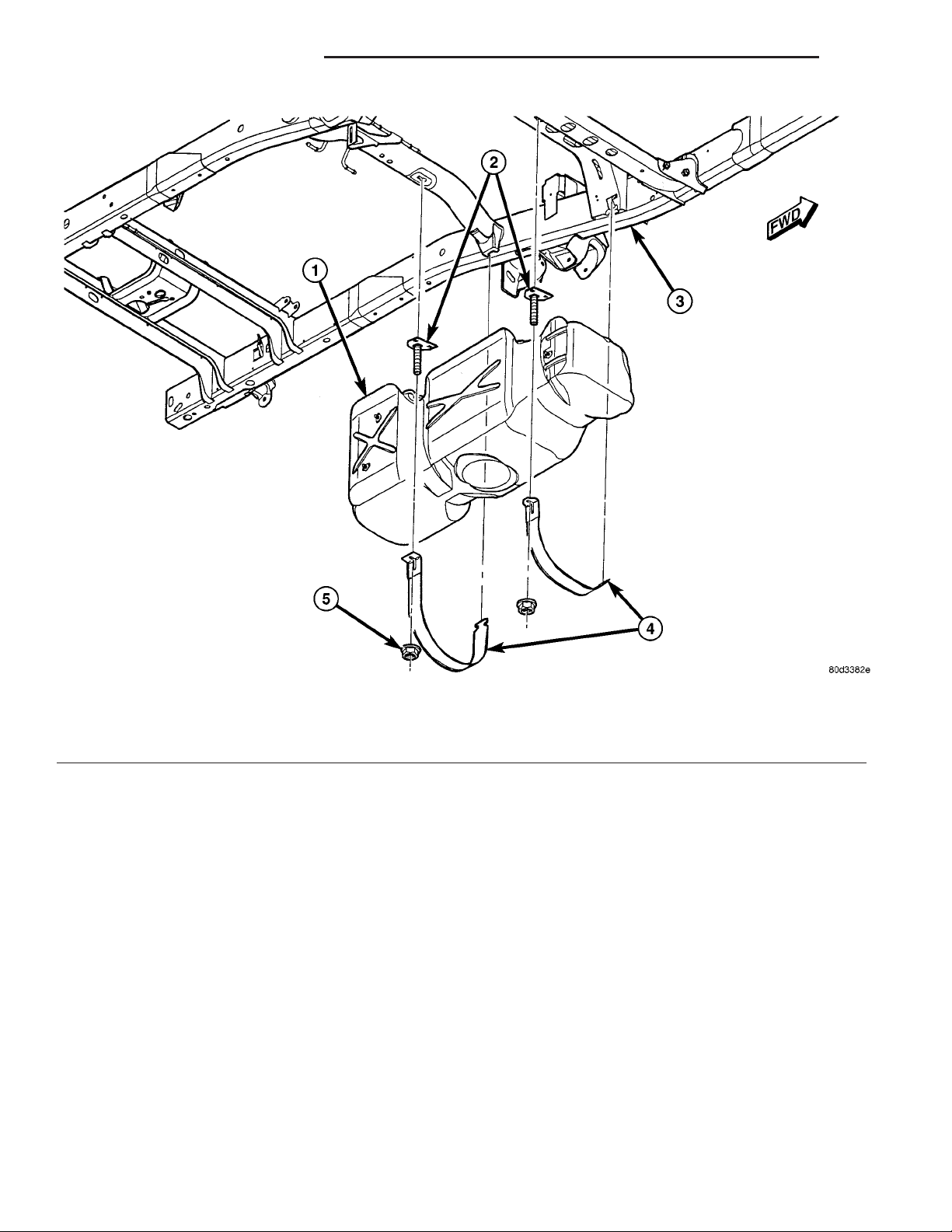

(2) Support tank with a hydraulic jack.

(3) Remove 2 fuel tank strap nuts (Fig. 29) and

remove both tank support straps.

(4) Carefully lower tank a few inches and disconnect fuel pump module electrical connector (Fig. 30)

at top of tank. To disconnect electrical connector:

Push upward on red colored tab to unlock. Push on

black colored tab while removing connector.

(5) Disconnect fuel line at fuel filter / fuel pressure

regulator (Fig. 30) by pressing on tabs at side of

quick-connect fitting.

(6) Disconnect EVAP line at top of tank (Fig. 1).

(7) Continue to lower tank for removal.

(8) If fuel tank is to be replaced, remove fuel pump

module from tank. Refer to Fuel Pump Module

Removal/Installation procedures.

1 - BEZEL SCREWS

2 - FUEL FILL BEZEL

3 - HOSE CLAMPS

Fig. 28 FUEL TANK FILL / VENT HOSES

4 - VENT HOSE

5 - FUEL TANK

6 - FILL HOSE

14 - 22 FUEL DELIVERY - GAS DR

FUEL TANK (Continued)

Fig. 29 FUEL TANK MOUNTING

1 - FUEL TANK

2 - STRAP MOUNTING STUDS

3 - VEHICLE FRAME

INSTALLATION - EXCEPT DIESEL

(1) If fuel tank is to be replaced, install fuel pump

module into tank. Refer to Fuel Pump Module

Removal/Installation procedures.

