Dodge Fe Bumpers Service Manual

DR FRAMES & BUMPERS 13 - 1

FRAMES & BUMPERS

TABLE OF CONTENTS

page page

BUMPERS

SPECIFICATIONS - TORQUE ...............1

FRONT AIR DAM

REMOVAL .............................2

INSTALLATION ..........................2

FRONT BUMPER

REMOVAL .............................2

INSTALLATION ..........................2

FRONT FASCIA

REMOVAL .............................3

INSTALLATION ..........................3

REAR BUMPER

REMOVAL .............................4

INSTALLATION ..........................4

FRAME

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY

FRONT FRAME RAIL TIP REPLACEMENT....4

STANDARD PROCEDURE - HYDROFORM

FENDER RAIL REPAIR .................12

STANDARD PROCEDURE - REAR FRAME

H-SECTION REPLACEMENT .............15

BUMPERS

SPECIFICATIONS

SPECIFICATIONS - FRAME DIMENSIONS . . . 17

SPECIFICATIONS - TORQUE ............23

FRONT CROSSMEMBER

REMOVAL .............................23

INSTALLATION .........................23

FRONT SKID PLATE

REMOVAL .............................24

INSTALLATION .........................24

TRANSMISSION CROSSMEMBER

REMOVAL .............................24

INSTALLATION .........................25

TRAILER HITCH

REMOVAL .............................25

INSTALLATION .........................25

TRANSFER CASE SKID PLATE

REMOVAL .............................26

INSTALLATION .........................26

FRONT TOW HOOK ASSEMBLY

REMOVAL .............................26

INSTALLATION .........................26

SPECIFICATIONS - TORQUE

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Front bumper center bracket nuts 95 70 —

Front bumper stud plate nuts 95 70 —

License plate hitch reinforcement bolts 54 40 —

Rear bumper support bracket stud plate nuts 54 40 —

Rear bumper support bracket to hitch bolts 54 40 —

Rear bumper to hitch bolts 54 40 —

TORQUE SPECIFICATIONS

13 - 2 FRAMES & BUMPERS DR

FRONT AIR DAM

REMOVAL

(1) Using a trim stick C-4755 or equivalent,

remove the fog lamp trim bezels. (Fig. 1)

(2) Remove the air dam screws through the fog

lamp opening (1 per side).

(3) Remove the two outboard screws.

(4) Remove the three middle screws and remove

the air dam.

FRONT BUMPER

REMOVAL

(1) Using a grease pencil or equivalent, mark the

position of the bumper on the frame rail tip to aid

installation.

(2) Disconnect the fog lamp electrical connector at

the left frame rail.

(3) Support the bumper with a suitable lifting

device.

(4) Remove the center bracket nuts and bolts and

remove bumper. (Fig. 2)

Fig. 1 FOG LAMP BEZEL

1 - BUMPER

2 - BEZEL

INSTALLATION

(1) Position the air dam onto the bumper and seat

the carrot type fasteners fully.

(2) Starting at the center screw install the three

middle screws.

(3) Install the screws through the fog lamp open-

ing.

(4) Install the two outboard screws.

(5) Position the fog lamp trim bezels into the

bumper and seat fully.

