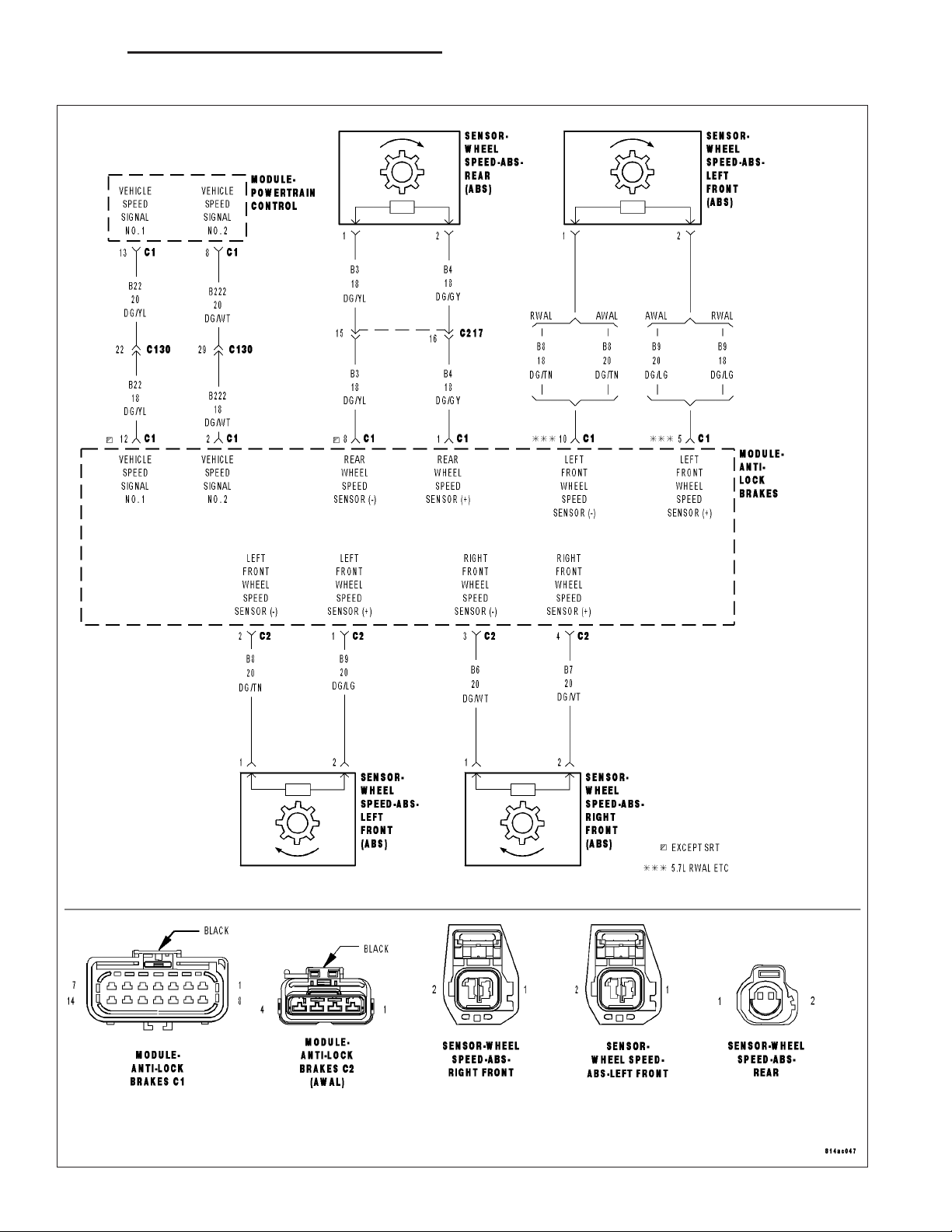

Dodge Brakes 3500 2005, 2500 2005, 1500 2005 Service Manual

DR/DH BRAKES 5 - 1

BRAKES

TABLE OF CONTENTS

page page

BRAKES - ABS - ELECTRICAL DIAGNOSTICS .... 1

BRAKES - BASE - SERVICE INFORMATION.... 200

BRAKES - ABS - ELECTRICAL DIAGNOSTICS

TABLE OF CONTENTS

page page

BRAKES - ABS - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

*ABS VERIFICATION TEST — VER 1 .......3

*APS VERIFICATION TEST — VER 1 .......4

BODY STYLE MISMATCH — 85 ...........5

BRAKE SWITCH CIRCUIT — 81 ...........6

ECU INTERNAL FAILURE -75 ............10

EXCESSIVE DUMP TIME — 69 ...........11

FOUNDATION BRAKE — 78 .............13

INTERMITTENT SIGNAL FROM LEFT

FRONT SENSOR — 27 .................17

INTERMITTENT SIGNAL FROM REAR

SENSOR — 37 .......................25

INTERMITTENT SIGNAL FROM RIGHT

FRONT SENSOR — 27 .................33

LEFT FRONT SENSOR OPEN — 25 .......41

LEFT FRONT SENSOR SHORTED — 90 ....47

NO SIGNAL FROM LEFT FRONT

SENSOR - 26.........................52

NO SIGNAL FROM REAR SENSOR - 36 ....60

NO SIGNAL FROM RIGHT FRONT

SENSOR — 22 .......................67

REAR SENSOR OPEN — 35 .............74

REAR SENSOR SHORTED — 93 .........80

RIGHT FRONT SENSOR OPEN — 21 ......85

RIGHT FRONT SENSOR SHORTED — 91 . . . 91

INTERNAL MAIN RELAY OPEN — 65 ......96

INTERNAL MAIN RELAY SHORTED — 66 . . 100

LEFT FRONT DUMP SOLENOID OPEN - 46 . 104

LEFT FRONT DUMP SOLENOID

SHORTED - 48.......................109

LEFT FRONT ISOLATION SOLENOID

OPEN-45..........................114

BRAKES - ABS - SERVICE INFORMATION..... 287

LEFT FRONT ISOLATION SOLENOID

SHORTED - 47 .......................119

RIGHT FRONT DUMP SOLENOID

OPEN-42..........................124

REAR DUMP SOLENOID SHORTED - 53 . . . 129

REAR ISOLATION SOLENOID OPEN - 51 . . 134

REAR ISOLATION SOLENOID SHORTED -

53 ................................139

RIGHT FRONT DUMP SOLENOID

OPEN-42..........................144

RIGHT FRONT DUMP SOLENOID SHORTED

-44 ...............................149

RIGHT FRONT ISOLATION SOLENOID

OPEN-41..........................154

RIGHT FRONT ISOLATION SOLENOID

SHORTED - 43.......................159

MISMATCHED VIN — 84 ...............164

NUMBER OF TONE RING TEETH OUT OF

RANGE - 82 .........................166

PUMP MOTOR CIRCUIT OPEN — 67 .....167

PUMP MOTOR STALLED — 68 ..........172

RAM READ/WRITE — 71 ...............177

REAR RESET SWITCH CLOSED — 63 ....178

ROM CHECKSUM – 71 ................179

TIRE REVS EPR MILE OUT OF RANGE . . . 180

WATCHDOG — 73 ....................182

SYSTEM CONTROL MODE TMEOUT — 74 . 186

SYSTEM OVER/UNDER VOLTAGE - 96 ....189

*REPLACING THE ANTILOCK BRAKE

MODULE ...........................190

APS RELAY CONTROL CIRCUIT HIGH ....191

APS RELAY CONTROL CIRCUIT LOW .....194

APS RELAY CONTROL CIRCUIT OPEN ....197

5 - 2 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

BRAKES - ABS - ELECTRICAL DIAGNOSTICS

DIAGNOSIS AND TESTING

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 3

*ABS VERIFICATION TEST — VER 1

Diagnostic Test

*ABS VERIFICATION TEST — VER 1

1.

Turn the ignition off.

Connect all previously disconnected components and connectors.

Make sure all accessories are turned off and the battery is fully charged.

With the scan tool, clear DTCs in all modules.

Cycle the ignition off for 10 seconds, then on.

With the scan tool, select View DTCs in the ABS module.

If any DTCs have reset, perform the appropriate diagnostic procedure before continuing with this test.

If there are no DTCs present, road test the vehicle above 40 m.p.h. for at least two minutes.

CAUTION: Make sure braking capability is available before road testing the vehicle. During the test drive,

perform several anti-lock braking stops.

With theDRBIIIT, select View DTCs in the Anti-Lock Brake Module.

Are there any DTCs present?

Yes >>

No >>

Perform the appropriate diagnostic procedure(s).

Test Complete

5 - 4 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

*APS VERIFICATION TEST — VER 1

Diagnostic Test

*APS VERIFICATION TEST — VER 1

1.

Turn the ignition off.

Connect all previously disconnected components and connectors.

Ensure all accessories are turned off and the battery is fully charged.

Ensure that the Ignition is on, and with the DRBIIIT, erase all Diagnostic Trouble Codes from ALL modules. Start the

engine and allow it to run for 2 minutes and fully operate the system that was malfunctioning.

Turn the ignition off and wait 5 seconds. Turn the ignition on and using the DRBIII, read DTC’s from ALL modules.

If any Diagnostic Trouble Codes are present, return to Symptom list and troubleshoot new or recurring symptom.

If there are no DTC’s present after turning ignition on, road test the vehicle for at least 5 minutes. Perform several

antilock braking stops.

CAUTION: Ensure braking capability is available before road testing.

Again, with the DRBIIIT read DTC’s. If any DTC’s are present, return to Symptom list.

If there are no Diagnostic Trouble Codes (DTC’s) present, and the customer’s concern can no longer be duplicated,

the repair is complete.

Are any DTC’s present or is the original concern still present?

Yes >>

No >>

Perform the appropriate diagnostic procedure(s).

Test Complete

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 5

BODY STYLE MISMATCH — 85

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on.

• Set Condition:

When both the traceability code number and body style can not be read from the NVRAM or they are invalid.

Possible Causes

WRONG CAB OR CAB NOT PROGRAMMED FROM THE FACTORY

Diagnostic Test

DTC VERIFICATION

1.

NOTE: Diagnose and repair any Powertrain Control Module VIN or Communication DTCs before continuing

with this test.

Turn the ignition on.

With the scan tool, clear DTCs.

Turn the ignition off.

Turn the ignition on.

With the scan tool, select View DTCs.