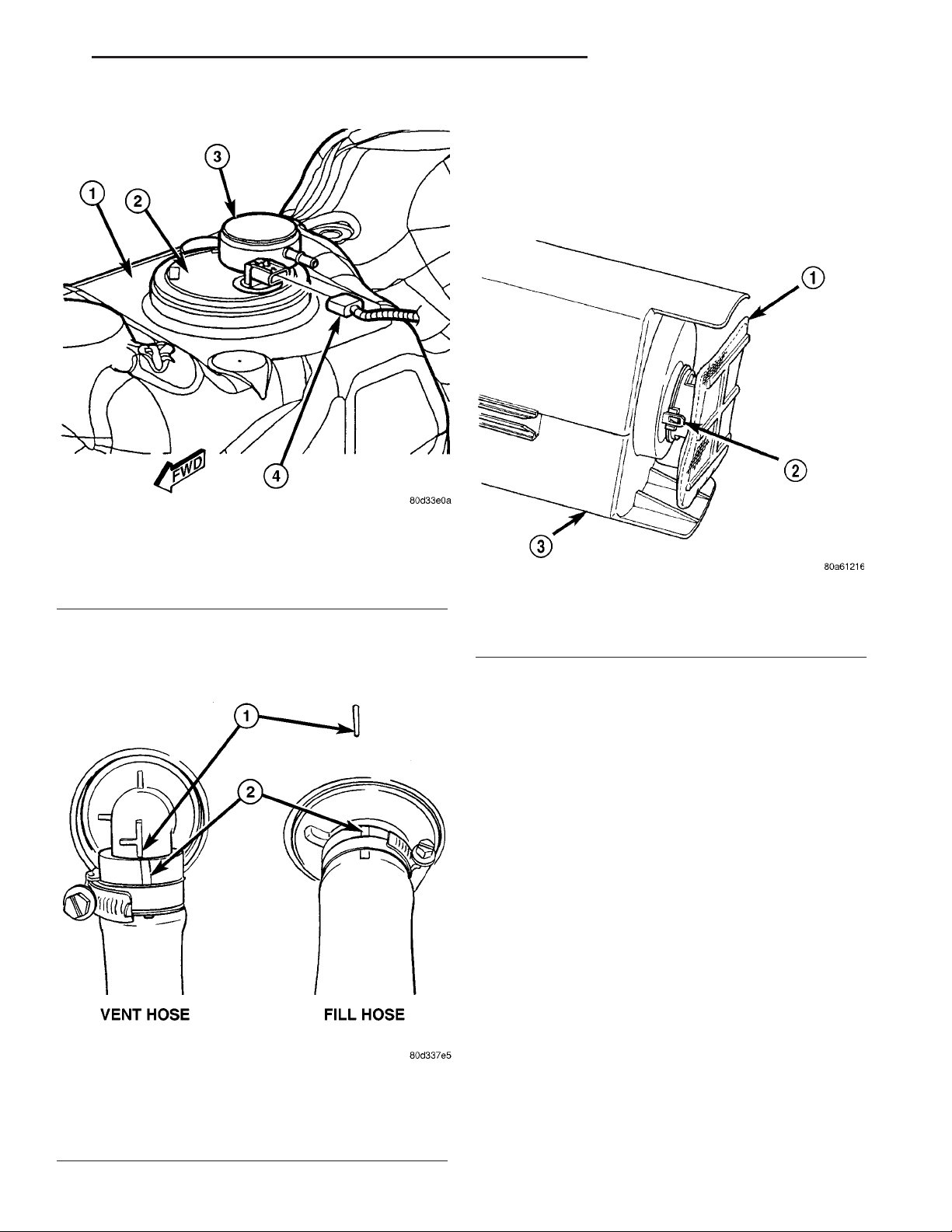

(2) Disconnect clamps and remove rubber fuel fill

hose and fuel vent hose at fuel fill tube. Install these

2 hoses to 2 fuel tank fittings. Rotate hoses until

paint marks on hoses line up with alignment marks

(Fig. 31). Tighten both clamps.

(3) Position fuel tank to hydraulic jack.

(4) Raise tank until positioned near body.

(5) Connect EVAP line at tank (Fig. 1).

(6) Connect fuel pump module electrical connector

(Fig. 30) at top of tank.

4 - MOUNTING STRAPS

5 - STRAP NUTS

(7) Connect fuel line quick-connect fitting to fuel

filter / fuel pressure regulator (Fig. 1) or (Fig. 30).

(8) Continue raising tank until positioned snug to

body.

(9) Install and position both tank support straps.

Install 2 fuel tank strap nuts (Fig. 29) and tighten.

