BR/BE BRAKES 5 - 1

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE ........................... 1 BRAKES - ABS ........................... 35

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

SPECIFICATIONS

BASE BRAKE .........................2

TORQUE CHART ......................3

SPECIAL TOOLS

BASE BRAKES ........................4

HYDRAULIC/MECHANICAL

DESCRIPTION ..........................4

WARNING .............................4

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM .............................5

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL

BLEEDING............................7

STANDARD PROCEDURE - PRESSURE

BLEEDING............................8

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE

INVERTED FLARING ....................8

STANDARD PROCEDURE - ISO FLARING . . . 8

COMBINATION VALVE

DESCRIPTION ..........................8

OPERATION ............................9

DIAGNOSIS AND TESTING - COMBINATION

VALVE ...............................9

REMOVAL .............................9

INSTALLATION ..........................9

DISC BRAKE CALIPERS

DESCRIPTION .........................10

OPERATION ...........................10

REMOVAL

REMOVAL - REAR .....................10

REMOVAL - FRONT ....................11

DISASSEMBLY .........................11

CLEANING ............................12

INSPECTION ..........................12

ASSEMBLY ............................13

INSTALLATION

INSTALLATION - REAR .................14

INSTALLATION - FRONT ................14

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION .....................15

STANDARD PROCEDURE - BRAKE FLUID

LEVEL ..............................15

SPECIFICATIONS

BRAKE FLUID ........................15

FLUID RESERVOIR

REMOVAL .............................15

INSTALLATION .........................15

PEDAL

DESCRIPTION .........................17

OPERATION ...........................17

REMOVAL .............................17

INSTALLATION .........................17

POWER BRAKE BOOSTER

DIAGNOSIS AND TESTING - HYDRAULIC

BOOSTER ...........................18

STANDARD PROCEDURE - BLEEDING ......19

REMOVAL .............................19

INSTALLATION .........................19

ROTORS

DIAGNOSIS AND TESTING

DISC BRAKE ROTOR ..................20

REMOVAL

REMOVAL - REAR .....................21

REMOVAL - FRONT – 2500 ..............22

REMOVAL - FRONT - 3500 ..............22

INSTALLATION

INSTALLATION - REAR .................22

INSTALLATION - FRONT – 2500 ..........23

INSTALLATION - FRONT - 3500 ...........23

5 - 2 BRAKES - BASE BR/BE

BRAKE PADS/SHOES

REMOVAL

REMOVAL - REAR .....................23

REMOVAL - FRONT ....................24

INSTALLATION

INSTALLATION - REAR .................25

INSTALLATION - FRONT ................26

MASTER CYLINDER

DESCRIPTION .........................26

OPERATION ...........................26

DIAGNOSIS AND TESTING - MASTER

CYLINDER/POWER BOOSTER ...........26

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING ..................27

REMOVAL .............................27

INSTALLATION .........................28

PARKING BRAKE

DESCRIPTION .........................28

OPERATION ...........................28

PEDAL

REMOVAL .............................28

INSTALLATION .........................29

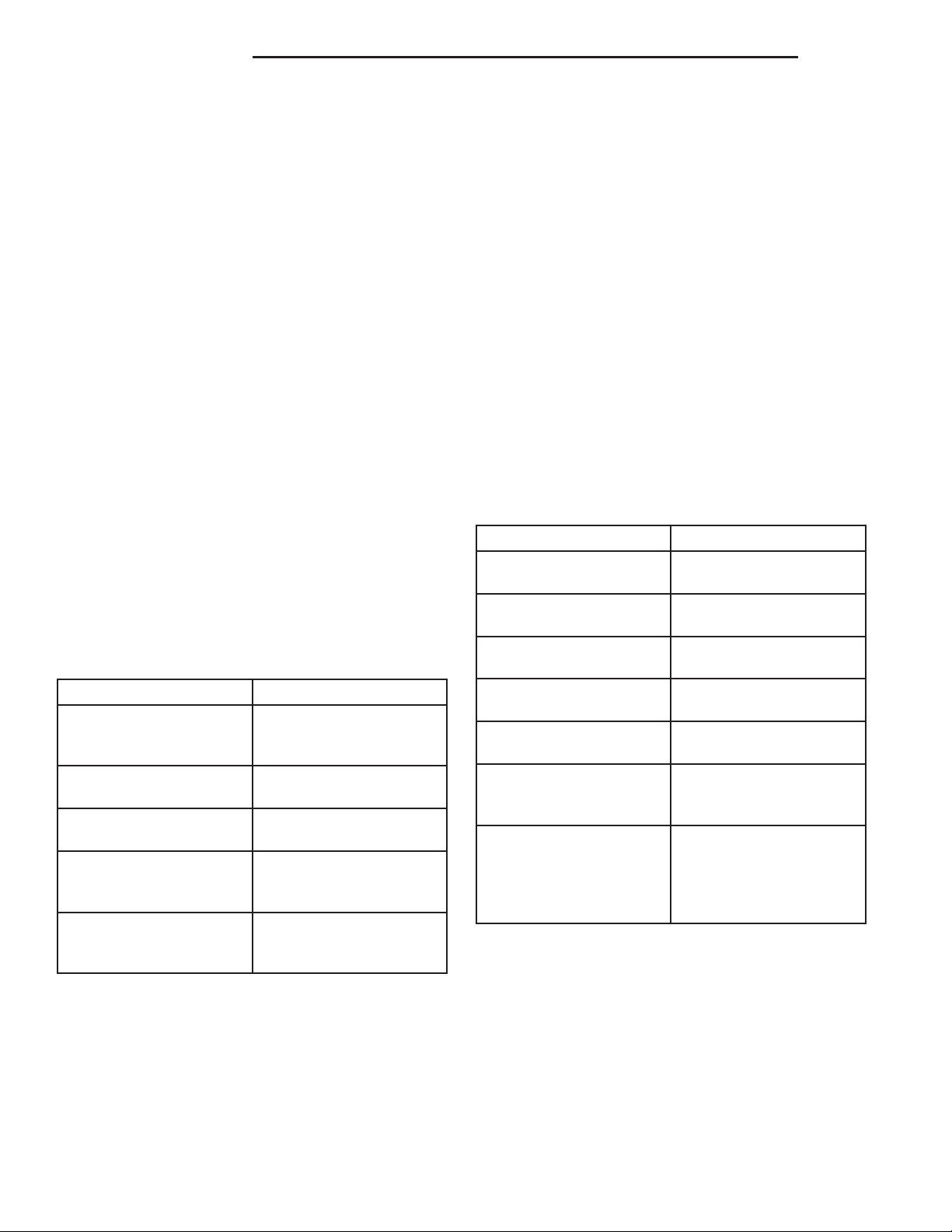

BRAKES - BASE

SPECIFICATIONS

BASE BRAKE

SPECIFICATIONS

DESCRIPTION SPECIFICATION

Front/Rear Disc Brake

Caliper

Type

Front Disc Brake Caliper

Piston Diameter HD

Front Disc Brake Rotor 326.5×36 mm

Front/Rear Disc Brake

Rotor

Max. Runout

Front/Rear Disc Brake

Rotor

Max. Thickness Variation

Dual Piston Sliding

56 mm (2.00 in.)