Does the DTC reset?

Yes >>

No >>

Replace the Controller Antilock Brake in accordance with the Service Information. Refer to the symptom

*Replacing the Controller Antilock Brake for additional information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Use the scan tool to read DTCs in all other modules. If any communication DTCs are present, perform

the appropriate diagnostic procedure. Refer to any Technical Service Bulletins that apply. If no problems

are found, test is complete.

5 - 6 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

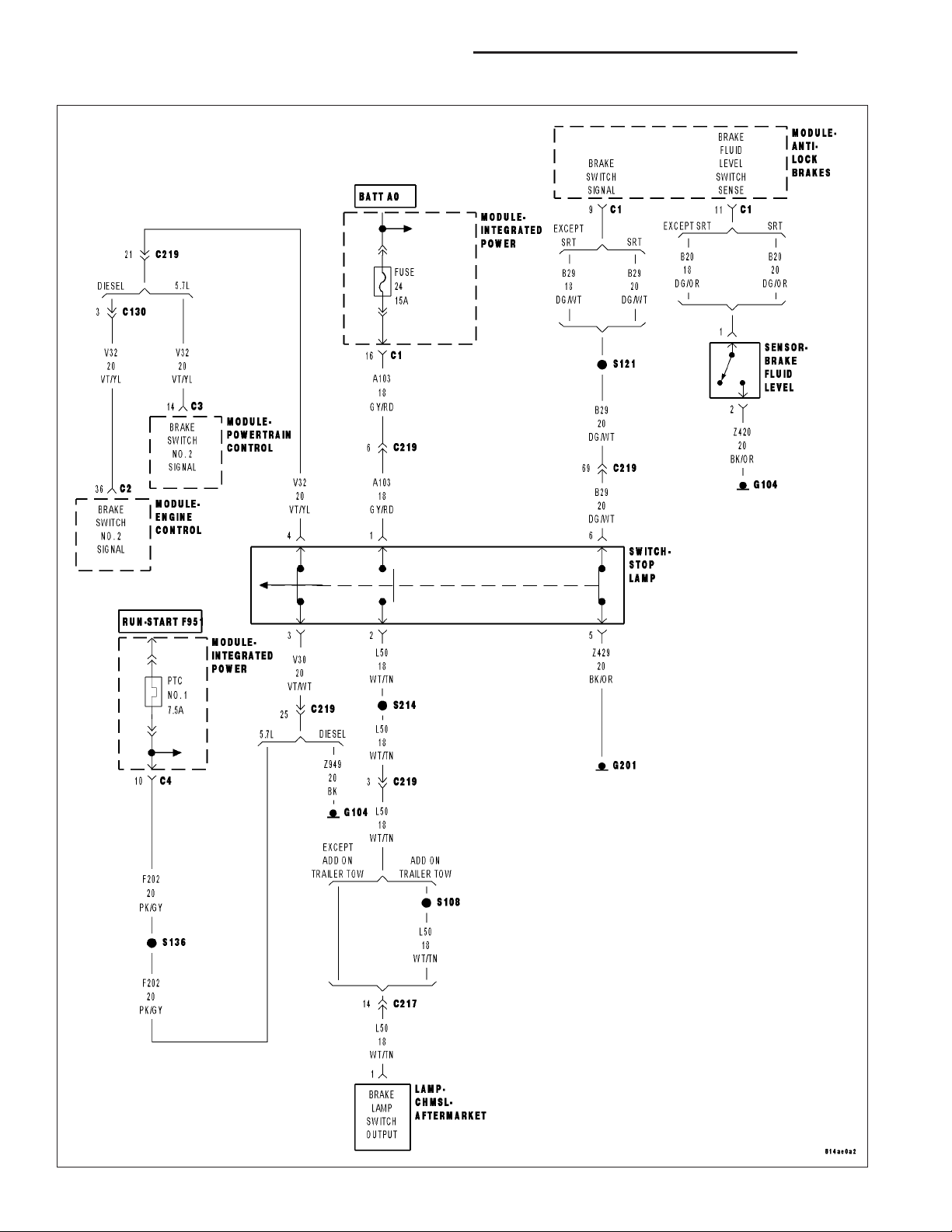

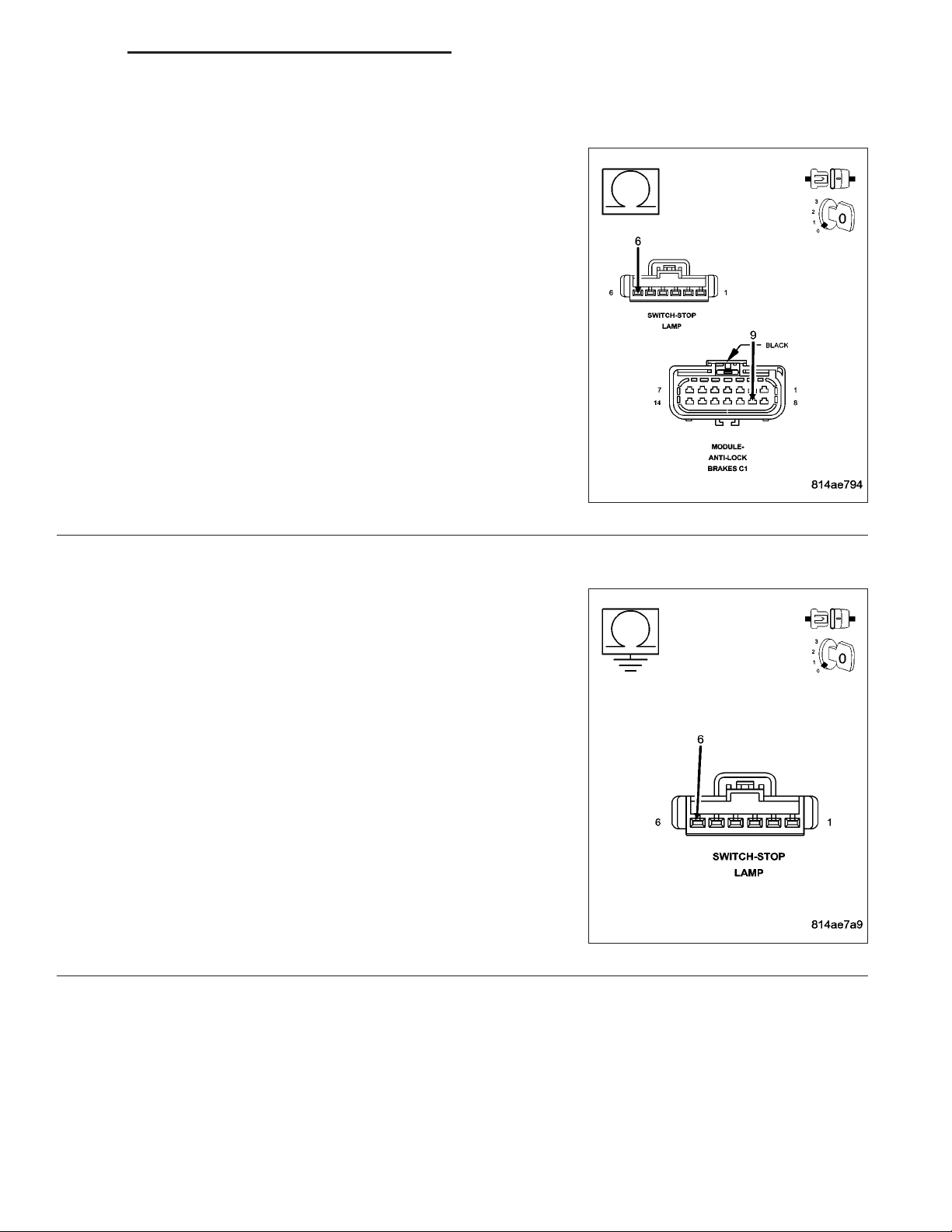

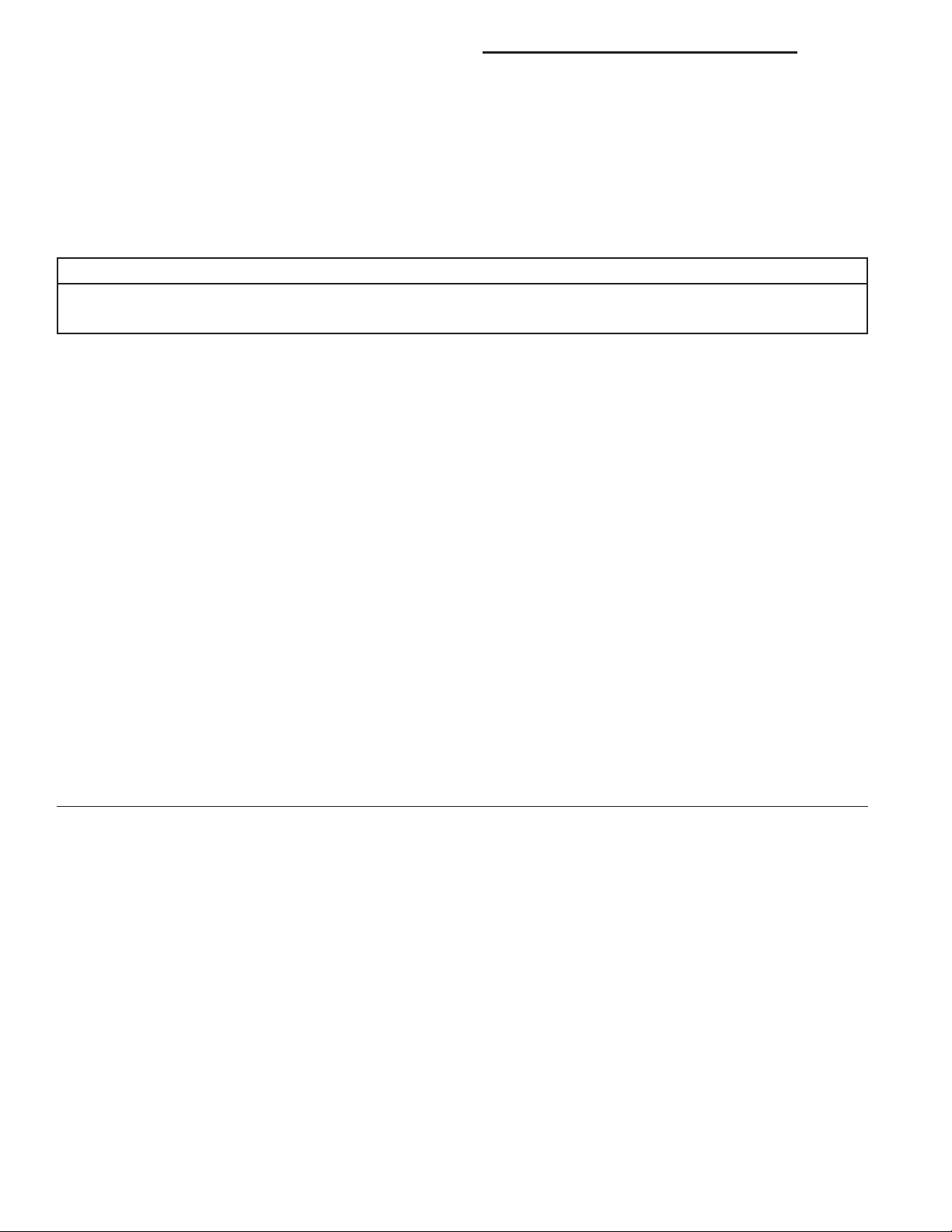

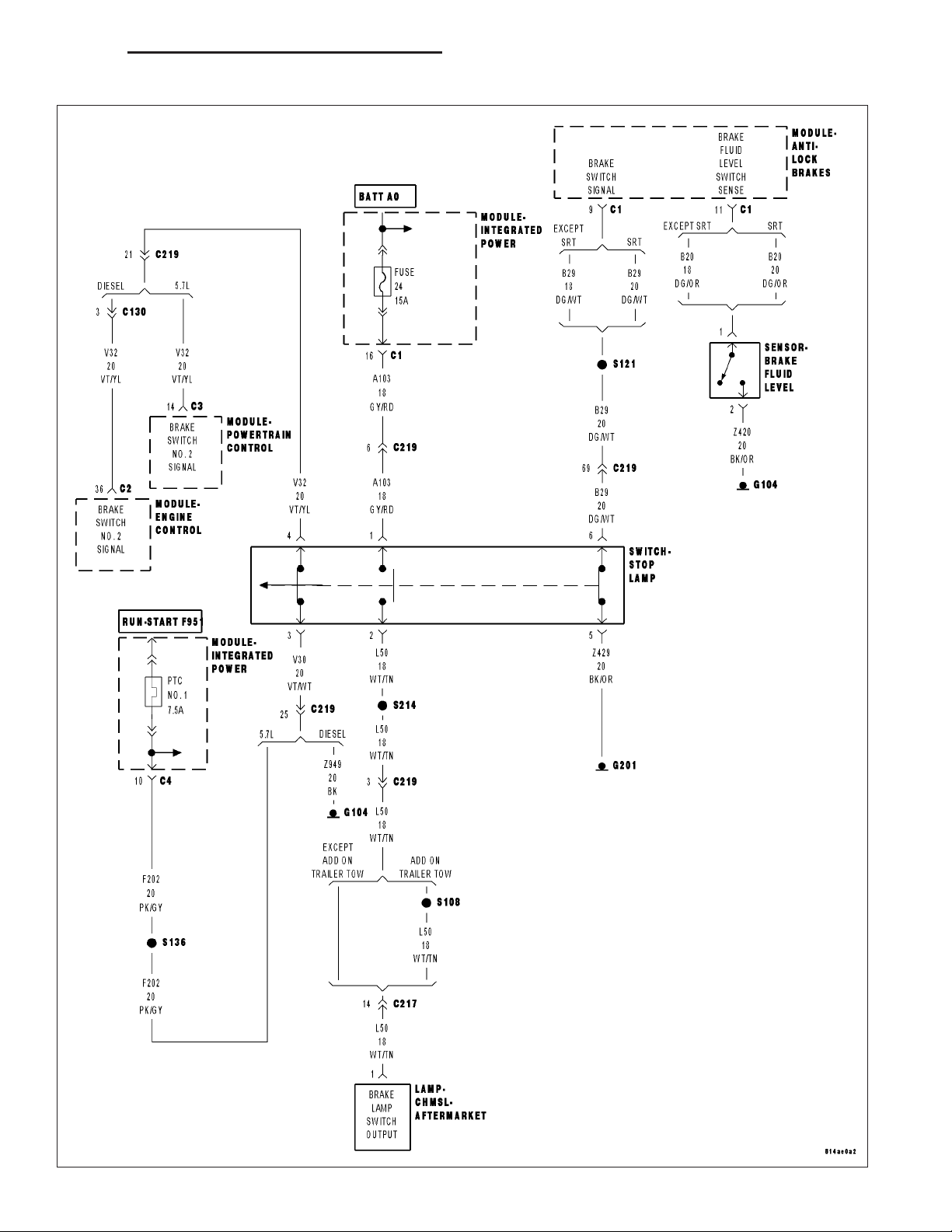

BRAKE SWITCH CIRCUIT — 81

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 7

BRAKE SWITCH CIRCUIT — 81 (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on.

• Set Condition:

Continuous brake applied signal after ignition turn-on and remaining with sensed speed above 37.5 MPH

(RWAL) or 15 MPH (ABS) for over 10 seconds and/or ABS active for at least a second with brake switch

released and never sensed brake applied since power up.

Possible Causes

INTERMITTENT BRAKE SWITCH CIRCUIT DTC

BRAKE SWITCH SIGNAL CIRCUIT SHORT TO VOLTAGE

BRAKE SWITCH SIGNAL CIRCUIT OPEN

GROUND CIRCUIT OPEN

BRAKE LAMP SWITCH

CAB

Diagnostic Test

VERIFY THE CONDITION

1.