Tighten rear strap nut first. Refer to Torque Specifications.

(10) Connect rubber fill and vent hoses to fuel fill

tube and tighten clamps.

(11) Lower vehicle.

(12) Fill fuel tank with fuel.

DR FUEL DELIVERY - GAS 14 - 23

FUEL TANK (Continued)

INLET FILTER

REMOVAL

The fuel pump inlet filter (strainer) is located on

the bottom of the fuel pump module (Fig. 32). The

fuel pump module is located inside of fuel tank.

Fig. 30 FUEL PUMP MODULE CONNECTIONS

1 - TOP OF FUEL TANK

2 - FUEL PUMP MODULE

3 - FUEL FILTER / FUEL PRESSURE REGULATOR

4 - ELEC. CONNECT.

(13) Start engine and check for fuel leaks near top

of module.

Fig. 32 FUEL PUMP INLET FILTER

1 - FUEL PUMP INLET FILTER

2 - LOCK TABS (2)

3 - FUEL PUMP MODULE (BOTTOM)

(1) Remove fuel tank. Refer to Fuel Tank Removal/

Installation.

(2) Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Remove filter by carefully prying 2 lock tabs at

bottom of module with 2 screwdrivers. Filter is

snapped to module.

(4) Clean bottom of pump module.

INSTALLATION

The fuel pump inlet filter (strainer) is located on

the bottom of the fuel pump module (Fig. 32). The

fuel pump module is located inside of fuel tank.

(1) Snap new filter to bottom of module. Be sure

o-ring is in correct position.

(2) Install fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

Fig. 31 HOSE ALIGNMENT MARKS

1 - ALIGNMENT MARKS (MARK FOR FILL HOSE IS LOCATED

ON FUEL TANK - MARK FOR VENT HOSE IS LOCATED ON

FITTING)