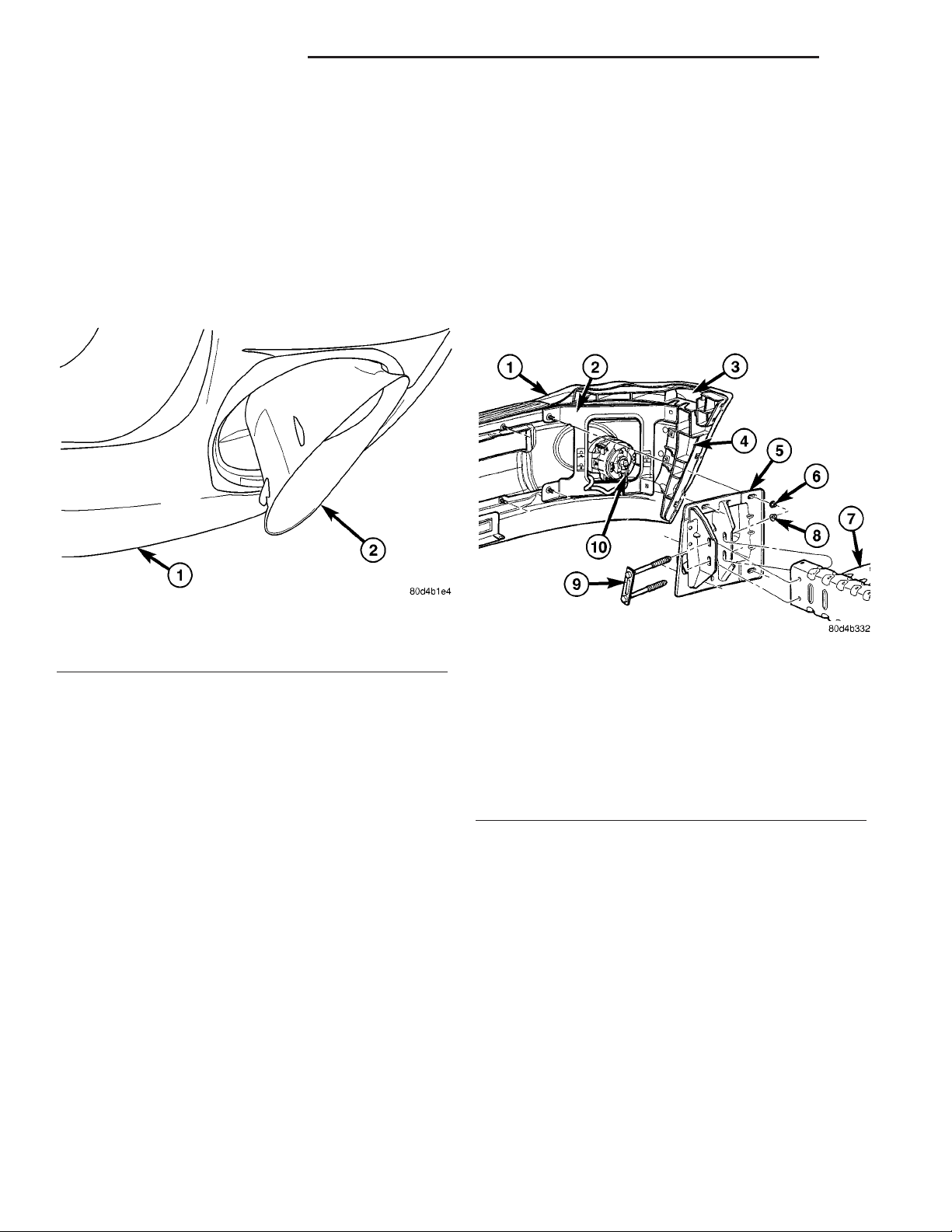

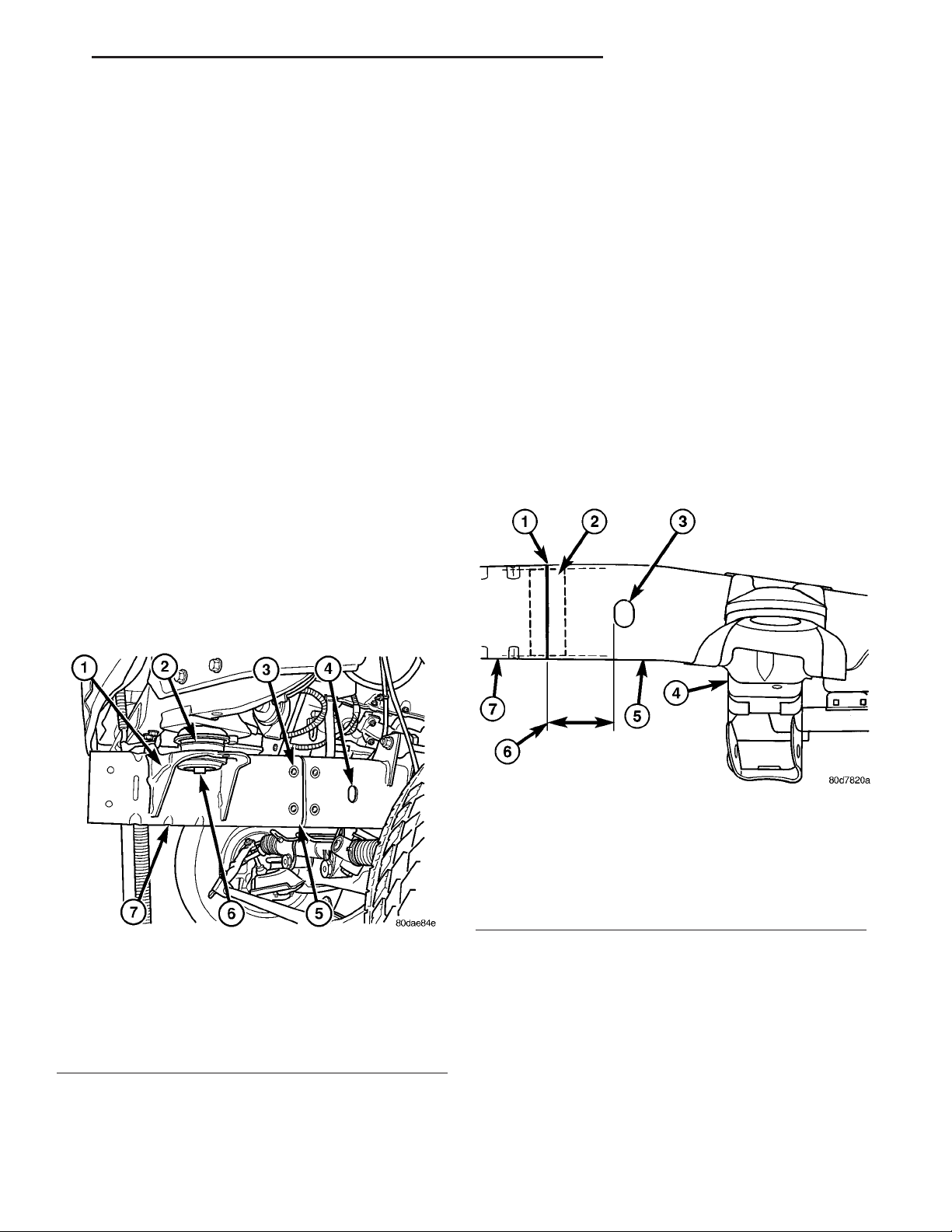

Fig. 2 BUMPER SUPPORT BRACKET - TYPICAL

1 - FASCIA - SPORT MODEL

2 - SUPPORT BRACKET

3 - FASCIA SUPPORT BRACKET

4 - WHEELHOUSE SPLASH SHIELD SUPPORT BRACKET

5 - BUMPER CENTER BRACKET

6 - NUTS (4 PER SIDE)

7 - FRAME RAIL TIP

8 - CENTER BRACKET NUTS (2 PER SIDE)

9 - CENTER BRACKET BOLTSASSEMBLY (1 PER SIDE)

10 - FOG LAMP

INSTALLATION

(1) Install the bumper onto the frame rails and

position the wheelhouse splash shield into the support brackets.