(12.5×1.5 in.)

0.127 mm (0.005 in.)

0.025 mm (0.001 in.)

CABLES

REMOVAL

REMOVAL - REAR PARK BRAKE CABLE . . . 29

REMOVAL - FRONT PARKING BRAKE

CABLE..............................29

INSTALLATION

INSTALLATION - REAR PARK BRAKE

CABLE..............................30

INSTALLATION - FRONT PARKING BRAKE

CABLE..............................30

CABLE TENSIONER

ADJUSTMENTS

ADJUSTMENT ........................30

RELEASE HANDLE

REMOVAL .............................31

INSTALLATION .........................32

SHOES

REMOVAL .............................32

INSTALLATION .........................32

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES . . 33

DESCRIPTION SPECIFICATION

Minimum Front Rotor

Thickness

Mininium Rear Rotor

Thickness

Rear Disc Brake Caliper

2500

Rear Disc Brake Caliper

3500

Rear Disc Brake Rotor

2500/3500

Brake Booster

Type

2500 Gasoline Engines

Brake Booster

Type

All 3500/

2500 Diesel Engines

Only

33.90 mm (1.334 in.)

28.39 mm (1.117 in)

2x45 mm (1.77 in)

2x51 mm (2.00 in)

323.5x30 mm (1.18 in)

Vacuum Dual Diaphragm

Hydraulic

BR/BE BRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

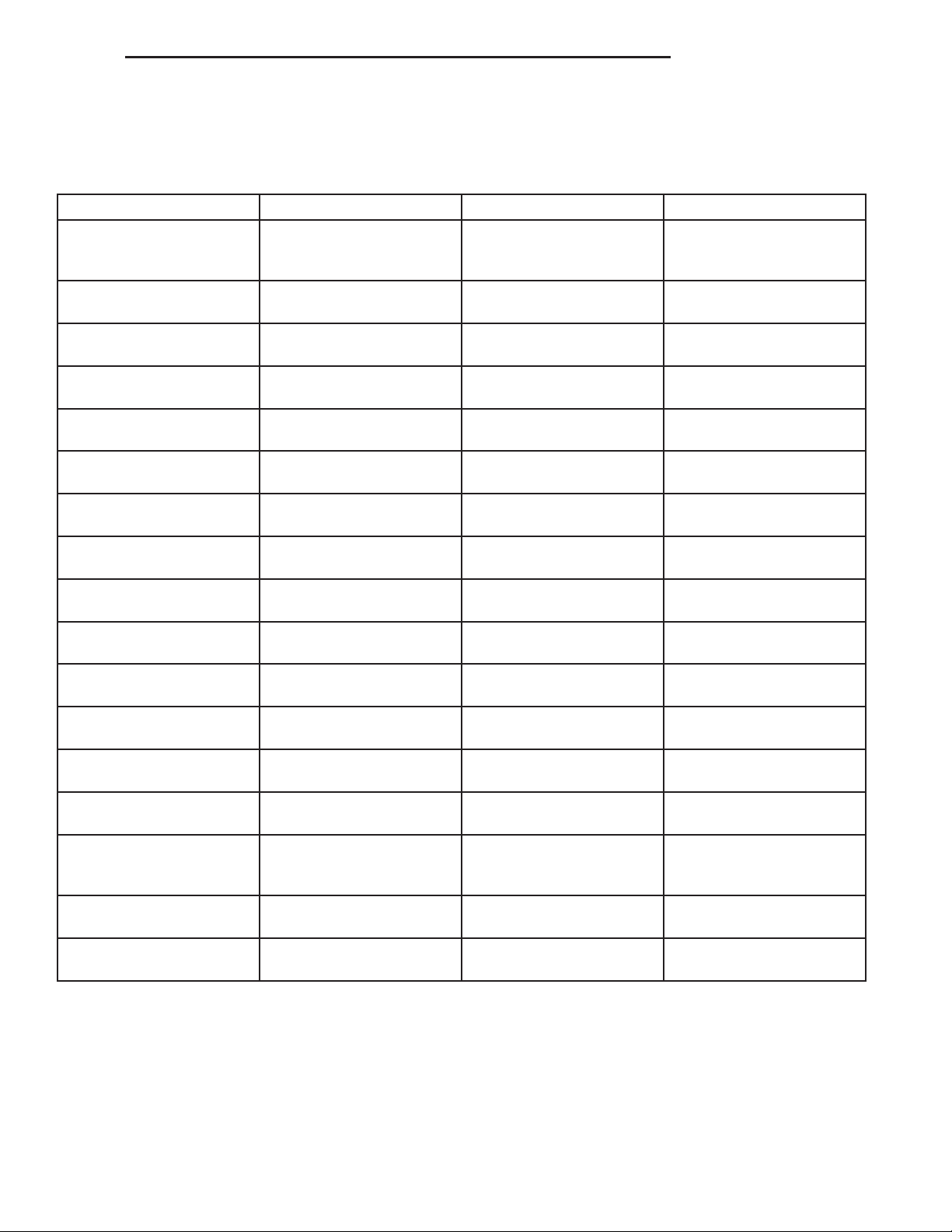

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N·m Ft. Lbs. In. Lbs.