2 - PAINT MARKS ON RUBBER HOSES

14 - 24 FUEL INJECTION - GAS DR

FUEL INJECTION - GAS

TABLE OF CONTENTS

page page

ACCELERATOR PEDAL

REMOVAL .............................24

INSTALLATION .........................24

ACCELERATOR PEDAL POSITION SENSOR

DESCRIPTION .........................25

OPERATION ...........................25

REMOVAL .............................25

INSTALLATION .........................25

CRANKSHAFT POSITION SENSOR

DESCRIPTION .........................26

OPERATION ...........................26

REMOVAL .............................29

INSTALLATION .........................30

FUEL INJECTOR

DESCRIPTION .........................32

OPERATION

OPERATION - FUEL INJECTOR ..........32

OPERATION - PCM OUTPUT ............32

REMOVAL .............................32

INSTALLATION .........................33

FUEL PUMP RELAY

DESCRIPTION .........................33

OPERATION ...........................33

REMOVAL .............................33

INSTALLATION .........................33

IDLE AIR CONTROL MOTOR

DESCRIPTION .........................33

OPERATION ...........................33

REMOVAL .............................34

INSTALLATION .........................35

INTAKE AIR TEMPERATURE SENSOR

DESCRIPTION .........................36

OPERATION ...........................36

REMOVAL .............................36

INSTALLATION .........................38

MAP SENSOR

DESCRIPTION .........................39

OPERATION ...........................39

REMOVAL .............................40

INSTALLATION .........................42

OXYGEN SENSOR

DESCRIPTION .........................43

OPERATION ...........................43

REMOVAL .............................44

INSTALLATION .........................45

THROTTLE BODY

DESCRIPTION .........................45

OPERATION ...........................45

REMOVAL .............................45

INSTALLATION .........................47

THROTTLE CONTROL CABLE

REMOVAL .............................49

INSTALLATION .........................51

THROTTLE POSITION SENSOR

DESCRIPTION .........................52

OPERATION ...........................52

REMOVAL .............................53

INSTALLATION .........................54

ACCELERATOR PEDAL

REMOVAL

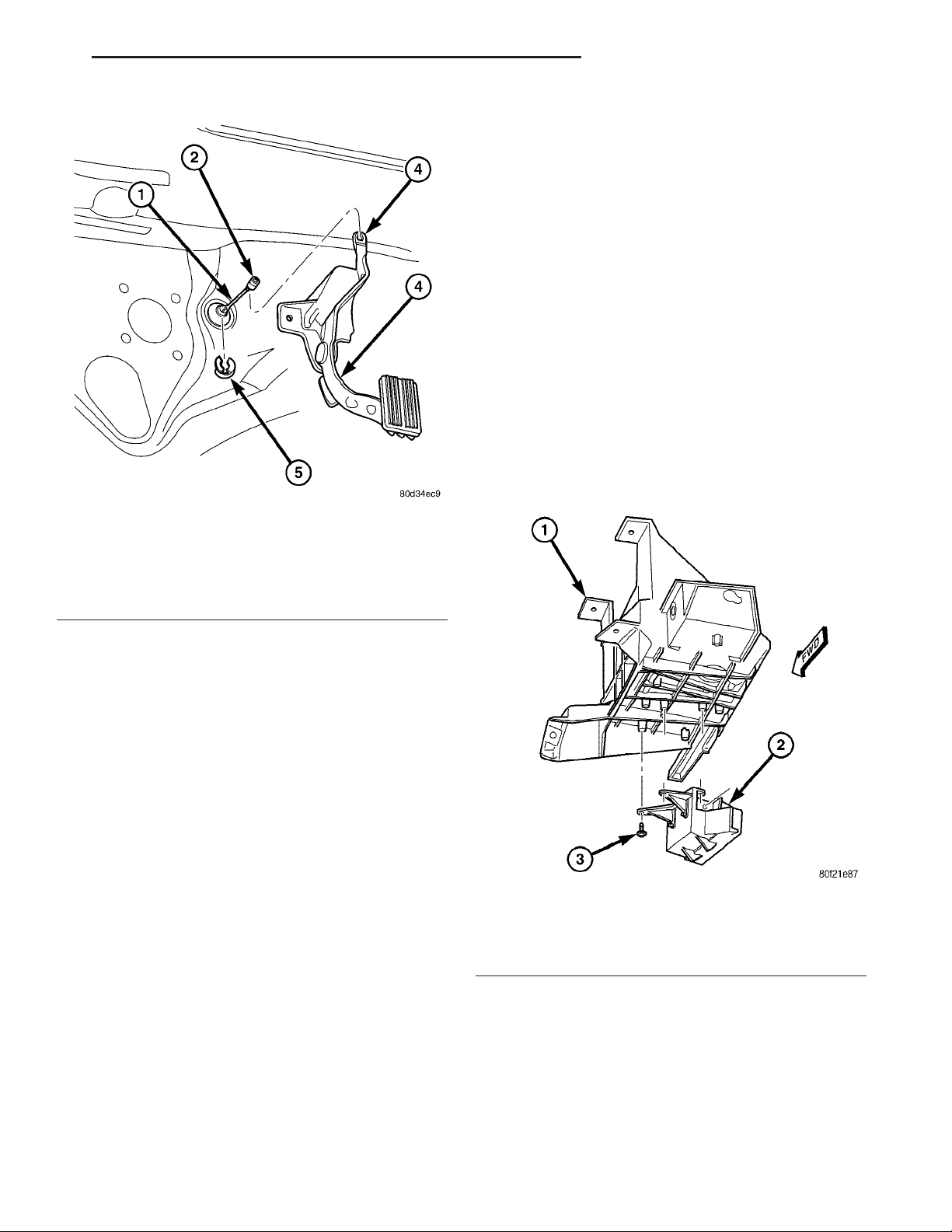

The following procedure applies only to vehicles

without the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper

part of the accelerator pedal arm by a plastic

retainer (clip) (Fig. 1). This plastic retainer snaps

into the top of the accelerator pedal arm.

(1) From inside the vehicle, hold up accelerator

pedal. Remove plastic cable retainer (clip) and throttle cable core wire from upper end of accelerator

pedal arm (Fig. 1). Plastic cable retainer (clip) snaps

into pedal arm.

(2) Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.

INSTALLATION

(1) Place accelerator pedal assembly over 2 studs.

(2) Install and tighten 2 mounting nuts. Refer to

Torque Specifications.

(3) Slide throttle cable into opening slot in top of

pedal arm.

(4) Push plastic cable retainer (clip) into accelera-

tor pedal arm opening until it snaps into place.

(5) Before starting engine, operate accelerator

pedal to check for any binding.

DR FUEL INJECTION - GAS 14 - 25

ACCELERATOR PEDAL (Continued)