(2) Install the bolts and nuts.

(3) Line up the bumper with the marks made previously and tighten the bolts and nuts to 95 N·m (70

ft. lbs.).

(4) Check and adjust the bumper alignment as

necessary. (Refer to 23 - BODY/BODY STRUCTURE/

GAP AND FLUSH - SPECIFICATIONS)

DR FRAMES & BUMPERS 13 - 3

FRONT FASCIA

REMOVAL

ST/SLT/SLT+ - FASCIA REMOVAL

(1) Remove the two screws at each trailing edge of

the fascia. (Fig. 3)

(2) Using a trim stick C-4755 or equivalent, carefully release the six lower clips and remove the close

out panel.

(3) Using a trim stick C-4755 or equivalent, carefully remove the step pad.

(4) Remove and discard the four push pin fasteners and remove the fascia.

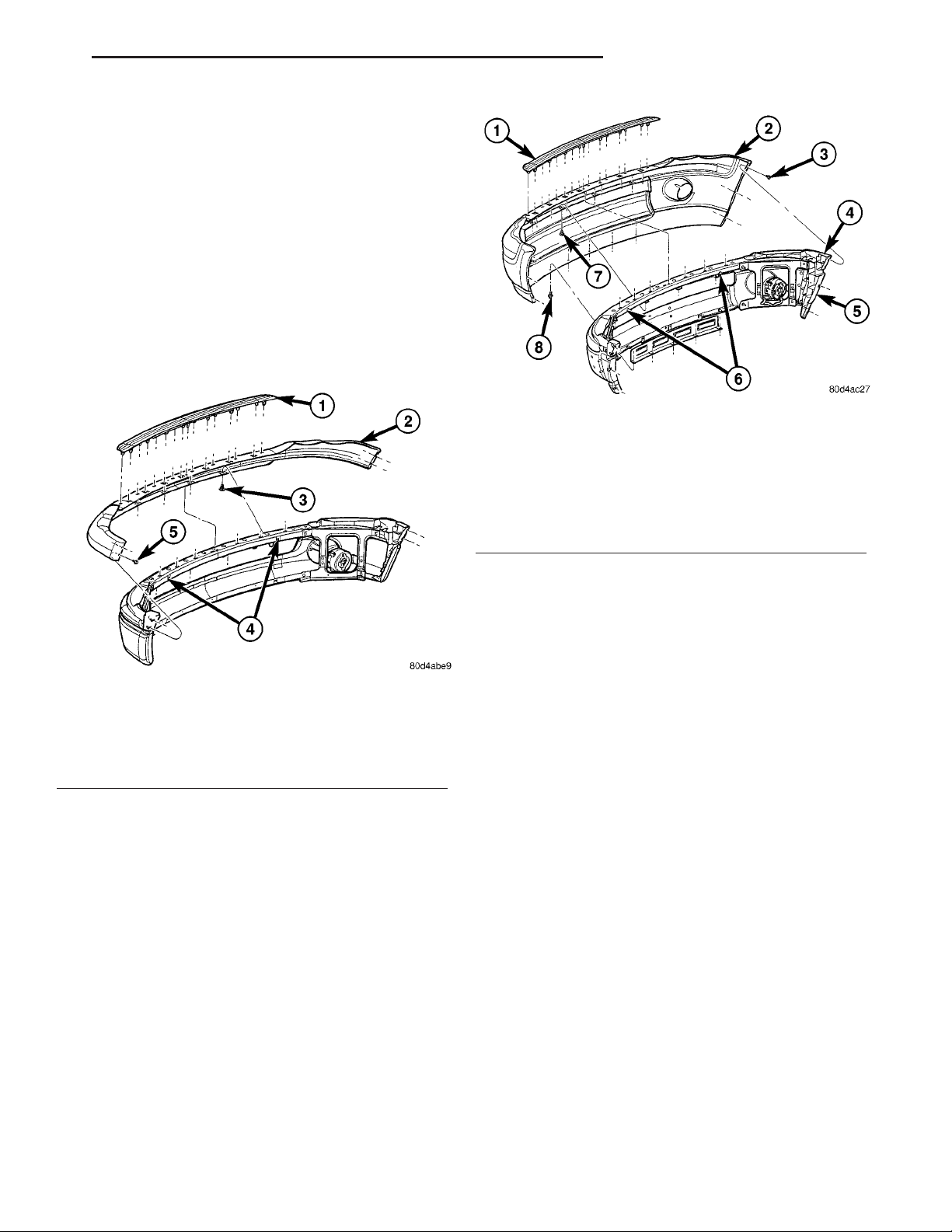

Fig. 4 SPORT FASCIA

1 - STEP PAD

2 - FASCIA (SPORT MODEL ONLY)

3 - SCREWS (3 PER SIDE)

4 - UPPER FASCIA SUPPORT BRACKET

5 - WHEELHOUSE SPLASH SHIELD BRACKET

6 - INBOARD BUMPER BRACKET ATTACHMENTS

7 - PUSH PIN FASTENERS (4)

8 - LOWER SCREWS (5)

Fig. 3 UPPER FASCIA - ST/SLT/SLT+

1 - STEP PAD

2 - UPPER FASCIA (ST/SLT/SLT+ MODEL ONLY)

3 - INBOARD BUMPER BRACKET ATTACHMENTS

4 - SCREWS (4)

5 - PUSH PIN FASTENERS (4)

SPORT FASCIA REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING STANDARD PROCEDURE)

(2) Remove the three screws at each trailing edge

of the fascia. (Fig. 4)

(3) Remove the five lower screws.