NOTE: Driving with the brake applied may set this code.

Turn the ignition off.

Ensure all accessories are turned off and the battery is fully charged.

Turn the ignition on.

With the scan tool, monitor the status of the brake switch while pressing and releasing the brake pedal several

times.

With the scan tool, erase DTCs.

CAUTION: Determine that braking capability is available before road testing the vehicle.

Road test the vehicle for at least 5 minutes over 40 MPH. Perform several anti-lock braking stops.

With the scan tool, read DTCs.

Does the original DTC reset and/or does intermittent brake switch operation occur?

Yes >>

No >>

Go To 2

The condition necessary to set this DTC is not present at this time. Using the wiring diagram/schematic

as a guide, inspect the wiring and connectors relative to this circuit.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

5 - 8 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

BRAKE SWITCH CIRCUIT — 81 (CONTINUED)

BRAKE LAMP SWITCH

2.

Turn ignition off.

Disconnect the Brake Lamp Switch harness connector.

Turn ignition on.

With the scan tool, monitor the brake switch status.

Connect and disconnect a jumper wire between the Ground circuit and the Brake Switch Signal circuit.

Does the scan tool display correctly with the jumper wire connected and disconnected?

Yes >>

No >>

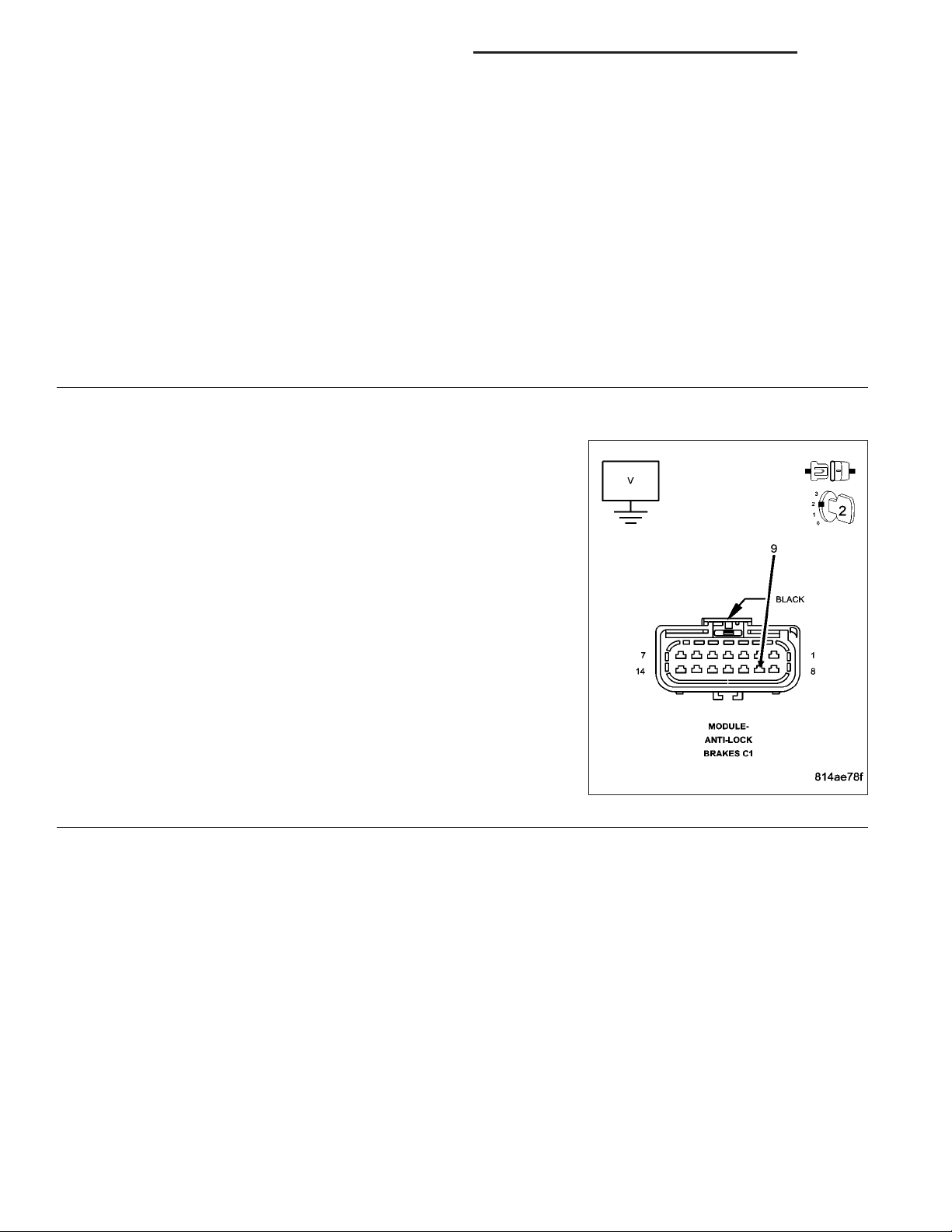

BRAKE SWITCH SIGNAL CIRCUIT SHORT TO VOLTAGE

3.