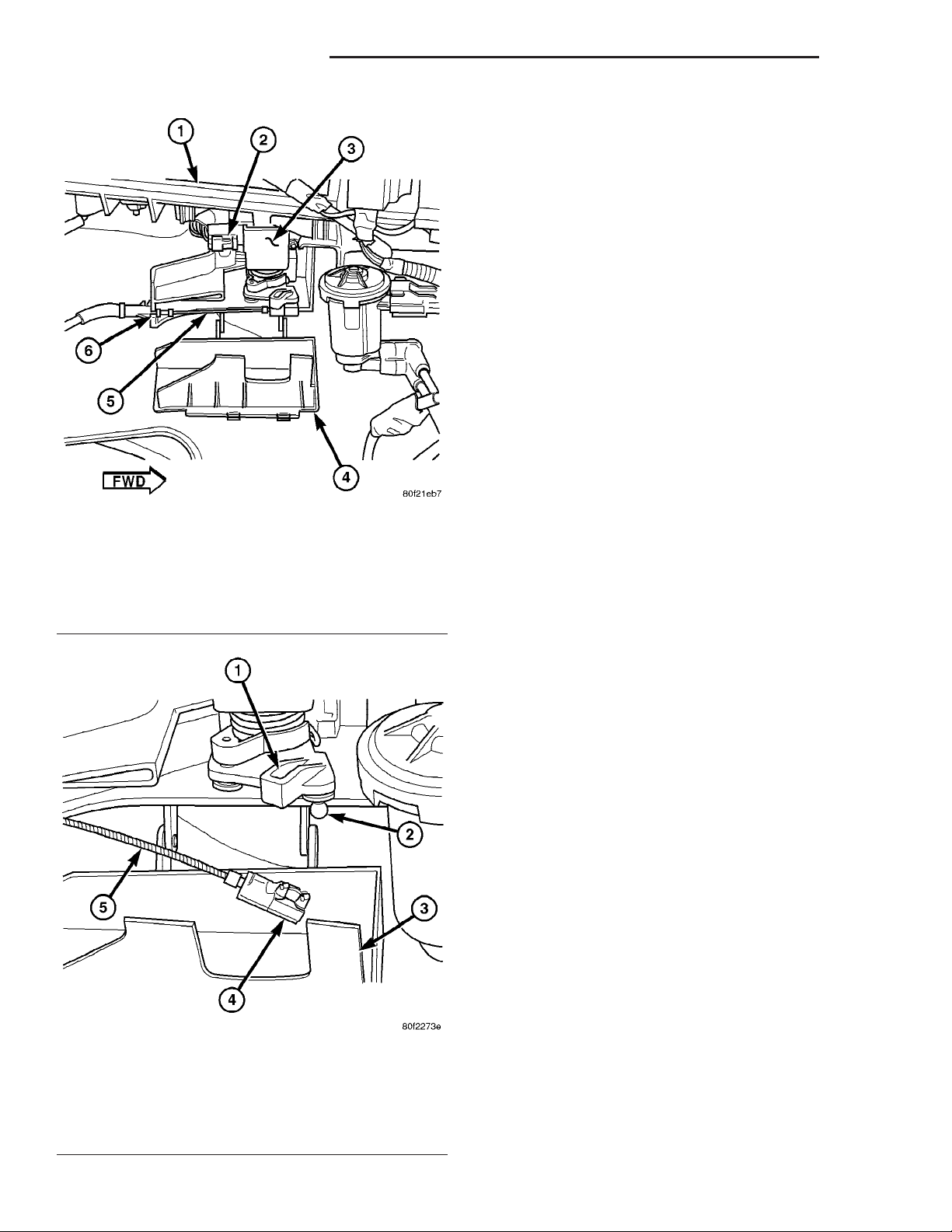

REMOVAL

The APPS is serviced (replaced) as one assembly

including the sensor, plastic housing and cable. The

APPS assembly is located under the vehicle battery

tray (Fig. 2). Access to APPS is gained from over top

of left / front tire.

(1) Disconnect negative battery cable at battery.

(2) Disconnect APPS cable at accelerator pedal.

Refer to Accelerator Pedal Removal / Installation.

(3) Remove wheel house liner at left / front wheel.

Refer to Body.

(4) Gain access to APPS electrical connector by

opening swing-down door (Fig. 3). Disconnect electrical connector.

(5) Remove 3 mounting bolts (Fig. 3).

(6) Remove APPS assembly from battery tray.

(7) If cable is to be separated at APPS, unsnap

cable clip from ball socket (Fig. 4). Release cable from

plastic housing by pressing on small cable release tab

(Fig. 3).

Fig. 1 ACCELERATOR PEDAL MOUNTING

1 - ACCELERATOR CABLE

2 - PLASTIC RETAINER (CLIP)

3 - THROTTLE PEDAL ARM

4 - PEDAL / BRACKET ASSEMBLY

5 - CABLE CLIP

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

The Accelerator Pedal Position Sensor (APPS)

assembly is located under the vehicle battery tray. A

cable connects the assembly to the accelerator pedal.

A plastic cover with a movable door is used to cover

the assembly.

The APPS is used only with the 5.7L V-8 engine.

OPERATION

The Accelerator Pedal Position Sensor (APPS) is a

linear potentiometer. It provides the Powertrain Control Module (PCM) with a DC voltage signal proportional to the angle, or position of the accelerator

pedal. The APPS signal is translated (along with

other sensors) to place the throttle plate (within the

throttle body) to a pre-determined position.

A mechanical cable is used between the accelerator

pedal and the APPS assembly. Although a cable is

used between the pedal and APPS, a mechanical

cable is not used at the throttle body. Throttle plate

position is electrically determined.

Fig. 2 APPS LOCATION

1 - BATTERY TRAY

2 - APPS LOCATION

3 - APPS MOUNTING BOLTS

INSTALLATION

(1) Install Accelerator Pedal Position Sensor

(APPS) cable to accelerator pedal. Refer to Accelerator Pedal Removal / Installation.

(2) Connect electrical connector to APPS.

(3) If necessary, connect cable to APPS lever ball

socket (snaps on).

(4) Snap APPS cable cover closed.