(4) Remove and discard the four upper push pins.

(5) Using a trim stick C-4755 or equivalent, carefully release the six lower clips and remove the close

out panel.

(6) Using a trim stick C-4755 or equivalent, carefully remove the step pad.

(7) Spread the fascia out at the wheels and remove

from the vehicle.

INSTALLATION

NOTE: The left and right inboard bumper to bracket

attachments must be secured before installing the

fascia and step pad.

ST/SLT/SLT+ FASCIA INSTALLATION

(1) Install the fascia.

(2) Position the close out panel and seat the 6

lower clips fully.

(3) Install four new upper push pin fasteners.

(4) Position the step pad onto the fascia and fully

seat the attachment clips.

(5) Align the fascia to the fender with a 19 mm

(0.75 inch) gap and install the two screws at each

trailing edge of the fascia.

SPORT FASCIA INSTALLATION

(1) Position the fascia onto the bumper.

(2) Position the step pad onto the fascia and fully

seat the attachment clips.

(3) Install four new upper push pin fasteners.

(4) Install the five lower screws.

(5) Install the three screws at each trailing edge of

the fascia.

13 - 4 FRAMES & BUMPERS DR

REAR BUMPER

REMOVAL

(1) Raise and support the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING STANDARD PROCEDURE)

(2) Remove the license plate.

(3) Remove the bolts behind the plate.

(4) Disconnect the license plate light electrical connectors.

(5) Disconnect the trailer light connector electrical

connection, if equipped.

(6) Remove the two bolts along the front upper

edge of the bumper near the frame tips.

Support the bumper with a suitable lifting device.

(7)

(8) Remove the bolts attaching the bumper support

brackets to the trailer hitch. (Fig. 5)

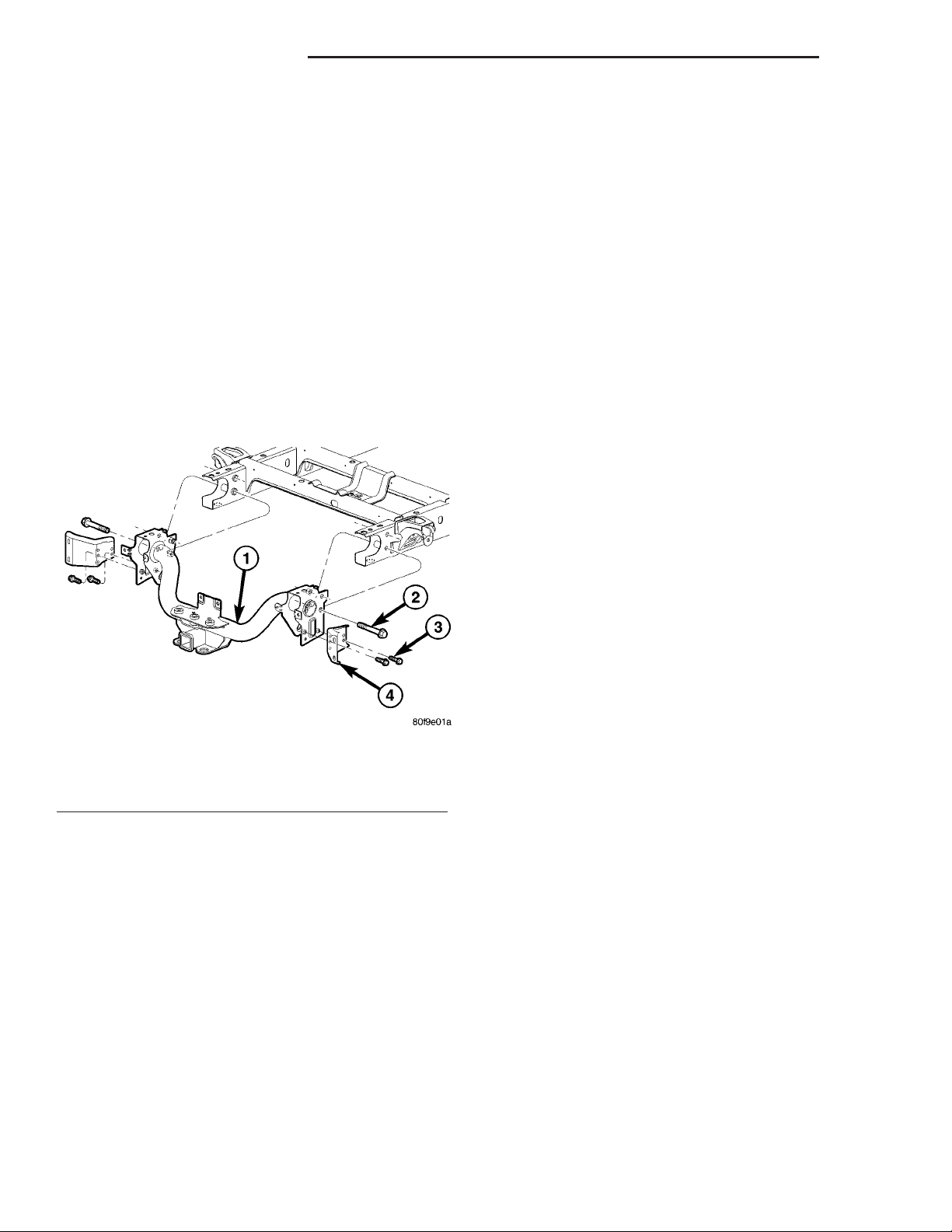

Fig. 5 TRAILER HITCH

1 - HITCH

2 - HITCH BOLTS (4)