Booster

Mounting Nuts To

Dashpanel

Master Cylinder

Mounting Nuts

Master Cylinder

Brake Lines

Combination Valve

Mounting Bolt

Combination Valve

Brake Lines

Proportioning Valve

Mounting Nuts

Proportioning Valve

Brake Hose

Proportioning Valve

Brake Lines

Front Caliper

Mounting Bolts

Front Caliper

HD Adapter Bolts

Rear Caliper

Slide Pins

Rotor to Hub Rear

Bolt

All Caliper

Banjo Bolts

Support Plate

Mounting Bolts

Park Brake Pedal

Assembly

Mounting Bolts/Nuts

Hub/Bearing

HD 4x2 Spindle Nut

Hub/Bearing

4x4 Hub/Bearing Bolts

28 21 250

23 17 200

21 16 190

23 17 210

21 16 190

34 25 300

31 23 276

21 16 190

33 24 —

285 210 —

33 24 300

128 95 —

40 30 360

58 43 —

28 21 250

380 280 —

170 125 —

5 - 4 BRAKES - BASE BR/BE

BRAKES - BASE (Continued)

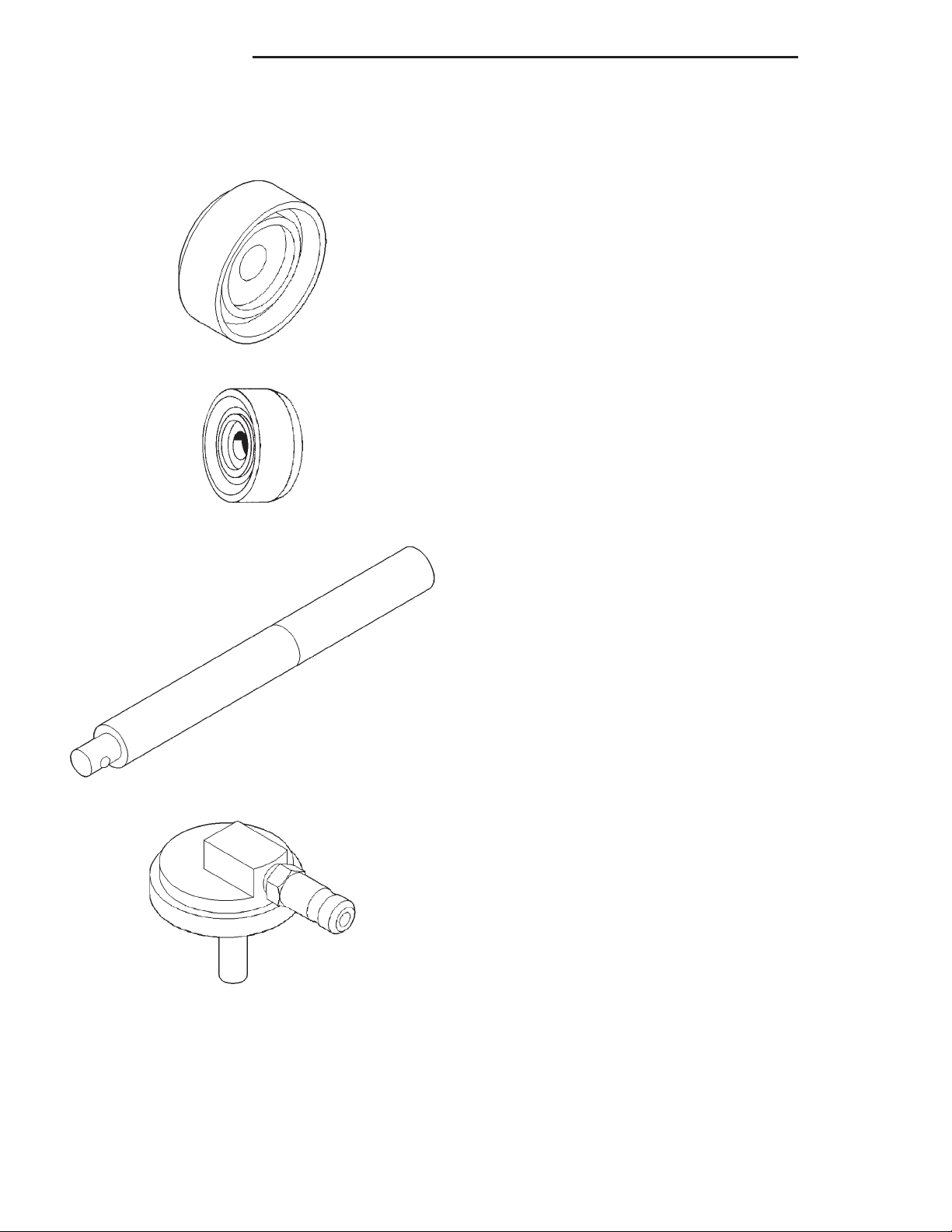

SPECIAL TOOLS

BASE BRAKES

Installer, Brake Caliper Dust Boot C-4340

Installer, Brake Caliper Dust Boot C-3716-A

HYDRAULIC/MECHANICAL

DESCRIPTION

This vehicle is equipped with front disc brakes and

rear drum brakes also certain vehicles have four

wheel disc brakes. The front and rear disc brakes

consist of dual piston calipers and ventilated rotors.

The rear brakes are dual brake shoe, internal

expanding units with cast brake drums. The parking

brake mechanism is cable operated and connected to

the rear brake trailing shoes. Power brake assist is

standard equipment. A vacuum operated power brake

booster is used on gas engine vehicles. A hydraulic

booster is used on diesel engine vehicles.

Two antilock brake systems are used on this vehicle. A rear wheel antilock (RWAL) brake system and

all-wheel antilock brake system (ABS). The RWAL

and ABS systems are designed to retard wheel

lockup while braking. Retarding wheel lockup is

accomplished by modulating fluid pressure to the

wheel brake units. Both systems are monitored by a

microprocessor which controls the operation of the

systems.

Handle C-4171

Cap, Master Cylinder Pressure Bleed 6921

WARNING

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CONTAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET LININGS. BREATHING EXCESSIVE

CONCENTRATIONS OF ASBESTOS FIBERS CAN

CAUSE SERIOUS BODILY HARM. EXERCISE CARE

WHEN SERVICING BRAKE PARTS. DO NOT CLEAN

BRAKE PARTS WITH COMPRESSED AIR OR BY

DRY BRUSHING. USE A VACUUM CLEANER SPECIFICALLY DESIGNED FOR THE REMOVAL OF

ASBESTOS FIBERS FROM BRAKE COMPONENTS.

