Dodge Exhaust Service Manual

DR EXHAUST SYSTEM 11 - 1

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION ........................1

DESCRIPTION – 5.9L DIESEL .............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE . . . 2

DIAGNOSIS AND TESTING - DIESEL

ENGINE..............................3

SPECIFICATIONS - TORQUE ...............4

SPECIAL TOOLS ........................4

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER .....4

OPERATION ............................4

REMOVAL

REMOVAL ............................5

REMOVAL ............................5

INSPECTION ...........................5

INSTALLATION

INSTALLATION ........................5

INSTALLATION ........................5

EXHAUST PIPE

REMOVAL

REMOVAL — 5.9L ......................5

REMOVAL ............................5

INSPECTION ...........................6

INSTALLATION

INSTALLATION — 5.9L ..................6

INSTALLATION ........................7

EXHAUST PIPE

REMOVAL .............................7

INSPECTION ...........................7

INSTALLATION ..........................7

HEAT SHIELDS

DESCRIPTION ..........................7

REMOVAL .............................7

INSTALLATION ..........................8

MUFFLER

REMOVAL .............................8

INSTALLATION ..........................8

MUFFLER - 5.9L DIESEL

REMOVAL .............................9

INSTALLATION ..........................9

TAILPIPE - 5.9L DIESEL

REMOVAL .............................9

INSPECTION ...........................9

INSTALLATION ..........................9

TAILPIPE

REMOVAL .............................10

INSPECTION ..........................10

INSTALLATION .........................10

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING -

TURBOCHARGER BOOST PRESSURE .....10

TURBOCHARGER

DESCRIPTION .........................11

OPERATION ...........................11

REMOVAL .............................13

CLEANING ............................14

INSPECTION ..........................14

INSTALLATION .........................14

CHARGE AIR COOLER AND PLUMBING

DESCRIPTION .........................15

OPERATION ...........................15

DIAGNOSIS AND TESTING - CHARGE AIR

COOLER SYSTEM - LEAKS ..............15

REMOVAL .............................15

CLEANING ............................16

INSPECTION ..........................16

INSTALLATION .........................16

EXHAUST SYSTEM

DESCRIPTION

DESCRIPTION

CAUTION: Avoid application of rust prevention compounds or undercoating materials to exhaust system floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

The federal gasoline engine exhaust system consists of engine exhaust manifolds, exhaust pipes, catalytic converter(s), extension pipe (if needed),

exhaust heat shields, muffler and exhaust tailpipe.

The California emission vehicles exhaust system

also contains the above components as well as mini

catalytic converters added to the exhaust pipe.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. Minimum

clearance between any exhaust component and the

body or frame is 25.4 mm (1.0 in.). If the system contacts any body panel, it may amplify objectionable

noises from the engine or body.

11 - 2 EXHAUST SYSTEM DR

EXHAUST SYSTEM (Continued)

DESCRIPTION – 5.9L DIESEL

CAUTION: Avoid application of rust prevention compounds or undercoating materials to exhaust system floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