Turn the ignition off.

Disconnect the CAB Module harness connector.

Turn the ignition on.

Measure the voltage of the Brake Switch Signal circuit.

Is there any voltage present?

Yes >>

No >>

Replace the Brake Lamp Switch in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 3

Repair the Brake Switch Signal circuit for a short to voltage.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 4

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 9

BRAKE SWITCH CIRCUIT — 81 (CONTINUED)

BRAKE SWITCH SIGNAL CIRCUIT OPEN

4.

Turn the ignition off.

Measure the resistance of the Brake Switch Signal circuit between the

CAB harness connector and the brake switch harness connector.

Is the resistance above 5.0 ohms?

Yes >>

No >>

GROUND CIRCUIT OPEN

5.

Using a 12–volt test light connected to 12 volts, check the Ground circuit at the brake switch harness connector.

NOTE: The test light should be illuminated and bright. Compare

the brightness to that of a direct connection to the battery.

Is the test light illuminated and bright?

Repair the open Brake Switch Signal circuit.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 -

BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 5

Yes >>

No >>

Replace the Controller Anti-lock in accordance with the

Service Information. Refer to the symptom *Replacing the

Controller Anti-lock Brake for additional information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Repair the Ground circuit for an open circuit or high resistance.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

5 - 10 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

ECU INTERNAL FAILURE -75

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on.

• Set Condition:

When the CAB internal micro processor has an open/short in the status line which fails to transmit at the

correct frequency.

Possible Causes

WHEEL SPEED SENSOR FAILURE

CONTROLLER ANTI-LOCK BRAKE

Diagnostic Test

VERIFYING DTC

1.

NOTE: Before continuing, check the Controller Anti-lock Brake harness connector terminals for corrosion,

damage, or terminal push out. Repair as necessary.

Turn the ignition on.

With the DRBIIIT, erase DTC’s.

Turn the ignition off.

Turn the ignition on.

NOTE: Ensure that the Wheel Speed sensor are working properly.

With the DRBIIIT, read DTC’s.

Does the DRBIIIT display ECU INTERNAL FAILURE and a WHEEL SPEED SENSOR DTC’S?

Yes >>

No >>

Refer to the symptom list and diagnose the display Wheel Speed DTC.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Replace the Controller Anti-lock Brake in accordance with the Service Information. Refer to the symptom

*Replacing the Controller Anti-Lock Brake for additional information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 11

EXCESSIVE DUMP TIME — 69

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition on.

• Set Condition:

Antilock mode is active. Wheel speed is below 4 MPH (RWAL) and above 4 MPH (ABS). Vehicle is in two

wheel drive mode. Wheel speed history ruling out any unusual events during the proceeding 15 second

(RWAL) and 9 second (ABS). Need for more then maximum allowable dump cycles.

Possible Causes

INTERMITTENT EXCESSIVE DUMP TIME DTC

WHEEL SPEED WIRING HARNESS AND CONNECTORS

SUSPENSION

TONE WHEEL

WHEEL BEARING

BRAKE SYSTEM MECHANICAL CONDITION

ANTI-LOCK BRAKE HYDRAULIC CONTROL UNIT

Diagnostic Test

BRAKE SYSTEM MECHANICAL CONDITION

1.

Inspect the front and rear brakes for a mechanical condition that would cause any wheel(s) to lock-up during braking.

Inspect the Parking Brake to make sure it releases properly.

Were any problems found?

Yes >>

No >>

TONE WHEEL

2.

Inspect each Tone Wheel for damage, missing teeth or looseness in accordance with the Service Information.

NOTE: The Tone Wheel Teeth should be perfectly square, not bent or nicked.

Were any problems found?

Yes >>

No >>

Repair the braking system as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 2

Replace the Tone Wheel as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 3

5 - 12 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

EXCESSIVE DUMP TIME — 69 (CONTINUED)

WHEEL BEARING

3.

Inspect each wheel bearing for excessive run out or improper clearance in accordance with the Service Information.

Were any problems found?

Yes >>

No >>

WHEEL SPEED SENSOR WIRING HARNESS AND CONNECTORS

4.

Start the engine.

With the scan tool, monitor the output of each Wheel Speed Sensor.

Raise and properly support the vehicle.

WARNING: BE SURE TO KEEP HANDS, FEET AND CLOTHING CLEAR OF ROTATING COMPONENTS.

Allow the drive wheels to rotate.

Rotate the non-driven wheels by hand.

Wiggle test the Wheel Speed wiring harnesses and connectors.

Look for any excessive variations in sensed wheel speed.

Were any problems found?

Yes >>

No >>

Repair or replace the wheel bearing(s) as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 4

Repair the wiring harness or connectors as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 5

LOADED WHEEL BEARING/SUSPENSION CONCERN

5.

CAUTION: Make sure that the vehicle has braking capability before performing a road test.

NOTE: Have an assistant drive the vehicle while monitoring the scan tool.

With the scan tool, monitor the output of each Wheel Speed Sensor.

Road test vehicle so wheel bearings and suspension are loaded.

Look for any excessive variations in sensed wheel speed.

Were any problems found?

Yes >>

No >>

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Replace the Hydraulic Control Unit in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 13

FOUNDATION BRAKE — 78

5 - 14 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

FOUNDATION BRAKE — 78 (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

With the ignition on and no system under voltage DTC present.

• Set Condition:

Low feedback voltage from the Brake Fluid Level Switch Sense circuit.

Possible Causes

INTERMITTENT BRAKE FLUID LEVEL LOW DTC

BRAKE FLUID LEVEL LOW

BRAKE FLUID LEVEL SWITCH SENSE CIRCUIT SHORT TO GROUND

GROUND CIRCUIT OPEN OR HIGH RESISTANCE

BRAKE FLUID LEVEL SENSOR

CONTROLLER ANTI-LOCK BRAKE

Diagnostic Test

DTC CONDITION IS PRESENT

1.

Release the Parking Brake.

Turn the ignition off.

Turn the ignition on.

Monitor the Instrument Cluster.

Does the red Brake Warning Indicator stay on?

Yes >>

No >>

BRAKE FLUID LEVEL LOW

2.

Turn the ignition off.

Inspect the Brake Fluid Level in accordance with the Service Information.

Is the Brake Fluid Level Low?

Yes >>

No >>

Go To 2

Go To 6

Inspect the system and repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 3

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 15

FOUNDATION BRAKE — 78 (CONTINUED)

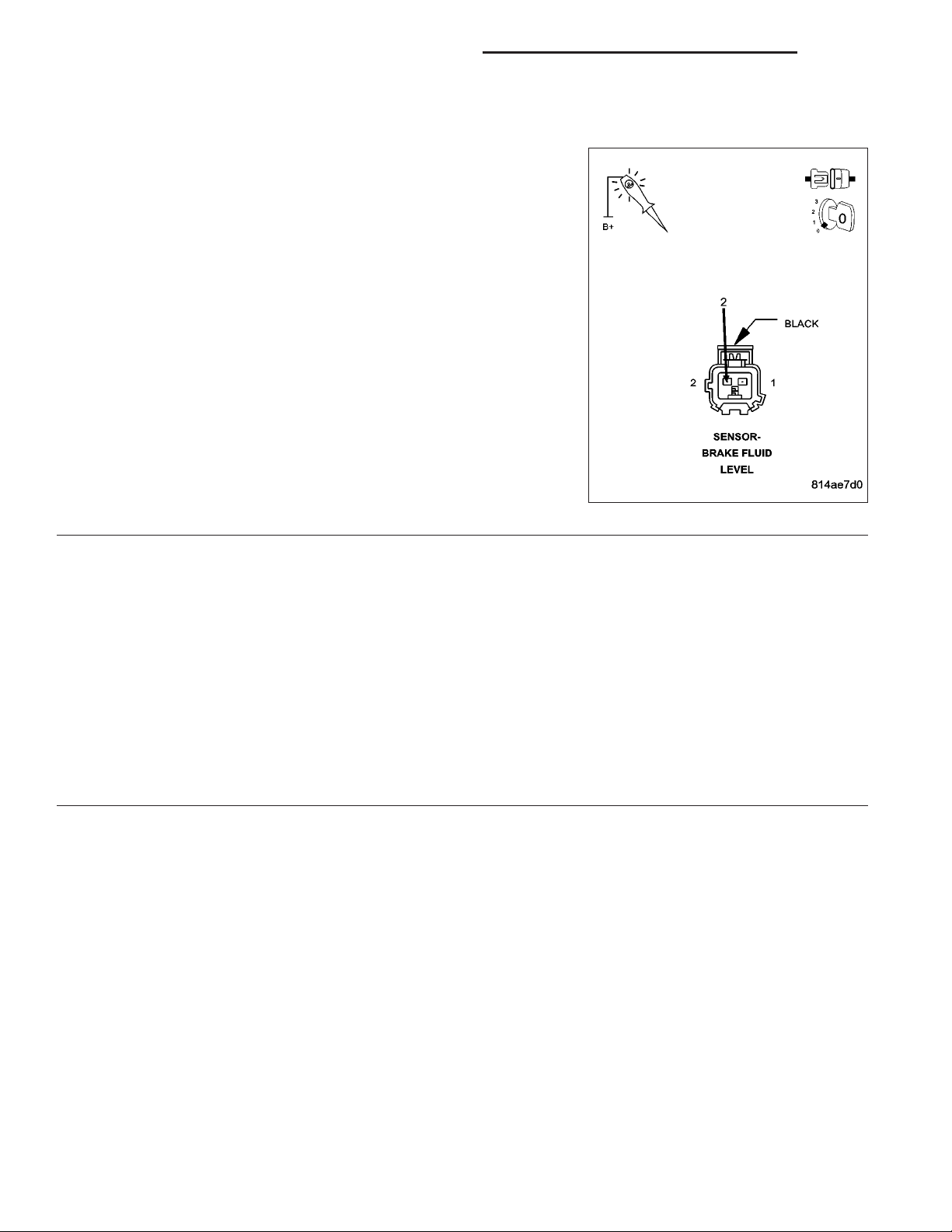

BRAKE FLUID LEVEL SWITCH SENSE CIRCUIT SHORT TO GROUND

3.