IF A SUITABLE VACUUM CLEANER IS NOT AVAILABLE, CLEANING SHOULD BE DONE WITH A

WATER DAMPENED CLOTH. DO NOT SAND, OR

GRIND BRAKE LINING UNLESS EQUIPMENT USED

IS DESIGNED TO CONTAIN THE DUST RESIDUE.

DISPOSE OF ALL RESIDUE CONTAINING ASBESTOS FIBERS IN SEALED BAGS OR CONTAINERS

TO MINIMIZE EXPOSURE TO YOURSELF AND OTHERS. FOLLOW PRACTICES PRESCRIBED BY THE

OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION AND THE ENVIRONMENTAL PROTECTION

AGENCY FOR THE HANDLING, PROCESSING, AND

DISPOSITION OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

BR/BE BRAKES - BASE 5 - 5

HYDRAULIC/MECHANICAL (Continued)

CAUTION: Never use gasoline, kerosene, alcohol,

motor oil, transmission fluid, or any fluid containing

mineral oil to clean the system components. These

fluids damage rubber cups and seals. Use only

fresh brake fluid or Mopar brake cleaner to clean or

flush brake system components. These are the only

cleaning materials recommended. If system contamination is suspected, check the fluid for dirt, discoloration, or separation into distinct layers. Also

check the reservoir cap seal for distortion. Drain

and flush the system with new brake fluid if contamination is suspected.

CAUTION: Use Mopar brake fluid, or an equivalent

quality fluid meeting SAE/DOT standards J1703 and

DOT 3. Brake fluid must be clean and free of contaminants. Use fresh fluid from sealed containers

only to ensure proper antilock component operation.

CAUTION: Use Mopar multi-mileage or high temperature grease to lubricate caliper slide surfaces,

drum brake pivot pins, and shoe contact points on

the backing plates. Use multi-mileage grease or GE

661 or Dow 111 silicone grease on caliper slide pins

to ensure proper operation.

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

Base brake components consist of the brake shoes,

calipers, wheel cylinders, brake drums, rotors, brake

lines, master cylinder, booster, and parking brake

components.

Brake diagnosis involves determining if the problem is related to a mechanical, hydraulic, or vacuum

operated component.

The first diagnosis step is the preliminary check.

PRELIMINARY BRAKE CHECK

(1) Check condition of tires and wheels. Damaged

wheels and worn, damaged, or underinflated tires

can cause pull, shudder, vibration, and a condition

similar to grab.

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear. Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contamination.

(a) If fluid level is abnormally low, look for evidence of leaks at calipers, wheel cylinders, brake

lines, and master cylinder.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a substance other than brake fluid. The system seals

and cups will also have to be replaced after flushing. Use clean brake fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and pedal. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake operation such as low pedal, hard pedal, fade, pedal pulsation, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only and note grab, drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper/wheel cylinder. If leakage is severe, fluid will

be evident at or around the leaking component.

Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS or RWAL system may

also be the problem with no physical evidence.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn linings,

rotors, drums, or rear brakes out of adjustment are

the most likely causes. The proper course of action is

to inspect and replace all worn component and make

the proper adjustments.

5 - 6 BRAKES - BASE BR/BE

HYDRAULIC/MECHANICAL (Continued)

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin brake drums or substandard

brake lines and hoses can also cause a spongy pedal.

The proper course of action is to bleed the system,

and replace thin drums and substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness variation, or out of round brake drums. Other causes are

loose wheel bearings or calipers and worn or damaged tires.

NOTE: Some pedal pulsation may be felt during

ABS/EBD activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake shoe release.

Drag can be minor or severe enough to overheat the

linings, rotors and drums.

Minor drag will usually cause slight surface charring of the lining. It can also generate hard spots in

rotors and drums from the overheat-cool down process. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In

severe cases, the lining may generate smoke as it

chars from overheating.

Common causes of brake drag are:

• Seized or improperly adjusted parking brake

cables

• Loose/worn wheel bearing

• Seized caliper or wheel cylinder piston

• Caliper binding on damaged or missing anti-rat-

tle clips or bushings

• Loose caliper mounting

• Drum brake shoes binding on worn/damaged

support plates

• Mis-assembled components

• Long booster output rod

If brake drag occurs at all wheels, the problem

may be related to a blocked master cylinder return

port, or faulty power booster (binds-does not release).

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

• Contaminated lining in one caliper

• Seized caliper piston

• Binding caliper

• Loose caliper

• Damaged anti-rattle clips

• Improper brake shoes

• Damaged rotor

A worn, damaged wheel bearing or suspension

component are further causes of pull. A damaged

front tire (bruised, ply separation) can also cause

pull.

A common and frequently misdiagnosed pull condition is where direction of pull changes after a few

stops. The cause is a combination of brake drag followed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE GRAB OR PULL

Rear grab or pull is usually caused by improperly

adjusted or seized parking brake cables, contaminated lining, bent or binding shoes and support

plates, or improperly assembled components. This is

particularly true when only one rear wheel is

involved. However, when both rear wheels are

affected, the master cylinder or proportioning valve

could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

BR/BE BRAKES - BASE 5 - 7

HYDRAULIC/MECHANICAL (Continued)

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and/or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or wheel cylinders, worn seals, driving through deep water puddles, or lining that has

become covered with grease and grit during repair.

Contaminated lining should be replaced to avoid further brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibration and generate shudder during brake operation. A

tire with internal damage such as a severe bruise,

cut, or ply separation can cause pull and vibration.

BRAKE NOISES

Some brake noise is common with rear drum

brakes and on some disc brakes during the first few

stops after a vehicle has been parked overnight or

stored. This is primarily due to the formation of trace

corrosion (light rust) on metal surfaces. This light

corrosion is typically cleared from the metal surfaces

after a few brake applications causing the noise to

subside.

THUMP/CLUNK NOISE

Thumping or clunk noises during braking are frequently not caused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components. However,

calipers that bind on the slide surfaces can generate

a thump or clunk noise. In addition, worn out,

improperly adjusted, or improperly assembled rear

brake shoes can also produce a thump noise.

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

(1) Remove reservoir filler caps and fill reservoir.

(2) If calipers, or wheel cylinders were overhauled,

open all caliper and wheel cylinder bleed screws.

Then close each bleed screw as fluid starts to drip

from it. Top off master cylinder reservoir once more

before proceeding.