The diesel engine exhaust system consists of an

engine exhaust manifold, turbocharger, exhaust pipe,

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - GAS ENGINE

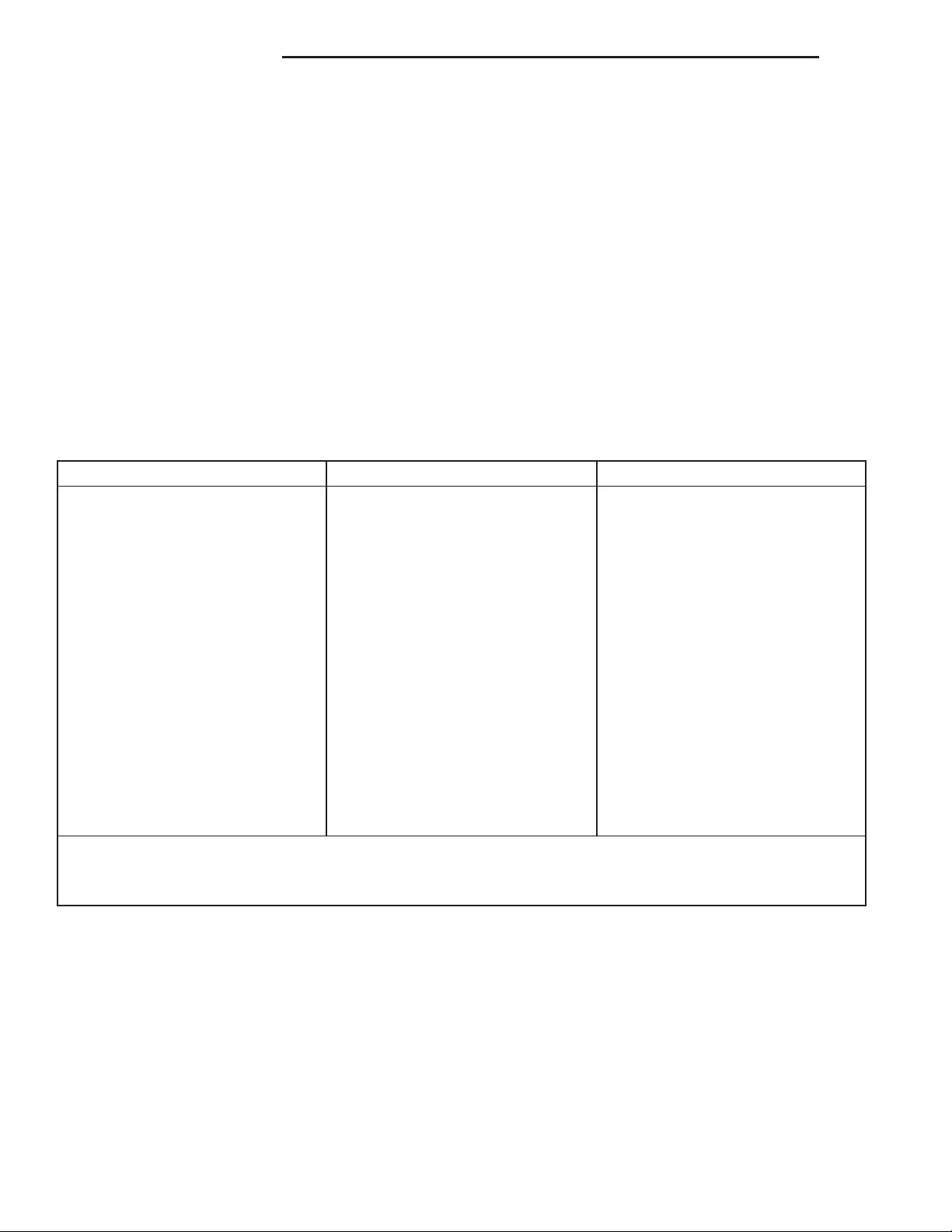

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES

1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

3. Broken or rusted out exhaust

pipe.

4. Exhaust pipe leaking at manifold

flange.

5. Exhaust manifold cracked or

broken.

6. Leak between exhaust manifold

and cylinder head.

7. Catalytic converter rusted or

blown out.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

resonator, extension pipe (if needed), muffler and

exhaust tailpipe.

California emission vehicales include a catalytic

converter.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. The

exhaust components should be kept a minimum of

25.4 mm (1.0 in.) away from the body and frame. If

the system contacts any body panel, it may amplify

objectionable noises from the engine or body.

joints.

system.

3. Replace exhaust pipe.

4. Tighten/replace flange attaching

nuts/bolts.

5. Replace exhaust manifold.

6. Tighten exhaust manifold to

cylinder head bolts.

7. Replace catalytic converter assy.

Replace restricted part if necessary.

CAUTION:

When servicing and replacing exhaust system components, disconnect the oxygen sensor connector(s). Allowing

the exhaust to hang by the oxygen sensor wires will damage the harness and/or sensor.

DR EXHAUST SYSTEM 11 - 3

EXHAUST SYSTEM (Continued)