Turn the ignition off.

Disconnect the Brake Fluid Level Sensor harness connector.

Disconnect the CAB harness connector.

NOTE: Check connector - Clean/repair as necessary.

Measure the resistance between ground and the Brake Fluid Level

Switch Sense circuit.

Is the resistance below 5.0 ohms?

Yes >>

No >>

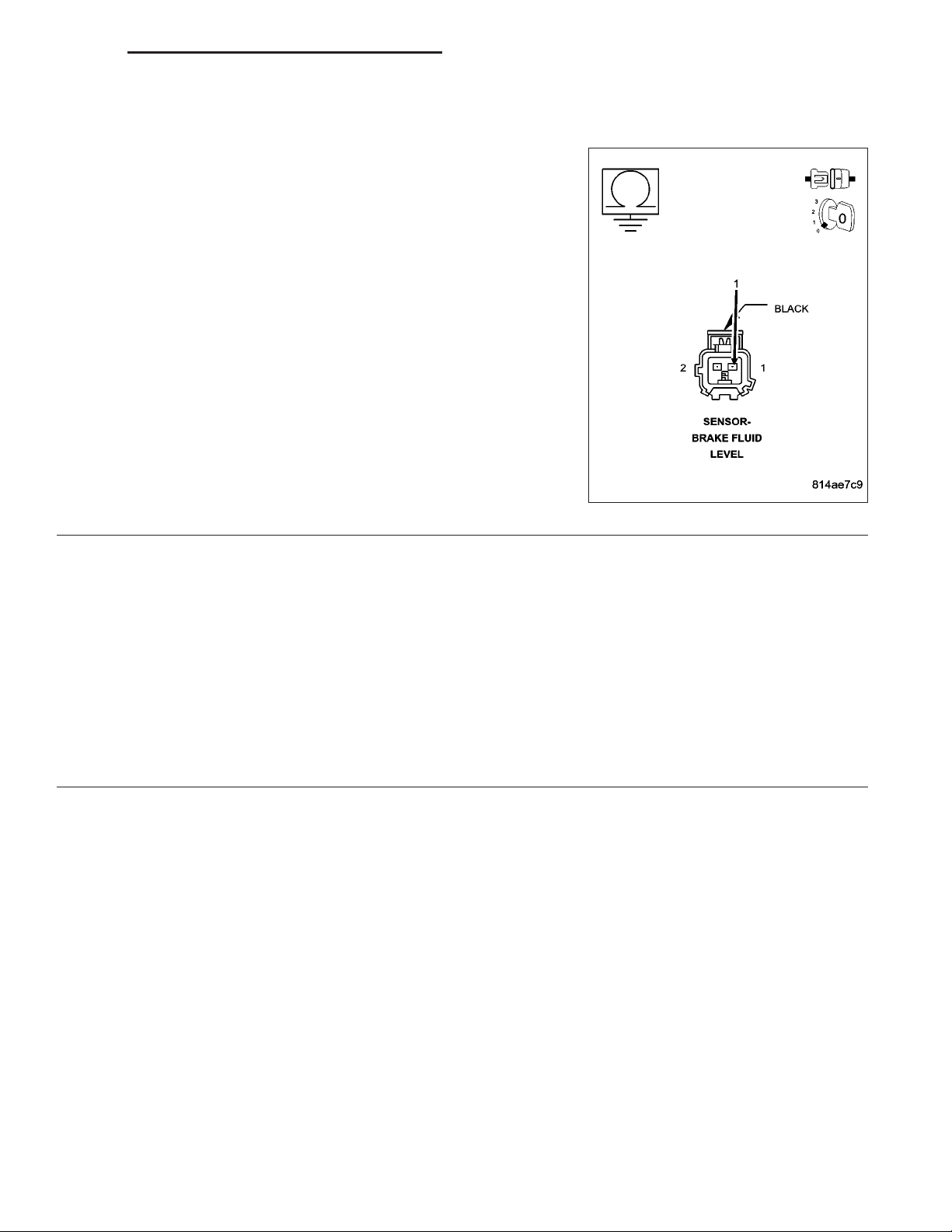

BRAKE FLUID LEVEL SENSOR

4.

NOTE: Determine if the Brake Fluid Level Sensor is stuck in the down position. Repair as necessary.

Measure the resistance of the Brake Fluid Level Sensor at the sensor terminals.

NOTE: Resistance should be approximately 10,000 ohms with the reservoir full.

Is the resistance between 9,500 and 10,500 ohms?

Yes >>

No >>

Repair the Brake Fluid Level Switch Sense circuit for a

short to ground.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 4

Go To 5

Replace the Brake Fluid Level Switch in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

5 - 16 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

FOUNDATION BRAKE — 78 (CONTINUED)

GROUND CIRCUIT OPEN OR HIGH RESISTANCE

5.

Using a 12–volt test light connected to 12 volts, check the Ground circuit.

NOTE: The test light should be illuminated and bright. Compare

the brightness to that of a direct connection to the battery.

Is the test light illuminated and bright?

Yes >>

No >>

WIRING HARNESS INSPECTION

6.

Turn the ignition off.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Refer to any Technical Service Bulletins that may apply.

Were any problems found?

Yes >>

No >>

Replace the Controller Anti-lock Brake in accordance with

the Service Information. Refer to the symptom *Replacing

the Controller Anti-lock Brake for additional information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Repair the Brake Fluid Level Switch ground circuit for an

open circuit or high resistance.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Repair as necessary.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Test Complete.

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 17

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27

5 - 18 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27 (CONTINUED)