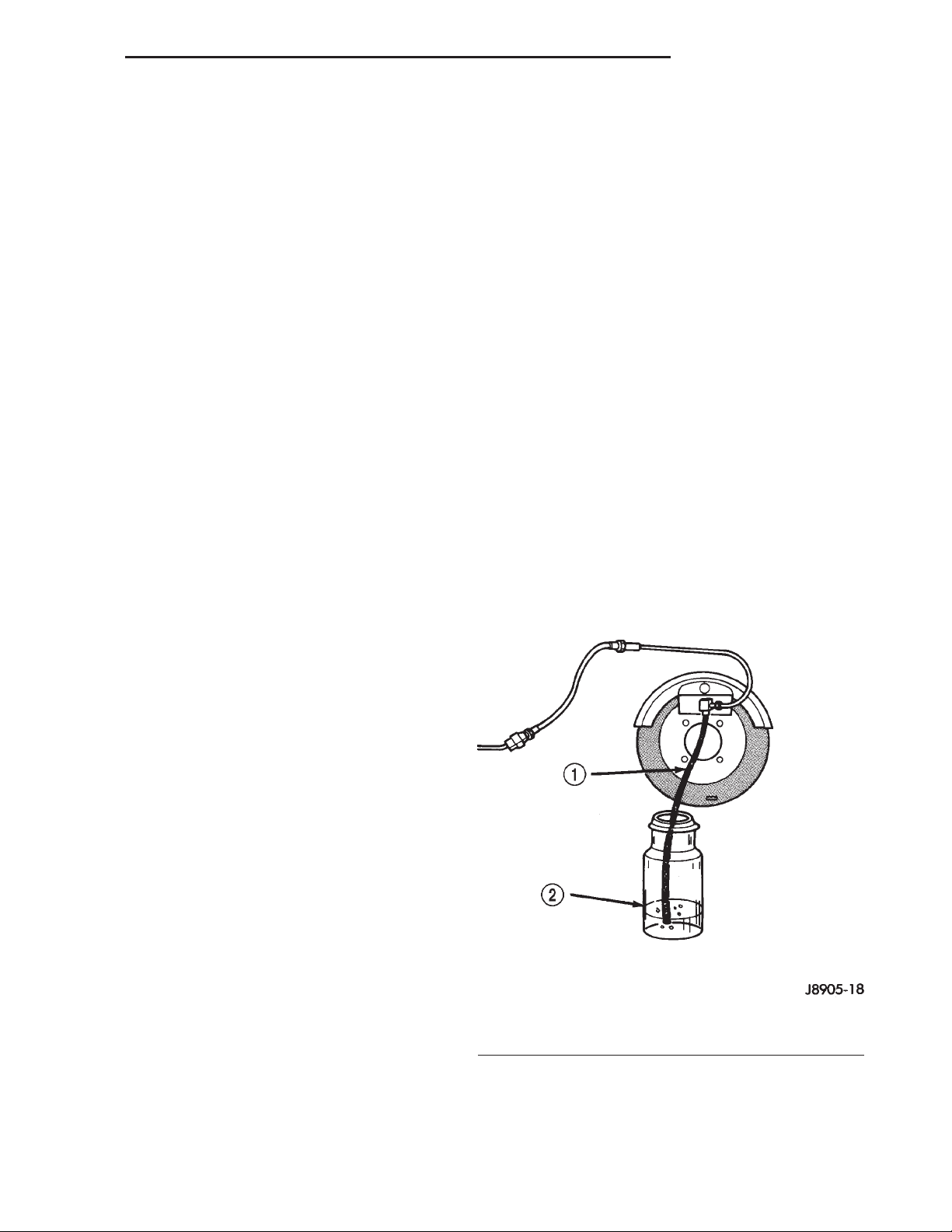

(3) Attach one end of bleed hose to bleed screw

and insert opposite end in glass container partially

filled with brake fluid (Fig. 1). Be sure end of bleed

hose is immersed in fluid.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or

oil. Glazed linings and rotors with hard spots can

also contribute to squeak. Dirt and foreign material

embedded in the brake lining will also cause squeak/

squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors and drums can become so scored that replacement is necessary.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

Fig. 1 Bleed Hose Setup

1 - BLEED HOSE

2 - FLUID CONTAINER PARTIALLY FILLED WITH FLUID

Open up bleeder, then have a helper press down

(4)

the brake pedal. Once the pedal is down close the

bleeder. Repeat bleeding until fluid stream is clear and

free of bubbles. Then move to the next wheel.

5 - 8 BRAKES - BASE BR/BE

HYDRAULIC/MECHANICAL (Continued)

STANDARD PROCEDURE - PRESSURE

BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

If pressure bleeding equipment will be used, the

front brake metering valve will have to be held open

to bleed the front brakes. The valve stem is located

in the forward end or top of the combination valve.

The stem must either be pressed inward, or held outward slightly. A spring clip tool or helper is needed to

hold the valve stem in position.

Follow the manufacturers instructions carefully

when using pressure equipment. Do not exceed the

tank manufacturers pressure recommendations. Generally, a tank pressure of 15-20 psi is sufficient for

bleeding.

Fill the bleeder tank with recommended fluid and

purge air from the tank lines before bleeding.

Do not pressure bleed without a proper master cylinder adapter. The wrong adapter can lead to leakage, or drawing air back into the system. Use

adapter provided with the equipment or Adapter

6921.

BRAKE LINES

STANDARD PROCEDURE

STANDARD PROCEDURE - DOUBLE INVERTED

FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

(1) Cut off damaged tube with Tubing Cutter.

(2) Ream cut edges of tubing to ensure proper

flare.

(3) Install replacement tube nut on the tube.

(4) Insert tube in flaring tool.

(5) Place gauge form over the end of the tube.

(6) Push tubing through flaring tool jaws until

tube contacts recessed notch in gauge that matches

tube diameter.

(7) Tighten the tool bar on the tube

(8) Insert plug on gauge in the tube. Then swing

compression disc over gauge and center tapered flaring screw in recess of compression disc (Fig. 2).

(9) Tighten tool handle until plug gauge is

squarely seated on jaws of flaring tool. This will start

the inverted flare.

(10) Remove the plug gauge and complete the

inverted flare.

STANDARD PROCEDURE - ISO FLARING

A preformed metal brake tube is recommended and

preferred for all repairs. However, double-wall steel

tube can be used for emergency repair when factory

replacement parts are not readily available.