14 - 26 FUEL INJECTION - GAS DR

ACCELERATOR PEDAL POSITION SENSOR (Continued)

(5) Position APPS assembly to bottom of battery

tray and install 3 bolts. Refer to Torque Specifications.

(6) Install wheelhouse liner. Refer to Body.

(7) Perform the following procedure:

(a) Connect negative battery cable to battery.

(b) Turn ignition switch ON, but do not crank

engine.

(c) Leave ignition switch ON for a minimum of

10 seconds. This will allow PCM to learn electrical

parameters.

(8) If the previous step is not performed, a Diag-

nostic Trouble Code (DTC) will be set.

(9) If necessary, use DRB IIIt Scan Tool to erase

any Diagnostic Trouble Codes (DTC’s) from PCM.

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

Fig. 3 APPS REMOVE / INSTALL

1 - BOTTOM OF BATTERY TRAY

2 - ELECTRICAL CONNECTOR

3 - APPS

4 - SWING-DOWN DOOR

5 - CABLE (TO PEDAL)

6 - CABLE RELEASE TAB

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

4.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.7L V-8

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block. It is

positioned and bolted into a machined hole.

5.9L V-8 Gas

The Crankshaft Position (CKP) sensor is located

near the outer edge of the flywheel (starter ringear).

It is bolted to the rear of the engine.

8.0L V-10

The Crankshaft Position (CKP) sensor is located on

the right-lower side of the cylinder block, forward of

the right engine mount, just above the oil pan rail.

Fig. 4 APPS CABLE

1 - APPS LEVER

2 - BALL SOCKET

3 - SWING-DOWN DOOR

4 - CABLE CLIP

5 - CABLE

OPERATION

3.7L V-6

Engine speed and crankshaft position are provided

through the CKP (Crankshaft Position) sensor. The

sensor generates pulses that are the input sent to the

Powertrain Control Module (PCM). The PCM interprets the sensor input to determine the crankshaft

position. The PCM then uses this position, along with

DR FUEL INJECTION - GAS 14 - 27

CRANKSHAFT POSITION SENSOR (Continued)

other inputs, to determine injector sequence and ignition timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