3 - BUMPER BRACKET BOLTS (4)

4 - BUMPER SUPPORT BRACKETS

INSTALLATION

(1) Align the holes in the bumpers to the trailer

hitch pins and install the bumper.

(2) Install the support bracket to the hitch bolts,

loosely.

(3) Install the front upper edge to the trailer hitch

bolts and tighten to 54 N·m (40 ft. lbs.).

(4) Install the license plate reinforcement to hitch

bolts and tighten to 54 N·m (40 ft. lbs.).

(5) Tighten the left bumper bracket bolts to 54

N·m (40 ft. lbs.).

(6) Tighten the right bumper bracket bolts to 54

N·m (40 ft. lbs.).

(7) Connect the trailer light connector electrical

connection, if equipped.

(8) Connect the license plate light electrical connectors.

(9) Install the license plate.

FRAME

STANDARD PROCEDURE

STANDARD PROCEDURE - LIGHT DUTY FRONT

FRAME RAIL TIP REPLACEMENT

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRINDING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

• BEFORE PROCEEDING WITH FRAME REPAIR

INVOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

• DO NOT ALLOW OPEN FLAME OR HEAT AND

METAL SPATTER FROM ARC WELDING, TO CONTACT PLASTIC BODY PANELS. FIRE OR EXPLOSION CAN RESULT.

• WHEN WELDED FRAME COMPONENTS ARE

REPLACED, ENSURE COMPLETE PENETRATION

WELD IS ACHIEVED DURING INSTALLATION. IF

NOT, DANGEROUS OPERATING CONDITIONS CAN

RESULT.

• STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHTENING OPERATIONS, PERSONAL INJURY CAN

RESULT.

• DO NOT VENTURE UNDER A HOISTED VEHICLE THAT IS NOT SUPPORTED ON SAFETY

STANDS, PERSONAL INJURY CAN RESULT.

CAUTION: 1500 series Dodge Ram Trucks (2002 and

later) are not designed for snow plow equipment.

The front collision repair tips must not be installed

on any truck equipped with a snow plow, or even

intended to be equipped with a snow plow.

CAUTION: This procedure is designed to replace

the front frame rail tips that have been damaged in

the crush initiator zones. Prior to any cutting, the

vehicle must be mounted on the appropriate frame

repair equipment (“frame rack”), checked with three

dimensional measuring equipment, and the necessary pull corrections made. If damage remains in

the frame beyond the area covered by this service

part after the pull, the frame must be replaced in its

entirety.

DR FRAMES & BUMPERS 13 - 5

FRAME (Continued)

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect. Failure to use only production fasteners or fasteners of equivalent hardness can result in loosening or failure. Do not drill

any holes in the frame that are not specifically outlined in this or other, DaimlerChrysler procedure as

frame rail failure can result. When using heat to

straighten frame components do not exceed 566°C

(1050°F), metal fatigue can result.

NOTE: Procedures for 4X2 and 4X4 are common

except as noted in this procedure.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front wheelhouse splash shield.

(Refer to 23 - BODY/EXTERIOR/FRONT WHEELHOUSE SPLASH SHIELD - REMOVAL)

(3) Remove the bolts and position aside the wire

harness and grounds, if required.

(4) Remove the front bumper. (Refer to 13 FRAME & BUMPERS/BUMPERS/FRONT BUMPER

- REMOVAL)

(5) Loosen and lower the stabilizer bar mount and

bar. (Refer to 2 - SUSPENSION/FRONT/STABILIZER BAR - REMOVAL)

(6) Remove the front cab mount bolt to the Front

End Sheet Metal (FESM) bracket. (Fig. 6)

(7) Make a vertical mark on the inside and outside

face of the frame rail 112 mm (4.5 in.) from the forward edge of the PLP hole in the sides of the rail.

(Fig. 8)

(8) Using a straightedge, connect the two lines on

the top and bottom of the rail.

(9) Using the service tip as a guide, re-check your

cut lines to ensure the service tip will fit when the

cut is made.

CAUTION: Do not use any flame or plasma cutting

equipment to cut the frame in this procedure. This

is due to the inaccurate nature of the cut-line and

the fact that the high temperatures achieved during

flame or plasma cutting will change the metal characteristics and may weaken the frame and/or repair

location.

(10) Using a reciprocating saw or equivalent, carefully cut and remove the damaged frame rail tip.

(Fig. 7)

Fig. 6 REPLACEMENT FRAME TIP

1 - FRONT END SHEET METAL (FESM) BRACKET

2 - CAB INSULATOR

3 - RING-FILLET WELD/HOLE

4 - PRINCIPLE LOCATING POINT (PLP)

5 - WELD ROOT GAP 4 mm-6mm(0.16 in. - 0.24 in.)