To make a ISO flare use an ISO flaring tool kit.

(1) Cut off damaged tube with Tubing Cutter.

(2) Remove any burrs from the inside of the tube.

(3) Install tube nut on the tube.

(4) Position the tube in the flaring tool flush with

the top of the tool bar (Fig. 3). Then tighten the tool

bar on the tube.

(5) Install the correct size adaptor on the flaring

tool yoke screw.

(6) Lubricate the adaptor.

(7) Align the adaptor and yoke screw over the tube

(Fig. 3).

(8) Turn the yoke screw in until the adaptor is

squarely seated on the tool bar.

COMBINATION VALVE

DESCRIPTION

The combination valve/rear brake proportioning

valve are not repairable and must be replaced as an

assembly.

The pressure differential switch is connected to the

brake warning lamp.

Fig. 2 Inverted Flare Tools

BR/BE BRAKES - BASE 5 - 9

COMBINATION VALVE (Continued)

(3) Connect bleed hose to a rear wheel cylinder

and immerse hose end in container partially filled

with brake fluid.

(4) Have helper press and hold brake pedal to floor

and observe warning light.

(a) If warning light illuminates, switch is operat-

ing correctly.

(b) If light fails to illuminate, check circuit fuse,

bulb, and wiring. The parking brake switch can be

used to aid in identifying whether or not the brake

light bulb and fuse is functional. Repair or replace

parts as necessary and test differential pressure

switch operation again.

(5) If warning light still does not illuminate,

switch is faulty. Replace combination valve assembly,

bleed brake system and verify proper switch and

valve operation.

REMOVAL

(1) Remove pressure differential switch wire con-

nector (Fig. 4) from the valve.

(2) Remove the brake lines from the valve.

Fig. 3 ISO Flaring

1 - ADAPTER

2 - LUBRICATE HERE

3 - PILOT

4 - FLUSH WITH BAR

5 - TUBING

6 - BAR ASSEMBLY

(3) Remove the valve mounting bolt and remove

the valve from the bracket.

OPERATION

PRESSURE DIFFERENTIAL SWITCH

The switch is triggered by movement of the switch

valve. The purpose of the switch is to monitor fluid

pressure in the separate front/rear brake hydraulic

circuits.

A decrease or loss of fluid pressure in either

hydraulic circuit will cause the switch valve to shuttle forward or rearward in response to the pressure

differential. Movement of the switch valve will push

the switch plunger upward. This closes the switch

internal contacts completing the electrical circuit to

the warning lamp. The switch valve may remain in

an actuated position until repair restores system

pressures to normal levels.

DIAGNOSIS AND TESTING - COMBINATION

VALVE

Pressure Differential Switch

(1) Have helper sit in drivers seat to apply brake

pedal and observe red brake warning light.

(2) Raise vehicle on hoist.

Fig. 4 Pressure

1 - COMBINATION VALVE

2 - BRAKE LINES

3 - MOUNTING BOLT

4 - PRESSURE DIFFERENTIAL SWITCH

INSTALLATION

(1) Position the valve on the bracket and install

the mounting bolt. Tighten the mounting bolt to 23

N·m (210 in. lbs.).

(2) Install the brake lines into the valve and

tighten to 19-23 N·m (170-200 in. lbs.).

5 - 10 BRAKES - BASE BR/BE

COMBINATION VALVE (Continued)

(3) Connect the pressure differential switch wire

connector.

(4) Bleed base brake system, (Refer to 5 BRAKES/HYDRAULIC/MECHANICAL - STANDARD PROCEDURE).

DISC BRAKE CALIPERS

DESCRIPTION

The caliper is a one-piece casting. The piston bores

are located in the inboard side. A square-cut piston

seal is located in a machined groove in the cylinder

bore.

The caliper pistons dust boot prevents dirt, water

and road splash from entering the piston bore. The

boot is seated in a groove machined at the outer end

of the caliper piston. The boot retaining flange is

seated in a counterbore machined in the outer end of

the caliper piston bore.

Ventilated disc brake rotors are used for all applications. The rotors are serviceable and can be

machined to restore surface finish when necessary.

OPERATION

When the brakes are applied fluid pressure is

exerted against the caliper piston. The fluid pressure

is exerted equally and in all directions. This means

pressure exerted against the caliper piston and

within the caliper bore will be equal (Fig. 5).

Fluid pressure applied to the piston is transmitted

directly to the inboard brake shoe. This forces the

shoe lining against the inner surface of the disc

brake rotor. At the same time, fluid pressure within

the piston bore forces the caliper to slide inward on

the mounting bolts. This action brings the outboard

brake shoe lining into contact with the outer surface

of the disc brake rotor.

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamping action. When sufficient force is applied, friction

will attempt to stop the rotors from turning and

bring the vehicle to a stop.

Application and release of the brake pedal generates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and piston return to a rest position. The brake shoes do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The reasons for this are to keep road debris from getting

between the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of piston extension needed to compensate for normal lining

wear.

1 - CALIPER

2 - PISTON

3 - PISTON BORE

4 - SEAL

5 - INBOARD SHOE

6 - OUTBOARD SHOE

During brake application, the seal is deflected outward by fluid pressure and piston movement (Fig. 6).

When the brakes (and fluid pressure) are released,

the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

the amount of seal deflection. Generally the amount

is just enough to maintain contact between the piston and inboard brake shoe.

REMOVAL

REMOVAL - REAR

(1) Raise and support the vehicle.

(2) Remove the tire and wheel assembly.

(3) Compress the disc brake caliper using tool

#C4212F.

(4) Remove the caliper pin bolts.

(5) Remove the banjo bolt and discard the copper

washer.

CAUTION: Never allow the disc brake caliper to

hang from the brake hose. Damage to the brake

hose with result. Provide a suitable support to hang

the caliper securely.

(6) Remove the rear disc brake caliper (Fig. 7).

Fig. 5 Brake Caliper Operation

BR/BE BRAKES - BASE 5 - 11

DISC BRAKE CALIPERS (Continued)

Fig. 6 Lining Wear Compensation By Piston Seal

1 - PISTON

2 - CYLINDER BORE

3 - PISTON SEAL BRAKE PRESSURE OFF

4 - CALIPER HOUSING

5 - DUST BOOT

6 - PISTON SEAL BRAKE PRESSURE ON

1 - WASHERS

2 - MOUNTING BOLTS

3 - HOSE BOLT

Fig. 8 Caliper

Fig. 7 REAR CALIPER

1 - Banjo Bolt

2 - Caliper Pin Bolts

REMOVAL - FRONT

(1) Raise and support vehicle.