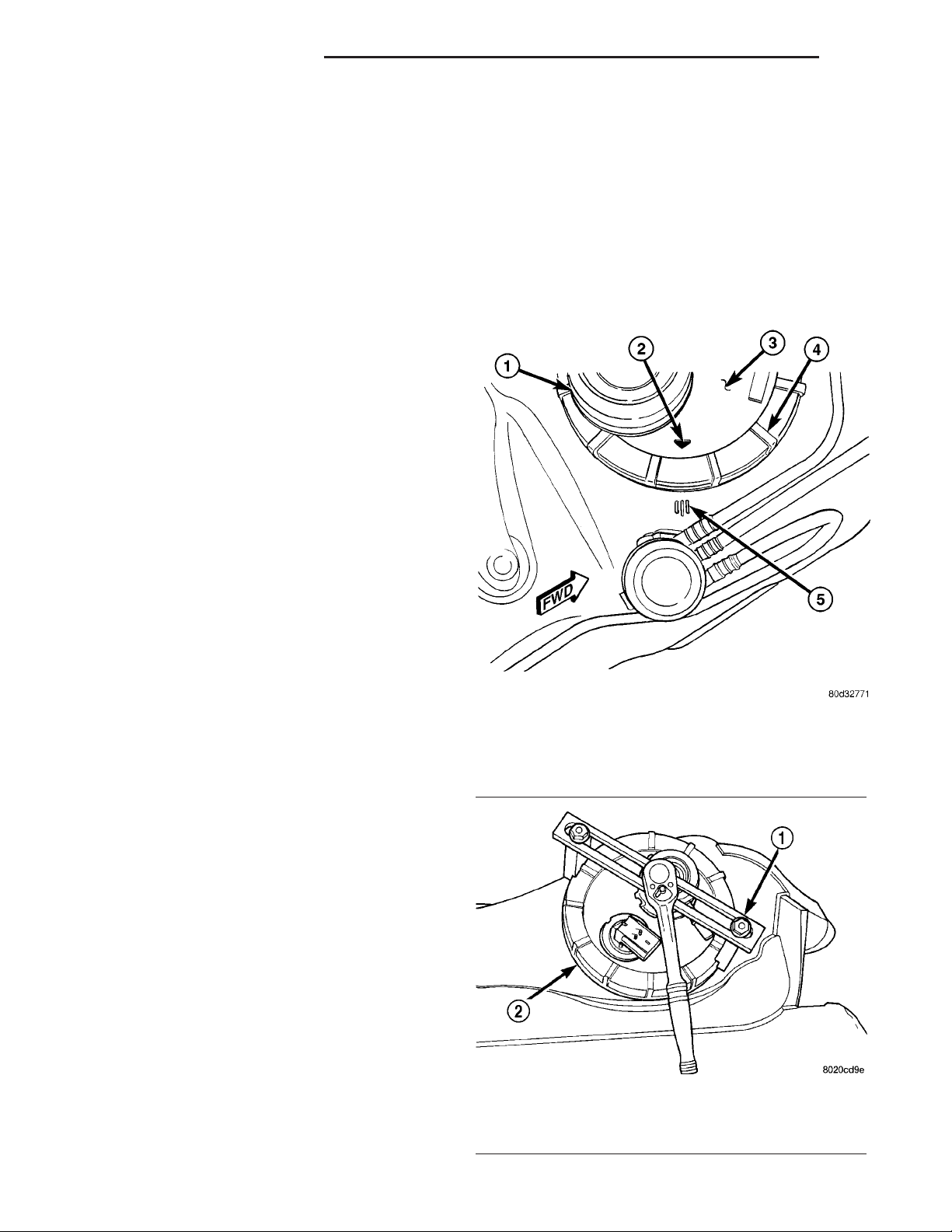

A tonewheel (targetwheel) is bolted to the engine

crankshaft (Fig. 5). This tonewheel has sets of

notches at its outer edge (Fig. 5).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

Fig. 5 CKP OPERATION - 3.7L V-6

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

4.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the powertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft position. The PCM then uses this position, along with

other inputs, to determine injector sequence and ignition timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 4.7L V–8 engine, a tonewheel is bolted to

the engine crankshaft (Fig. 6). This tonewheel has

sets of notches at its outer edge (Fig. 6).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

Fig. 6 CKP SENSOR OPERATION AND TONEWHEEL

- 4.7L V-8

1 - TONEWHEEL

2 - NOTCHES

3 - CRANKSHAFT POSITION SENSOR

4 - CRANKSHAFT

5.7L V-8

Engine speed and crankshaft position are provided

through the crankshaft position sensor. The sensor

generates pulses that are the input sent to the powertrain control module (PCM). The PCM interprets

the sensor input to determine the crankshaft position. The PCM then uses this position, along with

other inputs, to determine injector sequence and ignition timing.

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On the 5.7L V–8 engine, a tonewheel is bolted to

the engine crankshaft. This tonewheel has sets of

notches at its outer edge (Fig. 7).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM.

5.9L V-8 Gas

Engine speed and crankshaft position are provided

through the CKP sensor. The sensor generates pulses

that are the input sent to the Powertrain Control

Module (PCM). The PCM interprets the sensor input

to determine the crankshaft position. The PCM then

uses this position, along with other inputs, to determine injector sequence and ignition timing.

14 - 28 FUEL INJECTION - GAS DR

CRANKSHAFT POSITION SENSOR (Continued)

Fig. 7 CKP SENSOR OPERATION AND NOTCHES -

5.7L V-8

1 - RIGHT / REAR SIDE OF CYLINDER BLOCK

2 - MACHINED HOLE

3 - NOTCHES

The sensor is a hall effect device combined with an

internal magnet. It is also sensitive to steel within a

certain distance from it.

On 5.9L V-8 engines, the flywheel/drive plate has 8

single notches, spaced every 45 degrees, at its outer

edge (Fig. 8).

The notches cause a pulse to be generated when

they pass under the sensor. The pulses are the input

to the PCM. For each engine revolution, there are 8

pulses generated on V-8 engines.

The engine will not operate if the PCM does not

receive a CKP sensor input.

8.0L V-10

The Crankshaft Position (CKP) sensor detects

notches machined into the middle of the crankshaft

(Fig. 9).

There are five sets of notches. Each set contains

two notches. Basic ignition timing is determined by

the position of the last notch in each set of notches.

Once the Powertrain Control Module (PCM) senses

the last notch, it will determine crankshaft position

(which piston will next be at Top Dead Center). An

input from the camshaft position sensor is also

needed. It may take the module up to one complete

engine revolution to determine crankshaft position

during engine cranking.

Fig. 8 CKP SENSOR OPERATION – 5.9L V-8

1 - CRANKSHAFT POSITION SENSOR

2 - NOTCHES

3 - FLYWHEEL

Fig. 9 CKP SENSOR OPERATION – 8.0L V-10

ENGINE

1 - CRANKSHAFT NOTCHES

2 - CRANKSHAFT

3 - CRANKSHAFT POSITION SENSOR

The PCM uses the signal from the camshaft position sensor to determine fuel injector sequence. Once

crankshaft position has been determined, the PCM

begins energizing a ground circuit to each fuel injector to provide injector operation.

DR FUEL INJECTION - GAS 14 - 29

CRANKSHAFT POSITION SENSOR (Continued)

REMOVAL

3.7L V-6

The Crankshaft Position (CKP) sensor is mounted

into the right rear side of the cylinder block (Fig. 10).

It is positioned and bolted into a machined hole.

(1) Raise vehicle.

(2) Disconnect sensor electrical connector.

(3) Remove sensor mounting bolt (Fig. 10).