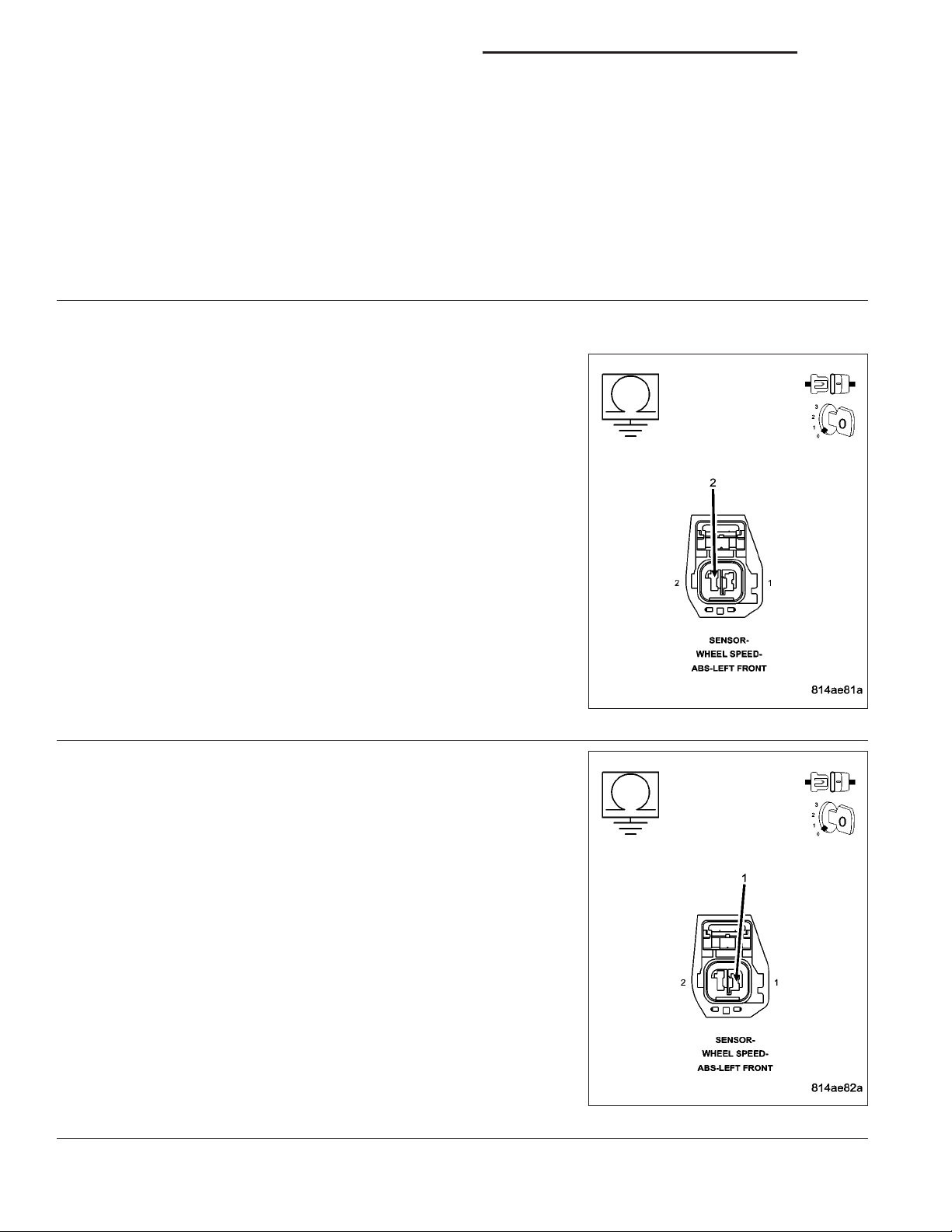

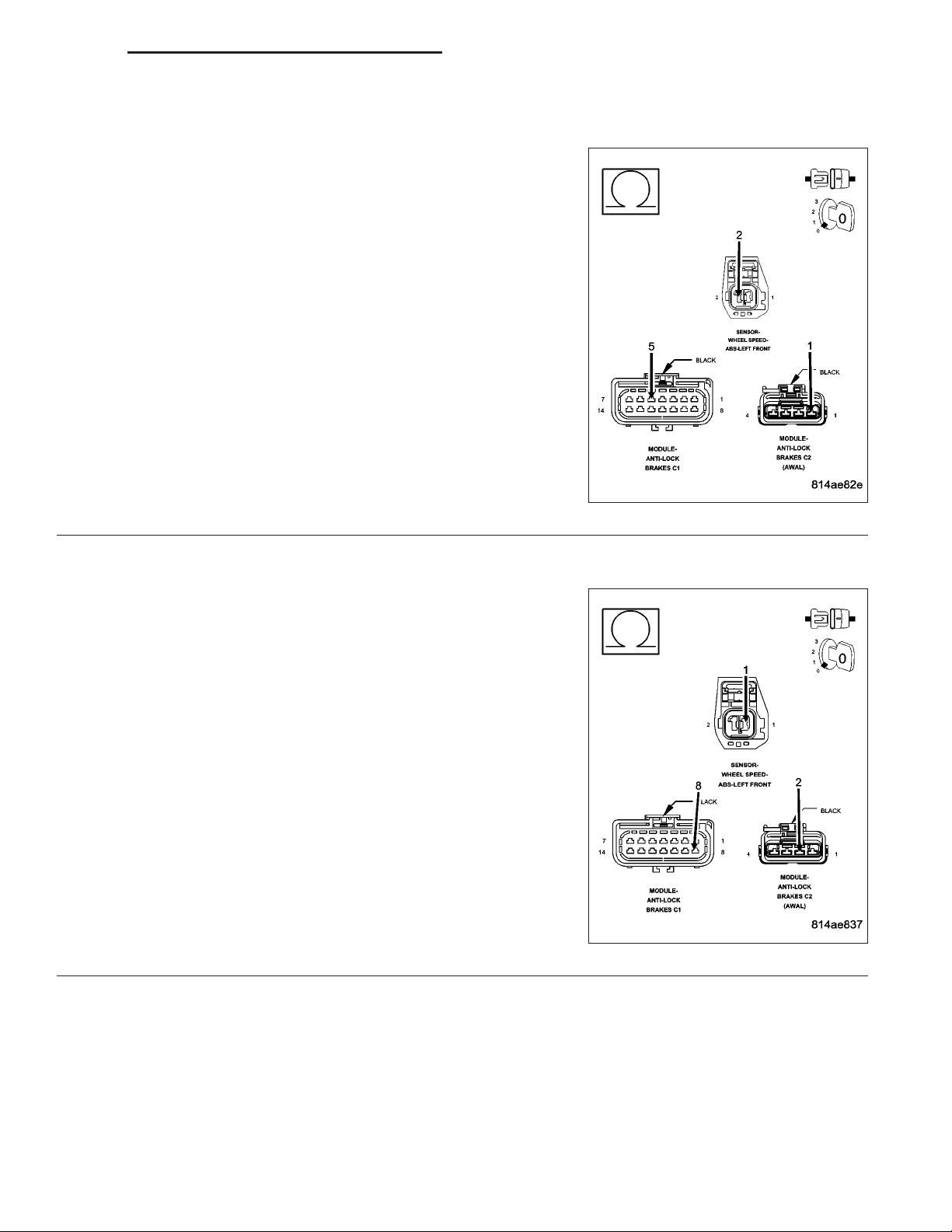

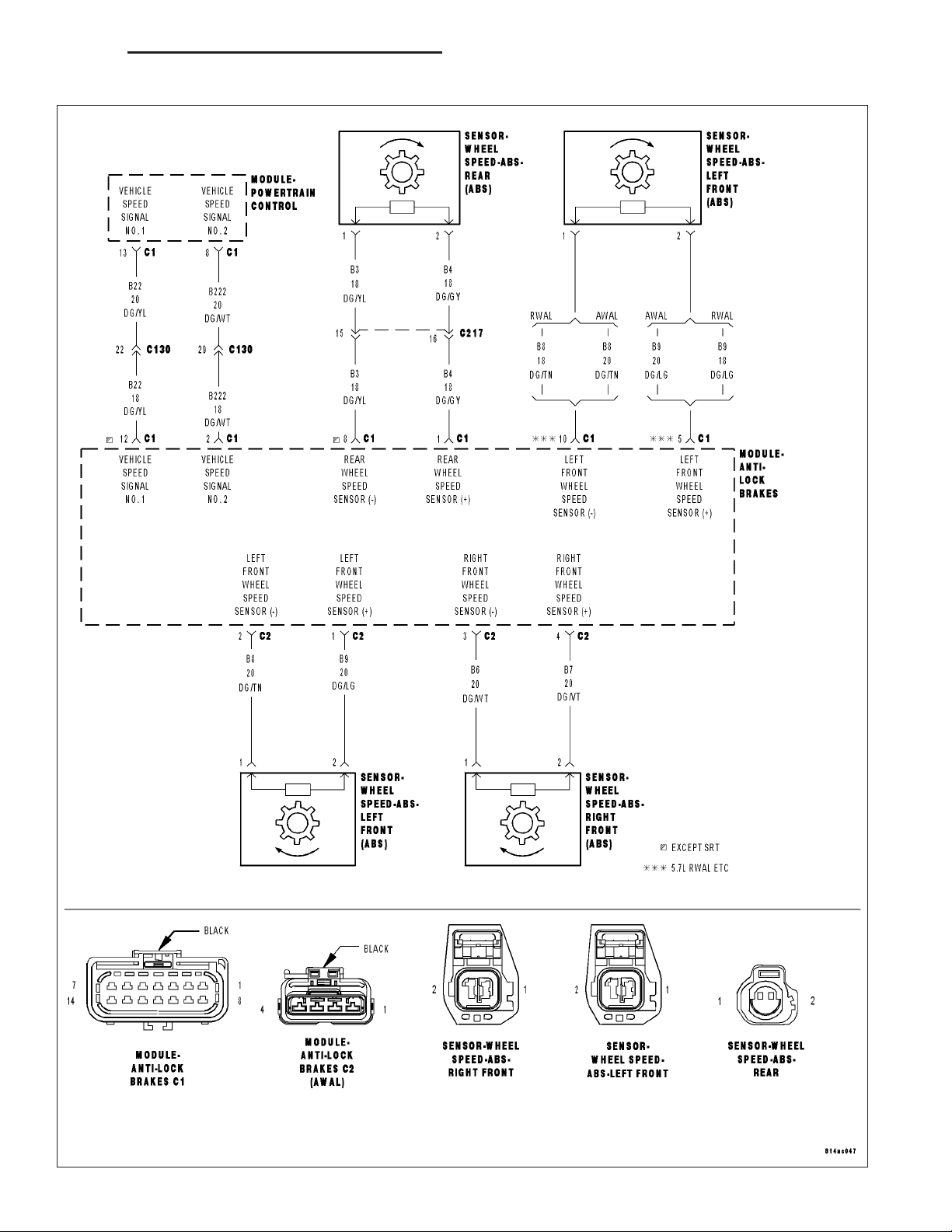

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition turned on for at least 3.5 seconds. Average filtered speed for the two front wheels above 6km/h

(4MPH). Speed for each suspect sensor above 32 km/h (20 MPH) (brake applied or ABS active) or 19 km/h

(12 MPH) (brake released or ABS inactive).

• Set Condition:

When there is a sudden change of output signal from the sensor.

Possible Causes

INTERMITTENT LEFT FRONT WHEEL SPEED SENSOR DTC

LEFT FRONT WHEEL SPEED SENSOR (+) CIRCUIT SHORT TO GROUND

LEFT FRONT WHEEL SPEED SENSOR (-) CIRCUIT SHORT TO GROUND

LEFT FRONT WHEEL SPEED SENSOR (+) CIRCUIT OPEN

LEFT FRONT WHEEL SPEED SENSOR (-) CIRCUIT OPEN

LEFT FRONT WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO VOLTAGE

LEFT FRONT WHEEL SPEED SENSOR (-) CIRCUIT SHORTED TO VOLTAGE

LEFT FRONT WHEEL SPEED SENSOR (-) CIRCUIT SHORTED TO THE LEFT FRONT WHEEL SPEED

SENSOR (+) CIRCUIT

TONE WHEEL

EXCESSIVE LEFT FRONT WHEEL SPEED SENSOR AIR GAP

WHEEL BEARING

LEFT FRONT WHEEL SPEED SENSOR

CONTROLLER ANTI-LOCK BRAKE

Diagnostic Test

DTC IS ACTIVE

1.

Turn the ignition on.

With the DRBIIIT, clear DTCs.

Turn the ignition off.

Turn the ignition on.

With the DRBIIIT, read DTCs.

Does the DRBIIIT display the DTC??

Yes >>

No >>

Go To 2

Go To 16

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 19

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27 (CONTINUED)

CONTROLLER ANTI-LOCK BRAKE HARNESS CONNECTOR INSPECTION

2.

Turn the ignition off.

Inspect the CAB wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Inspect the CAB wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Were any problems found?

Yes >>

No >>

WHEEL SPEED SENSOR INSPECTION

3.

Turn the ignition off.

Inspect the Wheel Speed Sensor for proper mounting.

Inspect the Wheel Speed Sensor harness and connector.

Inspect the Wheel Speed Sensor for excessive debris on the sensor.

Were any problems found?

Yes >>

No >>

TONE WHEEL DAMAGED/MISSING

4.

Inspect the Tone Wheel in accordance with the Service Information.

NOTE: The Tone Wheel Teeth should be perfectly square, not bent or nicked.

Clean or Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 3

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 4

Were any problems found?

Yes >>

No >>

EXCESSIVE WHEEL SPEED SENSOR AIR GAP

5.

Measure the Wheel Speed Sensor Air Gap in accordance with the Service Information.

Were any problems found?

Yes >>

No >>

Replace the Tone Wheel in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 5

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 6

5 - 20 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27 (CONTINUED)

WHEEL BEARING LOOSE/BINDING

6.

Inspect the wheel bearings for excessive run out or improper clearance in accordance with the Service Information.

Were any problems found?

Yes >>

No >>

LEFT FRONT WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO GROUND

7.

Turn the ignition off.

Disconnect the Left Front Wheel Speed Sensor harness connector.

Disconnect the Controller Anti-lock Brake harness connector.

NOTE: Check connector - Clean/repair as necessary.

Measure the resistance between the Left Front Wheel Speed Sensor

(+) circuit and ground.

Is the resistance above 5.0 ohms?

Yes >>

No >>

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 7

Go To 8

Repair the Left Front Wheel Speed Sensor (+) circuit for a

short to ground.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 -

BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

LEFT FRONT WHEEL SPEED SENSOR (-) CIRCUIT SHORTED

8.

TO GROUND

Measure the resistance between the Left Front Wheel Speed Sensor

(-) circuit and ground.

Is the resistance above 5.0 ohms?