6 - FRONT CAB MOUNT BOLT

7 - REPLACEMENT FRAME TIP

Fig. 7 FRAME CUT LOCATION

1 - REPAIR ROOT OPENING

2 - SERVICE SLEEVE

3 - PRINCIPLE LOCATING POINT (PLP)

4 - SUSPENSION BRACKETS

5 - FRAME

6 - FRAME CUTOFF LOCATION - 112 mm (4.5 in.)

7 - FRAME SERVICE TIP

13 - 6 FRAMES & BUMPERS DR

FRAME (Continued)

(11) Assemble the service sleeve. Refer to SERVICE SLEEVE ASSEMBLY at the end of this procedure.

NOTE: Any burned surface coatings will need to be

removed from the sleeve prior to installation and

application of corrosion preventative coatings.

(12) Smooth and square the cut edges of the original frame. (Fig. 7)

(13) Dress the cut edge of the existing frame in

preparation for the new rail tip.

(a) Drill four 13 mm (0.5 in.) diameter holes in

the new tip and four more in the existing frame to

accommodate ring-fillet welds. Center these holes

19 mm (0.75 in.) from the cut face of the rail and

38 mm (1.5 in.) from the top and bottom of the rail.

(Fig. 8)

(b) Bevel the edges of the new tip, existing

frame, and ring-fillet holes 25° - 30°. Scribing a

line 2 mm from the cut edge and then grinding

back to the mark will simplify the bevel creation

process and accuracy. (Fig. 9)

(c) Remove any burrs at the holes and beveled

edges.

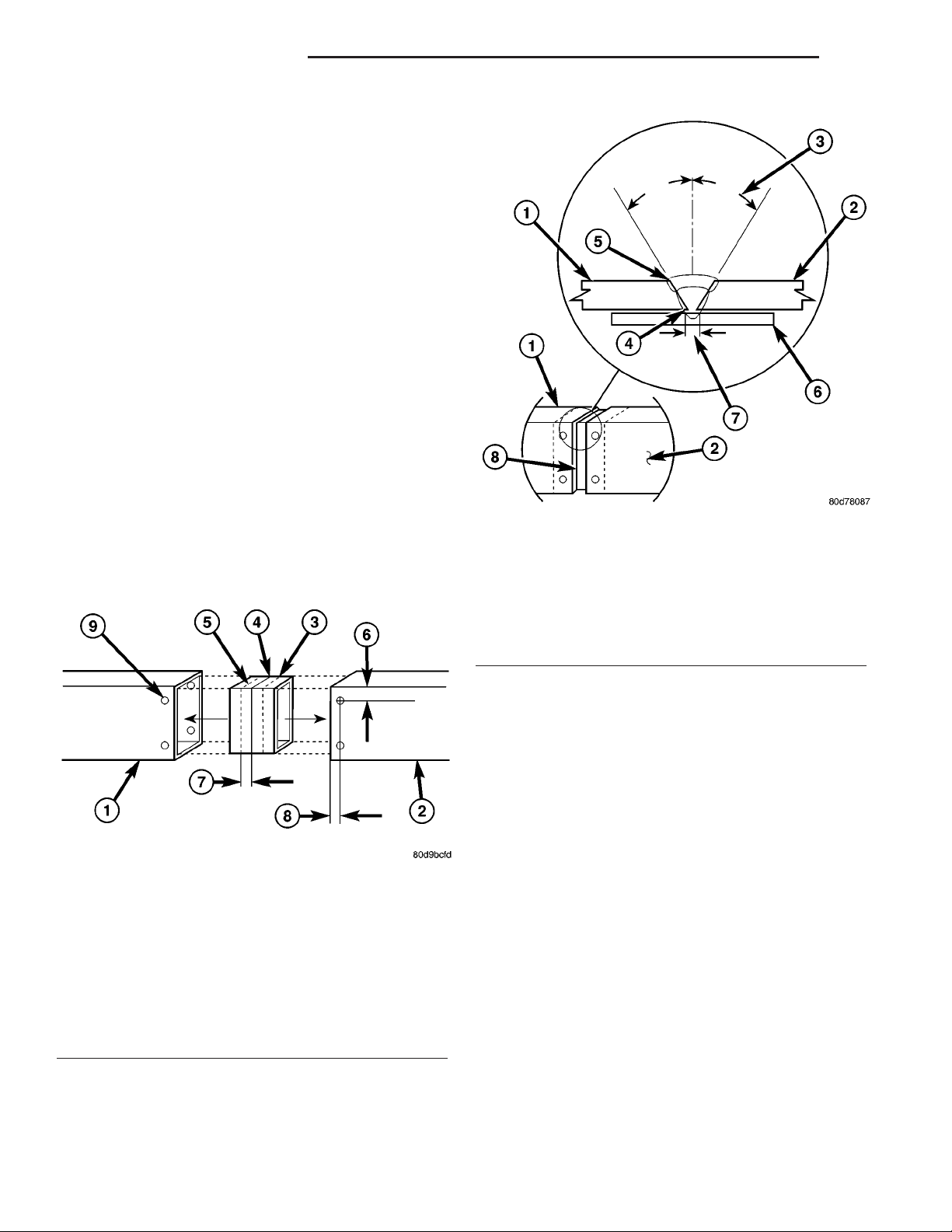

1 - FRAME REPLACEMENT TIP

2 - FRAME RAIL

3 - FRAME DRESS ANGLE 25°-30°

4 - ROOT PASS

5 - COVER PASS

6 - SERVICE SLEEVE

7 - WELD ROOT GAP 4 mm-6mm(0.16 in. - 0.24 in.)