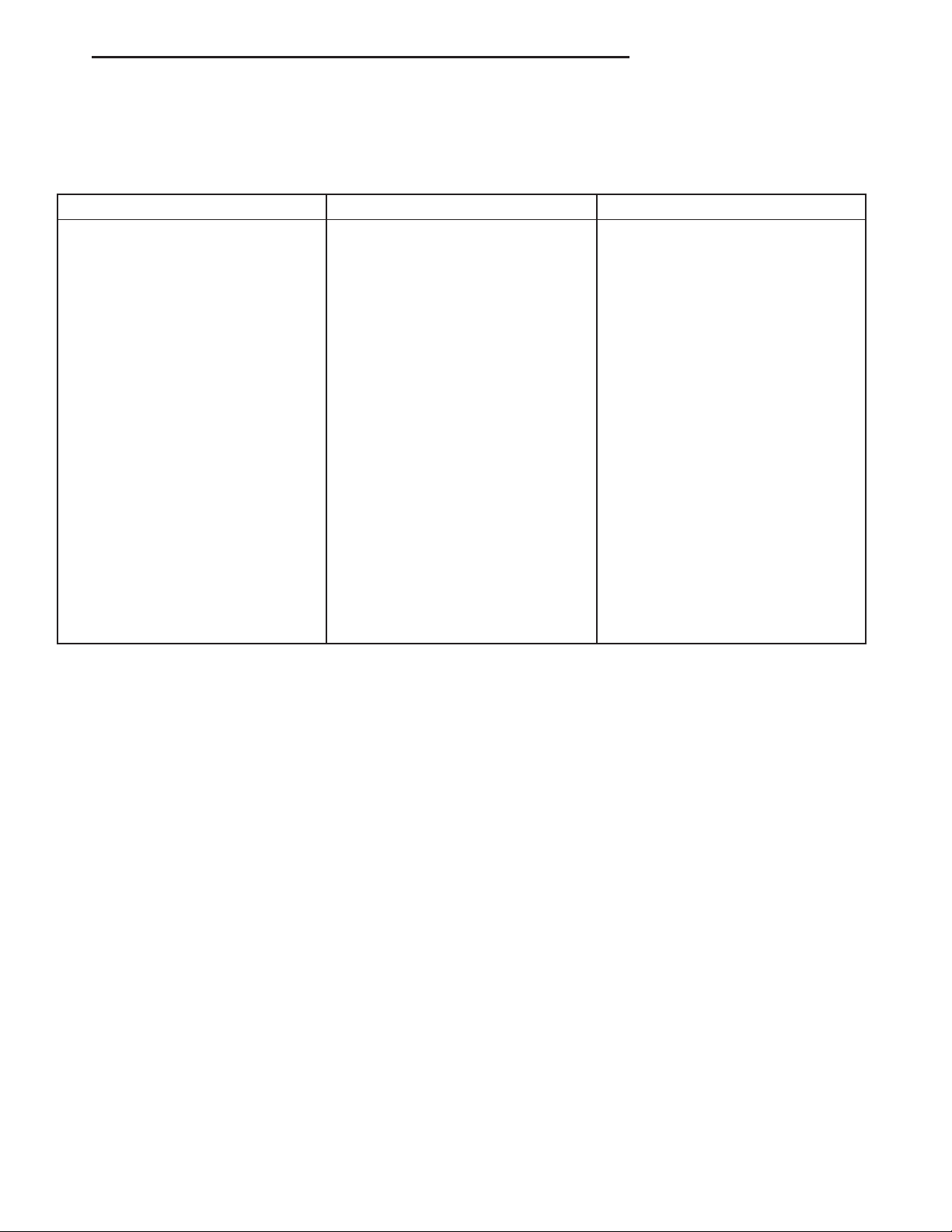

DIAGNOSIS AND TESTING - DIESEL ENGINE

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES

1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking

joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.

4. Exhaust pipe leaking at manifold

flange.

5. Exhaust manifold cracked or

broken.

6. Leak between exhaust manifold

and cylinder head.

7. Turbocharger mounting flange

cracked.

8. Restriction in exhaust system. 8. Remove restriction, if possible.

3. Replace exhaust pipe.

4. Tighten/replace flange attaching

nuts/bolts.

5. Replace exhaust manifold.

6. Tighten exhaust manifold to

cylinder head bolts. Replace gasket

if necessary.

7. Remove turbocharger and

inspect. (Refer to 11 - EXHAUST

SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER REMOVAL).

Replace restricted part if necessary.

11 - 4 EXHAUST SYSTEM DR

EXHAUST SYSTEM (Continued)