(2) Remove front wheel and tire assembly.

(3) Remove caliper brake hose bolt, washers and

hose (Fig. 8).

(4) Remove caliper mounting bolts.

(5) Tilt the top of the caliper up and remove it

from the adapter.

(6) Remove anti-rattle springs.

NOTE: Upper and lower anti-rattle springs are not

interchangeable.

DISASSEMBLY

(1) Drain the brake fluid from caliper.

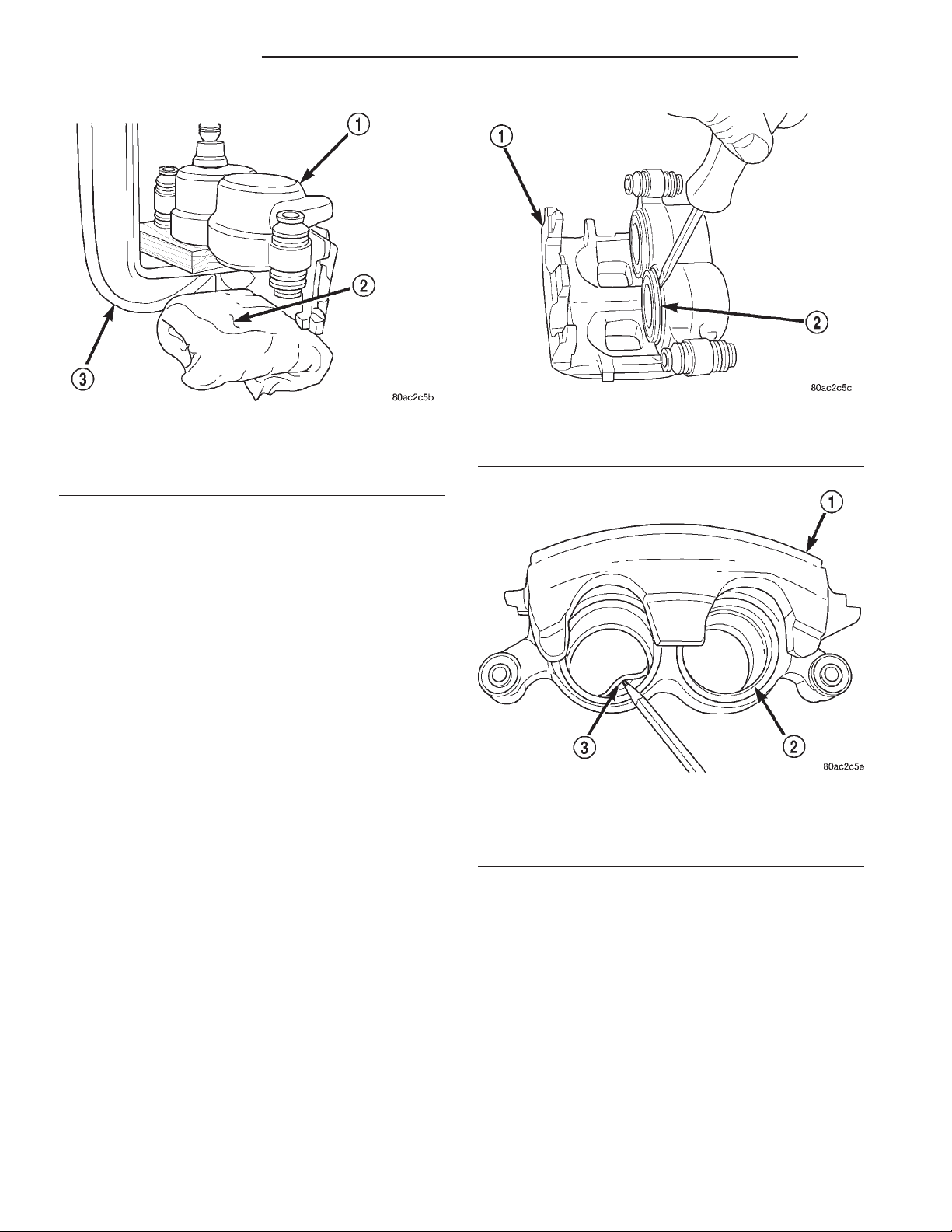

(2) C-clamp a block of wood over one piston (Fig.

9).

Fig. 9 C-Clamp One Piston

1 - BLOCK OF WOOD

2 - C-CLAMP

3 - CALIPER

(3) Take another piece of wood and pad it with

one-inch thickness of shop towels. Place this piece in

the outboard shoe side of the caliper in front of the

other piston. This will cushion and protect caliper

piston during removal (Fig. 10).

(4) To remove the caliper piston direct short

bursts of low pressure air with a blow gun

through the caliper brake hose port. Use only enough

air pressure to ease the piston out.

5 - 12 BRAKES - BASE BR/BE

DISC BRAKE CALIPERS (Continued)

Fig. 10 Protect Caliper Piston

1 - CALIPER

2 - PADDED BLOCK OF WOOD

3 - C-CLAMP

CAUTION: Do not blow the piston out of the bore

with sustained air pressure. This could result in a

cracked piston.

WARNING: NEVER ATTEMPT TO CATCH THE PISTON AS IT LEAVES THE BORE. THIS COULD

RESULT IN PERSONAL INJURY.

(5) Remove the C-clamp and block of wood from

the caliper and clamp it over the dust boot of the

first piston removed. This will seal the empty piston

bore.

(6) Move the padded piece of wood in front of the

other piston.

(7) Remove the second piston using the same procedure with short bursts of low pressure air.

(8) Remove piston dust boots with a suitable pry

tool (Fig. 11).

(9) Remove piston seals from caliper (Fig. 12).

Fig. 11 Piston Dust Boot Removal

1 - CALIPER

2 - DUST BOOT

Fig. 12 Piston Seal

1 - CALIPER

2 - PISTON BORE

3 - PISTON SEAL

CAUTION: Do not scratch piston bore while removing the seals.