(4) Carefully twist sensor from cylinder block.

(5) Check condition of sensor o-ring.

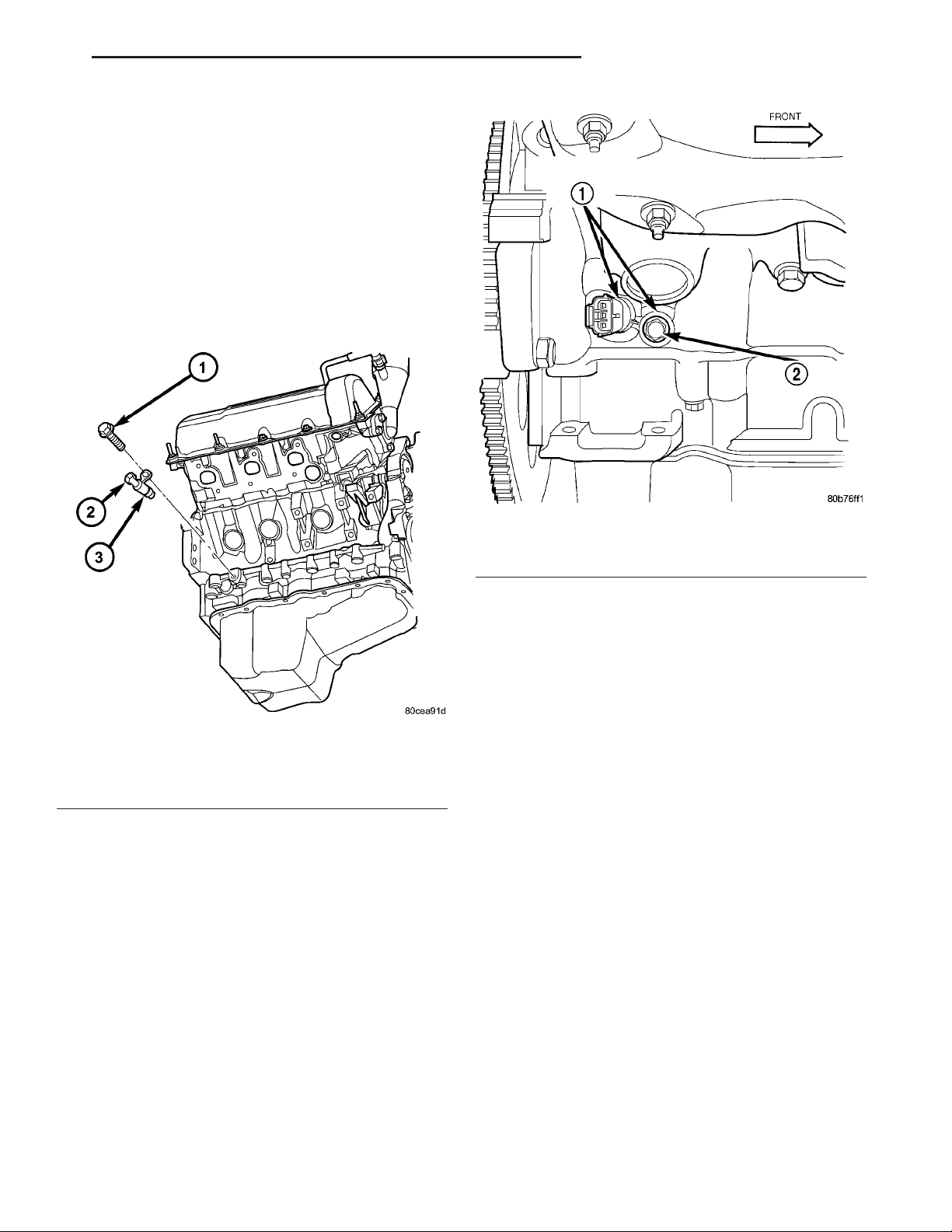

Fig. 10 CKP REMOVAL / INSTALLATION - 3.7L

1 - MOUNTING BOLT

2 - CKP SENSOR

3 - O-RING

4.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

11). It is positioned and bolted into a machined hole

in the engine block.

(1) Raise vehicle.

Fig. 11 CKP REMOVAL / INSTALLATION - 4.7L

1 - CRANKSHAFT POSITION SENSOR

2 - MOUNTING BOLT

(2) Disconnect CKP electrical connector at sensor.

(3) Remove CKP mounting bolt (Fig. 11).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

5.7L V-8

The Crankshaft Position (CKP) sensor is located at

the right-rear side of the engine cylinder block (Fig.

12). It is positioned and bolted into a machined hole

in the engine block.

(1) Raise vehicle.

(2) Disconnect CKP electrical connector at sensor

(Fig. 12).

(3) Remove CKP mounting bolt (Fig. 12).

(4) Carefully twist sensor from cylinder block.

(5) Remove sensor from vehicle.

(6) Check condition of sensor o-ring.

Loading...

Loading...