8 - SERVICE SLEEVE

Fig. 9 WELD DIMENSIONS

Fig. 8 REPAIR SLEEVE INSTALLATION (TYPICAL)

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - CENTER LINE

5 - LOCATOR LINES (2)

6 - HORIZONTAL WELD HOLE LOCATION - 38 mm (1.5 in.)(BOTH

FRAME SECTIONS)

7 - LOCATOR LINE DIMENSION-2mm(0.08 in.)

8 - VERTICAL WELD HOLE LOCATION - 19 mm (0.75 in.)(BOTH

FRAME SECTIONS)

9 - RING FILLET WELD HOLES

(14) Dry fit the new rail to ensure alignment and

fit and make any adjustments as necessary.

(15) Remove all internal and external OEM e-coat

within 51 mm (2.0 in.) of the weld joint on the

replacement tip and the existing frame rail.

NOTE: Any burned surface coatings will need to be

removed prior to application of corrosion preventative coatings.

CAUTION: Shield the surrounding area and components from exposure to the welding spatter and

heat.

DR FRAMES & BUMPERS 13 - 7

FRAME (Continued)

(16) On 4X4 models use the service sleeve as a

template to drill a hole in the frame tip to accommodate the sway bar mounting bolt. (Fig. 12)

(17) Slide the service sleeve into the replacement

frame tip and align to the 2 mm (0.08 in.) off center

line made previously during the sleeve assembly and

tack the ring fillet welds to hold them in place. (Fig.

10) (Fig. 11) (Fig. 12) (Fig. 13)

(18) On 4X4 models, install the sway bar tapping

plate and secure with tack welds. (Fig. 12) (Fig. 13)

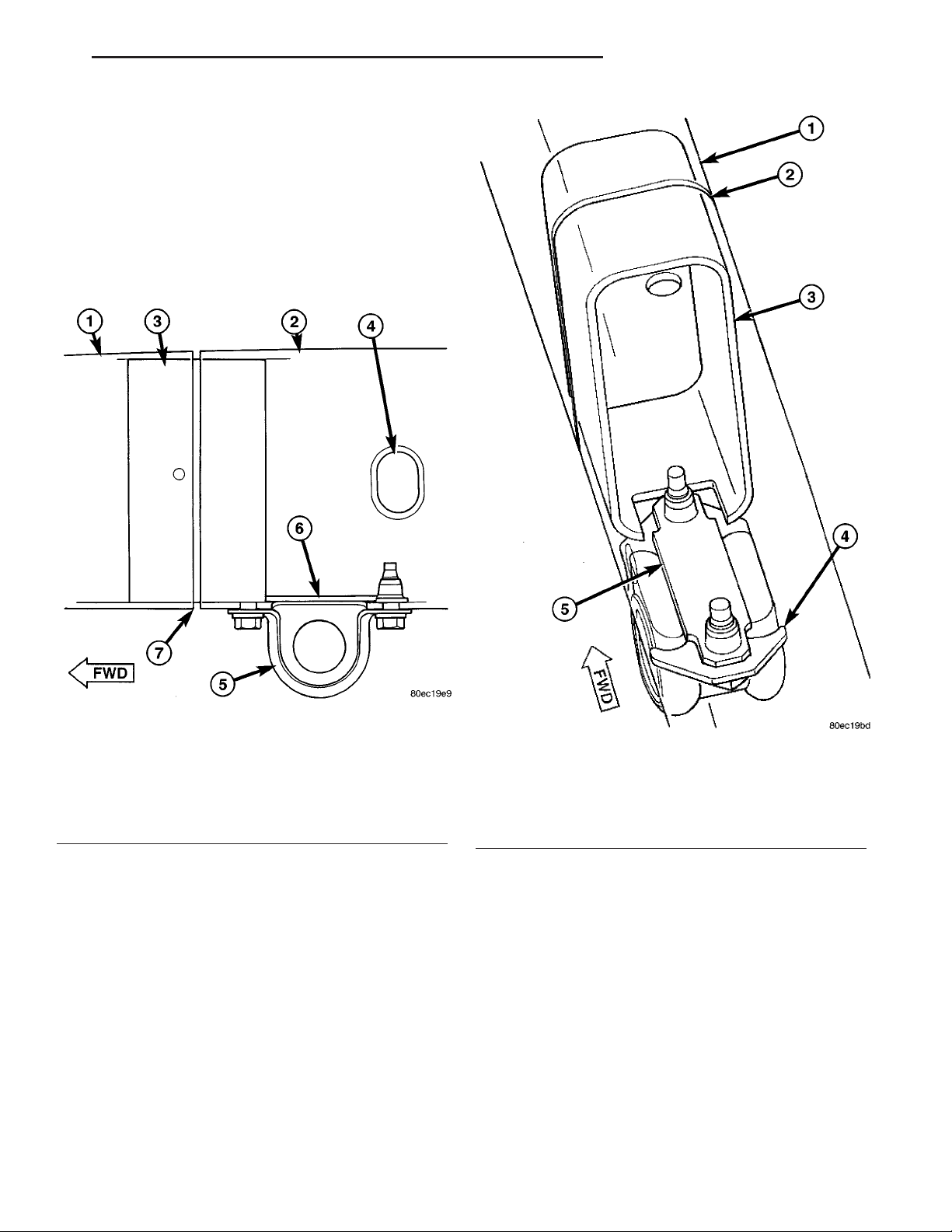

Fig. 10 4X2 SLEEVE INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - PLP

5 - SWAY BAR MOUNTING BRACKET

6 - TAPPING PLATE

7 - ROOT WELD GAP

Fig. 11 4X2 SLEEVE INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - ROOT WELD GAP