Yes >>

No >>

Go To 9

Repair the Left Front Wheel Speed Sensor (-) circuit for a

short to ground.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 -

BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 21

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27 (CONTINUED)

LEFT FRONT WHEEL SPEED SENSOR (+) CIRCUIT OPEN

9.

Measure the resistance of the Left Front Wheel Speed Sensor (+) circuit.

Is the resistance below 5.0 ohms?

Yes >>

No >>

10.

Measure the resistance of the Left Front Wheel Speed Sensor (-) circuit.

Is the resistance below 5.0 ohms?

Yes >>

No >>

Go To 10

Repair the open Left Front Wheel Speed Sensor (+) cir-

cuit.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 -

BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

LEFT FRONT WHEEL SPEED SENSOR (-) CIRCUIT OPEN

Go To 11

Repair the open Left Front Wheel Speed Sensor (-) circuit.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

5 - 22 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27 (CONTINUED)

LEFT FRONT WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO VOLTAGE

11.

Turn the ignition on.

Measure the voltage of the Left Front Wheel Speed Sensor (+) circuit.

Is there any voltage present?

Yes >>

No >>

12.

Measure the voltage of the Left Front Wheel Speed Sensor (-) circuit.

Is there any voltage present?

Yes >>

No >>

Repair Left Front Wheel Speed Sensor (+) circuit for a

short to voltage.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 12

LEFT FRONT WHEEL SPEED SENSOR (-) CIRCUIT SHORTED TO VOLTAGE

Repair the Left Front Wheel Speed Sensor (-) circuit for a

short to voltage.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 13

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 23

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27 (CONTINUED)

13.

Turn the ignition off.

Measure the resistance between the Left Front Wheel Speed Sensor

(+) circuit and the Left Front Wheel Speed Sensor (-) circuit at the

Controller Anti-lock Brake harness connector.

Yes >>

No >>

LEFT FRONT WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO THE LEFT FRONT WHEEL SPEED

SENSOR (-) CIRCUIT

Is the resistance below 5.0 ohms?

Repair Left Front Wheel Speed Sensor (+) circuit for a

short to the Left Front Wheel Speed Sensor (-) circuit.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 14

14.

Turn the ignition off.

Connect the Left Front Wheel Speed Sensor harness connector.

Measure the resistance between the Left Front Wheel Speed Sensor (+) circuit and Left Front Wheel Speed Sensor

(-) circuit at the Controller Anti-lock Brake harness connector.

NOTE: The resistance should be approximately 1800–2200 ohms at 76 degrees F.

Yes >>

No >>

15.

Turn the ignition off.

Inspect the related wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Refer to any Technical Service Bulletins that may apply.

Yes >>

No >>

LEFT FRONT WHEEL SPEED SENSOR

Is the resistance within the noted range?

Go to 15

Replace the Left Front Wheel Speed Sensor in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

CONTROLLER ANTI-LOCK BRAKE

Were any problems found?

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Replace the Controller Anti-lock Brake in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

5 - 24 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

INTERMITTENT SIGNAL FROM LEFT FRONT SENSOR — 27 (CONTINUED)

16.

Turn the ignition off.

NOTE: Towing the vehicle with ignition ON may set this DTC.

Inspect the related wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Refer to any Technical Service Bulletins that may apply.

Yes >>

No >>

WIRING HARNESS INSPECTION

Were any problems found?

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Test Complete.

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 25

INTERMITTENT SIGNAL FROM REAR SENSOR — 37

5 - 26 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

INTERMITTENT SIGNAL FROM REAR SENSOR — 37 (CONTINUED)

For a complete wiring diagram Refer to Section 8W.

• When Monitored:

Ignition turned on for at least 3.5 seconds. Average filtered speed for the wheels above 19 km/h (12 MPH)

(brake released of ABS inactive) or 32 km/h (20 MPH) (brake applied or ABS active).

• Set Condition:

When the is a sudden change of output signal from the sensor.

Possible Causes

INTERMITTENT REAR WHEEL SPEED SENSOR DTC

REAR WHEEL SPEED SENSOR (+) CIRCUIT SHORT TO GROUND

REAR WHEEL SPEED SENSOR (-) CIRCUIT SHORT TO GROUND

REAR WHEEL SPEED SENSOR (+) CIRCUIT OPEN

REAR WHEEL SPEED SENSOR (-) CIRCUIT OPEN

REAR WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO VOLTAGE

REAR WHEEL SPEED SENSOR (-) CIRCUIT SHORTED TO VOLTAGE

REAR WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO THE REAR WHEEL SPEED SENSOR (-) CIRCUIT

TONE WHEEL

EXCESSIVE REAR WHEEL SPEED SENSOR AIR GAP

WHEEL BEARING/REAR DIFFERENTIAL

REAR WHEEL SPEED SENSOR

CONTROLLER ANTI-LOCK BRAKE

Diagnostic Test

DTC IS ACTIVE

1.

Turn the ignition on.

With the DRBIIIT, clear DTCs.

Turn the ignition off.

Turn the ignition on.

With the DRBIIIT, read DTCs.

Does the DRBIIIT display the DTC?

Yes >>

No >>

CONTROLLER ANTI-LOCK BRAKE HARNESS CONNECTOR INSPECTION

2.

Turn the ignition off.

Inspect the CAB wiring harness. Look for any chafed, pierced, pinched, or partially broken wires.

Inspect the CAB wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Were any problems found?

Yes >>

No >>

Go To 2

Go To 16

Clean or Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 3

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 27

INTERMITTENT SIGNAL FROM REAR SENSOR — 37 (CONTINUED)

WHEEL SPEED SENSOR INSPECTION

3.

Turn the ignition off.

Inspect the Wheel Speed Sensor for proper mounting.

Inspect the Wheel Speed Sensor harness and connector.

Inspect the Wheel Speed Sensor for excessive debris on the sensor.

Were any problems found?

Yes >>

No >>

TONE WHEEL DAMAGED/MISSING

4.

Inspect the Tone Wheel in accordance with the Service Information.

NOTE: The Tone Wheel Teeth should be perfectly square, not bent or nicked.

Were any problems found?

Yes >>

No >>

EXCESSIVE WHEEL SPEED SENSOR AIR GAP

5.

Measure the Wheel Speed Sensor Air Gap in accordance with the Service Information.

Were any problems found?

Yes >>

No >>

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 4

Replace the Tone Wheel in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 5

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 6

WHEEL BEARING/REAR DIFFERENTIAL

6.

Inspect the wheel bearings for excessive run out or improper clearance in accordance with the Service Information.

Inspect the rear differential for proper operating. Refer to the Service information.

Were any problems found?

Yes >>

No >>

Repair as necessary in accordance with the Service Information.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 - BRAKES/ELECTRICAL - DIAGNOSIS AND

TESTING)

Go To 7

5 - 28 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

INTERMITTENT SIGNAL FROM REAR SENSOR — 37 (CONTINUED)

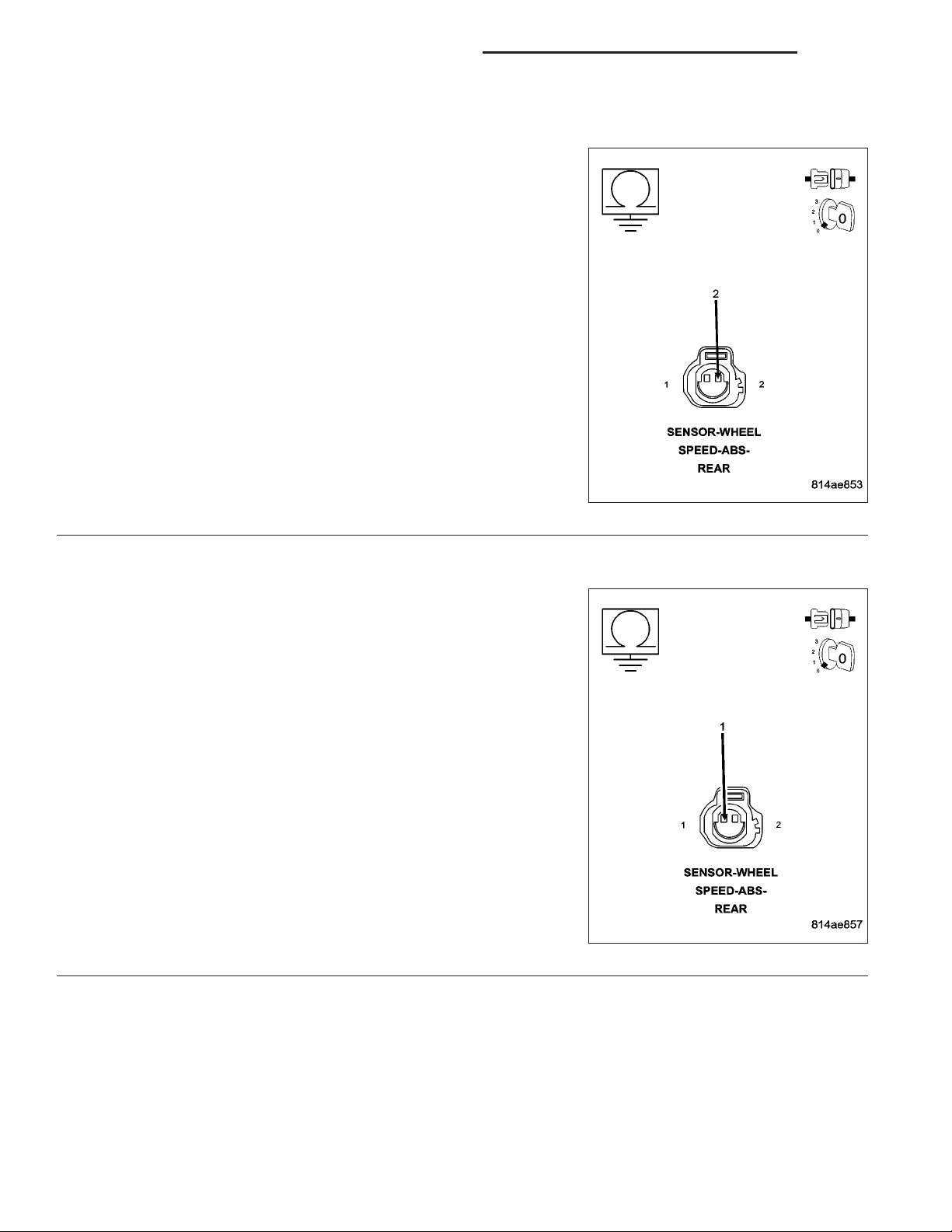

REAR WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO GROUND

7.