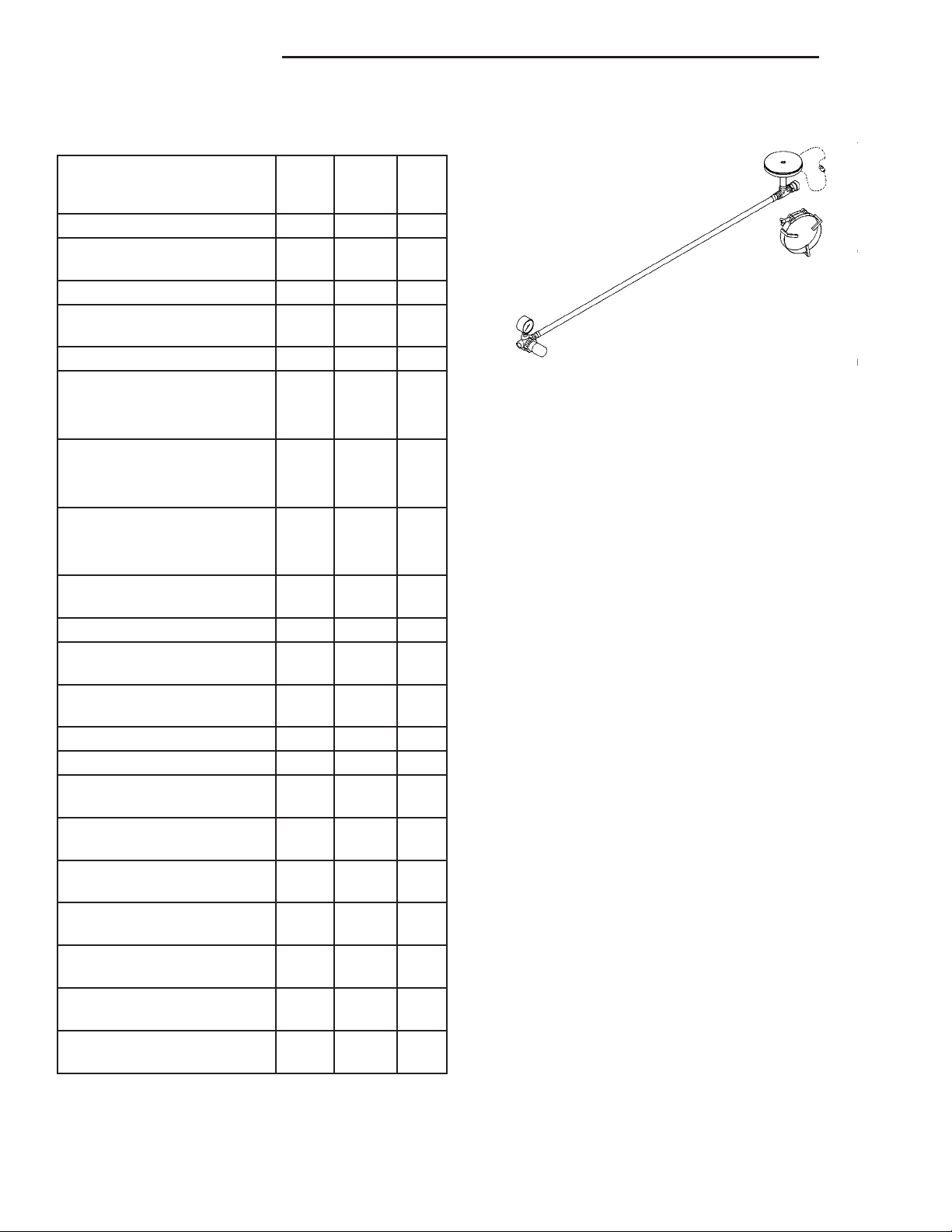

SPECIFICATIONS - TORQUE

DESCRIPTION N·m Ft. In.

Lbs. Lbs.

Adjusting Strap—Bolt 23 — 200

Air Heater Power Supply—

Nuts

Air Inlet Housing—Bolts 24 18 —

Cab Heater Supply/Return

Line—Nuts

Exhaust Clamp—Nuts 48 35 —

Exhaust Manifold to Cylinder

Head—Bolts

(Diesel Engine) 43 32 —

Exhaust Manifold to Cylinder

Head—Bolts

(5.9L) 31 23 —

Exhaust Manifold to Cylinder

Head—Bolts

(8.0L) 22 — 195

Exhaust Pipe to Manifold—

Bolts

Generator Mounting—Bolts 41 30 —

Charge Air Cooler

Mounting—Bolts

Charge Air Cooler Duct—

Nuts

Heat Shield—Nuts and Bolts 11 — 95

Turbocharger flange studs 24 18 —

Turbocharger Mounting—

Nuts

Turbocharger Oil Drain

Tube—Bolts

Turbocharger Oil Supply

Line—Fitting

Turbocharger V-Band

Clamp—Nut

Turbocharger Oil Supply

fitting (at Turbocharger)

Turbocharger Oil Supply

fitting (at lube filter head)

Turbocharger Drain Hose

Clamps

14 — 124

24 18 —

31 23 —

2—17

11 — 95

43 32 —

24 18 —

24 18 —

9—75

36 27 —

24 18 —

8—71

SPECIAL TOOLS

TURBOCHARGER TESTER 9022

CATALYTIC CONVERTER

DESCRIPTION - CATALYTIC CONVERTER

WARNING: THE NORMAL OPERATING TEMPERATURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CONVERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

CAUTION: DO NOT remove spark plug wires from

plugs or by any other means short out cylinders.