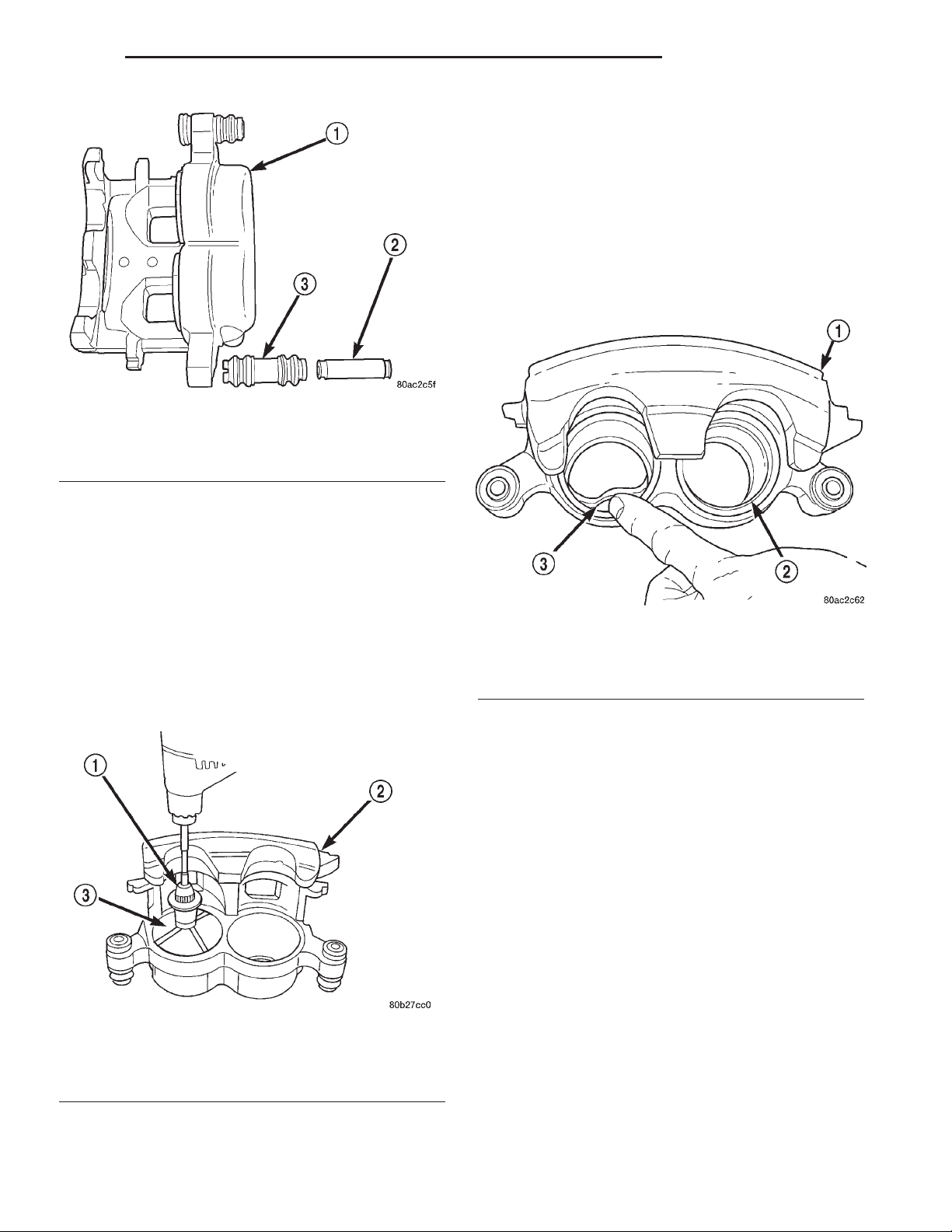

(10) Push caliper mounting bolt bushings out of

the boot seals and remove the boot seals from the

caliper (Fig. 13).

(11) Remove caliper bleed screw.

CLEANING

Clean the caliper components with clean brake

fluid or brake clean only. Wipe the caliper and piston

dry with lint free towels or use low pressure compressed air.

CAUTION: Do not use gasoline, kerosene, thinner,

or similar solvents. These products may leave a

residue that could damage the piston and seal.

INSPECTION

The piston is made from a phenolic resin (plastic

material) and should be smooth and clean.

The piston must be replaced if cracked or scored.

Do not attempt to restore a scored piston surface by

sanding or polishing.

BR/BE BRAKES - BASE 5 - 13

DISC BRAKE CALIPERS (Continued)

ASSEMBLY

CAUTION: Dirt, oil, and solvents can damage caliper seals. Insure assembly area is clean and dry.

(1) Lubricate caliper pistons, piston seals and piston bores with clean, fresh brake fluid.

(2) Install new piston seals into caliper bores (Fig.

15).

NOTE: Verify seal is fully seated and not twisted.

Fig. 13 Bushings And Boot Seals

1 - CALIPER

2 - BUSHING

3 - BOOT SEAL

CAUTION: If the caliper piston is replaced, install

the same type of piston in the caliper. Never interchange phenolic resin and steel caliper pistons.

The pistons, seals, seal grooves, caliper bore and

piston tolerances are different.

The bore can be lightly polished with a brake

hone to remove very minor surface imperfections

(Fig. 14). The caliper should be replaced if the bore is

severely corroded, rusted, scored, or if polishing

would increase bore diameter more than 0.025 mm

(0.001 inch).

Fig. 14 Polishing Piston Bore

1 - HONE

2 - CALIPER

3 - PISTON BORE

Fig. 15 Piston Seal

1 - CALIPER

2 - PISTON BORE

3 - PISTON SEAL

(3) Lightly lubricate lip of new boot with silicone

grease. Install boot on piston and work boot lip into

the groove at the top of piston.

(4) Stretch boot rearward to straighten boot folds,

then move boot forward until folds snap into place.

(5) Install piston into caliper bore and press piston

down to the bottom of the caliper bore by hand or

with hammer handle (Fig. 16).

(6) Seat dust boot in caliper (Fig. 17) with Handle

C-4171 and Installer:

• HD 56 mm caliper: Installer C-4340

• LD 54 mm caliper: Installer C-3716-A

(7) Install the second piston and dust boot.

(8) Lubricate caliper mounting bolt bushings, boot

seals and bores with Mopar brake grease or Dow

Corningt 807 grease only.

CAUTION: Use of alternative grease may cause

damage to the boots seals.

(9) Install the boot seals into the caliper seal bores

and center the seals in the bores.

Loading...

Loading...