Turn the ignition off.

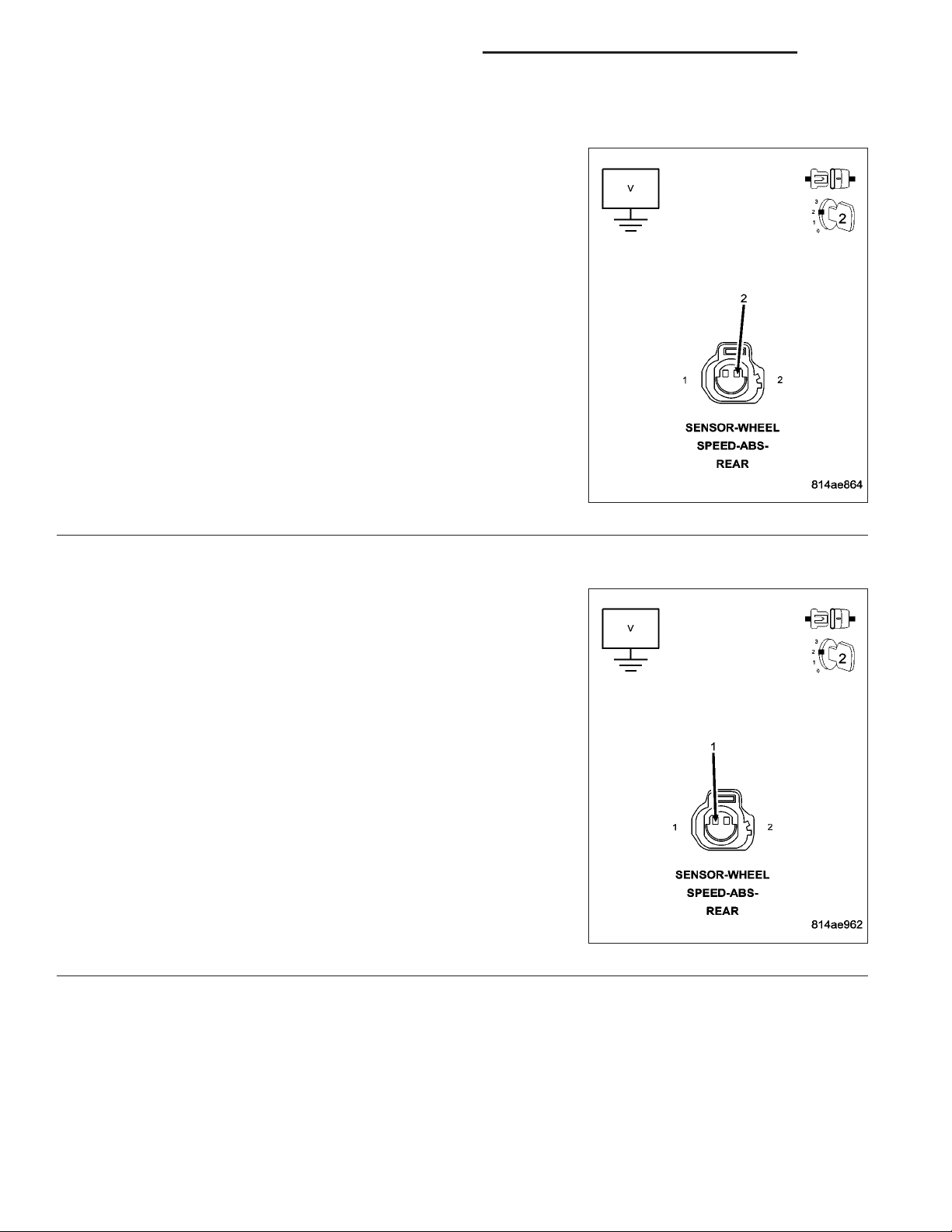

Disconnect the Rear Wheel Speed Sensor harness connector.

Disconnect the Controller Anti-lock Brake harness connector.

NOTE: Check connector - Clean/repair as necessary.

Measure the resistance between the Rear Wheel Speed Sensor (+)

circuit and ground.

Is the resistance above 5.0 ohms?

Yes >>

No >>

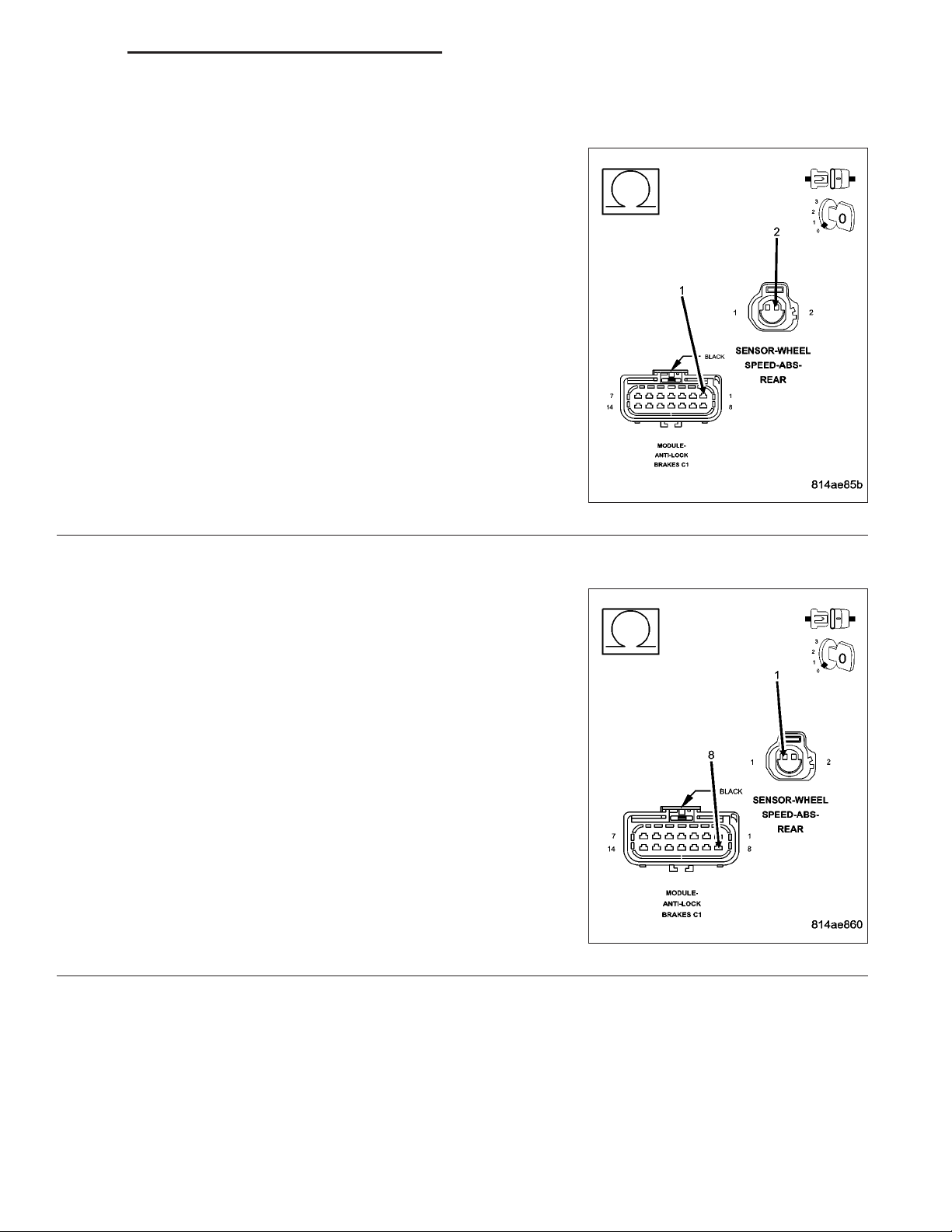

REAR WHEEL SPEED SENSOR (-) CIRCUIT SHORTED TO GROUND

8.

Measure the resistance between the Rear Wheel Speed Sensor (-) circuit and ground.

Is the resistance above 5.0 ohms?

Yes >>

No >>

Go To 8

Repair the Rear Wheel Speed Sensor (+) circuit for a

short to ground.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 -

BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 9

Repair the Rear Wheel Speed Sensor (-) circuit for a short

to ground.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 -

BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

DR/DH BRAKES - ABS - ELECTRICAL DIAGNOSTICS 5 - 29

INTERMITTENT SIGNAL FROM REAR SENSOR — 37 (CONTINUED)

REAR WHEEL SPEED SENSOR (+) CIRCUIT OPEN

9.

Measure the resistance of the Rear Wheel Speed Sensor (+) circuit.

Is the resistance below 5.0 ohms?

Yes >>

No >>

10.

Measure the resistance of the Rear Wheel Speed Sensor (-) circuit.

Is the resistance below 5 ohms?

Yes >>

No >>

Go To 10

Repair the open Rear Wheel Speed Sensor (+) circuit.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

REAR WHEEL SPEED SENSOR (-) CIRCUIT OPEN

Go To 11

Repair the open Rear Wheel Speed Sensor (-) circuit.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

5 - 30 BRAKES - ABS - ELECTRICAL DIAGNOSTICS DR/DH

INTERMITTENT SIGNAL FROM REAR SENSOR — 37 (CONTINUED)

REAR WHEEL SPEED SENSOR (+) CIRCUIT SHORTED TO VOLTAGE

11.

Turn the ignition on.

Measure the voltage of the Rear Wheel Speed Sensor (+) circuit.

Is there any voltage present?

Yes >>

No >>

12.

Measure the voltage of the Rear Wheel Speed Sensor (-) circuit.

Is there any voltage present?

Yes >>

No >>

Repair Rear Wheel Speed Sensor (+) circuit for a short to

voltage.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 12

REAR WHEEL SPEED SENSOR (-) CIRCUIT SHORTED TO VOLTAGE

Repair the Rear Wheel Speed Sensor (-) circuit for a short

to voltage.

Perform ABS VERIFICATION TEST - VER 1. (Refer to 5 BRAKES/ELECTRICAL - DIAGNOSIS AND TESTING)

Go To 13

Loading...

Loading...