Failure of the catalytic converter can occur due to a

temperature increase caused by unburned fuel

passing through the converter.

The stainless steel catalytic converter body is

designed to last the life of the vehicle. Excessive heat

can result in bulging or other distortion, but excessive heat will not be the fault of the converter. If

unburned fuel enters the converter, overheating may

occur. If a converter is heat-damaged, correct the

cause of the damage at the same time the converter

is replaced. Also, inspect all other components of the

exhaust system for heat damage.

Unleaded gasoline must be used to avoid contaminating the catalyst core.

50 State emission vehicles incorporate two mini

catalytic converters located after the exhaust manifolds and before the inline catalytic converter.

OPERATION

The catalytic converter captures and burns any

unburned fuel mixture exiting the combustion chambers during the exhaust stroke of the engine. This

process aids in reducing emissions output.

DR EXHAUST SYSTEM 11 - 5

CATALYTIC CONVERTER (Continued)

REMOVAL

REMOVAL

WARNING: IF TORCHES ARE USED WHEN WORKING ON THE EXHAUST SYSTEM, DO NOT ALLOW

THE FLAME NEAR THE FUEL LINES.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove the bolts from the crossover pipe to the

catalytic converter connection.

(4) Disconnect oxygen sensor wiring.

(5) Loosen the nuts from the clamp that hold the

catalytic converter to the exhaust pipe flange connection.

NOTE: Do not remove nut from T-Bolt. Only remove

nut far enough, so that the T end can be removed

from the clamp.

(6) Remove the T bolt end of the fastener, from the

clamp.

(7) Spread the clamp, and remove the catalytic

converter from the vehicle.

(8) Discard the clamp.

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

(1) Position the catalytic converter onto the

exhaust pipe flange connection. Tighten the nuts to

28 N·m (250 in. lbs.) torque.

(2) Install the muffler onto the catalytic converter

until the alignment tab is inserted into the alignment slot.

(3) Install the exhaust clamp at the muffler and

catalytic converter connection. Tighten the clamp

nuts to 47 N·m (35 ft. lbs.) torque.

(4) Connect oxygen sensor wiring.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels.

Adjust the alignment, if needed.

INSTALLATION

(1) Assemble converter and clamps loosely in

place.

(2) Install the exhaust pipe onto exhaust manifolds, tighten 31 N·m (23 ft. lbs.).

(3) Tighten all clamp nuts to 48 N·m (35 ft. lbs.)

torque.

(4) Lower the vehicle.

(5) Start the engine and inspect for exhaust leaks

and exhaust system contact with the body panels. A

minimum of 25.4 mm (1.0 in.) is required between

exhaust system components and body/frame parts.

Adjust the alignment, if needed.

EXHAUST PIPE

REMOVAL

(1) Raise and support vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove clamps and nuts.

(4) Remove the catalytic converter.

INSPECTION

Look at the stainless steel body of the converter,

inspect for bulging or other distortion that could be a

result of overheating. If the converter has a heat

shield attached make sure it is not bent or loose.

If you suspect internal damage to the catalyst, tapping the bottom of the catalyst with a rubber mallet

may indicate a damaged core.

INSTALLATION

INSTALLATION

NOTE: The catalytic converter to exhaust manifold

clamp is not reusable. Always use a new clamp

when reinstalling the catalytic converter.

REMOVAL

REMOVAL — 5.9L

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with heat valve

lubricant. Allow 5 minutes for penetration.

(3) Remove exhaust pipe to manifold bolts, retain-

ers and nuts.

(4) Remove the clamp nuts.

(5) Remove the exhaust pipe (Fig. 1).

REMOVAL

CAUTION: When servicing or replacing exhaust

system components, disconnect the oxygen sensor

connector(s). Allowing the exhaust to hang by the

oxygen sensor wires will damage the harness

and/or sensor.

(1) Raise and support the vehicle.

(2) Saturate the bolts and nuts with Mopart Rust

Penetrant. Allow 5 minutes for penetration.

(3) Disconnect the oxygen sensor(s).

Loading...

Loading...