3 - SERVICE SLEEVE

4 - SWAY BAR MOUNTING BRACKET

5 - TAPPING PLATE

13 - 8 FRAMES & BUMPERS DR

FRAME (Continued)

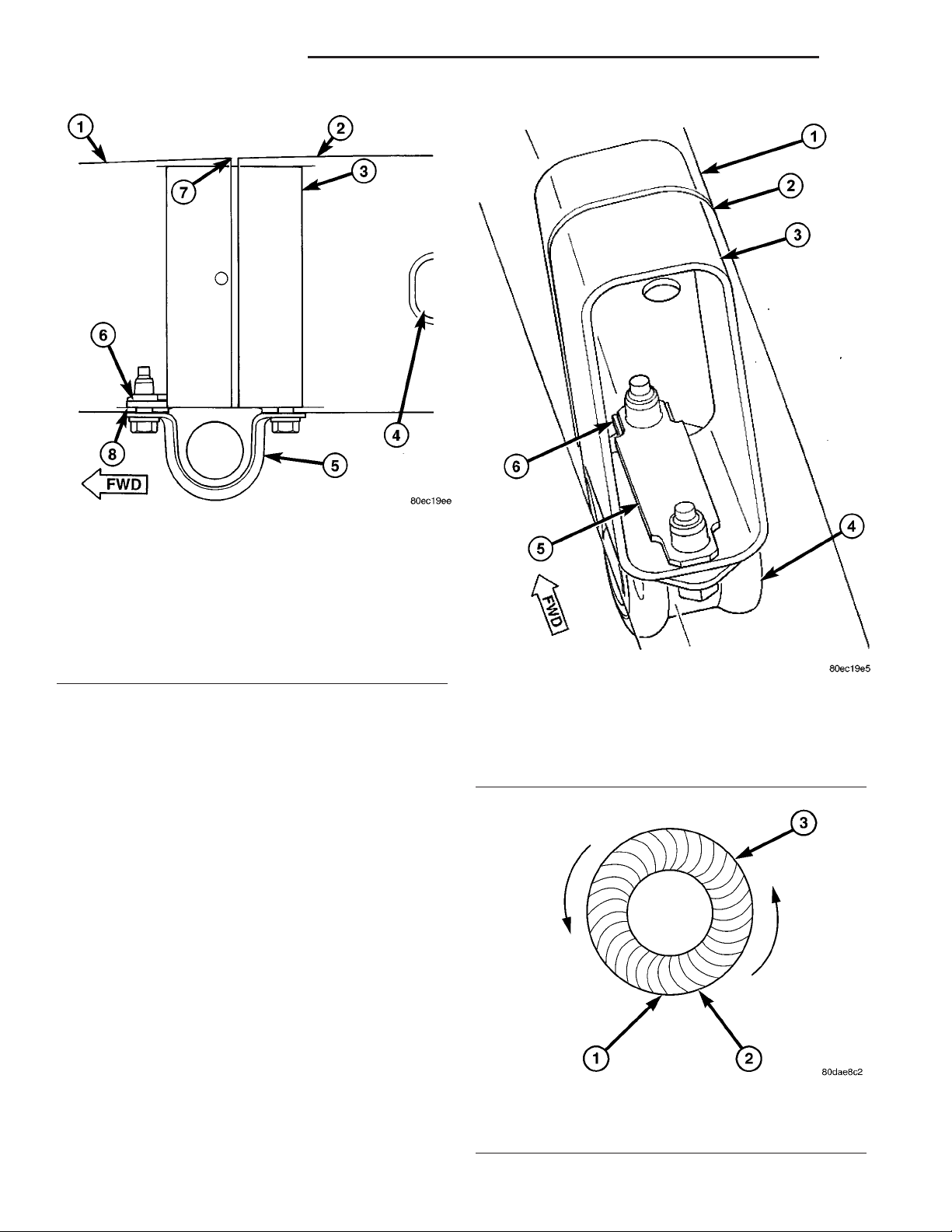

Fig. 12 4X4 TAPPING PLATE/SLEEVE

INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - FRAME RAIL

3 - SERVICE SLEEVE

4 - PLP

5 - SWAY BAR MOUNTING BRACKET

6 - TAPPING PLATE

7 - ROOT WELD GAP

8 - SLEEVE TAB

(19) Apply ring-fillet welds into the ring-fillet weld

holes on the replacement frame tip, using the Weld

Process Specifications table. (Fig. 14)

(20) Install the upper FESM insulator onto the

replacement tip and position the service sleeve/replacement tip into the existing frame rail.

(21) Loosely install the lower FESM insulator and

cab mounting bolt.

Fig. 13 4X4 TAPPING PLATE/SLEEVE INSTALLATION

1 - REPLACEMENT FRAME TIP

2 - ROOT WELD GAP

3 - SERVICE SLEEVE

4 - SWAY BAR MOUNTING BRACKET

5 - TAPPING PLATE

6 - SLEEVE TAB

Fig. 14 RING FILLET WELD

1 - WELD START LOCATION

2 - WELD END LOCATION

3 - RING-FILLET WELD

Loading...

Loading...